Patents

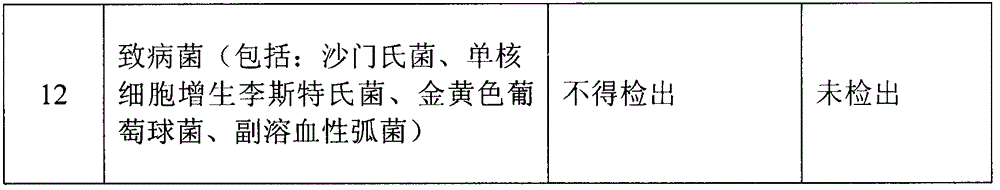

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

244 results about "Food engineering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Food engineering is a multidisciplinary field which combines microbiology, applied physical sciences, chemistry and engineering for food and related industries. Food engineering includes, but is not limited to, the application of agricultural engineering, mechanical engineering and chemical engineering principles to food materials. Food engineers provide the technological knowledge transfer essential to the cost-effective production and commercialization of food products and services. Physics, chemistry, and mathematics are fundamental to understanding and engineering products and operations in the food industry.

Preparation method of lycopersicin microcapsule

InactiveCN101015342ANo smellNo residueCosmetic preparationsHydrocarbon active ingredientsPink colorSolubility

The invention relates to a method for preparing lycopene microcapsule, belonging to food engineering technique. It comprises following steps: (1) putting compound emulsifier and water into solid lycopene powder, grinding in ball grinder to form emulsion; (2) dissolving wall material into water, stirring and getting wall material solution; (3) mixing said lycopene emulsion with wall material, homogenizing with colloid mill; (4) spray drying homogenized mixing liquid and getting lycopene microcapsule. The invention is characterized by simple process, no organic solvent residual, high productivity, and suitability for large production. The produced lycopene microcapsule is characterized by sphere shape, pink color, homogenous granular size, smooth surface, no smelly odor, good fluidity, good water solubility, high content of lycopene, restoration at normal temperature and packed with polyethylene film bag of 0.2mm, and long storage period of more than 4 months.

Owner:SHANGHAI JIAO TONG UNIV

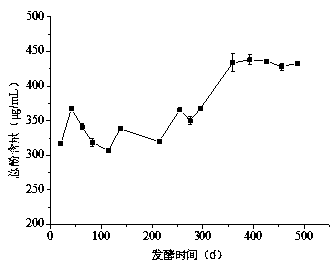

Production method for improving quality of Liupu tea

ActiveCN101669559AImprove qualityGood for post-fermentationPre-extraction tea treatmentTea substituesSporeFood engineering

The invention relates to application of eurotium cristatum in the production of Liupu tea, which belongs to the crossing field of food engineering and biotechnology. The production method for the Liupu tea is an improvement on the prior Liupu tea production flow through biotechnology, namely after primary distillation, a bacterial suspension containing eurotium cristatum spores is used for spray inoculation, and after redistillation, tea strains are crushed into pieces for inoculation again. Thus, when the Liupu tea is in composting fermentation, the eurotium cristatum can quickly become predominant bacteria to inhibit the growth of other bacteria, and when the Liupu tea is in ageing, golden flowers grow out frondently and universally so as to improve the quality of the Liupu tea. The application of the eurotium cristatum improves the quality of the Liupu tea, and solves the problems that in the prior art, the quality is unstable, the ageing time is long, the growing golden flowers aredifficult to control and are easy to pollute and the like. Simultaneously, the invention discloses a method for simply and easily obtaining and expanding the cultivation of eurotium cristatum strains.

Owner:GUANGXI UNIV FOR NATITIES

Carboxymethyl chitosan fruit preserving coating agent and preparation method thereof

InactiveCN101120697AReduce respirationSmall water absorptionFruits/vegetable preservation by coatingWater bathsGlycerol

A carboxymethyl chitosan fruit fresh-keeping coating agent in the technical field of food engineering and a preparation method thereof. The fresh-keeping coating agent is: 0.5%-4% of carboxymethyl chitosan, 0.1-1% of glycerin, 0.3-2.4% of Tween 80, 0.1-1% of DL-α-tocopheryl acetate, 92% of water -99%. Heat water in a water bath to constant temperature, add carboxymethyl chitosan, stir until completely dissolved, then add glycerin, stir well with Tween, then add DL-α-tocopheryl acetate and stir until completely dissolved, let it sit at room temperature Cooling, followed by filtering to remove undissolved substances, degassing under vacuum, standing overnight at room temperature, degassing again under vacuum, standing at room temperature, and obtaining carboxymethyl chitosan fruit fresh-keeping coating agent. The fresh-keeping coating agent of the present invention is coated on the surface of fruits by soaking or spraying to form a fresh-keeping film and maintain the quality of the fruits during storage.

