Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

325results about How to "Consistent strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

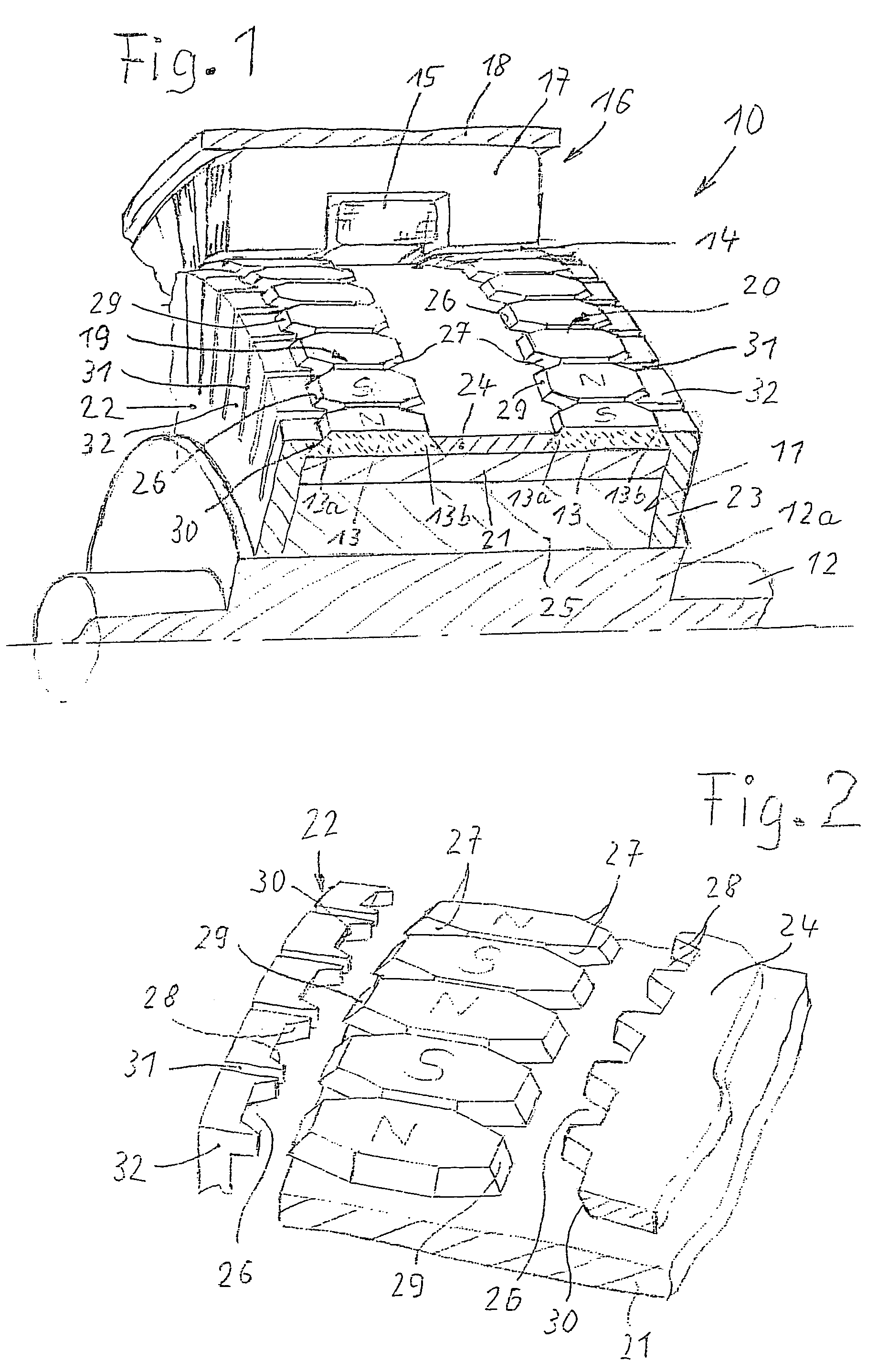

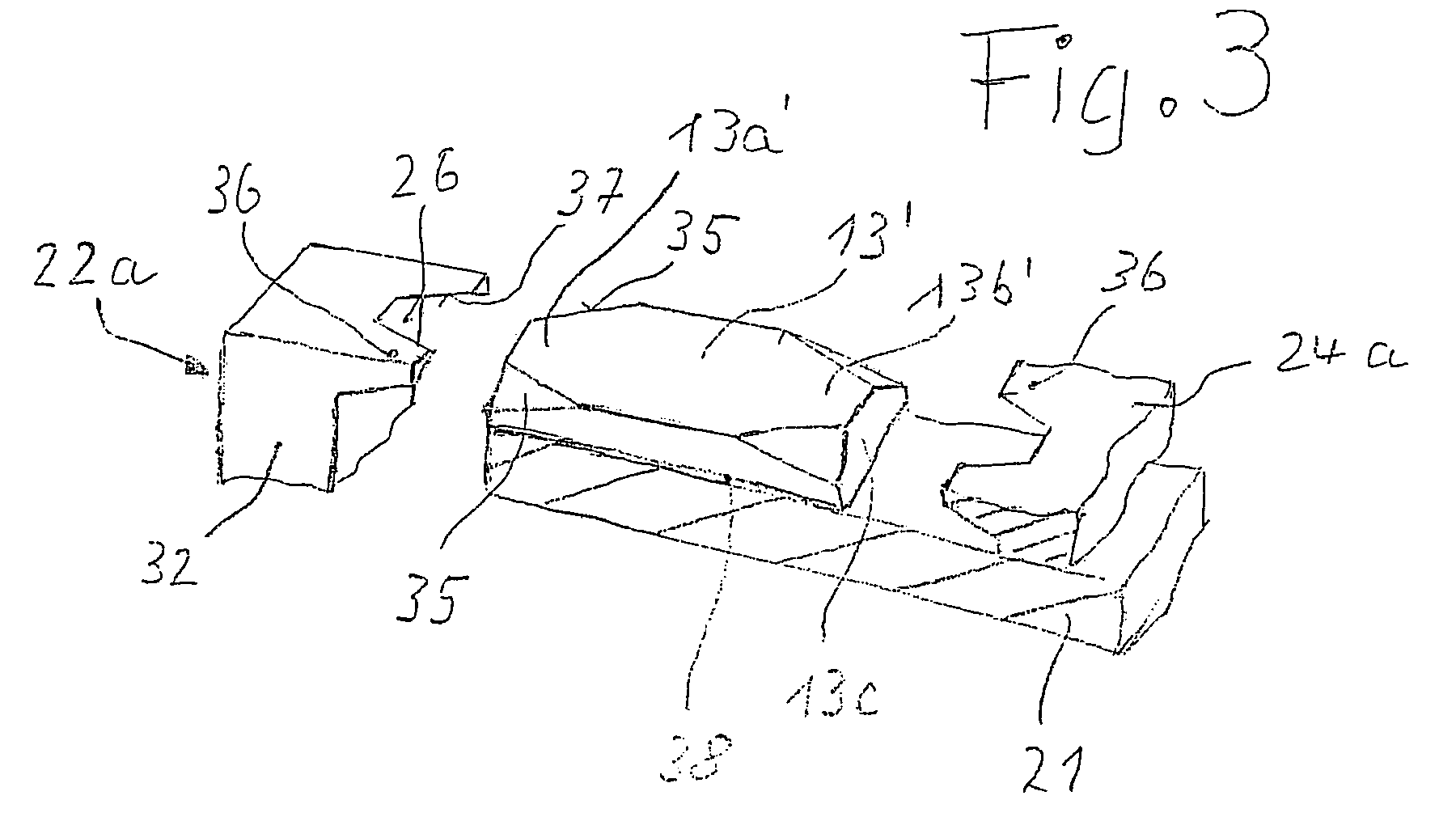

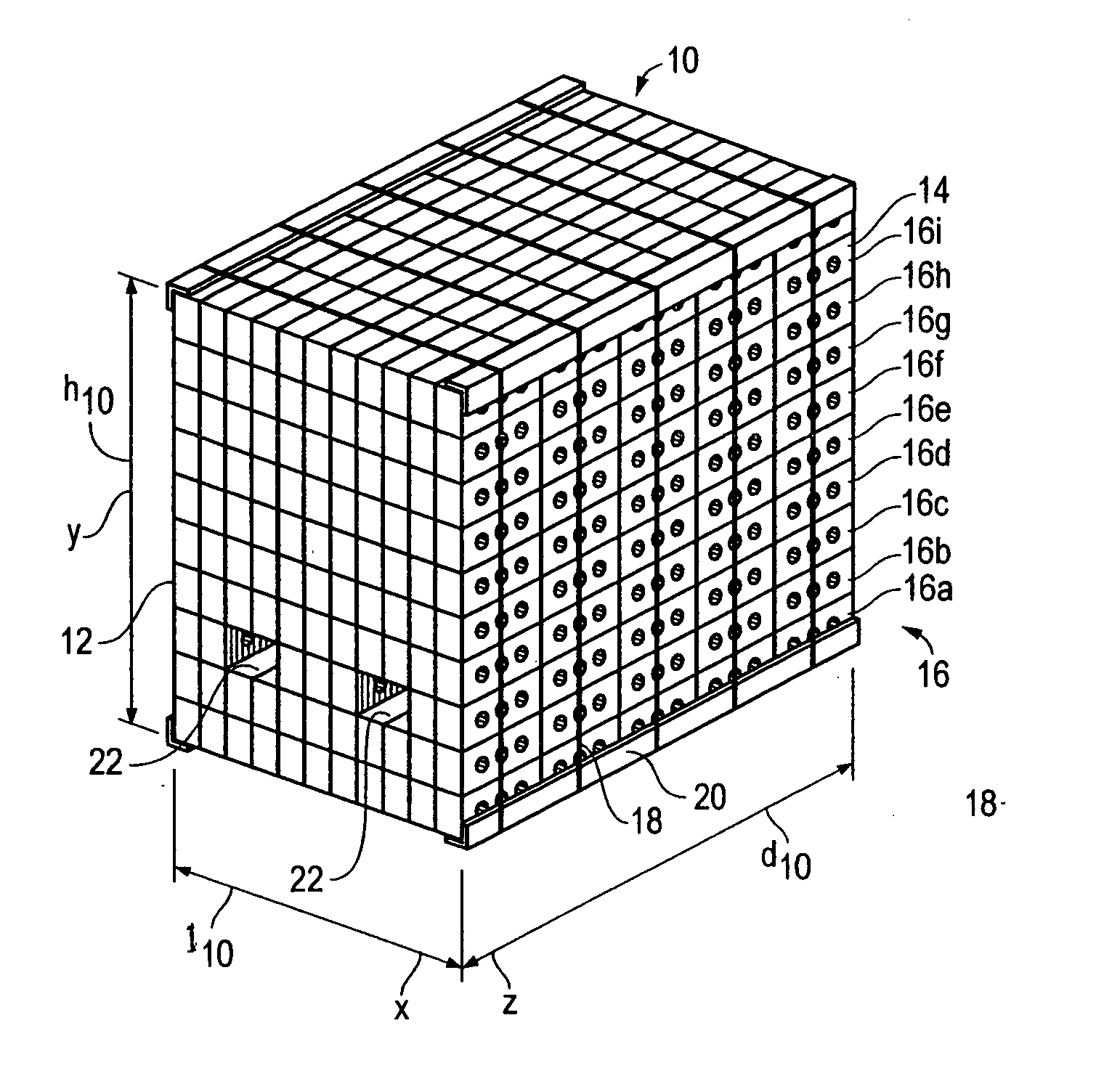

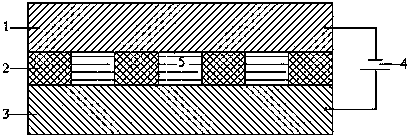

Electrical machines, especially engines excited by permanent magnets

InactiveUS7030529B2Easy to makeEasy to installMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsElectric machineMagnet

Owner:ROBERT BOSCH GMBH

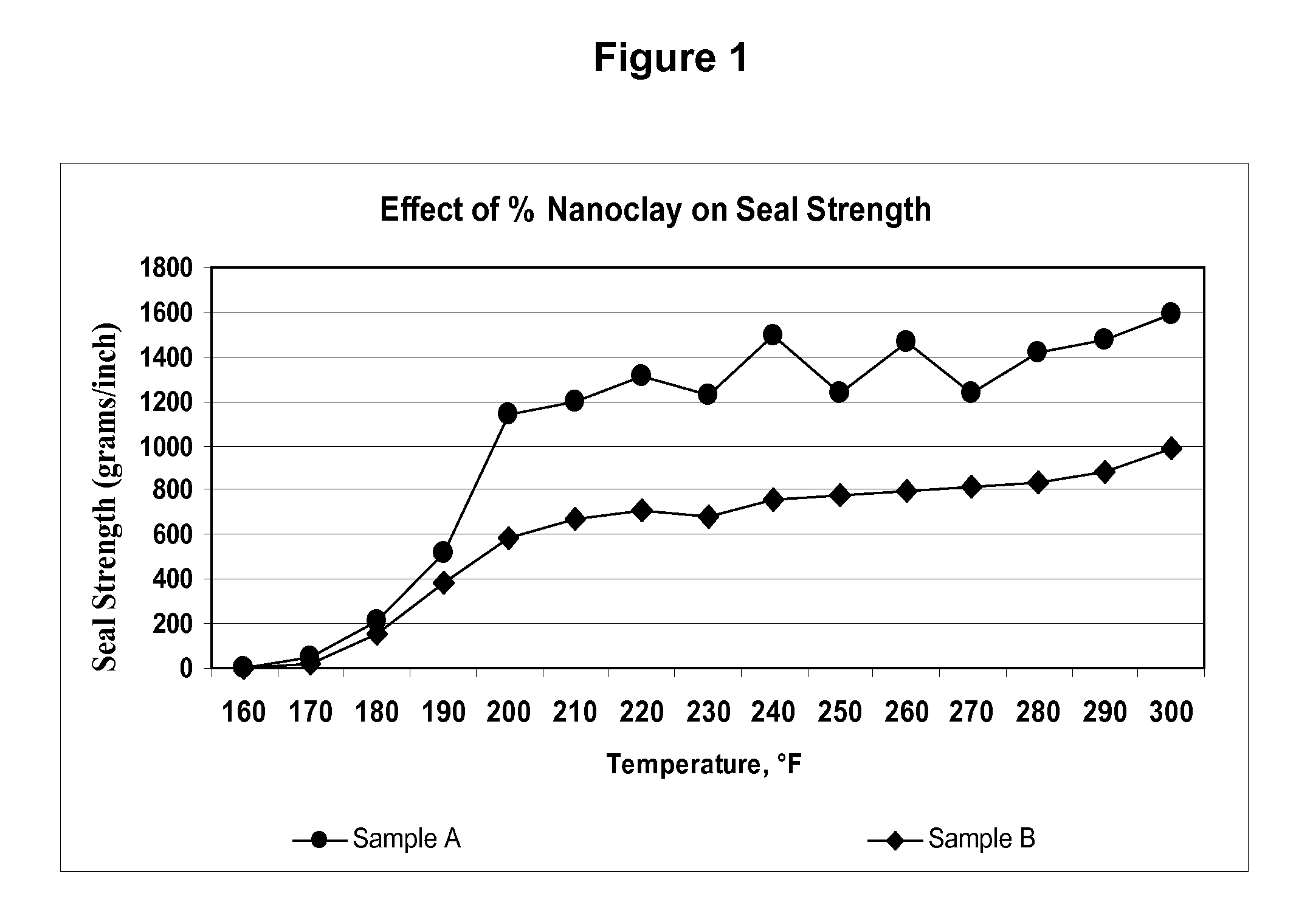

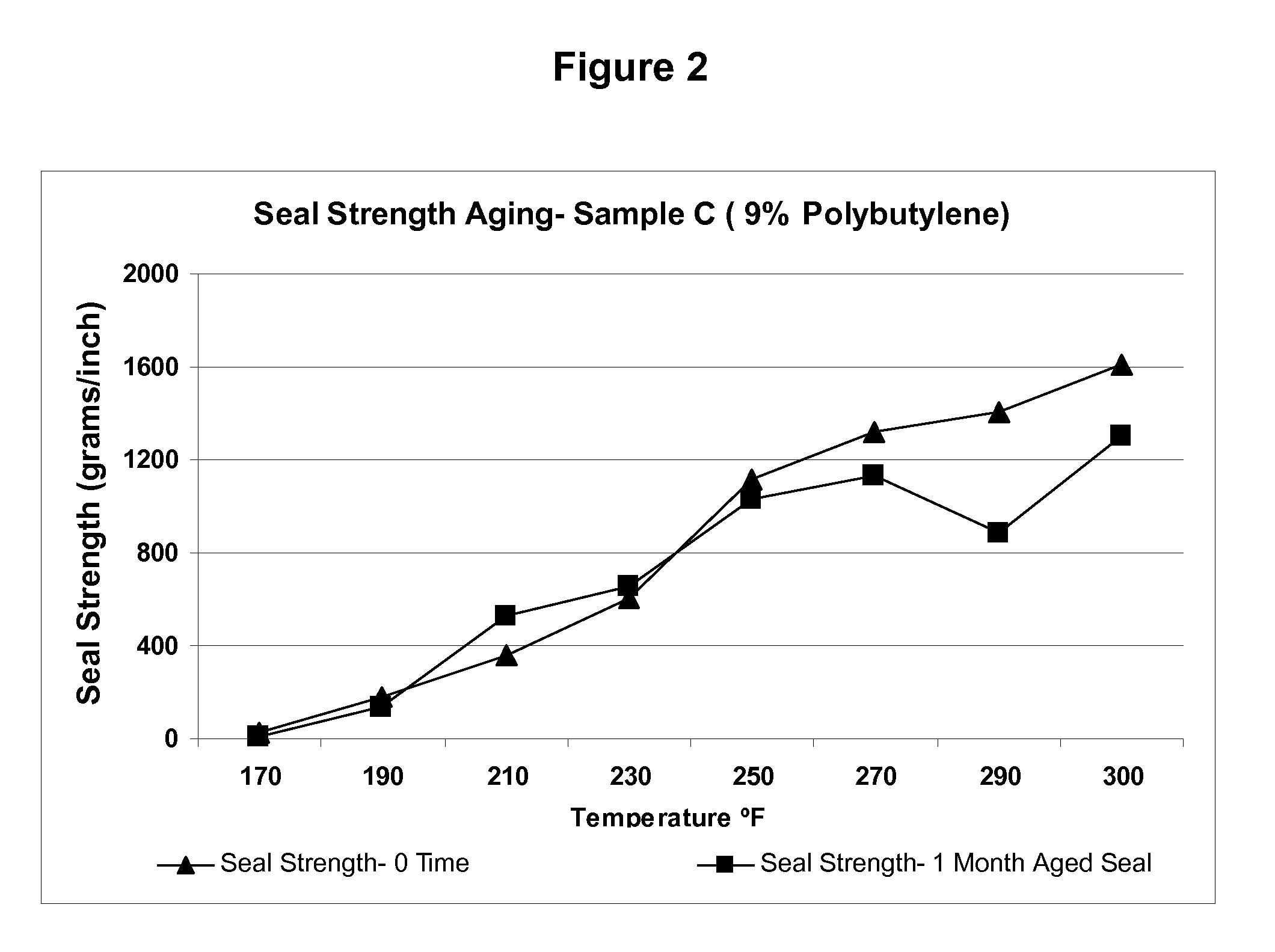

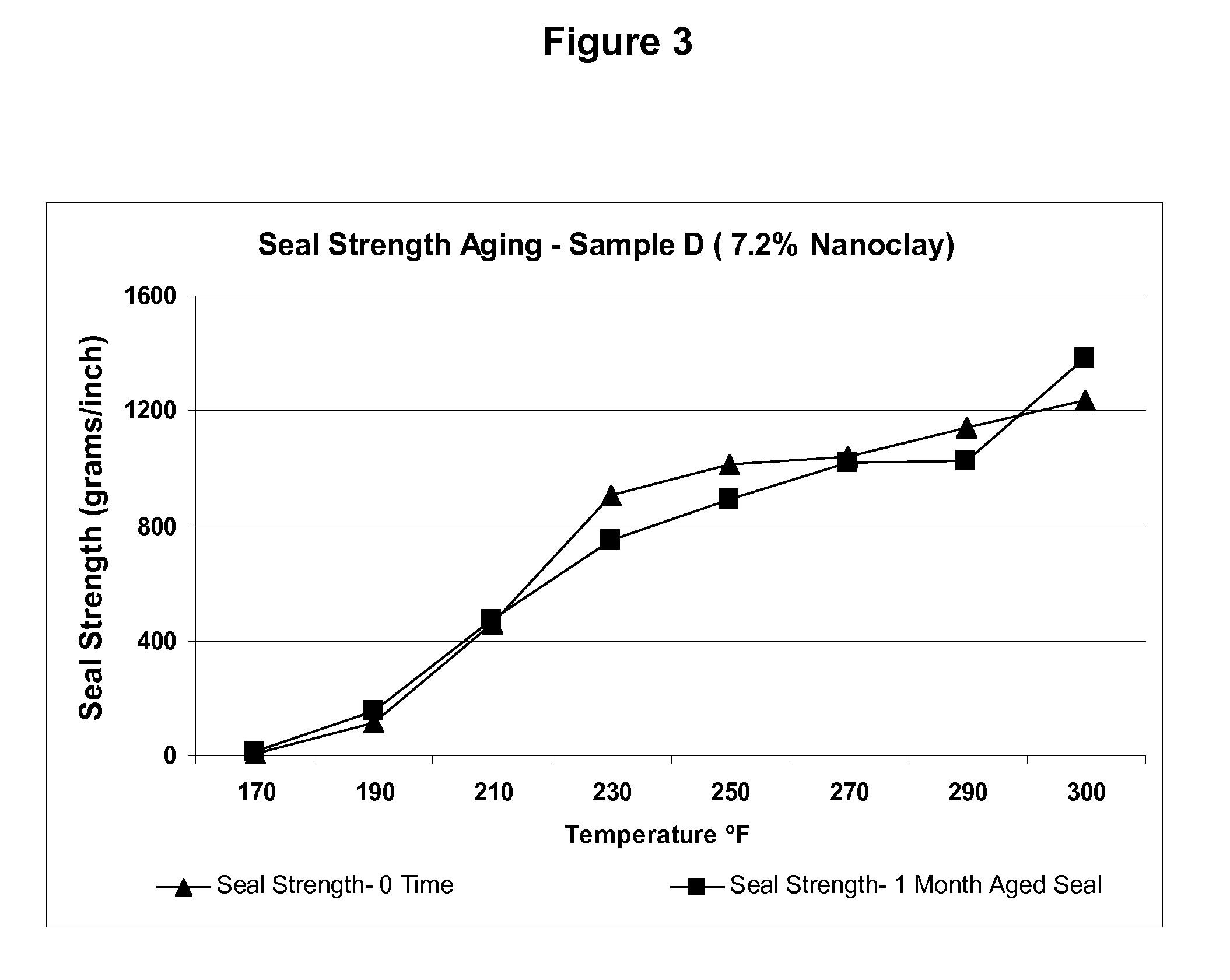

Peelable Films Containing Nano Particles

InactiveUS20100092793A1Consistent seal strengthLess effectSynthetic resin layered productsCeramic shaping apparatusEthylene HomopolymersNanometre

The present technology relates generally to peelable films and processes for making peelable films. The present technology also relates to peelable layers in films, and packages or lid stock that incorporate peelable films. In some embodiments, the present technology relates to peelable layers of monolayer or multilayer films that comprise at least one base polymer or copolymer and a nanoclay. In some embodiments, the at least one base polymer or copolymer comprising ethylene homopolymers, ethylene copolymers, propylene homopolymers, propylene copolymers, blends thereof, and mixtures thereof. Further, in some embodiments, the nanoclay is from about 1% to about 25% by weight of the peelable layer of a peelable seal film.

