Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1960results about "Bituminous coatings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nontoxic antifouling paint for oceanographic ship and facilities and method for preparing paint

ActiveCN101967316AInhibit Adhesive CorrosionTo achieve non-toxicRubber derivative coatingsAntifouling/underwater paintsNon toxicityBiofouling

The invention discloses a nontoxic antifouling paint for an oceanographic ship and facilities and a method for preparing the paint. The paint consists of the following components in percentage by weight: 15 to 55 percent of base material, 0.01 to 10 percent of antifouling agent, 10 to 30 percent of filler, 0.3 to 25 percent of pigment, 2 to 8 percent of auxiliary agent and 3 to 55 percent of solvent, wherein the antifouling agent is silver grains with average grain diameter of between 1 and 200nm. The paint does not contain toxic agents, such as dichloro-diphenyl-trichloroethane, organic tin,cuprous oxide and the like, at all while effectively suppressing corrosion of marine biological attachments, meets the related regulations of international maritime organization and future development trend of the antifouling paint, realizes non-toxicity and environmental friendliness of the marine antifouling technology, and can be widely applied to the facilities and the fields, such as ships, floating piers, marine oil platforms, submarine cables, cooling pipes of power plant near the sea, sea water culture net cage and the like.

Owner:CHINA LUCKY FILM CORP +1

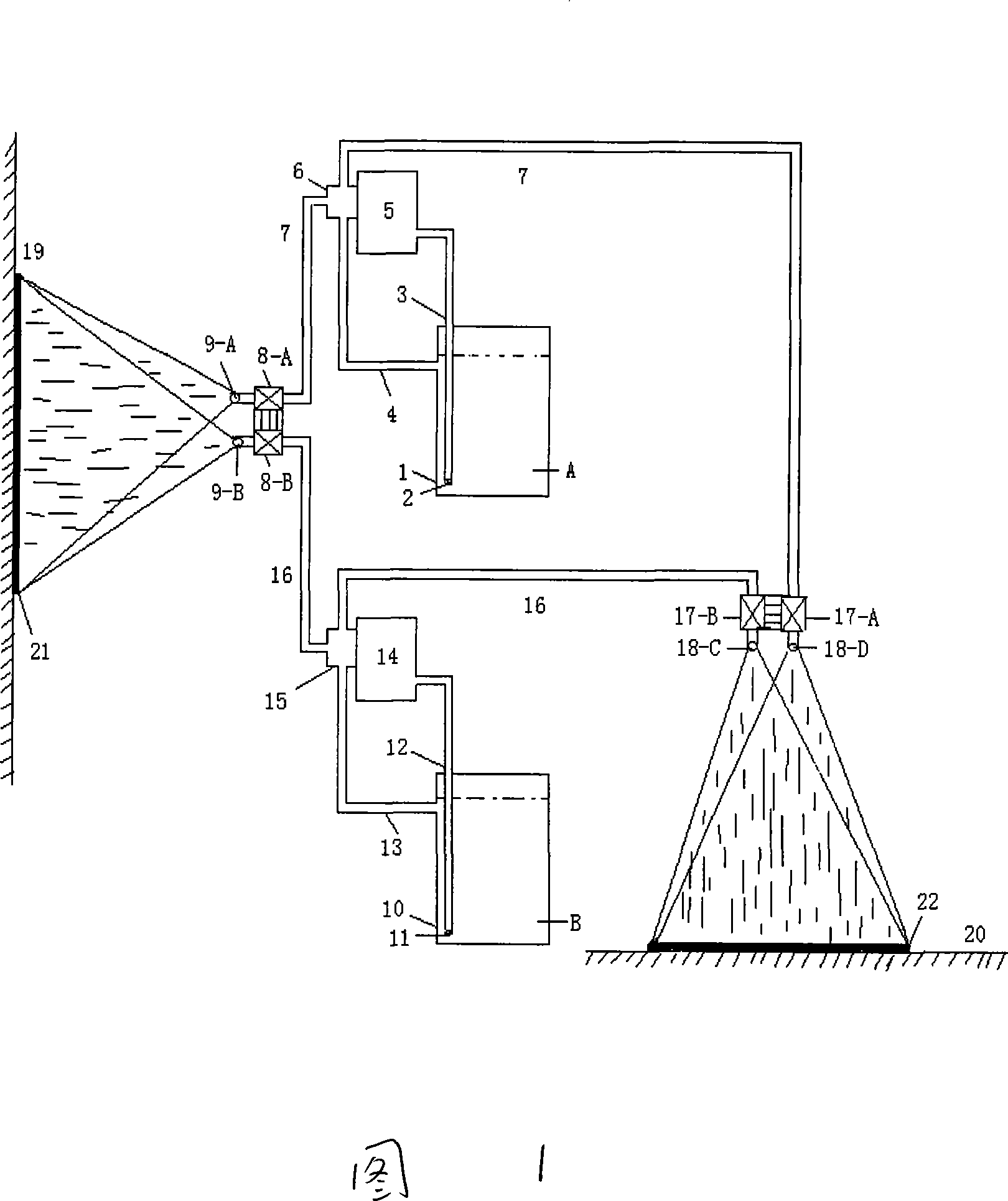

Multifunctional liquid rubber spray-coating material, preparation method, using method and special-purpose device

InactiveCN101235252AGood extensibilityImprove performanceSpraying apparatusConjugated diene hydrocarbon coatingsPolymer scienceSpray coating

Multifunctional liquid rubber spray coating comprises components of A, B, wherein A component comprises liquid rubber asphalt emulsion whose solid content is 50-75%, wherein 2-65% rubber elusion content, 30-97% asphalt elusion content, 0.0-5.0% carbon black, 0.0-6.0% ultra-fine powder, 0.025-2.50% anion dispersing agent and 0.025-3.00% anion surface activator, which is waterborne spray coating, and B component is water solution which comprises 3.0-18.0% concentration calcii chloridum (89.0-99.2%), sodium chloride (0.50-4.0%) and composite aluminum iron polymer (0.3-7.0%). The two components are sprayed on the same basal plane through adopting a double-component airless spraying device to form a gelatin film with 0.5-4mm after 3-5 seconds solidification, which has the characteristics of strong bonding, temperature resistance, weather resistance, and excellent chemical stability, heat insulation and puncture resistance. The A component can be individually sprayed, or can be combined with the double components.