Owner:上海伊禾农产品科技发展股份有限公司

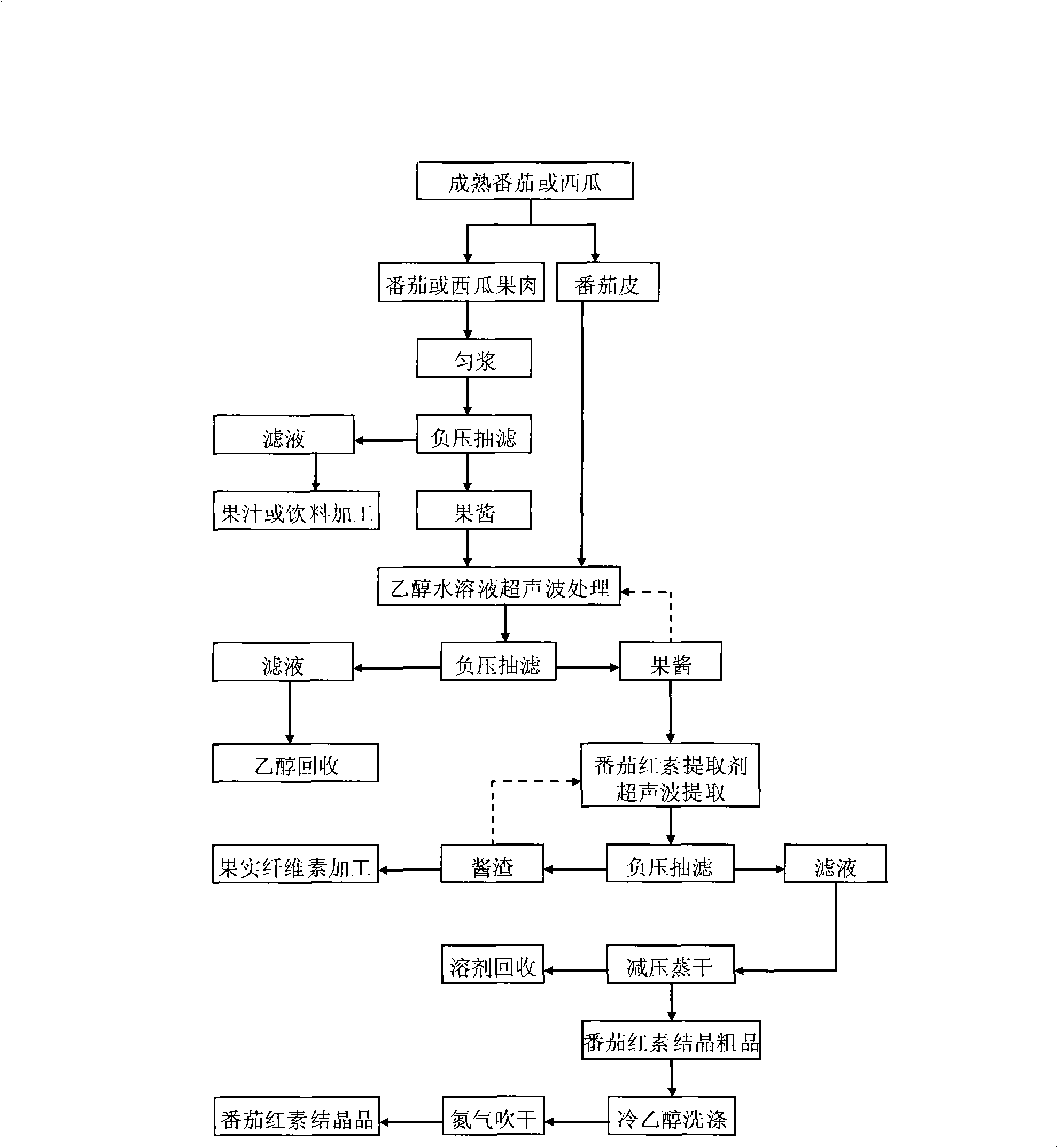

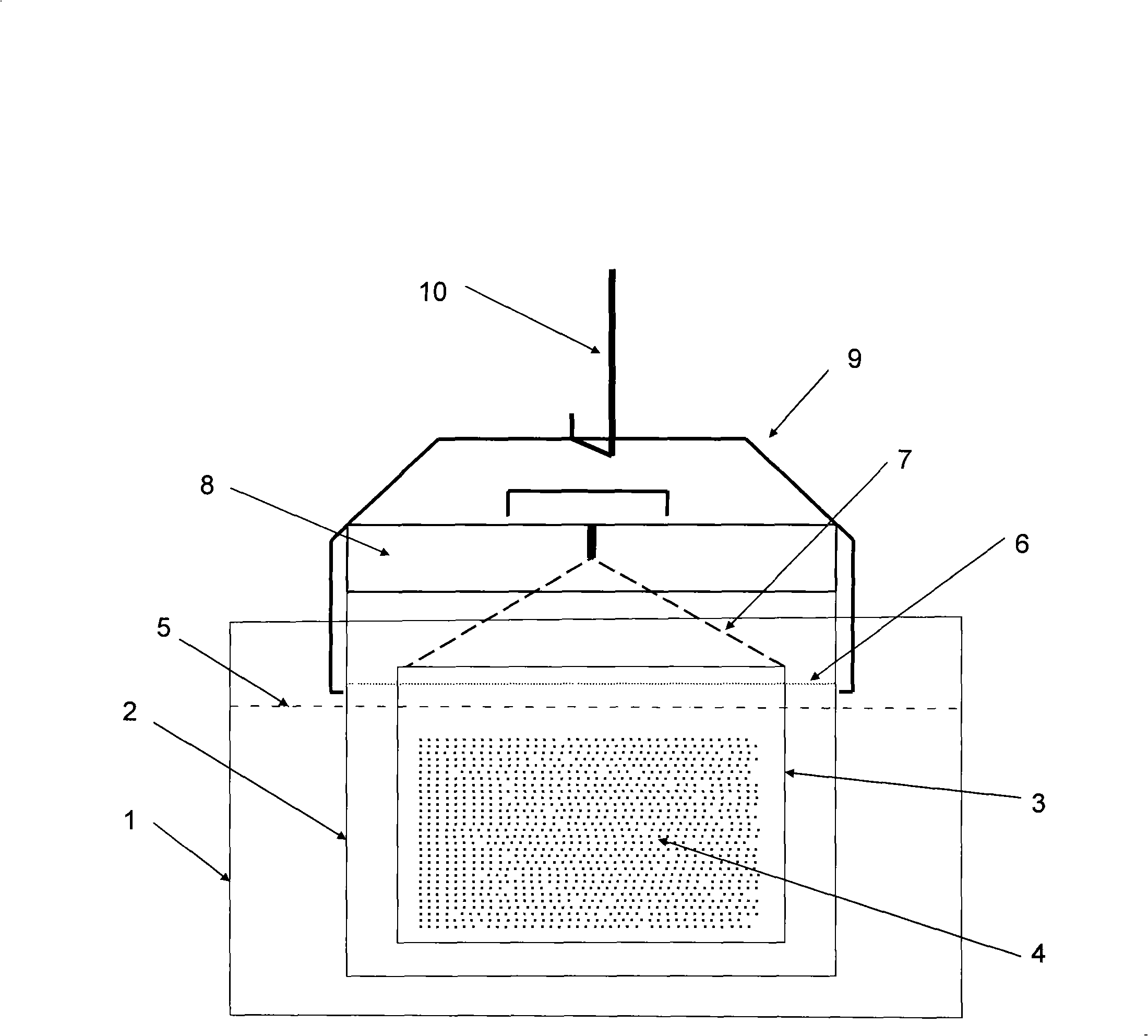

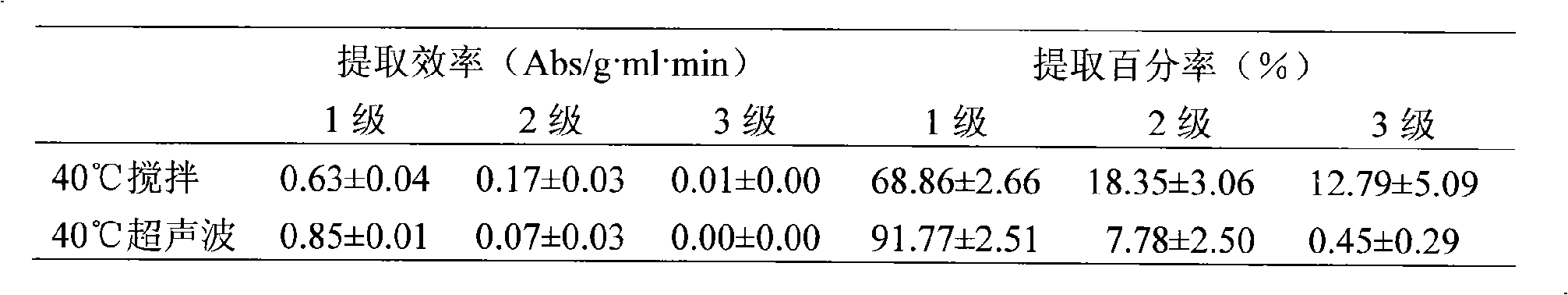

Method for preparing and abstracting lycopene

InactiveCN101289364AHigh speedHigh extraction rateHydrocarbon purification/separationHydrocarbonsLycopeneFood engineering

The invention discloses an extraction preparation method of lycopene, belonging to the technical field of food engineering. The method uses tomatoes or watermelon flesh as raw materials and adopts the technology of ultrasonic and extraction bags, which comprises the following steps: (1) the treatment of the raw materials and beating; (2) the separation of solid puree and liquid puree of fruit puree; (3) the ethanol water treatment of jam;(4) the extraction of the lycopene extractant of the jam and (5) the preparation of crystallization products of the lycopene. The extraction time of the invention is reduced to 10 to 60min from the10 to 20h of conventional time, and moreover the purity content of products is obviously improved from 10 to 20 percent in general to 70 to 80 percent. Therefore, the extraction preparation method is characterized by being efficient and fast, being convenient to be operated, low cost, high content of lycopene in the products, etc and is suitable for the promotion and the application in the industrialized and large scale production enterprises of natural lycopene with high purity.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

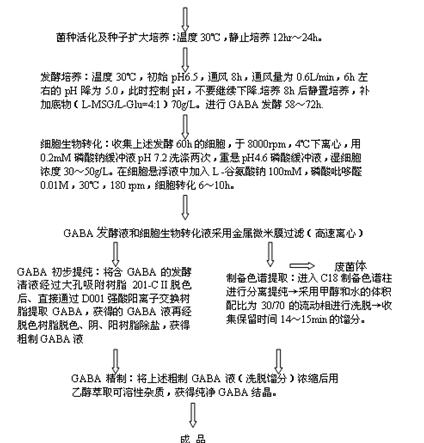

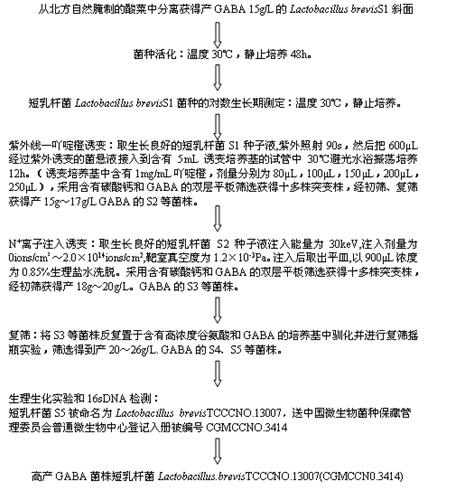

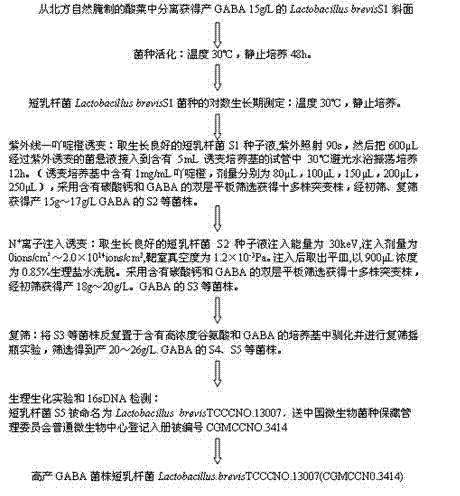

Method for producing high-yield gamma-propalanine and application thereof

InactiveCN102174449ALow costImprove brain functionBacteriaChemical industryFood engineeringBioconversion

The invention relates to a method for producing high-yield gamma-propalanine and an application thereof, belonging to the technical field of biotechnology medicine and food engineering. The method comprises the following steps: carrying out strain separated screening, acridine orange-ultraviolet ray mutagenesis and N<+> injection mutagenesis to obtain a high-yield gamma-propalanine LactobacillusbrevisTCCC (CGMCC No.3414) strain; optimizing a fermentation medium and fermentation conditions; coupling fermentation of the gonotokont of the strain with resting cell biotransformation of the strain to produce the gamma-propalanine; employing the membrane filtration technology, the adsorbent resin decoloration technology, the strong acid resin cation exchange technology, the ethanol recrystallization technology, the preparative chromatography technology and the energy-saving and cost-reducing technology to separate the gamma-propalanine from the fermentation fluid and the biotransformation fluid; and then carrying out purification to obtain the crystallized gamma-propalanine with the purity of 99%. The method has the advantages of cheap raw materials, low energy consumption for production, low production cost, good product security and easy realization of industrialized production. Applied to glutamic acid fermentation waste liquor for producing the gamma-propalanine, the strain has good potential for generating social and economic benefits.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Preparation method of comprehensive yeast liquid with anti-tumor activity and application of comprehensive yeast liquid

The invention relates to the field of food engineering, in particular to a preparation method of a comprehensive yeast liquid with anti-tumor activity and application of the comprehensive yeast liquid. The preparation method mainly comprises the following steps: pretreating raw materials, performing enzymolysis, filtering, adding dried lucid ganoderma powder for fermentation, performing acetic fermentation, filtering and sterilizing, and performing sterile filling. The preparation method of the comprehensive yeast liquid with anti-tumor activity, which is provided by the invention, is simple in operation step, wide in raw material source, rich and comprehensive in nutrition as multiple vegetables, fruits and bacteria are matched and combined, very good in taste and applicable to daily drinking as the components are reasonably proportioned and matched, and capable of inhibiting invisible tumor cell growth in human bodies, improving the immunity and promoting body health.

