Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

535results about How to "Consistent speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

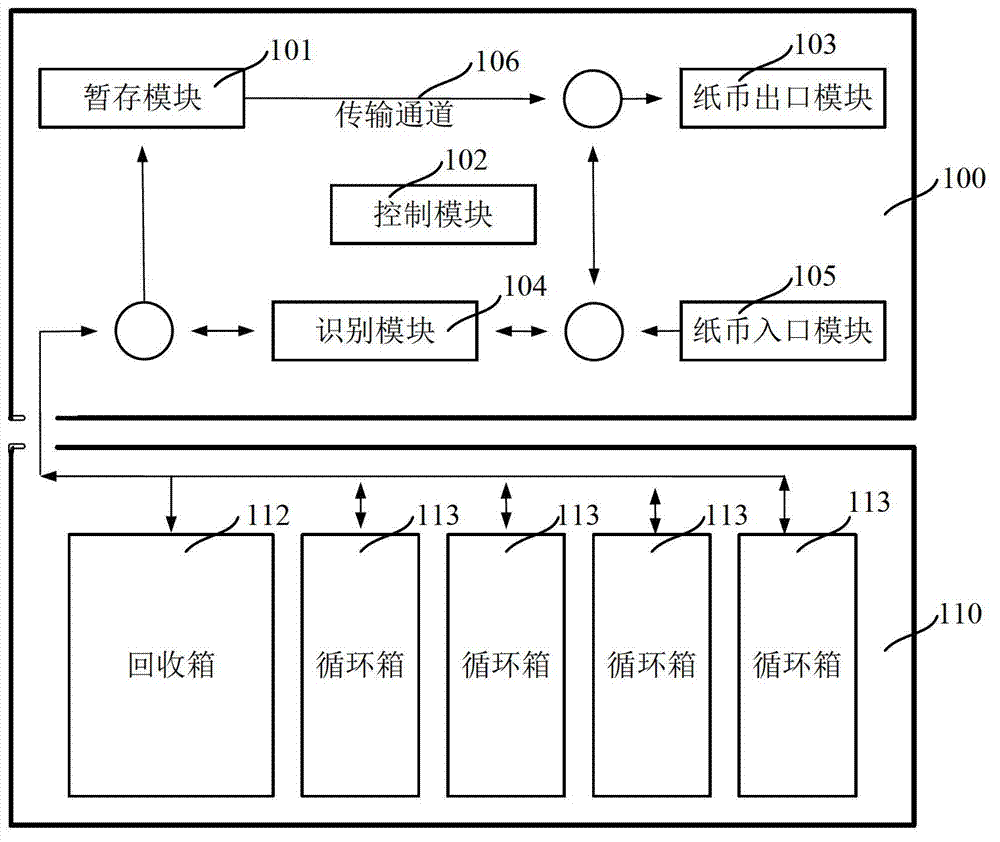

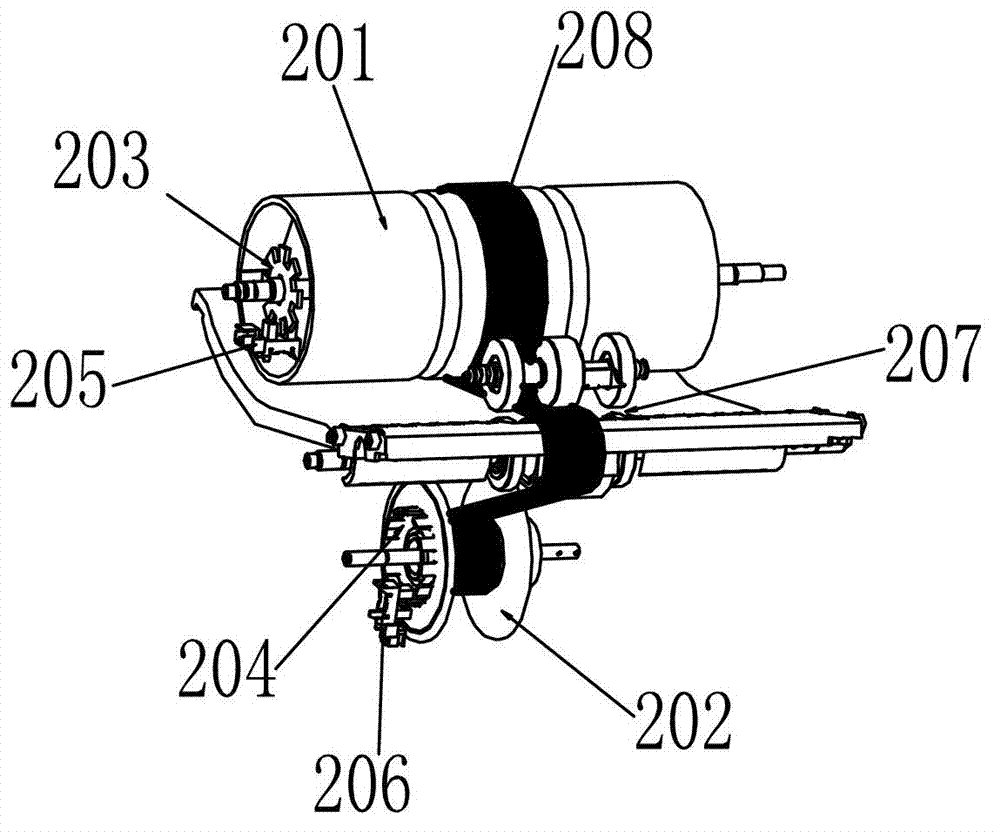

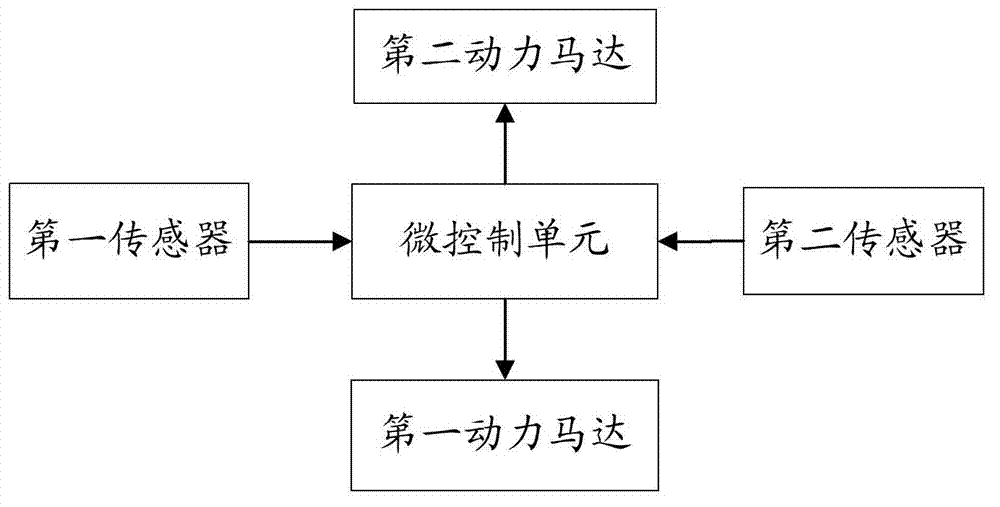

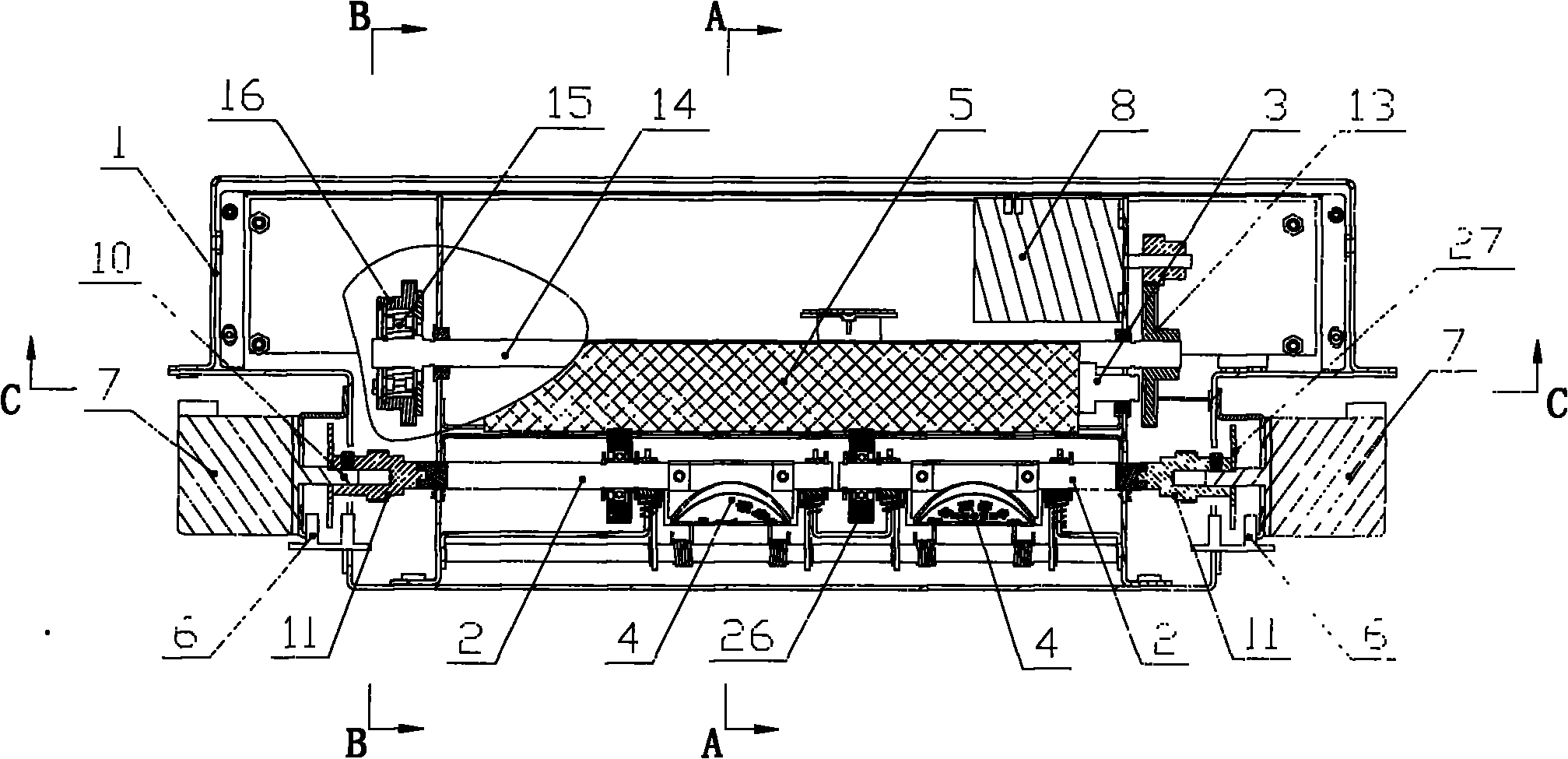

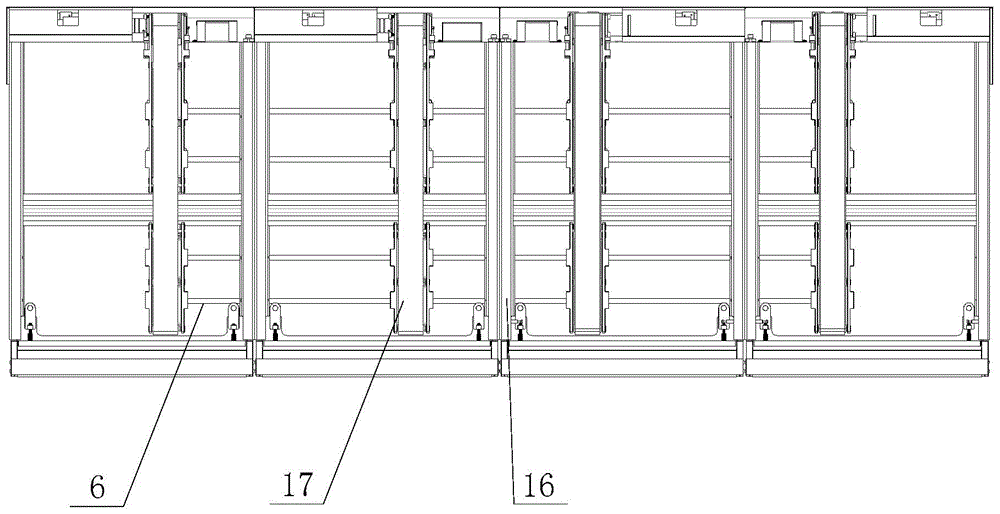

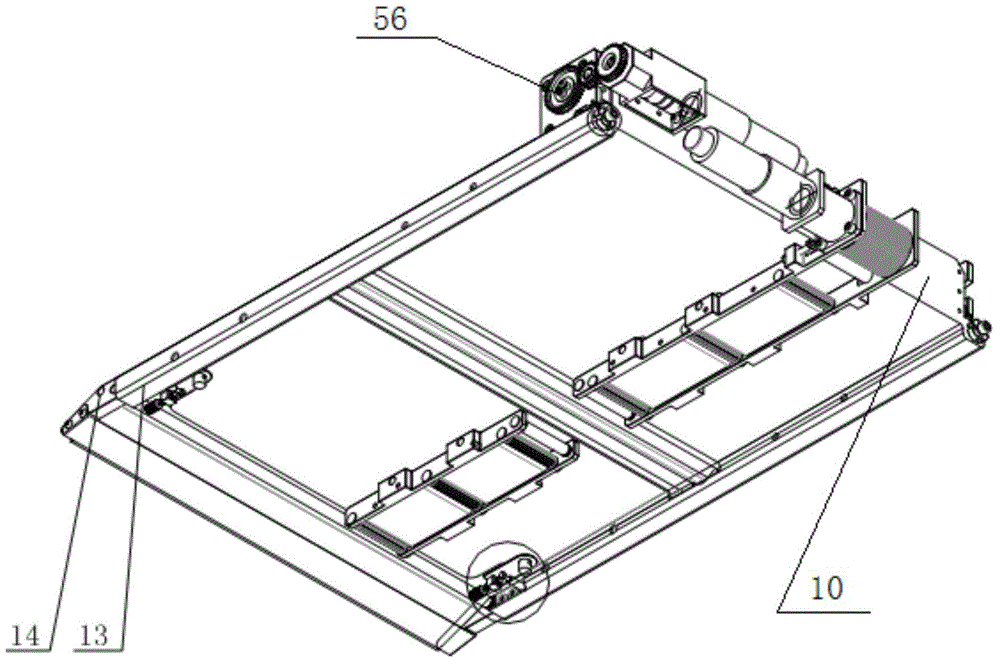

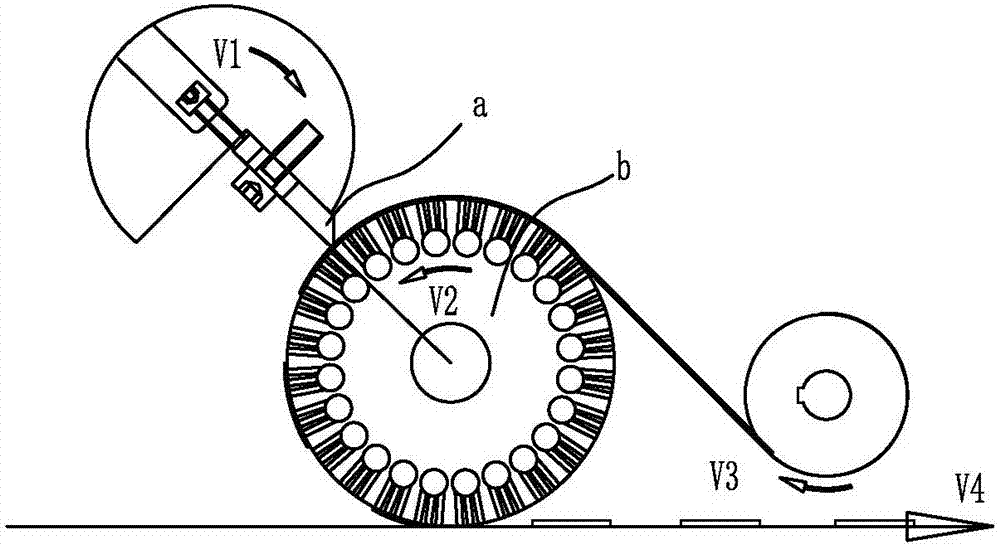

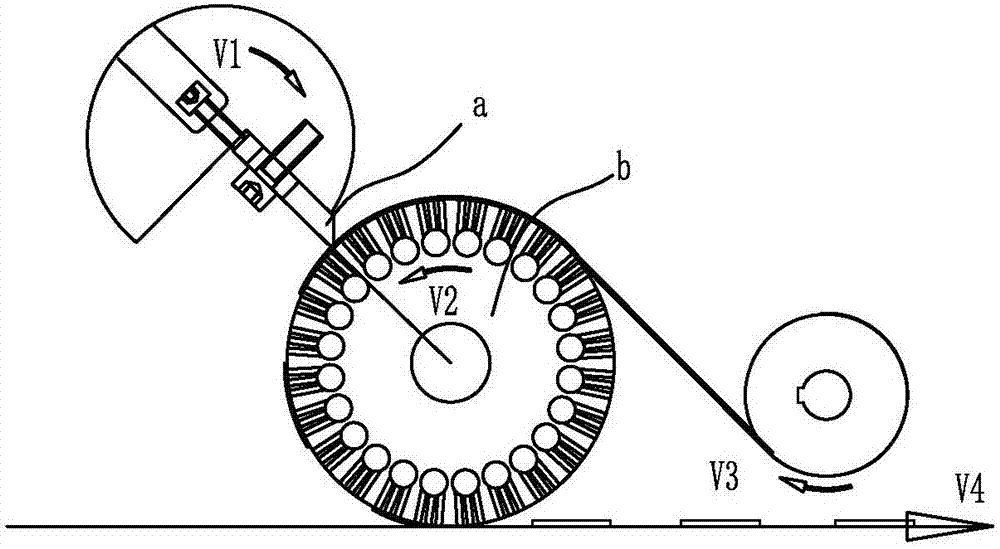

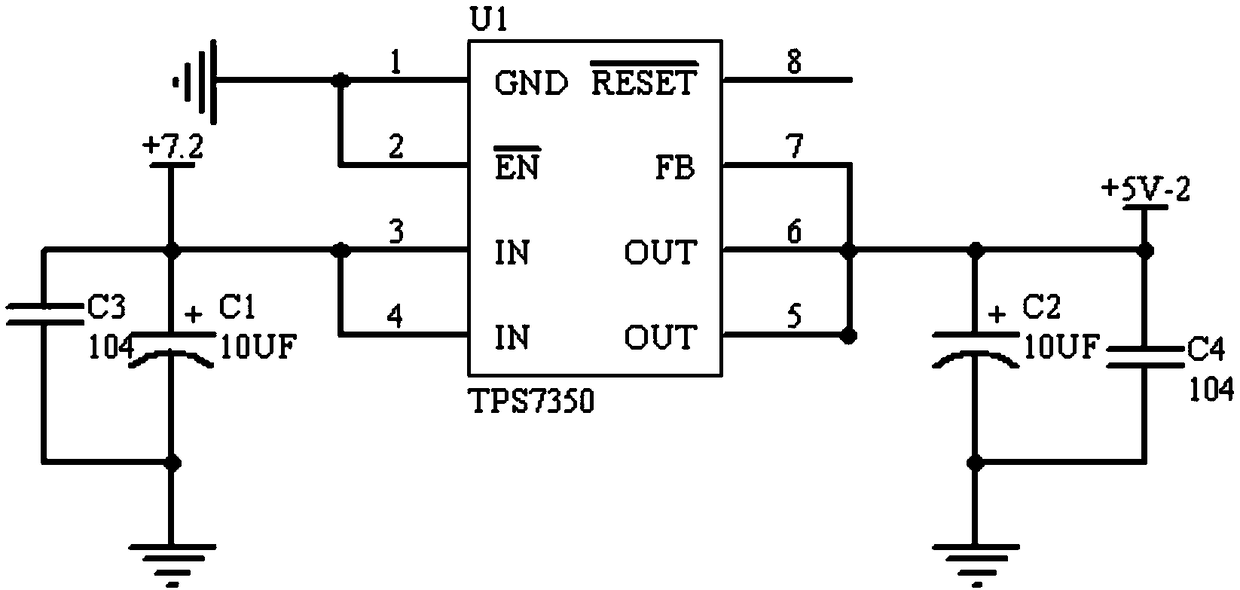

Paper money temporary storage module and reel rotating speed control method thereof

ActiveCN102930638AAvoid downtimeReduce lossFunction indicatorsCoin/currency accepting devicesAngular velocityTemporary storage

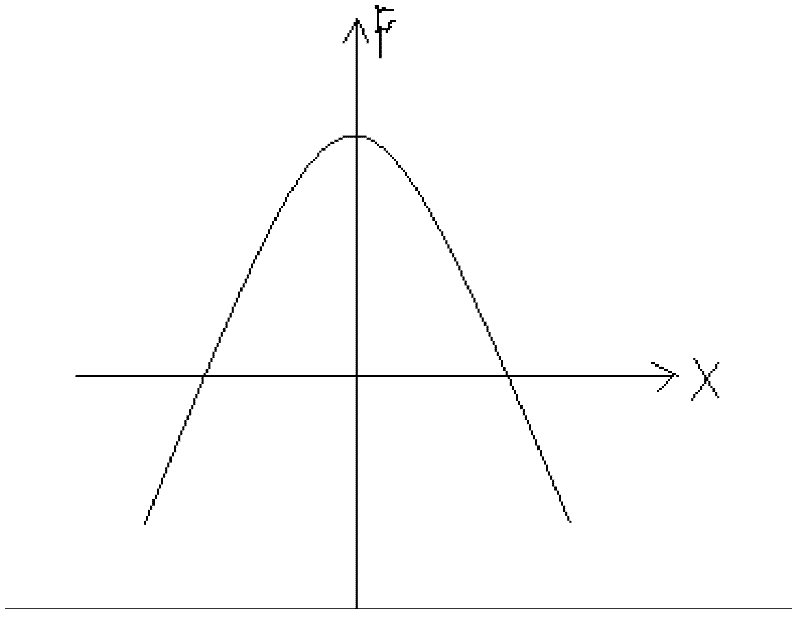

The invention relates to a paper money temporary storage module and a reel rotating speed control method thereof. The paper money temporary storage module comprises a large reel driven by a first power motor, a small reel driven by a second power motor, a coiling tape, a first coded disc, a second coded disc, a first sensor, a second sensor and a microcontroller, wherein two ends of the coiling tape are respectively fixed on the large reel and the small reel and the coiling tape is retracted and wound between the large reel and the small reel; the first coded disc is fixed on a rotating shaft of the large reel; the second coded disc is fixed on a rotating shaft of the small reel; the first sensor is arranged corresponding to the first coded disc and is used for monitoring the rotating angle of the large reel; the second sensor is arranged corresponding to the second coded disc and is used for monitoring the rotating angle of the small reel; and the microcontroller is used for calculating the length of the coil tape released by the small reel when the large reel rotates for a circle according to output signals of the first sensor and the second sensor and further calculating the current radius of the large reel, and thus angular velocities of the large reel and the small reel are controlled and the linear velocity of the large reel is enabled to be consistent with that of the small reel.