Owner:大连美宸特环保节能产品有限公司

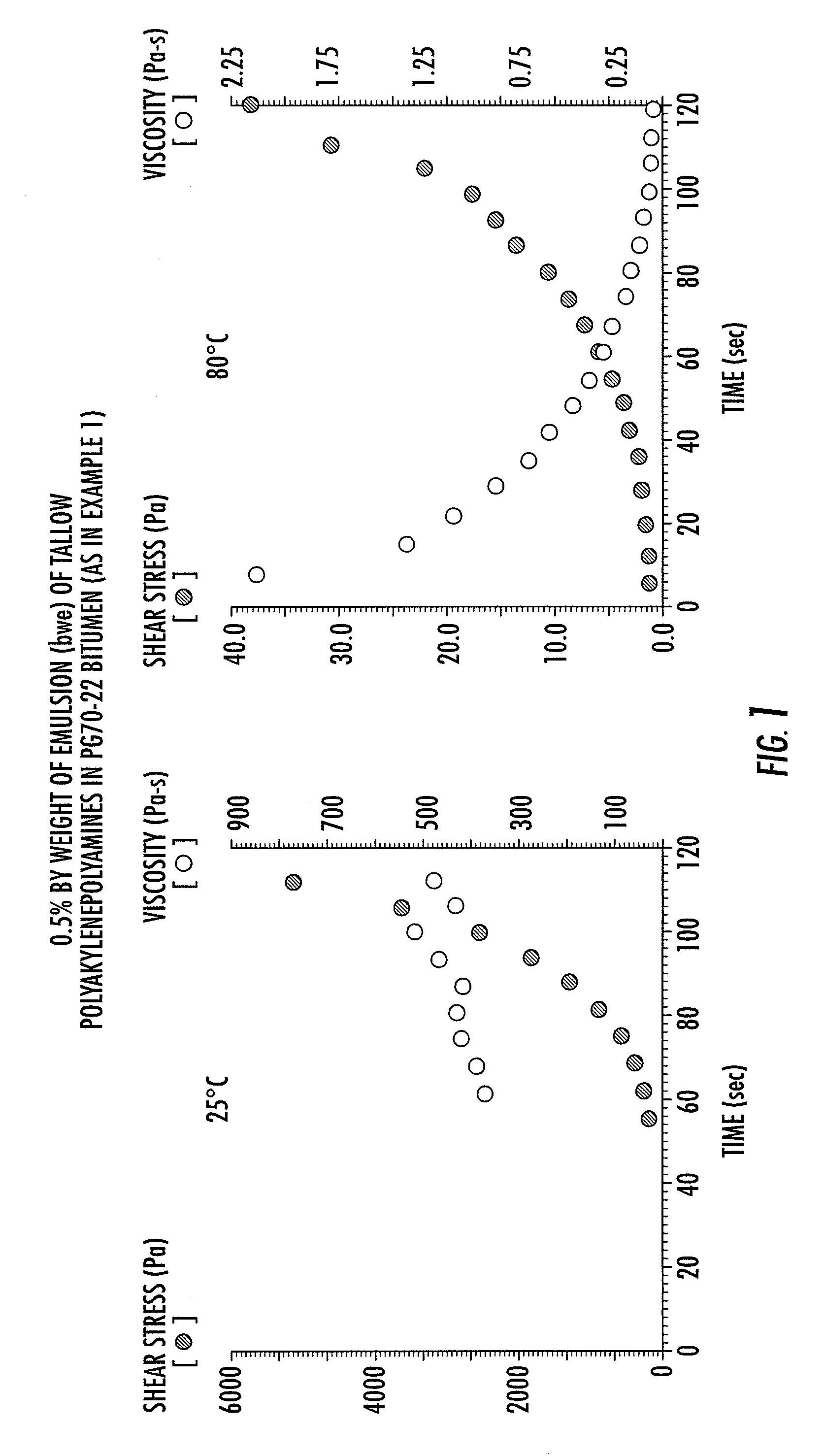

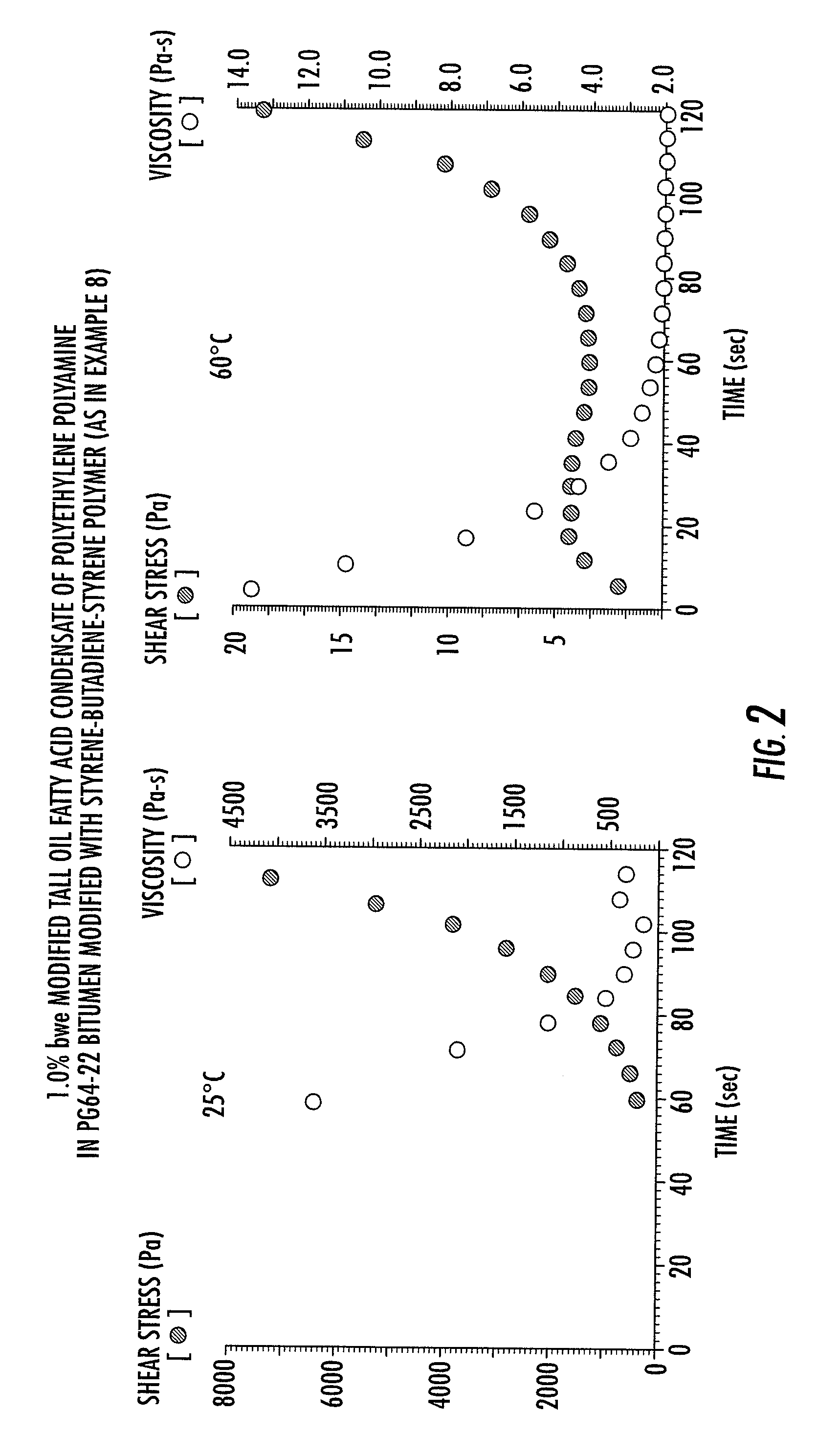

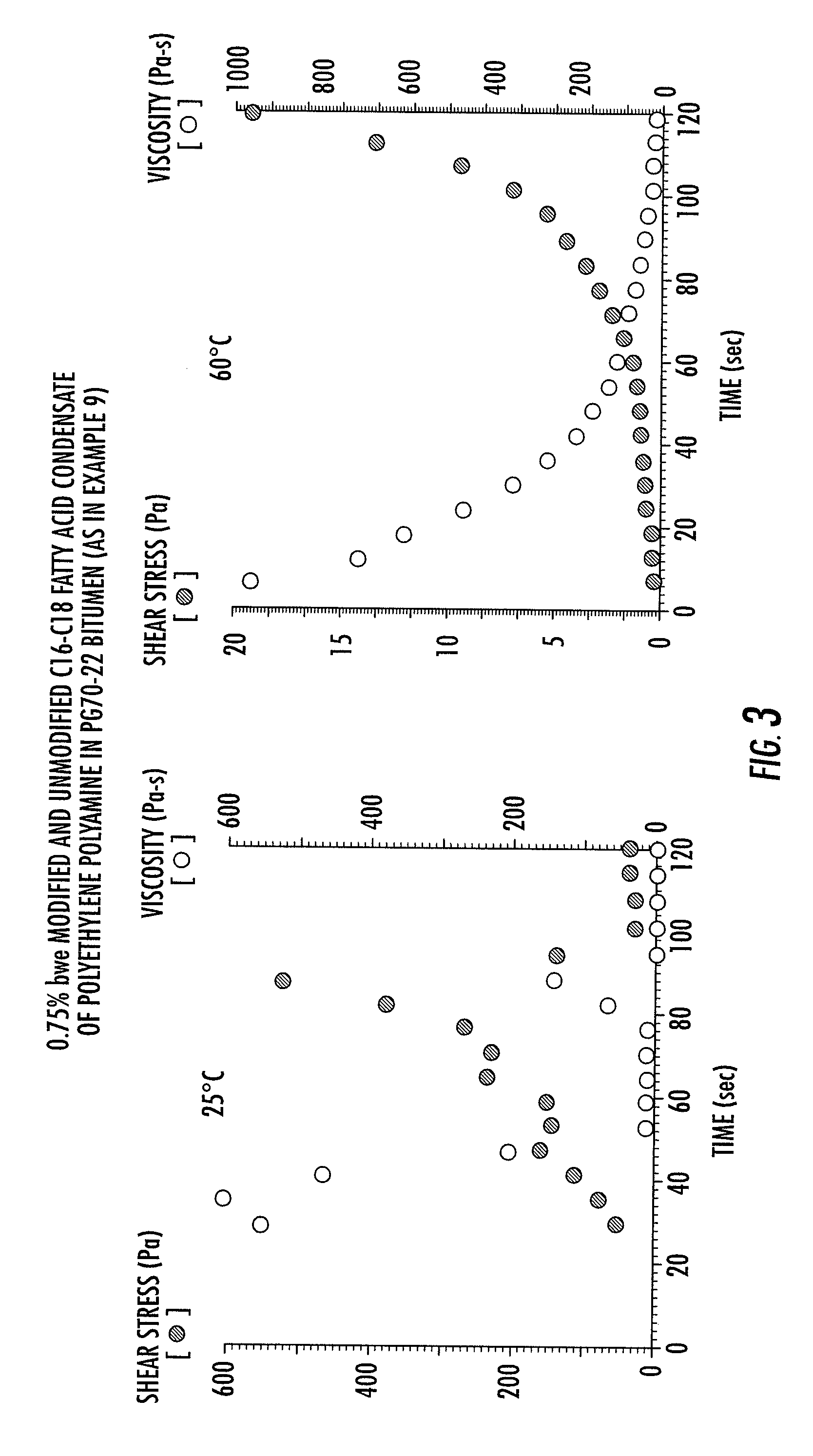

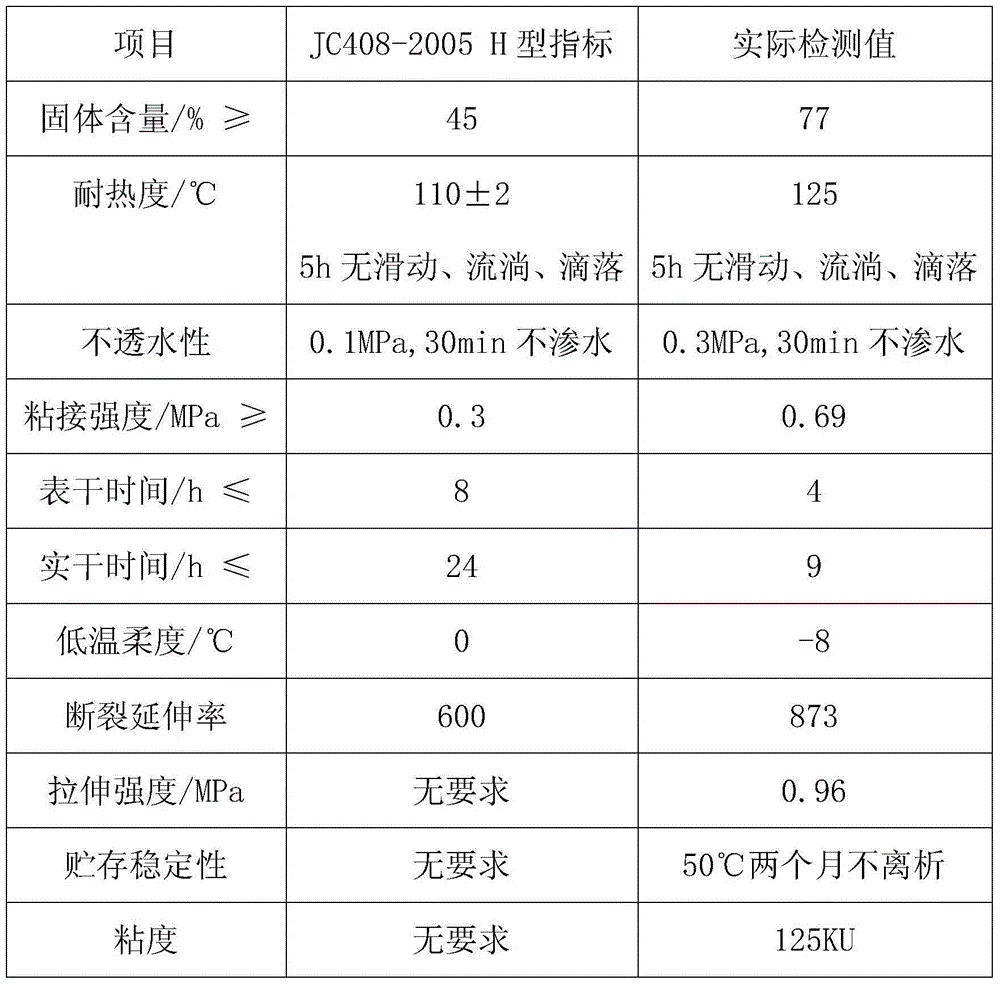

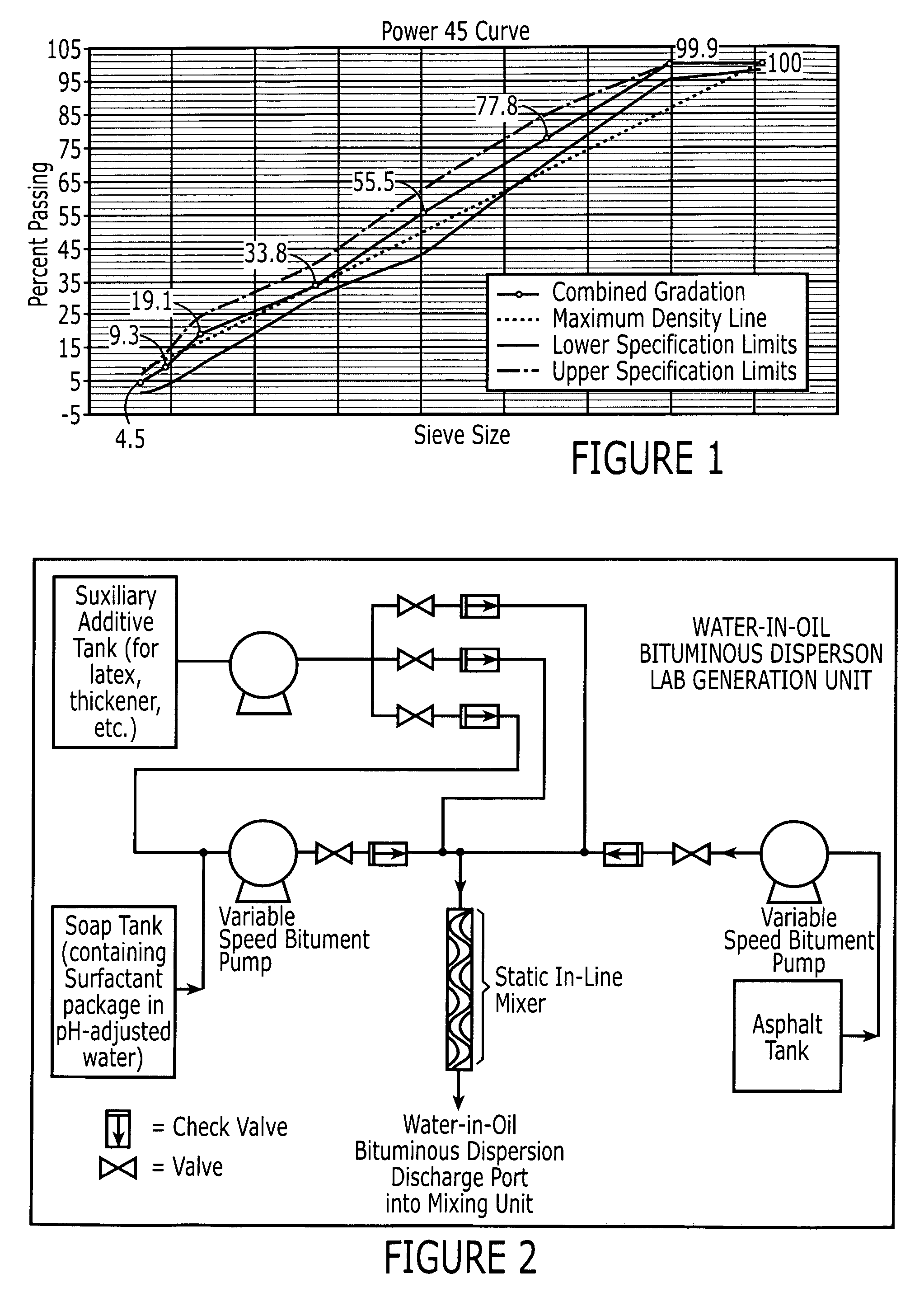

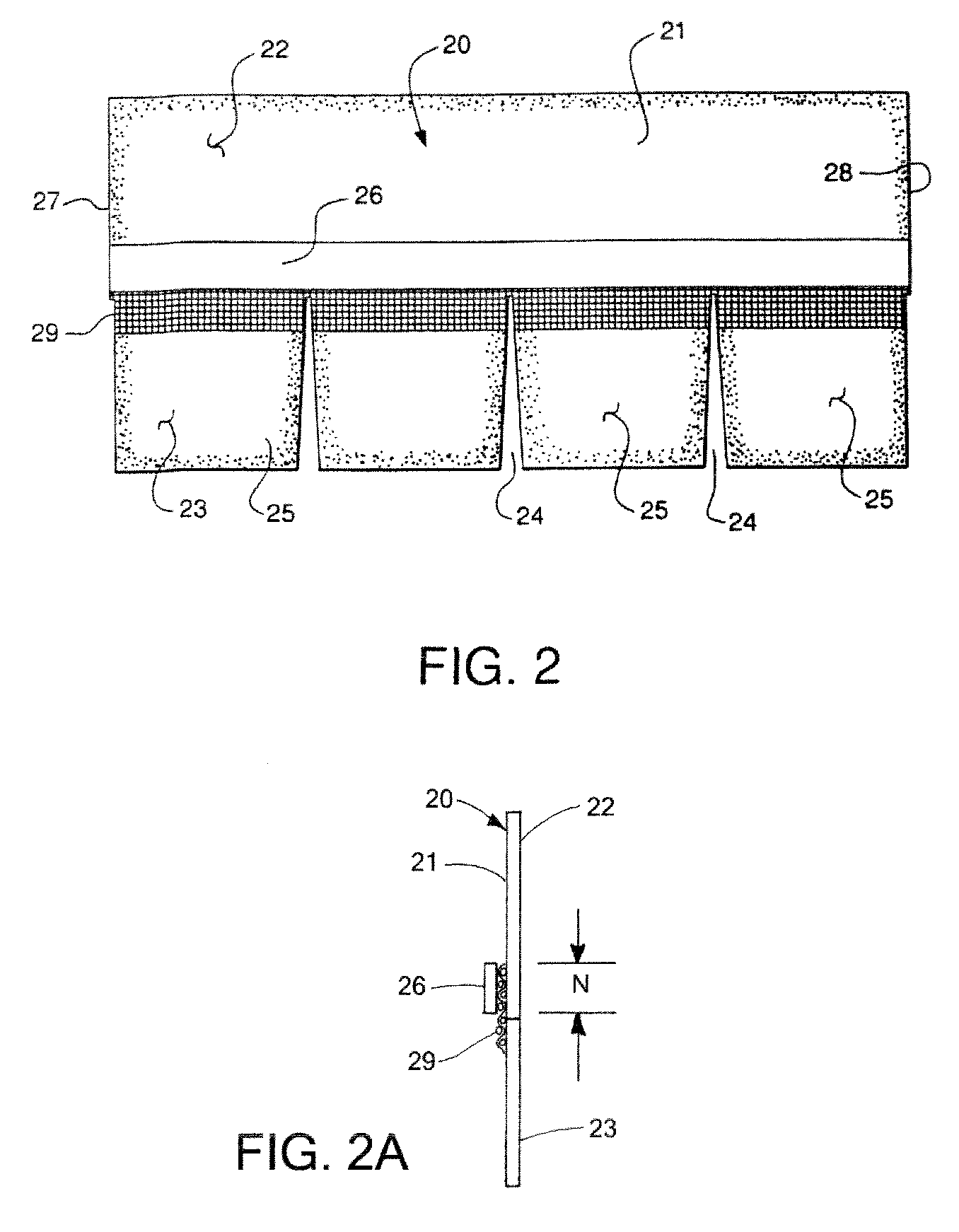

