Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

193 results about "Titanium electrode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

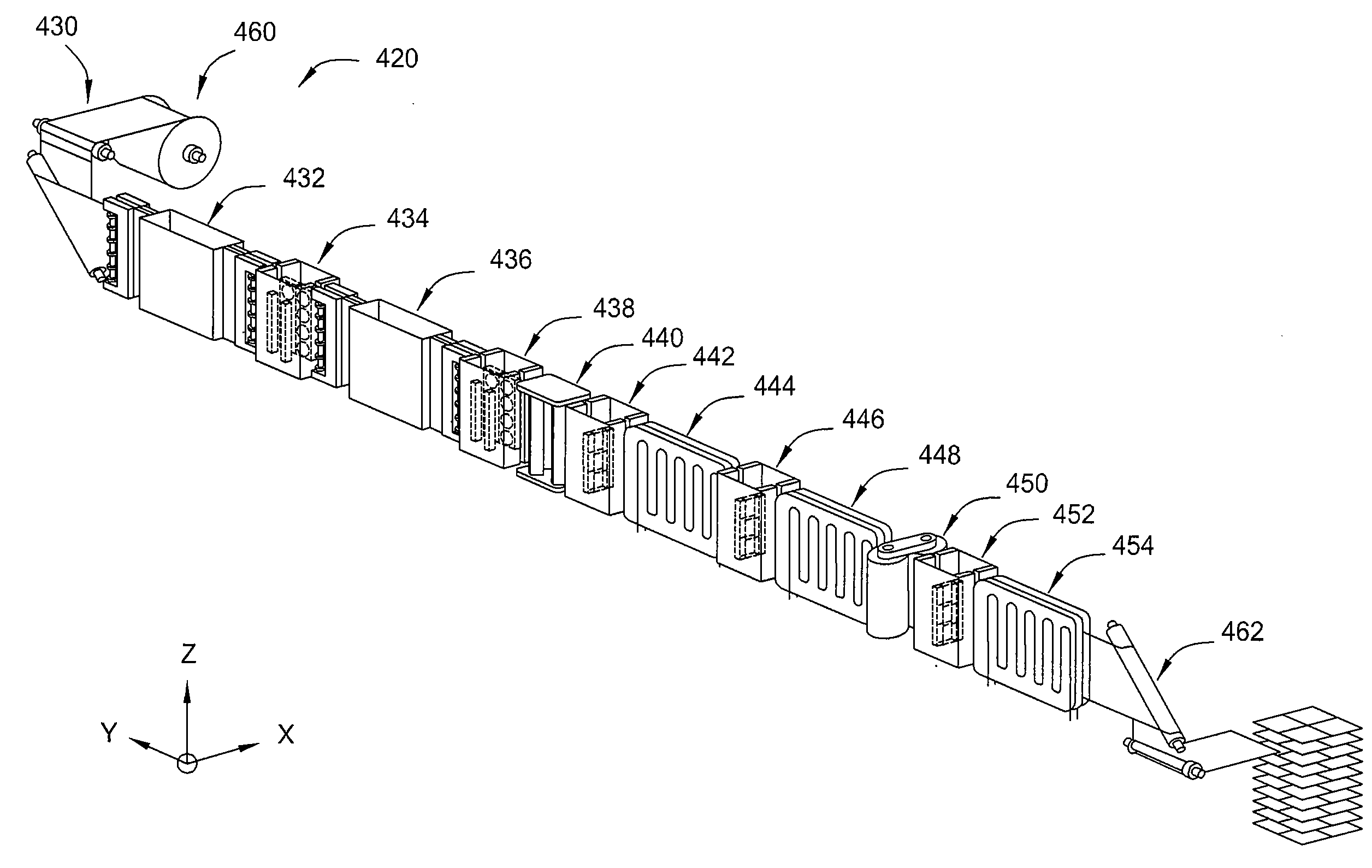

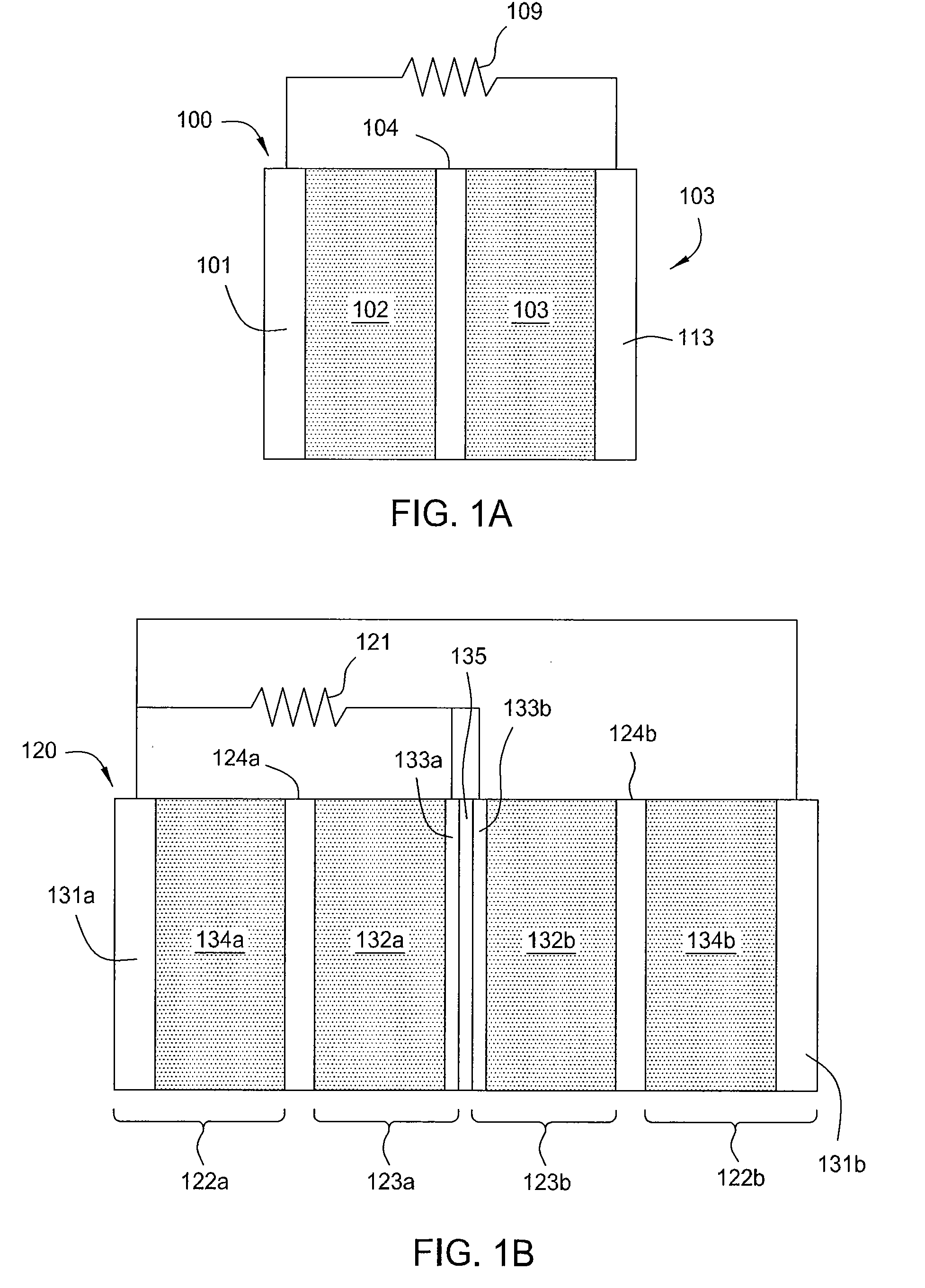

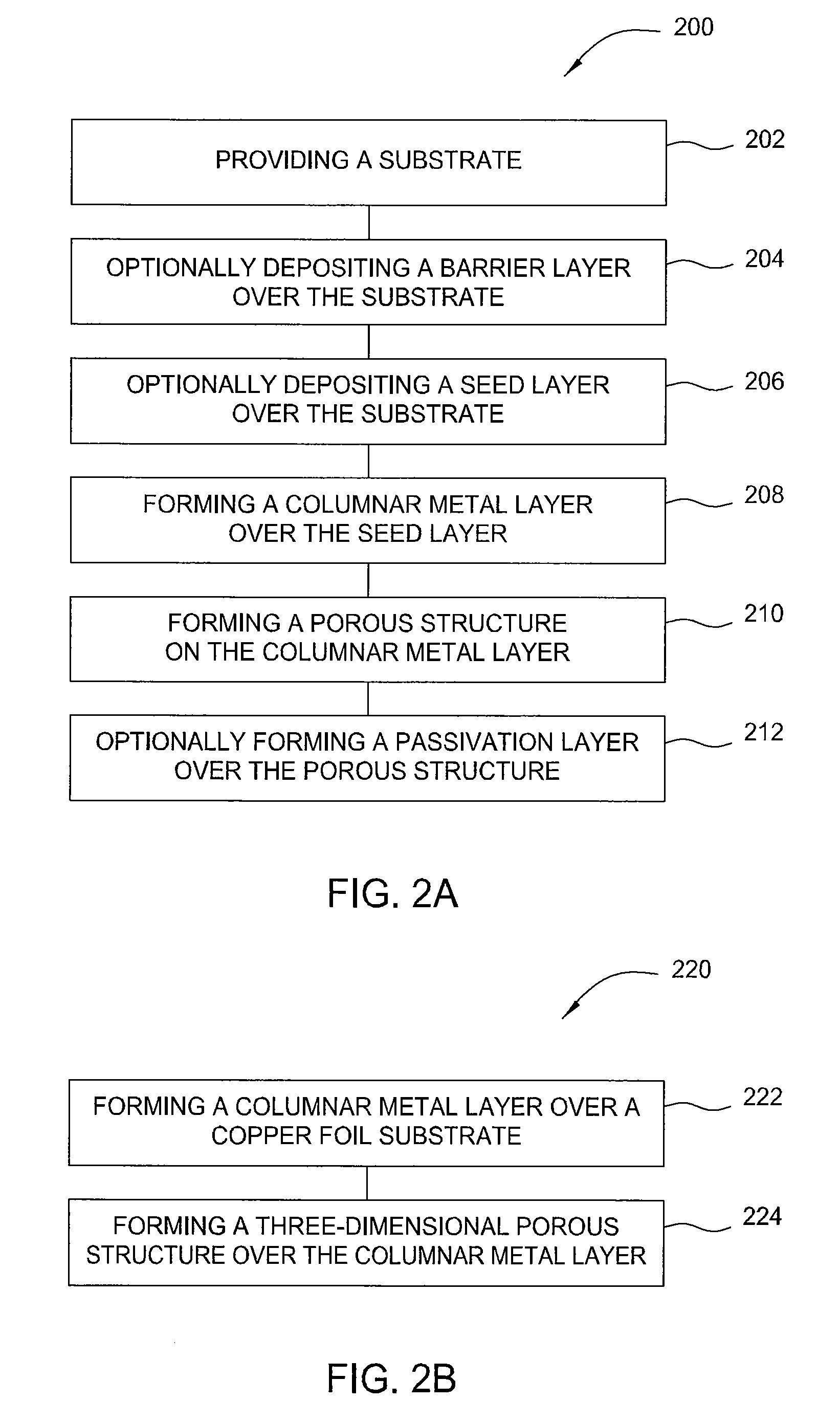

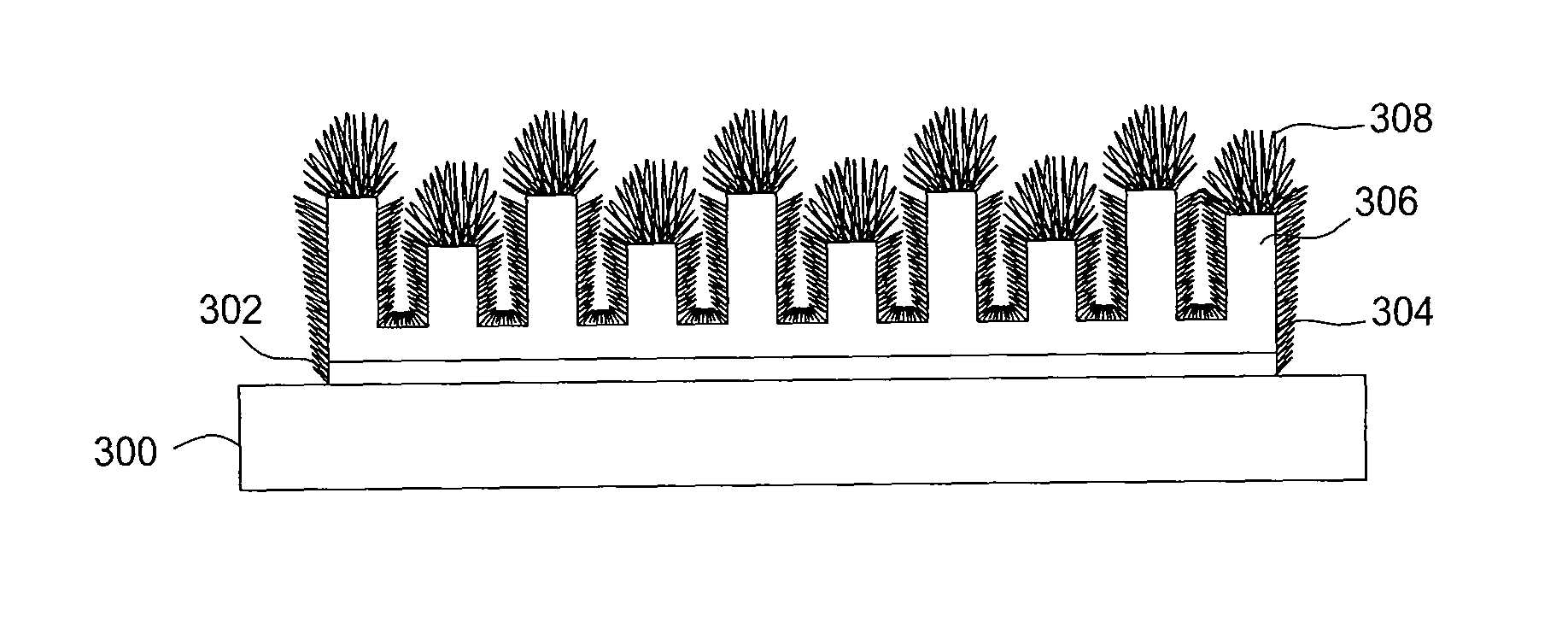