Owner:PLIANT CORP

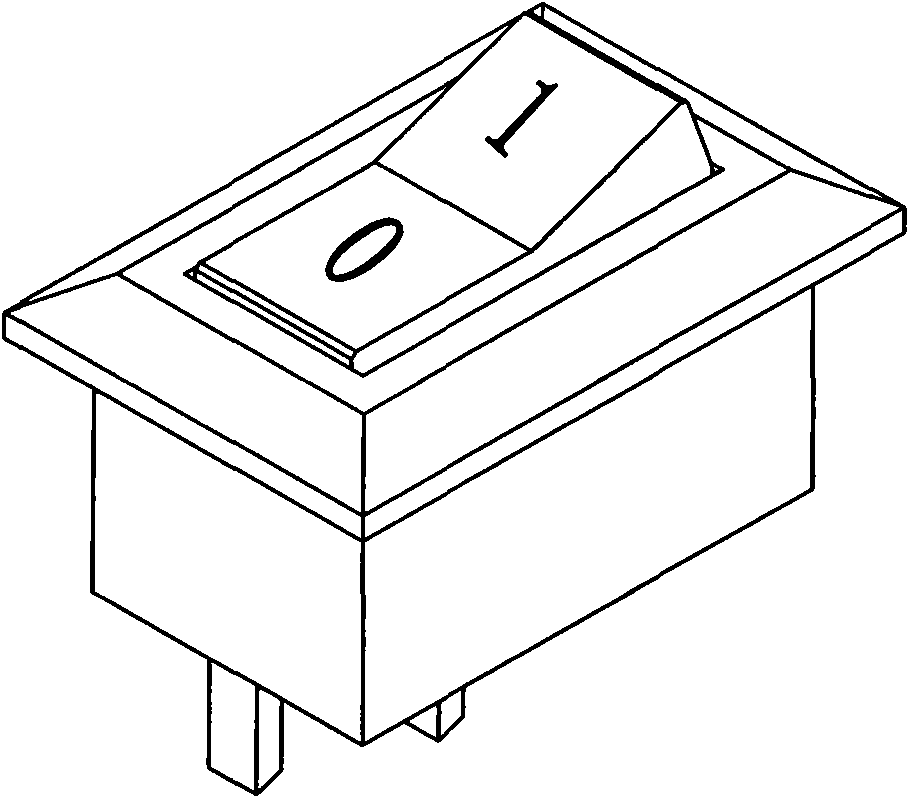

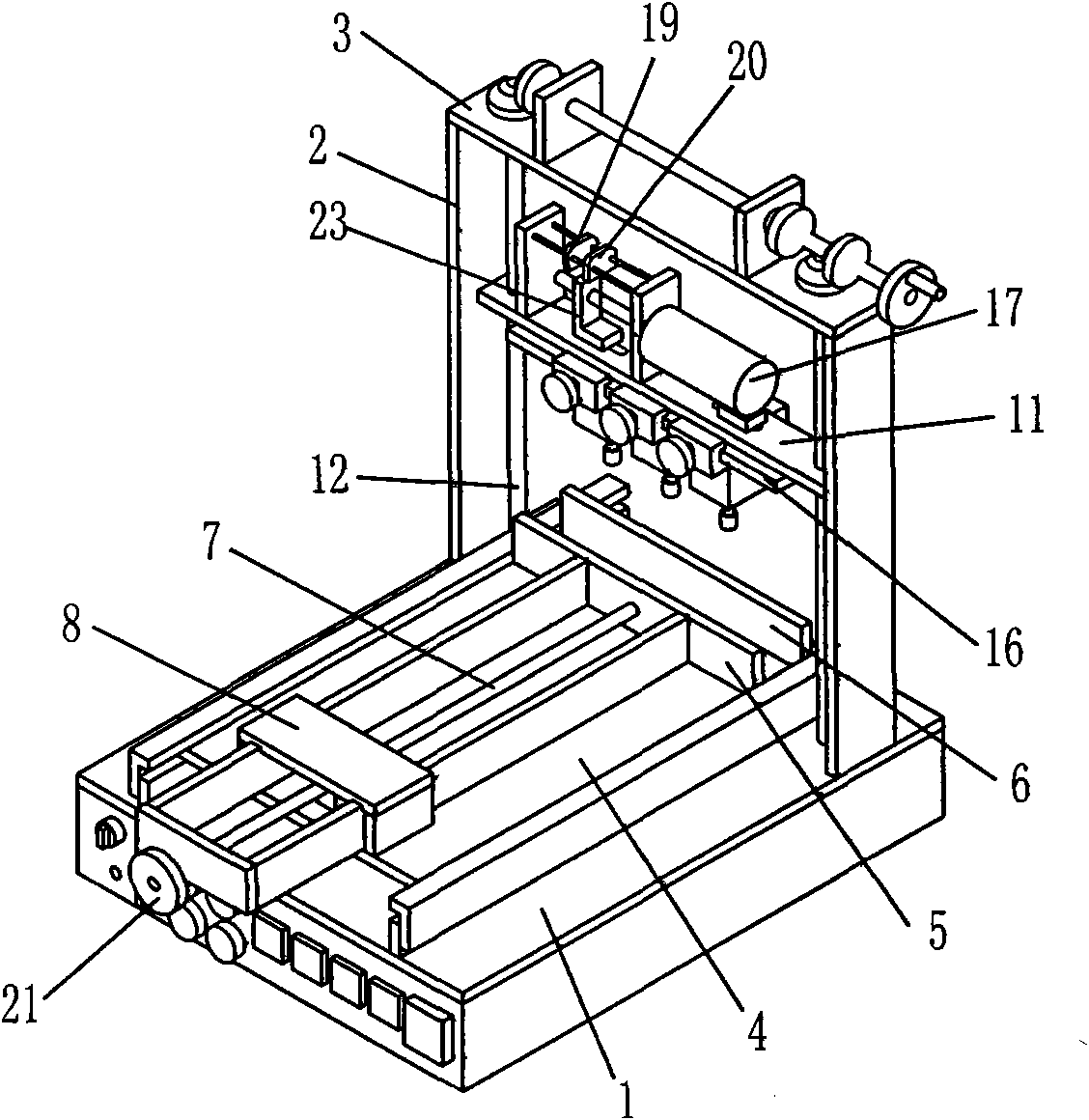

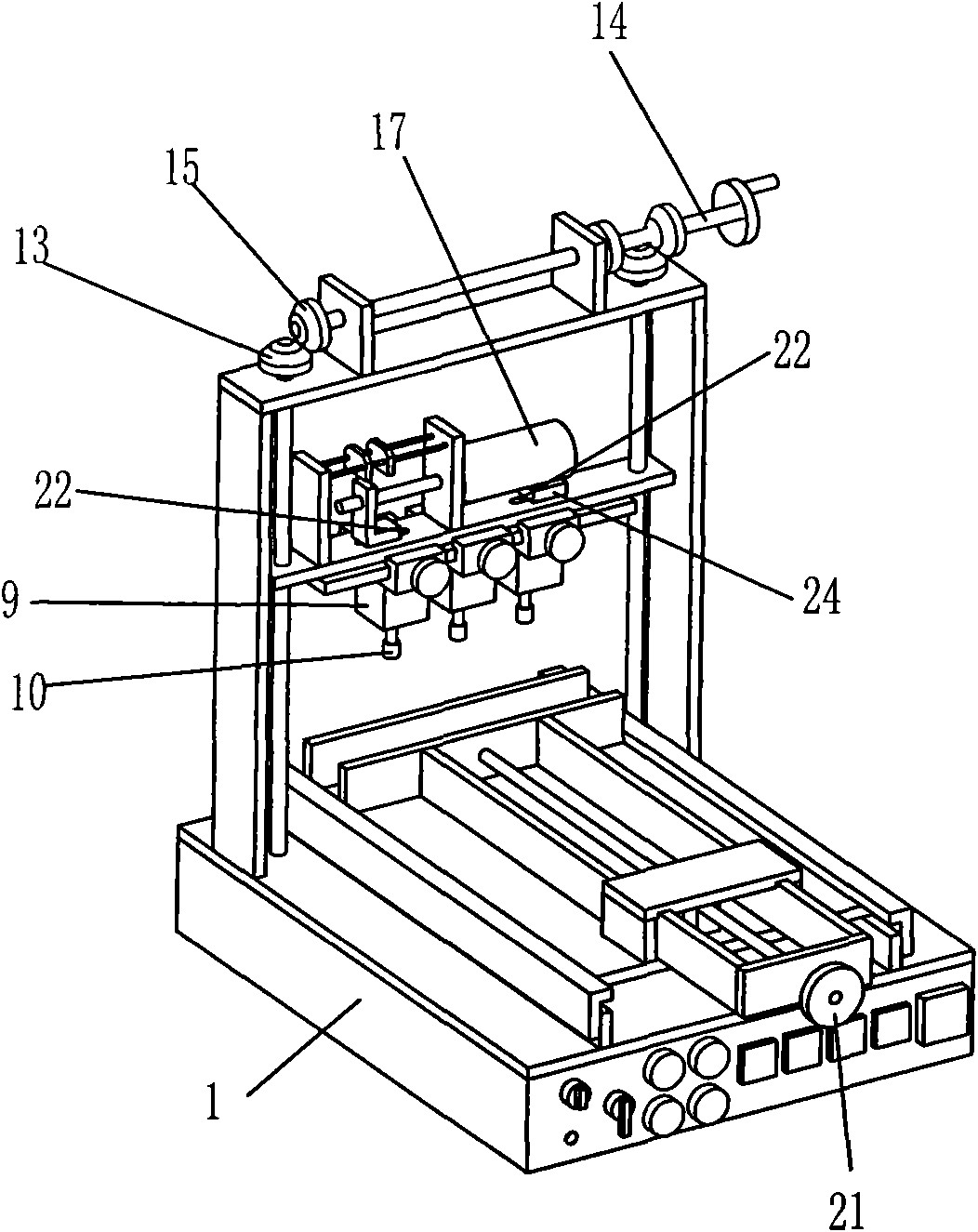

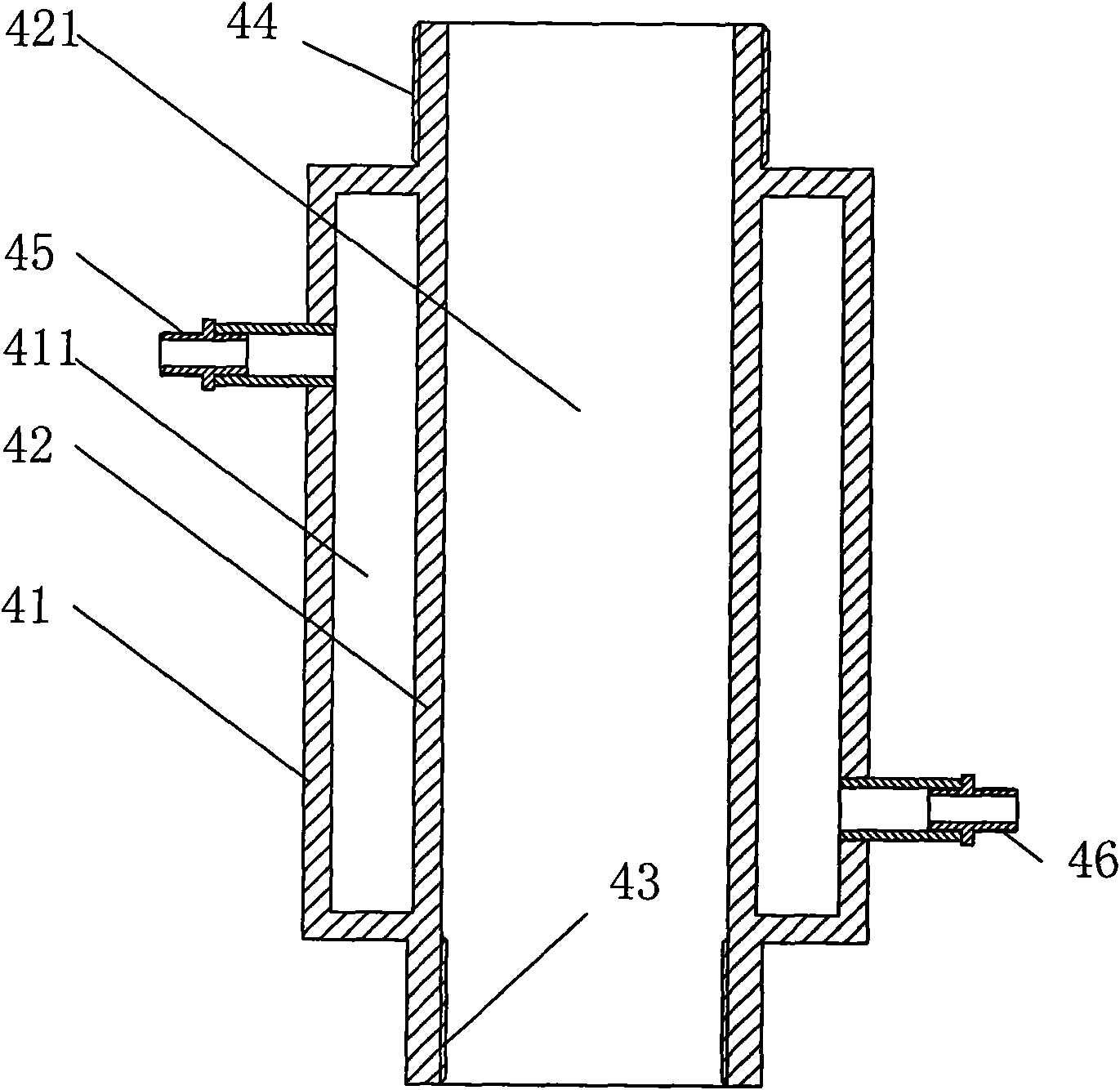

Ship-shaped switch fatigue test device

InactiveCN101660977AImprove test efficiencyConsistent strengthStructural/machines measurementCircuit interrupters testingTest efficiencyFatigue testing

The invention relates to a ship-shaped switch fatigue test device which is used for testing a ship-shaped switch comprising two press ends. The ship-shaped switch fatigue test device comprises a working platform, a bracket, a first drive device and a second drive device, wherein the working platform is used for fixing the ship-shaped switch; the bracket is fixed on the working platform, and a press column for pressing the ship-shaped switch is arranged on the bracket; the first drive device is used for driving the press column to move up and down so as to press the ship-shaped switch; and thesecond drive device is used for driving the press column to horizontally move above the ship-shaped switch. The ship-shaped switch fatigue test device can carry out a fatigue test on a plurality of ship-shaped switches simultaneously and improves the test efficiency, the force and the frequency for pressing the ship-shaped switch each time keep consistent, and the test effect is better.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD

Double-layer titanium mesh for cranioplasty

The invention relates to a double-layer titanium mesh for cranioplasty, which is characterized by comprising an inner-layer titanium mesh and an outer-layer titanium mesh, wherein the outer-layer titanium mesh coincides with the defective edge on the outer surface of the cranial bone; the curvature of the outer-layer titanium mesh conforms to the appearance of the head; the gap between the inner-layer titanium mesh and the outer-layer titanium mesh is filled with autologous bone granules or artificial bone granules; the outer-layer titanium mesh comprises a scalp contact surface and fixed-end grooves; the curvature of the outer-layer titanium mesh conforms to the outer surface of the skull; the edge of the outer-layer titanium mesh coincides with the defective edge on the outer surface of the cranial bone; the outer-layer titanium mesh is fixed on the defective position on the outer surface by screws, so that the outer surface of the cranial bone can be closed; and the outer-layer titanium mesh is provided with holes. The titanium mesh can simultaneously repair the inner surface and the outer surface of the cranial bone, thereby realizing full anatomical and functional recovery and avoiding the brain tissue damage caused by inner surface defects.

