Stator paint dipping and drying device of permanent magnet motor

A drying device and permanent magnet motor technology, which is applied in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of low utilization rate and difficult stator separation, so as to prolong the service life, speed up the drying rate, and reduce the damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

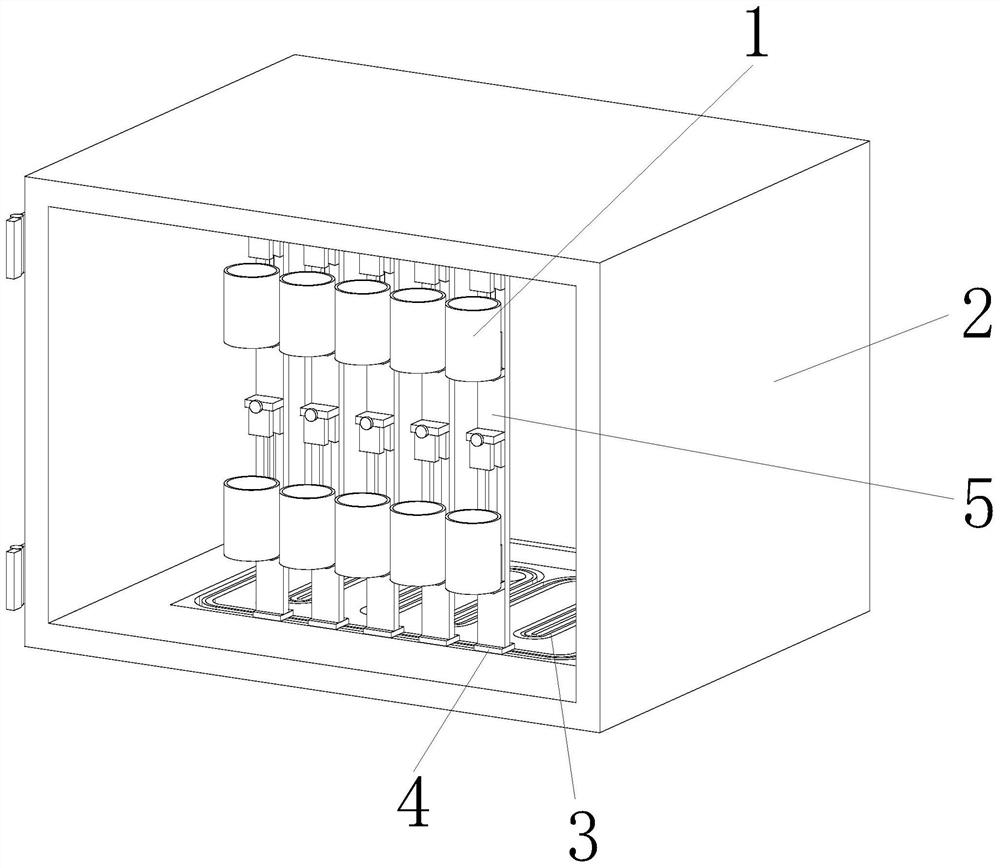

[0050] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0051] refer to Figure 1-12 shown

[0052] A stator dipping paint drying device for a permanent magnet motor,

[0053] The motor stator 1 is in the shape of a circular cylinder, and the drying device includes a drying box 2, a chain conveyor 3, a chain attachment 4 and a clamp 5; the chain conveyor 3 includes a chain 3a and a meshing wheel 3b;

[0054] Fixture 5 is equidistant and vertically installed on the top of chain conveyor 3 through chain attachment 4;

[0055] The chain 3a is used to drive the fixture 5 to move regularly inside the drying box 2;

[0056] The chain 3a is composed of a first transmission shaft 3a1 and a second transmission shaft 3a2, and the first transmission shaft 3a1 is be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com