Walnut oil microcapsule and preparation method thereof

A technology of walnut oil and microcapsules, which is applied in the fields of edible oil/fat, edible oil/fat product preservation, food science, etc., can solve the problems of poor compactness of the microcapsule wall, cracks and depressions on the surface, and uneven particles, etc., to achieve High density, reduced sugar content, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

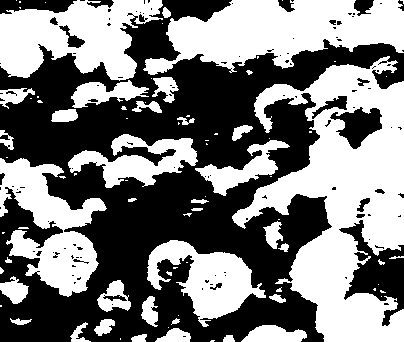

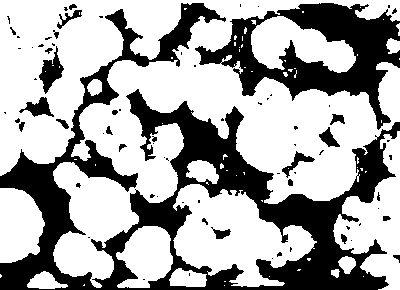

Image

Examples

Embodiment 1

[0031] (1) Weigh 250g of walnut oil and place it in a water bath at 60°C.

[0032] (2) Add 18g of monoglyceride to the walnut oil and fully dissolve it.

[0033] (3) Add 6g of sucrose ester to the walnut oil, stir evenly, and dissolve for later use.

[0034] (4) Weigh 250g of maltodextrin and add 300ml of water to dissolve it, then add 23g of dipotassium hydrogen phosphate and 75g of sucrose, stir evenly; then place it in a water bath at 85°C until the solution is transparent.

[0035] (5) Weigh 280g of peanut protein isolate, add 300ml of water to dissolve, place in a water bath at 85°C, fully stir to dissolve, and maintain for 80 minutes.

[0036] (6) Mix the maltodextrin-sucrose solution and peanut protein isolate solution into the colloid mill, start the colloid mill and slowly add the dissolved walnut oil, keep the colloid mill running for 2 minutes, and pass the mixed solution through the colloid mill twice.

[0037] (7) Add the mixed solution passed through the colloi...

Embodiment 2

[0042] (1) Weigh 250g of walnut oil and place it in a water bath at 60°C.

[0043] (2) Add 18g of monoglyceride to the walnut oil and fully dissolve it.

[0044] (3) Add 6g of sucrose ester to the walnut oil, stir evenly, and dissolve for later use.

[0045] (4) Weigh 250g of maltodextrin and add 300ml of water to dissolve it, then add 23g of dipotassium hydrogen phosphate and 75g of xanthan gum, stir evenly; then place in a water bath at 85°C until the solution is transparent.

[0046] (5) Weigh 280g of peanut protein isolate, add 300ml of water to dissolve, place in a water bath at 85°C, fully stir to dissolve, and maintain for 80 minutes.

[0047] (6) Mix the maltodextrin-xanthan gum solution and peanut protein isolate solution into the colloid mill, start the colloid mill and slowly add the dissolved walnut oil, keep the colloid mill running for 2 minutes, and pass the mixed solution through the colloid mill for 2 minutes Second-rate.

[0048] (7) Add the mixed solution...

Embodiment 3

[0052] (1) Weigh 150g of walnut oil and place it in a water bath at 60°C.

[0053] (2) Add 30g of monoglyceride into the walnut oil and fully dissolve it.

[0054] (3) Add 34g of sucrose ester to the walnut oil, stir evenly, and dissolve for later use.

[0055] (4) Weigh 180g of maltodextrin and add 300ml of water to dissolve it, then add 35g of dipotassium hydrogen phosphate and 30g of xanthan gum, stir evenly; then place it in a water bath at 85°C until the color of the solution is transparent.

[0056] (5) Weigh 176g of peanut protein isolate, add 300 ml of water to dissolve, place in a water bath at 85°C, fully stir to dissolve, and maintain for 80 minutes.

[0057] (6) Mix the maltodextrin-xanthan gum solution and peanut protein isolate solution into the colloid mill, start the colloid mill and slowly add the dissolved walnut oil, keep the colloid mill running for 2 minutes, and pass the mixed solution through the colloid mill for 2 minutes Second-rate.

[0058] (7) Ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com