Owner:中国人民解放军第四军医大学唐都医院

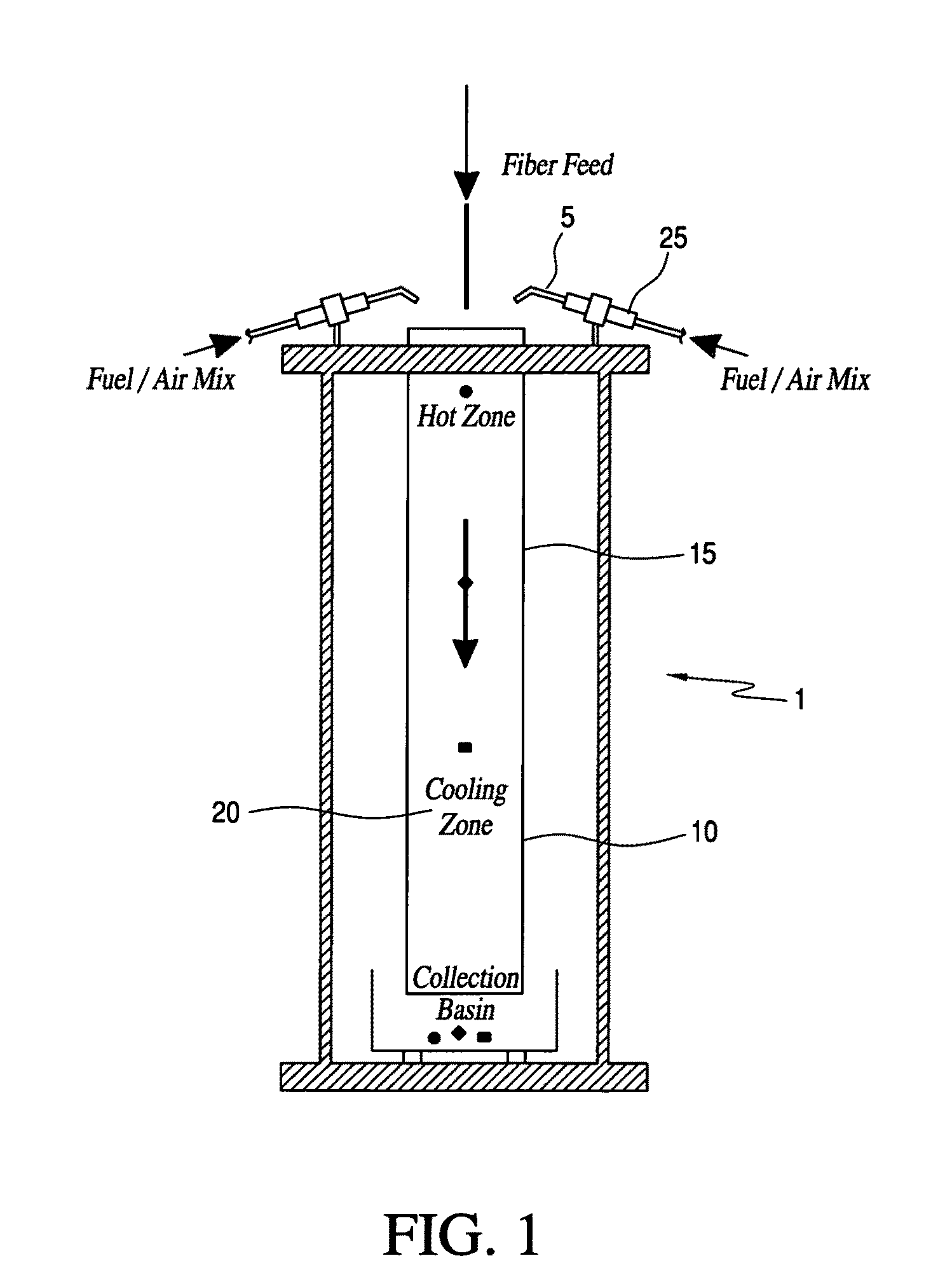

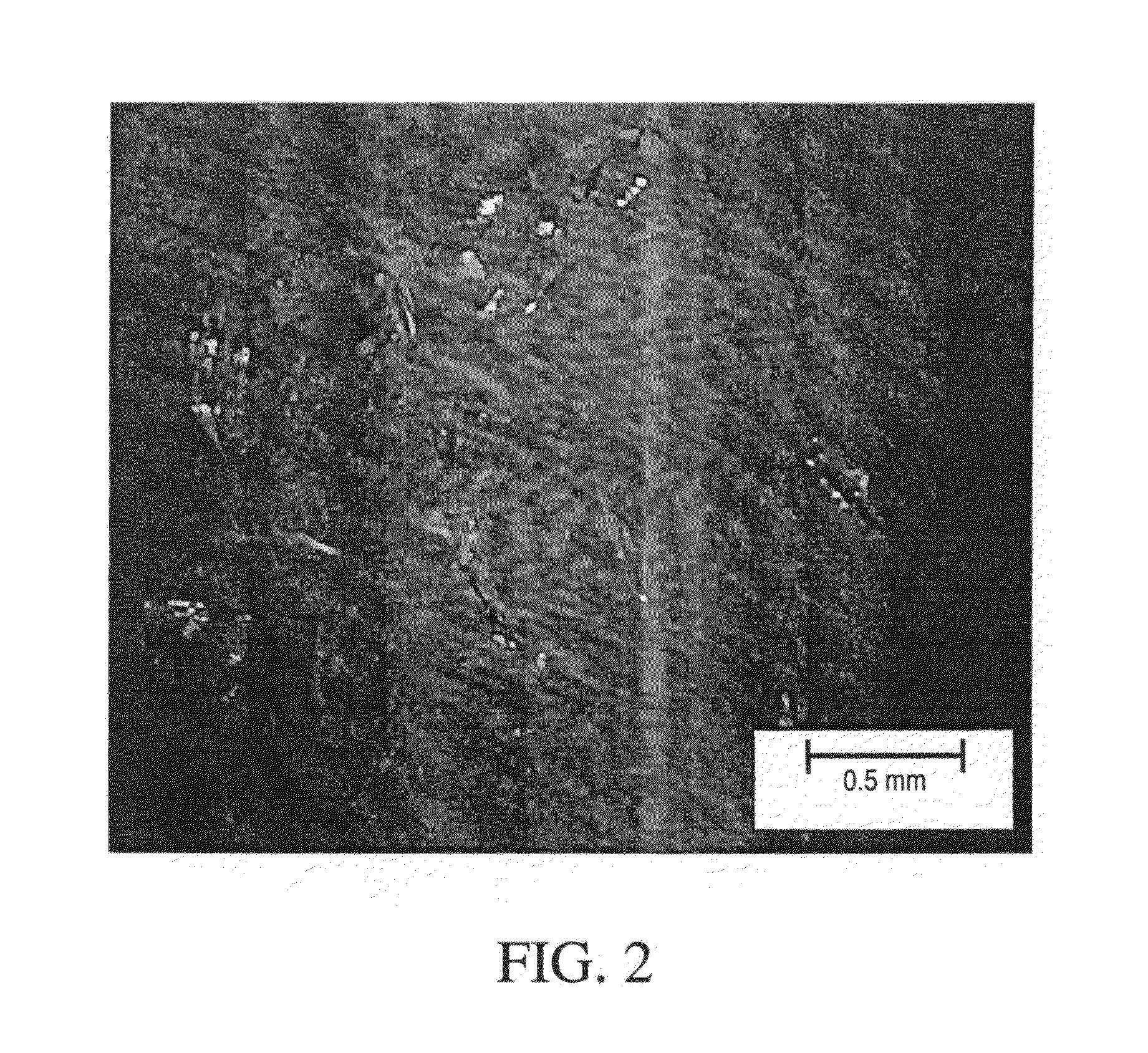

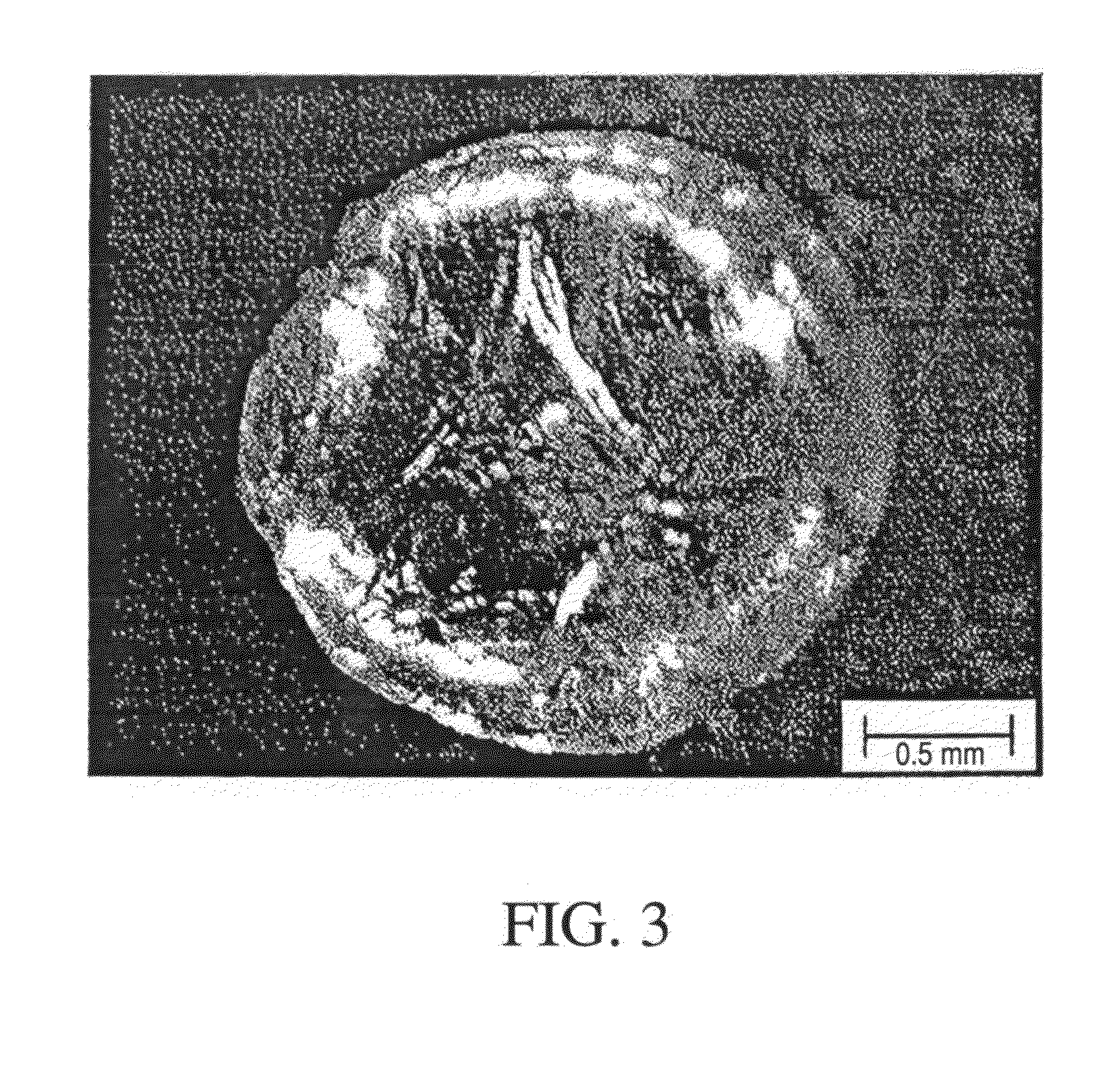

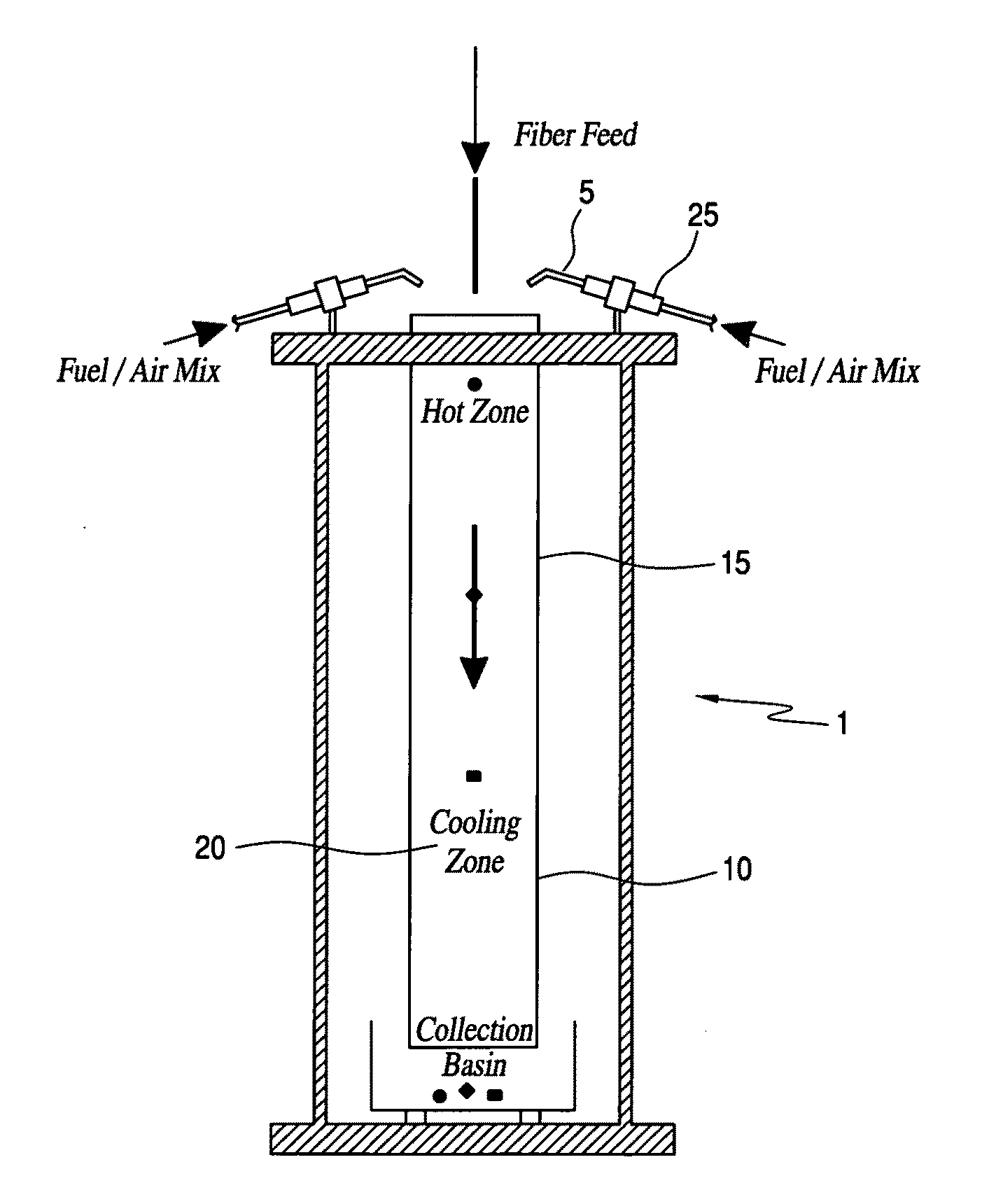

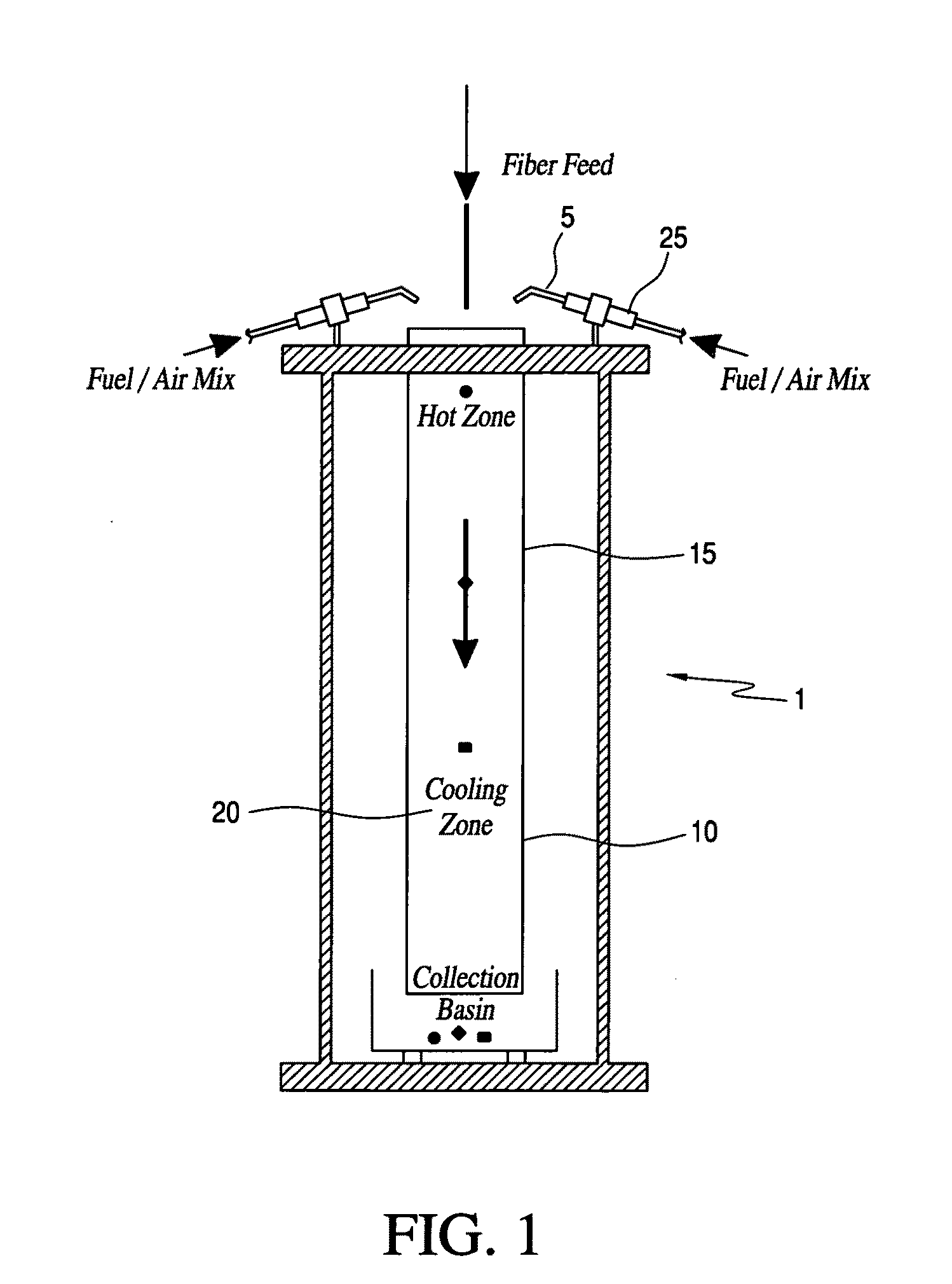

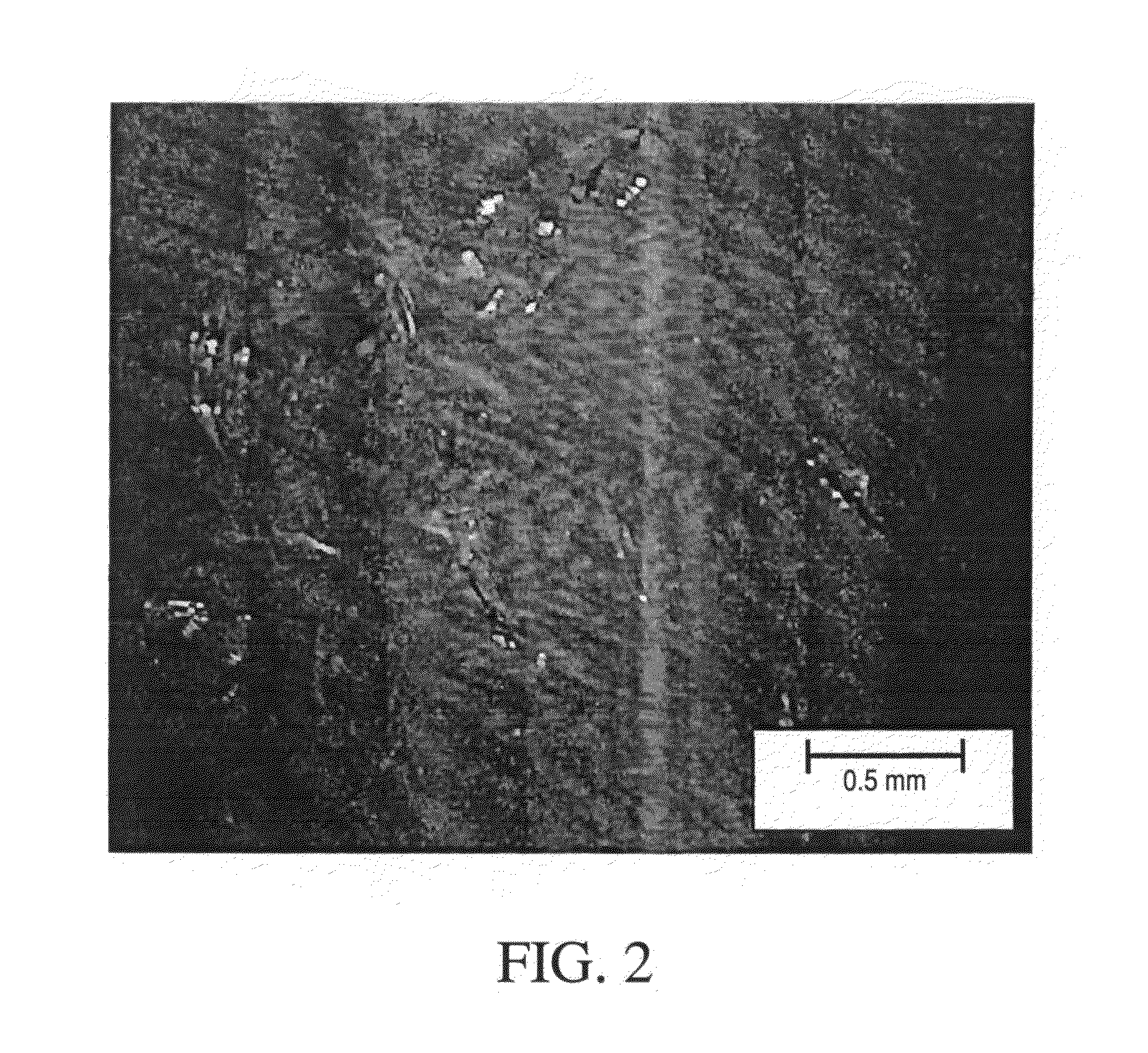

Treatment of particles for improved performance as proppants

ActiveUS8193128B2Reduce the amount requiredDecreased fractionFluid removalFlushingMolten saltIon exchange