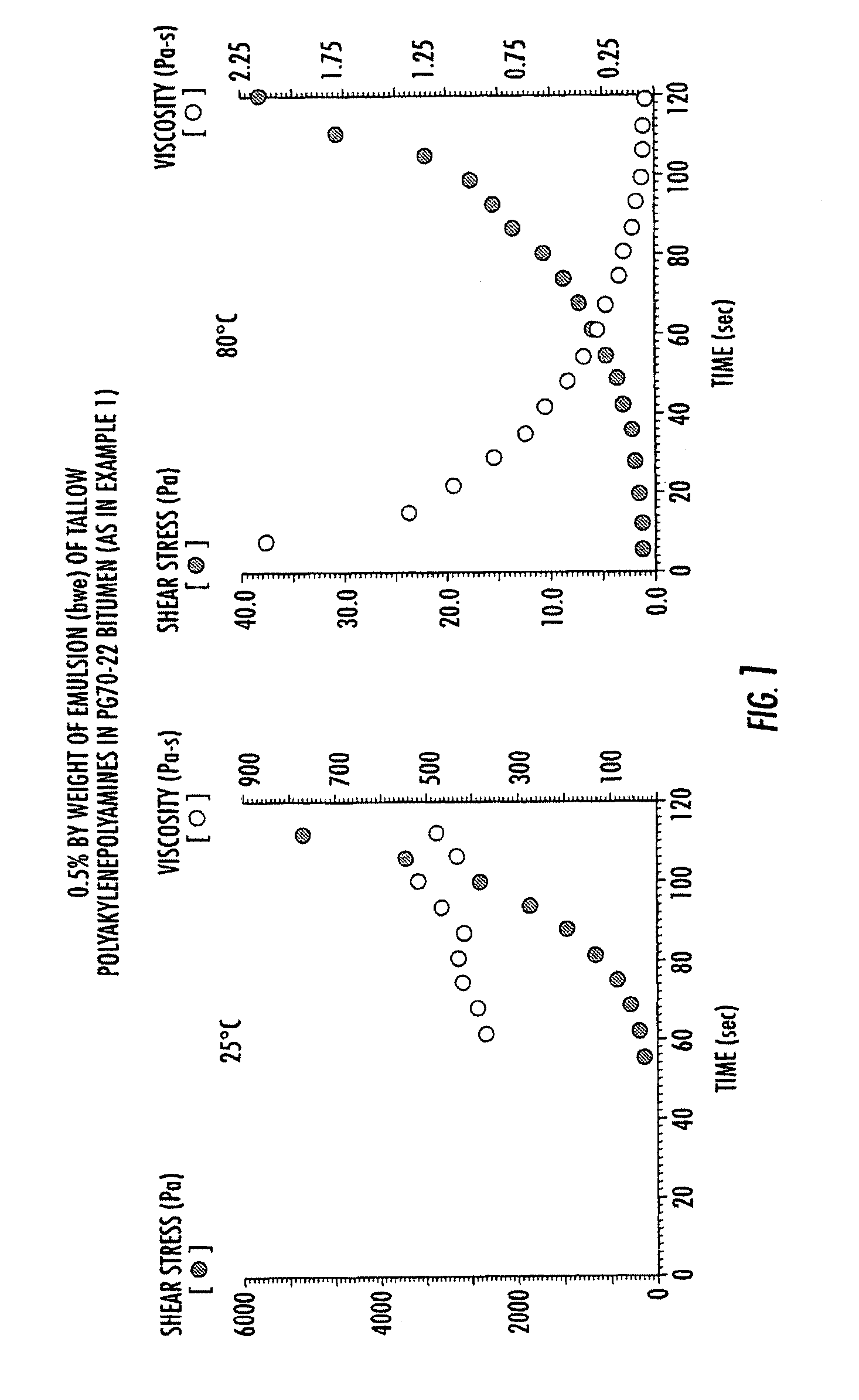

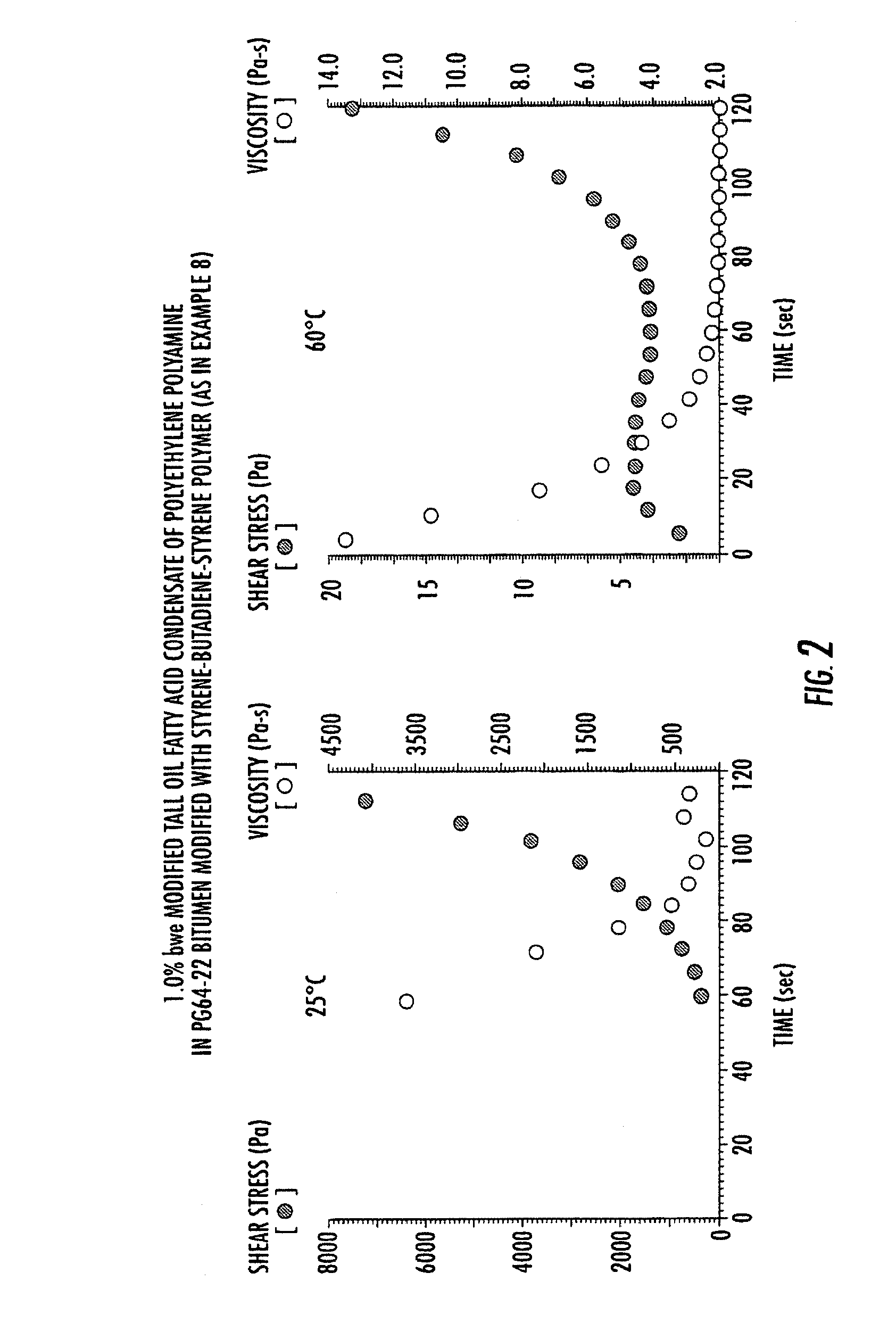

Method for producing bituminous compositions

InactiveUS20070039520A1Low viscosityHighly preventive effectOrganic chemistrySingle unit pavingsEmulsionSolvent free

