Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1028results about How to "Improve drying rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

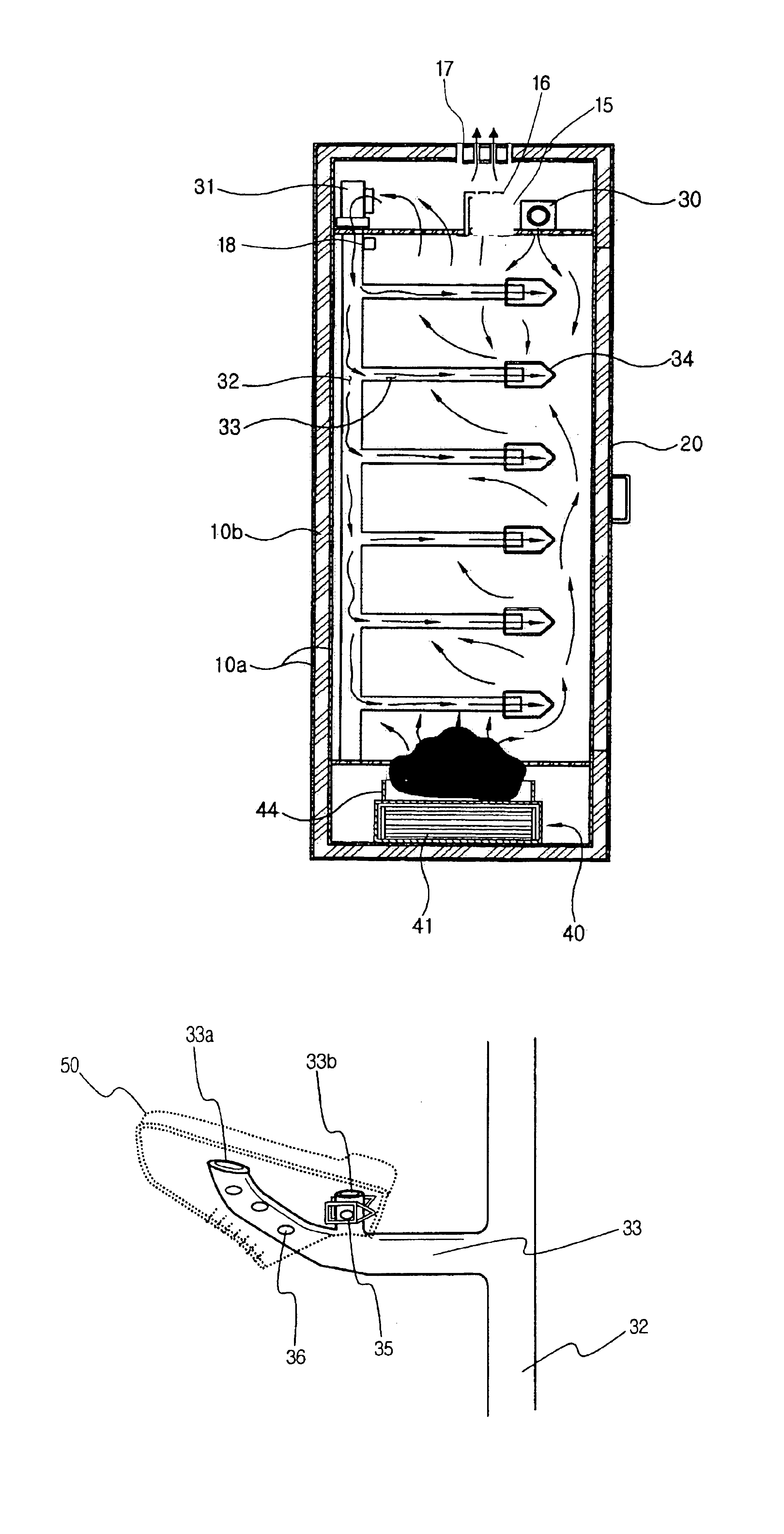

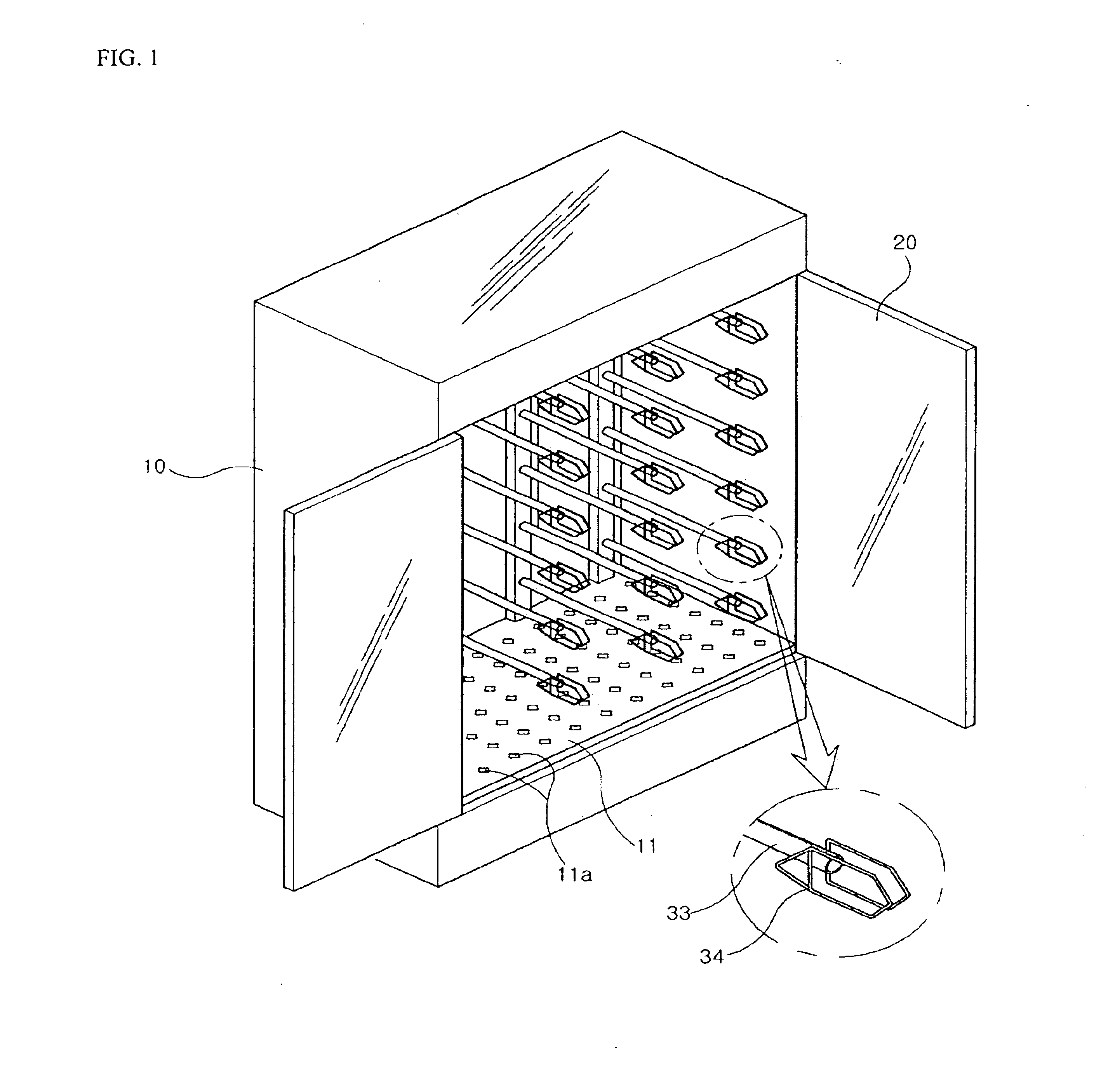

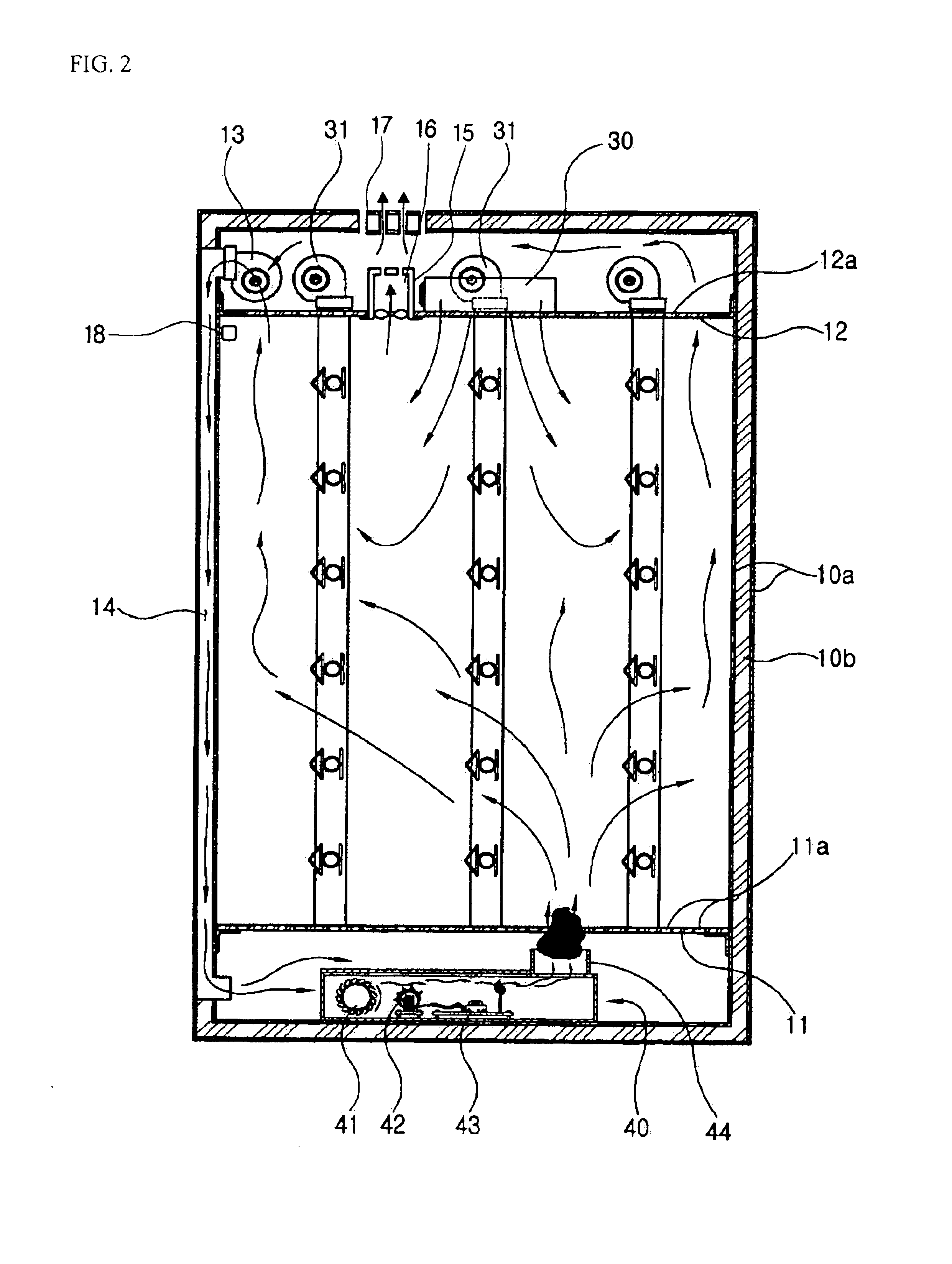

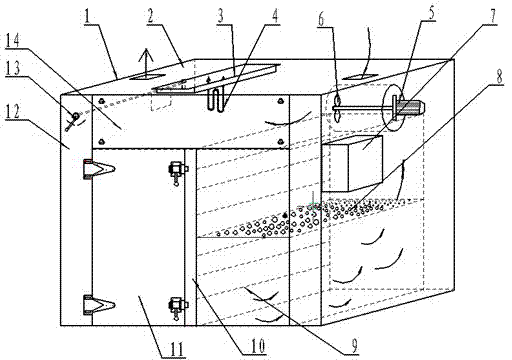

Shoe drying apparatus

InactiveUS6845569B1Short timeReduce maintenanceDrying chambers/containersDrying solid materialsEngineeringHollow core

The present invention provides a new and improved shoe drying apparatus that can dry washed and / or unwashed shoes in a short period of time by circulating ozone-containing air in the airtight interior of the apparatus and also deodorize and sanitize shoes by removing odor and bacteria from the shoes. The shoe drying apparatus comprises a housing having a front door, a first porous plate installed in the bottom interior of the housing, a sanitizing-deodorizing assembly for generating ozone-containing air (“mixed air”), a second porous plate installed in the top interior of the housing, a ventilating fan for dispersing the mixed air into the central interior of the housing, an intake fan for bringing back air present in the upper space of the second plate to the sanitizing-deodorizing assembly, a plurality of hollow main conduits extending vertically from the second plate to the first plate, a plurality of hollow auxiliary conduits extending horizontally from each main conduit, and a shoe-holding member on which a shoe is fixed for drying.

Owner:KIM SOO KIL

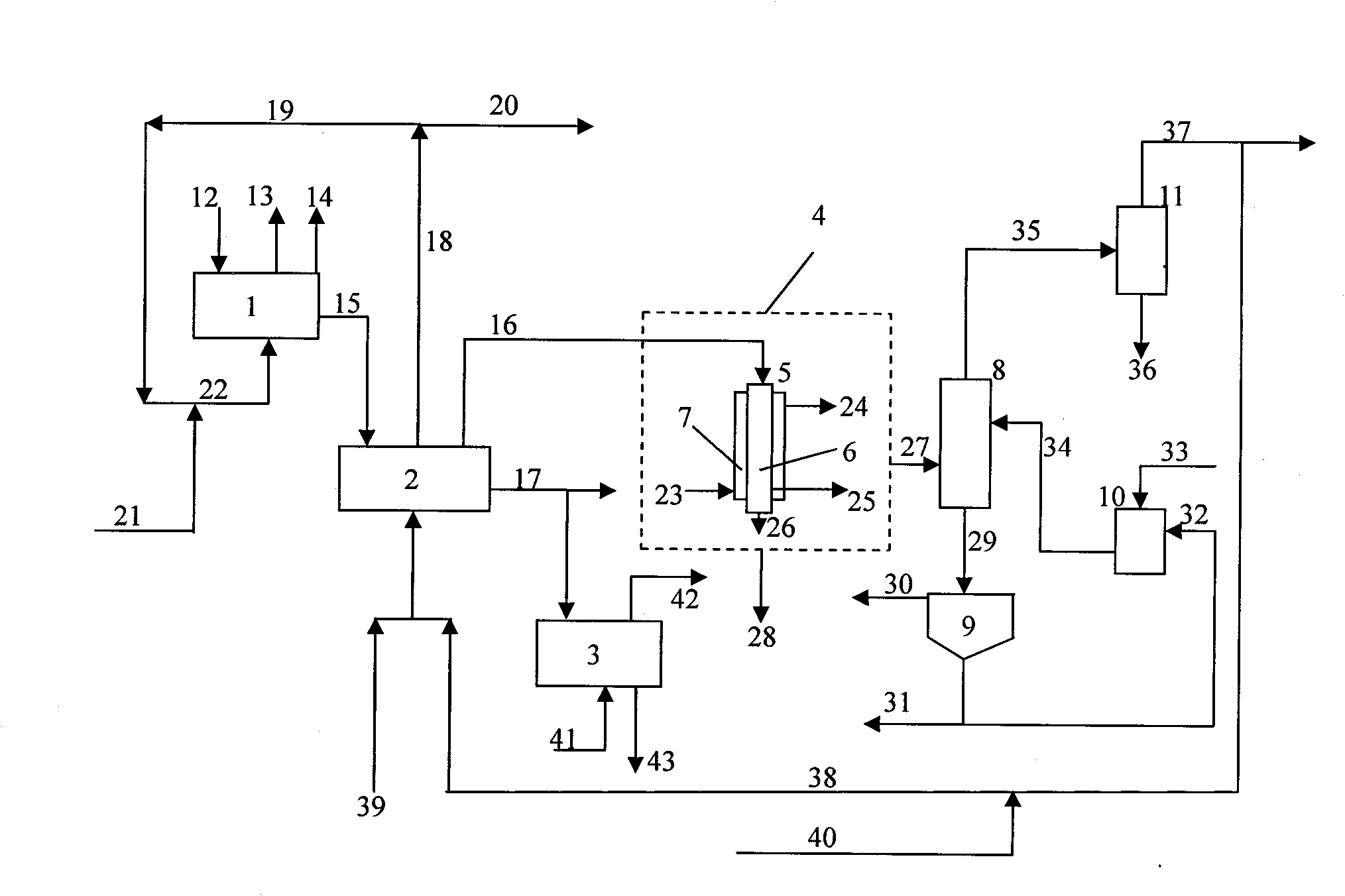

Low-coalification degree pulverized coal pyrolysis method and product prepared through the same

ActiveCN101880540AAlleviate the difficulty of efficient utilizationAlleviate the problem of secondary pyrolysisCoke quenchingSpecial form destructive distillationCoal pyrolysisCoal tar

The invention relates to a low-coalification degree pulverized coal pyrolysis method and a product prepared through the same. The method comprises the following four steps: low-coalification degree pulverized coal pre-drying, low-coalification degree pulverized coal pyrolysis reaction, gas cooling and tar recovery, and hot semi-coke cooling. The method is applicable to heat treatment to low-coalification degree pulverized coal resources so as to obtain high-quality pyrolysis gas and tar products, wherein the gas contains low inert component content, tar contains high light component content and low dust content, and semi-coke products with wide purposes are obtained. The process method is characterized by high comprehensive utilization rate of energy, large amount of treated material, lowdevice investment, easy industrialization realization, environmental friendliness and the like while improving the raw material utilization efficiency.