Owner:GRG BAKING EQUIP CO LTD

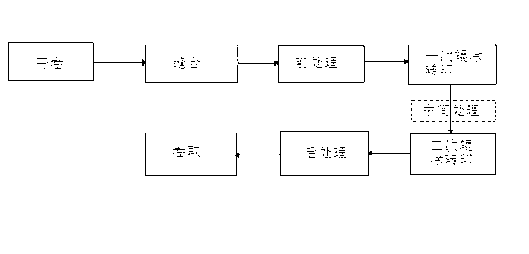

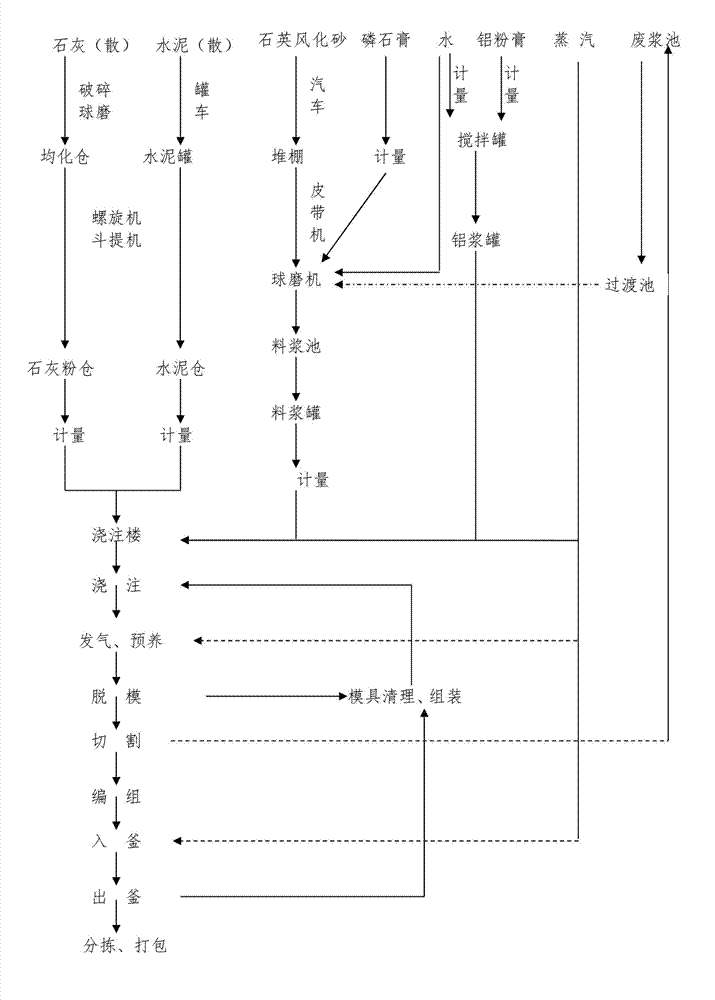

Aerated concrete block and its production process

InactiveCN101066886AHigh reactivityIncreased affinity and contact areaSolid waste managementCeramicwareGypsumPre treatment

The aerated concrete block is produced with fly ash 50-65 weight portions, lime 18-22 weight portions, gypsum 6-10 weight portions, cement 7-16 weight portions, composite gas former 4-8 weight portions, efficient fly ash activator 1-2 weight portions, composite stabilizer 1.5-3 weight portions and water in proper quantity; and through the production process including the steps of fly ash pre-treatment, crushing lime and gypsum, pre-activating fly ash, mixing the materials to prepare slurry and pouring, pre-curing, cutting, and steam curing to obtain the product. The production process adopts pre-activating and secondary activating and composite stabilizer, and the aerated concrete block product has low cement consumption, low cost and high strength.

Owner:张江

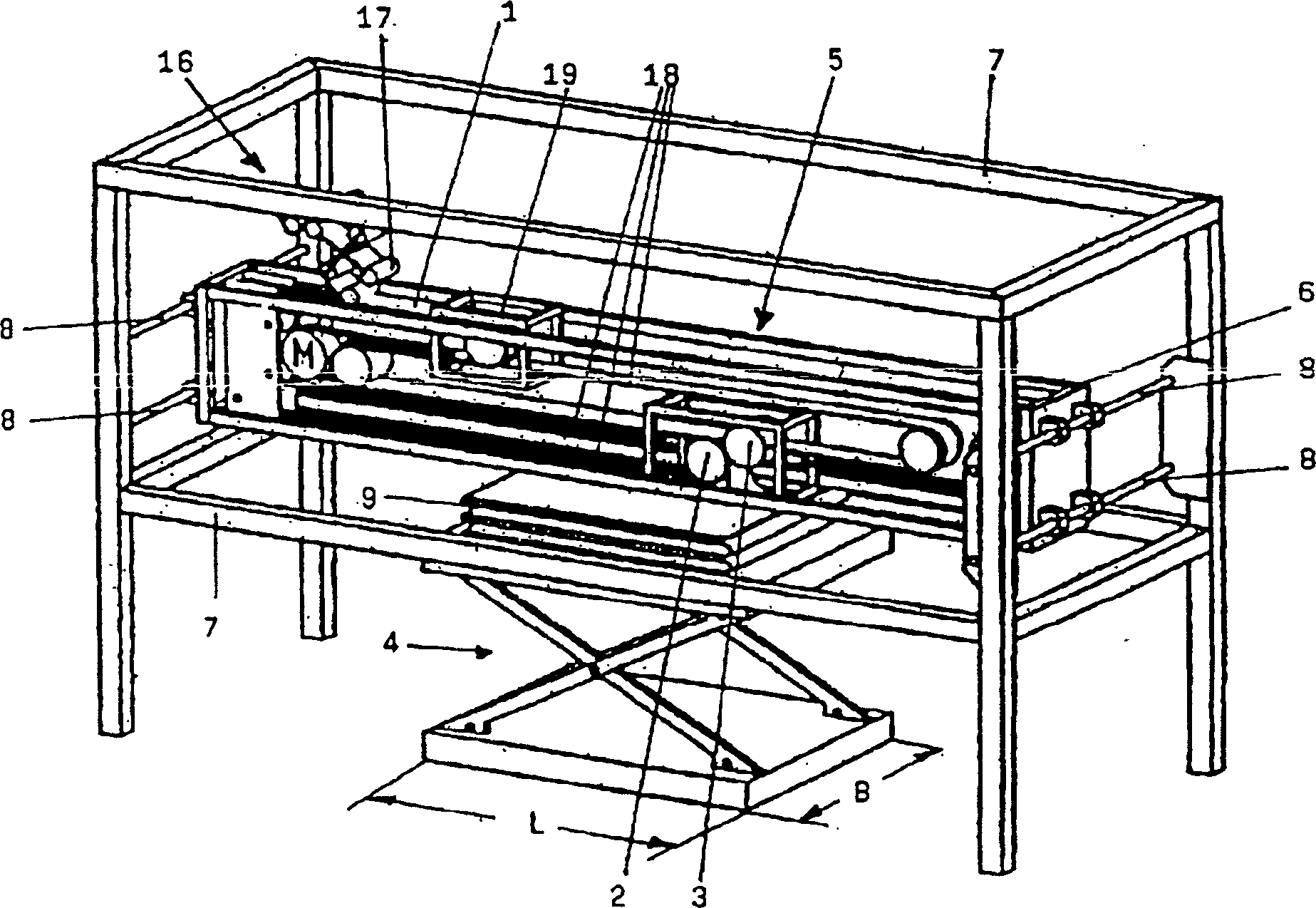

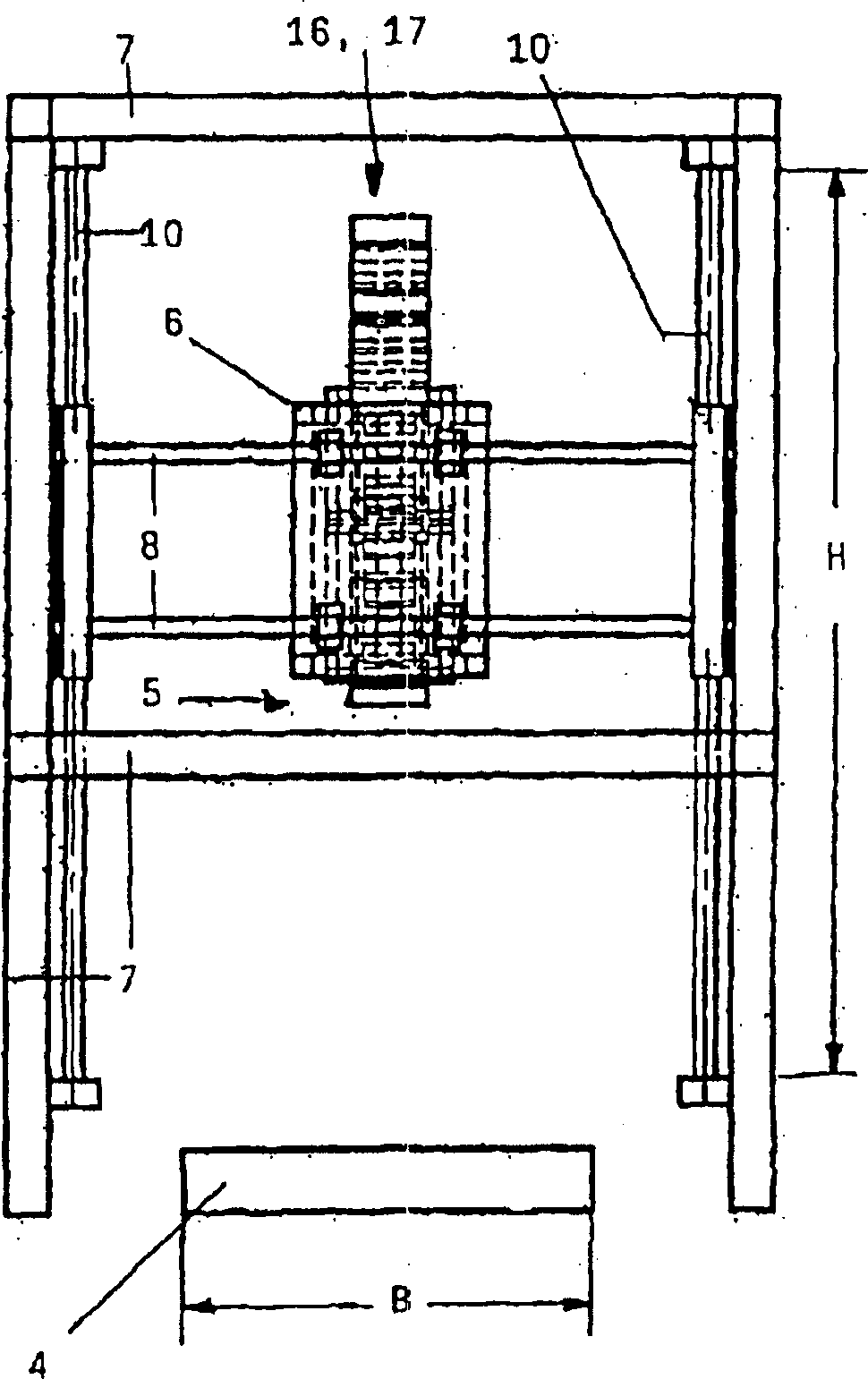

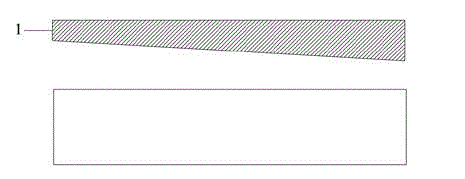

Device for laying a flexible material web

A device for laying a flexible material web 1 on a point of deposit 4 and which has at least one pair of deposit rollers 2, 3 that rotate in opposite directions. The deposit rollers 2, 3 form part of a deposit carriage 5 which is reciprocated in a reversible direction over at least the deposit length L of the material web 1. The device is more cost-effective in that the deposit carriage 5 has a smaller width than the point of deposit 4 and is reciprocated in a reversible direction over at least the deposit width B of the point of deposit 4.

Owner:SAURER GMBH & CO KG

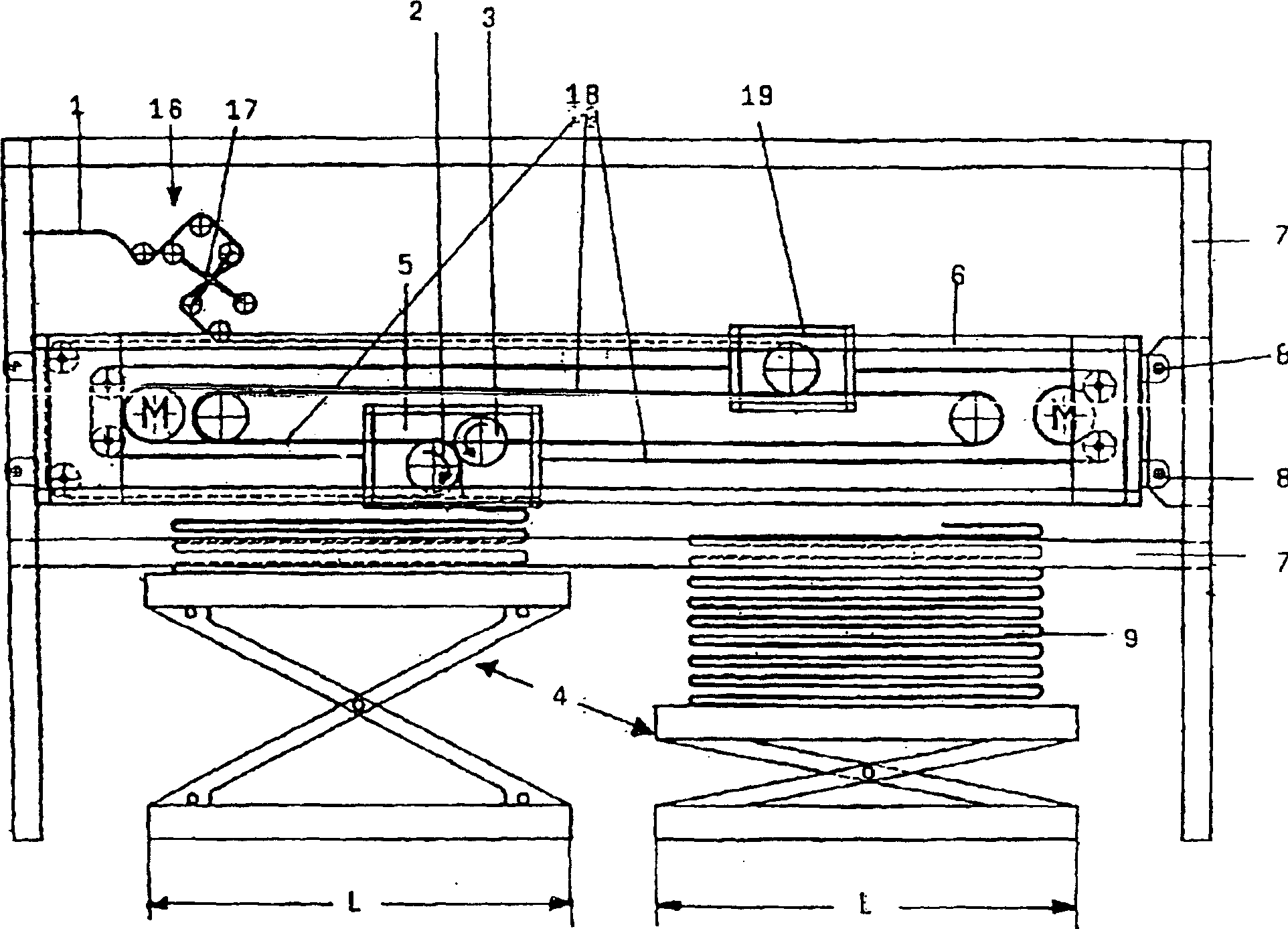

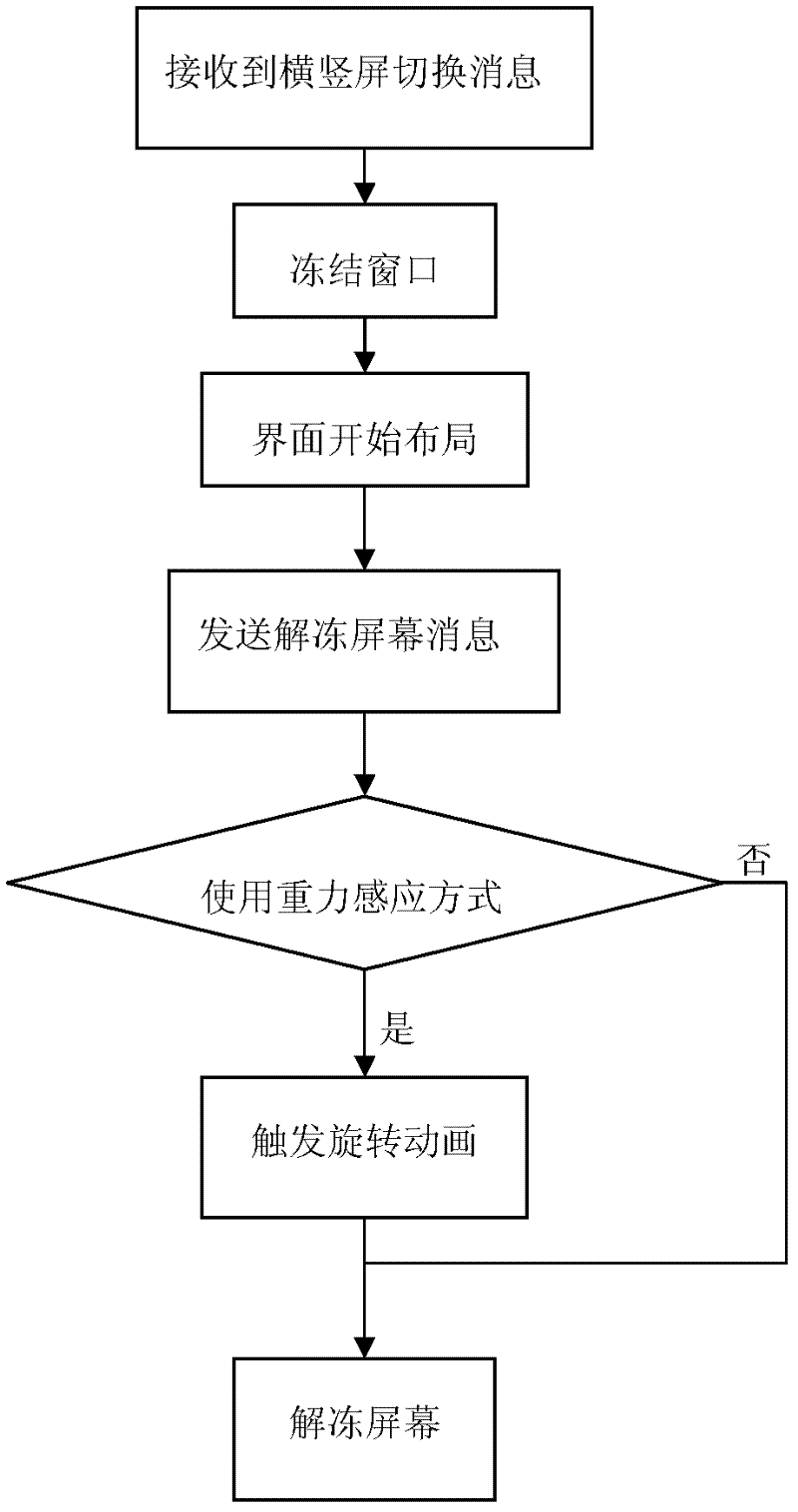

Horizontal-vertical screen switching rotation control method for hand-held devices

InactiveCN102520842ASmooth switchingDynamic continuous display effect is goodSubstation equipmentInput/output processes for data processingHand heldHand held devices

The invention relates to a horizontal-vertical screen switching rotation control method for hand-held devices. The horizontal-vertical screen switching rotation control method includes the following steps: according to gravity sensing, a rotation direction and a switched angle Phi m are acquired; a screen is frozen, and a direction-changed interface image is acquired; the current angle Phi i of the interface image is calculated and displayed until Phi i is equal to Phi m, wherein Phi i is equal to Phi 0 plus (Phi n minus Phi 0) multiplied by Ai, Ai is equal to (m minus (m minus i) multiplied by (m minus i) divided by m) divided by m, m is the total number of rotation display times, i is the current number of rotation display times, and is greater than or equal to 1 and less than or equal to m, m and i are natural numbers, Ai is acceleration percentage, and the initial angles Phi 0, Phi i and Phi m are in the same rotation direction; the display of the hand-held device screen is not changed, the interface image is rotated around the central point of the screen on the surface of the screen, and the screen only displays the part of the rotated interface image, which is in the screen; and the screen is defrozen. The control method can perfectly connect the rotation act of a user and bring vivid natural experience to the user.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