Owner:PENN STATE RES FOUND

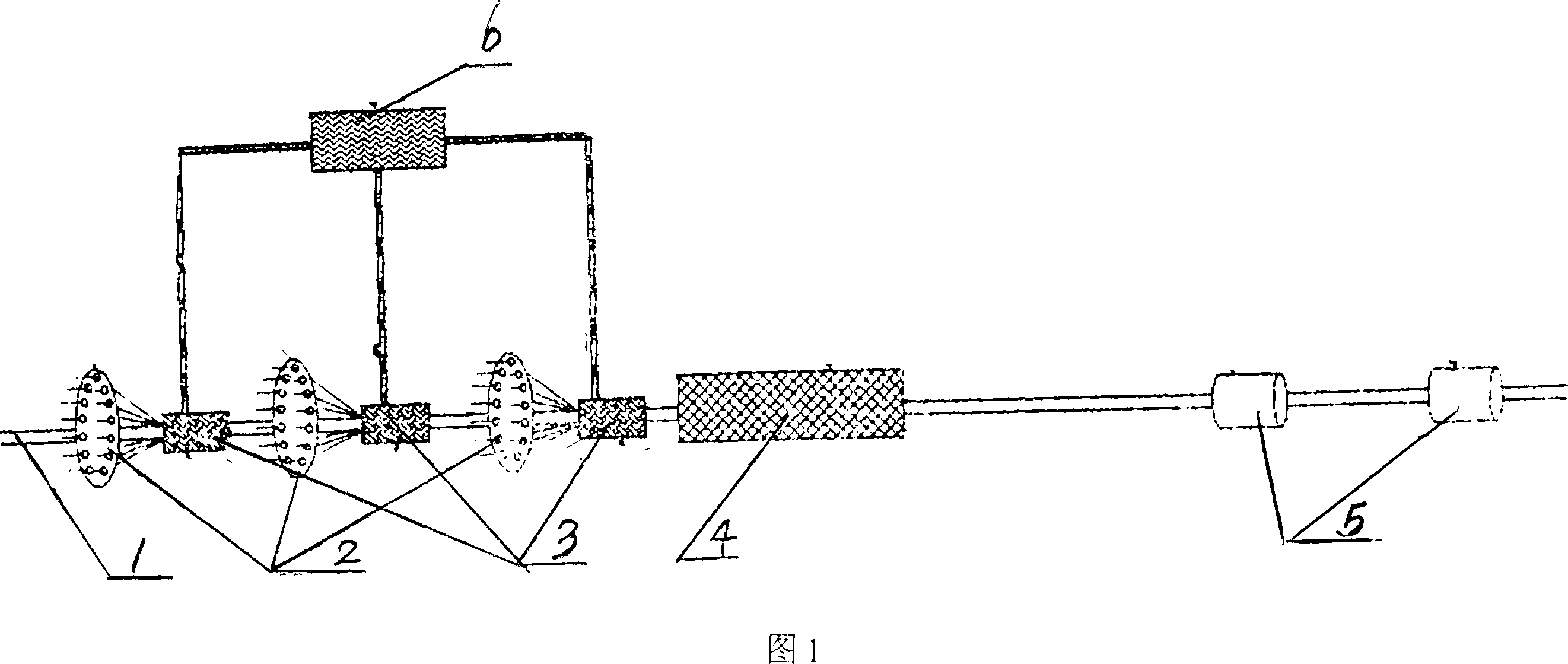

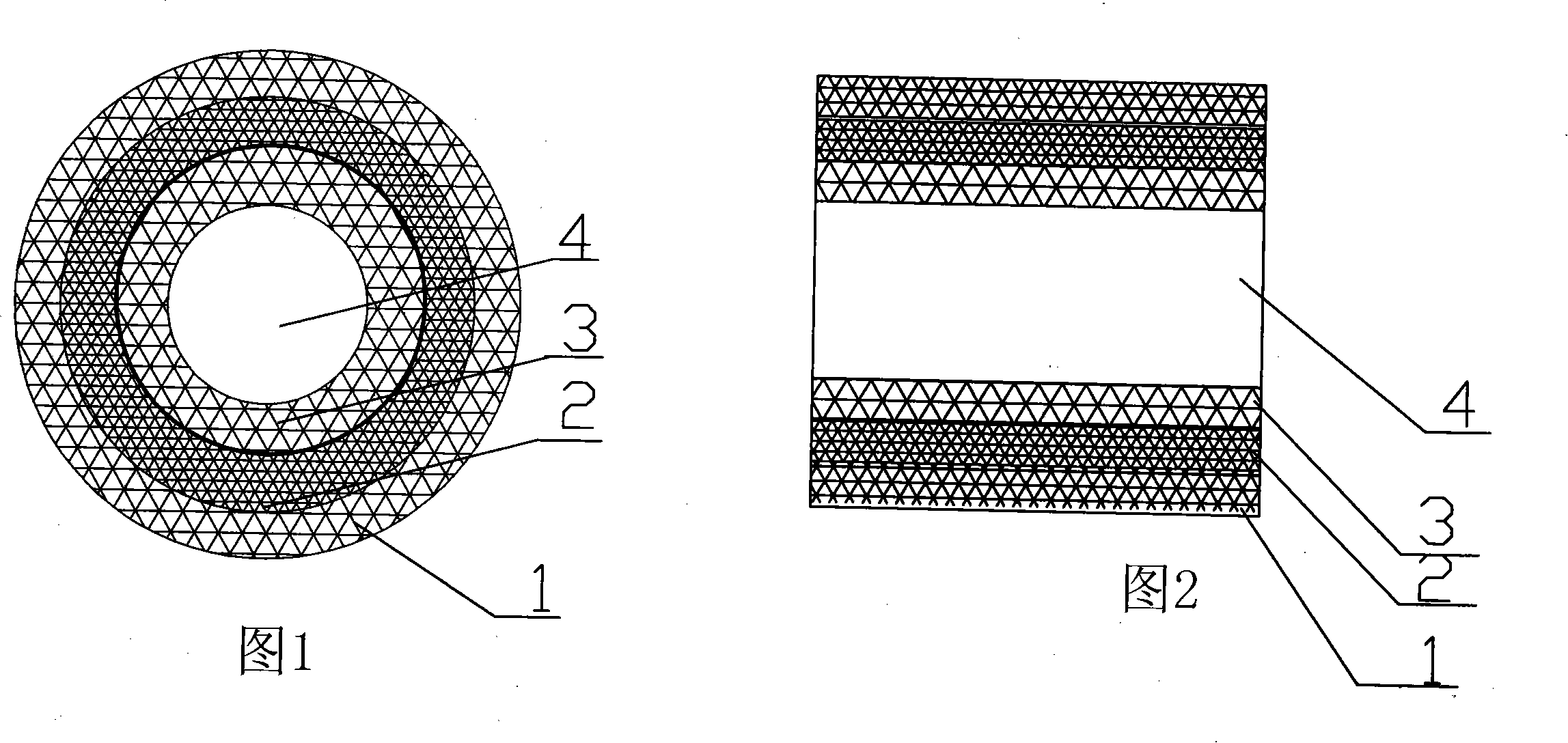

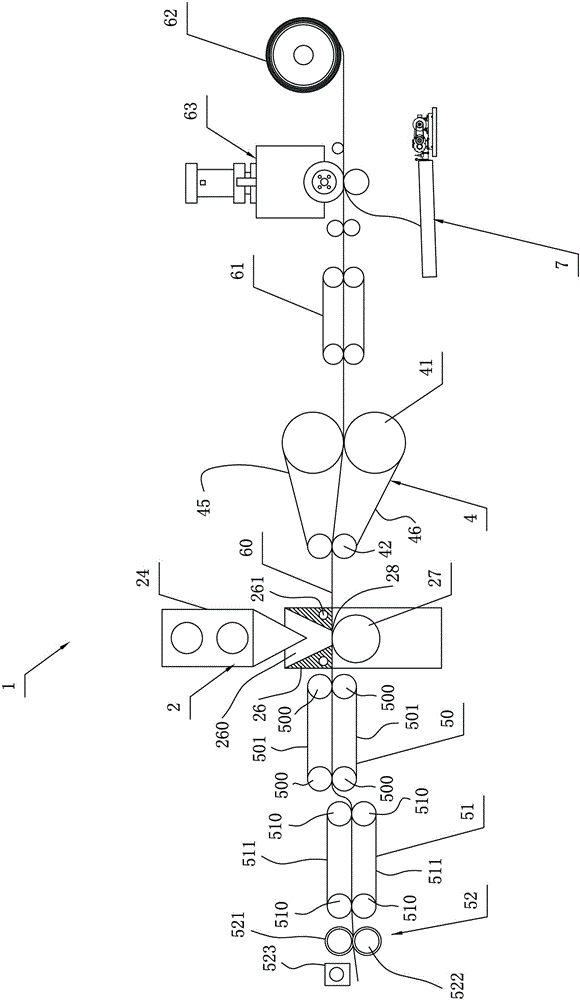

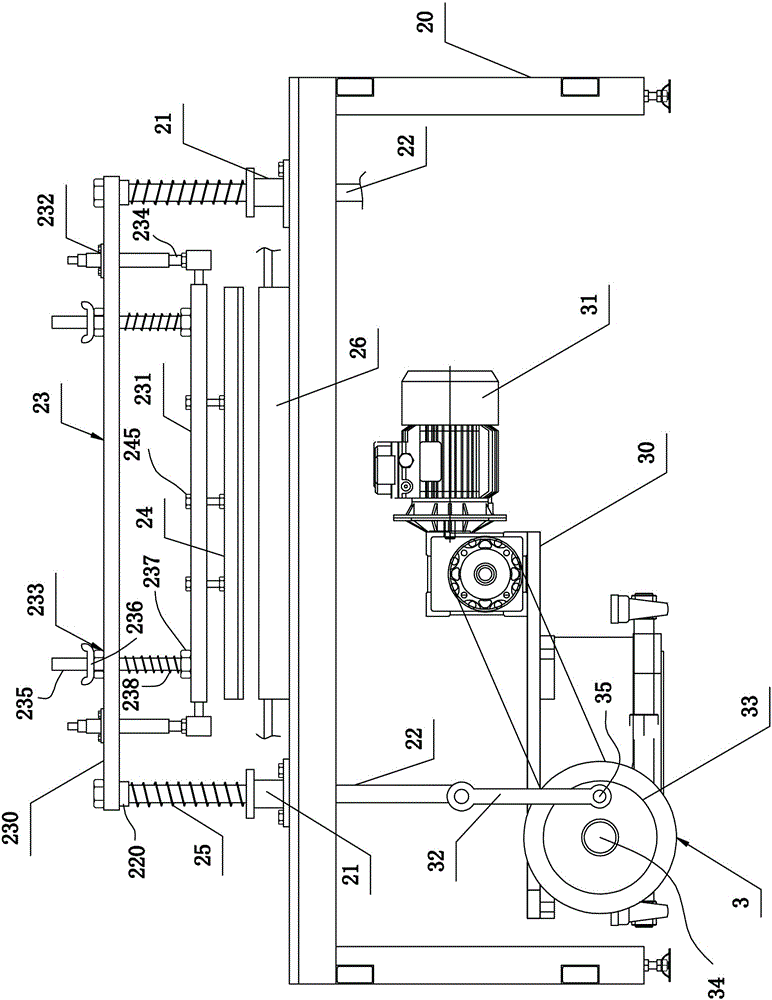

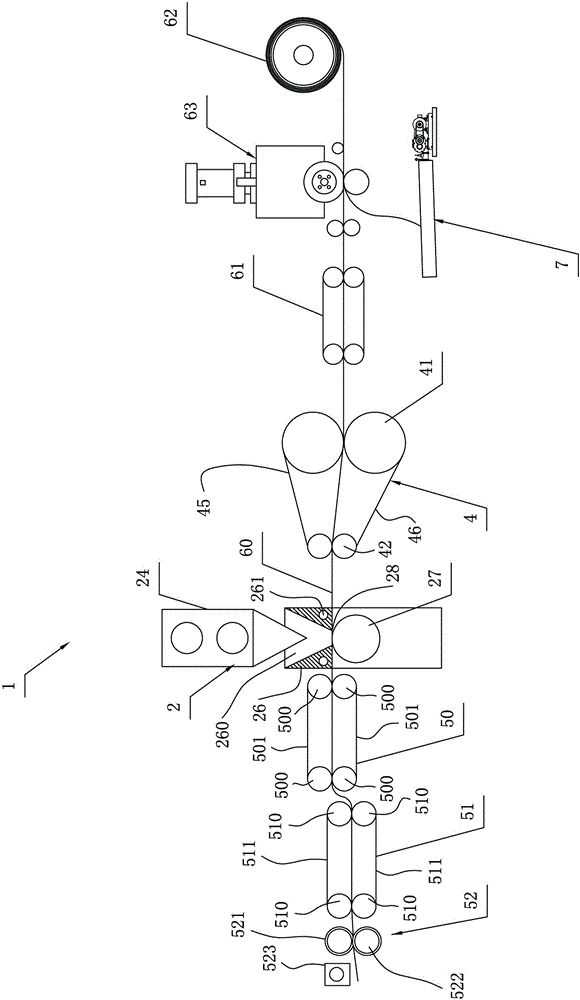

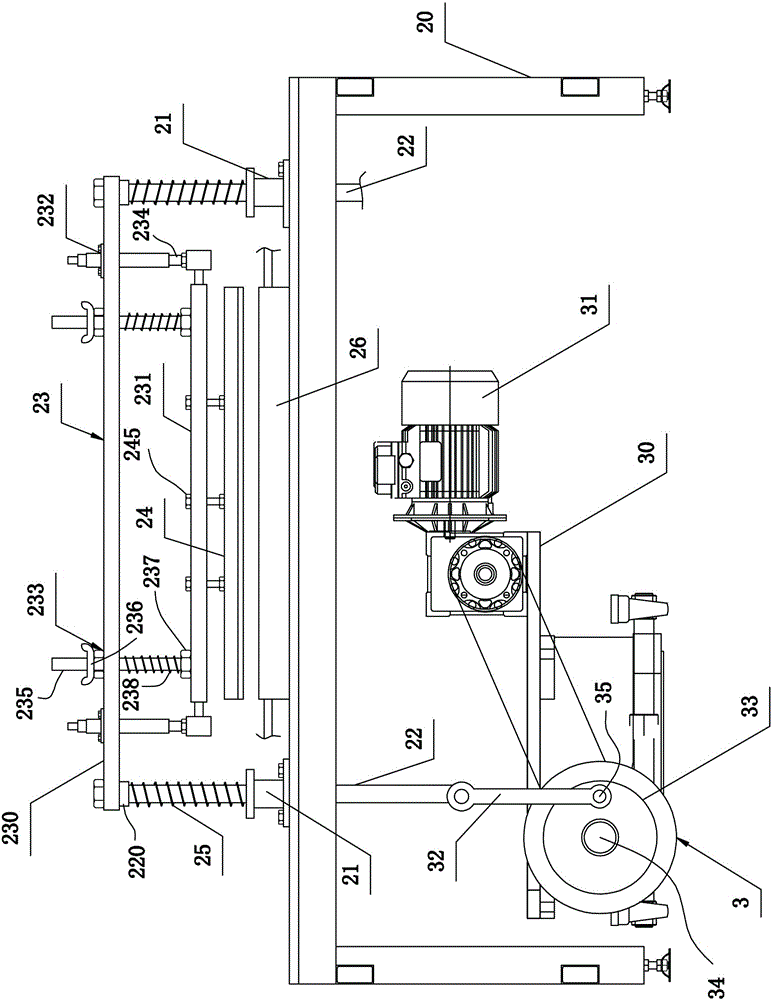

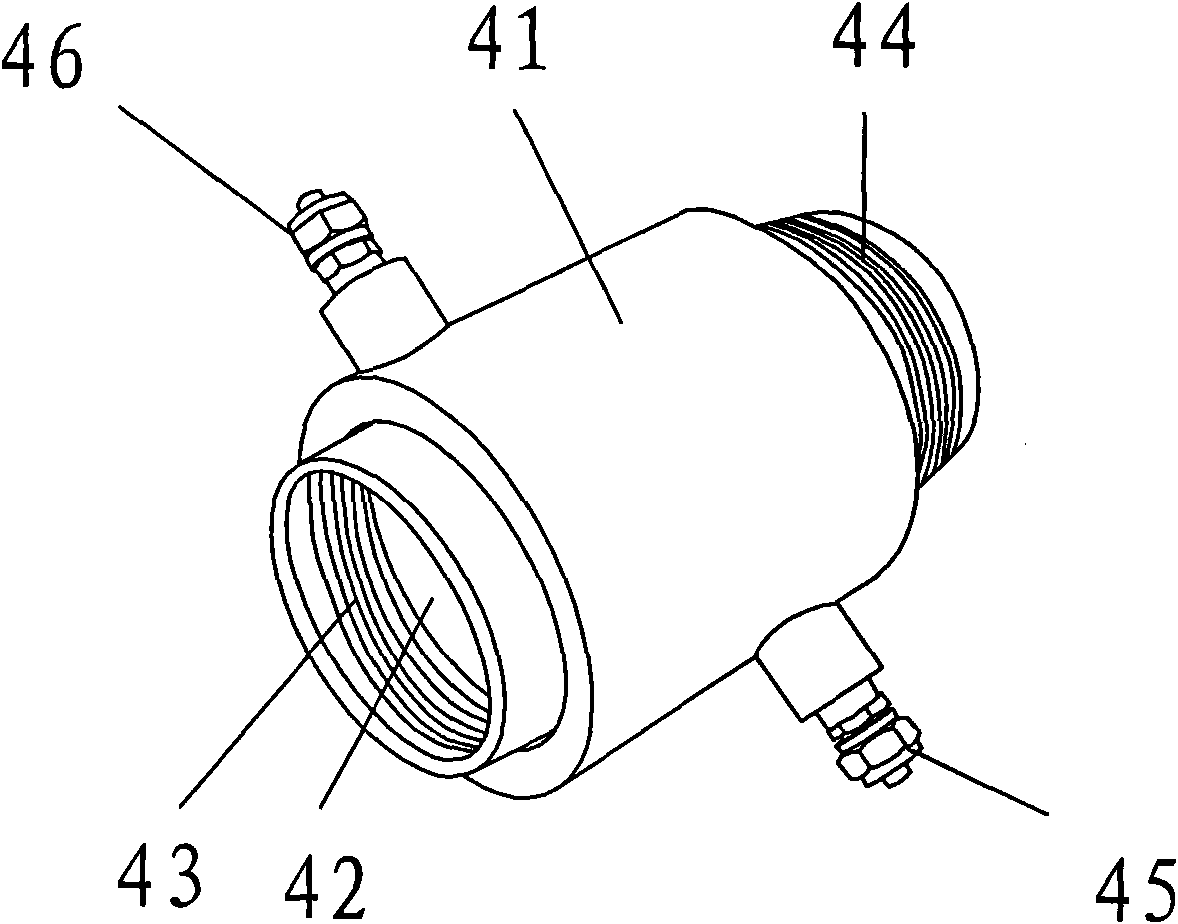

Preparation method for on-line pulling and extruding glass steel tube with multilayer annular weaving structure

InactiveCN101085551AWeave evenlyHigh precision of inner and outer diameterTubular articlesFiberMaterials science

The invention relates to the making of multi layer knitting structure on the wire pulling glass steel tube using several computers controlling the two dimensional horizontal knitter, using core mold, stretch mold, extractor synthesizing the glass steel tube, setting resin dipping slot at the back of each knitter, even direct core mold at both ends of the core mold that follows with the movement of the ring knitting layer in the direction from the first two dimensional horizontal knitter to the last knitter through the dipping slot to the stretch mold. The glass tube in and out radius has high precision, thickness of each knitting layer adjustable, even in each dipping and consistent in strength.

Owner:郝跟进

Treatment of particles for improved performance as proppants

ActiveUS20100326657A1Reduce the amount requiredDecreased fractionFluid removalFlushingMolten saltIon exchange

The disclosed invention relates to a process of using molten salt ion exchange to treat particles such as spherically shaped soda-lime-silica glass particles. The treated particles may be used as proppants in hydrofractured oil and natural gas wells.

Owner:PENN STATE RES FOUND

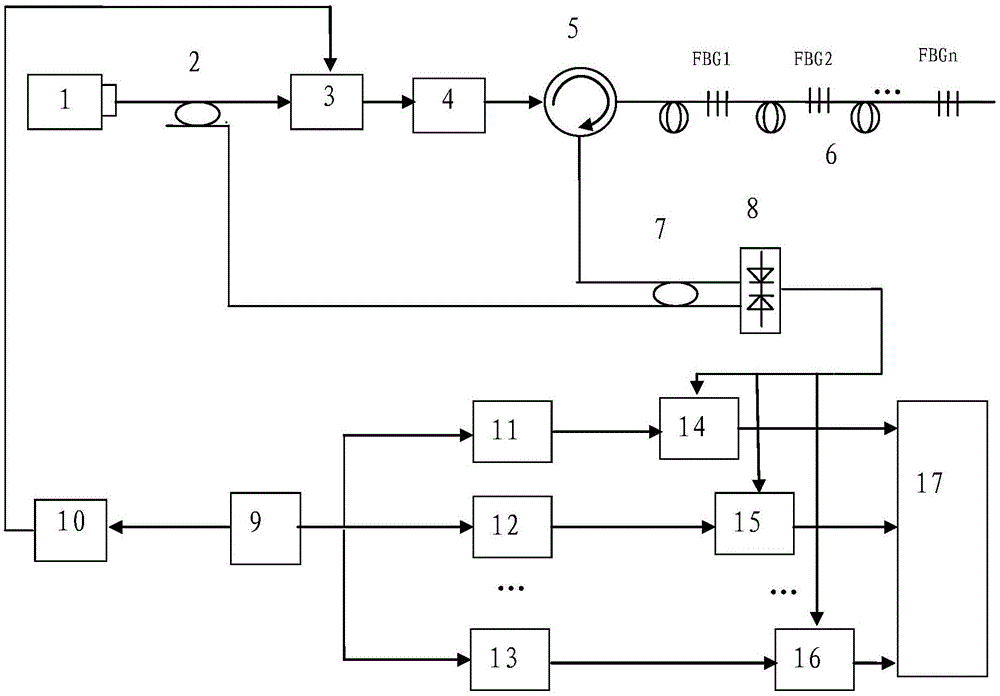

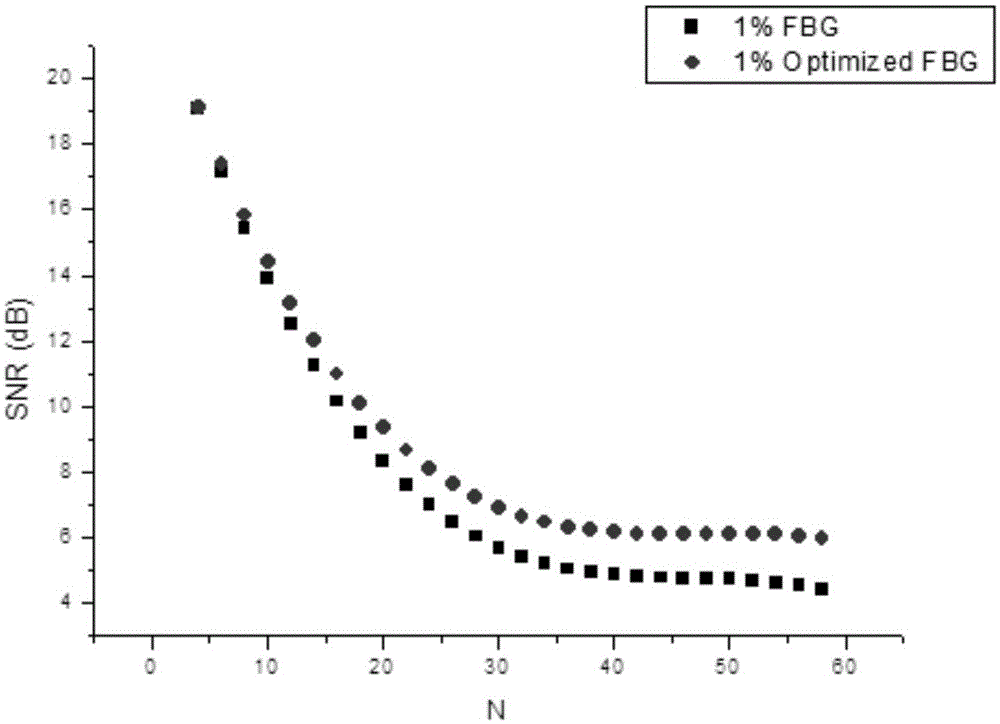

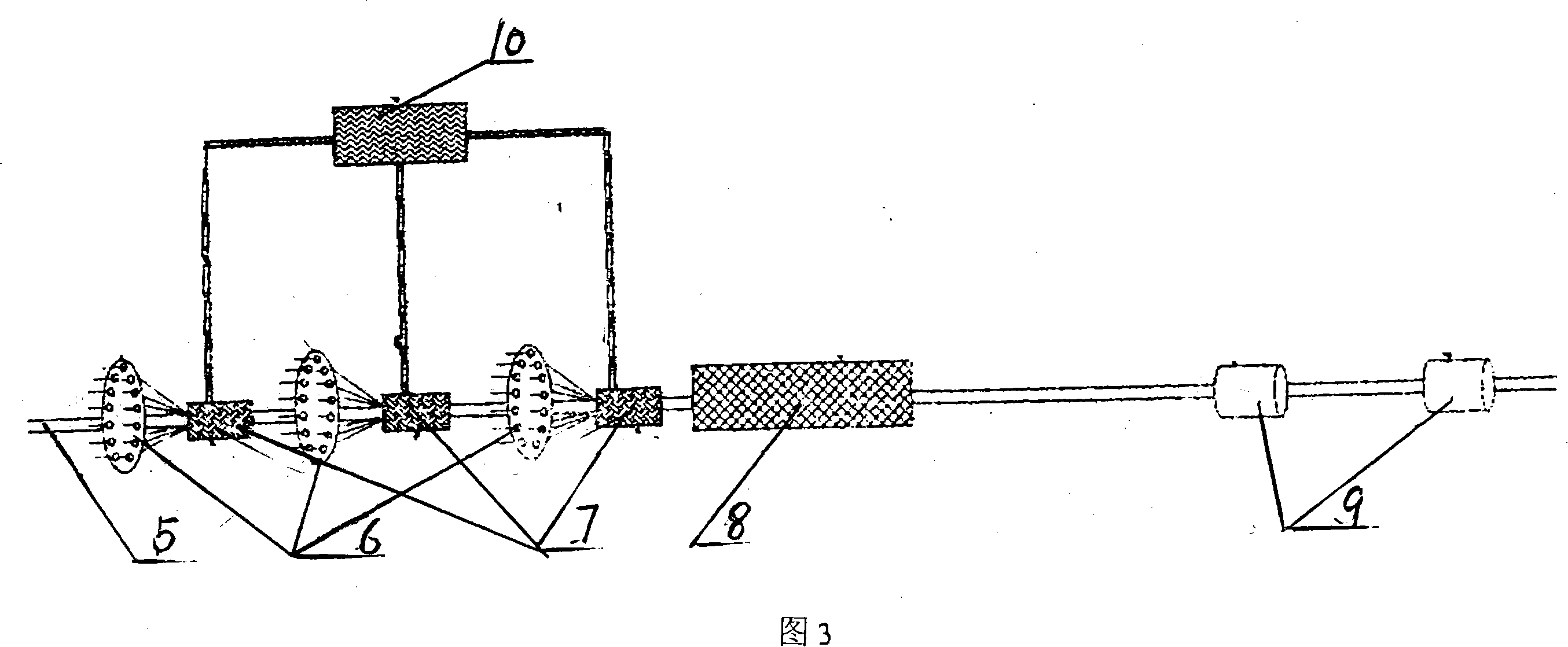

Digital enhanced interference-based high-sensitivity quasi-distributed fiber bragg grating vibration sensor

InactiveCN105157812ASuppress noiseImprove signal-to-noise ratioSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansFiber couplerGrating

The invention discloses a digital enhanced interference-based high-sensitivity quasi-distributed fiber bragg grating vibration sensor, which comprises a narrow linewidth laser, a first fiber coupler, an electro-optic modulator, an acousto-optic modulator, a circulator, a weak reflection fiber bragg grating array, a second fiber coupler, a double-balanced detector, an arbitrary waveform generator, an electrical amplifier, n electrical delayers, n multipliers and a phase demodulator, wherein the output port of the narrow linewidth laser is connected with the input port of the first fiber coupler; the first output port of the first fiber coupler is connected with the light signal input end of the electro-optic modulator; the output port of the electro-optic modulator is connected with the light signal input port of the acousto-optic modulator; the light signal output port of the acousto-optic modulator is connected with the first port of the circulator; and the second port of the circulator is connected with the input port of the weak reflection fiber bragg grating array.

Owner:NANJING PIONEER AWARENESS INFORMATION TECH CO LTD

Fiberglass insulating tube with multi-layer ring shaped braiding structure

InactiveCN101119042AWeave evenlyHigh precision of inner and outer diameterWindings insulation materialWindings insulation shape/form/constructionUltimate tensile strengthManufacturing efficiency

The present invention discloses a glass steel insulating tube with the multi-layer round structure, which is compounded with the multi-layer glass steel insulating tube, each glass steel insulating tube of the compounded glass steel insulating tube is the glass steel insulating weaving tube which is weaved at the moving type core tube by the horizontal knitting machine, each layer of the lass steel insulating weaving tube is dipped by the bond before the compound; the compounded glass steel insulating tube is compound under the same straight core mould, and finally shape and solidified by a pulling mould; the glass steel insulating tube is formed by the 2 to 5 layers of the glass steel insulating weaving tube. Compared with prior compound tube, the intensity and the accuracy of the glass steel insulating tube are improved greatly, the thickness of the tube wall only differ from 1 to 2 threads, in particular to the application of the micro electromotor double insulating tubes make the manufacture efficiency of the micro electromotor improve, and the cost is reduced, and the production craftwork is simple.

Owner:郝跟进

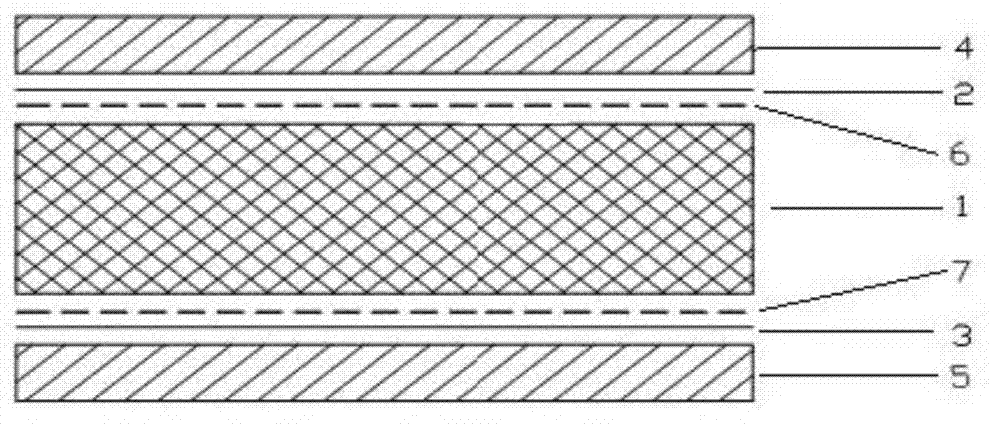

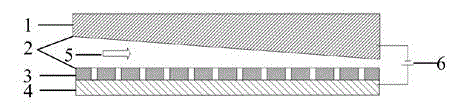

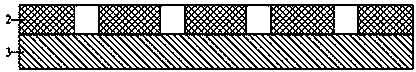

Continuous fiber reinforced polypropylene sandwich plate and preparation method thereof

InactiveCN103921511ALow priceReduce processing requirementsSynthetic resin layered productsLaminationPolymer scienceNonwoven fabric

The invention belongs to the technical field of polymer materials, and relates to a continuous fiber reinforced polypropylene sandwich plate and a preparation method thereof. The sandwich plate sequentially comprises an upper prepreg layer, an upper nonwoven fabric layer, an upper glue film material, a honeycomb core material layer, a lower glue film material, a lower nonwoven fabric layer and a prepreg layer from top to bottom, wherein the adjacent layers are connected through hot pressing. According to the present invention, the prepared continuous fiber reinforced polypropylene sandwich plate has advantages of high strength, high modulus, corrosion resistance, good water resistance, no electric conduction, high dielectric strength, easy processing, easy cleaning, no requirement of special storage conditions and long storage life, provides inertia for a variety of acids and alkalis, has low molding pressure and low molding temperature so as to reduce the mold cost, has a short molding period so as to be repeatedly molded, and has good design flexibility so as to adopt the appropriate fiber type, the appropriate fiber content and the appropriate fiber orientation to meet requirements of specific uses; and 100% of the waste material during production and the final product can be recycled, and the technology belongs to the green product technology.

Owner:LIAONING LIAOJIE SCI & TECH

Caulking anti-crack mortar

The invention discloses a caulking anti-crack mortar comprising the following components, by weight: 10-30 parts of calcined gypsum, 5-15 parts of cement, 50-75 parts of sand, 8-20 parts of fly ash, 1-5 parts of mineral powder, 1.5-3 parts of re-dispersible latex powder, 0. 2-0.5 parts of a water-retaining agent, 0.5-3 parts of an extender, 0.5-3 parts of an activator, 0.1-0.3 parts of polypropylene fiber, 0.15-0.2 parts of a water reducing agent, 0.2-0.5 parts of a waterproof agent, and 0.02-0.2 parts of a retarder. The mortar has the advantages of simple preparation and convenient construction. The prepared caulking anti-crack mortar has high bonding strength, and does not shrink, such that the flatness of a joint is ensured, and cracking and falling phenomena are avoided.

Owner:UNIV OF JINAN

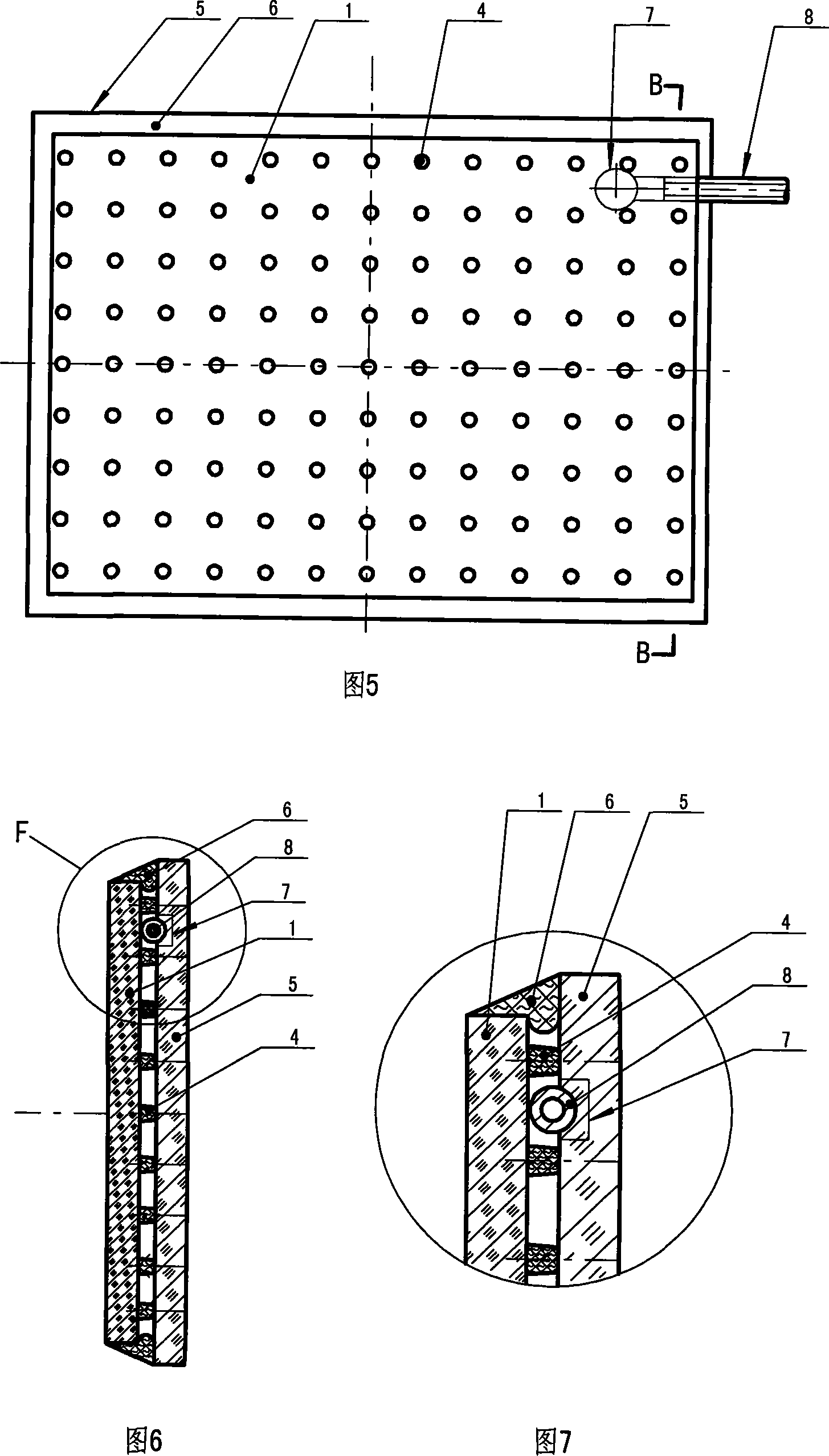

Method for preparing vacuum glass

ActiveCN101215076AImprove molding qualityImprove molding efficiencyGlass reforming apparatusPulp and paper industryHeating furnace

The invention relates to a process for preparing vacuum glass. The steps of the process are, (1) keeping a leaking plate mould flat on a glass substrate, on which die orifices are equispaced and compartmentally prepared, (2) coating the supporting pulp on the leaking plate mould to form backstops which are distributed compartmentally and have the same height, inverting the glass substrate on bottom glass, (3) preparing an opening which is inserted in a suction glass tube on the glass, and adopting supporting pulp to seal edges, (4) putting the glass into a heating furnace and treating, (5) connecting the suction glass with a vacuum device until vacuum degree in the vacuum glass reaches 10-2-10-4Pa, hot fusing and sealing the glass tube, thereby obtaining vacuum glass finished products. The invention has the advantages of simple preparation technology, easy operation, lower investment, lower rejection rate, perfect quality and higher production efficiency. Further, the invention adopts mechanical separator system to replace manual operation, which effectively reduces costs of vacuum glass and is applicable for industrial production.

