Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

83results about How to "Different speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

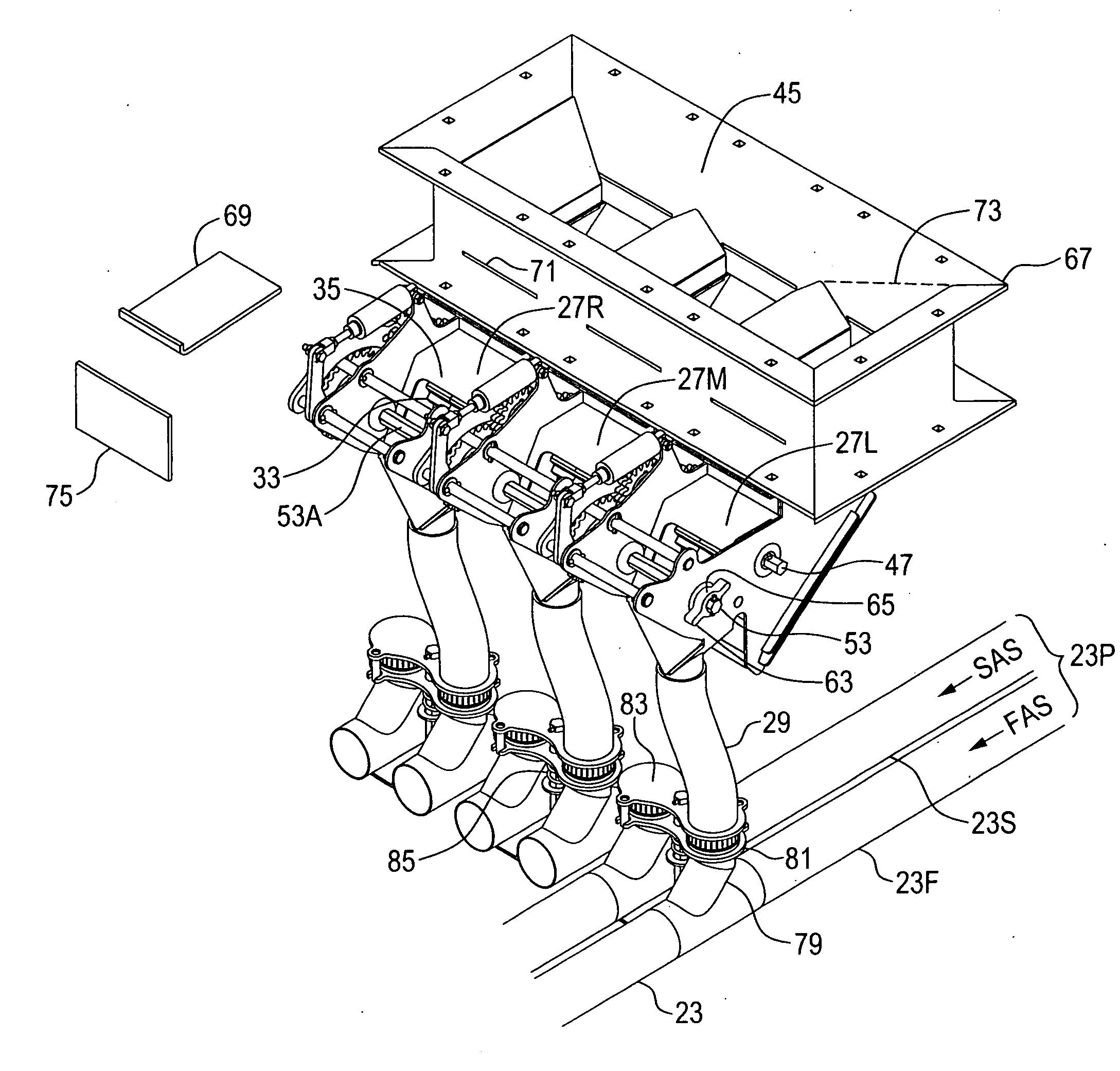

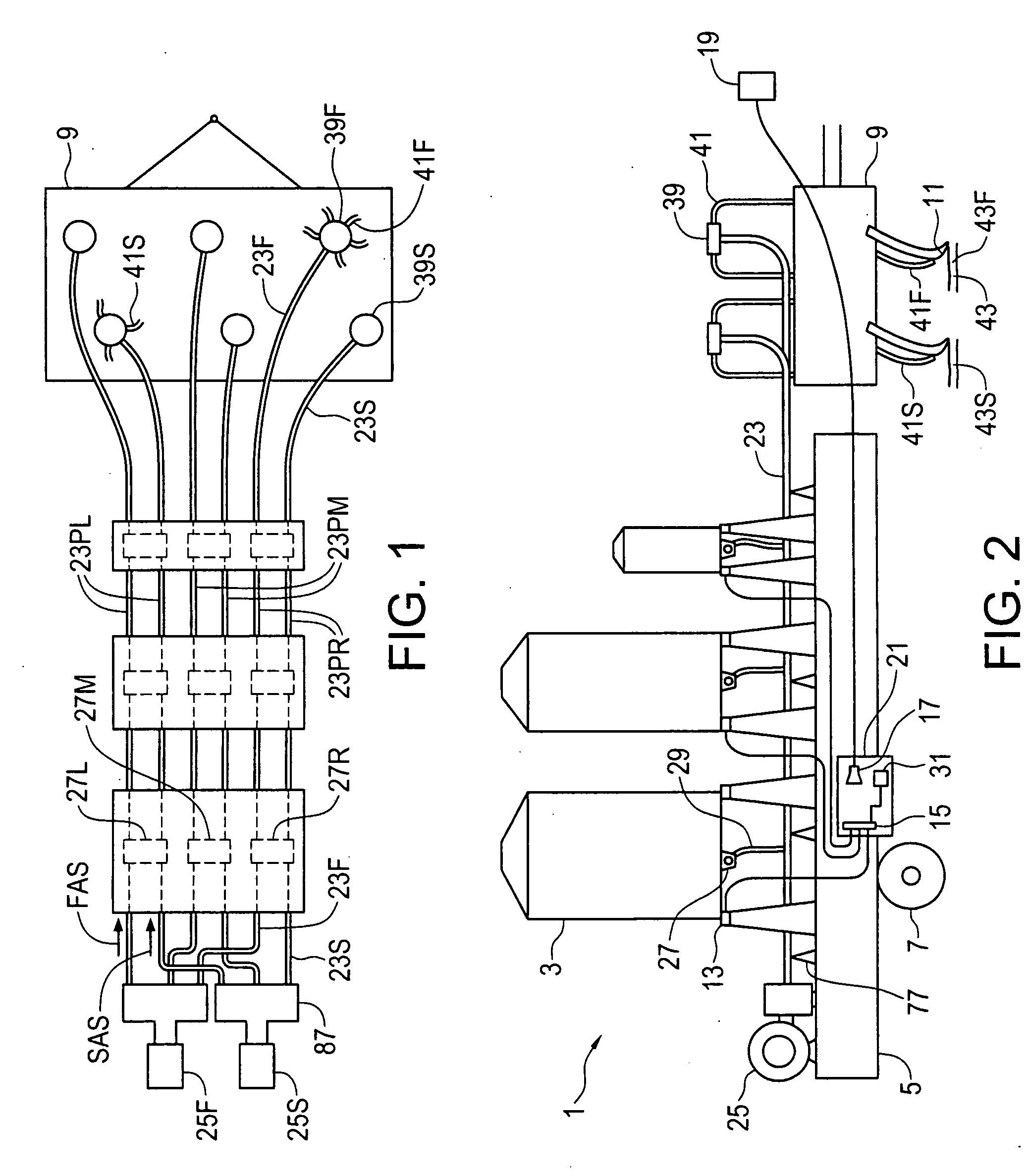

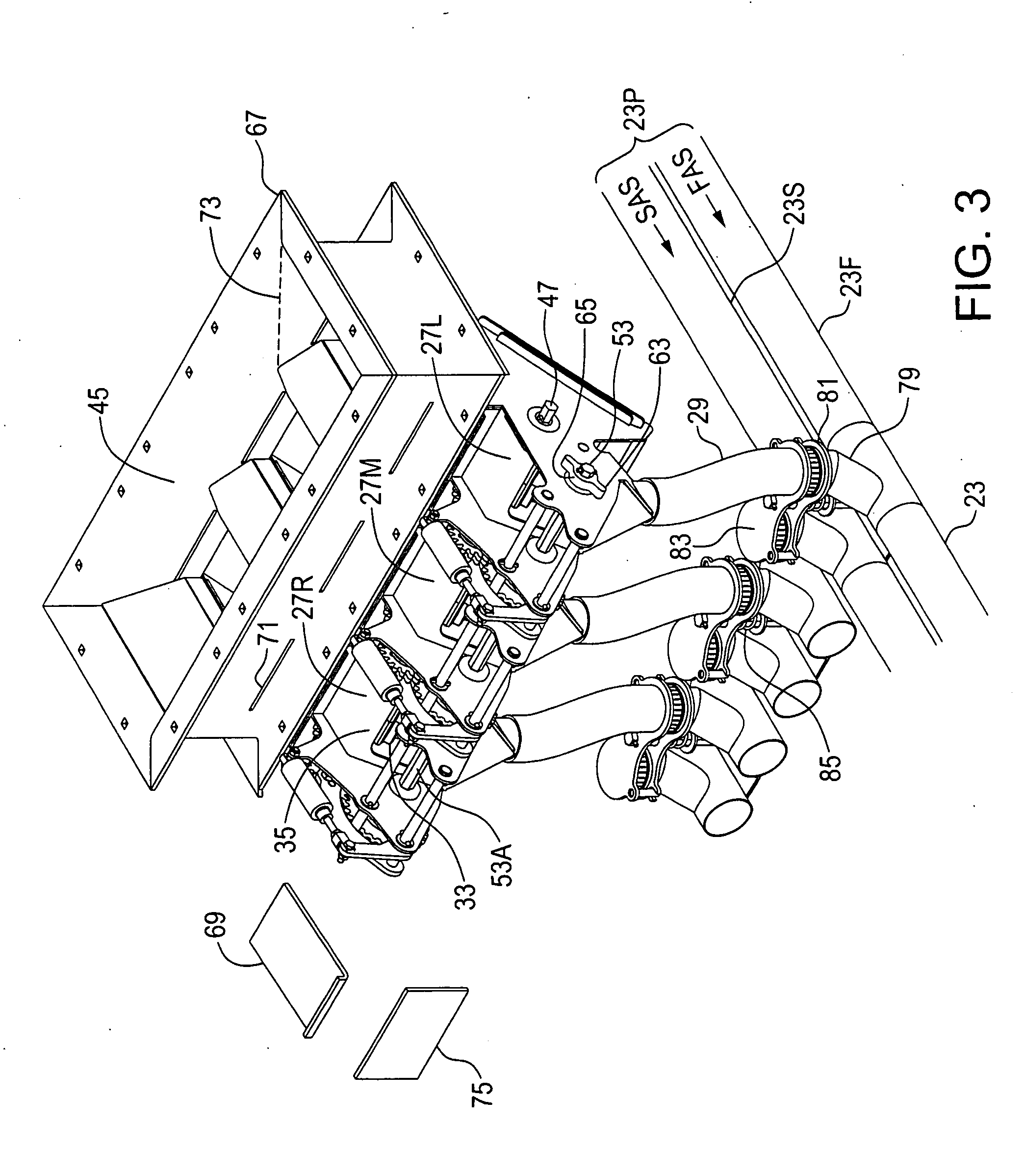

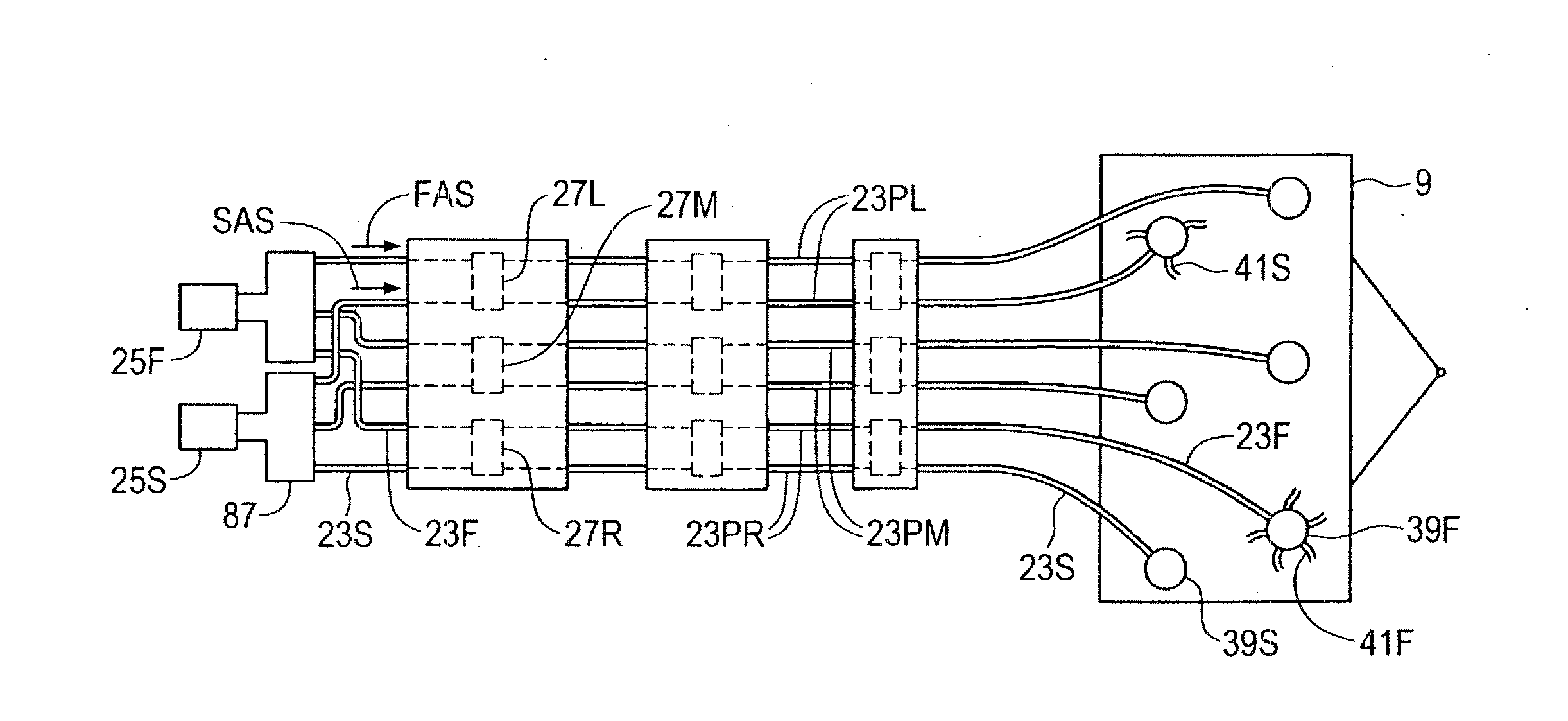

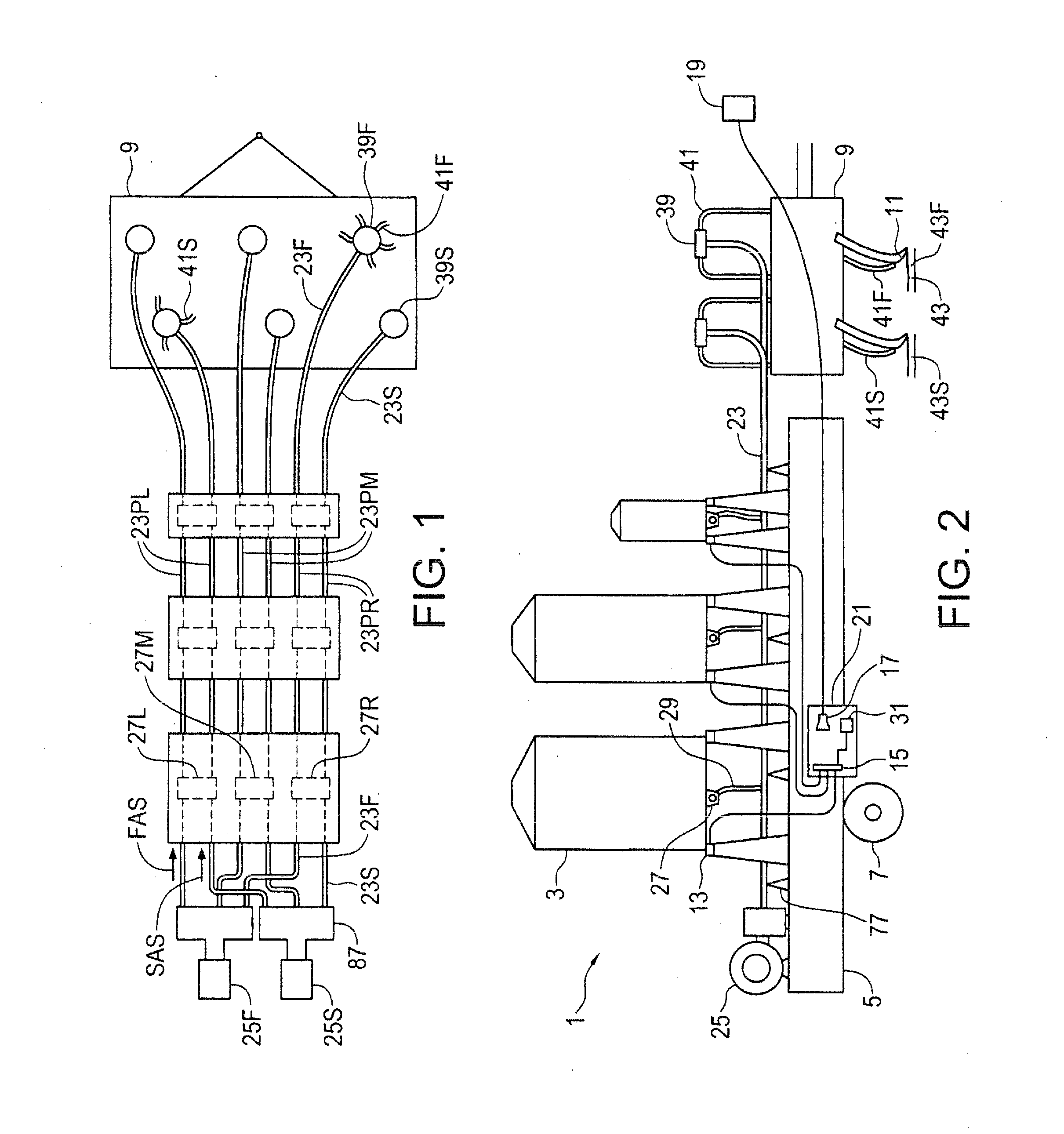

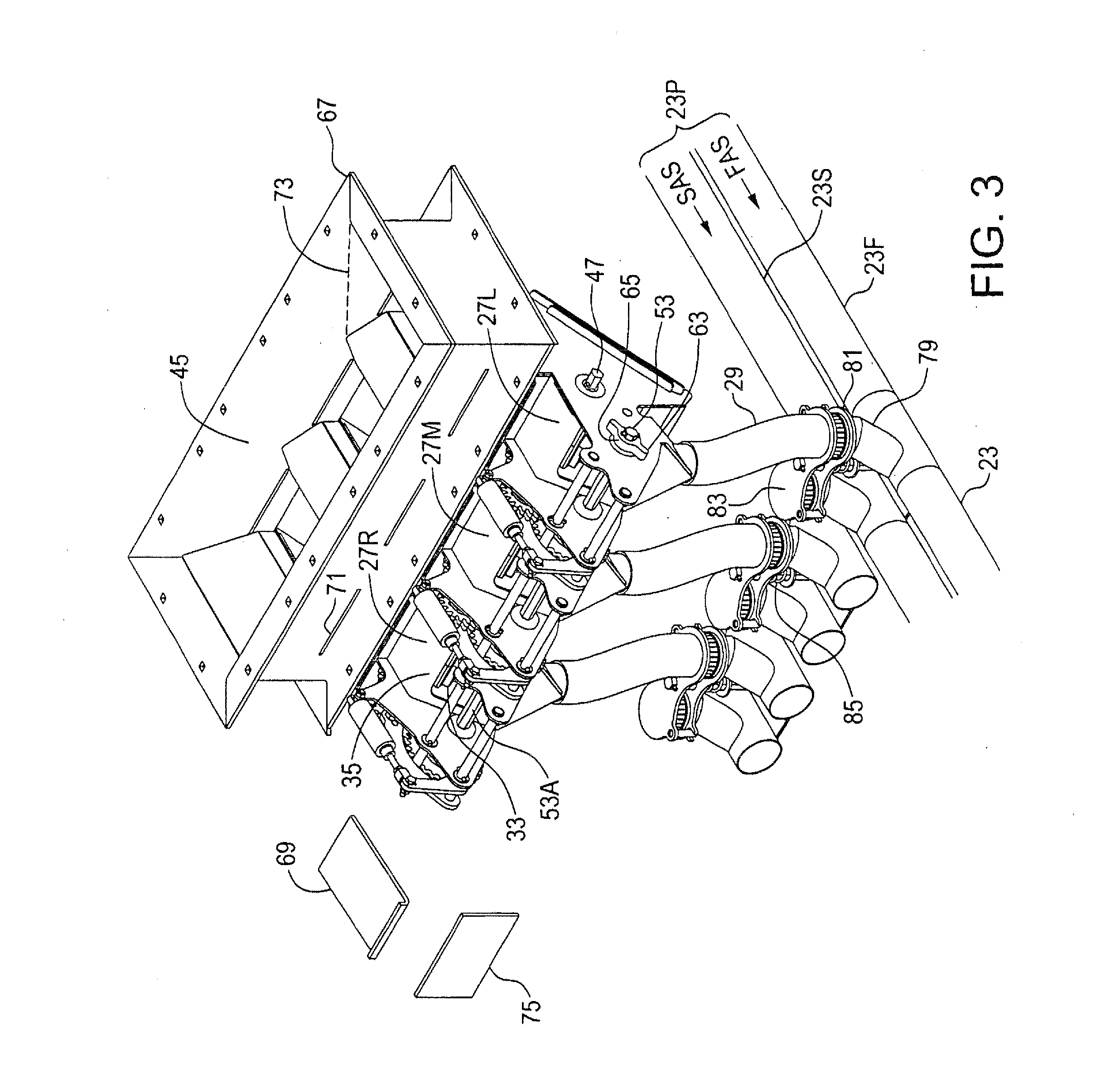

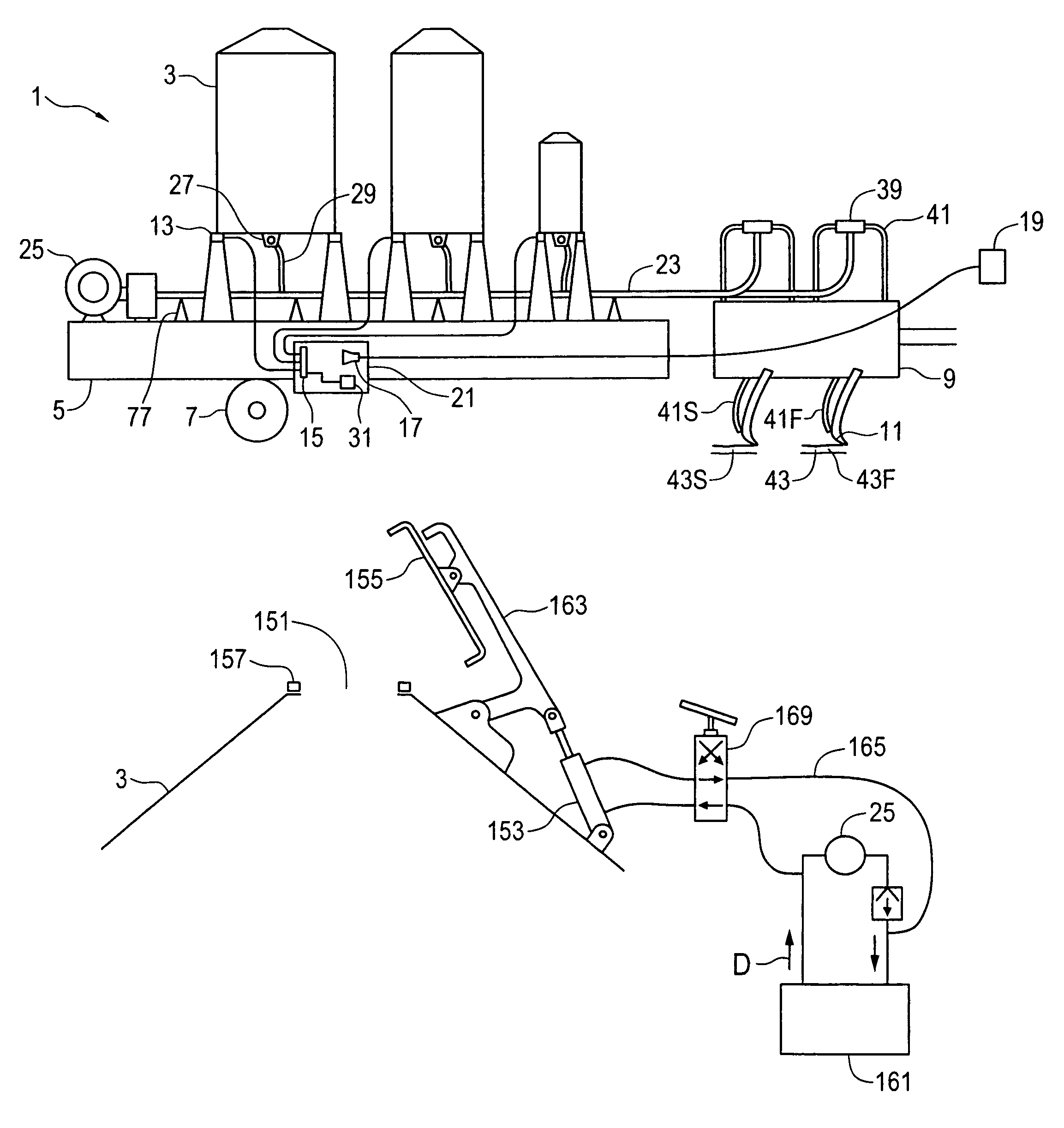

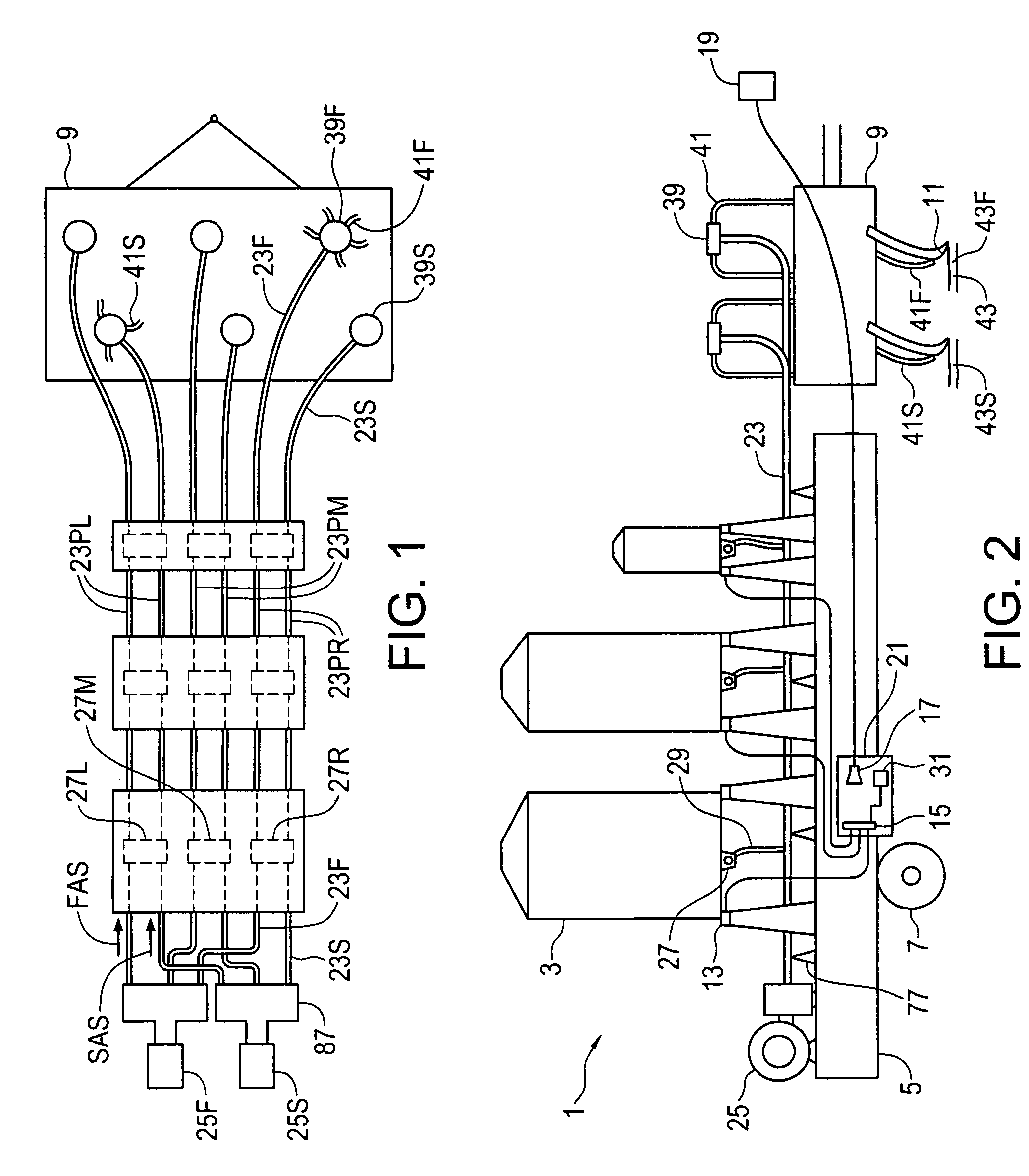

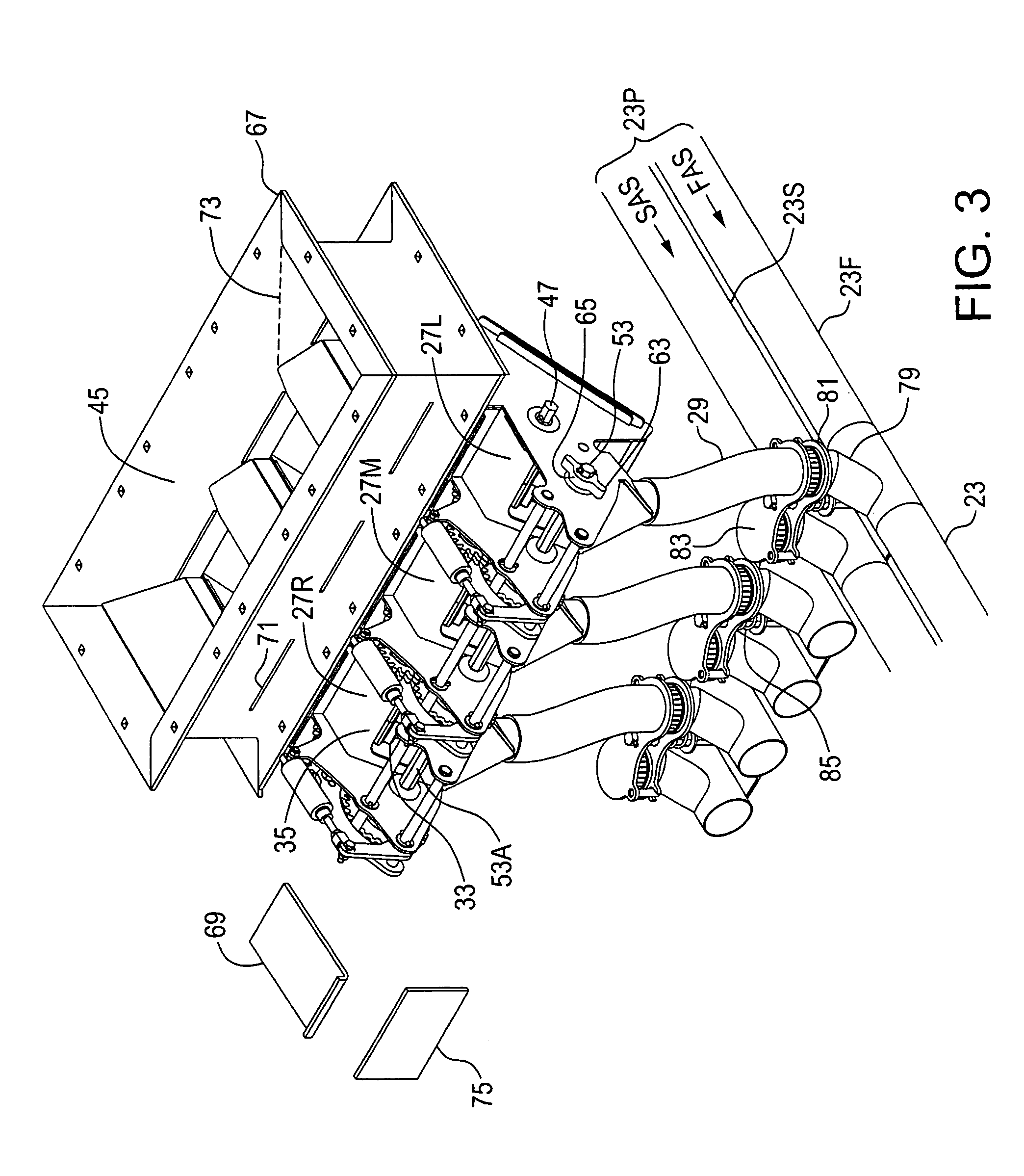

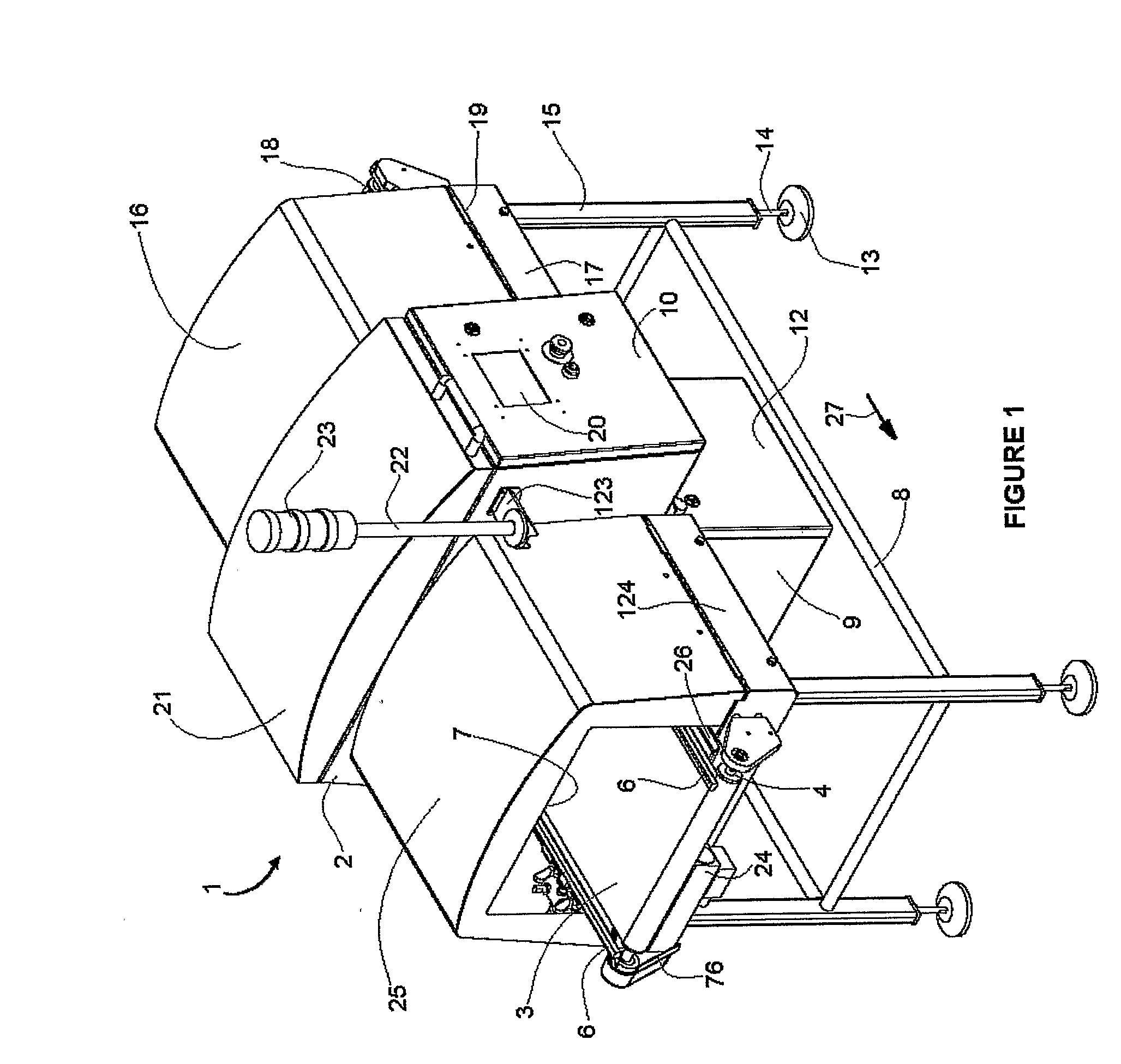

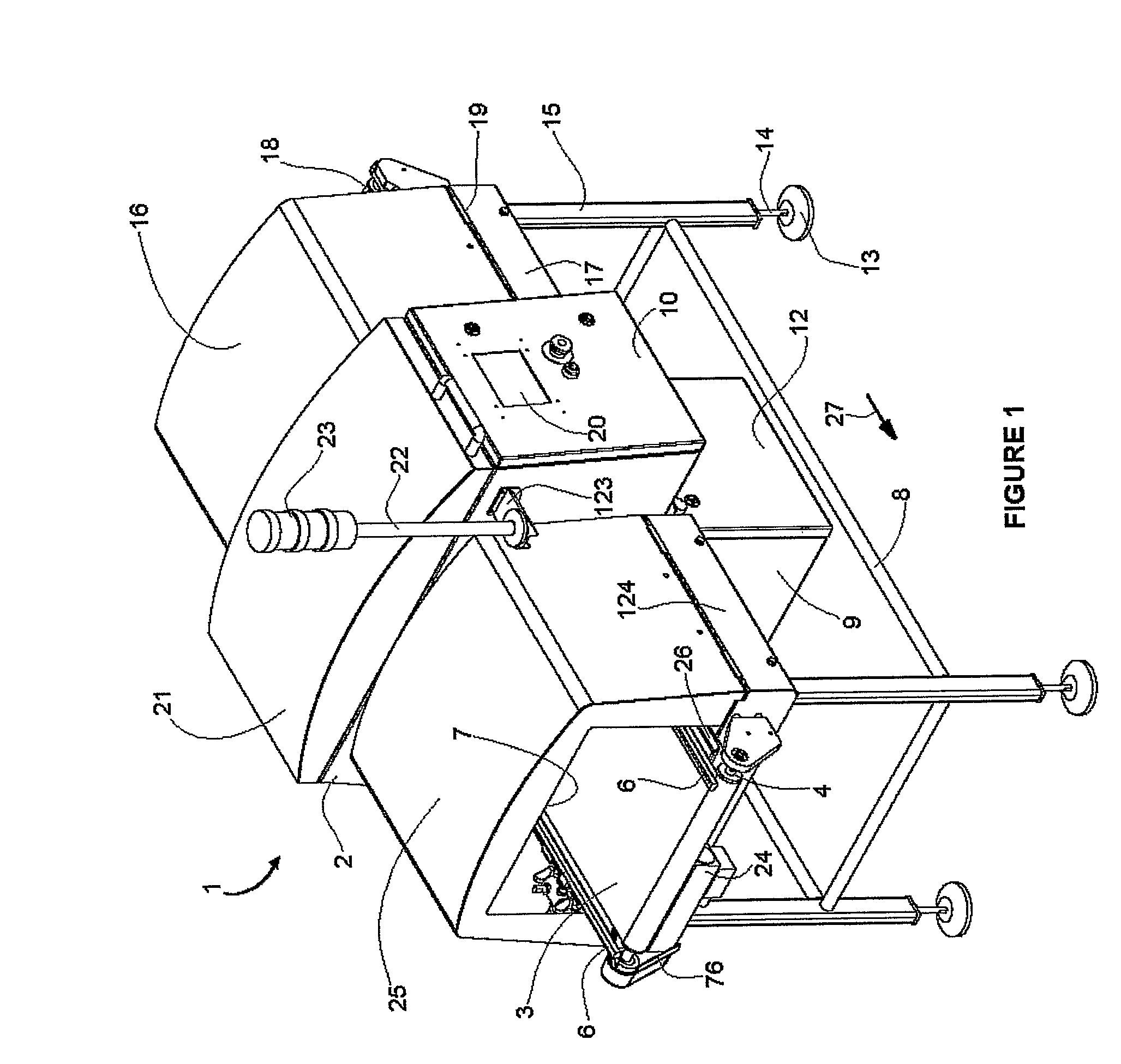

Air seeder tank and distribution apparatus

ActiveUS20120103238A1Different air speedDifferent pressureFertiliser distributersAgriculture and animal husbandary industryInternal pressureMechanical engineering

An air seeder distribution apparatus has seed and fertilizer tanks, and a like plurality of metering devices mounted on each product tank. A manifold set comprises a like plurality of product manifolds and each manifold is separately fed from one metering device on each of the seed and fertilizer tanks. A control selectively starts and stops rotation of the feed roller of each metering device to feed product from either tank, or both tanks to the connected manifold. The weight of each tank can be displayed on a weight indicator. Balancing of the pressure in each supply conduit can be provided. A remote opener exerts downward force on the tank lid to maintain interior pressure.

Owner:SEEDMASTER MFG

Air seeder tank and distribution apparatus

ActiveUS20140216315A1Different pressureDifferent speedFertiliser distributersAgriculture and animal husbandary industryInternal pressureMechanical engineering

An air seeder distribution apparatus has seed and fertilizer tanks, and a like plurality of metering devices mounted on each product tank. A manifold set comprises a like plurality of product manifolds and each manifold is separately fed from one metering device on each of the seed and fertilizer tanks. A control selectively starts and stops rotation of the feed roller of each metering device to feed product from either tank, or both tanks to the connected manifold. The weight of each tank can be displayed on a weight indicator. Balancing of the pressure in each supply conduit can be provided. A remote opener exerts downward force on the tank lid to maintain interior pressure.

