Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

89results about How to "There will be no offset" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bag making machine hot-sealing and hot-pressing mechanism capable of working stably

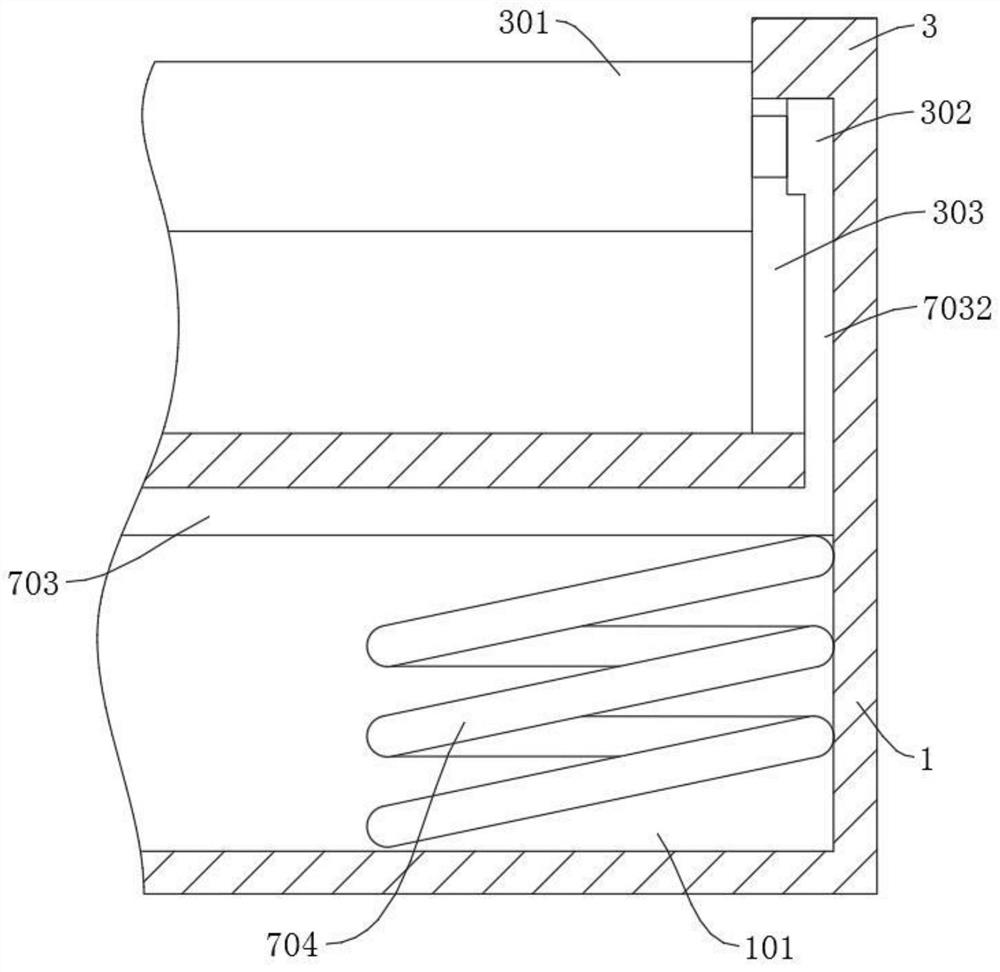

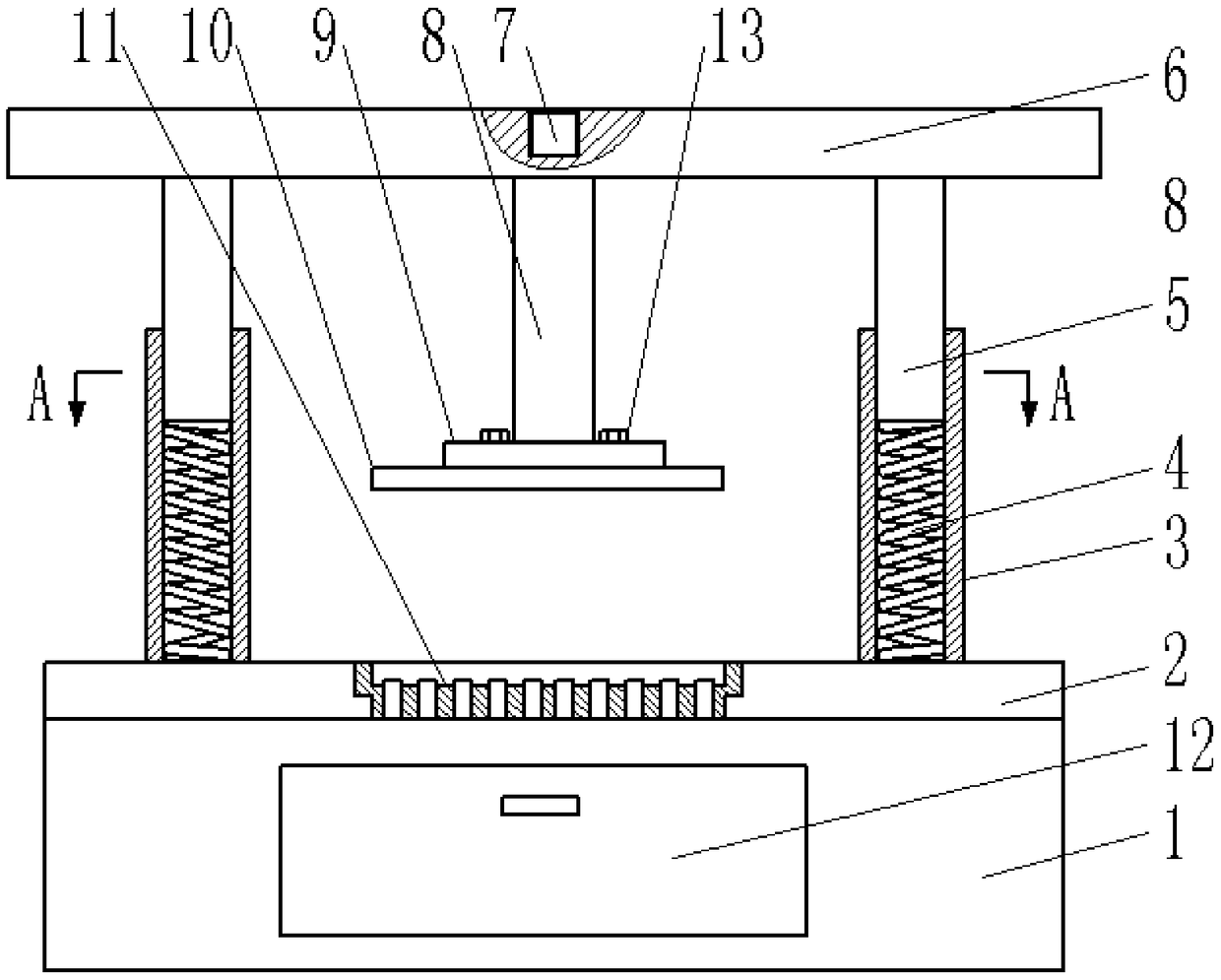

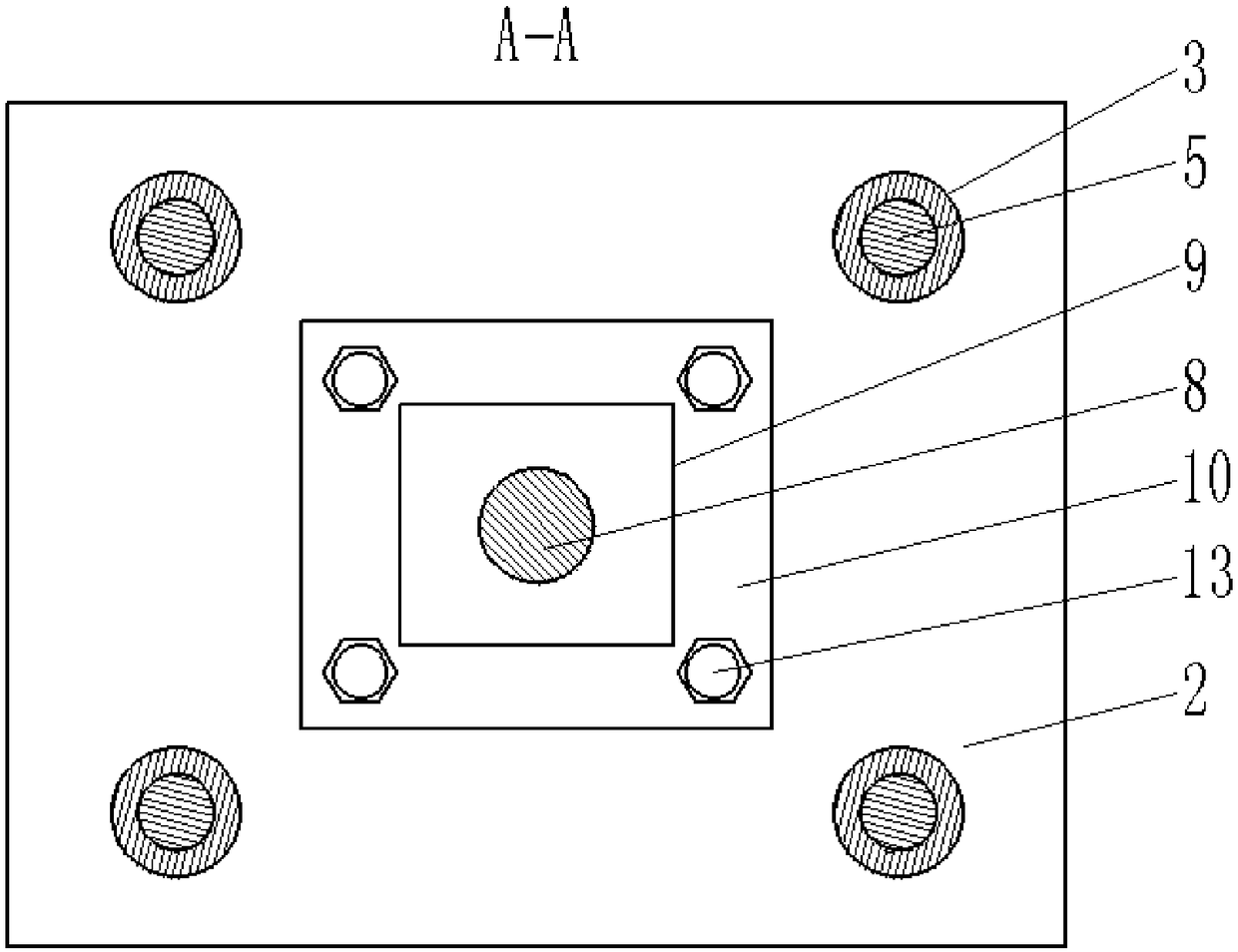

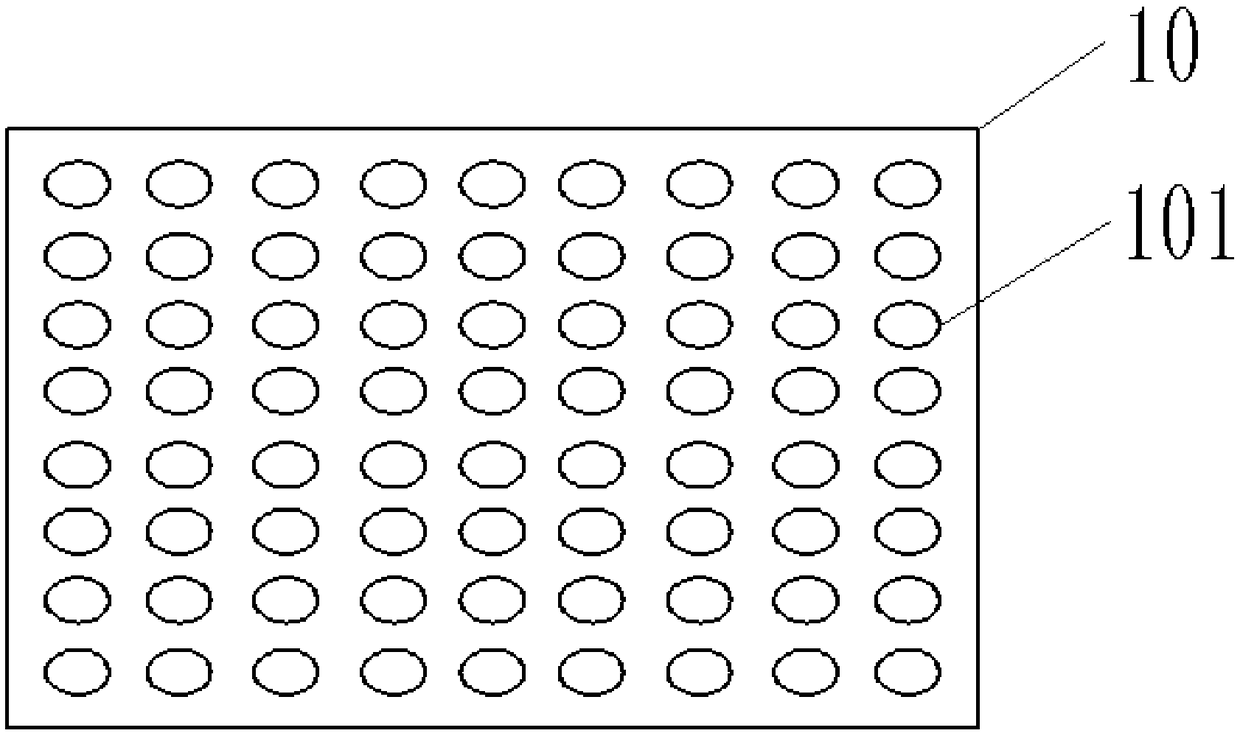

The invention discloses a bag making machine hot-sealing and hot-pressing mechanism capable of working stably. The mechanism comprises a fixing frame body, two guide sleeves, pull rods, a cutter fixing frame and a hot-sealing cutter. The upper ends of the pull rods are fixedly connected to the two ends of the cutter fixing frame respectively and each provided with an upper end abutting portion. The side wall of the upper portion of each pull rod is sleeved with a compression spring. The upper end and the lower end of each compression spring are connected to the corresponding upper end abutting portion and the top of the corresponding sleeve respectively in an abutting mode. At least one pull rod penetrates through the corresponding guide sleeve and then is in transmission connection with an intermittent motion mechanism. According to the bag making machine hot-sealing and hot-pressing mechanism, it can be ensured that the hot-sealing and hot-pressing positions and motion strengths of the hot-sealing cutter for air bubble films or pearl wool films under the hot-sealing and hot-pressing cutter are consistent all the time, and the hot-sealing cutter will not shift even if hot-sealing and hot-pressing are frequently and constantly carried out; accordingly, the working efficiency of the bag making machine hot-sealing and hot-pressing mechanism is greatly improved, and the service life of the bag making machine hot-sealing and hot-pressing mechanism is greatly prolonged.

