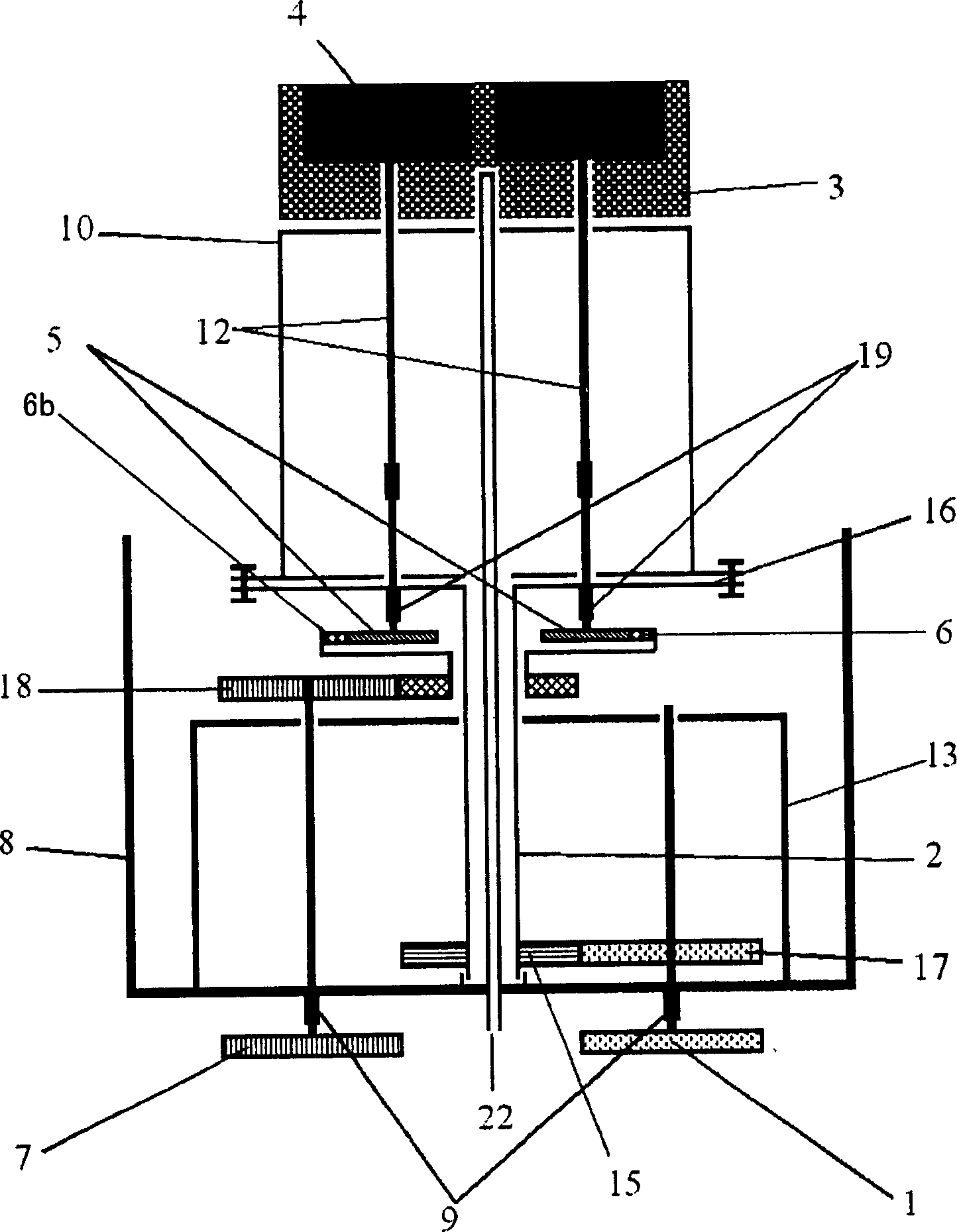

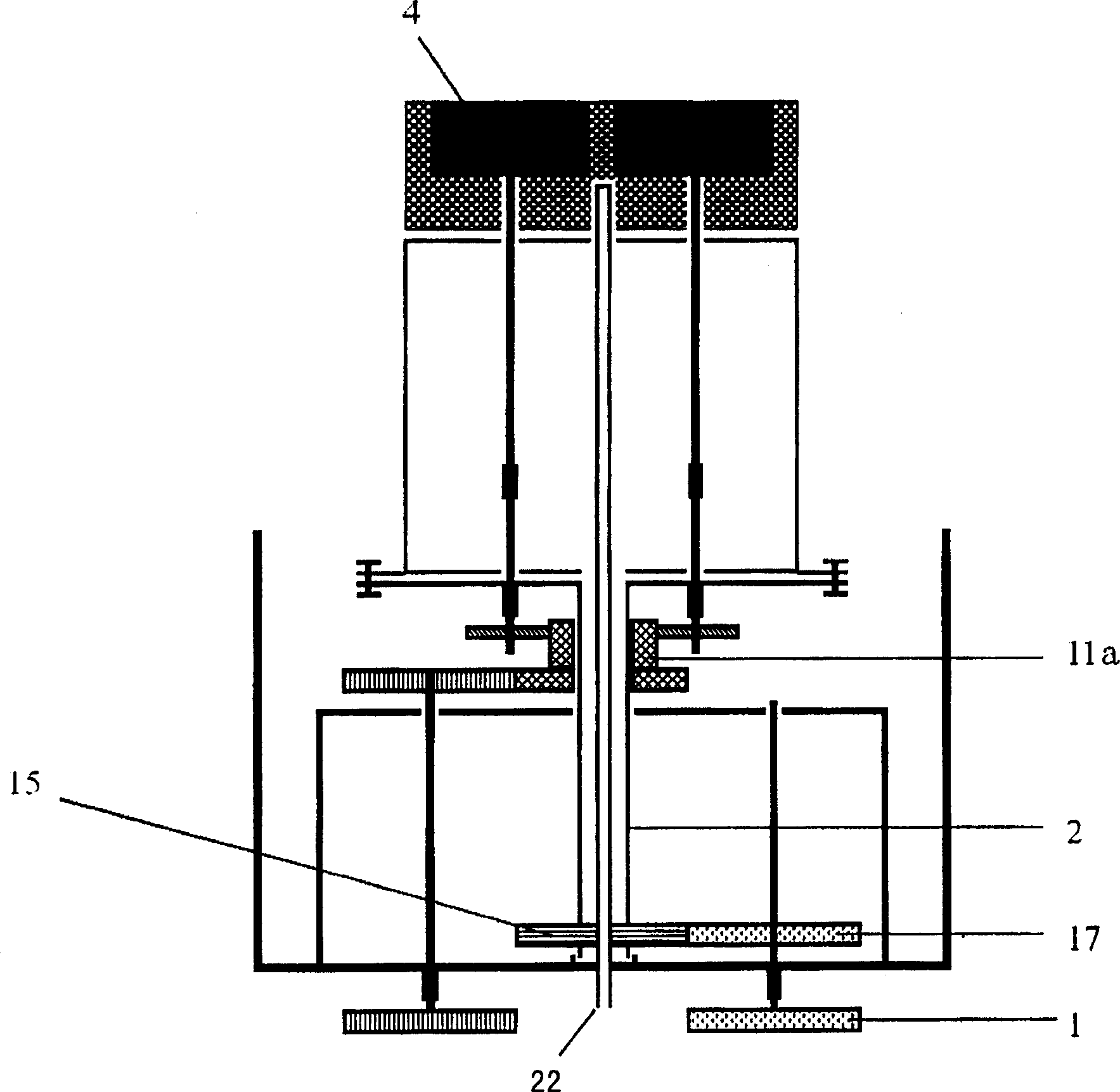

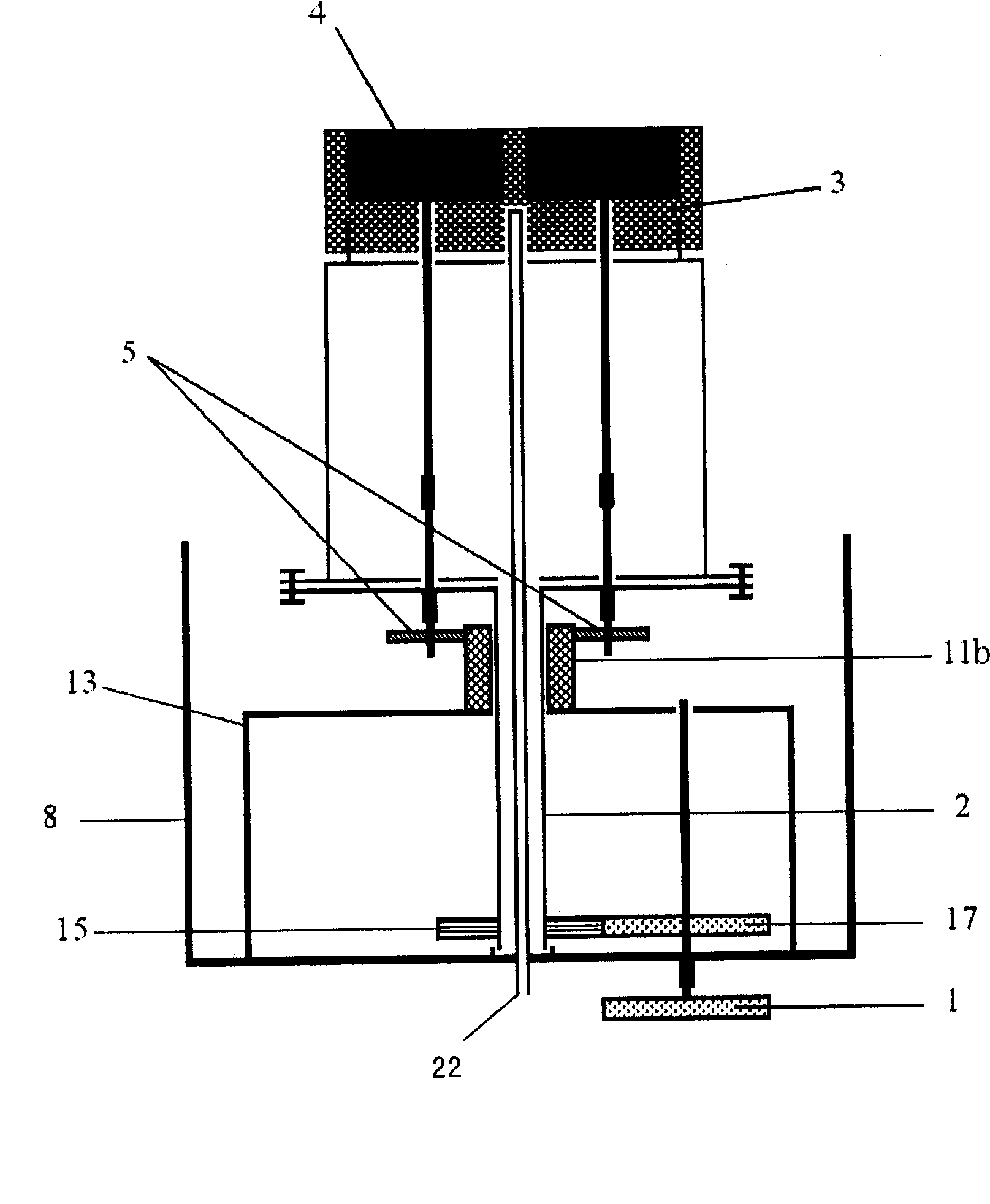

Revolution and rotation arrangement in reaction chamber of metallorganics chemical vapor deposition device

A chemical vapor deposition, metal organic technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve problems such as difficulty in ensuring the consistency of rotation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to better illustrate the meaning of the present invention, the words mentioned are further explained below.

[0051] The so-called "raw material" refers to the raw materials needed to grow thin film materials by using metal organic chemical vapor deposition and other equipment and growth methods, especially metal organic compounds and gas raw materials, but generally does not include carrying gases (such as hydrogen , nitrogen, etc.).

[0052] The term "substrate" or "substrate" refers to the base used for growing thin film materials, on which thin film materials are grown.

[0053] The so-called "reaction chamber" refers to the area where the growth film material is located. Because the growth of thin film materials by metal organic chemical vapor deposition is basically a chemical reaction process, the area where it is located is the reaction chamber.

[0054] The so-called "revolution" refers to the rotation of all the substrates around the same center. J...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com