Owner:XIAN ORIGIN CHEM TECH

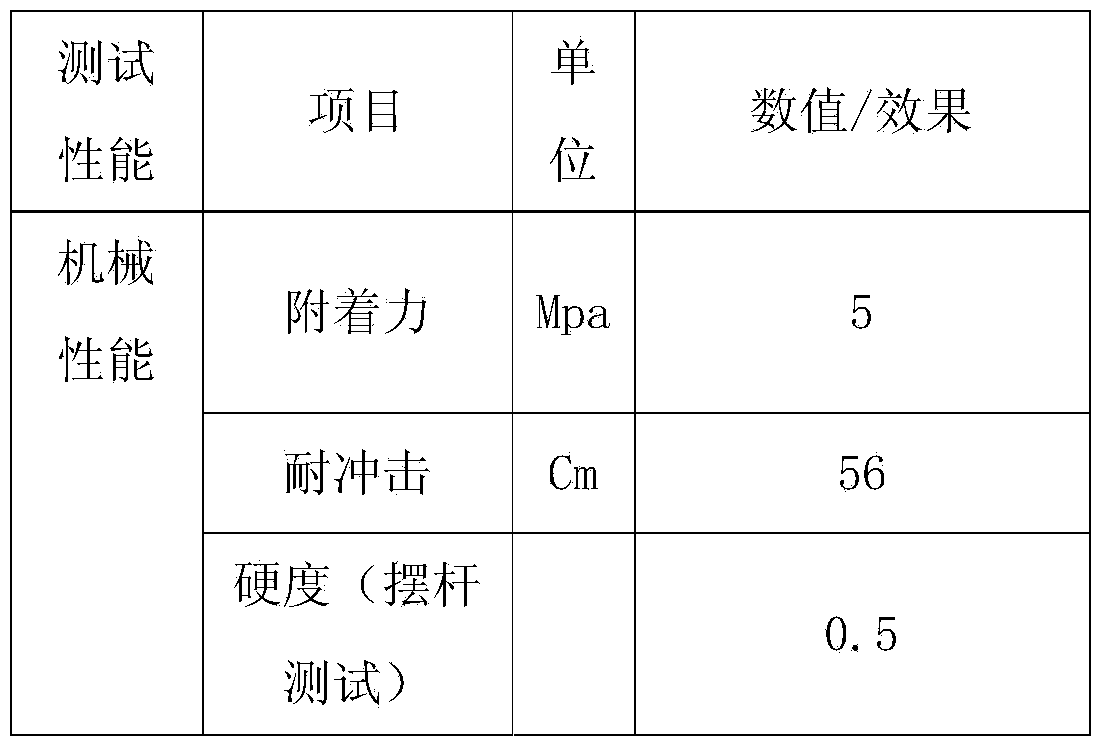

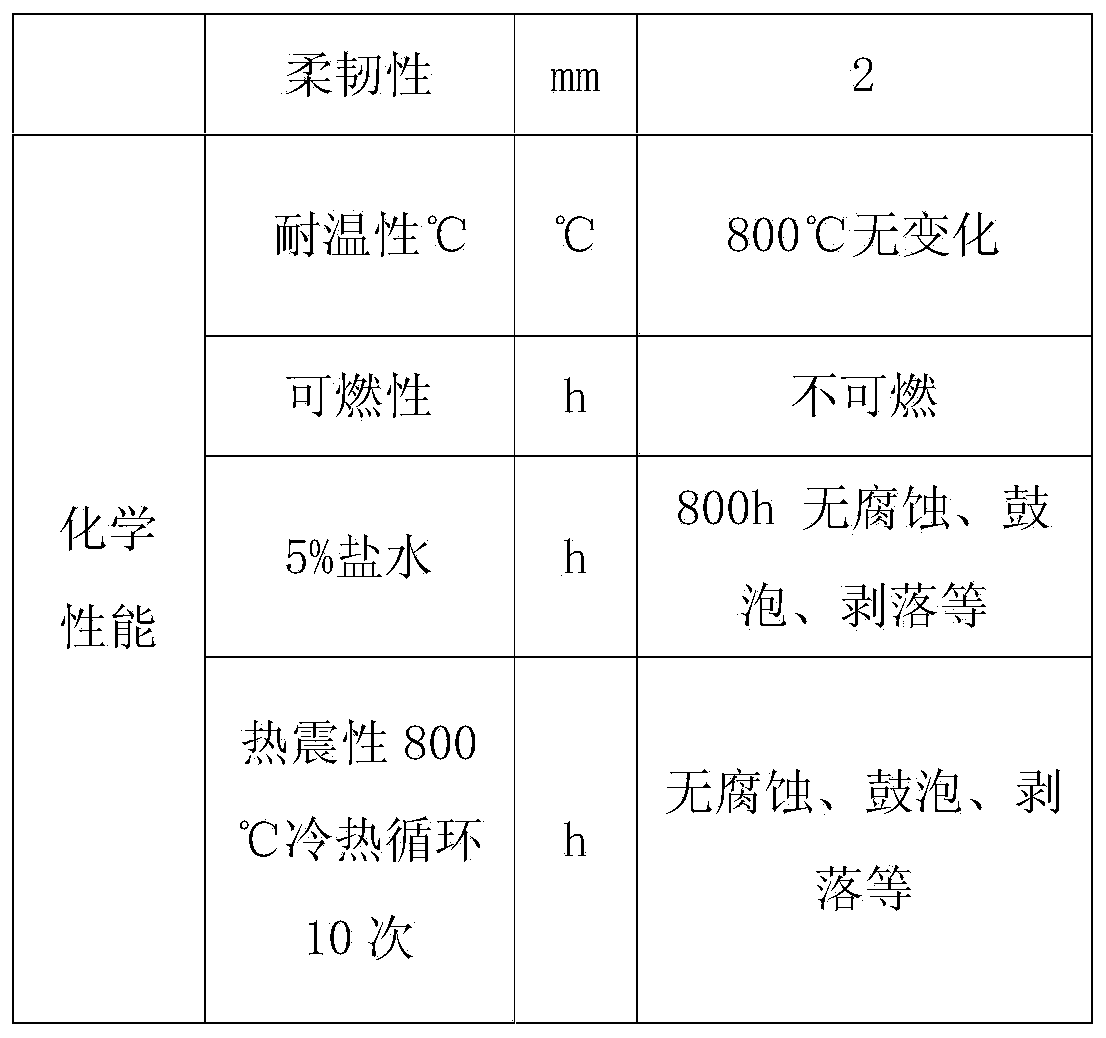

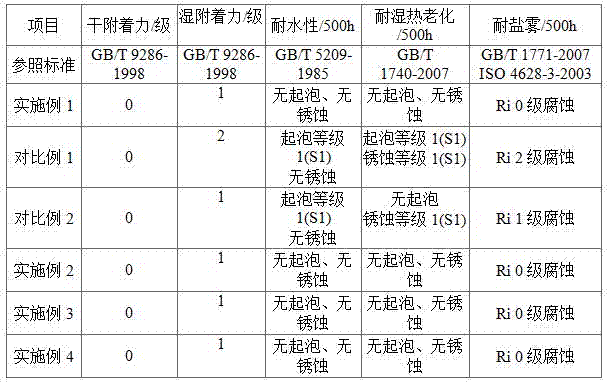

Boron-modified organic silicon resin high-temperature-resistant coating and preparation method thereof

The invention discloses a boron-modified organic silicon resin high-temperature-resistant coating which comprises the following components in percentage by mass: 45%-58% of boron-modified organic silicon resin, 35%-45% of heat-resisting pigment fillers and 2%-4% of auxiliary agents, wherein the boron-modified organic silicon resin is boric-acid-modified organic silicon resin or epoxy-modified silicon-boron resin; and the mass ratio of nanometer silicon dioxide to barrier function fillers to aluminum powder which are contained in the heat-resisting pigment fillers is 1.5:1:1. The invention also discloses a preparation method of the boron-modified organic silicon resin high-temperature-resistant coating. The preparation method disclosed by the invention can be implemented on an existing coating preparation production line without increasing equipment investment; the prepared high temperature-resistant organic silicon coating can be coated by adopting a spray coating process and constructed by adopting a roll coating process, can be subjected to high temperature of 800 DEG C for a long time and has corrosion-resistant property.