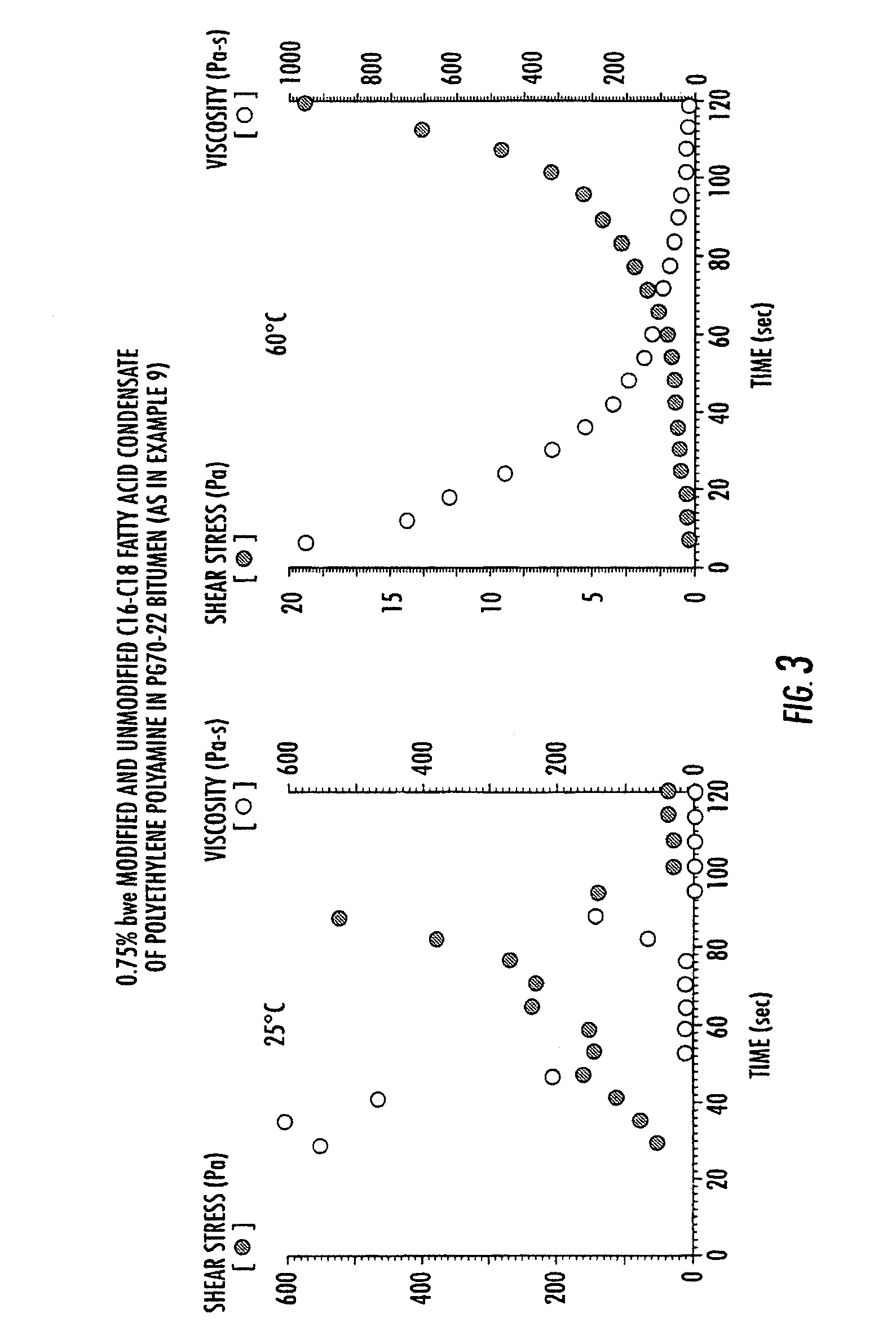

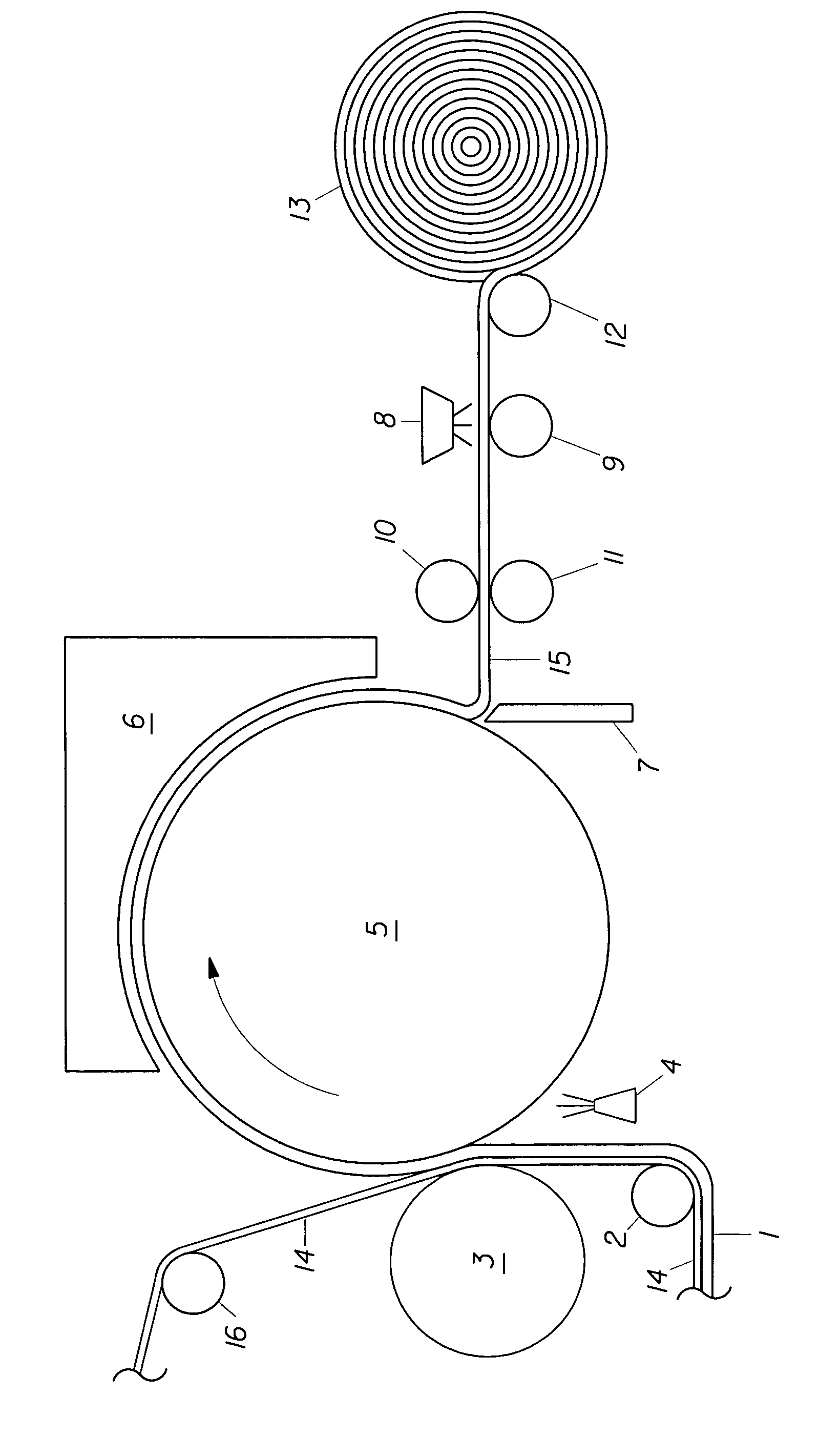

This invention relates to bituminous compositions and methods of producing the same. More particularly, the invention relates to the production of bituminous compositions formulated with performance-graded bitumen-containing solvent-free bitumen emulsions which exhibit controllable, temperature-dependent interfacial rheology. When employed in paving applications, these bituminous compositions develop adhesive strength and load-bearing strength properties at rates comparable to traditional hot mix paving compositions and at rates faster than traditional cold mix paving compositions.

Owner:MEADWESTVACO CORP

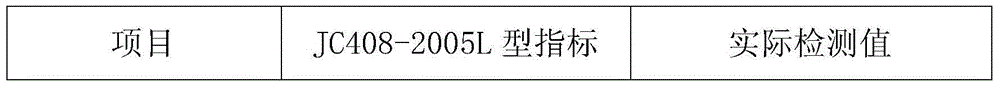

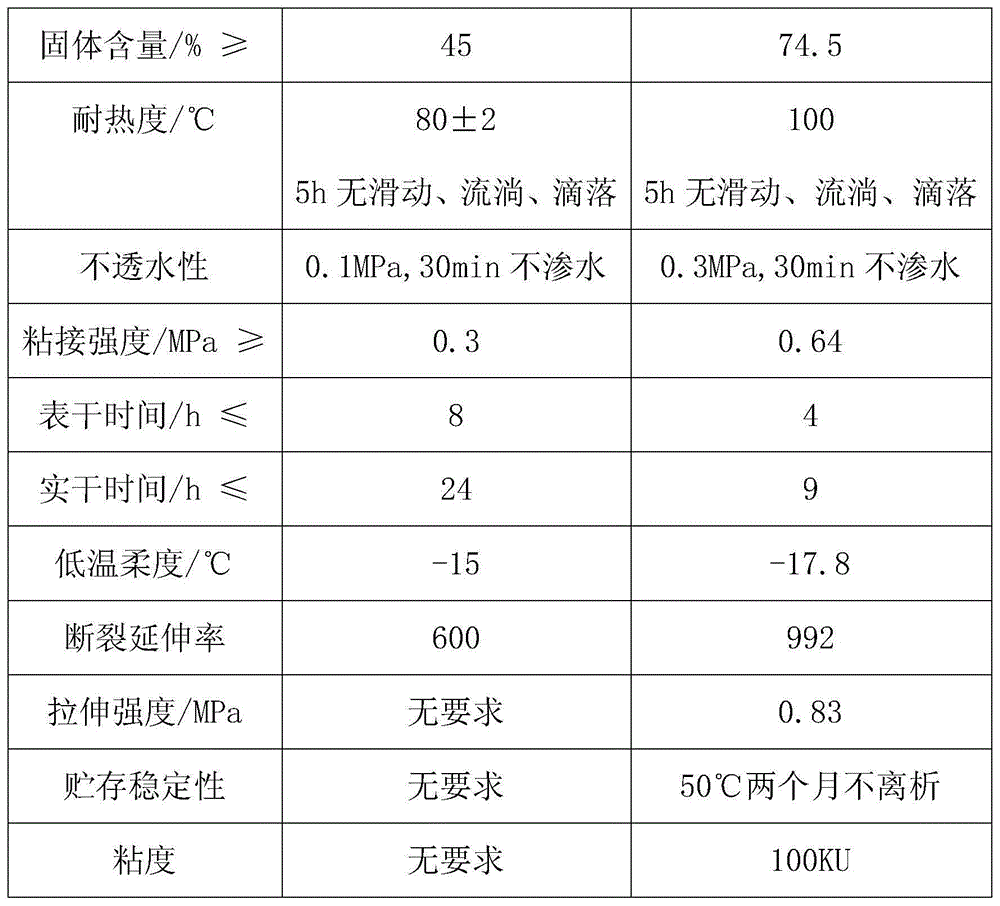

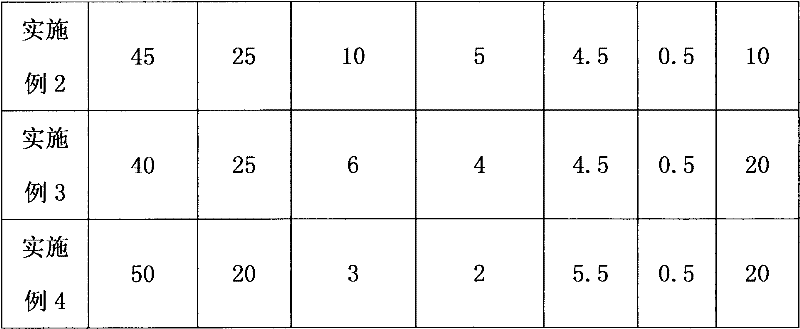

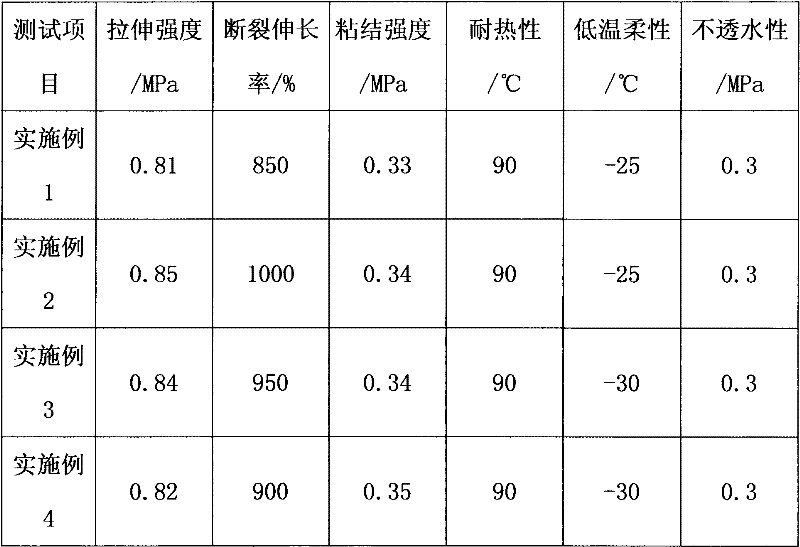

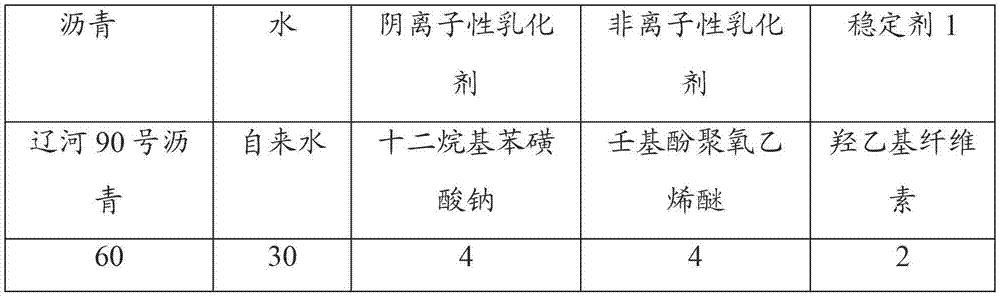

Composite emulsified asphalt waterproof coating and preparation method thereof

InactiveCN104449381AGood dispersionHigh viscosityConjugated diene hydrocarbon coatingsNatural rubber coatingsBituminous waterproofingEmulsion

The invention relates to a composite emulsified asphalt waterproof coating and a preparation method thereof. The composite emulsified asphalt waterproof coating is prepared from the following raw materials in parts by weight: 150-220 parts of emulsified asphalt, 50-105 parts of a polymeric emulsion, 70-130 parts of inorganic powder, 0.5-2 parts of a stabilizer, 6-10 parts of a dispersant, 2-5 parts of a wetting agent, 1-3 parts of a thickener I, 1-3 parts of a thickener II, 2-7 parts of a defoaming agent and 15-40 parts of water. The invention further relates to a preparation method of the composite emulsified asphalt waterproof coating. The viscosity, strength, application property, solid content and storage stability of the emulsified asphalt waterproof coating are remarkably improved, and the cost is lowered to a great extent.

Owner:JINZHOU DONGFANG YUHONG BUILDING MATERIALS

Water-in-oil bituminous dispersions and methods for producing paving compositions from the same

ActiveUS7297204B2Low viscosityHighly preventive effectProductsIn situ pavingsSolvent freeSURFACTANT BLEND

Owner:INGEVITY SOUTH CAROLINA

Acid based micro-emulsions of surfactants and solvents

InactiveUS6984610B2Organic detergent compounding agentsTransportation and packagingEmulsionOil sludge

Acid based micro-emulsions are disclosed comprising water, an acid blend, an anionic surfactant, a nonionic surfactant, a co-solvent, a solvent and an oxidizer. The micro-emulsions have particular utility in cleaning oil sludges and drilling mud residues from well cuttings, well formations and down hole and surface oil well drilling and production equipment.

Owner:INTEGRITY IND +1

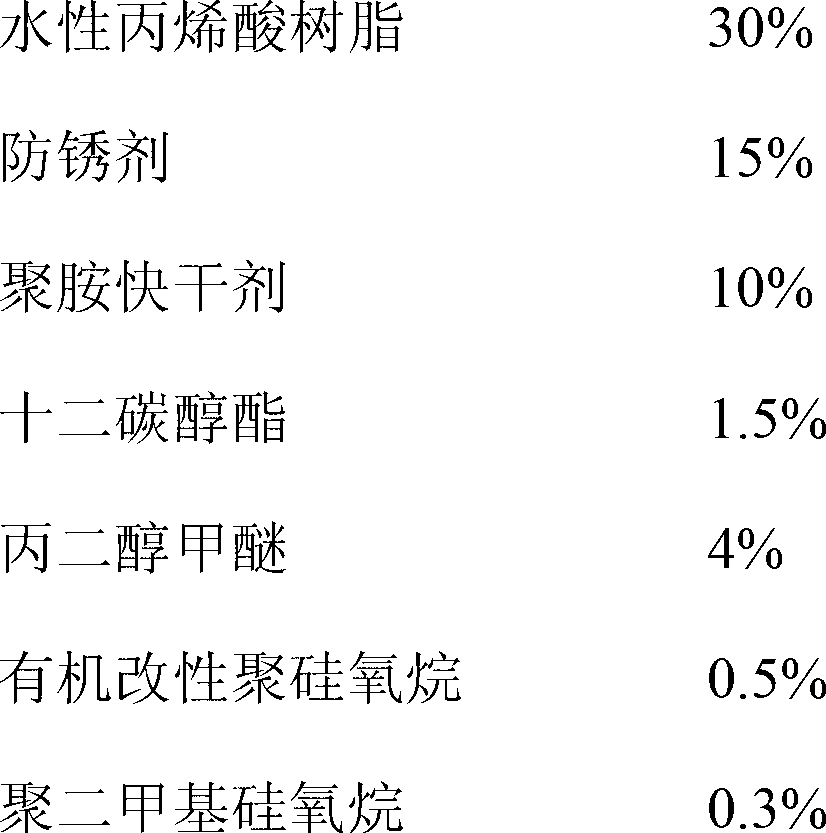

General water-based quick-drying anti-rust paint and preparation method thereof

InactiveCN102993810AAdvanced Technology FormulaAdvanced DesignRosin coatingsAnti-corrosive paintsWater basedLacquer

The invention relates to a general water-based quick-drying anti-rust paint and a preparation method thereof. The general water-based quick-drying anti-rust paint comprises the following components in percentage by weight: 18%-55% of film-forming substance, 6%-22% of anti-rust agent and the balance of water. The preparation method comprises the following steps of: firstly pre-dispersing the components except the anti-rust agent according to the formula ratio; then adding the anti-rust agent according to the formula ratio; and re-dispersing to obtain the general water-based quick-drying anti-rust paint. The general water-based quick-drying anti-rust paint disclosed by the invention is safe and nontoxic, contains no lead, chromium or other hazard pigments and derivatives, can not burn or explode, is suitable for safe production, has the advantages of plump paint film, excellent decoration and protection, excellent adhesive force and adjustable glossiness, and is simpler in production process compared with an oil paint.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

Reaction bonding modified emulsified asphalt waterproof paint and preparation method thereof