Owner:SEEDMASTER MFG

Air seeder tank and distribution apparatus

ActiveUS8733257B2Different pressureDifferent speedFertiliser distributersAgriculture and animal husbandary industryInternal pressureSeeder

An air seeder distribution apparatus has seed and fertilizer tanks, and a like plurality of metering devices mounted on each product tank. A manifold set comprises a like plurality of product manifolds and each manifold is separately fed from one metering device on each of the seed and fertilizer tanks. A control selectively starts and stops rotation of the feed roller of each metering device to feed product from either tank, or both tanks to the connected manifold. The weight of each tank can be displayed on a weight indicator. Balancing of the pressure in each supply conduit can be provided. A remote opener exerts downward force on the tank lid to maintain interior pressure.

Owner:SEEDMASTER MFG

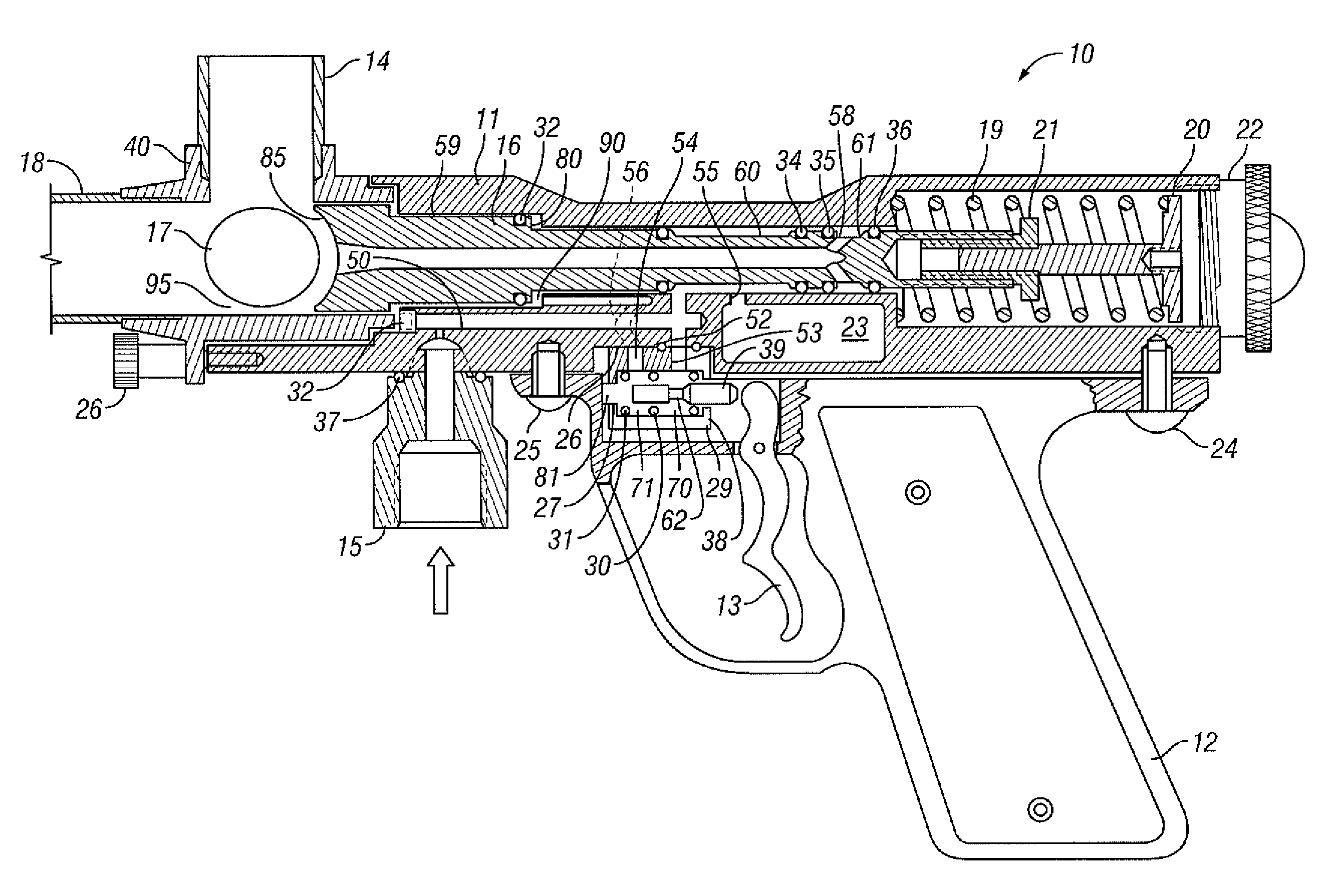

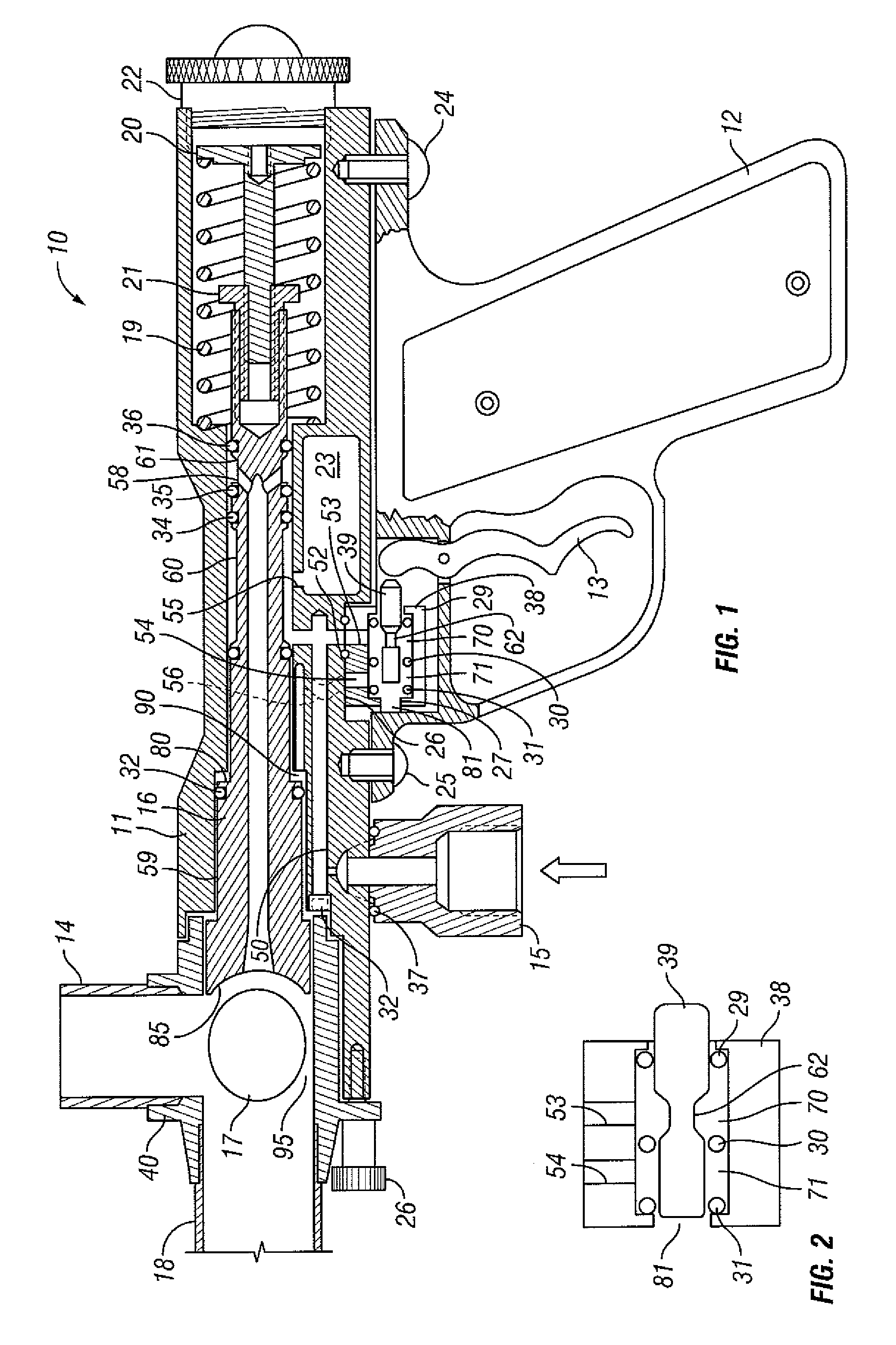

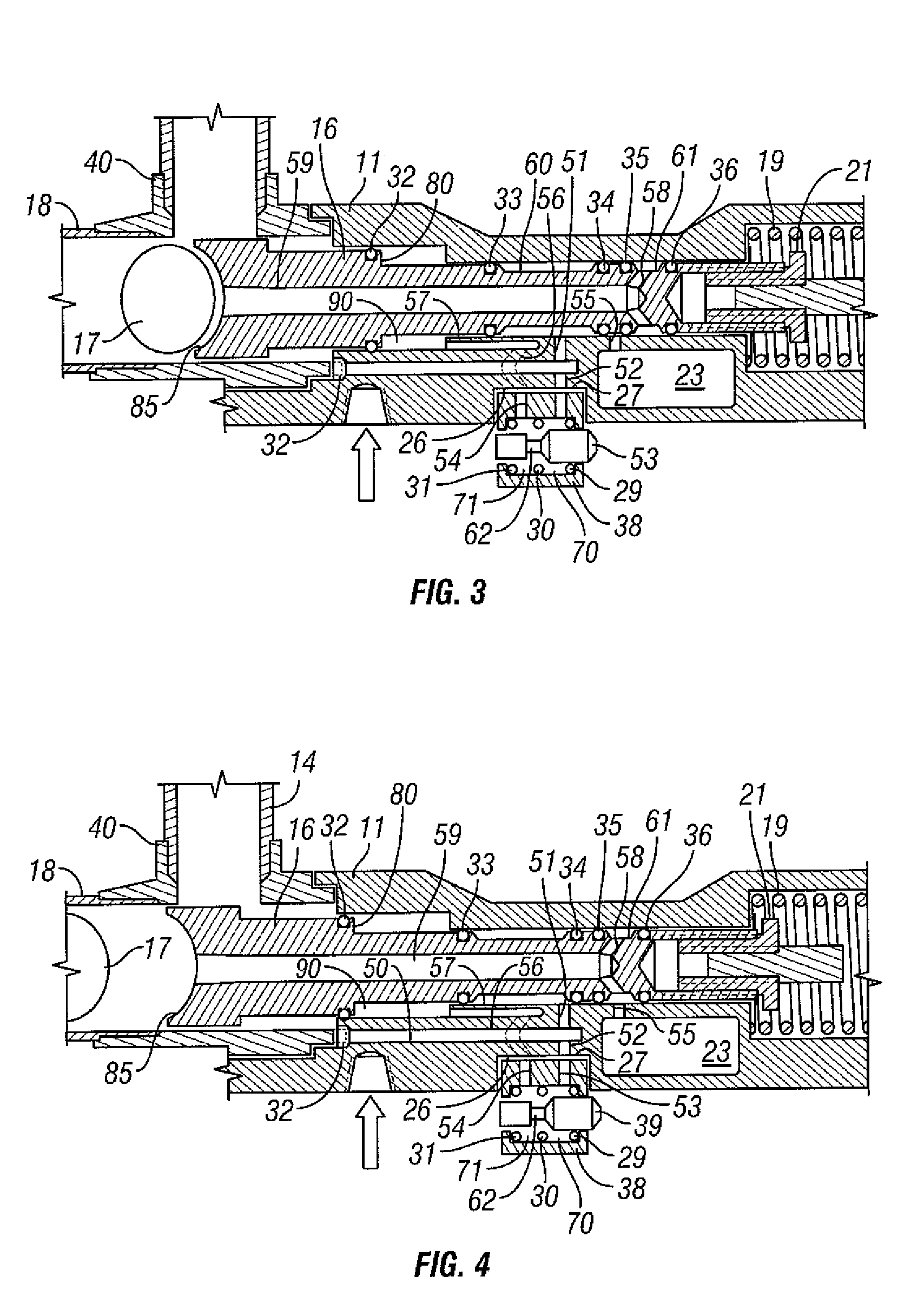

Cost effective paintball gun system

InactiveUS7882830B1Simplified firing mechanismEfficiently provideCompressed gas gunsCost effectivenessMechanical engineering

A paintball gun system comprises a bolt defining a propellant passageway and a gun body defining the following elements: a receptacle for receiving the bolt, a firing charge storage chamber adjacent to but separate from the bolt receptacle, a gas inlet port, a first passageway between the storage chamber and the receptacle, a second fixed passageway between the gas inlet and the receptacle. The first passageway communicates with a first flow opening into the receptacle and the second passageway communicates with a second flow opening into the receptacle. The bolt is axially movable between a chargeup position and a firing position. In the chargeup position, the bolt and the body together define a confined flow circuit between the first opening and the storage chamber. In the firing position, the bolt and the body together define a confined flow circuit between the storage chamber and the discharge inlet.