Owner:厦门元之道生物科技有限公司

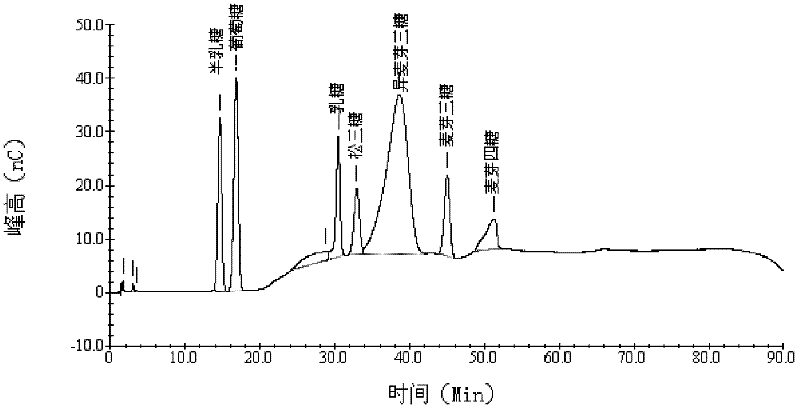

Detection method for galacto-oligosaccharide based on biological enzyme technology

InactiveCN102353730AQuantitatively accurateHigh precisionComponent separationSodium acetateIon chromatography

The invention provides a detection method for galacto-oligosaccharide based on biological enzyme technology, which belongs to the technical field of food engineering. According to the invention, at first, the method of removing proteins by using trichloroacetic acid and lead acetate is employed for pretreatment of an object to be detected, and membrane filtration is utilized to remove impurities so as to obtain a sample to be detected; then, sodium hydroxide and sodium acetate with different concentration are utilized for ion exchange and gradient elution; finally, a four-potential pulsed amperometric detector is used for detection. The invention is applicable to separation and detection of cow's milk containing galacto-oligosaccharide and a variety of galacto-oligosaccharide components in a galacto-oligosaccharide solution system; employment of ion chromatography, utilization of the methods of ion exchange and gradient elution for separation of galacto-oligosaccharide and cooperativedetection with the four-potential pulsed amperometric detector enable contamination and interference to an analytical column, the detector and the like caused by macro-molecular substances such as proteins, fat and emulsifiers which might exist in the sample to be eliminated, thereby allowing accurate and rapid detection to be achieved.

Owner:SHANGHAI JIAO TONG UNIV

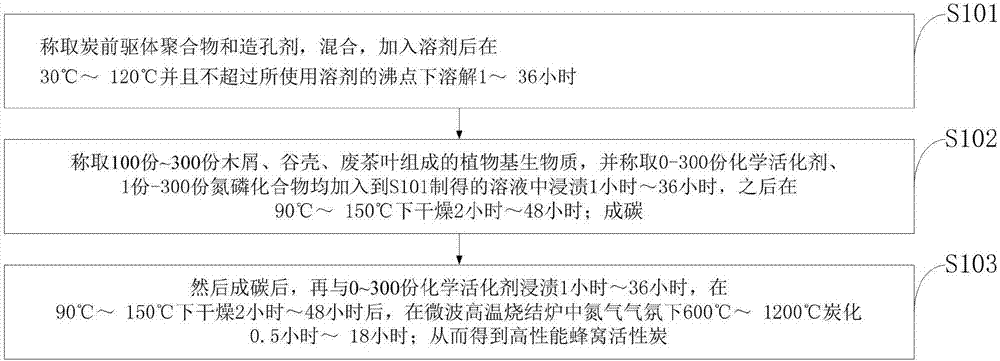

High-performance honeycomb activated carbon and preparation method thereof

InactiveCN106946251AInhibition formationHigh yieldCarbon compoundsTemperature control using electric meansNitrogen gasSolvent

The invention belongs to the technical field of materials and discloses high-performance honeycomb activated carbon and a preparation method thereof. The preparation method comprises the following steps: weighing a carbon precursor polymer and a pore forming agent, mixing, adding a solvent and dissolving; weighing a plant-based biomass, weighing a chemical activator and a nitrogenous and phosphorous compound and adding the chemical activator and the nitrogenous and phosphorous compound into the prepared solution and immersing, and drying; forming carbon; immersing carbon in a chemical activator, drying for 2-48 h, and charing in the nitrogen atmosphere in a microwave high-temperature sintering furnace so as to obtain the high-performance honeycomb activated carbon. The invention has the following characteristics: yield of activated carbon is high; the preparation process is simple; cost of raw materials is low; and pore structure and surface functional groups are easy to control. The prepared activated carbon has excellent adsorption and can be widely applied in food engineering, chemical engineering, environmental protection and home.

Owner:FUJIAN XINSEN CARBON

Clean processing process of Yellow Mountain Songluo tea

InactiveCN101884353ARealization of clean processingMechanizationPre-extraction tea treatmentHair twistingMicrowave

The invention relates to a clean processing process of Yellow Mountain Songluo tea. The process comprises the following steps of: fresh leaf picking; green curing, fixing, cooling, kneading and twisting, primary roasting, shaping, perfume extracting, enough drying and finished product screening. The green curing process comprises the following steps of: (1) thin and uniformly spreading, wherein the thickness is 2-3cm, the time is 4-8 hours, and indoor temperature is about 20 DEG C; and (2) slightly turning by hands after spreading for certain time for secondary withering until the leaves become deep green, veins become white, and tender stems become soft. In the process, a roller type fixing machine integrating high-temperature hot wind and electric heating into a whole is used for fixing; the cooling time is about 1 hour; a type-35 kneading and twisting machine is used for kneading and twisting, and the barrelage of tea leaves of the kneading and twisting machine is 12kg, wherein 5-8kg of the tea leaves are pressurized within 2 minutes firstly, then 8-10kg of the tea leaves are pressurized within 2 minutes, and finally, 4-6kg of the tea leaves are pressurized within 3 minutes; the primary roasting comprises three times of roasting, and microwaves are utilized to dry and sterilize; a type-50 hair twisting machine is used for shaping; and a magnetic substance electromagnetic clearing step is also set. The process combines a food engineering technology and a green tea processing principle and systematically solves the problems of tea making processes, machine type selection and matching and clean production.

Owner:黄山王光熙松萝茶业股份公司

Preparation method of pitaya enzyme

InactiveCN108294301AFully dissolvedHas nutritional functionFood scienceBULK ACTIVE INGREDIENTBlood sugar

The invention relates to a preparation method of a pitaya enzyme, and belongs to the field of fermented food engineering. The method comprises the following steps: selection and pretreatment of raw materials, raw material mixing, step-by-step fermentation, post-fermentation treatment, solid-liquid separation, chelation aging, preparation of a liquid enzyme product, and recycle of enzyme solid residues. According to the invention, pitayas and pitaya flowers are taken as raw materials, and a pitaya enzyme stock solution or concentrated primary pulp is obtained by natural fermentation or external-inoculation strain fermentation or the combination of the natural fermentation and the external-inoculation strain fermentation. The pitaya enzyme obtained by the preparation method of the inventioneffectively maintains the functional active ingredients of the pitayas and the pitaya flowers, and has good antioxidant activity and blood sugar-reducing activity, so that a pitaya enzyme product withhealth-care functions and special nutrients which are reasonable in amino acid composition and protein nutrient composition structure and special is obtained.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Chenopodium quinoa semi-dry noodle and preparation method thereof

InactiveCN104920971AFull of nutritionEasy cookingFood preservationFood preparationAlcoholAdditive ingredient

The present invention belongs to the technical field of food engineering and particularly relates to a chenopodium quinoa semi-dry noodle and a preparation method thereof. The semi-dry noodle is composed of the following raw materials in parts by weight: 40-60 parts of sprouted chenopodium quinoa pulp, 0.5-1 part of amorphophallus konjac flour, 80-100 parts of flour, 3-5 parts of green tea powder, 1-3 parts of edible salt, 0.05-0.3 part of edible base, 0.1-0.5 part of compound phosphate and 5 parts of 75% edible alcohol. The semi-dry noodles are prepared as follows: firstly the chenopodium quinoa is processed by sprouting treatment and then other raw materials are added in sequence, the preparation process is simple, has few steps, can maximumly retain the nutrients in the chenopodium quinoa. The prepared semi-dry noodle is convenient to be cooked, has strong fragrance, is chewy, and has a long storage time.