Owner:洪东坡

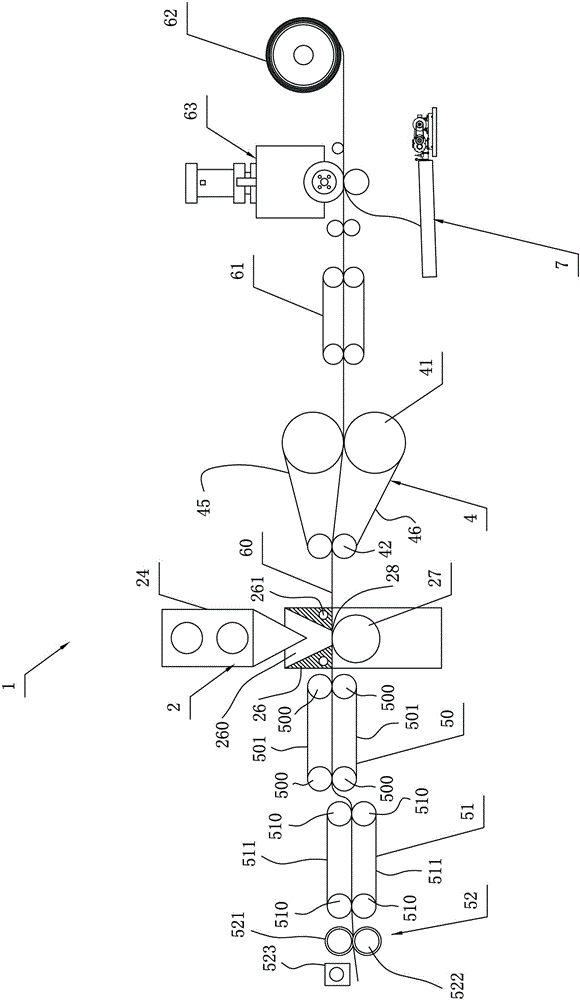

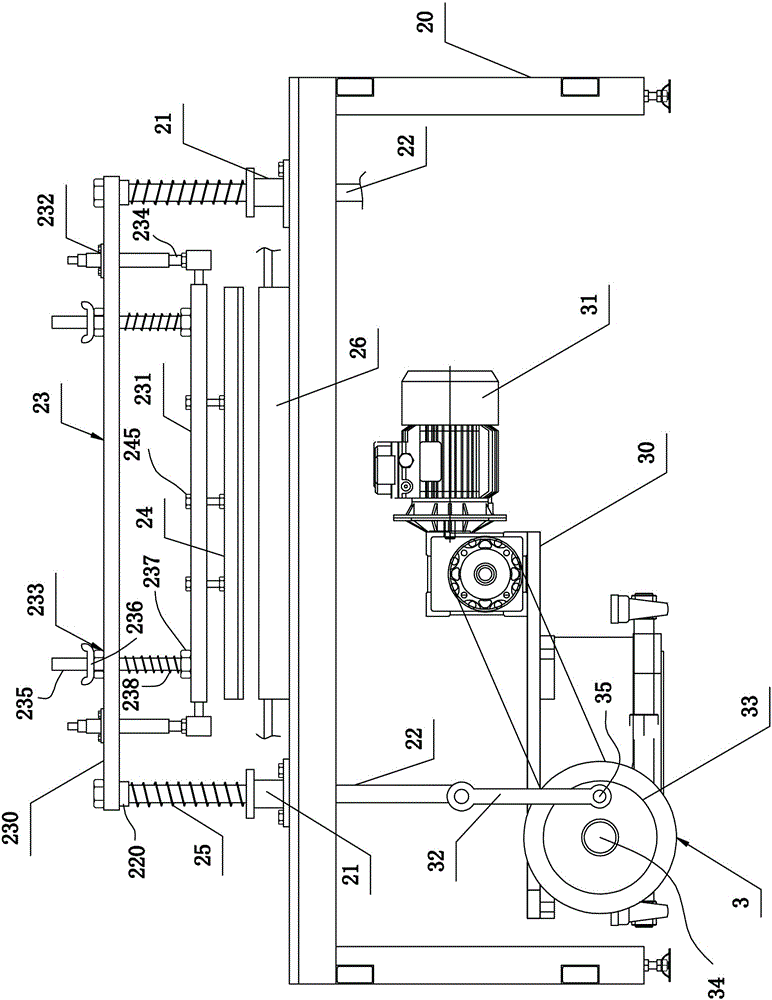

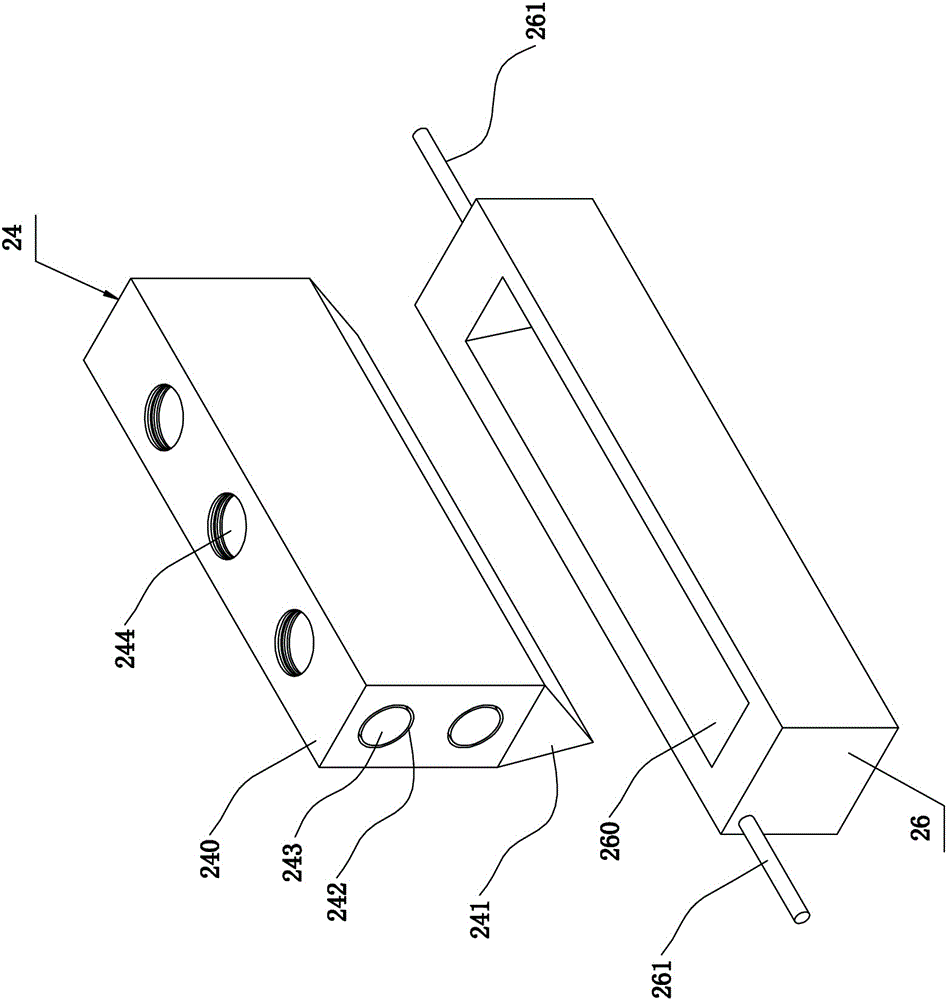

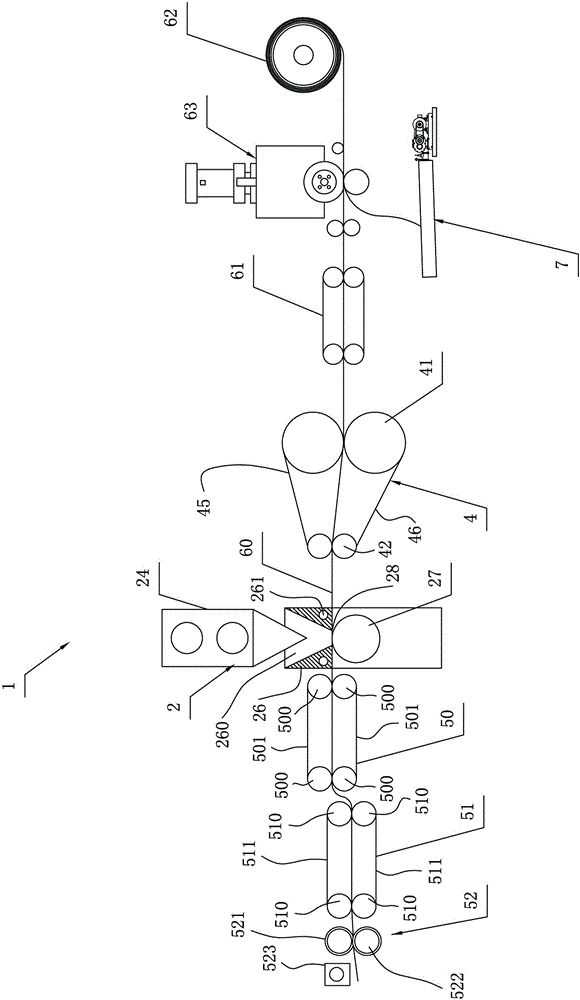

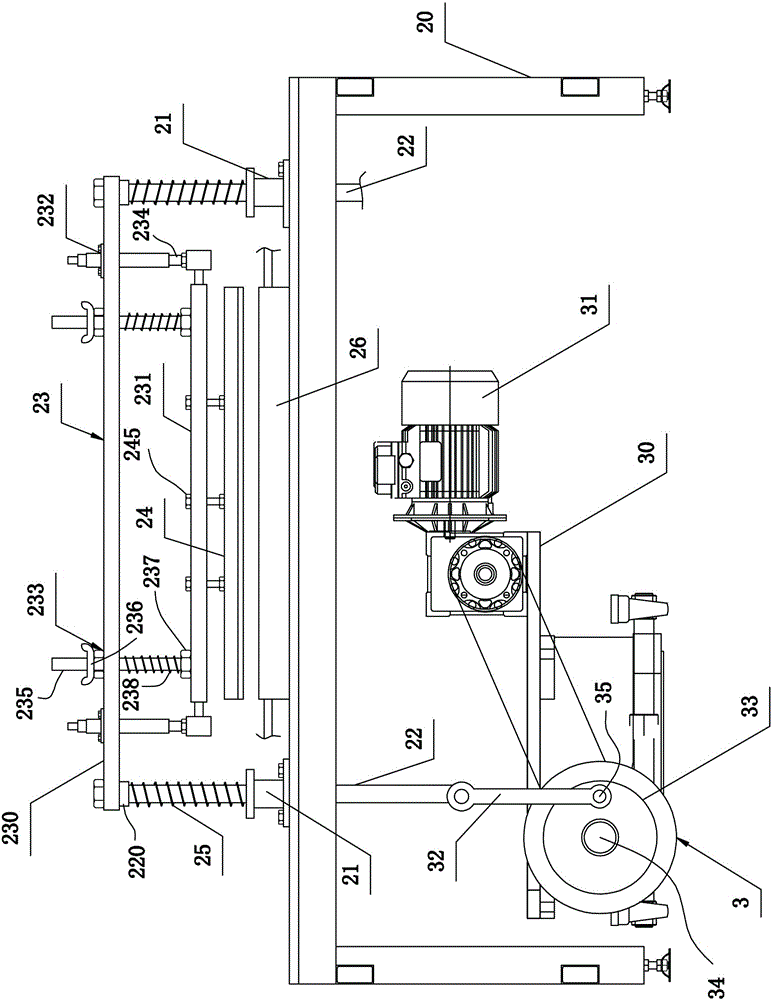

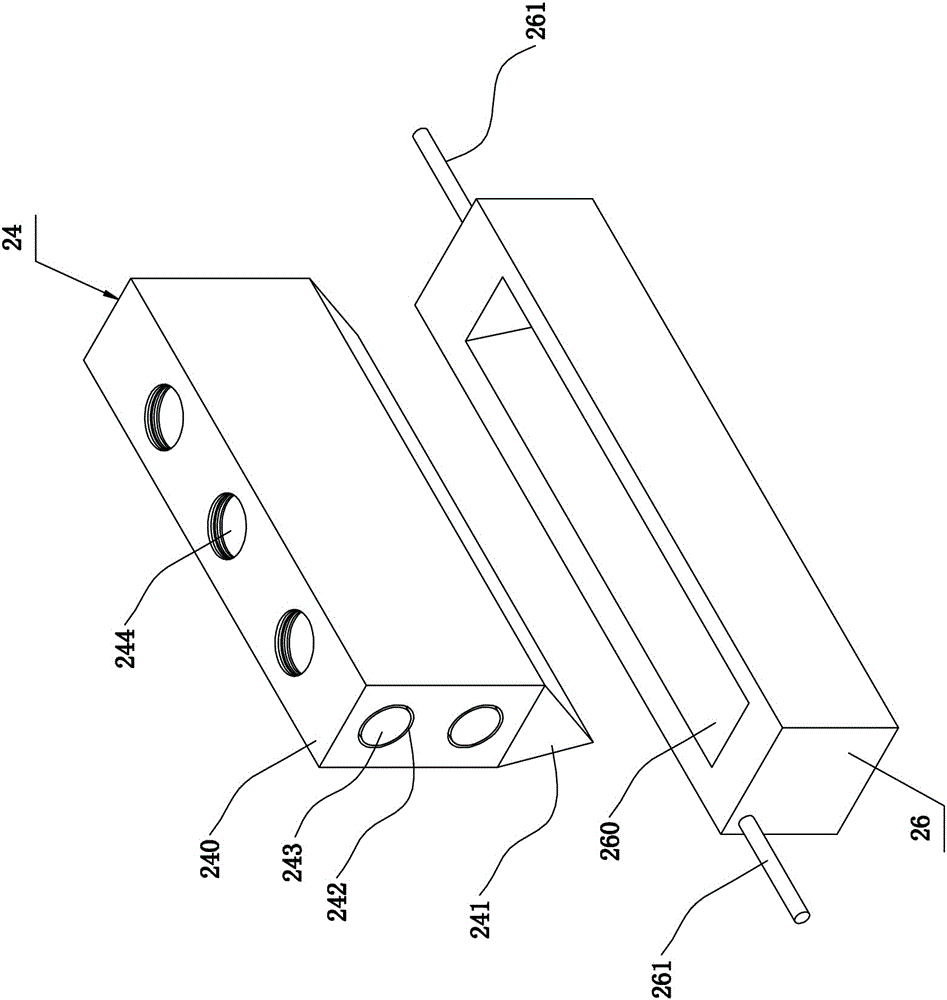

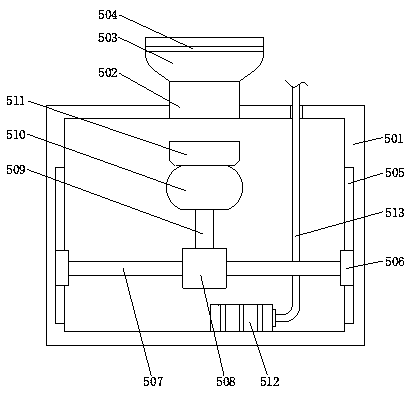

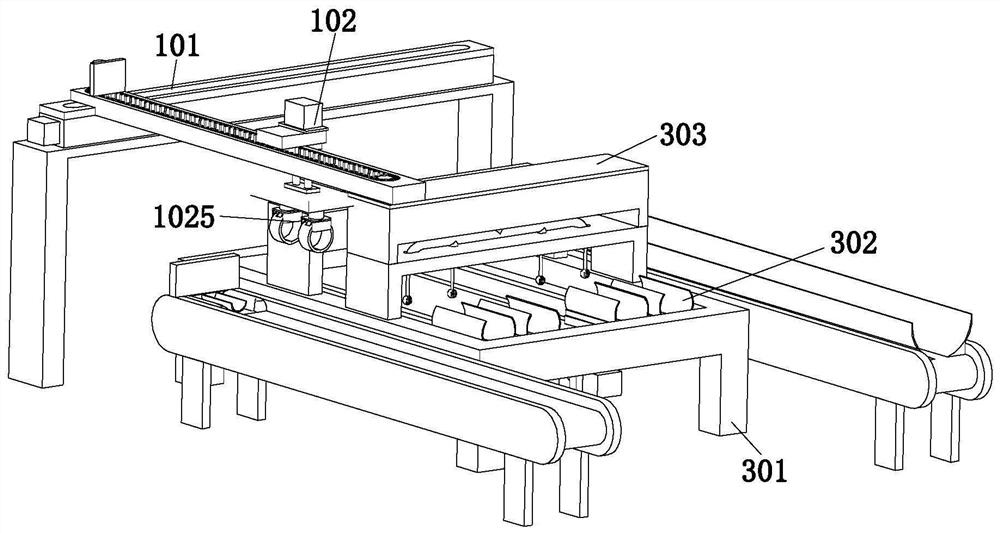

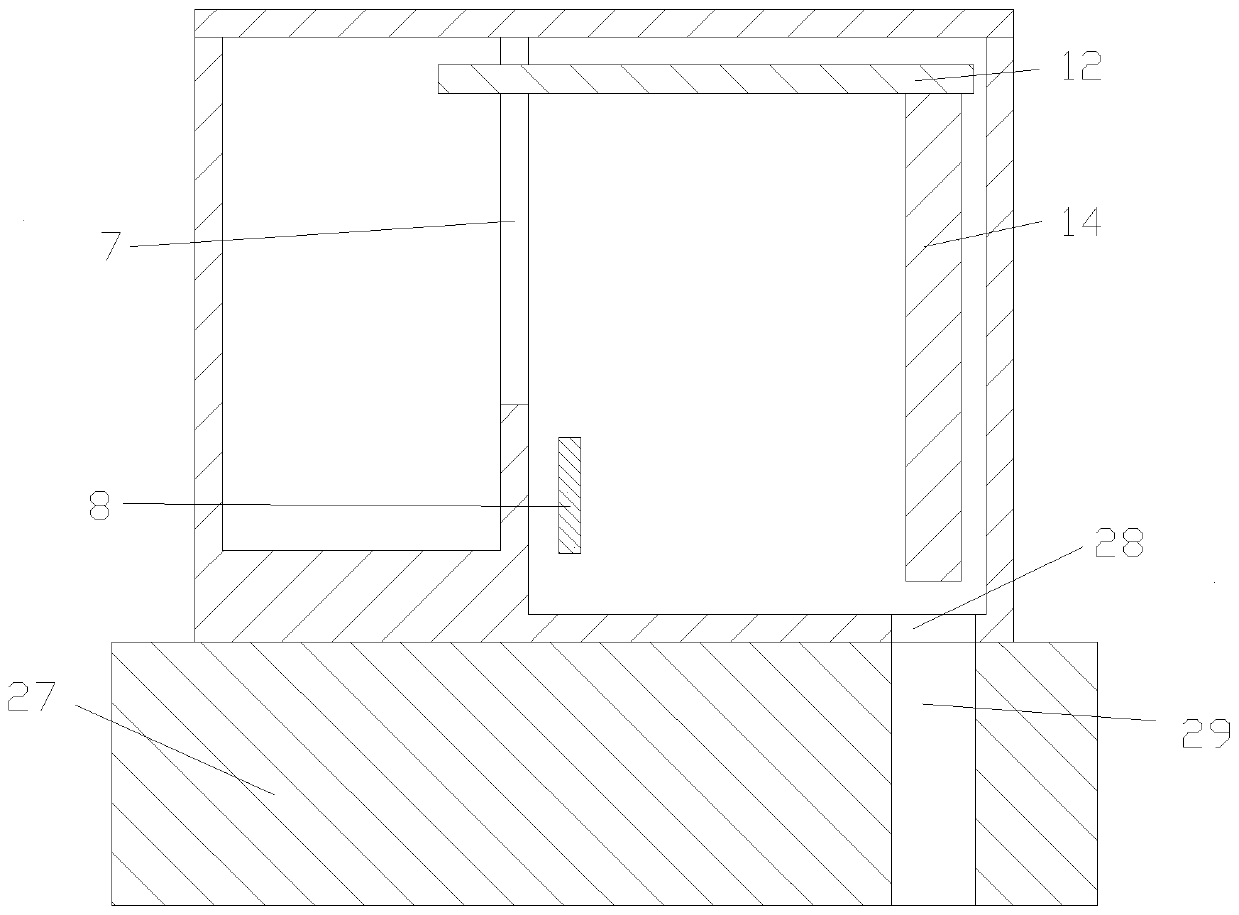

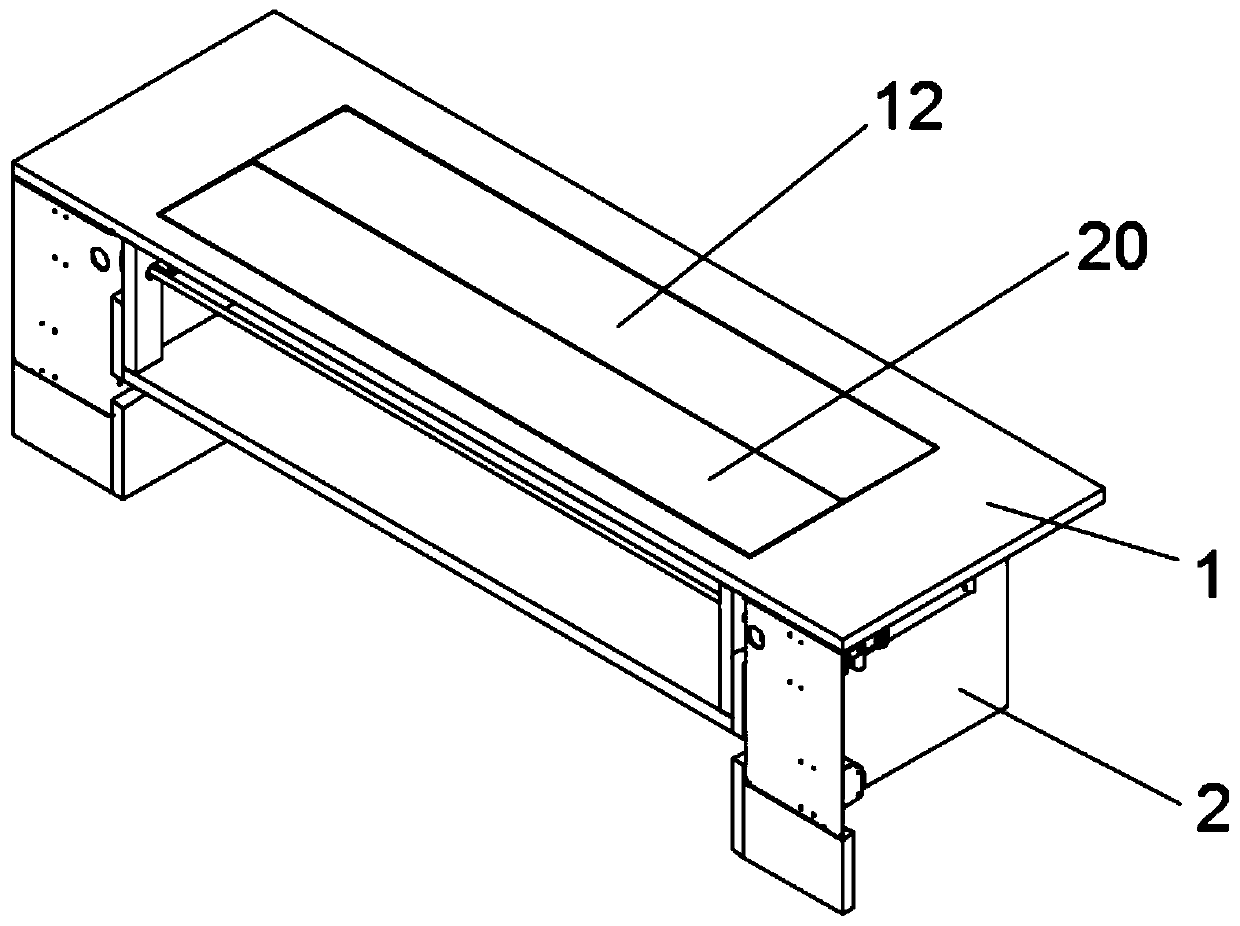

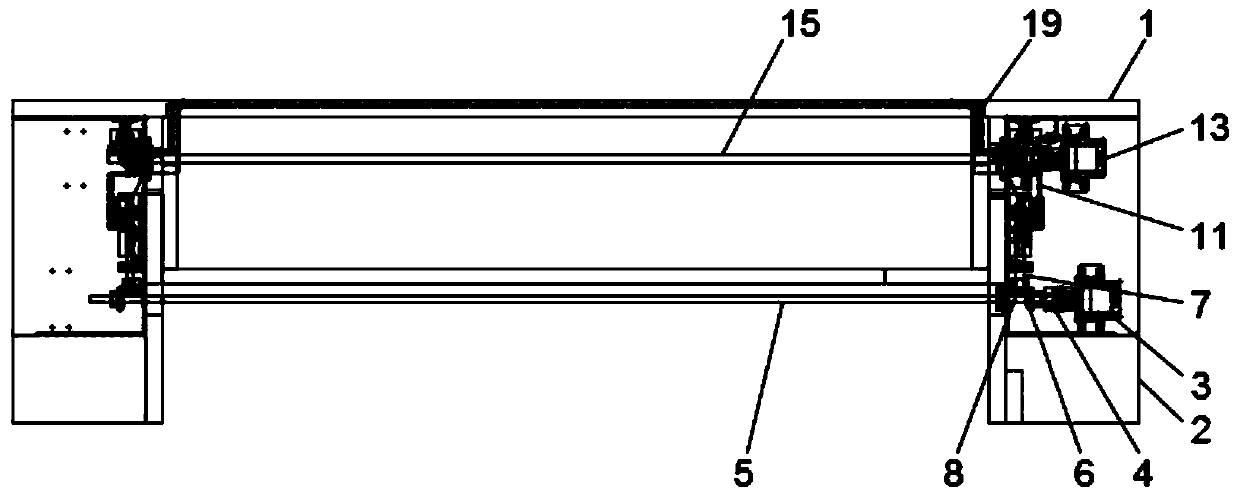

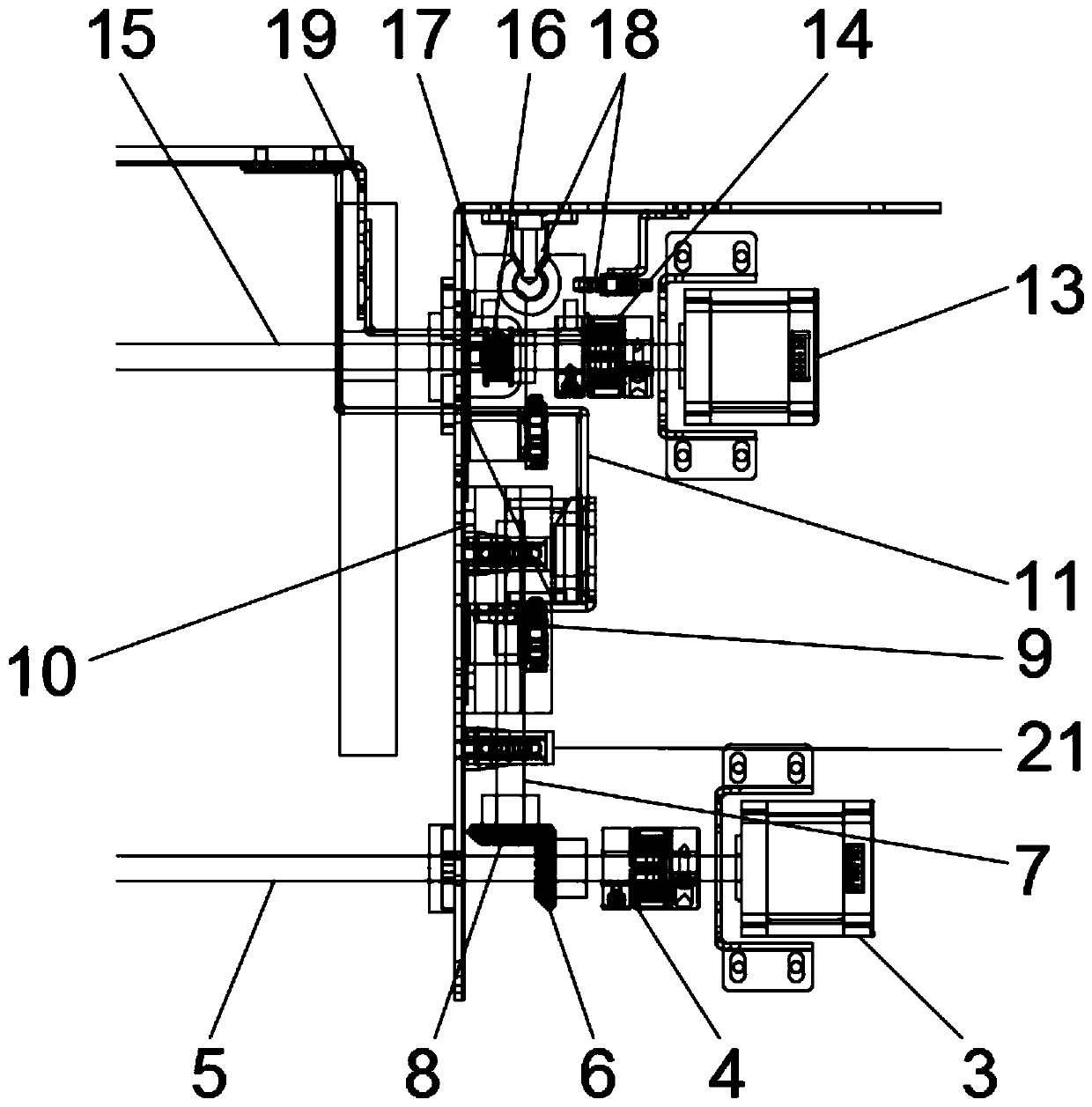

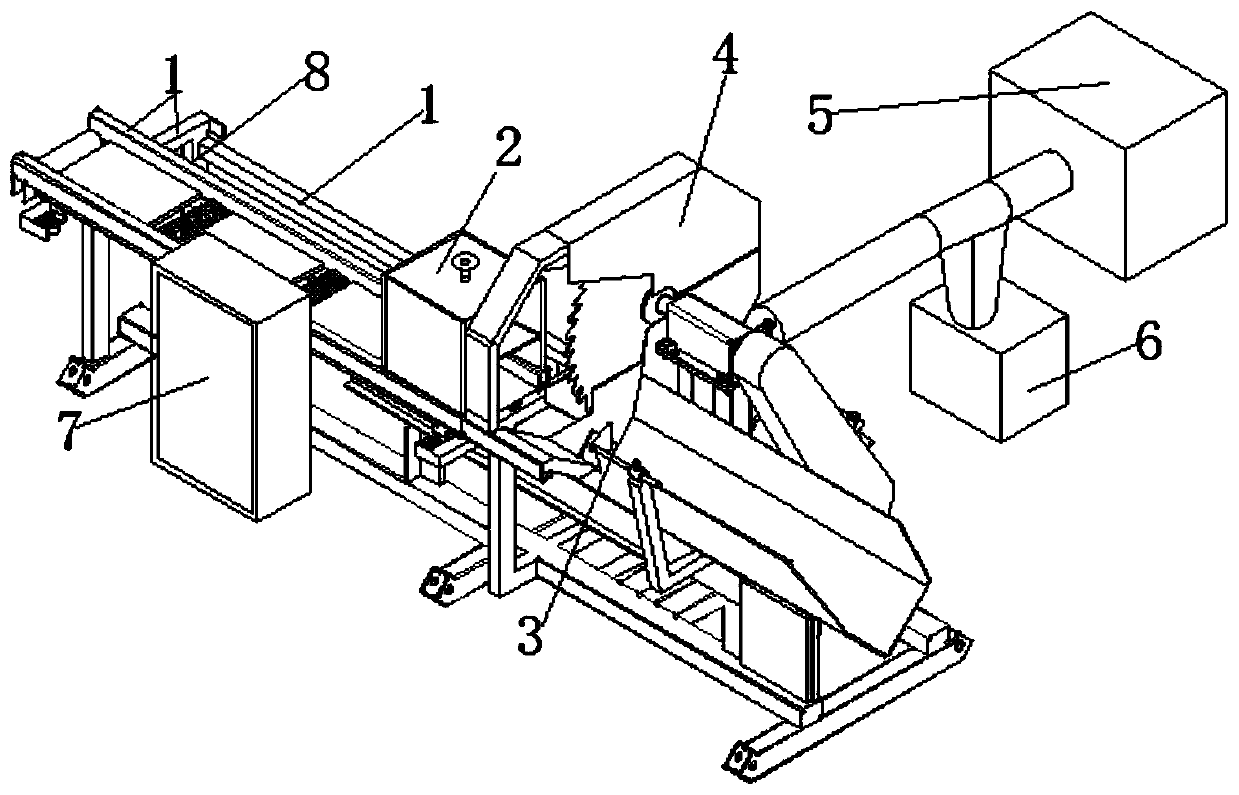

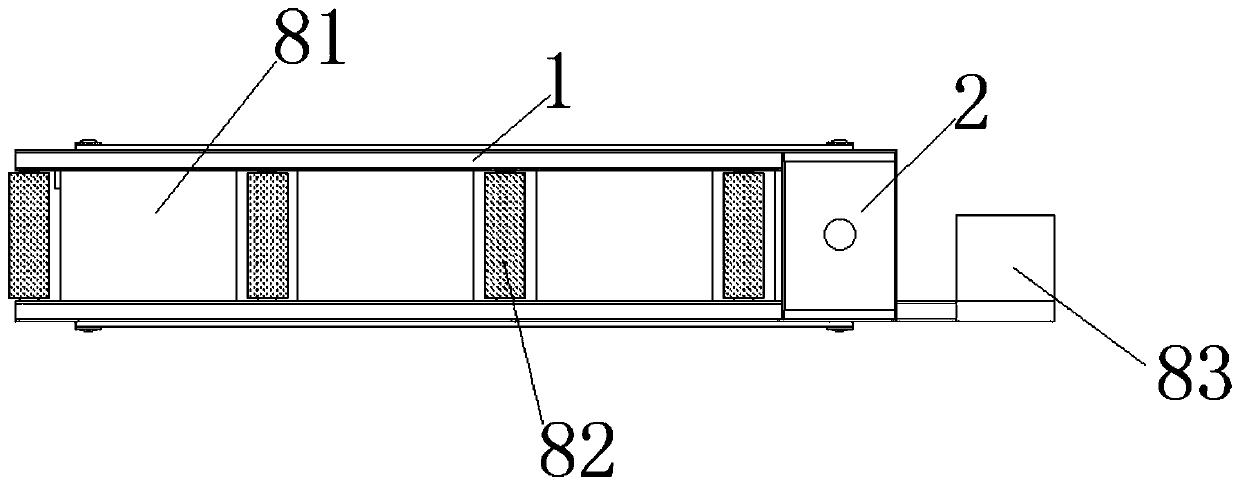

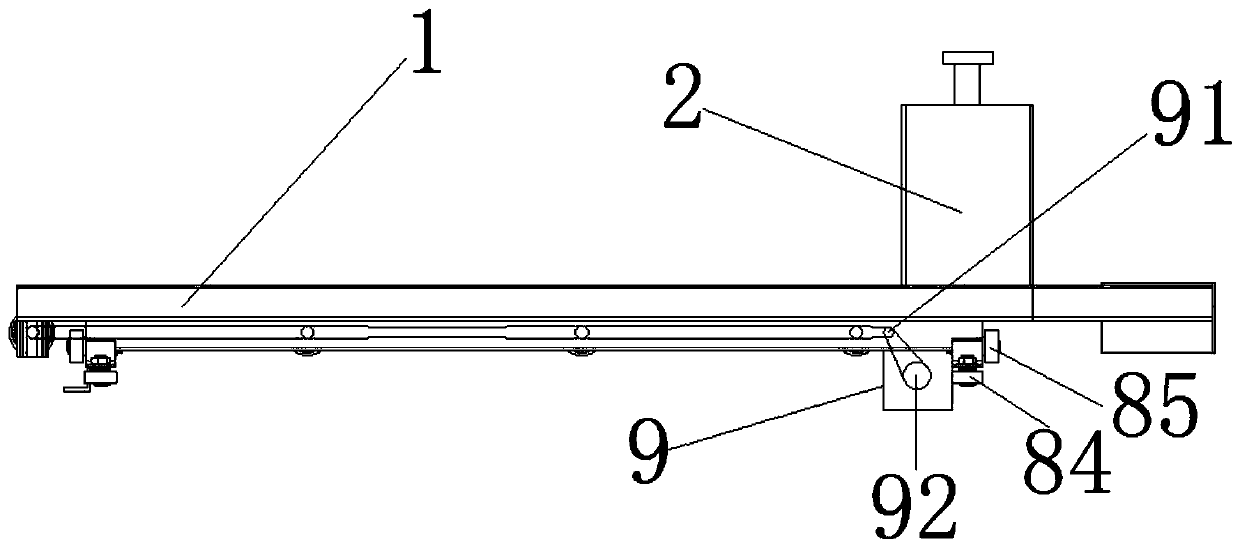

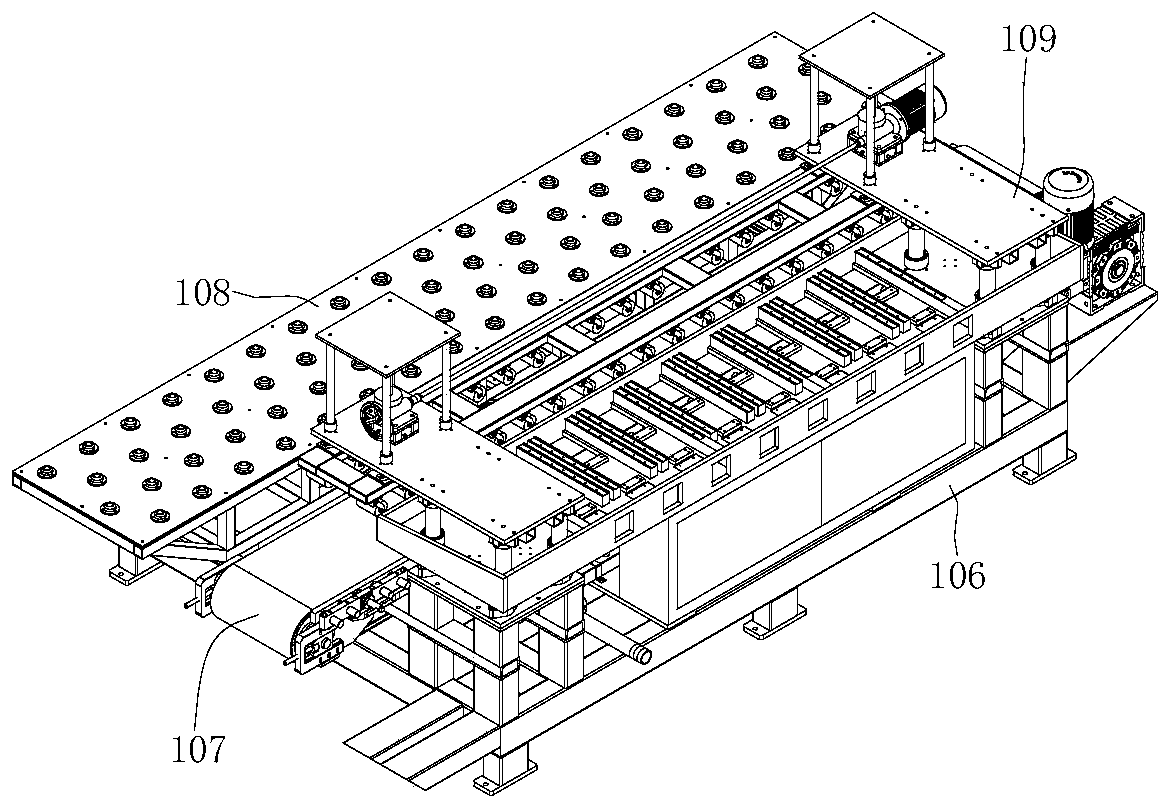

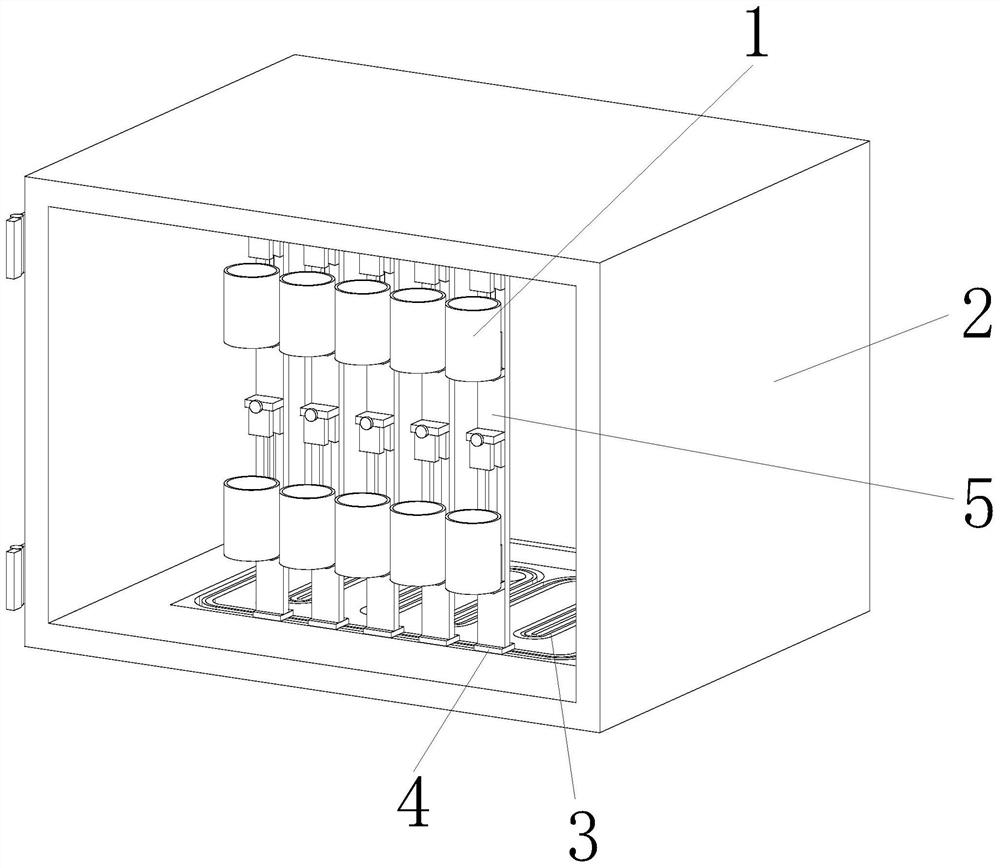

Bag machine with improved structure

ActiveCN104985864AThere will be no offsetSimple structureBox making operationsPaper-makingEngineeringMechanical engineering

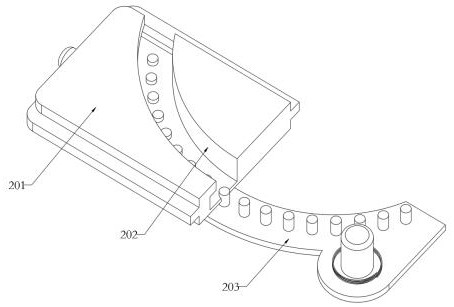

A bag machine with an improved structure comprises a convey assembly, a feed assembly, and a hot-sealing hot-pressing mechanism; the hot-sealing hot-pressing mechanism comprises a fixed rack, two guide sleeves, pull rods, a cutter fixing rack and a hot-sealing cutter; tops of each pull rod are respectively fixed on two ends of the cutter fixing rack; each pull rod is provided with a top abut portion; an upper side wall of each pull rod is sleeved by a compression spring; at least one pull rod penetrates the corresponding guide sleeve and is in transmission connection with an intermittence motion mechanism, wherein the intermittence motion mechanism is used for controlling the cutter fixing rack to complete up-down mobile motions in cycle in a fixed time. The bag machine can ensure the hot-sealing cutter to carry out hot-sealing hot-pressing for right blow bubble films or pearl cotton films with consistent positions and motion forces in each time; even under frequent continuously hot-sealing hot-pressing, no hot-sealing cutter offset condition is generated, thus greatly improving work efficiency and life of the bag machine.