Owner:天津沽上创新真空玻璃有限公司

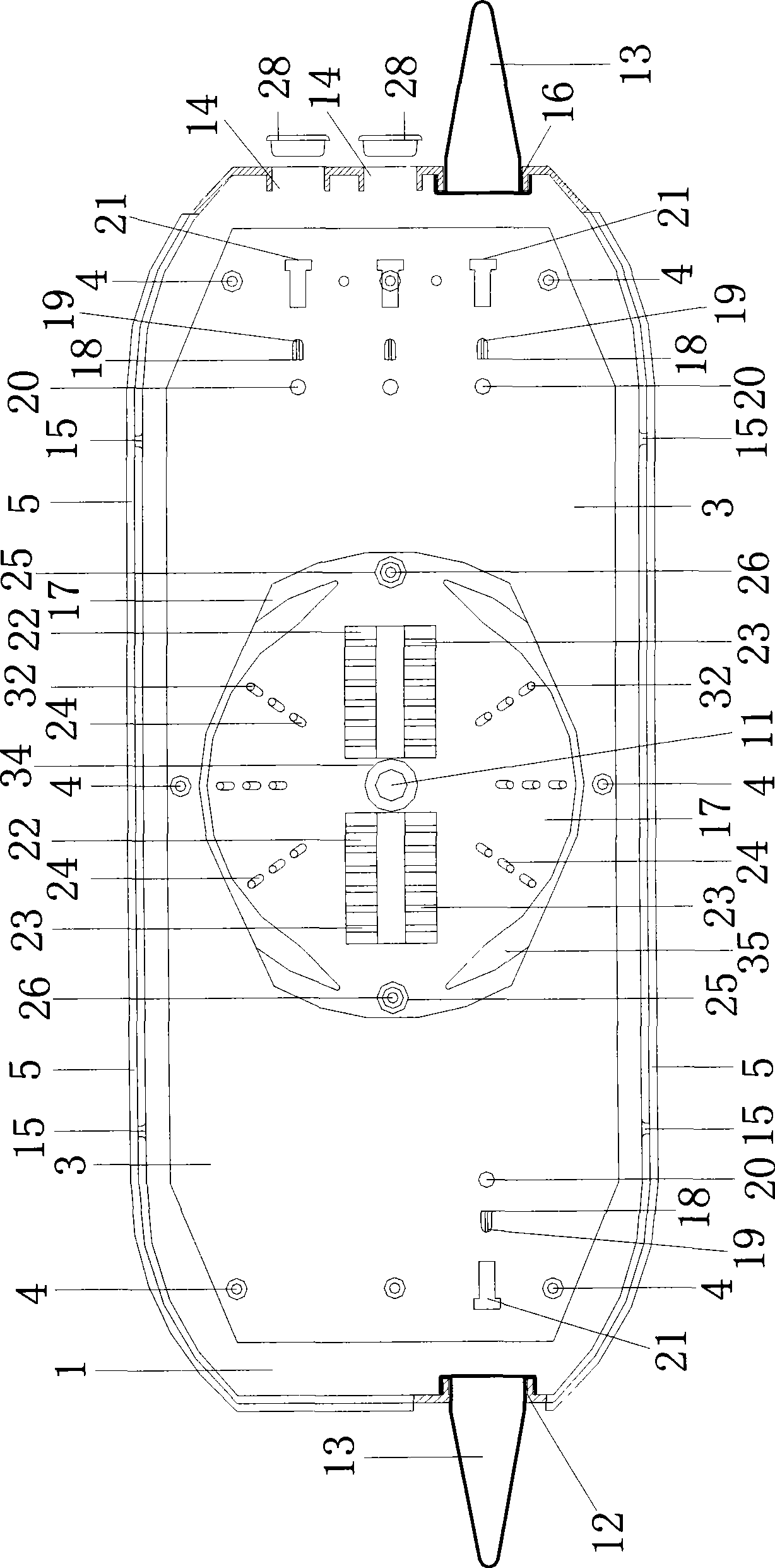

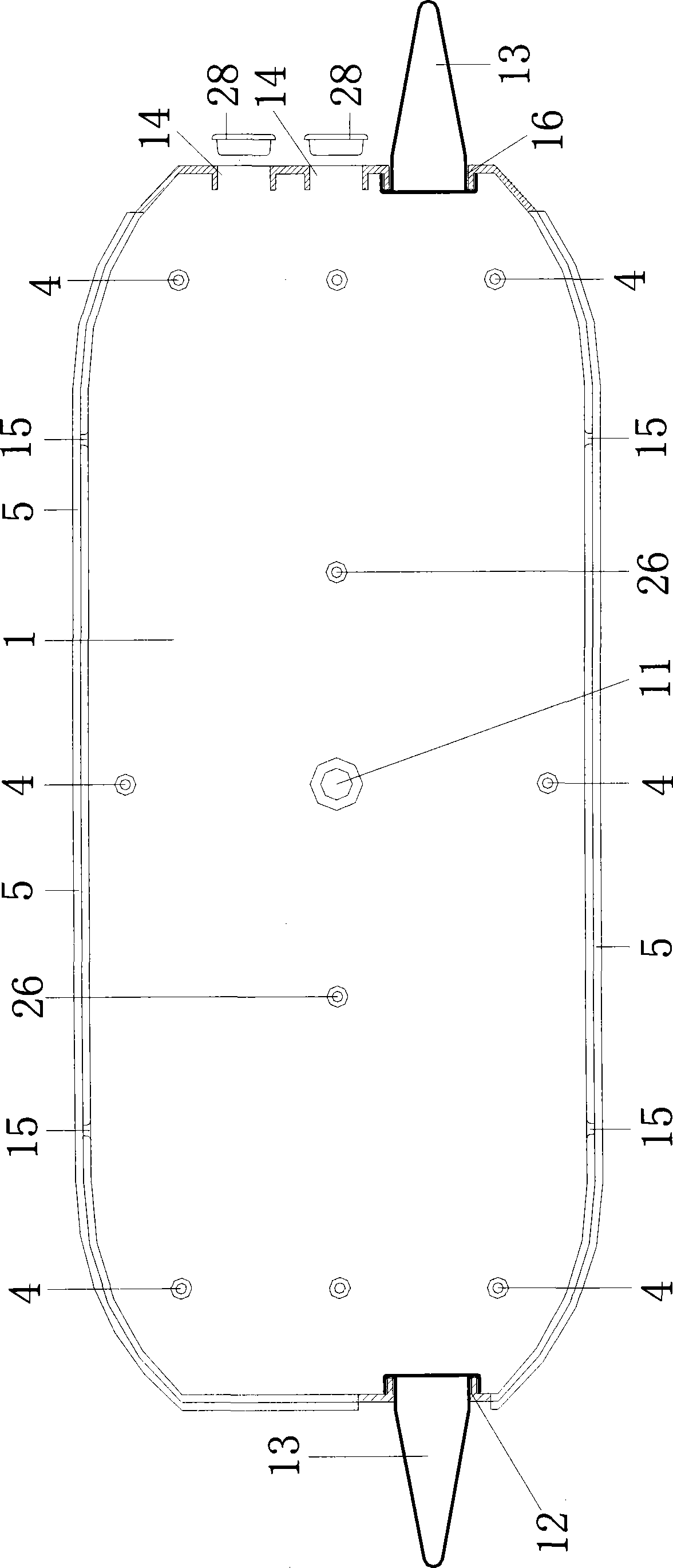

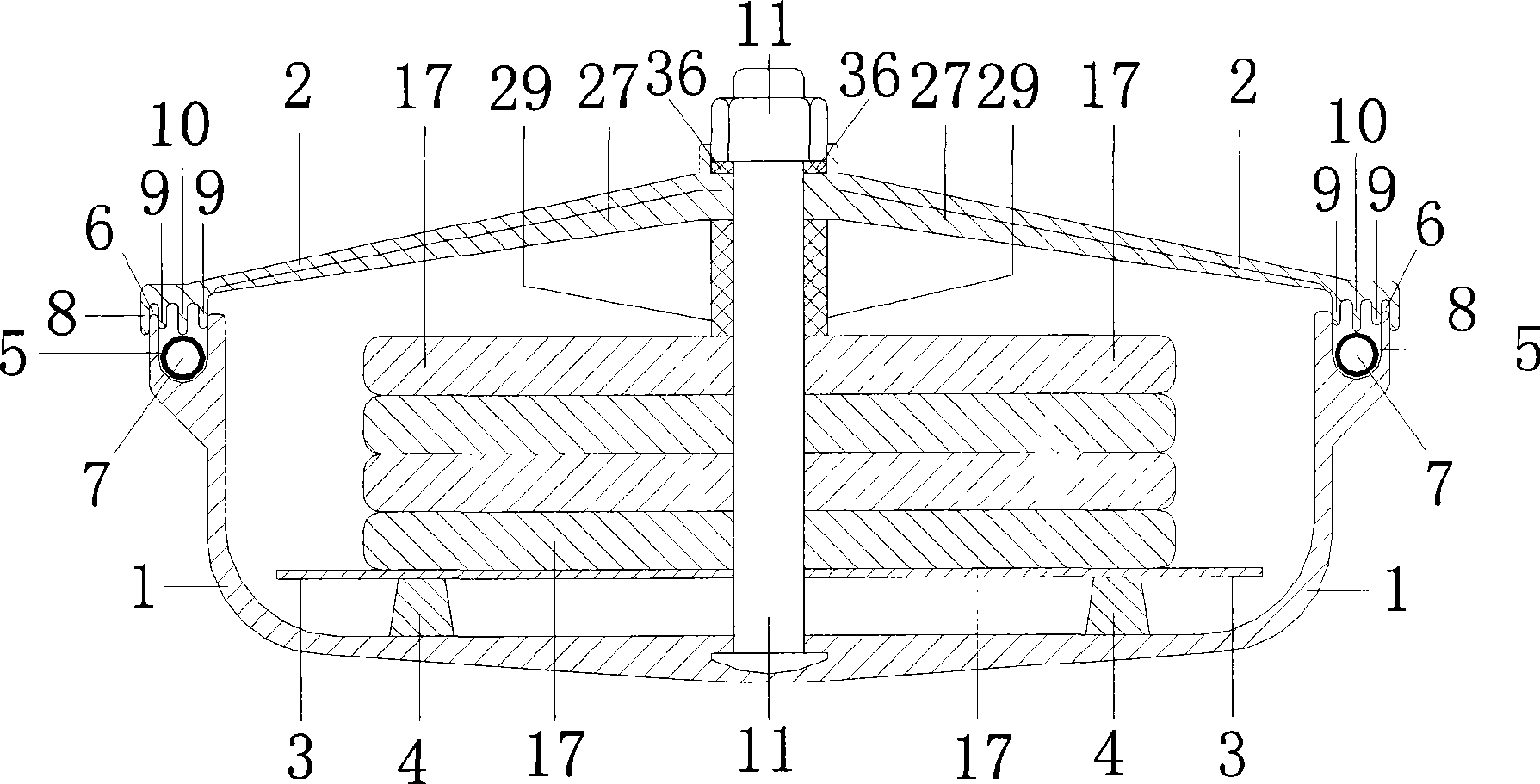

Optical cable switching box, its production method and use method

InactiveCN101504479AStrong penetrating powerImprove sealingFibre mechanical structuresFiberSwitch box

The invention relates to a cable splice closure and a manufacturing method and the use of the same. The cable splice closure consists of a splice closure body, a splice general support bracket, a fiber holding plate and a splice closure upper cover, wherein the whole shape of the splice closure body is a box shape; the box of the splice closure body accommodates the splice general support bracket and the fiber holding plate; the splice closure body is provided with a sealing groove, an general support bracket pillar, a fiber holding plate positioning pillar, a closing and fastening bolt structure, a cable entrance hole, a cable exit hole, a covered wire cable exit hole and a preserved hole; the outer side of the upper bead of the splice closure body is provided with the sealing groove; the sealing groove surrounds the outer side of the upper bead; the shape of the whole section of the sealing groove is a U shape; an annular hollow sealing strip is placed in the sealing groove; and the outside diameter of the hollow sealing strip is matched with the inside diameter of the sealing groove. The cable splice closure is unique in design concept, reasonable in structure, low in cost, excellent in sealing effect and simple in construction operation, saves labor, improves efficiency, can be used as a pipeline, underground straight buried, overhead, wall attached cable splice closure, is wide in application range, and achieves a multifunction effect.

Owner:天津市千迈电讯器材研制所

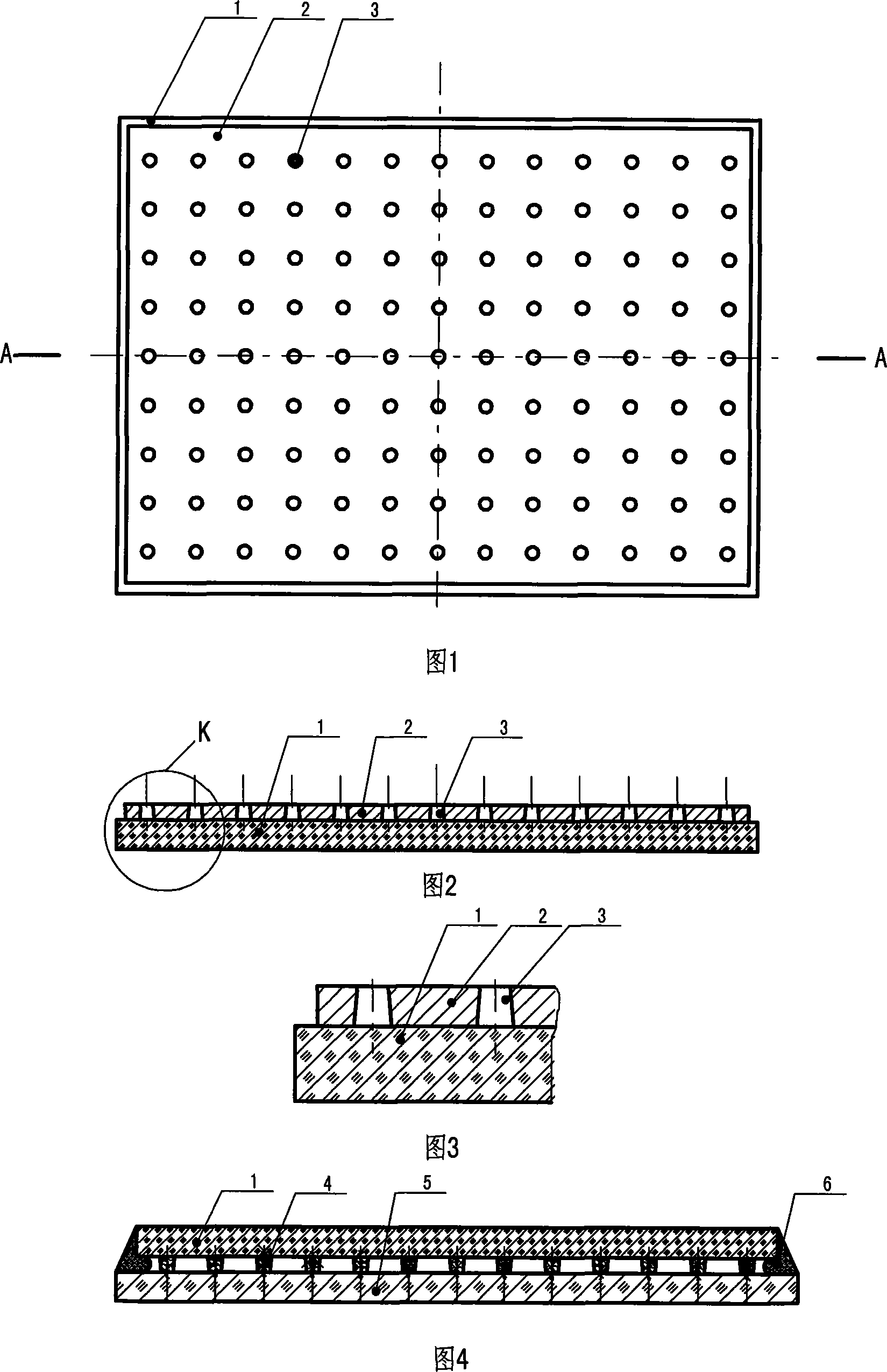

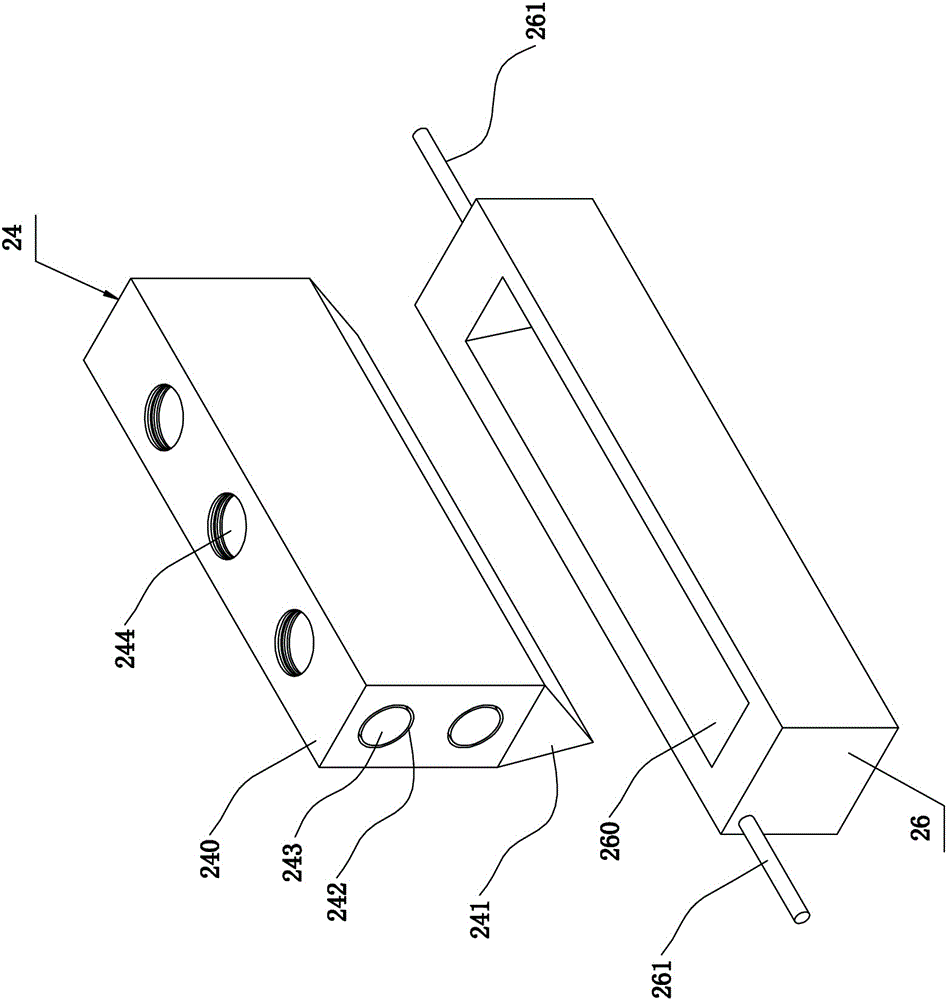

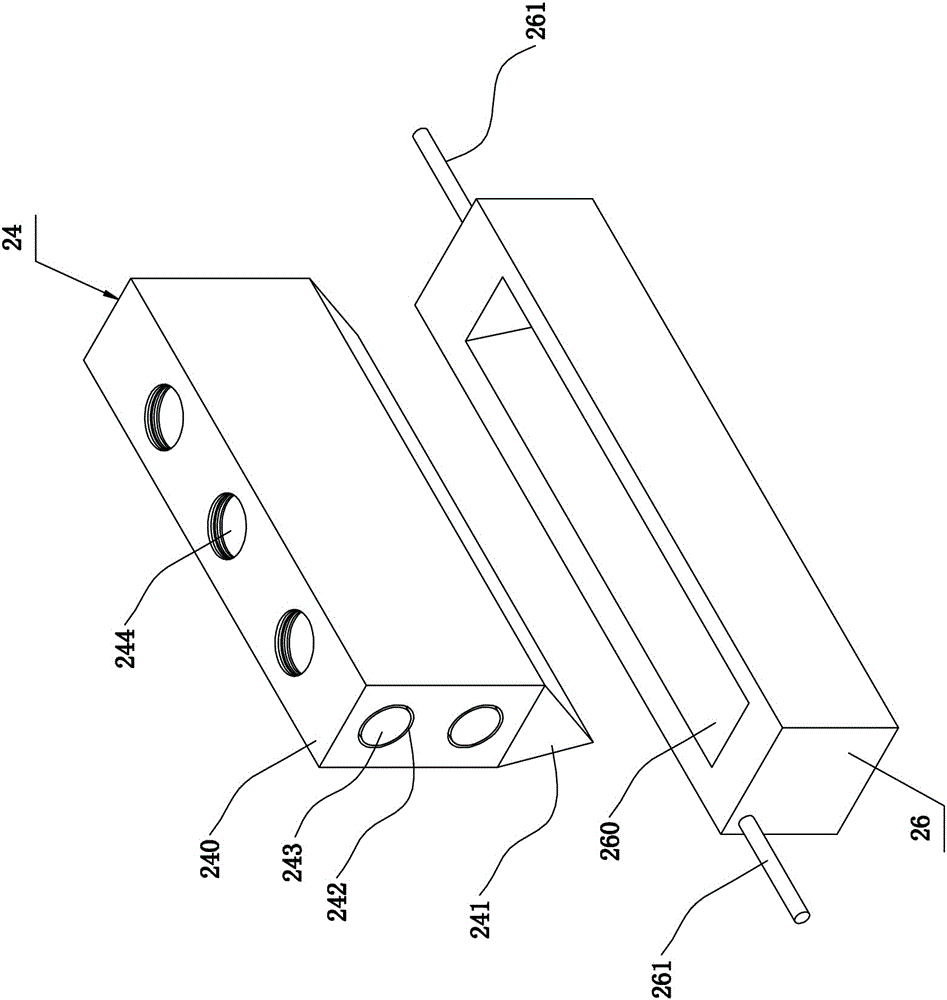

Method and device for electrolytic machining of massive array tiny pits through wedge-shaped runner

ActiveCN103600144AImprove uniformity and machining accuracyHigh bonding strengthMachining electrodesElectrical-based machining electrodesElectric fieldCorrosion

The invention discloses a method and a device for electrolytic machining of massive array tiny pits through a wedge-shaped runner, and belongs to the technical field of electrolytic machining. The method includes processing the surface of a mask plate to enable the surface to fit with the surface of a workpiece anode; fixing a wedge-shaped tool cathode above the mask plate to enable the wedge-shaped runner to be formed between the wedge-shaped tool cathode and the mask plate; connecting the workpiece anode and the wedge-shaped tool cathode with an anode and a cathode of a power source respectively; feeding an electrolyte into the wedge-shaped runner, wherein the electrolyte reaches the surface of the workpiece anode through penetrating group holes in the mask plate; switching on the power source for electrolytic machining. The runner is arranged to be wedge-shaped, so that electric field intensity and electrolyte flowing speed are enabled to be progressively increased along the direction of the runner, both corrosion strength and speed of a workpiece are enabled to tend to be uniform, and uniformity and machining accuracy of electrolytic machining are improved. A PDMS (polydimethylsiloxane) template is taken as the mask plate, bonding strength of the mask plate and the workpiece anode can be guaranteed, stray corrosion, of the electrolyte, to places around a machining area can be effectively reduced, and locality and uniformity of electrolytic machining can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Bag making machine hot-sealing and hot-pressing mechanism capable of working stably

The invention discloses a bag making machine hot-sealing and hot-pressing mechanism capable of working stably. The mechanism comprises a fixing frame body, two guide sleeves, pull rods, a cutter fixing frame and a hot-sealing cutter. The upper ends of the pull rods are fixedly connected to the two ends of the cutter fixing frame respectively and each provided with an upper end abutting portion. The side wall of the upper portion of each pull rod is sleeved with a compression spring. The upper end and the lower end of each compression spring are connected to the corresponding upper end abutting portion and the top of the corresponding sleeve respectively in an abutting mode. At least one pull rod penetrates through the corresponding guide sleeve and then is in transmission connection with an intermittent motion mechanism. According to the bag making machine hot-sealing and hot-pressing mechanism, it can be ensured that the hot-sealing and hot-pressing positions and motion strengths of the hot-sealing cutter for air bubble films or pearl wool films under the hot-sealing and hot-pressing cutter are consistent all the time, and the hot-sealing cutter will not shift even if hot-sealing and hot-pressing are frequently and constantly carried out; accordingly, the working efficiency of the bag making machine hot-sealing and hot-pressing mechanism is greatly improved, and the service life of the bag making machine hot-sealing and hot-pressing mechanism is greatly prolonged.

Owner:洪东坡

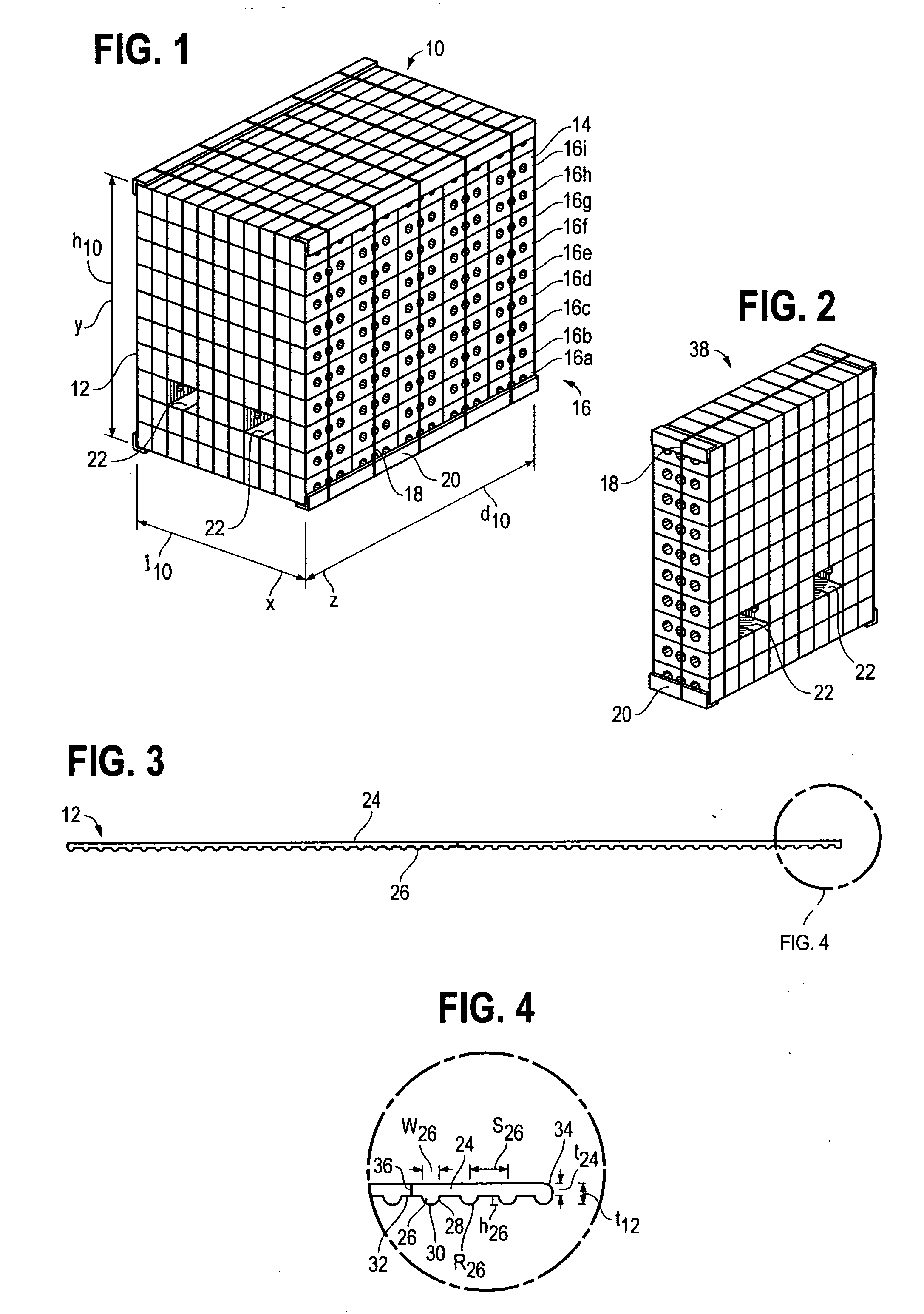

Polymeric void-board

An extruded polymeric void-board is configured for placement between adjacent horizontal layers of bricks to maintain an opening in a lower layer of the bricks. The void-board is formed as a relatively thin planar element having first and second surfaces. A plurality of parallel ribs extend from and generally transverse to the first side. The ribs have a predetermined height to width ratio and have a height that is less than a thickness of the planar element. The ribs being formed parallel to one another. A method for forming a bundle of bricks with the void-board is also disclosed.