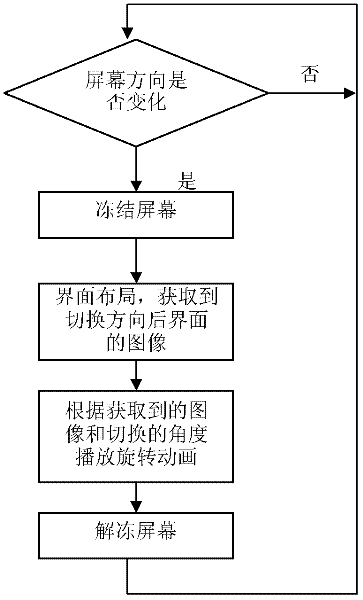

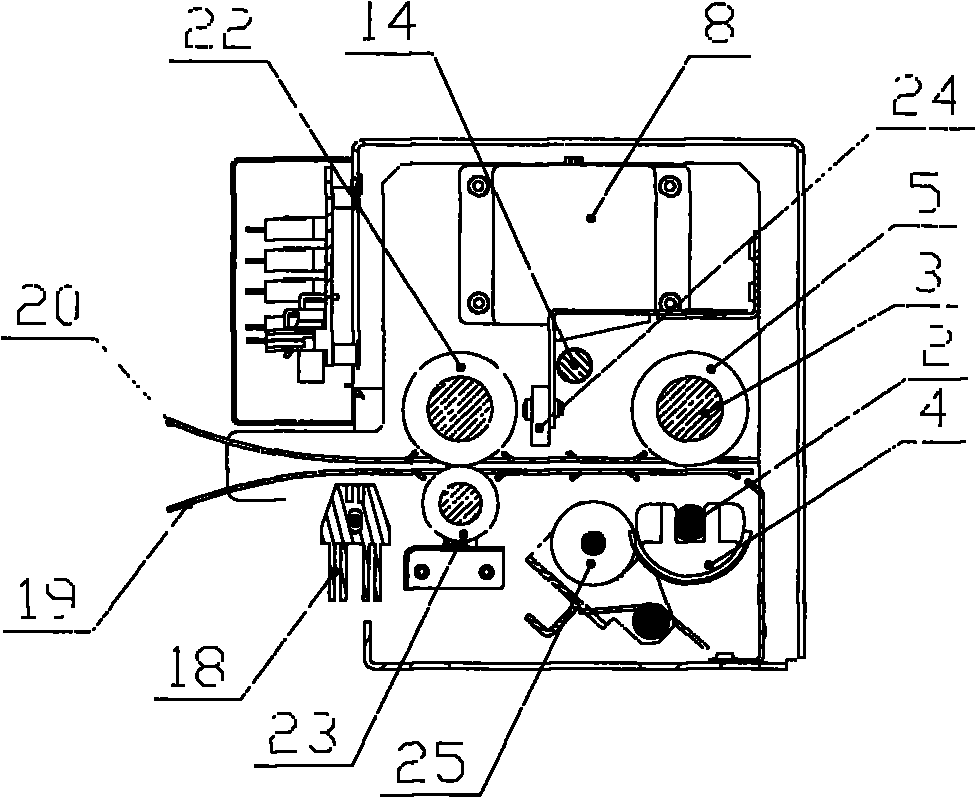

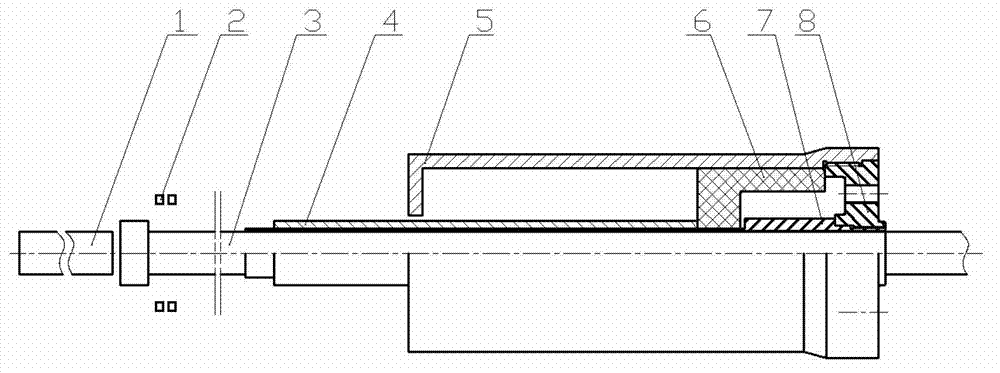

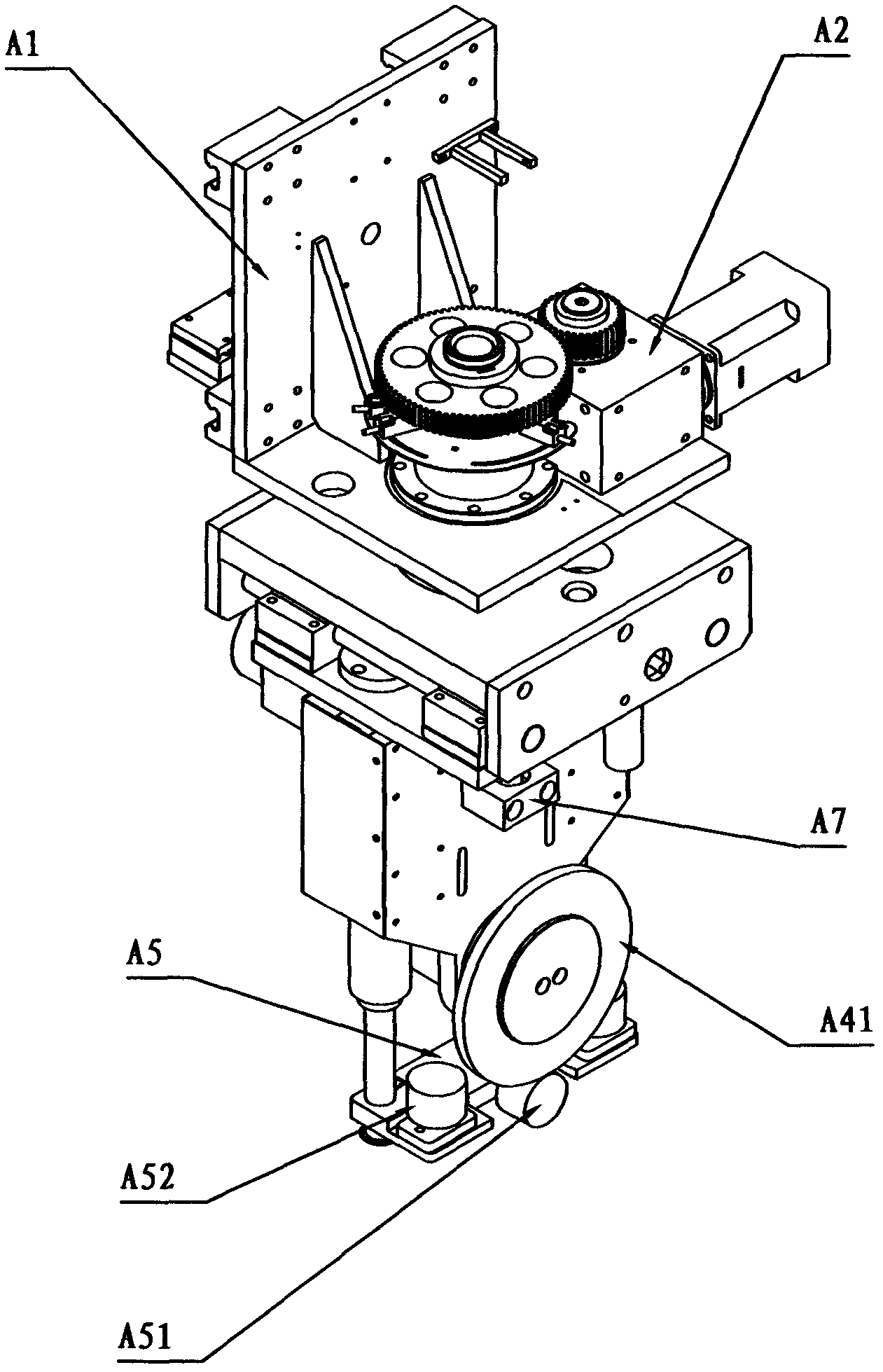

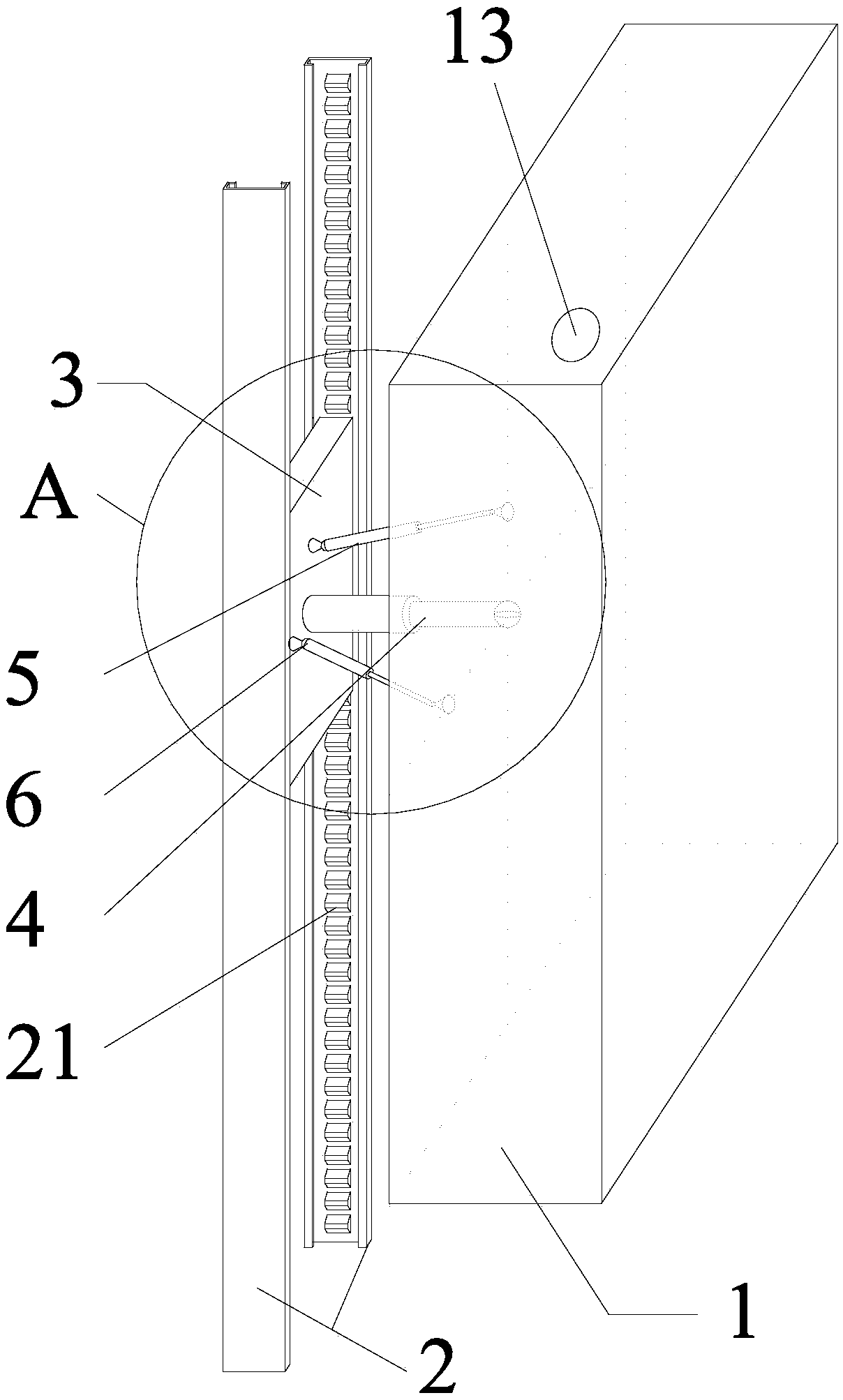

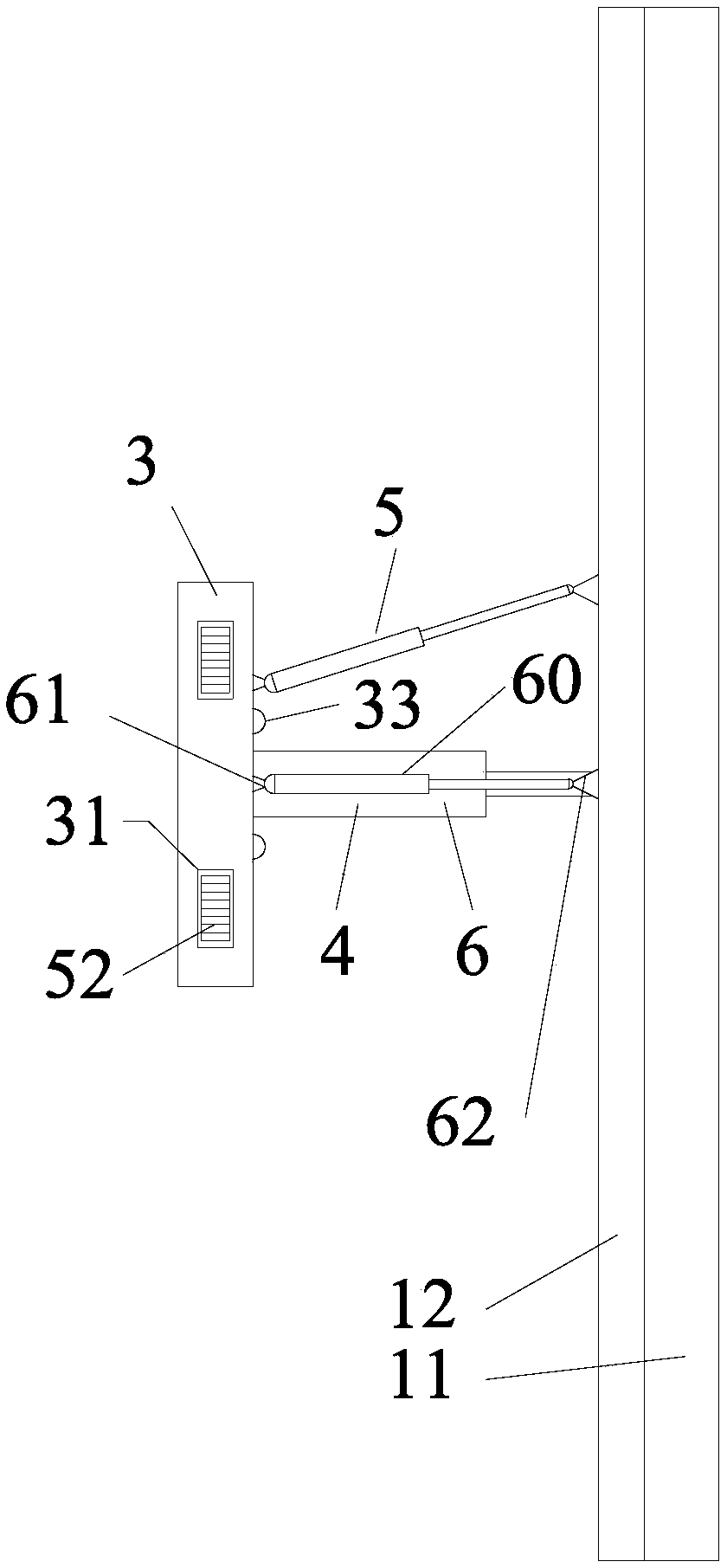

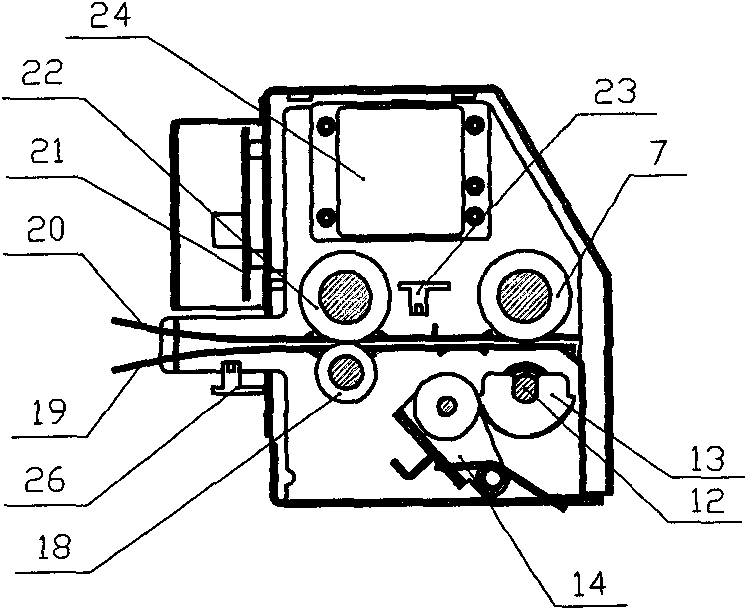

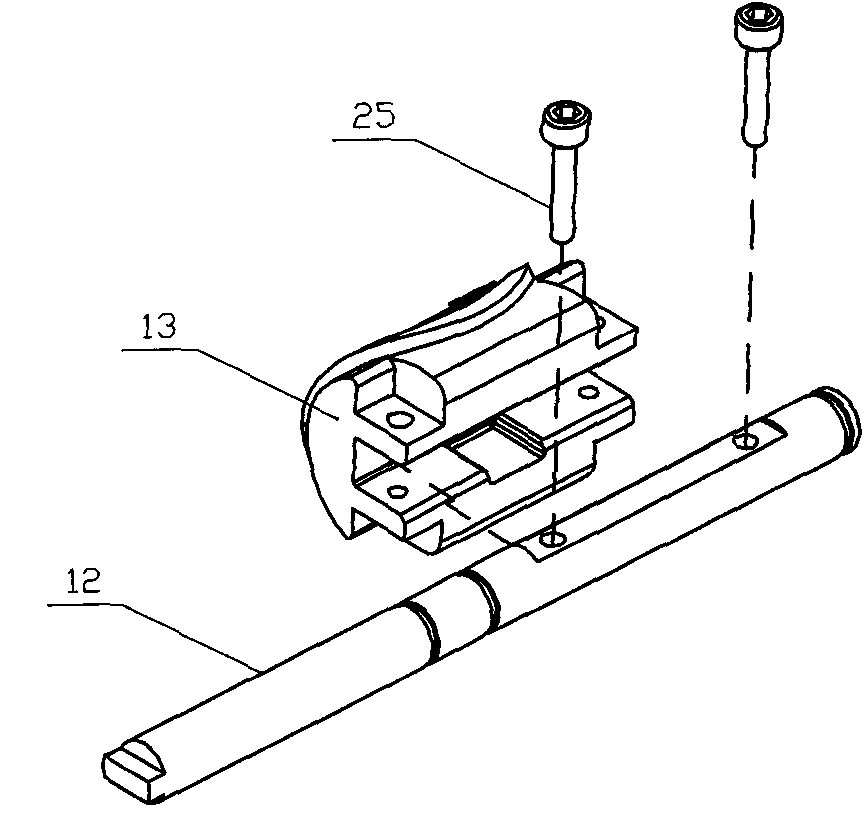

Automatic roll stamping seal device

ActiveCN101786386AReduce the chance of spin-stop failureConsistent speedStampingInlet channelDrive motor

The invention discloses an automatic roll stamping seal device which can accurately detect the rotating position of a rolling seal; the automatic roll stamping seal device comprises a paper feed channel, a seal rotating shaft and a roll stamping rotating shaft which are arranged at two sides of the paper inlet channel, a rolling seal is arranged on the seal rotating shaft, a roll stamping roll which is arranged corresponding to the rolling seal is arranged on the roll stamping rotating shaft, the seal rotating shaft and the roll stamping rotating shaft are connected with a drive motor in a transmitting way, a position sensor is arranged on the rack beside the rolling seal, and an encoder is connected with the seal rotating shaft; all around monitoring can be carried out within 360-degree range of the seal rotating shaft, and the control position is more accurate; in addition, the position of the rolling seal can be accurately tracked owning to the arrangement of the encoder; a mechanical damping part in the background technology can be cancelled, the rotation and halt of the rolling seal can be accurately controlled by a motor, so as to improve the control reliability and reduce the effectiveness lose odds of the rotation and halt of the rolling seal; the device is particularly suitable for being popularized and applied to the automatic seal device.

