Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2428 results about "Colloid mill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

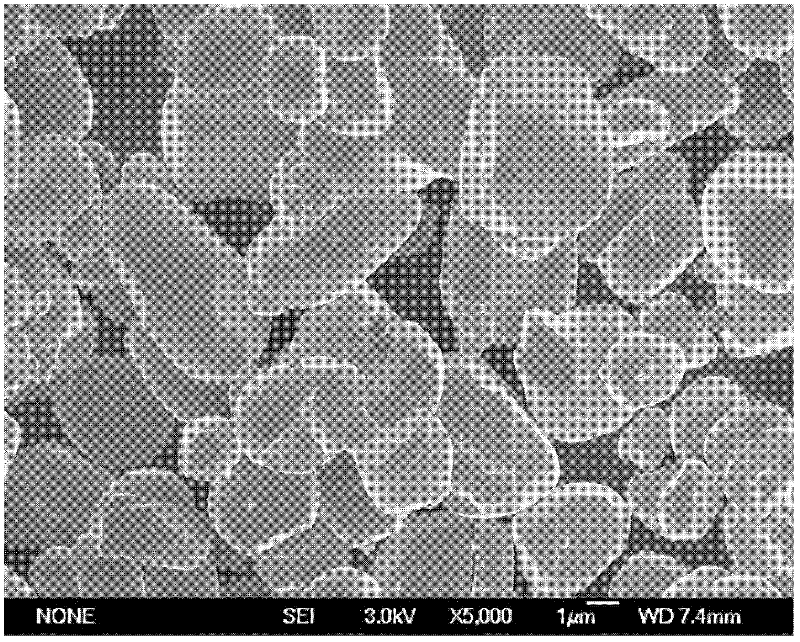

A colloid mill is a machine that is used to reduce the particle size of a solid in suspension in a liquid, or to reduce the droplet size in emulsions. Colloid mills work on the rotor-stator principle: a rotor turns at high speeds (2000 - 18000 RPM). The resulting high levels of hydraulic shear applied to the process liquid disrupt structures in the fluid. Colloid mills are frequently used to increase the stability of suspensions and emulsions, but can also be used to reduce the particle size of solids in suspensions. Higher shear rates lead to smaller droplets, down to approximately 1 μm which are more resistant to emulsion separation.

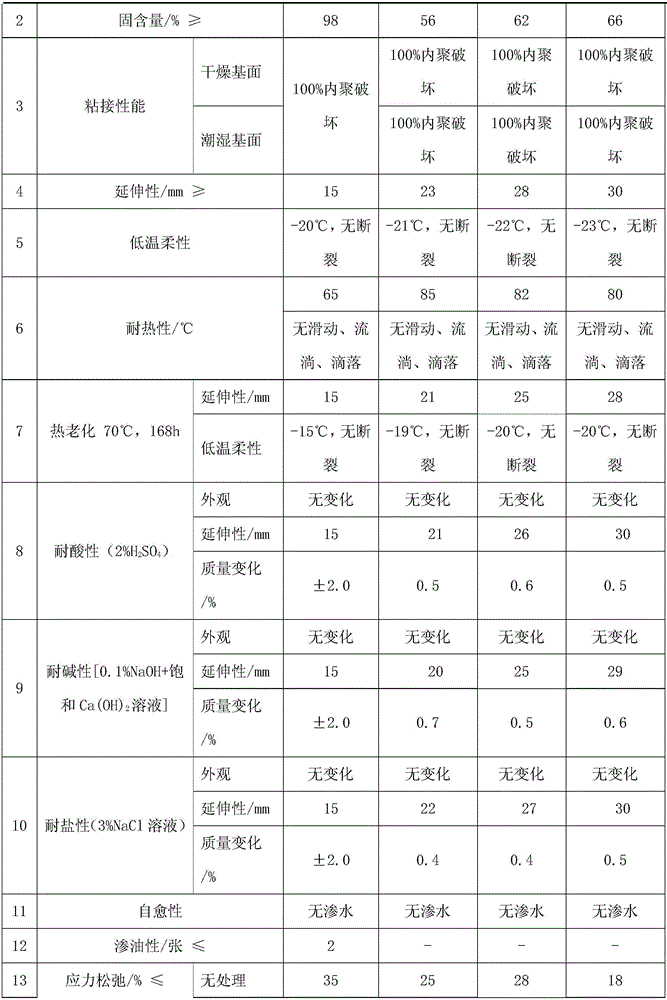

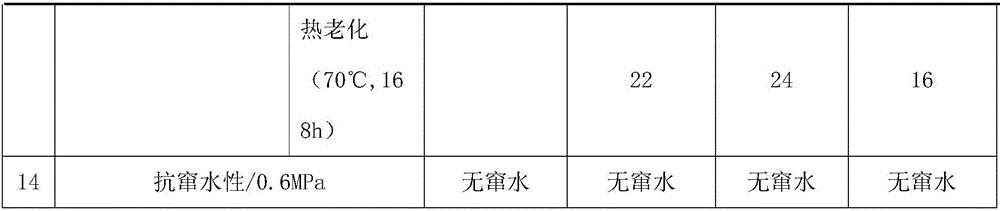

Waterproof roll capable of carrying out chemical bonding and physical crosslinking synergism with concrete

ActiveCN101694114AImprove stabilityIncreased durabilityRoof covering using flexible materialsTextiles and paperAntioxidantPlasticizer

The invention discloses a wet-laying and pre-laying waterproof roll which is made by the following processes: dipping and coating a modified asphalt compound on a blank body, controlling the thickness and sizing, coating a membrane, rolling, and the like, wherein the modified asphalt compound contains modified asphalt, a plasticizer, an antioxidant, a functional auxiliary agent and a filling gent. A preparation method of the waterproof roll comprises the following steps: putting substrate asphalt in a reaction pot, adding a thickening agent, irregular polyethylene and styrene-polybutadiene-styrene segmented copolymer, evenly mixing, heating and stirring for 1.5-2 hours, then reducing the temperature to about 180 DEG C, adding padding, the plasticizer, the antioxidant and the functional auxiliary agent into the reaction pot and stirring for 0.5-1h, evenly mixing and modifying, then conveying into a colloid mill for repeatedly milling to the material, then dipping and coating the modified asphalt on the blank body, controlling the thickness, sizing, coating the membrane and rolling, and finally preparing the waterproof roll which has excellent performance and can carry out chemical bonding and physical crosslinking synergism with the concrete, namely, a CPS waterproof roll for short.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

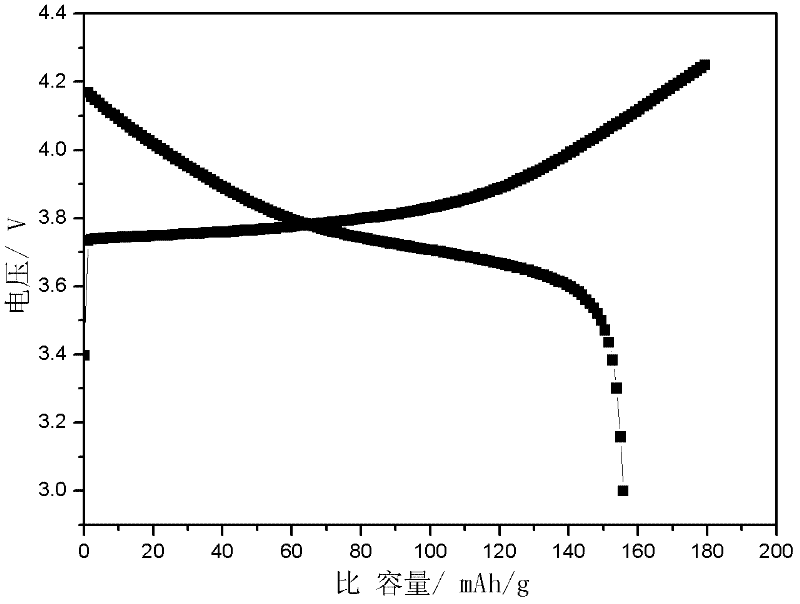

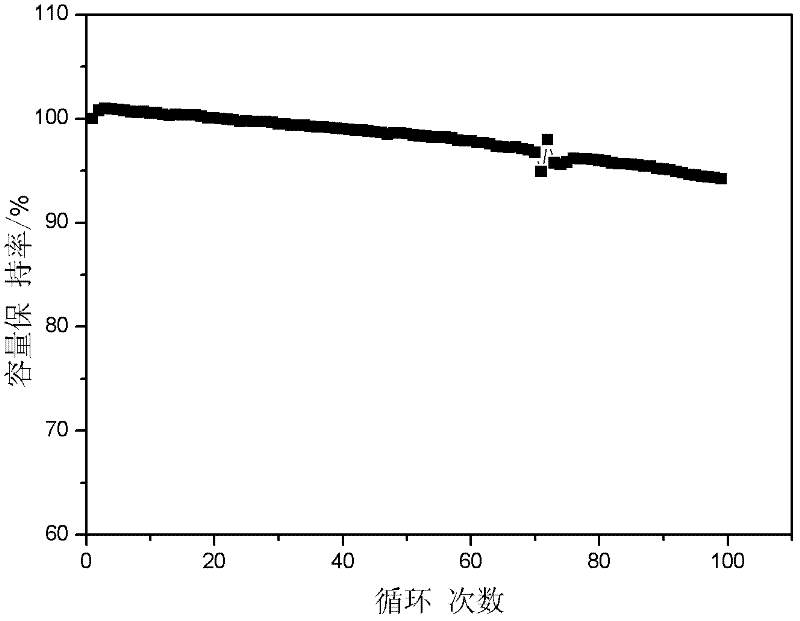

Preparation method of lithium ion battery ternary cathode material

The invention discloses a preparation method of a lithium ion battery ternary cathode material. According to the preparation method, full grinding is performed through a colloid mill to improve the reactivity of a precursor and a lithium salt and the uniformity of a mixed material; and a carbon chain organic additive is added in the process of grinding to improve the viscosity of a sizing material, inhibit raw material segregation in the process of drying, quickly balance the temperature of each part of a system in the process of high-temperature reaction and inhibit agglomeration among particles, so that a uniform-appearance and regular mono-crystal ternary cathode material is obtained. Meanwhile, the ternary cathode material is doped and subjected to surface coating modification, so that the structure of the material is stabilized, the side reaction between the material and electrolyte is inhibited, and the high-temperature cycle performance of the material is improved.

Owner:PULEAD TAIAN TECH IND

Asphalt modified with desulfurized rubber powder

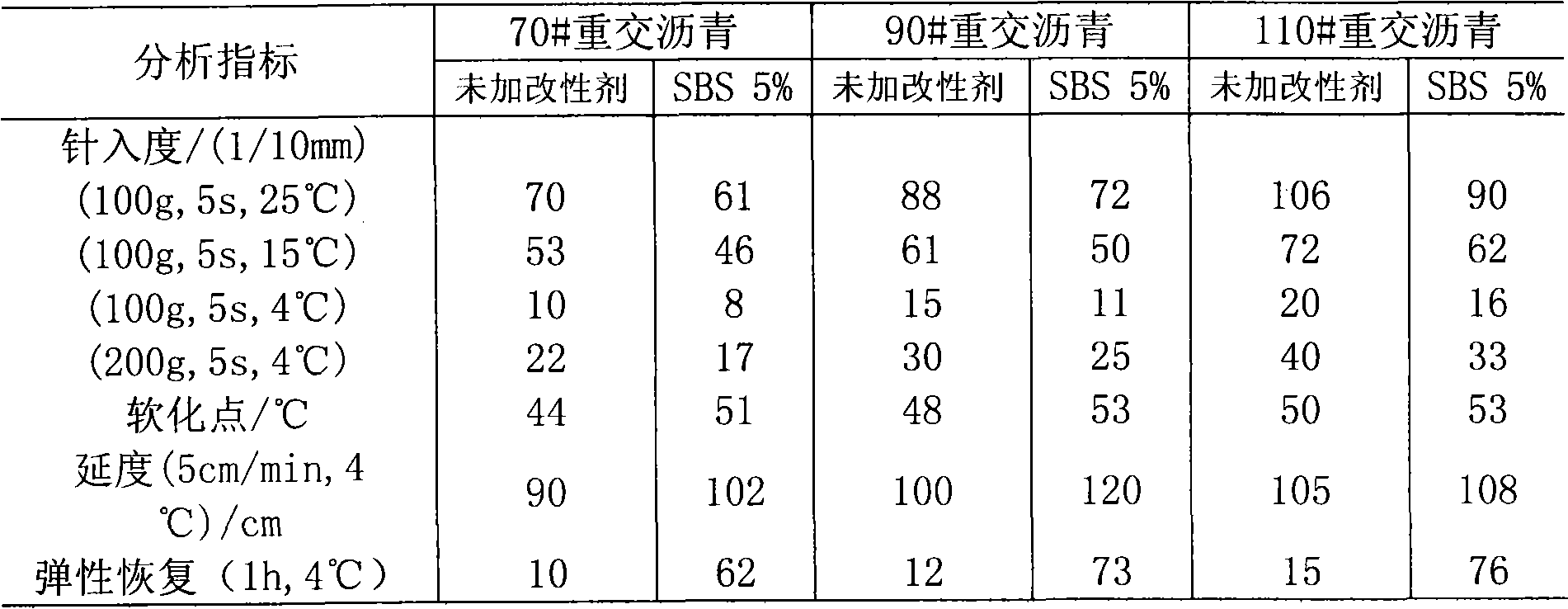

The present invention relates to asphalt modified with desulfurized rubber powder for road construction. The modified asphalt is produced with desulfurized rubber powder 5-30 wt%, asphalt 70-95 wt% and compatibilizer 0-1.5 wt% and through high speed shearing stirring for grinding in colloid mill. The modifier desulfurizing rubber powder has good dissolving and swelling performance in asphalt and has much active radicals in the surface for bonding with asphalt, and the compatilizer can further increase the interaction between the rubber powder and asphalt, so that the modified asphalt has excellent high and low temperature performance and storage stability.