Owner:洪东坡

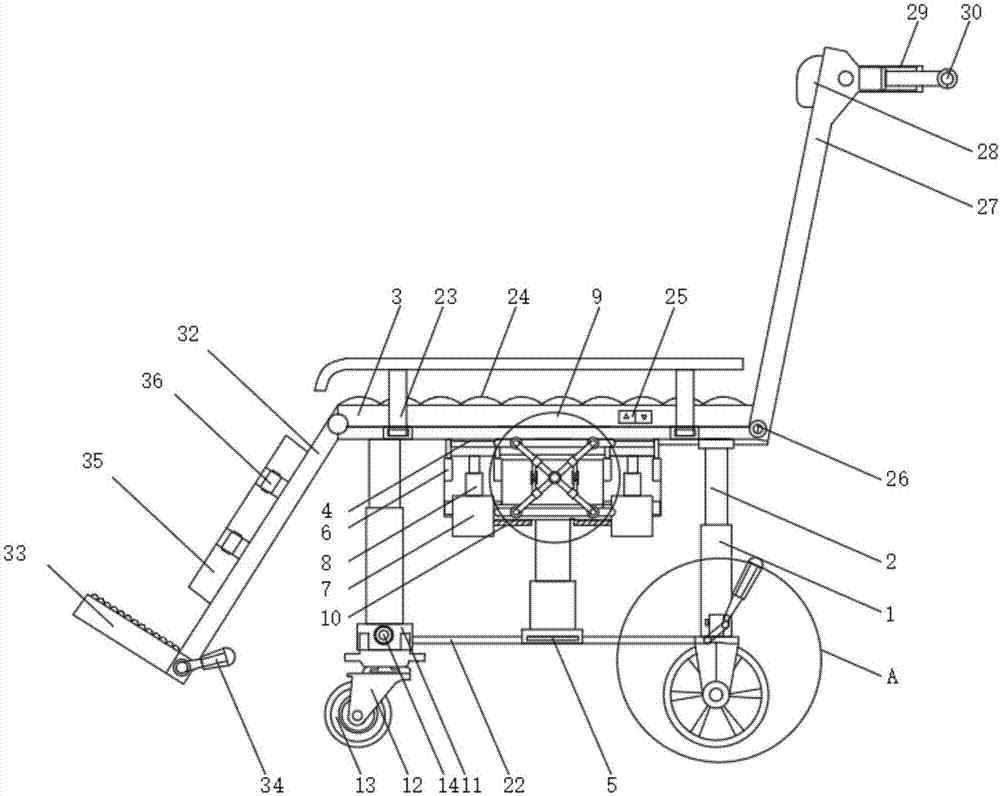

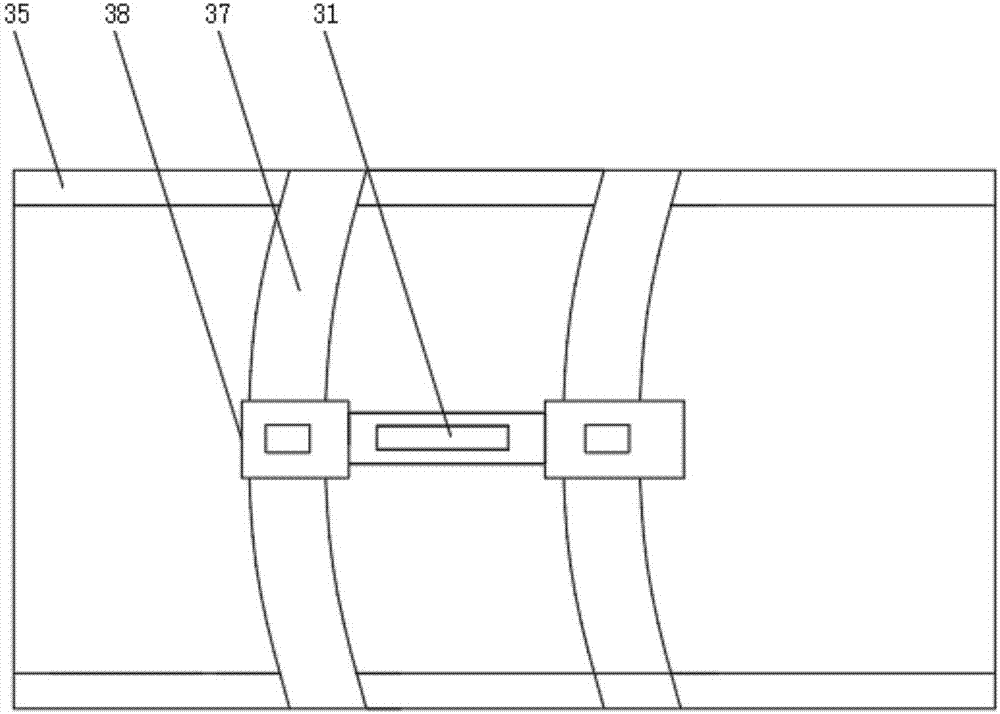

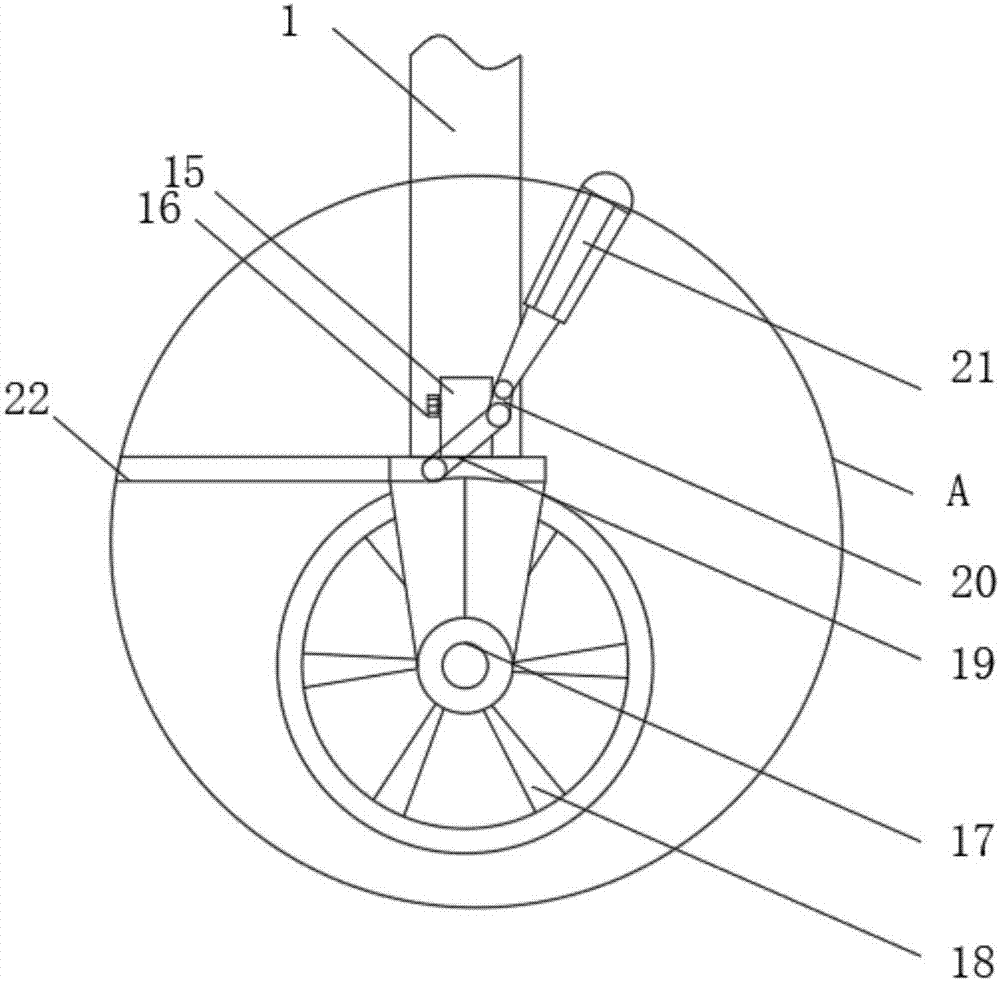

Protective wheelchair for recovery in orthopedics department

PendingCN107981994APrevent slidingSit comfortablyDiagnosticsWheelchairs/patient conveyanceWheelchairOrthopedic department

The invention discloses a protective wheelchair for recovery in an orthopedics department. The protective wheelchair for recovery in the orthopedics department comprises support legs, wherein a retractable leg is mounted on the top of each support leg; the tops of the retractable legs are fixedly connected with a bottom plate; the bottom of the bottom plate is fixedly connected with a buffering support; the bottom of the buffering support is fixedly connected with a hydraulic retractable rod; the bottom of the buffering support is fixedly connected with an explosion-resisting bottom plate; thetop of the explosion-resisting bottom plate is fixedly connected with a buffering device; a seat cushion is arranged on the top of the bottom plate; the outer wall of the bottom plate is fixedly connected with detachable armrests; an adjusting switch is arranged on the outer wall of the bottom plate and is positioned between the detachable armrests; a rotation adjuster is mounted at one end of the bottom plate; and the top of the rotation adjuster is fixedly connected with a backrest. The invention relates to the technical field of recovery in the orthopedics department. By the protective wheelchair for recovery in the orthopedics department, the problem that in a recovery process of a patient, a large amount of nursing time of nursing staff in the orthopedics department is required for protection to the leg of the patient is solved, the patient can comfortably sit on the wheelchair for a long time, and feeling of fatigue is relieved.

Owner:湖南丹尼尔智能科技有限公司

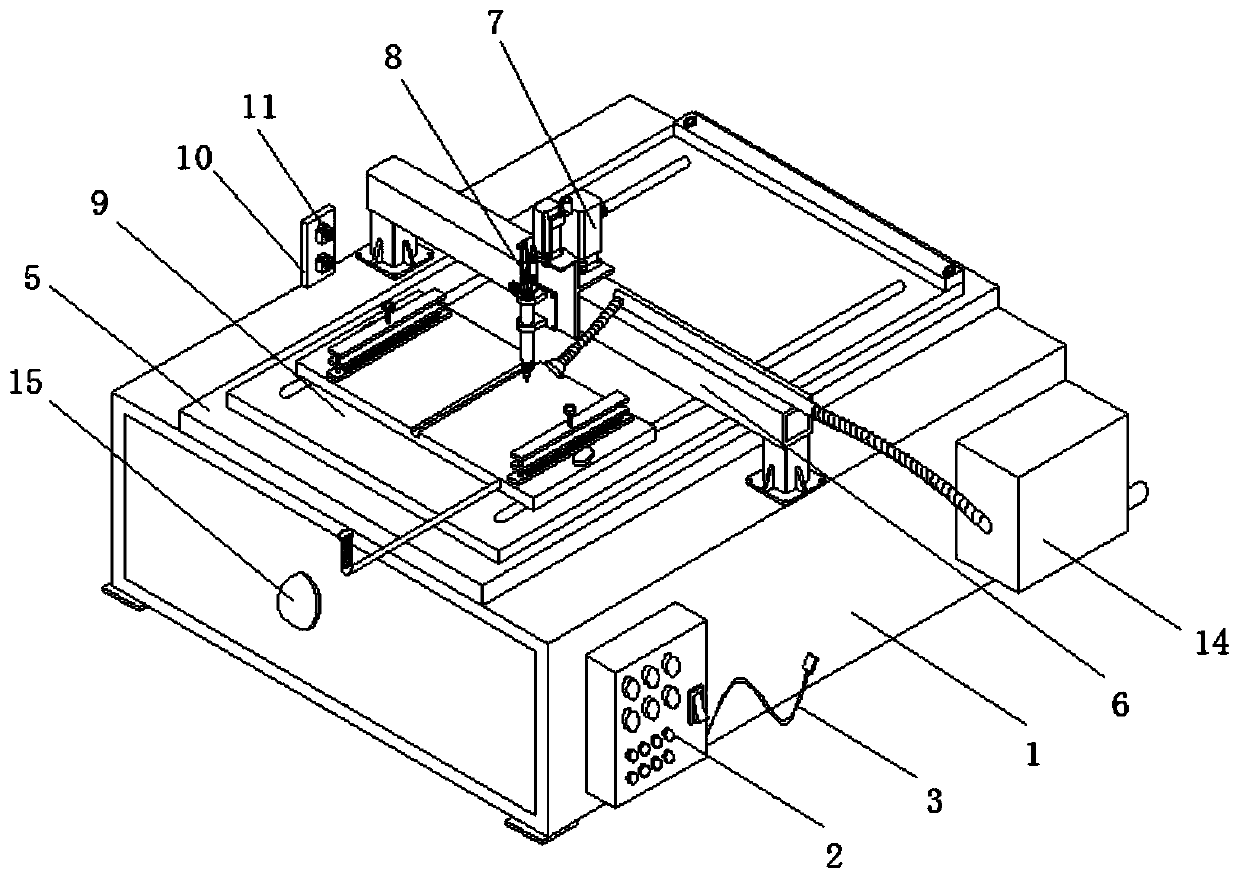

Tail gas pipe cutting device for vehicle manufacturing

PendingCN108746958AThere will be no offsetEasy to cutWelding/cutting auxillary devicesDirt cleaningLean manufacturingExhaust gas

The invention discloses a tail gas pipe cutting device for vehicle manufacturing. The device comprises a workbench, a first slide rail, a supporting table, a control panel, a power line, a cross beam,a machine head, a motor, an electrode bar, a clamping device and a dust sucking device; the supporting table is arranged at the upper end of the first slide rail and is in sliding connection with theouter side of the first slide rail; the front and back ends of the bottom of the control panel are fixed to the front side of the top end of the supporting table through screws; after a hand wheel isrotated, the distance between a left clamping rod and a right clamping rod changes, a tail gas pipe is put between the left clamping rod and the right clamping rod, then the left clamping rod and theright clamping rod clamp and position the tail gas pipe after the hand wheel is rotated reversely, the shifting condition is avoided during cutting, cutting is more convenient, and the work efficiency is improved. By arranging a rotary mechanism, after the tail gas pipe is fixed on a positioning board, a rocker can be pulled to change the angle of a rotary disc and the positioning board, then theangle of the tail gas pipe is adjusted accordingly, the tail gas pipe can be cut with the accurate angle, and the cutting quality is ensured.

Owner:WENZHOU UNIV OUJIANG COLLEGE

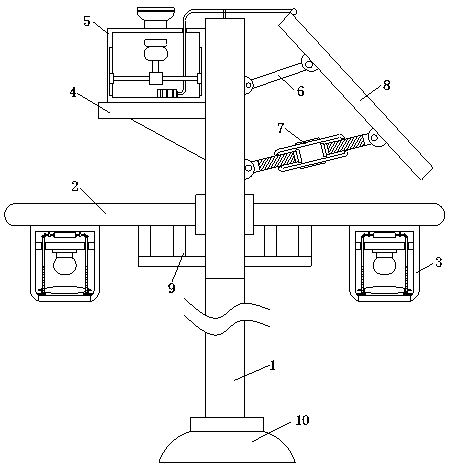

LED street lamp capable of adjusting light-emitting area

InactiveCN110985978AAdjustable luminous areaStrong penetrating powerPhotovoltaic supportsSolar heating energyEngineeringLED lamp

The invention relates to the technical field of LED street lamps. The utility model relates to an LED street lamp capable of adjusting a light-emitting area. The LED street lamp comprises a lamp pole,lamp arms are fixedly connected to the two sides of the lamp pole, one side, away from the lamp pole, of the bottom of the lamp arm is fixedly connected with a light-emitting area regulating device,a tripod is fixedly connected to the top of the left side of the lamp pole, a cleaning device is fixedly connected to the top of the tripod, a supporting rod is movably connected to the top of the right side of the lamp pole, an angle adjusting device is movably connected to the right side of the lamp pole and located below the supporting rod, and solar panels are movably connected to the sides, away from the lamp pole, of the supporting rod and the angle adjusting device. According to the invention, a convex lens can be driven to move up and down, when the convex lens is close to the LED lamp, light rays emitted by the LED lamp can be condensed, the penetrating power of the LED lamp is higher, illumination is provided for people when the visibility is low in foggy days, and when the convex lens is far away from the LED lamp, the light rays emitted by the LED lamp can be diffused, so that the light emitting area is increased to meet different requirements.

Owner:扬州市月丰照明器材有限公司

Device for manufacturing pipeline through high-end equipment

ActiveCN112058546AUniform spraying jobReduce scrap ratePretreated surfacesCoatingsPipeMachining process

Owner:舒婷

Cotton cloth cutting equipment for textile production

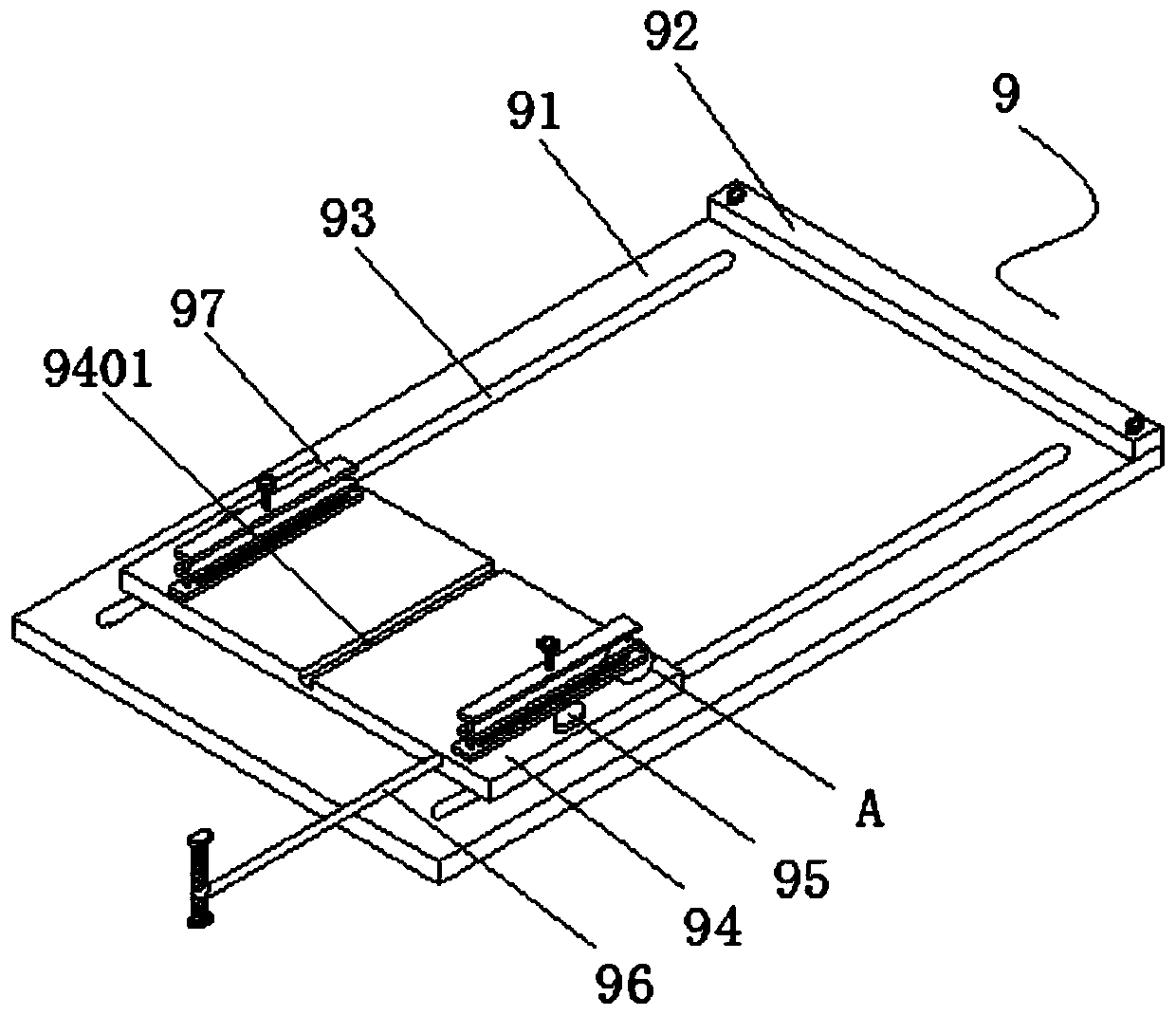

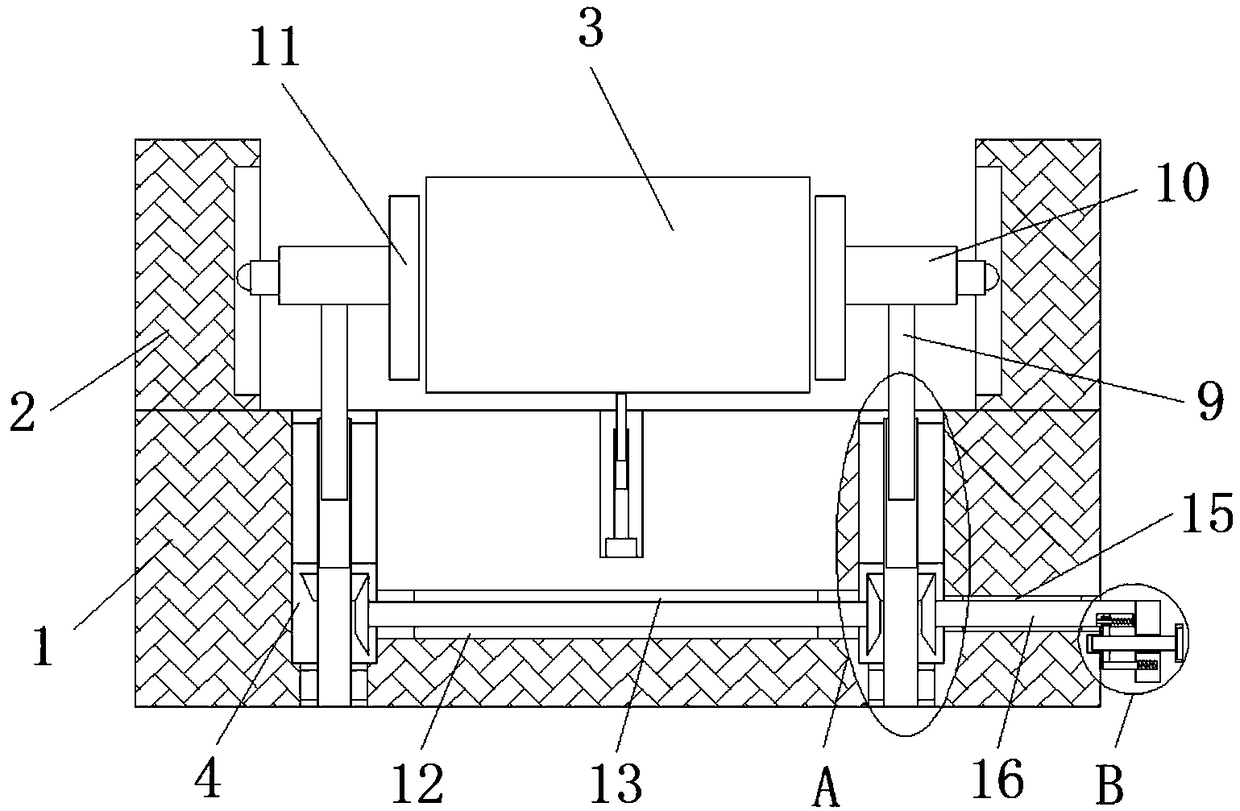

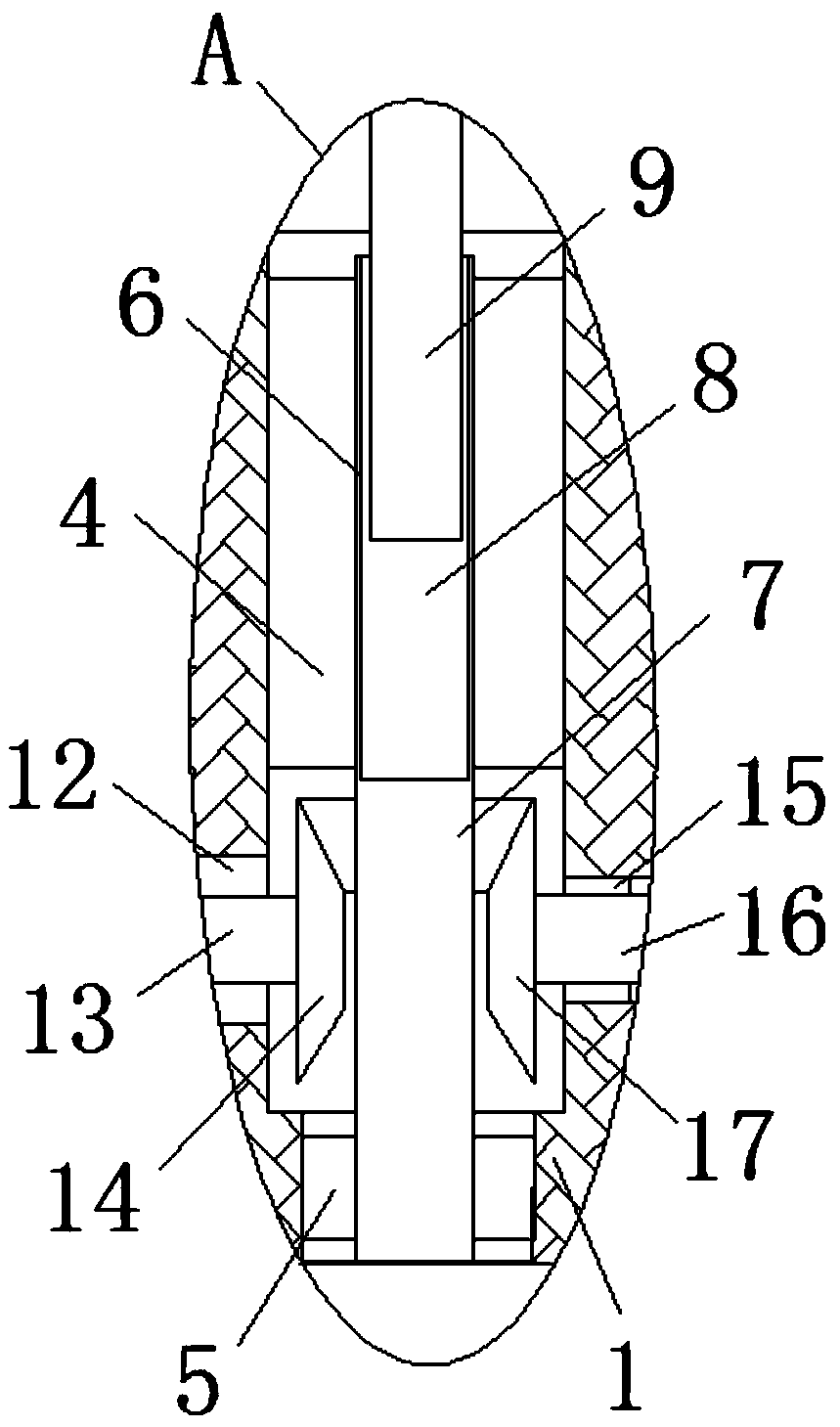

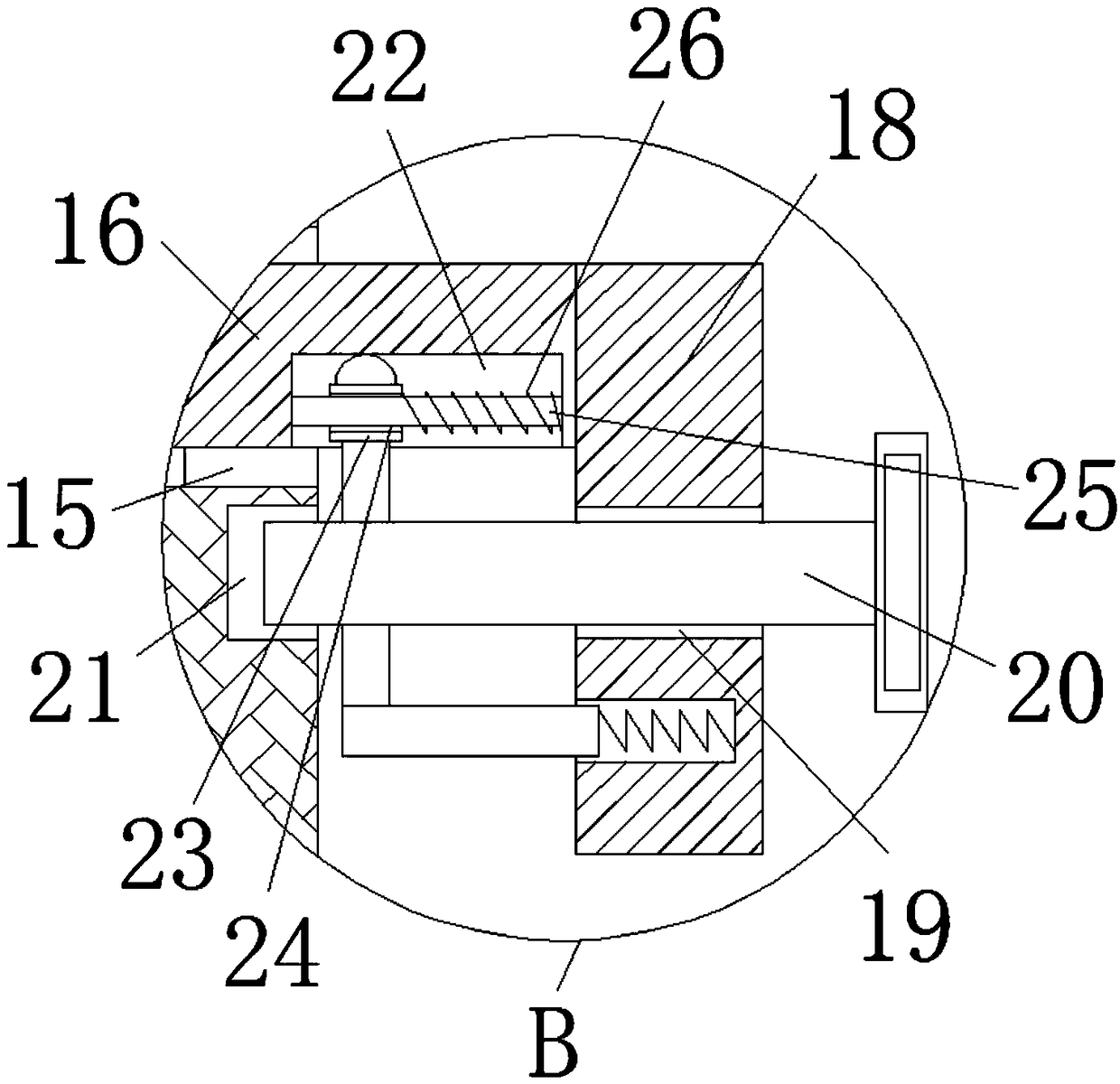

InactiveCN109850658AEasy cutting workThere will be no offsetRegistering devicesArticle deliveryLaser transmitterPulp and paper industry

The invention discloses cotton cloth cutting equipment for textile production. The cotton cloth cutting equipment comprises a machine box, a control box, a power line, a storage battery, a working table, a cross beam, a laser emitter, a laser tube, a pushing device, a support, an infrared sensor, a single chip microcomputer, a circuit breaker, an exhaust device and an alarm, wherein the control box is welded to the front side of the right end of the machine box, the power line is inserted in the rear end of the control box, the storage battery is arranged at the right end of the interior of the machine box, the working table is welded to the middle of the top end of the machine box, and the bottom of the left end and the bottom of the right end of the cross beam are fixed on the left sideand the right side of the middle part of the top end of the machine box through screws on the periphery of the support frame. According to the cotton cloth cutting equipment, a pushing device is arranged on the working table, after cotton cloth is fixed, a push rod is pushed to enable a sliding plate to slide on a bottom plate, a sliding rod slides in a sliding groove so that the sliding plate canbe kept sliding along a straight line, then the cotton cloth can be linearly cut when passing through laser, the cutting work of workers is facilitated, meanwhile, the deviation is avoided, and the quality of the cotton cloth after being cut is improved.

Owner:泉州朔康工业设计服务有限公司

Conveyer applied to aluminum plate production line

InactiveCN108714816AIncrease productivityMeet needsMetal working apparatusProduction lineArchitectural engineering

The invention discloses a conveyer applied to an aluminum plate production line. The conveyer comprises a mounting seat, wherein stand columns are fixedly mounted on the two sides of the top of the mounting seat; a conveyer body is mounted at the top of the mounting seat; first grooves located between the two stand columns are formed in the top of the mounting seat; a rotating groove is formed inthe inner wall of the bottom of each first groove; the same rotating column is rotationally mounted in each rotating groove and the corresponding first groove and is fixedly sleeved with a first bevelgear; a threaded groove is formed in the top end of each rotating column, and a screw is in threaded connection with inside of the threaded groove; the top ends of the screws extend to the position above the mounting seat, and fixing blocks are fixedly mounted at the top ends of the screws. The conveyer is simple in structure and convenient to operate, an aluminum plate can be rapidly and conveniently prevented from deflecting in a conveying process, and production efficiency of the aluminum plate is improved; the conveyer adapts to conveying of different sizes of the aluminum plates by meansof lifting of partition boards, so that demands of workers are met.