Owner:JIANGSU MARINE VICTORY COATING

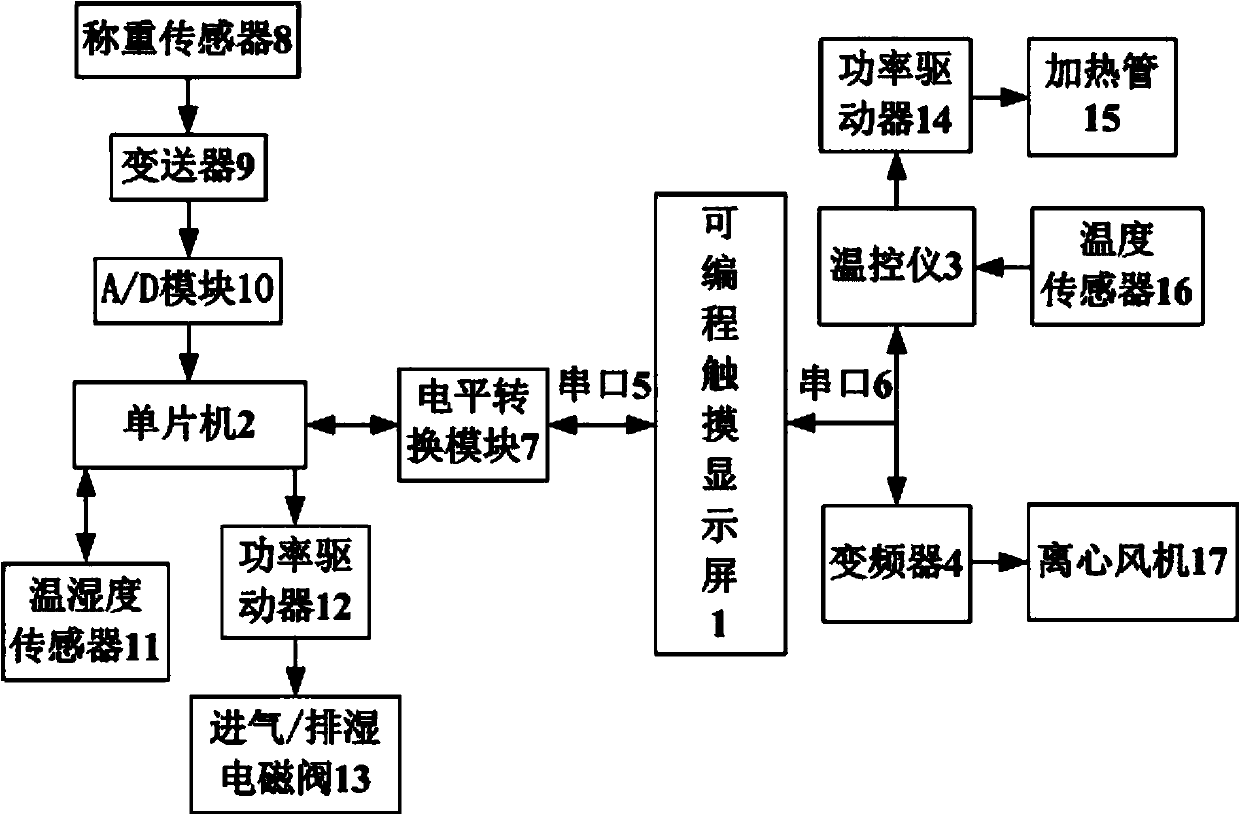

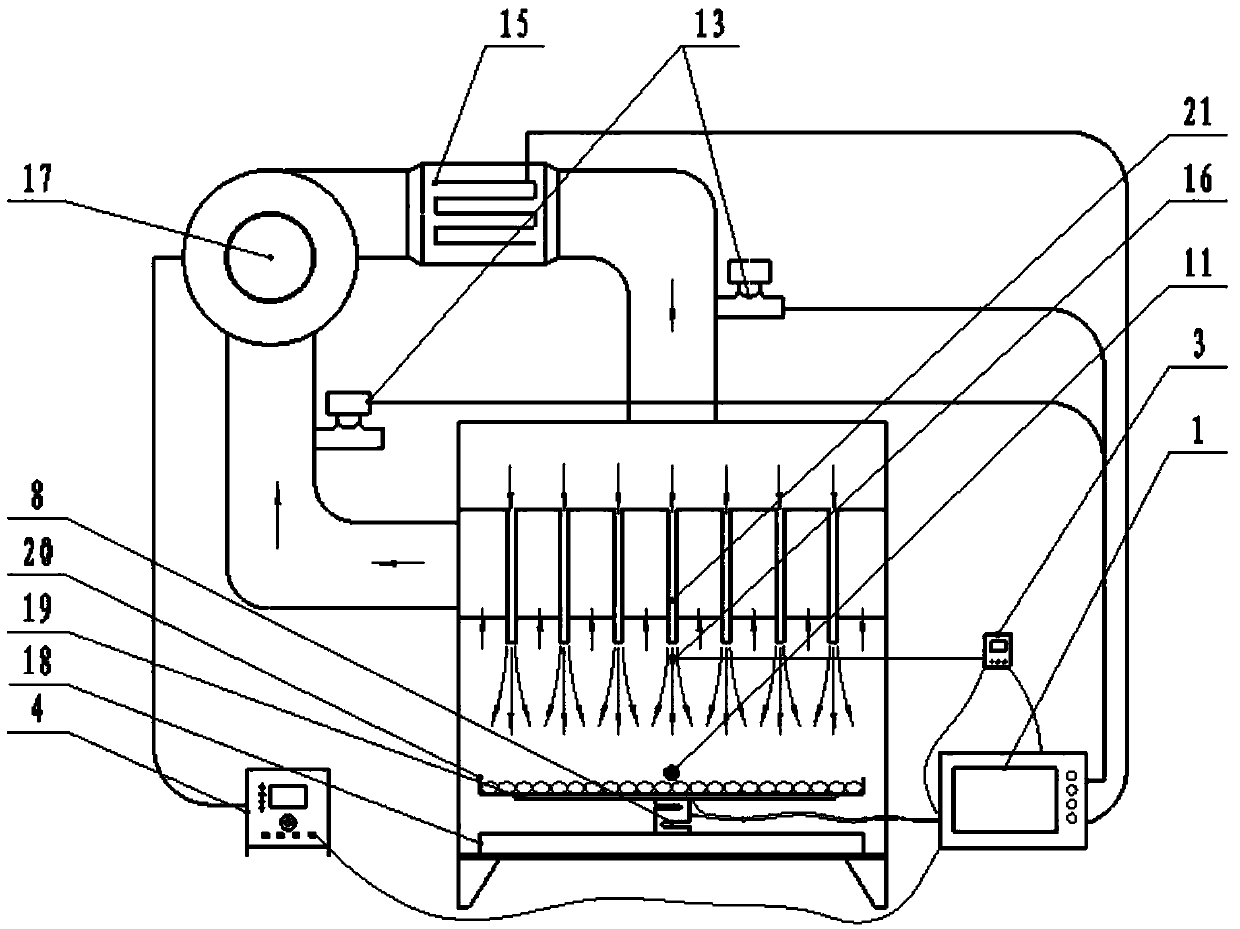

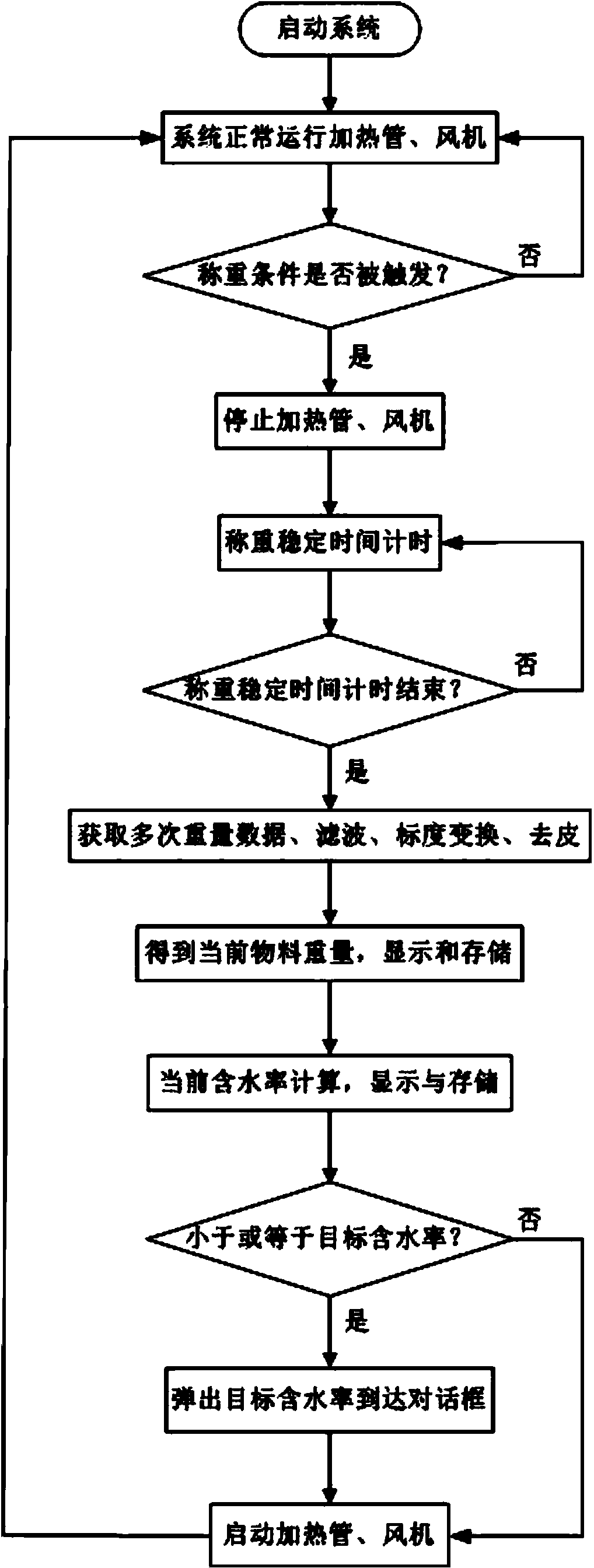

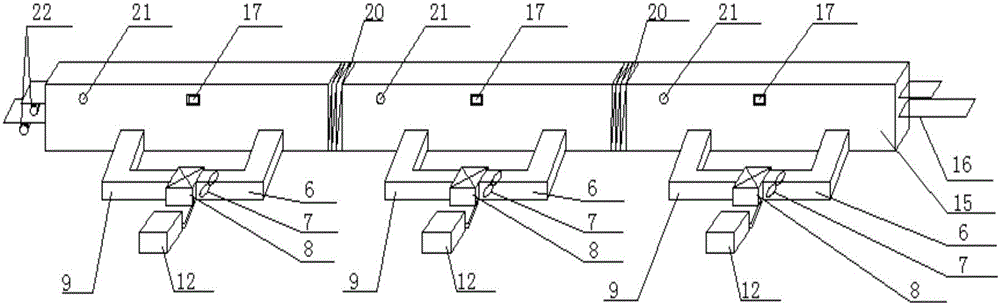

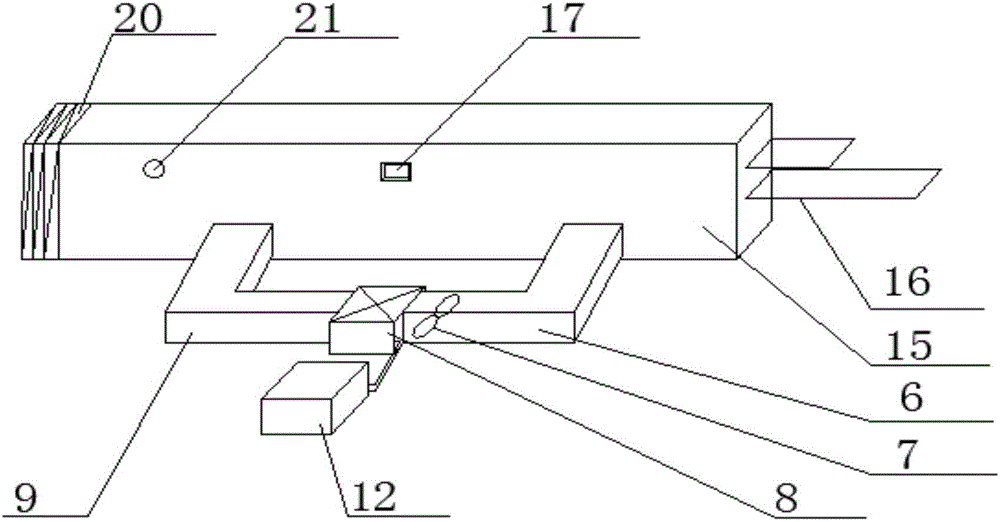

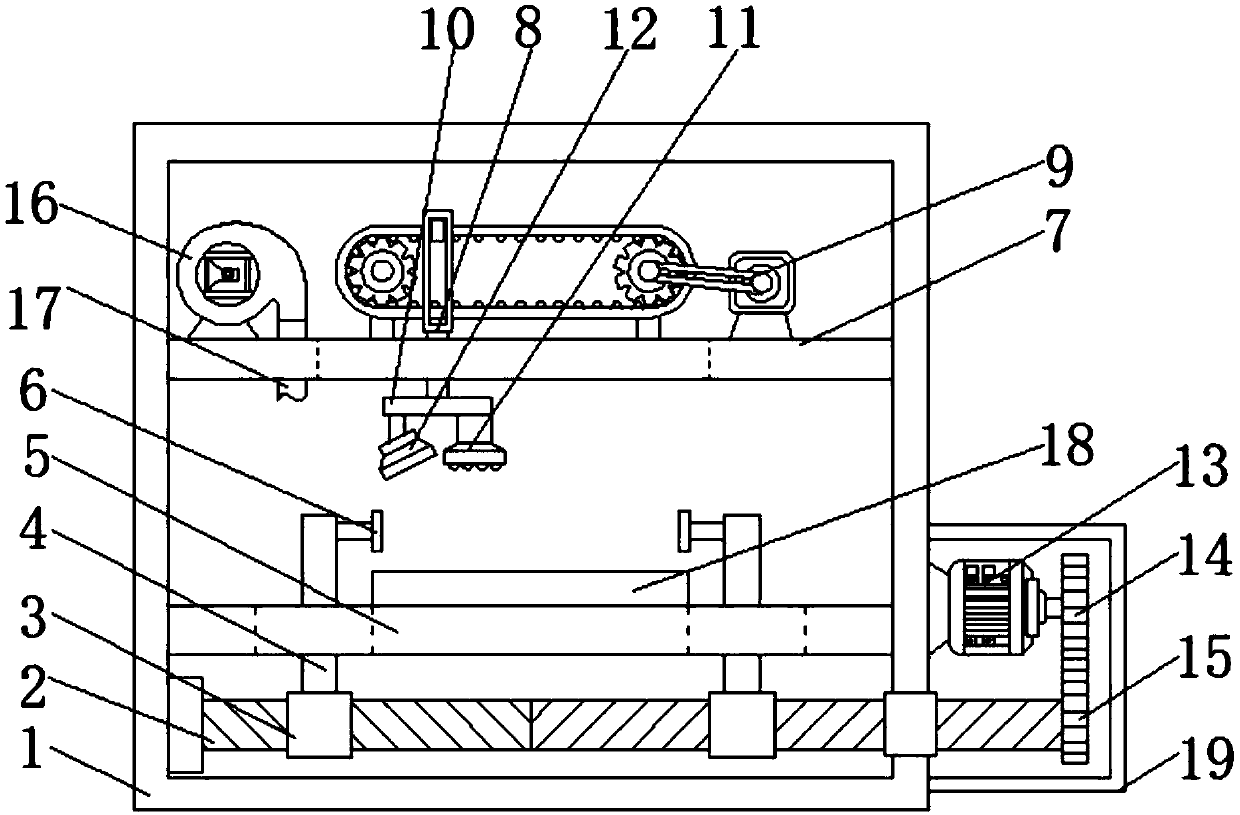

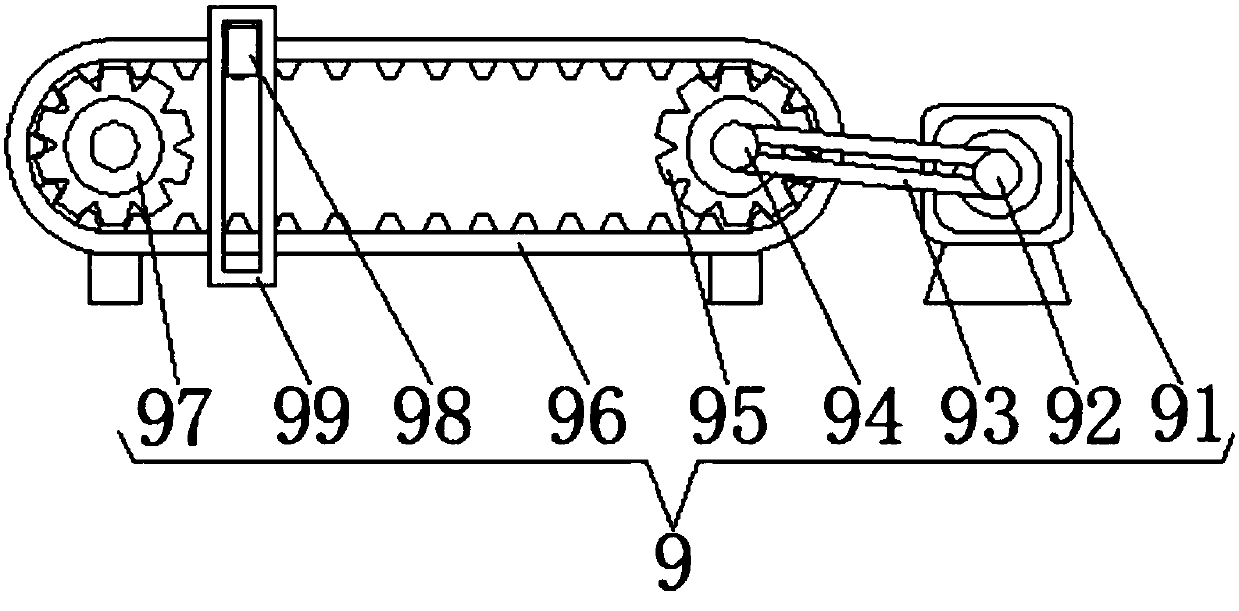

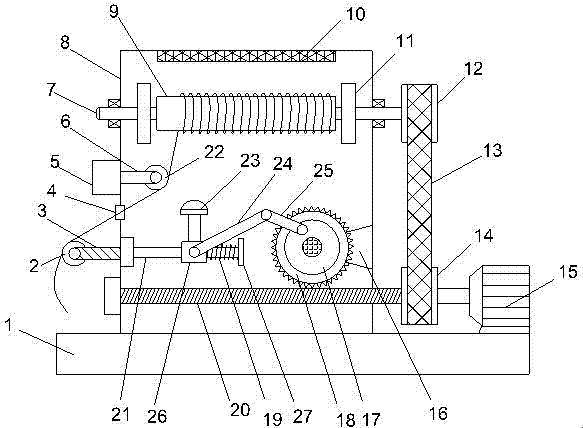

Automatic control system of gas jet impact drying machine

InactiveCN103438693AReduced impact on weighing accuracyElimination of influence on weighing accuracyDrying solid materialsAutomatic controlEngineering

The invention discloses an automatic control system of a gas jet impact drying machine, and belongs to the technical field of drying machines. The system comprises a programmable touch display screen (1), a single chip microcomputer (2), a weighing sensor (8), a temperature and humidity sensor (11), an air inflow / moisture discharging electromagnetic valve (13), a temperature controller (3), a heating pipe (15), a temperature sensor (16), a frequency converter (4) and a centrifugal fan (17). According to the automatic control system, in a drying process, the functions of automatic weighing of materials, moisture content detection, drying temperature precise controlling, drying temperature automatic regulation, drying air speed automatic conversion and the like can be achieved, the problem that the materials need to be weighed relying on manual work when the moisture content in a product is obtained in the drying process is solved, labor intensity of operating staff is reduced, meanwhile the quality of drying products can be effectively guaranteed, and automatic and intelligent level of gas jet impact drying equipment is improved.

Owner:CHINA AGRI UNIV

Seamless filled capsules

Spherical capsule having a liquid core and a seamless solid shell surrounding the core, in which: the diameter of the capsule is in the range of 4-8 mm; the thickness of the shell is in the range of 20-200 μm; the shell thickness to capsule diameter ratio is in the range of 0.004-0.04; the shell contains 70-90% (m / m) gelatin and 10-30% (m / m) plasticizer, based on the solids content of the shell; and the core has a flavoring content in the range of 1-100% (m / m), based on the total mass of the core.

Owner:SYMRISE GMBH & CO KG

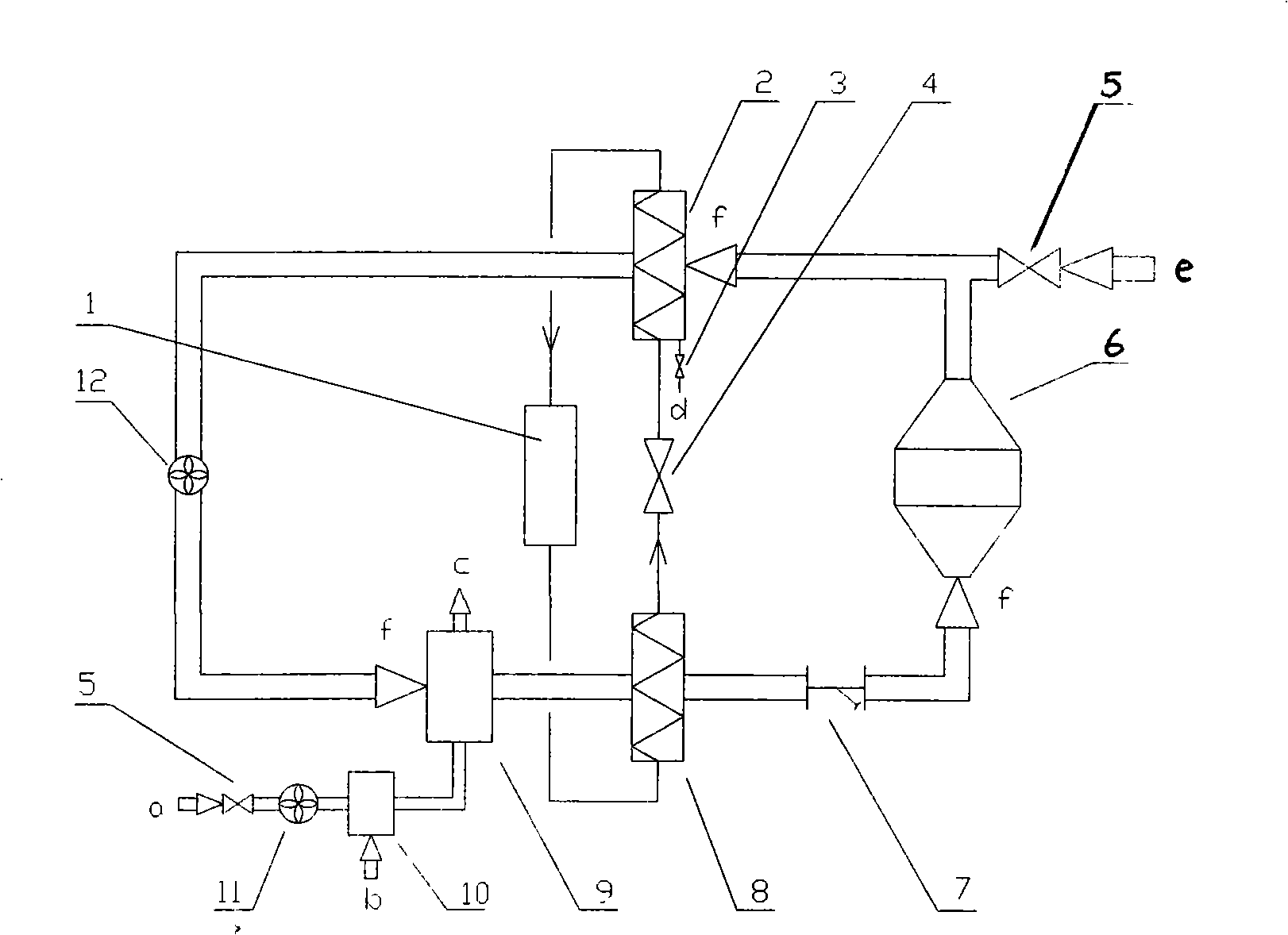

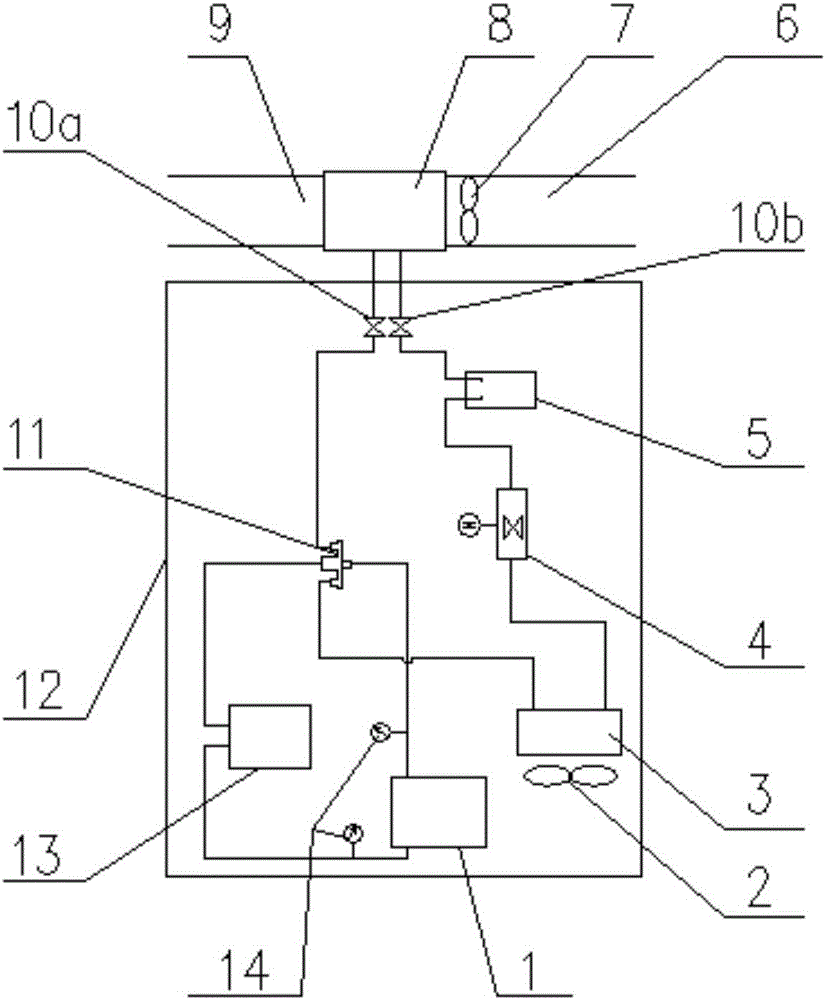

Adsorption-heatpump coupling drying system

InactiveCN101526301AReduce humidityImprove qualityHeat pumpsDispersed particle separationCouplingProduct gas

The invention relates to an adsorption-heatpump coupling drying system which is formed by coupling a heatpump system, a drying system and an adsorption dehumidifying system, wherein the heatpump system comprises a heatpump set 1, an evaporator 2, a throttle valve 4 and a condenser 8; the drying system comprises a drying box 6, a filter 7 and a drying fan 12; and the adsorption dehumidifying system comprises an adsorption dehumidifier 9, a recuperative fan 11 and a heater 10. The coupling course of the adsorption-heatpump coupling drying system comprises the following steps: drying medium gas f is led into the evaporator 2 by the drying fan 12 after drying material in the drying box 6, then enters the adsorption dehumidifier 9 for adsorption and dehumidification, and enters the condenser 8 to be adjusted to the drying temperature, finally enters into the drying box 6 for drying material after passing through the filter 7. The adsorption-heatpump coupling drying system has the advantages of high drying speed, high quality of dried material, low energy consumption during drying, and the like.