Owner:WUHAN UNIV OF TECH

Anionic water-based non-curing rubber asphalt waterproof coating and preparation method thereof

The invention discloses an anionic water-based non-curing rubber asphalt waterproof coating and a preparation method thereof. The preparation method comprises the steps that 85-95 parts by mass of anionic rubber modified asphalt emulsion, 2-5 parts by mass of anionic SBR latex, 4-7 parts by mass of anionic neoprene latex, 0.1-1 part by mass of hydrophobing agent and 0.5-2.5 parts by mass of permeability-reducing agent are stirred and mixed to be uniform to obtain a component A; inorganic salt is dissolved in water, an inorganic salt solution with the concentration being 10% to 30% is prepared, and a component B is obtained; the component A and the component B are sprayed and mixed through a spraying gun according to the mass ratio being (5-15):1, and the anionic water-based non-curing rubber asphalt waterproof coating is obtained, wherein the anionic rubber modified asphalt emulsion is prepared by emulsifying matrix asphalt, a tackifier, rubber elastomers, an anionic emulsifier, a stabilizer, a PH modifier and water through a colloid mill. The product is stable in storage, environmentally friendly, free of pollution, good in non-curing effect, high in waterproof performance and simple in process.

Owner:KESHUN WATERPROOF TECH CO LTD

Waste rubber powder modified asphalt and its prepn process

ActiveCN1609165AAvoid separationUniform storageWorking-up pitch/asphalt/bitumenBuilding insulationsColloid millAsphalt

The present invention provides one kind of waste rubber powder modified asphalt and its preparation process. In the temperature of 150-200 deg.c, waste tyre rubber powder of different grain size within 60 mesh, thermoplastic rubber and stabilizer in certain proportion are added into asphalt; and the mixture is processed in high shearing apparatus or colloid mill to prepare the asphalt product with high storage stability and excellent high and low temperature performance. The simple production process is suitable for industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

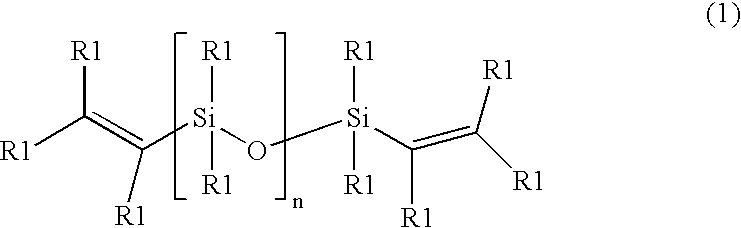

Method for dispersing highly viscous organosilicon mixture

The invention provides a method for dispersing high viscosity of silicone mixtures, which is characterized in that: an emulsion prepared by the method is composed of 5 to 25 percent of high viscosity of silicone mixtures, 4 to 25 percent of a high viscosity of silicone emulsifier, 0 to 15 percent of a normal emulsifier, 1 to 5 percent of a thickener and 60 to 90 percent of water; the preparation method comprises the steps that: (1) the high viscosity of silicone emulsifier, the normal emulsifier and the high viscosity of silicone mixtures are mixed, stirred and heated to the temperature of 50 to 80 DEG C and the heat is preserved for 20 to 60 minutes to guarantee full and even mixing of the silicone mixtures and the emulsifiers; (2) water is added slowly and the mixture is stirred quickly during phase transition to ensure that a W / O type emulsion is changed into an O / W type emulsion, and then water is continued to be added until the quality concentration of a crude emulsion gets to 40 to 60 percent; (3) the crude emulsion is carried out colloid mill to be further emulsified; (4) the mixture is diluted by a thickener aqueous solution. The method can obtain a stable emulsion of high viscosity of silicone mixtures and the storage and application stability of the emulsion are improved.

Owner:滁州四新科技有限责任公司

Layered double hydroxide and preparation method thereof

InactiveCN101665233AParticle size controlRegular layered structureOxide/hydroxide preparationIndividual molecule manipulationDivalent metal ionsCrystallinity

The invention relates to a layered double hydroxide and a preparation method thereof, belonging to the technical field of metal hydroxide preparation. A chemical formula of the layered double hydroxide is as follows: (M1(1-x)M2x(OH)2)(A<n->)x / n), wherein x is larger than or equal to 0.2 and smaller than or equal to 0.33; M1 represents any one or more of divalent metal ions including Mg<2+>, Zn<2+>, Ni<2+>, Co<2+>, Ca<2+>, Cu<2+>, Fe<2+> and Mn<2+>; M2 represents any one or two of trivalent metal ions including Fe<3+> and Al<3+>; A<n-> represents any one of interlayer anions including CO3<2->,NO3<->, Cl<-> and SO4<2->; and the grain size ranges from 12 nm to 80 nm. The invention has the advantages that the preparation method is a direct method for preparing the layered double hydroxide with high crystallinity, layered structure regularity, wide application range and adjustable particle size. The preparation method comprises the following steps: obtaining highly dispersed metal nanoparticle sol by utilizing the action of colloid mill axial shear force and the sodium borohydride reducibility, and then performing slow oxydrolysis in a hydrothermal system, and the like to generate thenano layered double hydroxide with layered structure regularity and adjustable particle size. The method has the advantages of wide application range, low cost, simple operation and environmental protection.

Owner:BEIJING UNIV OF CHEM TECH

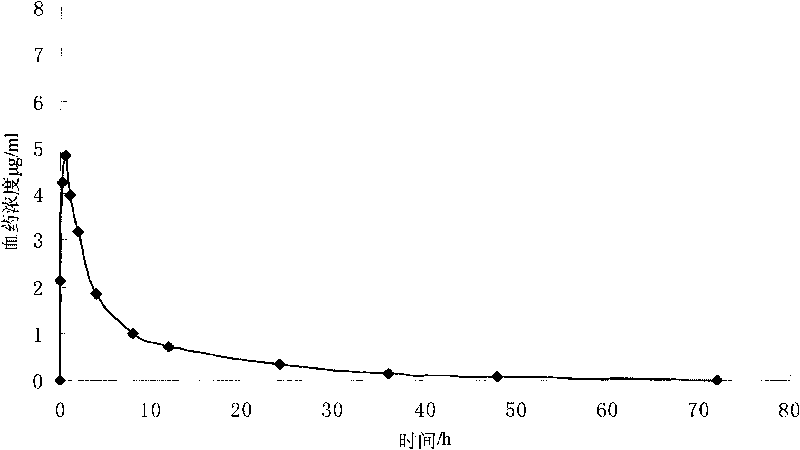

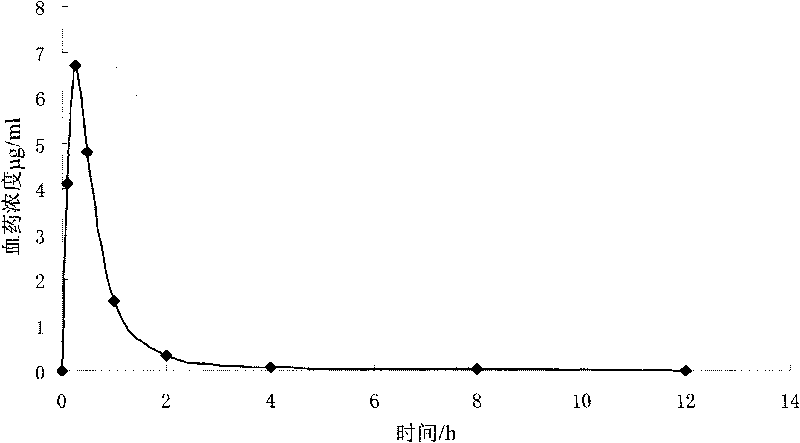

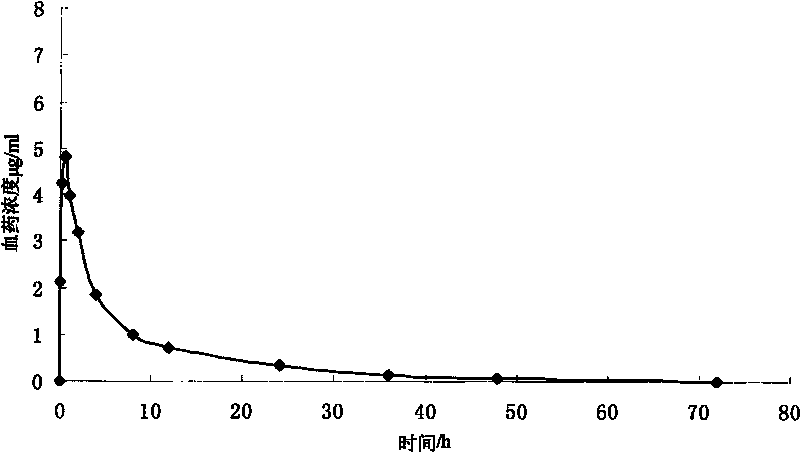

Components and preparation method of beta-lactam injection

ActiveCN101721366AReduce the number of dosesReduce stressAntibacterial agentsSolution deliverySterile environmentVegetable oil

The invention discloses the components and preparation method of beta-lactam injection. The beta-lactam injection comprises 5 to 20 percent of beta-lactam antibiotics, 0.05 to 5 percent of suspending agent, 0.005 to 0.3 percent of antioxygen, 0.1 to 0.2 percent of nonionic surfactant and the balance of vegetable oil or grease for injection. The injection can be used for preventing and curing animal bacterial infectious diseases and can be injected hypodermically or in muscle and be applied through breast for a few times. The preparation method provided by the invention comprises: firstly, making the antibiotics and the antioxygen into micro powder and making the suspending agent into fine powder; secondly, adding the vegetable oil or grease for injection, which is sterilized at high temperature, into the fine powder of the suspending agent, heating the mixture, uniformly mixing the mixture and keeping the mixture in a sterile environment to cool the mixture to room temperature for later use; and finally, transferring the prepared oil or grease added with the suspending agent to a colloid mill, adding medicament micro powder, the antioxygen and the non-ionic surfactant with stirring, and performing uniform mixing and sterilization to obtain the beta-lactam injection.

Owner:LUOYANG HUIZHONG ANIMAL MEDICINE

Preparation method of lycopersicin microcapsule

InactiveCN101015342ANo smellNo residueCosmetic preparationsHydrocarbon active ingredientsPink colorSolubility

The invention relates to a method for preparing lycopene microcapsule, belonging to food engineering technique. It comprises following steps: (1) putting compound emulsifier and water into solid lycopene powder, grinding in ball grinder to form emulsion; (2) dissolving wall material into water, stirring and getting wall material solution; (3) mixing said lycopene emulsion with wall material, homogenizing with colloid mill; (4) spray drying homogenized mixing liquid and getting lycopene microcapsule. The invention is characterized by simple process, no organic solvent residual, high productivity, and suitability for large production. The produced lycopene microcapsule is characterized by sphere shape, pink color, homogenous granular size, smooth surface, no smelly odor, good fluidity, good water solubility, high content of lycopene, restoration at normal temperature and packed with polyethylene film bag of 0.2mm, and long storage period of more than 4 months.

Owner:SHANGHAI JIAO TONG UNIV

Magnesium-alloy metal-type casting coating and preparation method thereof

ActiveCN101658899ASimple componentsEasy to prepareFoundry mouldsFoundry coresSodium BentoniteSuspending Agents

The invention relates to a magnesium-alloy metal-type casting coating and a preparation method thereof. Magnesia and forsterite are used as refractory aggregates; titania, asbestos powder or talcum powder or diatomite, and the like are added as heat-insulation aggregates; a mixed caking agent with favorable high-temperature caking property and a compound suspending agent are selected; and boric acid is added as a flame retardant. The preparation method comprises the following steps: mixing the magnesia, the forsterite, the titania, and the asbestos powder or talcum powder or diatomite, and preparing A after ball milling; mixing the caking agent and bentonite, and adding water to activate so as to obtain B; mixing the boric acid, sodium carboxymethyl cellulose and polyacrylamide, and addingwater to activate so as to obtain C; and finally, mixing A, B and C, and carrying out ball milling or colloid milling for more than 30 minutes to obtain the magnesium-alloy metal-type casting coating. The coating has the advantages of favorable heat insulation, caking property, coating property, flame retardance, stability and durability, is beneficial to continuous production and convenient forobtaining magnesium-alloy metal-type castings with favorable surface quality and superior performance, and prolongs the service life of moulds.