Owner:INST OF AGRO FOOD SCI & TECH SHANDONG ACAD OF AGRI SCI

Method for making spicy spareribs with chili

InactiveCN101606717AGuaranteed nutritionGuaranteed deliciousFood preparationPreservativeFood engineering

The invention relates to a method for making spicy spareribs with chili. The method comprises the following steps: spareribs are cut, pickled and fried, then barbecue sauce is made, and afterwards, the spareribs and the sauce are proportionally packaged, sterilized and loaded into a big packaging bag to obtain a finished product. The invention takes diet spicy spareribs with chili as a basis and organically combines a traditional diet technique and a modern food engineering technique, the product does not contain any chemical additive or any preservative, and the invention not only ensures that the self nutrition and taste of the spicy spareribs with chili is not lost, but also shows a certain advantage in the aspects of food sanitation and eating convenience.

Owner:山西百世特食品有限公司

A kind of preparation method of Zizania bacon

InactiveCN102293415AGuaranteed nutritionDelicious not lostFood preparationAdditive ingredientPreservative

The invention discloses a method for making bacon with wild asparagus. Firstly, boil the asparagus with water, and then stir-fry the seasoning sauce; After conditioning and multi-stage mild sterilization. The invention is based on catering Zizania bacon, organically combines traditional catering technology and food engineering technology, and is industrially produced without any chemical additives and preservatives. Conditioning multi-stage sterilization not only ensures that the nutrition and deliciousness of Zizania bacon itself will not be lost, it can be eaten immediately and is convenient and hygienic. After heating, it can be eaten.

Owner:河南省淇县永达食业有限公司

Making method of crisp muscle and bone stick

The invention discloses a making method of a crisp muscle and bone stick. The making method of the crisp muscle and bone stick is characterized in that principal raw materials are cut into dices first, matched in a balance mode according to a proportion, subjected to the processes of stirring, pickling, syrup adding and flour wrapping to enrich taste, prefrying, coloring, shaping, cooking and the like, and then quickly frozen and packaged to form a finished product. The making method of the crisp muscle and bone stick organically combines a traditional catering technology and a food engineering technology, exquisite technological operation is conducted, the crisp muscle and bone stick contains no preservative, and the quality guarantee period is one year under the condition of refrigerated storage; the crisp muscle and bone stick is novel, crisp in taste, balanced in nutrition, ready to eat, convenient to eat and healthy. The crisp muscle and bone stick is convenient to eat, delicious, and capable of being eaten after being heated simply.

Owner:河南省淇县永达食业有限公司

Method for making shredded chicken with salted vegetable or shredded chicken with Sichuan pickled cabbage

The invention discloses a method for making shredded chicken with salted vegetable or shredded chicken with Sichuan pickled cabbage, which includes steps of scalding main materials, such as shredded chicken, shredded salted vegetable in oil and water, then stir-frying sauce for the shredded chicken; filling in nitrogen for packaging and sealing for the shredded chicken, the salted vegetable or the Sichuan picked cabbage, the sauce and the like after the main materials and the sauce are cooled naturally; and finally obtaining the finished product via conditioning and multi-stage mild disinfection. Based on the dish of shredded chicken with salted vegetable or shredded chicken with Sichuan pickled cabbage, the traditional catering technique is organically combined with the food engineering technique, and the shredded chicken industrially produced contains no chemical additives or preservatives. By means of conditioning and multi-stage disinfection, loss of nutrition and flavor of the shredded chicken with salted vegetable is avoided, and the shredded chicken with salted vegetable is edible, convenient and sanitary. The shredded chicken with salted vegetable or the shredded chicken with Sichuan picked cabbage made by the method can be eaten after being heated.

Owner:河南省淇县永达食业有限公司

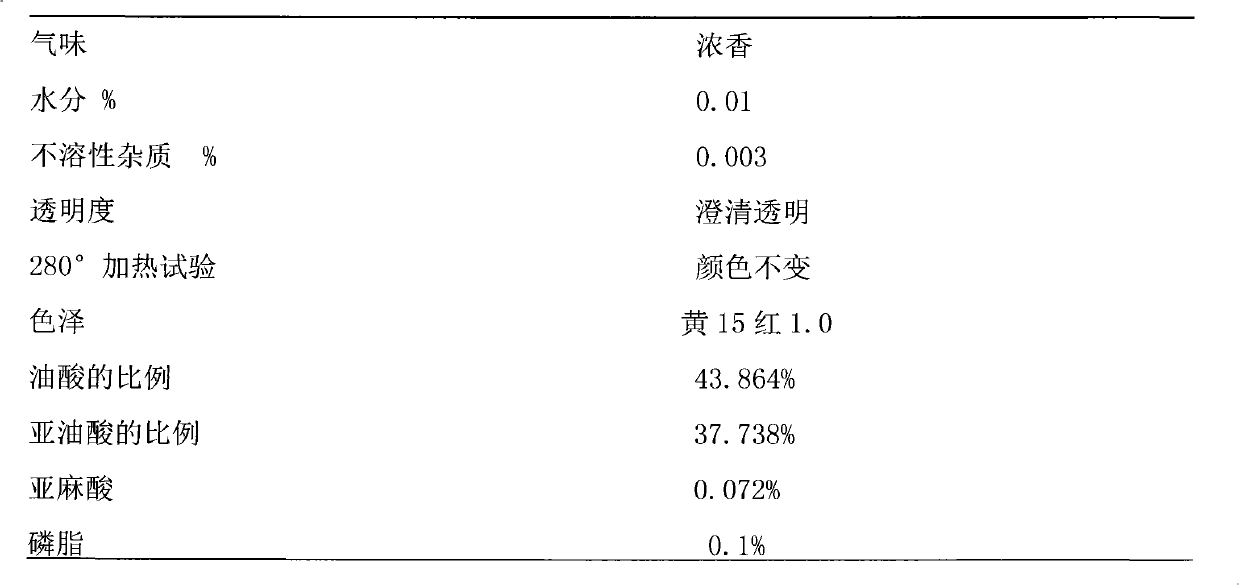

Biological selenium-rich aromatic peanut oil and production method thereof

ActiveCN102643713BImprove oil yieldIncrease contentFatty-oils/fats refiningFatty-oils/fats productionFood engineeringChemistry

The invention belongs to the technical field of food engineering, and discloses a biological selenium-rich aromatic peanut oil and a production method thereof. On the basis of the conventional oil-pressing process, the invention carries out a lot of creative improvement to develop a simple, feasible selenium-rich peanut oil preparation technique which is suitable for industrial mass production. The content of the biological selenium-rich aromatic peanut oil prepared by the technique can reach 0.103mg / kg. The biological selenium-rich aromatic peanut oil is rich in nutrition, gains the unanimous recognition of consumers, and has a tremendous commercial value.

Owner:山东金胜粮油食品有限公司

Burdock fermented composite polysaccharide beverage

InactiveCN105105236AHigh activityChange usageFood ingredient functionsFood preparationBiotechnologyMycelium

The invention relates to the fields of fermentation engineering and food engineering, and discloses a burdock fermented composite polysaccharide beverage and a method for preparing the composite polysaccharide beverage through fermenting burdock by using a Mythic Fungus mycelium liquid. The method comprises the following steps: preparing a fermentation medium, fermenting by using the Mythic Fungus mycelium liquid, and blending to prepare the composite polysaccharide beverage. The composite polysaccharide beverage prepared in the invention is rich in Mythic Fungus polysaccharides and burdock polysaccharides, and the preparation method of the composite polysaccharide beverage has the advantages of strong operability, good motuhfeel of the above obtained product, and good economic benefit.

