Composite slab with symmetric structure and manufacturing method thereof

A technology of composite board and symmetrical structure, which is applied in the direction of manufacturing tools, jointing of wooden veneers, chemical instruments and methods, etc., to achieve the effect of balancing internal stress, preventing deformation and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

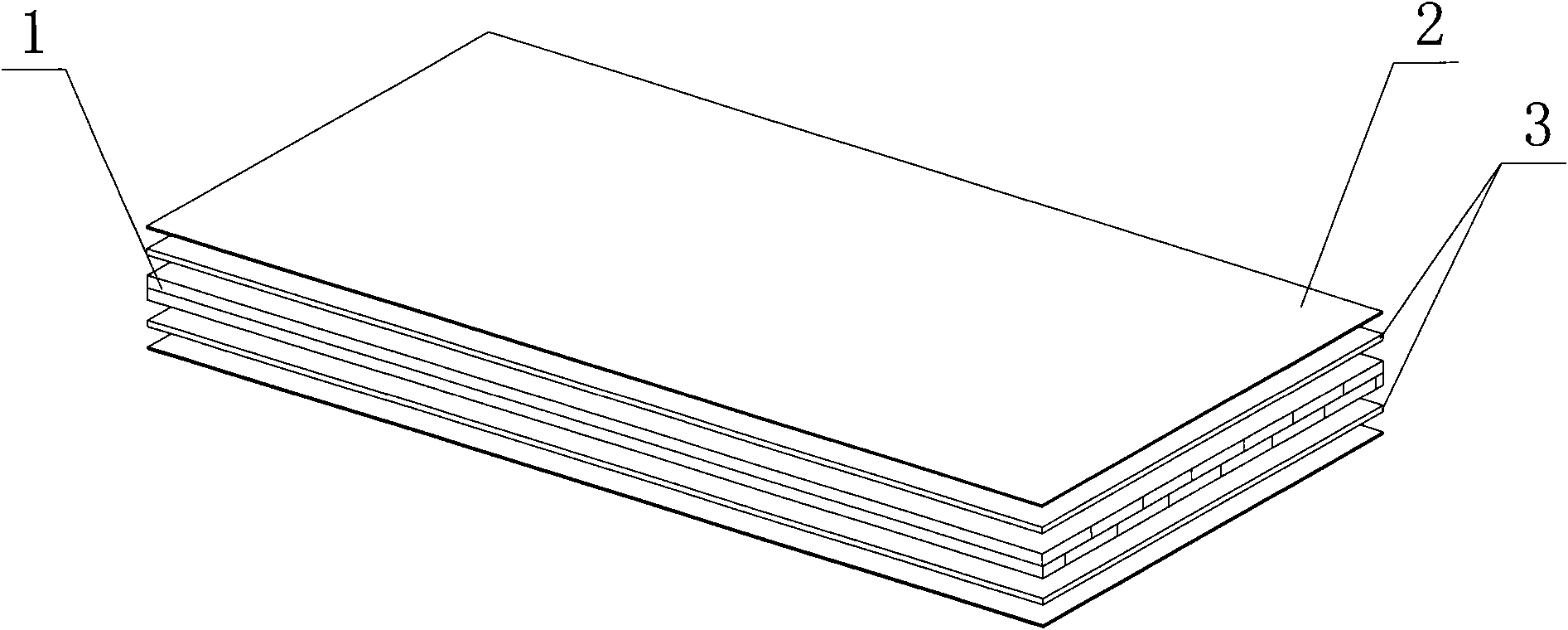

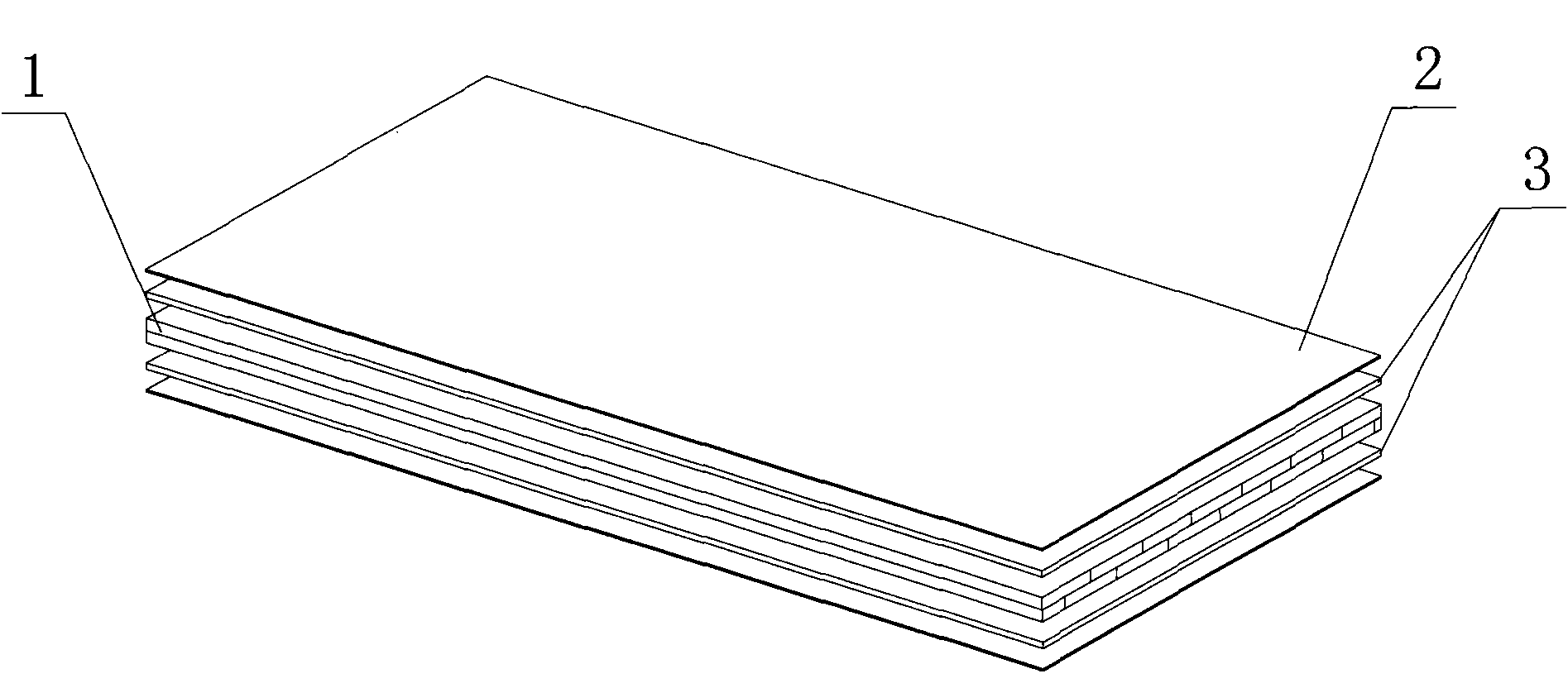

[0040] Such as figure 1 As shown, a kind of composite sheet material of symmetrical structure provided by the present invention comprises two surface layers 2 and the inner core layer 1 thereof, and the surface layer 2 is preferably made of teak wood, Dalbergia japonica, ash, and oak with a thickness of 0.6 mm. Decorative veneer of peeled wood or birch. The core layer 1 is composed of overlapping sawing boards, wherein the core layer 1 is composed of even-numbered layers of sawing boards, and the surface wood grains are parallel to each other to form a blank, and the sawing boards of each layer are glued together The core layer 1 is made of overlapping sawn boards with a thickness of 10 mm, and the sawn boards used in the core layer 1 are processed by poplar, fir, pine, birch or wax gourd; There is also an intermediate layer 3 between the surface layer 2 and the core layer 1; the intermediate layer 3 is a veneer with a thickness of 2.2 mm, and the veneer in the intermediate l...

Embodiment 2

[0042] Such as figure 1 As shown, a composite board with a symmetrical structure provided by the present invention includes two surface layers 2 and a core layer 1 inside, and the surface layer 2 is preferably a melamine board with a thickness of 0.3 mm. The core layer 1 is composed