Walnut powder and production method thereof

A production method and technology of walnut powder, applied in application, food preparation, food science and other directions, can solve problems such as poor solubility, low purity, and inability to achieve aseptic production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

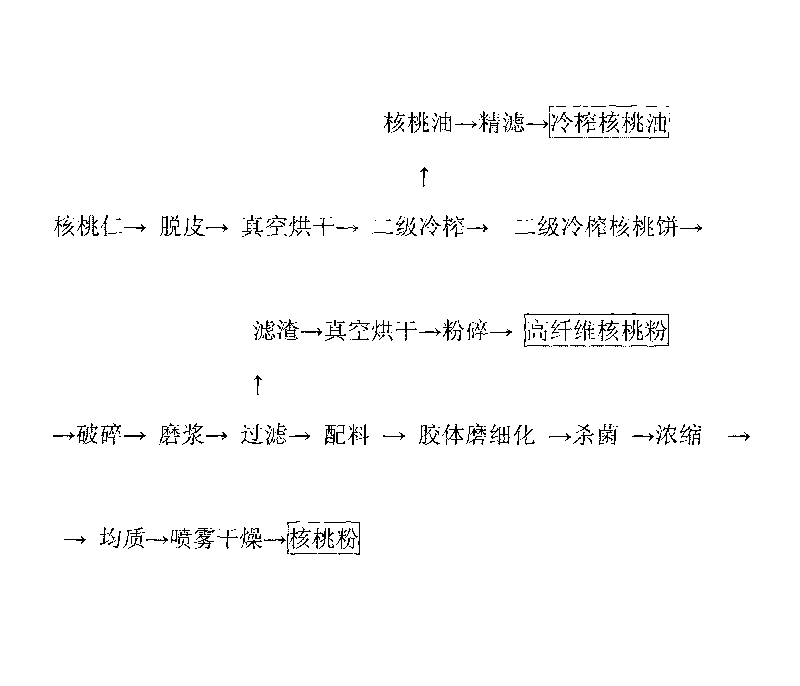

[0139] Walnut powder production method of the present invention is as follows:

[0140] ①Material selection: select plump walnut kernels that are free from insects, mildew, and oil spills, and remove walnut shells and impurities;

[0141] ② Peeling: Use walnut kernels containing 0.1% CaCl 2 Soak with 0.5% NaOH compound lye for 5 minutes, the soaking temperature is 60-63°C, the amount of compound lye is 4 times the weight of walnut kernels, spray with 0.3Mpa high pressure and small flow water gun after soaking and combine with bubbling water flow impact Combined with ultrasonic vibration three-effect washing peeling, ultrasonic vibration power ≥ 2000W, time 5min;

[0142] ③Centrifugal dehydration: Centrifugal dehydration of peeled walnut kernels;

[0143] ④ Drying: Put the peeled walnut kernels into a vacuum drying oven at a temperature of 48-50°C and a pressure of 0.07Mpa, and dry until the moisture content is about 5%;

[0144] ⑤ Crushing: Use a crusher to break the peeled...

Embodiment 2

[0153] Walnut powder production method of the present invention is as follows:

[0154] ①Material selection: select plump walnut kernels that are free from insects, mildew, and oil spills, and remove walnut shells and impurities;

[0155] ② Peeling: Use walnut kernels containing 0.1% CaCl 2 Soak with 0.5% NaOH compound lye for 3 minutes, soaking temperature is 60-63°C, the amount of compound lye is 4 times the weight of walnut kernels, spray with 0.5Mpa high pressure and small flow water gun after soaking and combine with bubbling water flow impact Washing and peeling combined with ultrasonic vibration three effects, ultrasonic vibration power ≥ 2000W, time 3min;

[0156] ③Centrifugal dehydration: Centrifugal dehydration of peeled walnut kernels;

[0157] ④ Drying: Put the peeled walnut kernels into a vacuum drying oven at a temperature of 48-50°C and a pressure of 0.07Mpa, and dry until the moisture content is about 5%;

[0158] ⑤ Crushing: Use a crusher to break the peele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com