Owner:SHANGHAI JIAO TONG UNIV

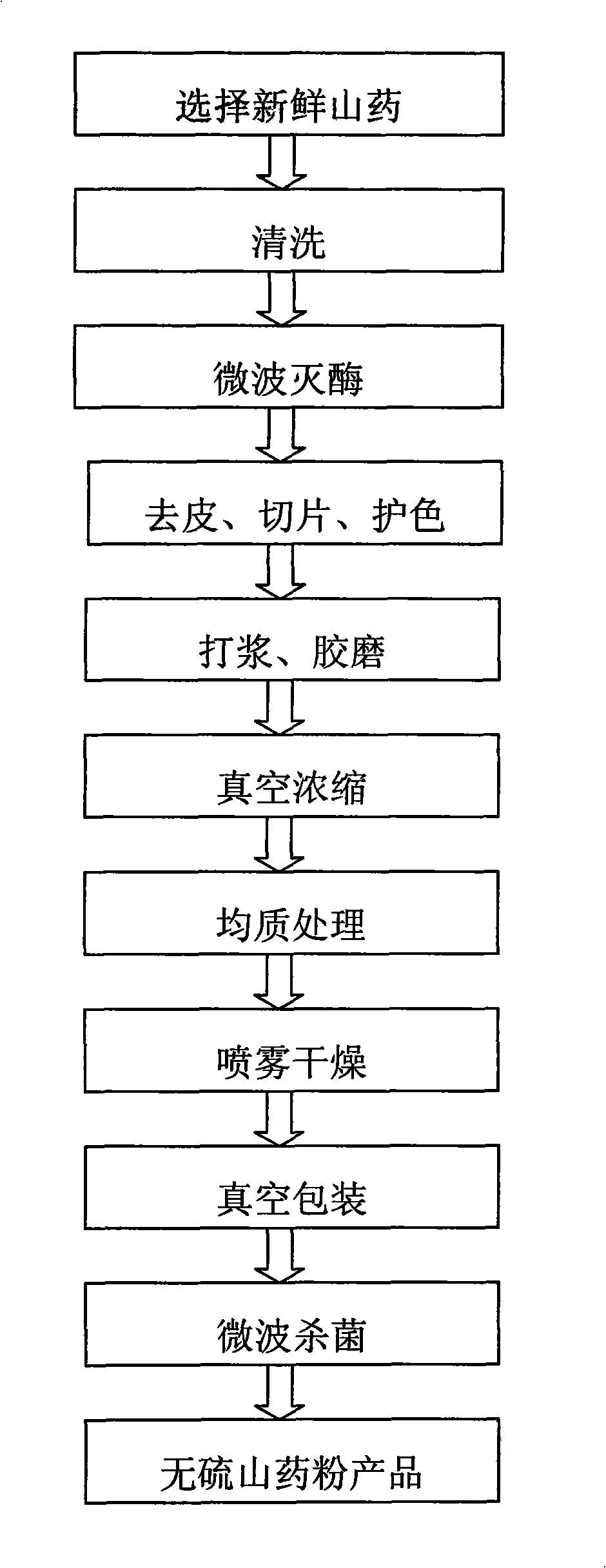

Production method for spray-drying Chinese yam powder without using sulfur to protecting color

InactiveCN101513241AImprove quality and efficiencyIncrease productivityHair cosmeticsDead plant preservationVitamin CAdditive ingredient

The invention relates to a production method for spray-drying Chinese yam powder without using sulfur to protecting color. The Chinese yam is prepared from fresh Chinese yam and is obtained by the steps of microwave enzyme deactivation, shelling, slicing, color protection, pulping, grinding, vacuum condensation, homogenization, spray-drying, vacuum packaging and microwave sterilization. The Chinese yam raw material is deactivated by microwave at temperature of 60 DEG C, cut to slice, and is soaked in sulfur-free color protection liquid containing phytic acid, Ethylenediaminetetraacetic acid disodium, vitamin C and citric acid, the color protection liquid and the Chinese yam slice is pulped together and is milled by a colloid mill, the Chinese yam slurry is concentrated by a vacuum condensation equipment until the content of solid is 15-25% and is homogeneously processed, homogenized liquid material is sprayed and dried by a centrifugal spray-drying machine, the obtained Chinese yam powder is packaged by vacuum and is sterilized by a microwave sterilization equipment to prepare the sulfur-free Chinese yam powder product. The invention has high production efficiency and low cost, the produced Chinese yam product has good color, high safety and complete nutrient composition, and can applied for field such as foodstuff, medicine and cosmetic product.

Owner:袁书林

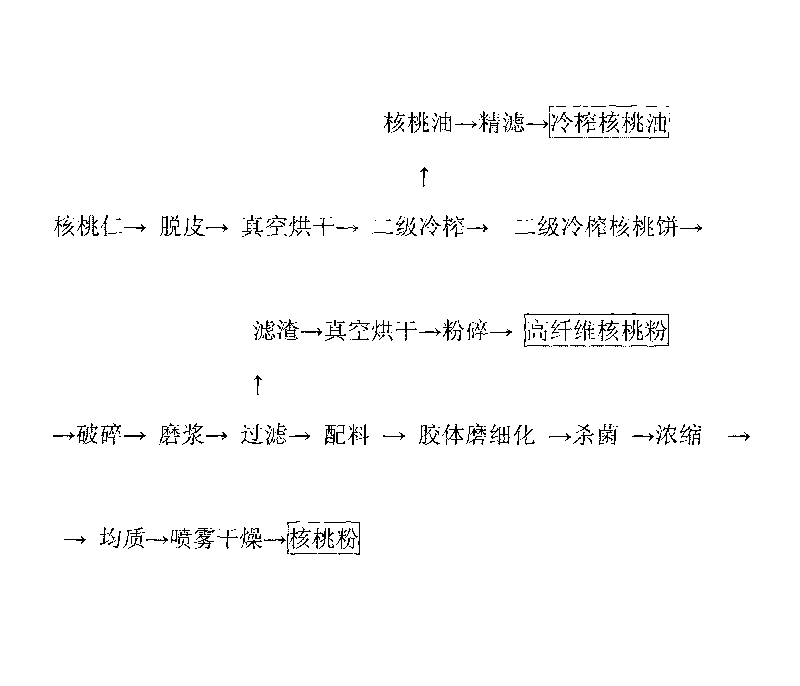

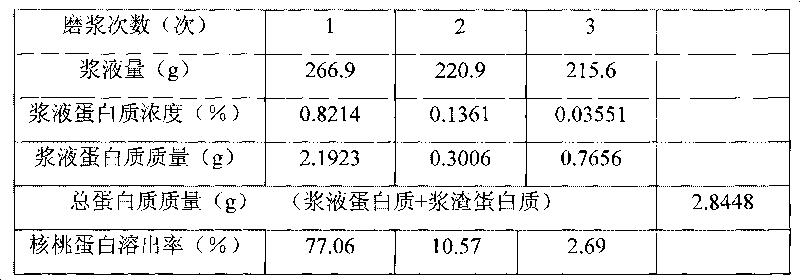

Walnut powder and production method thereof

InactiveCN101690596AReduce the degree of protein denaturationRealize comprehensive utilizationFood preparationSocial benefitsSolubility

The invention provides walnut powder and a production method thereof; walnut kernel is peeled by high pressure water spraying, bubble water stream impact and ultrasonic wave vibration after being soaked by compound alkaline liquid, and then second-grade cold pressing is carried out to the peeled walnut kernel after the peeled walnut kernel is dried and crushed, the walnut kernel is crushed, filtered, batched and colloid-milled to be refined, and then a complex stabilizer is added in the walnut kernel to be sterilized, concentrated, homogenized and dried to obtain the walnut powder. The method has low damage degree, can effectively prevent protein denaturation and reduce alkaline liquid amount; the second-grade cold pressing technology is adopted, the denaturation degree of the protein of the walnut cake is reduced, and the walnut powder is prepared by high-pressure homogeneity and spraying drying; the visual color and luster, solubility and the content of the protein and other indexes of the product are superior to the similar products in the current market. The invention realizes the comprehensive utilization of the walnut resource, the technology is advanced, simple and practical and is easy to popularize, thereby having good economic and social benefits.

Owner:石家庄市丸京干果有限公司

Chicken essence and preparation method thereof

ActiveCN103750254ALong storage timeGreat tasteFood homogenisationFood dryingMaillard reactionMonosodium glutamate

The invention relates to a preparation method of chicken essence. The method comprises the steps of weighing chicken breast and chicken skeleton, adding water, boiling at high temperature, and then, passing through a colloid mill, so as to obtain colloidal chicken juice; hydrolyzing the colloidal chicken juice, then, carrying out enzyme deactivation and filtrating, so as to obtain enzymolysis chicken juice; uniformly mixing the enzymolysis chicken juice, L-cysteine hydrochloride, ribose, L-proline, xylose, dextrose monohydrate, L-glycine, water and chicken oil, and then, adding the mixture into a reaction kettle for Maillard reaction, so as to obtain a chicken juice reactant; uniformly mixing the chicken juice reactant, salt, white granulated sugar, monosodium glutamate, modified starch, maltodextrin, cyclodextrin, water, I+G, chicken oil and chicken flavoring base, then, passing through a colloid mill, filtrating to obtain colloidal chicken cream, emulsifying the colloidal chicken cream, and then, carrying out spray drying on the emulsified colloidal chicken cream through a homogenizer, thereby obtaining the chicken essence. The invention further relates to a product of the preparation method of the chicken essence. Compared with the existing products, the chicken essence prepared by the method has the advantages that the chicken fragrance is unique, the flavor is harmonious, the taste of chicken is strong and full, and the fragrance and the flavor can be of long-term coexistence.

Owner:GUANGZHOU TIANHUI FOOD

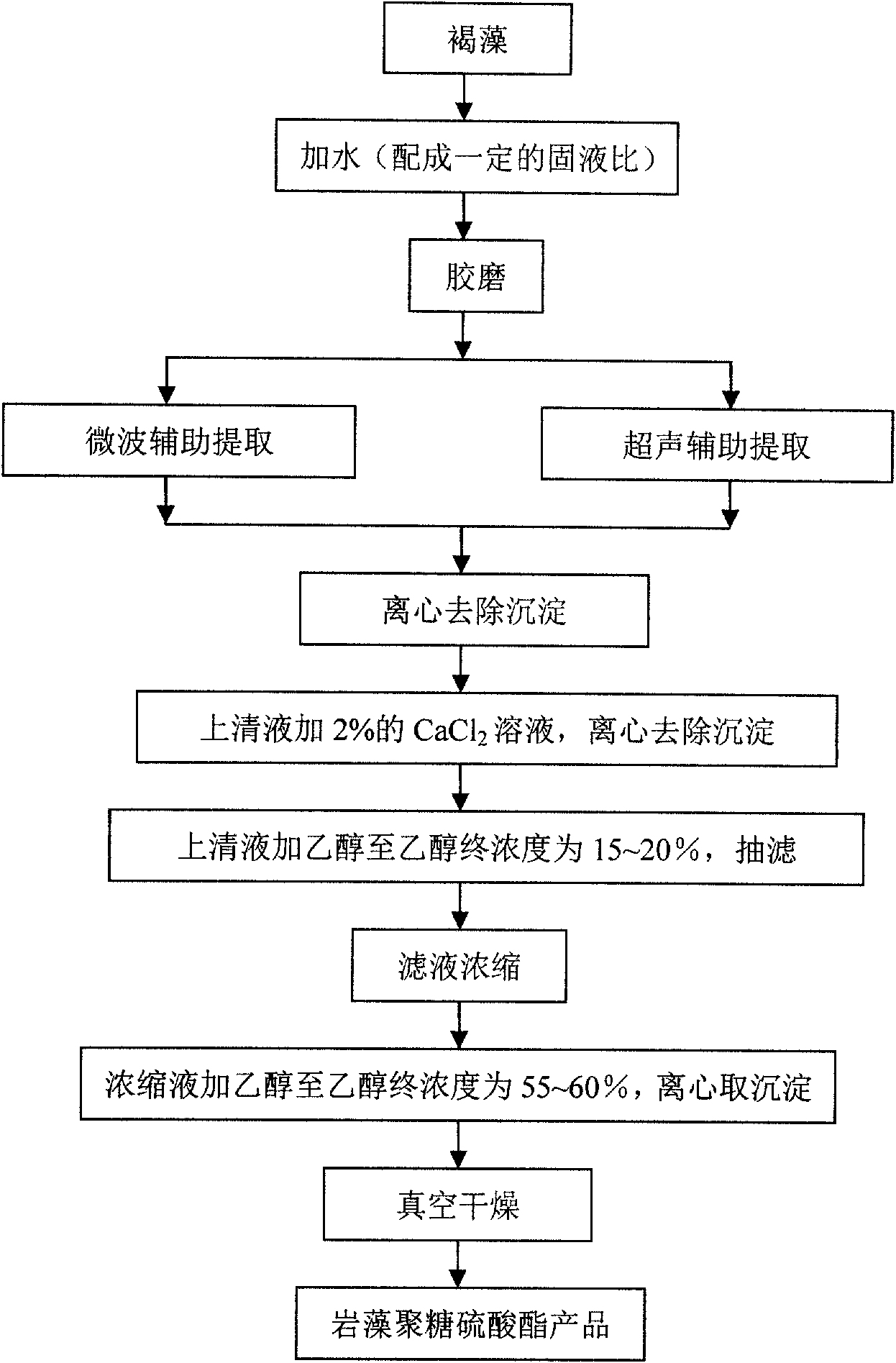

Method for preparing fucoidan

InactiveCN101993501AComprehensive utilization value has no impactComprehensive utilization value impactFood additiveLiquid ratio