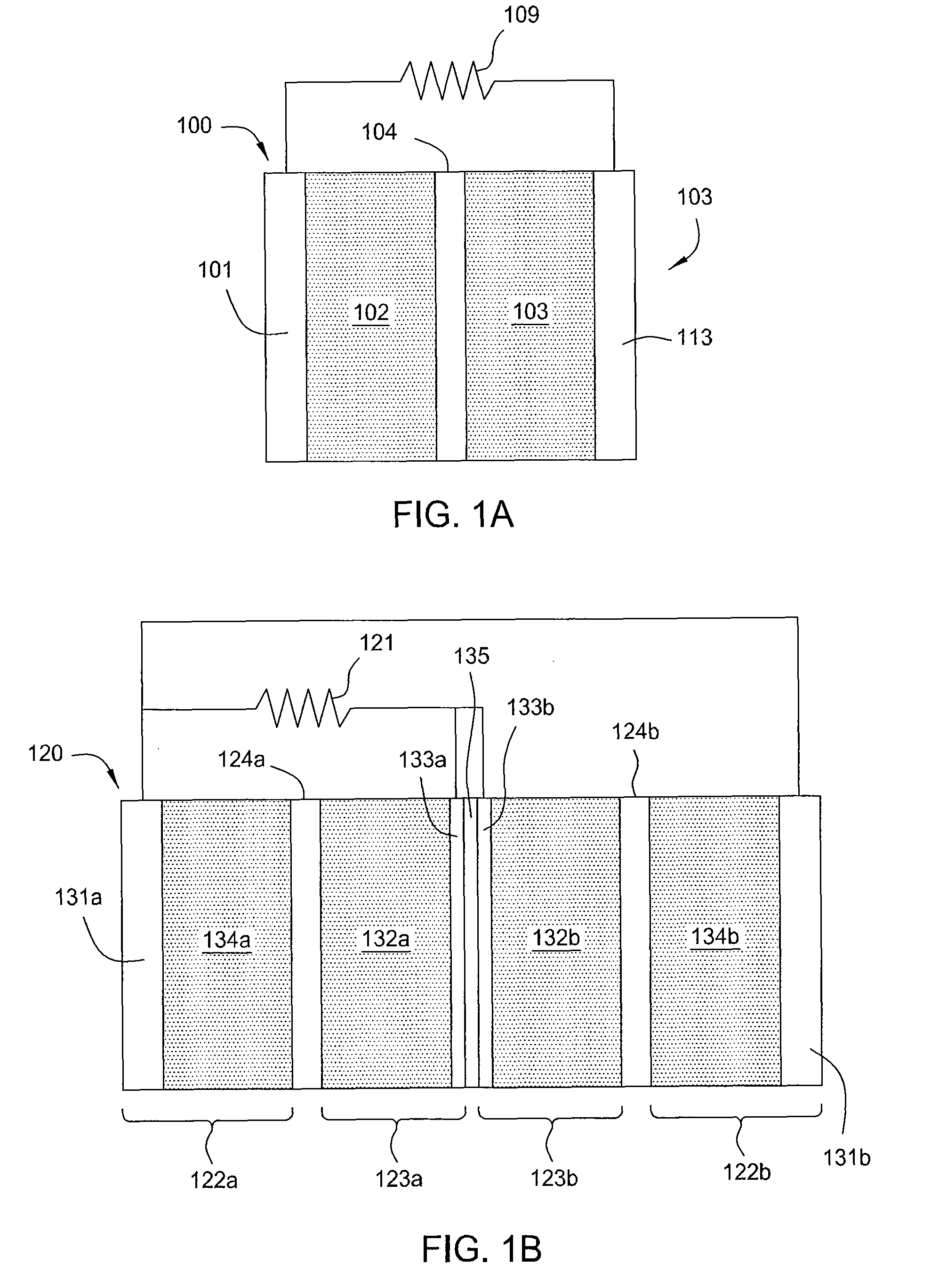

Porous three dimensional copper, tin, copper-tin, copper-tin-cobalt, and copper-tin-cobalt-titanium electrodes for batteries and ultra capacitors

InactiveUS20100193365A1Electrochemical processing of electrodesElectrolysis componentsTitanium electrodePorous electrode