of overlapping sawing boards, wherein the core layer 1 is composed of odd-numbered layers of sawing boards, and the surface wood grains are perpendicular to each other. The core layer 1 is made of overlapping sawn boards with a thickness of 10.5 mm, and the sawn boards used in the core layer 1 are processed by poplar, fir, pine or birch; the surface layer 2 There is also an intermediate layer 3 between the core layer 1; the intermediate layer 3 is a veneer with a thickness of 2.0 mm, and the veneer in the intermediate layer 3 is also a veneer made of poplar, fir, pine or birch; The surface of the sawn board of the core layer 1 is provided with several point-line cracks along the wood grain directi...

Embodiment 3

[0044] Such as figure 1 As shown, a composite board with a symmetrical structure provided by the present invention includes two surface layers 2 and a core layer 1 inside, and the surface layer 2 is preferably a melamine board with a thickness of 0.3 mm. The core layer 1 is composed of overlapping sawing boards, wherein the core layer 1 is composed of even-numbered layers of sawing boards, and the surface wood grains are perpendicular to each other to form a billet, and the sawing boards of each layer are glued The core layer 1 is made of overlapping sawn boards with a thickness of 5.5 mm, and the sawn boards used in the core layer 1 are processed by poplar, fir, pine or birch; the surface layer 2 There is also an intermediate layer 3 between the core layer 1; the intermediate layer 3 is a veneer with a thickness of 1.6 mm, and the veneer in the intermediate layer 3 is also a thin plate with a high and medium density; the core layer 1 saws the surface of the board There are s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com