Owner:ILLINOIS TOOL WORKS INC

Bag machine with improved structure

ActiveCN104985864AThere will be no offsetSimple structureBox making operationsPaper-makingEngineeringMechanical engineering

A bag machine with an improved structure comprises a convey assembly, a feed assembly, and a hot-sealing hot-pressing mechanism; the hot-sealing hot-pressing mechanism comprises a fixed rack, two guide sleeves, pull rods, a cutter fixing rack and a hot-sealing cutter; tops of each pull rod are respectively fixed on two ends of the cutter fixing rack; each pull rod is provided with a top abut portion; an upper side wall of each pull rod is sleeved by a compression spring; at least one pull rod penetrates the corresponding guide sleeve and is in transmission connection with an intermittence motion mechanism, wherein the intermittence motion mechanism is used for controlling the cutter fixing rack to complete up-down mobile motions in cycle in a fixed time. The bag machine can ensure the hot-sealing cutter to carry out hot-sealing hot-pressing for right blow bubble films or pearl cotton films with consistent positions and motion forces in each time; even under frequent continuously hot-sealing hot-pressing, no hot-sealing cutter offset condition is generated, thus greatly improving work efficiency and life of the bag machine.

Owner:洪东坡

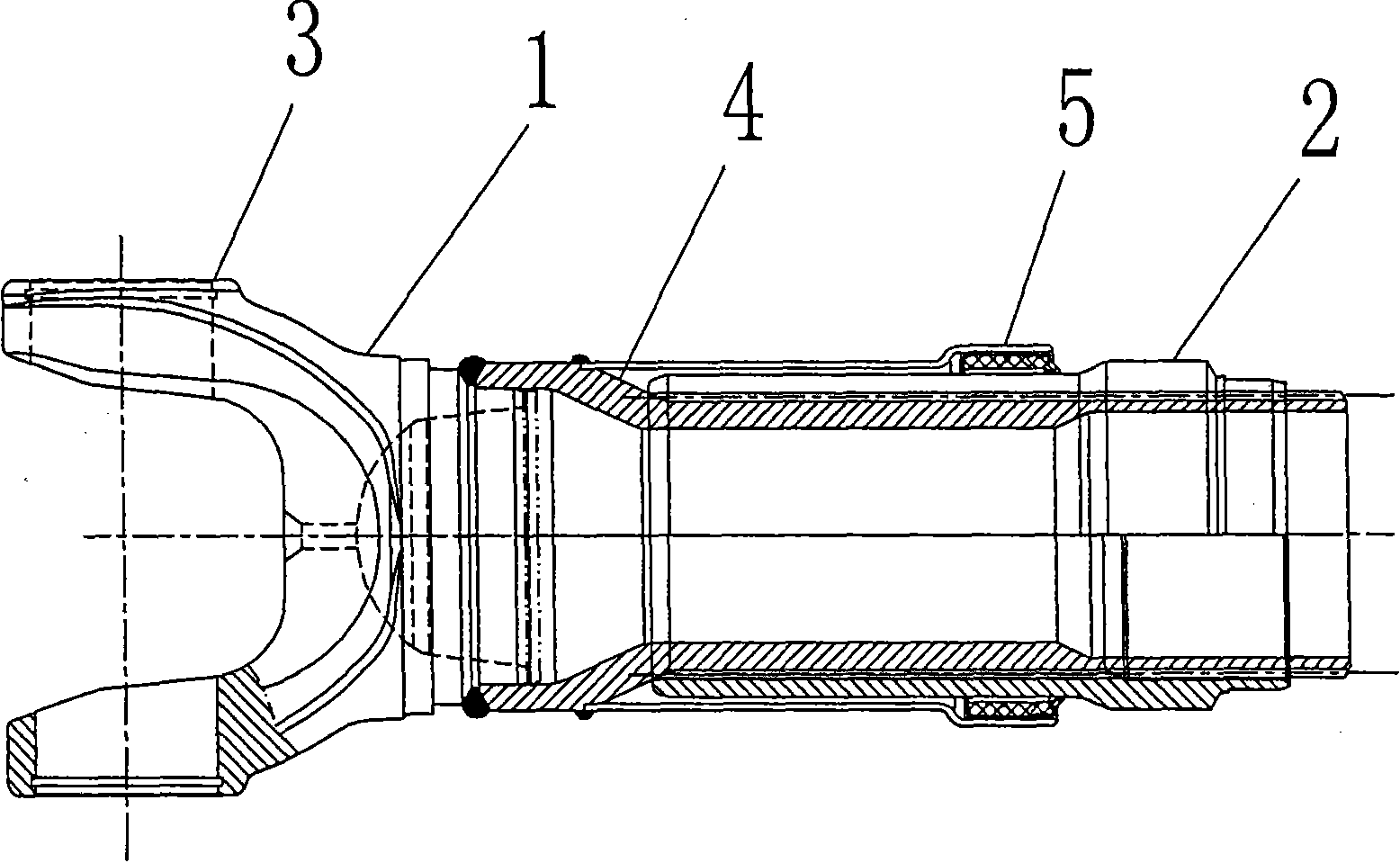

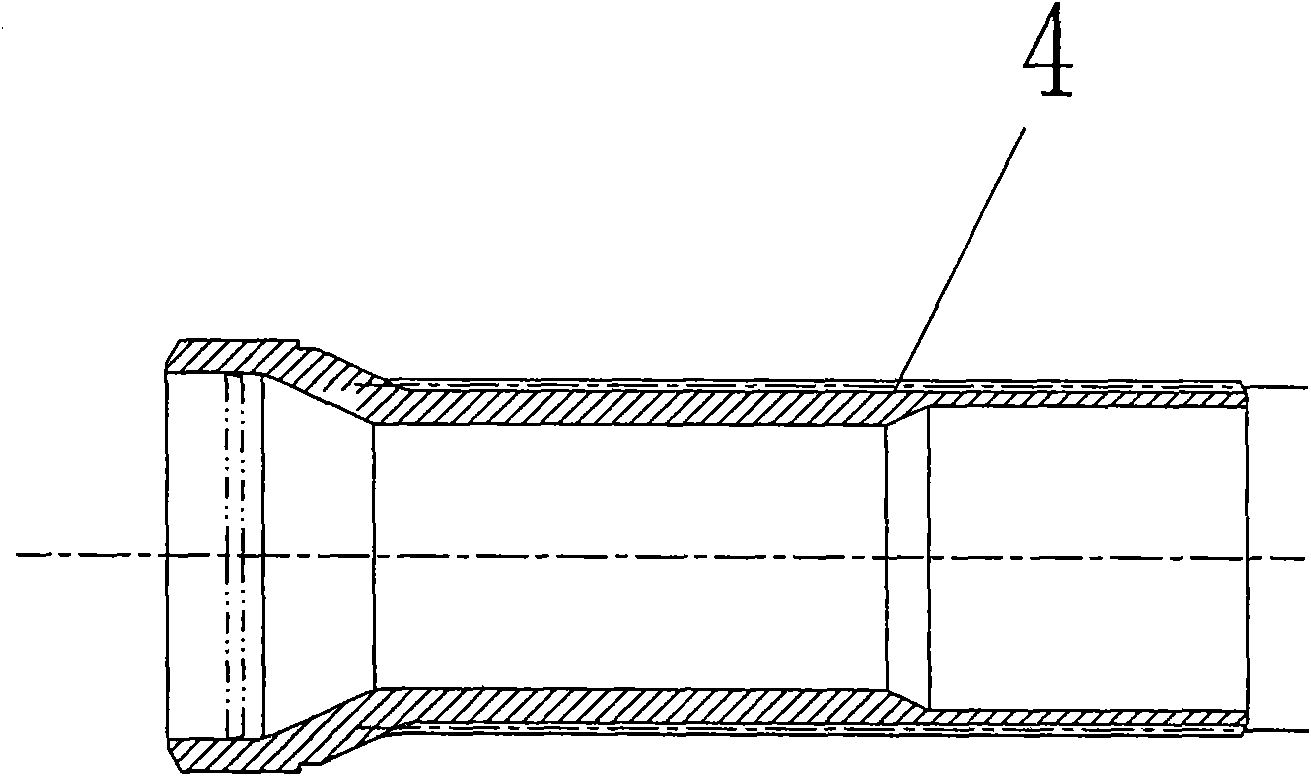

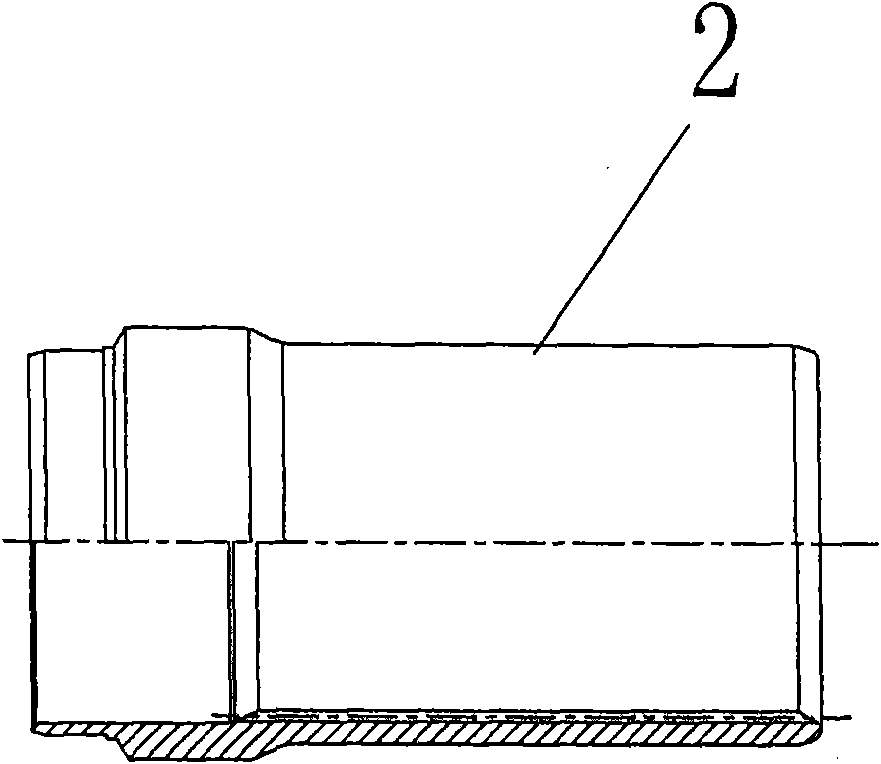

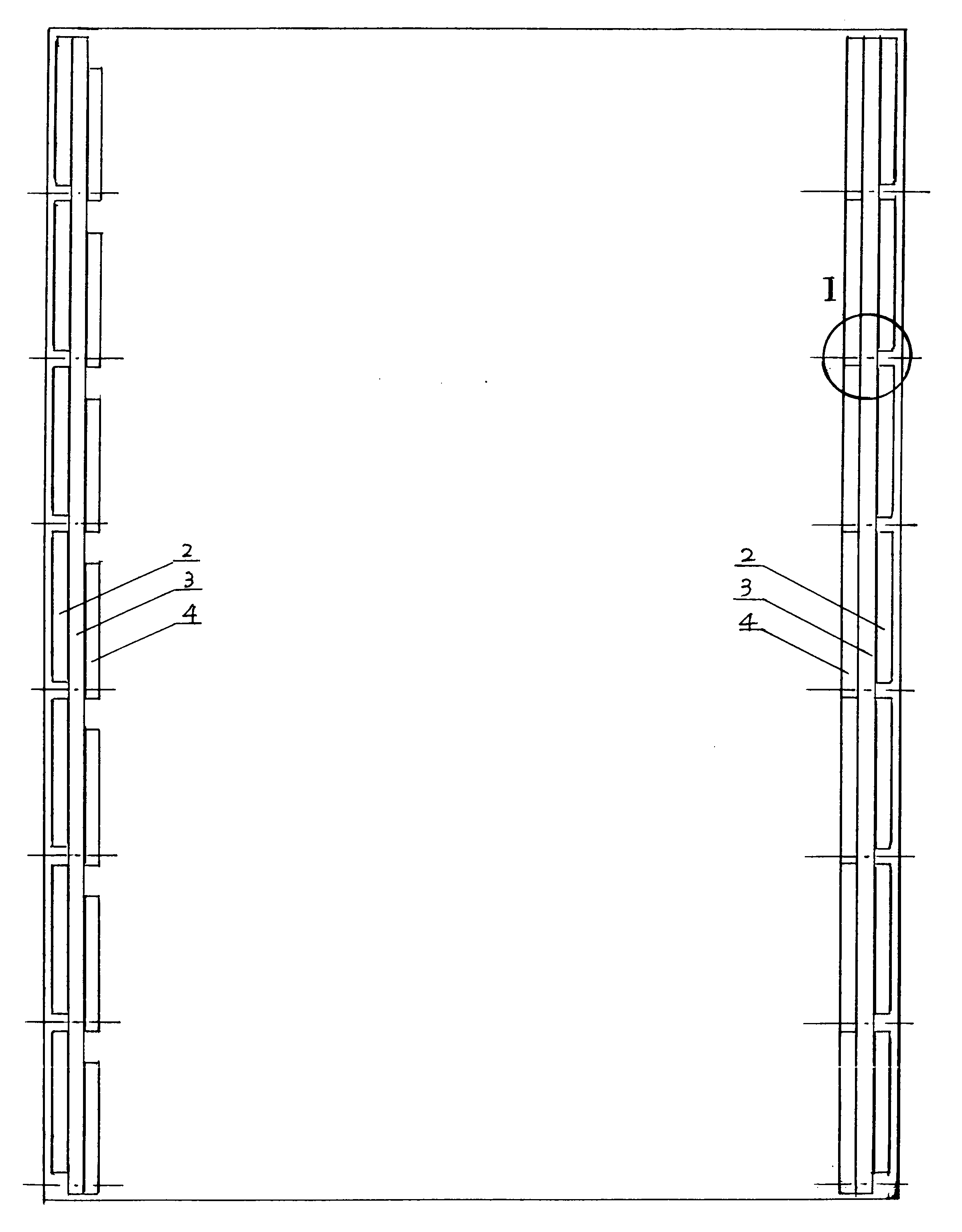

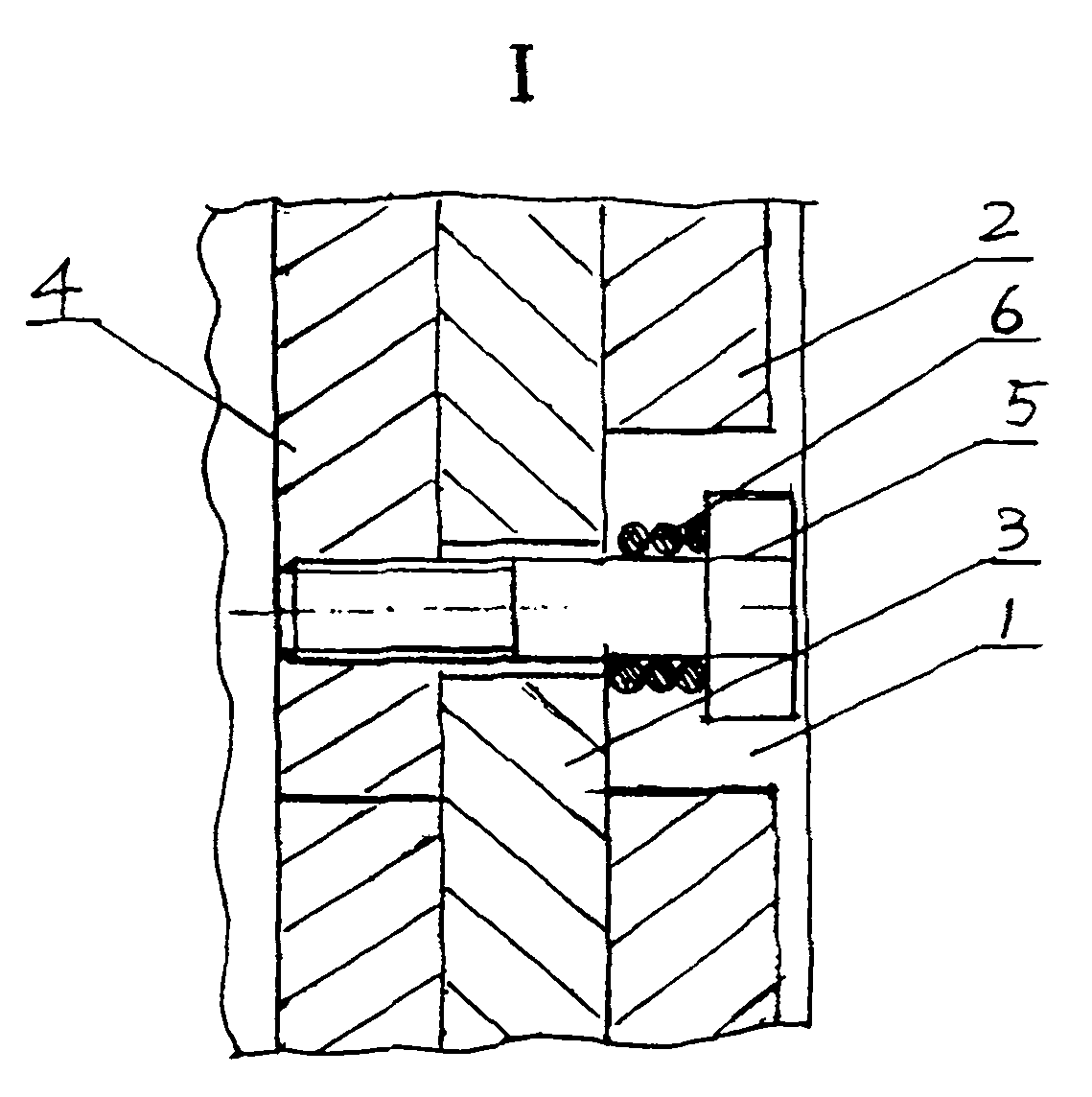

Spline pair of hollow shaft fork

InactiveCN101852251AReduce weightConsistent stressYielding couplingCouplings for rigid shaftsEngineeringMechanical engineering

The invention relates to a spline pair of a hollow shaft fork. The spline pair mainly comprises a spline shaft fork and an internal splined sleeve, wherein the spline shaft fork consists of a welding fork and an external splined sleeve; the internal splined sleeve is sleeved outside the external splined sleeve and matched with the external splined sleeve; and the external splined sleeve has a hollow structure. The spline pair has the advantages that: the weight for the raw materials of the spline fork can be reduced by 37.7 percent; and after a mathematical model is established to perform static stress analysis by using CAE software, the stress is only increased by about 5 percent while the weight of the hollow spline shaft is reduced by 37.7 percent. The fact shows that the strength of the hollow spline shaft fork is substantially the same as that of a solid spline shaft fork while the weight is greatly reduced, namely the hollow spline shaft fork has higher comprehensive performance; and meanwhile, the structure ensures higher working performance for the spline pair.

Owner:WANXIANG QIANCHAO TRANSMISSION SHAFT +1

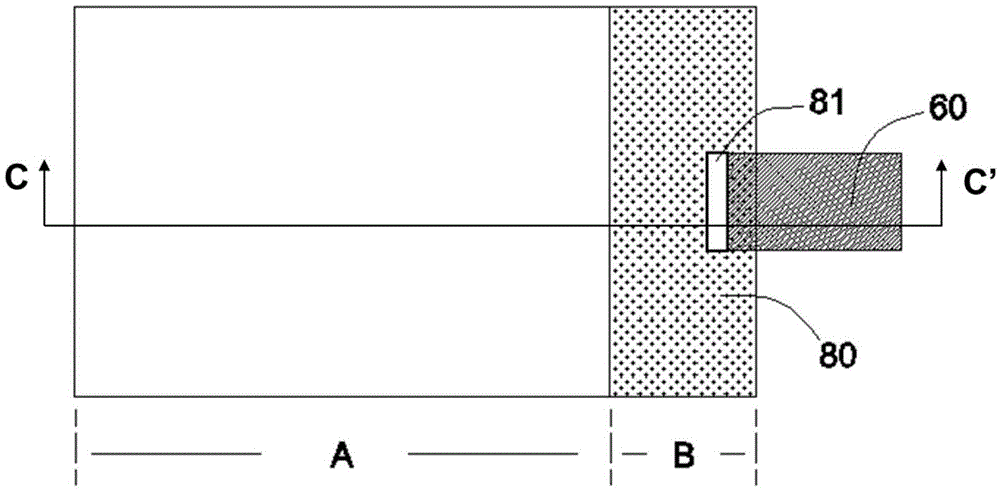

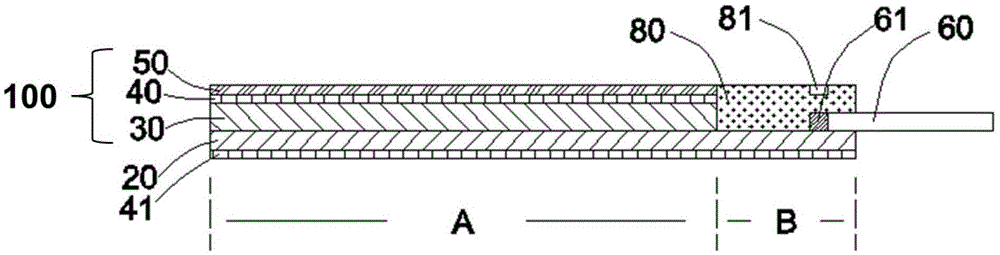

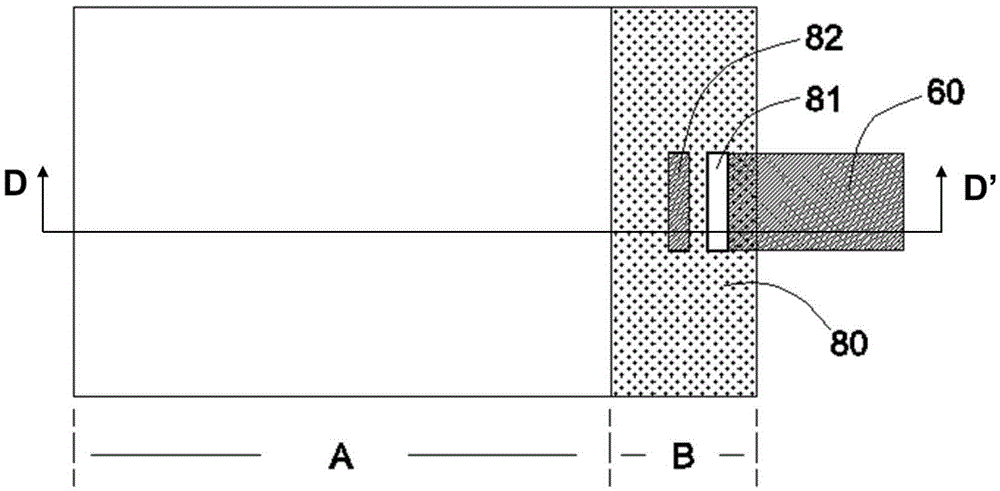

Flexible display panel and manufacturing method thereof and display equipment

ActiveCN105551377AConsistent strengthAvoid breakingIdentification meansManufacturing technologyEngineering

The invention provides a flexible display panel and a manufacturing method thereof and display equipment. The flexible display panel comprises a flexible substrate, a display function layer, an electronic element and a flattening layer; the flexible substrate comprises a display area and a step area arranged on one side of the display area; the display function layer is arranged in the display area arranged on the first face of the flexible substrate, and the electronic element and the flattening layer are arranged in the step area arranged on the first face of the flexible substrate; the surface of the flattening layer is flush with the surface of the display function layer, the electronic element is arranged between the flexible substrate and the flattening layer, the flattening layer comprises a groove, and the groove is overlapped with projection of the electronic element in the direction perpendicular to the flexible substrate. According to the flexible display panel and the display equipment, the phenomenon that damage such as breakage is caused by bending of the flexible display panel can be avoided, the electronic element on the flexible display panel is prevented from being destroyed, and therefore the reliability is improved; meanwhile, the manufacture technology can be simplified, the production efficiency can be improved, and the yield can be increased.