Owner:浙江旗创科技集团有限公司

Hydraulic plate shearing machine

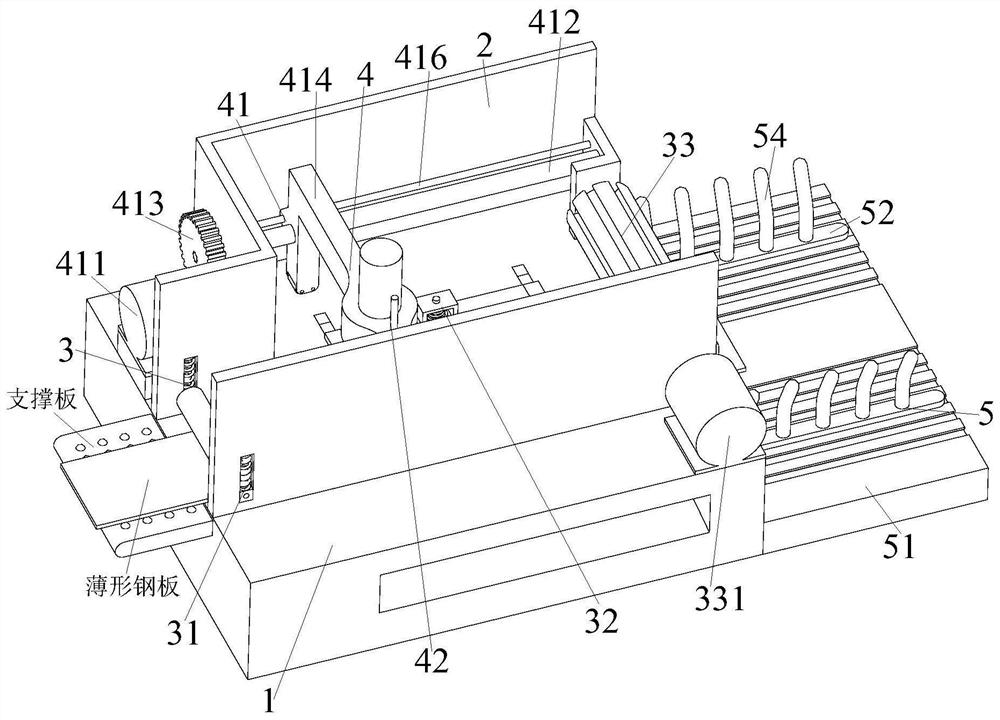

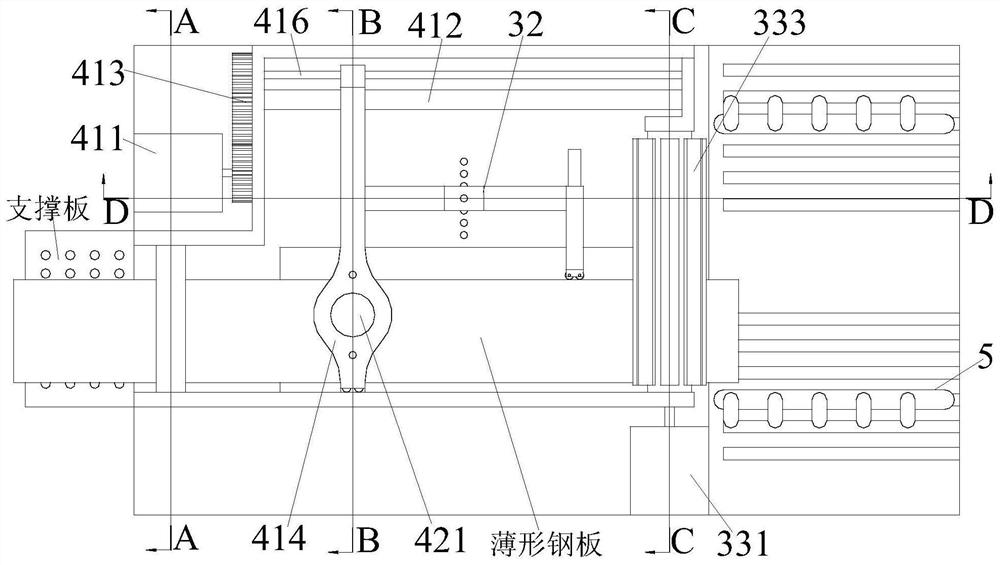

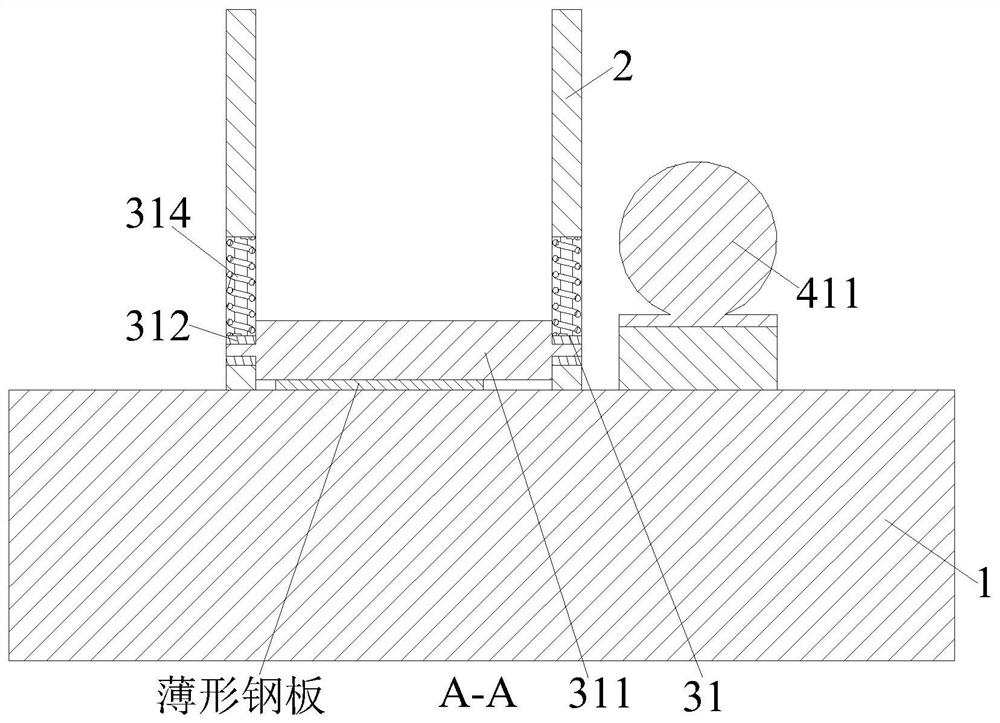

InactiveCN112974950AThere will be no offsetIncrease shear rateShearing machinesShearing machine accessoriesStructural engineeringHydraulic pressure

The invention relates to a hydraulic plate shearing machine. Cutting work of thin steel plates is completed through cooperation of a bottom plate, side plates, a feeding device, a cutting device and a stacking device. The hydraulic plate shearing machine can solve the problems that during manual shearing, because unreeled thin steel plates are directly sheared firstly, and then the sheared thin steel plates are manually collected and stacked, manual shearing wastes time and labor, and in the shearing process, it is difficult to guarantee that the sizes of the sheared thin steel plates are consistent, and when an existing hydraulic plate shearing machine shears the thin steel plates, because an intermittent feeding and shearing mode is usually adopted for shearing the thin steel plates, the shearing efficiency of the thin steel plates is low due to intermittent feeding and shearing, and because the existing hydraulic plate shearing machine does not limit and guide the thin steel plates in the movable feeding process during shearing, the thin steel plate deviates in the feeding process, and then the shapes of the thin steel plates are irregular after the thin steel plates are sheared.

Owner:彭威海

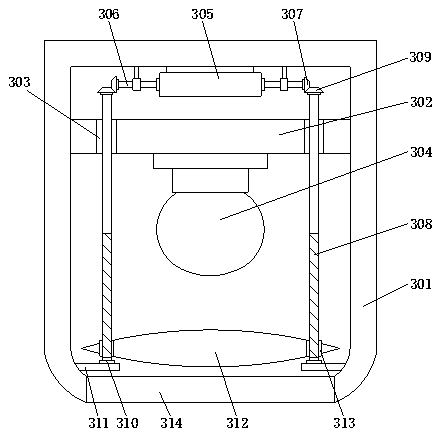

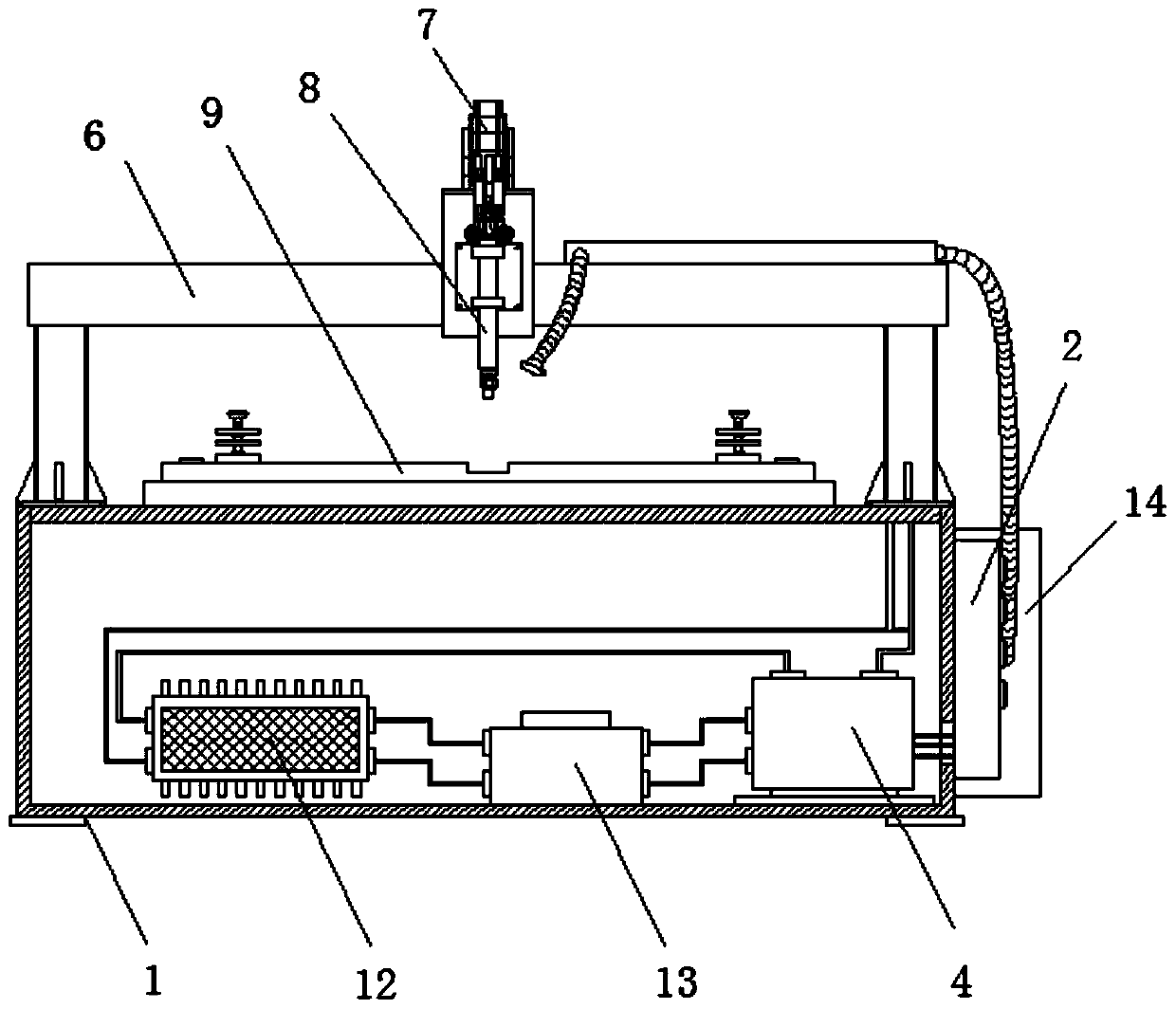

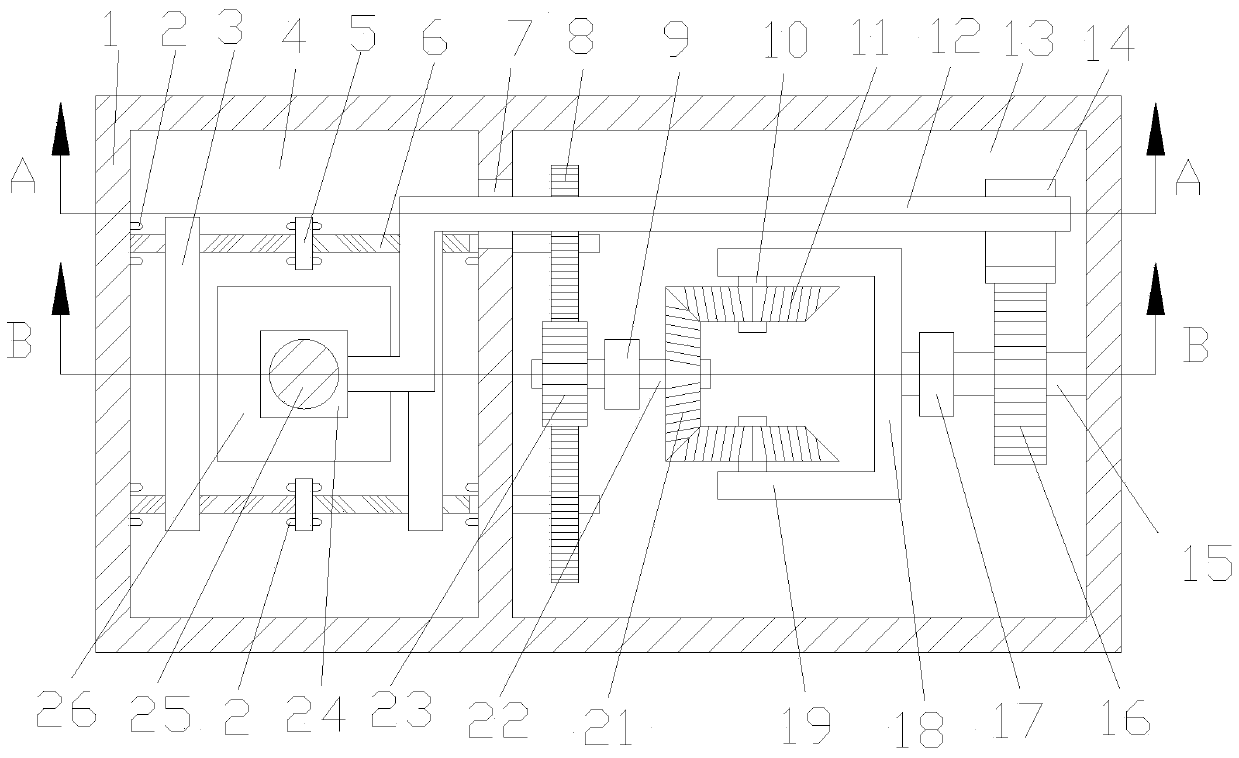

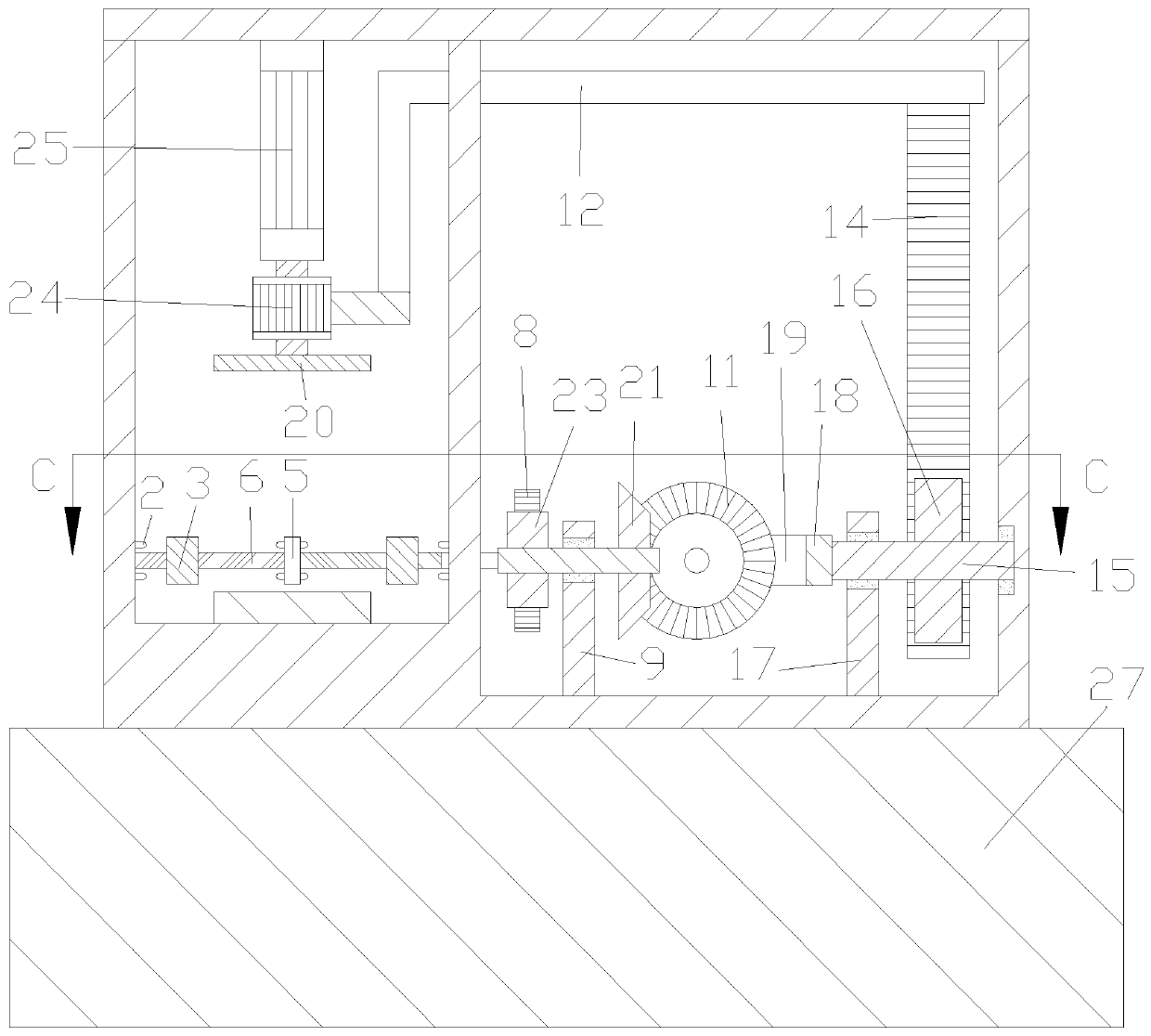

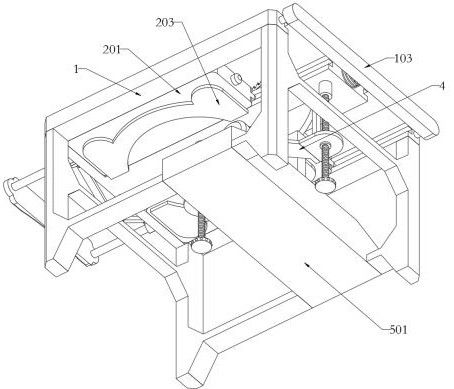

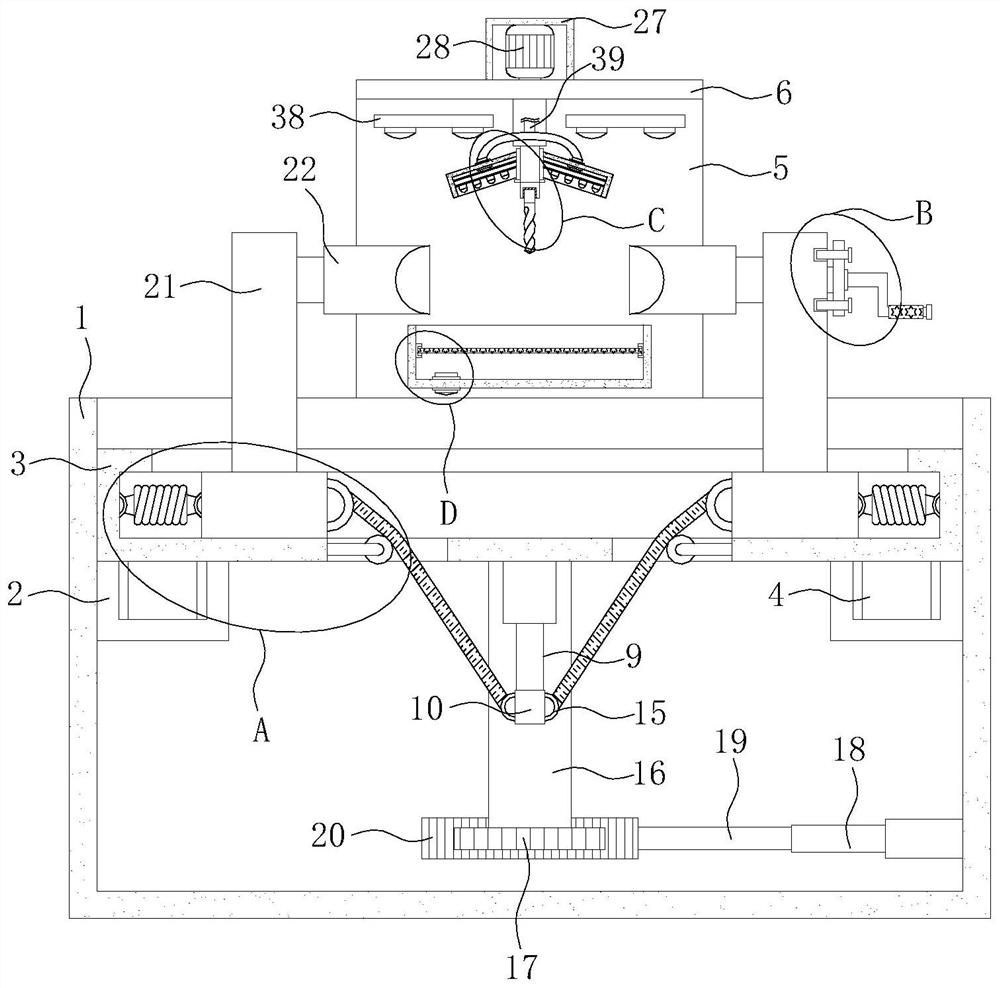

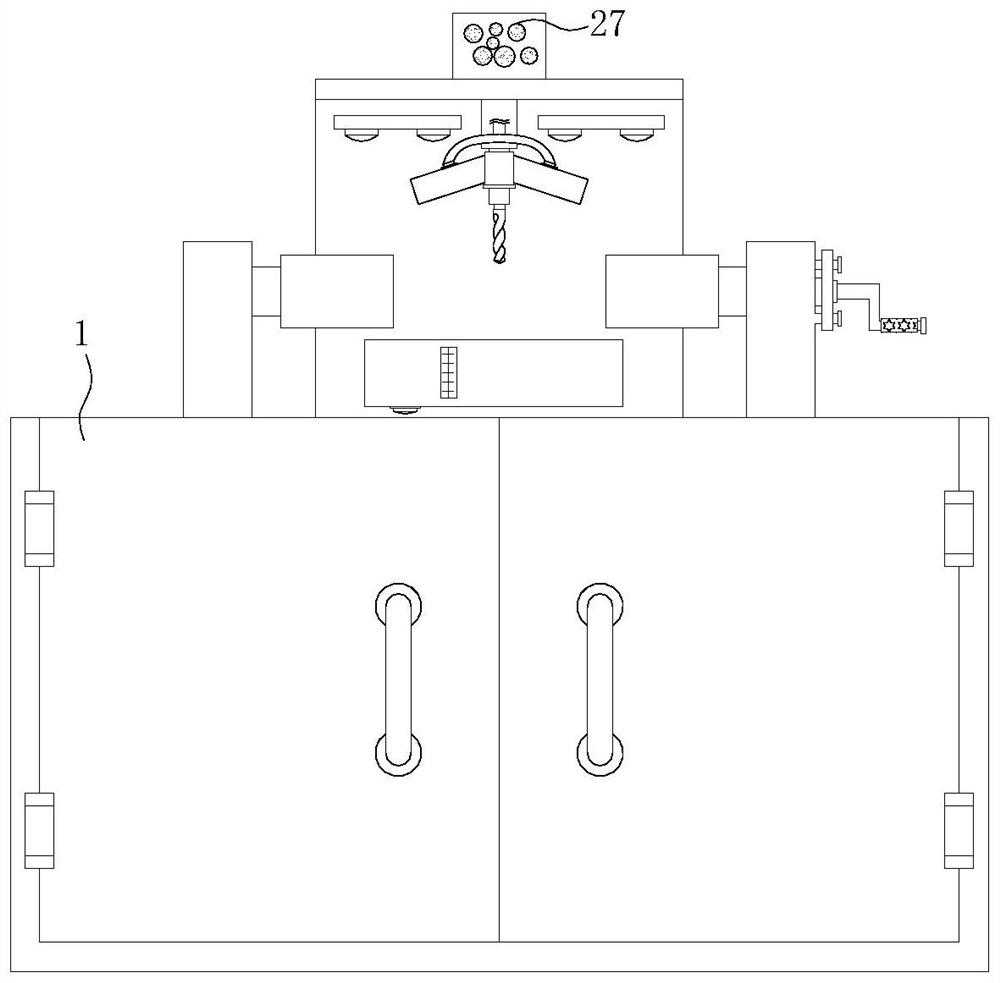

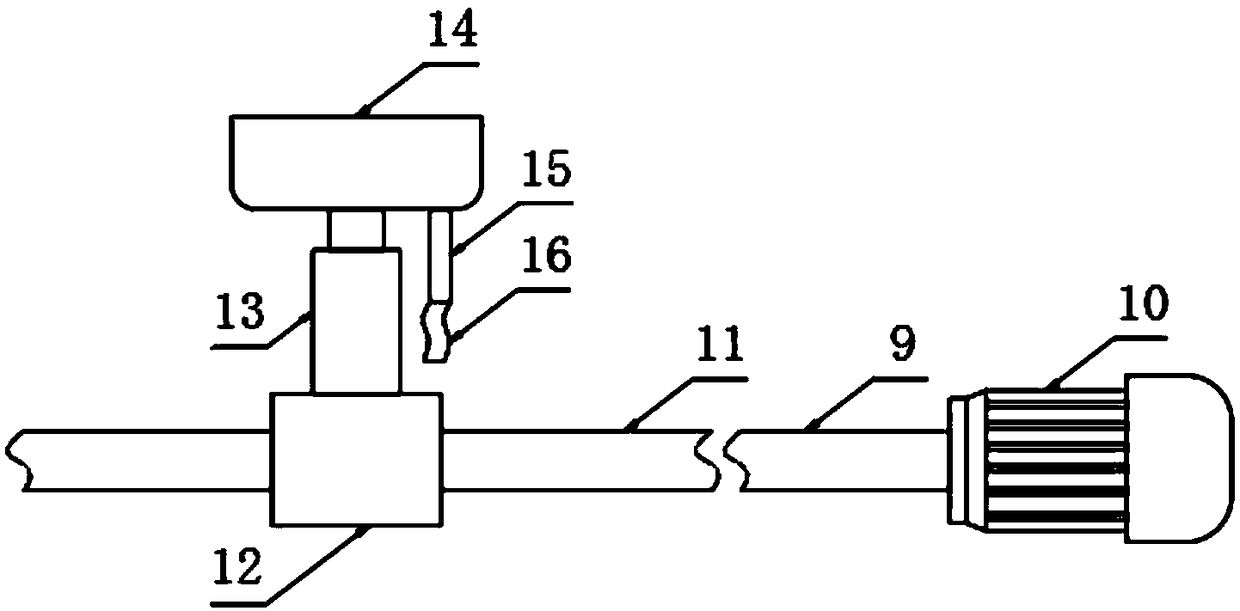

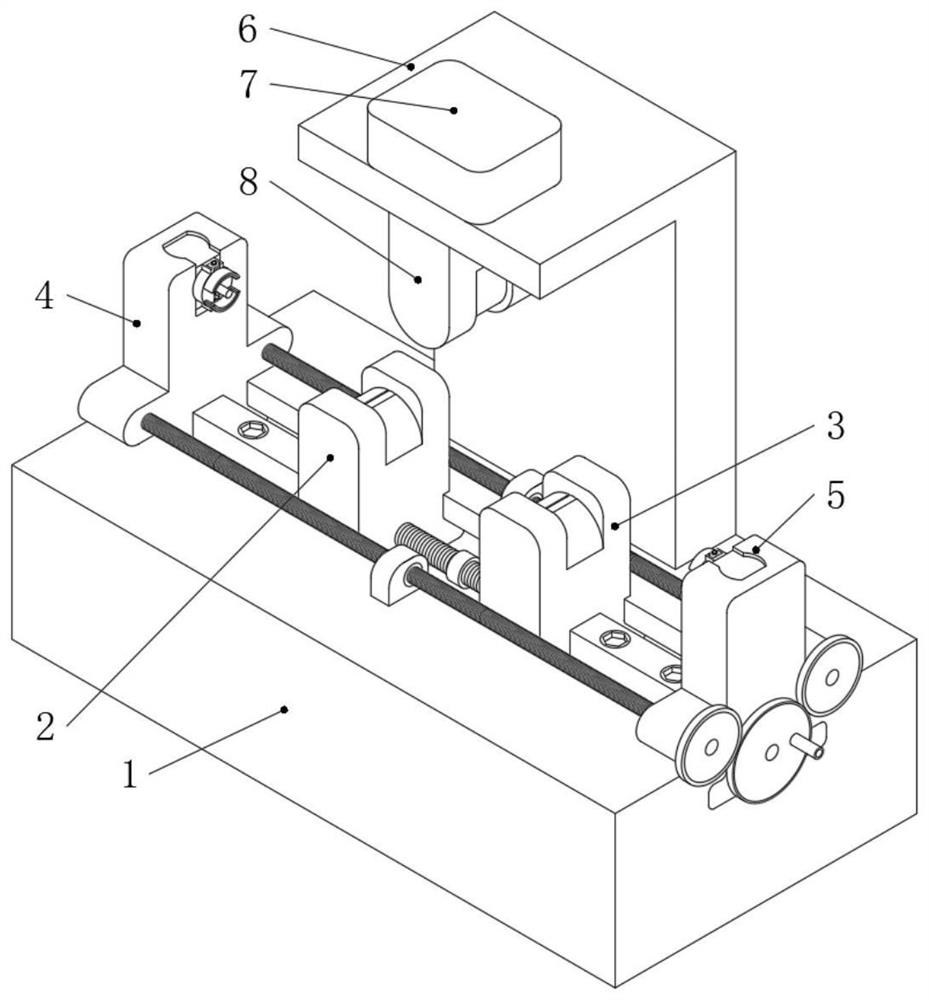

Automatic fixed-disassembly differential grinding machine and using method thereof

ActiveCN110253396AEasy to fixThere will be no offsetGrinding machinesGrinding work supportsEngineeringSelf adaptive

The invention provides an automatic fixed-disassembly differential grinding machine. The automatic fixed-disassembly differential grinding machine comprises a box body, wherein a base is fixedly arranged at the bottom of the box body, a grinding cavity and a clamping cavity which are not communication with each other are arranged in the interior of the box body respectively, and a bearing base used for containing workpieces is fixedly installed at the center of the bottom of an inner wall of the grinding cavity. The automatic fixed-disassembly differential grinding machine and a using method thereof has the advantages of being simple in structure and simple and convenient to operate, so that the materials can be well fixed during grinding, the situations that the materials cannot be effectively fixed by a general grinding machine and the materials cannot deviate during grinding are avoided, the materials are fixed more stably, the situation that the materials shake when the materials are ground is avoided, and the grinding quality is improved, self-adaptive clamping can be carried out on the workpieces with different lengths, and the clamping force for clamping each workpiece is the same, and manual clamping is not needed; and after the workpieces are machined, the workpieces can be automatically disassembled, so that the efficiency is greatly improved.