ActiveCN102898947AImprove stabilityImprove bindingConjugated diene hydrocarbon coatingsChloropene polymer coatingsCross-linkBituminous waterproofing

The invention aims to provide a reaction bonding modified emulsified asphalt waterproof paint and a preparation method thereof. The reaction bonding modified emulsified asphalt waterproof paint comprises asphalt, a modifying agent, an emulsifying agent, a cross-linking agent and water. In the formula system of the reaction bonding modified emulsified asphalt waterproof paint, more modifying agents in an appropriate amount are adopted compared with the prior art, so that a rubber-asphalt mixture can achieve a good emulsifying effect, the elasticity and strength of a dried sealing layer are greatly improved, and the sealing effect can be better and lasting; and by using the cross-linking agent, a chemical coupling effect is achieved between the paint and concrete, so that the cohesive force of the concrete is promoted. The reaction bonding modified emulsified asphalt waterproof paint can be applied to waterproof construction of wall surfaces, roofs, roads, bridges and the like, and has a very high practical value.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

Asphalt additive

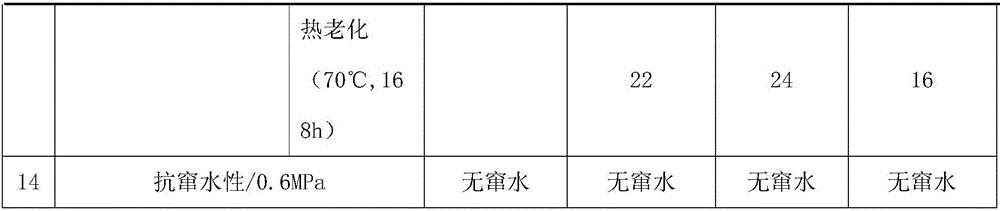

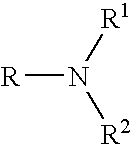

InactiveUS6024788AHigh affinityImprove solubilityBuilding insulationsBituminous coatingsAliphatic hydrocarbonPhenyl group

The present invention provides an asphalt composition comprising an asphalt and antistripping additive comprising at least one of the compound having the formula (I), (II) or (III):[R1O-(PO)m(EO)n]x-P(=O)-(OH)y(I)wherein R1 represents a linear hydrocarbon radical having 8 to 24 carbon atoms or an alkyl phenyl group having 8 to 24 carbon atoms, PO represents oxypropylene group, EO represents oxyethylene group, each of m and n represents the number of added molecules, m is a number of 1 to 6, n is a number of 0 to 6;[R2O-(PO)m(EO)n]x-P(=O)-(OH)y(II)wherein R2 represents an aliphatic hydrocarbon radical having a branched methyl group and having 8 to 24 carbon atoms, PO represents oxypropylene group, EO represents oxyethylene group, each of m and n represents the number of added molecules, m is a number of 0 to 6, n is a number of 0 to 6; and[R3O-(PO)m(EO)n]x-P(=O)-(OH)y(III)wherein R3 represents an aliphatic hydrocarbon radical having two or more branched methyl groups or at least one of branched group including 2 or more carbons and having 8 to 24 carbon atoms, PO represents oxypropylene group, EO represents oxyethylene group, each of m and n represents the number of added molecules, m is a number of 0 to 6, n is a number of 0 to 6, each of x and y of the formula (I), (II) or (III) being a number of 1 to 2, the sum total of x and y being 3, R1,R2 and R3 being saturated or unsaturated.

Owner:KAO CORP

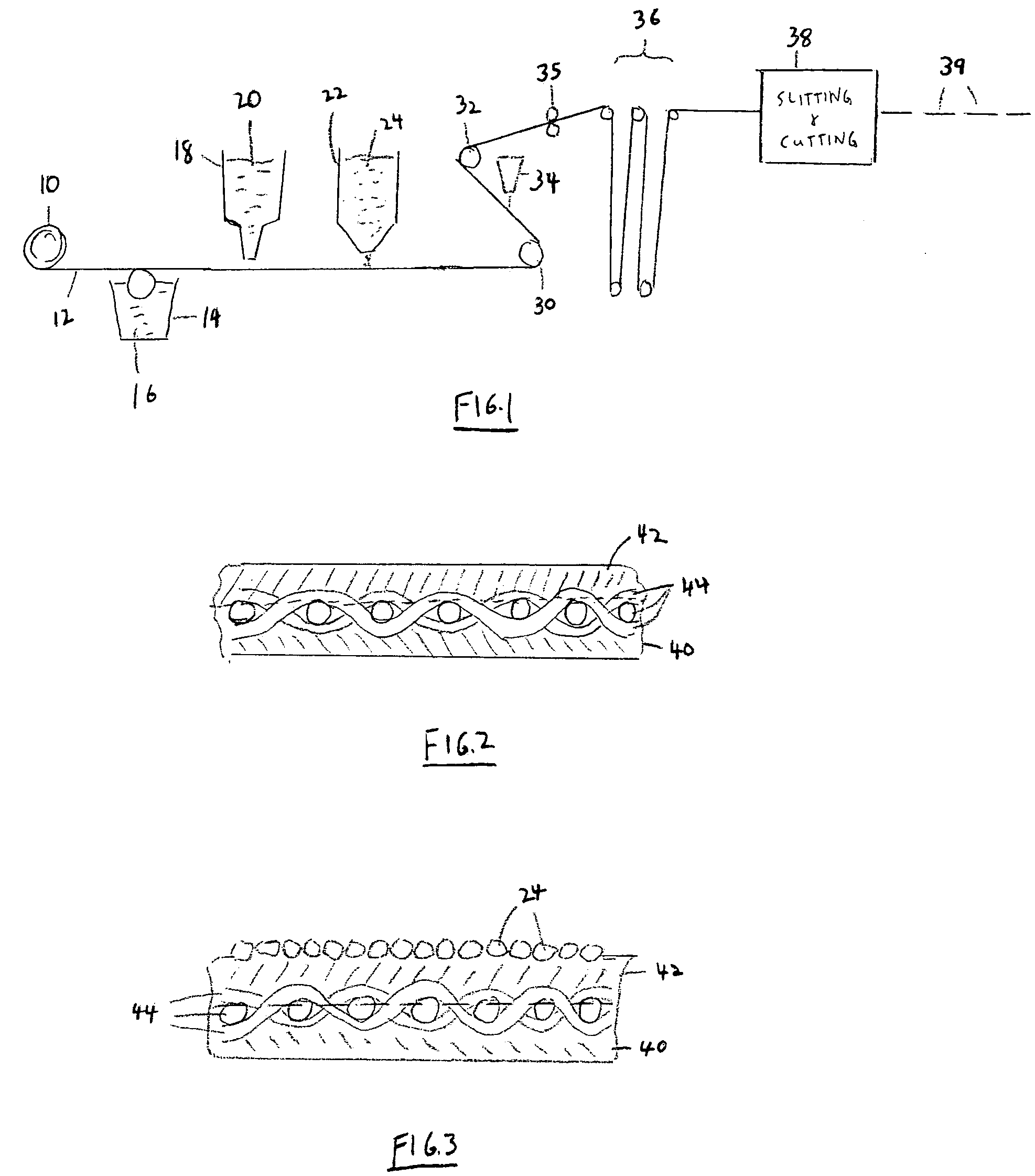

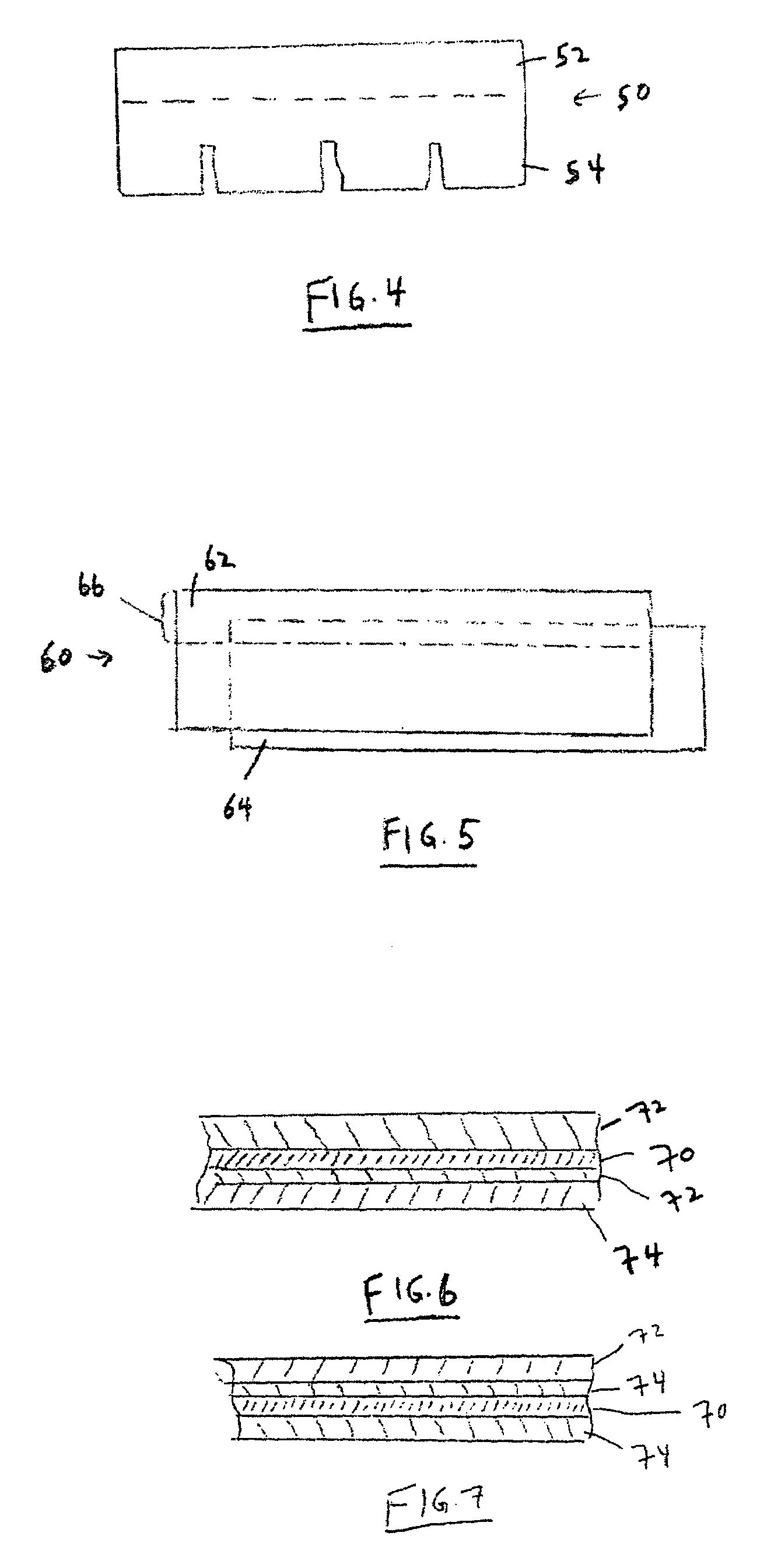

Dual layer shingle

ActiveUS7048990B2Less costlyEfficient use ofLiquid surface applicatorsWallsPolymer modifiedPliability

A shingle formed from a base sheet, with a layer of polymer modified asphalt coating the top of the base sheet, and a layer of conventional oxidized asphalt, free from polymer additives, coating the bottom of the base sheet. Both layers preferably directly contact the strands of the base sheet for good adhesion. This improves the strength, flexibility and ultraviolet resistance of the shingle, while reducing the cost as compared with a shingle which utilized only polymer modified asphalt, and in addition it increases the stiffness of the shingle as compared with one using only polymer modified asphalt.

Owner:IKO INDS

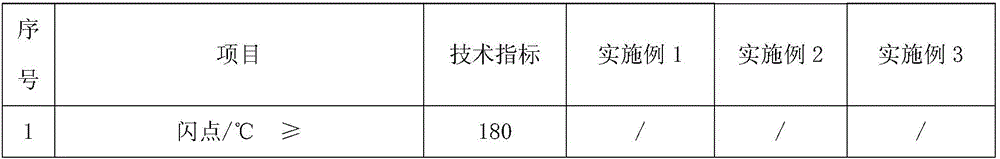

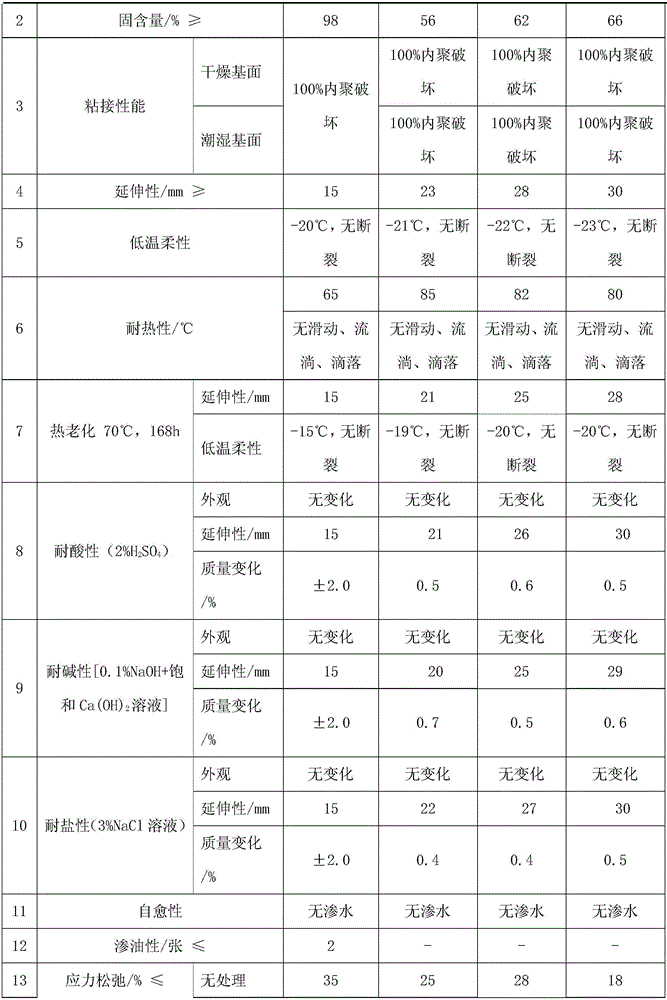

Anionic water-based non-curing rubber asphalt waterproof coating and preparation method thereof

The invention discloses an anionic water-based non-curing rubber asphalt waterproof coating and a preparation method thereof. The preparation method comprises the steps that 85-95 parts by mass of anionic rubber modified asphalt emulsion, 2-5 parts by mass of anionic SBR latex, 4-7 parts by mass of anionic neoprene latex, 0.1-1 part by mass of hydrophobing agent and 0.5-2.5 parts by mass of permeability-reducing agent are stirred and mixed to be uniform to obtain a component A; inorganic salt is dissolved in water, an inorganic salt solution with the concentration being 10% to 30% is prepared, and a component B is obtained; the component A and the component B are sprayed and mixed through a spraying gun according to the mass ratio being (5-15):1, and the anionic water-based non-curing rubber asphalt waterproof coating is obtained, wherein the anionic rubber modified asphalt emulsion is prepared by emulsifying matrix asphalt, a tackifier, rubber elastomers, an anionic emulsifier, a stabilizer, a PH modifier and water through a colloid mill. The product is stable in storage, environmentally friendly, free of pollution, good in non-curing effect, high in waterproof performance and simple in process.