Owner:KORE OUTDOOR US INC

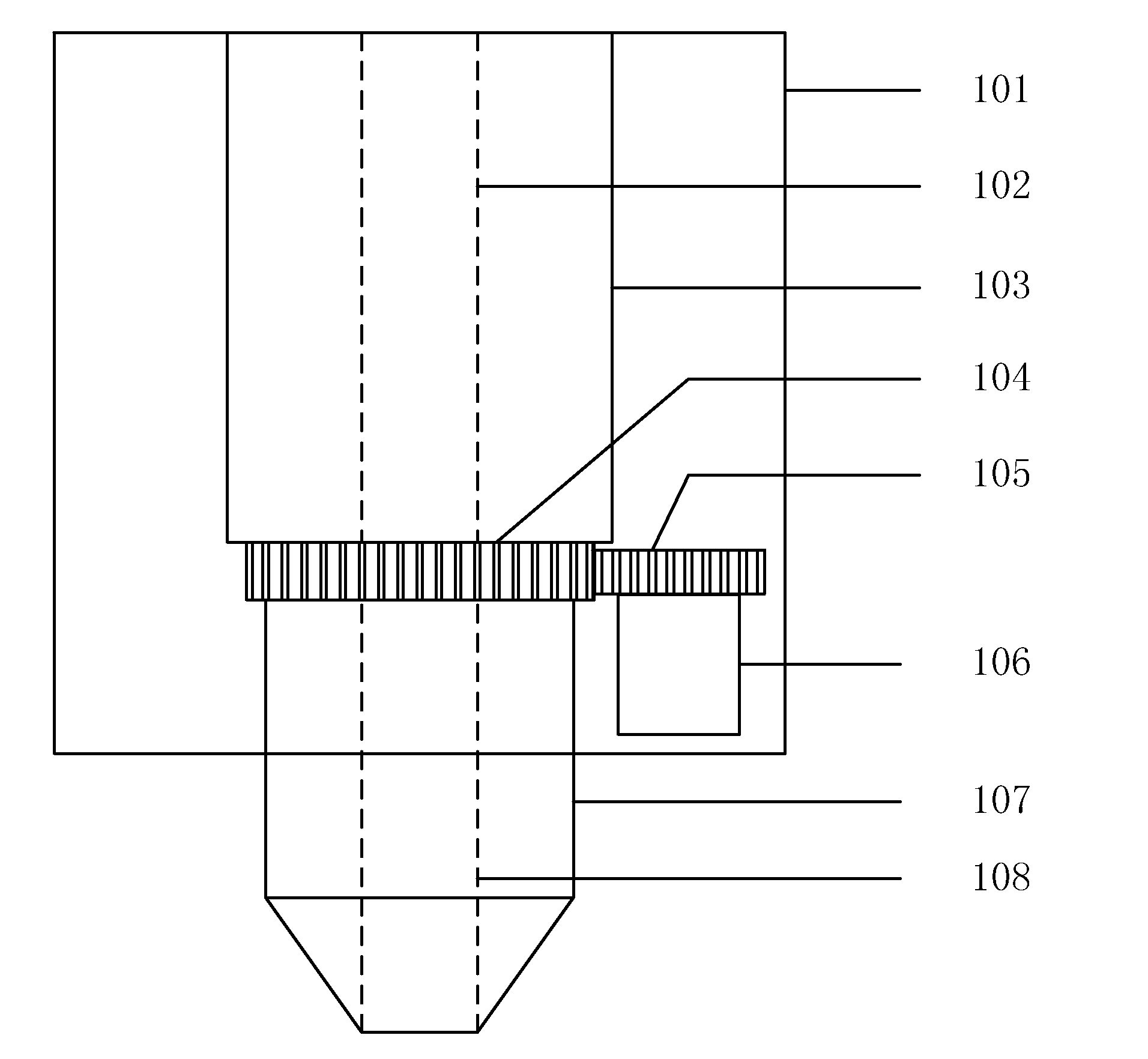

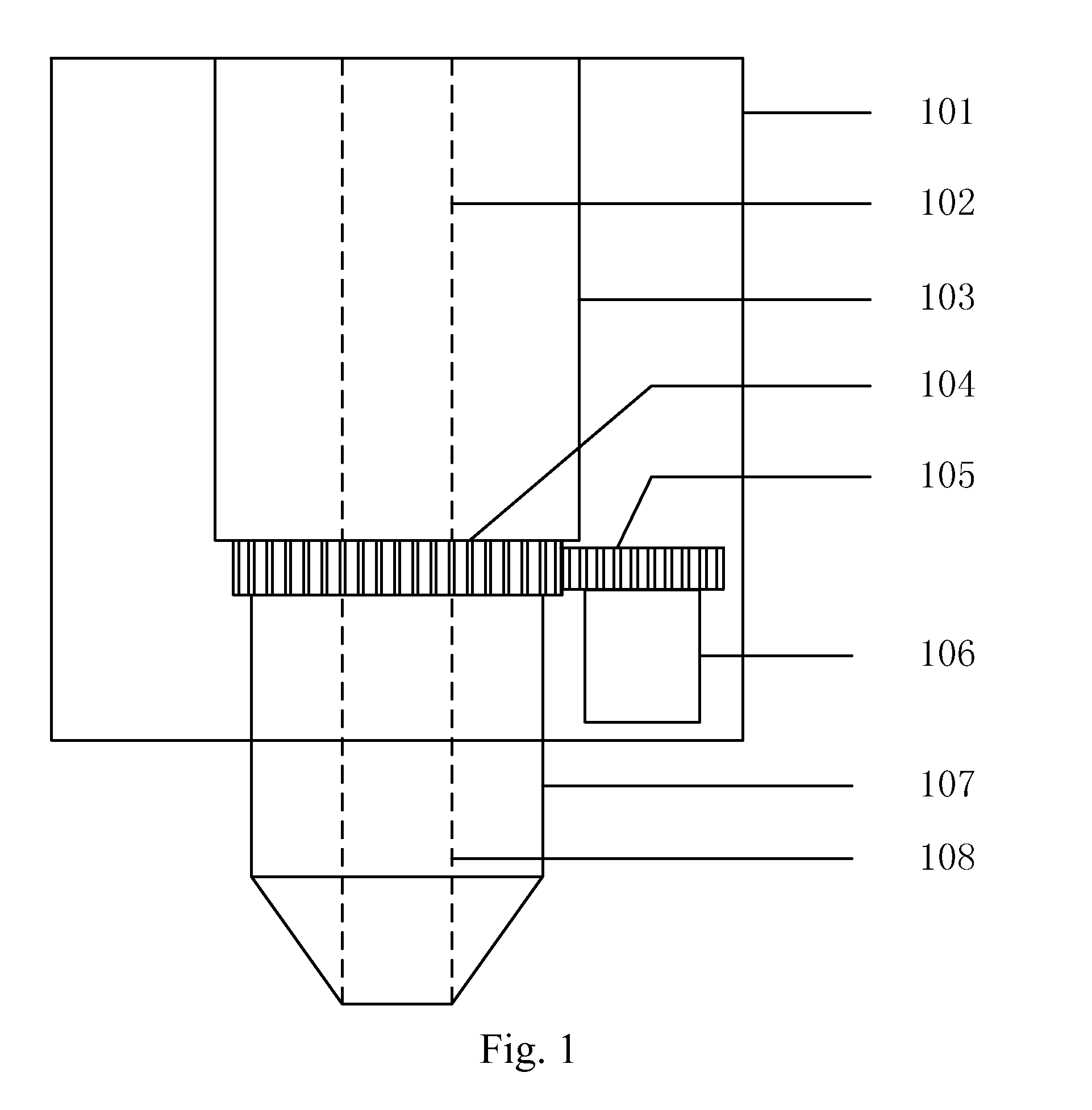

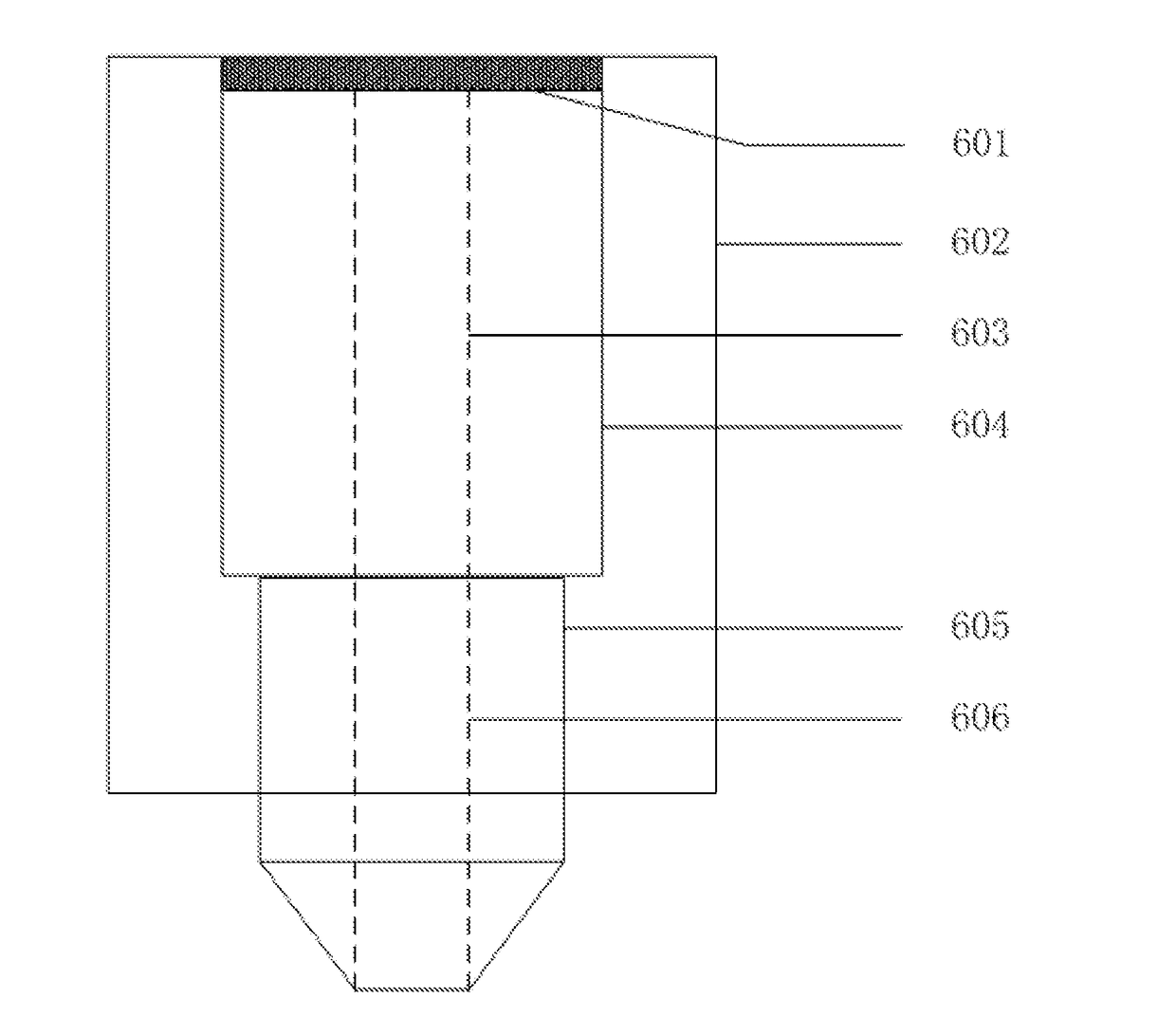

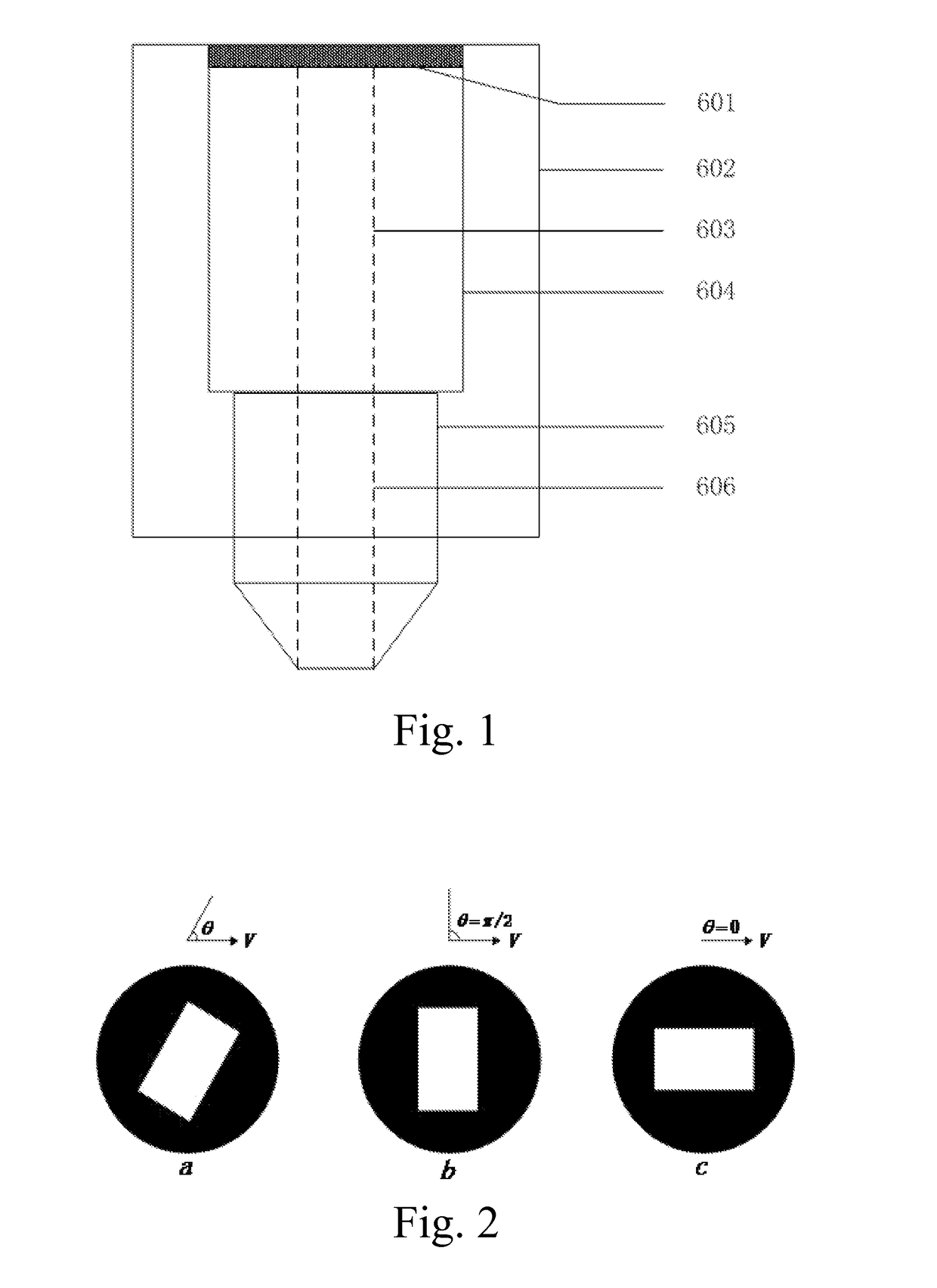

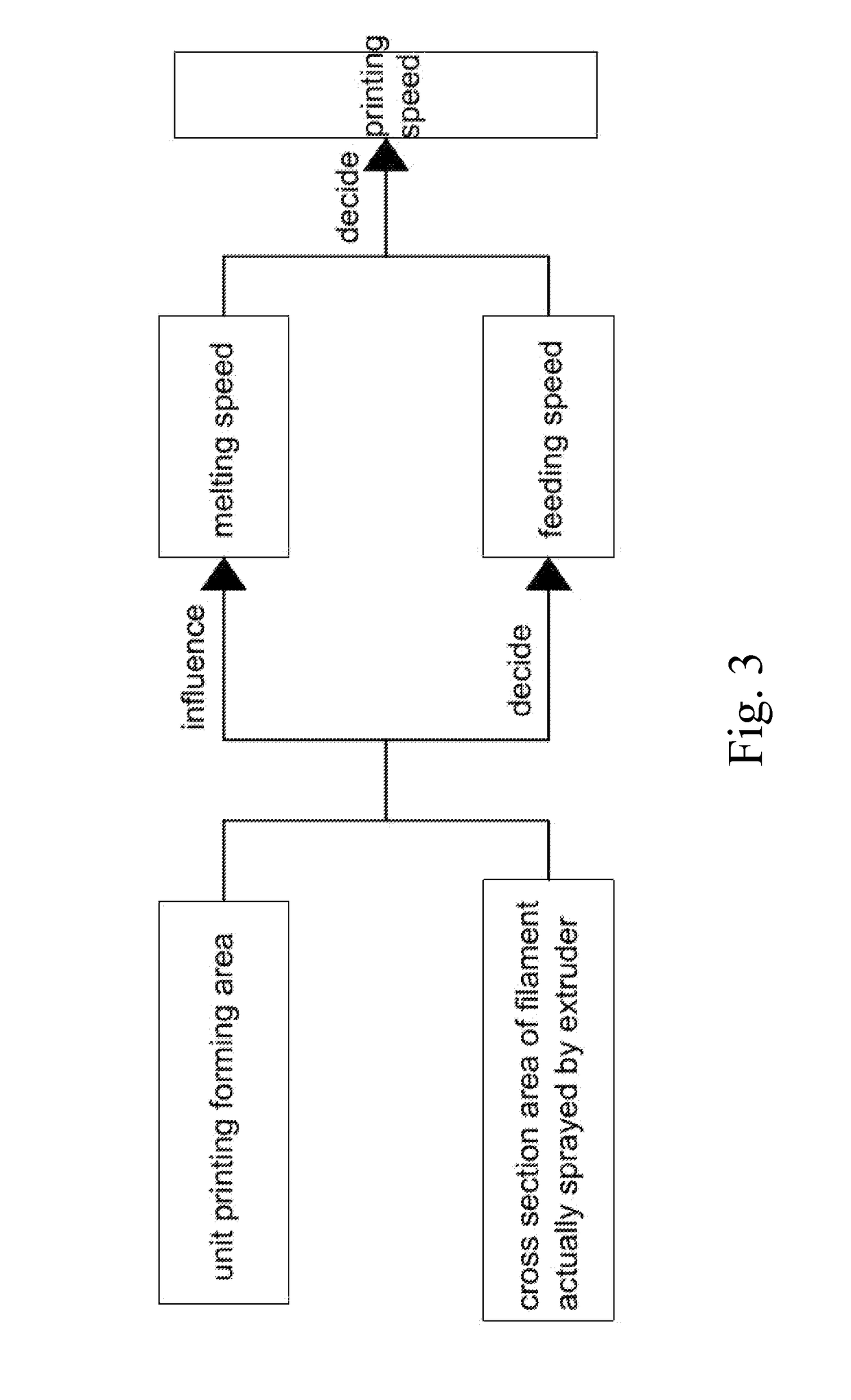

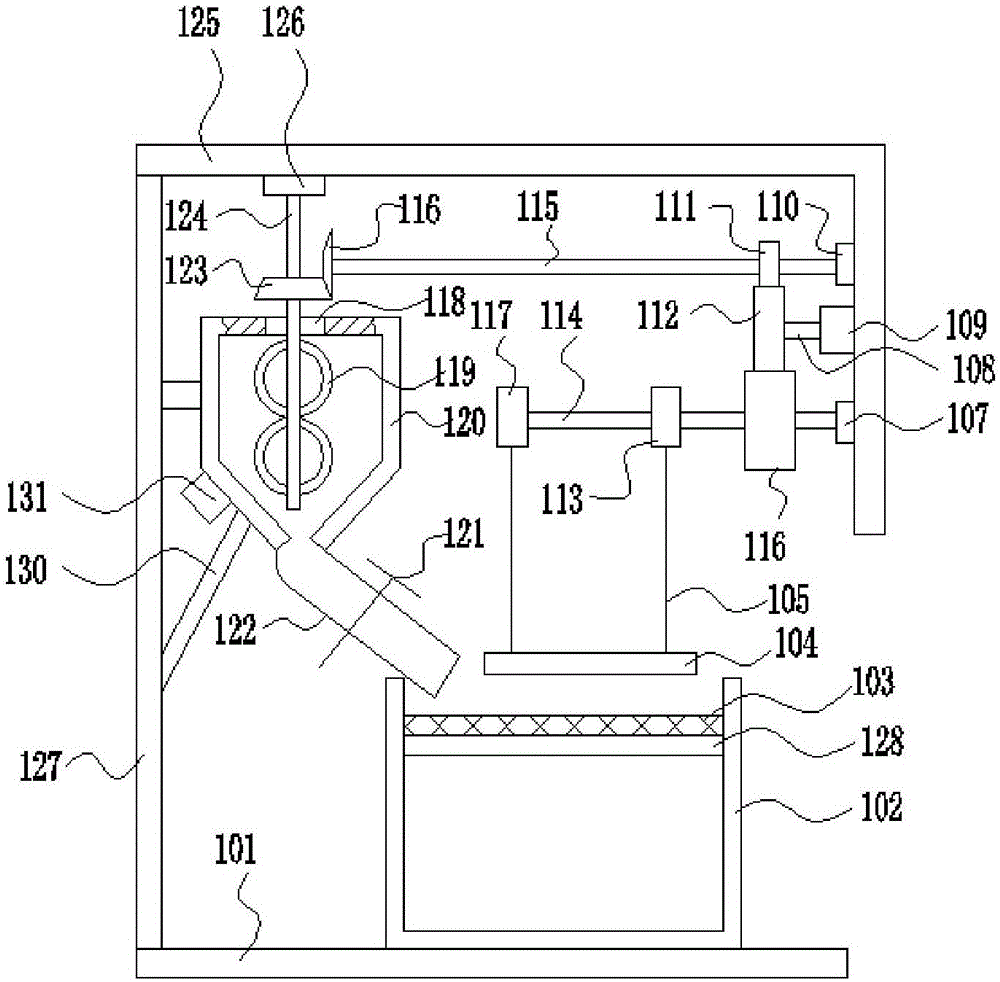

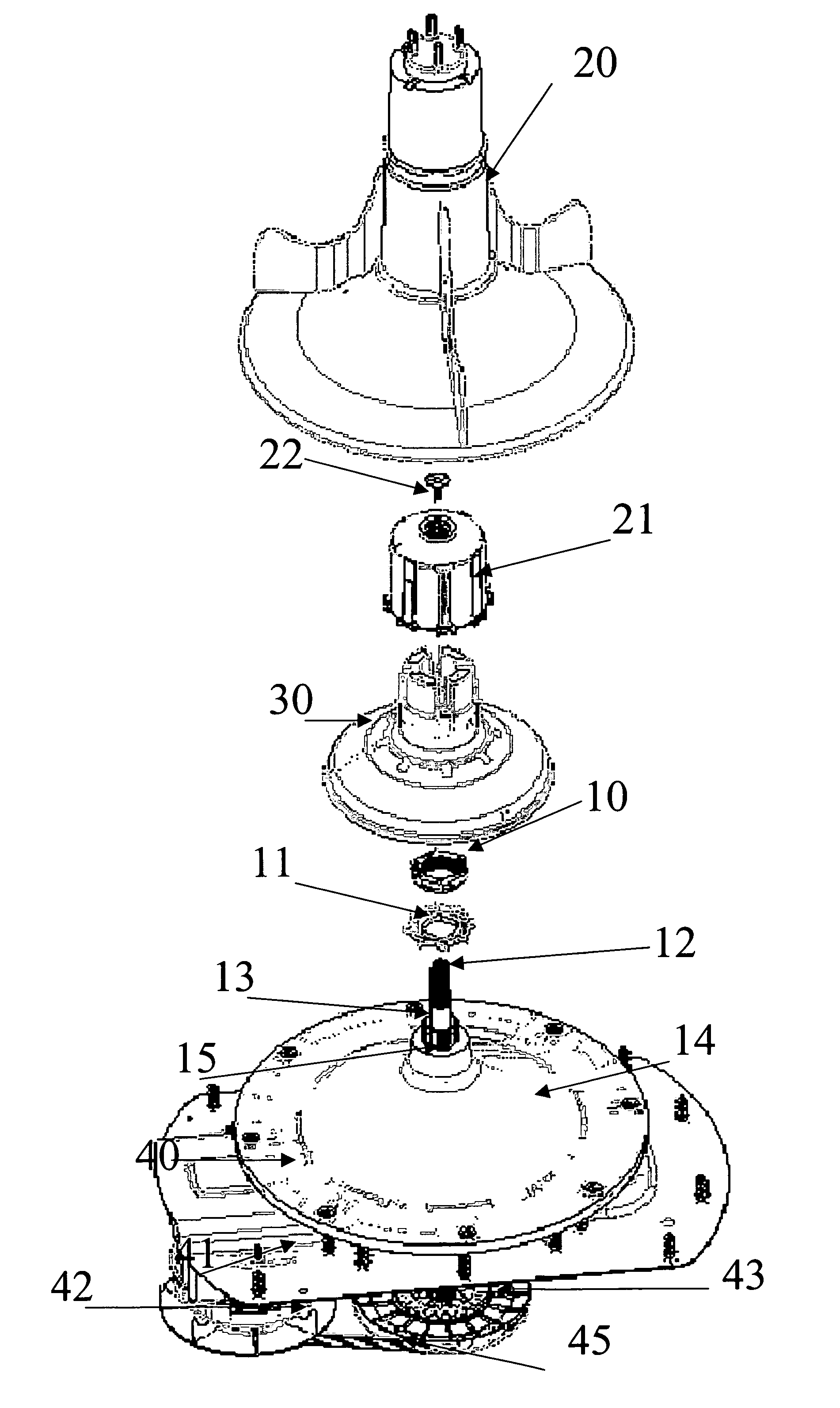

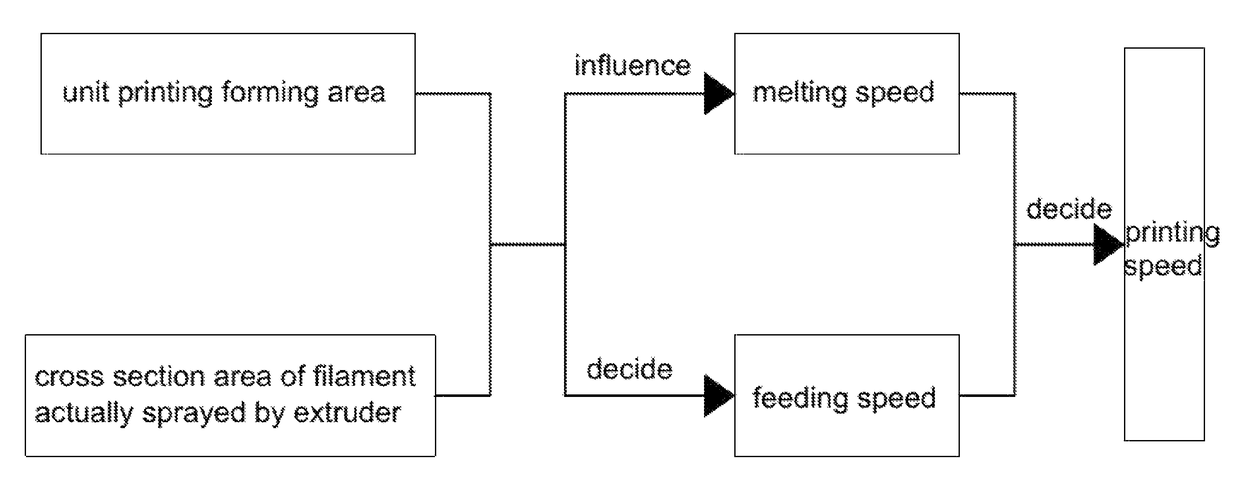

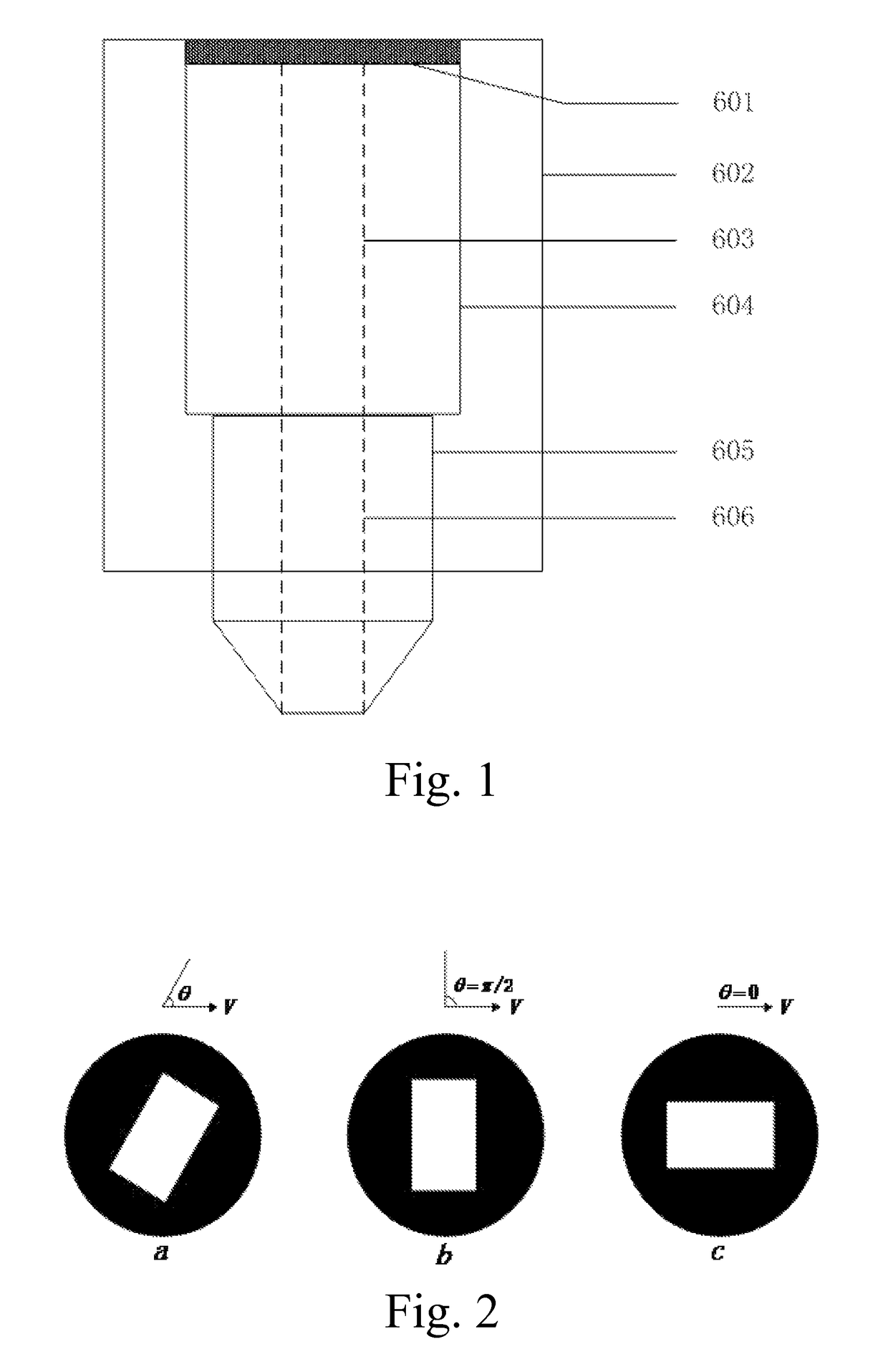

3D printer spray nozzle structure and method thereof for controlling speed and precision

ActiveUS20160288395A1Limited cross sectional areaDifferent precisionProgramme controlManufacturing driving meansSpray nozzle3d printer

The present invention relates to a technical field of 3D printing, and more particularly to a 3D printer spray nozzle structure and a method thereof for controlling speed and precision. According to the present invention, a feeding pipeline is embedded in an external shell, the feeding pipeline and an extruder are coaxially connected; the extruder is driven by a driving device, so as to rotate relative to the feeding pipeline. A rotation angle of the extruder relative to the feeding pipeline is controlled by rotation of a motor, for controlling a filament area actually sprayed by the extrude, in such a manner that printing speed and precision is controlled for suiting different requirements of different printing area. The present invention controls the printing speed and precision, for improving overall printing speed with precision requirements satisfied, and is applicable to 3D printer spray nozzle structure and controlling.