Owner:HUAIYIN TEACHERS COLLEGE

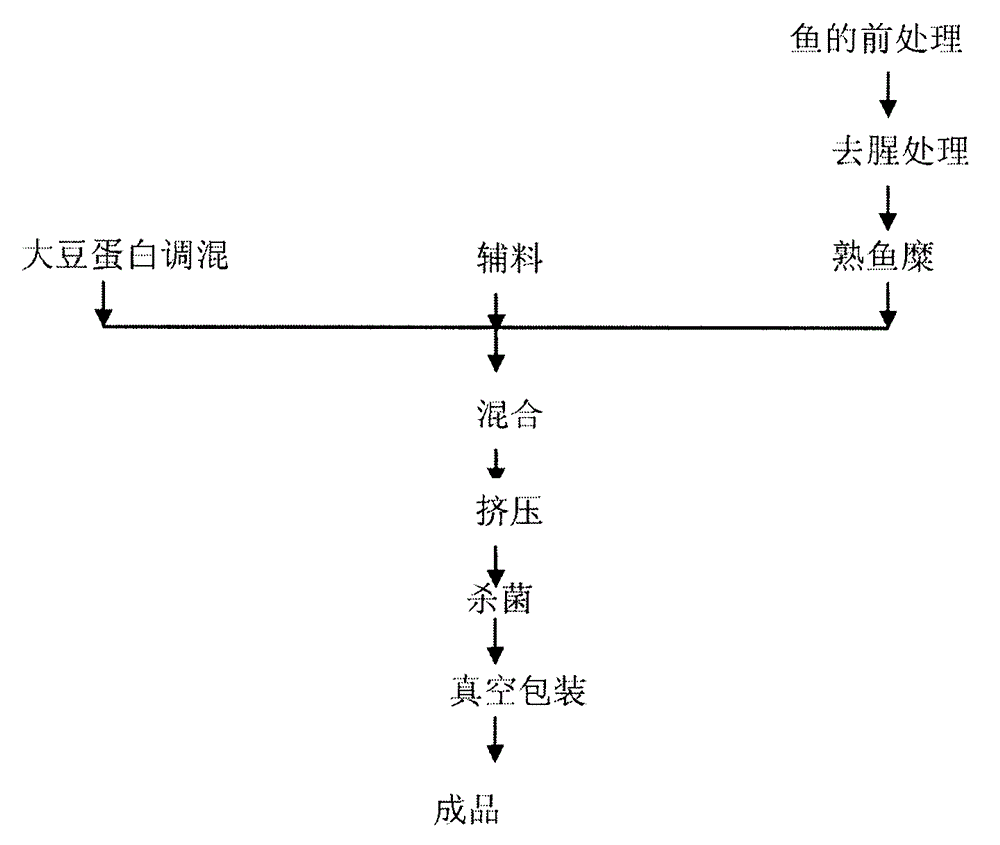

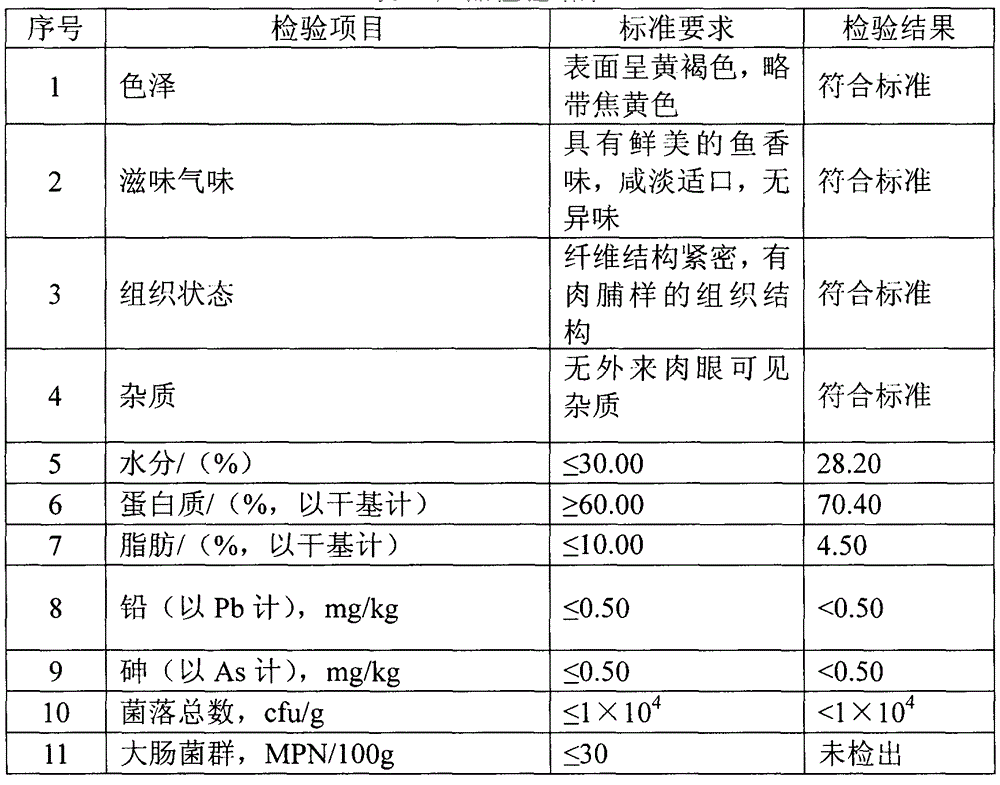

Fish and soy bean protein compound instant food and preparation method thereof

InactiveCN104783233AHigh nutritional valueReduce cholesterolFood preparationNutritive valuesPowder mixture

The invention discloses fish and soy bean protein compound instant food and a preparation method thereof, and relates to instant food and a preparation method thereof, aiming at solving the problems that the existing food which takes soya beans and fish as raw materials is low in nutrient value and not prone to digest and absorb by the human body. The instant food contains soya protein powder, cooked minced fillets, water and auxiliary materials. The preparation method comprises the following steps: I, mixing low-denaturation soya bean meal, dispersion type soybean isolate protein and gel type soybean isolate protein to obtain soya bean protein powder; II, cooking the fish and crushing to obtain the cooked minced fillets; III, mixing the cooked minced fillets with the soya bean protein powder, adding water and auxiliary materials to mix and mince, mincing and mixing to prepare an animal and plant protein powder mixture; IV, extruding the animal and plant protein powder mixture into a fish and soy bean protein compound crude product; V, sterilizing and packaging. The compound food prepared by the method is high in protein, low in cholesterol and low in fat, rich in eight necessary amnion acids required by the human body, easy to digest and high in nutrient value. The fish and soy bean protein compound instant food is used for the field of food engineering.

Owner:HARBIN UNIV OF COMMERCE

Method for producing high-yield gamma-propalanine and application thereof

InactiveCN102174449BLow costImprove brain functionBacteriaChemical industryFood engineeringBioconversion