Owner:TIANMA MICRO ELECTRONICS CO LTD +1

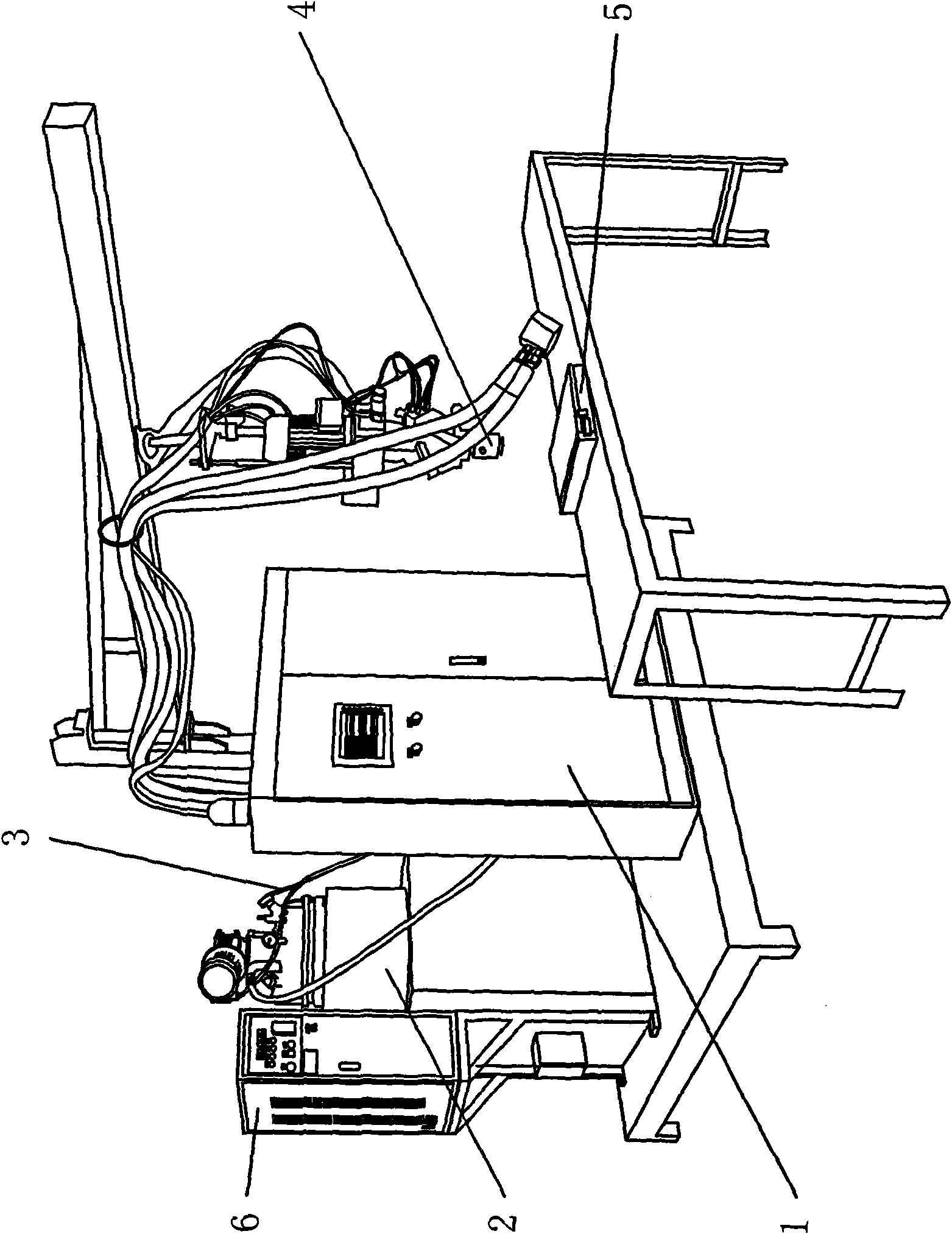

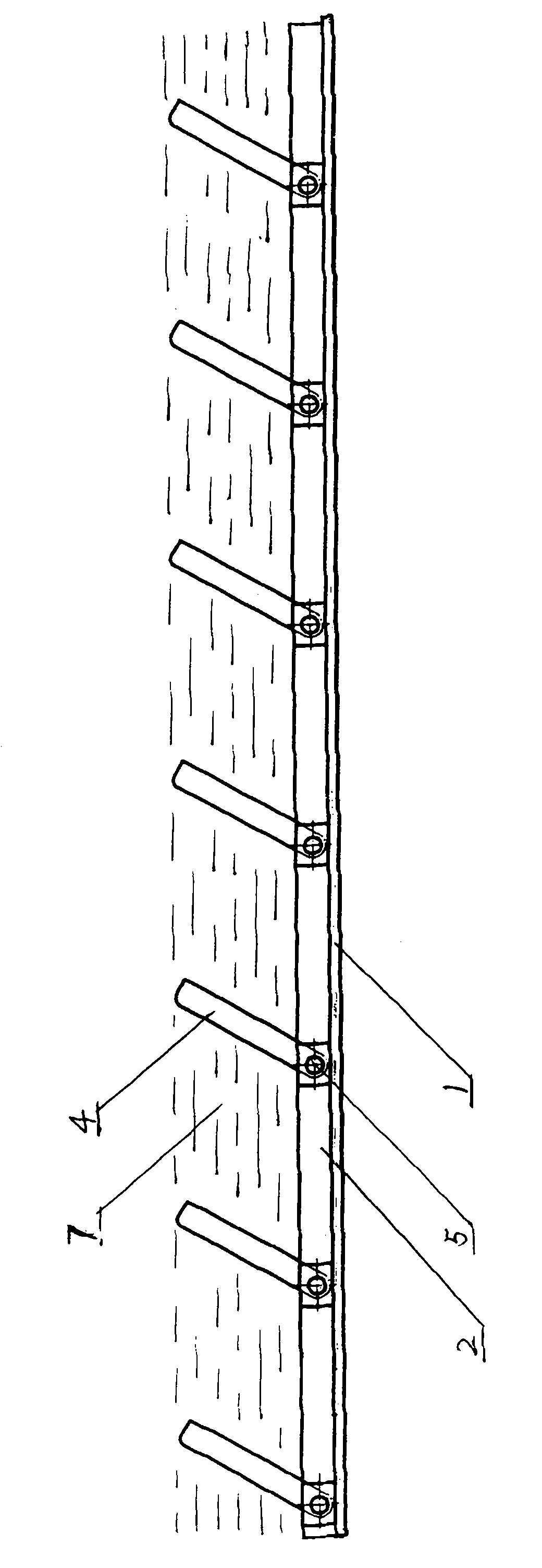

Composite pole formed by winding fiber and manufacturing method thereof

The invention provides a composite pole formed by winding fiber and having high strength and rigidity, good surface finish and low cost. The composite pole comprises the components as follows: 50 to 65 parts of glass fiber, 25 to 35 parts of polyurethane multi-base resin, and 10 to 15 parts of inorganic filling material. The manufacturing method of the composite pole comprises the following steps: the polyurethane multi-base resin and the inorganic filling material are mixed uniformly; the glass fiber is wound on a mould after being steeped with the mixture; and heating and curing are performed to form the composite pole. Under the premise of ensuring the strength of the pole, the inorganic filling material is added in the raw materials; particularly, quartz sand is added to increase the rigidity of the pole, reduce the oscillation angle at the top end of the pole in gale weather and improve the safety of electric wires on the pole; and the method that the glass fiber is steeped with the mixture of the inorganic filling material and the polyurethane multi-base resin through a fiber reinforced plastic winding forming glue injection system instead of a steeping vat improves the strength and the rigidity of the pole and endows the pole with high surface finish.

Owner:天津邦尼鑫龙玻璃钢设备有限公司

Improved structure of polyurethane elastomer casting machine

The invention belongs to the technical field of casting machines, in particular to an improved structure of a polyurethane elastomer casting machine, comprising a controller, a charging bucket and a heater which are both connected with the controller, a stirrer connected with the feed delivery pipe of the discharge bucket and a forming mold. The lower part of the discharge bucket is provided with an insulated cabinet wrapping the lower devices of the discharge bucket; the external surface of a stirrer casing is provided with an external sleeve for charging cooling medium in a sleeving way; the side wall of the forming mold is provided with an opening and articulated with a side cover; and the feed delivery pipe adopts a thin plastic pipe without a heater. The improved structure of the polyurethane elastomer casting machine has the advantages of remarkable heat insulation and energy-saving effects, reduction of the cooling time of raw materials in the stirrer, improvement of production efficiency, attractive shape, consistent strength, saving of the raw materials and waste reduction due to the thin plastic pipe used as the feed delivery pipe and improvement of the production benefits of an enterprise, and is suitably applied to polyurethane elastomer casting machines of the same type.

Owner:ZHEJIANG TIANTAI XIANGHE IND CO LTD

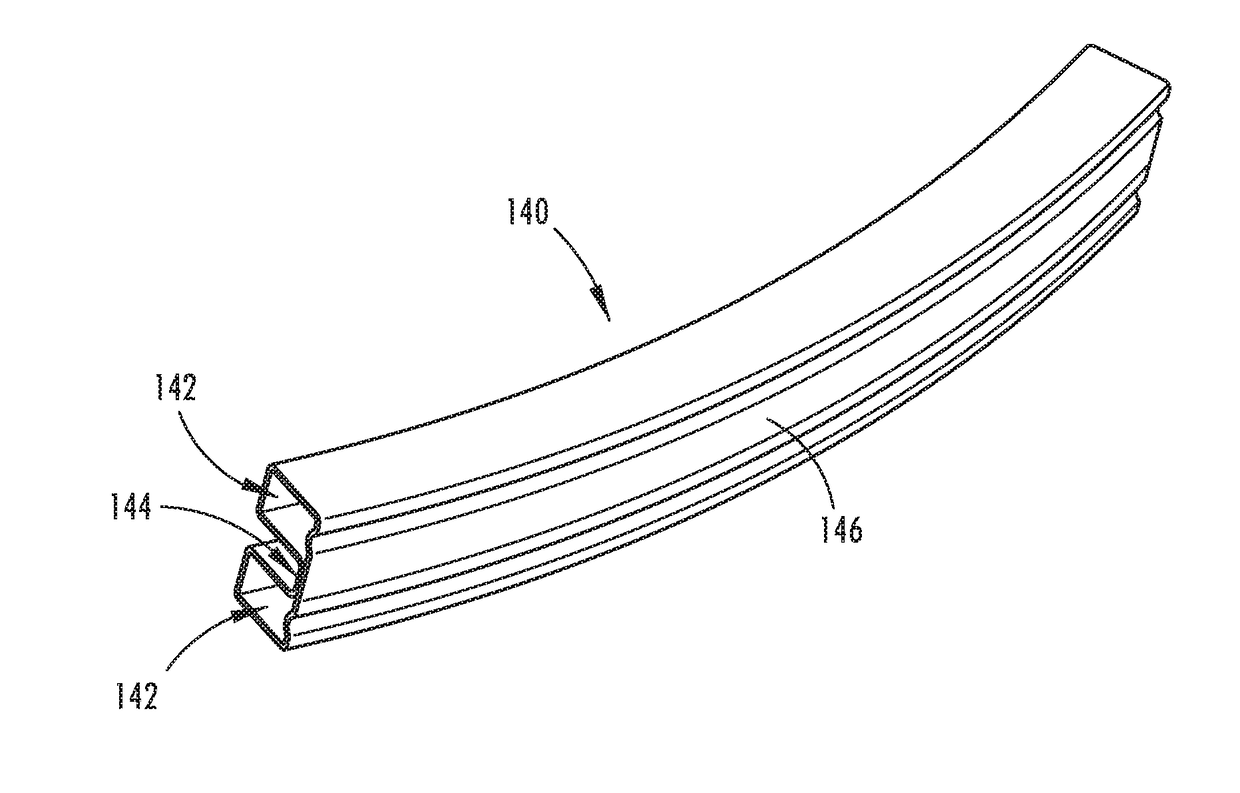

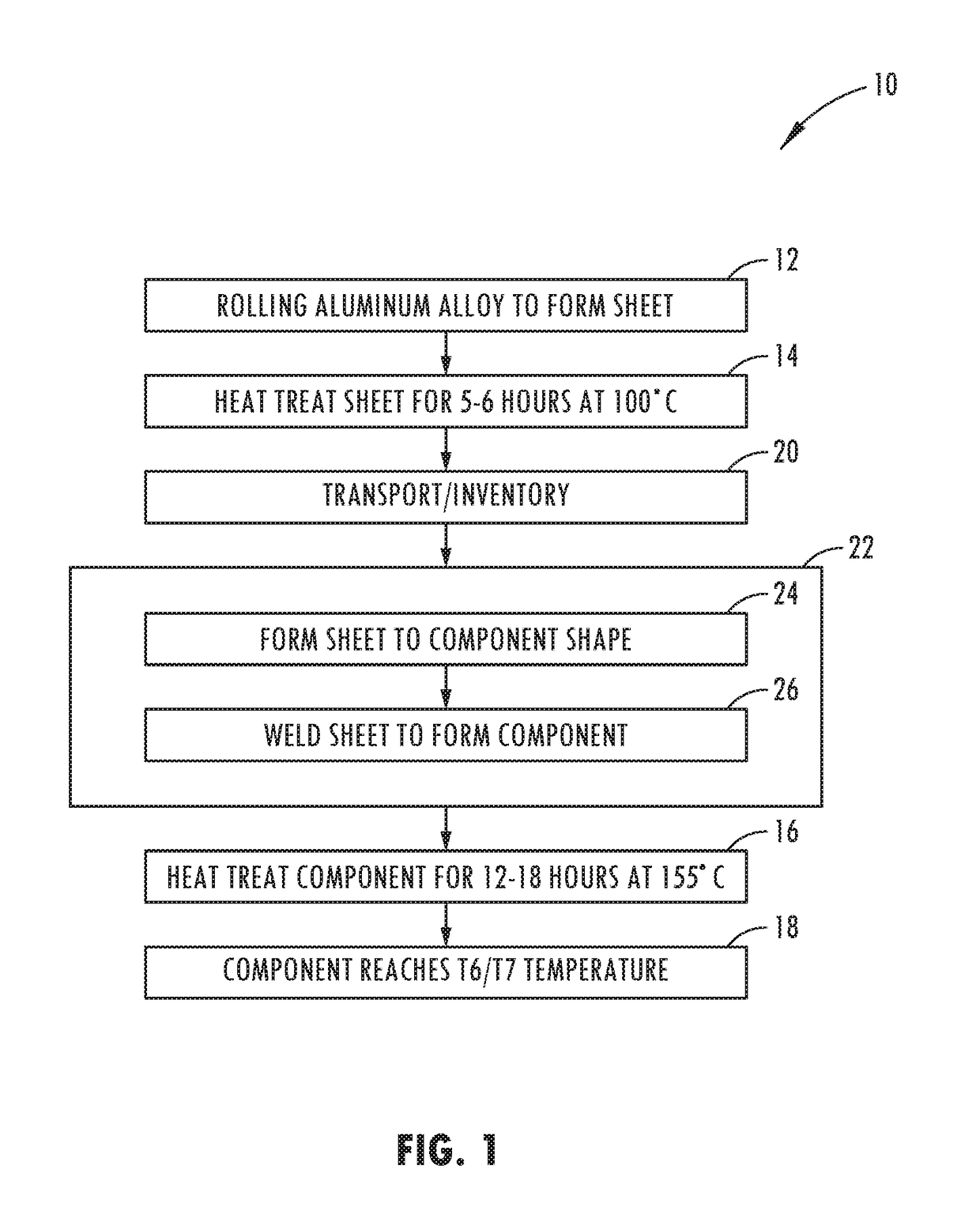

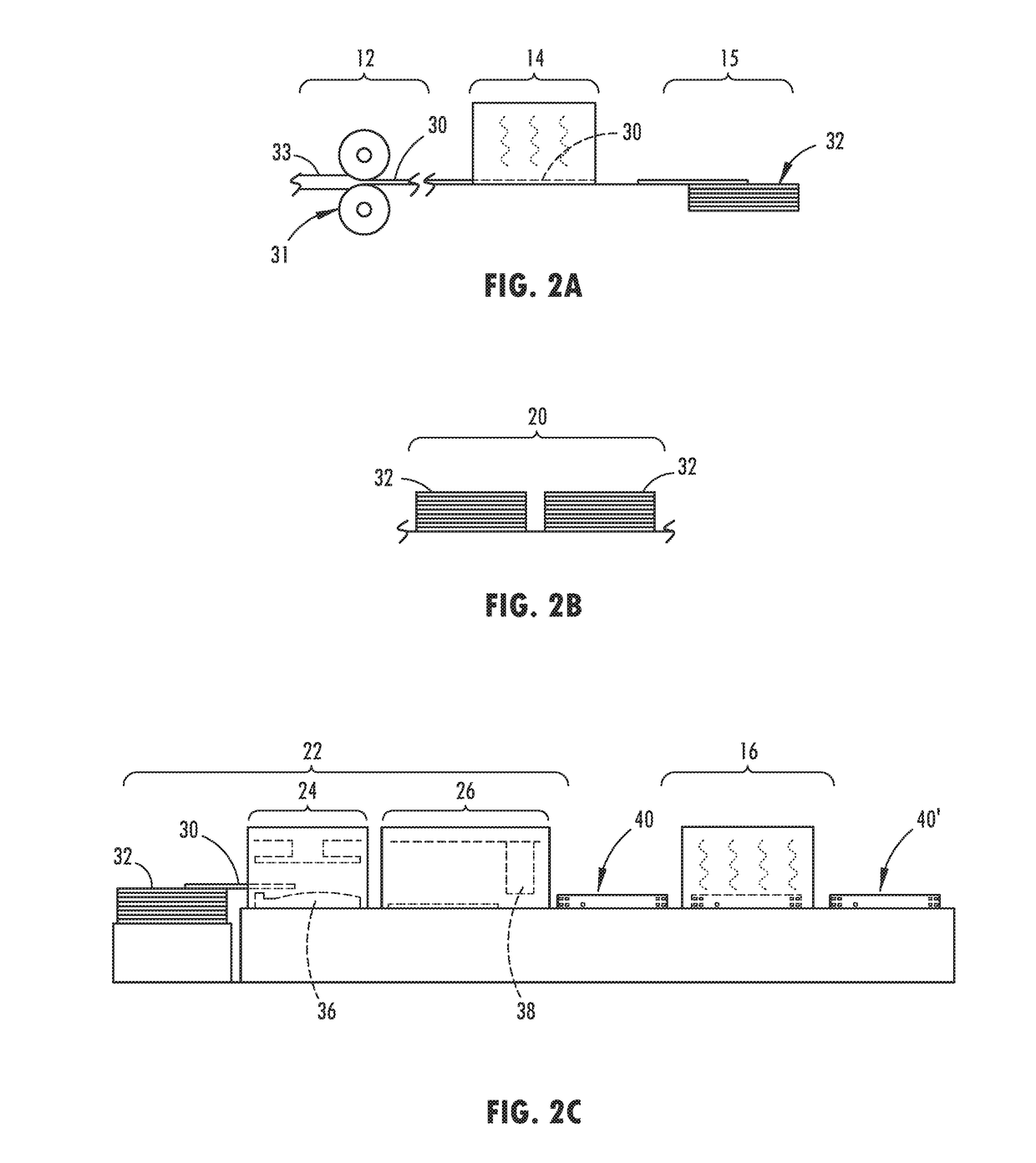

Multi-stage aluminum alloy forming and thermal processing method for the production of vehicle components

ActiveUS20180112298A1Not easy to corrodeConsistent material strengthWelding/soldering/cutting articlesMetal rolling arrangementsMetal sheetHigh intensity

A method of forming and processing a high strength aluminum alloy for the production of a vehicle component includes providing a metal sheet that was rolled from an aluminum alloy. The sheet is heat treated through a first aging step of a set of aging steps that are necessary to achieve a T6 or a T7 temper state. Prior to achieving the T6 or a T7 temper state, the sheet is formed to a desired shape and welded in the desired shape to produce a desired vehicle component. Once formed, the vehicle component is heat treated through a remaining aging step to achieve a T6 or T7 temper state homogeneously throughout the vehicle component.

Owner:SHAPE CORP

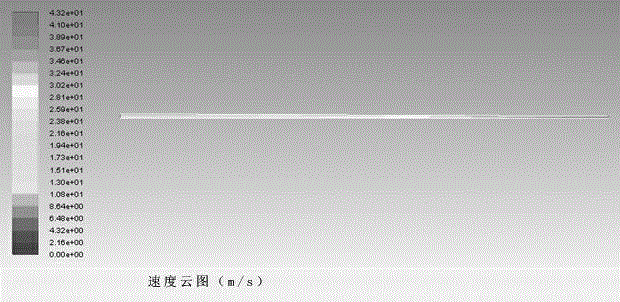

Contact type array tiny pit electrochemical machining method

ActiveCN104001997AConsistent strengthConsistent speedElectrochemical machining apparatusElectrolysisElectrical field strength

The invention provides a contact type array tiny pit electrochemical machining method and belongs to the technical field of electrochemical machining. The contact type array tiny pit electrochemical machining method comprises obtaining photoresist film patterns required to be performed electrolysis from a workpiece positive pole surface through a photographing masking mode; enabling a workpiece positive pole and a tool negative pole to be respectively connected with a positive pole and a negative pole of a power source; immersing the workpiece positive pole in the electrolyte; enabling the tool negative pole to be in contact with a photoresist film on the workpiece positive pole; switching on the power source to perform electrochemical machining. According to the contact type array tiny pit electrochemical machining method, the tool negative pole is in contact with the photoresist film on the workpiece positive pole, so that electric filed distribution in a machining area can be improved, the electric field intensity on the periphery and in the middle of the machining area tends to be consistent, and the array tiny pit electrochemical machining accuracy and locality are obviously improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Swing type multi-rod blocking edge for blanking pad plate

InactiveCN103072178AConsistent densityConsistent strengthLaminationWood working apparatusEngineeringExtrusion

The invention discloses a swing type multi-rod blocking edge for a blanking pad plate, and relates to a multi-rod blocking edge for the blanking pad plate of a multi-layer hot press which is used for recombining a bamboo floor. The multi-rod blocking edge comprises a check block, a bottom rod and a plurality of movable blocking rods, wherein the check block is fixedly arranged on a pad plate and leans against the outside of the bottom rod in a blocking way, and the movable blocking rods are connected with the inside of the bottom rod through bolts. The movable blocking rods can be inclined at any angle or horizontally lie down, when the movable blocking rods horizontally lie down, and adjacent movable blocking rods are in end-to-end connection. The multi-rod blocking edge has the beneficial effects that when the pad plate placed with a blank is pushed between hot press plates of the hot press for compression, the height of the blank is gradually smaller and thinner under extrusion of an upper and lower hot press plates, meanwhile, under extrusion, the inclined angle and the height of each movable blocking rod of the swing type multi-rod blocking edge become smaller, and the vertical height of each movable blocking rod and the height of the blank synchronously become smaller. Since the swing type multi-rod blocking edge with a changeable height is always blocked on two sides of the blank, the blank is enabled not to collapse during a compression process, overall density and strength of a finished plate are enabled to be uniform, the quality is good, collapsed offcut does not occur, saving is realized, and the production cost is lowered.

Owner:QINGDAO GUOSEN MACHINERY

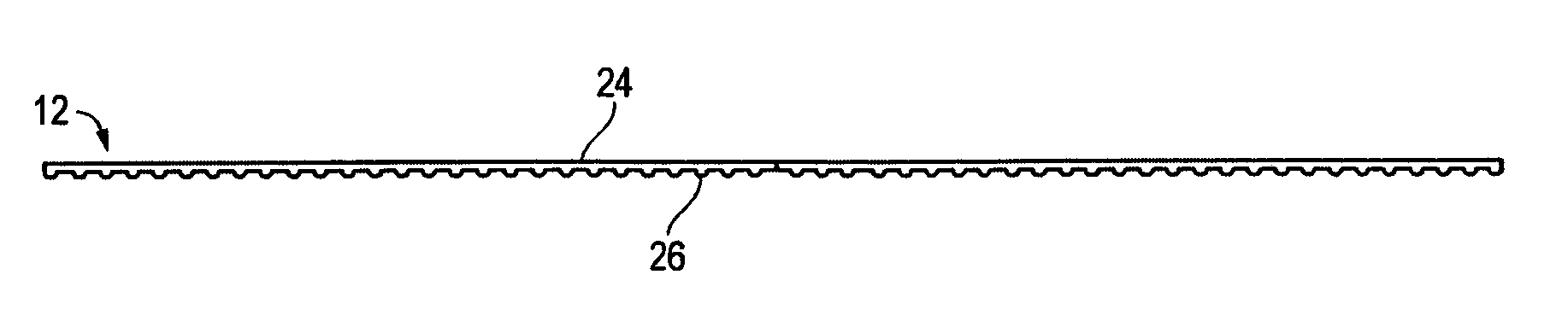

Polymeric void-board

InactiveUS6989184B2Consistent qualityConsistent consistencyStampsWrappersBrickMechanical engineering

An extruded polymeric void-board is configured for placement between adjacent horizontal layers of bricks to maintain an opening in a lower layer of the bricks. The void-board is formed as a relatively thin planar element having first and second surfaces. A plurality of parallel ribs extend from and generally transverse to the first side. The ribs have a predetermined height to width ratio and have a height that is less than a thickness of the planar element. The ribs being formed parallel to one another. A method for forming a bundle of bricks with the void-board is also disclosed.