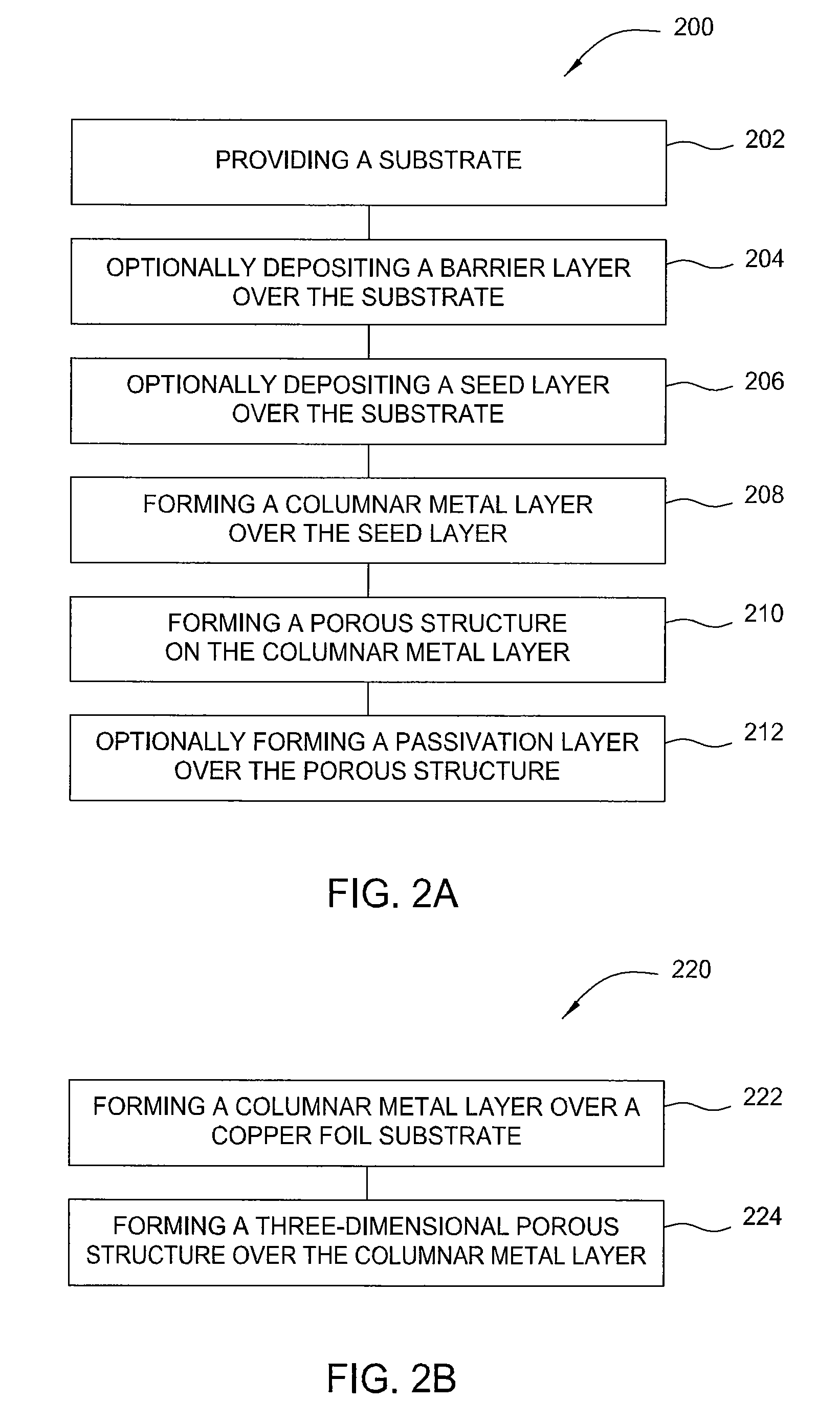

A method and apparatus for forming a reliable and cost efficient battery or electrochemical capacitor electrode structure that has an improved lifetime, lower production costs, and improved process performance are provided. In one embodiment a method for forming a three dimensional porous electrode for a battery or an electrochemical cell is provided. The method comprises depositing a columnar metal layer over a substrate at a first current density by a diffusion limited deposition process and depositing three dimensional metal porous dendritic structures over the columnar metal layer at a second current density greater than the first current density.

Owner:APPLIED MATERIALS INC

Water catalyst sterilizing and detoxifying device and producing and using method thereof

InactiveCN102370106ASimple structureReasonable designCleaning using gasesCleaning using liquidsTitanium electrodePesticide residue

The invention discloses a water catalyst sterilizing and detoxifying device and a producing and using method thereof. The device comprises a water catalyst generator and a DC (direct current) power supply, wherein the water catalyst generator comprises an anode electrode and a cathode electrode which are both titanium electrodes; and the anode electrode is coated with a composite material coating. The producing method comprises the following steps of: (I) making electrodes; and (II) making the composite material coating: preparing composite material coating liquid, and brushing, drying and sintering the coating liquid in multiple times. The using method comprises the following steps of: a, placing the cleaned article and the water catalyst generator in the cleaning water; b, connecting the water catalyst generator with the DC power supply; and c, purifying the cleaned article with the water catalyst generator and the cleaning water. According to the invention, the design is reasonable, the producing and using processes are simple, and the purifying effect is good; and moreover, the problems of poor using effect, possible new pollution, easy damage to the nutrient components of thecleaned food and the like of the existing sterilizing and pesticide residue removing methods can be solved.