Owner:TIANJIN UNIV OF SCI & TECH

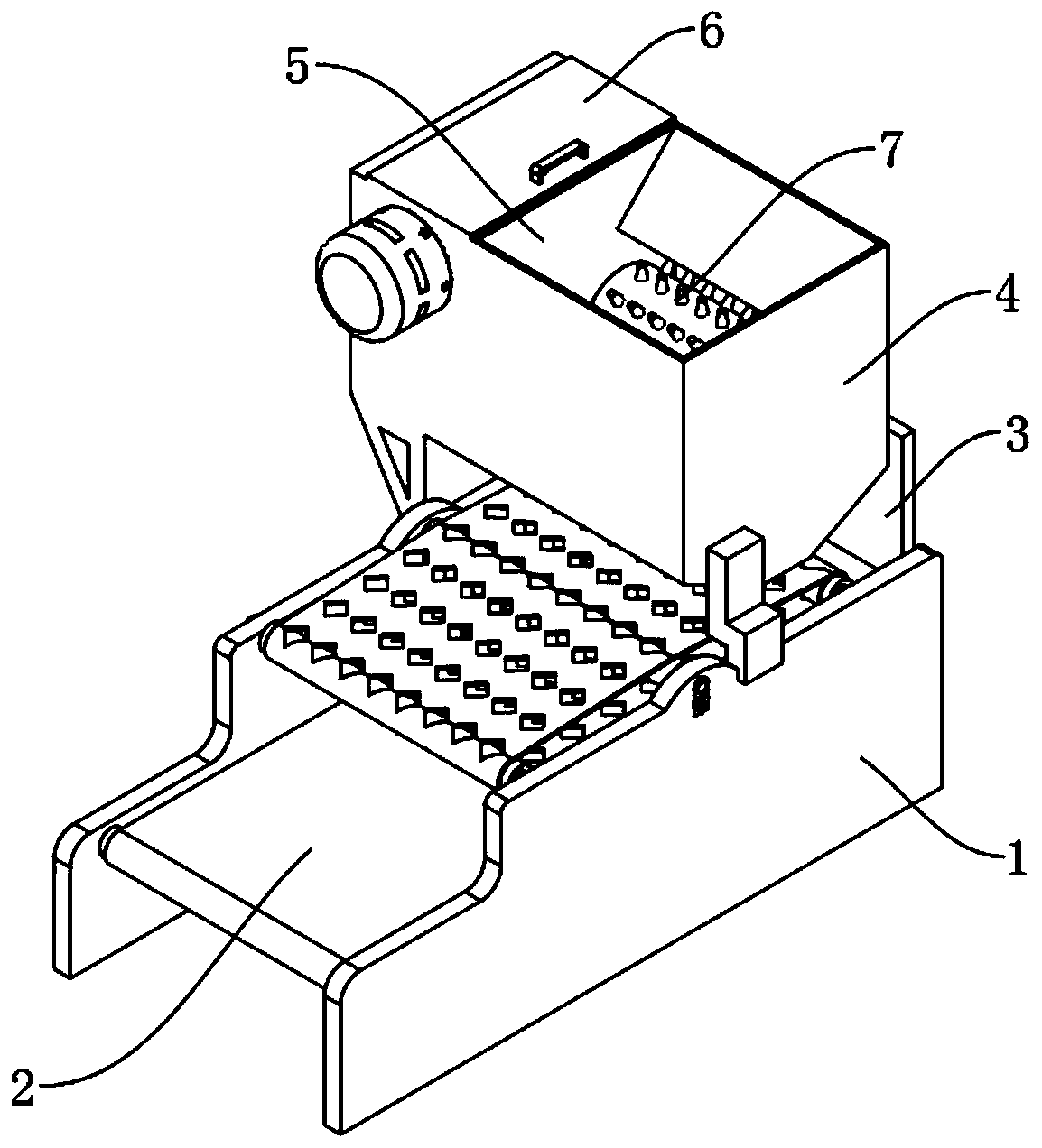

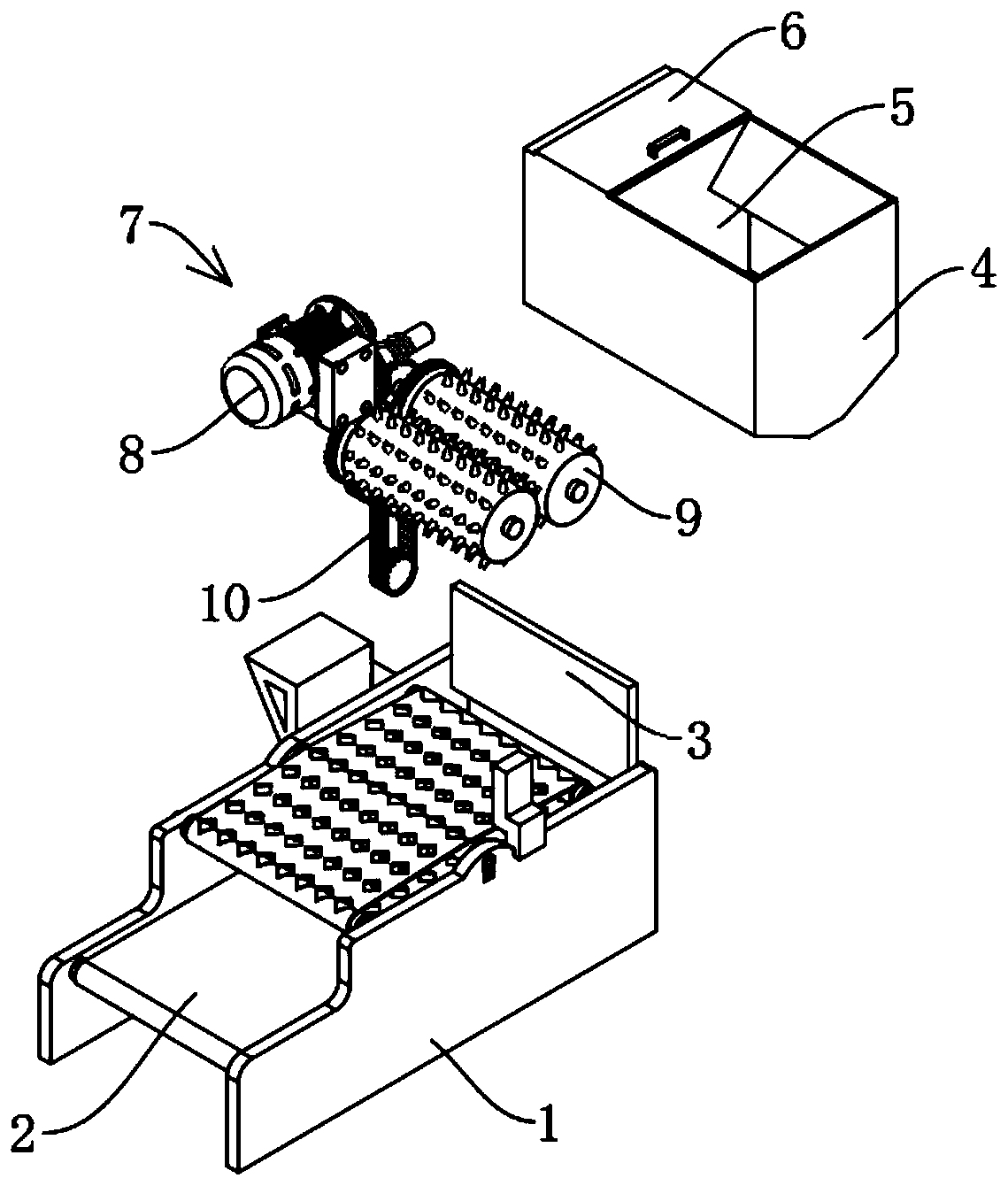

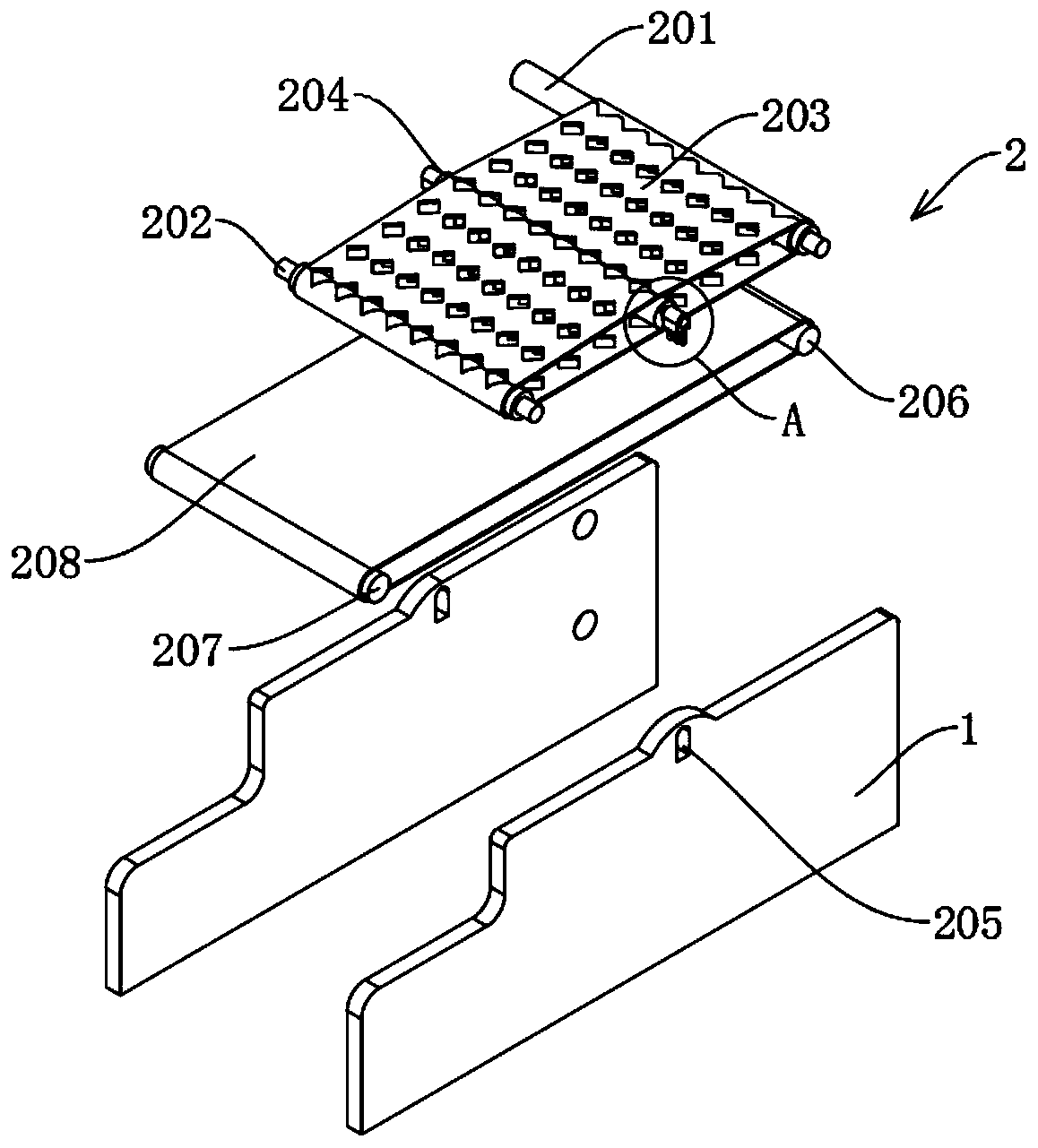

Machining breaking device for food engineering

The invention discloses a machining breaking device for food engineering, and belongs to the technical field of food engineering. The machining breaking device for food engineering comprises bottom mounting frames, a connecting frame and a treatment shell, a screening conveying mechanism is mounted between the bottom mounting frames, the connecting frame is fixedly connected to the top ends of thebottom mounting frames, the treatment shell is fixedly connected with the connecting frame, a breaking cavity is formed in the treatment shell, an inclined surface is fixedly connected to an openingof the breaking cavity, a cover plate is movably connected to the treatment shell through a hinge, a mounting cavity is mounted below the cover plate, a driving and breaking device is mounted in the breaking cavity and the mounting cavity, and comprises a driving mechanism, a breaking mechanism and a linkage mechanism, and the problems that in existing design, during breaking work, a breaking roller is prone to being clamped, mechanical failures and damage are prone to happening, the structure is simple, and the function is too single can be solved.

Owner:YANTAI ENG & TECH COLLEGE YANTAI TECHNICIAN INST

Method for preparing liquid enzyme through cell wall breaking

PendingCN106616578ABreed fastEfficient use ofFood ingredient as antioxidantFood preservationFruit juiceCell wall

The invention discloses a method for preparing liquid enzyme through cell wall breaking, and belongs to the field of food engineering. The method comprises the specific steps of step one, preparing raw material vegetables and fruits, washing, sterilizing and air-drying; step two, putting the raw material vegetables and fruits in a high-power high-speed wall breaking pulverizer, operating the high-power high-speed wall breaking pulverizer, breaking cell walls of the raw material vegetables and fruits, and enabling cytoplasm in the cell walls of the raw material vegetables and fruits to flow out; step three, putting vegetable and fruit juice after wall breaking and pulverizing into a fermentation tank according to a ratio, inoculating, standing and fermenting; step four, after fermenting is finished, obtaining the liquid enzyme. The method for preparing the liquid enzyme through cell wall breaking, disclosed by the invention, has the advantages that the cell walls can be effectively broken, the cytoplasm of the vegetables and fruits can be released, enough basal nutrition can be provided for probiotics, the fermentation efficiency is increased, and fermentation raw materials are efficiently utilized.