Owner:ILLINOIS TOOL WORKS INC

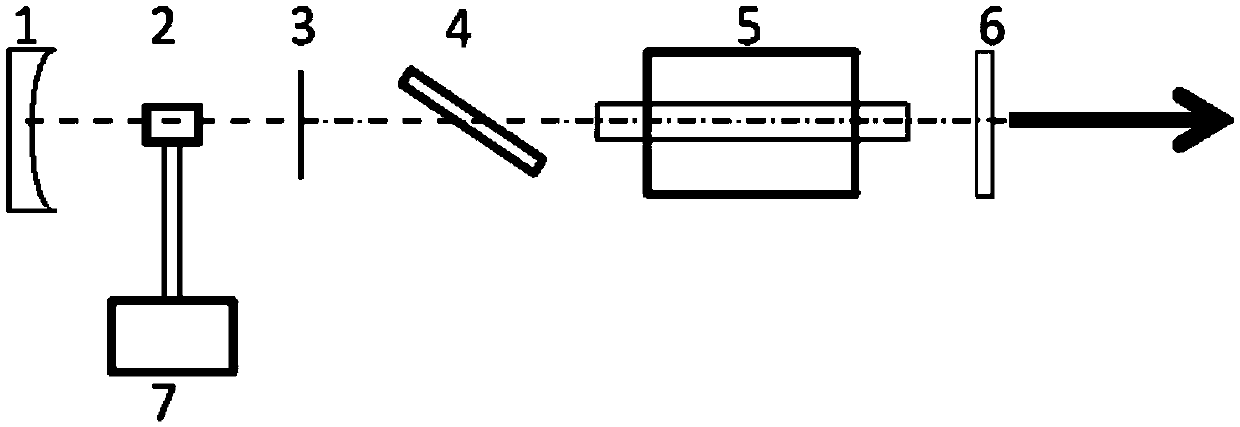

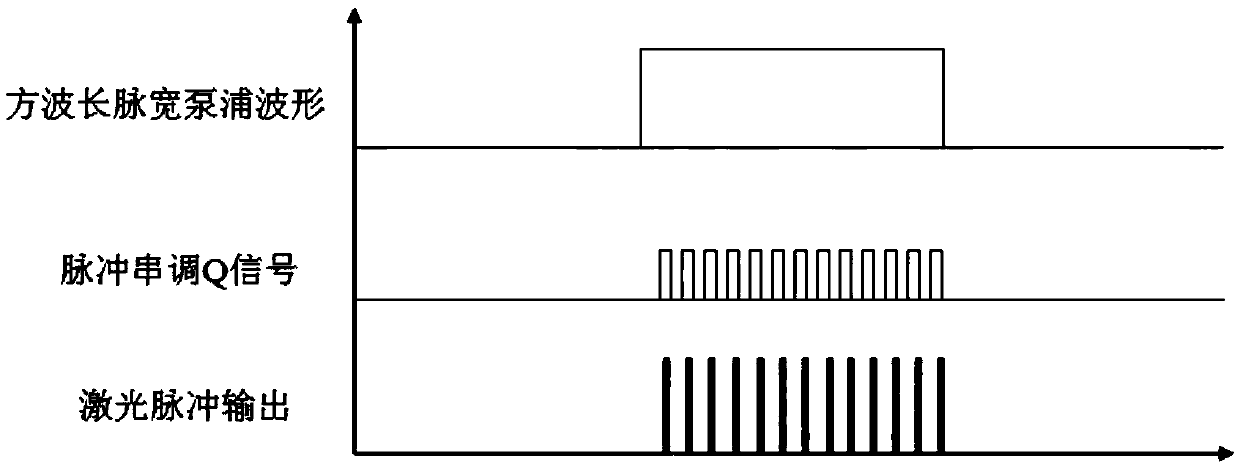

Laser device and method for generating adjustable series pulse by square wave pumping to adjust Q for multiple times

The invention discloses a laser device and method for generating adjustable series pulse by square wave pumping to adjust Q for multiple times, relating to the technical field of laser. The device comprises a Q adjusting unit, and a total reflection mirror, a Q adjusting crystal, a quarter-wave plate, a polaroid, a pumping device and an output mirror which are coaxially and sequentially arranged in the laser beam transmission direction of the device. The method comprises the following steps: enabling a pumping source to start working, and accumulating high energy level electrons, wherein laser pulse output does not occur; when the accumulation of the high energy level electrons reaches a preset value, starting to apply voltage on the Q adjusting crystal, forming laser oscillation in a resonant cavity, and enabling the accumulated high energy level electrons to transit to a low energy level and release photons, thus outputting a first laser pulse; by starting from the output of the first laser pulse, outputting one laser pulse at every time interval t to form a laser pulse string until the pumping source stops working. By adopting the laser device and method, adjustable series pulse laser is generated by using long pulse square wave pumping to adjust Q for multiple times, and output parameter change of a laser and damage to optical devices of the laser are avoided.

Owner:北京镭宝光电技术有限公司 +1

Fabricating method of vacuum glass with uniform stress

InactiveCN101565268AIncrease the support areaAvoid crackingGlass reforming apparatusBreakage rateHeating furnace

The invention relates to a fabricating method of vacuum glass with uniform stress, which comprises the following steps: firstly, arranging bonding points on substrate glass; secondly, bonding low melting glass powder and solid support; thirdly, combining sheet and arranging a seal edge; fourthly, heating the sheet in a heating furnace; and fifthly, vacuumizing and sealing so that the vacuum glass can be obtained. The invention has simple process, convenient operation, low cost, high yield and high production efficiency, reduces the breakage rate to be less than 10 percent and is easy to realize the industrial massive production. The fabricated vacuum glass has uniform and consistent stress, good quality, high strength and long service life, is the creative development on the fabricating process of the vacuum glass, and has great promotion function on the development of the vacuum glass industry.

Owner:左树森

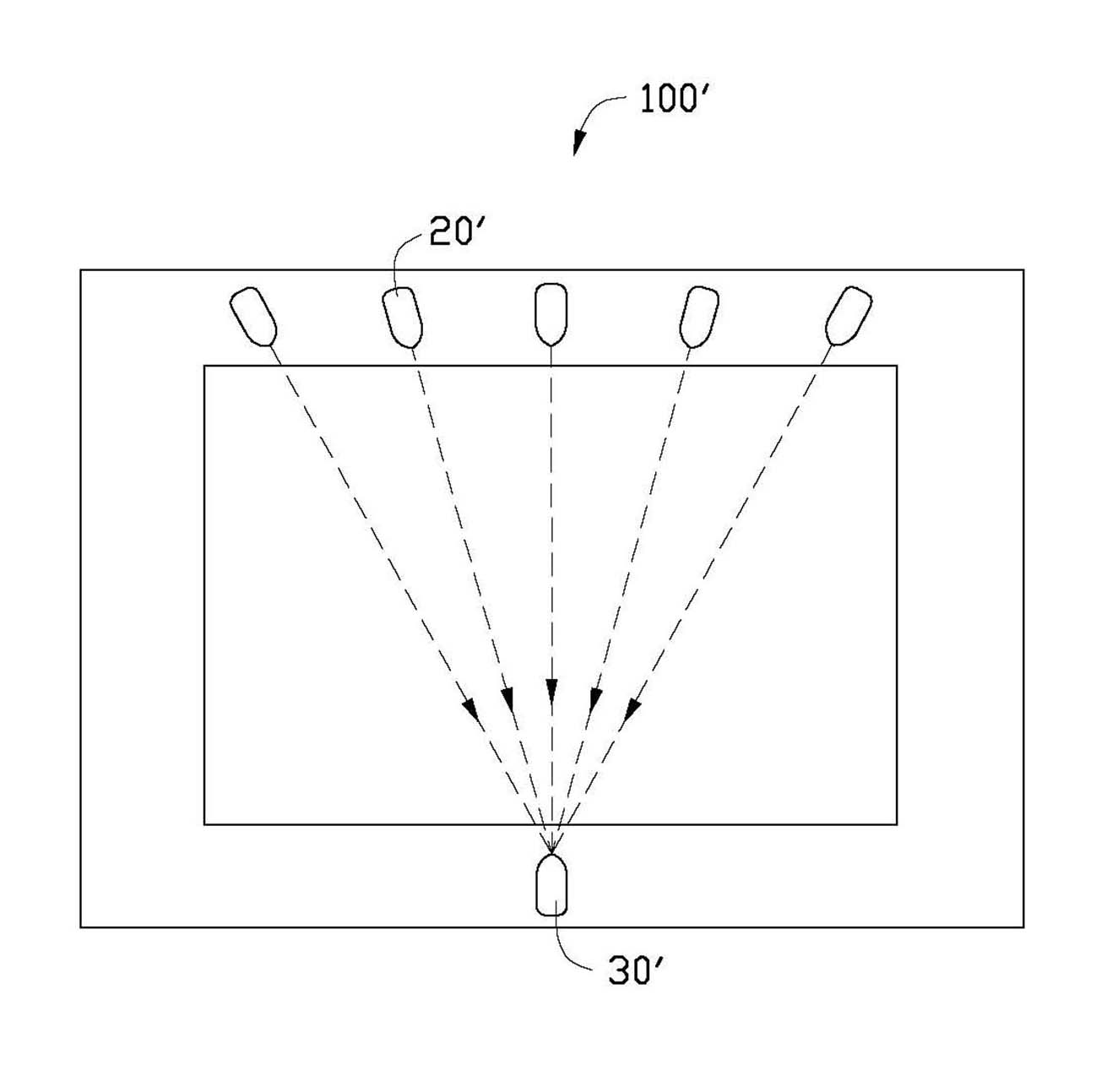

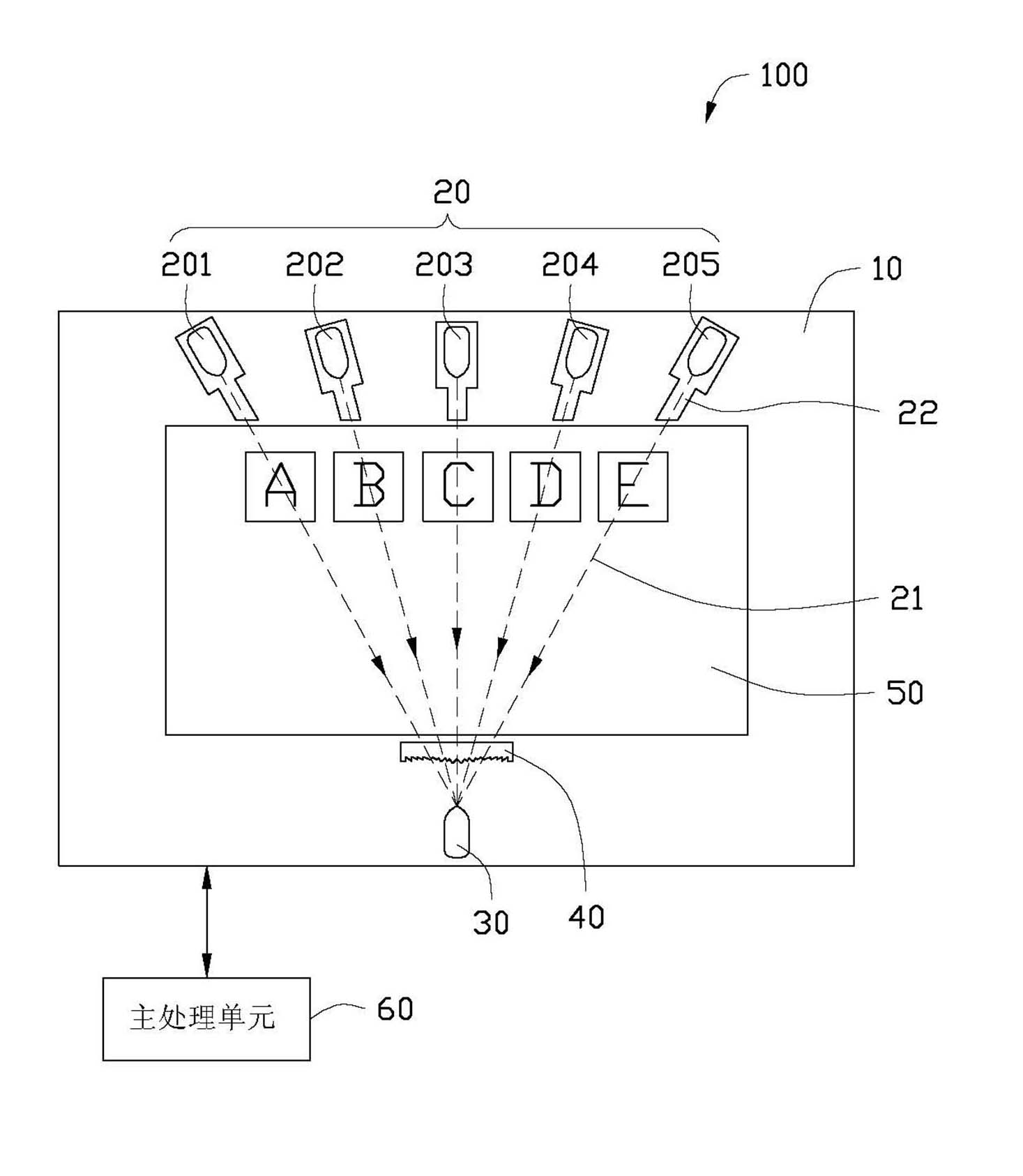

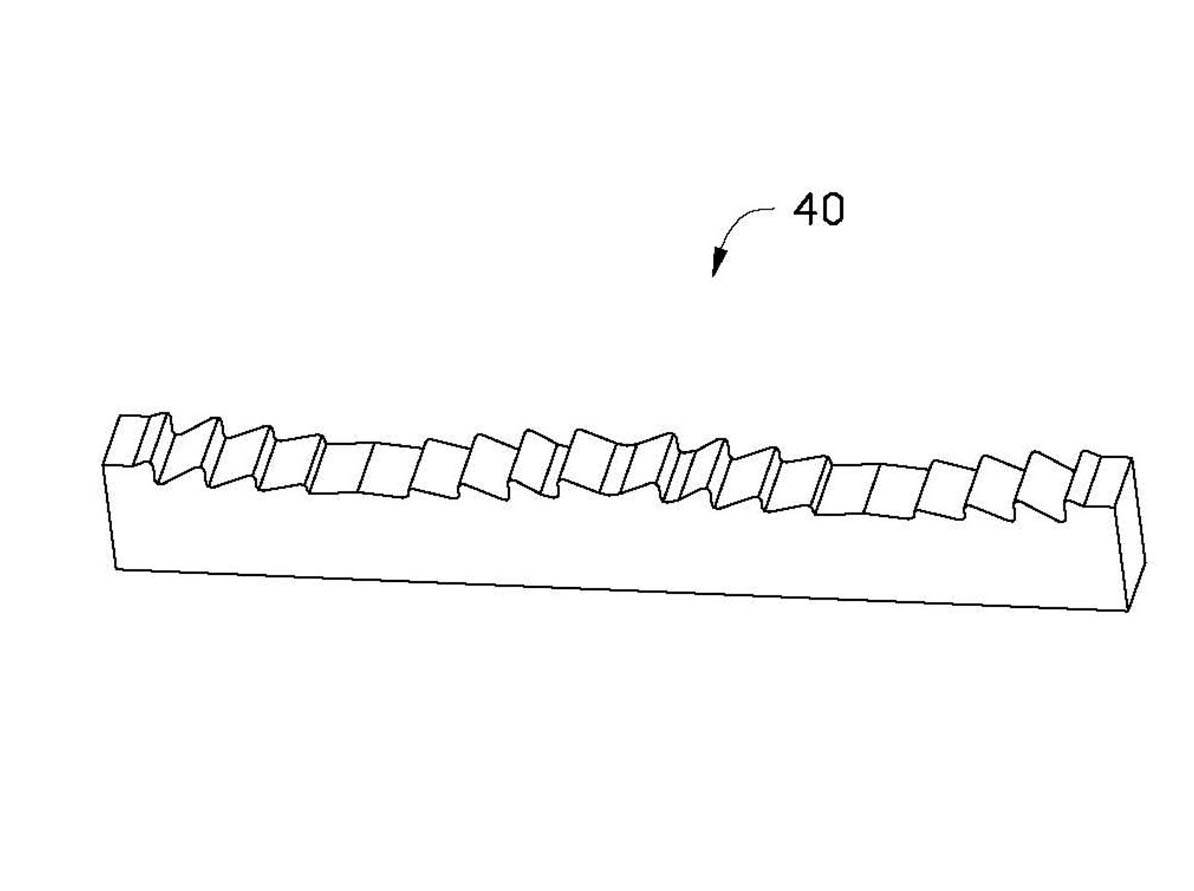

Compound optical lens and touch-control device using the same

InactiveCN102156590AEasy to gatherConsistent strengthInput/output processes for data processingLensOptical axisOptoelectronics

The invention relates to a compound optical lens which is applied to a touch-control device, wherein the touch-control device comprises a plurality of emitters and a receiver which is arranged opposite to the emitters; the compound optical lens is arranged in front of the receiver and is provided with a plurality of lens parts and a plurality of mutually parallel optical axes corresponding to the lens parts; the lens parts are corresponding to the emitters one by one; the width proportion of each lens part in the whole compound optical lens is correspondingly arranged according to the distance and angle between the corresponding emitter and the compound optical lens; and the infrared light emitted from each emitter is transmitted to the receiver after having the optical action by passing through the corresponding lens part. By using the touch-control device using the compound optical lens, the lights emitted by the emitters at different positions and directions can be excellently gathered and the intensities of the signals received by the receiver can be kept consistently.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

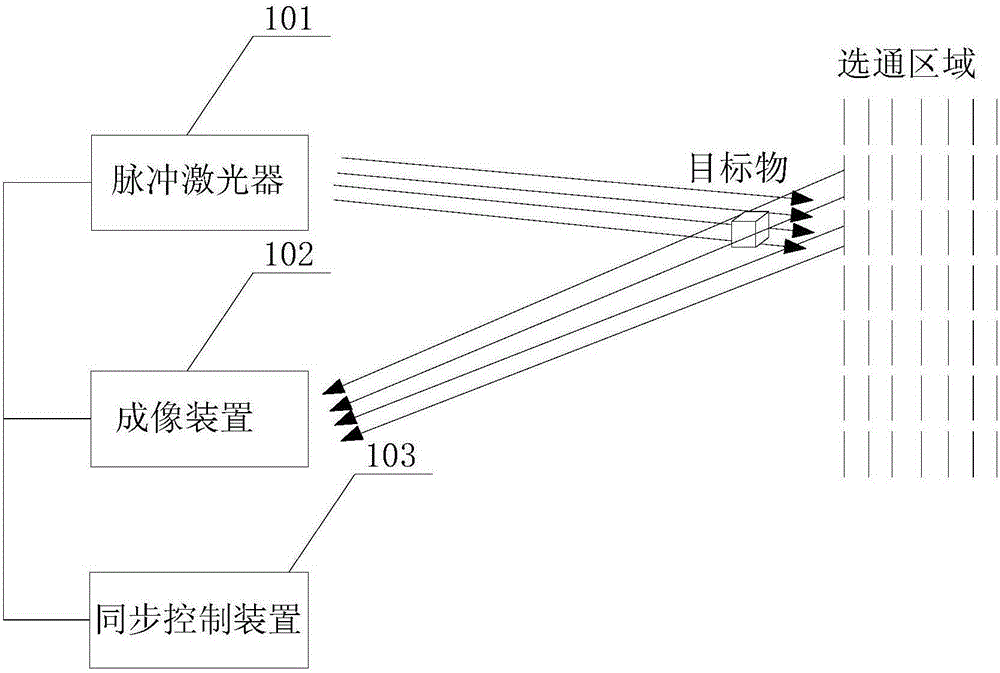

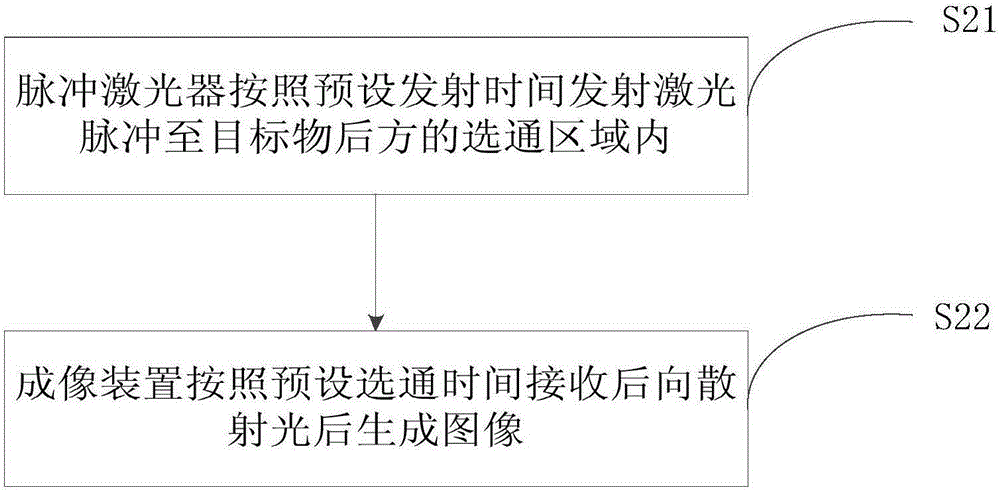

Range-gated imaging system and method based on back scattering illumination

InactiveCN105223584AConsistent strengthQuality improvementElectromagnetic wave reradiationImaging qualitySignal light

An embodiment of the invention provides a range-gated imaging system and method based on back scattering illumination, and belongs to the field of range-gated imaging. The system includes a pulse laser and an imaging device, the imaging device is arranged in a propagation path of back scattering light of a medium in a gated region behind a target object, wherein the back scattering light is scattering light emitted to the target object by laser pulses after being scattered by the medium in the gated region, the laser pulses being emitted by the pulse laser; the laser pulses emitted by the pulse laser according to preset emission time form back scattering light after being scattered by the medium of the gated region behind the target object, the back scattering light is emitted to the imaging device, and the imaging device generates an image after receiving the back scattering light according to preset gating time. The range-gated imaging system based on back scattering illumination can prevent the intensity of signal light reflected by the target object from being too weak when the target object is a mirror reflection object or strongly absorbs an illumination laser wavelength, and prevent imaging quality from being too poor.

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

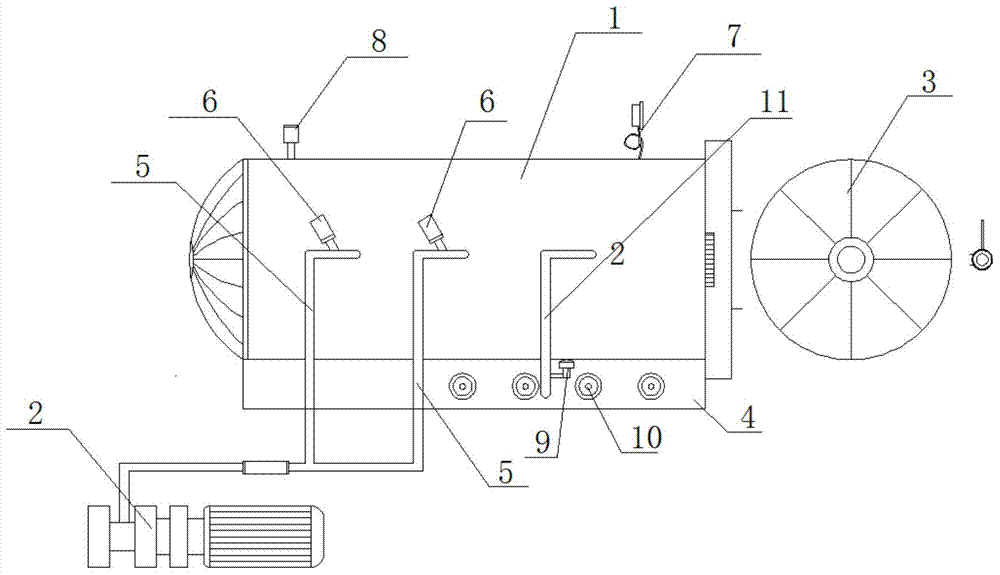

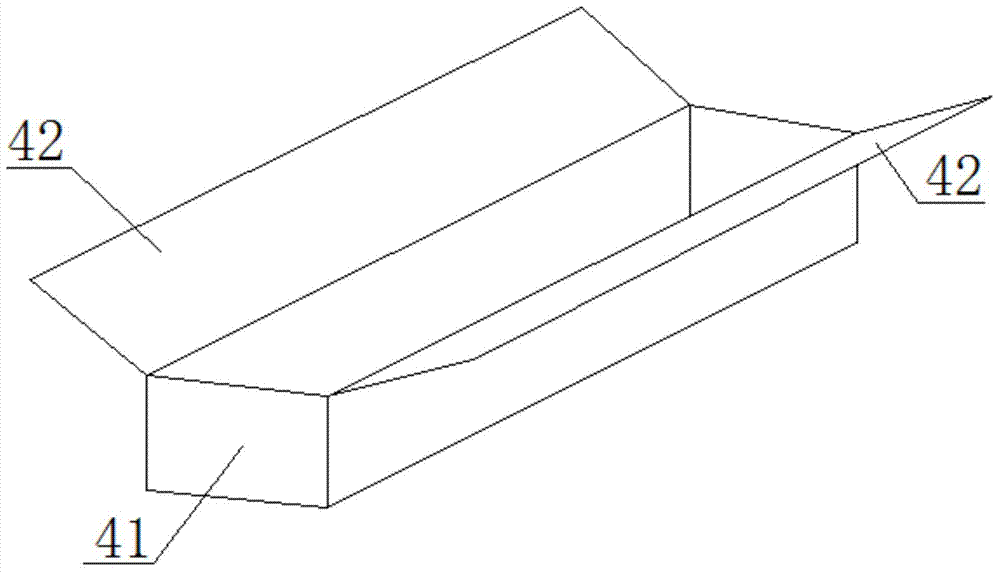

Vacuum type yarn steaming forming equipment and application method thereof

ActiveCN104278455ALow boiling pointEvenly distributed moistureTextile treatment machine arrangementsLiquid/gas/vapor yarns/filaments treatmentYarnThermal insulation

The invention discloses vacuum type yarn steaming forming equipment which mainly comprises a box, a water ring vacuum pump, a box door and a water tank. A water level meter and a heating pipe are arranged in the water tank. A water inlet pipe and a water outlet pipe are arranged on the lateral wall of the box. A suction pipe is arranged in the box. A filter cover is disposed on the suction pipe. A pressure gauge and a surface temperature meter are further disposed on the surface of the top end of the box. The invention further provides an application method of the vacuum type yarn steaming forming equipment. The method includes: sequentially performing preheating, vacuumizing, heating, standing thermal insulation, secondary vacuumizing, heating and thermal insulation on the box. The vacuum type yarn steaming forming equipment has the advantages that the equipment is simple in structure, low in manufacturing cost, low in energy consumption, high in controllability and good in thermal insulation performance, water inlet amount, humidity and temperature change can be well adjusted, mildew and off-shade of the yarn processed by the equipment are avoided, yarn damage is avoided, condensing spots are avoided, processing time is short, yarn weight loss is compensated, and yarn quality is improved.

Owner:JIANGSU JINDA TEXTILE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com