Owner:KESHUN WATERPROOF TECH CO LTD

Wax emulsion preservative compositions and method of manufacture

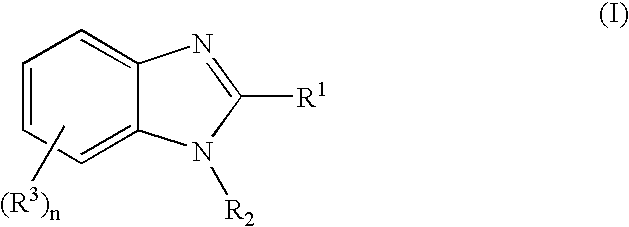

An emulsion comprising water as the continuous phase, a wax as the discontinuous phase, an emulsifier and a preservative having the general structure:wherein R1 can be a heterocycle containing nitrogen and sulfur, such as thiazolyl, isothiazolyl, or thiadiazolyl, which can optionally be substituted with C1–C6 alkyl; R2 can be hydrogen or C1–C6 alkyl, specifically hydrogen; n is 0, 1, 2, or 3; each instance of R3 can independently be hydrogen, C1–C6 alkyl, phenoxy, C1–C6 alkoxy, halo, amino, C1–C6 alkylamino, di C1–C6 alkyl amino, imidazolyl, thiazolyl, isothiazolyl, thiadiazolyl, thienyl, furyl, pyrryl, naphthyl, phenyl, halophenyl, C1–C6 alkyl phenyl, or C1–C6 alkoxyphenyl. The preservative may be added to the emulsion after the emulsion is formed. The emulsion can be incorporated into a gypsum product such as gypsum board or gypsum wood fiber board. The gypsum product may be made by forming a slurry containing gypsum, water, and the emulsion into a solid product. A method for improving the water resistance of a lignocellulosic composite product prepared by mixing lignocellulosic material with a binder to form a mixture and solidifying the mixture in a selected configuration to form the composite product may include adding to the mixture an emulsion as described above.

Owner:MOMENTIVE SPECIALTY CHEMICALS

Environment-friendly road surface ice and snow melt coating material, preparation method thereof and using method thereof

ActiveCN102199398AEnsure Snowmelt RequirementsPrevent loose grainsIn situ pavingsOther chemical processesSnow removalSnowpack

The invention relates to an environment-friendly road surface ice and snow melt coating material, a preparation method thereof and a using method thereof. Serious consequences such as traffic jam and the like can be caused by snow accumulation in winter; and at present, a snow removal method comprises passive snow removal and active snow removal, wherein in the passive snow removal, the operating efficiency of manual snow removal is low, mechanical snow removal is incomplete relatively in clearing, and for the spreading of a snow melt agent, substances with the snow melt effect are mixed simply only, so the spreading is non-uniform, and the snow melt agent dispersed to peripheral air has the major influence on environment; and the active snow removal is high in cost, and has a certain damage to structures of road surfaces, so the service life of roads is shortened. In the environment-friendly road surface ice and snow melt coating material, after being loaded on a carrier material, the snow melt substances are mixed with emulsified asphalt, water-soluble epoxy resin and a curing agent and sprayed on the road surfaces to form an ice and snow melt coating, so that the roads have the function of melting snow actively. By the environment-friendly road surface ice and snow melt coating material, an ice point of water is reduced to between -5 and -20 DEG C so as to clear the ice and snow of the roads, and the coating material has the sustained-release function, is high in coating adhesivity and wear-resisting effect, low in cost and convenient to maintain, and can prolong the life of the road surfaces effectively.

Owner:CCCC CIVIL ENG SCI & TECH

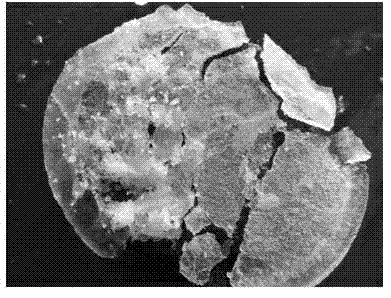

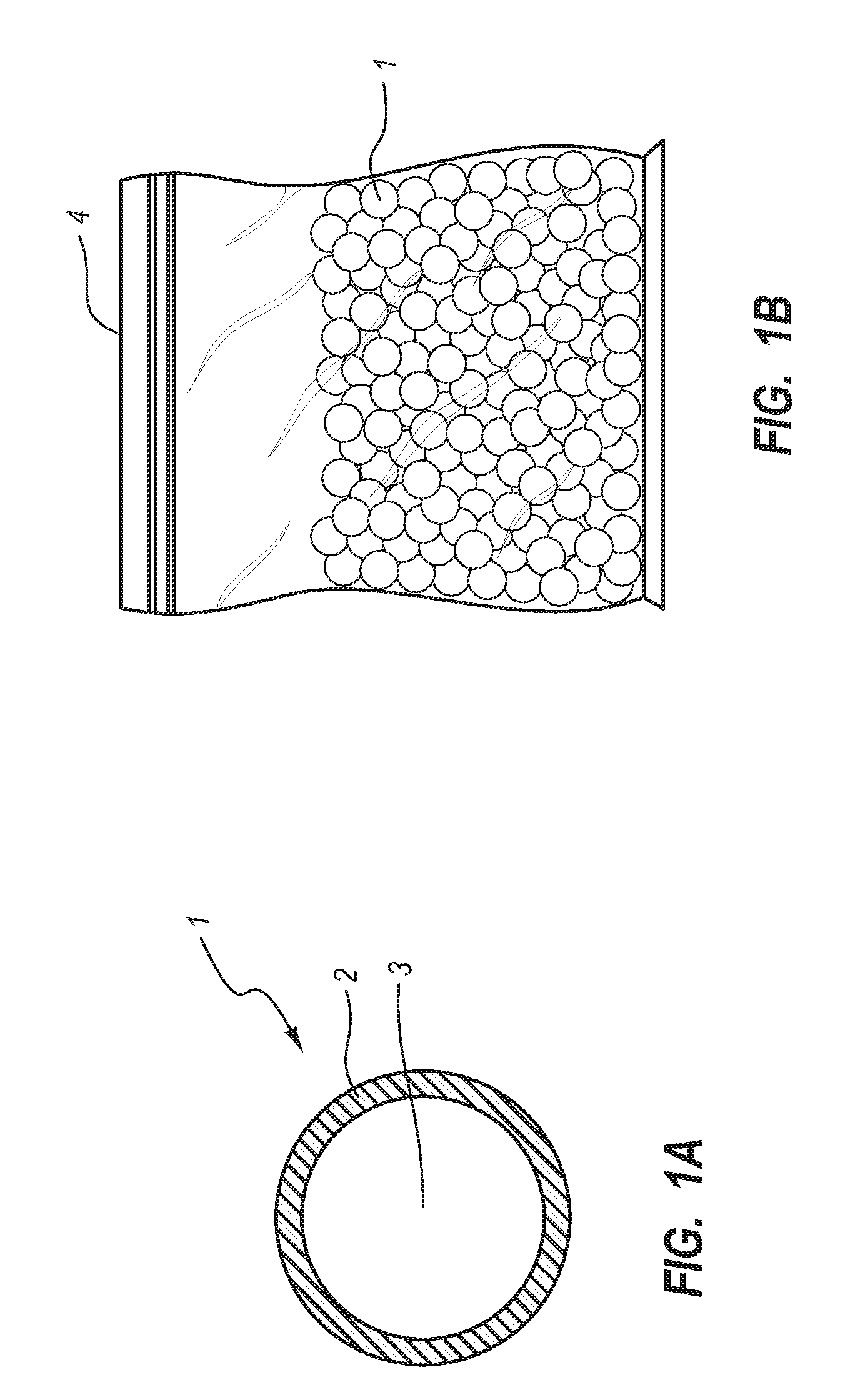

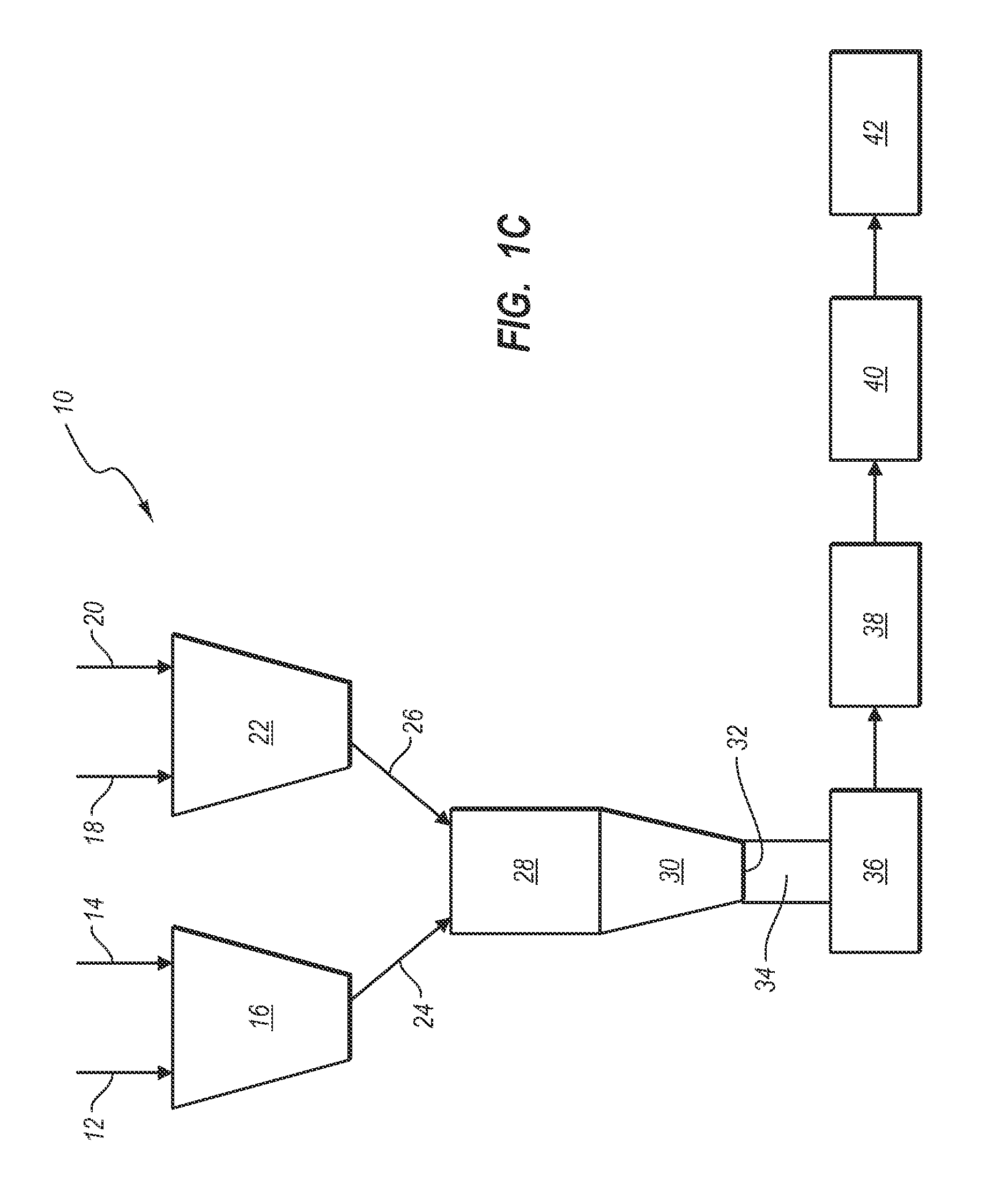

Rubberized asphalt pellets

A storage-stable rubberized asphalt paving pellet can include fines in the core. The core can be an asphalt-based binder at about 70% to about 95% by weight of the core. The asphalt-based binder can include: ground tire rubber from about 15% to about 30% by weight of the asphalt-based binder, and pavement grade asphalt from about 85% to about 70% by weight of the asphalt based binder. The core can include fines at about 30% to about 1% by weight of the core. The shell coating the core can provide the pellet with a maximum dimension of about 1 / 16 inch to about 2 inches. The shell can include a water-resistant polymer or wax, or a coating of fines. In one aspect, the fines are lime fines or ground asphalt pavement fines. Optionally, the fines can be mineral or rock fines as described herein.