Owner:应晓科

Method for producing levulose seed crystal with cooperation of ethyl alcohol-ultrasound wave

InactiveCN101220398AShort processing timeReduce energy consumptionSugar crystallisationFructose productionFructoseUltrasound - action

The invention relates to an ethanol-ultrasonic synergistic preparation method of fructose crystal seed, which pertains to the field of food engineering technology. The invention particularly relates to a procedure that the crystallized fructose is dissolved in water, the fructose solution is vacuum concentrated at 60 DEG C till the supersaturation degree of the fructose syrup achieves 1.1 to 1.8; anhydrous ethanol which is 0.2 to 3 times of the volume of the over-saturated fructose syrup and contains the surfactant is added, at the same time, ultrasonic waves with the frequency-domain current of 0.2 to 0.8A are applied, the frequency of the ultrasonic waves is 23MHz, the processing time of the ultrasonic waves is 30s to 5 min; meanwhile, appropriate stirring is applied to lead the fructose syrup to receive the even ultrasonic function. The method of the invention is time-saving and energy-saving, the shape of the prepared crystal seed is better, which shows the typical orthogonal dual-wedge prismatic crystal shape with a complete and smooth surface and even size, the mobility is good and the adding is convenient. The synergistic crystallization method of the invention is a novel crystallization method and is a good substitute of the traditional preparation method of the fructose crystal seed.

Owner:JIANGNAN UNIV

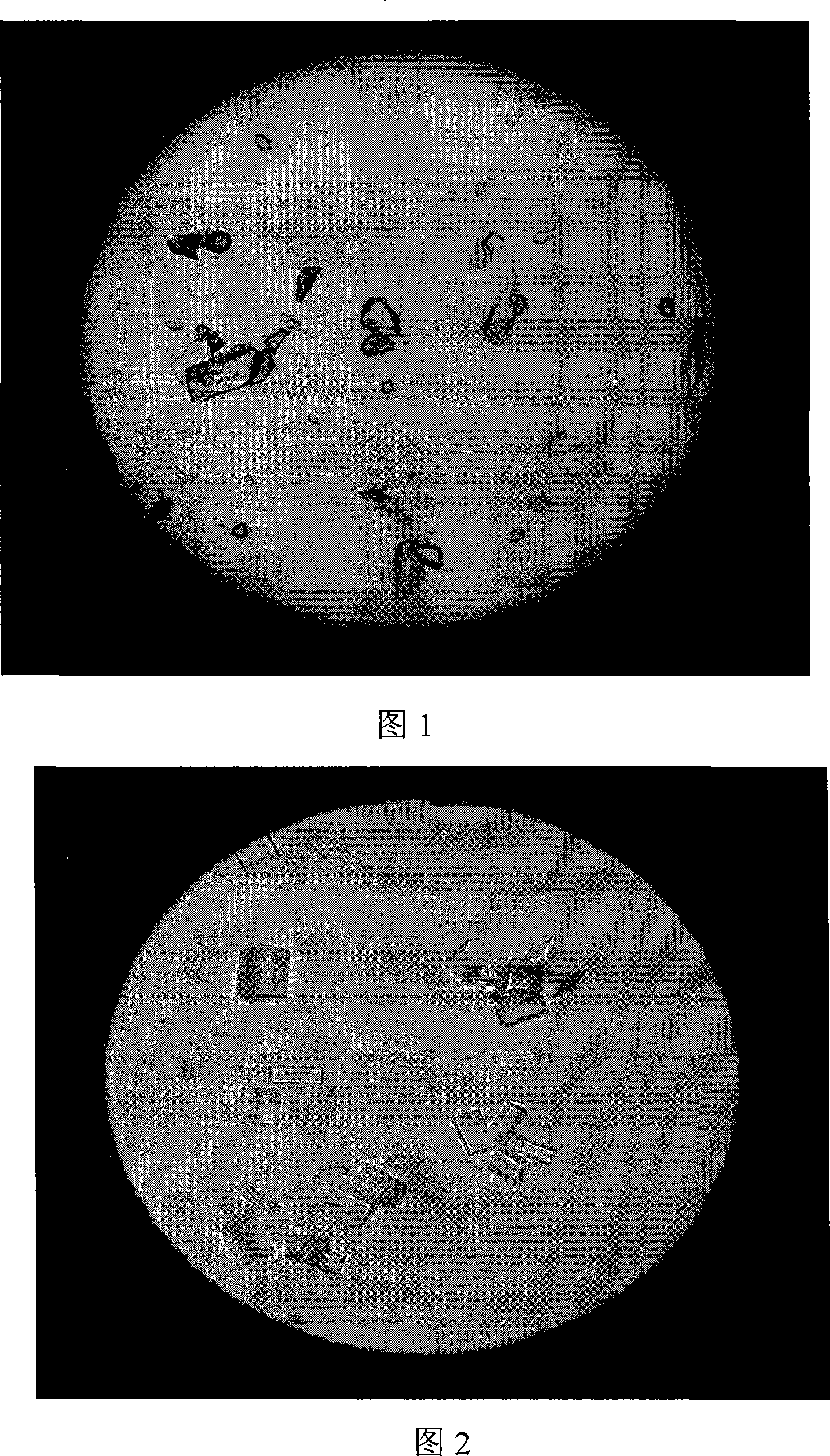

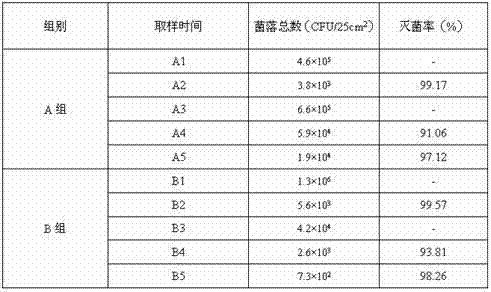

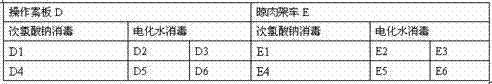

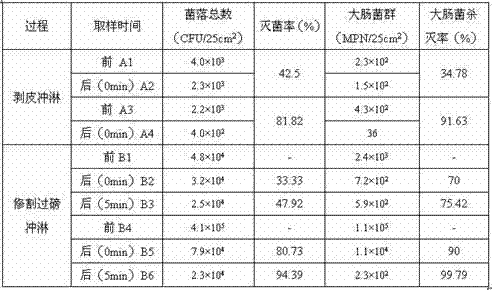

Application of sterilization electrochemical water to processing and disinfection of pork white bars

InactiveCN104489055AImprove the bactericidal effectRealize aseptic operationFood processingMeat/fish preservation using chemicalsFood engineeringFood sanitation

The invention belongs to the technical field of food engineering and particularly relates to application of sterilization electrochemical water to processing and disinfection of pork white bars. The safe, efficient and environment-friendly sterilization electrochemical water can be used for disinfecting the surface of pork and a processing tool, and microorganisms in a pork processing process can be effectively killed, so that a whole process is sterilely carried out and secondary pollution is avoided; the safety of the pork is guaranteed and the shelf life is prolonged; and the food sanitation standards are met. The application and the method are simple and convenient to operate, have rapid effect and are wide in application prospect, and energy conservation and environmental friendliness are realized.

Owner:TONGWEI

Fish-flavored shredded pork making method

InactiveCN101416749AGuaranteed nutritionDelicious not lostFood preparationFish FlavorMonosodium glutamate

The invention relates to a method of making shredded pork with garlic sauce, comprising rinsing shredded pork with clean water to remove blood, draining, starching the pork in egg white, frying for 1-2 minutes in oil pan, cooling naturally, thus forming cooked shredded pork; deep-frying shredded lettuces and shredded agarics in water, draining, cooling naturally, thus forming cooked shredded lettuces and shredded agarics; making cooking liquor with edible oil, soyabean paste, ketchup, ketchup, salt, cooking wine, monosodium glutamate, capsicums, bruised gingers, minced shallots and water; packing the cooked shredded pork, cooked shredded lettuces, cooked shredded agarics and cooking liquor with certain weight when charging nitrogen, sealing, sterilizing, and filling in big bags, thus forming finished products. The invention combines the traditional dishes with the modern food engineering technology to form industrial production without any chemical additive and preservative, thus guaranteeing that the nutrition and taste of the traditional shredded pork with garlic sauce do not lose and the shredded pork with garlic sauce is convenient and sanitary to eat, only needing to be heated.