Owner:CLOUD COMPUTING CENT CHINESE ACADEMY OF SCI

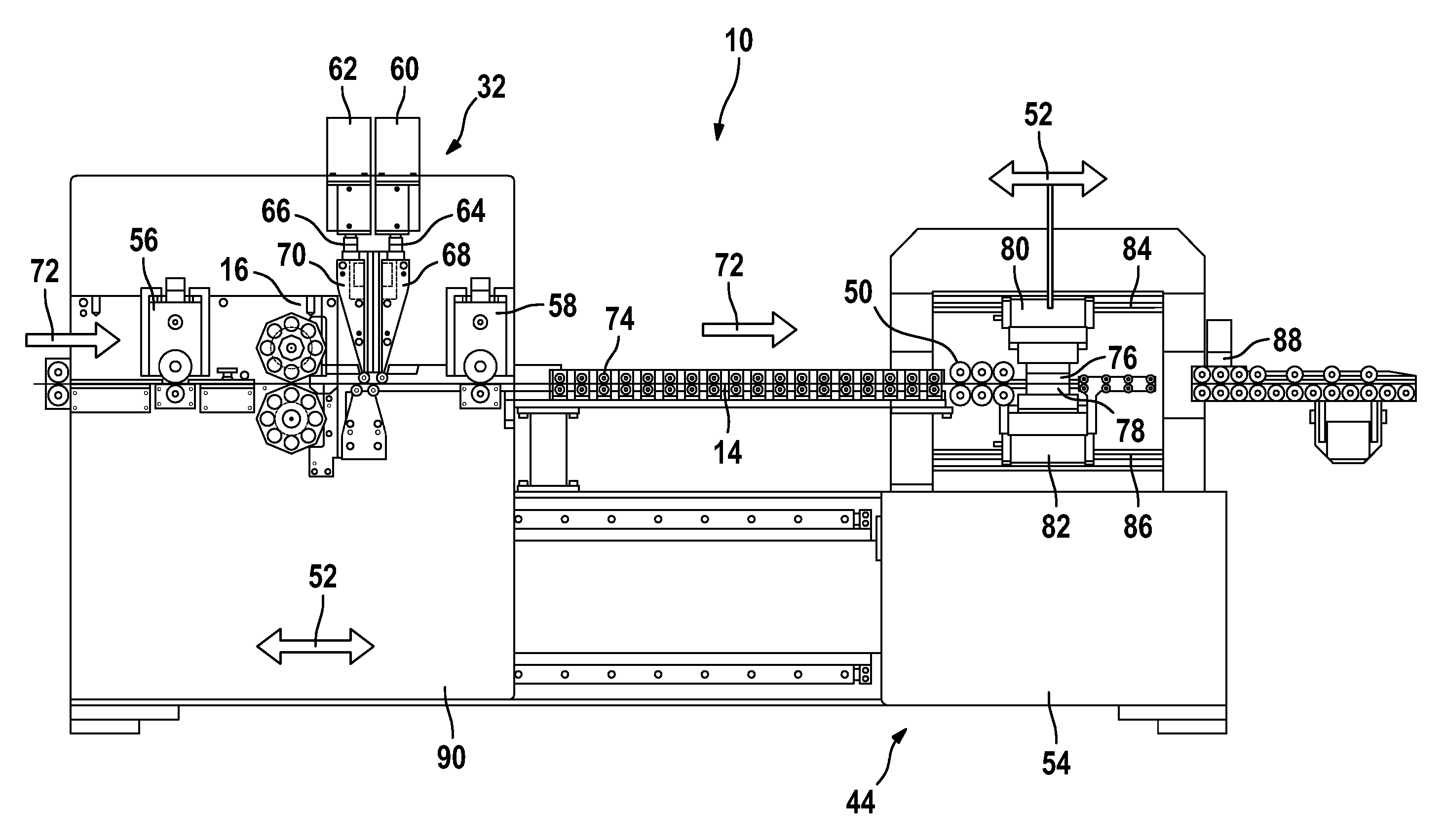

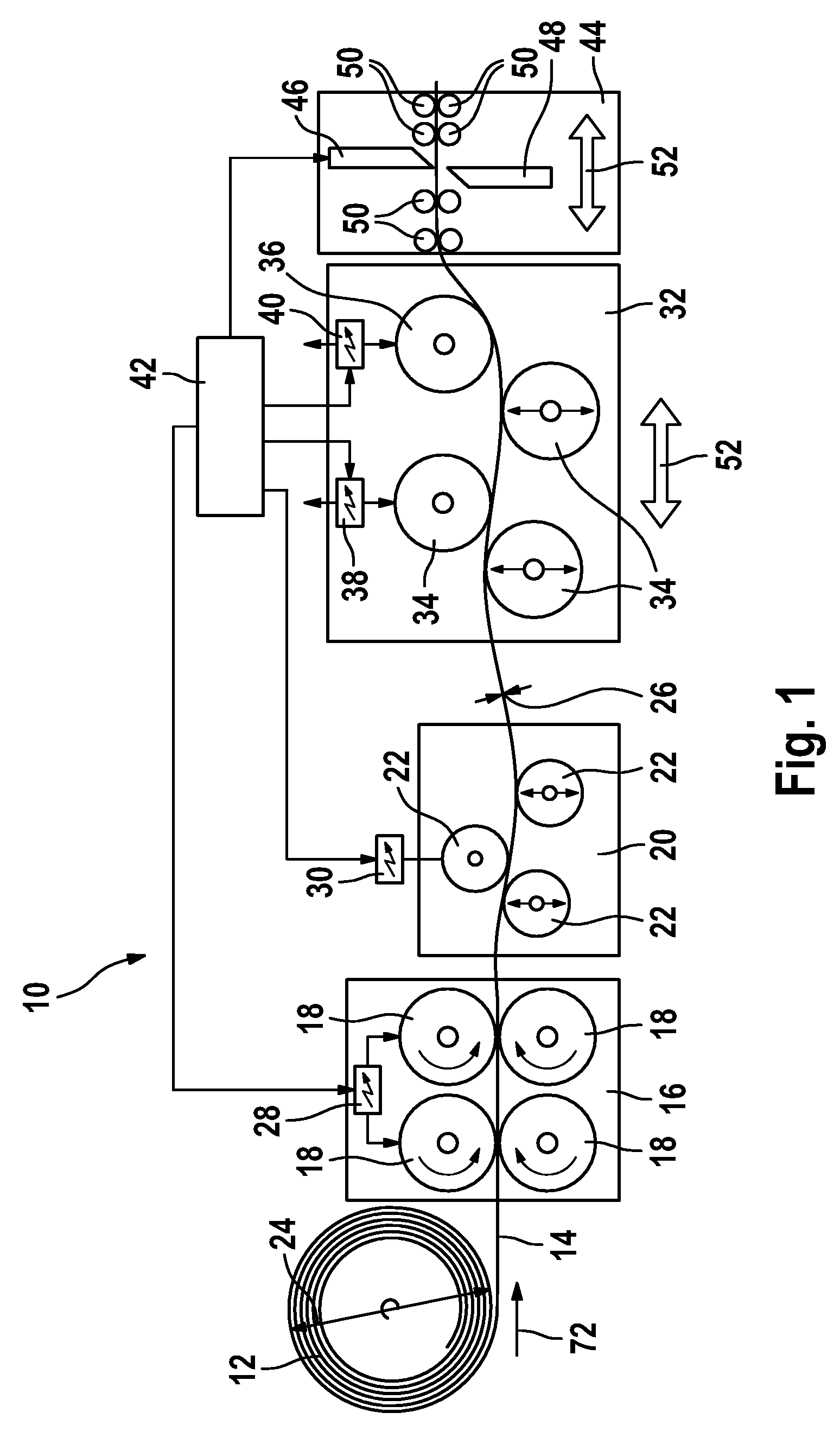

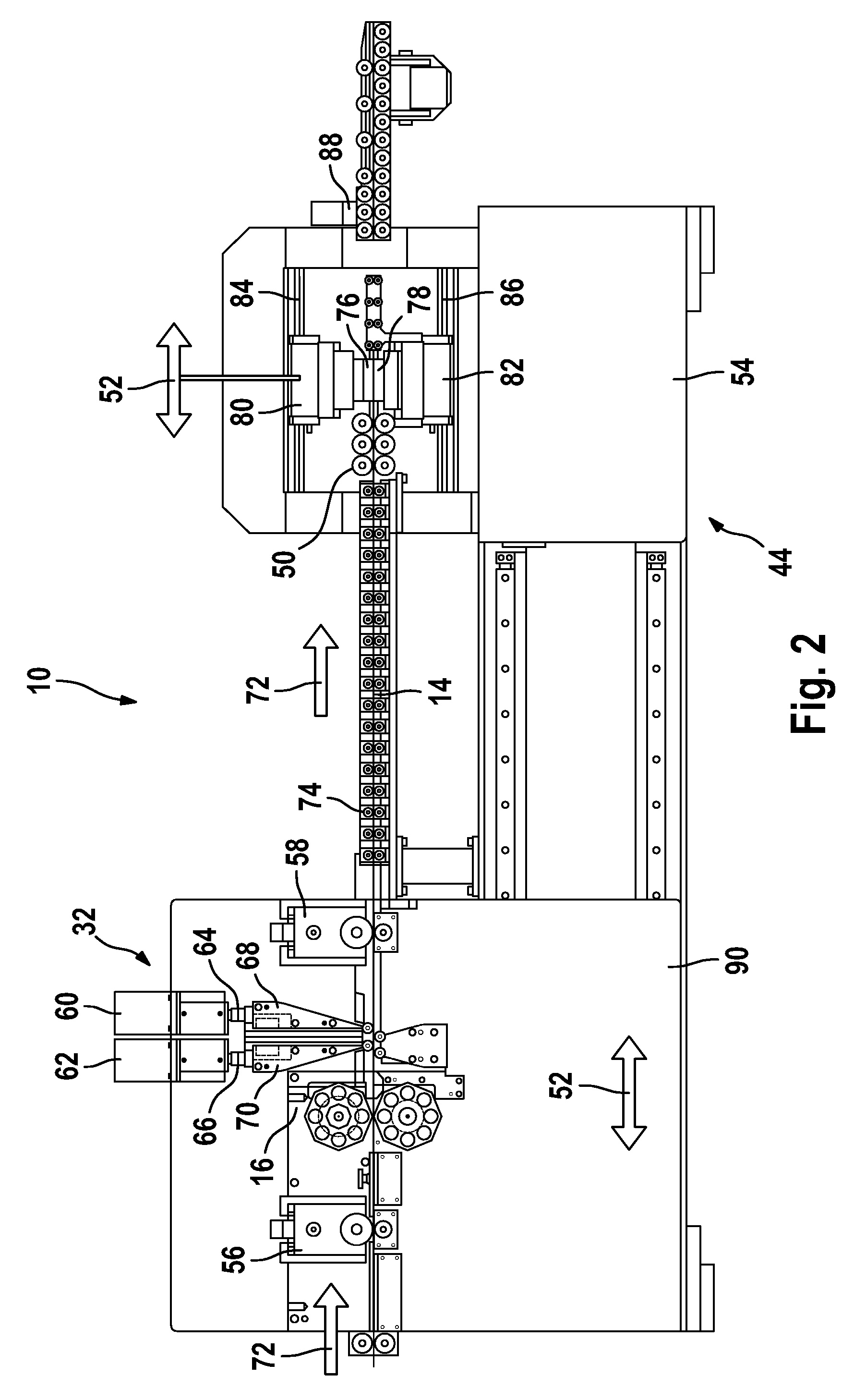

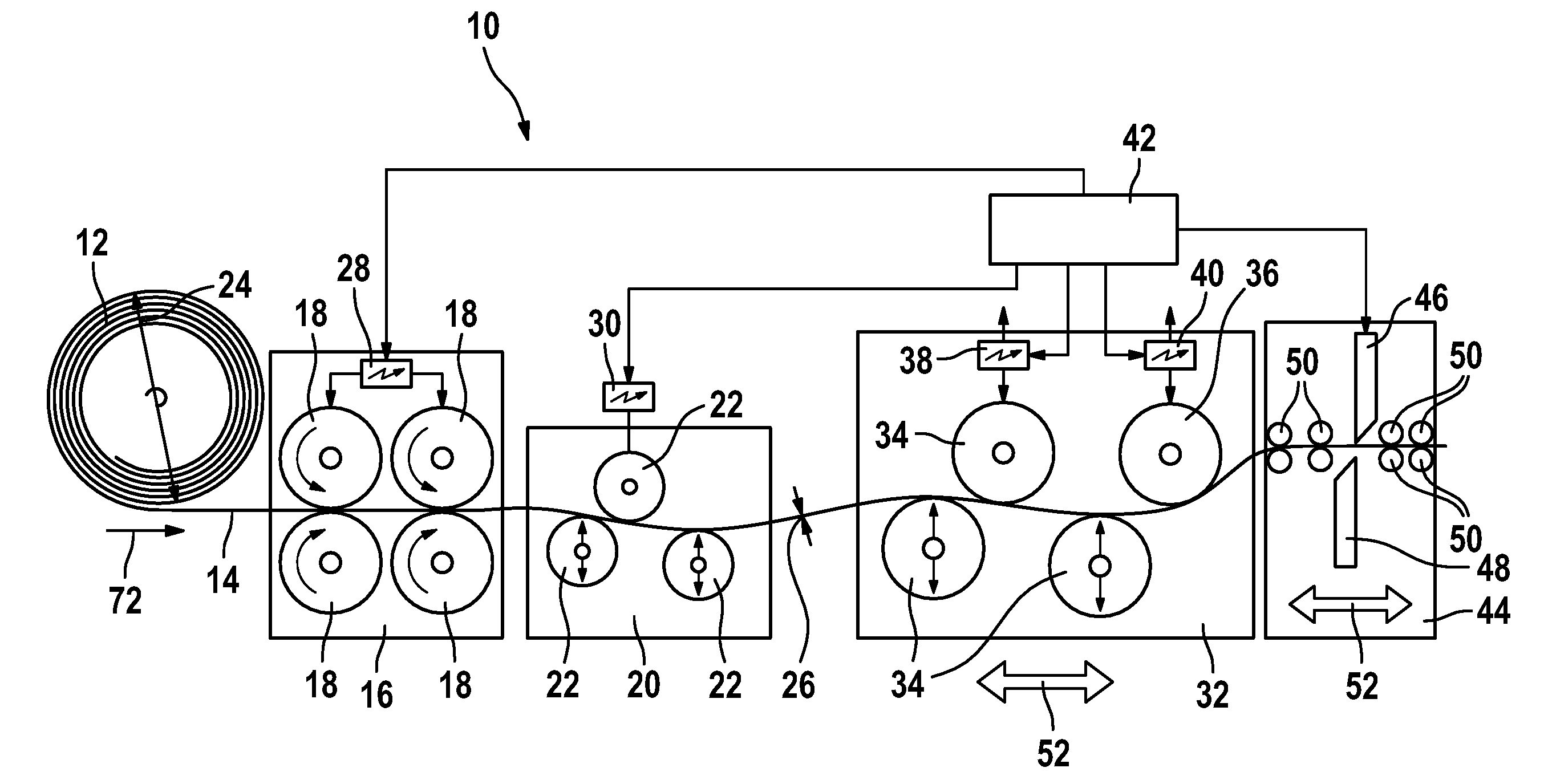

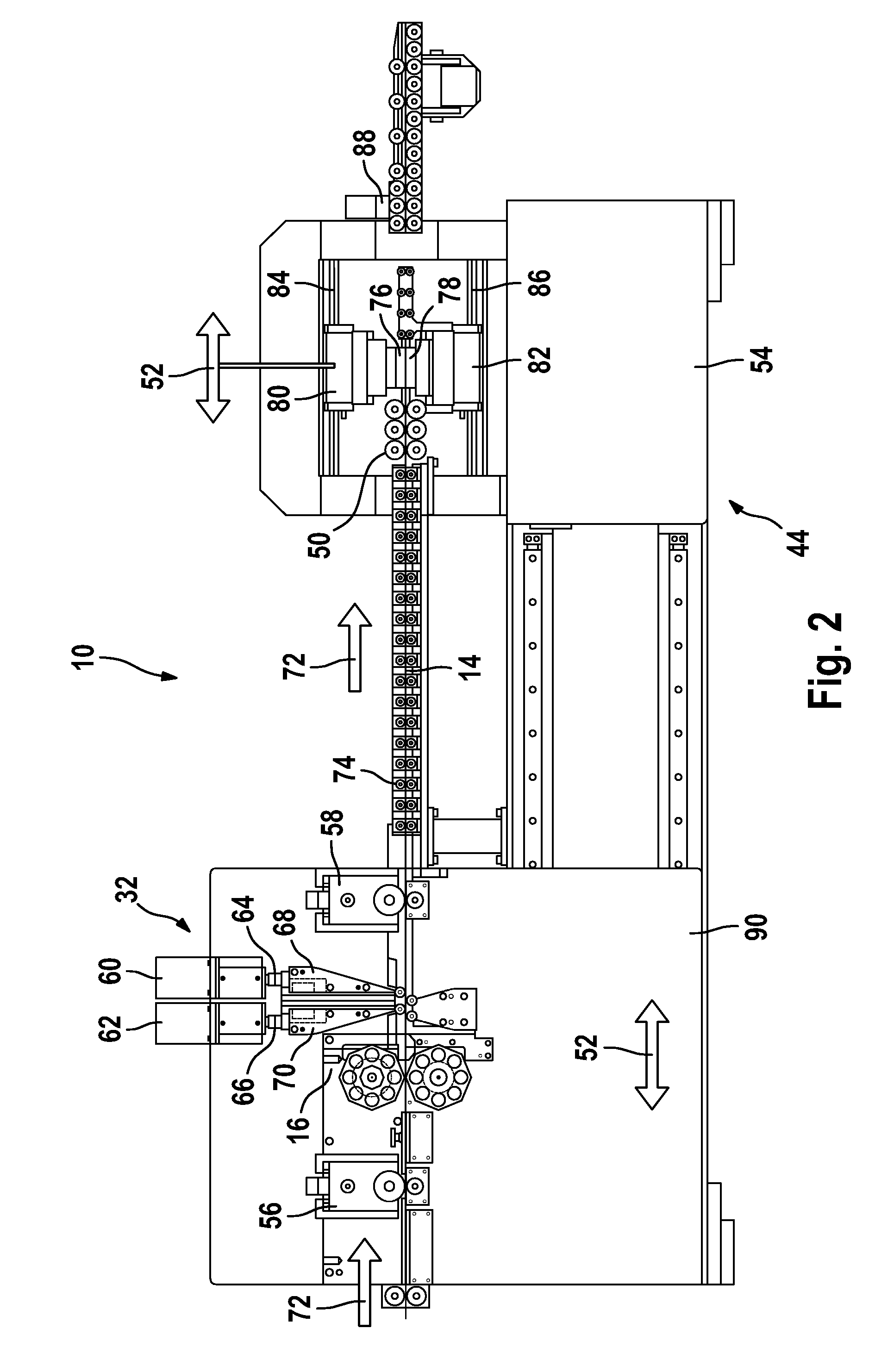

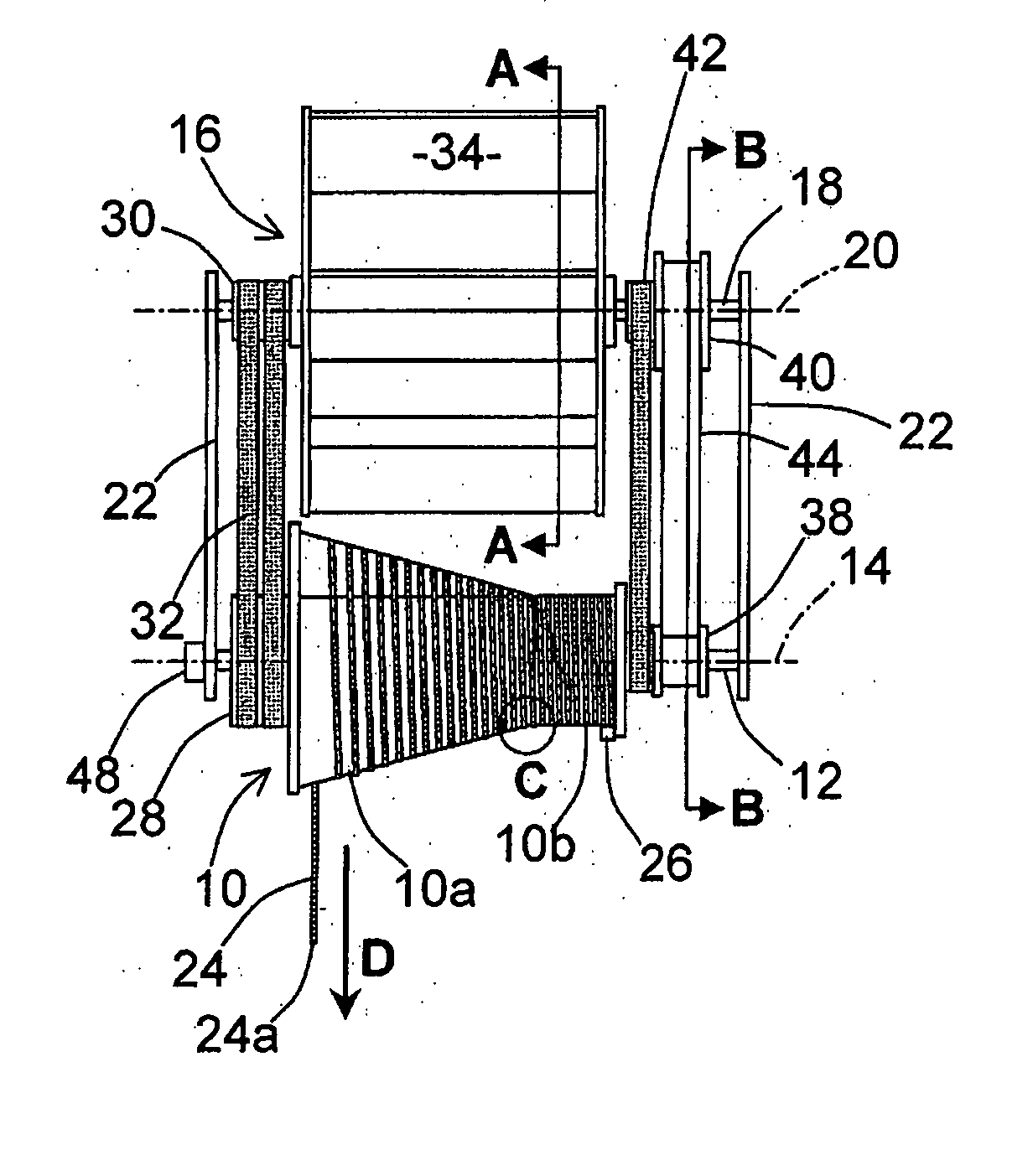

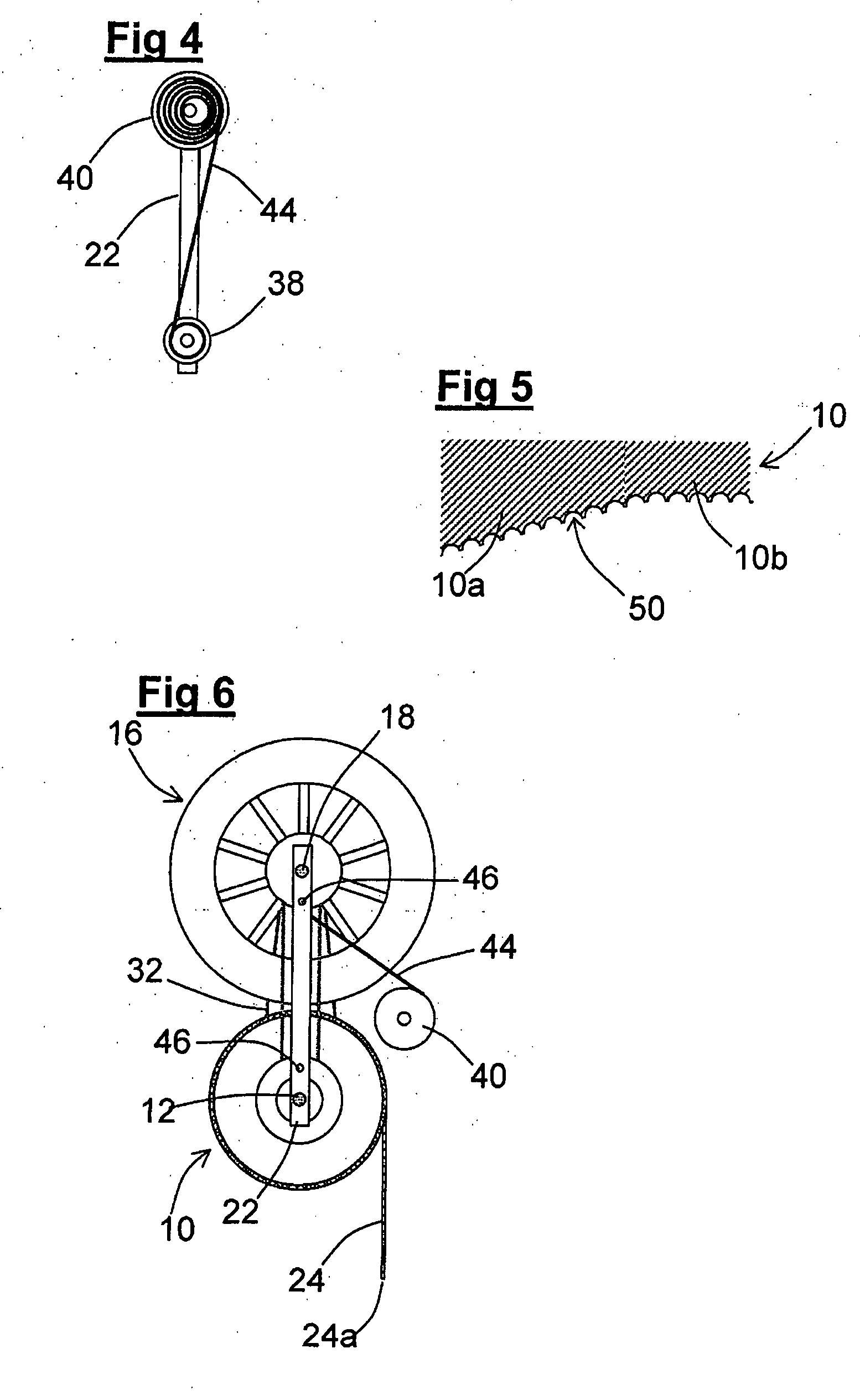

Method and device for producing bent spring elements

InactiveUS8333093B2Different speedImprove the level ofStock shearing machinesVehicle cleaningControl mannerSpring steel

The invention is based on a method of producing bent spring elements from a spring steel strip (14), wherein a feed unit (16) delivers the spring steel strip (14) from a supply roll (12) to a bending unit (32) having at least three bending rollers (34) and a reverse bending roller (36), of which at least one bending roller (34) and the reverse bending roller (36) can be adjusted transversely to the spring steel strip (14) by bending motors (60, 62), and wherein a cutting-off unit (44) adjoins the bending unit (32), said cutting-off unit (44) cutting off the spring steel strip (14) into individual spring elements by means of cutting-off tools (46, 48; 76, 78). It is proposed that the cutting-off tools (46, 48; 76, 78) be movable in the longitudinal direction of the spring steel strip (14) in a numerically controlled manner and that they be synchronized with the feed movement of the spring steel strip (14) during the cutting-off operation.

Owner:ROBERT BOSCH GMBH

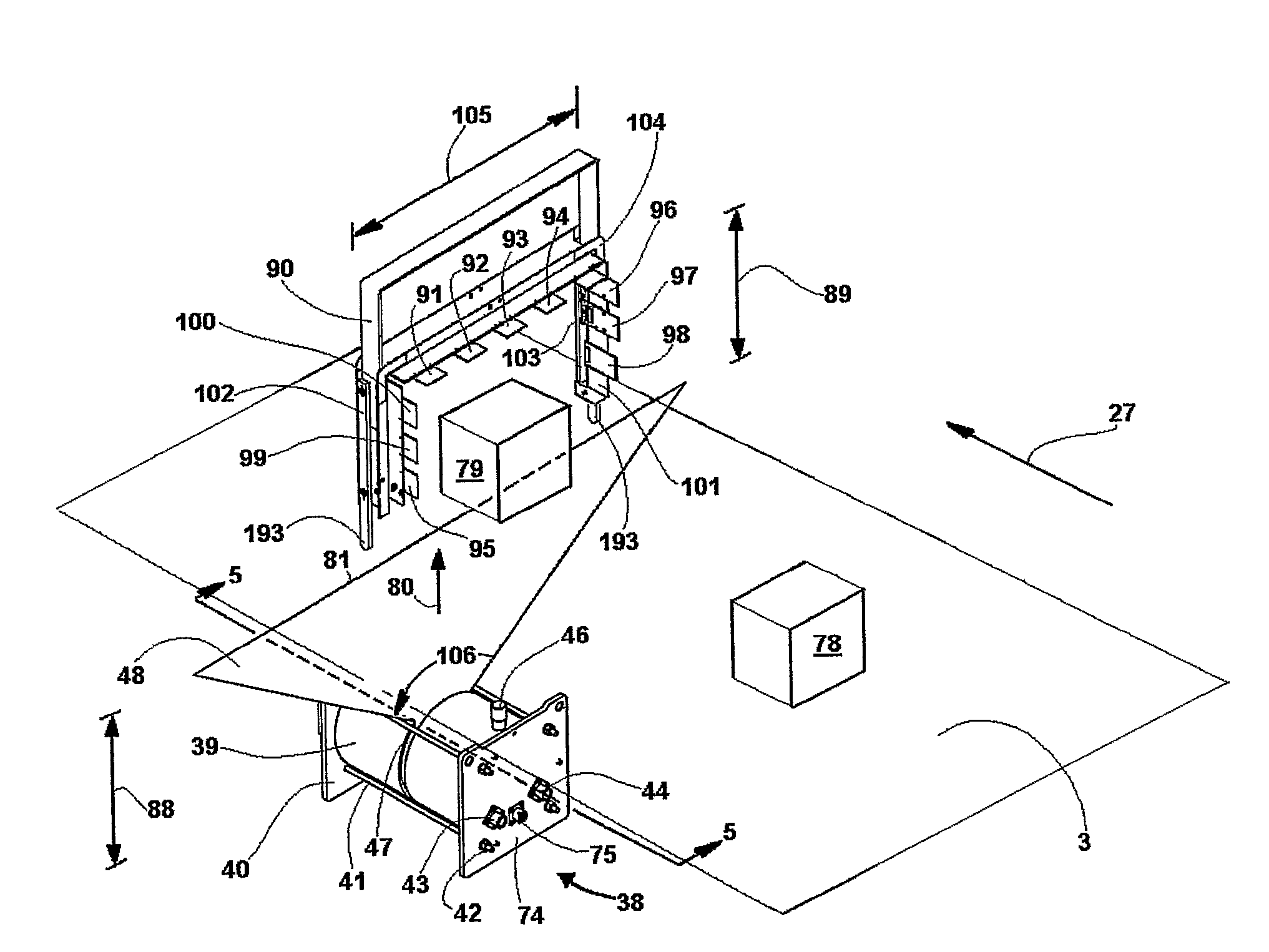

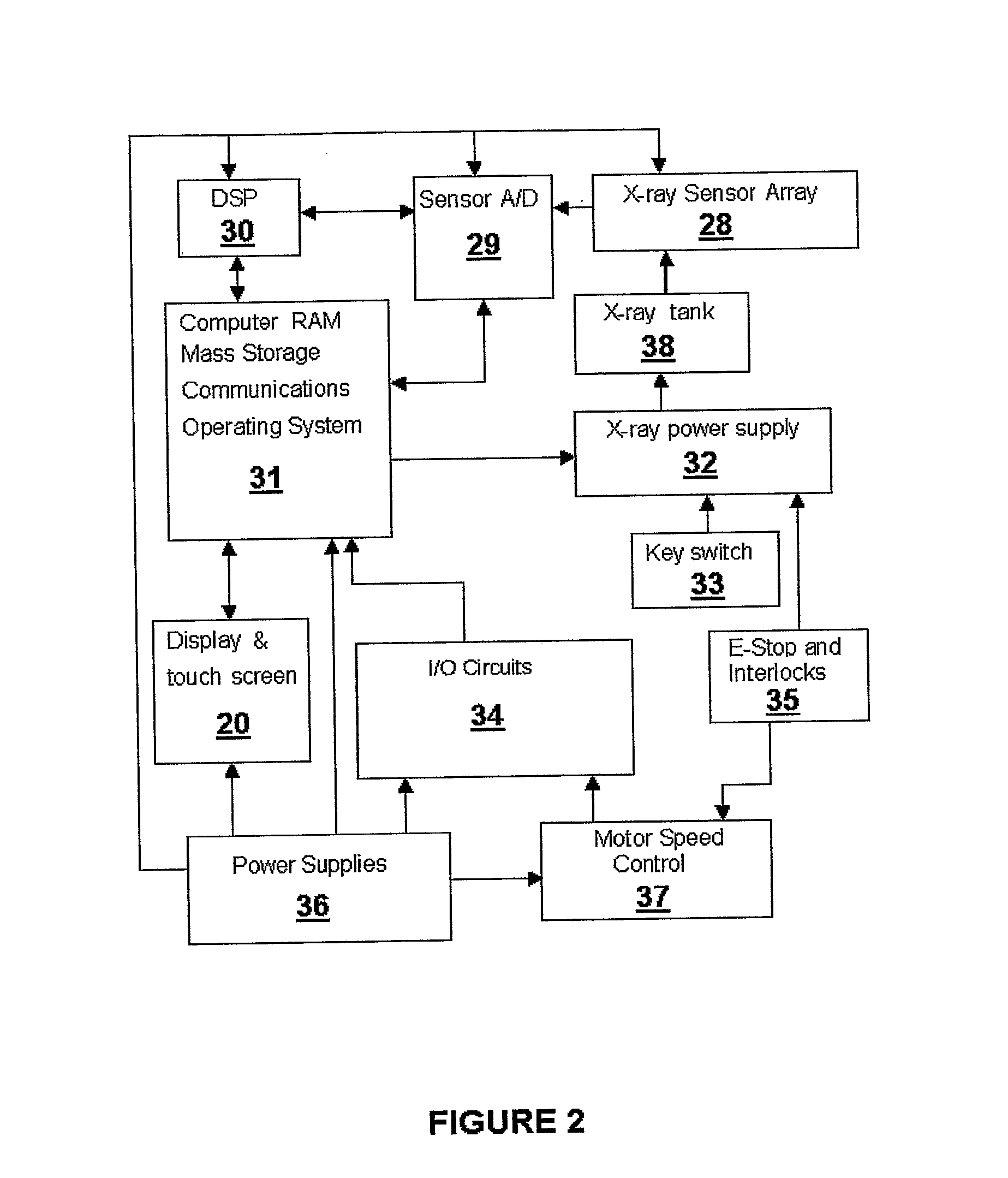

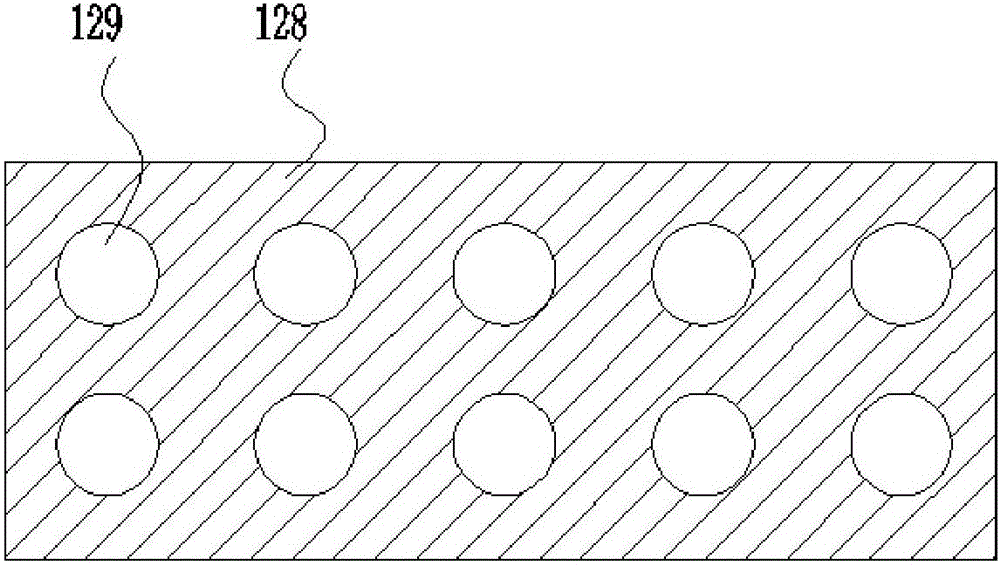

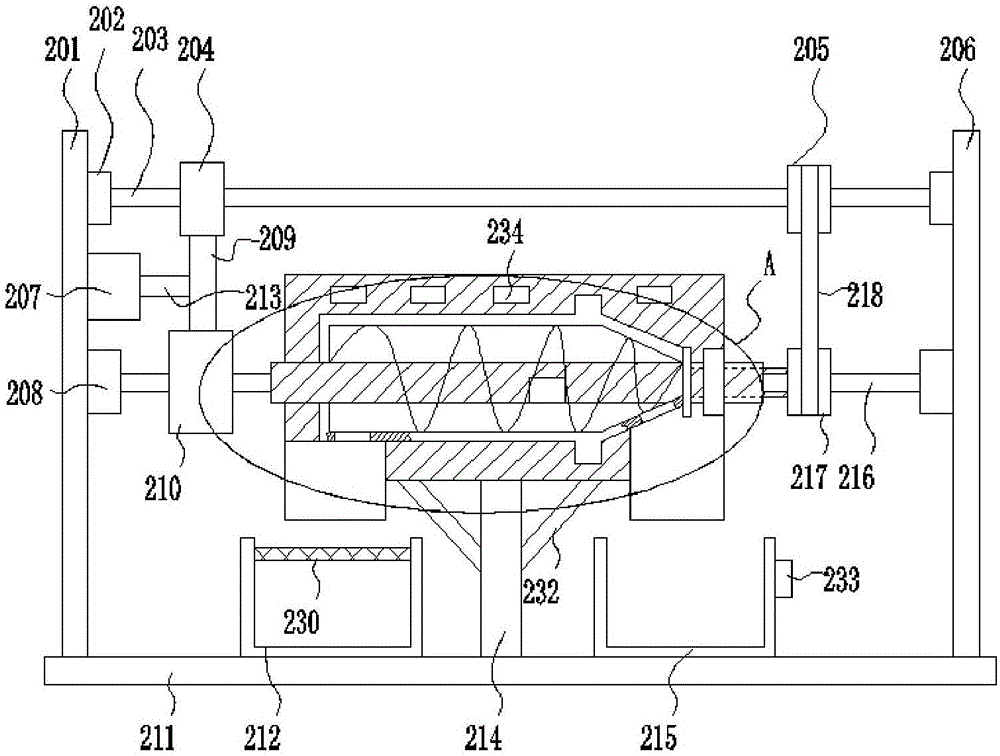

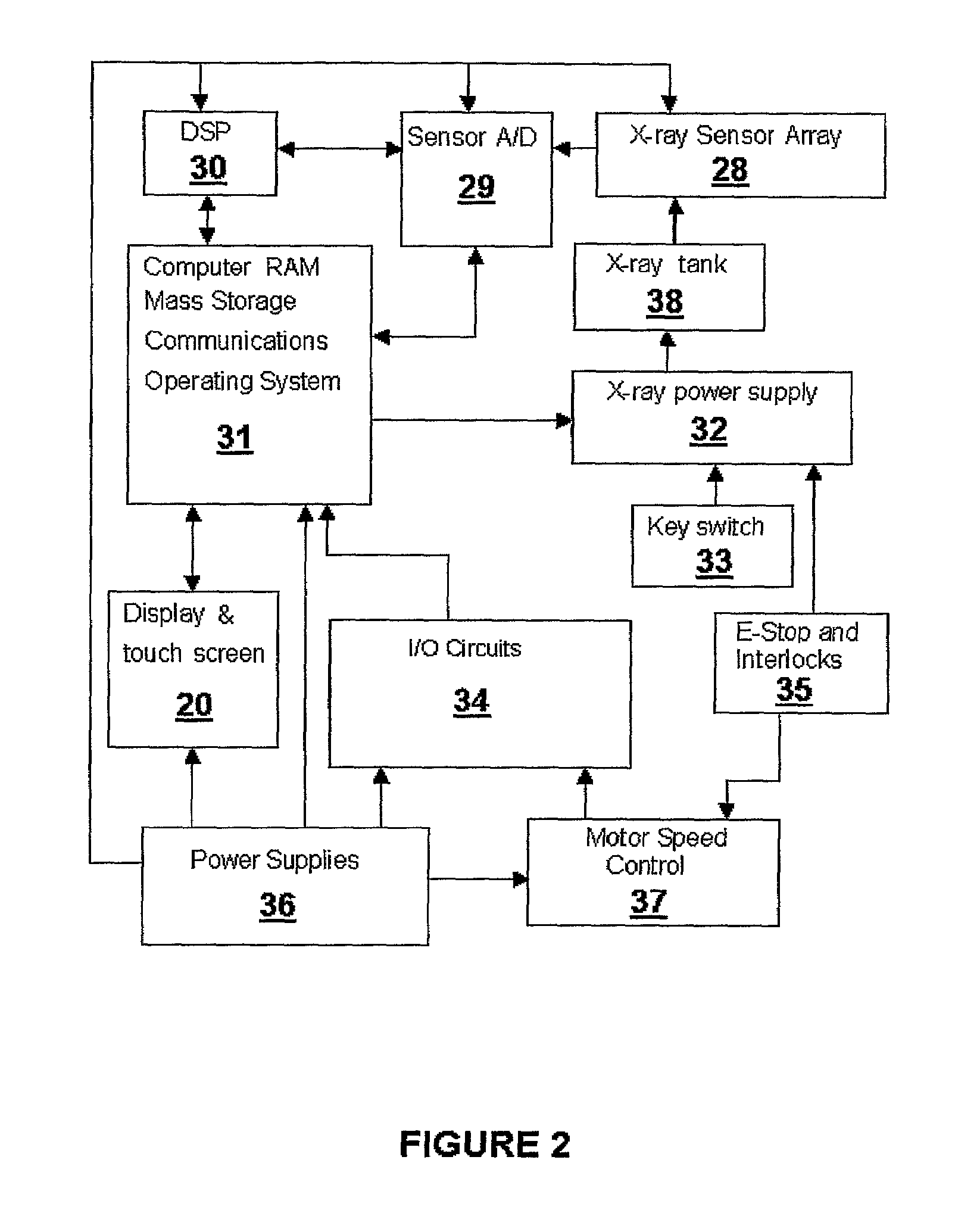

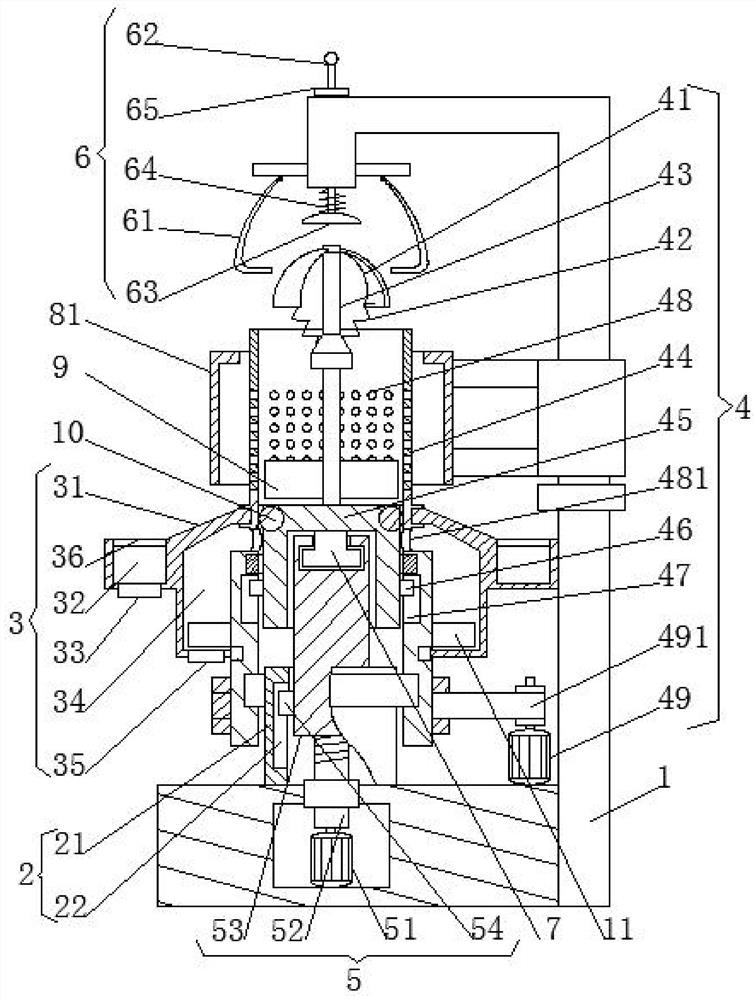

Contaminant Detector For Food Inspection

InactiveUS20080118026A1Low costLow production costRadiation/particle handlingX-ray tube electrodesX-rayDetector array

A contaminant detection machine (1) including a conveyor (3) which causes an object under inspection (79) to pass through a plane (48) of emitted x-ray radiation. The plane is generated by an x-ray tube (55) that emits a lateral beam, thereby permitting the distance (88) between the x-ray tube and the object under inspection to be reduced. A photo diode arch mounting assembly (104) is placed above the object under inspection and is mated to a collimator assembly (125) that also serves as the mounting bracket for the x-ray generation assembly (38), thereby preserving optical alignment between the photo diode detector array (28) and the emitted x-ray plane (48). The detector array (28) scans the object under inspection (79) so as to produce a continuous series of discrete lines, each line being analyzed by an image processing unit (116) to determine the presence or absence of a contaminant. The conveyor (3) passes over a pair of slider bed surfaces (155, 156) which are mounted in a hinged manner such that the leading edge (168) of one surface (156) is parallel to and spaced apart from the trailing edge (172) of the other surface (155), thereby creating a gap that is coplanar with the collimation slot (129) and the emitted x-ray plane (48). Each bed surface (155, 156) is rigidly constrained within open ended mounting brackets (159, 160, 161 and 162) yet can be removed by hand without the use of tools. Similarly, the conveyor (3) is supported by a roller assembly (182) that includes a tracking block (142) and pivot pin (143) which permits the roller assembly to be mounted to and removed from flip up mounts (151, 152) by hand and without the need of tools. Graphical user interfaces (249, 260, 261, 266, 275, 282 and 288) permit a user to operate the machine (1) by means of a liquid crystal display touch screen (20).