Owner:NANJING UNIV OF TECH

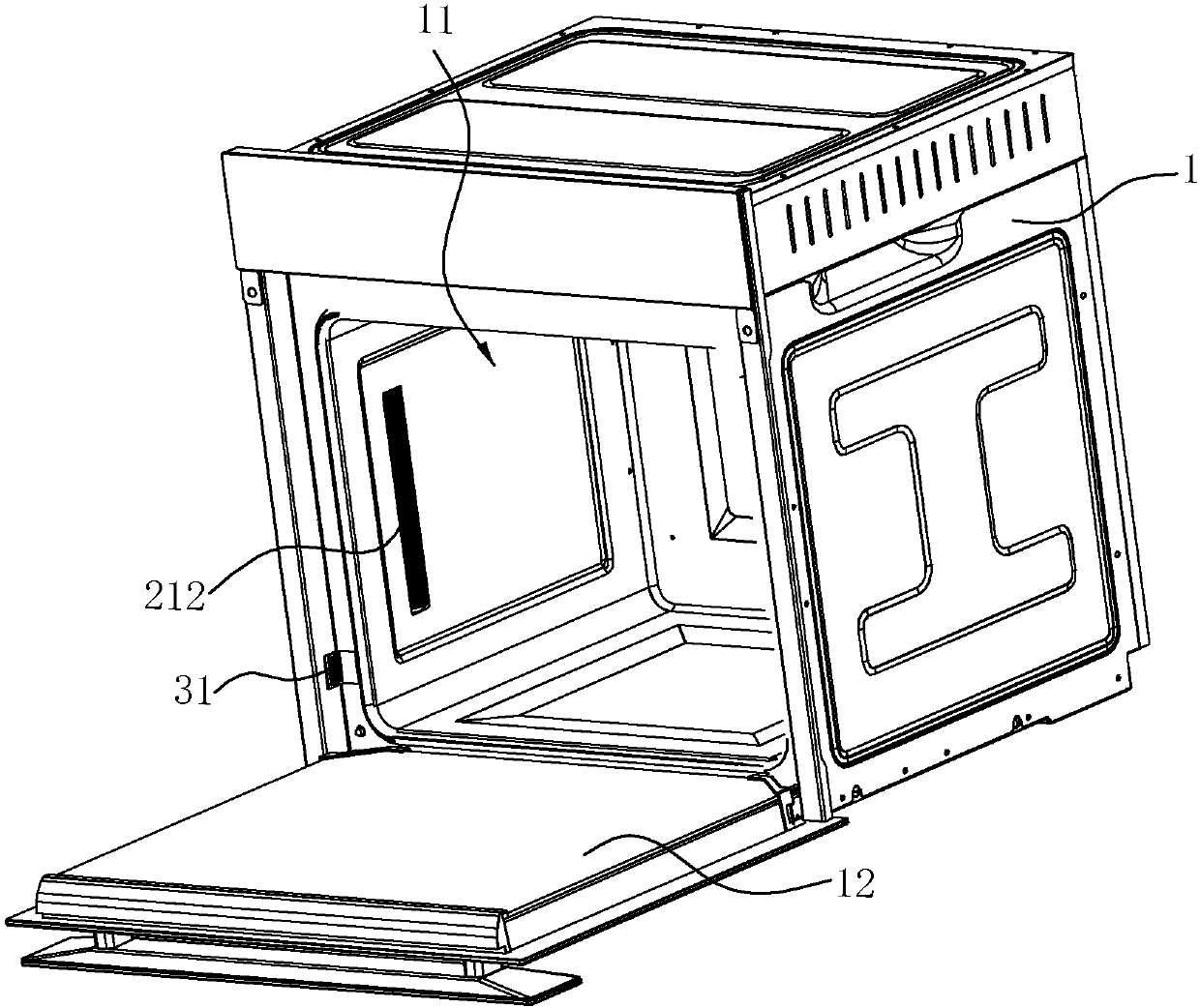

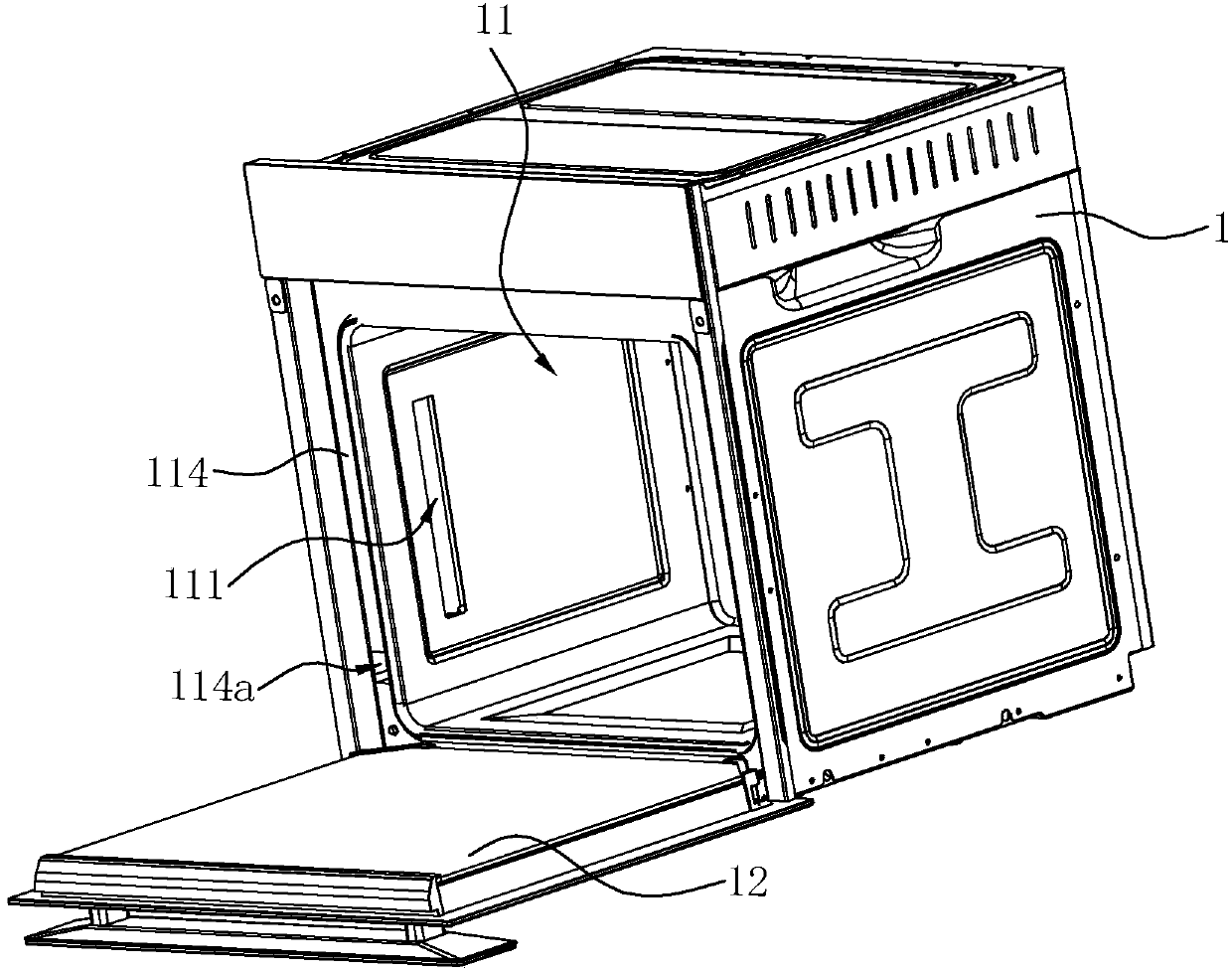

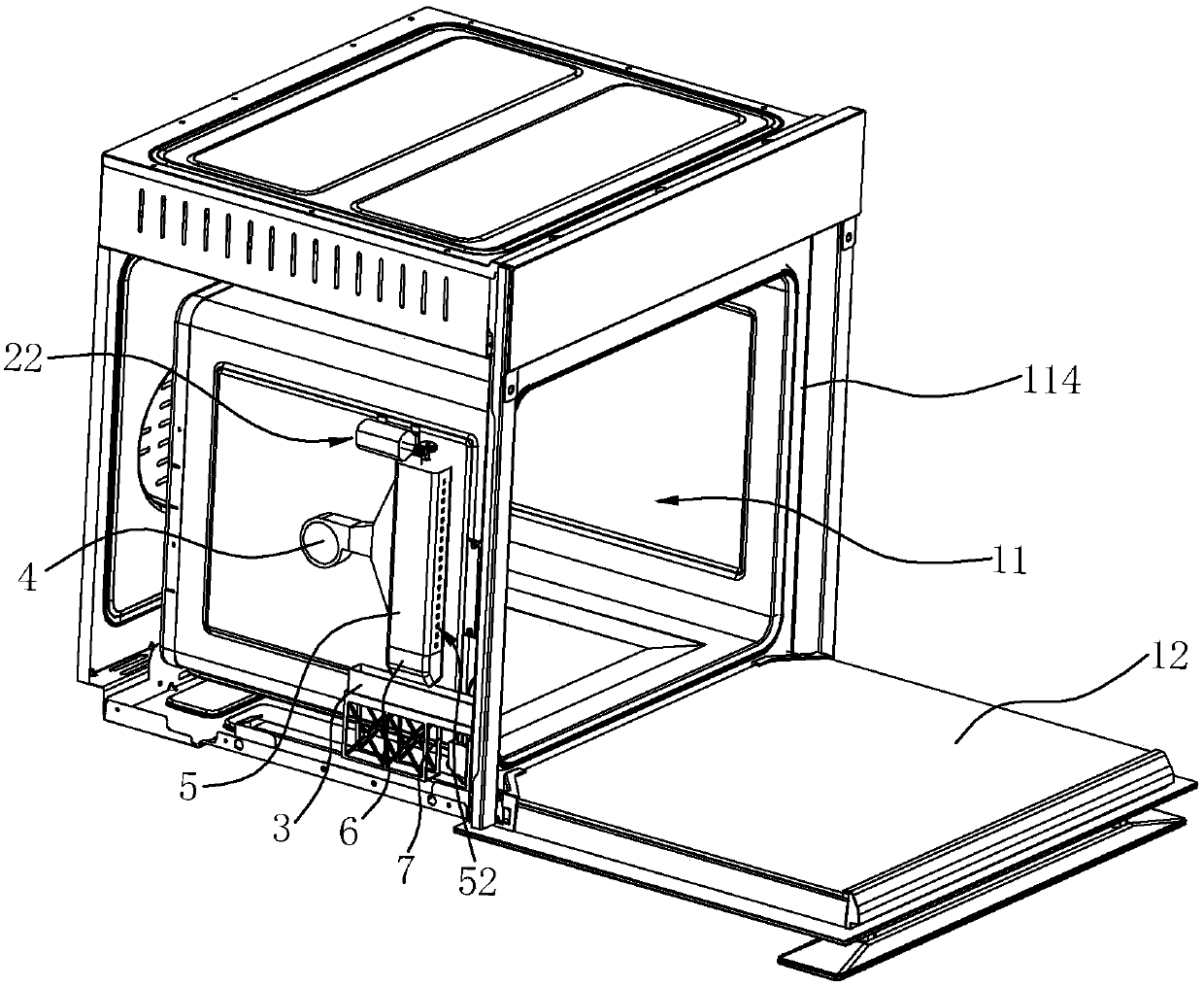

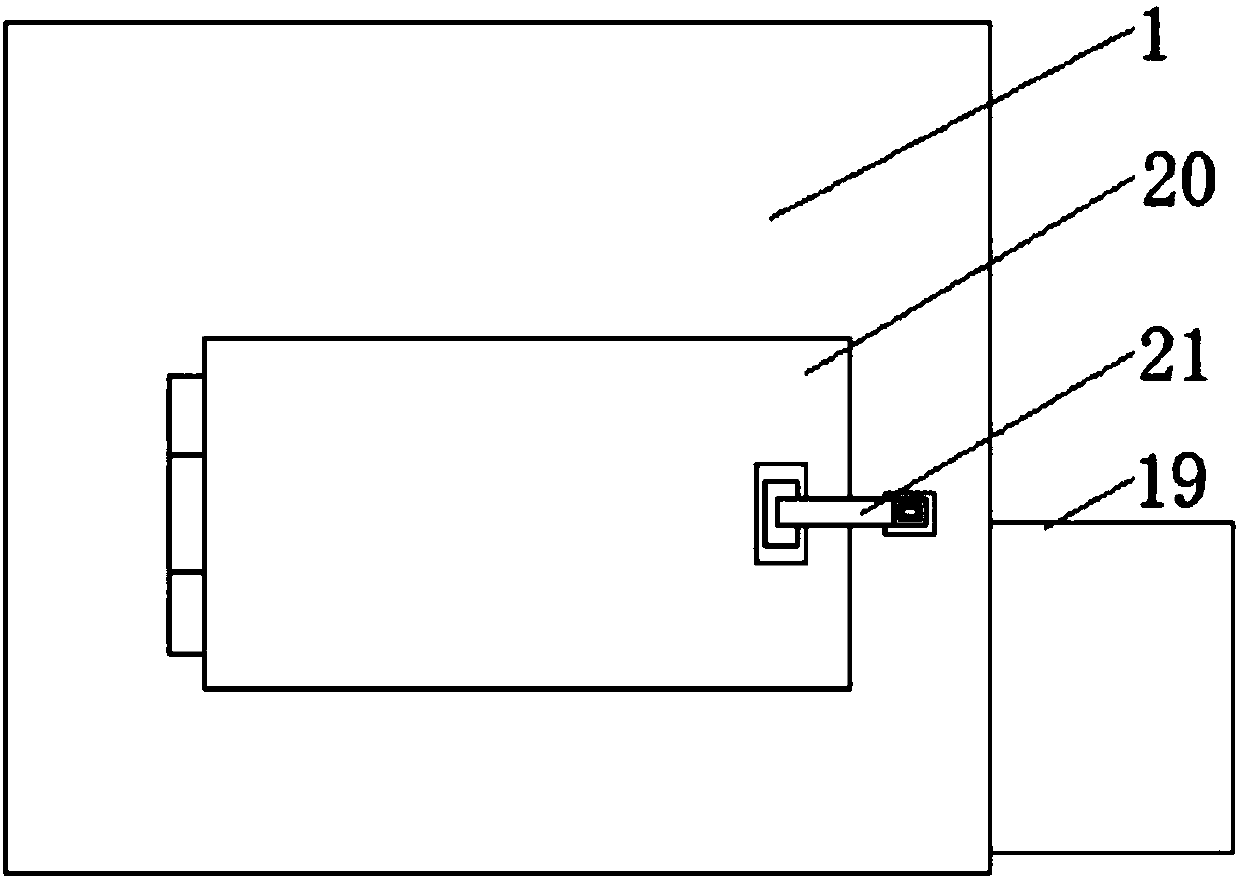

Oven with automatic moisture removing and drying functions

PendingCN110025227AImprove drying rateWith automatic dehumidification and drying functionRoasters/grillsEnergy lossEngineering

The invention relates to an oven with automatic moisture removing and drying functions. The oven comprises a cooking chamber and is characterized by further comprising a dehumidifying device, a through hole and a water storage box. The dehumidifying device is arranged on the outer side wall of the cooking chamber and comprises a rotating part and a driving structure for driving the rotating part to rotate. The outer side wall of the cooking chamber is provided with the through hole for holding the rotating part, and in a rotating process of the rotating part in the through hole, local surfacesof the rotating part are alternately exposed inside or outside the cooking chamber. The water storage box is arranged below the rotating part. Compared with the prior art, the oven has advantages that steam in the cooking chamber can be continuously condensed, and condensate water is guided to flow out of the cooking chamber, so that steam moisture in the cooking chamber is continuously reduced,and the interior drying rate of the cooking chamber is increased; in addition, energy loss caused by long-time opening of an oven door is avoided, and convenience and practicality are realized.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

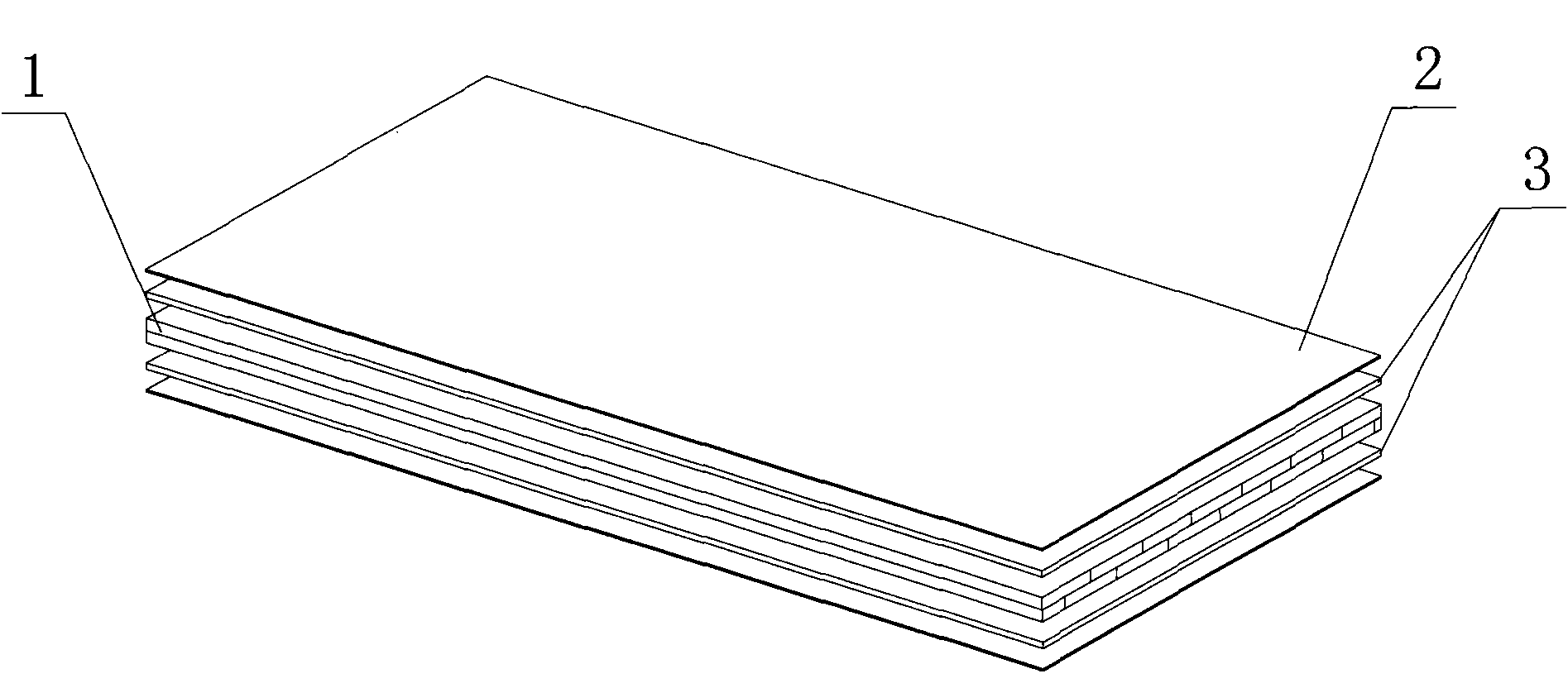

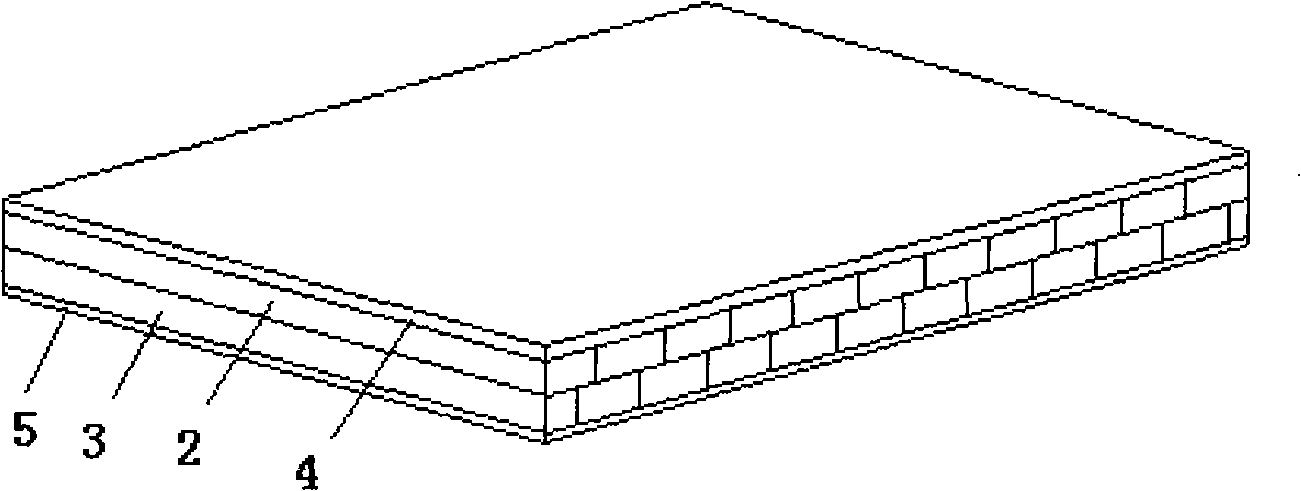

Composite slab with symmetric structure and manufacturing method thereof

InactiveCN101890739ASimple structureHigh strengthWood veneer joiningWood layered productsSurface layerAdhesive

The invention discloses a composite slab with a symmetric structure and a manufacturing method thereof. The composite slab with the symmetric structure comprises two surface layers and core layers inside the two surface layers, wherein the core layers are formed by overlapping a plurality of layers of saw cutting plates, and each layer of saw cutting plates is adhered with each other by using an adhesive. The core layers are formed by overlapping the saw cutting plates with the thickness of 5 to 1.5 mm; a middle layer is arranged between each surface layer and each core layer and is a single plate with the thickness of 1.5-2.5 mm; the surfaces of the saw cutting plates are provided with a plurality of dot-line shaped crackles along a direction of wood grain; and the average length of the cracks is between 2.5 mm and 4.8 mm, the width is between 0.5 mm and 2.5 mm, the depth is 40 to 60 percent of the thickness of the saw cutting plates of the core layers, and the distance between the crackles is between 1 cm and 4.8 cm. The invention has the advantages of simple structure, firmness, durability, concise procedures of the manufacturing method, wide application range and easy popularization, can be used as raw materials of any panel-type furniture, and is suitable for processing and manufacturing various kinds of fast-growing tree timber composite plates.