Owner:CHENGDU JIAYITONG INFORMATION TECH CO LTD

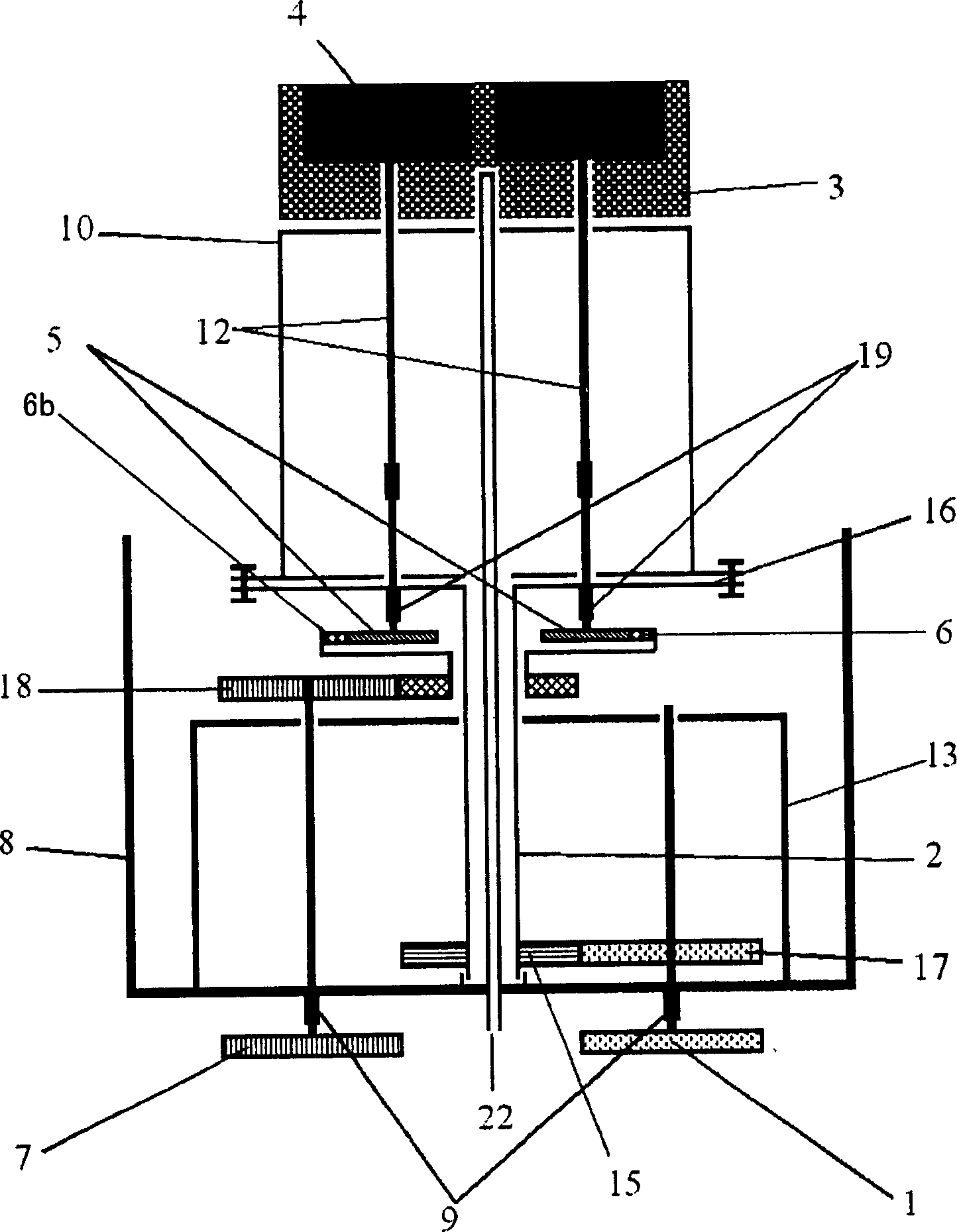

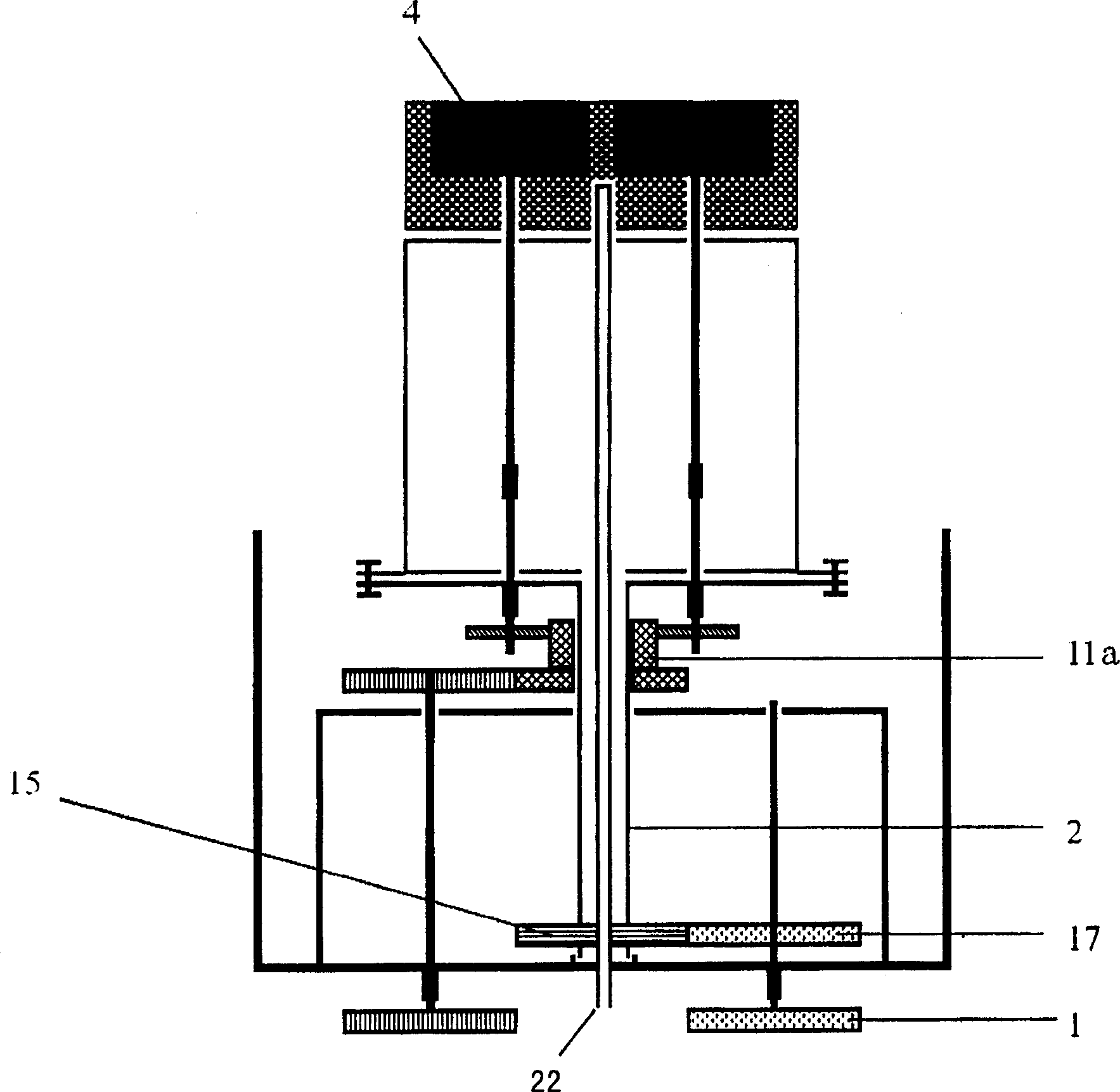

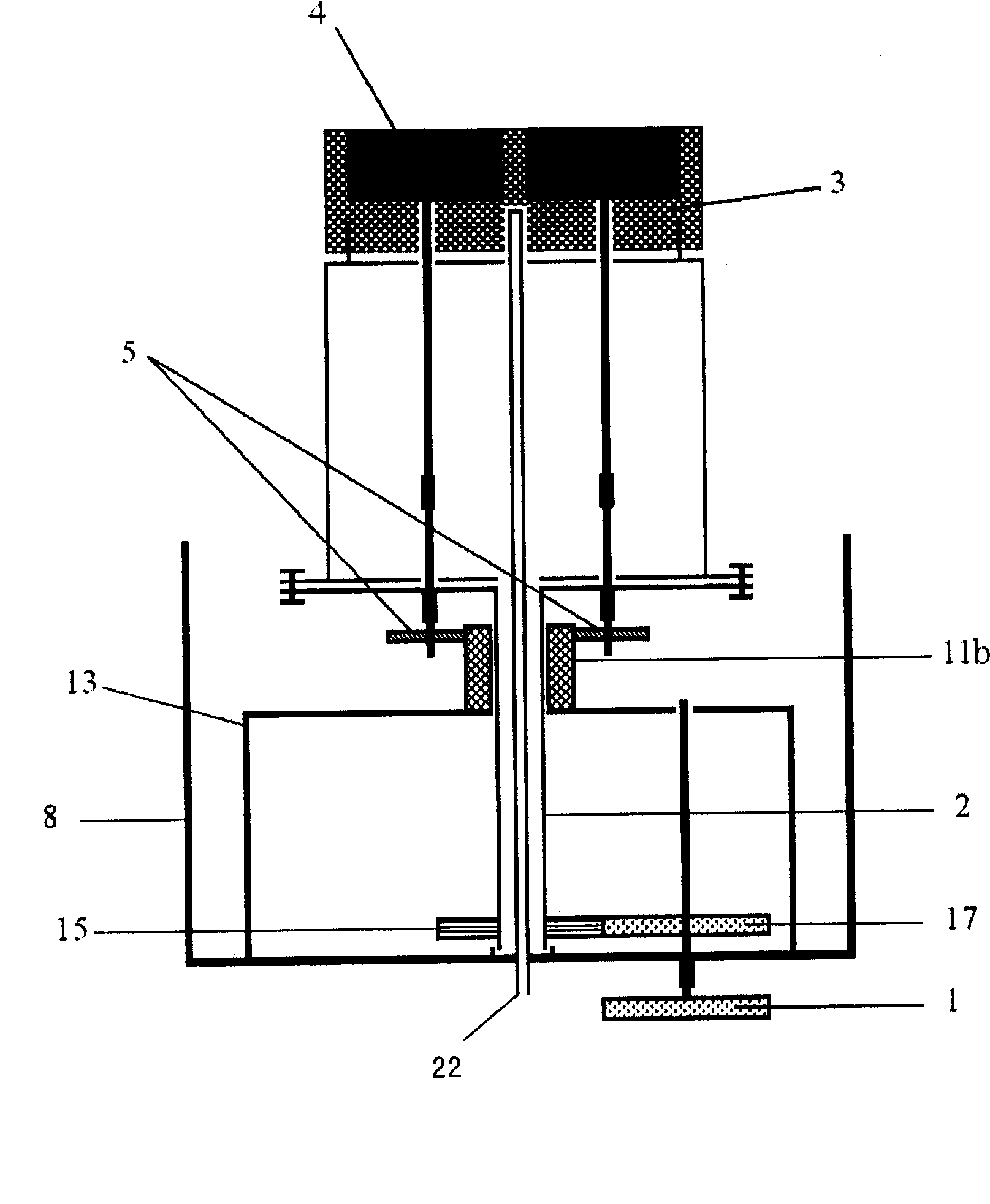

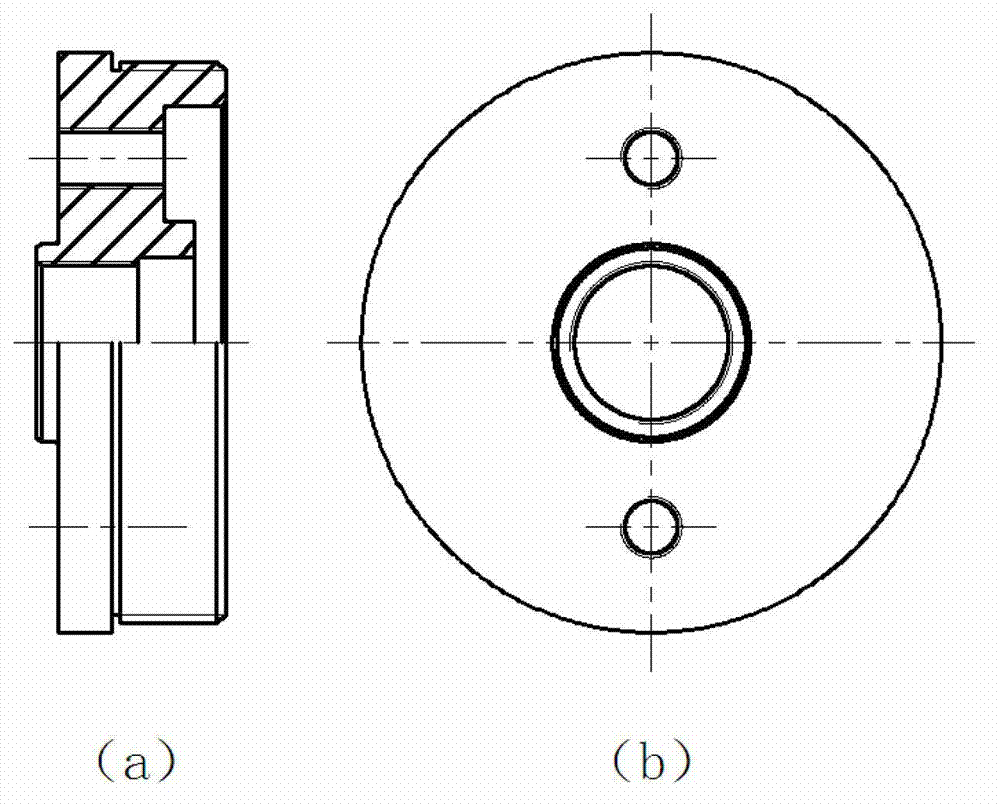

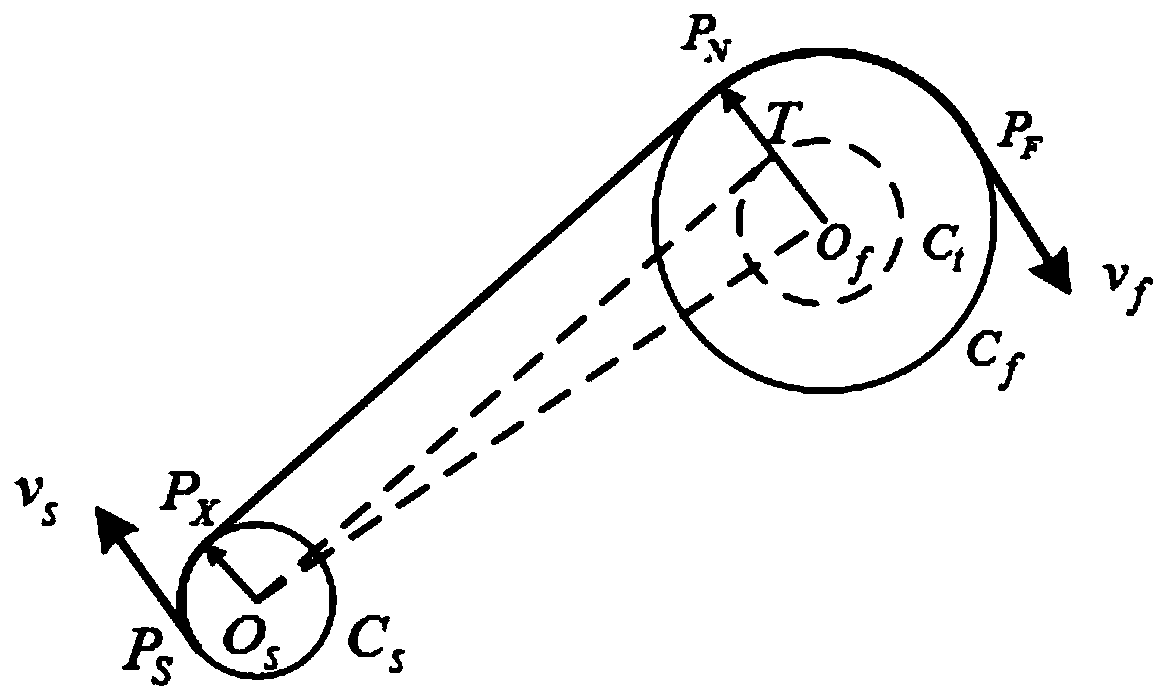

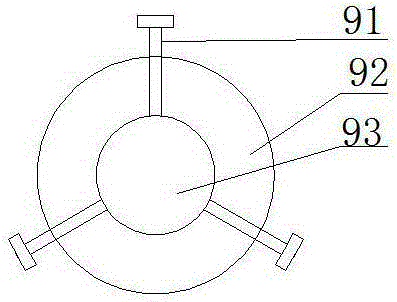

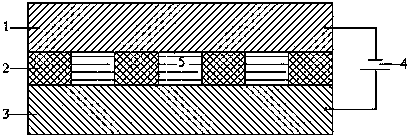

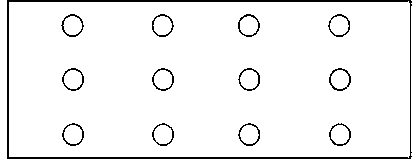

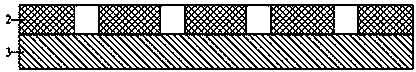

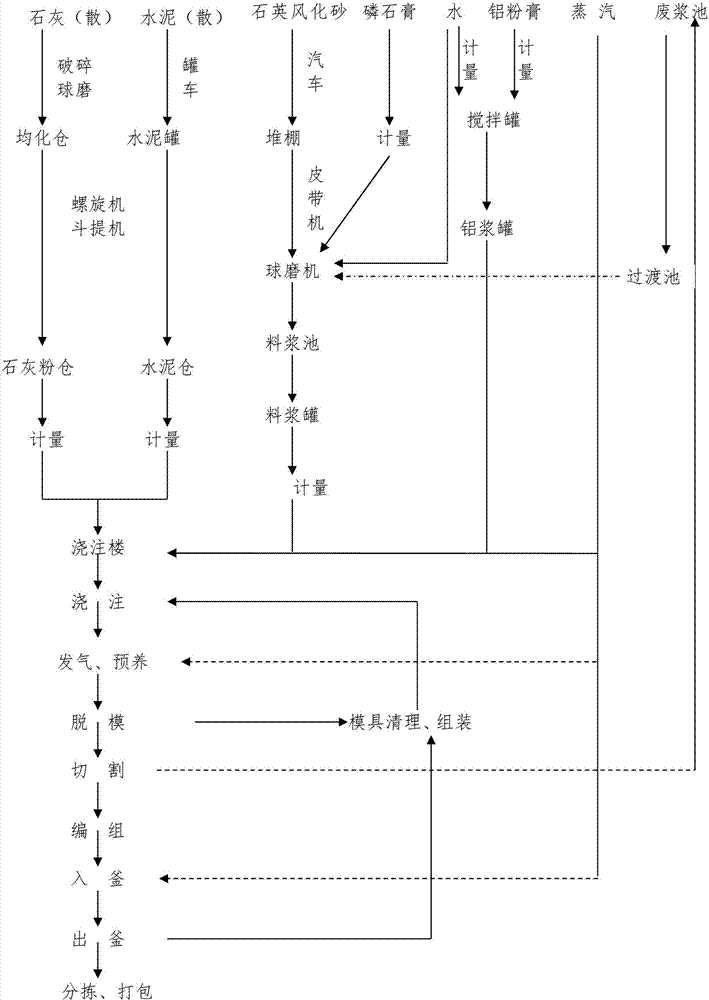

Revolution and rotation arrangement in reaction chamber of metallorganics chemical vapor deposition device

InactiveCN1865495ALower growth costsSave raw materialsChemical vapor deposition coatingGas phaseGraphite

The invention discloses a substrate base rotary structure in the metal organic chemical vapor deposition (MOCVD) equipment, which is characterized by the following: (1) the big graphite boat in the reacting chamber revolves one public fixing point; the small graphite boat rotates each center point; (2) the motor anchors substrate base (big graphite boat) to revolve; (3) the motor anchors the substrate base (small graphite boat) rotates; (4) the high-temperature region (substrate base) and low-temperature region (rotary dynamic structure) are separated by heat-durability material, which transmits the rotary dynamics.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

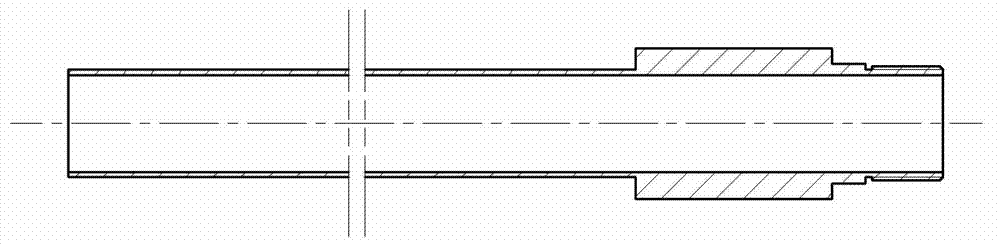

Launcher based on Hopkinson pull rod test equipment

The invention designs a launcher according to a principle and requirements of a Hopkinson pull rod test. The launcher mainly comprises a sleeve, a base, a piston, a sliding rail and a supporting base and the like, and is mainly structurally characterized in that high-pressure gas pushes the piston to move so as to push a tubular bullet to speed up, so that the bullet knocks a launching rod at a certain speed; and the thin-wall cylindrical sliding rail is used for supporting movement of the piston and the tubular bullet, thereby achieving a tensile loading way with relatively good reliability and consistency. The launcher is simple and reliable in structure, relatively low in cost, obvious in accelerating effect, thereby ensuring a relatively high bullet speed within a relatively short stroke, and good in test consistency, thereby ensuring a consistent bullet speed under a certain condition; through pressure regulation of the high-pressure gas, different bullet loading speeds can be obtained; and through a design of the sliding rail, the bullet does not contact the launching rod during acceleration, thereby avoiding influence of interaction of the bullet and the launching rod on a test result.

Owner:NANJING UNIV OF SCI & TECH

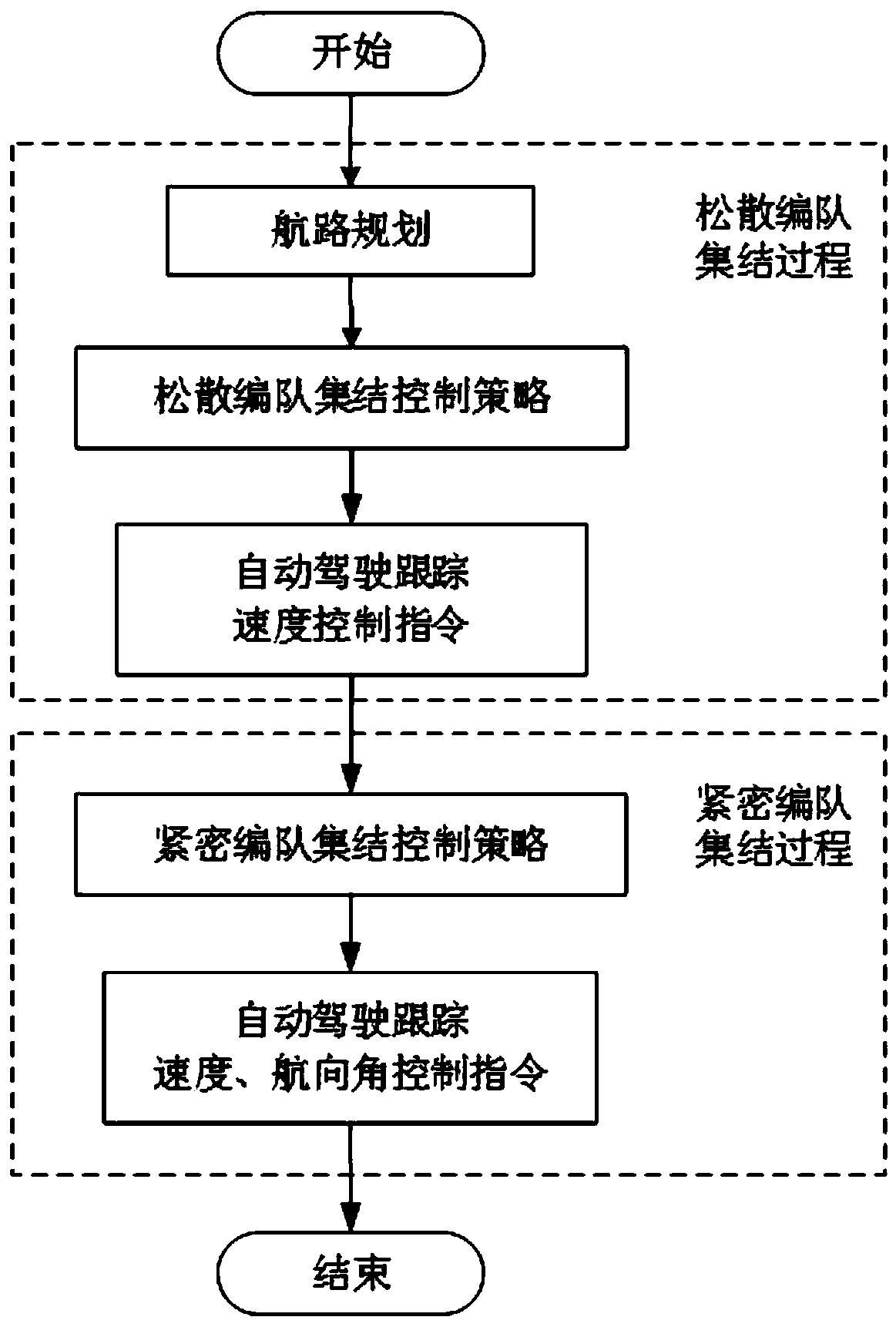

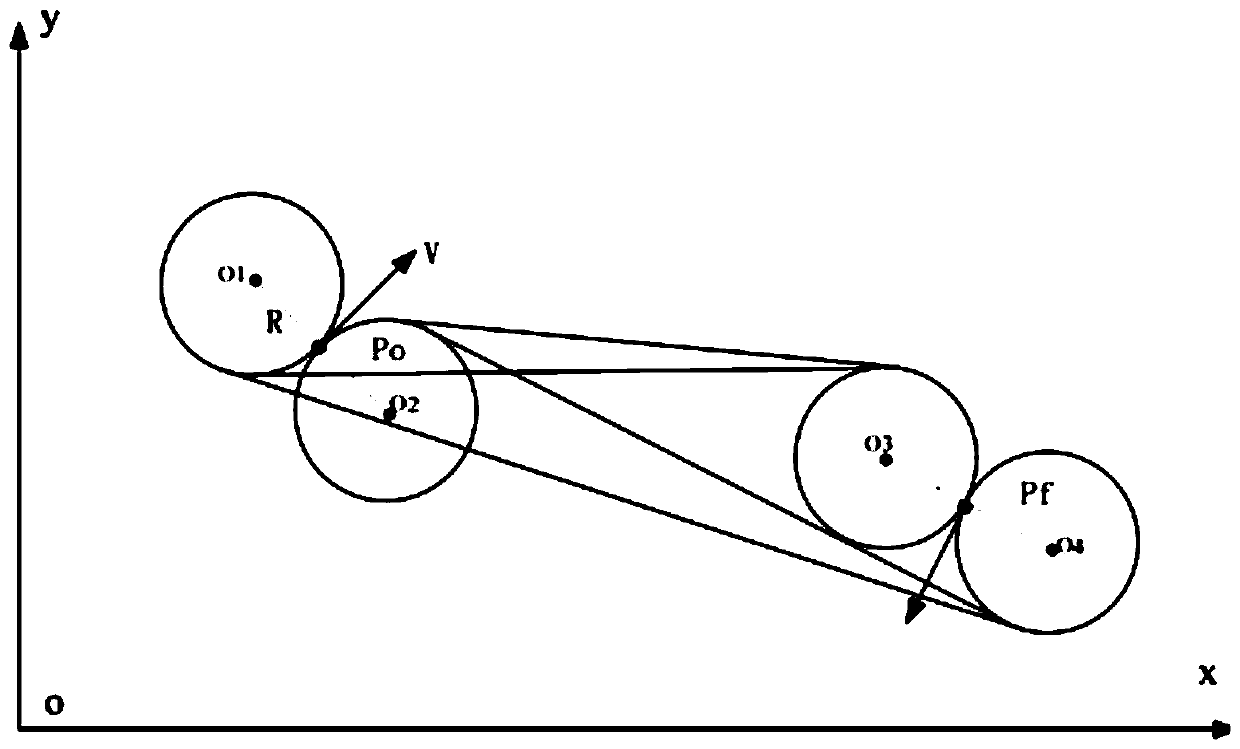

Aggregated-distributed control method of multi-unmanned-aerial-vehicle task area

InactiveCN110032209ASolve the problem of not being able to reach at the same timeConsistent speedPosition/course control in three dimensionsUncrewed vehicleConductor Coil

The invention belongs to the technical field of the multi-unmanned-aerial-vehicle cooperative control, and specifically relates to an aggregated-distributed control method of multi-unmanned-aerial-vehicle task area. The method comprises the following steps: dividing aggregation process into loose formation aggregation and tight formation aggregation, wherein a traditional aggregation task target is accomplished at the loose formation aggregation stage through a loose formation aggregation control strategy based on a first-order consistency algorithm; the transition to the tight formation fromthe loose formation is accomplished at the tight formation aggregation stage through the tight formation aggregation control strategy based on a second-order consistency algorithm. Through the methoddisclosed by the invention, a winding waiting strategy is imported into the first-order consistency algorithm, an aggregation control strategy of a virtual lead plane is imported into the second-orderconsistency algorithm; and the state convergency of the unmanned aerial vehicle formation is realized by controlling the movement of the virtual lead plane, and finally the speeds and course angles of various unmanned aerial vehicles can realize consistency.