Owner:姚广兴

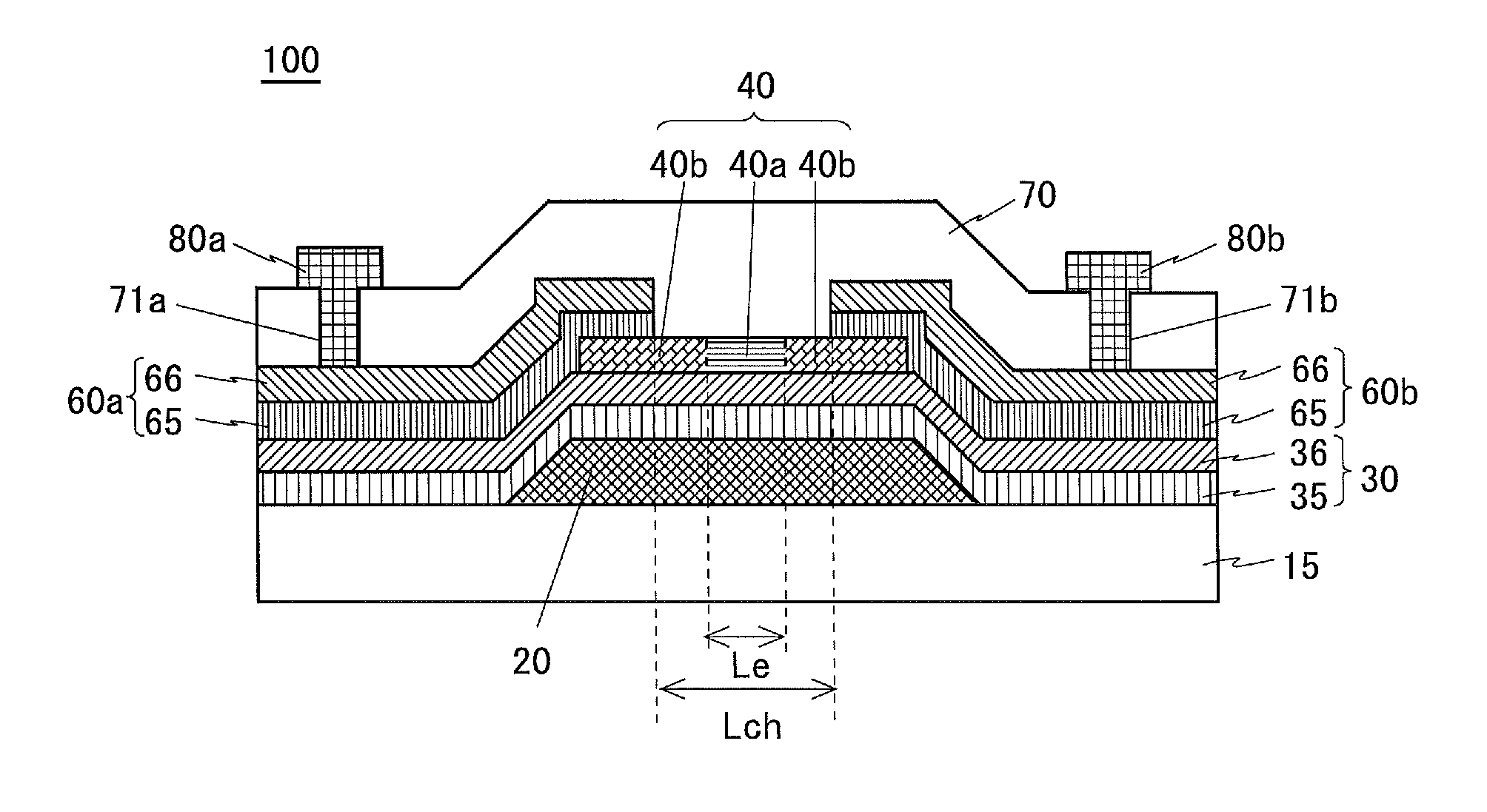

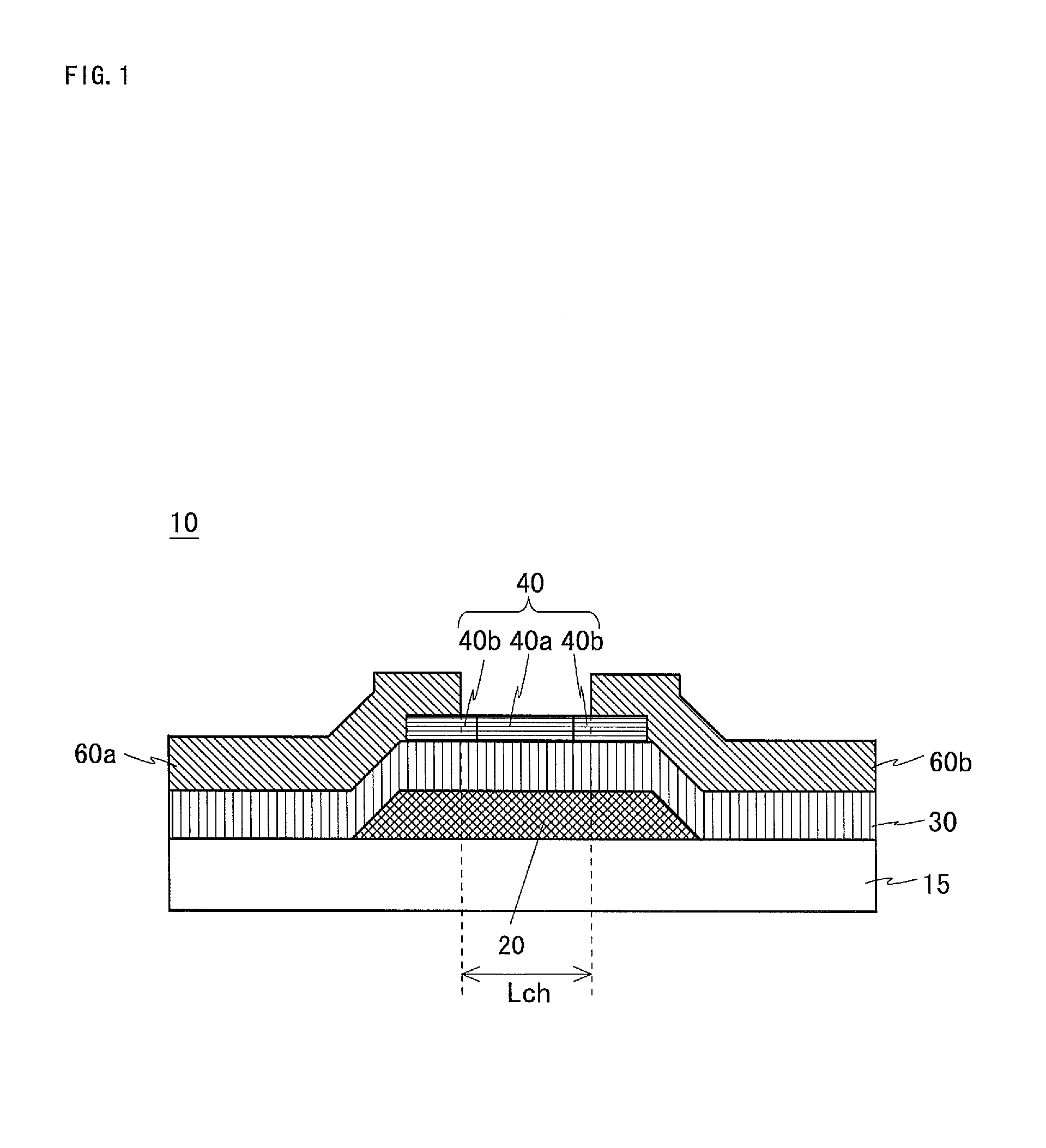

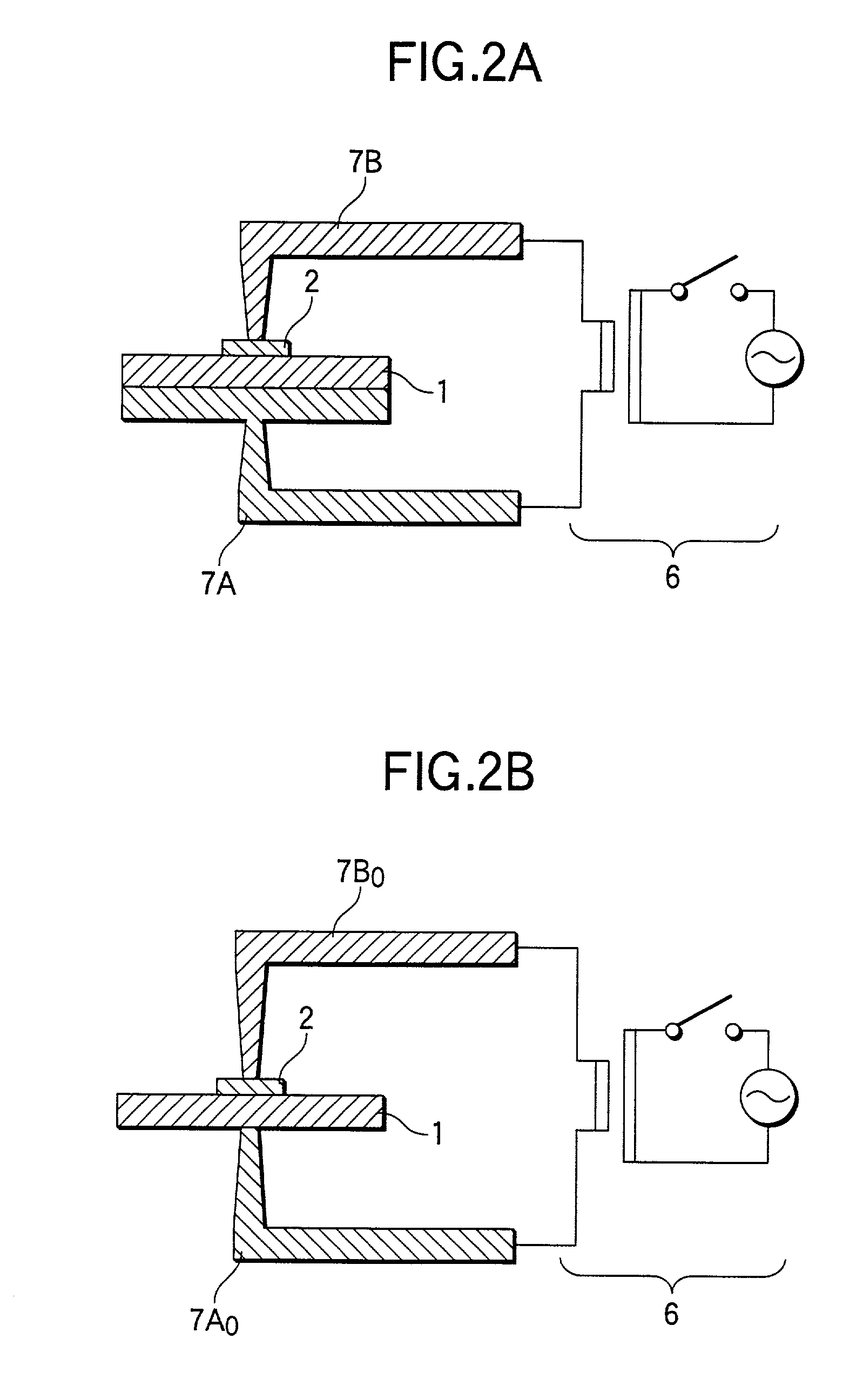

Thin film transistor and manufacturing method therefor, and display device

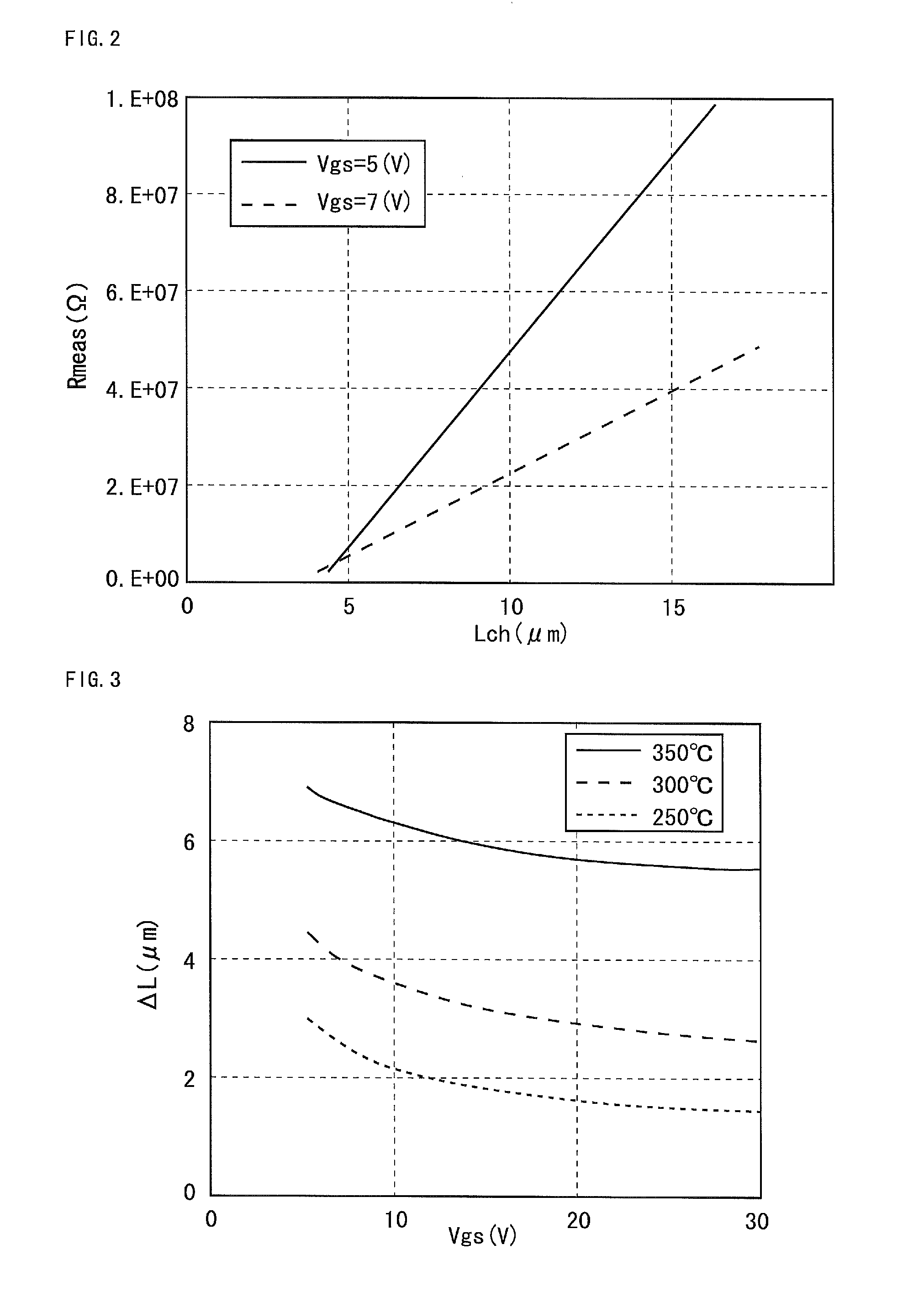

ActiveUS20140035478A1High currentShort channel lengthTransistorSolid-state devicesHigh resistanceTitanium electrode

The invention provides a thin film transistor having current driving force that can be substantially improved. By heat treatment, the IGZO layer (45) from which oxygen is taken away by the titanium electrodes (65) becomes the low resistance regions (40b), and the IGZO layer (45) from which oxygen is not taken away remains as the high resistance region (40a). In this state, when the gate voltage is applied to the gate electrode (20), electrons in the low resistance regions (40b) near the boundaries with the high resistance region (40a) move respectively to the titanium electrode (65) sides. As a result, the length of the low resistance regions (40b) becomes short, and oppositely, the length of the high resistance region (40a) becomes longer by the size of the shortened low resistance regions. However, the electrical channel length (Le) becomes shorter than the source / drain interval space (Lch) as the limit resolution of the exposure device, and the current driving force becomes large.