Owner:THERMO FISHER SCIENTIFIC INC

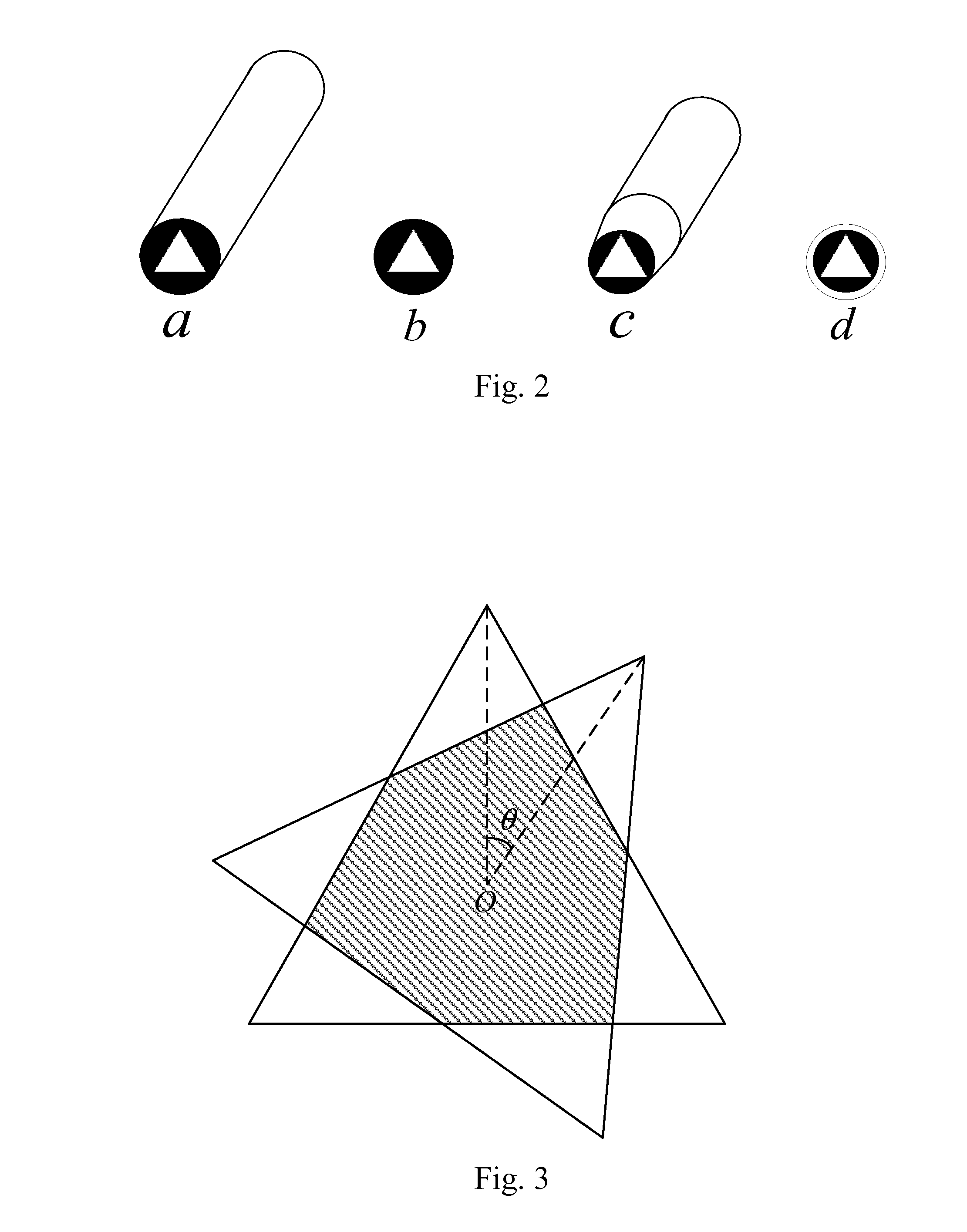

3D printer spray nozzle capable of adjusting cross section areas of extruded materials and method for controling printing speed and precision of the 3D printer spray nozzle

ActiveUS20180079139A1Control precisionControl speedProgramme controlManufacturing driving meansSpray nozzle3d printer

A 3D printer spray nozzle includes a feeding pipeline, an extruder located under the feeding pipeline, an external housing and a driving device; wherein the feeding pipeline is embedded in the external housing, the extruder is coaxially fixed under the feeding pipeline, a center of gravity of a cross section area of an inner channel of the feeding pipeline and that of the extruder are located on a same axis which is perpendicular to the cross section area of the inner channel of the feeding pipeline and that of the extruder, the feeding pipeline is driven by the driving device to rotate around the axis relative to the extruder, thereby aiming at different rotation angles, widths of extruding forming areas of the extruder at a same direction are different so as to adjust a cross section area of a sprayed filament.

Owner:CLOUD COMPUTING CENT CHINESE ACADEMY OF SCI

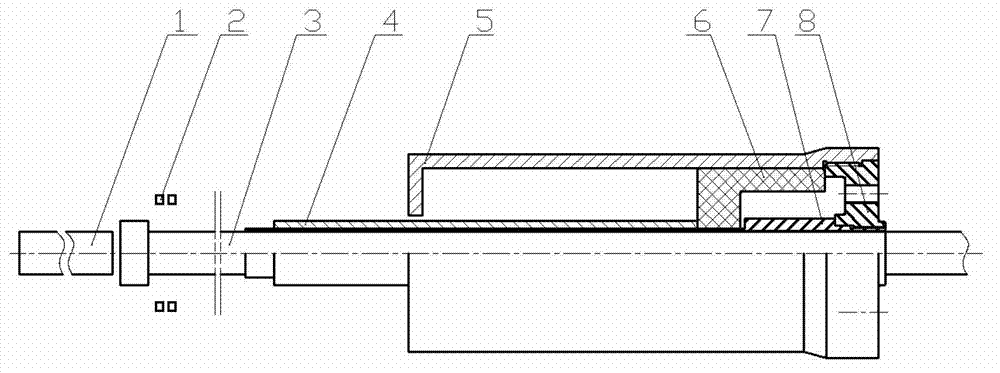

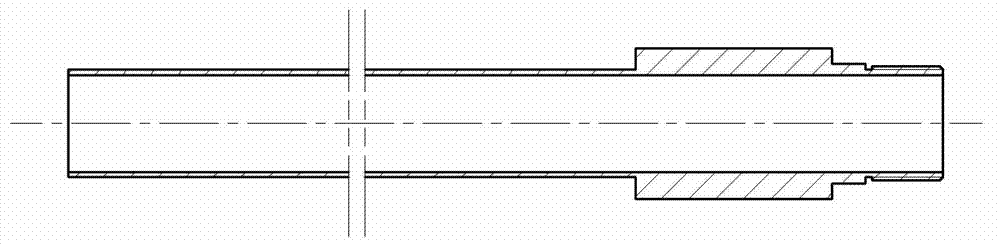

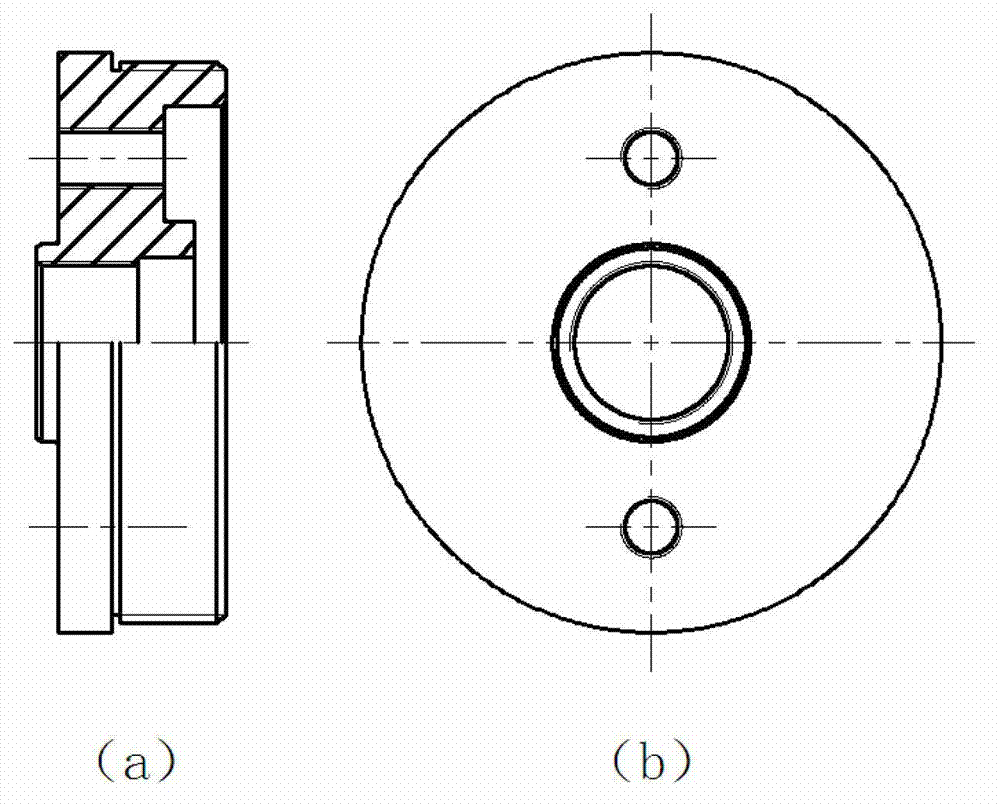

Launcher based on Hopkinson pull rod test equipment

The invention designs a launcher according to a principle and requirements of a Hopkinson pull rod test. The launcher mainly comprises a sleeve, a base, a piston, a sliding rail and a supporting base and the like, and is mainly structurally characterized in that high-pressure gas pushes the piston to move so as to push a tubular bullet to speed up, so that the bullet knocks a launching rod at a certain speed; and the thin-wall cylindrical sliding rail is used for supporting movement of the piston and the tubular bullet, thereby achieving a tensile loading way with relatively good reliability and consistency. The launcher is simple and reliable in structure, relatively low in cost, obvious in accelerating effect, thereby ensuring a relatively high bullet speed within a relatively short stroke, and good in test consistency, thereby ensuring a consistent bullet speed under a certain condition; through pressure regulation of the high-pressure gas, different bullet loading speeds can be obtained; and through a design of the sliding rail, the bullet does not contact the launching rod during acceleration, thereby avoiding influence of interaction of the bullet and the launching rod on a test result.

Owner:NANJING UNIV OF SCI & TECH

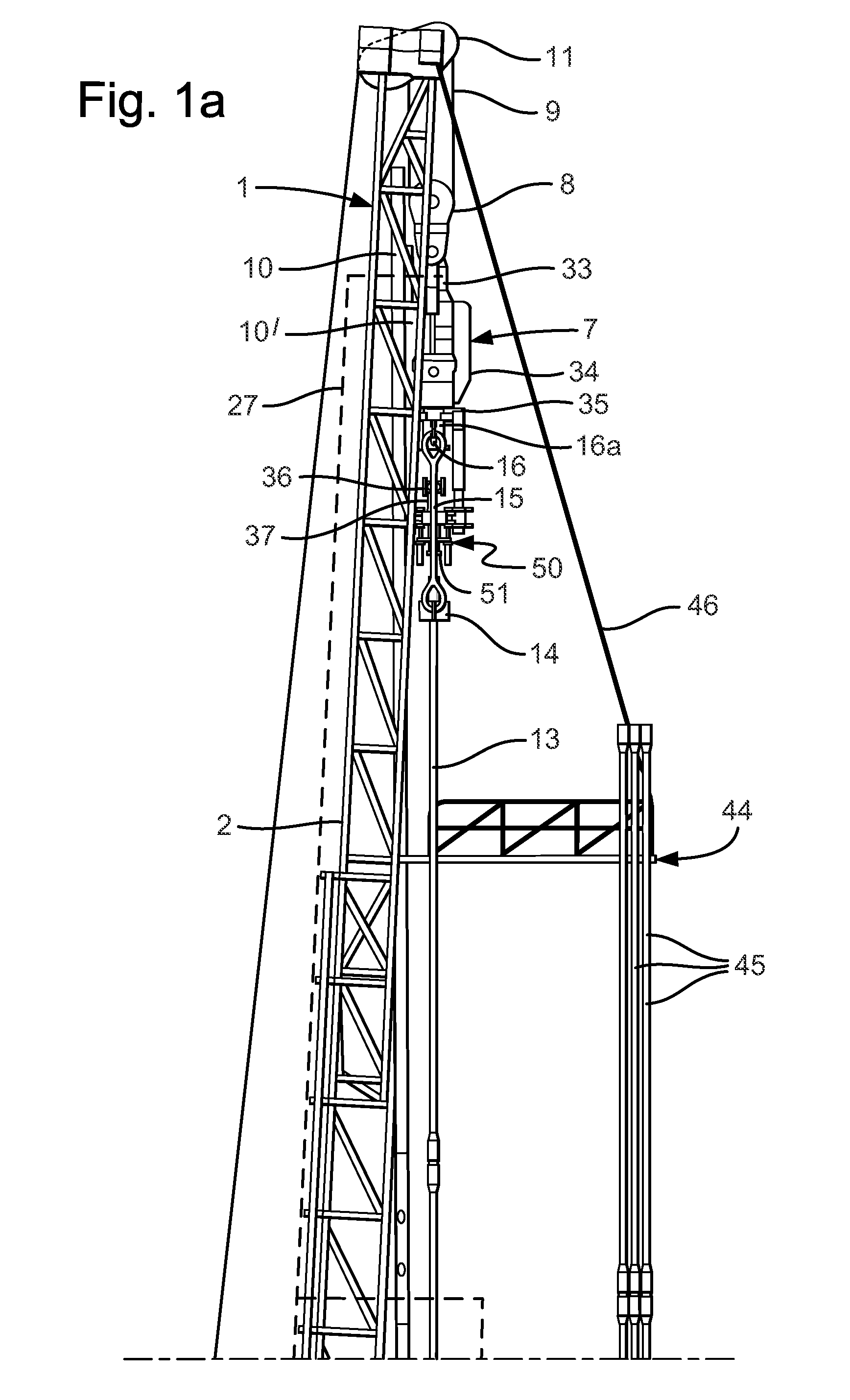

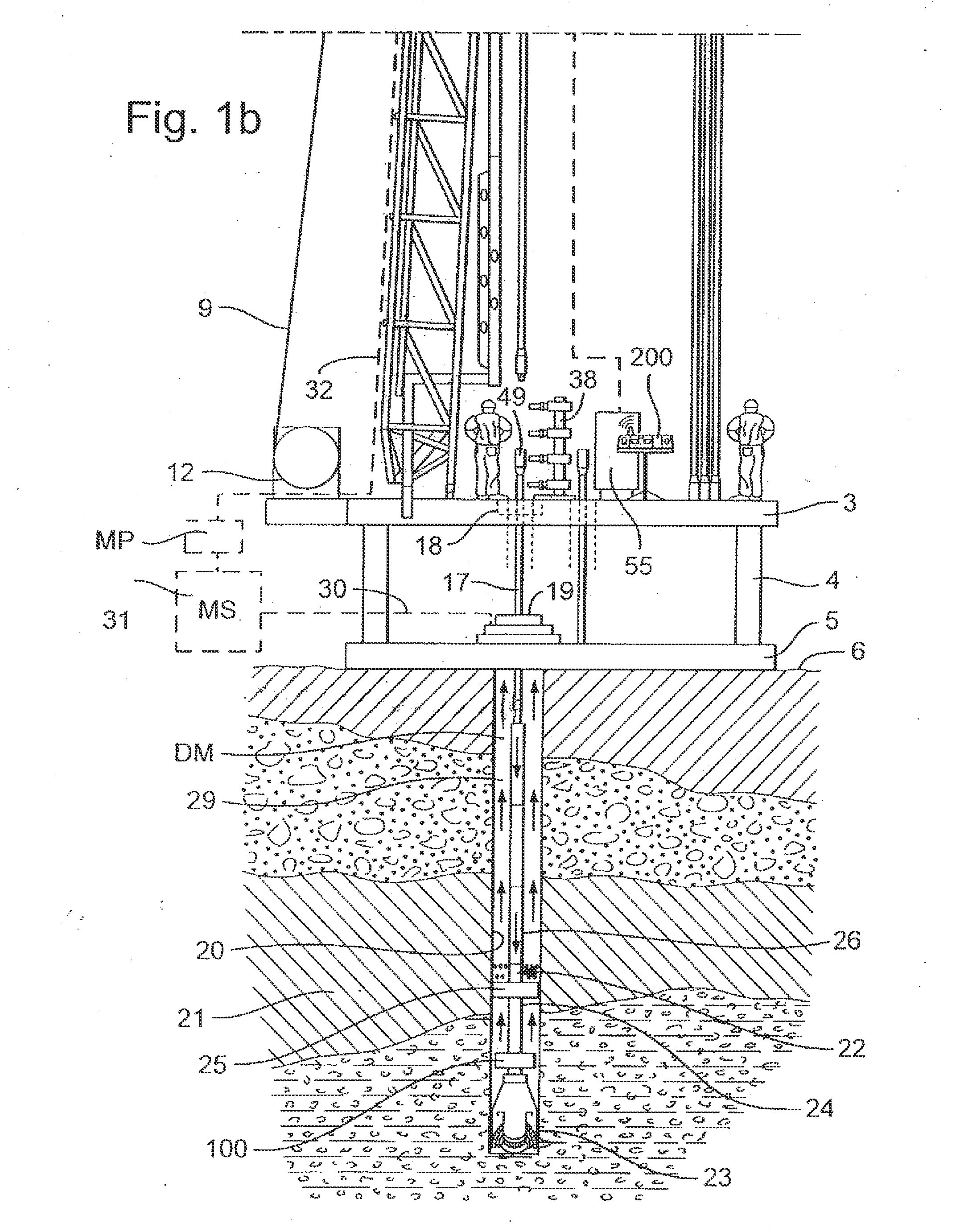

Component of bottom hole assembly having upwardly-directed fluid cleaning flow and methods of using same

InactiveUS20160290067A1Increase in sizeAvoid cakingDrilling rodsDrilling casingsEngineeringMechanical engineering

A stabilizer, drill bit, or other component of a bottom hole assembly for use in drilling a borehole includes an elongate and generally cylindrical body, a flow bore in the body, a plurality of outwardly-extending blades, with a valley disposed between adjacent blades. A ring segment that is spaced from the body and extends across at least one valley to define a flow passage through which cuttings-laden drilling mud is conveyed with an upwardly-direct trajectory. The body includes a hole or passageway for conveying drilling mud from the flow bore to between the blades. The passageway terminates in an exit directed toward the flow passage so as to provide fresh drilling mud with a trajectory such that the fluid passes through the flow passage.

Owner:NOV DOWNHOLE EURASIA LTD

Method and Device For Producing Bent Spring Elements

InactiveUS20080302157A1Avoid excessive wearIncrease productionWire springsStock shearing machinesControl mannerEngineering

The invention is based on a method of producing bent spring elements from a spring steel strip (14), wherein a feed unit (16) delivers the spring steel strip (14) from a supply roll (12) to a bending unit (32) having at least three bending rollers (34) and a reverse bending roller (36), of which at least one bending roller (34) and the reverse bending roller (36) can be adjusted transversely to the spring steel strip (14) by bending motors (60, 62), and wherein a cutting-off unit (44) adjoins the bending unit (32), said cutting-off unit (44) cutting off the spring steel strip (14) into individual spring elements by means of cutting-off tools (46, 48; 76, 78). It is proposed that the cutting-off tools (46, 48; 76, 78) be movable in the longitudinal direction of the spring steel strip (14) in a numerically controlled manner and that they be synchronized with the feed movement of the spring steel strip (14) during the cutting-off operation.

Owner:ROBERT BOSCH GMBH

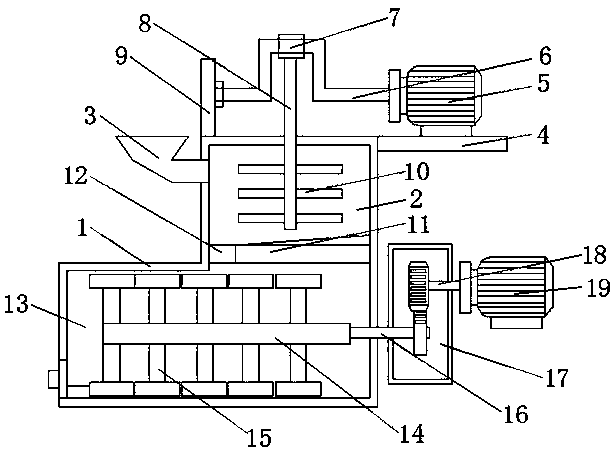

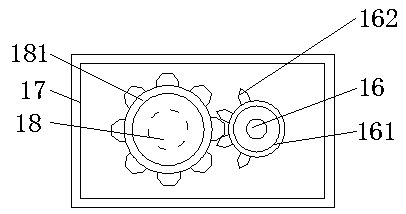

Preparation device of fructus hippophae juice

The present invention discloses a preparation device of a fructus hippophae juice. The preparation method comprises a squeezing device, a horizontal screw centrifuging device, a concentrating device and a filling device. A material outlet of the squeezing machine is connected with a material inlet of the horizontal screw centrifuging machine; a material inlet of the concentrating device is located at the lower part of a liquid collecting box of the horizontal screw centrifuging machine and a material inlet of the filling device is connected to a material outlet of the concentrating device; and the horizontal screw device comprises a horizontal screw main body, a rotary drum and a screw inside, a material feeding tube with a material inlet, a speed reduction motor, a liquid collection tank, and a residue discharge port and a pressure sensor arranged on the residue discharge port used for controlling the outflow of the residues. The device can effectively remove pectin and fibers in the fructus hippophae juice and realizes the automatic production of the fructus hippophae juice.

Owner:新疆慧华沙棘生物科技有限公司

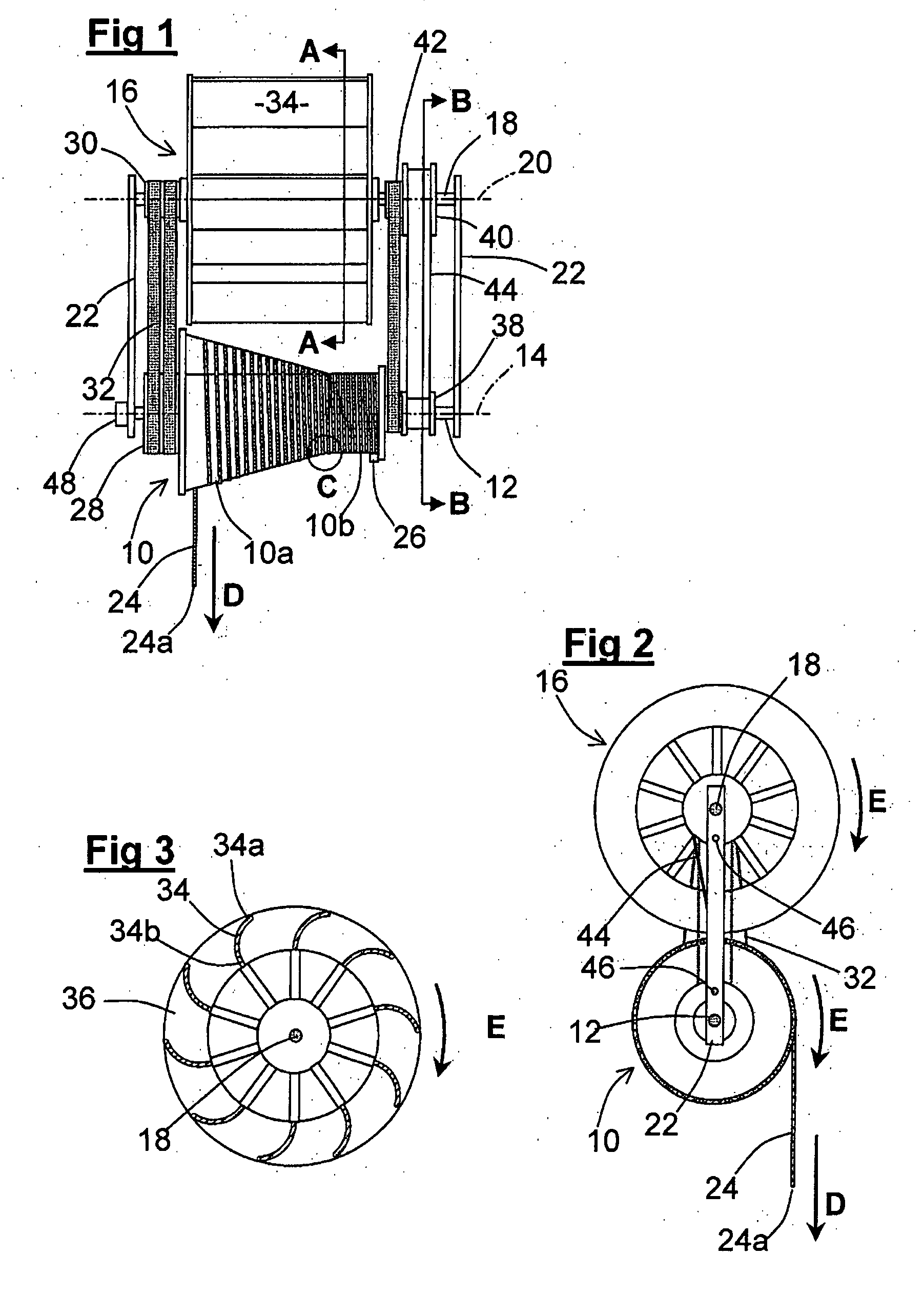

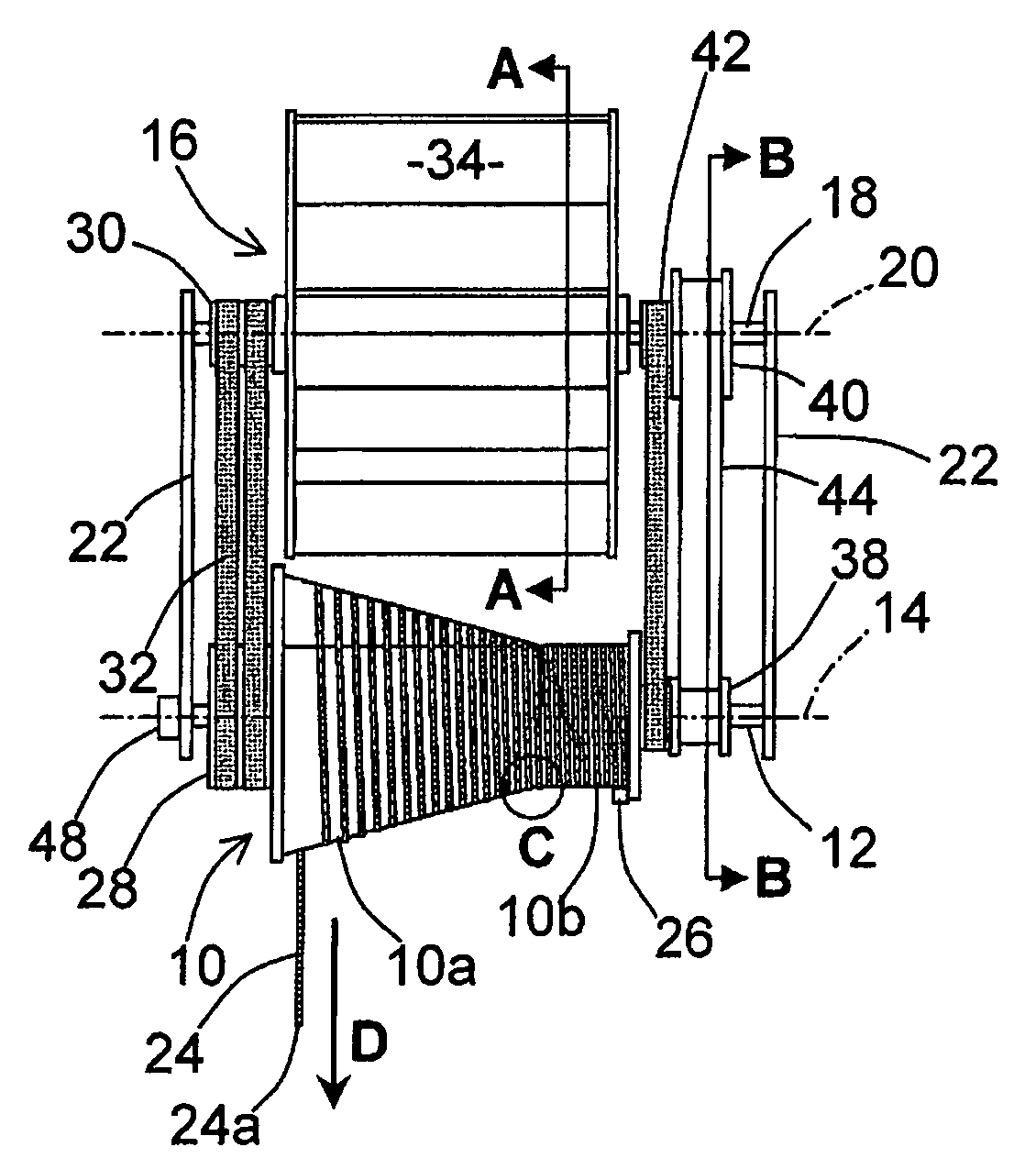

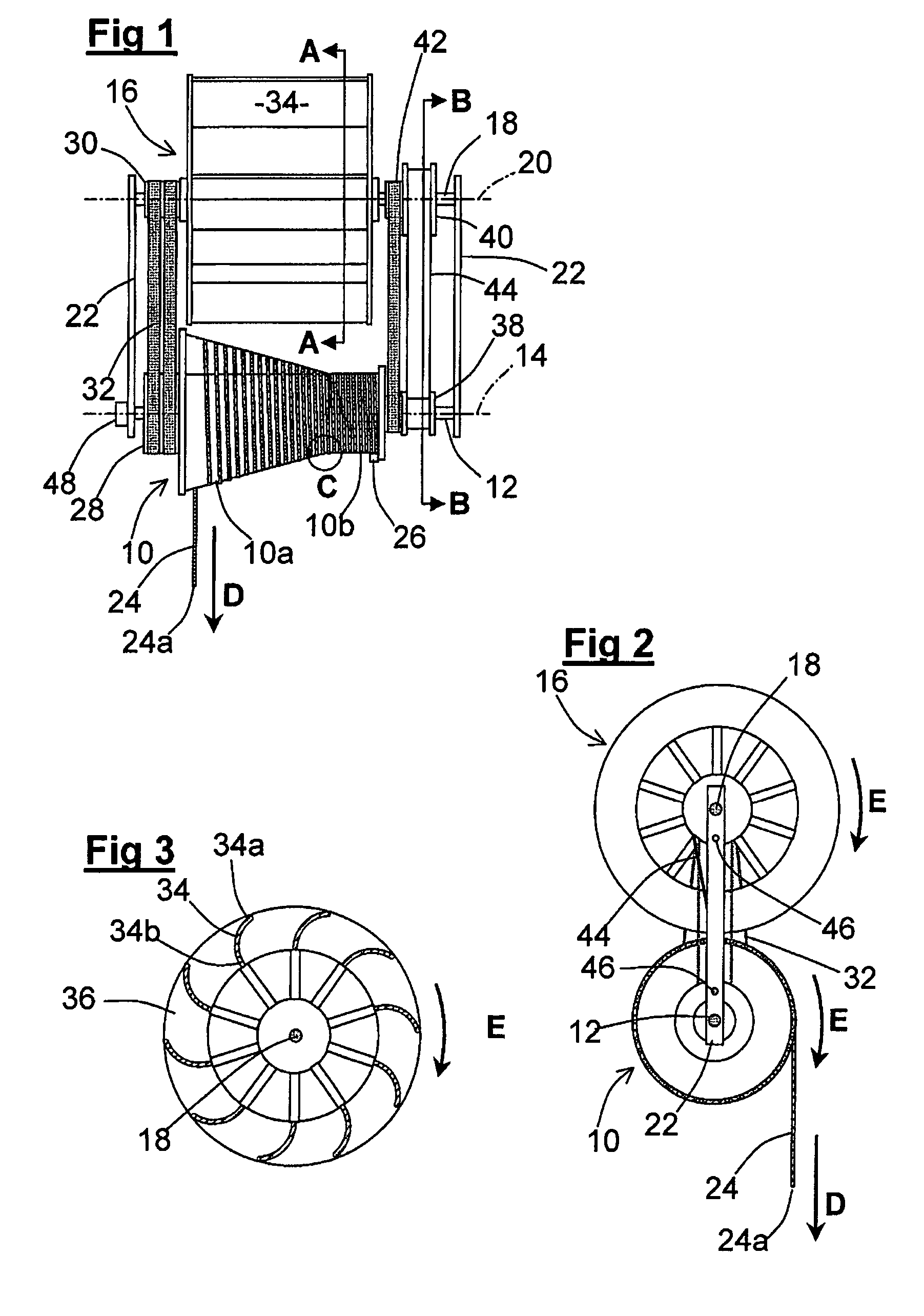

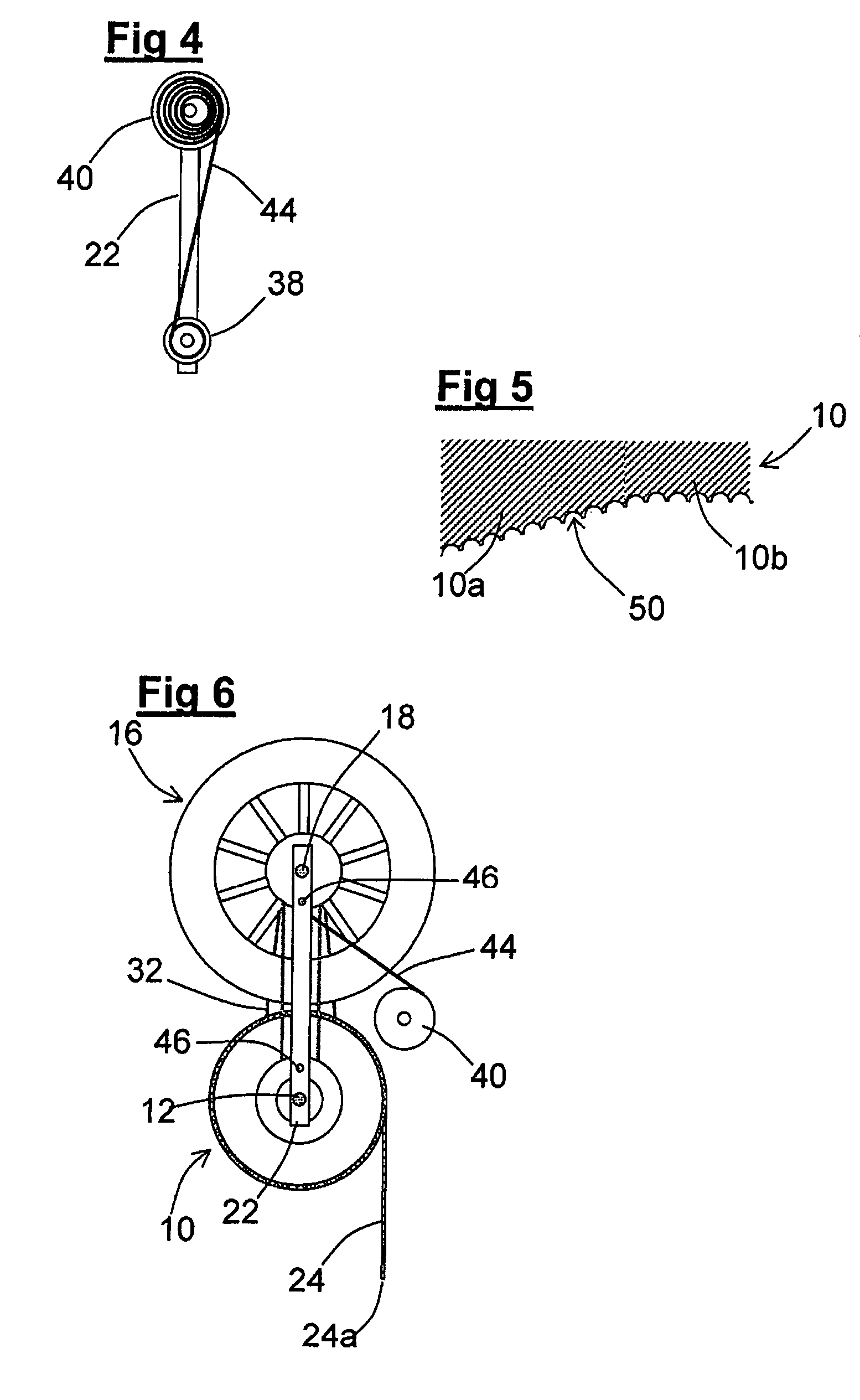

Windage braking

ActiveUS20070240940A1Compact windage brakeDifferent speedBuilding rescueHoisting equipmentsImpellerEngineering

A windage brake for a fan descender comprises a rotatable spool connected by drive belts to a fan comprising a radial flow air impeller. A line is wound helically upon the spool. A user of the fan descender puts on a harness (not shown) at the free end of the line and jumps from an elevated position. The line is thereby drawn off the spool and rotates it. The rotating spool drives the fan and also winds a power spring formed by a resilient strip. The windage of the fan regulates the descent of the jumper, the fan being accelerated to a speed at which the braking force is such that the jumper descends at a rate safe for landing on the ground. When the jumper is on the ground, he removes the harness and releases the free end of the line. The line is then automatically retrieved by the power spring and rewound on the spool.