Owner:CHINESE AERONAUTICAL RADIO ELECTRONICS RES INST

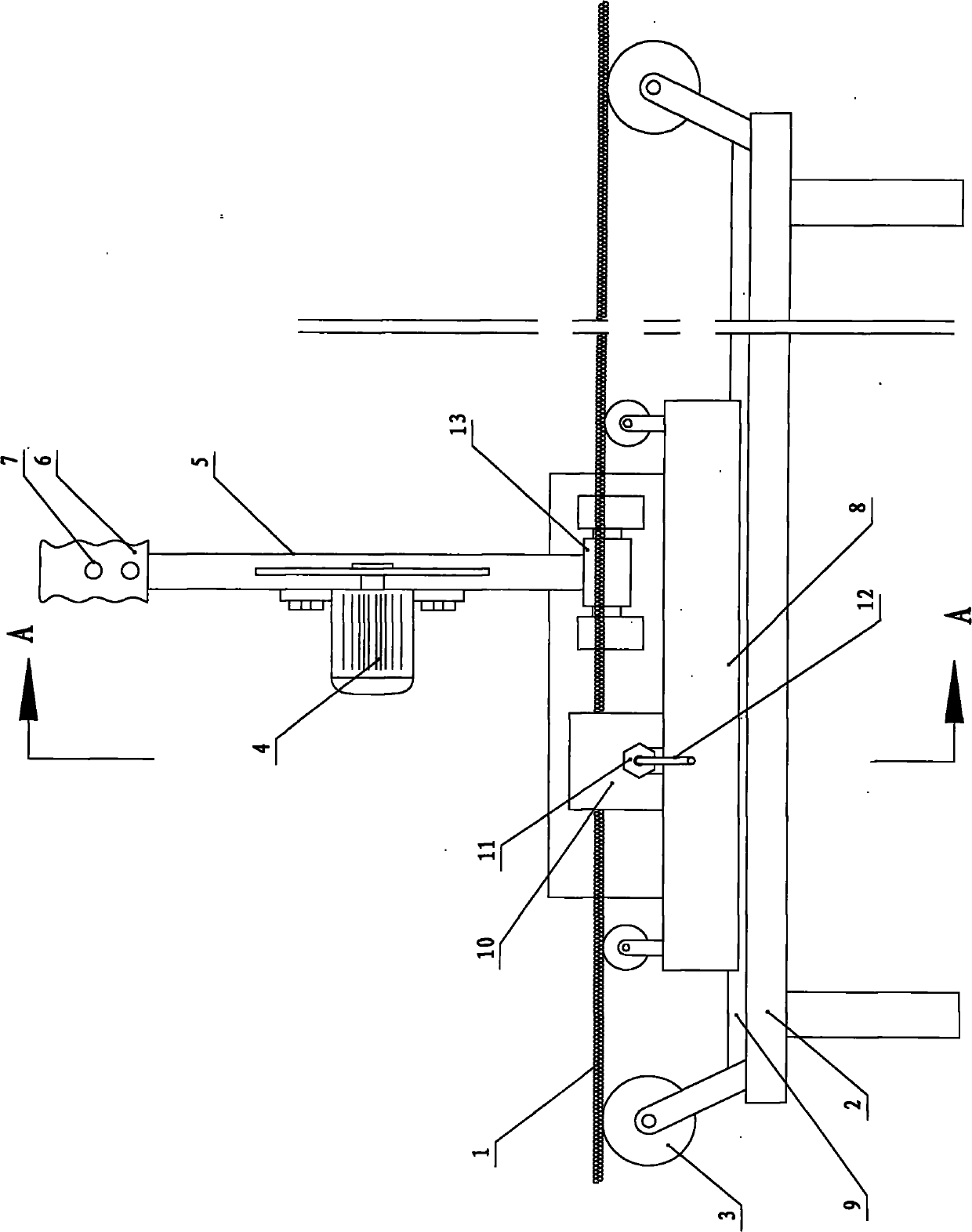

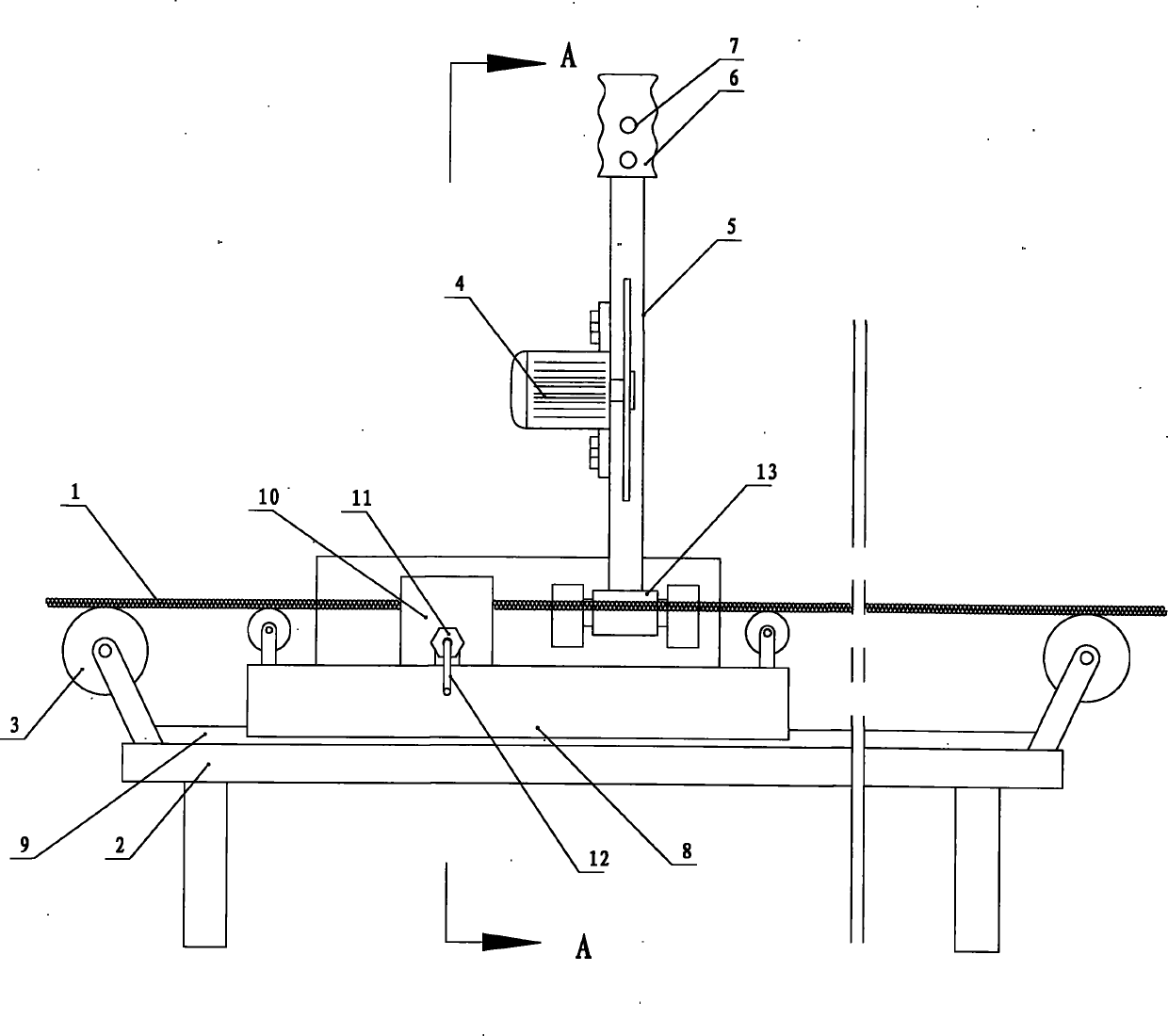

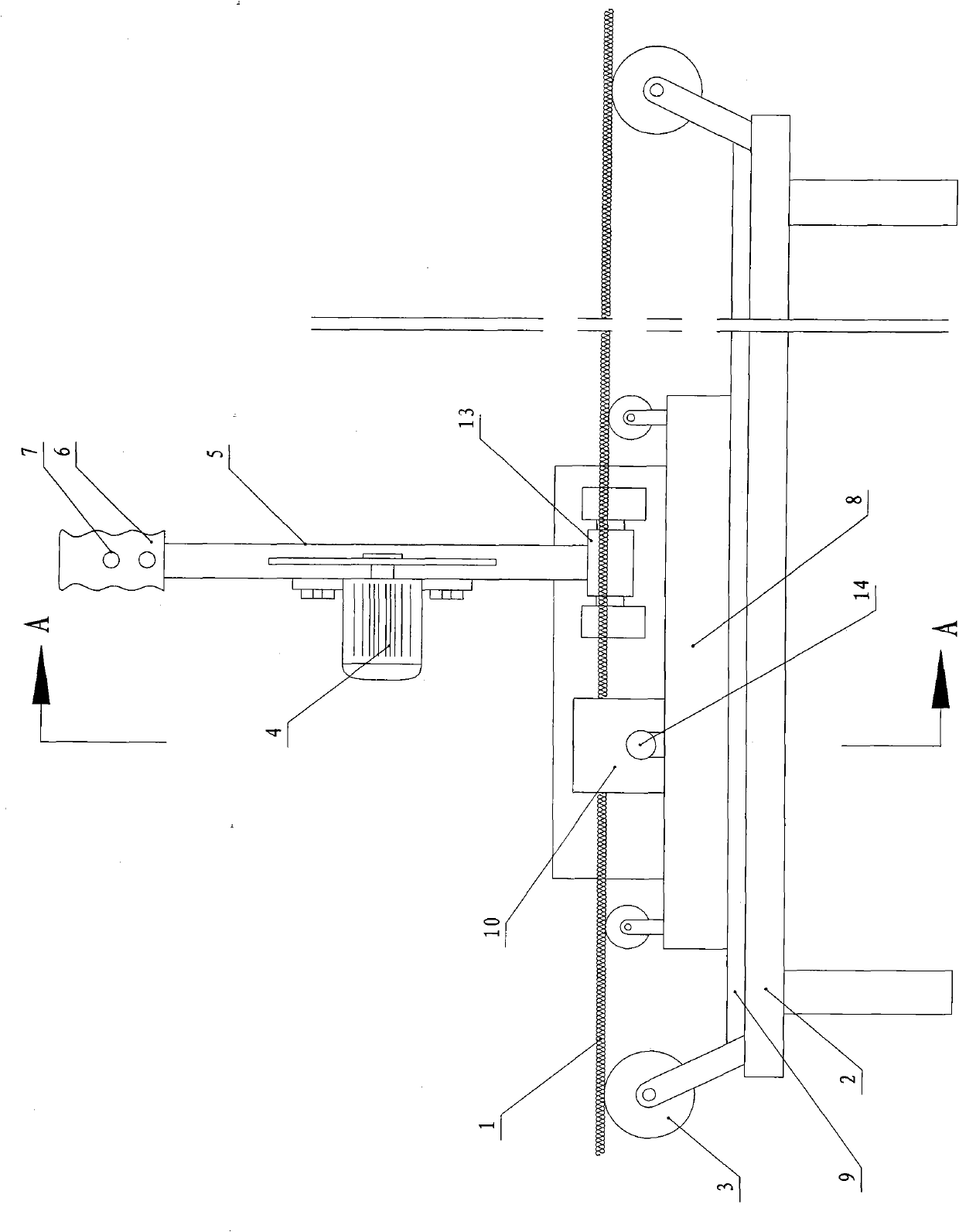

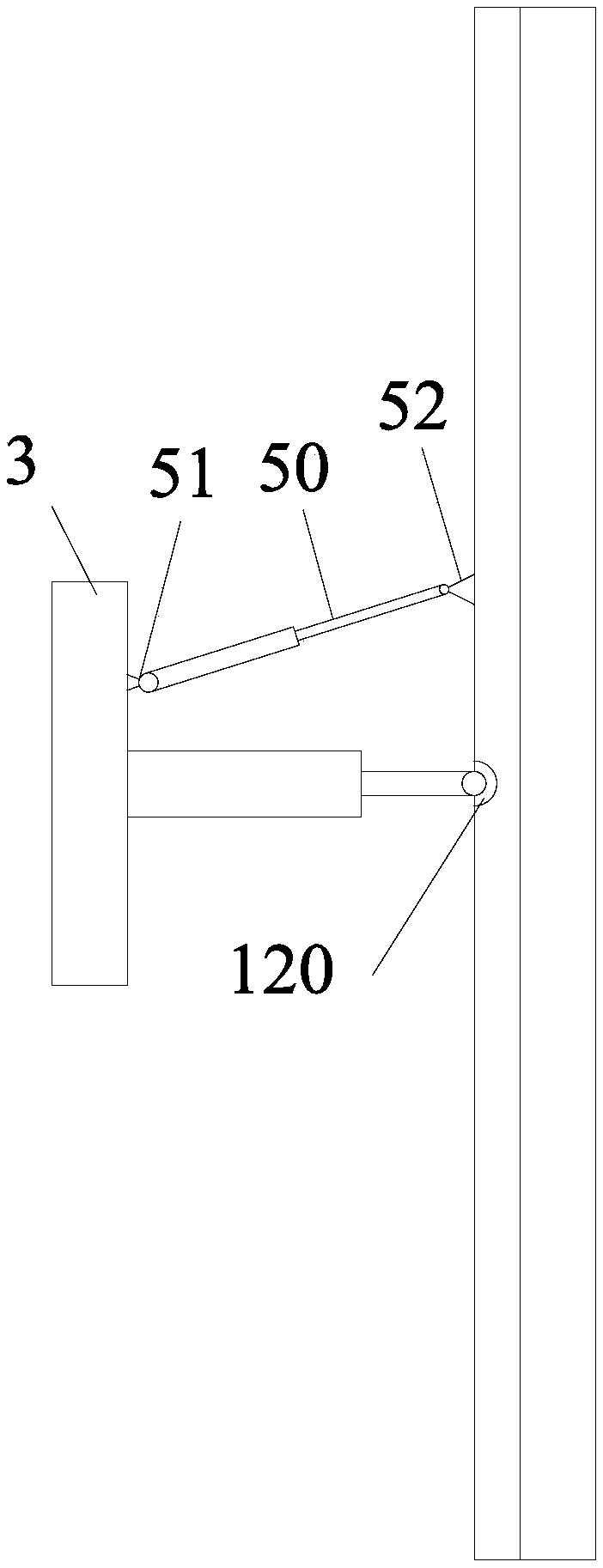

Steel cable follow-up cutting device

The invention relates to a steel cable follow-up cutting device, comprising an underframe, a travelling trolley arranged on the underframe as well as a cutting mechanism and a claming mechanism which are arranged on the travelling trolley; wherein the two ends of the underframe are provided with a steel cable guide wheel, the underframe is fixedly connected with a movable guide rail, and the bottom of the travelling trolley is provided with a chute matched with the movable guide rail; the cutting mechanism comprises an operating rod and a cutting machine arranged on the operating rod, the lower end of the operating rod is hinged on the travelling trolley by a hinge; and the clamping mechanism comprises a fixed clamping plate and a movable clamping plate, the fixed clamping plate is fixedly connected on the travelling trolley, and the movable clamping plate is pressed on the fixed clamping plate by a jacking mechanism. The device can realize follow-up cutting without shutdown, the production efficiency is improved, and the stability of production quality is ensured.

Owner:河南恒星钢缆股份有限公司

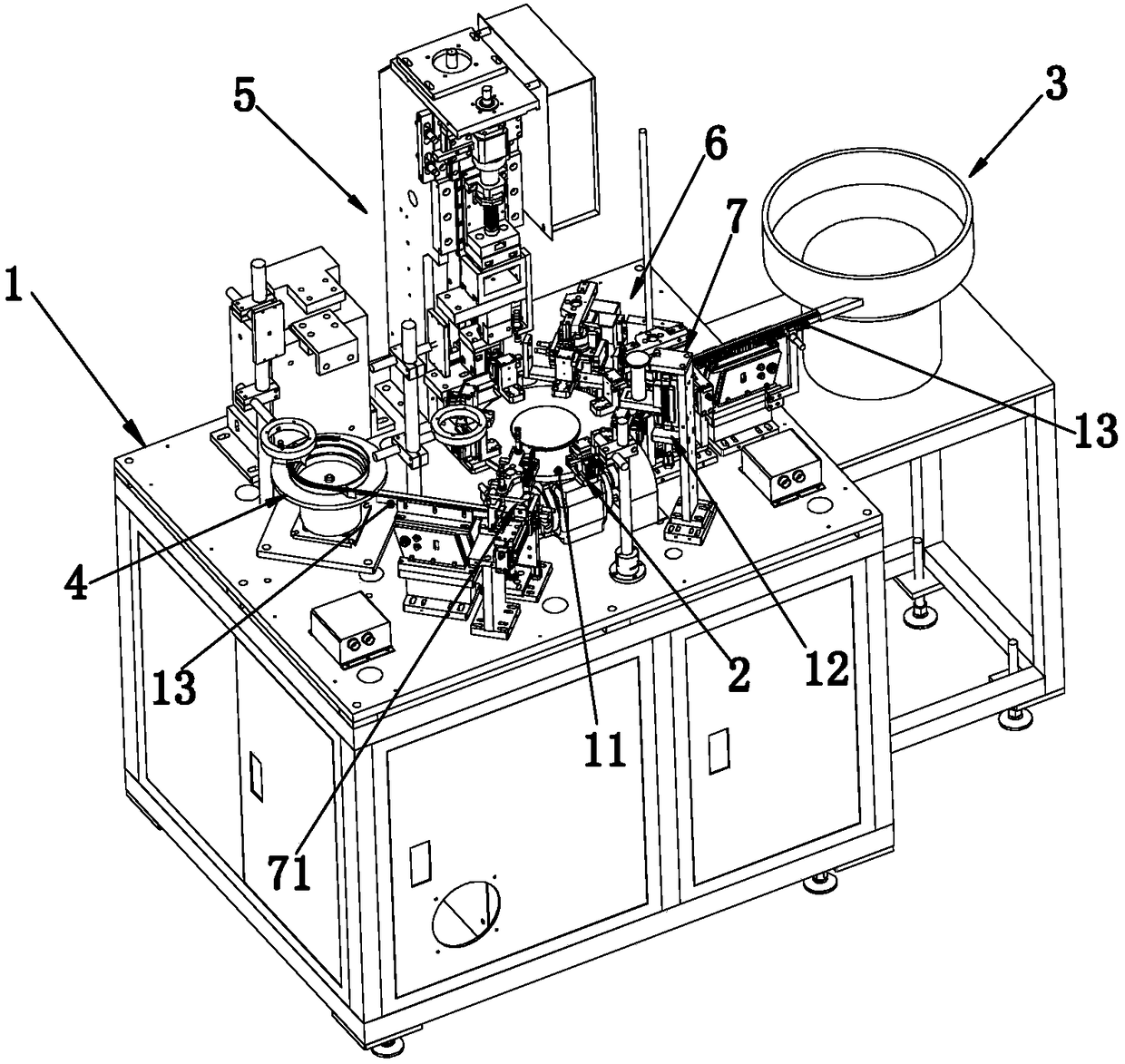

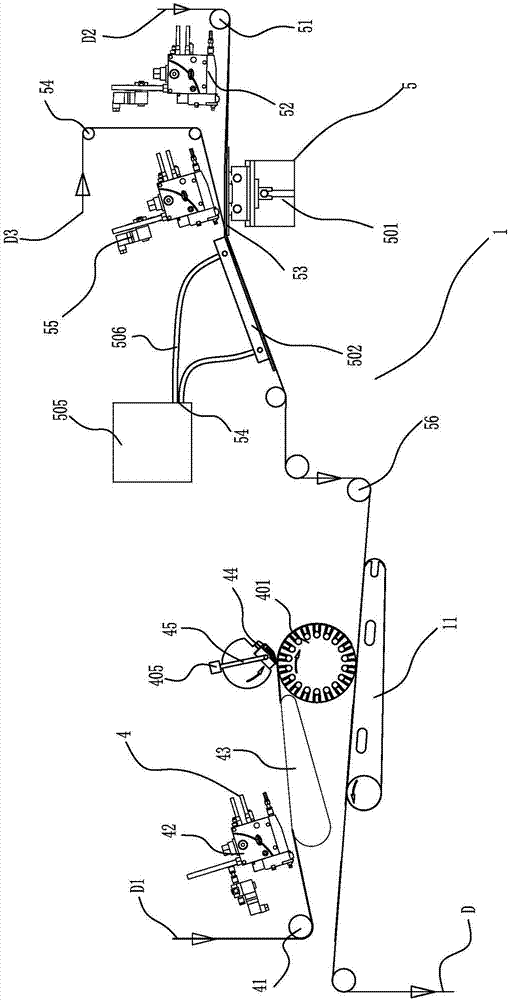

Full-automatic circuit breaker contact and silver point welding equipment

PendingCN108321037AFast transit deliveryShort transfer distanceEmergency protective device manufactureSolder feeding devicesEngineeringOutput device

The invention relates to full-automatic circuit breaker contact and silver point welding equipment. The full-automatic circuit breaker contact and silver point welding equipment comprises a machine body a rotation disc, a clamping device arranged along the edge of the rotation disc, a contact vibration charging tray, a contact drop soldering paste device, a silver point vibration charging tray, acontact and silver point welding device and a product output device. The contact vibration charging tray and the silver point vibration charging tray are connected to the clamping device through a transport channel. Conveying devices are arranged between the contact vibration charging tray and the contact drop soldering paste device and between the silver point vibration charging tray and the welding device. The welding device comprises a support seat erected on the machine body, a welding mechanism, a lifting component and a welding seat. The support seat is provided with a slide rail, wherein the welding seat carries out reciprocation slip on the slide rail. And the support seat is provided with a linkage component. In the technical scheme, the full-automatic circuit breaker contact andsilver point welding equipment is provided; and through using the equipment, welding efficiency is increased, a welding point is accurate, linkage performance is good, clamping is stable and the structure is simple.