Owner:SHARP KK

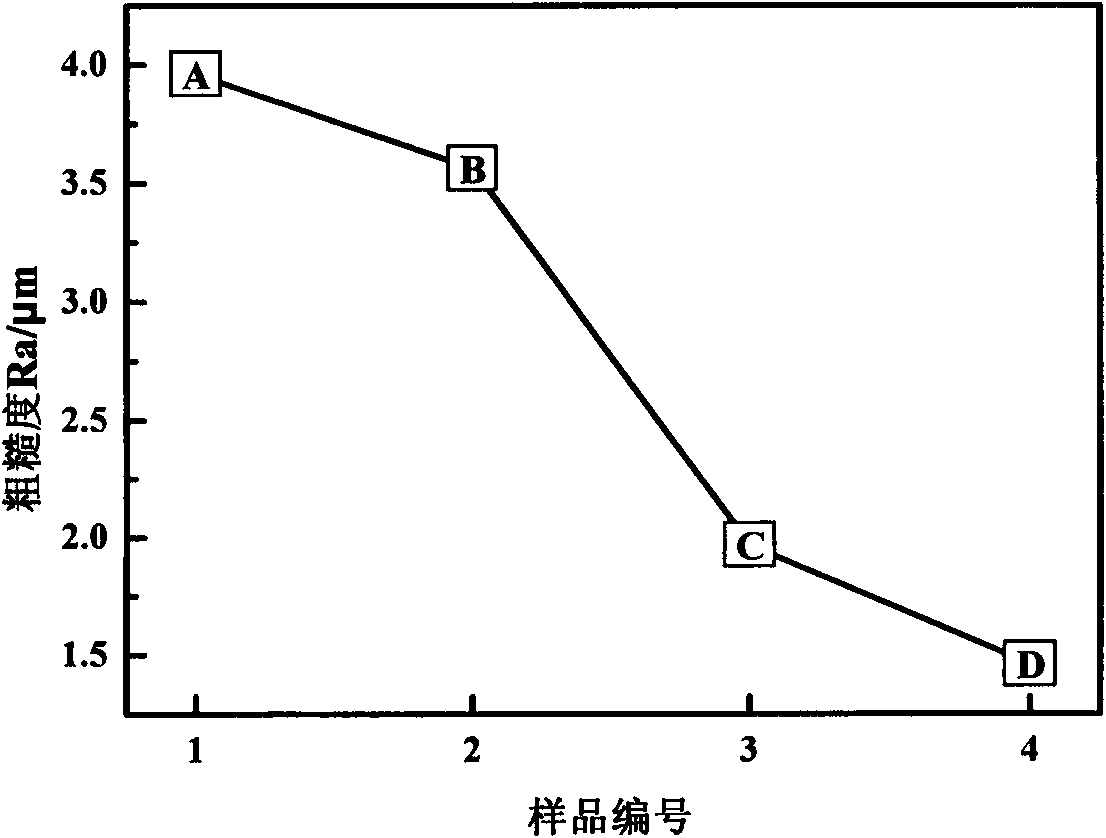

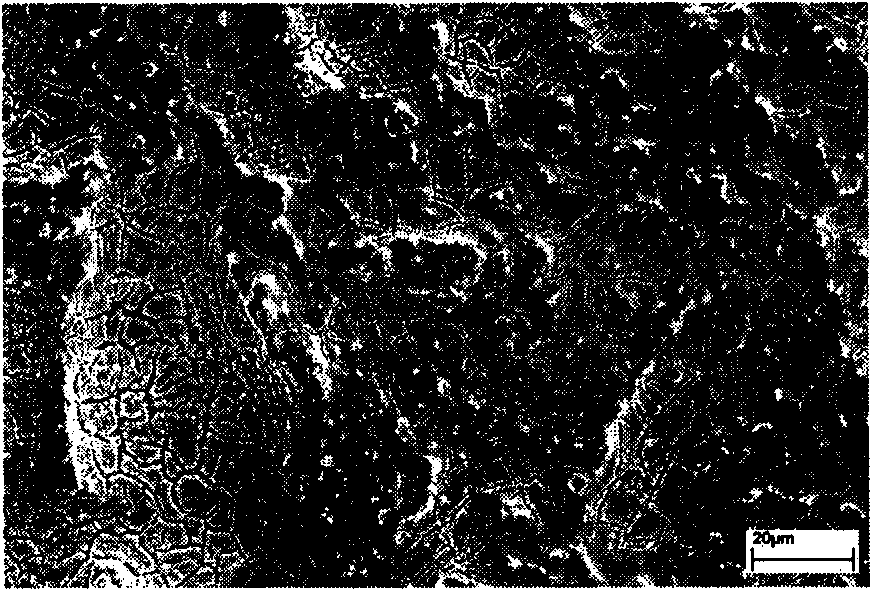

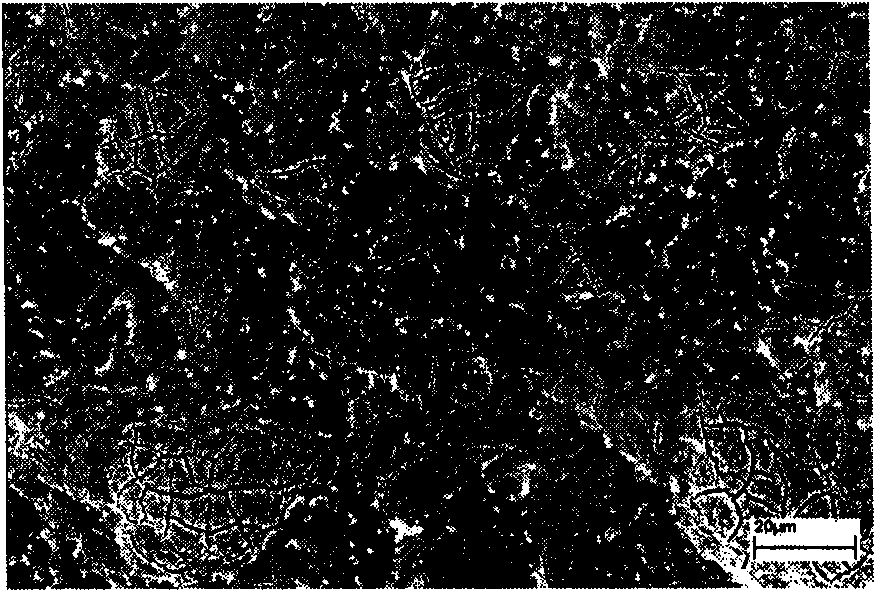

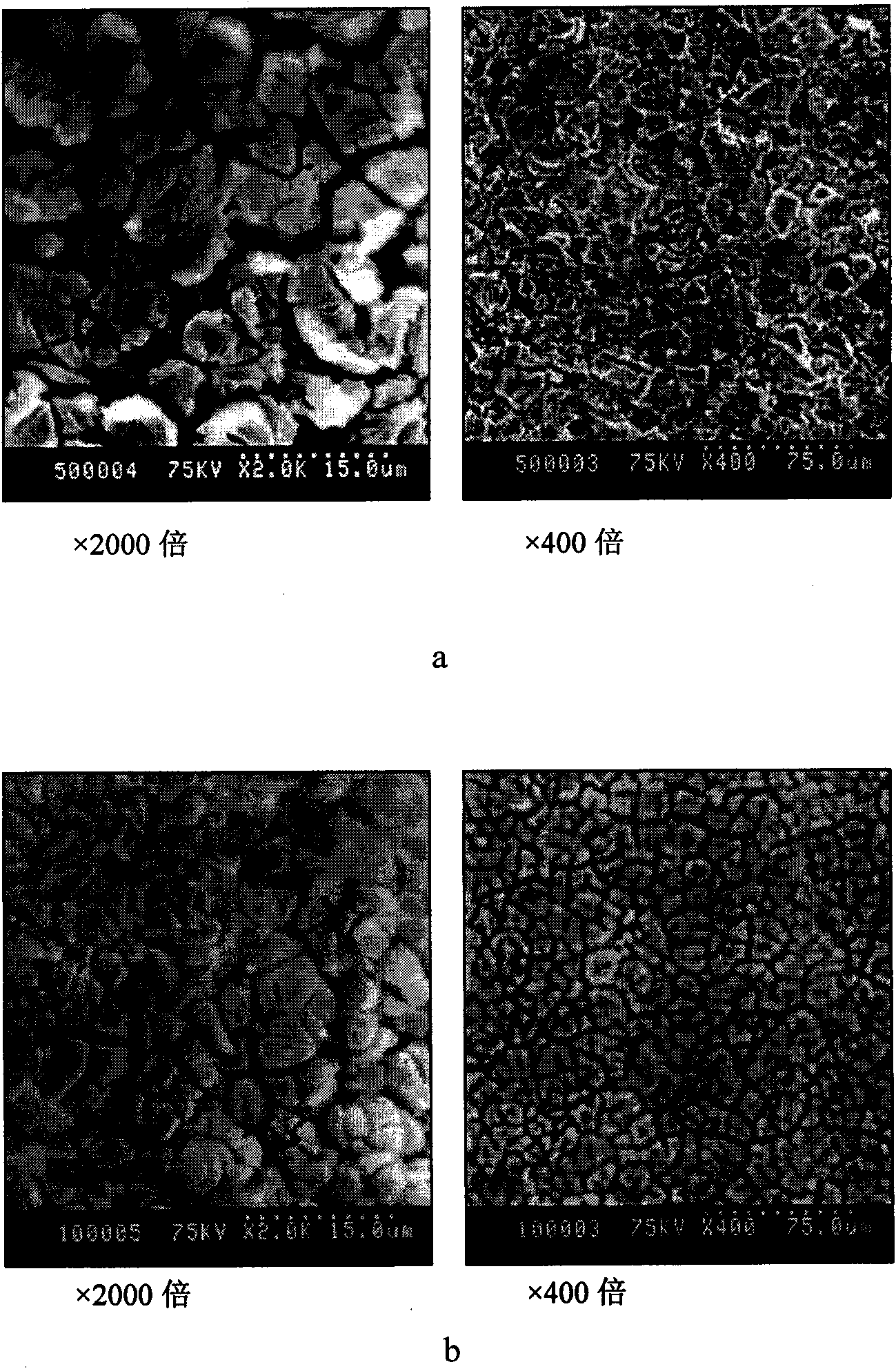

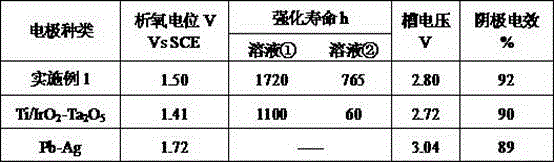

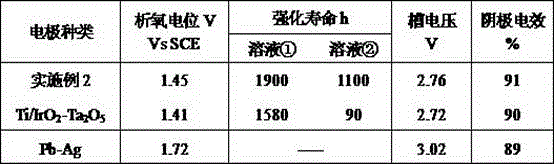

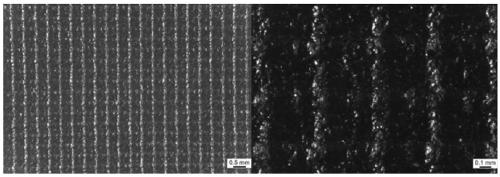

Method for surface pre-treatment of titanium electrode substrate

InactiveCN101565834AOptimal Preprocessing ParametersEnhanced electrocatalytic activity for oxygen evolutionElectrodesTitanium electrodeMetallic materials