Owner:DROP ZONE UK

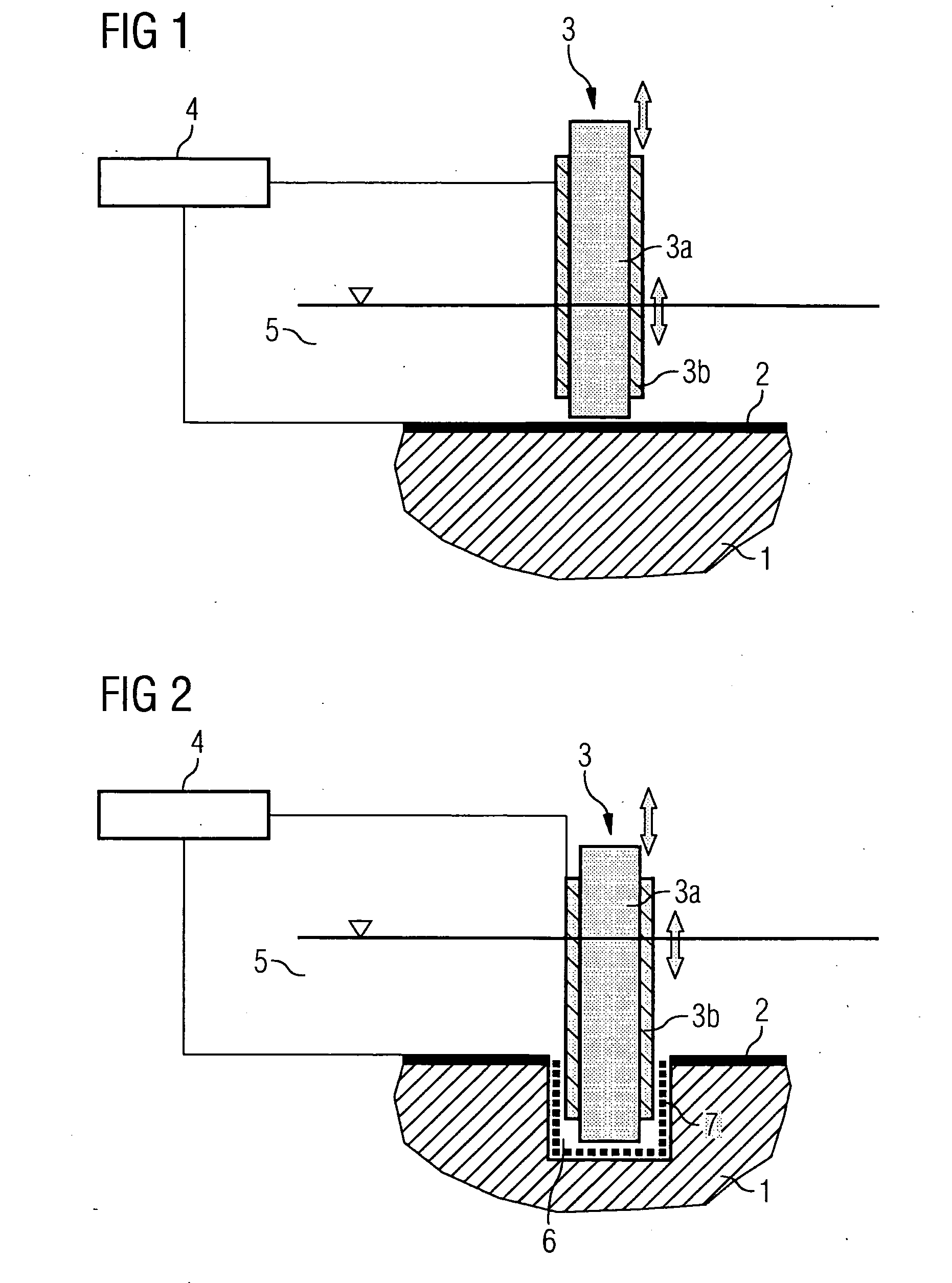

Electrode Arrangement for Electrical Discharge Machining on an Electrically Non-Conductive Material

InactiveUS20090200274A1Rapid and reliable formationErosion is goodArc welding apparatusElectrical-based machining electrodesConductive materialsElectrical discharge machining

The invention relates to an electrode arrangement for the electrical discharge machining of an electrically non-conductive material, which comprises a first component for removing the electrically non-conductive material and a second component for depositing an electrically conductive substance on the electrically non-conductive material.

Owner:SIEMENS AG

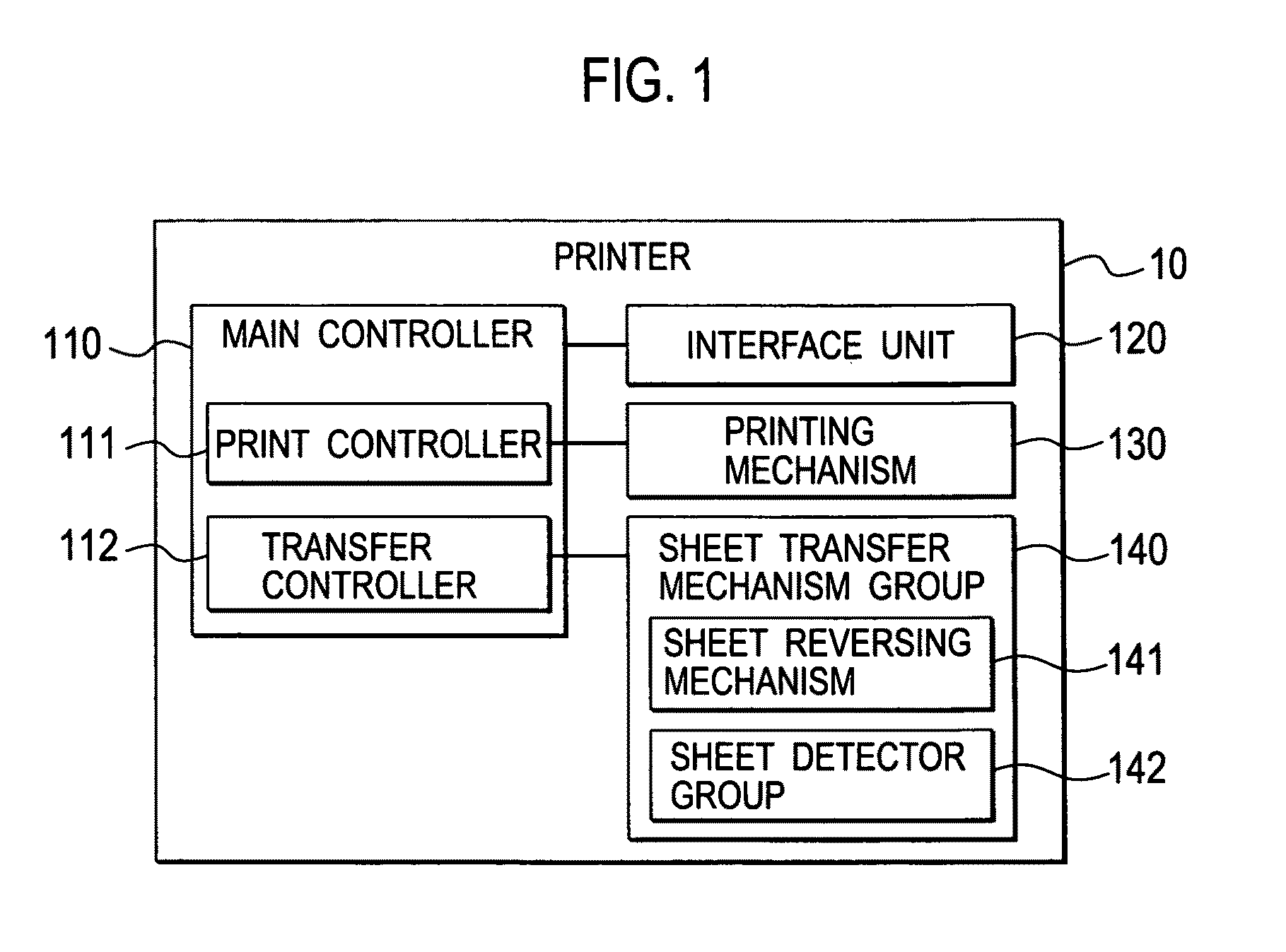

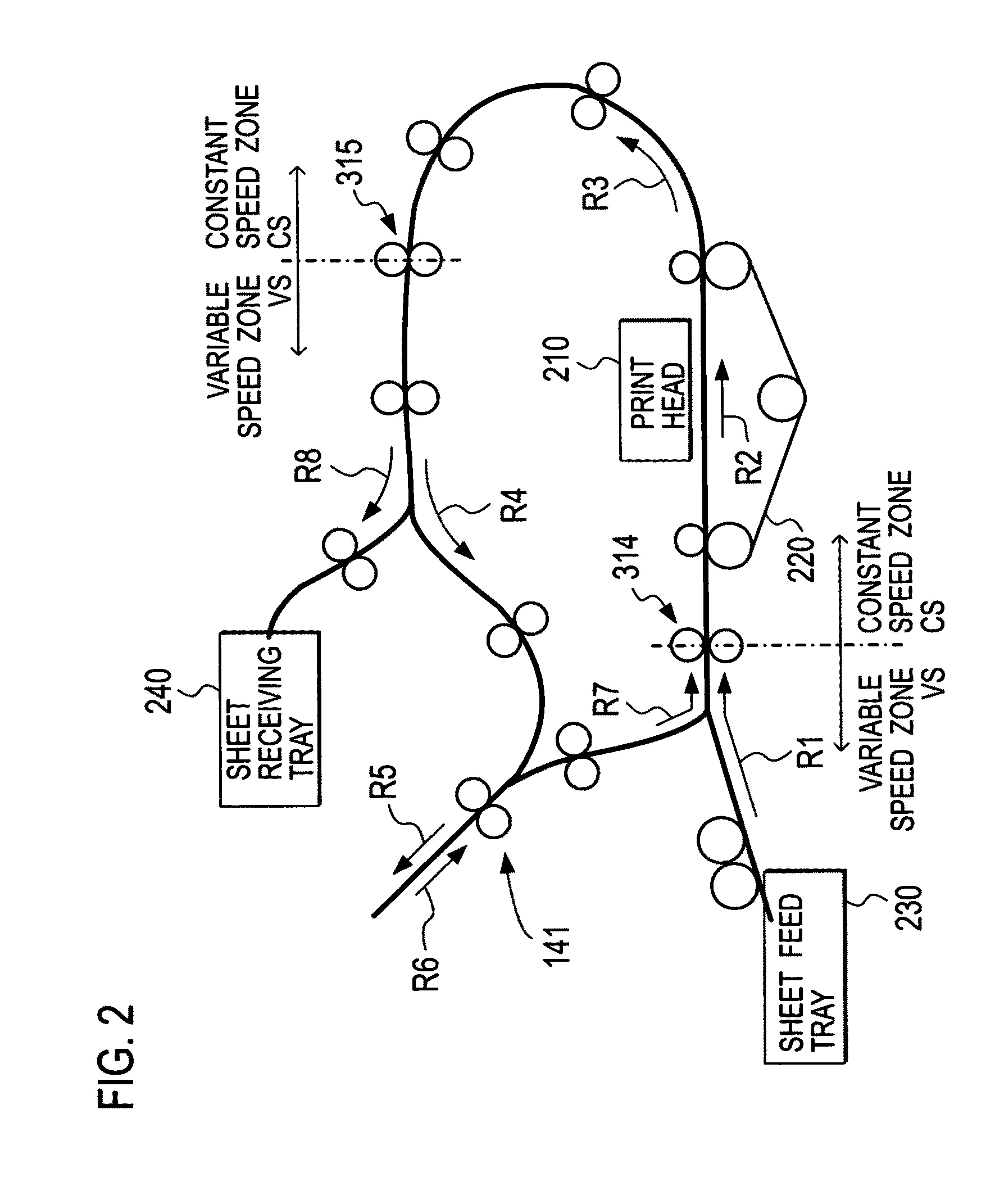

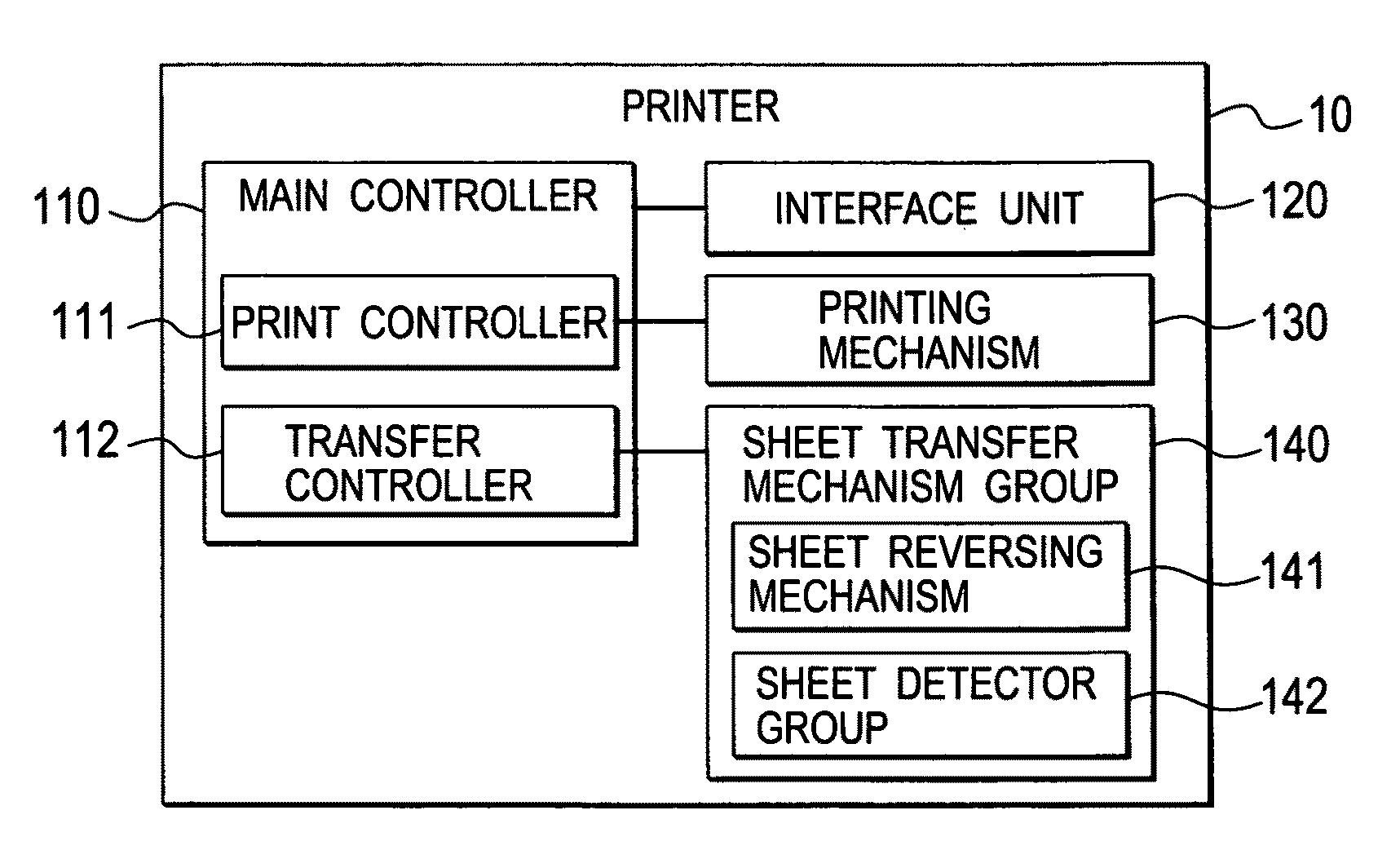

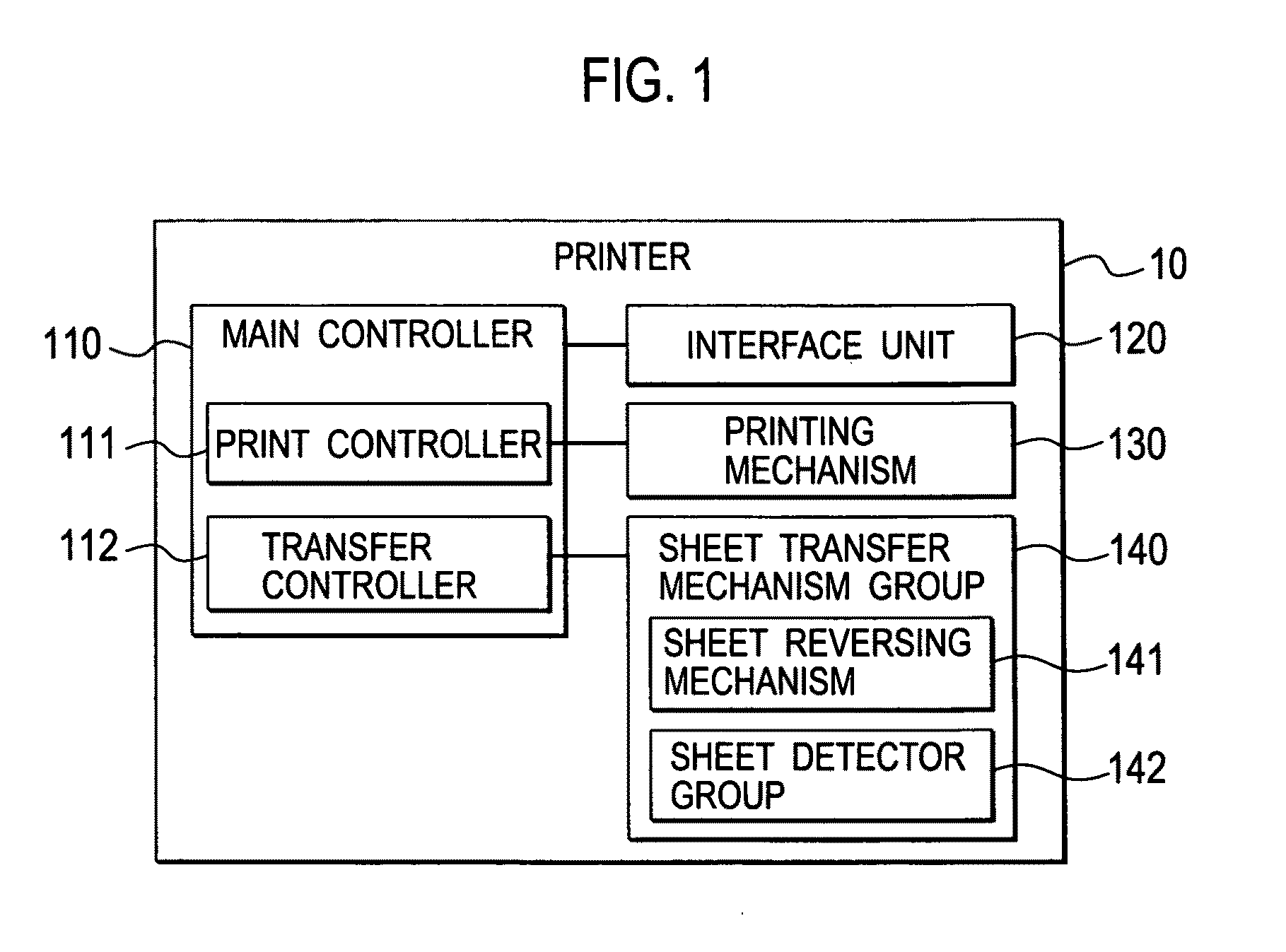

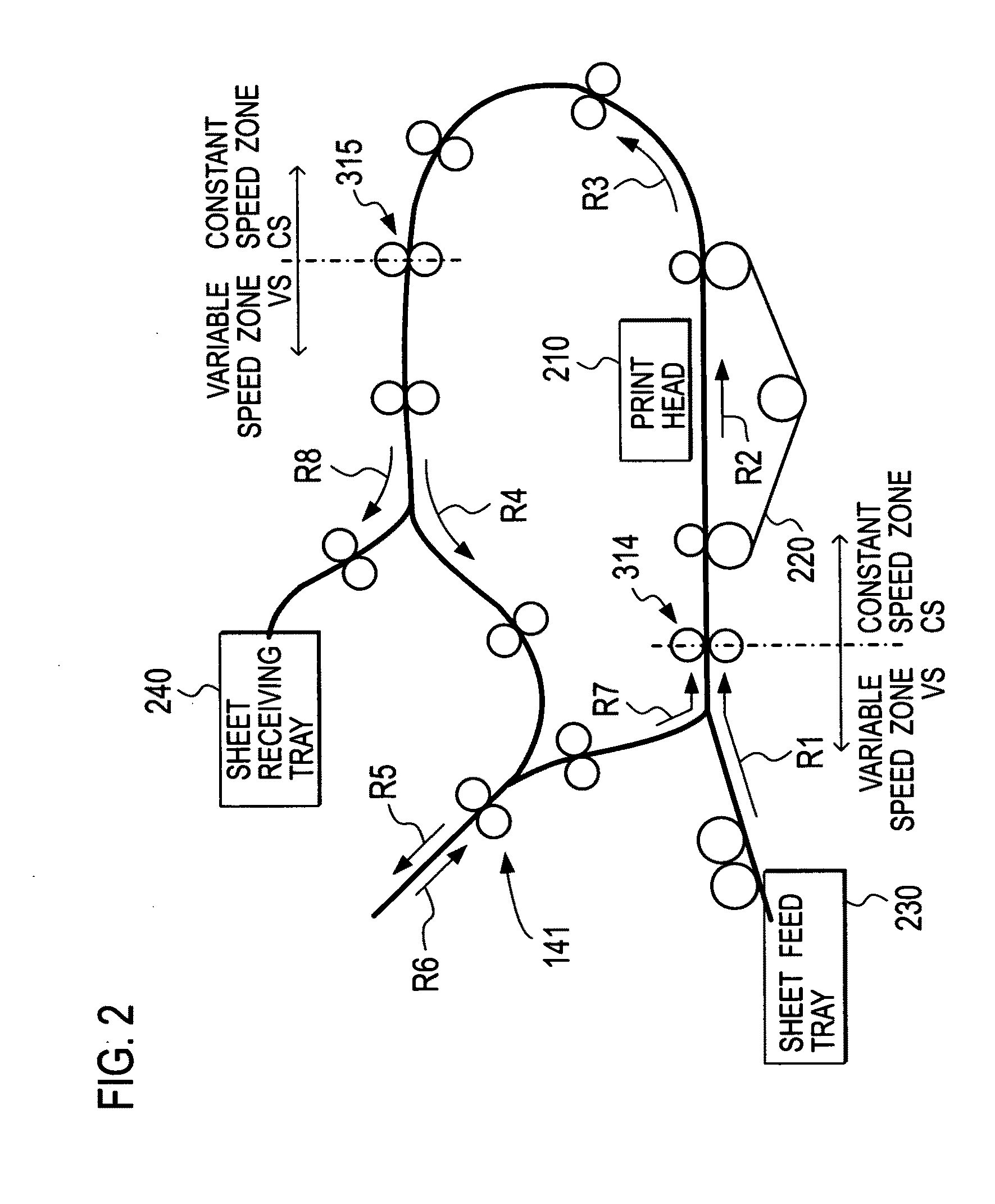

Image forming apparatus

ActiveUS8038144B2Easy to controlDifferent speedFunction indicatorsArticle feedersImage formationEngineering

In an image forming apparatus, a sheet reversing mechanism is configured to take over and transfer, at a transfer speed Vr, a print sheet with an image already formed on one side being transferred at the transfer speed Vr from a first transfer mechanism, to stop the print sheet once, then to start transfer of the print sheet in an opposite direction, and to pass the print sheet to a second transfer mechanism at the transfer speed Vr. The first and second transfer mechanisms are located on upstream and downstream of a switchback reverse path for reversing print sheets respectively Upon lapse of a time T1 after detection of the print sheet by a print sheet detection unit, a transfer control unit drives the sheet reversing mechanism to start acceleration from a stopped state to the transfer speed Vr, the time T1 calculated based on the transfer speed Vr.

Owner:RISO KAGAKU CORP

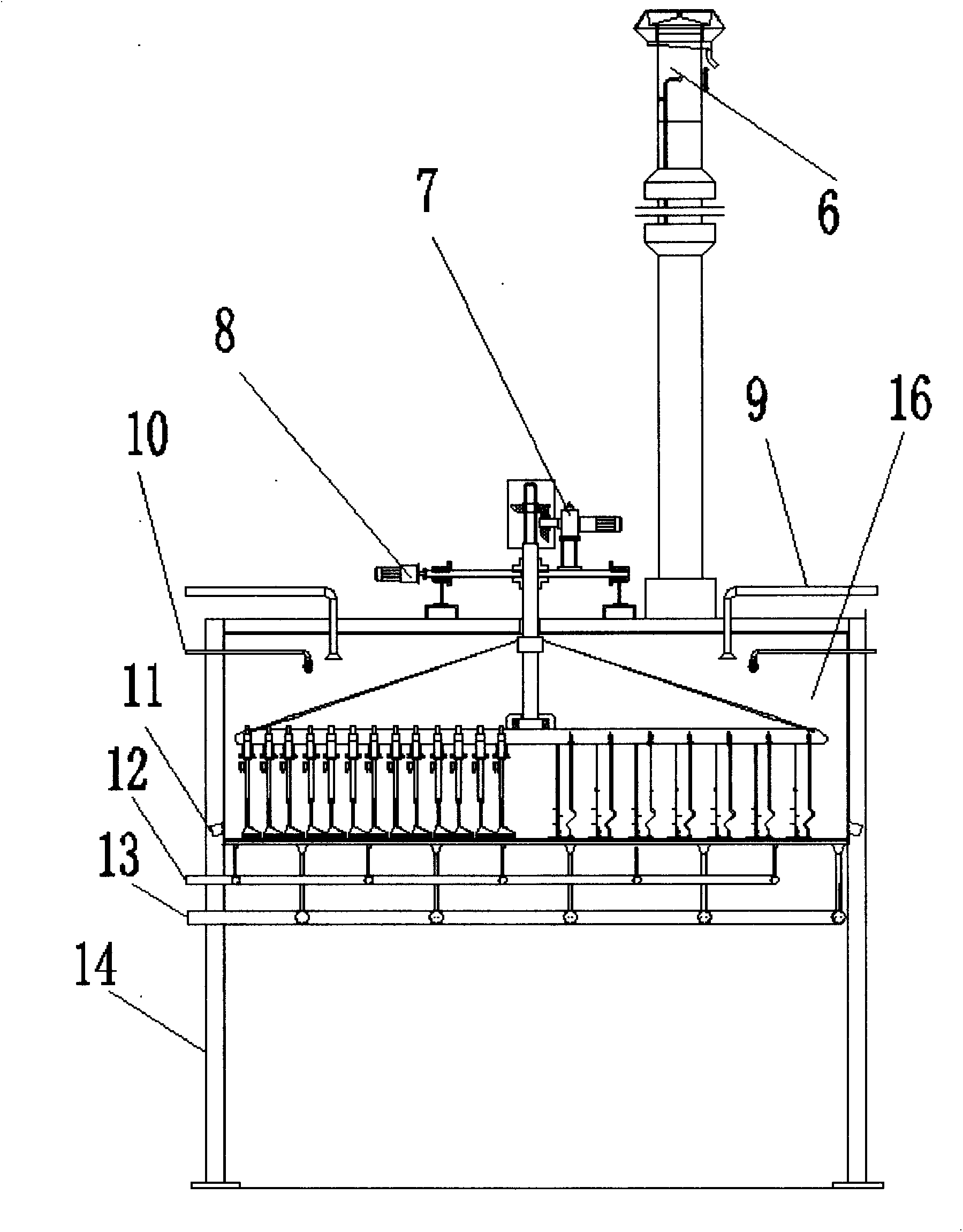

Square filtering tank for beer saccharification filtering system

The invention discloses a square filtering tank for a beer saccharification filtering system, and relates to a filtering system special for beer saccharification. The square filtering tank comprises a filtering plate, an exhaust barrel, a vinasse discharging lifting device, a vinasse raking reciprocating device, a tank washing water inlet, a washing water inlet, supporting legs, a mash inlet, a backwashing water inlet and a wheat juice outlet, wherein the exhaust barrel is fixed at the top of a tank body; the vinasse discharging lifting device and the vinasse raking reciprocating device are arranged on the tank body in a sliding manner and are both connected with a large vinasse raking arm in the tank body; the tank washing water inlet is also formed in the tank body; the washing water inlet is formed in the side surface of the tank body; the mash inlet is formed below the washing water inlet; the filtering plate is arranged in the tank body; a vinasse discharging door is arranged on the filtering plate; the backwashing water inlet and the wheat juice outlet are formed in the lower end of the tank body. According to the square filtering tank for the beer saccharification filtering system, the linear speeds of raking cutters in the tank during vinasse raking are consistent, so that the original concentration of the collected wheat juice at different positions after mash is filtered is the same, and the pure flavor of wheat juice is guaranteed.

Owner:青岛啤酒工程有限公司

Contaminant detector for food inspection

InactiveUS7450686B2Low costFree of ChargeRadiation/particle handlingX-ray tube electrodesDetector arrayImage manipulation

Owner:THERMO FISHER SCIENTIFIC INC

Windage braking

ActiveUS8061483B2Compact windage brakeDifferent speedBraking element arrangementsSafety beltsImpellerEngineering

A windage brake for a fan descender comprises a rotatable spool connected by drive belts to a fan comprising a radial flow air impeller. A line is wound helically upon the spool. A user of the fan descender puts on a harness (not shown) at the free end of the line and jumps from an elevated position. The line is thereby drawn off the spool and rotates it. The rotating spool drives the fan and also winds a power spring formed by a resilient strip. The windage of the fan regulates the descent of the jumper, the fan being accelerated to a speed at which the braking force is such that the jumper descends at a rate safe for landing on the ground. When the jumper is on the ground, he removes the harness and releases the free end of the line. The line is then automatically retrieved by the power spring and rewound on the spool.

