Preparation method for hemp seed oil microcapsules

A technology of hemp seed oil and microcapsules, which is applied in the field of preparation of vegetable oil microcapsules, can solve the problems that linseed oil cannot be embedded and protected, the embedding rate is only 90%, and the temperature change is too complicated, etc., to achieve emulsion emulsification Good condition, good embedding effect, easy to obtain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

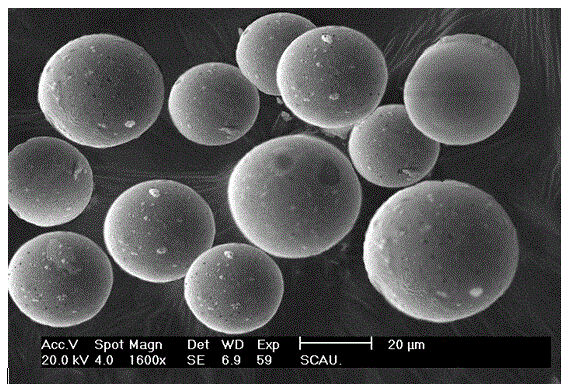

Image

Examples

Embodiment 1

[0046] (1) Prepare the wall material solution: use 49% maltodextrin, 22% modified starch, 10% gum arabic, 5% β-cyclodextrin and 14% sucrose as the wall material, add it to the batching tank at room temperature, and add water to prepare A wall material solution with a solids content of 43%.

[0047] (2) Sterilization: The wall material solution was sterilized in a 75°C water bath for 40 min.

[0048] (3) Emulsification: After cooling the sterilized wall material solution to 50°C, mix it with hemp seed oil, in which the mass ratio of wall material and hemp seed oil is 1:1.5, stir for 15 min to make it fully mixed , add water to form an emulsion with a solid content of 45%.

[0049] (4) High-pressure homogenization: Use a high-pressure homogenizer to homogenize the emulsion obtained in step (3) twice at a pressure of 20 MPa (200 bar) and three times at a pressure of 50 MPa (500 bar) to obtain a uniform Stable emulsion.

[0050] (5) Spray drying: Spray dry the emulsion obtained...

Embodiment 2

[0053] (1) Preparation of wall material solution: use 53% maltodextrin, 21% modified starch, 11% gum arabic, 5% β-cyclodextrin and 10% sucrose as wall materials, add them to the batching tank at room temperature, and add water to prepare A wall material solution with a solids content of 43%.

[0054] (2) Sterilization: The wall material solution was sterilized in a water bath at 85°C for 35 minutes.

[0055] (3) Emulsification: After cooling the sterilized wall material solution to 50°C, mix it with hemp seed oil, wherein the mass ratio of wall material and hemp seed oil is 1:1.25, and stir for 15 min to make it fully mixed , add water to form an emulsion with a solid content of 47%.

[0056] (4) High-pressure homogenization: Use a high-pressure homogenizer to homogenize the emulsion obtained in step (3) twice at a pressure of 25 MPa (250 bar), and then homogenize twice at a pressure of 55 MPa (550 bar) to obtain a homogeneous Stable emulsion.

[0057] (5) Spray drying: Spr...

Embodiment 3

[0060] (1) Prepare the wall material solution: use 57% maltodextrin, 21% modified starch, 10% gum arabic, 5% β-cyclodextrin and 6% sucrose as the wall material, add it to the batching tank at room temperature, and add water to prepare A wall material solution with a solids content of 43%.

[0061] (2) Sterilization: The wall material solution was sterilized in a 95°C water bath for 30 minutes.

[0062] (3) Emulsification: After cooling the sterilized wall material solution to 50°C, mix it with hemp seed oil, wherein the mass ratio of wall material and hemp seed oil is 1:1, stir for 15 min to make it fully mixed , add water to form an emulsion with a solid content of 50%.

[0063] (4) High-pressure homogenization: Use a high-pressure homogenizer to homogenize the emulsion obtained in step (3) twice at a pressure of 30MPa (300bar), and then homogenize twice at a pressure of 60MPa (600bar) to obtain a uniform and stable emulsion , 50 ℃ insulation 60min.

[0064] (5) Spray dryi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com