The invention belongs to the field of metal material and relates to a method for surface treatment of a titanium electrode substrate. The service life and the electrocatalysis performance of the titanium electrode are greatly increased by the abrasive blasting pretreatment to the substrate. The abrasive blasting treatment is carried out on the titanium substrate; the nozzle pressure of an abrasive blasting machine is 0.3-0.5MPa; the Al2O3 grinding medium of 70-90 meshes is adopted; the blasting angle is 45-90 degrees; the distance from the nozzle to a workpiece is 1-2cm; the coarsening time is 15-30s; the titanium substrate is then pickled for pickling treatment in a 10wt.% of oxalic acid solution for 1.5-2.5 hours at the temperature of 90-95 DEG C; a Ti / IrO2.Ta2O5 oxide coating electrode is prepared on the obtained substrate by a thermal decomposition method, wherein the Ir is chloro-iridic acid, Ta is tantalum pentachloride and the molar ratio of Ir to Ta is 7:3; a coating solution is uniformly coated on the pre-treated titanium substrate by a soft hair brush; the titanium substrate is dried for 10min at the temperature of 120 DEG C, is subsequently arranged in a box-type resistance furnace and sintered for 10min at the temperature of 450 DEG C; the above operations of coating, drying and sintering are repeatedly carried out by 5-20 times; and the final sintering is carried out for 1h at the temperature of 450 DEG C. The method provides optimum pretreatment parameters, greatly prolongs the service life of the titanium electrode, effectively improves the electrocatalytic activity and greatly reduces the running and repairing cost for the electrode.