Owner:BILLIAN I P

Sulfur-in-oil in asphalt and polymer composition and process

InactiveUS6133351AImprove liquidityImprove permeabilityIn situ pavingsWorking-up pitch/asphalt/bitumen by mixing fractionsSulfurSlurry

A sulfur in oil in asphalt and polymer blend is disclosed. An asphalt and polymer blend is first prepared and then a slurry of solid sulfur in liquid oil added. Addition of a slurry of solid sulfur in oil or oil containing sulfur compounds, permits rapid and effective uniform dispersion of the sulfur component in the asphalt / polymer blend. Uneven mixing, which can occur when sulfur is separately added as a solid to the asphalt blend, is avoided. Polymer use is optimized because polymer matrix development (digestion / swelling) can be completed before cross-linking occurs. The method is safer because formation of explosive clouds of sulfur dust is avoided.

Owner:MARATHON PETROLEUM

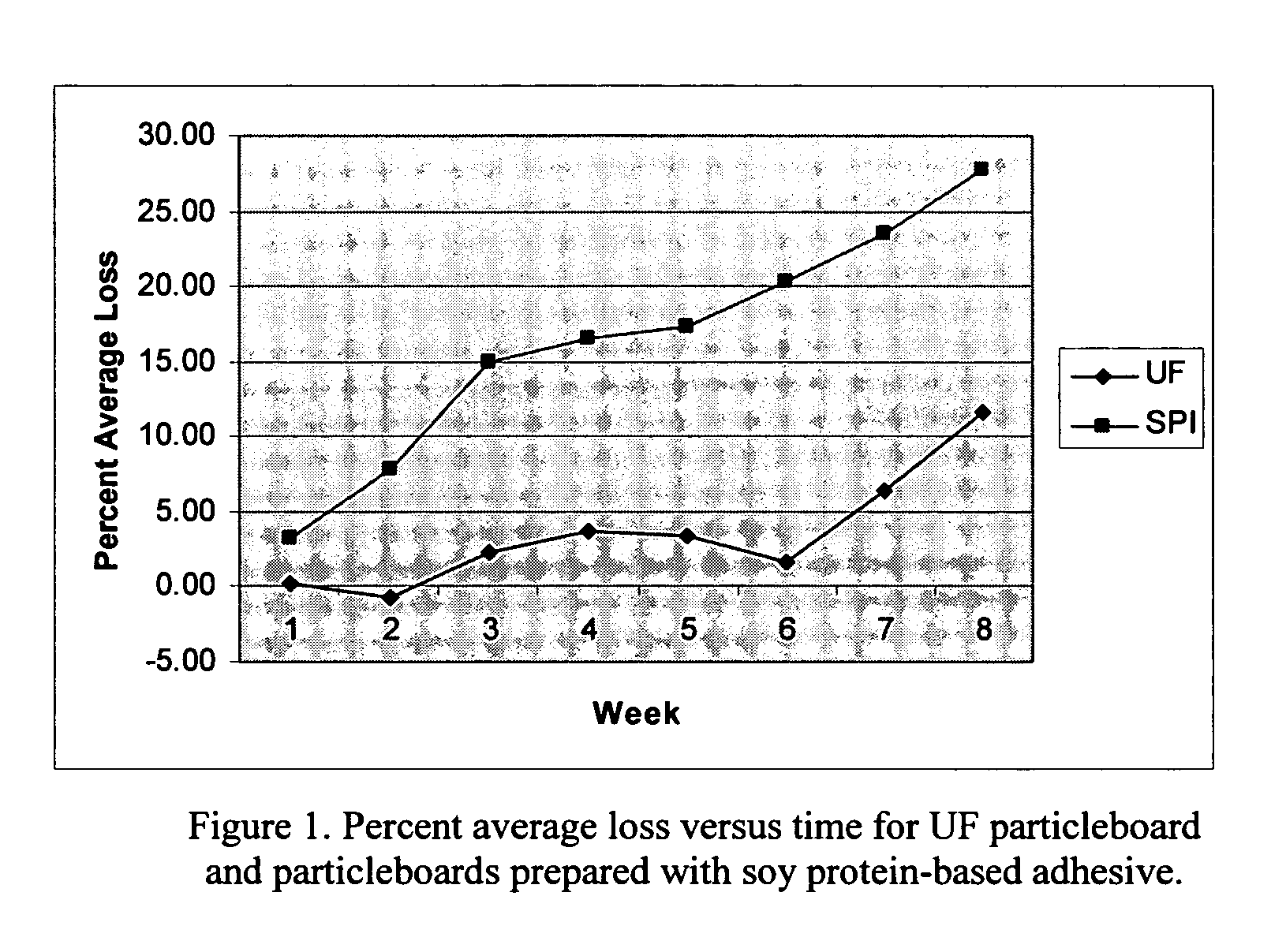

Soy protein based adhesive and particleboard

An adhesive composition that can be used in particleboards and other composites is formed from an aqueous mixture of soy protein, zinc sulfate heptahydrate, calcium oxide, sodium benzoate, pine oil, wax emulsion and non-sulfonated kraft lignin. In a second embodiment the composition further includes an acid.

Owner:UNIVERSITY OF SOUTHERN MISSISSIPPI

Shingle with reinforcement layer

Owner:CERTAINTEED CORP

Bituminous Composition

ActiveUS20110021672A1Low viscosityHighly preventive effectOrganic chemistryIn situ pavingsEmulsionSolvent free

This invention relates to bituminous compositions and methods of producing the same. More particularly, the invention relates to the production of bituminous compositions formulated with performance-graded bitumen-containing solvent-free bitumen emulsions which exhibit controllable, temperature-dependent interfacial rheology. When employed in paving applications, these bituminous compositions develop adhesive strength and load-bearing strength properties at rates comparable to traditional hot mix paving compositions and at rates faster than traditional cold mix paving compositions.

Owner:INGEVITY SOUTH CAROLINA

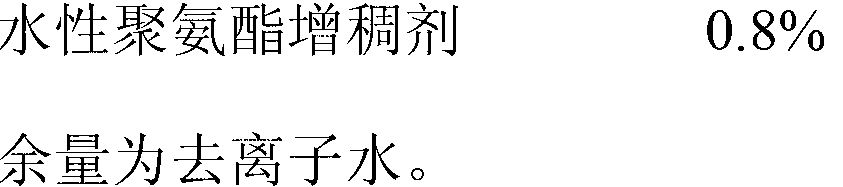

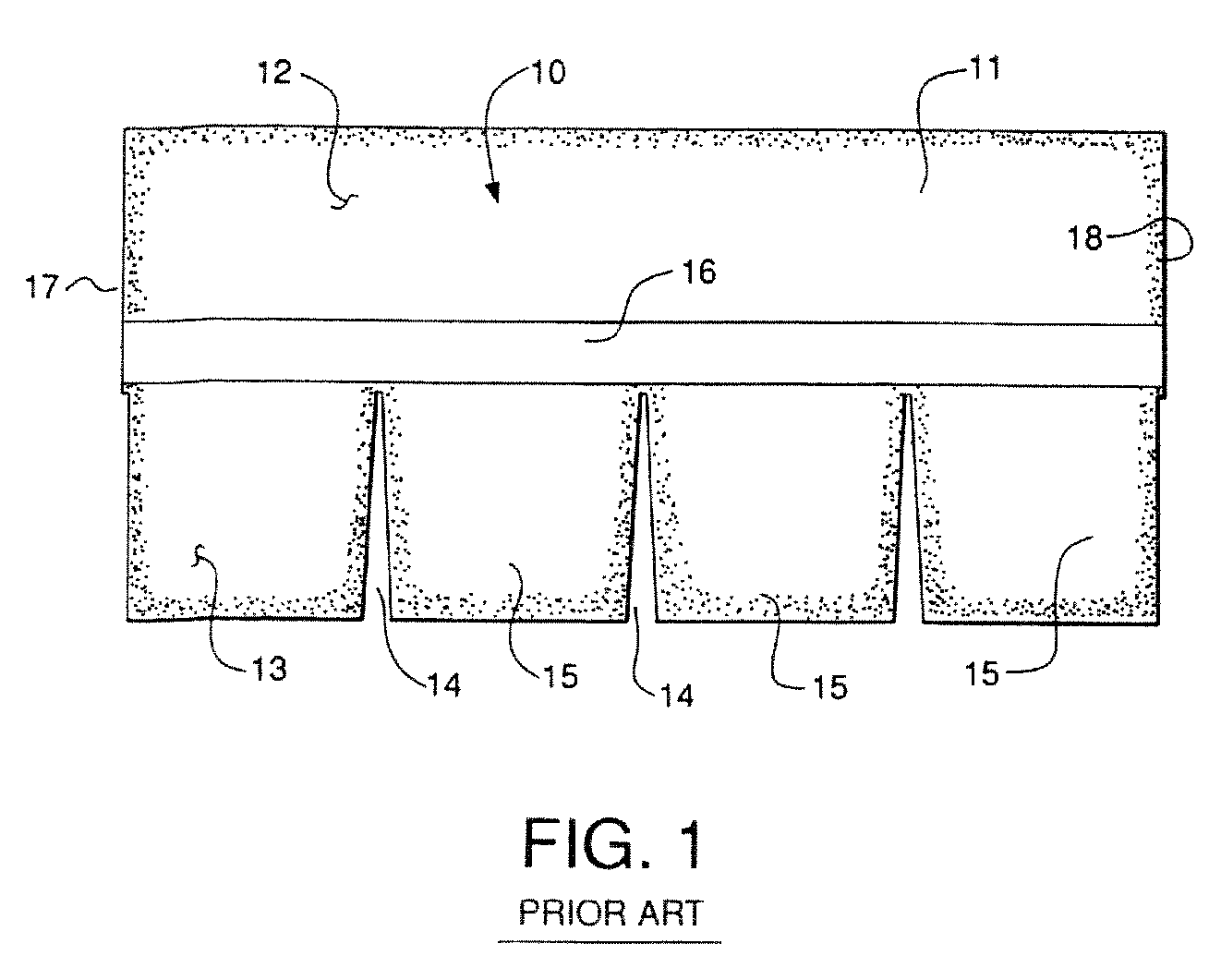

Method of manufacturing a bituminous coated material with pre-coating

InactiveUS20060240185A1Eliminate disadvantagesLiquid surface applicatorsIn situ pavingsMaterials scienceCoating materials

Owner:LEA INT

Paper softening compositions containing low levels of high molecular weight polymers and soft tissue paper products comprising said compositions

Disclosed is a composition suitable for atomizing without excessive aerosolization in the form of an oil-in-water emulsion comprising: a) a continuous aqueous phase, and b) a discontinuous oil phase wherein the rheology of the aqueous phase is modified by the addition of a water-in-oil emulsion comprising: i) a high molecular weight polymer in a discontinuous aqueous phase, and ii) a continuous organic solvent phase. Preferred embodiments of the present invention relate to compositions for softening an absorbent paper tissue comprising a) a quaternary ammonium softening active ingredient; b) an electrolyte; c) a high molecular weight polymer emulsion comprising: i) from about 20% to about 40% by weight of the premix of a high molecular weight polymer; ii) from about 40% to about 60% of water; and iii) from about 20% to about 40% of an organic solvent; and d) a vehicle in which said softening active ingredient is dispersed.