Owner:陈武琼

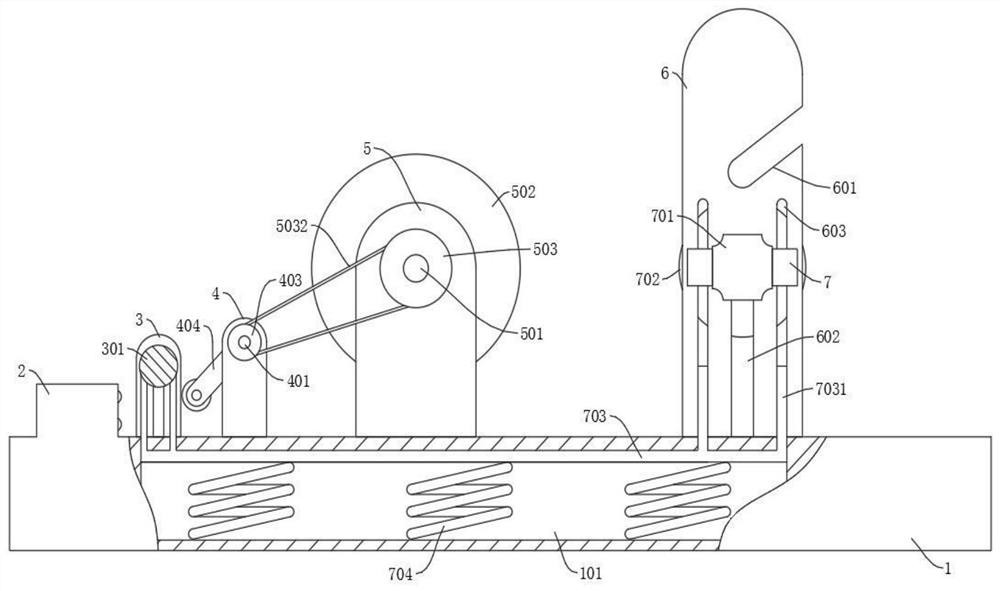

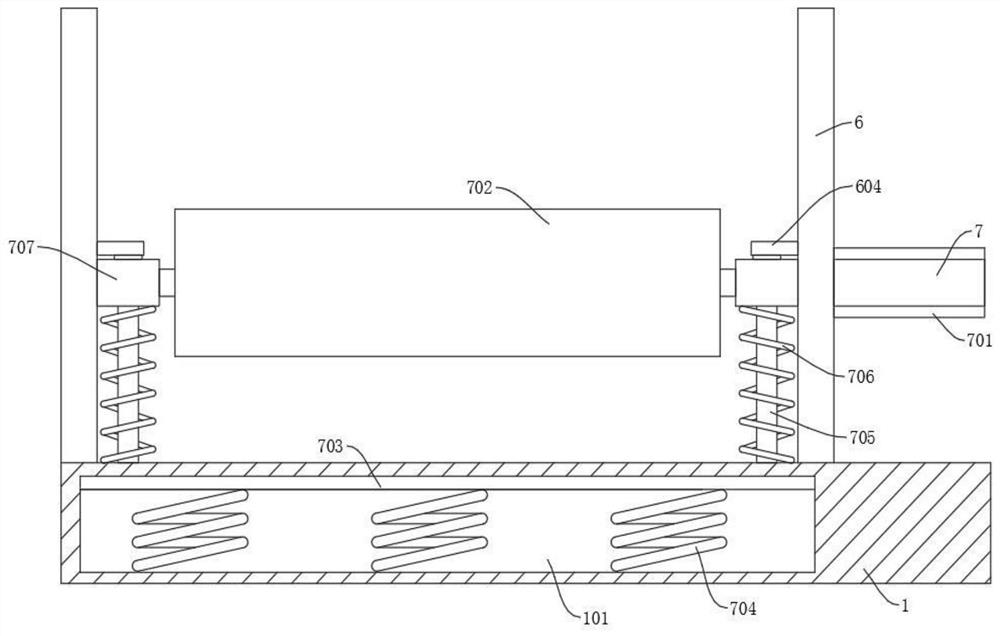

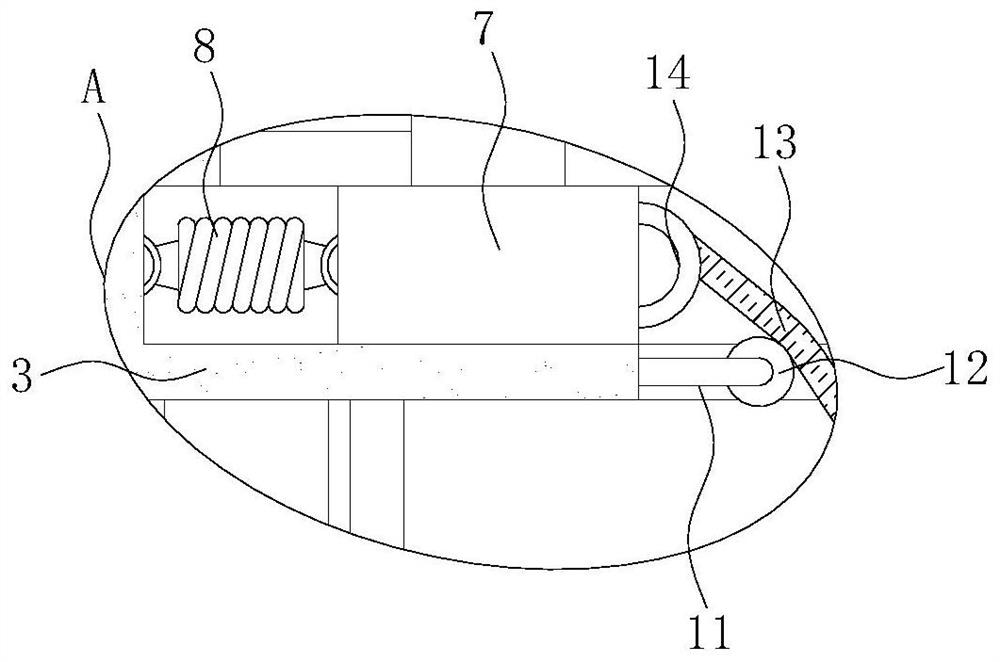

Cloth winding device with anti-deviation structure and for textile product production

ActiveCN111807120AFor subsequent tensioningGuaranteed precise tensionWebs handlingTorsion springCotton material

The invention discloses a cloth winding device with an anti-deviation structure and for textile product production, and belongs to the technical field of industrial cloth production. The cloth windingdevice with the anti-deviation structure and for textile product production comprises a base. A guide roller is rotationally connected in a guide table. An auxiliary mechanism is arranged on a firstmounting column. An adjusting roller is rotationally connected to a swing rod. A torsion spring is connected to a first rotating shaft in a sleeving manner. A first belt wheel is connected to the first rotating shaft. A second belt wheel is connected to a second rotating shaft. The first belt wheel is rotationally connected with the second belt wheel through a belt. An expansion disc is connectedto the second rotating shaft. First sliding blocks are in sliding connection in first sliding grooves. A first spring is arranged in each first sliding groove. An extending rod is rotationally connected to each first sliding block and is attached to the expansion disc. A tension roller is connected to each extending rod. A winding mechanism is arranged on a fourth mounting column. The angle of thetension rollers is automatically adjusted through the swing rod to change the tension, and the subsequent cloth winding tension is increased in real time through a lifting auxiliary roller.

Owner:江西给力纺织有限公司

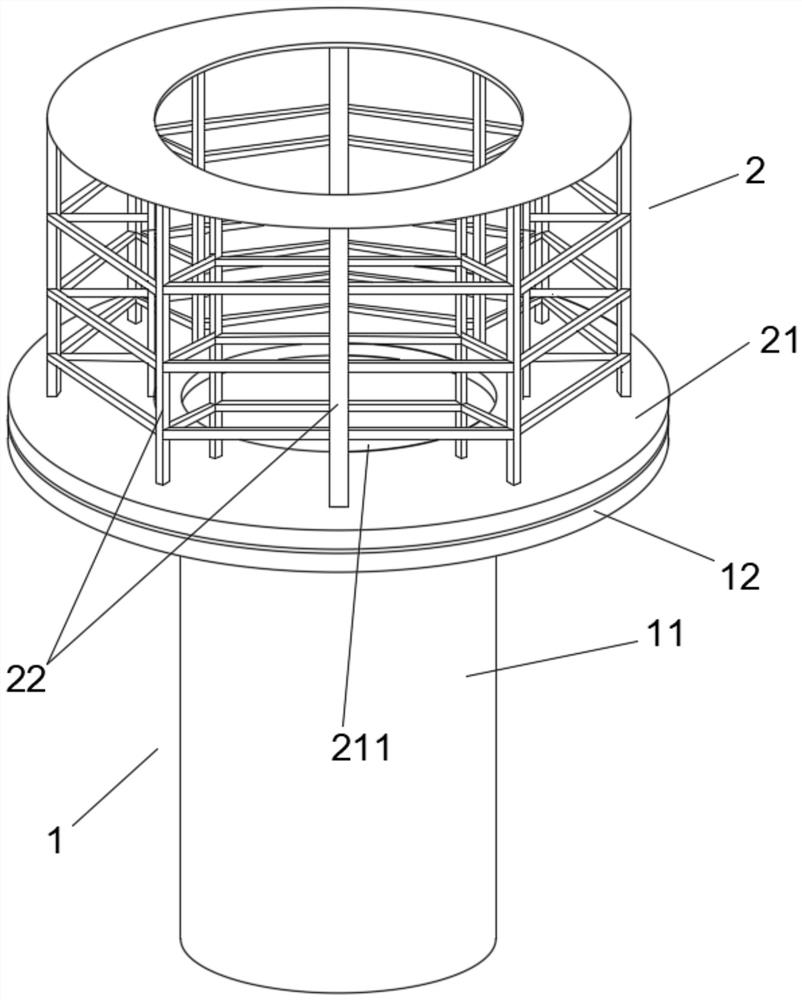

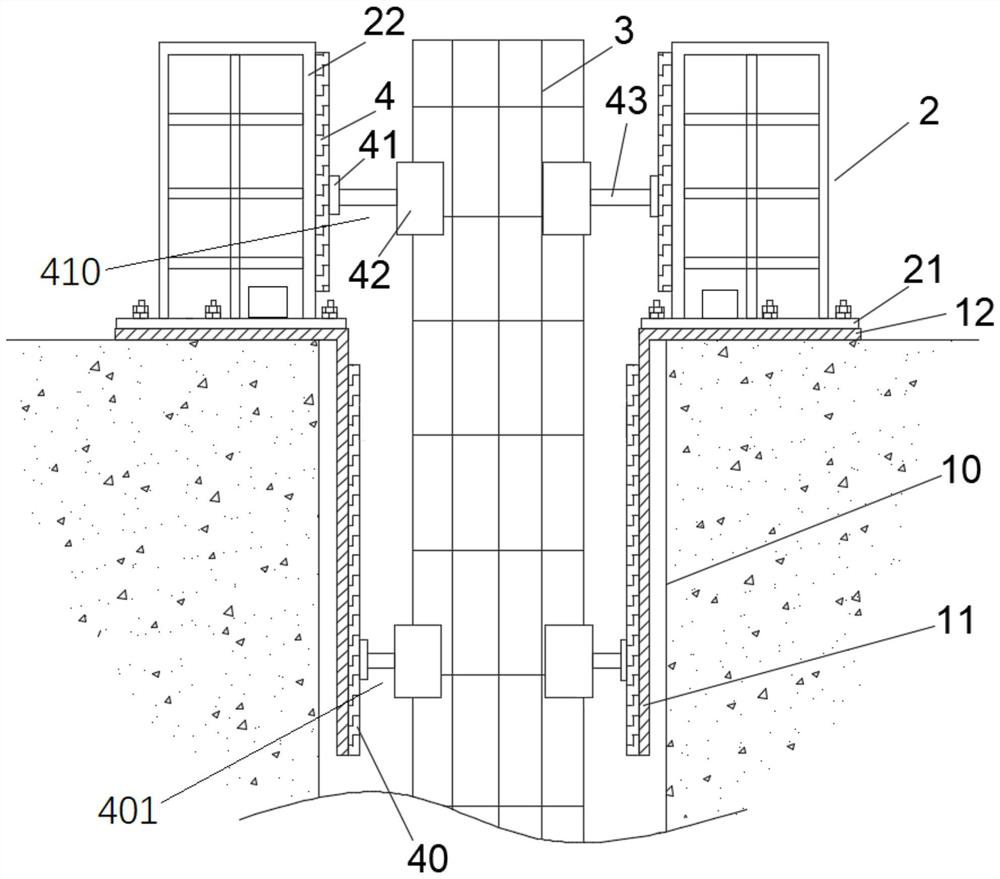

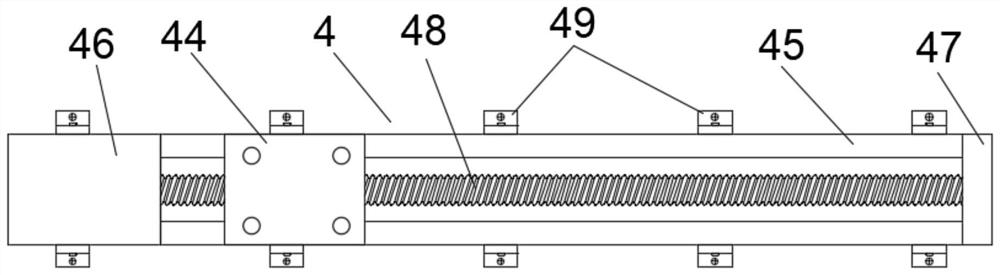

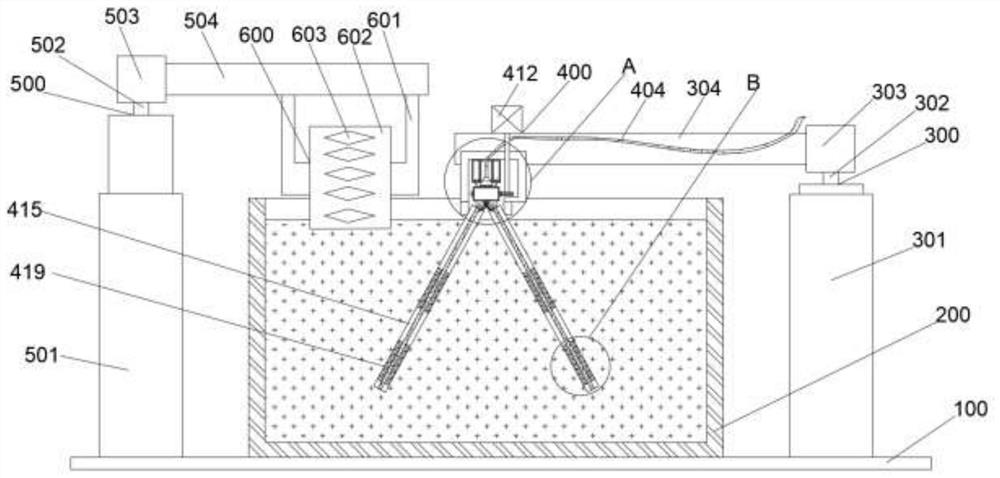

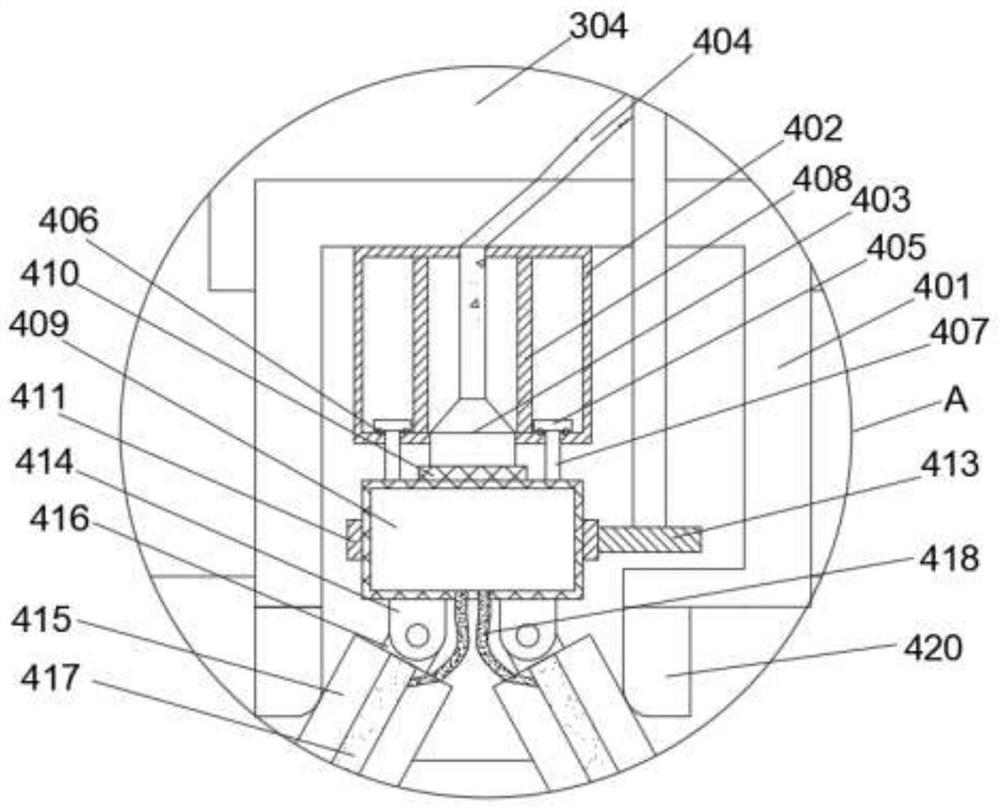

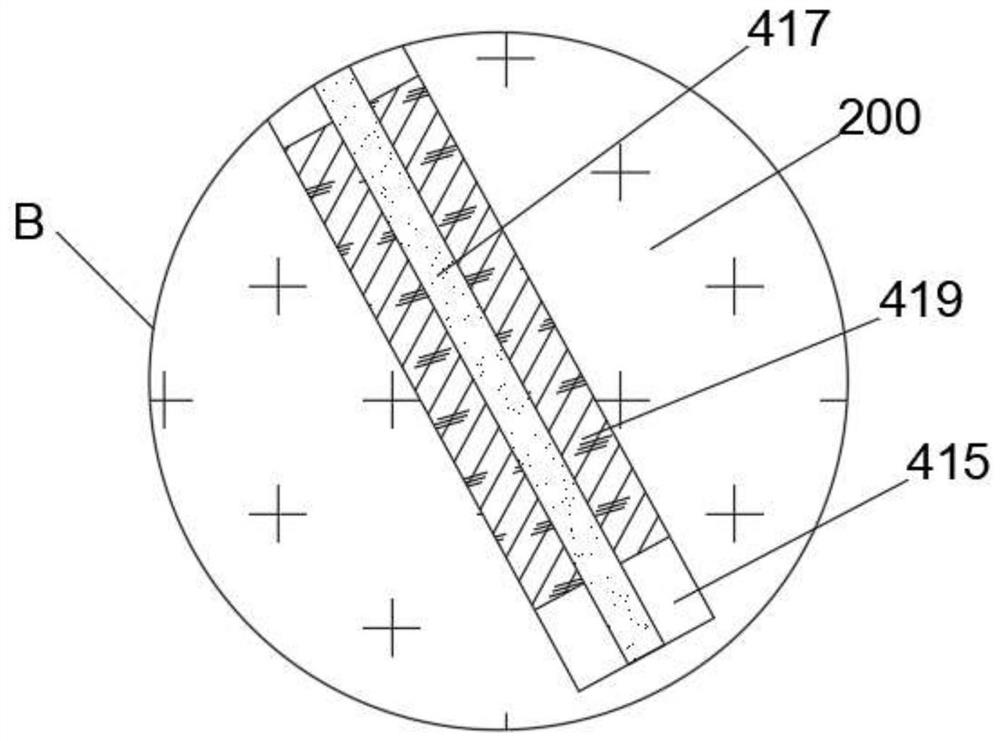

Device and method for preventing alignment offset of pile foundation engineering reinforcement cage

ActiveCN113389202AThere will be no offsetGuaranteed construction effectImage analysisWind energy generationProcessing elementElectric control

The invention provides a device for preventing alignment offset of a pile foundation engineering reinforcement cage. The device comprises a protective cylinder, a support and an image acquisition unit, wherein the image acquisition unit is fixed to the lower portion of the support; a processing unit is electrically connected with a guide rail, a driving unit and the image acquisition unit; the processing unit is further used for matching I0 with L01 and L02 and then continuing to put down the reinforcement cage, and the image acquisition unit is used for acquiring image information of the reinforcement cage every preset time T0 so as to obtain i image data of the reinforcement cage at the i moment; and the I0 is compared with the image information of the reinforcement cage, the telescopic stroke of the first driving unit and the telescopic stroke of the second driving unit are adjusted according to the comparison result, and meanwhile, the putting-down speed of the reinforcement cage is adjusted according to the telescopic stroke adjustment amount. According to the device, the reinforcement cage cannot deviate when being put down, then the reinforcement cage can be always located in the center of a pile hole, and the construction effect is guaranteed; and meanwhile, intelligent control is carried out in an electric control mode, and the construction efficiency can be effectively improved.

Owner:SHANDONG LUNAN GEOLOGICAL ENG SURVEY INST

Electric panel opening mechanism for rollable hidden laser television all-in-one machine

PendingCN110572599ARealize opening and closingPrevent dust from enteringTelevision system detailsProjectorsDevices fixationEngineering

The invention discloses an electric panel opening mechanism for a rollable hidden laser television all-in-one machine. The lifting panel mechanism is composed of a first driving motor, a first driver,a lifting driving rod, a first bevel gear, a lifting lead screw, a second bevel gear, a driving lead screw nut, a lifting guide rail assembly, a lifting connecting piece and a lifting aluminum alloypanel. The translation panel mechanism is composed of a second driving motor, a second driver, a translation driving rod, a synchronous belt assembly, a translation sliding block assembly, a translation guide rail assembly, a translation connecting piece and a translation aluminum alloy panel. The electric panel opening mechanism is reasonable in structure, the laser projection display equipment can be fixedly installed in the laser television all-in-one machine, when a user watches television, the lifting aluminum alloy panel and the translation aluminum alloy panel are moved away, the laserprojection display equipment is directly projected on a curtain, deviation is avoided, the position does not need to be adjusted every time, and when the laser projection display equipment is not used, the through groove in the cabinet body panel is in a closed state, and dust is prevented from entering.

Owner:JIANGSU SHUNHE INTERNET OF THINGS TECH CO LTD

Drilling device for electronic component machining

ActiveCN112059243AEasy to fixThere will be no offsetFeeding apparatusPositioning apparatusEngineeringElectronic component

The invention relates to the technical field of electronic components, and discloses a drilling device for electronic component machining. The drilling device for electronic component machining comprises a supporting plate; clamping devices are arranged on the upper surface of the supporting plate; the clamping devices comprise second electric push rods; horizontal plates are fixedly connected tothe inner side surfaces of the second electric push rods; clamping fixing plates are fixedly connected to the tops of the inner side faces of the horizontal plates; and buffer layers are arranged on the lower surfaces of the clamping fixing plates. According to the drilling device for electronic component machining, by enabling the inner side faces of the two groups of horizontally moving horizontal plates to abut against the left side face and the right side face of the electronic component to fix the electronic component for the first time, and then enabling the lower surfaces of the two groups of buffer layers to abut against the left side and the right side of the upper surface of the electronic component to fix the electronic component for the second time, the fixing effect of the electronic component is improved, and the situation that the electronic components deviate during punching is avoided; and moreover, the device can fix the electronic components with different sizes, sothat the accuracy of the device is guaranteed.

Owner:广州夕千科技有限公司

Tire patch cutting tool

PendingCN108724343AEven by forcePrecise positioningMetal working apparatusRubber sheetMechanical engineering

The invention discloses a tire patch cutting tool. The tire patch cutting tool is provided with a laser lamp. Once any point of the lower end of a pressing rod of a pressing device aligns to the center point of a pressing plate up to down, uniform stress during pressing and cutting can be guaranteed; accordingly, vertical positioning of the tool and the pressing rod of the pressing device can be completed conveniently and rapidly by only turning on the laser lamp to irradiate any position of the lower end of the pressing rod of the pressing device. The tire patch cutting tool is provided withguide sleeves and guide rods, and under action of the guide sleeves and the guide rods, a die-pressing plate can move up and down vertically only, without any offset during pressing downward. The tirepatch cutting tool is provided with the die-pressing plate and a die cutting plate, wherein a first groove which is opposite to the die-pressing plate vertically is arranged on the upper end face ofthe die cutting plate; thus, stamping and cutting position of a rubber sheet to be cut can be completed accurately rapidly by only placing the rubber sheet in the first groove.

Owner:德清信佑易汽车配件有限公司

Cutting equipment for wood furniture processing, and working method of cutting equipment

InactiveCN110625693ASolve the problem of unsafe manual workFire Hazard PreventionFeeding devicesCircular sawsFixed frameFire - disasters

The invention discloses cutting equipment for wood furniture processing. The cutting equipment for the wood furniture processing comprises fixed frames, a fixed device, a hydraulic box, a conveying device, a cutting disc and an exhaust fan; the fixed device comprises a tightening bolt, a fixed plate, baffles, a connecting plate and a movable plate; and the conveying device comprises the fixed frames, supporting plates, rotating wheels, an inclined plate, horizontal rollers and perpendicular rollers. The situation that people are injured due to contact between an operator and the cutting disc of a cutting machine can be avoided; and the problem that a notch of large wood is not tidy during cutting operation of the large wood can be solved through the fixed device and an accuracy rod. In addition, an air outlet is formed in the bottom of a housing, and collection of wood chips can be completed by using the exhaust fan and a collecting box, so that the problem that a fire disaster happensdue to the fact that the wood chips are not cleaned in time is solved.

Owner:安徽持家汉家居工艺品有限公司

Multi-angle cutting device for glass fiber reinforced plastic tube processing

The invention provides a multi-angle cutting device for glass fiber reinforced plastic tube processing, relates to the technical field of glass fiber reinforced plastic tube processing equipment, and aims to solve the problem that when an existing cutting device is used, a glass fiber reinforced plastic tube is pushed by hands to move, so that an operator feels tired. The multi-angle cutting device comprises a frame body, wherein a clamping groove is formed in the side face of a side face baffle plate of the frame body, and an adjusting mechanism is mounted at the top of the frame body; protruding blocks are arranged on the two sides of a sliding plate in the adjusting mechanism, and the sliding plate is mounted in a sliding groove in a sliding mode; a pushing mechanism is mounted on the side surface of the frame body; a push rod in the pushing mechanism penetrates through the side surface of the frame body and is mounted on the side surface of the sliding plate; threaded rods are mounted on the two sides of the top of a carrying plate, the carrying plate is mounted at the bottom of the frame body through the threaded rods on the side face of the top, and a motor is mounted on the top of the carrying plate; and a cleaning piece is mounted at the bottom of the frame body. An arc-shaped structure on the side face of a push plate fits the abdomen of an operator to assist movement of the sliding plate.