The invention provides a method for preparing fucoidan, relating to the field of production and application of food additives. The method comprises the following steps of: adding distilled water according to a material to liquid ratio of 1:40-4:80 g / mL with brown algae, such as kelps, undaria pinnatifida, and the like as raw materials; treating by a colloid mill and then carrying out microwave-assisted extraction or ultrasonic wave-assisted extraction, wherein, in the microwave-assisted extraction process, the microwave time lasts 20-40min, the microwave extraction temperature is 60-80 DEG C, and the microwave power is 400-500W; and in the ultrasonic wave-assisted extraction process, the ultrasonic power is 800-100W, the microwave time lasts 20-40min, and the extraction temperature is 60-90 DEG C; and centrifuging an extracting solution, adding a proper amount of 2% CaCl2 solution into a supernatant, stirring, keeping constant temperature for 20-30h at 35-40 DEG C, centrifuging, adding 50-100% ethanol into the supernatant until the ethanol concentration of the solution is 15-20%, stirring, filtering, concentrating, adding 90-100% ethanol into a concentrated solution until the ethanol concentration of the solution is 55-60%, centrifuging again and drying a precipitate in vacuum to obtain white or yellow-white fucoidan powder.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

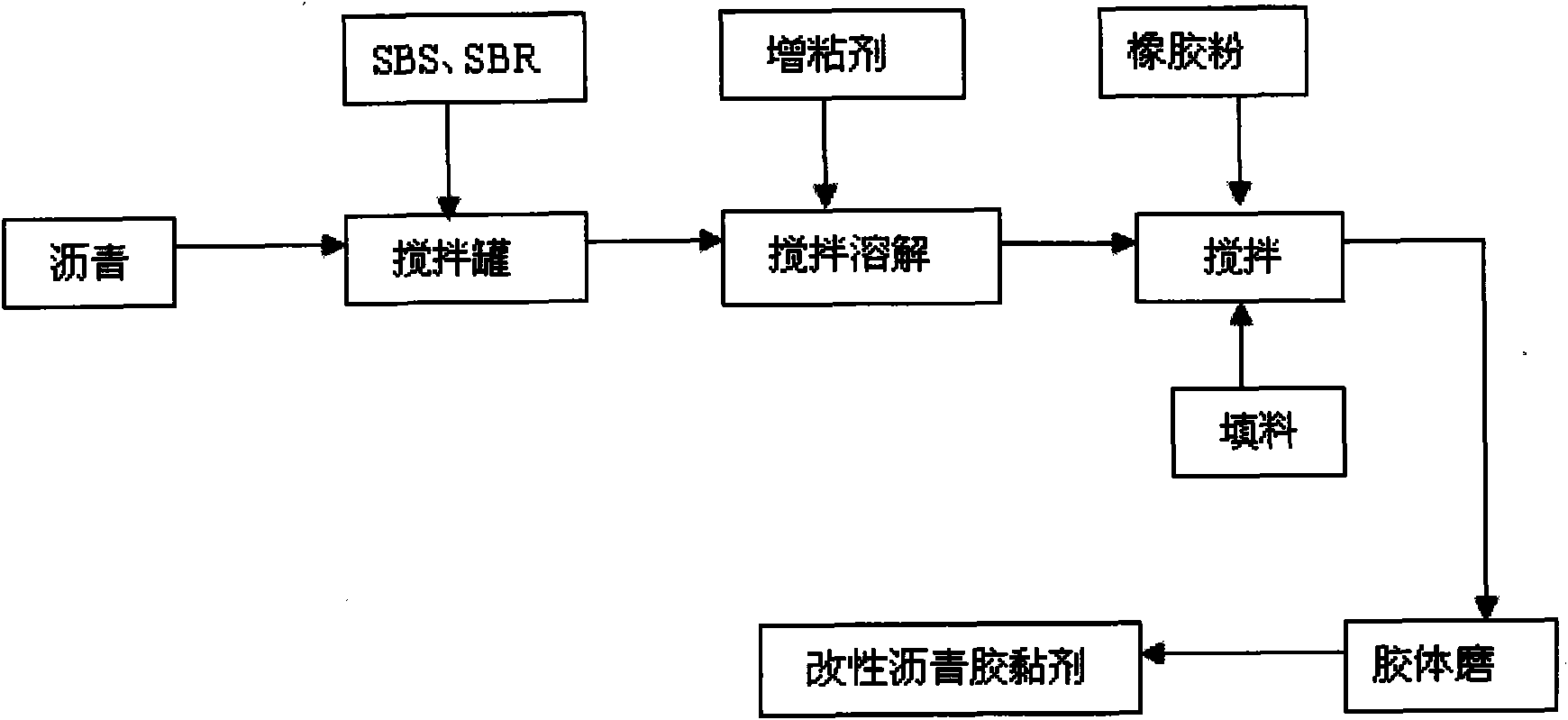

Modified asphalt adhesive and preparation method thereof

InactiveCN101982517AImprove adhesionImprove high temperature resistanceBituminous material adhesivesOther rubber adhesivesPolymer scienceAdhesive

The invention discloses a modified asphalt adhesive and a preparation method thereof. The preparation method comprises the following steps: pumping fused asphalt in a stirring kettle; starting a stirring paddle, wherein, the stirring speed is 60-200 revolutions / min, and the material temperature is 120-150 DEG C; stirring for 10-30min; adding styrene-butadiene block copolymer (SBS) and styrene butadiene rubber (SBR) and continuously stirring; heating to 160-180 DEG C; stirring for 1-2h; keeping the stirring temperature and the stirring speed; adding tackifier; continuously stirring for 30-60min; adding rubber powder and filler in sequence; continuously stirring for 30-60min; and grinding by a colloid mill to obtain the modified asphalt adhesive with good performance.