Owner:成都市双虎实业有限公司

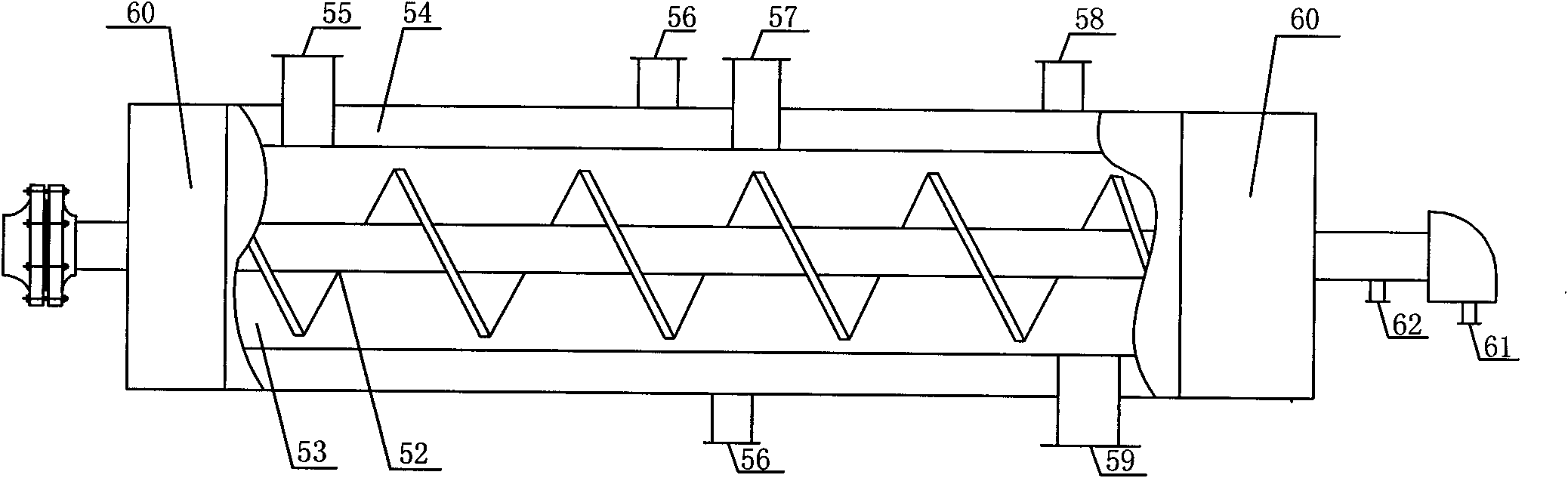

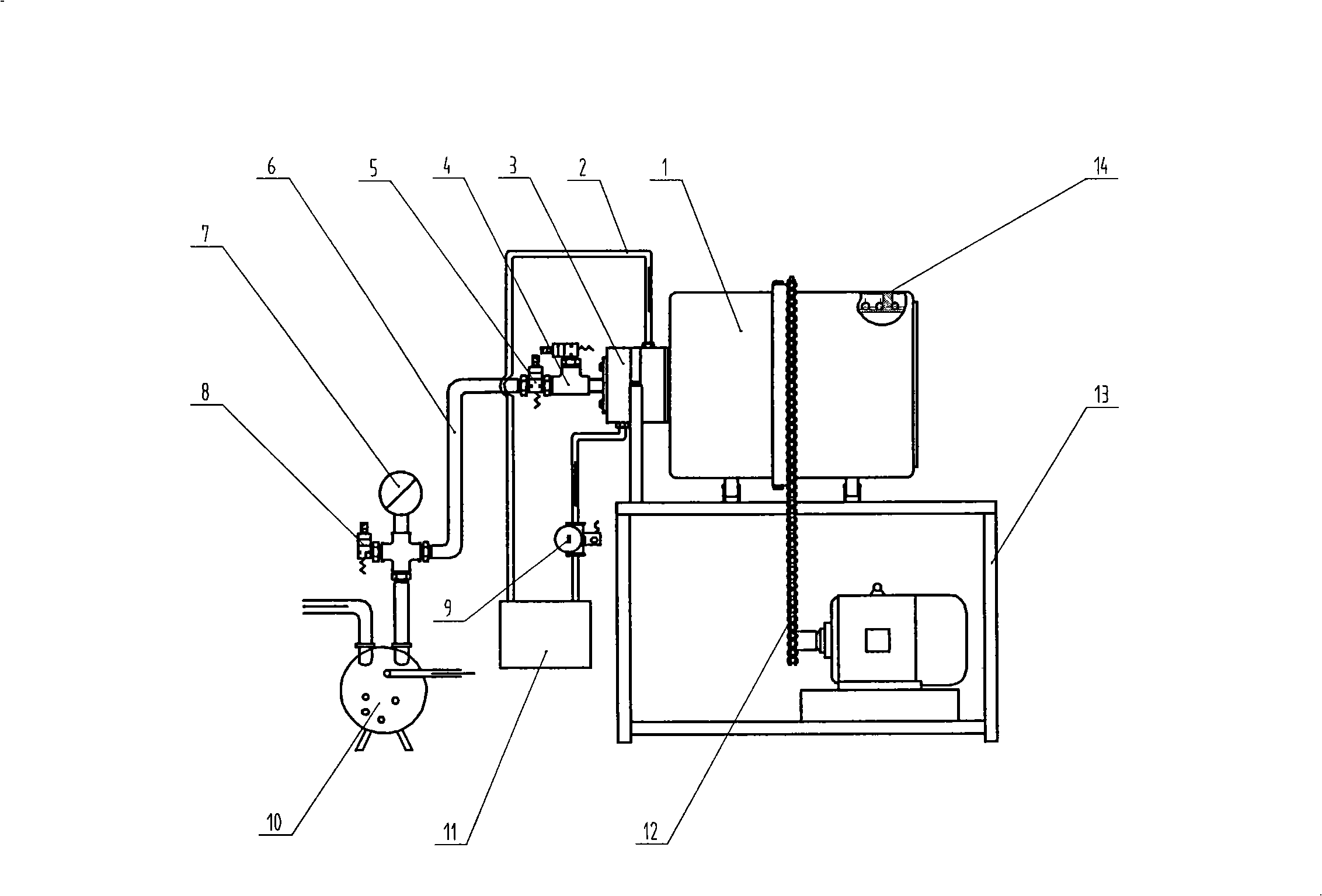

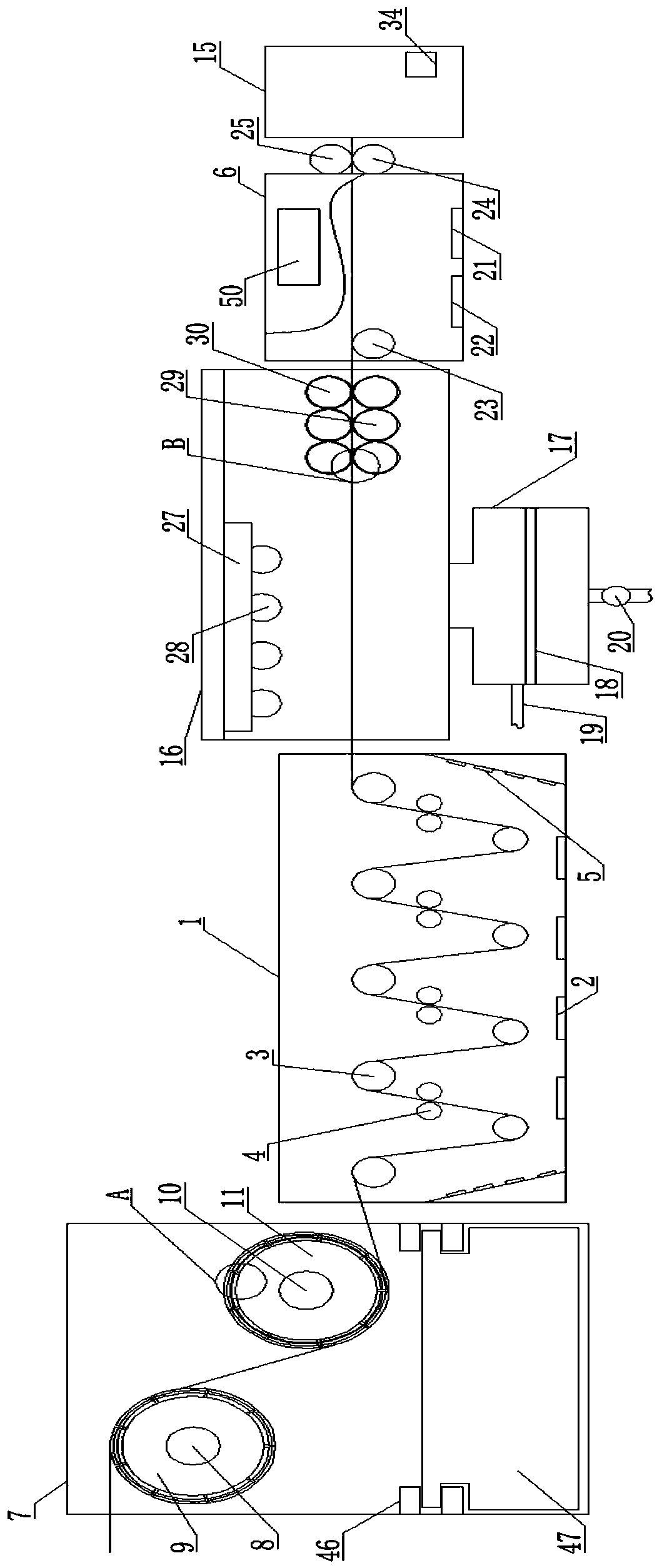

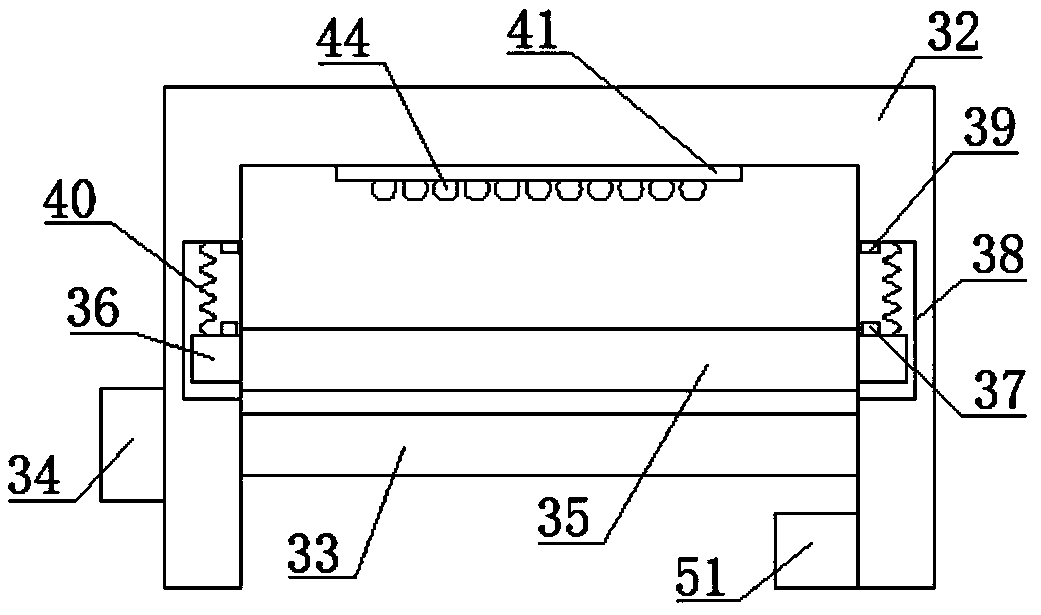

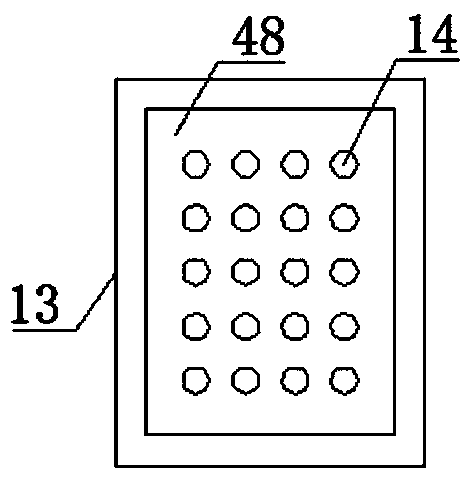

Drum-type vacuum pulsing temperature-variable drying method and apparatus

InactiveCN101261073AKeep drySolve delivery difficultiesDrying using combination processesDrying solid materials with heatControl systemChemical products

The invention discloses a drum-type vacuum pulsing transformation temperature drying method and a device, comprising a sealed circular roller, a heating circulating system, a pulsing vacuum system connected with the roller and a control system, wherein, the vacuum degree of the pulsing vacuum system connected with the roller varies with the material arranging from 0.097 MPa to 0 MPa, the heating temperature of the heating circulating system varies with the state of the material. The device has good heat transmitting performance, preserves the nutrient content and the active material of the material as well as the color and luster of the material well, greatly raises the drying speed, shortens the drying time, reduces the drying energy consumption and lowers the drying cost. The drum-type vacuum pulsing transformation temperature drying method and the device are suitable for drying the foods, the biological products, the drugs and the chemical products with good fluidness, particularly for drying the products thermally sensitive; especially, the effect for drying the foods and the biotechnology products with high added value is better.

Owner:CHINA AGRI UNIV

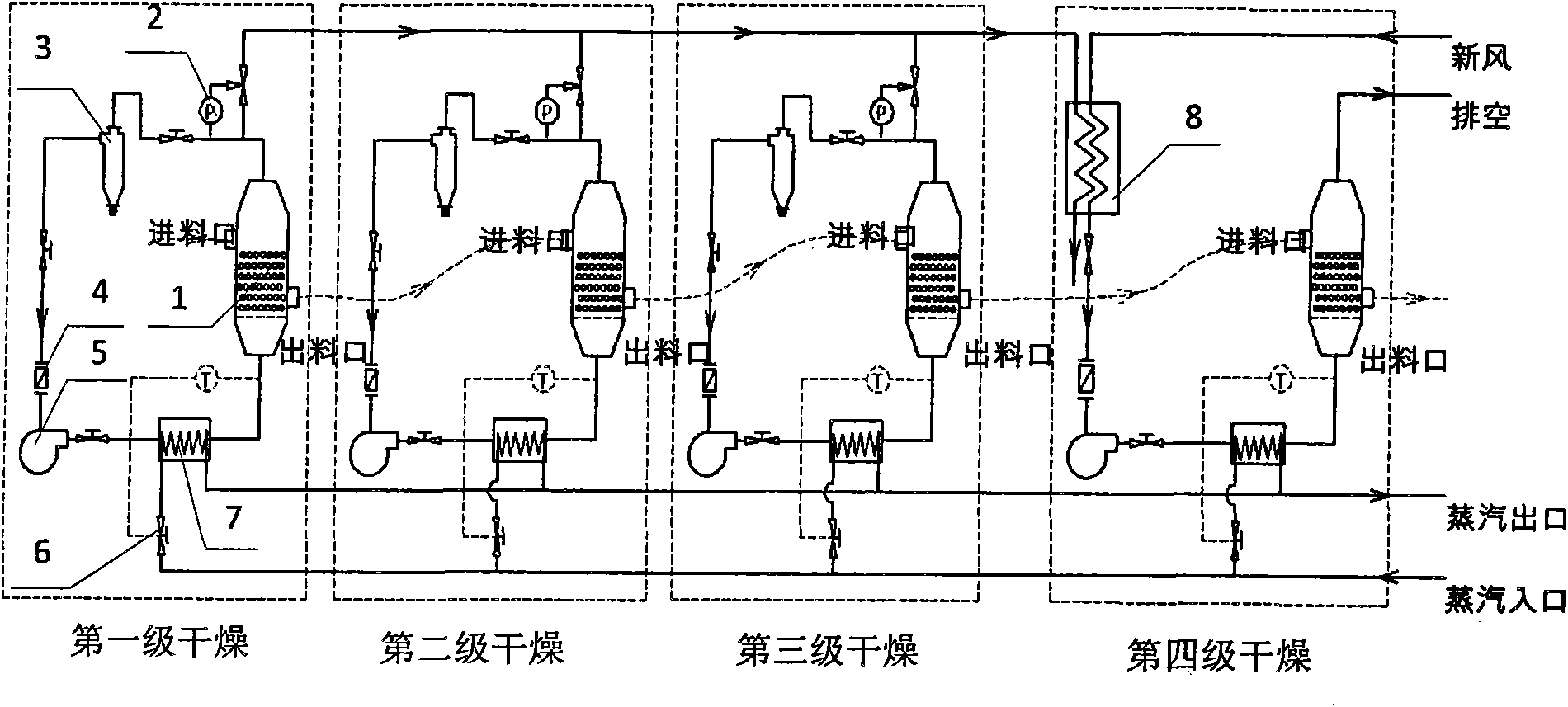

Novel silica gel energy-saving drying device and process thereof

ActiveCN101788221AImprove drying qualityImprove qualityDrying solid materials with heatDrying gas arrangementsThree stageProcess engineering

The invention discloses a novel energy-saving silica gel drying device and a process thereof, which can dry silica gel rapidly and efficiently with the drying thermal efficiency improved to 50 percent from 35 percent of the prior art. The device comprises at least one superheated steam drying unit and at least one hot air drying unit. A required material can be obtained through speed-raising drying and constant-speed drying of the superheated steam drying unit and drying of the hot air drying unit. The process is a superheated steam-hot air combined multi-stage silica gel drying process, the first three stages adopt superheated steam drying, the first-stage steam drying is mainly a speed-raising drying stage, the second stage and the third stage are respectively a stage of constant-speed drying at the corresponding temperature, wherein the silica gel drying speed is high, no breakage or cracking can be easily caused, good properties of the porous structure can be maintained, the drying quality is high, and the fourth-stage hot air drying can maintain a relatively high drying speed. The superheated steam-hot air combined multi-stage silica gel drying process has the advantages of good quality of the dried silica gel and high speed, and the closed drying circulation system has significant effect on energy conservation and emission reduction.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

A method for drying large-capacity lithium-ion power battery cells

ActiveCN104142045BShorten heating timeFast heatingFinal product manufactureDrying solid materials without heatPower batteryManufacturing technology

The invention discloses a method for drying large-capacity lithium-ion power battery cells, and belongs to the technical field of lithium battery production and manufacturing. The method comprises the following steps: (1) placing the battery cell to be dried in a drying furnace, heating to raise the temperature of the furnace, and evacuating to a relative vacuum degree ≤ -99.0; (2) evacuating the vacuum to a relative vacuum degree of - 5.0~-85.0; (3) Run the blower equipment in the drying furnace to keep warm; (4) Vacuumize to a relative vacuum degree ≤ -99.0 and continue to vacuumize; (5) Sequentially perform (2), (3), (4 ) steps to cycle. The method of the invention utilizes the dry and wet hot gas convection state and the vacuum state in the furnace to dry the battery cells alternately, which can effectively reduce the moisture content of the battery cells with a small number of cycles, improve the drying rate and efficiency of the battery cells, and reduce the circulating gas Dosage and reduce calorie consumption.

Owner:中创新航科技(江苏)有限公司

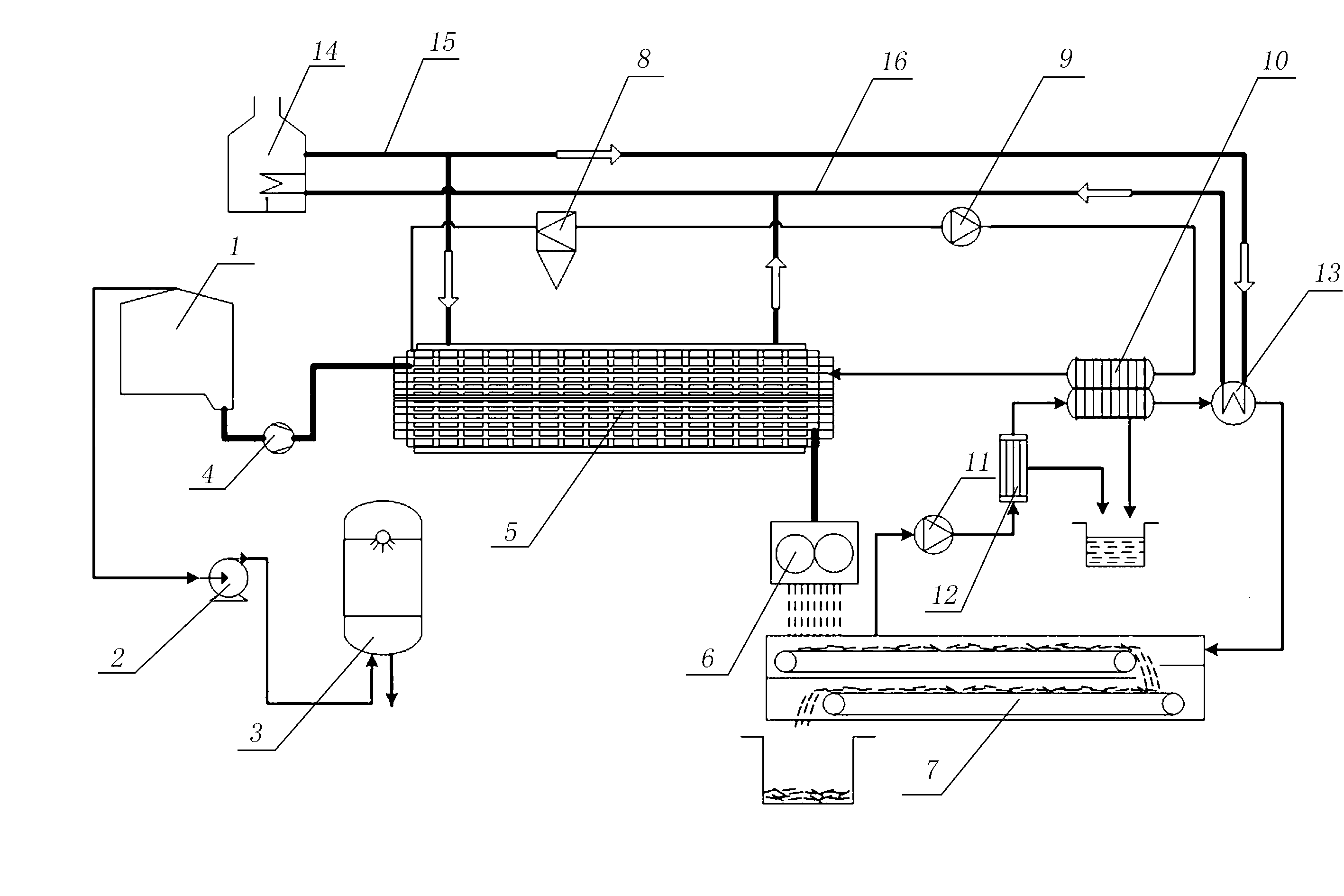

Two-stage sludge drying and energy recovering system and drying process thereof

ActiveCN103011546AReduce lossesImprove heat transfer efficiencySludge treatment by de-watering/drying/thickeningSludgeEnergy recovery

The invention discloses a two-stage sludge drying and energy recovering system and a drying process thereof. The two-stage sludge drying and energy recovering system comprises a sludge storage chamber. The two-stage sludge drying and energy recovering system is characterized in that an exhaust port of the sludge storage chamber is connected with a deodorization reactor through a first fan; a sludge outlet of the sludge storage chamber is connected with a sludge inlet end of a drier through a sludge pump; a sludge forming machine is arranged at the sludge outlet end of the drier; and a belt drier is arranged at the sludge discharge hole of the sludge forming machine. The system adopts a two-stage drying manner; and the sludge of which the moisture content is 70-85% is finally dried into granular sludge of which the solid content is 70-90%. The system is high in heat transfer efficiency, small in carrier gas quantity, and low in heat loss, and does not generate dust at all; the energy recovering system is efficient and energy-saving; the energy saving rate achieves about 30%, and the drying rate and the energy-saving rate are obviously improved from the aspect of actual use effect.

Owner:SHANGHAI SAFBON WATER SERVICE CO LTD

Belt-type temperature-variable type grain heat pump drying device

InactiveCN106568317AFull heat and moisture exchangeImprove storage efficiencyHeat recovery systemsFood processingNatural ventilationEngineering

The invention provides a belt-type temperature-variable type grain heat pump drying device which comprises at least three drying modules which are connected in sequence. Each drying module comprises a heat pump system, an air flue system connected with the heat pump system and a drying channel connected with an air supply opening and an air return opening of the air flue system. By means of the belt-type temperature-variable type grain heat pump drying device, the phenomenon of grain crack can be effectively prevented, quality of dried grains is improved, and the yield of the dried grains is raised; cooling is conducted directly after the grains are dried, and the defects that natural ventilation cooling time is long, and the grains absorb environmental moisture are overcome; time is saved, work efficiency is improved, the grains are dried in a layered manner in the drying channel, space can be effectively utilized, quality of the grains is improved, and the yield of the grains is raised.