Owner:禧天龙江苏科技发展有限公司

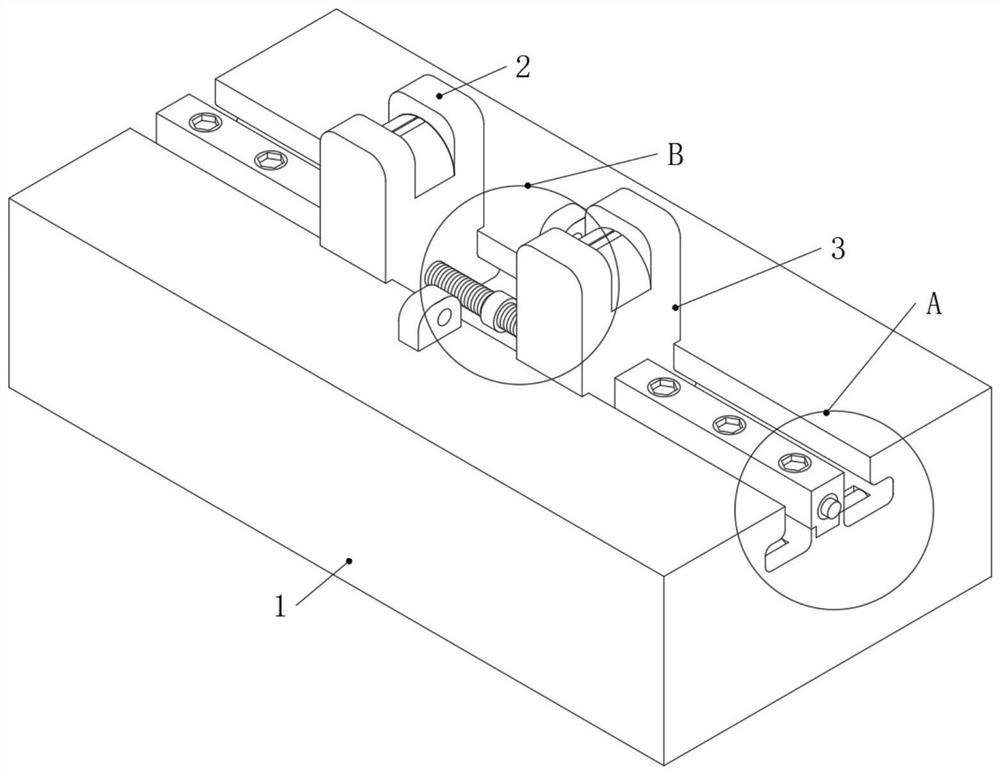

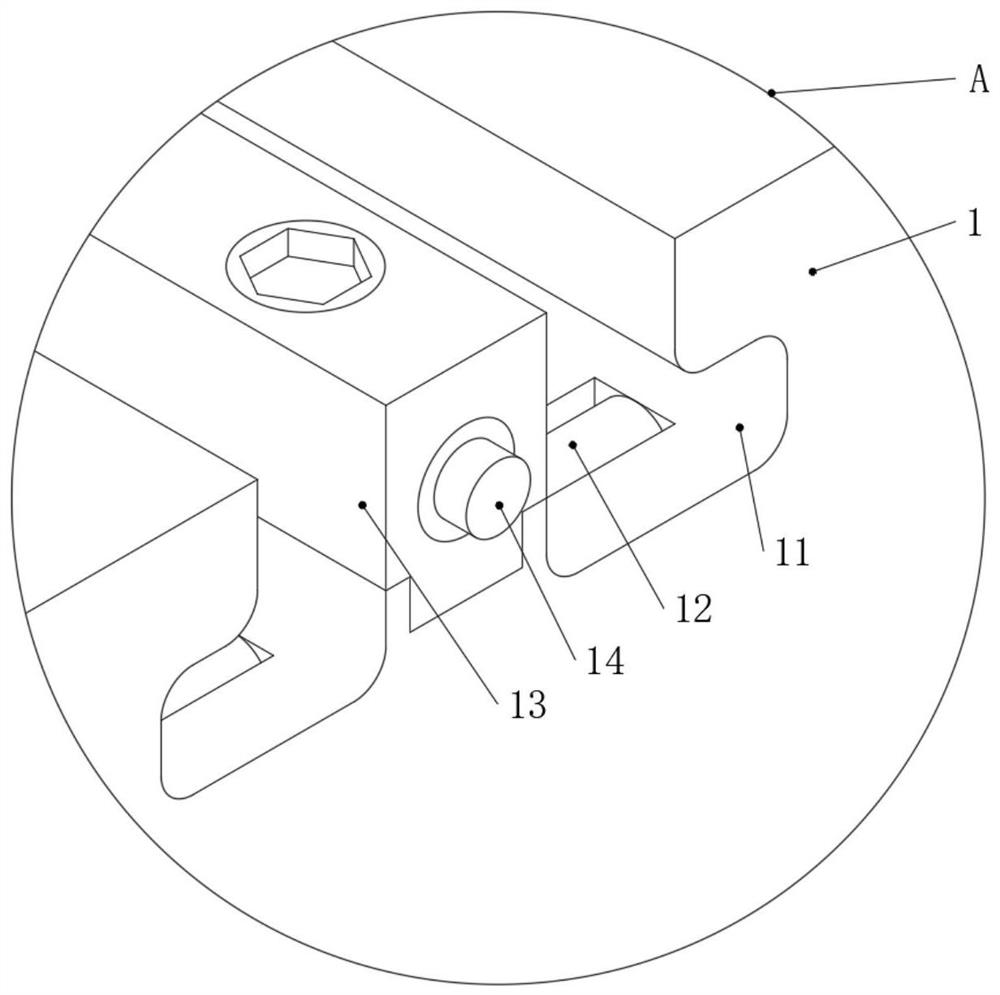

Indentation measuring device for detecting Brinell hardness tester

InactiveCN111157331AHigh precisionThere will be no offsetInvestigating material hardnessBrinellingSclerometer

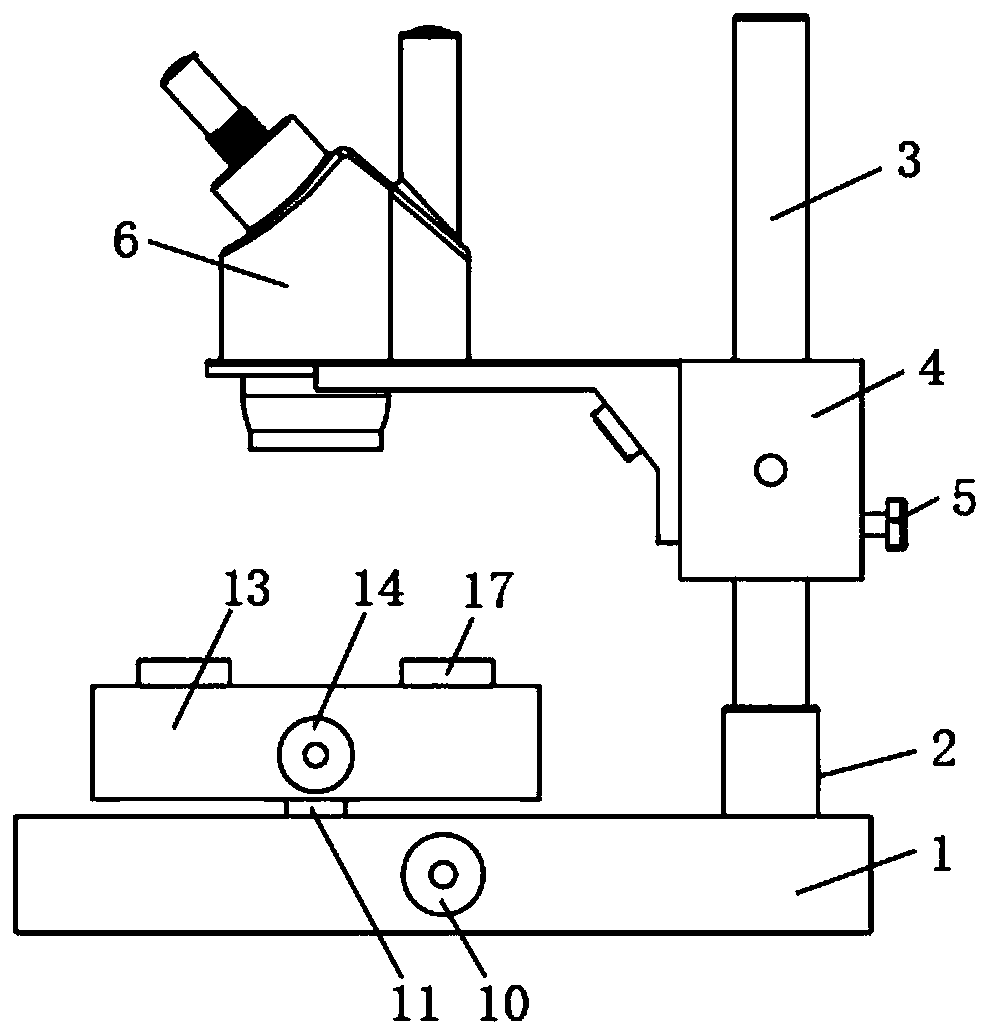

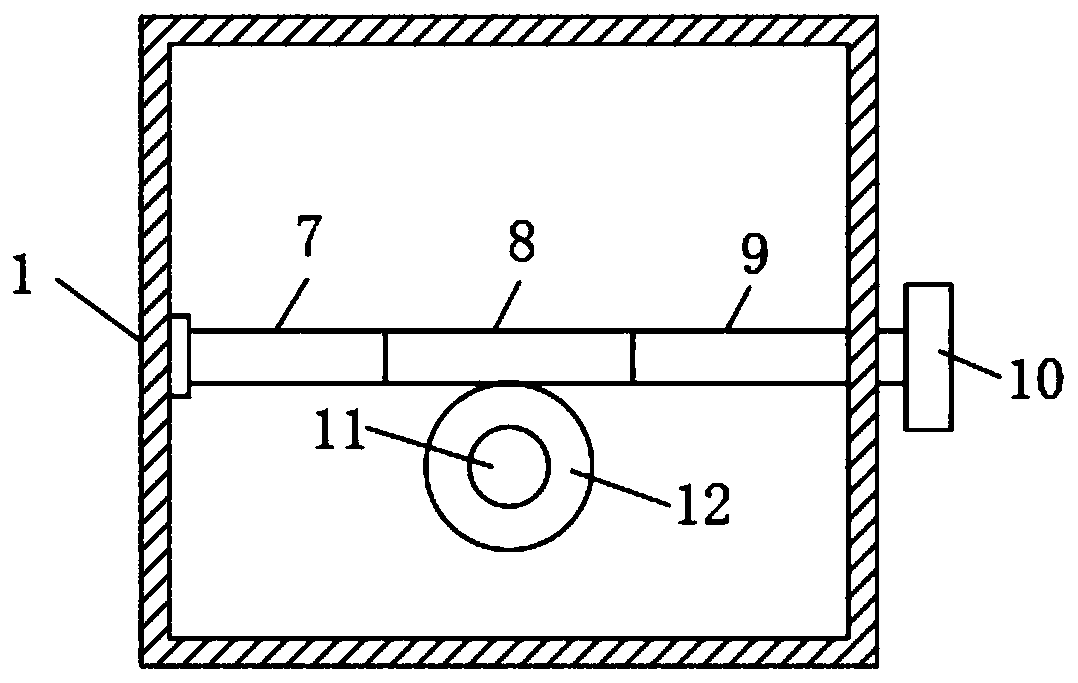

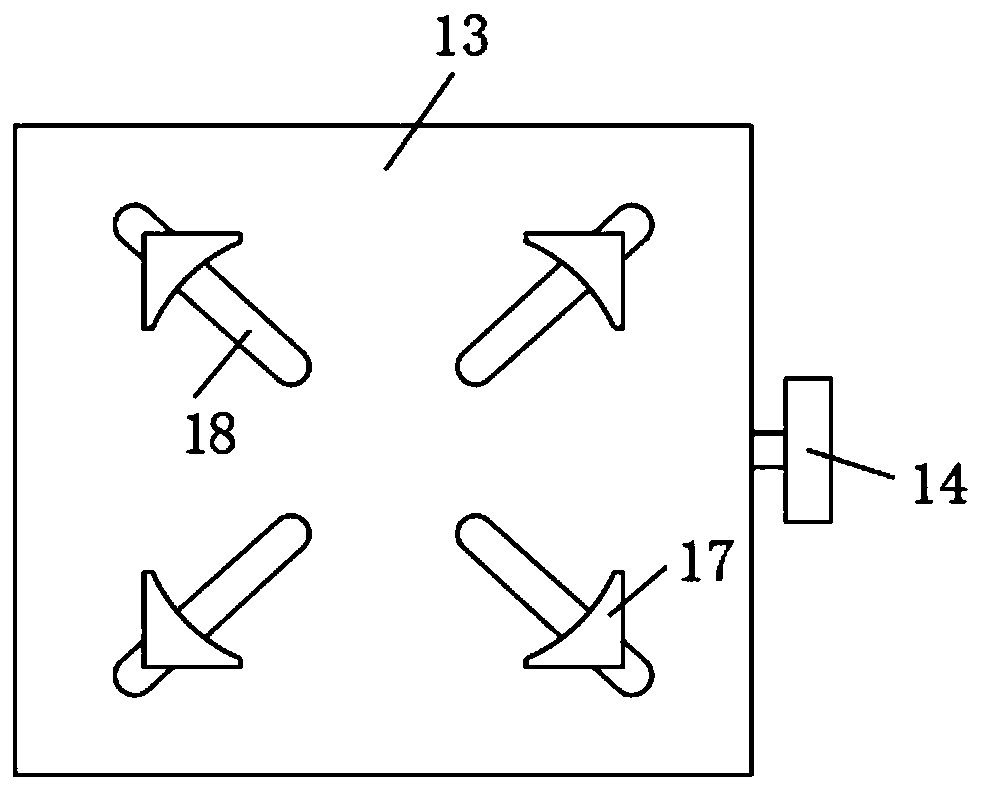

The invention provides an indentation measuring device for detecting a Brinell hardness tester, and relates to the technical field of indentation measurement. The indentation measuring device for detecting the Brinell hardness tester comprises a mounting base, wherein a fixing block is fixedly mounted on the upper surface of the mounting base; and the top of the fixing block is fixedly connected with a sleeving rod; the outer surface of the sleeving rod is sleeved with a sleeving block; one side of the sleeving block is fixedly provided with a reading microscope; the other side of the sleevingblock is in threaded connection with a locking bolt; and the inner side wall of the mounting base is rotatably connected with a first rotating rod through a bearing. According to the invention, through the cooperation of structures such as a first transmission assembly, a second transmission assembly and a third transmission assembly, a clamped standard hardness block is enabled to be always located under the reading microscope, the deviation condition is avoided, and the indentation measurement accuracy is improved. Meanwhile, the four clamping blocks can be suitable for standard hardness blocks with different diameters, the universality of the whole device is improved, and the practicability is high.

Owner:无锡商测检测技术有限公司

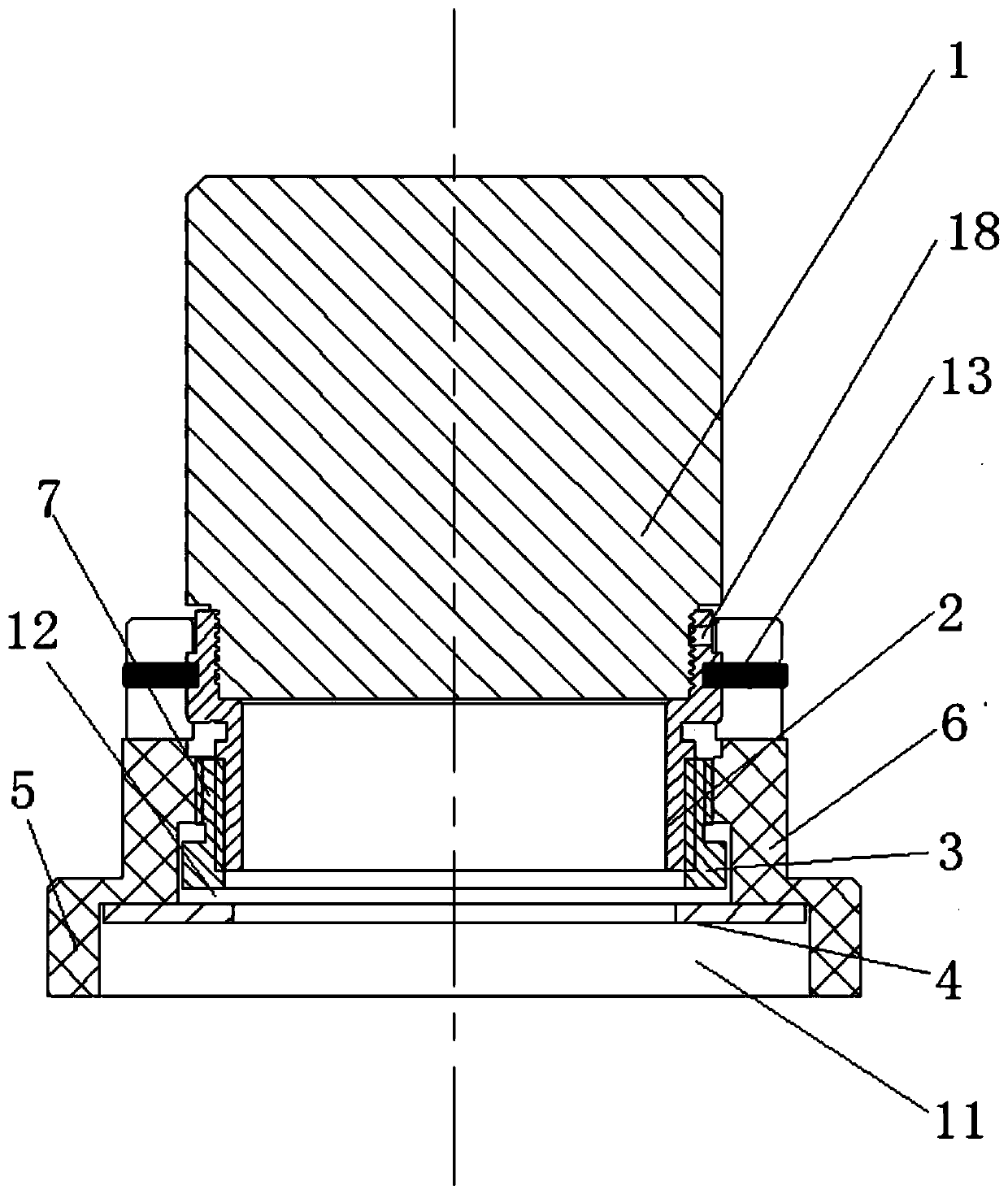

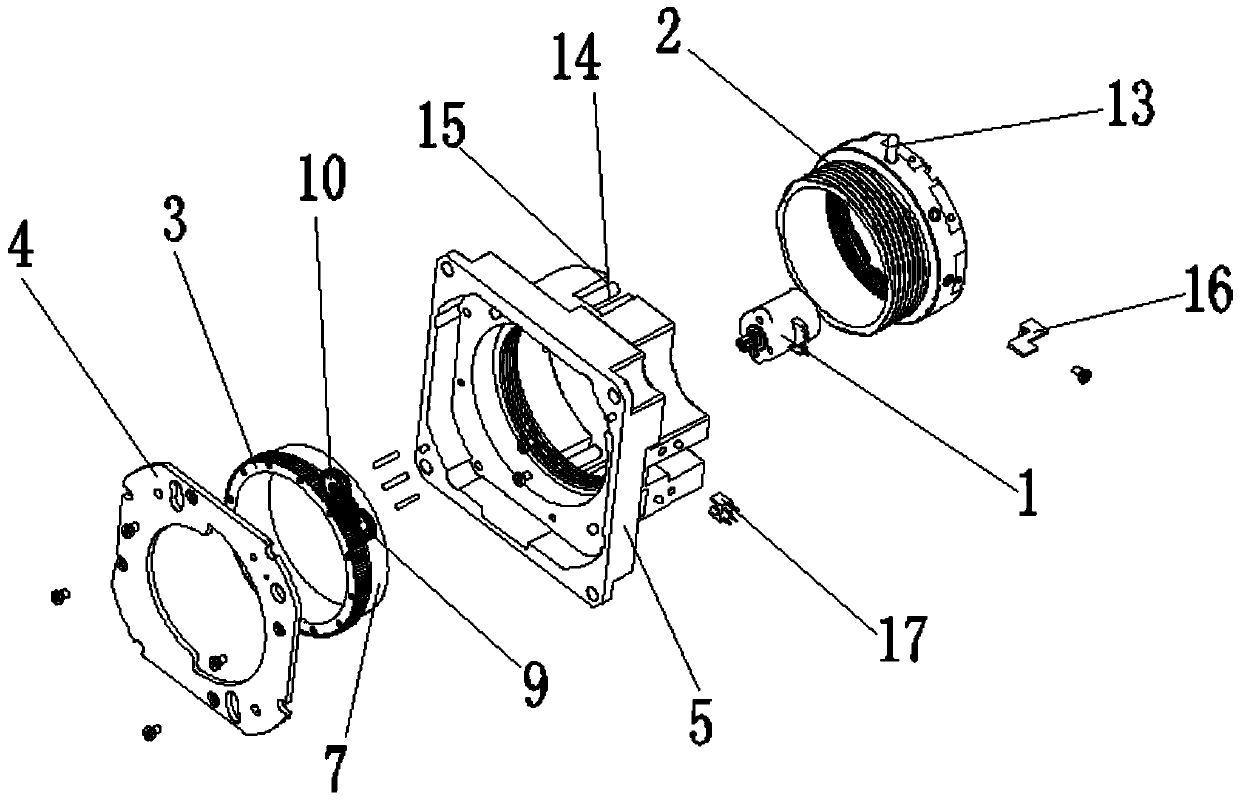

Fixing device for motor end cover machining

ActiveCN112091679AAvoid troubleEasy to drillMetal working apparatusPositioning apparatusStructural engineeringMachining

The invention discloses a fixing device for motor end cover machining, and relates to the technical field of motor machining. The fixing device for motor end cover machining comprises a mounting box,wherein an annular plate is welded and mounted in the mounting box; a mounting plate is arranged at the top of the annular plate; an annular sliding groove is formed in the annular plate; an annular sliding block is slidably mounted in the annular sliding groove; the bottom of the mounting plate and the top of the annular sliding block are fixedly mounted; the mounting plate and the annular sliding block are slidably mounted; and a fixing plate is welded to the top of the mounting box. According to the fixing device for motor end cover machining provided by the invention, a motor end cover canbe clamped and fixed, so that the next tapping operation is facilitated; and the motor end cover can still rotate after being fixed, so that the situation that the position needs to be repeatedly clamped and adjusted during transposition tapping is avoided, the problem that the machining efficiency is affected due to repeated clamping is avoided, on the other hand, troubles brought to an operatordue to repeated clamping are avoided, and the practicability and the convenience of the device are effectively enhanced.

Owner:浙江德易精密机械有限公司

Cutting machine with detection structure for electronic material processing

PendingCN114669870AConfirm cutting qualityEasy to carryGlass severing apparatusLaser beam welding apparatusElectric machineryDrive motor

The electronic material processing cutting machine with the detection structure comprises a bottom plate, a supporting box is mounted at the top of the bottom plate, fixing columns are mounted at the top of the supporting box through bolts, supporting rods are mounted on the opposite faces of the two fixing columns, a mounting shell is mounted at one end of each supporting rod, and a detection structure is mounted at the other end of each supporting rod. A driving motor is mounted in the mounting shell, and the output end of the driving motor is connected with a first screw rod; a controller is mounted at the top of the supporting box through bolts and located behind the fixing columns. The ultrasonic flaw detection device is installed, an ultrasonic generator in the ultrasonic flaw detection device emits ultrasonic waves to a workpiece passing through the lower portion, the ultrasonic waves penetrate through the interior of the workpiece and then are reflected, and an ultrasonic receiver in the ultrasonic flaw detection device receives the returned ultrasonic waves; whether scars exist in the cut workpiece or not is known, and the workpiece cutting quality is confirmed.