Owner:山西百世特食品有限公司

A kind of preparation method of aromatherapy leg steak

The invention discloses a method for preparing fragrant smoked leg chops, which comprises the following steps of: pricking peeled chicken thigh meat, adding materials, kneading, pre-cooling, flattening, and sizing; and steaming, baking and curing in a steam box, quickly freezing and packaging. On the basis of catering fragrant smoked leg chops, the conventional catering technology is integrated with a food engineering technology, and pricking and flattening processes are adopted, so that products are deeply tasty, fresh and tender in meat quality and nutritious and have the shelf life of one year when stored in a refrigerator; and the fragrant smoked leg chops are fragrant, tender and juicy in metal quality, refreshing and palatable, unique in flavor, ready to eat, convenient, sanitary, convenient to eat, and delicious, and can be eaten after being simply heated.

Owner:河南省淇县永达食业有限公司

Method for making bacon donkey meat

The invention discloses a method for making bacon donkey meat, wherein a finished product is made through the steps of material selection, reshaping, dehematizing, injection pickling, tenderization, tumbling, cooking, cooling, packaging, and sterilization. The invention organically combines the prior processing technique of local Cuisines of Changzhi bacon donkey meat with the modern food engineering technology, and scale industrial production technology is formed. Because the product does not contain any preservative, the bacon donkey meat can be kept for more one year at the constant temperature. The aims of nourishment, fresh, sanitation and instant eating are realized while ensuring the flavor of the traditional local Cuisines.

Owner:山西百世特食品有限公司

Method for preparing braised chicken chips with brown sauce

The invention discloses a method for preparing braised chicken chips with brown sauce, comprising the following steps: (1) preparing the raw material of the braised chicken chips with brown sauce according to the following weight in parts; (2) pulping the chicken blocks, soaking in hot oil, scalding kelp in hot water, and preparing seasoning sauce; (3) uniformly mixing the chicken blocks, the kelp, the chopped green onion with the seasoning oil; putting in high-temperature cooking bags; vacuumizing and filling nitrogen; and sealing; and (4) putting the packaged cooking bags in a sterilizationpan to sterilize at all stages. The invention adopts the eating and drinking braised chicken chips with brown sauce as base to organically combine the traditional dining technology with the food engineering technology, so it does not have any chemic additive and preservative after the industrial production. The invention not only ensures the nutrition of the braised chicken chips with brown sauce, but also ensues that the good taste does not lost. The invention can be eaten immediately, and it is convenient and sanitary. The greatest characteristic of the product is convenient and delicious, and can be eaten immediately after being heated.

Owner:河南省淇县永达食业有限公司

Honey throat-smoothing candy and preparation method thereof

ActiveCN102524499AHas health effectsSafe and non-toxic side effectsConfectionerySweetmeatsThroatMint extract

The invention discloses a honey throat-smoothing candy, which belongs to the field of food engineering, and is prepared by processing the following raw materials: 4-6 parts of honey, 1-2 parts of lily bulb extract, 2-4 parts of sophora japonyca flower concrete, 1-2 parts of wolfberry extract, 2-4 parts of licorice extract, 2-3 parts of Hang-zhou chrysanthemum flower extract, 1-2 parts of isatis-root extract, 1-2 parts of mint extract, 35-50 parts of starch syrup, and 40-50 parts of white granulated sugar. The honey throat-smoothing candy has the beneficial effect of having a certain efficacy for disinfecting and diminishing inflammation, and promoting tissue regeneration.

Owner:JIANGSU AISHINONG BIOLOGICAL TECH CO LTD

Burdock paste and manufacturing process thereof

The invention discloses a burdock paste and a manufacturing process thereof, and belongs to the technical field of food engineering. The burdock paste comprises the following components according to percent by weight: 40 percent of burdock, 15 percent of soybean paste, 10 percent of flour paste, 25 percent of salad oil, 3.5 percent of chili, 3 percent of preserved fruit steep sugar, 1 percent of green onion, 1 percent of ginger, 1 percent of salt, 0.5 percent of gourmet powder, and 1 percent of spice, and through the manufacture processes of raw material treatment, paste manufacture, filling and the like, the finished product is obtained. The invention has the benefits as follows: the economic value of the preciouse economical crop can be promoted greatly, the economical income of peasant for burdock planting can be increased, and a novel paste breed which can be stored for a long time and having rich nutrtions can be provided for people.

Owner:天益食品(徐州)有限公司

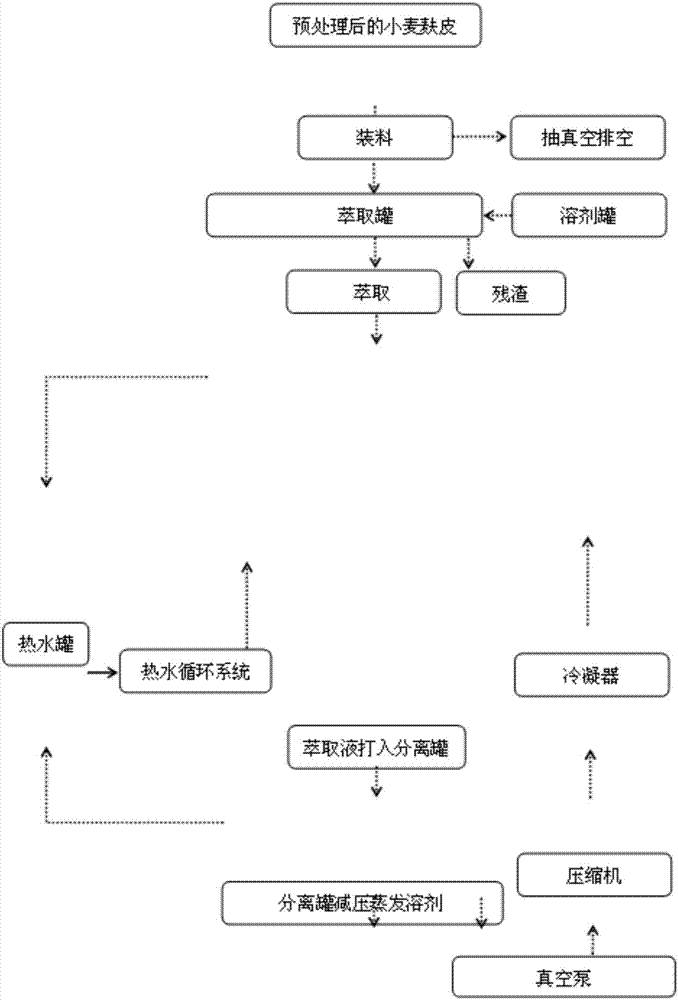

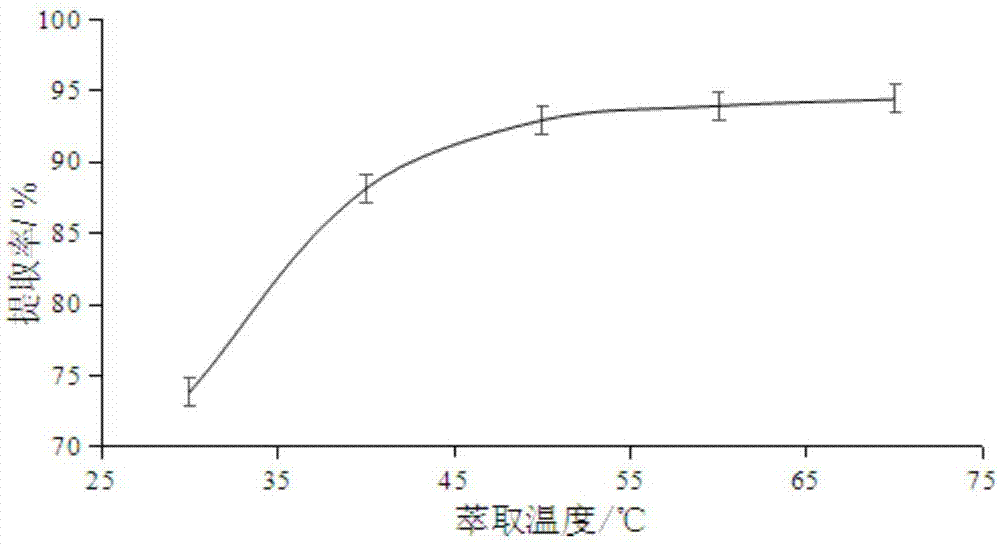

Wheat bran oil production technology using subcritical butane extraction

InactiveCN107338106ASimple processHigh extraction rateFatty-oils/fats productionMethyl linoleateDistillation

The invention discloses a wheat bran oil production technology using subcritical butane extraction, and belongs to the field of food engineering. Wheat bran undergoes subcritical butane extraction multiple times, and the obtained extract liquid undergoes reduced pressure distillation to remove an extractant to obtain the wheat bran oil containing methyl palmitate, methyl linoleate and methyl oleate. The wheat bran is cyclically extracted by adopting a subcritical butane technology, and technologic optimization researches of factors affecting the yield of the wheat bran oil are carried out by adopting Box-Benhnken center combination response surface test design in order to obtain optimum technologic parameters; and a gas chromatograph-mass spectrometer (GC-MS) is used to analyze the fatty acid components of the wheat bran oil obtained through the subcritical extraction in order to provide reference for the development and the utilization of wheat bran resources. The wheat bran oil production technology is simple, allows the extraction rate to reach up to 86.92%, is suitable for industrial application, and provides a new way for the further utilization of the wheat bran.

Owner:QILU UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com