Owner:浙江豪瓦特节能科技有限公司

Preparation method of natural lemon slice and fruit powder

InactiveCN102919743AImproves moisture migration conditionsPrevent browningFood preparationMicrowaveAdditive ingredient

The invention discloses a preparation method of natural lemon slice and fruit powder. The preparation method comprises the following steps: (1) slicing lemon fruit and performing dipping treatment, then carrying out microwave vacuum drying till the water content of lemon fruit slices is 12wt% to 15wt%; (2) then carrying out hot-air drying on the lemon fruit slices, then drying by using a hot-air drying oven till the water content of the fruit slices is lower than or equal to 9wt%, and then packing to obtain lemon slices; and (3) finally crushing the lemon slices into 80-100 meshes through a crusher so as to obtain lemon fruit powder. The method combines vacuum microwave puffing treatment and lemon slice preparation by hot-air drying and preparation of a natural fruit powder product, the color, flavor and nutrient content of the prepared product are effectively stored, and the product quality is improved. Along with the growth of the living standard of people and attention to food safety, the preparation method can be applied to composite vegetable and fruit powder and natural health leisure food. Moreover, through vacuum microwave drying, the processing cycle is shortened, the energy is saved, and the consumption is reduced.

Owner:SERICULTURE & AGRI FOOD RES INST GUANGDONG ACAD OF AGRI SCI +1

Plate paint spraying and drying device for automobile production

InactiveCN107899833AImprove drying rateFast processingSpray boothsAutomotive paintAgricultural engineering

The invention discloses a plate paint spraying and drying device for automobile production, which comprises a housing, a support plate is fixedly connected between the two sides of the inner wall of the housing, and a screw rod is rotatably connected between the two sides of the inner wall of the housing. Both sides of the surface of the screw rod are screw-connected with movable blocks, and the top of the movable block is fixedly connected with a vertical plate, and the top of the vertical plate passes through the support plate and extends to the top of the support plate, and the two vertical plates Both opposite sides are fixedly connected with clamping plates, and a horizontal plate is fixedly connected between the two sides of the inner wall of the housing. The invention relates to the technical field of painting of automobile panels. The paint spraying and drying device for plates used in automobile production blows air on the plates after painting to speed up the drying rate of the paint surface, which is beneficial to increase the processing speed and production efficiency, and fixes the plates so that the plates remain stable during processing It is beneficial to improve the uniformity of the paint surface and improve the production quality.

Owner:HEFEI DONGLU MACHINERY MFG

Microwave processing method for chrysanthemum tea

The invention relates to a microwave processing method for chrysanthemum tea. The method comprises the following steps of: firstly, picking out satisfactory fresh chrysanthemums, and spreading the chrysanthemums at room temperature to air; performing microwave green removing, quickly reducing the temperature after green removing, and repeatedly kneading the chrysanthemums; and drying, screening, inspecting and packing the chrysanthemums to obtain the finished product of chrysanthemum tea. Compared with the traditional common green removing method through heating, distilling and drying, the method can effectively reserve important drugs and nutrition constituents such as volatile oil, flavone, chlorogenic acid, stevia, choline, amino acids, vitamins, abundant mineral elements and the like contained in the chrysanthemums, and the disinfection effect is improved.

Owner:程雪翔

Method for uniformly drying lettuce by normal pressure and negative pressure combined microwave spouted bed

InactiveCN102405958AReduce lossesHigh retention rateFruits/vegetable preservation by dehydrationMicrowaveMagnesium acetate

The invention relates to a method for uniformly drying lettuce by a normal pressure and negative pressure combined microwave spouted bed, and belongs to the technical field of fruit and vegetable food processing. The main processes of the method comprises: removing leaves and peels from fresh lettuce, cleaning, cutting into cubes (cutting into sheets), adding a EDTA-Na solution to carry out colorprotection, blanching, adding a magnesium acetate solution and a zinc acetate solution to carry out color protection, and carrying out treatments of microwave spouted drying, packaging and storage. With the present invention, the microwave drying technology is adopted so as to shorten the drying time, reduce the drying energy consumption, and reduce the loss of the chlorophyll in the lettuce during the processing process; the normal pressure spouted bed drying technology and the negative pressure spouted bed drying technology are combined to dry the lettuce, and the material has the circular motion, such that the disadvantage of the nonuniformity of the microwave drying is overcome; the product dried by the microwave spouted drying method has characteristics of good water reabsorbing capacity, high water reabsorbing rate, good crisp taste after water reabsorbing, unique lettuce aroma, high chlorophyll content, good and uniform color.

Owner:NINGBO HAITONG FOOD SCI & TECH CO LTD +1

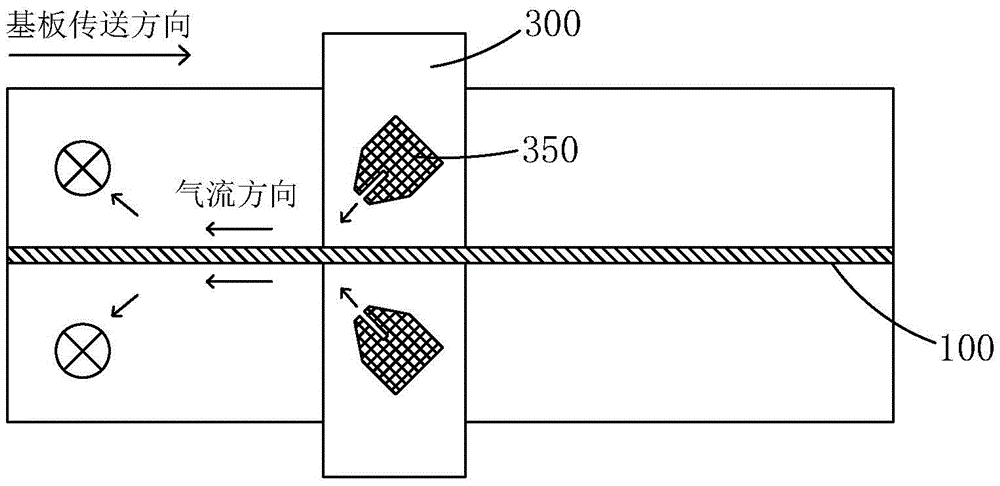

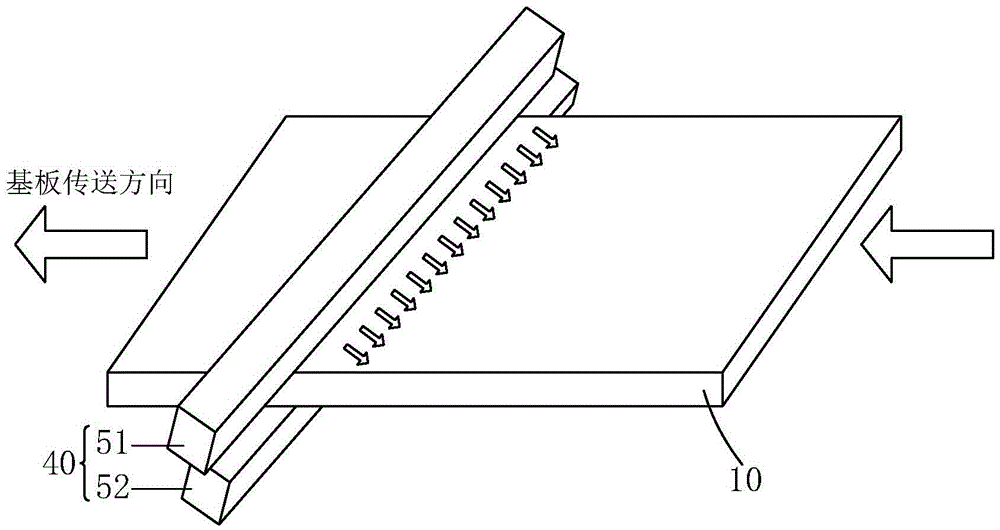

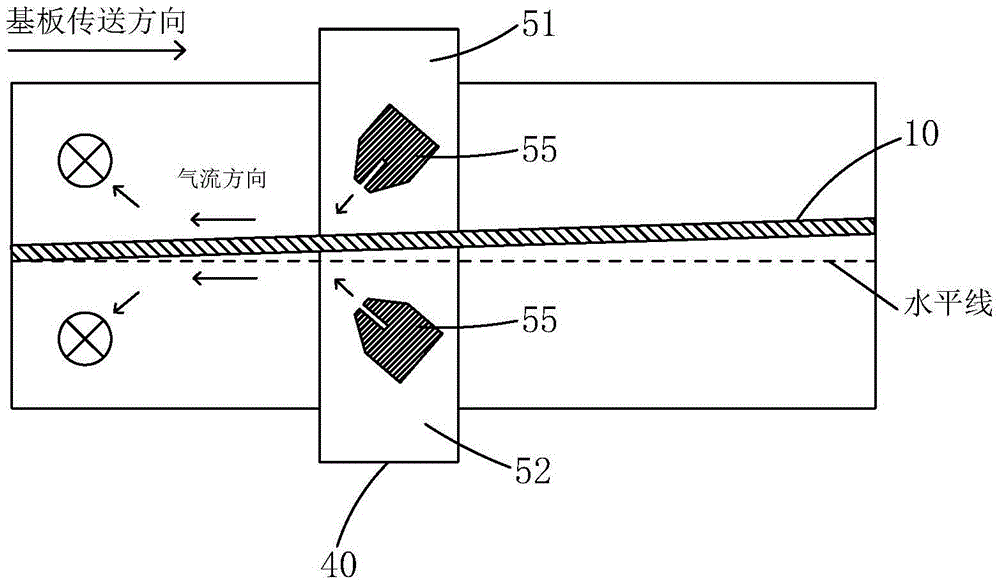

Substrate cleaning method

ActiveCN105605909AImprove shipping speedFast cleaningDrying gas arrangementsCleaning using liquidsEngineeringAir knife

The invention provides a substrate cleaning method. A substrate (10) is arranged to be at different inclination angles and in different inclination modes in the drying process, and a traditional air knife device (40) is adopted for thoroughly removing cleaning water remaining on the substrate (10). Or, a frequency-adjustable air knife device (70) is adopted as an air knife device for a first blow-drying procedure in the drying process, the traditional air knife device (40) is adopted as an air knife device for a second blow-drying procedure in the drying process, and the cleaning water remaining on the substrate (10) is thoroughly removed in the two blow-drying procedures; meanwhile, the substrate (10) can be further arranged to be at different inclination angles and in different inclination modes to prevent the cleaning water from flowing back, increase the drying speed and avoid that strip-shaped mura is generated in subsequent procedures. In addition, the substrate (10) conveying speed can be properly increased thanks to the high drying speed of the frequency-adjustable air knife device (70), so that the substrate (10) cleaning speed is increased.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

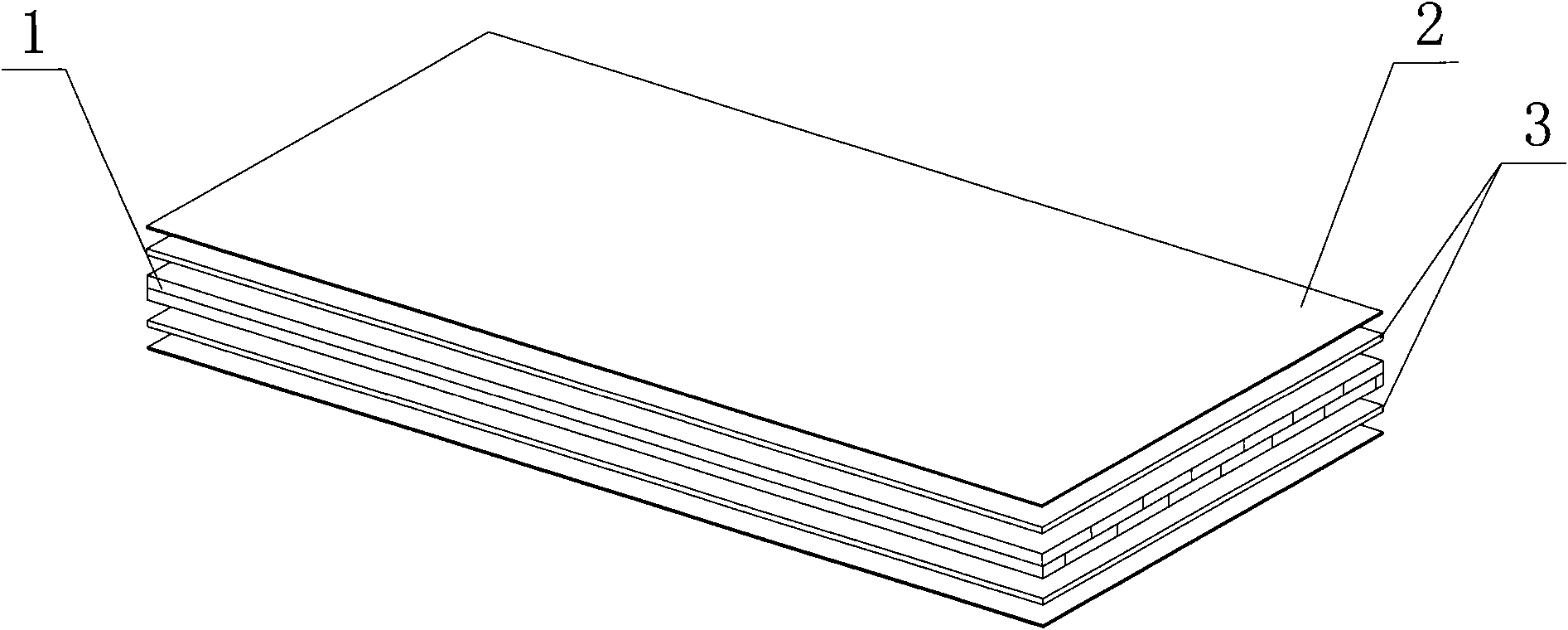

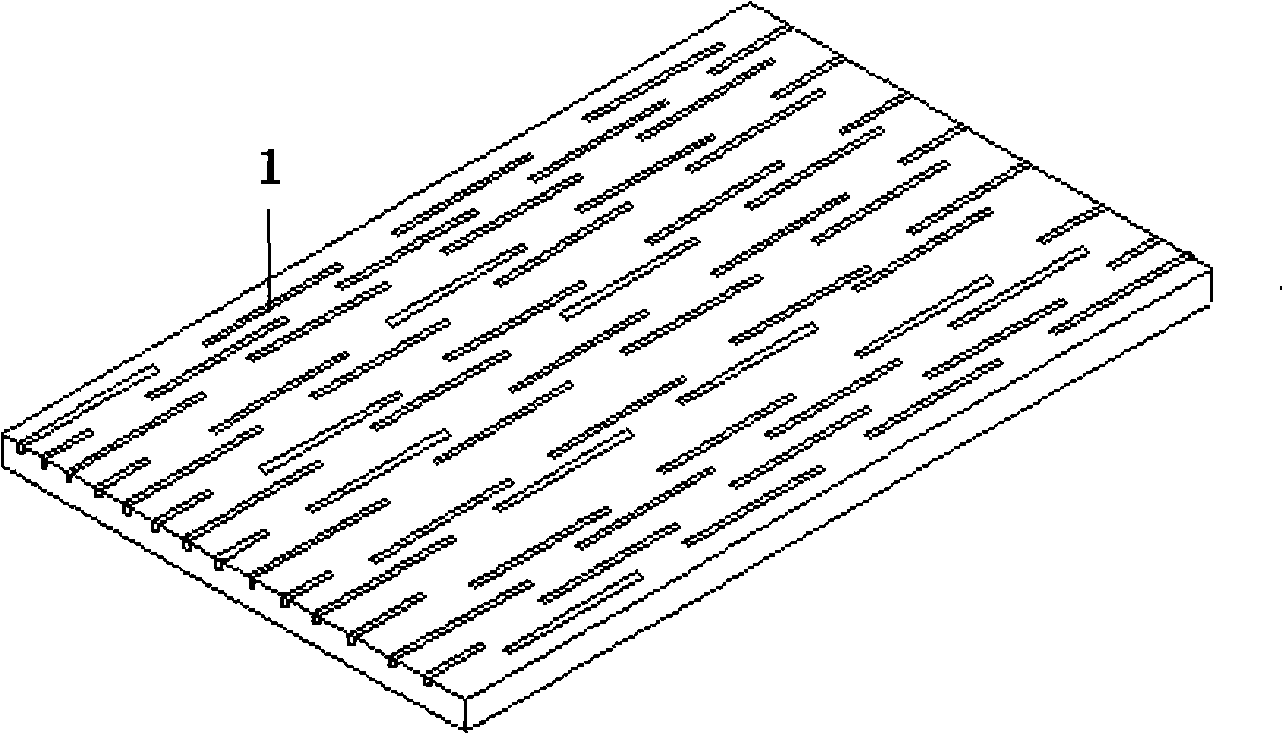

Solid-wood composite board made of super-thick single boards and producing method thereof

ActiveCN101524859ALarge specific surface areaImprove drying rateWood veneer joiningWood layered productsSolid woodSurface layer

The invention provides a solid-wood composite board made of super-thick single boards, which comprises two surface layers on external surfaces and a core layer between the two surface layers, adhesive is arranged among single boards, the core layer comprises a super-thick single board with the thickness of 6 mm to 12 mm, and the surface layers comprise single boards with the thickness of 0.2mm to1.5 mm. The super-thick single boards of the core layer are single boards made by rotatably cutting logs, and spot-shape or segment-shape crack grains are arranged on the loosened surface of the single boards in the direction along the grain. The solid-wood composite board made of super-thick single boards enables the composite board combined by the super-thick core boards to have no distortion or deformation by adopting the central-symmetric single-board assembly structure and forming spot-shape or segment-shape crack grains by discongesting on the surfaces of the single boards of the core layer, and has equal performance as that of the solid wood. The super-thick core board enables the glue layers of the veneer to be reduced, the applied glue amount is reduced, the cost is saved, and the release amount of the formol can be reduced to enable the solid-wood composite board to be more environmental friendly.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Preparation method of graphene oxide modified waterborne polyurethane anti-corrosive emulsion

ActiveCN107880237AImprove dispersion stabilityReduce van der Waals forcesAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyN dimethylformamide

The invention relates to a preparation method of a graphene oxide modified waterborne polyurethane anti-corrosive emulsion, relating to the technical field of preparation of aqueous coatings. The preparation method comprises the following steps: firstly, mixing N,N-dimethylformamide, graphene oxide, a catalyst and glycidyl neocyanate to react to obtain modified graphene oxide; then mixing the graphene oxide, isophorone diisocyanate and polyadipic acid-1,4-butanediol ester, raising the temperature to 85 DEG Ca and then reducing the temperature to 60 DEG C; then adding dibutyltin dilaurate, 5-N-methyl pyrrolidone, epoxy resin, 2,2-dimethylolpropionic acid and trimethylolpropane to react; adding triethylamine to react at the temperature of a reaction material of 60 DEG C; then adding deionized water at 60 DEG C to react; reducing the temperature to 40 DEG C; carrying out filtration; and taking the filtered object to obtain the graphene oxide modified waterborne polyurethane anti-corrosiveemulsion. The shielding capacity of a graphene oxide sheet layer can be further improved by means of hydrophobic effect formed by a long alkyl chain grafted to the surface of graphene oxide.