Owner:THE PROCTER & GAMBLE COMPANY

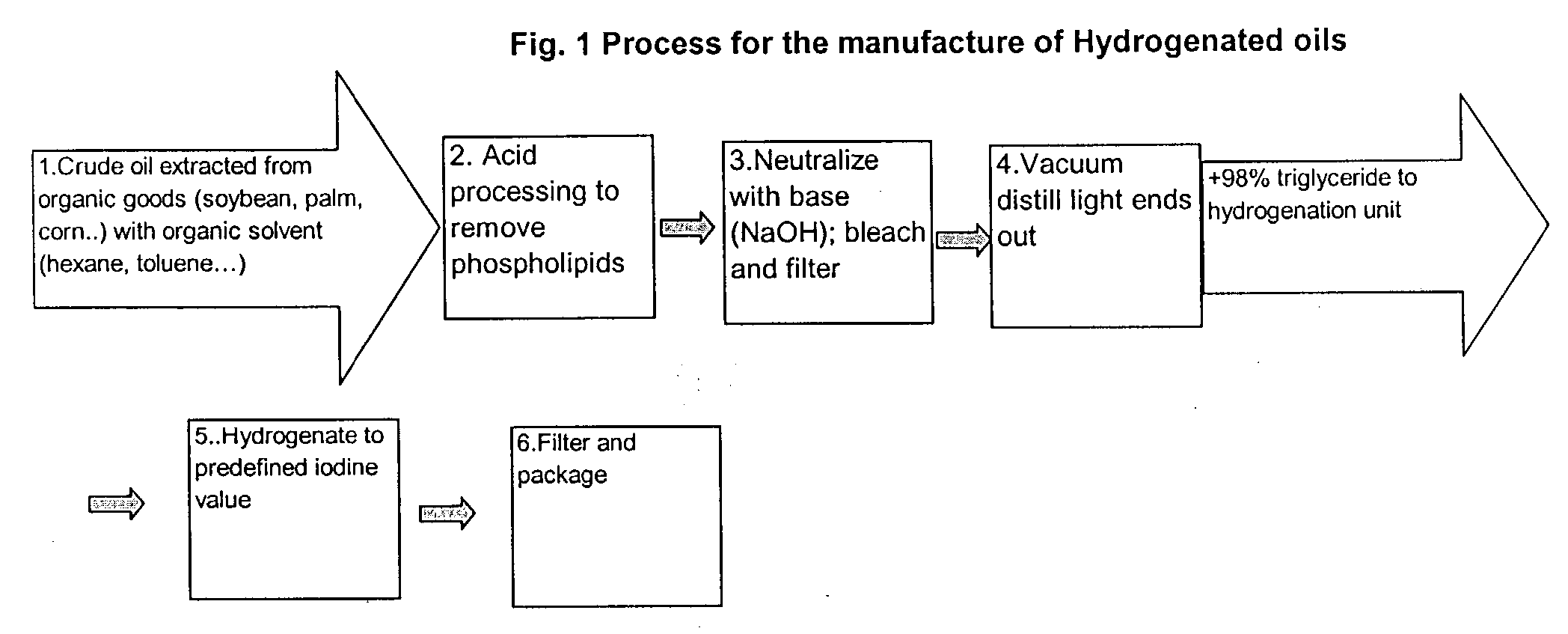

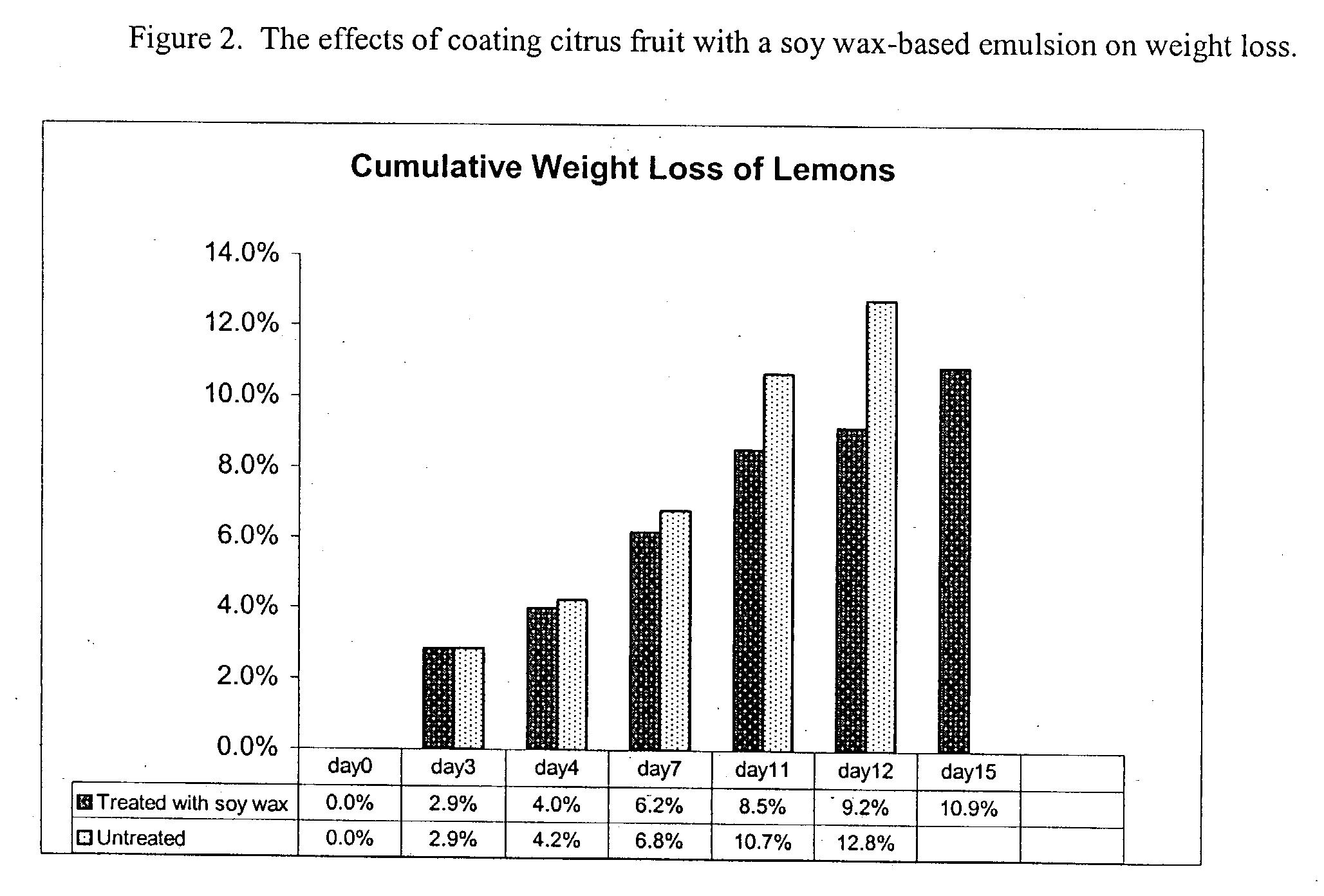

Novel wax emulsion coating applications

Waxes prepared from hydrogenated plant oils, such as castor, palm, and soybean, are used to prepare water based emulsions. The inventive waxes, obtained from naturally derived, renewable resources, were emulsified under anionic, cationic and nonionic conditions, producing emulsions having a solids content up to about 45% solids. When used to coat fibrous cellulosic articles, such as paperboard, the emulsions' performance was similar to emulsions containing petroleum-derived waxes. The inventive waxes have a low iodine value (between 2-5), and melting points between approximately 120-200 degrees F. (Mettler Drop Point). These waxes comprise a triglyceride whose fatty acids are predominantly stearic acid or ricinoleic acid. The inventive waxes are used as an alternative to petroleum-derived, or expensive naturally-occurring waxes in the manufacture of emulsions used in coatings, polishes, adhesives, paper products, paperboard and other manufacturing operations.

Owner:MARCUS OIL & CHEM

Asphalt composition and method

A paving asphalt composition for improving the durability and longevity of asphalt road surfaces is disclosed. The paving asphalt composition includes asphalt base stock, heavy residuum of re-refined motor oil, and a chemical modifier. The heavy residuum of re-refined motor oil preferably has an API gravity of at least about 12, a kinematic viscosity greater than about 400 centistokes at 140 DEG F., a flash point greater than about 400 DEG F. and a mass loss less than about 3%. The paving asphalt composition may also include a polymer. A method of forming the paving asphalt composition and a method of paving roads are also disclosed.

Owner:CROWN ASPHALT DISTRIBUTION L L C

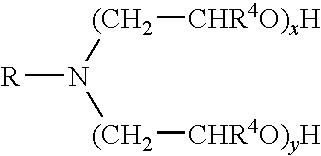

Asphalt modifiers for "warm mix" applications including adhesion promoter

ActiveUS20100319577A1Low viscosityImprove wetting propertiesIn situ pavingsWax coatingsRoad surfaceSurface-active agents

The present invention generally relates to an additive package for warm-mix asphalt formulations for the pavement of road surfaces, said additive package comprising a) surfactant component, and b) an asphalt rheology modifying component, wherein said asphalt rheology modifying component comprises at least one of a i) a wax component and ii) a resin component. The invention also relates to a warm mix asphalt having improved compaction at lower temperatures, and to a pavement made from said warm mix asphalt.

Owner:AKZO NOBEL CHEM INT BV

Quick-setting cationic aqueous emulsions using pre-treated rubber modified asphalt cement

Cationic aqueous emulsions of rubber modified asphalt cement (RMAC) useable for paving, seal coat, slurry seal, roofing, coating and other applications. First, a RMAC is prepared by combining 45 to 90% by weight asphalt with about 5% to about 55% by weight solid recycled rubber (e.g., crumb rubber from used vehicle tires) under conditions that cause at least a substantial portion of the solid rubber to become liquified or otherwise incorporated into the asphalt. The RMAC may be treated with dodecyl benzenesulfonic acid (DDBSA) which causes reaction(s) to occur and results in a lowering of the viscosity of the RMAC. The RMAC (or DDBSA-treated RMAC) may then be emulsified in an aqueous medium to provide an aqueous emulsion.

Owner:SABUR DIANA +1

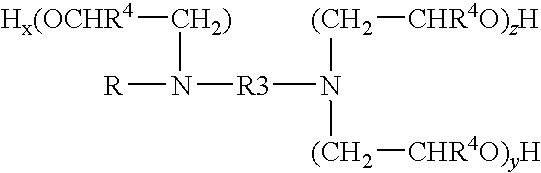

Pavement repair system utilizing solid phase autoregenerative cohesion

ActiveUS8992118B2Long and longer useful lifePaving propertyPaving reinforcementsIn situ pavingsOligomerEmulsion

A method for repairing an aged or damaged asphalt pavement is provided. The method involves preparing a surface of the aged or damaged asphalt pavement by filling in deviations from a uniform surface plane with dry aggregate and compacting the dry aggregate; applying a reactive asphalt emulsion to the prepared surface; and passing an emitter over the prepared pavement, wherein the emitter generates electromagnetic radiation having a wavelength of from 2-5 mm that penetrates into the pavement to a depth of at least 2 inches. The asphalt pavement is repaired by disturbing voids and interstices in the damaged pavement without dehydrogenation of the asphalt, such that oligomers present in the aged asphalt are linked together into longer polymer chains to improve ductility of the aged asphalt.

Owner:COE WILLIAM B

Additives for water-resistant gypsum products

ActiveUS20050250858A1Provides water resistanceFireproof paintsAntifouling/underwater paintsWater resistantChemistry

Emulsions are provided which are useful in imparting water-resistance to gypsum products. In one embodiment, the emulsions comprise at least one wax, an alkyl phenol, a salt of polynaphthalenesulfonic acid, and a complexed starch. Emulsions of this embodiment may be added to hot, even boiling, water without the emulsion separating or curdling. The emulsions of the present invention are stable for extended periods of time when stored at room temperature and do not require the addition of a bactericide. The emulsions of the present invention are pourable liquids at room temperature.

Owner:HEXION INC

Asphalt rubber waterproof coating material

ActiveCN102936460AUniform procedure is goodNot easy to embrittleConjugated diene hydrocarbon coatingsNatural rubber coatingsAcrylic resinStearic acid

The present invention provides a rubber asphalt waterproof coating material, and belongs to the technical field of coating materials. The coating material is prepared from the following raw materials, by weight, 20-35 parts of a natural rubber, 10-15 parts of a thermoplastic styrene-butadiene rubber, 5-10 parts of acrylic resin, 3-5 parts of ethylene glycol ethyl ether, 20-30 parts of asphalt, 5-10 parts of chlorinated polyethylene, 1-2 parts of silicon carbide crystal whiskers, 3-6 parts of talc powder, 2-4 parts of diatomite , 2-4 parts of stearic acid, 3-8 parts of polyacrylamide, 6-9 parts of an ethylene-vinyl acetate copolymer, 3-5 parts of a plasticizer, 1-2 parts of a defoaming agent, 8-15 parts of a pigment, 2-3 parts of a surfactant, and 40-50 parts of water. The waterproof coating material provided by the embodiments still has good watertightness and good mechanical property after high temperature and high humidity destruction.

Owner:武汉飞盛建设工程有限公司

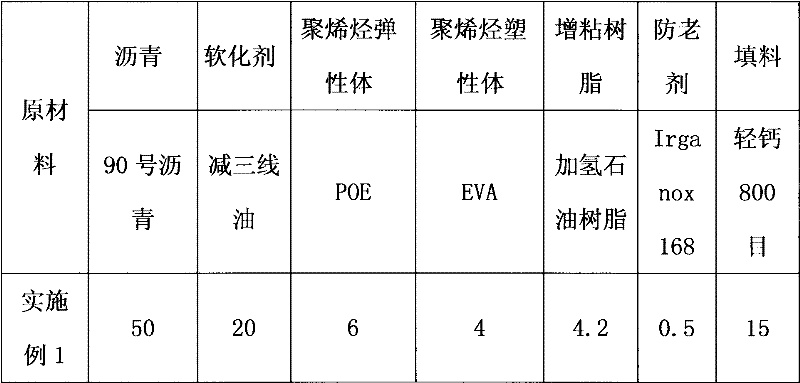

Hot melt type modified asphalt waterproof paint and preparation method thereof

InactiveCN102408829ASolve bonding problemsRepair crackBituminous coatingsSelf-healingBituminous waterproofing

The invention discloses hot melt type modified asphalt waterproof paint, which has the advantages that the creep performance is high, the basic layer deformation resistance capability is high, the fatigue resistance is good, the bonding strength is high, and in addition, good self healing capability is realized. Simultaneously, on the premise of 90 DEG C heat resisting experiments, the construction temperature of the paint is controlled to be lower 120 DEG C, the asphalt smoke is effectively reduced, and energy sources are saved. The paint can be coated for more than 3mm once and is independently used as a flexible waterproof layer with creep capability; and the paint can also be coated for more than 1mm to be used as a waterproof layer in a composite system, and a reliable composite waterproof layer is formed.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +2

Composition and process of using an asphalt emulsion to convert an unpaved surface into a paved surface

InactiveUS20100047015A1Eliminating and reducing costLow costIn situ pavingsSingle unit pavingsEmulsionRoad surface

The invention is a cost-effective method and formulation for cold paving applications that can be used to convert an unpaved surface, such as a gravel or dirt roadway, into a paved surface. The method includes applying an asphalt emulsion comprising asphalt, water, one or more emulsifiers, and a polymer to an existing unpaved surface to provide a layer of asphalt emulsion. An aggregate is then deposited over the emulsion layer to form a paved surface. The asphalt emulsion is formulated so that it can be used in a wide variety of conditions and with locally available aggregate. The set rate and viscosity of the asphalt emulsion can be selected so that it is able to penetrate partially into the unpaved surface to further improve the stability and rain resistance of the roadway.

Owner:BASF AG

High-strength rubber asphalt waterproof paint and preparation method thereof

ActiveCN103205204AHigh strengthIncrease elasticityConjugated diene hydrocarbon coatingsChloropene polymer coatingsEmulsionPolymer science

The invention discloses a high-strength rubber asphalt waterproof paint. The high-strength rubber asphalt waterproof paint is prepared from 55-65wt% of emulsified asphalt, 25-35wt% of modified latex, 5-10wt% filler and the like. The high-strength rubber asphalt waterproof paint is prepared from the following steps of adding the emulsified asphalt, the modified latex and the filler into a stirring cylinder, stirring for 20min at a high speed, standing for 1 hour and then filtering to obtain the rubber asphalt waterproof paint. According to the high-strength rubber asphalt waterproof paint disclosed by the invention, high-strength composite modified emulsion is used for modification. The high-strength rubber asphalt waterproof paint has the remarkable characteristics of high strength, perfect fit, high elasticity, seamlessness and the like and can be manually scrapped and coated; therefore, the defect that the strength of the traditional asphalt coating is insufficient is solved.

Owner:KUNMING FENGXING WATERPROOF MATERIAL +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com