Owner:天津市耀新科技发展有限公司

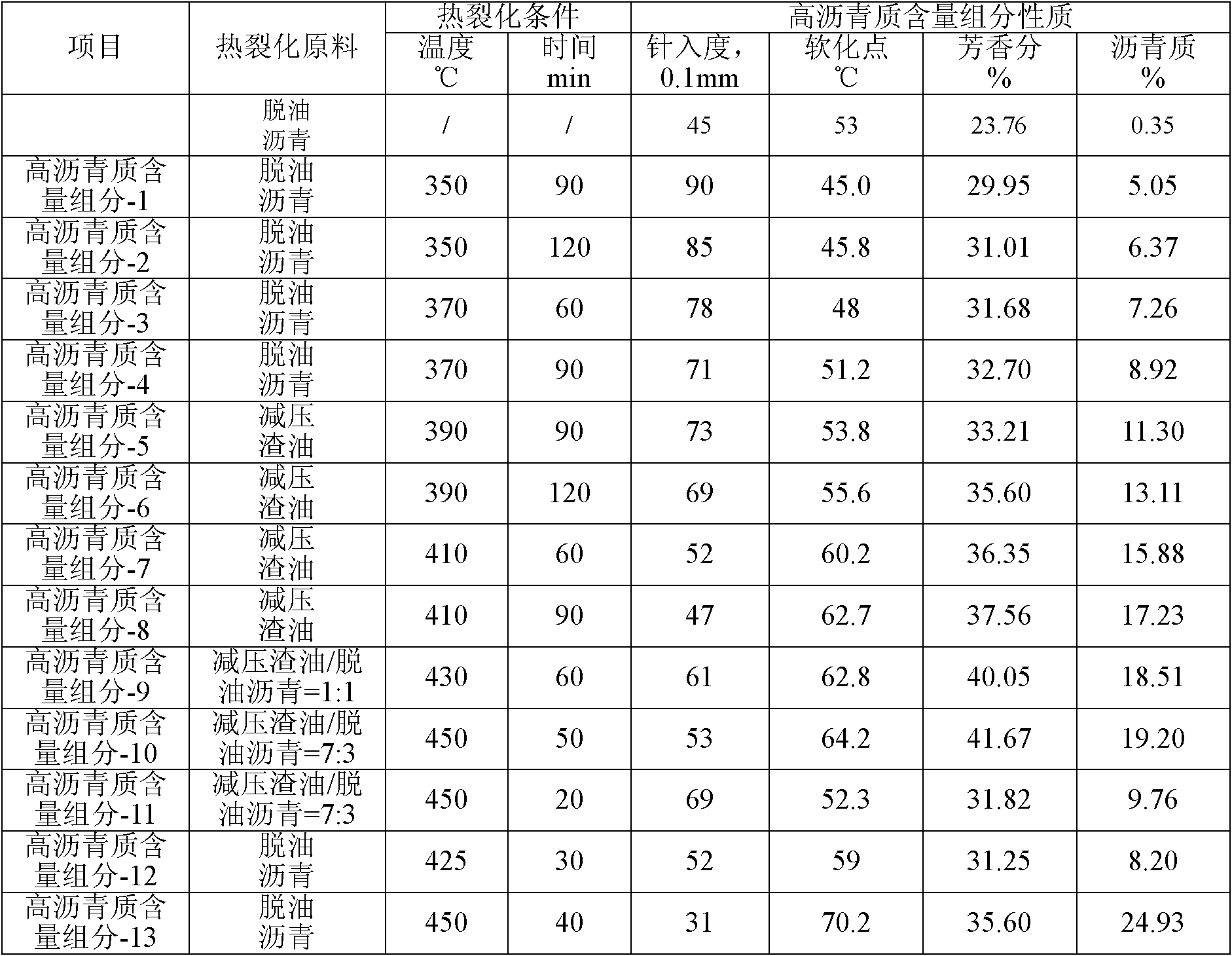

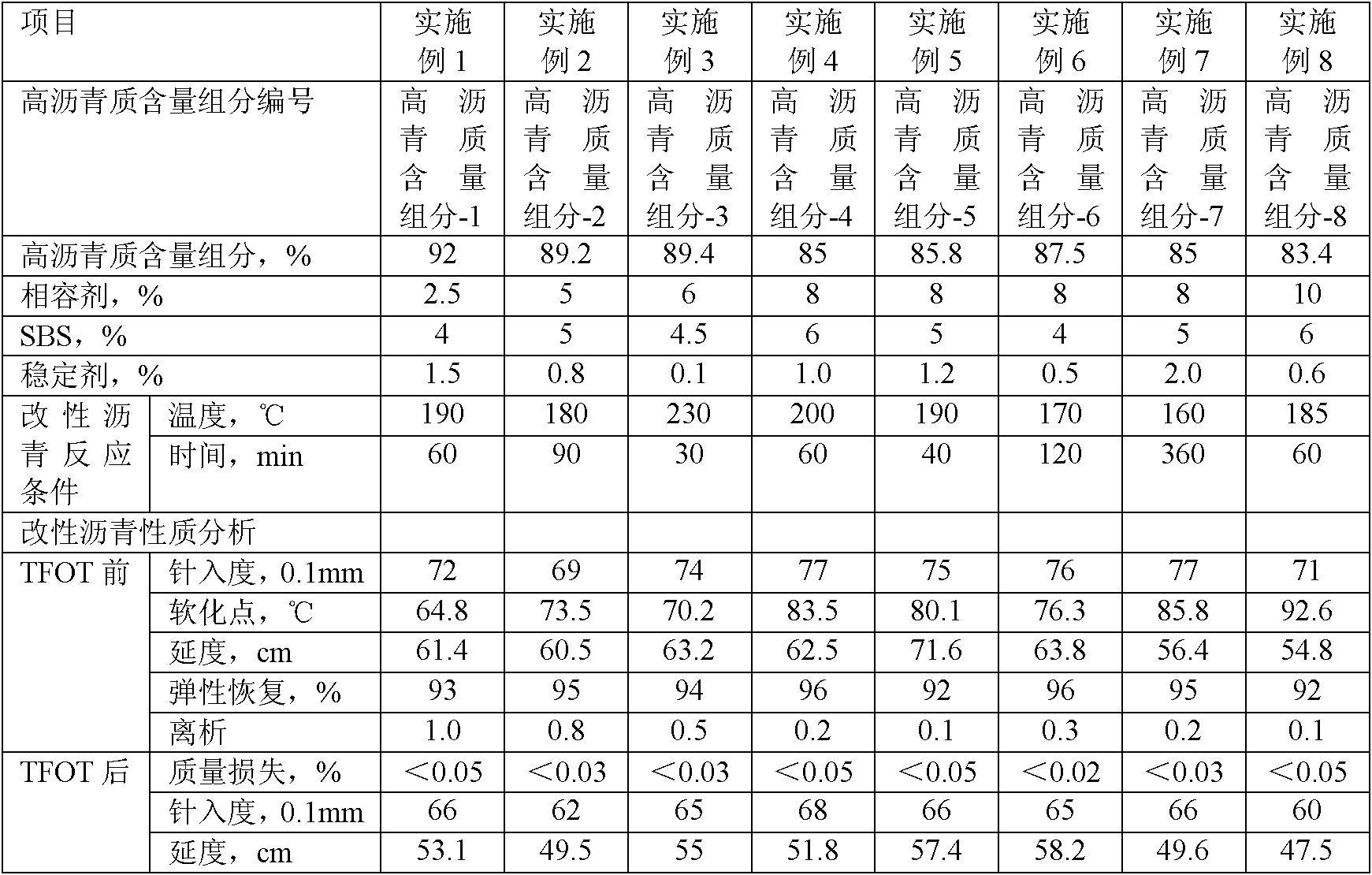

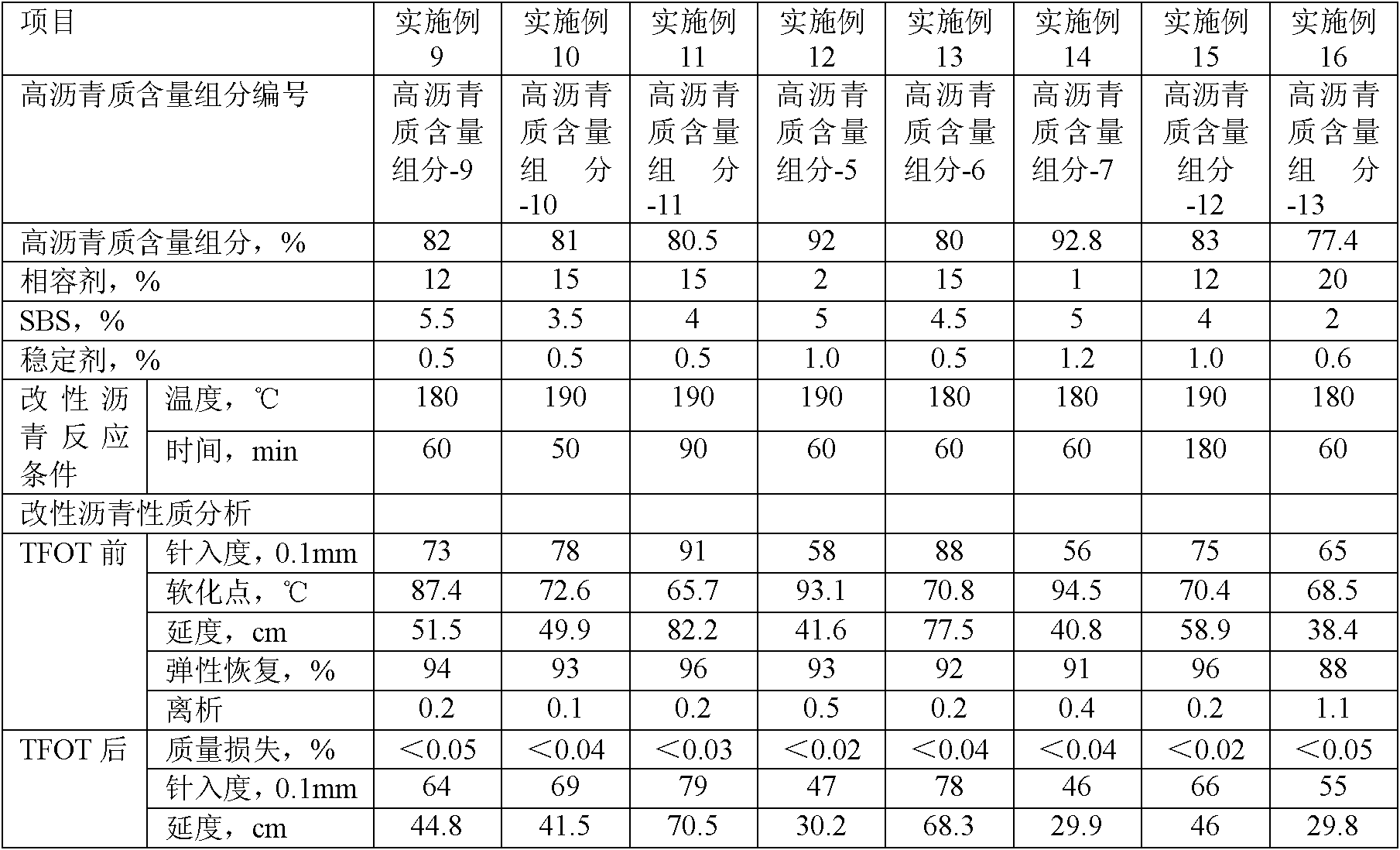

Method for preparing modified asphalt by adopting raw material with low asphaltene content

ActiveCN103044932AIncreased asphaltene contentGood compatibilityTreatment with plural serial stages onlyBuilding insulationsHigh temperature storagePolymer modified

The invention relates to a method for preparing modified asphalt by adopting a raw material with low asphaltene content. The method provided by the invention comprises the following steps of: carrying out thermal cracking reaction with reduced pressure residual oil, deoiled asphalt or mixture with the asphaltene content to be less than 5% at the temperature of 350-450 DEG C, then distilling and cutting to obtain tower bottom residue high-asphaltene-content component with the atmospheric boiling point of being higher than 350 DEG C; mixing the high-asphaltene-content component with a compatilizer at the temperature of 140-190 DEG C, adding a polymer modifier, shearing for 5-120 minutes at the temperature of 160-200 DEG C by adopting a high-speed shearing machine or a colloid mill, so as to disperse polymer into asphalt physically; and warming to a reaction temperature of 160-230 DEG C, adding stabilizer composition, stirring and reacting for 30-360 minutes, and carrying out chemical reaction on the polymer and the asphalt, so that the modified asphalt is obtained. The polymer modified asphalt obtained by the method provided by the invention has the advantages of high temperature storage stability, excellent high-and-low temperature performances and high ageing resistance, a technological process is simple, and production efficiency is high.

Owner:PETROCHINA CO LTD +1

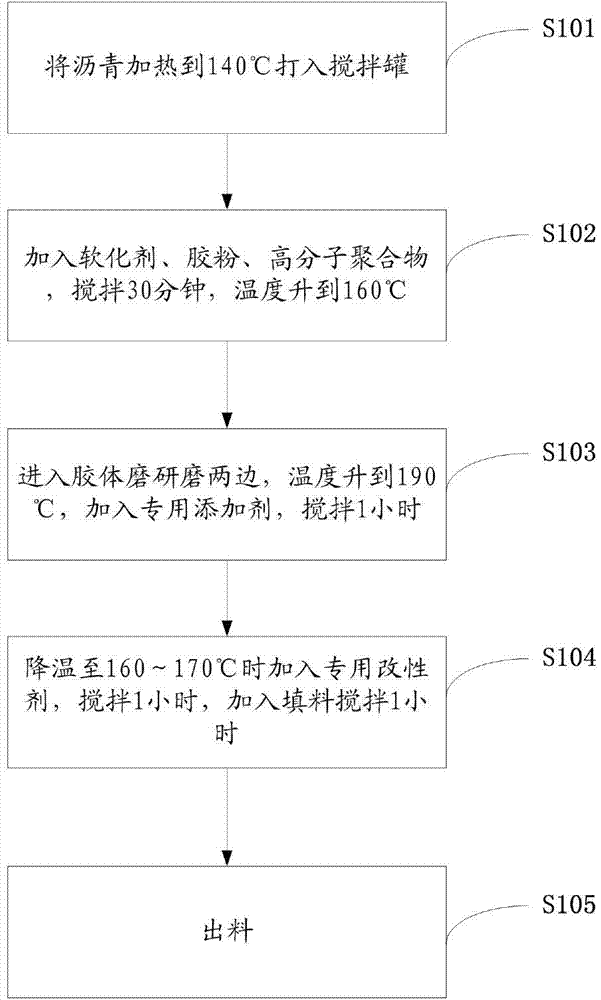

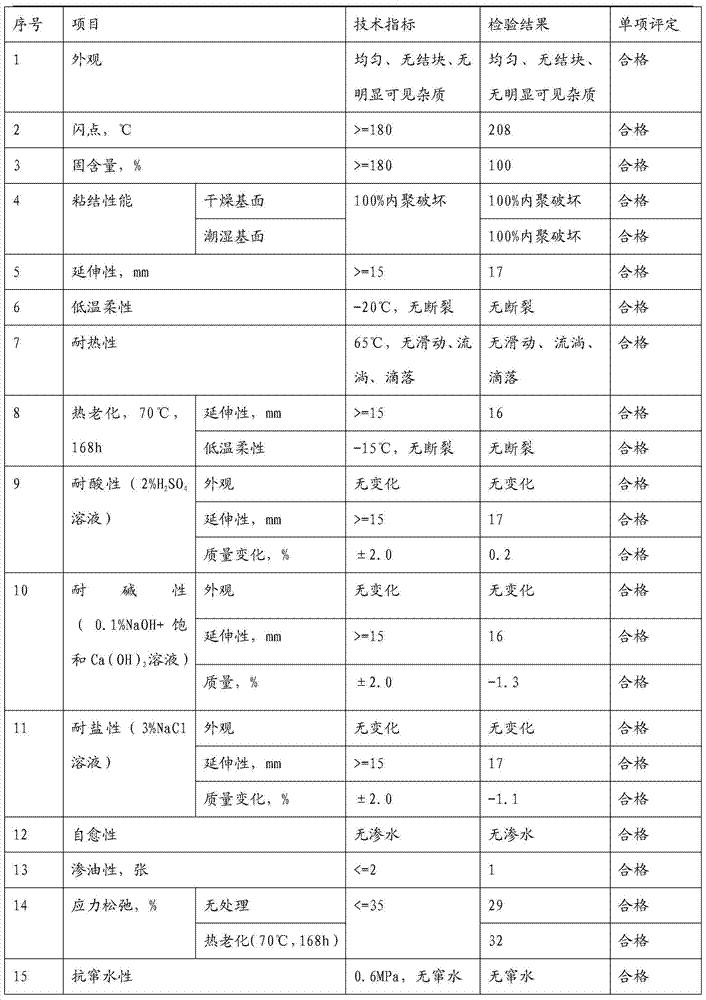

Non-cured rubber asphalt waterproof paint

InactiveCN104119799AWill not harmCompletely sealed and waterproofUnspecified rubber coatingsConjugated diene hydrocarbon coatingsBituminous waterproofingPolymer science

The invention discloses a non-cured rubber asphalt waterproof paint. The preparation technology of the paint comprises the following steps: heating the asphalt to 140 DEG C, loading the heated asphalt into a stirring tank, adding a softening agent, rubber powder, and polymer, stirring for 30 minutes, heating to 160 DEG C, delivering the mixture to a colloid mill to grind the two edges, heating to 190 DEG C, adding a special additive, stirring for one hour, cooling to 160 to 170 DEG C, adding an auxiliary agent, stirring for one hour, adding a filling material, stirring for one hour, and finally discharging. The paint solves the problems of waterproof layer fracture due to the cracking stress, which is transferred from the basic layer to the waterproof layer, and the accelerated aging due to the flexural fatigue and high stress state of the waterproof layer. Moreover, because of the cohesiveness of the paint, the capillary pores and cracks in the basic layer can be perfectly sealed by the paint, thus the problem of water leaking in the waterproof layer is solved, and the waterproof reliability is greatly improved.

