Continuous fiber reinforced polypropylene sandwich plate and preparation method thereof

A continuous fiber and polypropylene technology, applied in the field of continuous fiber reinforced polypropylene sandwich panels and their preparation, can solve the problems of poor product surface quality, difficult control of the production process, long production cycle, etc., and achieves easy processing and strength in all directions. Consistent, short cycle time results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

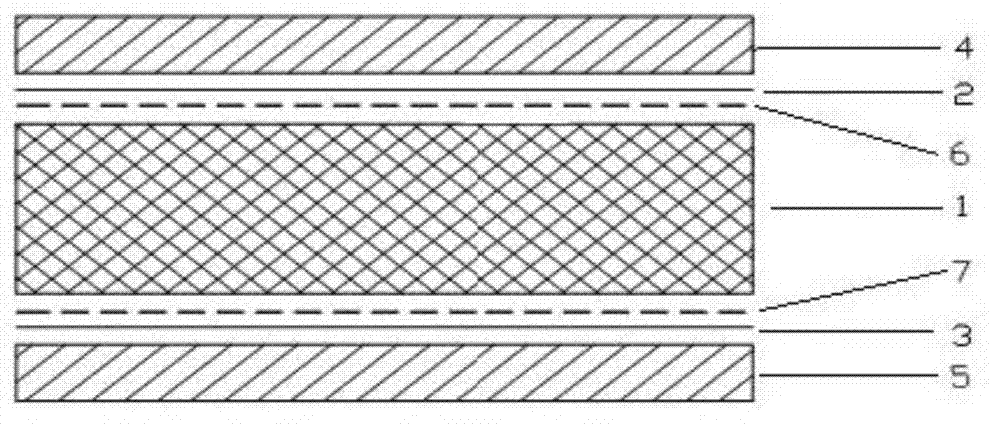

[0044] A continuous glass fiber reinforced polypropylene aluminum honeycomb panel, comprising an upper prepreg layer 4, an upper non-woven fabric layer 5, an upper adhesive film material 6, a honeycomb core material layer 1, and a lower adhesive film material 7 from top to bottom , the lower non-woven fabric layer 3, the prepreg layer 5, and the adjacent layers are connected to each other by hot pressing.

[0045] Among them, the thickness of the upper or lower prepreg layer is 1.5mm, the thickness of the upper or lower non-woven fabric layer is 0.7mm, the thickness of the upper or lower adhesive film material is 0.3mm, and the thickness of the honeycomb core material is 15mm.

[0046] The preparation method of the above-mentioned continuous fiber reinforced polypropylene sandwich panel is as follows: (1) adding 50 parts by weight of homopolypropylene into the extruder, extruding the film through the staggered double extrusion dies, adding 50 parts by weight Parts of continuou...

Embodiment 2

[0054] A continuous glass fiber reinforced polypropylene aluminum honeycomb panel, comprising an upper prepreg layer 4, an upper non-woven fabric layer 5, an upper adhesive film material 6, a honeycomb core material layer 1, and a lower adhesive film material 7 from top to bottom , the lower non-woven fabric layer 3, the prepreg layer 5, and the adjacent layers are connected to each other by hot pressing.

[0055] Among them, the thickness of the upper or lower prepreg layer is 2mm, the thickness of the upper or lower non-woven fabric layer is 0.8mm, the thickness of the upper or lower adhesive film material is 0.33mm, and the thickness of the honeycomb core material is 15mm.

[0056] The preparation method of the above-mentioned continuous fiber reinforced polypropylene sandwich panel is as follows: (1) adding 45 parts by weight of homopolypropylene into the extruder, extruding the film through the staggered double extrusion dies, adding 55 parts by weight Parts of continuous...

Embodiment 3

[0064] A continuous glass fiber reinforced polypropylene aluminum honeycomb panel, comprising an upper prepreg layer 4, an upper non-woven fabric layer 5, an upper adhesive film material 6, a honeycomb core material layer 1, and a lower adhesive film material 7 from top to bottom , the lower non-woven fabric layer 3, the prepreg layer 5, and the adjacent layers are connected to each other by hot pressing.

[0065] Among them, the thickness of the upper or lower prepreg layer is 3mm, the thickness of the upper or lower non-woven fabric layer is 0.9mm, the thickness of the upper or lower adhesive film material is 0.36mm, and the thickness of the honeycomb core material is 15mm.

[0066] The preparation method of the above-mentioned continuous fiber reinforced polypropylene sandwich panel is as follows: (1) adding 45 parts by weight of homopolypropylene into the extruder, extruding the film through the staggered double extrusion dies, adding 55 parts by weight Parts of continuous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com