Owner:NANTONG DINGSHANG ELECTRONICS MATERIAL CO LTD

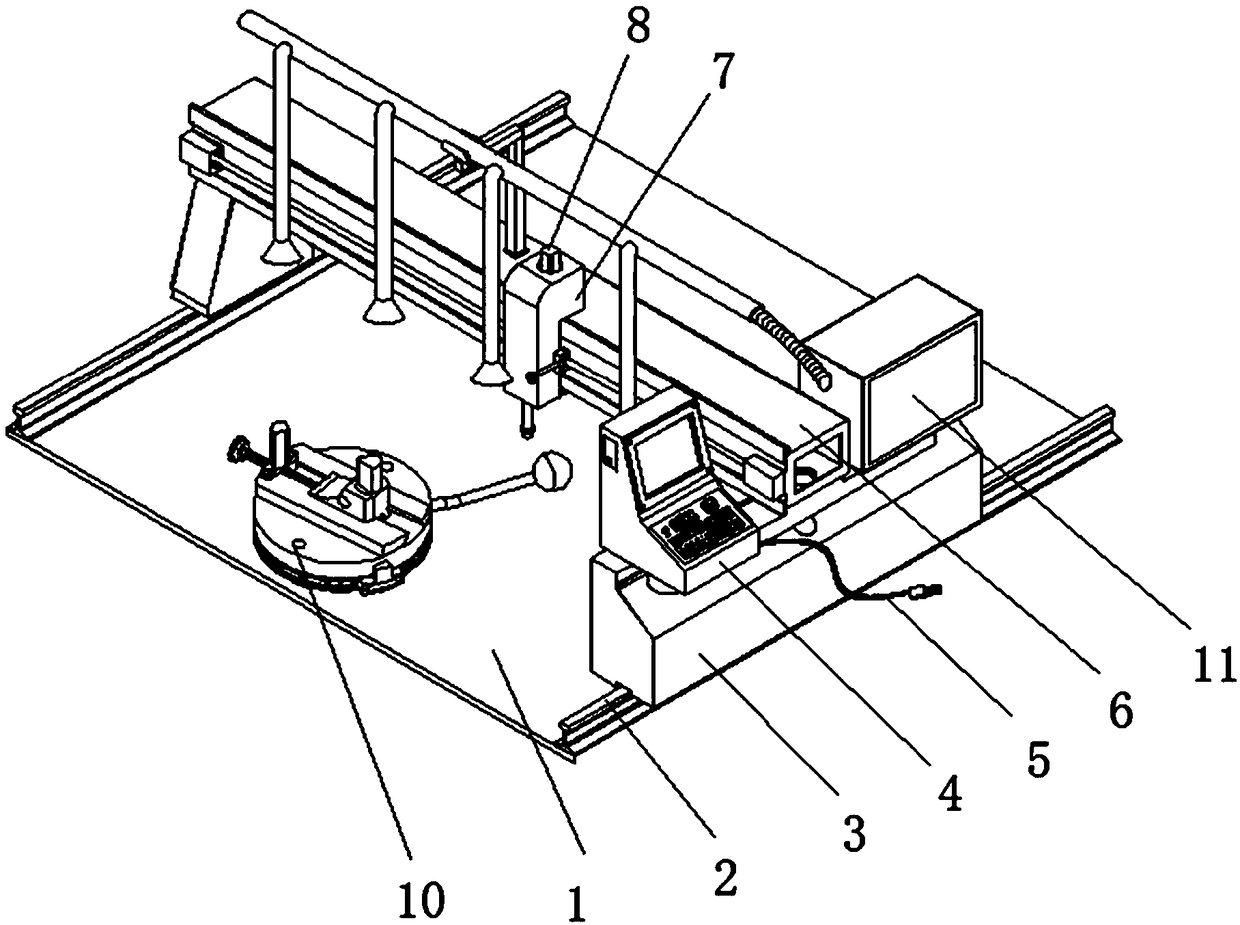

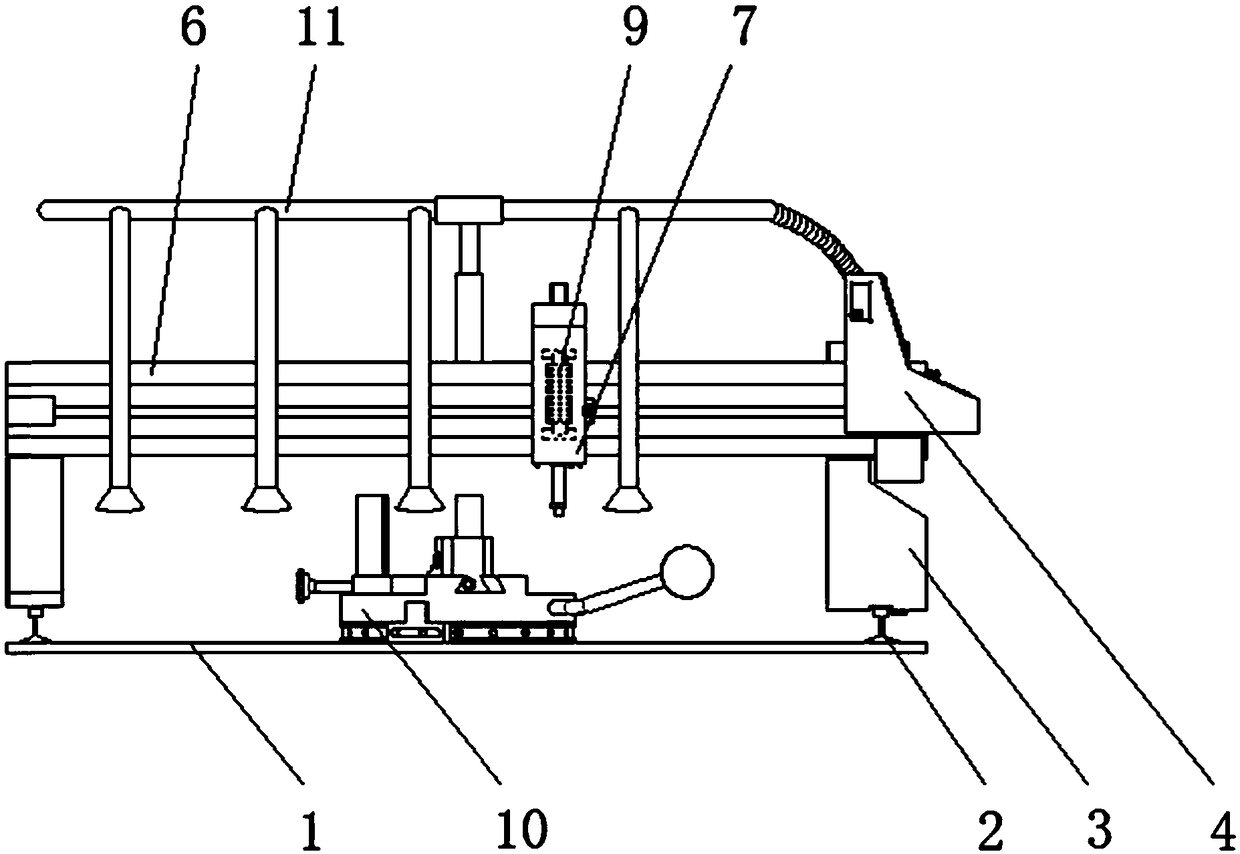

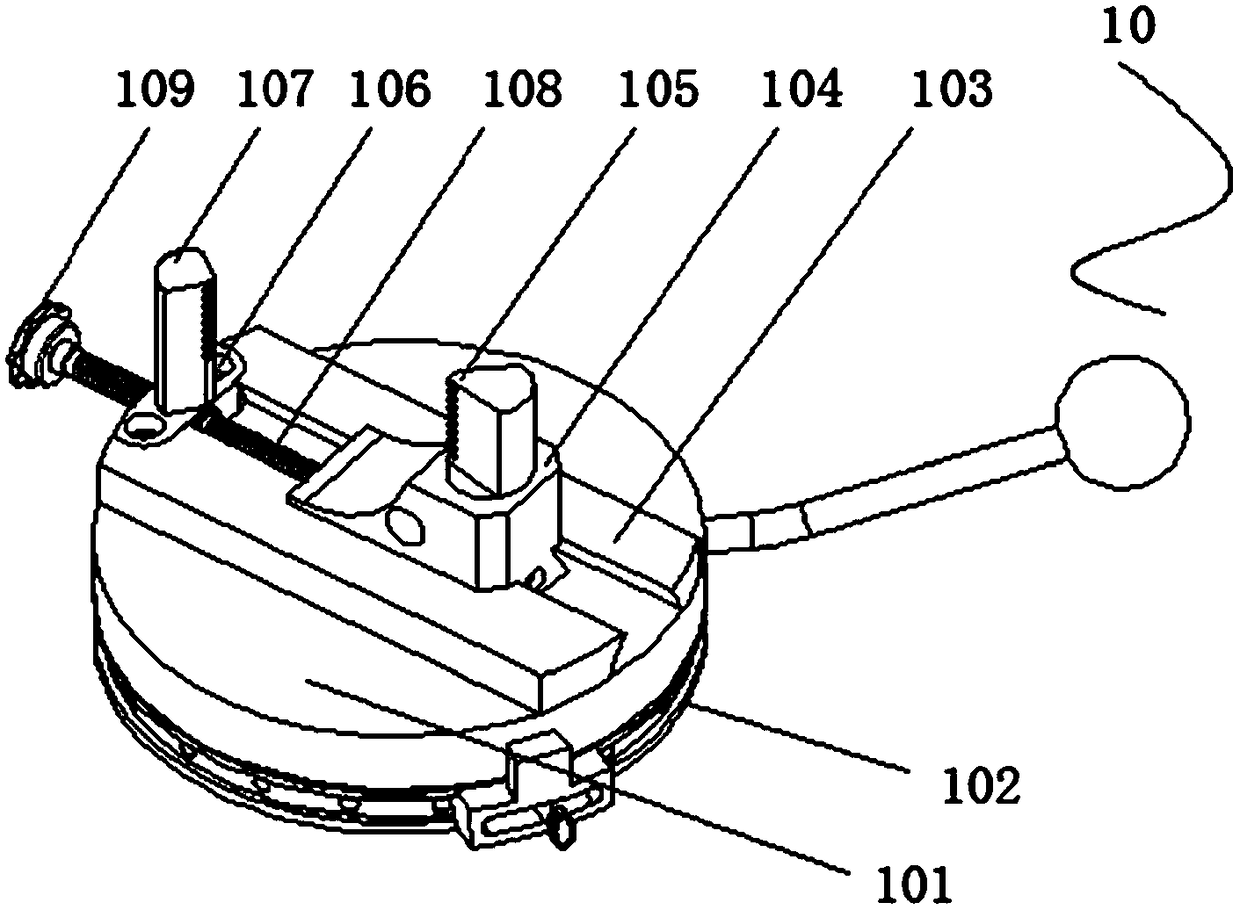

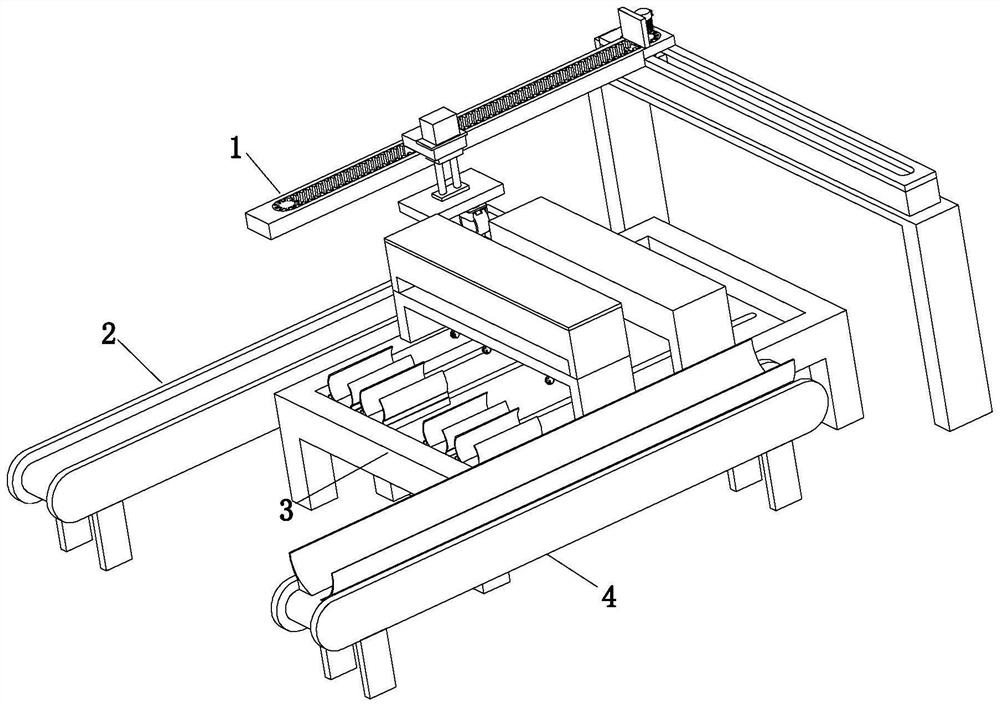

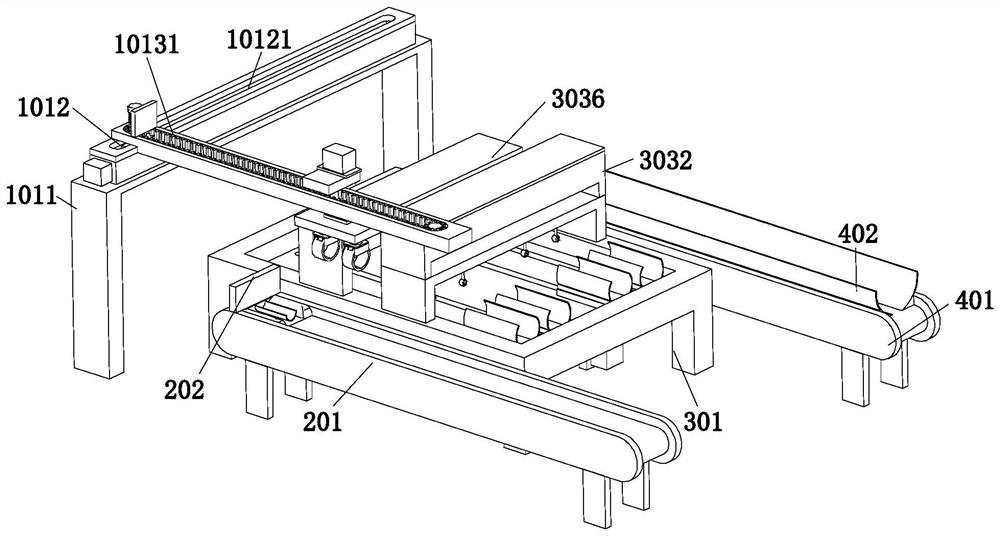

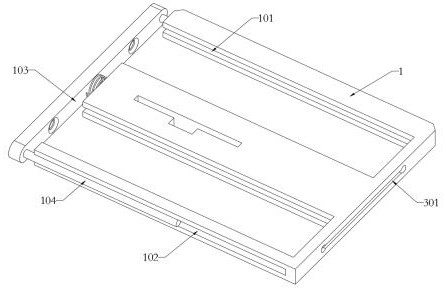

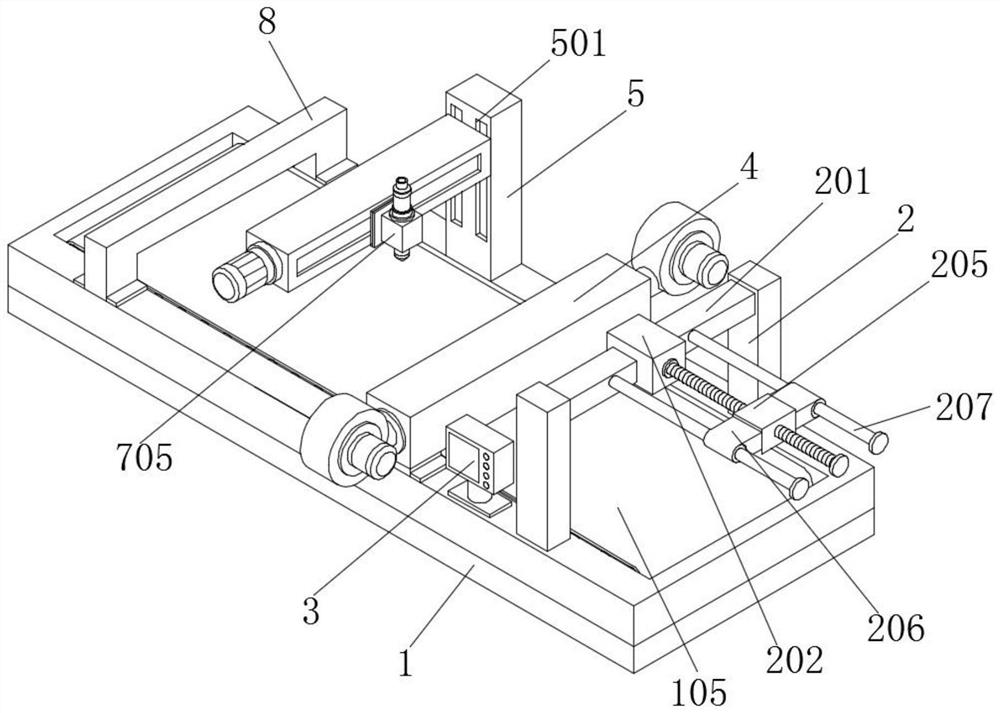

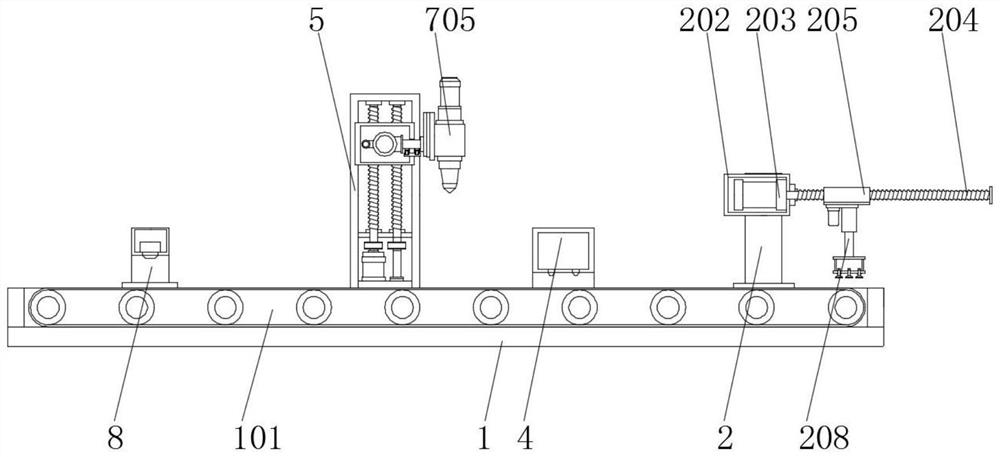

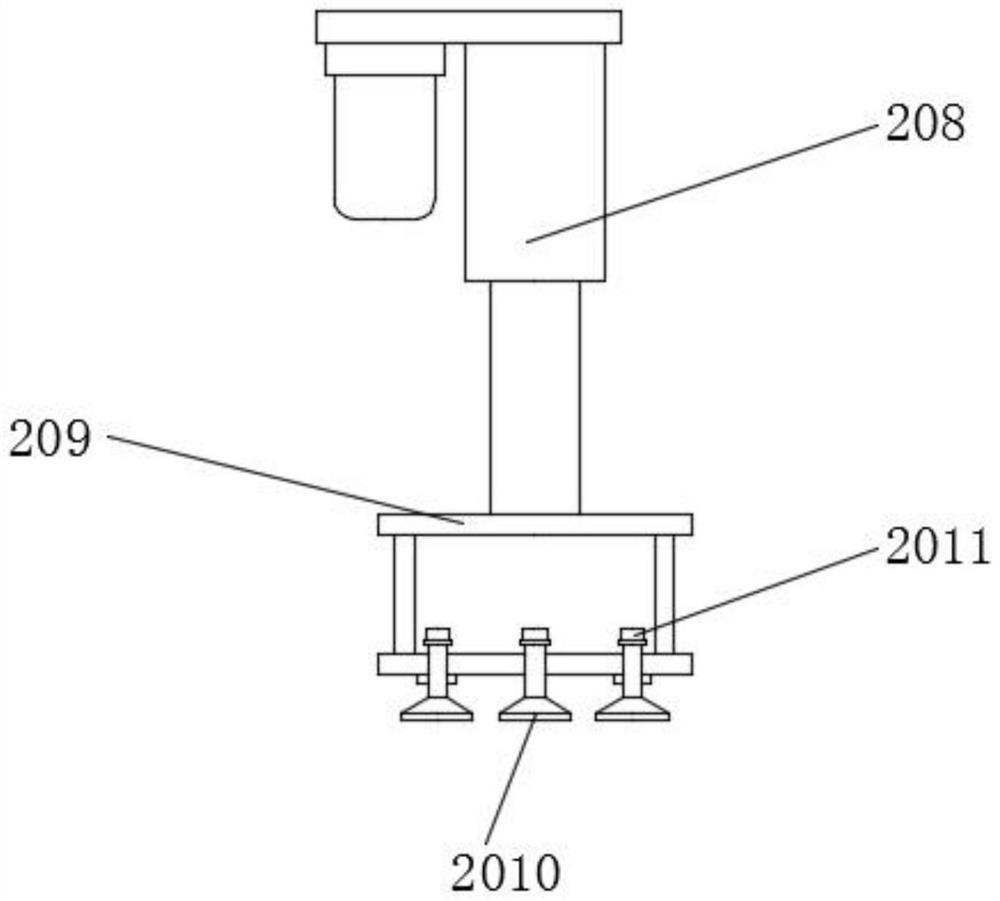

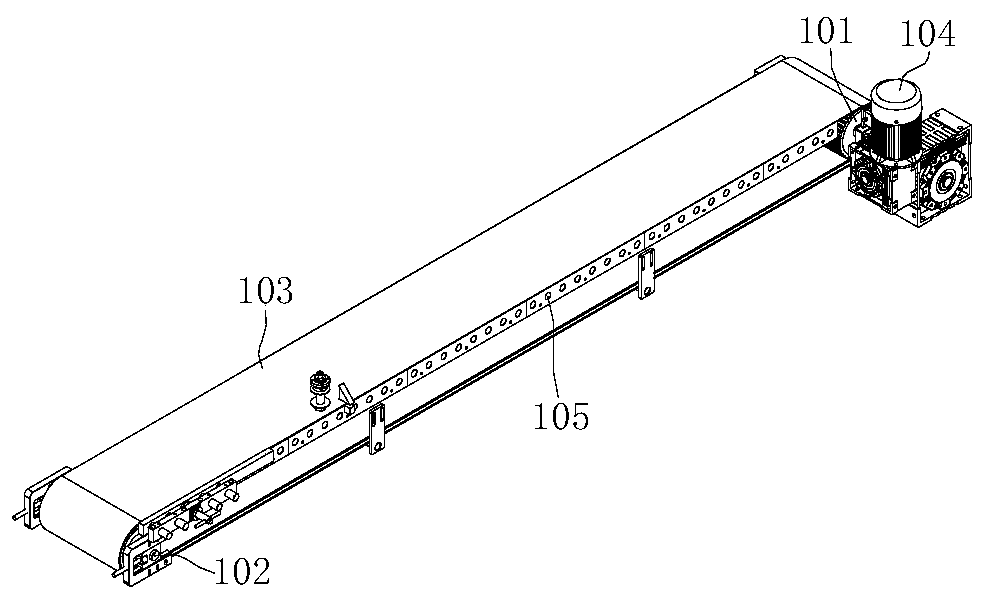

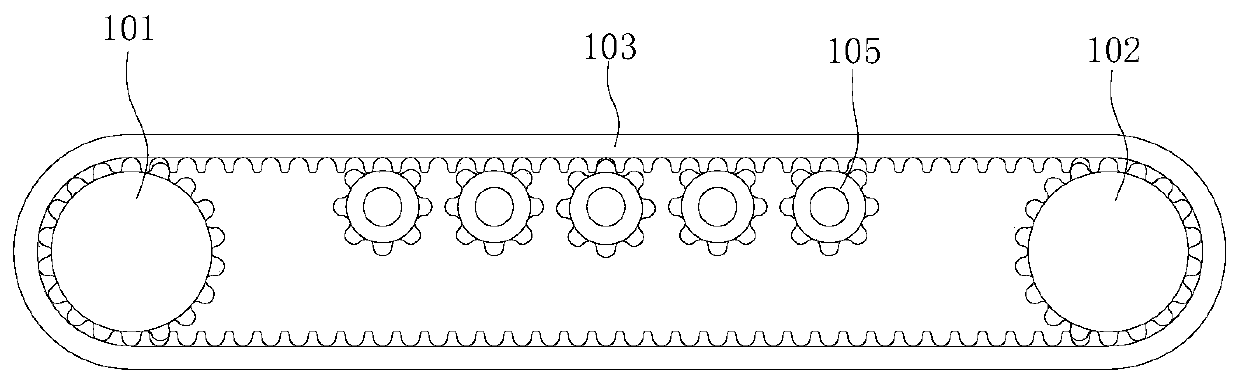

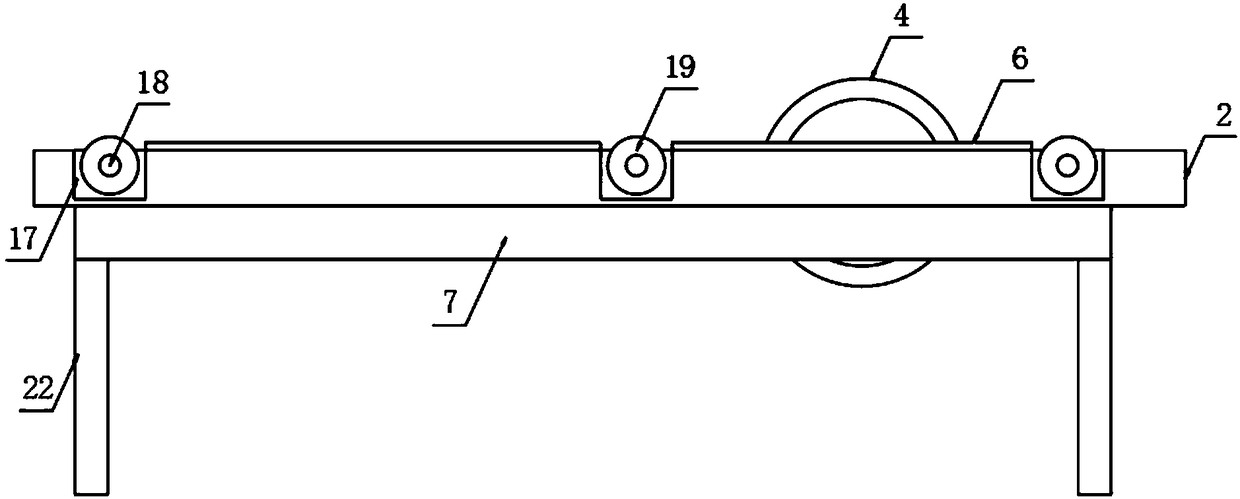

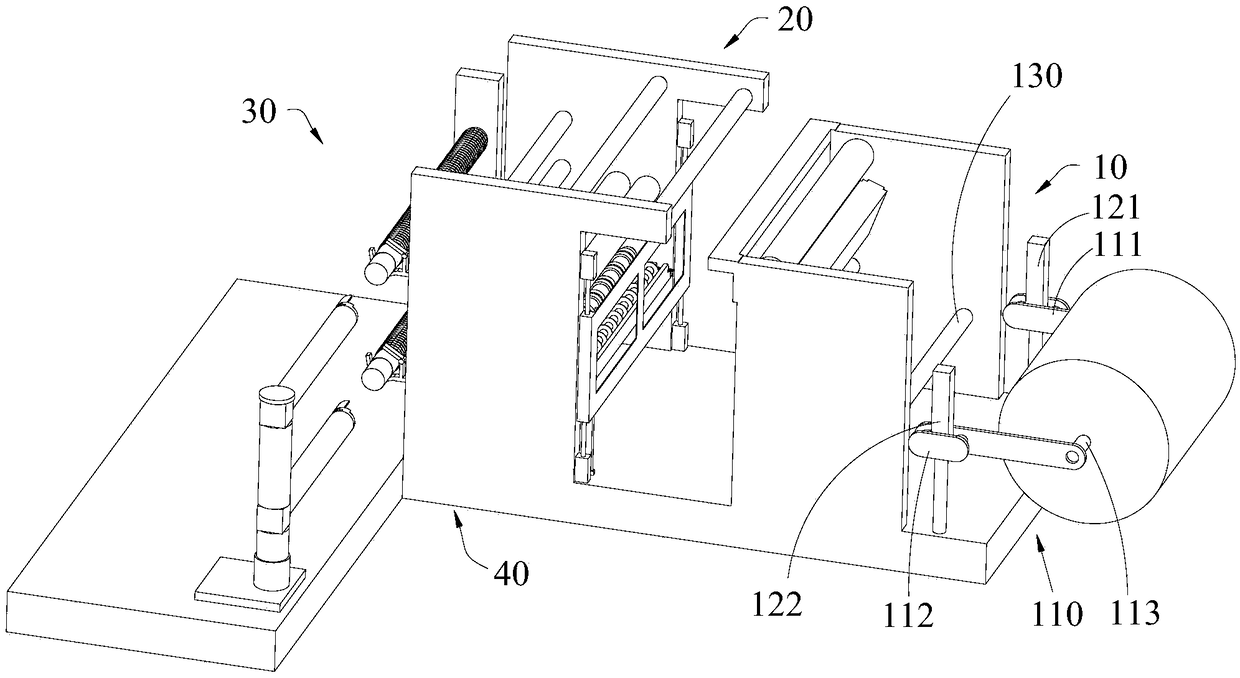

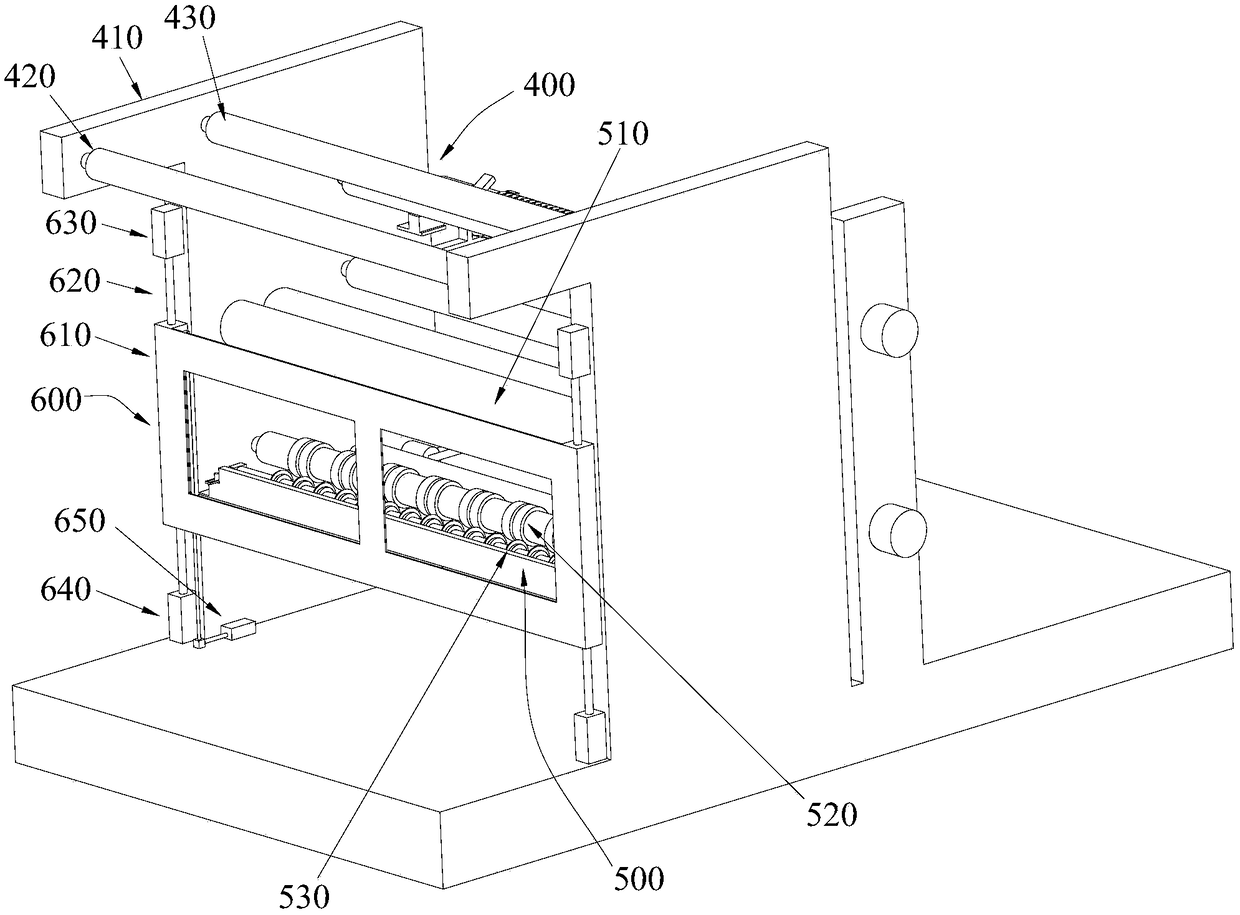

Main conveying device, feeding device and numerical control edging machining center

PendingCN109850491AEasy to shipGuaranteed straightnessConveyorsBelt grinding machinesNumerical controlEngineering

The invention provides a main conveying device, a feeding device and a numerical control edging machining center, and belongs to the field of machining centers. The main conveying device comprises a rack, a motor, a driving gear, a driven gear, a conveying belt and a plurality of rollers, wherein the motor, the driving gear and the driven gear are installed on the rack, the motor is in driving connection with the driving gear, the conveying belt is wound between the driving gear and the driven gear and engaged with the driving gear and the driven gear, the multiple rollers are installed on therack and arranged at intervals in the direction from the driving gear towards the driven gear, the rollers are engaged with the conveying belt, and the rollers are located on the inner side of the conveying belt. The main conveying device makes use of the engagement among the driving gear, the driven gear and the conveying belt to form stable conveying, the rollers can form a support to the conveying belt, the plates of various sizes and shapes can be better conveyed so that the plates can move along the straight line and can be avoided from lateral deviation, and the straightness of the processed plates is guaranteed.

Owner:佛山市西菱欧科技有限公司

Anti-crack freezing well wall concrete and preparation method thereof

ActiveCN112919867AIncrease preloadSecond Zero Stress Time ExtendedSolid waste managementFiberStructural engineering

The invention discloses anti-crack type freezing well wall concrete and a preparation method thereof. The concrete is C70 anti-crack type concrete, and comprises cement, fine aggregate, coarse aggregate, fly ash, an additive, an expanding agent, fibers and water. On the basis of the mix proportion of the inner wall of an existing freezing shaft, the expanding agent, the fibers and the like are added, and the quantity of the expanding agent and the fibers and a specific preparation method are determined through a mix proportion experiment. Compared with a reference group, the crack-resistant frozen well wall concrete has the advantages that: the early-stage compressive pre-stress is 36.6% higher, the second zero stress time is prolonged by 15%, the cracking temperature drop is increased by 20.7%, the tensile stress increase rate is reduced by 90%, and the cracking stress is increased by 10%. The concrete has high shrinkage compensation and early-stage temperature crack resisting effects.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

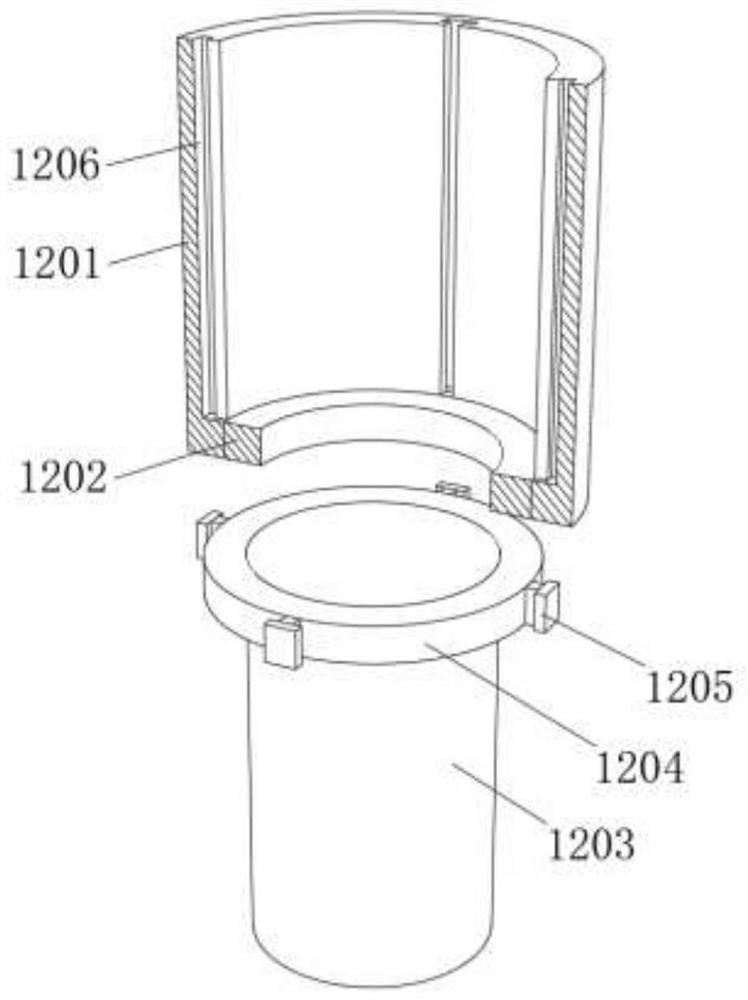

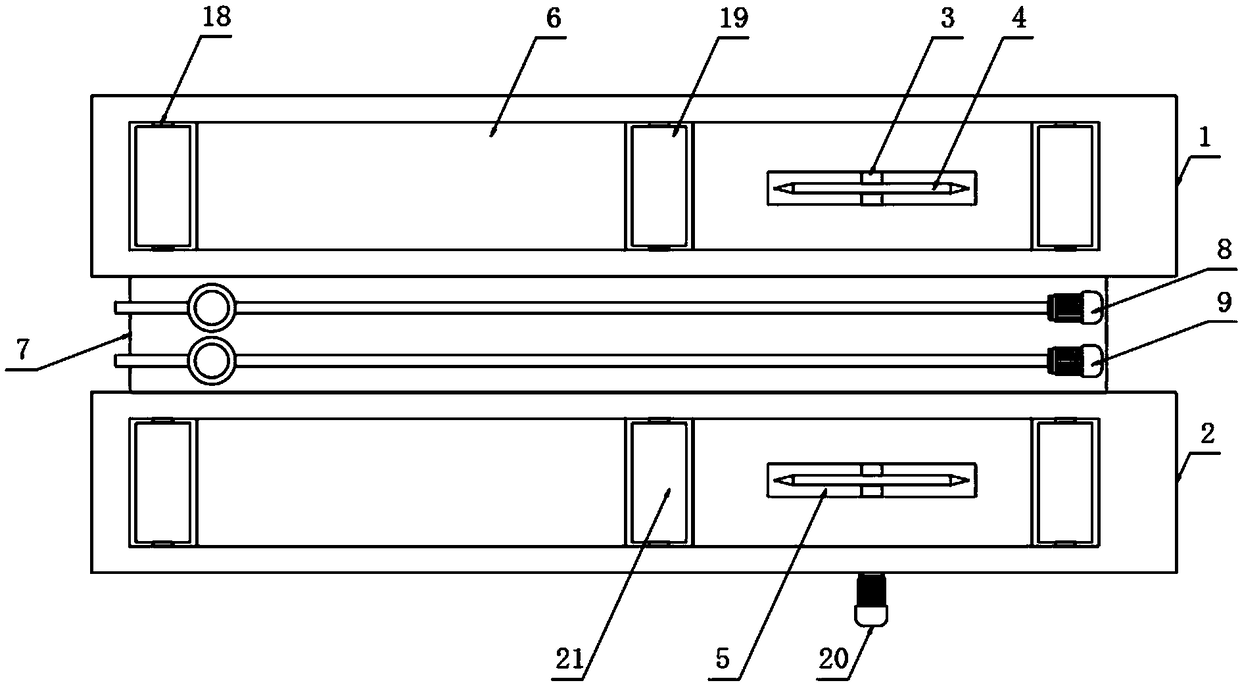

Stator paint dipping and drying device of permanent magnet motor

PendingCN114039466AHeat and dry evenlyImprove drying rateManufacturing dynamo-electric machinesElectric machineEngineering

The invention relates to the field of permanent magnet motor stator drying, in particular to a stator paint dipping and drying device of a permanent magnet motor. A motor stator is in an annular cylinder shape, and the drying device comprises a drying box, a chain type conveyor, chain accessories and clamps. The chain type conveyor comprises a chain and a meshing wheel; and the clamps are vertically installed on the top of the chain type conveyor at equal intervals through the chain accessories. After the motor stators are mounted on the clamps, the chain type conveyor is started to drive the clamps to regularly move in the drying box, so that the motor stators can be uniformly heated and dried, and the drying rate of the motor stators is increased; the internal space of the drying box can be well utilized through regular movement tracks to increase the drying number of the motor stators, and the motor stators cannot make contact with one another when the multiple motor stators are dried, so that the phenomenon that in the prior art, the motor stators are bonded together due to paint after drying, and are difficult to be seperated in the later period is prevented.