Owner:徐立

Method for preparing solid refuse composite modified asphalt

InactiveCN101200597AMeet road requirementsSufficient sourceBuilding insulationsMetallurgyWaste rubber

The present invention belongs to the technical field of asphalt modification. The present invention relates to solid wastes comprising waste rubber, waste plastic and waste pyrolysis carbon black, the composing of which is 2 percent to 22 percent of waste rubber powder, 1 percent to 8 percent of the waste plastic, 0.5 percent to 6 percent of the waste pyrolysis carbon black, 1 percent to 6 percent of surfactant, 0.02 percent to 3 percent of crosslinking agent and 75 percent to 90 percent of asphalt. A preparation technology is finished by two steps that a first step is modifying the rubber powder, under the temperature condition of 70 DEG C to 100 DEG C, the rubber powder and the surfactant are mixed and stirred for 5 to 20 minutes at the speed of 20 to 100r / min and are mixed uniformly for using; the second step is to prepare modified asphalt, the asphalt is heated up to 120 DEG C to 160 DEG C, the waste plastic is added while being stirred at the speed of 200 to 1000r / min and then is stirred fast for 5 to 10 minutes at the speed of 600 to 3000r / min, the temperature is kept about 170 DEG C, modified rubber powder is added while being stirred, the crosslinking agent and the waste pyrolysis carbon black are added to be stirred fast for 10 to 20 minutes, and a system is processed for high-speed cutting or colloid mill grinding to prepare the modified asphalt.

Owner:NANKAI UNIV

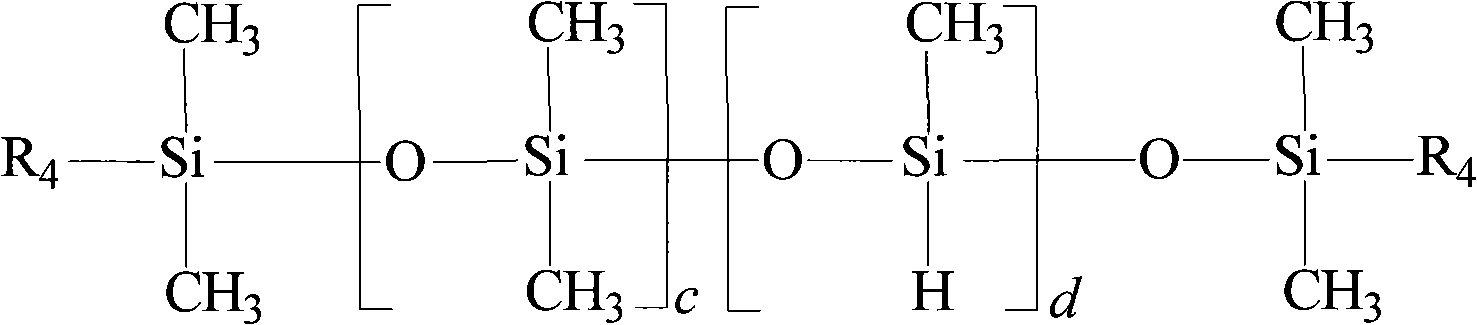

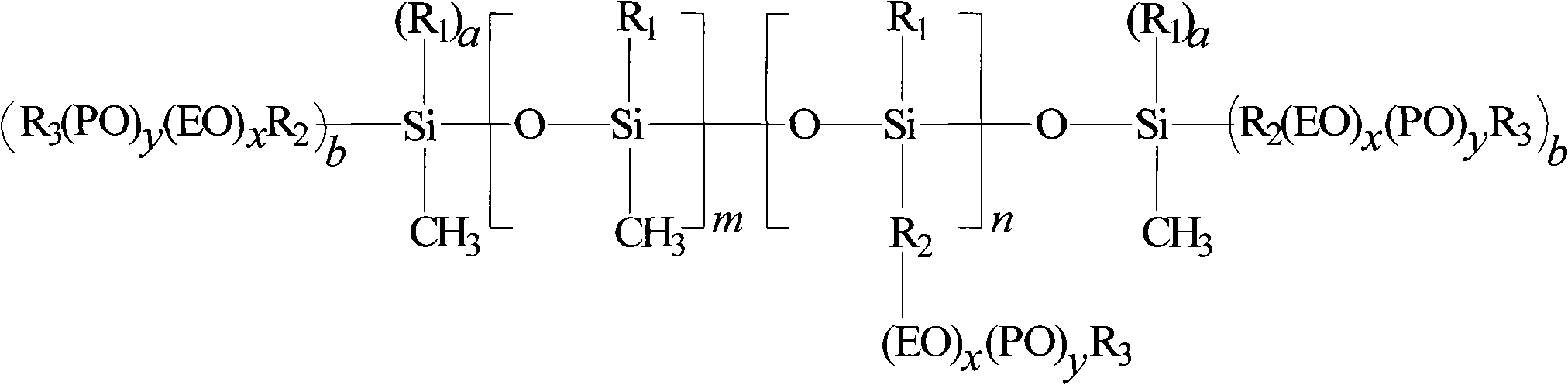

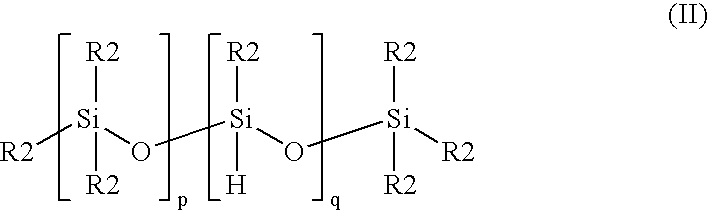

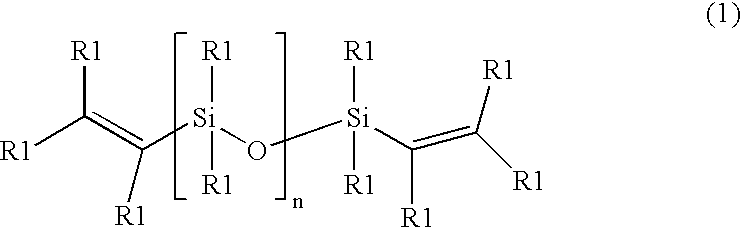

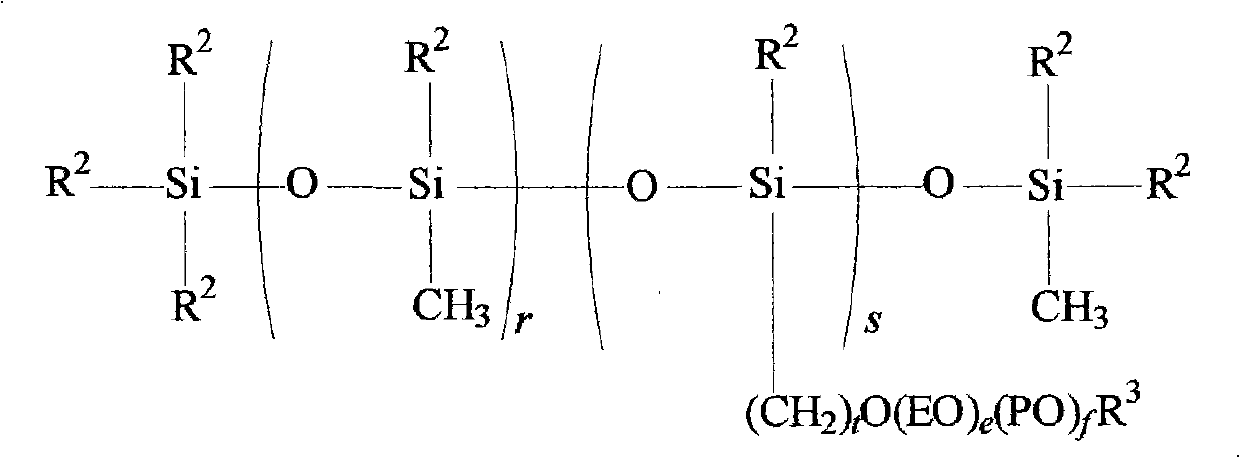

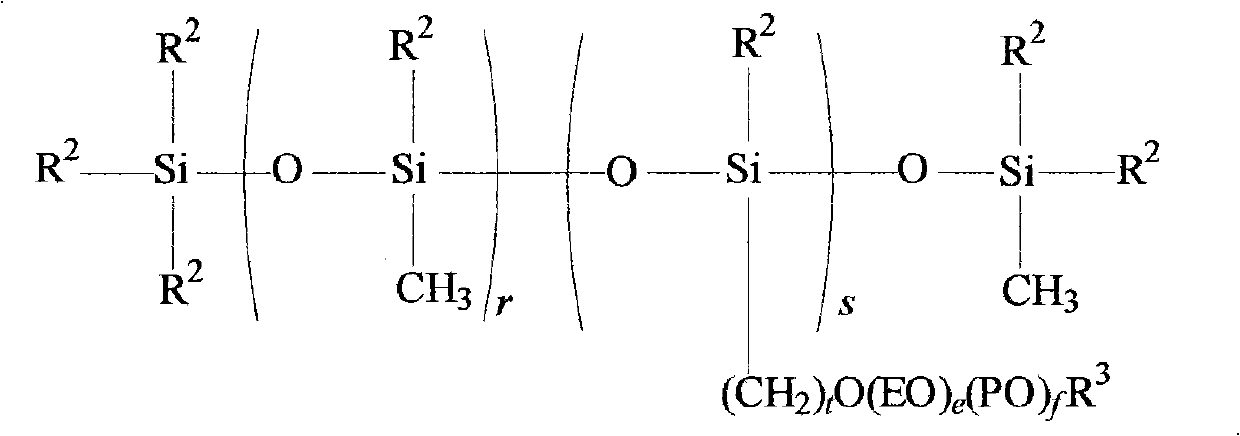

Cross-linked silicone gels; products containing the same; and methods of manufacture thereof

InactiveUS6936686B2High viscosityLittle elastomerCosmetic preparationsPowder deliveryCross-linkHydrosilylation

A polymerization product of an polyorganohydrosiloxane having a molecular weight of about 3500 to about 4000 and 6-7 Si—H bonds per molecule with a lower alkylene terminated polydimethylsiloxane having a molecular weight of about 20,000 to about 25,000 in the presence of a medium selected from low viscosity silicone oils, hydrocarbon oils typically with the aid of a hydrosilylation catalyst, where the amounts of the siloxanes are chosen such that the reaction product constitutes about 3% to about 15% of the cross-linked polymer and about 97 to about 85% of the reaction medium. The resultant gel is milled in a colloid mill, and if desired, diluted to a concentration of about 3% to about 8% with a diluent selected from the group consisting of low viscosity silicone oil, hydrocarbon oil, lower alkanol, or mixtures thereof. The so produced gel is useable as is or can be formulated into more complex cosmetic formulations having about 65% to about 99.9% of the gel, about 0.1% to about 30% of other non-diluent cosmetic materials (materials that are not low viscosity silicone oil, hydrocarbon oil, or lower alkanol), and up to about 5% lower alkanol.

Owner:ALZO INTTERNAT

Carbon nano-tube fiber cement-based material and preparation thereof

The invention relates to a cement-based material of carbon nano tube fiber and a preparation method thereof, in particular to a toughened cement-based material and a preparation method thereof. The invention solves the problems of relatively low anti-bending and anti-breaking intensity and toughness of the existing fiber toughened cement-based material. The material is produced by a fiber dispersant, an organic solvent, carbon fibers, carbon nano tubes, deionized water, a superplasticizer, a polymer emulsion, mineral admixture and cement. The preparation method of the invention is as follows: the fiber dispersant is added into mixed slurry of the cement and stirred; the primarily mixed slurry is fed into a high shearing colloid mill for shearing at high speed for 5 to 30min; the evenly stirred slurry is poured into a test mould which is moved to a vacuum drying case for pressure reducing and bubble-removing and heated for evaporation of the solvent for 0.5 to 3 hours; after 24 hours, and the material is obtained after tearing the mould and maintained in water at room temperature. The fracture energy GF and the fracture toughness of the material obtained by using the method of the invention respectively are 106.3N question mark m and 0.998Mpa / m<-1 / 2>, which are respectively 112.6 percent and 33.1 percent higher than the fracture energy and the fracture toughness of the existing fiber toughened cement-based material.