Owner:海安常州大学高新技术研发中心

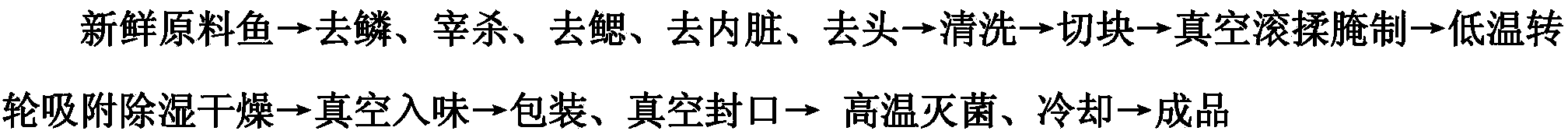

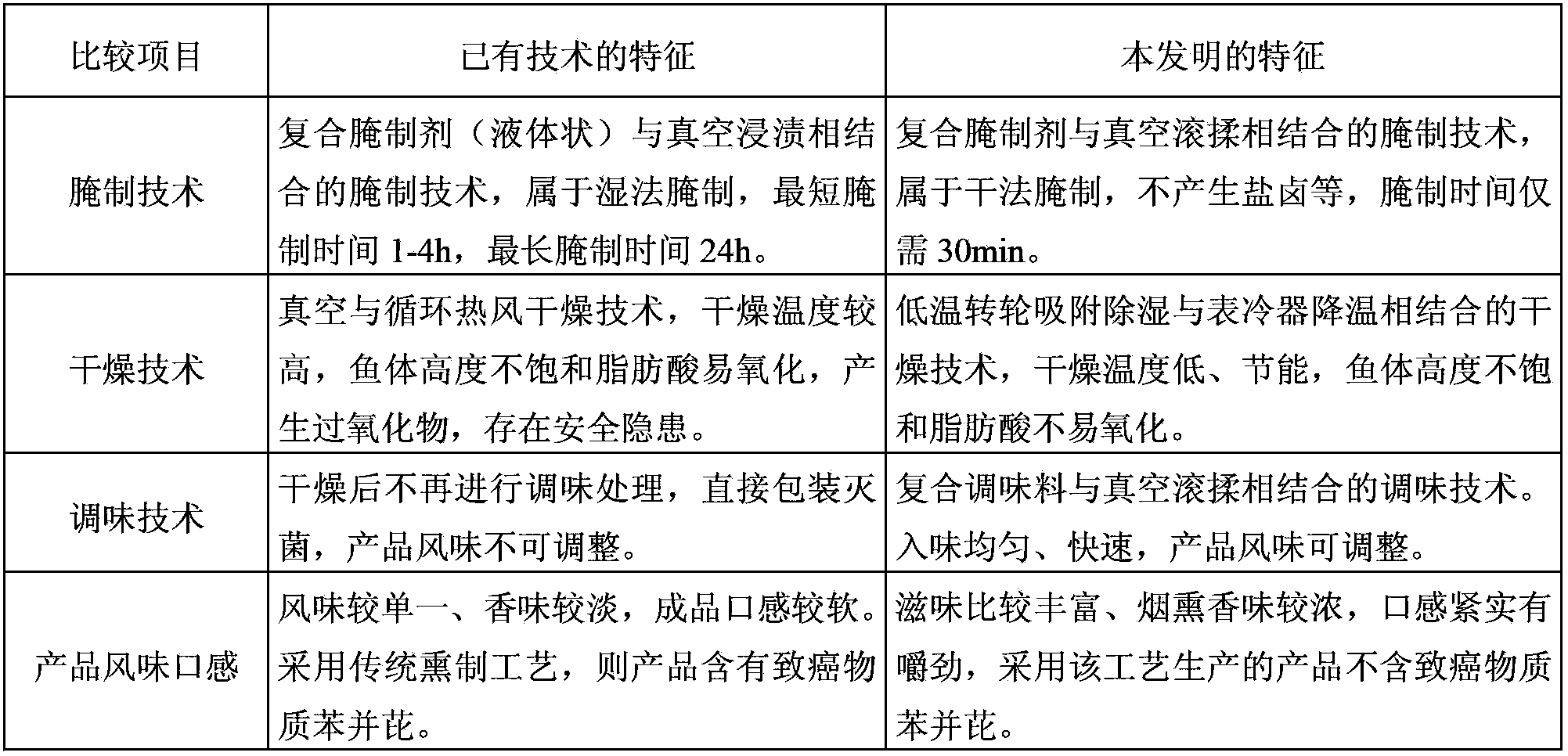

Ready-to-eat special flavor fish product subjected to cold smoking, and production process thereof

The invention belongs to the field of processing of aquatic products, and particularly relates to a ready-to-eat special flavor fish product subjected to cold smoking, and a production process thereof. The production process of the special flavor fish product comprises the following steps: using freshwater fish, a composite curing agent and a compound seasoning as raw materials, cutting the freshwater fish into square blocks after scaling, killing, gill removing, gutting removing, head removing and washing, then performing vacuum rolling and curing on the blocks, using a runner to absorb moisture of the blocks to realize drying at a low temperature, performing vacuum rolling for seasoning, and performing high-temperature sterilization and other processes to obtain the ready-to-eat special flavor fish product subjected to cold smoking. According to the invention, the curing process combines the curing agent with the vacuum rolling and curing, the drying manner that the runner is used to absorb moisture to realize drying at the low temperature is combined with a way that a surface air cooler is used to cool, and the compound seasoning is combined with the vacuum rolling technology, so that not only can the curing agent, the compound seasoning and a fish body be uniformly fixed, but also the curing time, the seasoning time and the drying time are remarkably reduced, the production cost is reduced, the fish tissue is promoted to be tighter, the texture and the taste are improved, the oxidation of highly unsaturated fatty acids in the fish body can be avoided, benzopyrene can not be produced, and the quality and safety of the product can be remarkably improved.

Owner:HUAZHONG AGRI UNIV +1

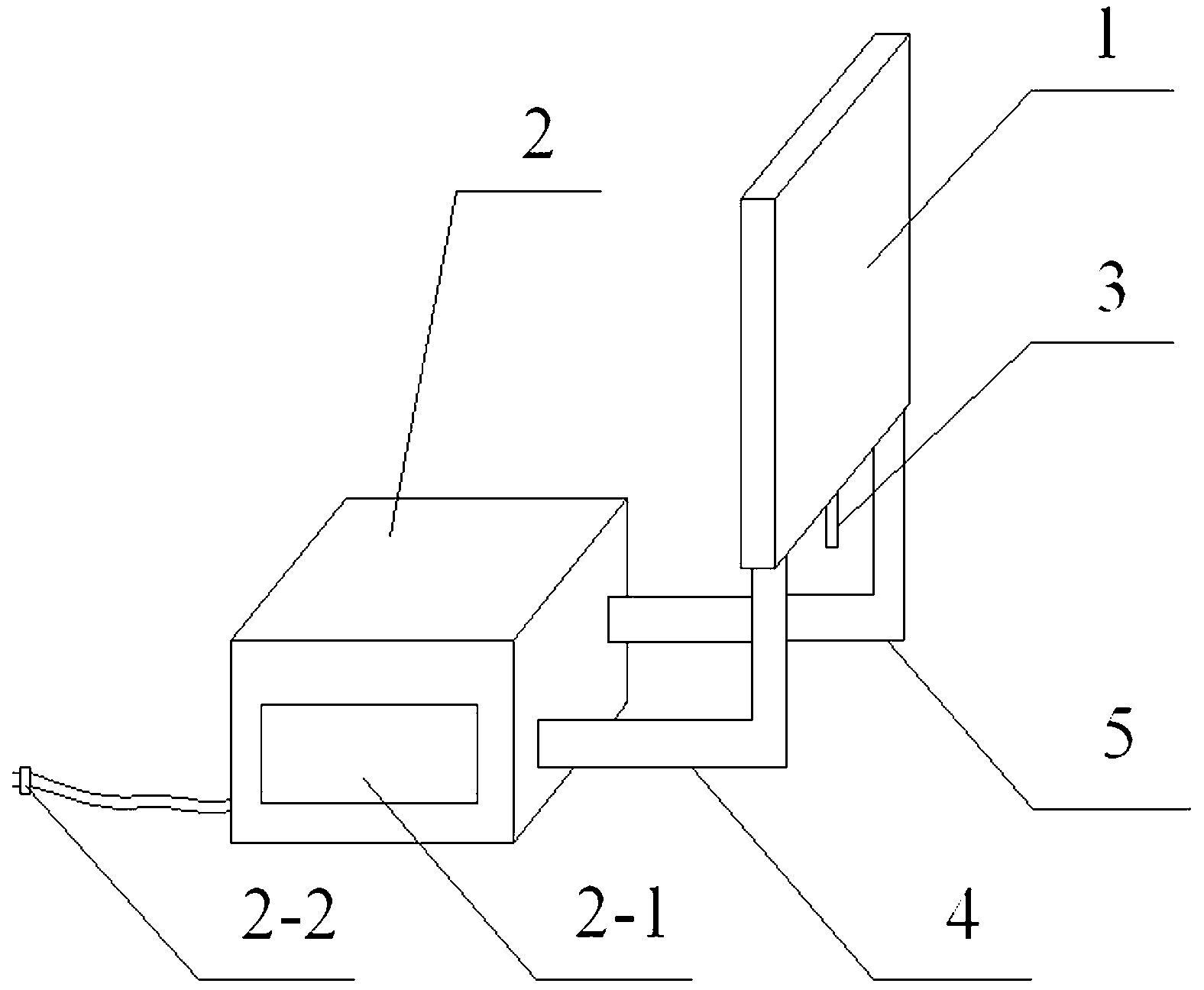

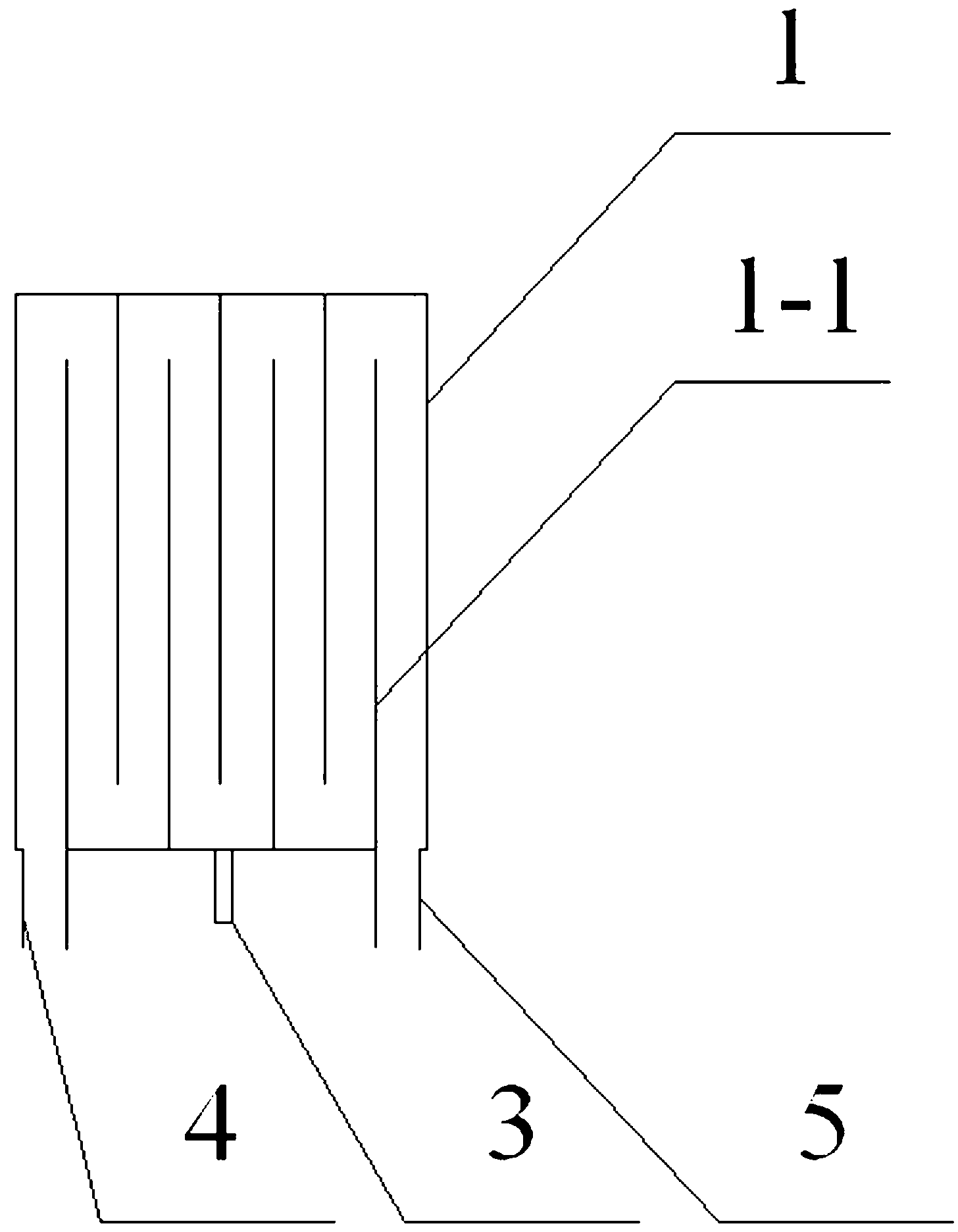

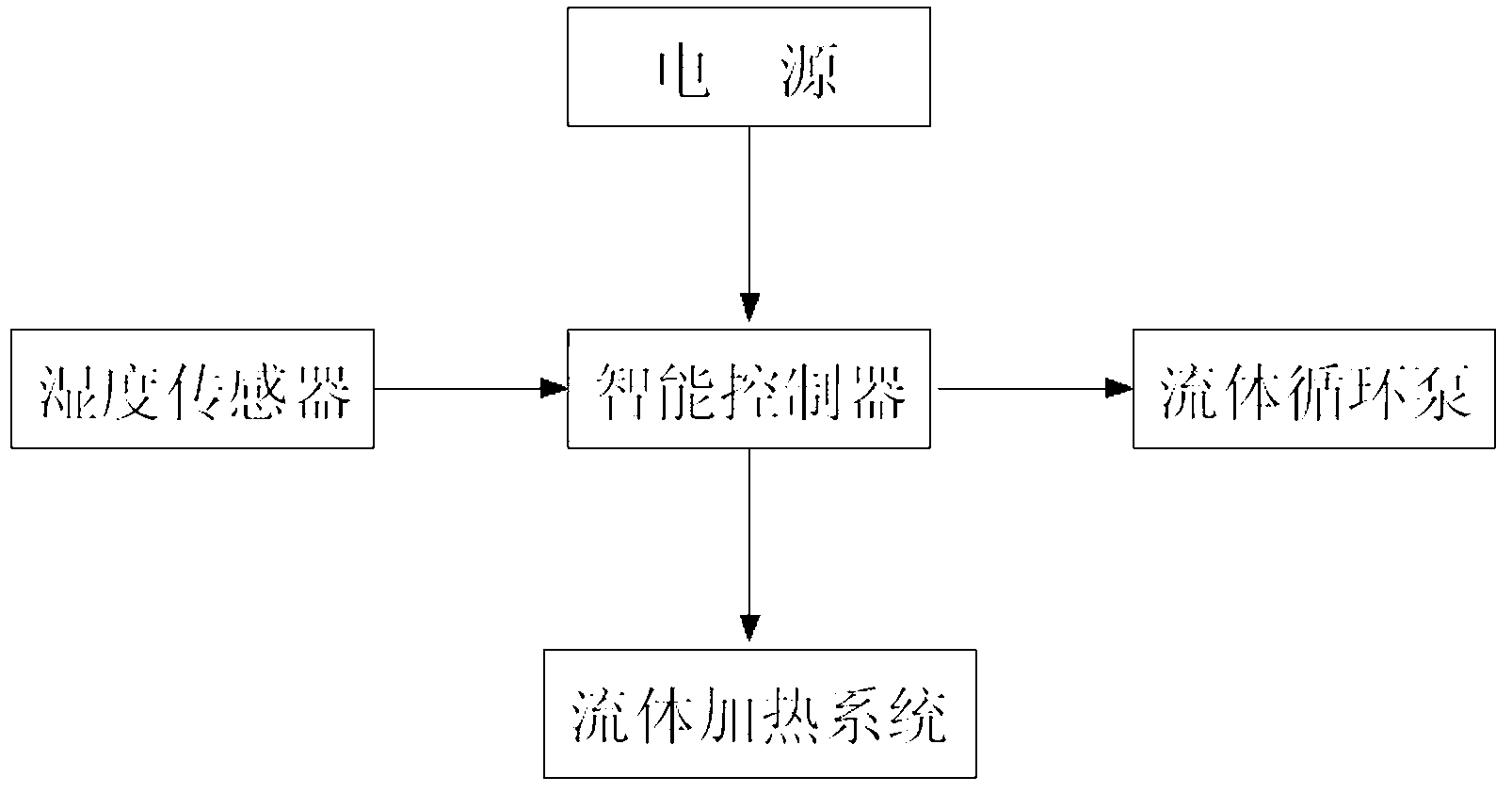

Intelligent towel drier and drying method

InactiveCN103263233AKeep dryImprove drying rateDomestic applicationsHeating arrangementProcess engineeringCirculating pump

The invention relates to the field of towel drying devices, in particular to an intelligent towel drier and a drying method. The intelligent towel drier comprises a drying frame, a control box and a humidity sensor, wherein the drying frame is used for hanging towels. The drying frame is in a box shape with a cavity inside. The cavity is communicated with a liquid inlet pipe and a liquid outlet pipe, wherein the liquid inlet pipe and the liquid outlet pipe are formed in the drying frame. The humidity sensor is arranged at the bottom of the drying frame. A fluid heating system, a fluid circulating pump and an intelligent controller are arranged inside the control box. A liquid outlet and a return port are formed in the control box. The liquid outlet is communicated with the liquid inlet pipe. The return port is communicated with the liquid outlet pipe. A control panel is arranged on the surface of the control box. The humidity sensor feeds signals back to the intelligent controller. The intelligent controller controls the fluid heating system to conduct temperature adjustment and controls output power of the fluid circulating pump to conduct flow speed adjustment. A user can adjust procedure parameters according to personal requirements so as to achieve completely dry effects on different towels after the intelligent drier is used. The intelligent towel drier is simple in operation, convenient to use and practical.

Owner:LUOYANG INST OF SCI & TECH

Integrated efficient dyeing and finishing device for textile fabric

InactiveCN109355838AGuaranteed liquidityGuaranteed uniformityMechanical cleaningLiquid/gas/vapor treatment machines driving mechanismsEnvironmental resistanceBristle

The invention discloses an integrated efficient dyeing and finishing device for textile fabric. The device comprises a fixation dyeing box, and multiple vibration plates, rolling shafts, brushing rollers and heating strips are installed in the fixation dyeing box; a drying box is arranged at one side of the fixation dyeing box, and a dust removal box is arranged at the outer side of the fixation dyeing box; a first dust removal roller and a second removal roller are arranged in the dust removal box; multiple arc static plates are both installed on the outer surface of the first dust removal roller and the outer surface of the second dust removal roller, and an arc brushing plate is arranged between each arc static plate and the second dust removal roller or between each arc static plate and the first dust removal roller; multiple evenly-distributed carding bristles are arranged on each arc brushing plate; a rolling device is connected to one side of the drying box, and a rinsing box isconnected to the outer side of the drying box; a dye filter box is connected to the lower portion of the rinsing box, and a filter screen, a return pipe and a water pump are arranged on the dye filter box. The integrated efficient dyeing and finishing device for the textile fabric has the advantages that the dyeing quality and working efficiency can be improved, dyeing is even, the utilization rate of dye is high, the environment is protected, the drying speed is high, sterilization is achieved, the cloth rolling effect is good, and the device is convenient to clean.

Owner:湖州市菱湖石淙兴吴绸厂

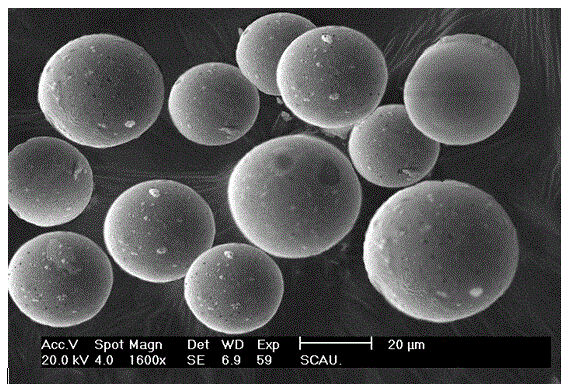

Preparation method for hemp seed oil microcapsules

InactiveCN104544069AHigh embedding rateHigh oil contentFood shapingFood preparationSucroseEconomic benefits

The invention discloses a preparation method for hemp seed oil microcapsules. The preparation method comprises the following steps: (1) preparation of a wall material solution : taking maltodextrin, modified starch, Arabic gum and saccharose as main wall materials, and mixing the main wall materials and water to prepare the wall material solution; (2) sterilization: sterilizing the wall material solution; (3) emulsification: mixing and emulsifying the sterilized wall material solution and hemp seed oil to obtain an emulsion; (4) drying: spray-drying the emulsion to obtain the hemp seed oil microcapsules. The hemp seed oil microcapsules prepared by the method have the advantages of high oil content, high encapsulation rate, good stability and long quality guarantee period; the method is simple, lower in cost and conductive to practical production and application, and brings better economic benefits.