Owner:UNIV OF SCI & TECH BEIJING

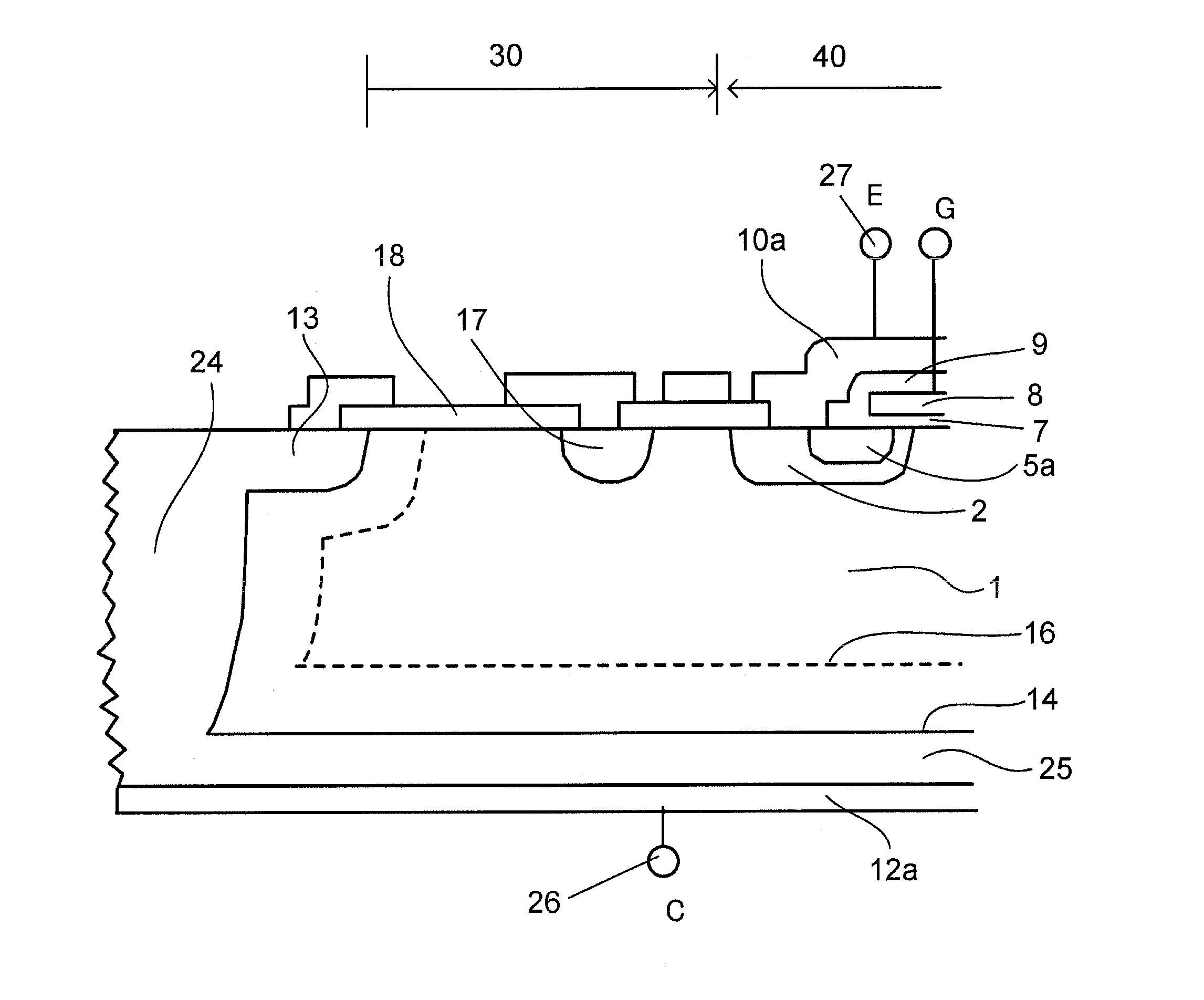

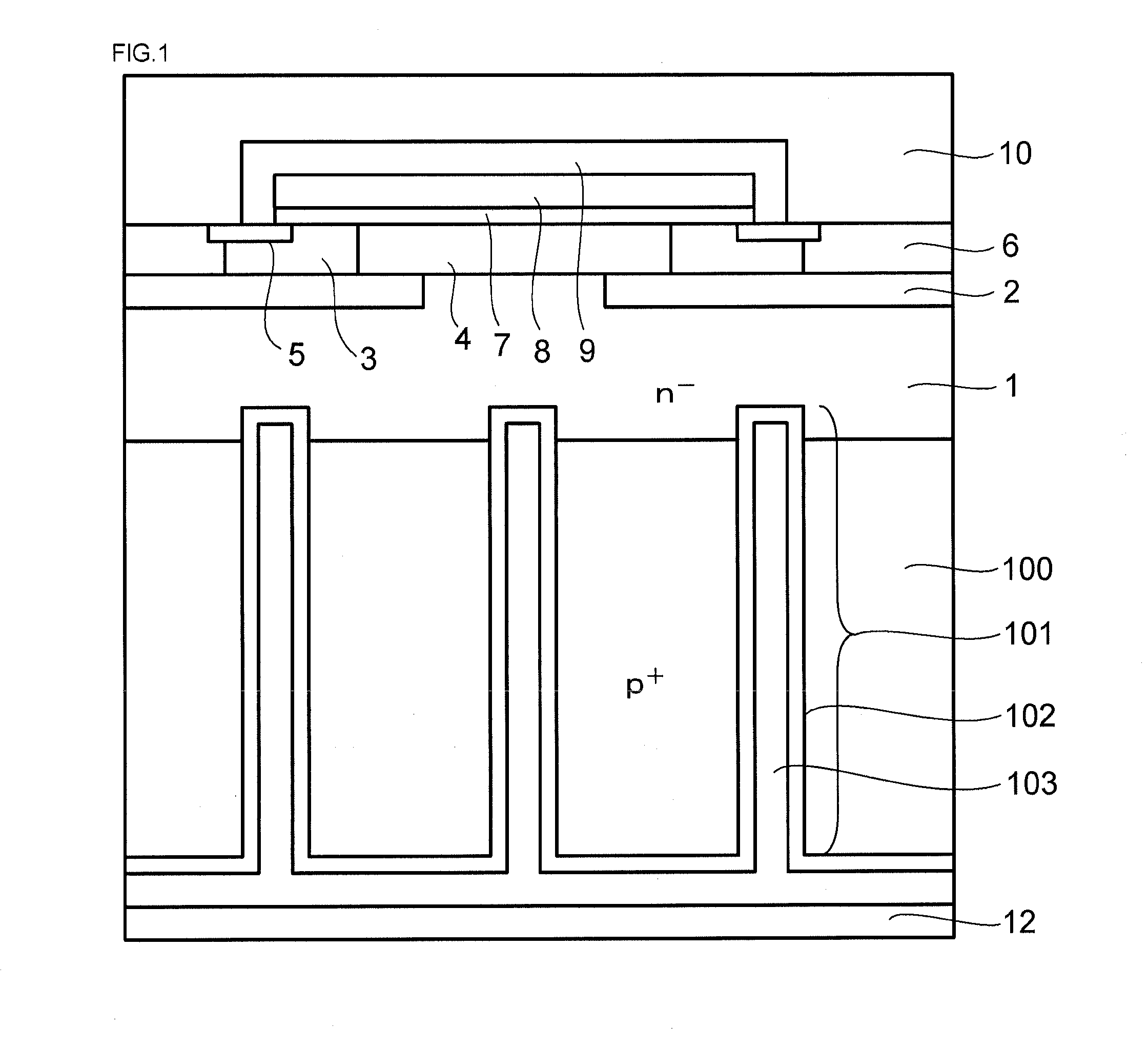

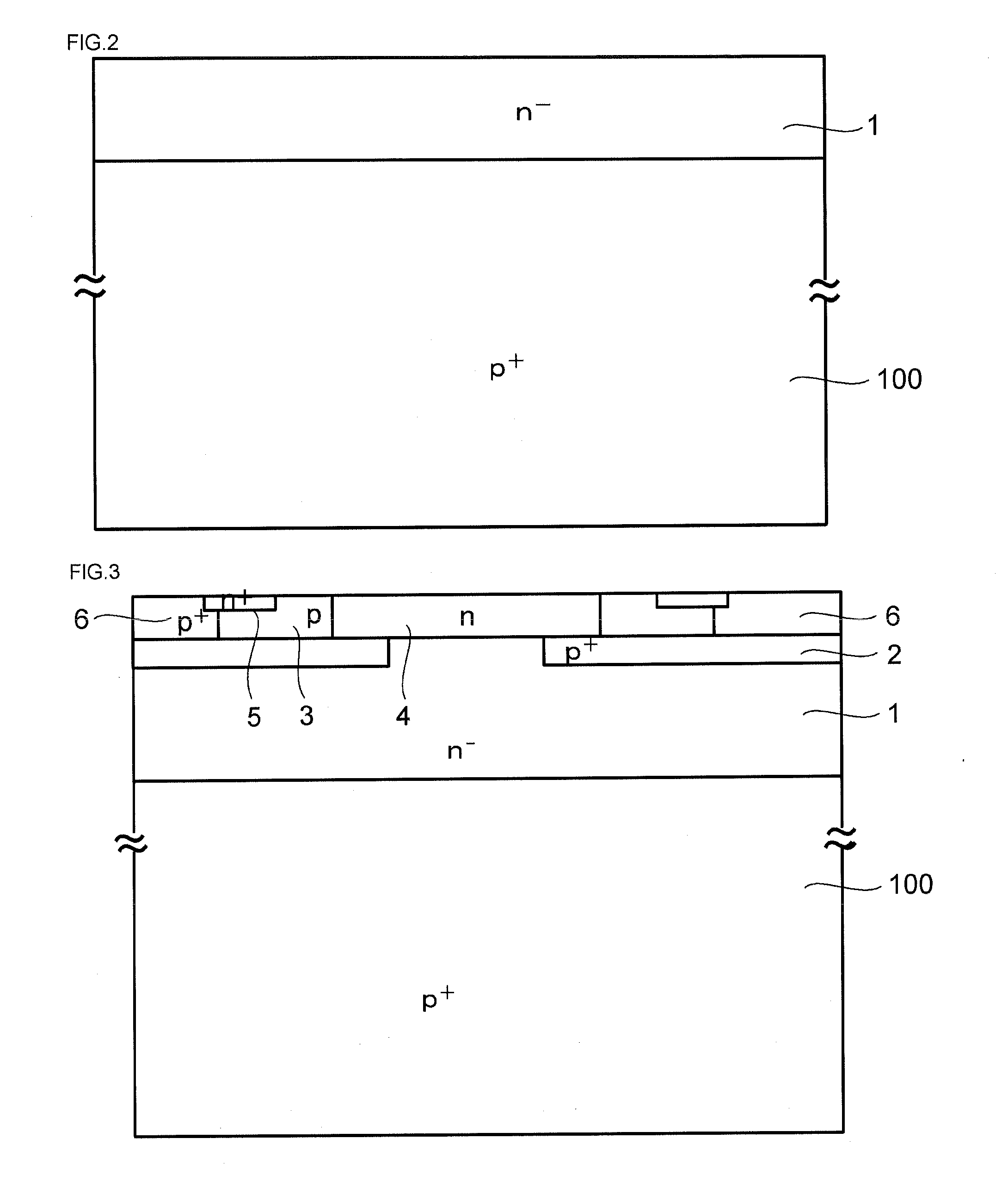

Wide-band-gap reverse-blocking MOS-type semiconductor device

InactiveUS20120211768A1Increase currentImprove rendering capabilitiesSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor devicePower flow

A wide-band-gap reverse-blocking MOS-type semiconductor device includes a SiC n−-type drift layer; a p+-type substrate on the first major surface side of the drift layer; a trench extending through a p+-type substrate into the drift layer; a titanium electrode in the trench bottom that forms a Schottky junction with the SiC n−-type drift layer; an active section including a MOS-gate structure on the second major surface side of the drift layer facing to the area, in which the Schottky junctions are formed; a breakdown withstanding section surrounding the active section; and a trench isolation layer surrounding the breakdown withstanding section, the trench isolation layer extending from the second major surface of the drift layer into p+-type substrate and including insulator film buried therein. The device facilitates making a high current flow with a low ON-voltage and exhibits a very reliable reverse blocking capability.

Owner:FUJI ELECTRIC CO LTD

Titanium electrode for chlorine generator and preparation method thereof

The invention provides a titanium electrode for a chlorine generator and a preparation method thereof, relating to a chlorine generator. The invention provides a titanium electrode with higher chlorine yield efficiency and longer service life for a chlorine generator and a preparation method thereof. The titanium electrode for the chlorine generator is provided with a titanium substrate on which a surface coating is arranged, wherein the surface coating is an oxide layer prepared from the following metals in percentage by mass: 0-70 percent of platinum, 10-80 percent of iridium and 20-90 percent of ruthenium. The preparation method comprises the following steps of: soaking the titanium substrate after surface treatment in water for later use; dissolving chloroplatinic acid, chloro-iridic acid and ruthenium trichloride in a mixed solution of isopropyl alcohol and hydrochloric acid to obtain a coating solution; and cooling, stirring and recoating the coating solution on the titanium substrate, drying, baking, recoating and baking to obtain the finished product.

Owner:INTEX IND (XIAMEN) CO LTD

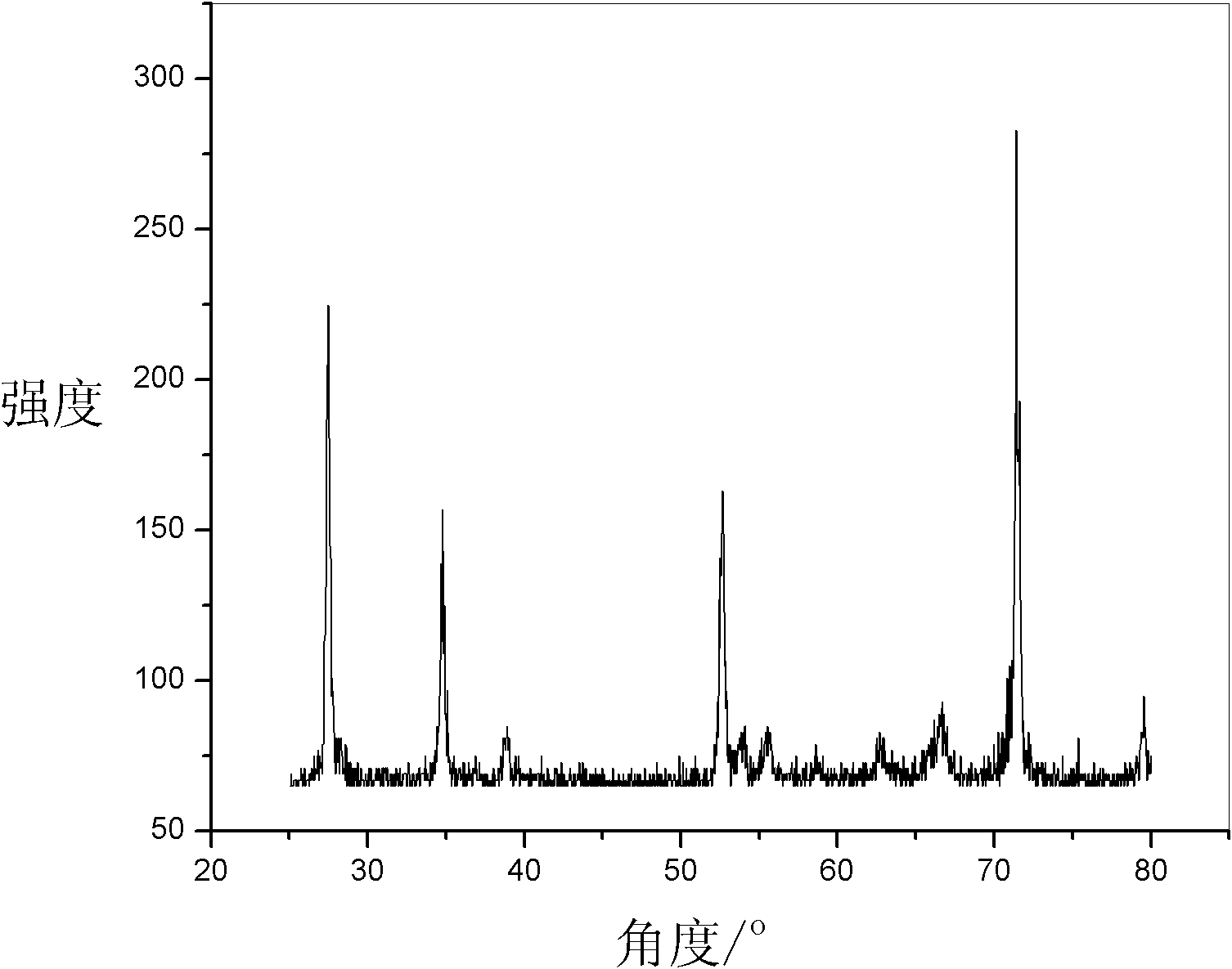

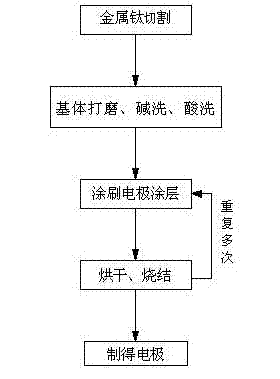

Preparation method of neodymium-doped titanium base tin dioxide-antimony electrode