Owner:HARBIN INST OF TECH

Preparation method of environment-friendly multi-scale zirconium gel dispersion plugging agent

ActiveCN102936490AExpand the affected volumeEnhanced overall recoveryDrilling compositionMicron scaleMass ratio

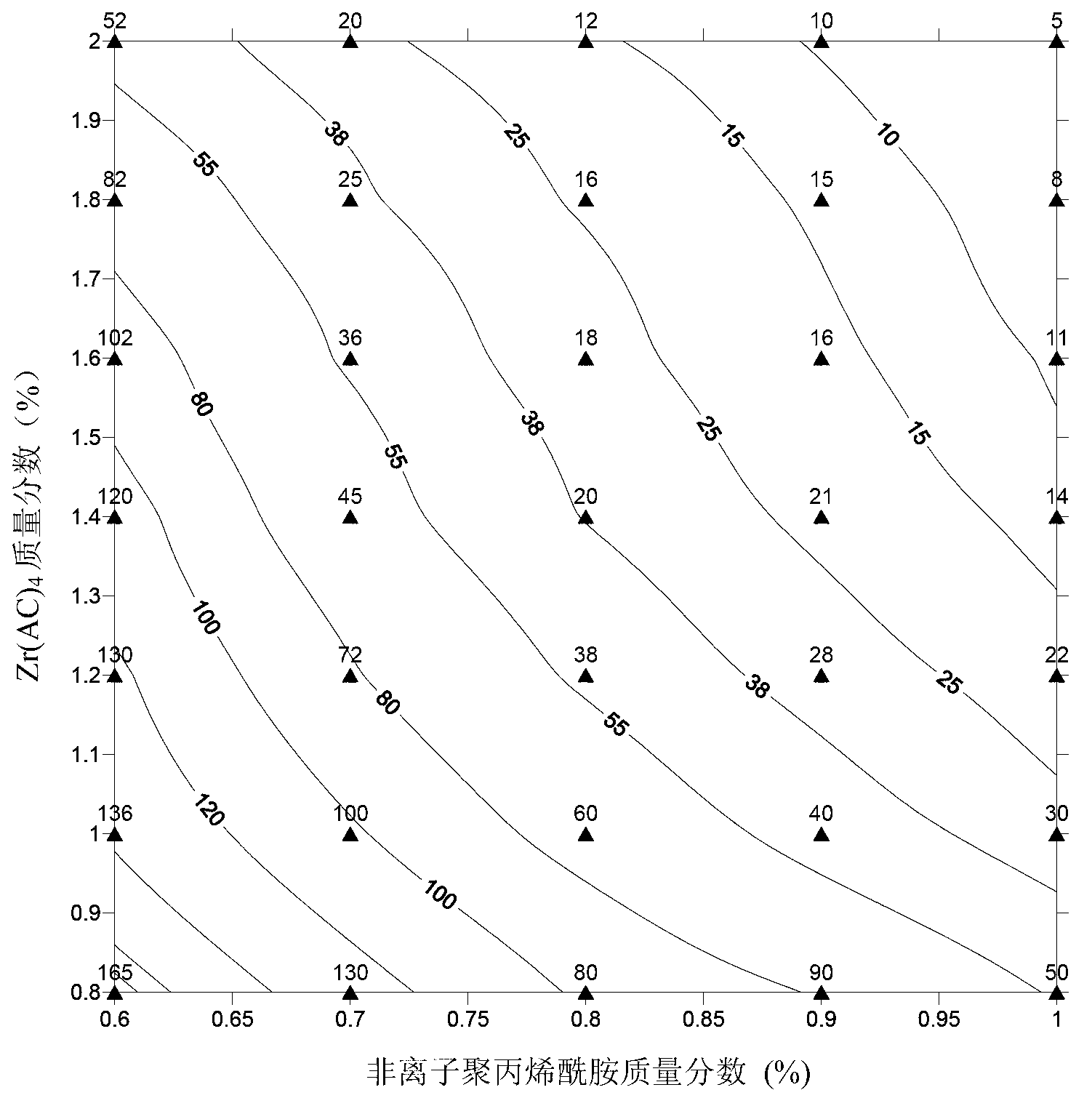

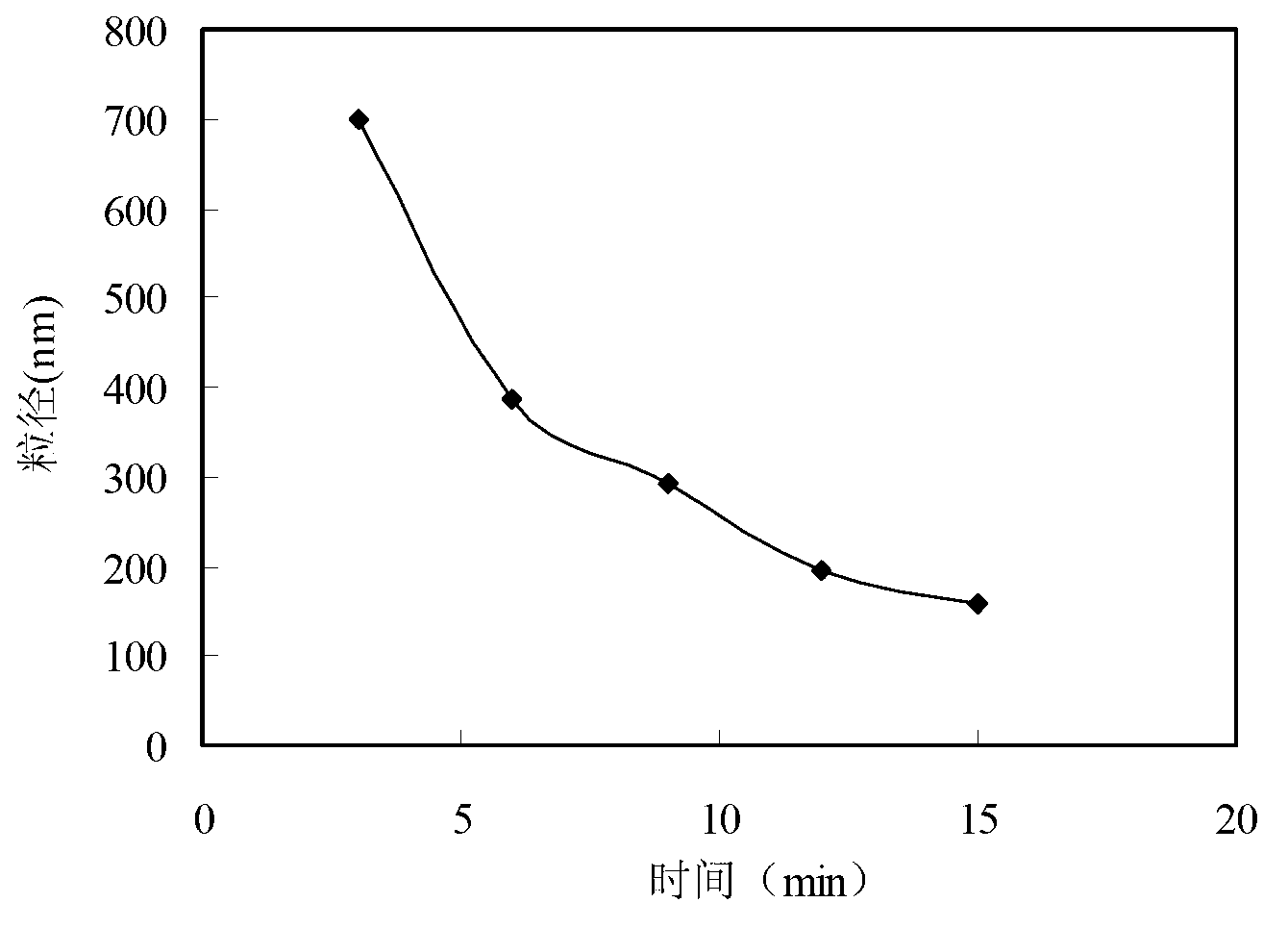

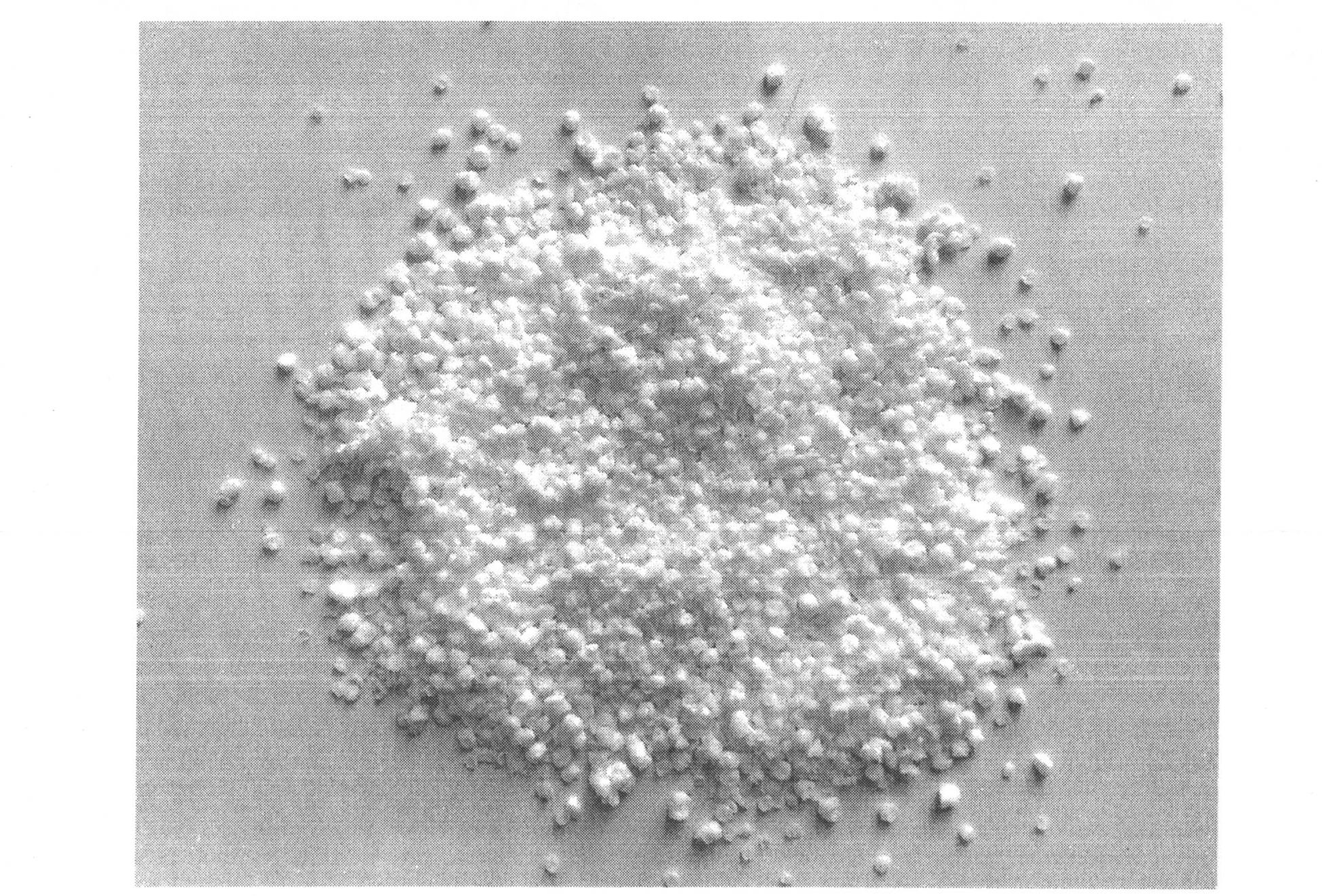

The invention relates to a preparation method of an environment-friendly multi-scale zirconium gel dispersion plugging agent. The method includes processing a formed gel system through a mechanical shearing method to enable the gel to form a nano-scale, micron-scale or millimeter-scale gel dispersion, wherein the mass fraction of nonionic polyacrylamide in gelling fluid is 0.6-1%, the mass fraction of a zirconium acetate cross-linking agent is 1-2%, and the gelling is performed at a temperature of 30 DEG C; and taking a colloid mill as a shearing device, adjusting the revolving speed and the shearing spacing of the colloid mill, adding the gel and water into the colloid mill according to a mass ratio of (1-6):1, performing circulating shearing until the gel is evenly dispersed to obtain a multi-scale zirconium gel dispersion solution. The plugging agent can enter the deep positions of stratums through the grain size, adjust water injection profiles effectively, and play a deep fluid diversion role, so that follow-up water is driven to low and medium permeable layers, the water swept volume is enlarged, and the oil recovery is further enhanced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Fogdrop-proof coating combination and preparation method thereof

ActiveCN101037559AGood dispersionImprove placement stabilityAntifouling/underwater paintsPaints with biocidesAdhesiveSmall particle

The invention relates to a anti-fogdrop painting composition, which includes four components of A, B, C and water, A is colloid aluminum oxide and content thereof is 0.9-3.6%, B is polyoxyethylene-containing non-ion surfactant and content thereof is 0.1-0.5%, C is water-soluble cellulose derivative adhesive and content thereof is 0.01-0.04%, and residual component is water. The composition possesses good dispersivity and placing stability, low viscosity, and small particle diameter; can reach to painting demand without grinding of colloid mill; and can endow thin film after coating to polyethylene thin film with good initial anti-fog property and long anti-drop validity period of at least three years. The invention also discloses preparation method for the anti-fogdrop painting composition, which is simple, low-cost and pollution-free to environment.