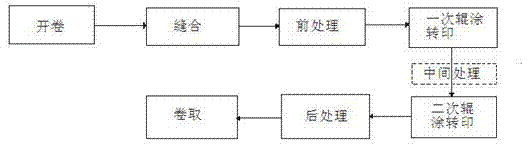

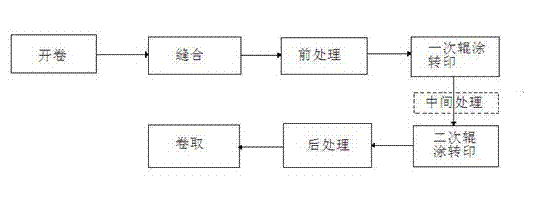

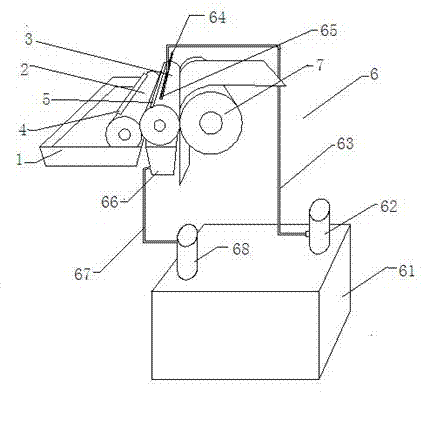

Production method of multicolor pattern color steel plate

InactiveCN103029502AConsistent speedConsistent workmanshipDecorative surface effectsRotary pressesProduction lineProgrammable logic controller

The invention provides a production method of a multicolor pattern color steel plate. For the once transfer printing, on one hand, a PLC (programmable logic controller) control module in a servo control system is used for computing the theoretical roller surface linear velocity of each roller in a roll coater set by acquiring the technical velocity and the rotation velocity of each roller in the roll coater set, and enables the theoretical roll surface linear velocity to be accordant with the technical rotation velocity; and on the other hand, a servo control module with a coder acquires the practical roller surface linear velocity of each roller in the roll coater set, and inputs the practical roller surface linear velocity into the PLC control module, so that a PLC control system can be used for comparing the practical roller surface linear velocity with the theoretical roller surface linear velocity, and adjusting the current frequency till the practical roller surface linear velocity is accordant with the theoretical roller surface linear velocity. According to the control method, the practical roller surface linear velocity is adjusted to be accordant with the theoretical roller surface linear velocity, and the theoretical roller surface linear velocity is adjusted to be accordant with the technical velocity, so that the practical roller surface linear velocity is adjusted to be accordant with the technical velocity, and furthermore, the adjustment by stopping a production line does not need in the process of production, so that the production efficiency can be improved.

Owner:LIAONING CHAOSHUO TOMA TECH STEEL PLATE PRINTING

Film winding mechanism for biodegradable film

The invention discloses a film winding mechanism for a biodegradable film. The film winding mechanism comprises a pneumatic supporting rod, a belt wheel, rotary shafts, infrared detectors, an air pump, a right end cover, a controller and a telescopic bottom plate. The pneumatic supporting rod is arranged on the surface of a roller. The two rotary shafts are arranged at the left end and the right end of the roller respectively. The rotary shafts are arranged on a fixed support and a movable support through rotary bearing sets. The belt wheel is arranged on the left rotary shaft and connected with a drive motor through a belt. The infrared detectors are arranged in the middle of the fixed support. The fixed support is arranged on a platform, and the fixed support and the platform are fixed through bolts. The telescopic bottom plate is arranged below the platform. The rotary shafts are provided with chucks, and the right end cover is arranged at the right end of the right rotary shaft. The film winding mechanism is reasonable in structure and safe and convenient to use, and by means of the telescopic bottom plate and a rotating speed controller, it is guaranteed that in the film winding process, no bubble exists, and flatness of finished products is achieved.

Owner:HUNAN KELAIBAO BIO ENERGY TECH CO LTD

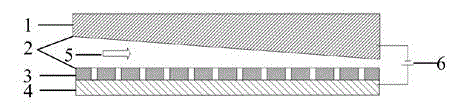

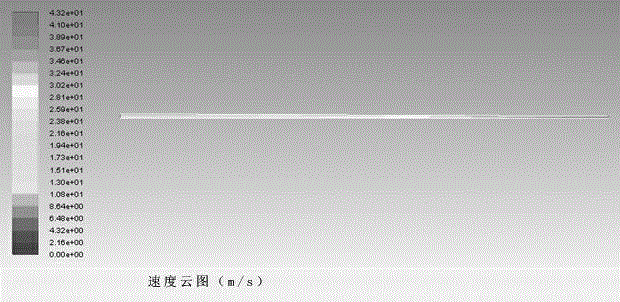

Method and device for electrolytic machining of massive array tiny pits through wedge-shaped runner

ActiveCN103600144AImprove uniformity and machining accuracyHigh bonding strengthMachining electrodesElectrical-based machining electrodesElectric fieldCorrosion

The invention discloses a method and a device for electrolytic machining of massive array tiny pits through a wedge-shaped runner, and belongs to the technical field of electrolytic machining. The method includes processing the surface of a mask plate to enable the surface to fit with the surface of a workpiece anode; fixing a wedge-shaped tool cathode above the mask plate to enable the wedge-shaped runner to be formed between the wedge-shaped tool cathode and the mask plate; connecting the workpiece anode and the wedge-shaped tool cathode with an anode and a cathode of a power source respectively; feeding an electrolyte into the wedge-shaped runner, wherein the electrolyte reaches the surface of the workpiece anode through penetrating group holes in the mask plate; switching on the power source for electrolytic machining. The runner is arranged to be wedge-shaped, so that electric field intensity and electrolyte flowing speed are enabled to be progressively increased along the direction of the runner, both corrosion strength and speed of a workpiece are enabled to tend to be uniform, and uniformity and machining accuracy of electrolytic machining are improved. A PDMS (polydimethylsiloxane) template is taken as the mask plate, bonding strength of the mask plate and the workpiece anode can be guaranteed, stray corrosion, of the electrolyte, to places around a machining area can be effectively reduced, and locality and uniformity of electrolytic machining can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

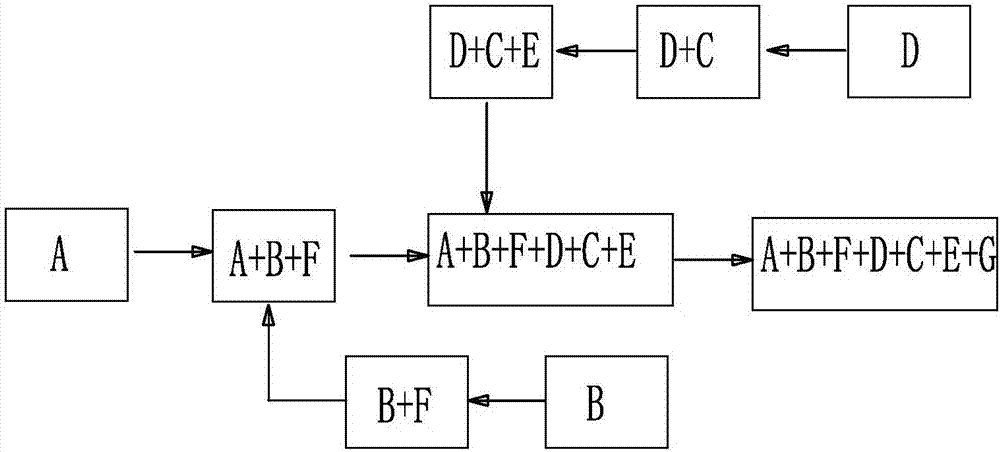

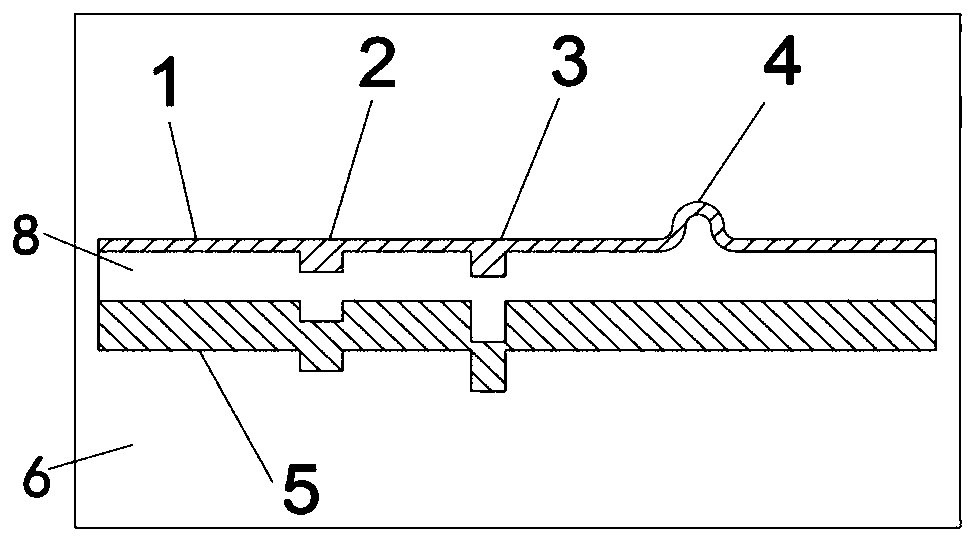

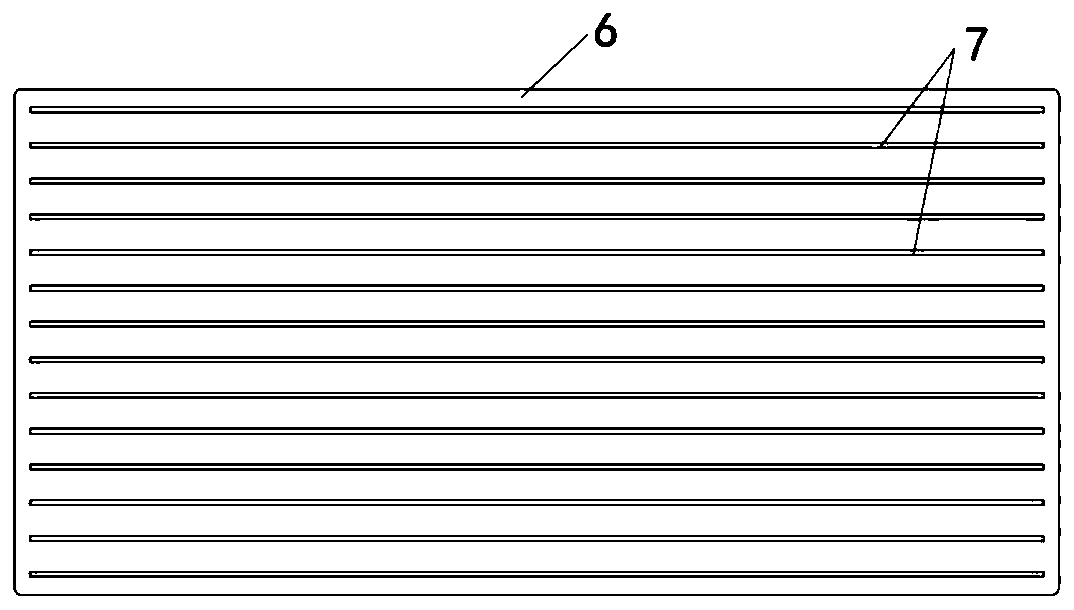

Production line of multi-color patterned roller-coated steel plate

InactiveCN102990360AConsistent speedConsistent workmanshipOther manufacturing equipments/toolsRotary pressesProduction lineProgrammable logic controller

The invention provides a production line of a multi-color patterned steel plate. On one hand, a PLC (programmable logic controller) control module in a servo control system is used for collecting the process speed and the rotating speed of every roller of a roller coating unit, calculating the theoretical linear speed of the surface of every roller in the roller coating unit and making the theoretical linear speed of the roller surfaces identical to the process speed; on the other hand, the actual linear speed of the surface of every roller in the rolling coating unit is collected by a servo control module with an encoder, the signal of the actual linear speed of the surface of every roller is input into the PLC control system, the actual linear speed of the surface of every roller is compared with the theoretical linear speed of the surface of every roller through the PLC control system, and the current frequency is adjusted until the actual linear speed of the surface of every roller is identical to the theoretical linear speed of the surface of every roller. By adopting the control method, the actual linear speed of the surface of every roller can be ensured to be identical to the process speed, stoppage is not needed in the production process for adjustment, and the production efficiency is improved. Moreover, a steel strip is subject to pre-transfer treatment in the production method in order to improve the adhesion between a coating and the surface of the steel strip and the moldability of the steel strip after printing.

Owner:LIAONING CHAOSHUO TOMA TECH STEEL PLATE PRINTING

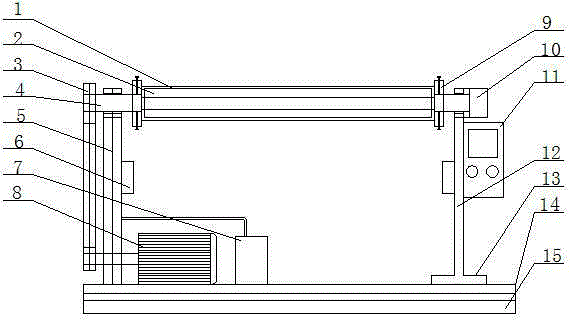

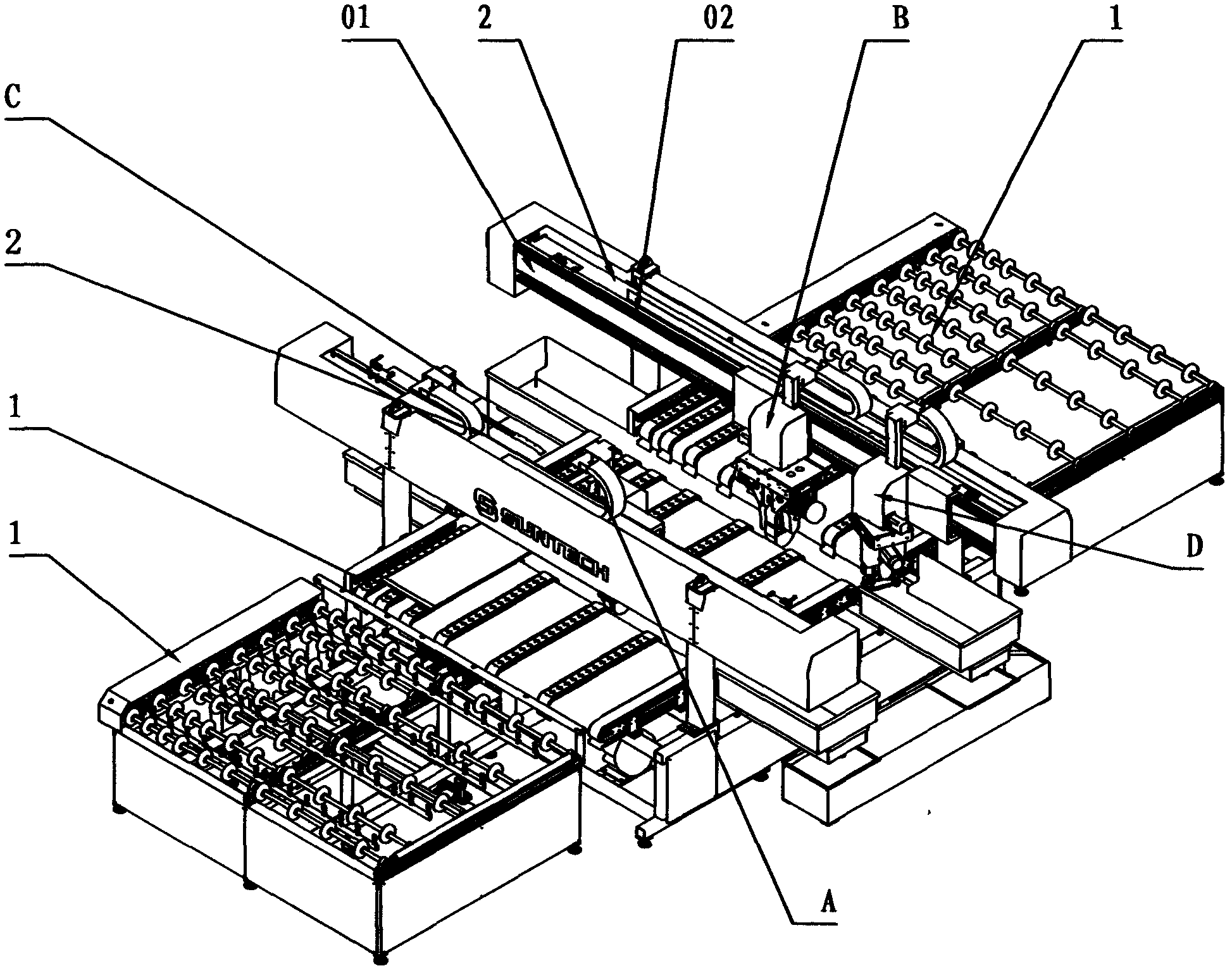

Full-automatic horizontal type glass edge polishing membrane removing machine

InactiveCN102554734ASuitable for mass production needsSave spaceEdge grinding machinesNumerical controlEngineering

The invention relates to an electromechanical integrated machine for glass machining, belonging to the technical field of glass machining machines, and particularly relates to a full-automatic horizontal type machine device with functions of glass edge polishing and membrane removing in the fields of numerical control electromechanical integration and automation. The machine comprises a conveying system assembly and an edge polishing mechanism assembly, wherein the edge polishing mechanism assembly is arranged on the conveying system assembly; the glass edge polishing machine further comprises a glass membrane removing mechanism; the glass membrane removing mechanism is hung under a linear guide track of a frame beam in the edge polishing mechanism assembly and is arranged in parallel to the edge polishing mechanism; the glass membrane removing mechanism can be driven by power to move along the linear guide track horizontally. According to the machine, membrane removing and polishing can be carried out synchronously; the machine is very applicable for large-scale production; the production efficiency is times that of a traditional technology; the guide track, a glass conveying system and a glass detection system of the edge polishing mechanism are shared; a great deal of space and resources are saved; and a membrane removing module can be closed when the membrane removing function is not needed.

Owner:广东新海岸机械有限公司

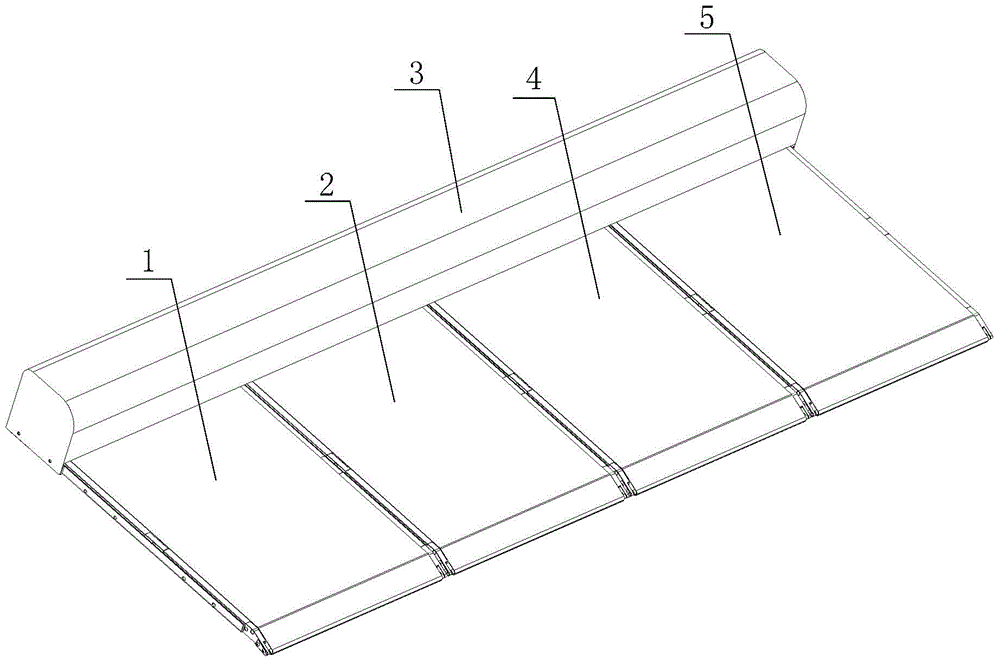

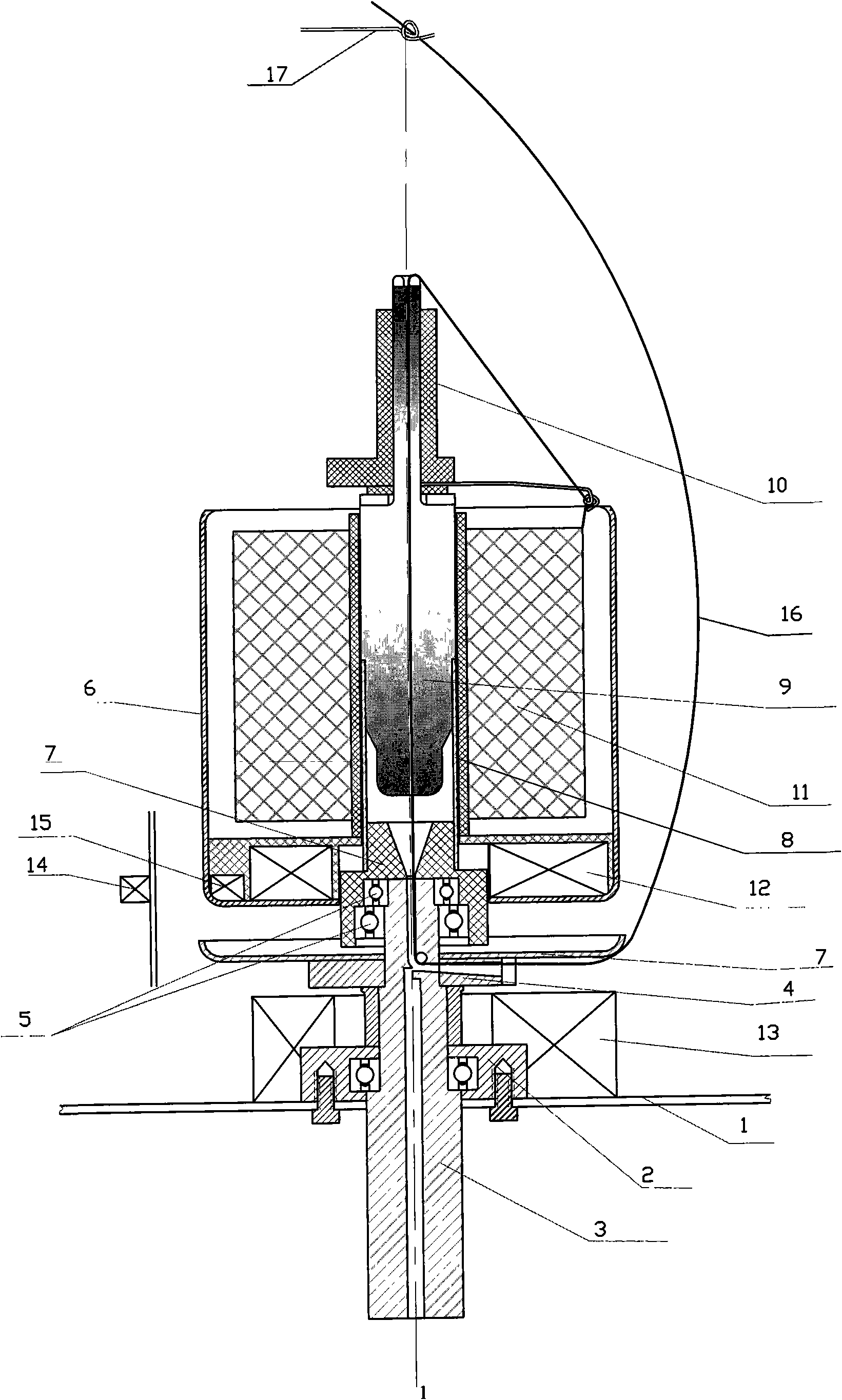

A2.0 B04 grade autoclaved aerated concrete block prepared from quartz eroded sand and preparation method thereof

ActiveCN104774031AAlleviate the problem of comprehensive utilizationInhibits digestive reactionsCeramicwareEngineeringPhosphogypsum

The invention discloses an A2.0 B04 grade autoclaved aerated concrete block prepared from quartz eroded sand. The A2.0 B04 grade high-performance autoclaved aerated concrete block is prepared from quartz eroded sand, cement, quick lime, industrial waste phosphogypsum, aluminum paste and water. The dry density of the concrete block is 415kg / m<3>, the cube crushing strength average value is 2.1 MPa, the single unit minimum value is 1.9 MPa, the ratio of splitting tensile is 0.19, the frost quality loss is 3.7%, the frost strength is 1.7 MPa, the heat conductivity coefficient (dry state) is 0.116 W / (m.K), the dry shrinkage value (standard value) is 0.22 mm / m and the percent of pass is greater than 98%. The raw material processing method is reasonable, the formula calculation is scientific, the production process is simple and the production waste can be recycled. The concrete block is a novel energy-saving and environmentally-friendly wall material and is suitable for industrial process.