Owner:江西东涵科技协同创新有限公司

Plate cutting machine and plate cutting method

InactiveCN109093180AEasy to absorb and fixLabor-saving processingShearing machinesAgricultural engineeringMachining

The invention discloses a plate cutting machine and a plate cutting method. The plate cutting machine comprises a left cutting platform and a right cutting platform, the right cutting platform is arranged on one side of the left cutting platform, a rubber pad is arranged on the top of each of the left cutting platform and the right cutting platform, a bearing bottom plate is fixedly arranged at the bottom of each of the left cutting platform and the right cutting platform, each of a first plate moving mechanism and a second plate moving mechanism are arranged at the bottom of the bearing bottom plate and comprises a first motor, a screw rod is arranged on each first motor, a mounting block sleeves each screw rod, an air cylinder is fixedly arranged at the top of each mounting block, a rubber sucker is fixedly arranged at the top of each air cylinder, an air suction pipe is arranged on each rubber sucker, and a hose is arranged at the end of each air suction pipe. The plate cutting machine is reasonable in design, more labor saving in plate machining, capable of avoiding plate deviation and ensuring the plate cutting effect and highly practical.

Owner:大连范特西西科技有限公司

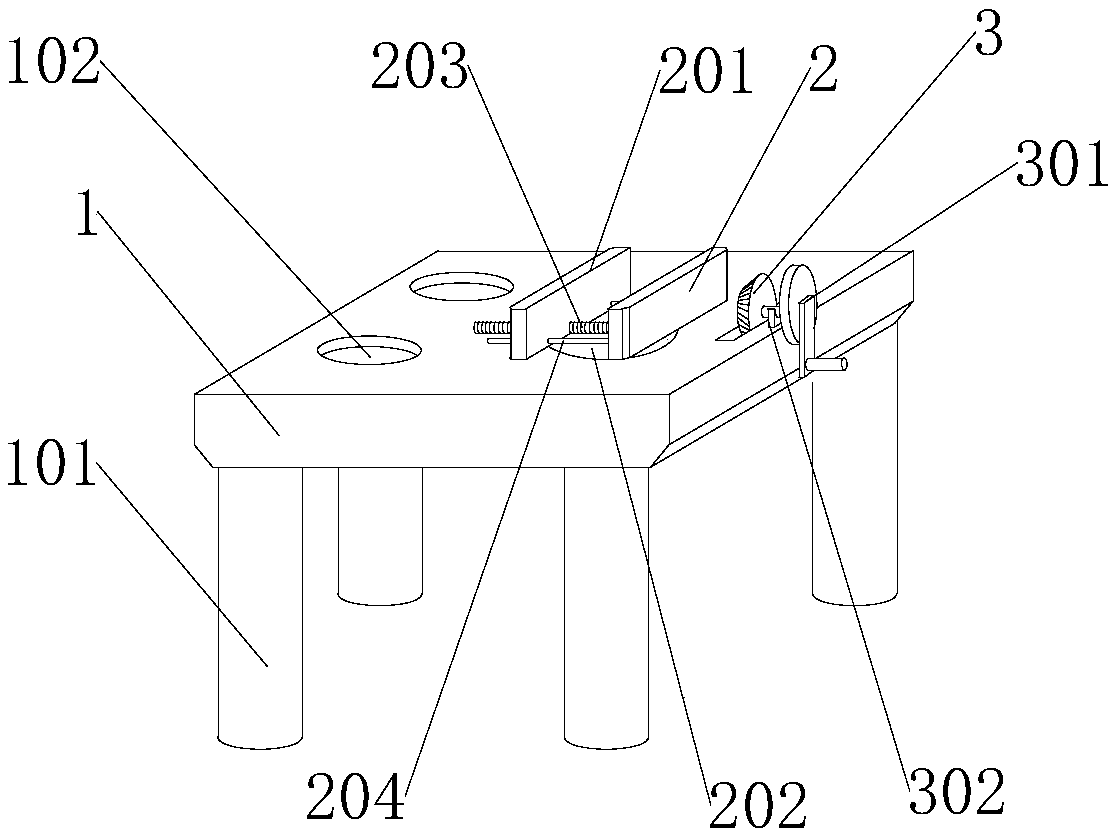

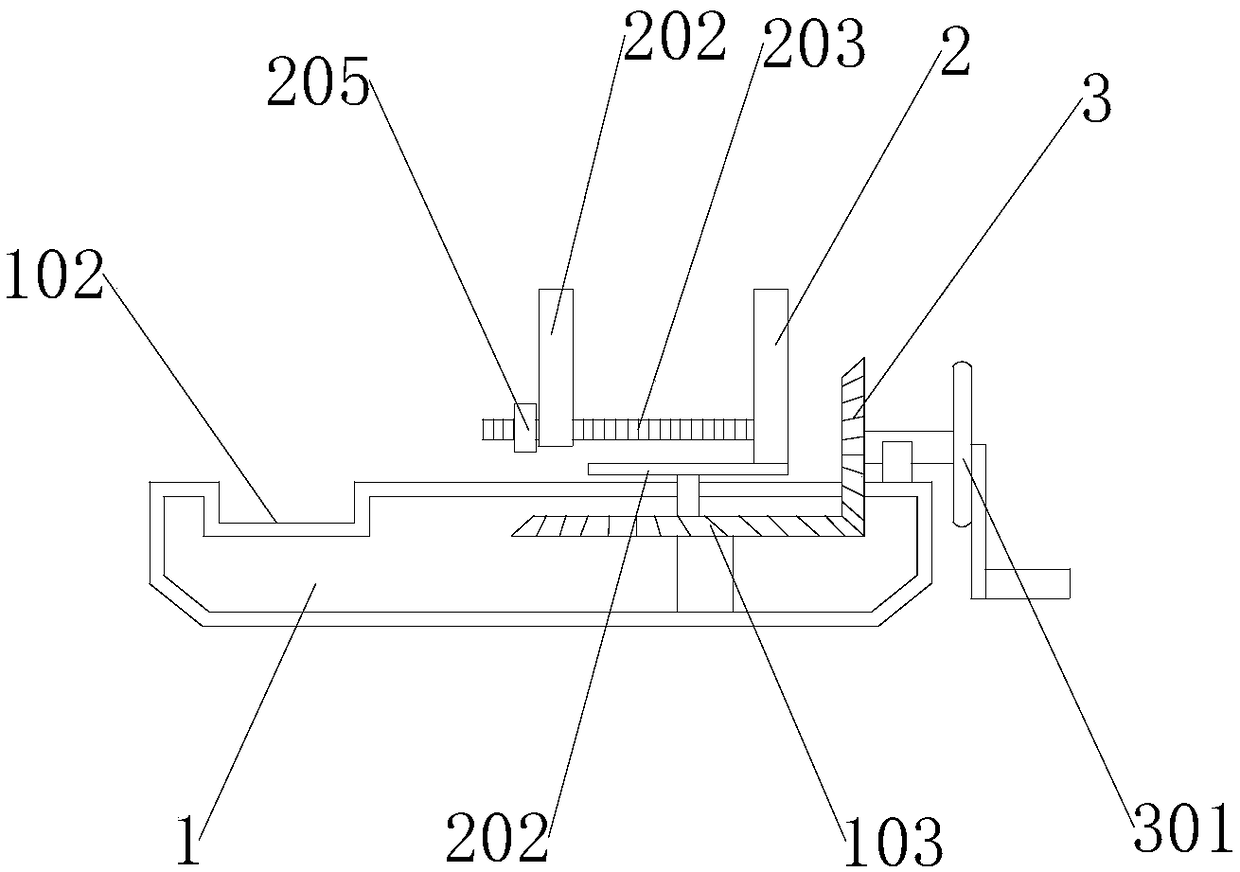

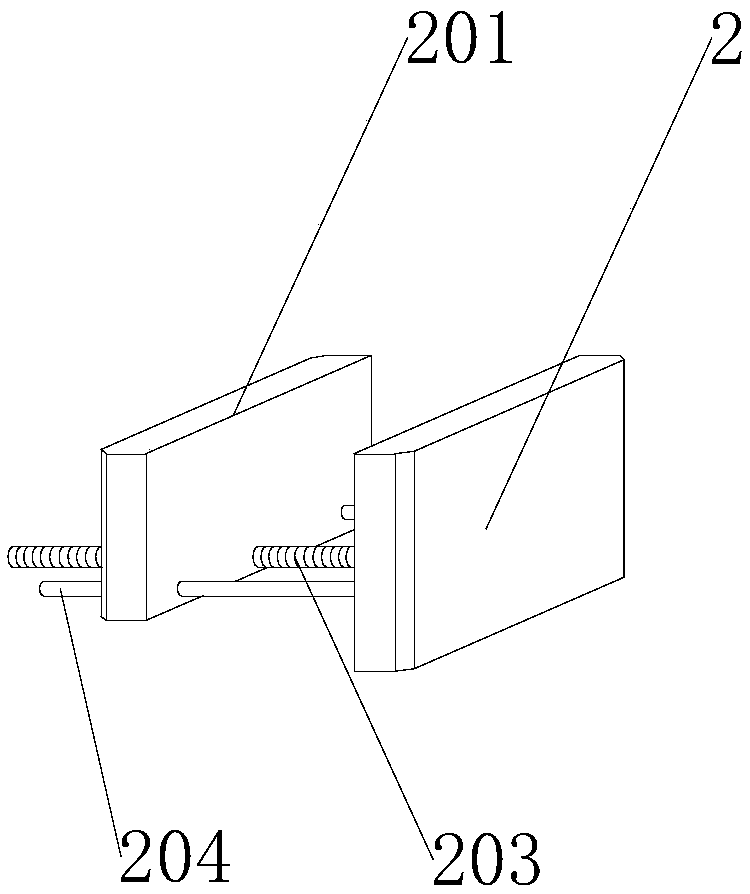

Multi-purpose platform device for mechanical part machining

InactiveCN108789227AImprove work efficiencyThere will be no offsetWork holdersEngineeringMachine parts

The invention provides a multi-purpose platform device for mechanical part machining, and relates to the field of machining. The multi-purpose platform device for mechanical part machining comprises an operation table, table feet and a storage groove; the table feet are welded to the four corners of the bottom of the operation table, the storage groove is embedded in one side of the top of the operation table, the side, away from the storage groove, of an inner cavity of the operation table is rotatably connected with a driven disc, a linking table is welded to the top end of the driven disc,and a fixed clamping plate is welded to one side of the top end of the linking table. The driven disc and a driving disc are arranged, the device can rotate, and therefore during part machining, partangle can be adjusted without detaching of the clamping plate, it is ensured that the work efficiency is improved, and the device has the good development prospect.

Owner:繁昌县亘通智能装备有限公司

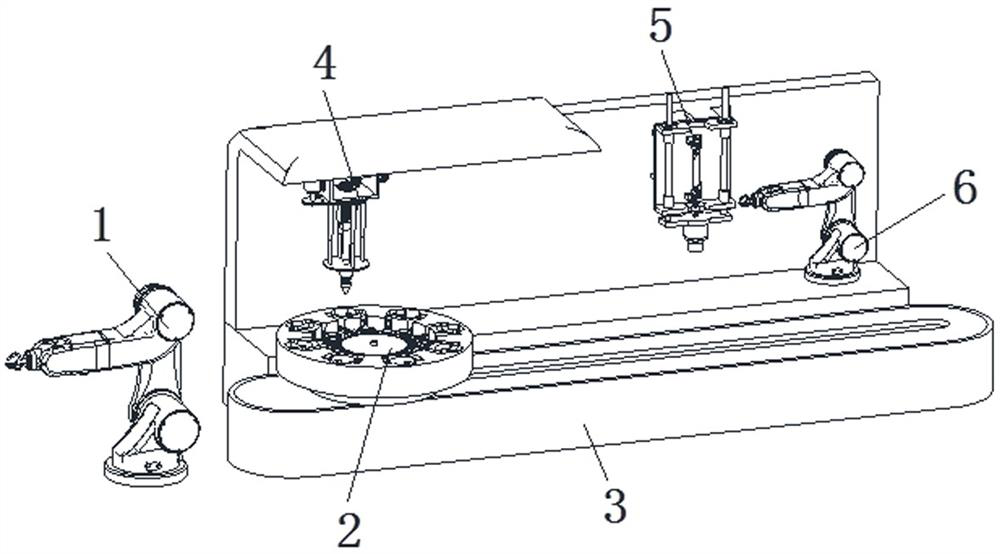

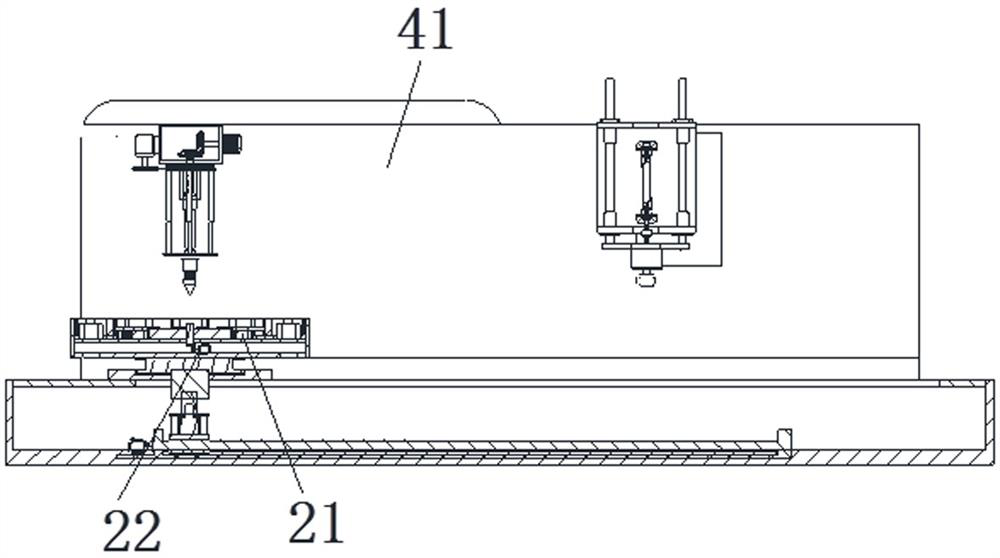

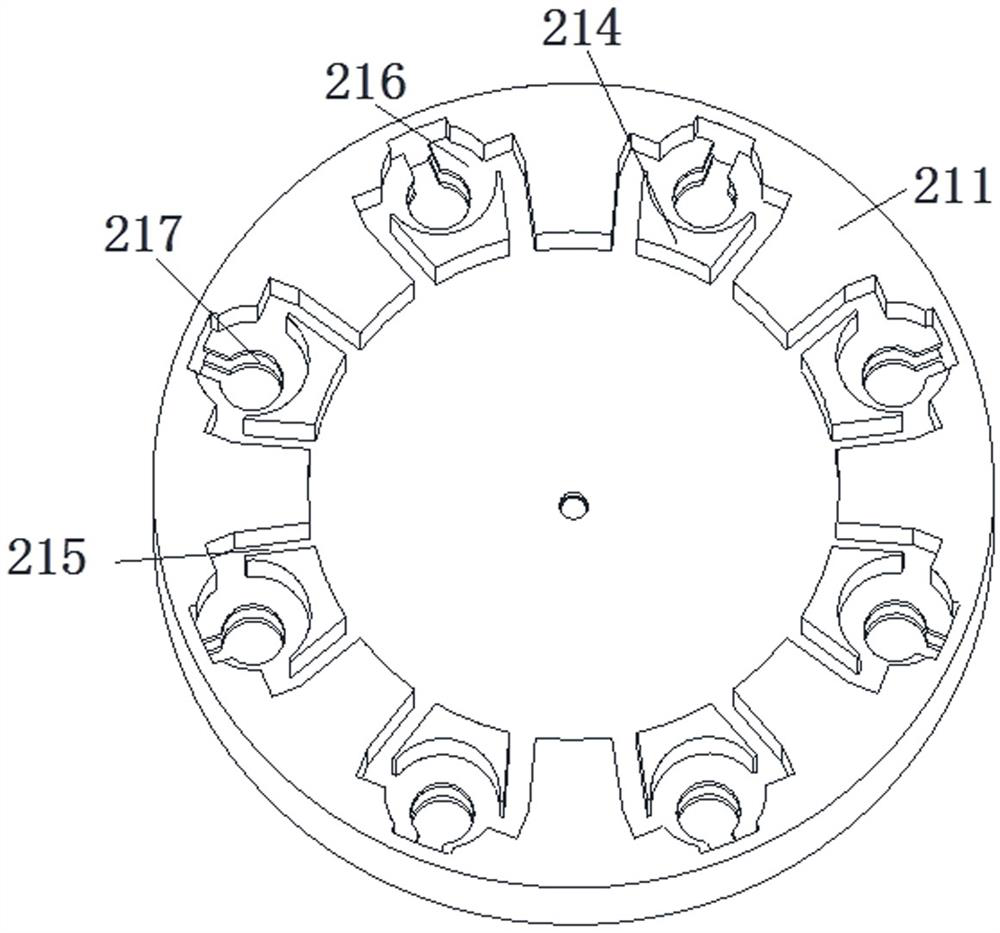

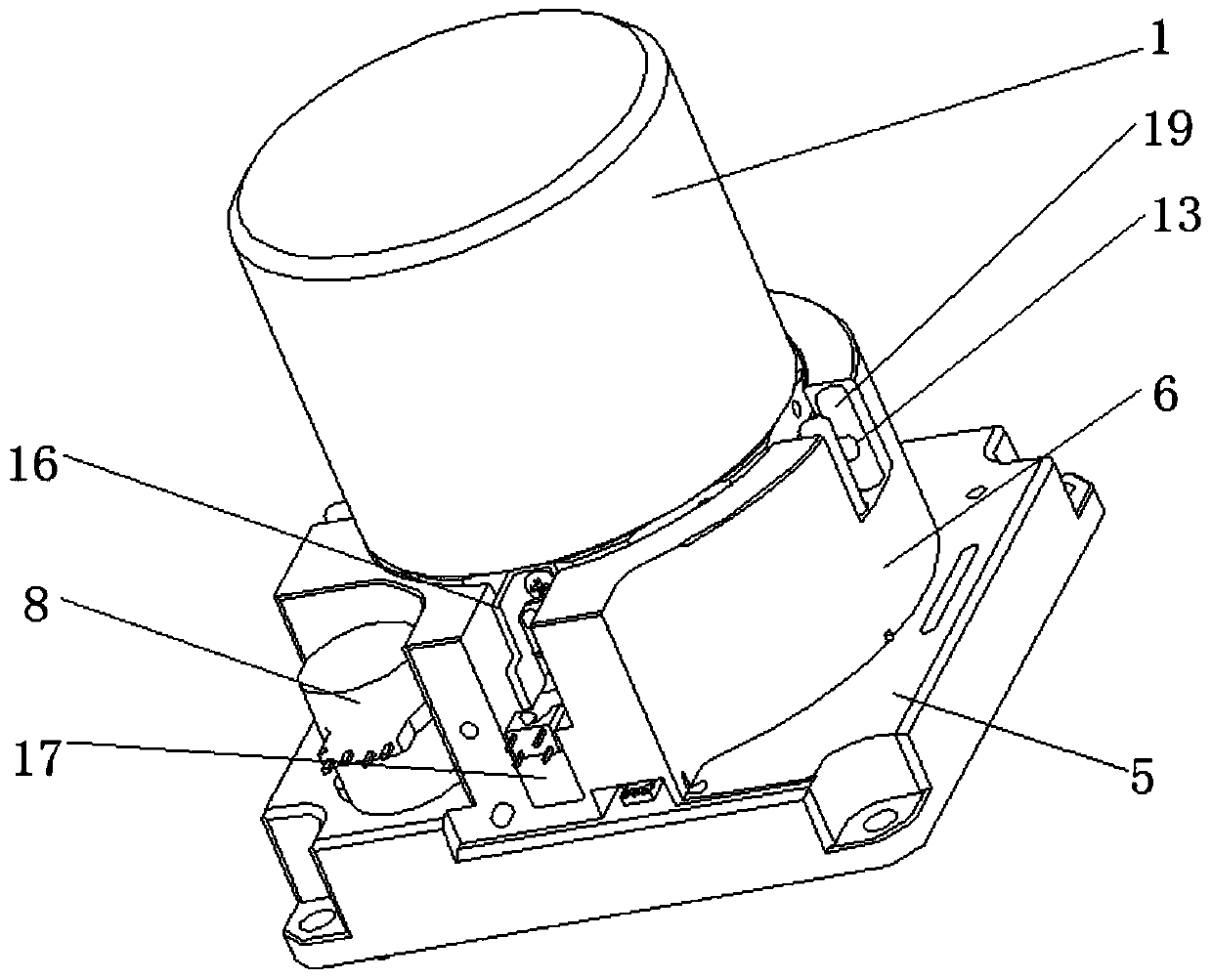

Equipment and method for processing fillets of inner rings of locknuts

ActiveCN112792574BSolve the processing costReduce processing costsOther manufacturing equipments/toolsMetal working apparatusRobot handPolishing

The invention discloses a fillet processing equipment for the inner ring of a lock nut, which relates to the technical field of lock nut processing, and includes a loading manipulator, a loading mechanism, a conveying mechanism, a hole opening mechanism, a polishing mechanism and a material unloading manipulator. The feeding mechanism is arranged above the conveying mechanism, and the bottom end of the loading mechanism is connected with the conveying mechanism, the feeding manipulator is arranged on one side of the conveying mechanism, the feeding manipulator corresponds to the loading mechanism, and the The opening mechanism and the polishing mechanism are arranged horizontally and side by side above the conveying mechanism, and the opening mechanism and the polishing mechanism are arranged at intervals, and the feeding manipulator is arranged on one side of the polishing mechanism; the present invention solves the problems of the prior art The nut processing operation in the form of an assembly line will cause the problem of high processing cost and material cost; the invention reduces the processing cost and improves the work efficiency.

Owner:温州鸿博汽车零部件有限公司

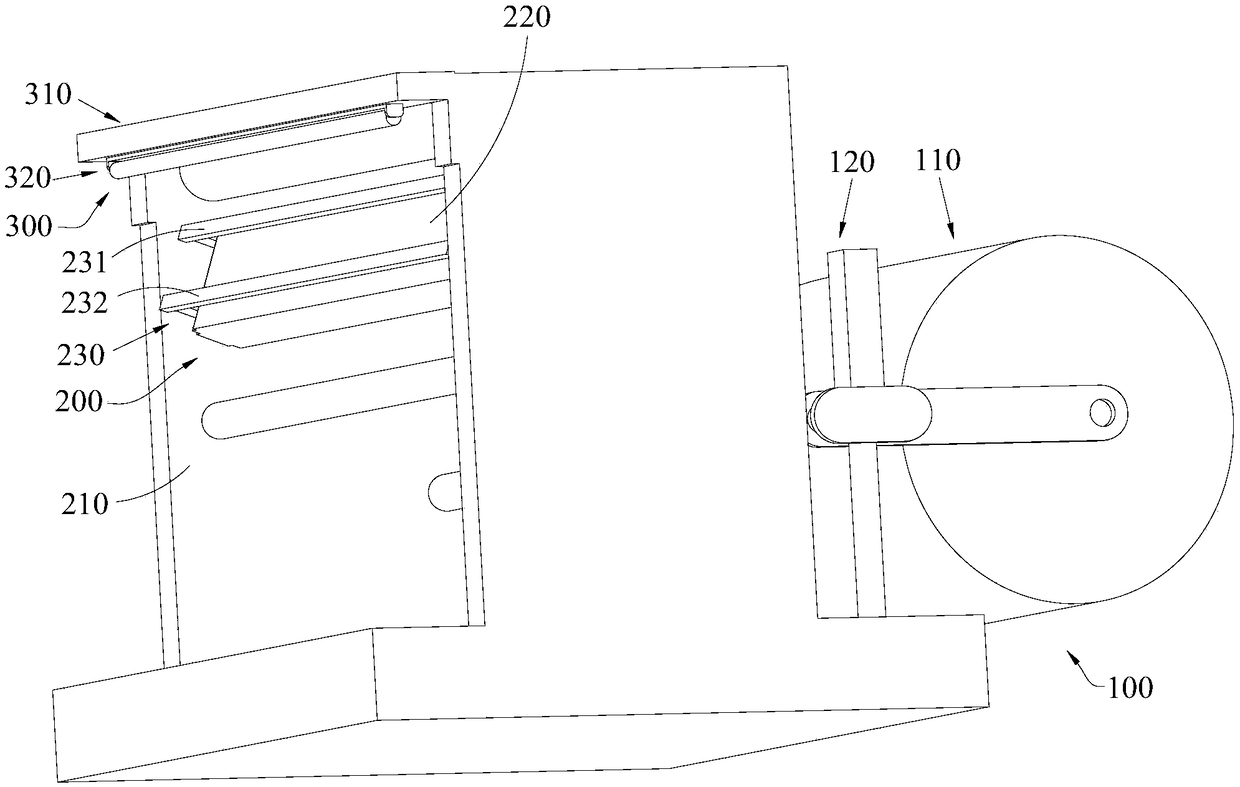

Rapid automatic zooming device

PendingCN110989270AGuaranteed stabilityGuaranteed directionalityMountingsFocusing aidsOphthalmologyGear wheel

Owner:WUHAN GUIDE SENSMART TECH CO LTD

Scratch-proof protective film winding mechanism and slitting module

Owner:HUIZHOU HAOMING SCI & TECH

Stainless steel pipe bending resistance testing device

PendingCN114136804AImprove stabilityEnsure stabilityMaterial strength using steady bending forcesHydraulic cylinderMetallurgy

The invention discloses a stainless steel pipe bending resistance testing device which is characterized in that a first clamping arm and a second clamping arm are symmetrically arranged at the top end of a supporting base, a first supporting body and a second supporting body are arranged between the first clamping arm and the second clamping arm, and mounting bodies are arranged on the back faces of the first supporting body and the second supporting body; a lifting hydraulic cylinder is fixedly mounted at the top end of the mounting body, and a detection body is fixedly connected to the bottom end of the lifting hydraulic cylinder. The device has the beneficial effects that the two ends of the to-be-detected steel pipe are clamped at the same time through the clamping bodies of the first clamping arm and the second clamping arm, the clamping stability is improved through the hard rubber layer, meanwhile, the to-be-detected steel pipe is always clamped in the steel pipe clamping groove through the characteristic of the gravity of the to-be-detected steel pipe, and the detection accuracy is improved. The stability of the to-be-detected steel pipe during testing is further guaranteed, it is guaranteed that the to-be-detected steel pipe does not deviate, and the safety of a testing instrument is guaranteed.

Owner:广东省粤钢新材料科技有限公司

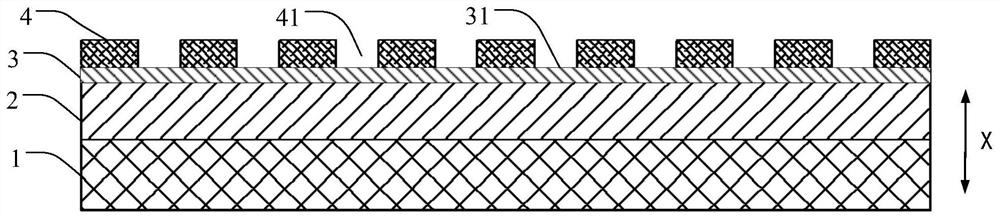

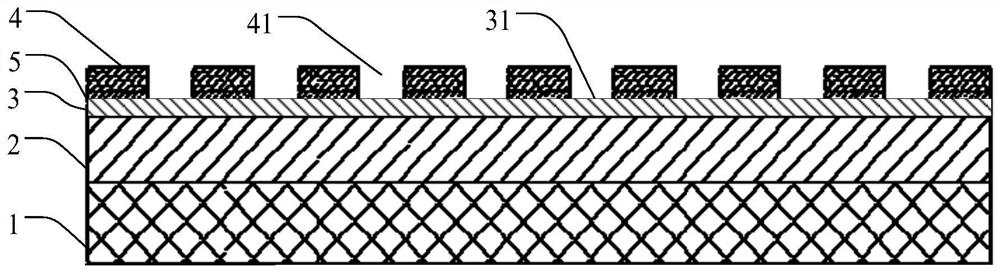

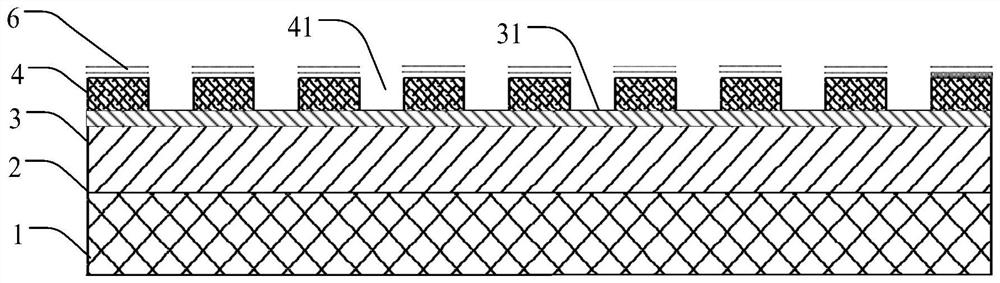

Printed circuit board, display module and LED display screen

ActiveCN112738990AAvoid offsetImprove printing accuracyElectrical connection printed elementsPrinted circuit non-printed electric components associationLED displayEngineering

The invention discloses a printed circuit board, a display module and an LED display screen. The display module comprises the printed circuit board, and the printed circuit board comprises a copper-clad plate layer, a first prepreg layer, a first copper foil layer and a first insulating layer which are stacked in sequence from bottom to top; the first copper foil layer is provided with a first bonding pad, and the first insulating layer is provided with a first through hole penetrating in the thickness direction; and the first bonding pad is located in the first through hole. When the display module is manufactured, soldering paste can be arranged in the first through hole, the positions of the first bonding pad and the soldering paste are relatively fixed under the limiting effect of the inner side wall of the first through hole, and the situation that the positions of the soldering paste and the first bonding pad deviate is avoided. Therefore, when the soldering paste is arranged, the inner side wall of the first through hole plays a role in limiting, the printing precision of the soldering paste is improved, and the problems of yin and yang screens of the display screen caused by position deviation of the bonding pad and the soldering paste are solved.

Owner:SHENZHEN ABSEN OPTOELECTRONIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com