Owner:PETROCHINA CO LTD

Preparation method of star-shaped SBS (styrene butadiene styrene block polymer)-modified asphalt and production method of waterproof coiled material

ActiveCN102220023AGood high and low temperature resistanceImprove stabilityBuilding insulationsBasementAdhesive

The invention provides star-shaped SBS (styrene butadiene styrene block polymer)-modified asphalt, which is a composition composed of asphalt, swelling star-shaped SBS, filler and aids and solves the problem that star-shaped SBS used as an asphalt modifier is difficult to process. The production method of the star-shaped SBS-modified asphalt involves the following steps: adding star-shaped SBS swelled by a non-polar solvent to asphalt, modifying at the temperature of 180-210 DEG C for 50-150 minutes by a colloid mill or a powerful high-speed shearing stirrer, adding the filler and aids and uniformly stirring so as to form the uniform and stable modified asphalt. The modified asphalt can be made into a waterproof coiled material with excellent performance as well as a waterproof and leak-proof adhesive used for building roofs, basements, expressways, sealants, tunnels or water conservancy facilities. The modified asphalt has the characteristics of better compatibility with asphalt and better high-temperature and low-temperature resistance, compared with existing SBS modified asphalt.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

SBS (Styrene-Butadiene-Styrene) modified asphalt and production method thereof

The invention discloses SBS (Styrene-Butadiene-Styrene) modified asphalt and a production method thereof. The SBS modified asphalt mainly comprises the components of matrix asphalt No.70, linear SBS, a solubilizer and a stabilizer, wherein the linear SBS accounts for 3.6% to 4.2% be weight of the of matrix asphalt No.70, the solubilizer accounts for 2.0% to 3.0% by weight of the matrix asphalt No.70, and the stabilizer accounts for 0.16-0.18% be weight of the matrix asphalt No.70. The production method of the SBS modified asphalt comprises the following steps of: (1) heating the matrix asphalt No.70 to 175 DEG C to 185 DEG C; (2) adding the linear SBS and uniformly stirring; and (3) adding the solubilizer and the stabilizer and thoroughly grinding twice by using a colloid mill to obtain the SBS modified asphalt. The production method adopted in the invention effectively shortens the modified time and is low in production cost.

Owner:XUZHOU CITY LUXING HIGHWAY ENG

Cabbage-celery-kelp composite vegetable paper and preparation method thereof

A preparation method of cabbage-celery-kelp composite vegetable paper, which relates to the field of intensive processing of fruits and vegetables. The composite vegetable paper involved in the present invention contains cabbage pulp 45% to 55%, celery pulp 25% to 35%, and kelp pulp 20% to 30%. The mass percentage of various auxiliary materials and binders in the composite vegetable slurry is: soluble starch 5% to 8%, soy protein isolate 0.5% to 1.0%, glycerin 1.5% to 2.2%, carboxymethyl cellulose sodium 1.0% to 1.5%, sodium alginate 0.2% to 0.4%, gelatin 0.3% to 0.4%. The preparation method is to cut the cabbage, celery and kelp into pulp appropriately, grind them through a colloid mill, add auxiliary materials and binders, homogenize and smear them into shapes, bake and peel them off to make the cabbage-celery-kelp composite. Vegetable paper. The composite vegetable paper of the invention is emerald green, has a crisp texture and fragrant vegetable flavor, is rich in nutrients, is easy to carry, and can be used as a snack food.

Owner:SHANDONG UNIV OF TECH

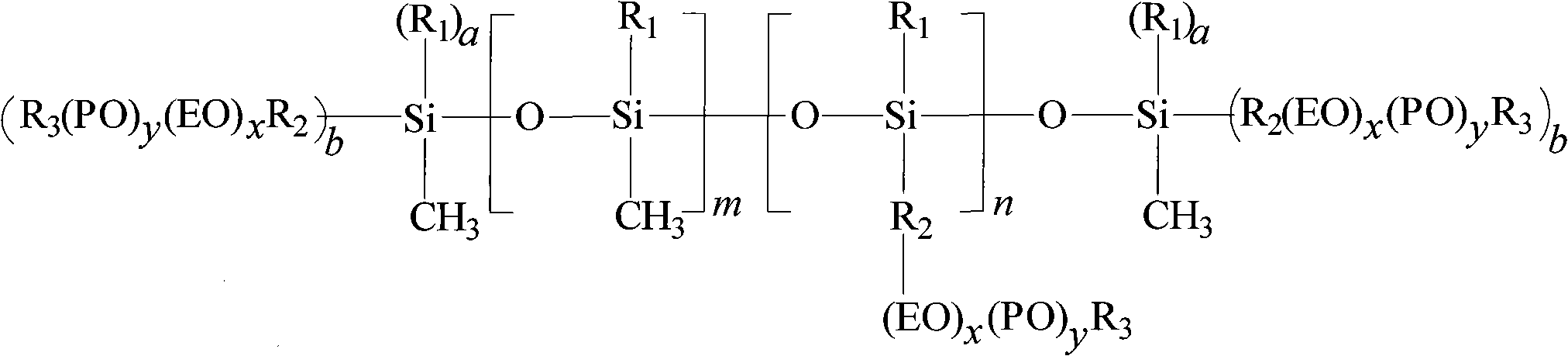

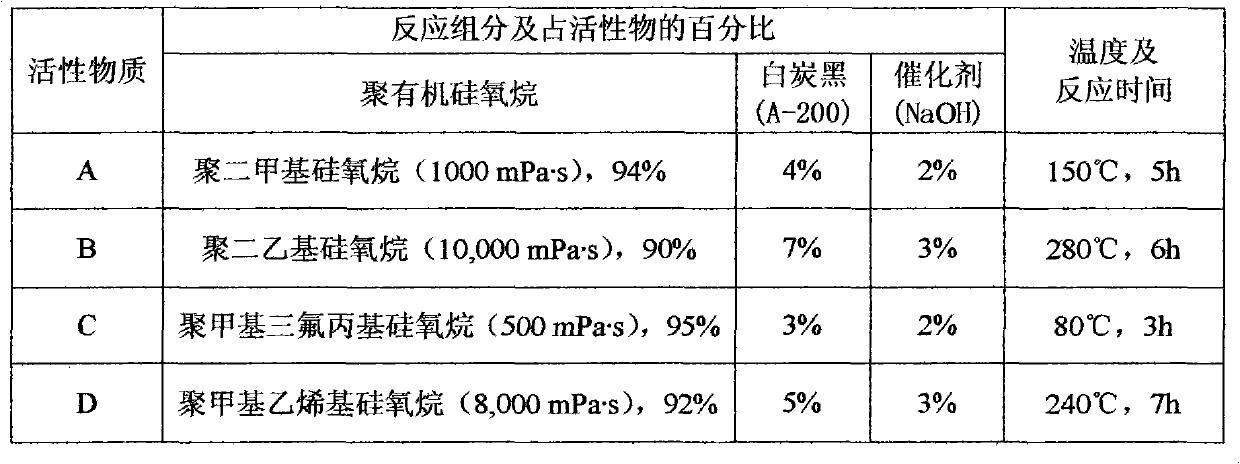

Method for improving stability of mineral oil defoaming agent

A method for improving the stability of a mineral oil defoaming agent, which belongs to the field of fine chemical preparations, is characterized in that the viscosity of the mineral oil defoaming agent system can be improved after strong shear action by adding hydrophilic inorganic particles into the system and uniformly dispersing the hydrophilic inorganic particles into the system, thereby improving the product stability. The defoaming agent comprises (1) mineral oil carrier 70% to 90%; (2) main defoaming substances 1% to 15%, containing hydrophobic white carbon black and ethylene bis stearamide (EBS); (3) defoaming aid 1% to 20%: RO(EO)x(PO)yH polyether; (4) nonionic surfactant 3% to 15%; and (5) hydrophilic inorganic particles 0.1% to 5%, containing hydrophilic white carbon black, aluminum oxide, zinc oxide and magnesium oxide. The operation comprises following steps: (A) adding the mineral oil into a flask, adding the main defoaming substance and the defoaming aid therein, stirring, heating to 80 to 150 DEG C, and keeping the temperature for 0.5 to 3 h; (B) lowering the temperature to 50 to 80 DEG C, adding an emulsifying agent, uniformly stirring, lowering the temperature of the mixture system below 40 DEG C and adding the hydrophilic inorganic particles; (C) passing through a colloid mill; and (D) vacuum degassing to obtain a mixture with good stability, i.e. the mineral oil defoaming agent.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

Method for manufacturing five-bean dried tofu

InactiveCN102239928ASolve a single problemSolve modeling difficultiesCheese manufactureFood scienceDry beanColloid

The invention discloses a method for manufacturing five-bean dried tofu, and the method comprises the following steps: 1. taking good-quality dry beans, dipping for 12-15 hours after cleaning, decontaminating, jordaning and filtering; 2. taking dry mixed beans, dipping, preliminarily grinding, jordaning again in a vertical colloid mill and filtering; and 3. mixing filtrates obtained in the step 1 and the step 2, carrying out once marinating, twice stewing in soy sauce, twice pressing and the like. According to the method, the problem of single raw material can be solved, and various types of beans are collocated to form a product trophic structure system with relative balanced nutrition by use of health promotion principle. The secondary shaping technology of the dried tofu is improved, so that the product has the advantages of better texture toughness and firmer pattern structure, and the problem that the bean product is difficult to shape can be solved. The five-bean dried tofu is packaged into a strip shape by use of a full-automatic stretch film packaging machine to achieve the purposes of improving the appearance shape and improving the efficiency by 10 times.

Owner:XIHUA UNIV +1

Organosilicon emulsion and preparation method thereof

The invention discloses an organosilicon emulsion which comprises active substances, high-grade fatty alcohol polyether, an emulsifying agent, polyether modified polysiloxane and water, wherein the active substrates are obtained from polysiloxane and lyophobic particles under the action of a catalyst. A preparation method of the organosilicon emulsion comprises the steps of: A, fully mixing the active substances, the high-grade fatty alcohol polyether, the emulsifying agent and the polyether modified polysiloxane for 10-50min through stirring; B, raising the temperature of the system in the step A to 55-85 DEG C; C, keeping the temperature of the system, slowly adding the water, increasing the stirring speed to ensure that a water-in-oil emulsion is changed into an oil-in-water emulsion, and continuously adding the water until the mass concentration is 40-70 percent; and D, further emulsifying crude emulsion through a colloid mill, and finally, diluting without thickening water until the needed emulsion concentration is reached. The organosilicon emulsion prepared by the method has stable property, and can be widely applied to the industries of papermaking, spinning and weaving, coating, leather, medicine, cosmetics and the like.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

Edible food package film and method for preparing same

InactiveCN1827672AImprove mechanical propertiesExcellent gas barrierFlexible coversWrappersPolymer sciencePullulan

The invention provides an edible packaging film for foodstuff and its process for preparing. The components and percentages by weight of this edible packaging film for foodstuff are as below: 20-50% of pullulan; 20-50 % of gelatin; 1-17 % of auxiliary membraneagne; 0.05-2 % of emulsifier; 0-1 % of pigment; and 0.1-10 % of water. The process for preparing the packaging film includes the following steps: preparing the raw materials for intimate mixing materials, then making the obtained materials pass the colloid mill, homogenize and degass, molding by disgorging and strickling through the film forming machine, then drying them to form the film. The edible packaging film provided by this invention has super mechanical property, gas resistivity, scent retention, water resistivity, oil resistivity and tasty retention, is capable of printing and heat-sealing, and is suitable for automatic operation of appliances of packaging film for foodstuff; and the said packaging film is edible and its wastes can be degraded without pollution to the environment. The preparation technology provided by this invention is of simple process and low factory cost, and there is no discharge of harmful substances in the industrial process, so it is of high safety.

Owner:林玉惠

Method for comprehensively extracting tea seed saponin, tea seed polypeptide and tea seed polysaccharide from tea seed cake

InactiveCN104177508AAchieve preparationIncrease added valueSugar derivativesPeptide preparation methodsWater bathsFiltration

The invention discloses a method for comprehensively extracting tea seed saponin, tea seed polypeptide and tea seed polysaccharide by using tea seed cake as a raw material. The extracting method comprises the steps of mixing degreased tea seed cake with ethanol, treating with a colloid mill and a homogenizer, then performing water bath ethanol extraction, centrifuging, performing ultra-filtration, and concentrating to obtain the tea seed saponin; mixing the centrifuged sediment with water, extracting with ultrasonic and microwave, centrifuging, regulating the pH of the supernate, centrifuging for the second time, dissolving the sediment, and performing enzymolysis, enzyme deactivation, ultra-filtration and spraying to obtain the tea seed polypeptide; and spraying the supernate obtained by secondary centrifuging to obtain coarse tea seed polysaccharide, and then performing ultra-filtration and ethanol precipitation to obtain the high-purity tea seed polysaccharide. The method is simple, low in production and equipment cost, high in product extraction rate and high in purity, and greatly improves the additional value of the tea seed cake. A new thought and a new method are provided for efficient comprehensive utilization of the tea seed cake.

Owner:NANCHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com