Owner:HUBEI YITONG CONSTR ENG CO LTD

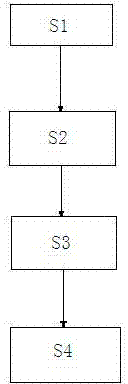

Modularized bed-ridden patient translation transfer machine

A modularized bed-ridden patient translation transfer machine comprises a first module, a second module, a third module and a fourth module which are sequentially connected in parallel through a plurality of threaded rods, wherein the first module, the second module, the third module and the fourth module adopt identical structures and each comprise a lower mechanical transmission device and an upper mechanical transmission device; each lower mechanical transmission device is used for driving the modularized bed-ridden patient translation transfer machine to move on a bed surface; each upper mechanical transmission device is located on the corresponding lower mechanical transmission device, and is driven by the corresponding lower mechanical transmission device to transfer a bed-ridden patient from one bed to another bed. The machine provided by the invention is convenient to dismount, mount and transport; the machine abandons the traditional method in which the lying patient is carried by multiple persons, and achieves automatic transfer of the patient who is injured or paralyzed, or who needs to be transferred before and after an operation; without changing the posture of the patient, a nurse can individually transfer the patient from a hospital bed to a stretcher, or from the stretcher to the hospital bed, so that the labor intensity of the nurse is reduced, the safety and comfort of the patient are improved, and secondary harm to the patient caused by the traditional method is avoided.

Owner:NINGBO INTELLIGENT MFG IND RES INST

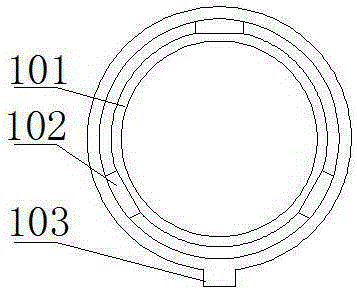

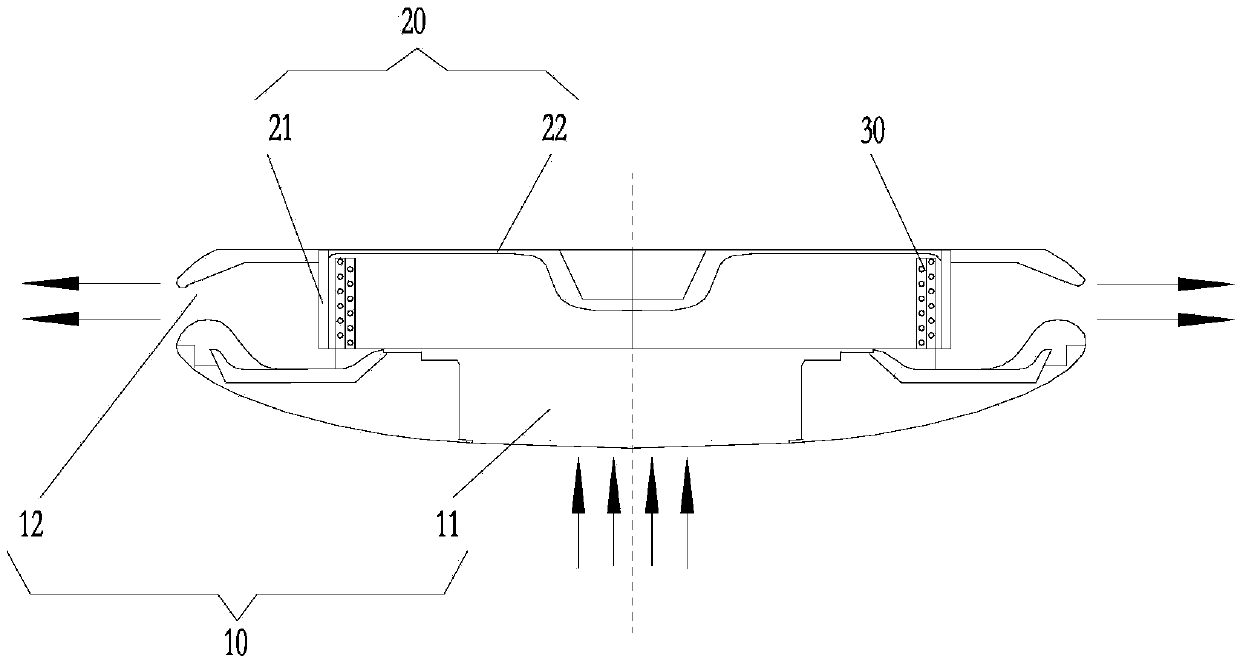

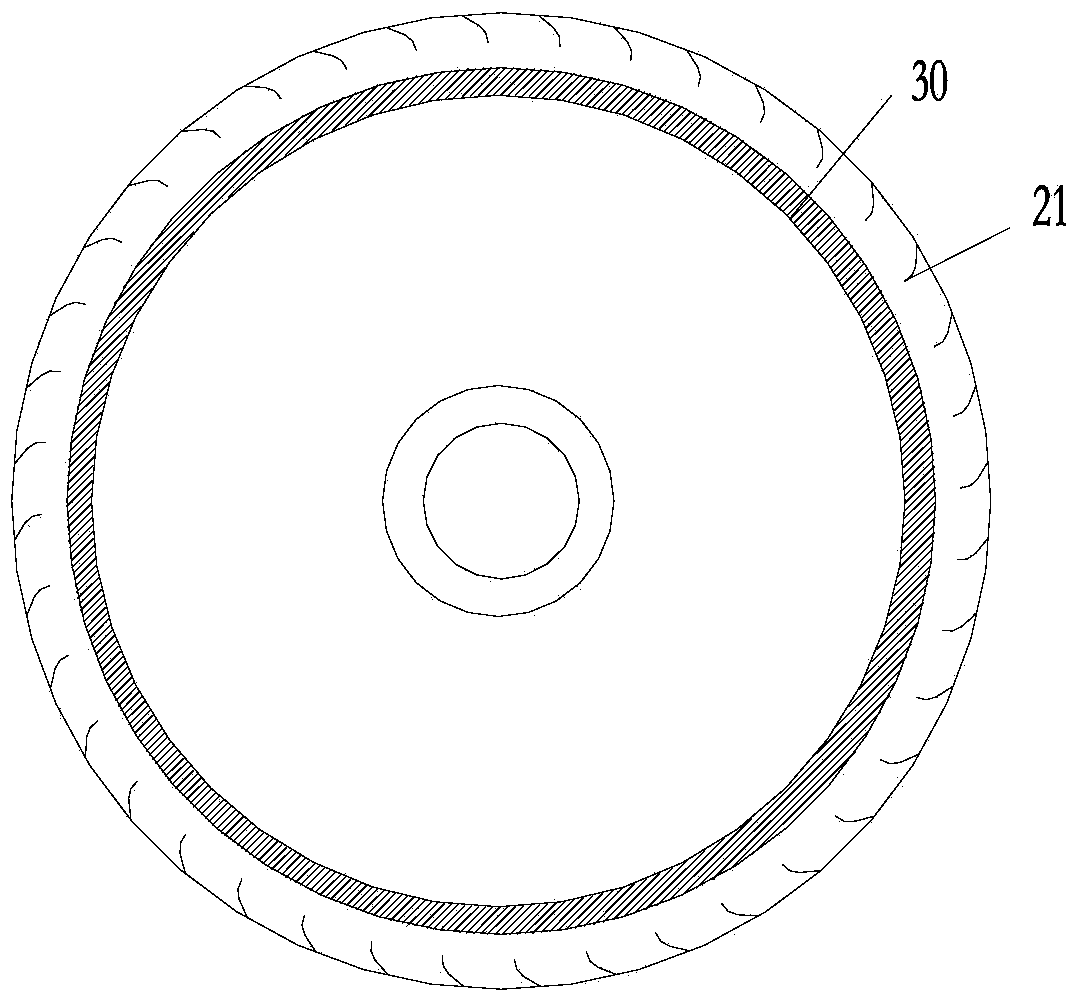

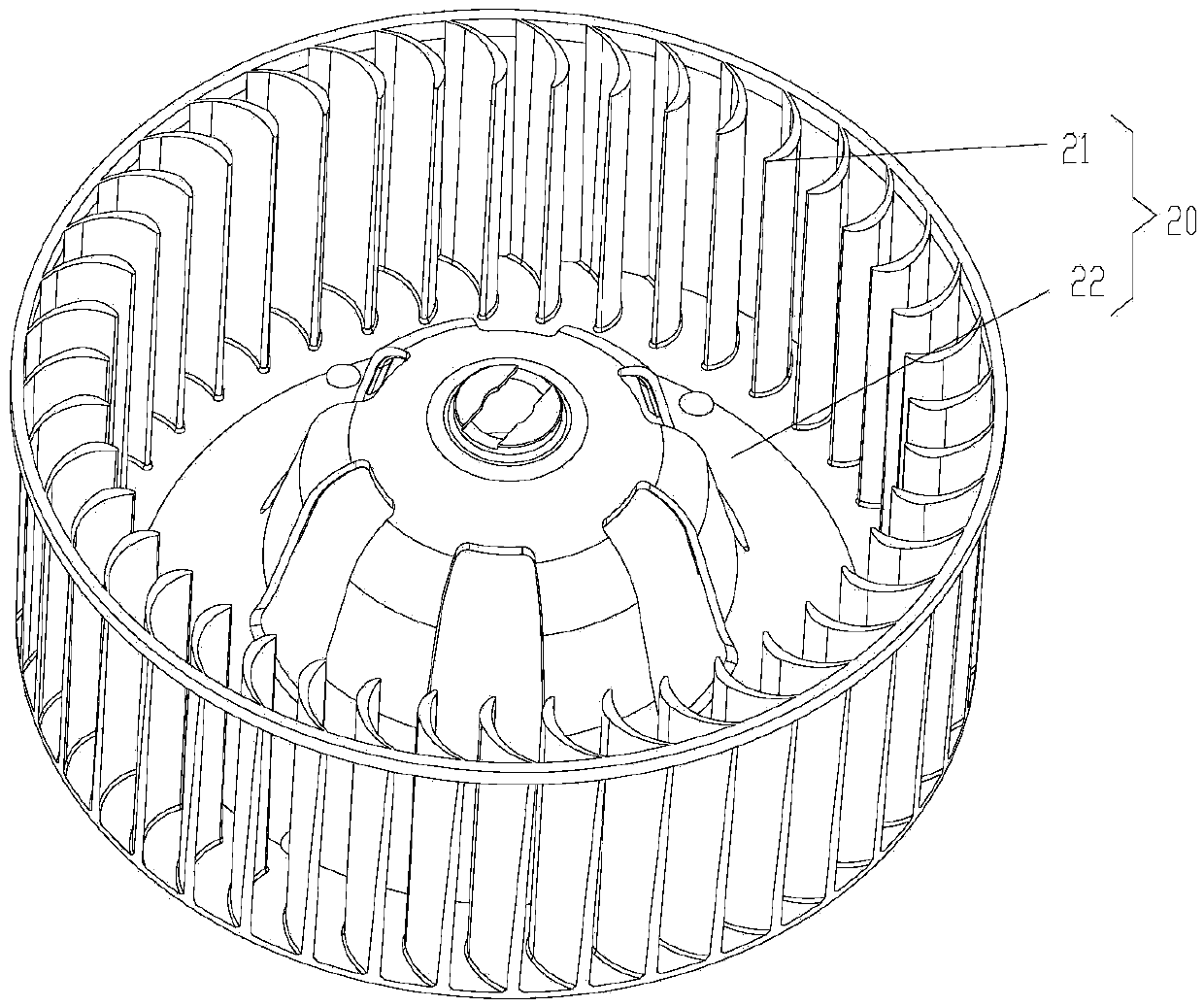

Air conditioner

ActiveCN105371374AConsistent speedUniform windCondensate preventionLighting and heating apparatusEngineeringFan blade

The invention provides an air conditioner. The air conditioner comprises a shell (10), a centrifugal fan (20) and a heat exchanger (30), wherein the shell (10) is provided with an air inlet (11) and an air outlet (12); the centrifugal fan (20) is arranged in the shell (10), and comprises a fan blade (21); and the heat exchanger (30) is arranged on the inner side of the periphery of the fan blade (21). By adopting the technical scheme disclosed by the invention, the problem of an air conditioner in the prior art that the noise is large, and air outlet is non-uniform are solved.

