Automatic temperature control pepper dryer

An automatic temperature control and dryer technology, which is applied in dryers, drying, local stirring dryers, etc., can solve the problems of inconvenient drying operation, low drying efficiency, temperature control settings without timer synchronization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

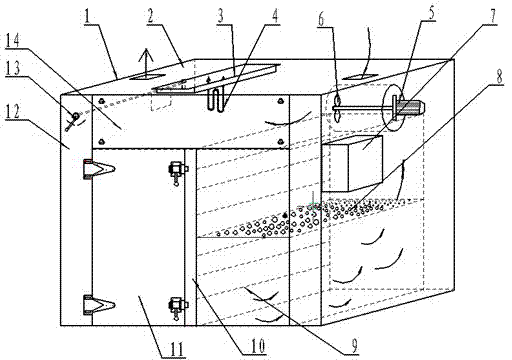

[0007] As shown in the figure, the automatic temperature-controlled pepper dryer has a box body composed of a main frame 1, a top cover 2, a column 10 and a side wall 12, and a door 11 is installed on the box body; an electric heating tube 4 is installed on the upper part of the box body A fan 5 is installed on one side of the electric heating tube 4, and a plurality of layered drying racks 9 are arranged at the lower part of the air inlet of the fan, and a sieve 8 is installed on the drying rack 9. The air outlet is used as a dehumidification outlet; at the same time, the temperature controller 7 is electrically connected to the electric heating tube 4, and the temperature controller 7 is equipped with a timer. The left and right sides of the box are located at the positions of the drying racks 9. There are air distribution devices that can adjust the air volume of the fan. An air filter is housed in the fan 5 air inlet. A dehumidifying device 13 is installed at the dehumidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com