Owner:DROP ZONE UK

High-efficiency production technology of middle and low-viscosity printing ink

InactiveCN108745174AEfficient production processSimple structureShaking/oscillating/vibrating mixersRotary stirring mixersDrive wheelMotor drive

The invention discloses a high-efficiency production technology of middle and low-viscosity printing ink in the technical field of printing ink. the bottom part of the left side of the rear end surface of a frosting cavity is provided with a material outlet; the left side of a baffle plate is provided with a through hole; a transmission rod is transversely arranged in the frosting cavity; the bottom part, which penetrates through a processing device, of a connecting rod is communicated with the bottom part of an inner cavity of a rotating speed regulating tank. A stirring rod is driven to moveup and down in a stirring cavity through the rotation of a crank shaft, multiple groups of blade-shaped stirring blades can also be driven to move when the stirring rod moves up and down, so that materials can be stirred, and not only the materials can be quickly stirred and fused, but also material bodies cannot be damaged; through the arrangement of the transmission rod of which the rotating speed can be adjusted, a driven wheel can be disassembled through a threaded hole and a fixed bolt, and a driven wheels in different size or different latch number can be replaced; when a servo motor drives a driving gear to rotate through a motor shaft, the driving gear drives different gears to rotate, so that different rotating speeds can be achieved by the transmission rod.

Owner:奥莱鑫科技股份有限公司

Method and device for controlling speed limit of urban traffic

InactiveCN110264752AConducive to unimpededEasy to driveArrangements for variable traffic instructionsTransmission systemsData processing systemCommunications system

The invention relates to the technical field of vehicle monitoring, in particular to a method and device for controlling speed limit of urban traffic. The method comprises the following steps: acquiring current first road condition information; transmitting the road condition information to a mobile edge computing platform and preprocessing the first road condition information by the mobile edge computing platform; transmitting the processed first road condition information to a data processing system; according to second road condition information acquired in the data processing system and the processed first road condition information, calculating an optimal speed limit and a recommended vehicle speed that correspond to each road; transmitting the optimal speed limit and the recommended vehicle speed to a road side unit of a corresponding road and converting the optimal speed limit and the recommended vehicle speed into speed limit signals by the road side unit; and transmitting the multiple speed limit signals to a road side display device and / or a vehicle in a preset range via a vehicle network communication system. According to the invention, the vehicle flow running speed becomes reasonable on different roads within different time; and urban development is promoted.

Owner:ZHEJIANG GEELY HOLDING (GROUP) CO LTD +1

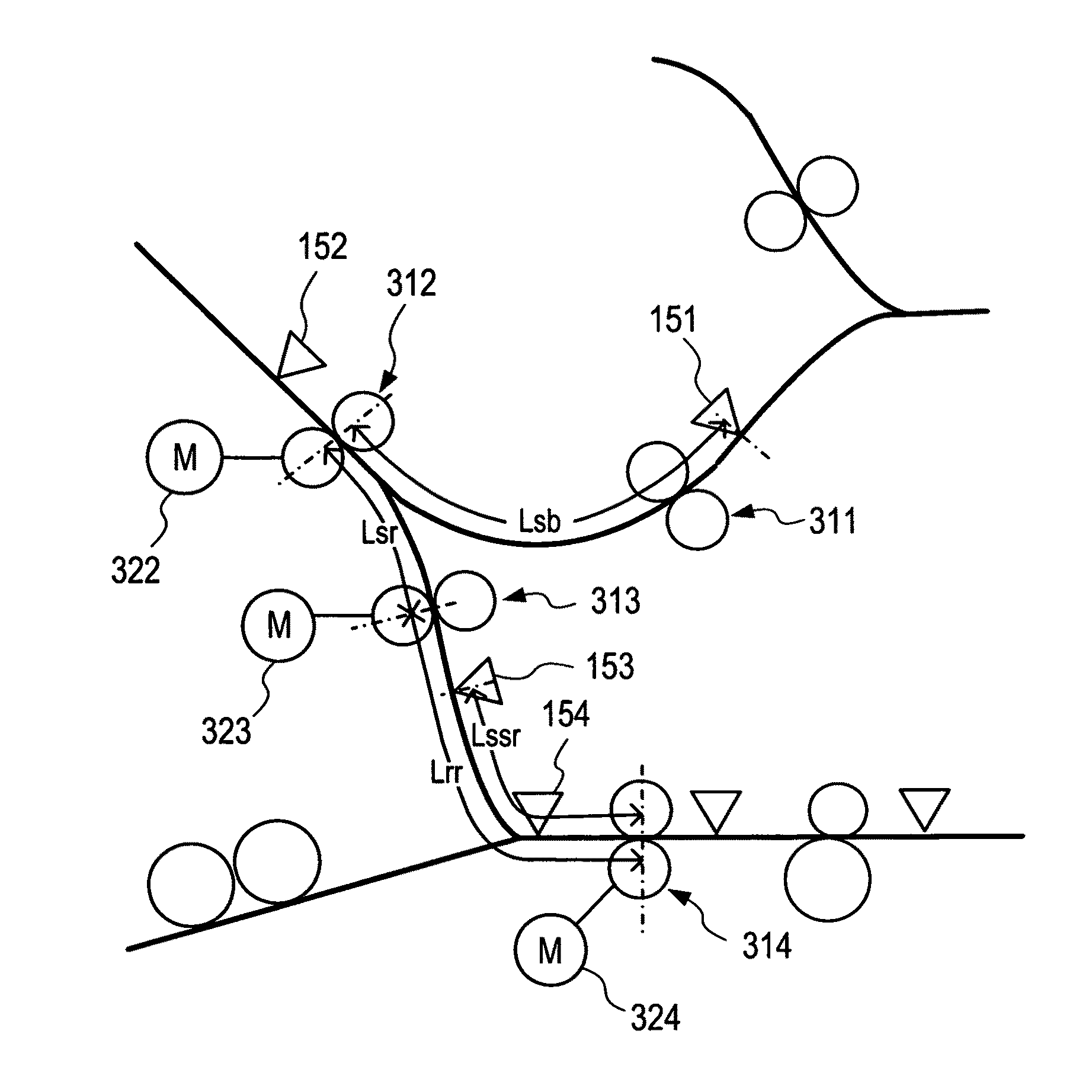

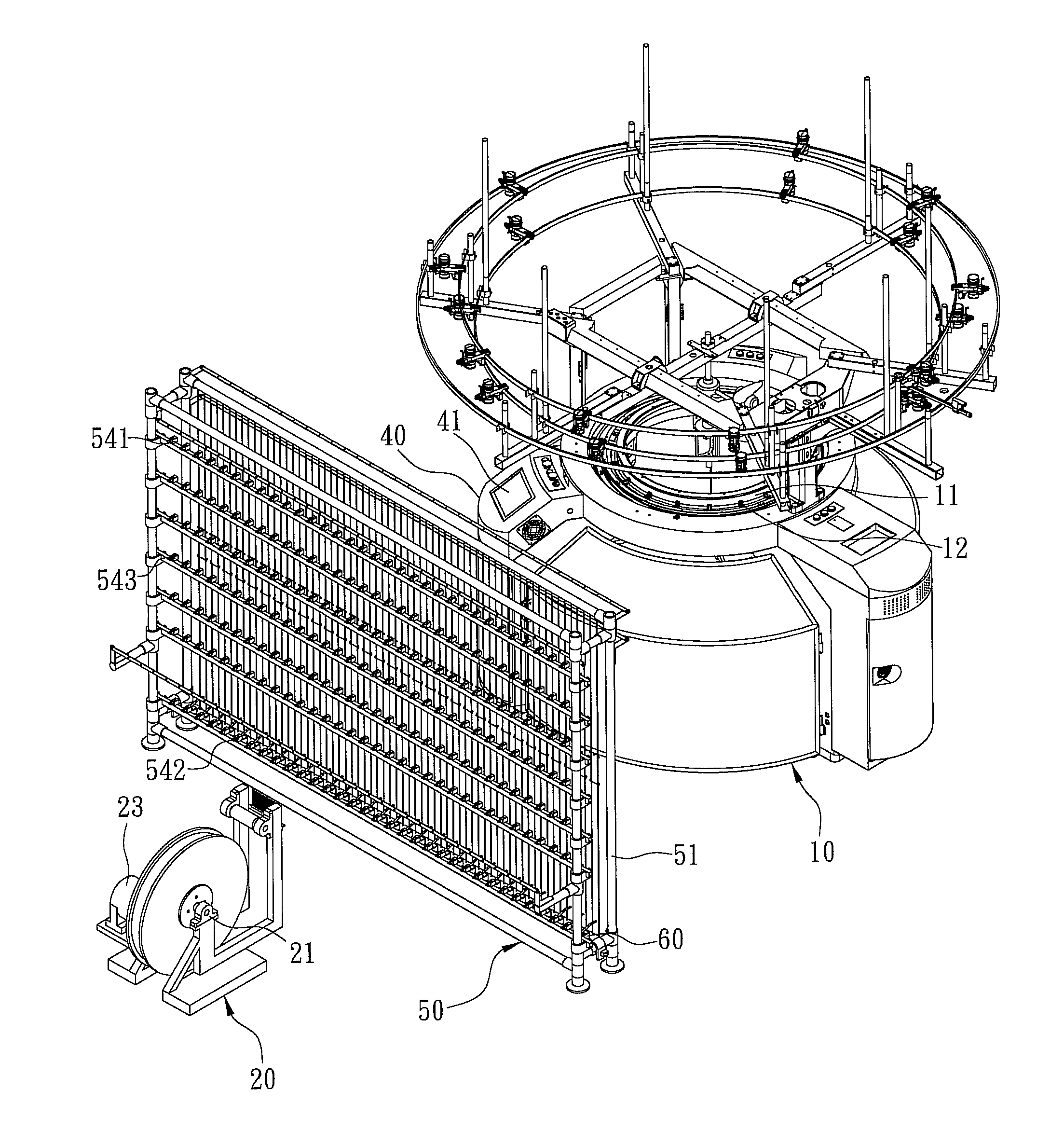

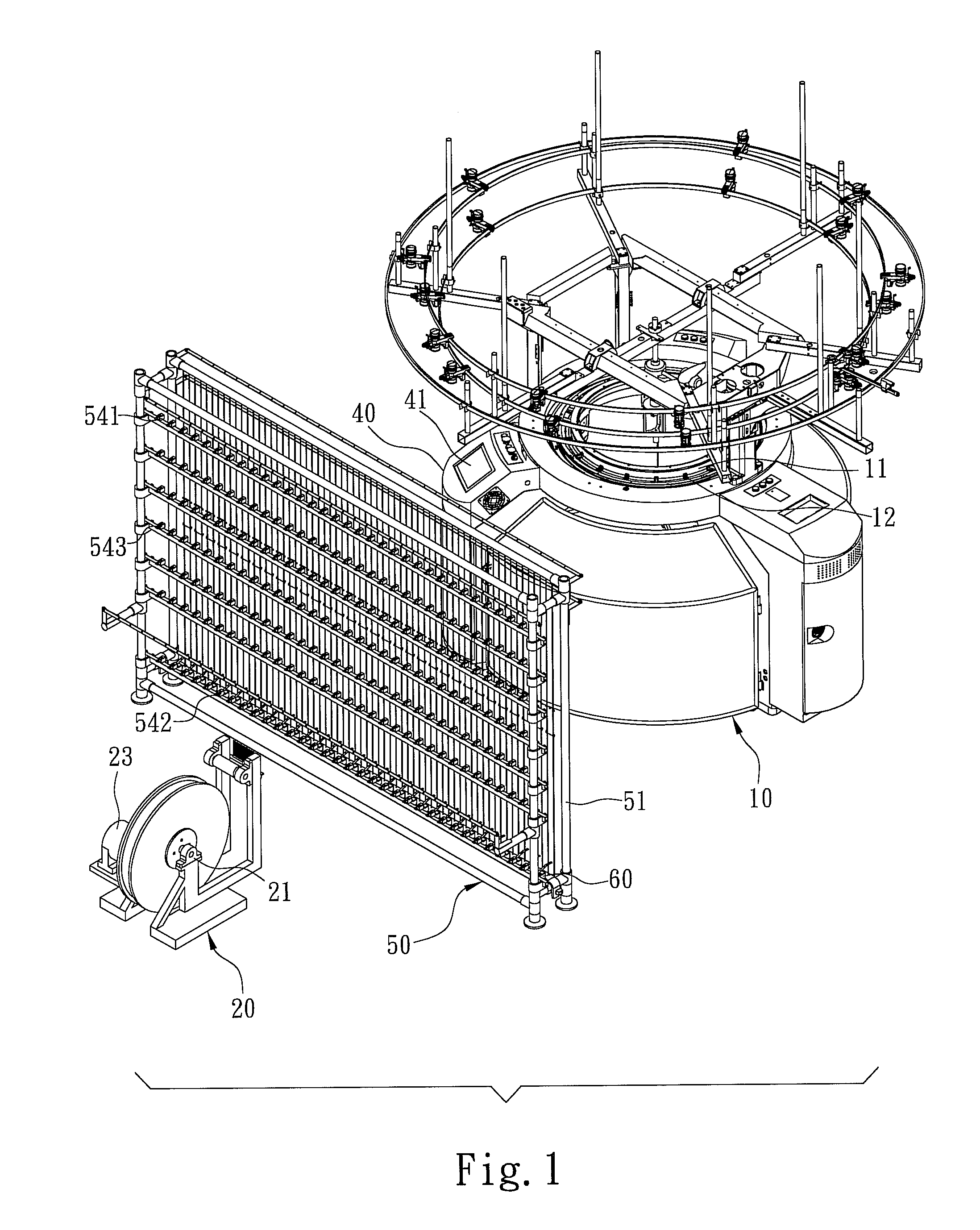

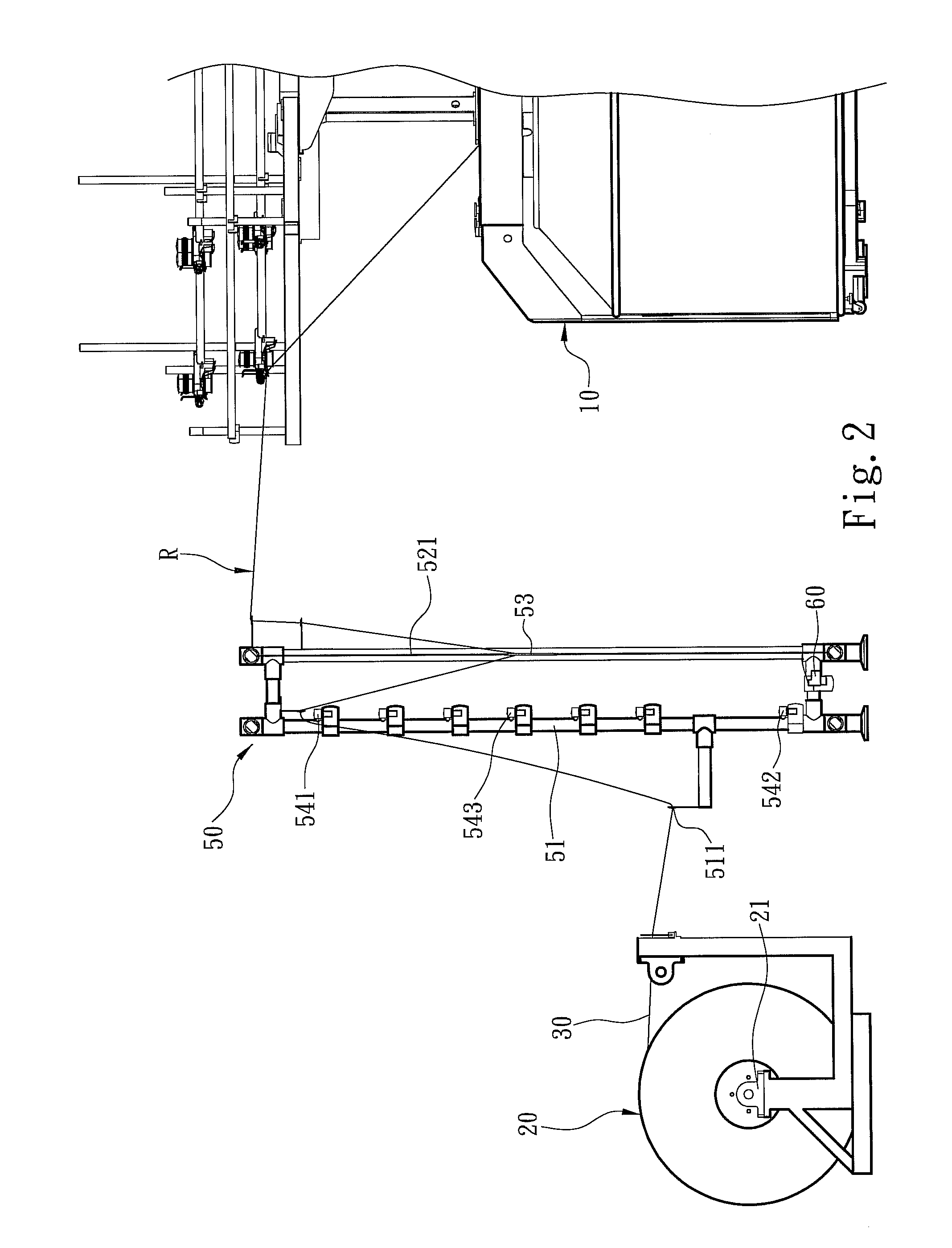

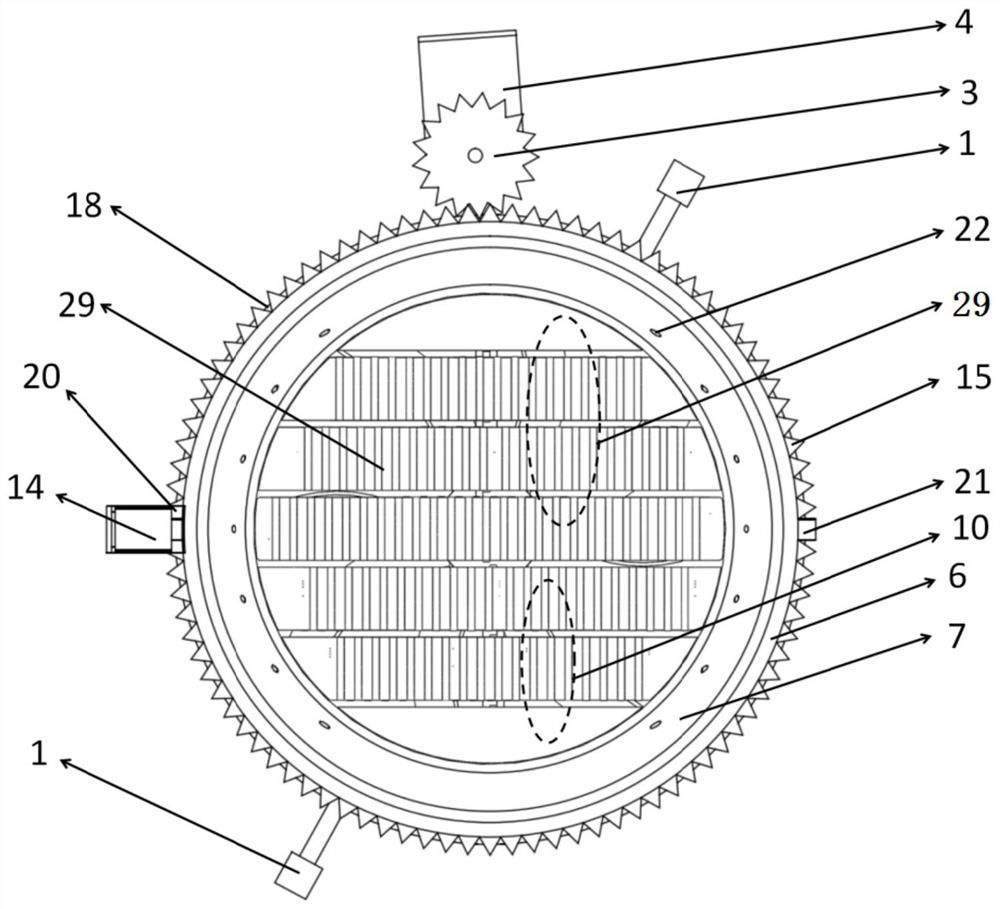

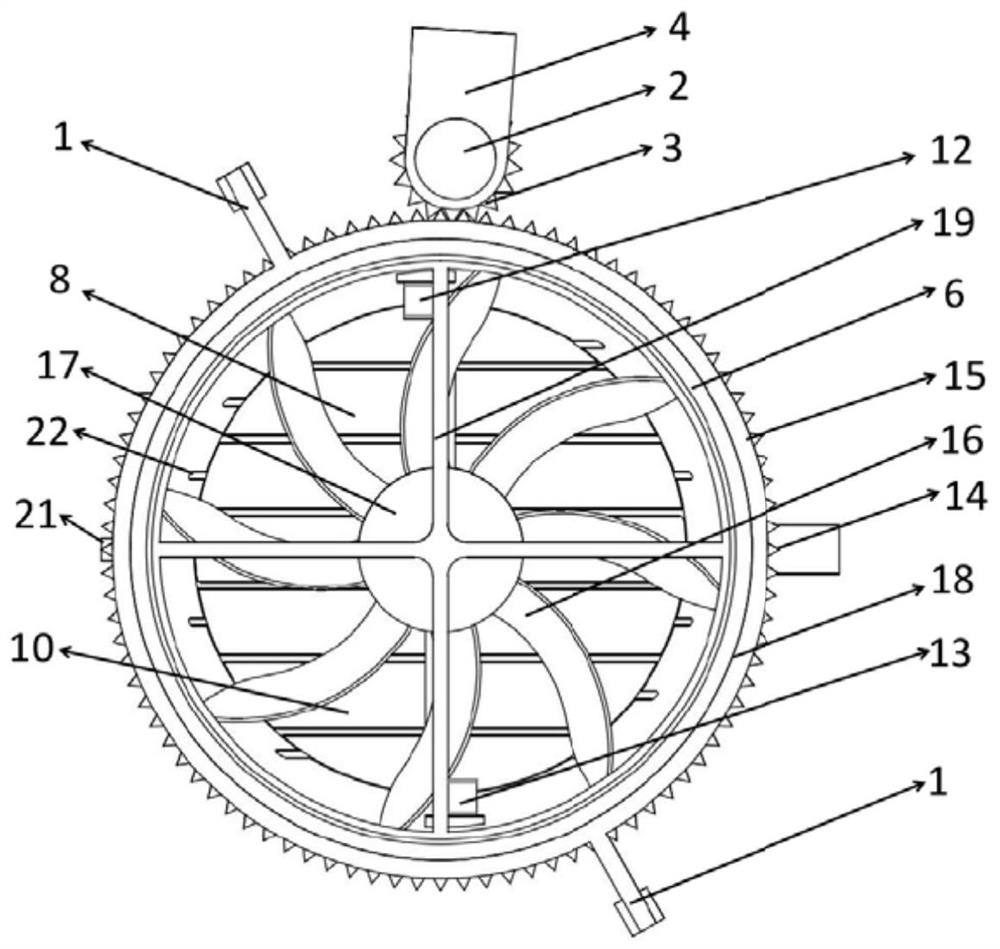

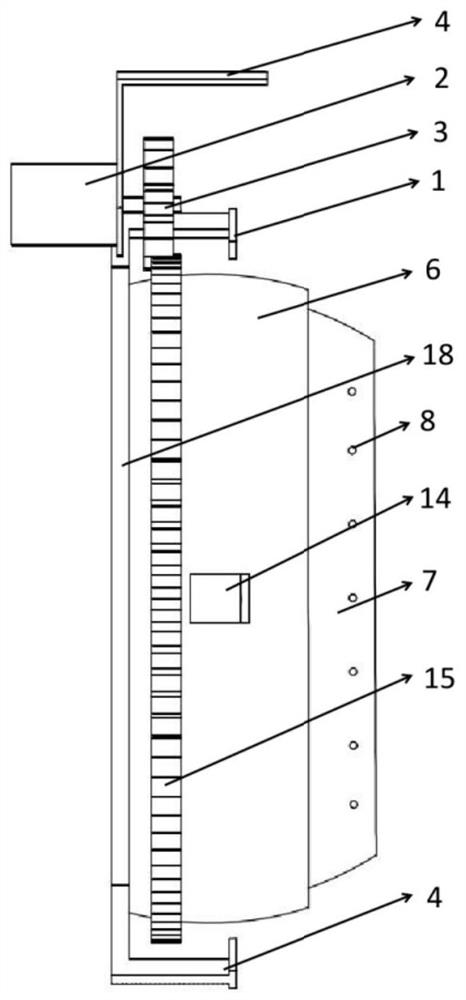

Yarn conveying system for circular knitting machines

A yarn conveying system includes a circular knitting machine, at least one yarn conveying tray and a control unit electrically connected to the circular knitting machine and yarn conveying tray. The circular knitting machine has a needle cylinder and at least one yarn feeder arranged annularly on the needle cylinder. The yarn conveying tray is wound by at least two separate yarns and includes a driving device to drive the yarn conveying tray rotating so that the yarns are supplied via a yarn conveying path to the yarn feeder. The control unit generates a yarn feeding signal to the circular knitting machine to control yarn feeding speed and a driving signal to the driving device to control rotational speed of the yarn conveying tray. Thus users can operate the control unit to control speed of the yarns supplied from the yarn conveying tray to the yarn feeder.

Owner:PAI LUNG MACHINERY MILL CO LTD

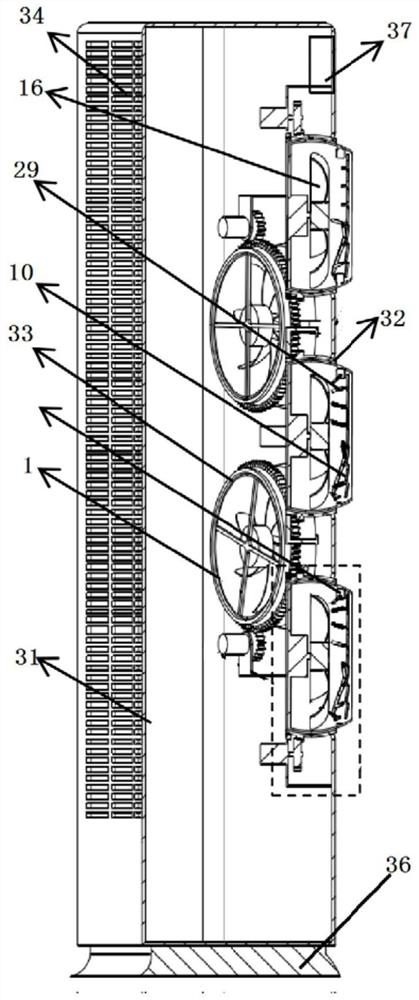

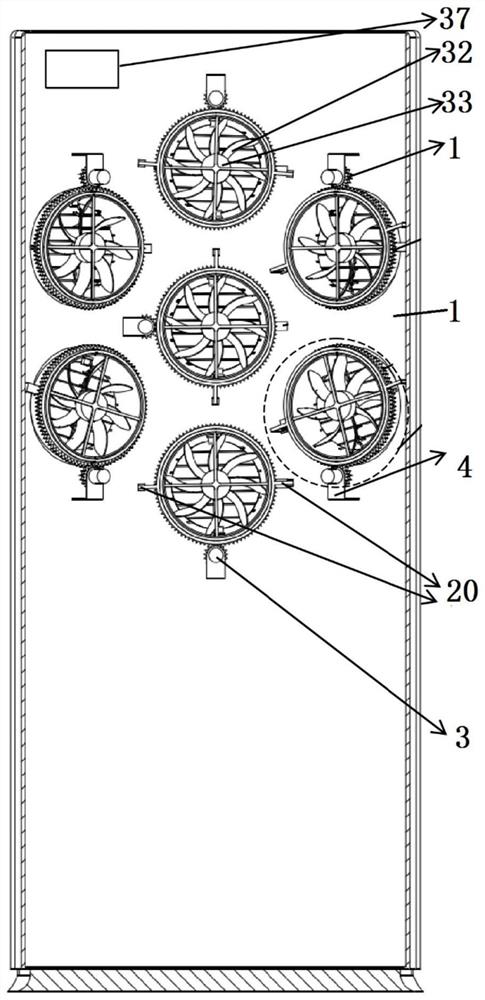

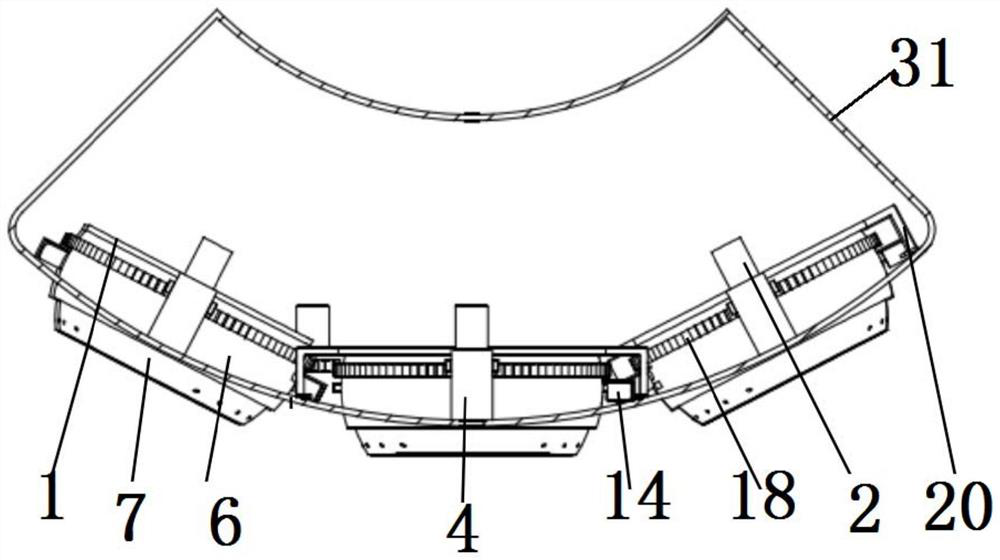

Swing air outlet device

ActiveCN111912088AStrong pulsationIncreased turbulenceMechanical apparatusLighting and heating apparatusIndoor airEngineering

The invention discloses a swing air outlet device. An air duct surface frame and a rotating air duct which both are of through hole structures in the axial directions are adopted, the rotating air duct is embedded into an inner cavity of the air duct surface frame, and is sleeved with the inner cavity of the air duct surface frame, two sides of the rotating air duct are rotatably connected with the air duct surface frame through rotating air duct rotating shafts, and the axes of the rotating air duct rotating shafts are perpendicular to that of the air duct surface frame; both the outer surface of the rotating air duct and an inner cavity surface of the air duct surface frame are spherical surfaces, a swing blade set is arranged on the end surface of one side of the rotating air duct, theair duct surface frame and the rotating air duct are used for forming the air outlet device, in a shape of a universal ball, which can rotate relatively, the angle and the direction of an air supply opening of the rotating air duct can be adjusted to make air flows reach assigned places under cooperation of the swing blade set, thus personalized precise air supply is achieved, the air flows are made to reach required places, thus multidimensional dynamic air supply is achieved, pulsation of the outlet air flows is made to be stronger, the turbulivity of the indoor air flows is improved, outletair of the air outlet device is made to be more similar to simulated natural air, a better blowing feeling is brought, and a comfort level of a human body is increased.

Owner:XI AN JIAOTONG UNIV

Image forming apparatus

ActiveUS20100207320A1Easy to controlDifferent speedFunction indicatorsArticle feedersTransfer mechanismEngineering

In an image forming apparatus, a sheet reversing mechanism is configured to take over and transfer, at a transfer speed Vr, a print sheet with an image already formed on one side being transferred at the transfer speed Vr from a first transfer mechanism, to stop the print sheet once, then to start transfer of the print sheet in an opposite direction, and to pass the print sheet to a second transfer mechanism at the transfer speed Vr. The first and second transfer mechanisms are located on upstream and downstream of a switchback reverse path for reversing print sheets respectively Upon lapse of a time T1 after detection of the print sheet by a print sheet detection unit, a transfer control unit drives the sheet reversing mechanism to start acceleration from a stopped state to the transfer speed Vr, the time T1 calculated based on the transfer speed Vr.

