Application of sterilization electrochemical water to processing and disinfection of pork white bars

A technology of electrified water and white strips, which is applied in food processing, meat/fish preservation with chemicals, etc., can solve the problems of high equipment cost, high cost, immature application technology, etc., and achieve easy operation, extended shelf life, and extended product The effect of shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The steps for processing and disinfecting peeled pork strips with sterilized electrolytic water are as follows:

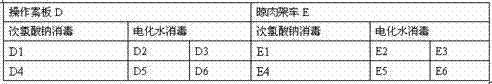

[0026] (1) Use sterilized electrochemical water to sterilize the processing equipment;

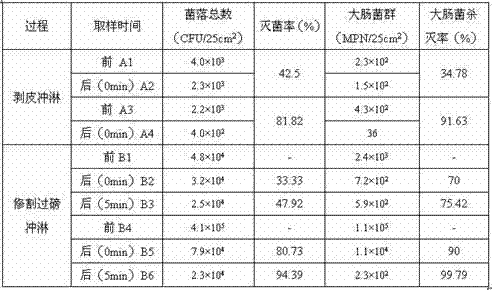

[0027] (2) Rinse the white strips of pork after slaughtering and peeling with sterilized electrochemical water for 10 seconds, the water temperature is 25°C, and the ambient temperature of the processing workshop is 20°C;

[0028] (3) After the skinless pork strips are trimmed, sliced, trimmed, and weighed, rinse them with sterilized electrolytic water for 15 seconds, the water temperature is 25°C, and the workshop temperature is 20°C;

[0029] The showering method is spray gun water showering; the intensity is a spray speed of 800mL / s; the showering time is related to the intensity, and the intensity affects the showering time.

[0030] (4) Stand still for 4-6 minutes after showering, and then pre-cool the pork strips at -1°C for 14 hours;

[0031] (5) After the ...

Embodiment 2

[0035] The steps for processing and disinfecting non-peeled pork white strips with sterilized electrolytic water are as follows:

[0036] (1) Use sterilized electrochemical water to sterilize the processing equipment;

[0037] (2) Rinse the non-peeled pork strips with sterilized electrochemical water for 15 seconds, the water temperature is 30°C, and the ambient temperature of the processing workshop is 25°C;

[0038] (3) After trimming, cutting, trimming, and weighing the white strips of non-peeled pork, rinse them with sterilized electrochemical water for 15 seconds, the water temperature is 30°C, and the workshop temperature is 25°C;

[0039] The showering method is spray gun water showering; the intensity is a spray speed of 800mL / s; the showering time is related to the intensity, and the intensity affects the showering time.

[0040] (4) After showering, let it stand for 4-6 minutes, then pre-cool the white strips of pork without skin, the pre-cooling temperature...

Embodiment 3

[0045] The steps for processing and disinfecting peeled pork strips with sterilized electrolytic water are as follows:

[0046] (1) Use sterilized electrochemical water to sterilize the processing equipment;

[0047] (2) Rinse the slaughtered pork strips with sterilized electrochemical water for 12 seconds, the water temperature is 28°C, and the ambient temperature of the processing workshop is 22°C;

[0048] (3) After trimming, slicing, trimming, and weighing the pork white strips, rinse them with sterilized electrochemical water for 10-15s, water temperature 26°C, and workshop temperature 23°C;

[0049] The showering method is spray gun water showering; the intensity is a spray speed of 800mL / s; the showering time is related to the intensity, and the intensity affects the showering time.

[0050] (4) After showering, let it stand for 4-6 minutes, then pre-cool the pork white strips, the pre-cooling temperature is 4°C, and the time is 16 hours;

[0051] (5) After the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com