Device for laying a flexible material web

A technology of flexible materials and material belts, which is applied in the field of flexible material belt stacking devices, can solve problems such as inability to move laterally, and achieve the effects of small structural costs, reduced quality and structural size, and material savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

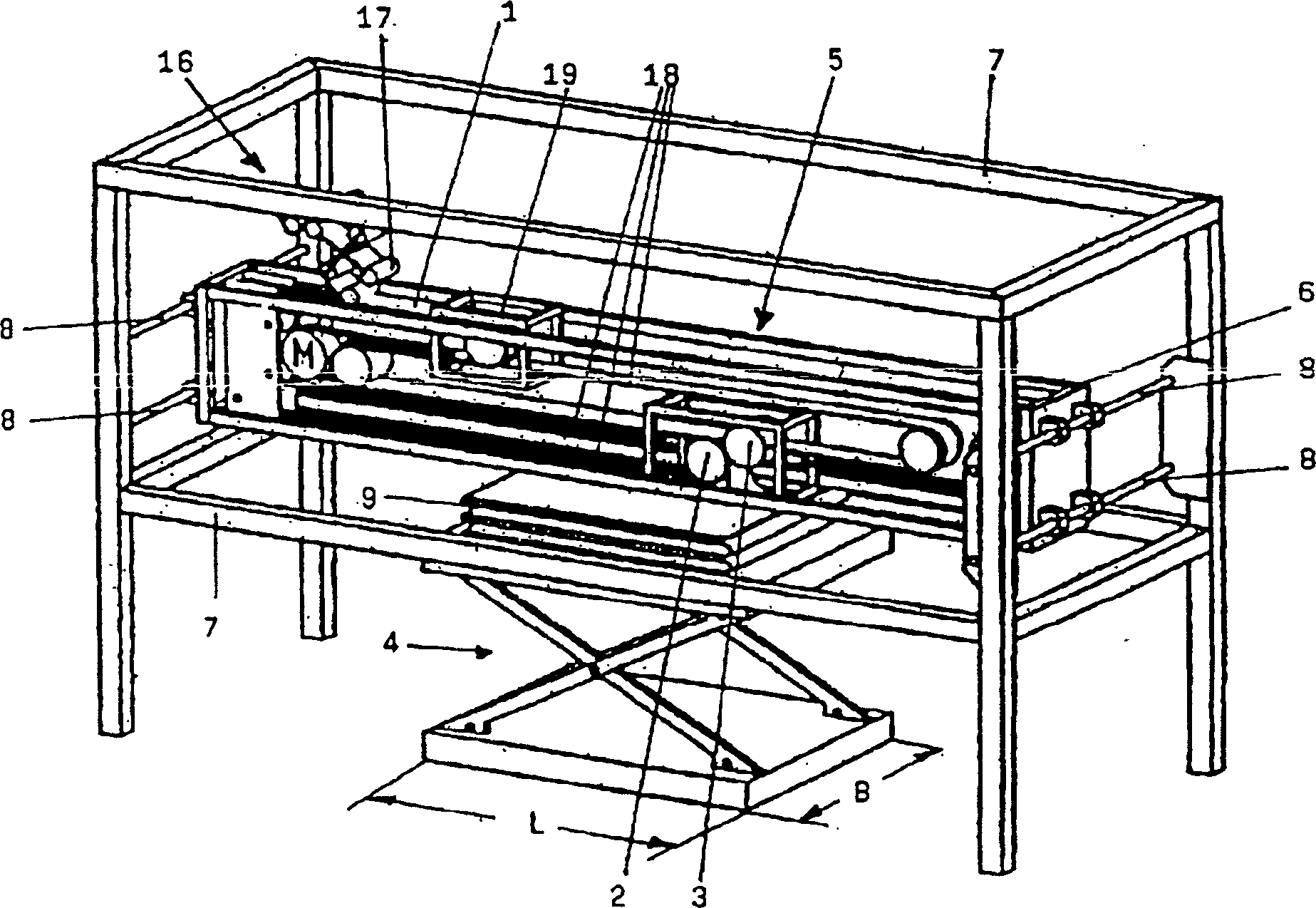

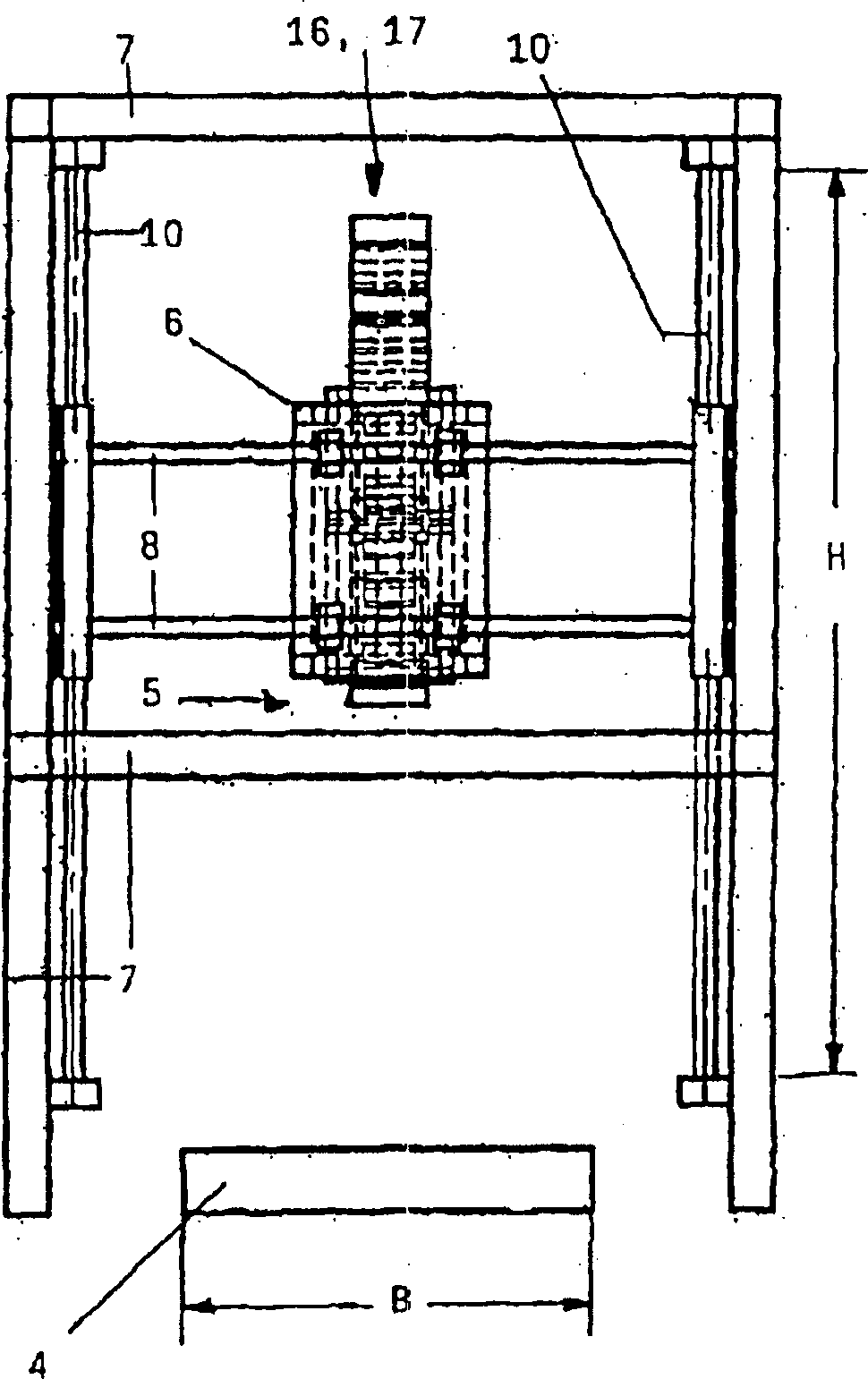

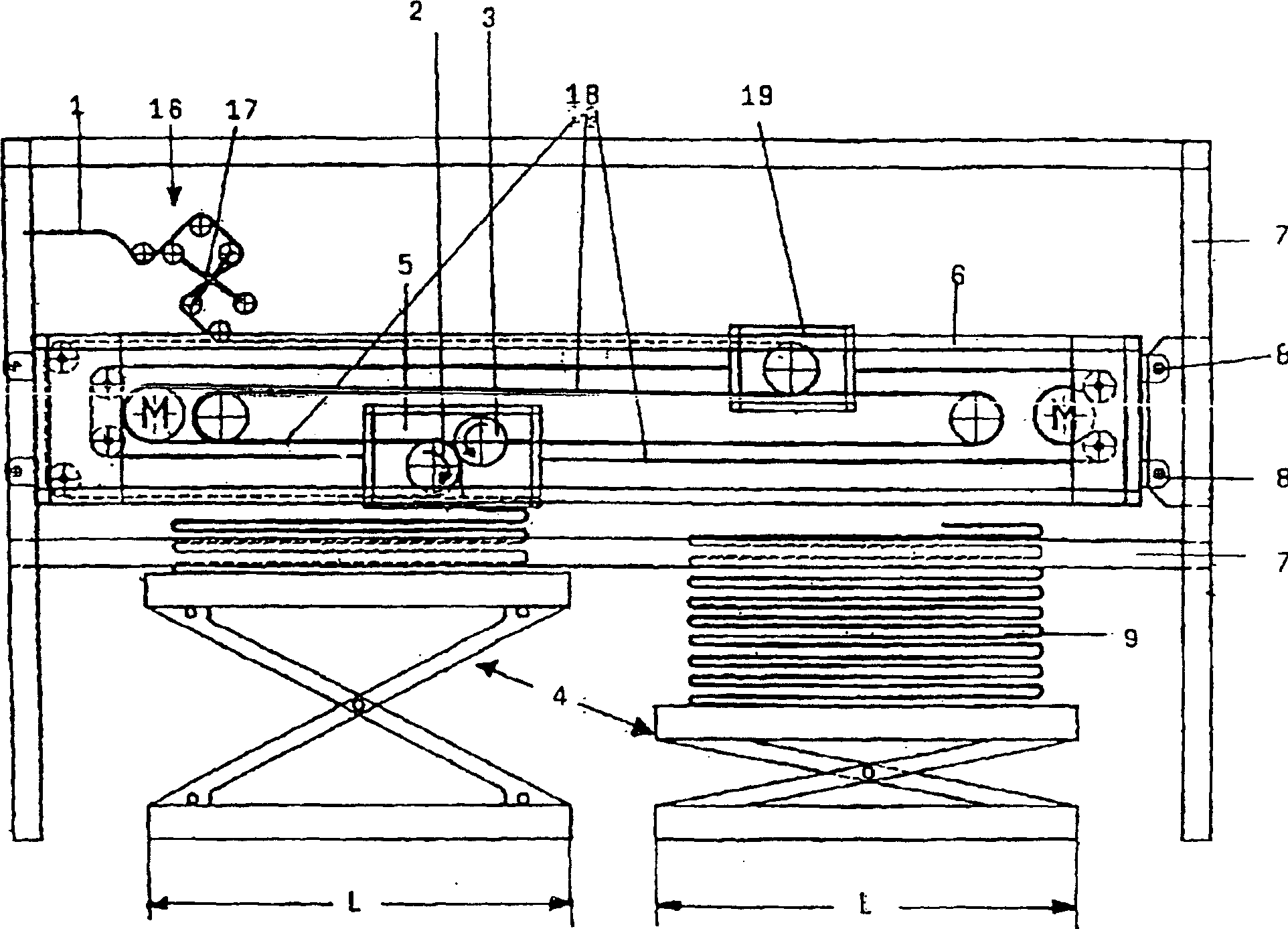

[0030] Figures 1 to 7 Denotes a device with at least one pair of counter-rotating stacking rollers 2, 3 for stacking a flexible material strip 1, wherein the material strip 1 can be transported to at least one stacking location 4 by means of the stacking rollers 2, 3, where the stacking roller 2 and 3 are a part of stacking dolly 5, which can travel by reversible orientation at least on the stacking length L of material strip 1.

[0031] According to the present invention, the stacking trolley 5 has a smaller width than the stacking location 4 and can travel reversibly on the stacking width B of the stacking location 4 . For this reason, the stacking trolley 5 is an integral part of a frame 6 mounted on the frame 7 in a laterally movable manner. The machine frame 7 has on its end faces transversely extending guide beams 8 on which the frame 6 is displaceably mounted.

[0032] exist figure 1 A first embodiment is represented in the middle, wherein the stacking position 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com