Owner:INFINITUS (CHINA) CO LTD

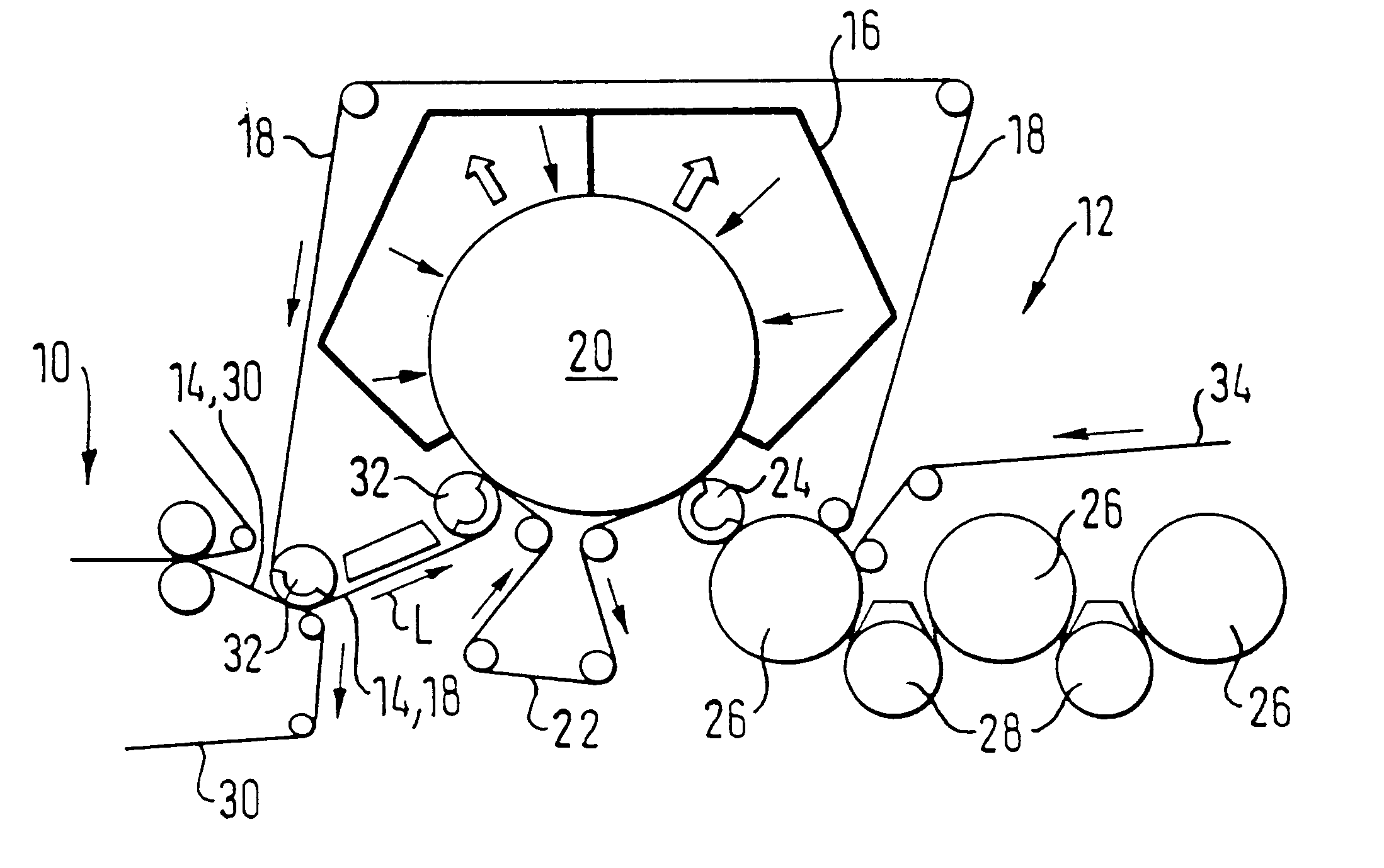

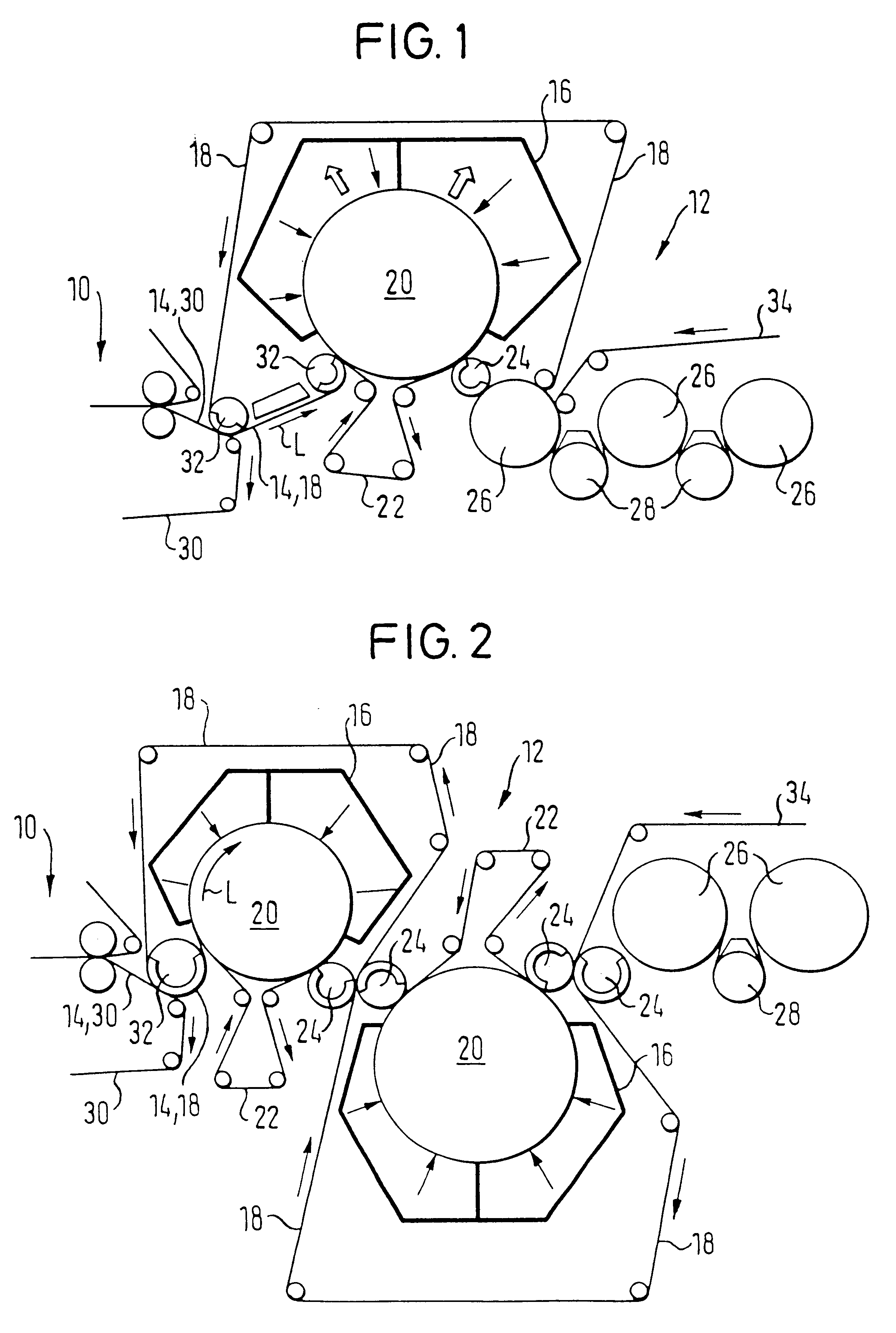

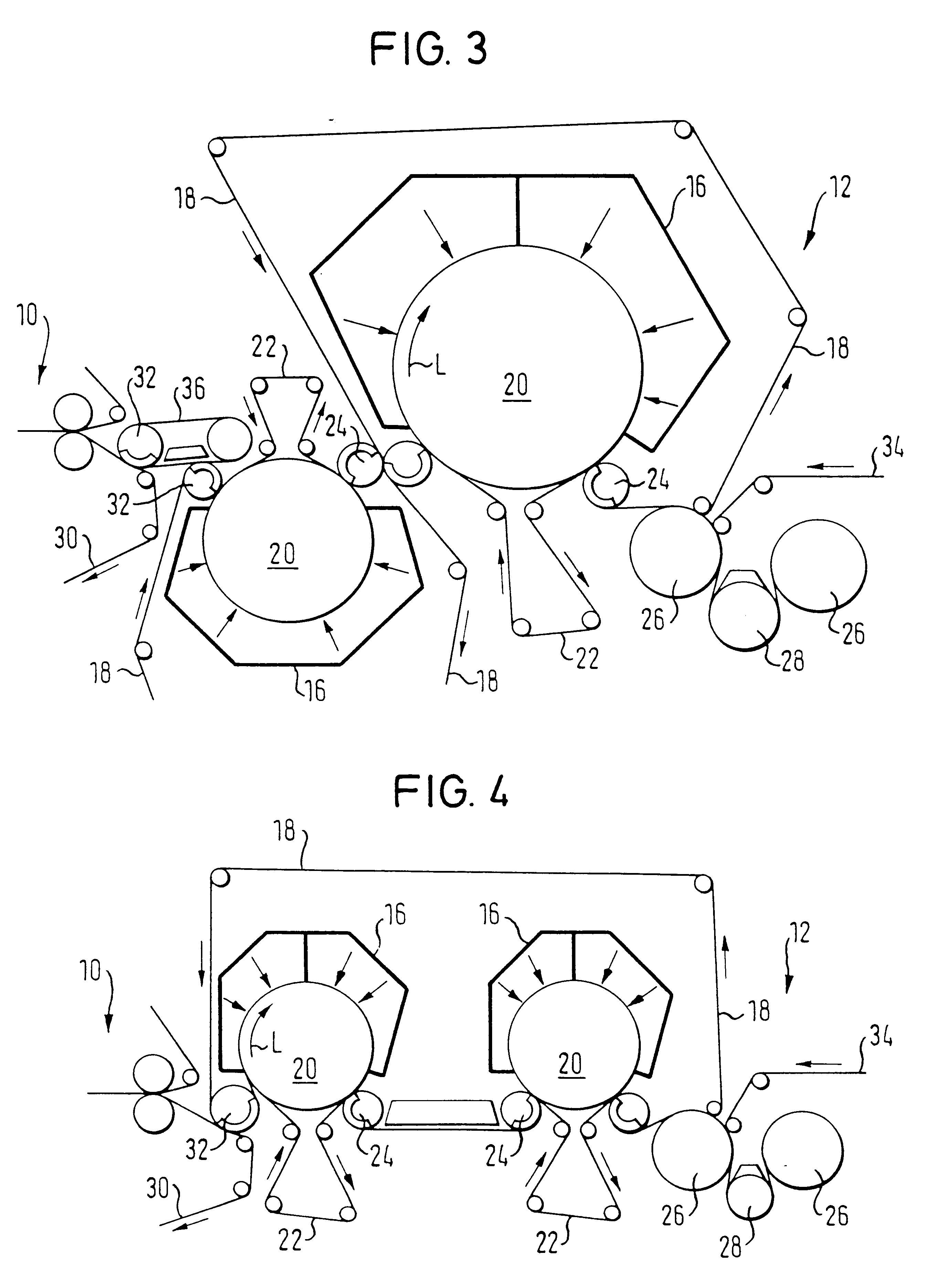

Drying end of a machine for the production of a material web and method of drying a material web

InactiveUS6294050B1Short possible overall lengthIncrease drying speedNon-fibrous pulp additionNatural cellulose pulp/paperCardboardPulp and paper industry

Drying end of a machine for the production of a material web such as paper or cardboard. The drying end includes at least one impact flow drier configured to bombard at least one surface of the material web with hot air or hot steam impact flow. Also provided is a method for drying a material web including bombarding the material web on at least one surface with hot air or hot steam impact flow, via at least one impact flow drier.

Owner:VOITH PATENT GMBH

Chemical fiber winding device with drying function

InactiveCN107352324ADry thoroughlyImprove drying rateDrying solid materials with heatFilament handlingFiberDrive wheel

A chemical fiber winding device with a drying function, comprising a base, a drying chamber is arranged on the base, a driven shaft is arranged horizontally in the drying chamber, a driving motor is arranged on the base, and a driving wheel is fixedly installed on the motor shaft of the driving motor. There is a transmission belt on the pulley and the driven wheel; a worm is fixedly installed on the coaxial line on the driving wheel, a baffle is set at the right end of the cantilever beam, a slider is slidably installed on the cantilever beam, and a fan is installed on the top of the slider. There is a first connecting rod hinged; a bracket is provided on the inner wall on the right side of the drying chamber, and a worm gear is rotated on the bracket, and the worm gear is connected with the worm. While winding, the slider reciprocates on the cantilever beam, so that the fan can reciprocate left and right, and blows and dries the chemical fibers wound on the winding roller. The winding and drying are carried out synchronously, and the chemical fiber Drying is more thorough and the rate of drying is greatly increased.

Owner:盐城千之诺机械有限公司

Automatic temperature control pepper dryer

InactiveCN103393203AImprove drying rateImprove heat utilizationDrying machines with local agitationDrying machines with materials at restTemperature controlAir cycle

The invention provides an automatic temperature control pepper dryer with an electric heating tube as a heat source. Air in a box is heated through heat exchange, heat is transferred to materials under the effect of an axial flow fan by means of forced circulation of the fan, and moisture volatilized by the materials is taken away. According to requirements of different materials and different states of the drying process, the purpose of improvement of the drying rate and the heat utilization rate is achieved through adjustment of the proportion of the air circulation amount to the air discharge amount. For enabling all points in the box to be uniform in temperature, the automatic temperature control pepper dryer transfers heat through forced circulation of air convection and is further provided with air distribution devices capable of being used for adjusting air volume on the left side of the box and the right side of the box so as to enable temperatures of all the points in the box horizontally and vertically to tend to be consistent.

Owner:FENGXIAN QINXIN MACHINERY MFG

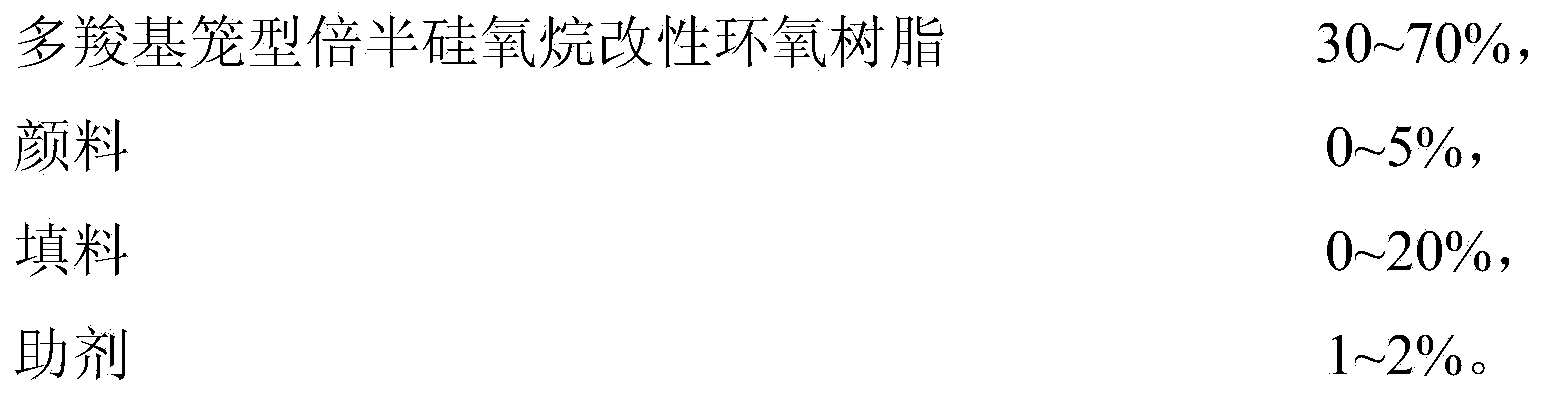

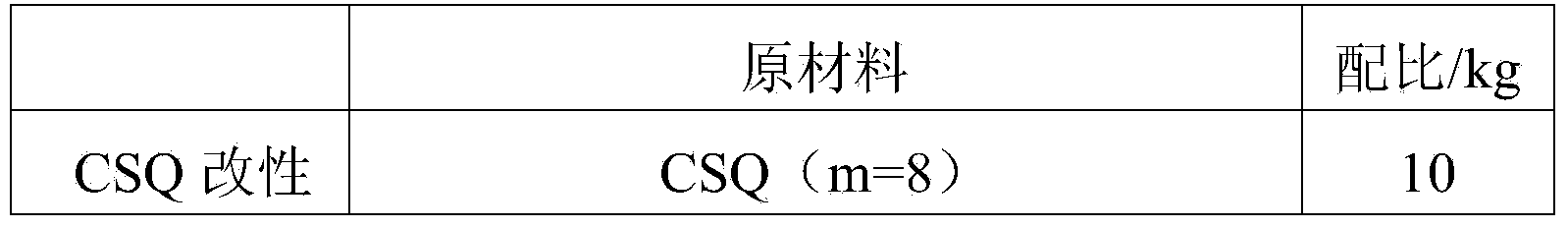

Multi-carboxyl cage silsesquioxane modified epoxy resin and application thereof in coating

InactiveCN103865033AImprove adhesionImprove fullnessPolyurea/polyurethane coatingsEpoxyResin coating

The invention belongs to the field of epoxy resin coating, and discloses a multi-carboxyl cage silsesquioxane (CSQ) modified epoxy resin and an application thereof in coating. The CSQ modified epoxy resin is prepared by following steps of throwing CSQ and epoxy resin into a reaction kettle according to the mass ratio of (1:4)-(1:7), adding a catalyst and an organic solvent, and mixing uniformly; reacting for 2-4 hours at 105-115DEG C, filtering and discharging, so as to obtain CSQ modified epoxy resin containing high activity hydroxyl; and then carrying out curing reaction on the hydroxyl and polyisocyanate group so as to prepare a high hardness quick curing coating, wherein the mass ratio of the organic coating to the curing agent is (30:50)-(70:25). The CSQ modified epoxy resin has high hardness, good abrasion performance and fast drying speed, so that the coating prepared based on the modified epoxy resin has advantages of high hardness, good toughness, fast drying speed, good shock resistance and good corrosion resistance.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI +1

Sludge drying and incinerating system, sludge drying machine and sludge drying method

InactiveCN102180578AFast and energy-saving dryingImprove drying efficiencySludge treatment by de-watering/drying/thickeningIncinerator apparatusHeat conductingSludge

The invention relates to a sludge drying and incinerating system, which comprises a sludge drying machine and a heat source, wherein the sludge drying machine comprises at least one first sludge drying module; the first sludge drying module comprises a first enclosed shell, a first heat conducting sludge support plate, a scraping mechanism, a first fan, an evaporating and condensing device and a first surface cooler which is connected with the heat source; and the evaporating and condensing device comprises a compressor, a condenser and an evaporator which are connected to form a loop, a cold medium in the loop and a drainer. Heat is transferred to the first sludge support plate by the condenser to heat sludge; air is supplied by the first fan to form evaporation-accelerated air current on the surface of the sludge; circulating air is condensed and dehydrated by the evaporator; and the sludge can be dried quickly by hot air with low moisture content in an energy-saving way. Moreover, a plurality of first sludge drying modules a plurality of second sludge drying modules can be connected together and combined segmentally for drying, so that the sludge drying rate is effectively increased and the water content of sludge is lowered.

Owner:SHENZHEN WATECH

Flame retardant composite board and manufacture method thereof

InactiveCN104552488AHigh mechanical strengthGood nail gripWood veneer joiningDomestic articlesBruciteComposite plate

The invention provides a flame retardant composite board. The flame retardant composite board comprises a homogeneous naked panel and a facing layer arranged on at least one surface of the homogeneous naked panel, wherein the homogeneous naked panel is prepared from raw materials of, based on weight parts, 65-98.5 parts of plant straw particles, 3-10 parts of binder and 3-10 parts of fire retardant, wherein the fire retardant is prepared from raw materials of magnesium oxide, calcium sulfate, aluminum hydroxide, brucite, zinc molybdate and zinc borate. The flame retardant composite board has good chemical properties of fire retarding, water prevention, insect prevention and the like, and good physical and mechanical properties, can replace wood artificial boards, and is used in various fields. The invention further provides a manufacture method of the flame retardant composite board. The manufacture method of the flame retardant composite board mainly adopts a normal temperature cold press molding technology to solidify and shape the raw materials of the naked panel, not only greatly saves energy, but also improves product performance, enables the flame retardant composite board to have water prevention and fire prevention functions, and simultaneously can substantially reduce equipment cost, achieves a whole green production process, and does not cause pollution during the whole production process.

Owner:信阳美丽真好秸秆新材科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com