Fluidized bed reactor

A fluidized bed reactor and reactor technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve problems such as high maintenance costs of circulating oil pumps, low reactor space utilization, and catalyst sinking and accumulation, etc., to achieve Shorten the residence time, improve the operation stability, and improve the effect of fluidization quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment -1

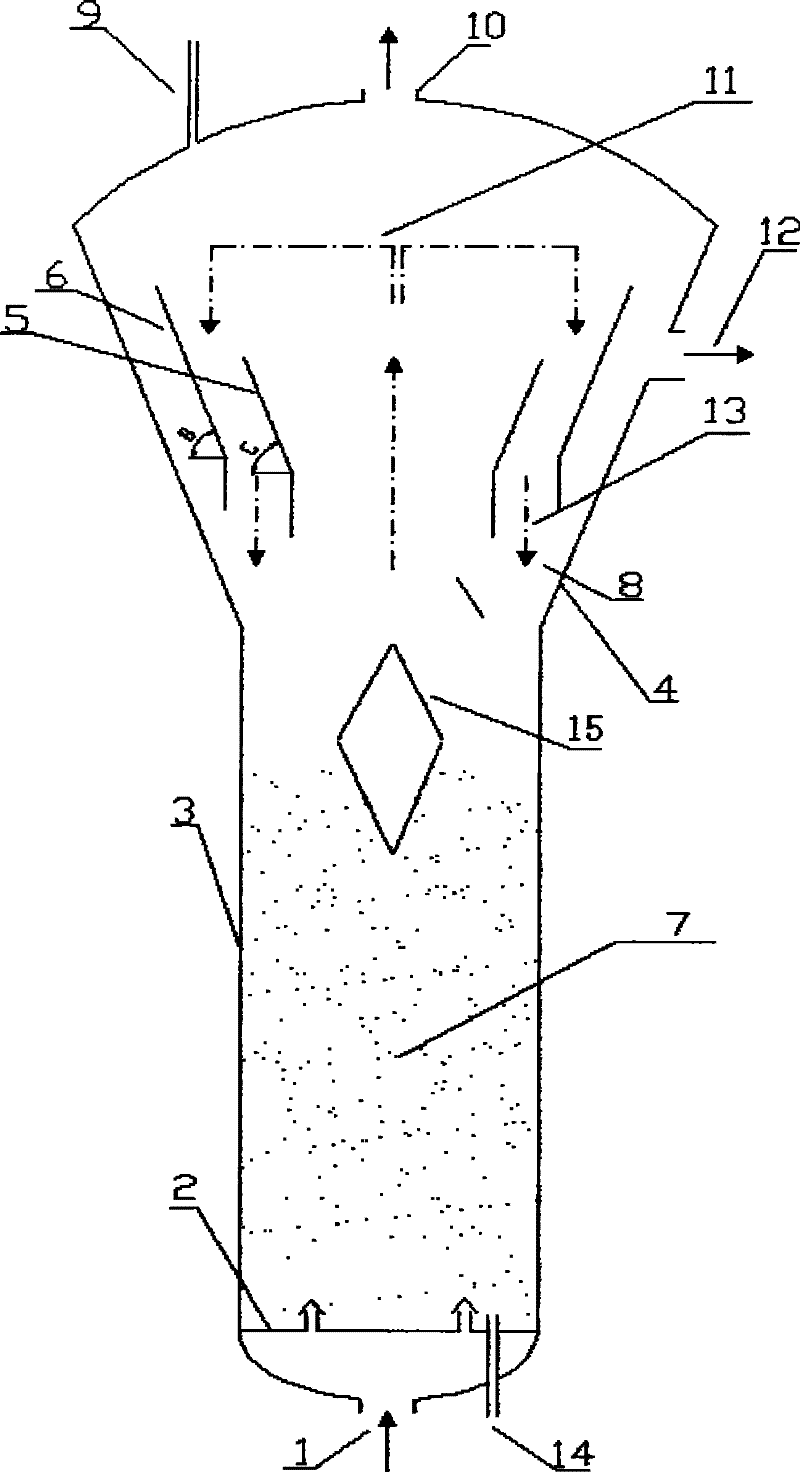

[0032] Such as figure 1 For the structure of the ebullating bed hydrogenation reactor shown, the cold model test of the three-phase separator ebullating bed medium-sized reactor was carried out. The dimensions of the cold model medium-sized device are: the inner diameter of the reactor shell = 160mm, the height of the reactor shell = 3000mm, the effective volume of the shell is 60L, the height of the separator = 500mm, the diameter of the cylindrical part of the central tube of the separator = 135mm, the diameter of the upper opening of the inner cylinder = 190mm, the height of the cylindrical part of the lower part of the inner cylinder = 35mm, the diameter of the cylindrical part of the outer cylinder =160mm, the diameter of the upper opening of the tapered part of the outer cylinder = 285mm, the height of the cylindrical lower part of the outer cylinder = 30mm, the upper opening of the outer cylinder is higher than the upper opening of the inner cylinder, the lower opening o...

Embodiment -2

[0035] On the basis of the cold model test, a hydrodemetallization test of an island atmospheric residue was carried out on a 60L medium-sized unit. Wherein the size of the reactor is the same as in Example 1, and the test conditions and results are shown in Table 2.

Embodiment -3

[0043] The operating conditions are the same as in Example-1. The middle part of the ebullating bed reactor is provided with an internal member, which is a diamond-shaped cone with a certain cross-sectional area. %, it can guide the fluid, promote the distribution of the continuous phase and the dispersed phase, inhibit the formation and coalescence of large bubbles, improve the fluidization quality, make the radial velocity distribution of the fluid more uniform, and at the same time interfere with the strong turbulent flow and improve the transmission efficiency. Mass and heat transfer efficiency, the process is strengthened. It can be seen that the mass transfer rate increases with internals and better fluidization quality can be obtained.

[0044] Table 3 Comparison results with and without internal components

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com