Owner:GREE ELECTRIC APPLIANCES INC

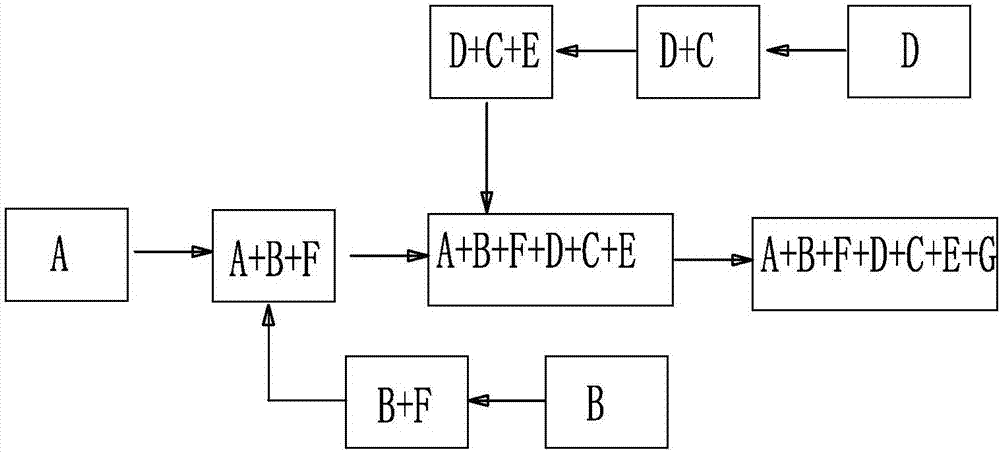

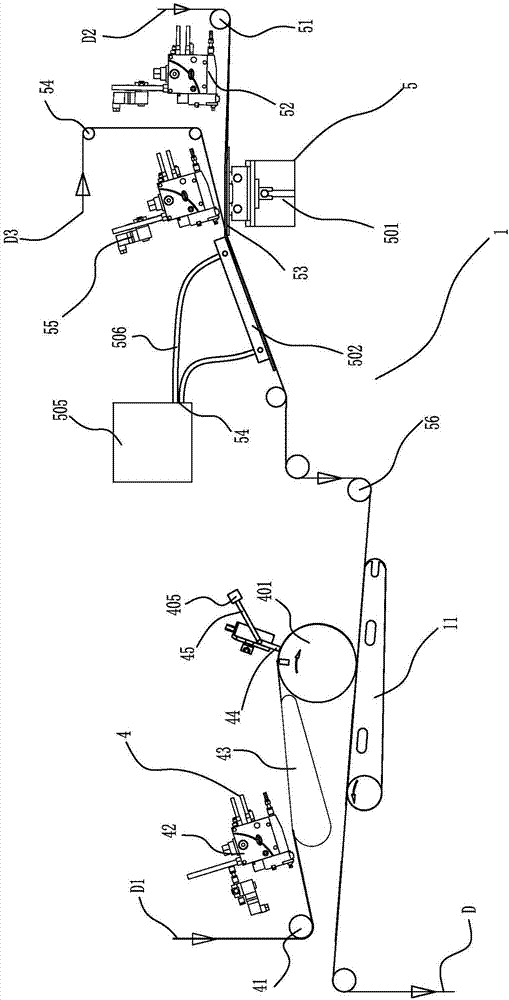

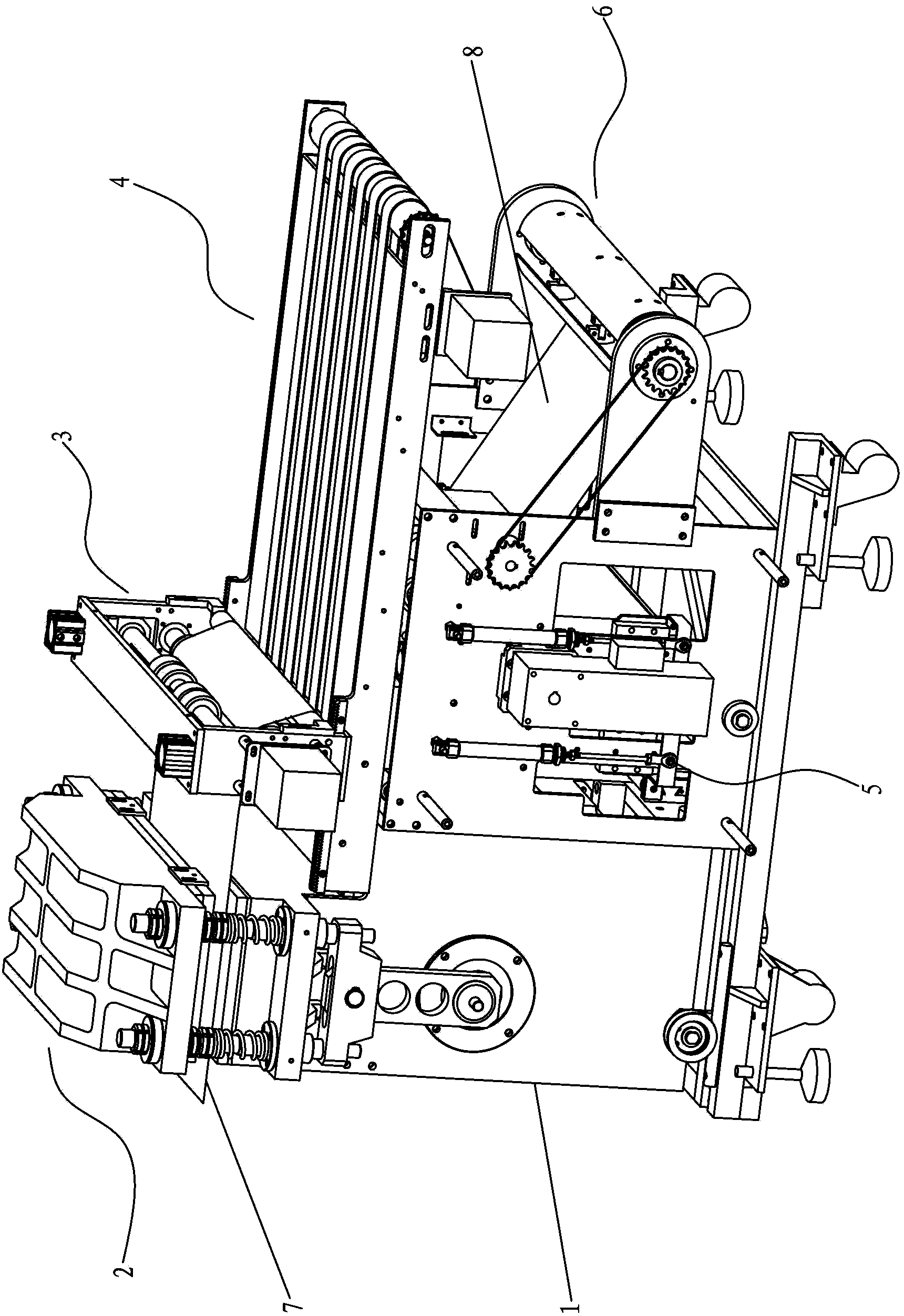

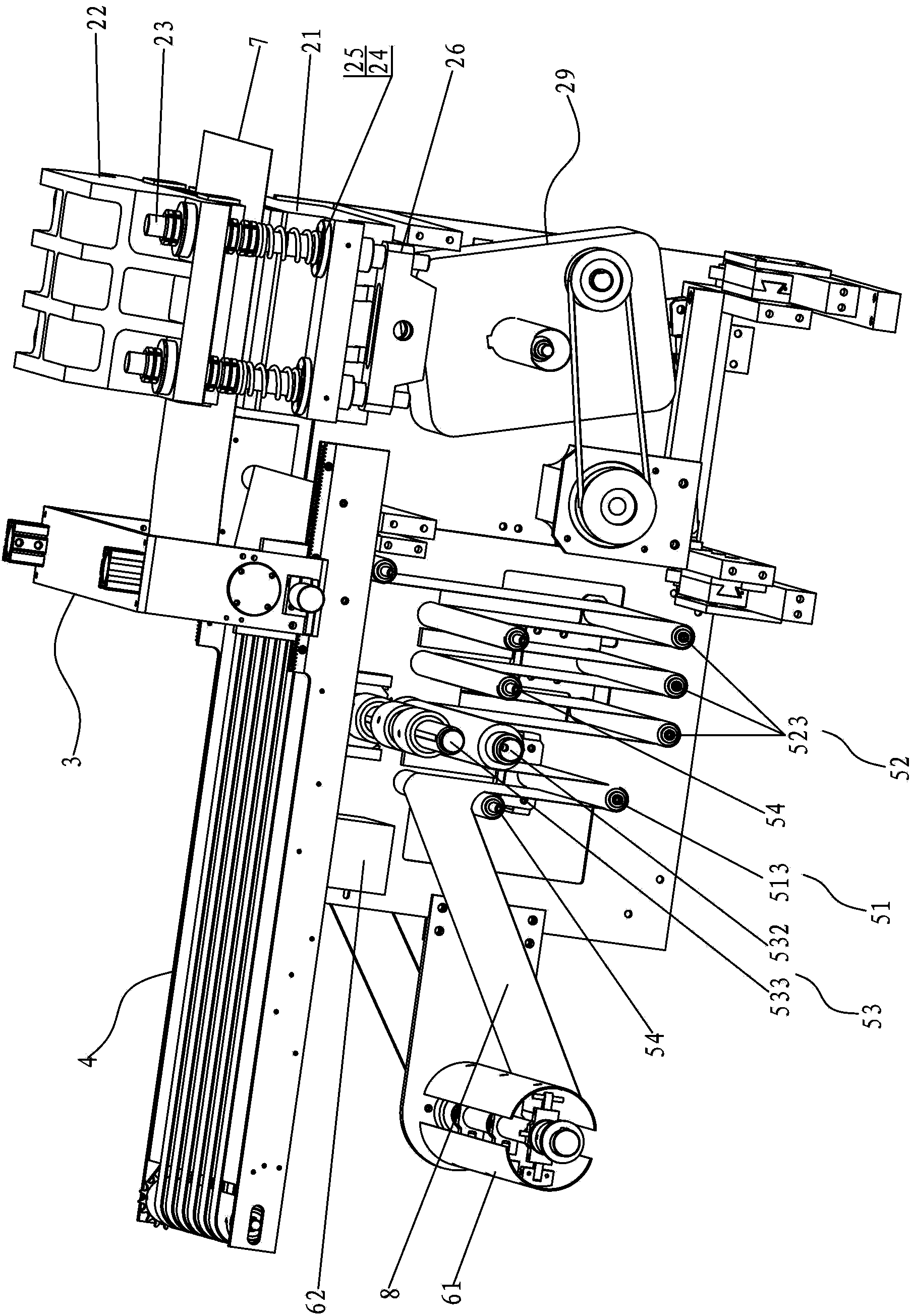

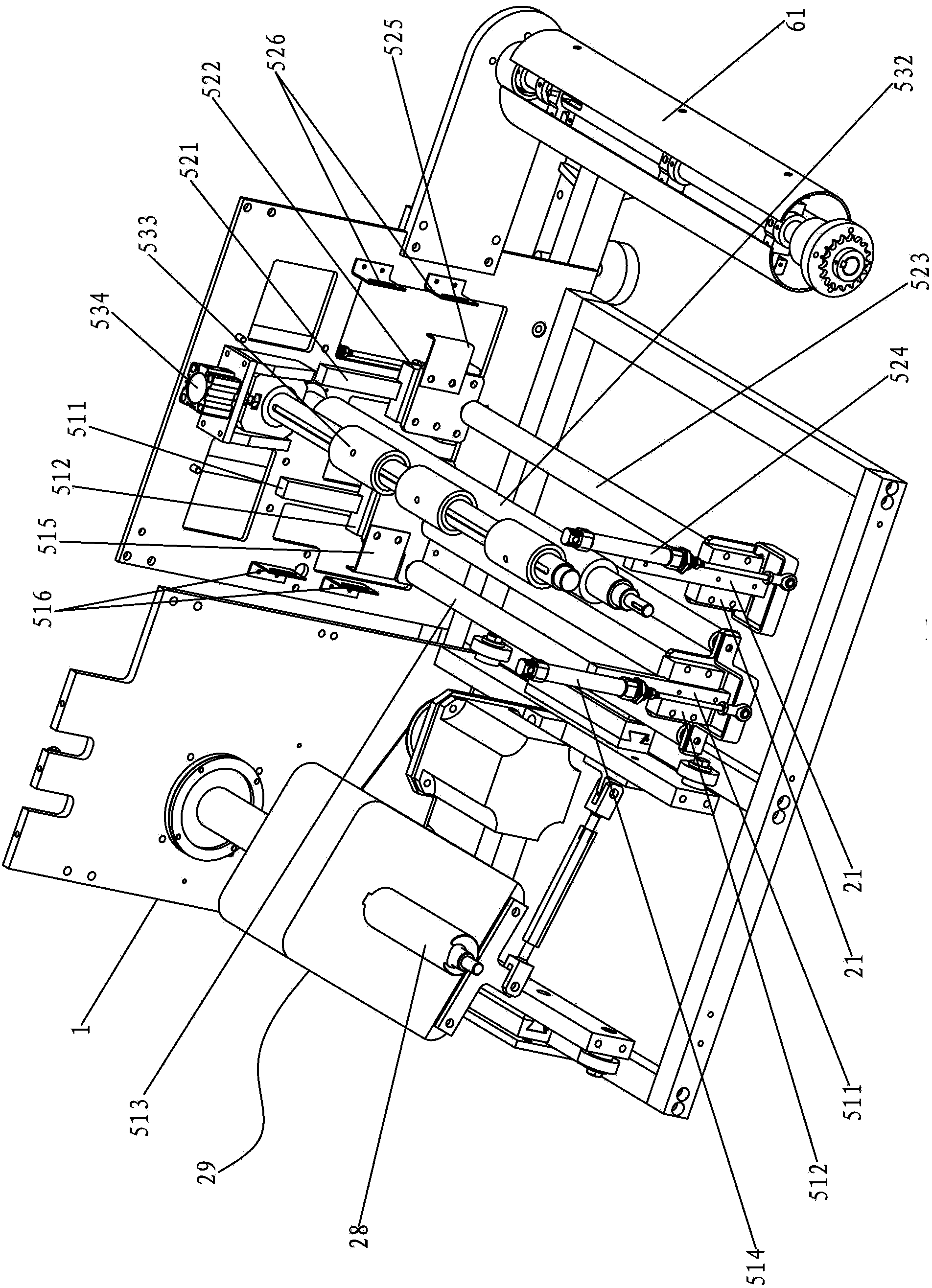

Production assembly line of paper diaper

InactiveCN107007396AStable lengthExtended service lifeAbsorbent padsBaby linensBiochemical engineeringAssembly line

The invention relates to an assembly line of paper diaper, and discloses a production assembly line of the paper diaper. The production assembly line of the paper diaper comprises a machine frame, a core body forming mechanism, a stereoscopic enclosure forming system, a rear elastic waistline forming system and a front waist paste forming system, the core body forming mechanism, the stereoscopic enclosure forming system, the rear elastic waistline forming system and the front waist paste forming system are arranged above the machine frame, the core body forming mechanism comprises a first delivery device, a second delivery device, a base membrane retractor, an SAP recycling device and an inversely-hung wind scoop; the stereoscopic enclosure forming system comprises a rear blocking wall non-woven fabric forming mechanism, an anti-leakage flank forming mechanism and an induced draught feeding device; the front waist paste forming system comprises a front waist paste retractor, a fourth glue gun, an induced draught feeding instrument, a third cutter device and a centrifugal pinch roller, and the front waist paste retractor, the fourth glue gun, the induced draught feeding instrument, the third cutter device and the centrifugal pinch roller are arranged in sequence. The production assembly line of the paper diaper has the advantages that the cost in production of the paper diaper is lowered, and the production efficiency and the rate of finished products of the paper diaper are high.

Owner:HANGZHOU COCO HEALTHCARE PRODS

Contact type array tiny pit electrochemical machining method

ActiveCN104001997AConsistent strengthConsistent speedElectrochemical machining apparatusElectrolysisElectrical field strength

The invention provides a contact type array tiny pit electrochemical machining method and belongs to the technical field of electrochemical machining. The contact type array tiny pit electrochemical machining method comprises obtaining photoresist film patterns required to be performed electrolysis from a workpiece positive pole surface through a photographing masking mode; enabling a workpiece positive pole and a tool negative pole to be respectively connected with a positive pole and a negative pole of a power source; immersing the workpiece positive pole in the electrolyte; enabling the tool negative pole to be in contact with a photoresist film on the workpiece positive pole; switching on the power source to perform electrochemical machining. According to the contact type array tiny pit electrochemical machining method, the tool negative pole is in contact with the photoresist film on the workpiece positive pole, so that electric filed distribution in a machining area can be improved, the electric field intensity on the periphery and in the middle of the machining area tends to be consistent, and the array tiny pit electrochemical machining accuracy and locality are obviously improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Vehicle-mounted LCD intelligent display screen capable of being adjusted in multiple dimensions

ActiveCN109159744AAdjust distanceRealize multi-dimensional adjustmentOptical viewingIdentification meansEngineeringAutomation

The invention discloses a vehicle-mounted LCD intelligent display screen capable of being adjusted in multiple dimensions. The LCD intelligent display screen is arranged on the center console or the seat back, includes a display screen body and a backplane, Vertical guide assembly, sliding support plate, an automatic telescopic device and a drive assembly hinged between the sliding support plate and the back plate for rotationally adjusting about the X axis and a drive assembly for rotationally adjusting about the Y axis, the sliding support plate can make lifting and lowering adjustment between the vertical guide rails, The automatic telescopic assembly can adjust the distance of the vehicle-mounted LCD intelligent display screen, and the automatic telescopic device is connected with theback plate through a ball hinge, and can realize the adjustment of any angle of the LCD intelligent display screen in cooperation with the driving assembly rotated and adjusted around the X axis and the driving assembly rotated and adjusted around the Y axis. The invention can automatically adjust the viewing angle to the best according to the needs of users, and has the advantages of good viewingeffect and high automation degree.

Owner:江苏亚楠电子科技有限公司

Production assembly line of paper diapers

InactiveCN107007395AStable lengthExtended service lifeAbsorbent padsBaby linensAssembly lineRetaining wall

The invention relates to an assembly line for producing paper diapers. The production assembly line of the paper diapers comprises a rack, a core body forming mechanism, a stereoscopic guard forming system, a rear elastic waistline forming system and a front waist patch forming system, wherein the core body forming mechanism, the stereoscopic guard forming system, the rear elastic waistline forming system and the front waist patch forming system are arranged on the rack. The core body forming mechanism comprises a first conveying device, a second conveying device, a bottom film retractor, an SAP recovery device and a hang-upside air scoop. The stereoscopic guard forming system comprises a rear retaining wall non-woven fabric forming mechanism, a leakage-proof side wing forming mechanism and an air draft feeding device. The front waist patch forming system comprises a front waist patch retractor, a fourth glue gun, an air draft feeder, a third cutter device and an eccentric pressing wheel which are sequentially arranged. The production assembly line of the paper diapers has the advantages that the production cost of the paper diapers is reduced, and the production efficiency and the yield of the paper diapers are high.

Owner:HANGZHOU COCO HEALTHCARE PRODS

Die-cutting machine for producing single output standing pouches

The invention discloses a die-cutting machine for producing single output standing pouches. When the single output standing pouches are produced, a film sequentially passes through a forming unit and a separation unit to perform die-cutting and separation on the standing pouches; mutual actions of a second floating roller, a tension regulating mechanism and a first floating roller enable the tensile force at two sides of generated film waste materials to be maintained consistent with the film drawing speed; the tension regulating mechanism controls a tension regulating roller to rotate and controls a tension regulating compression roller to enable the film waste materials to be tightly compressed with the tension regulating roller, so that the film waste materials winding on the second floating roller is tensioned, the second floating roller is lifted upward, and the first floating roller is correspondingly descended; accordingly the film generates no deviation when feeding is performed on the forming unit, the die-cutting procedure of the film is smoothly achieved, and then rolling the film waste materials through a rolling roller is achieved. The die-cutting machine for producing the single output standing pouches has the advantages of improving the processing quality of finished products of the single output standing pouches, reducing manual interference function on the film waste material rolling and reducing labor costs.

Owner:ZHONGSHAN NCA

Improved production method of multi-color patterned roller-coated steel plate

InactiveCN103158415AConsistent speedConsistent workmanshipLiquid surface applicatorsRotary intaglio printing pressProgrammable logic controllerControl system

The invention provides an improved production method of a multi-color patterned steel plate. On one hand, a PLC (programmable logic controller) control module in a servo control system is used for collecting the process speed and the rotating speed of every roller of a roller coating unit, calculating the theoretical linear speed of the surface of every roller in the roller coating unit and enabling the theoretical linear speeds of the roller surfaces to be identical to the process speed; and on the other hand, the actual linear speed of the surface of every roller in the rolling coating unit is collected by a servo control module with an encoder, a signal of the actual linear speed of the surface of every roller is input into the PLC control system, the actual linear speed of the surface of every roller is compared with the theoretical linear speed of the surface of every roller through the PLC control system, and the current frequency is adjusted until the actual linear speed of the surface of every roller is identical to the theoretical linear speed of the surface of every roller. By adopting the control method, the actual linear speed of the surface of every roller can be identical to the process speed, the stoppage is not needed in the production process for adjustment, and the production efficiency is improved.

Owner:LIAONING CHAOSHUO TOMA TECH STEEL PLATE PRINTING

Epoxy heating fiberglass mould and preparation method thereof

PendingCN110053279ASolve the deformationSolve the strength problemDomestic articlesTemperature controlEpoxy

The invention provides an epoxy heating fiberglass mould and a preparation method thereof. The preparation method comprises the following steps including female mould manufacturing, mould structural manufacturing; gel coat manufacturing; topcoat manufacturing; heating layer manufacturing; structural reinforcing layer manufacturing; heat preservation layer manufacturing; framework support manufacturing; temperature control system manufacturing; and silica gel surface mould manufacturing. The epoxy heating mould meets the requirements that the high temperature deformation temperature is above 120 DEG C, the shrinking percentage is low, and heating is uniform, and the technical problem that local overheating damages the mould is solved.

Owner:XIAMEN HANSHENG YACHT BUILDING

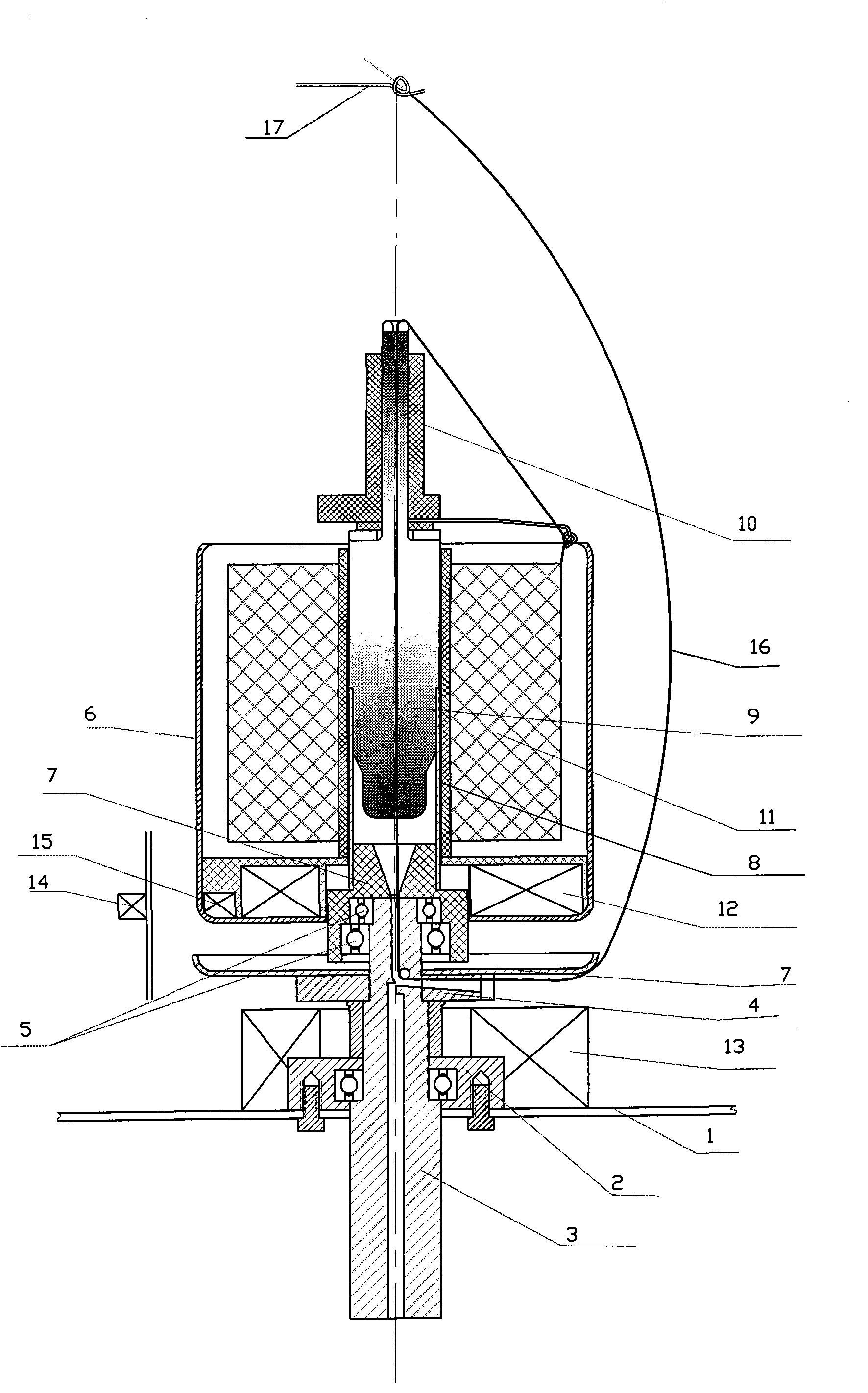

Energy-saving spindle for magnetic suspension two-for-one twister

InactiveCN101831734ADragon belt tension reducedReduce energy consumptionContinuous wound-up machinesRepulsion forceYarn tension

The invention provides an energy-saving spindle for a magnetic suspension two-for-one twister, which not only can be applied to the production of a new-made two-for-one twister, but also can be used for reforming the traditional two-for-one twister. The energy-saving spindle comprises a bottom plate, a bearing pedestal, a spindle blade, a yarn storage disc, a duplex bearing, a sleeve pipe, a hollow pipe, a circular tank shell, a yarn tension device, a flyer, a yarn supply creel and annular permanent magnets. The same poles of the annular permanent magnet installed under the circular tank shell and the annular permanent magnet attracted on the bottom plate (or the bearing pedestal) are opposite each other, so that the circular tank shell and the yarn supply creel float upward by using the polar repulsion principle of magnets; along with the enlargement of the floating distance, the repulsion force is relatively weakened; and when the repulsion force is equal to the total weight of the circular tank shell and the yarn supply creel, the circular tank shell suspends immovably; at the same time, the weight of the circular tank shell and the yarn supply creel presses against the bottom plate, the load on the spindle blade is greatly reduced, thereby achieving the purpose of energy saving and relatively improving the yield and the quality of the product.

Owner:王建伟

A3.5 B05 grade autoclaved aerated concrete block made of quartz weathered sand, and making method thereof

ActiveCN104844106AInhibits digestive reactionsResolve fast digestionCeramicwareIndustrial wasteAluminium

The invention provides an A3.5 B05 grade autoclaved aerated concrete block made of quartz weathered sand. The high-performance A3.5 B05 grade autoclaved aerated concrete block is made by using the quartz weathered sand, cement, quicklime, industrial waste phosphogypsum, aluminum powder paste and water as raw materials. The dry density of the block is 509kg / m<3>, the average cubic compressive strength of the block is 3.6MPa, the single component minimum of the block is 3.2Mpa, the split-to-compression ratio is 0.20, the mass loss after freezing is 2.8%, the strength after freezing is 3.1Mpa, the heat conduction coefficient (dry state) is 0.1251W / (m.K), the drying shrinkage value (standard process) is 0.32mm / m, and the qualified rate is greater than 98%. The method has the advantages of reasonable treatment of raw materials, scientific formula calculation, concise production flow, recycling of production wastes. The block is a novel energy saving and environmental protection wall material, and can be industrially produced.

Owner:HUBEI YITONG CONSTR ENG CO LTD

Mobile trolley traction control method and system

ActiveCN109116855AAccurate turnRapid changePosition/course control in two dimensionsInformation processingMathematical model

The invention belongs to the smart trolley information processing technical field and discloses a mobile trolley traction control method and system. The control method includes the following steps that: initialization is carried out, and current inductance values are acquired; two inductance values are normalized; normalized values are obtained, and whether the obtained values are greater than 0 or smaller than 0 is judged; direction judgment is performed; and the above steps are cycled continuously. A direction control algorithm used in the program of the present invention is fuzzy control, and a speed control algorithm in the present invention is PID control; and since the direction control of the invention adopts fuzzy control, and the robustness of the direction control is strong, andtherefore, the influence of interference and parameter variation on a control effect is greatly weakened, the direction control is especially suitable for the control of nonlinear, time-varying and pure-lag systems, and the accurate mathematical model of an object is not required.

Owner:HUBEI NORMAL UNIV

Sand blasting equipment, sand blasting system and sand blasting method

PendingCN109176321AIncrease freedomIncrease flexibilityBlast gunsAbrasive machine appurtenancesSand blastingEngineering

The invention provides sand blasting equipment, a sand blasting system and a sand blasting method. The sand blasting equipment is used for carrying out sand blasting on a tower drum, and comprises a spraying vehicle, a sand blasting device and a controller, wherein the spraying vehicle comprises a protective shell, a front wheel mechanism and a rear wheel mechanism are arranged at the bottom of the protective shell, the sand blasting device comprises a sand gun, a clamping mechanism used for fixing the sand gun and a swing mechanism for enabling the sand gun to rotate, the sand blasting deviceis arranged on the protective shell of the spraying vehicle, the swing mechanism is connected with the clamping mechanism, the controller is arranged on the spraying vehicle, and is correspondingly connected with and used for driving the front wheel mechanism and the rear wheel mechanism of the spraying vehicle and the swing mechanism of the sand blasting device. The sand blasting system comprises the above sand blasting equipment, a roller frame and the tower drum. The invention further provides the sand blasting method. According to the equipment, the system and the method, automatic sand blasting can be realized, artificial and manual swing for sand blasting operation can be replaced, uninterrupted continuous operation is carried out, and the sand blasting quality and the sand blastingefficiency are improved.

Owner:SUZHOU TITAN NEW ENERGY TECH CO LTD

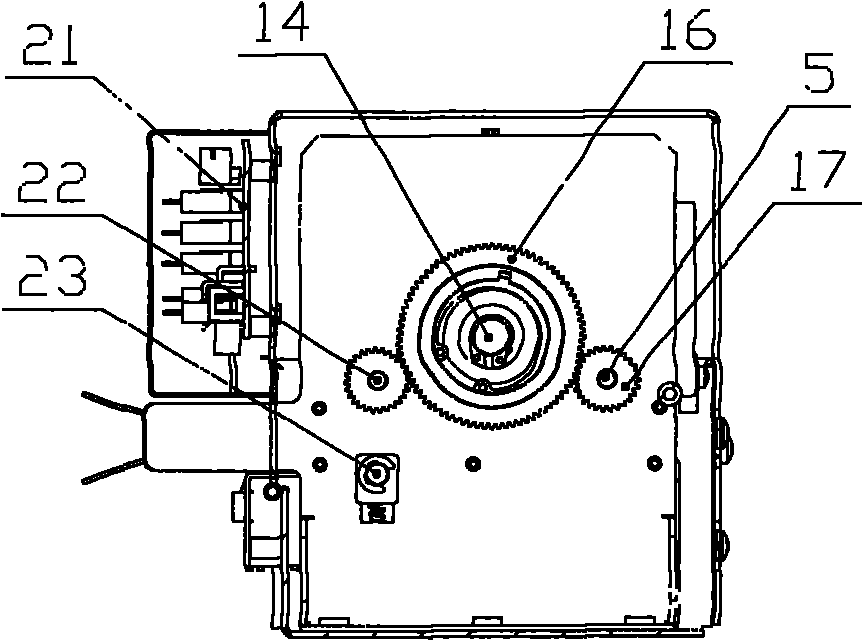

Automatic roll stamping seal device

The invention discloses an automatic roll stamping seal device which has the characteristic of effectively reducing the effectiveness lose odds of the mechanism; the automatic roll stamping seal device comprises a paper feed channel, a seal rotating shaft and a roll stamping rotating shaft which are arranged at two sides of the paper inlet channel, the seal rotating shaft and the roll stamping rotating shaft form a rotating shaft system, a rolling seal is arranged on the seal rotating shaft, a roll stamping roll which is arranged corresponding to the rolling seal is arranged on the roll stamping rotating shaft, the rotating shaft system is connected with a drive motor in a transmitting way, and an overrunning clutch is connected between the rotating shaft system and the drive motor in a transmitting way; when the drive motor drives the seal rotating shaft and the roll stamping rotating shaft to work, the overrunning clutch can drive the seal rotating shaft and the roll stamping rotating shaft to work, the overrunning clutch belongs to a mechanical standard part, the price of the overrunning clutch is far lower than that of an electromagnetic clutch of mechanical and electrical products; in addition, the mechanical structure is simple, and the mechanical standard part is hard to lose effectiveness like the mechanical and electrical products, so as to reduce the manufacturing cost and reduce the effectiveness lose odds of the whole machine; the device is particularly suitable for being popularized and applied to the automatic seal device.

Owner:CHENGDU JIAYITONG INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com