Owner:RISO KAGAKU CORP

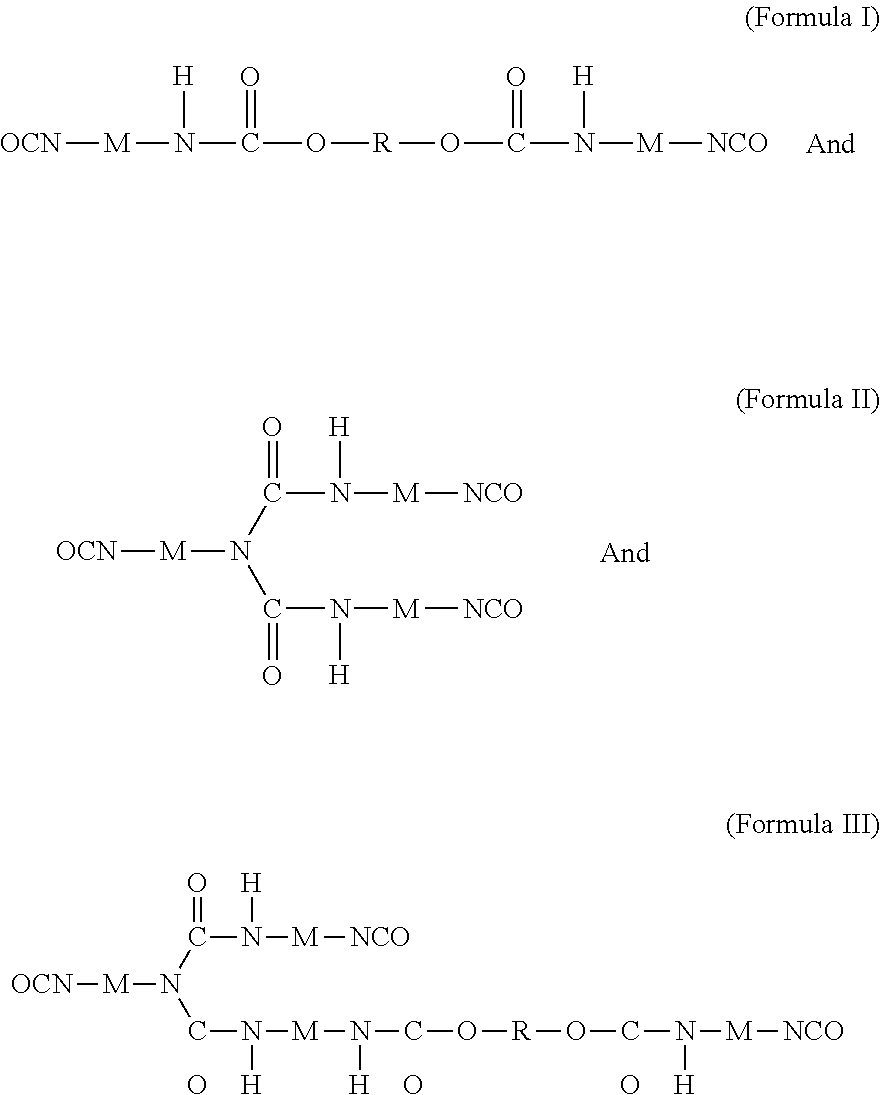

Modified Diphenylmethane Diisocyanate (MDI) Biuret Curing Agent and Preparation Method Thereof

InactiveUS20140252269A1Reduce activityAvoid generationOrganic chemistryOther chemical processesPrepolymerIsocyanate compound

Provided are a modified diphenylmethane diisocyanate (MDI) biuret curing agent and preparation method thereof, the curing agent being prepared by reacting dibasic alcohol, water and MDI in an organic solvent. The preparation method includes the steps of: firstly, using the dibasic alcohol to modify a part of MDI, dividing the metered water into multiple parts, and adding the water by multiple times; after adding the first part of water, reacting firstly under 70-100° C., then heating up to 120-140° C. for reaction; secondly, lowering the temperature to 70-100° C., adding the second part of water; and repeating the above processes until all the metered water is added, to produce the MDI curing agent with partial biuret structure. The curing agent is mainly used as the curing agent of polyurethane coating and adhesive agent, and has a higher NCO percentage and a slower curing speed than that of common MDI prepolymer curing agents.

Owner:J&H XIANGYANG CHEM

Air conditioner air supply device

ActiveCN111912003AStrong pulsationIncreased turbulenceMechanical apparatusLighting and heating apparatusEngineeringMechanical engineering

The invention discloses an air conditioner air supply device. Multiple air outlets are formed in a front panel of an air conditioner box, air outlet devices are installed in the air outlets through bearing supports, air duct surface frames and rotating air ducts which are all of through hole structures in the axial directions are adopted for forming the air outlet devices, the rotating air ducts are embedded into inner cavities of the air duct surface frames, and are sleeved with the inner cavities of the air duct surface frames, two sides of each rotating air duct are rotatably connected withthe corresponding air duct surface frame through corresponding rotating air duct rotating shafts, and the axes of the rotating air duct rotating shafts are perpendicular to those of the air duct surface frames; the outer surfaces of the rotating air ducts and inner cavity surfaces of the air duct surface frames are all spherical surfaces, a corresponding swing blade set is arranged on the end surface of one side of each rotating air duct, the air duct surface frames and the rotating air ducts are used for forming the air outlet devices, in shapes of universal balls, which can rotate relatively, the angles and the directions of air supply openings of the rotating air ducts can be adjusted to make air flows reach assigned places under cooperation of the swing blade sets, thus personalized precise air supply is achieved, the air flows are made to reach required places, thus multidimensional dynamic air supply is achieved, the turbulivity of the indoor air flows is improved, and outlet air of the air outlet devices is made to be more similar to simulated natural air.

Owner:XI AN JIAOTONG UNIV

Watermelon juicing device and method for juicing watermelon juice

ActiveCN111802655AImprove production efficiencySolve the problem of low efficiency of preparation operationsJuice extractionStrainersAgricultural engineeringMechanical engineering

The invention discloses a watermelon juicing device and a juicing method thereof. The device comprises a fixed frame, a positioning device is fixedly mounted above a base of the fixed frame; a discharging device is fixedly mounted in the middle of one side of the fixed frame, the upper end of the side surface of the positioning device is rotationally connected to a pulping device, a conveying device located in the positioning device is arranged above a base of the fixed frame, a fixed device is arranged at the upper end of the fixed frame, the pulping device is rotationally connected to the interior of the discharging device, the conveying device is rotatably connected to the pulping device through a T-shaped block, a collecting device located at the upper end of the side face of the pulping device is slidably connected to the upper portion of the side face of the fixed frame, the positioning device comprises a positioning pipe and a first limiting groove, and the positioning pipe is fixedly installed above the base of the fixed frame. The invention solves the problem that under the condition that watermelon juice is prepared step by step traditionally, the preparation operation efficiency of the watermelon juice is low, and the invention solves the problem that the watermelon juice and watermelon seeds are inconvenient to separate.

Owner:ANHUI DANGSHAN HAISHENG FRUIT

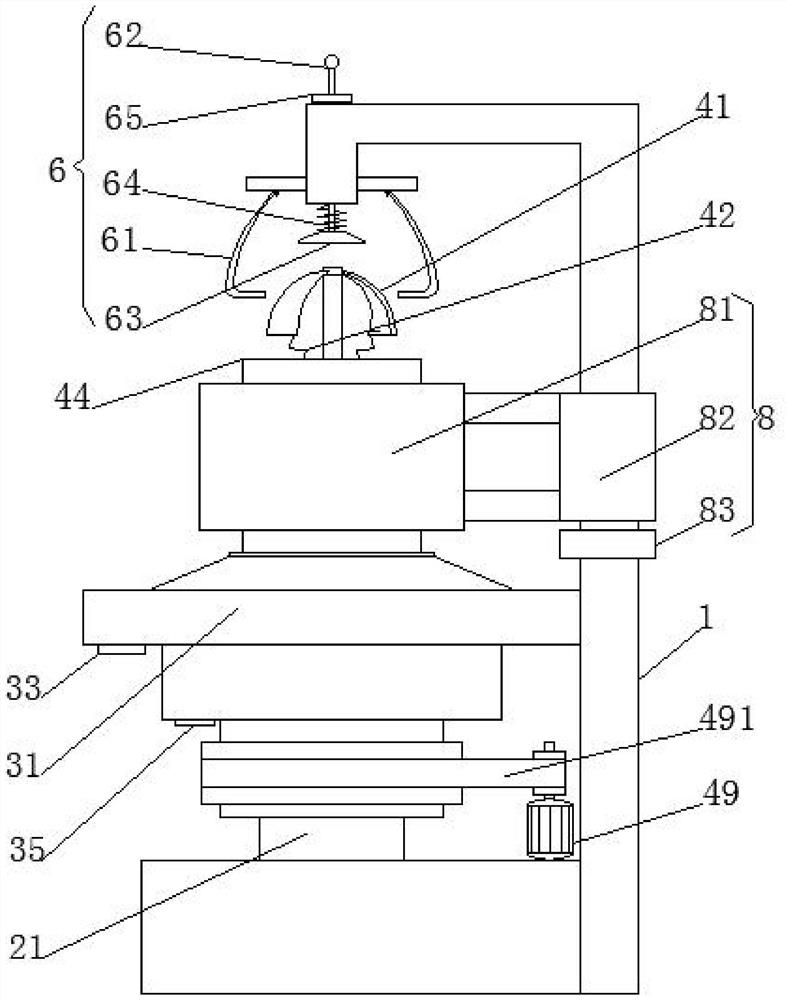

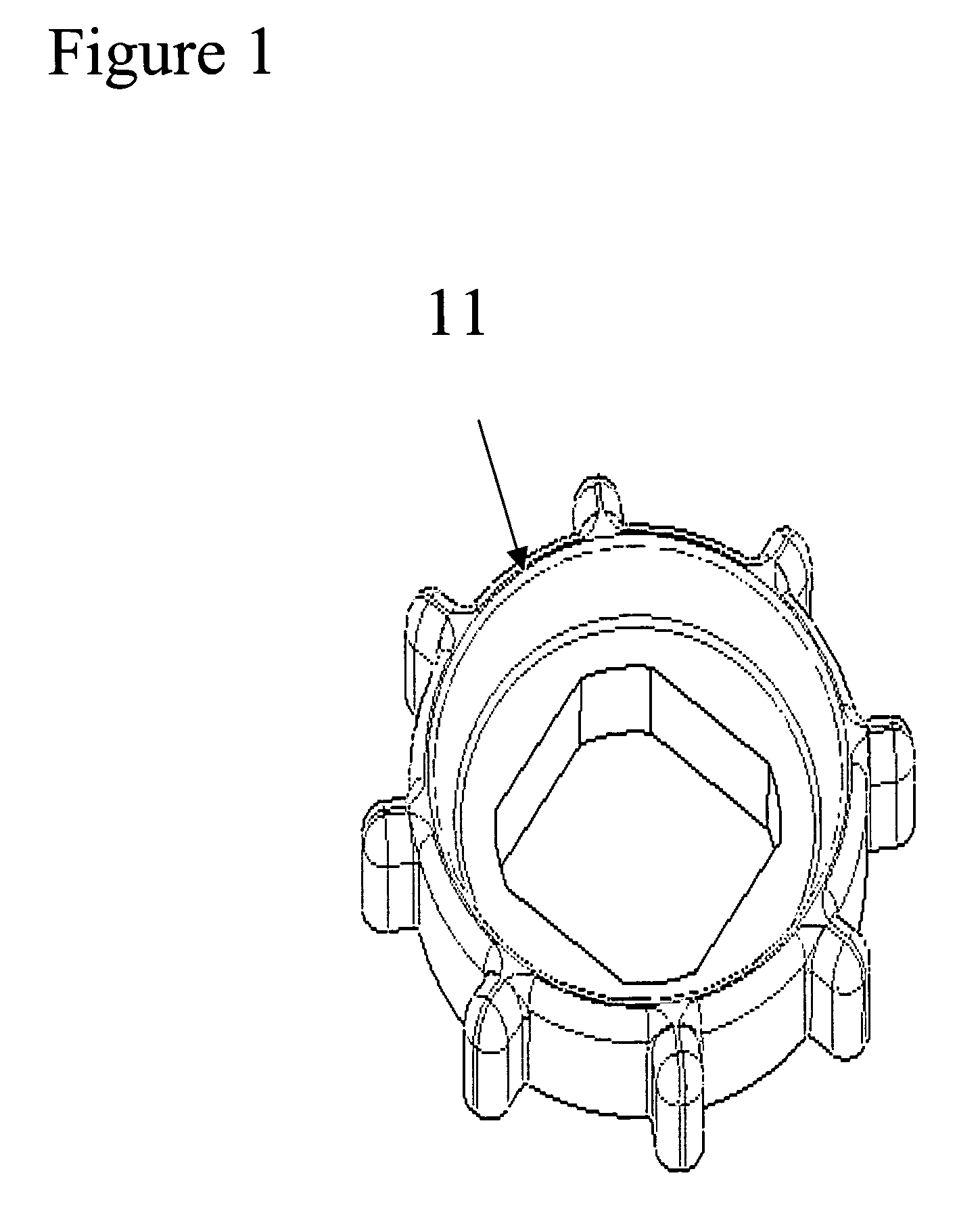

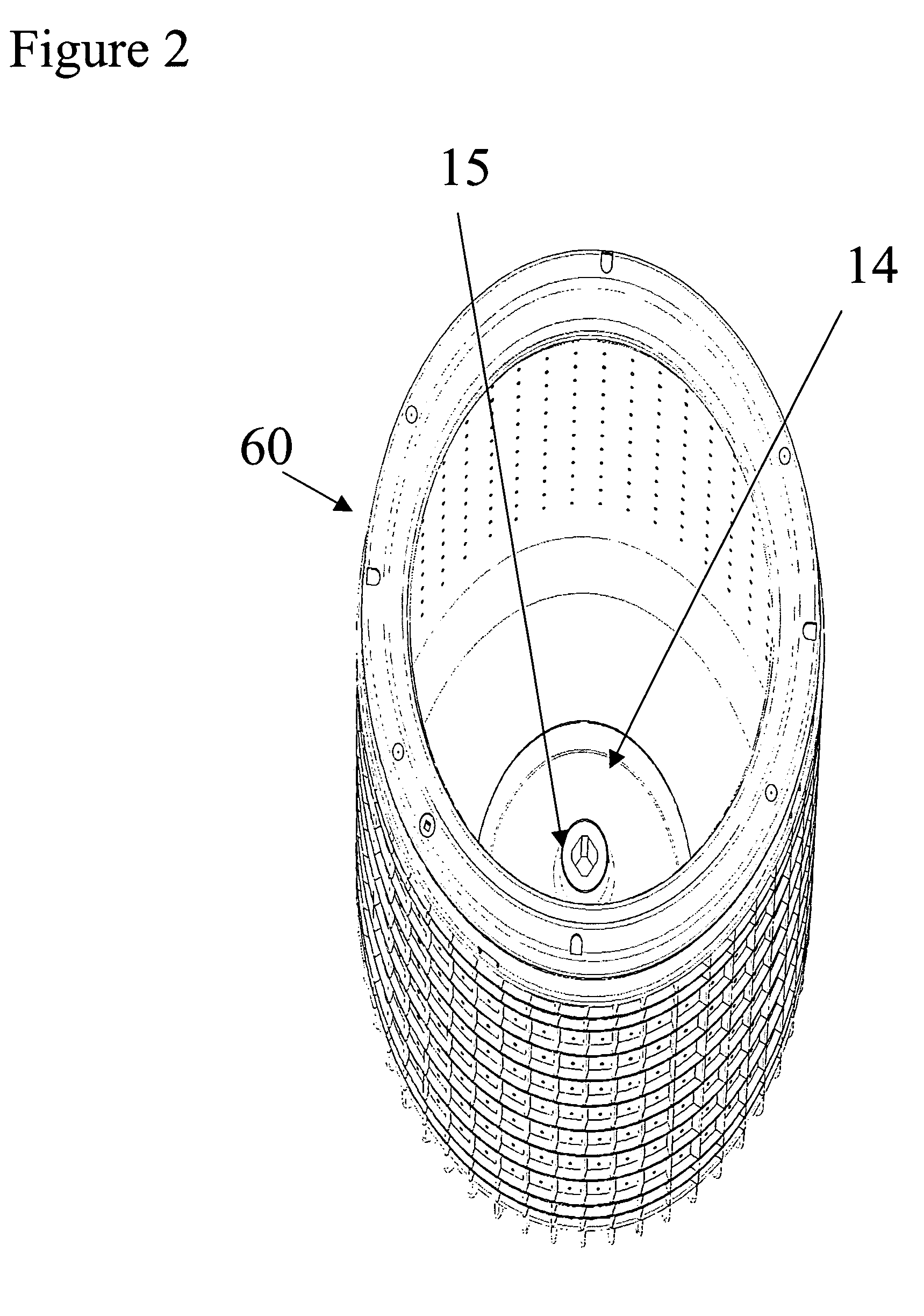

Floating clutch for dual concentric shafts arrangement

ActiveUS8833111B2Easy to manufacturePromote repairOther washing machinesControl devices for washing apparatusFiberEngineering

This invention consists of a floating clutch for two concentric shafts. This is achieved by means of a movable body transmitting energy from one shaft to the other via cogs that engage or disengage vertically depending on the presence of fluid; torque of the inner shaft is transmitted to the coupler and from the coupler to the movable body, and in turn, to the fixed cog, and then to the outer shaft, when it is in the clutch position. The invention also consists of a group of chambers and peripheral walls that allow the assembly to operate in optimal conditions, avoiding malfunctions, breakdowns and unhealthy conditions by preventing the buildup of fluff, scale, fibers, sediments, dirt or undesired objects hampering the correct operation of the invention and of a home-type washing machine.

Owner:MABE MEXICO S DE R L DE

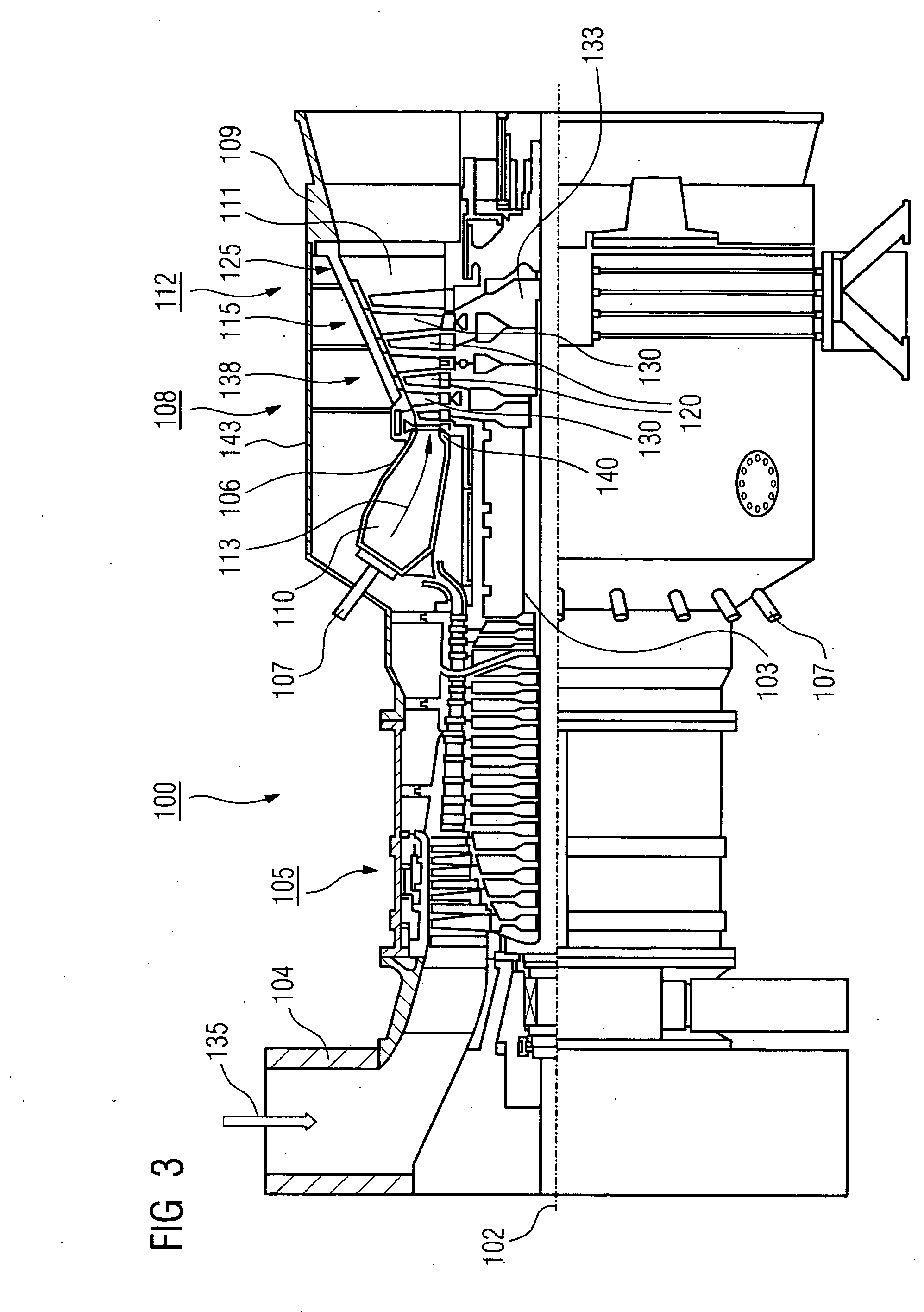

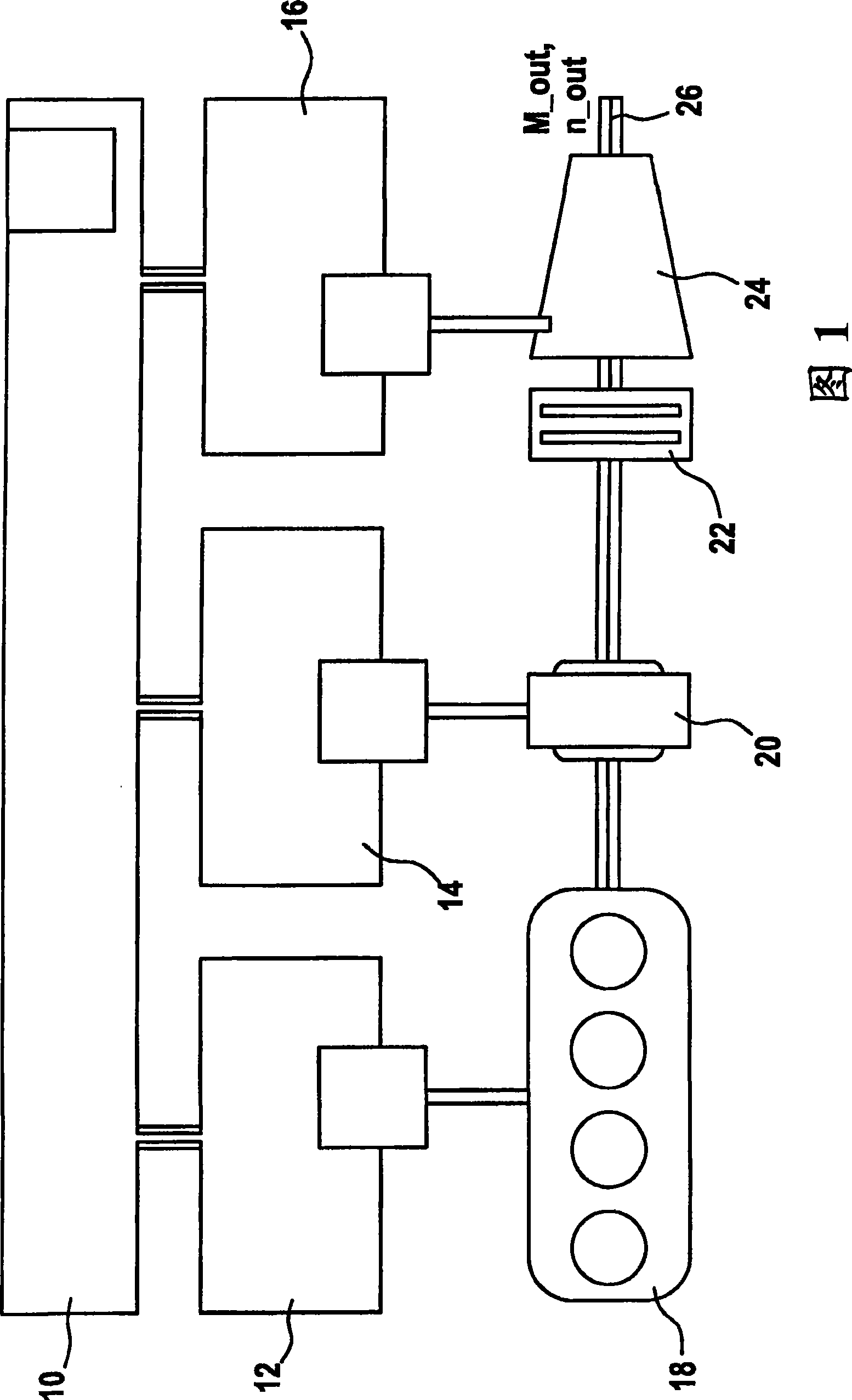

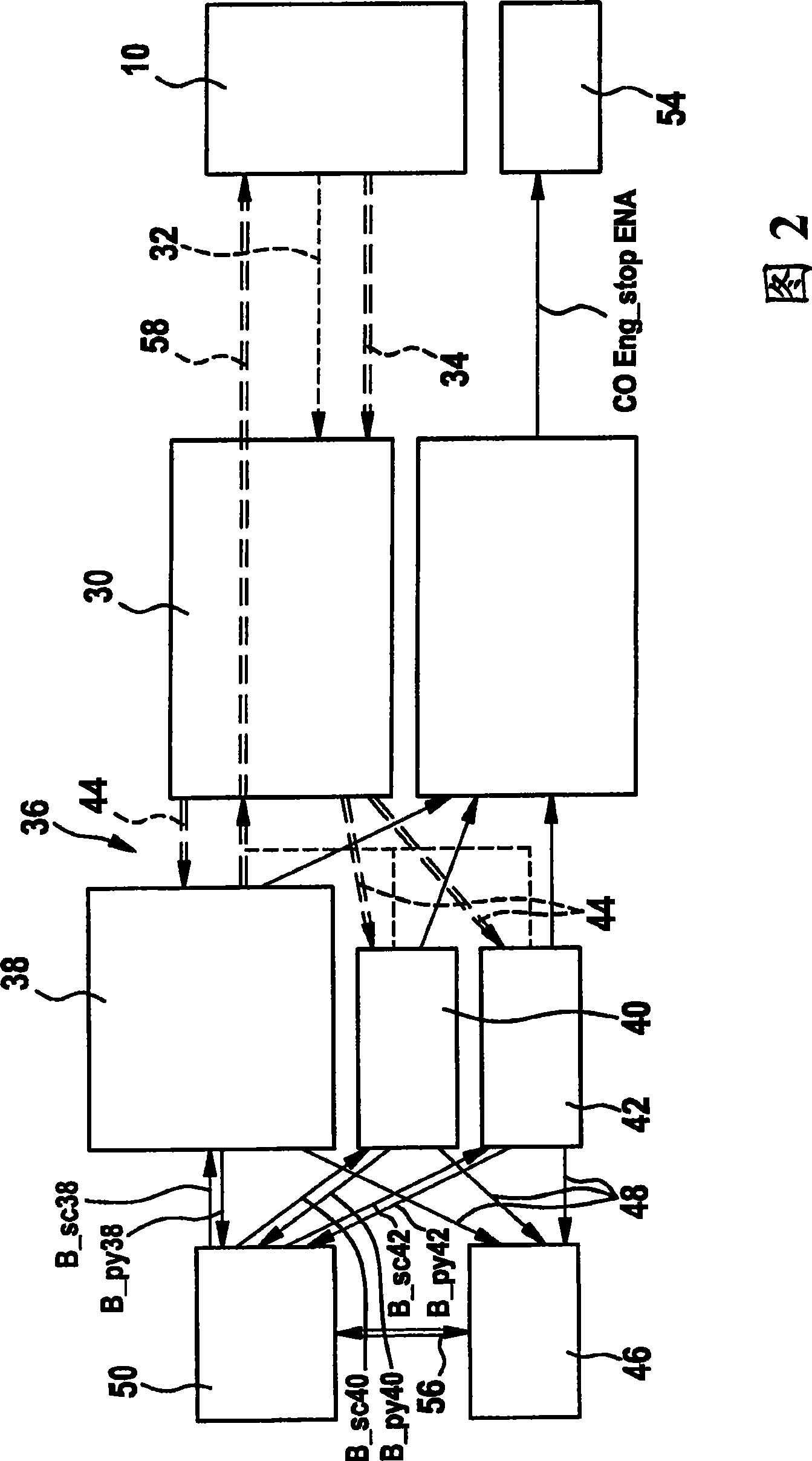

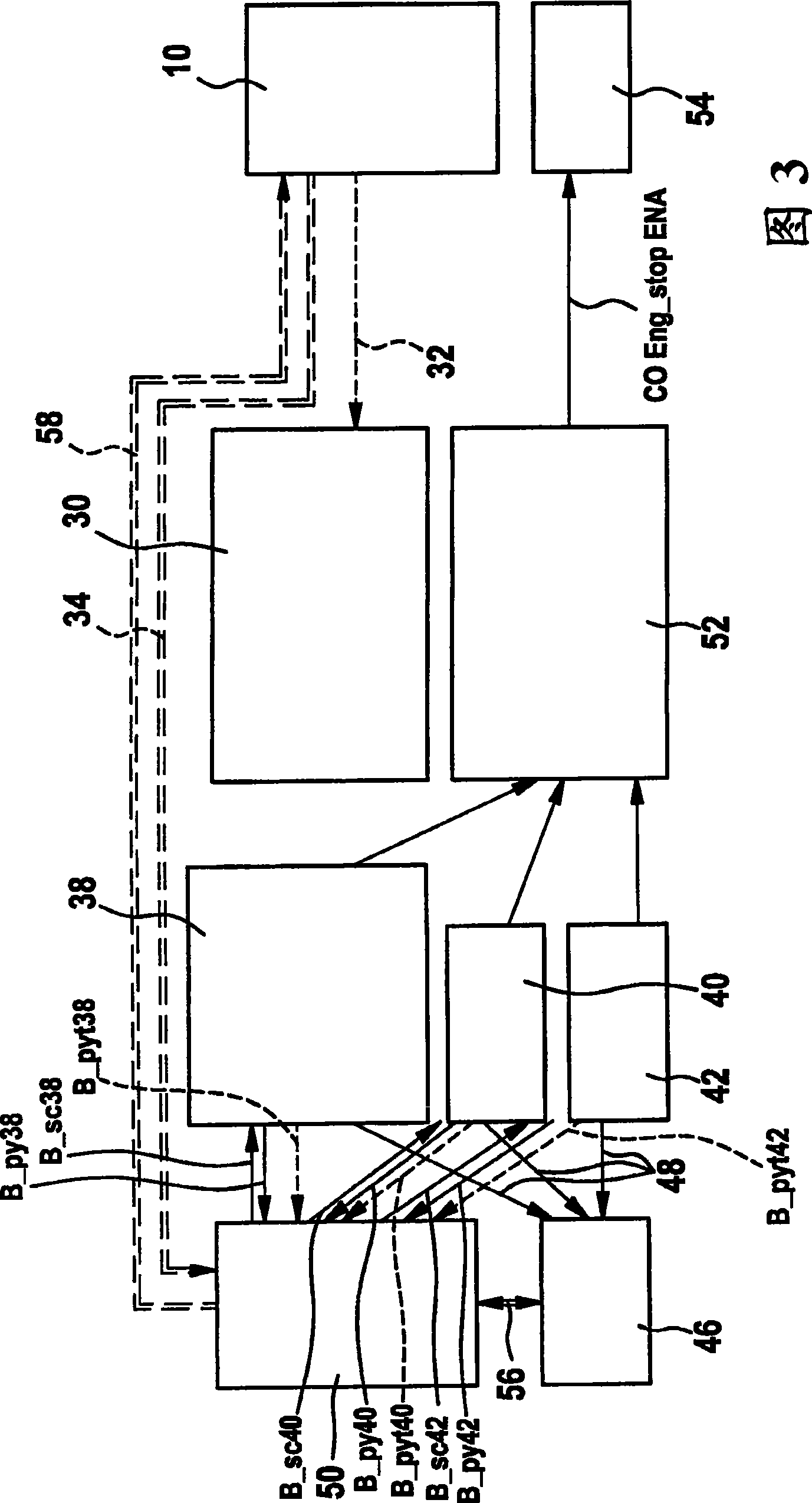

Defined internal combustion engine operation for vehicles with hybrid drive

InactiveCN101415592AEasy diagnosisEasy to operateOperating modesPropulsion using engine-driven generatorsElectric driveControl theory

The invention relates to a method for adjusting the operating conditions of an internal combustion engine (18), particularly an internal combustion engine (18) of a hybrid drive. In addition to the internal combustion engine (18), the hybrid drive comprises at least one electric drive (20), a hybrid co-ordinator (10) and a control unit (12, 30), which is allocated to the internal combustion engine (18) and in which functions (38, 40, 42) are implemented. The functions (38, 40, 42) request the provision of operating conditions (58) that benefit their running ability for the internal combustion engine (18) from the hybrid co-oordinator (10), which makes a corresponding modification to the distribution of power between the internal combustion engine (18) and the electric drive(s) (20).

Owner:ROBERT BOSCH GMBH

Straw returning machine for different crops

InactiveCN101112154ADifferent speedWork saves time and effortCrop conditionersMowersGear wheelTransmitted power

The invention discloses a straw returning machine that is convenient for different crops, comprising a stander, a first transmission device arranged on the top part of the stander and a second transmission device arranged at the side part of the stander which can drive a grinding knife-roller to rotate. An output shaft of the first transmission device is connected with an input shaft of the second transmission shaft; the first transmission device consists of a gear box that can transmit power vertically and is arranged at the middle part of the stander. On the premise of guaranteeing the crushing rate, the invention can endow the grinding knife-roller with different rotating speed through simple operation according to the crushing difficulty of the crop straw, which not only reduces the power consumption of a tractor, but also saves time and labor for no belt or belt wheel is needed to be dismantled.

Owner:李传良

3D printer spray nozzle capable of adjusting cross section areas of extruded materials and method for controlling printing speed and precision of the 3D printer spray nozzle

ActiveUS10016929B2Control precisionControl speedProgramme controlManufacturing driving meansSpray nozzleEngineering

A 3D printer spray nozzle includes a feeding pipeline, an extruder located under the feeding pipeline, an external housing and a driving device; wherein the feeding pipeline is embedded in the external housing, the extruder is coaxially fixed under the feeding pipeline, a center of gravity of a cross section area of an inner channel of the feeding pipeline and that of the extruder are located on a same axis which is perpendicular to the cross section area of the inner channel of the feeding pipeline and that of the extruder, the feeding pipeline is driven by the driving device to rotate around the axis relative to the extruder, thereby aiming at different rotation angles, widths of extruding forming areas of the extruder at a same direction are different so as to adjust a cross section area of a sprayed filament.

Owner:CLOUD COMPUTING CENT CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com