InactiveCN101654790AHigh catalytic activityImprove performanceWater/sewage treatmentElectrodesTin dioxideTitanium electrode

The invention relates to a preparation method of neodymium-doped titanium base tin dioxide-antimony electrode. The method comprises the following steps: 1) the pretreatment of electrode substrate: polishing, alkaline cleaning and pickling; 2) the preparation of masking liquid: dissolving SnCl4.5H2O, SbCl3 and Nd(NO3)3 according to a ratio of 100:15:1 in solvent to obtain the masking liquid; 3) thepreparation of electrode coating by using immersion method: (1) completely soaking the titanium electrode substrate in the masking liquid for 1min; (2) withdrawing the titanium electrode substrate, blowing away the excessive masking liquid with a blow drier; (3) drying in a baking oven at 100-120 DEG C for 10min to volatilize all the solvent; (4) placing the substrate in a muffle furnace to perform thermal oxidation at 550 DEG C for 15min; (5) cooling to room temperature, dipping again, drying, performing thermal oxidation and repeating the above steps for 15 times to obtain the Nb-doped Ti / Sb-SnO2 electrode. The Nb-doped Ti / Sb-SnO2 electrode prepared by the method of the invention has high oxygen evolution potential, catalytic performance and electricity.

Owner:SHANDONG UNIV

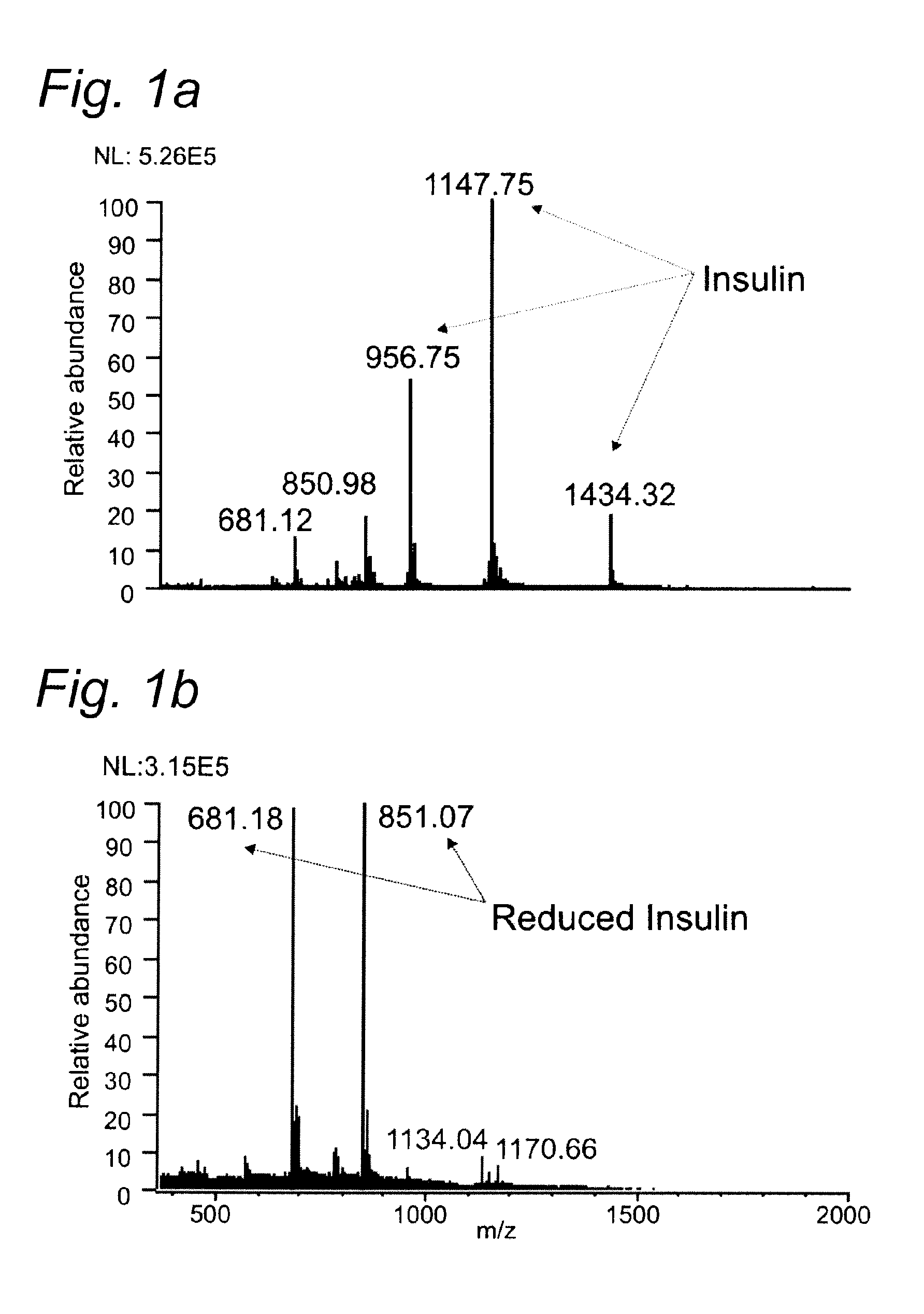

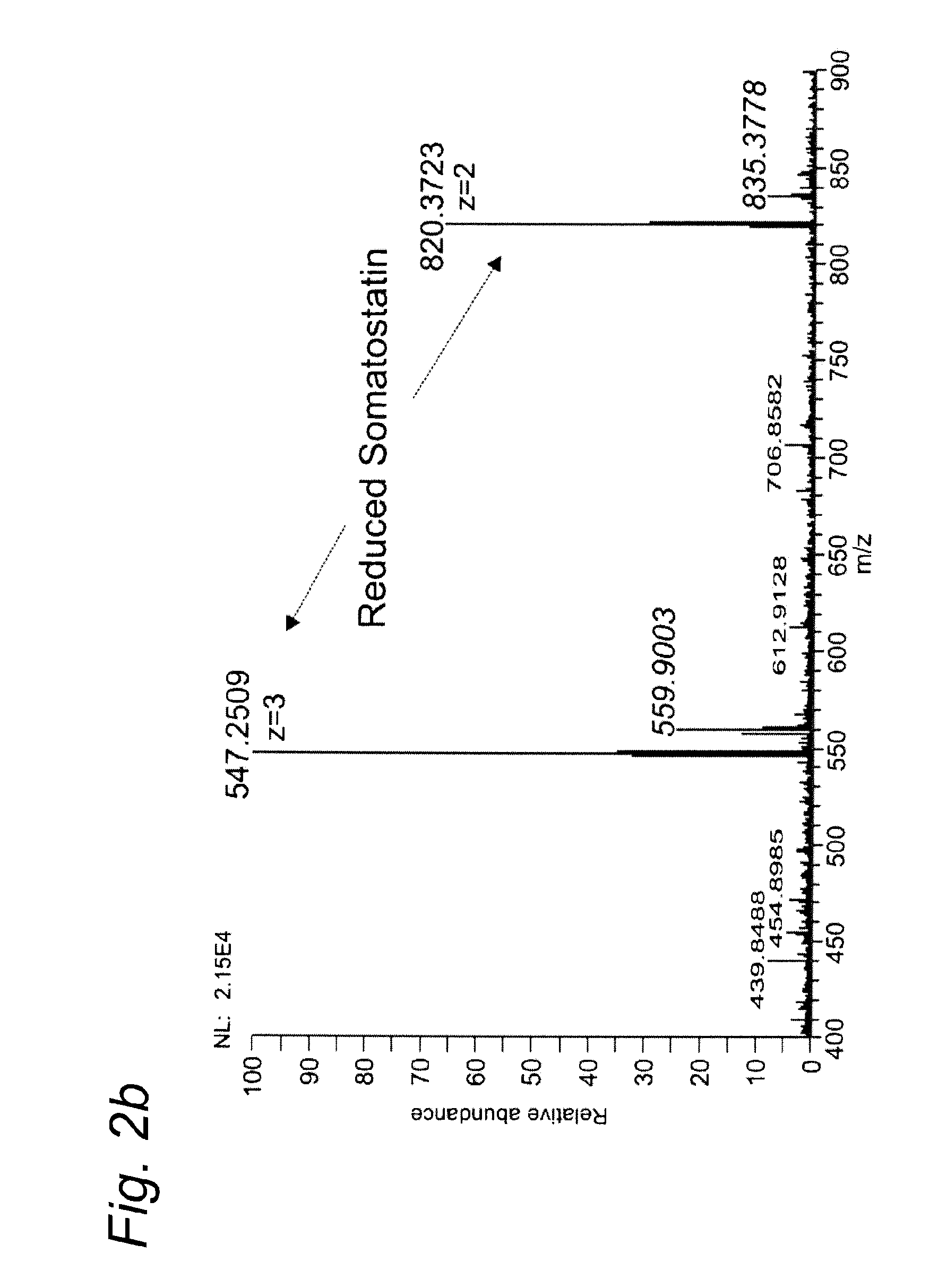

Electrochemical reduction of disulfide bonds in proteinaceous substances and electrochemical cell for carrying out such reduction

InactiveUS20140069822A1Fast and stable and substantially complete reduction of all disulfide bondReduce decreaseElectrolysis componentsLiquid separation by electricityTitanium electrodeRuthenium

A method of cleaving disulfide bonds is provided, which comprises: (a) introducing a liquid sample having disulfide bonds (e.g., proteins) into an electrochemical cell; and (b) subjecting the sample to a reducing potential to reduce the disulfide bonds, wherein the electrochemical cell comprises (i) a working electrode that contains titanium and (ii) an auxiliary electrode. An electrochemical flow cell for processing a sample fluid is also provided, which comprises: (a) a body comprising a flow path having inlet and an outlet; (b) a working electrode in fluid communication with the flow path; and (c) an auxiliary electrode; wherein the working electrode comprises at least 20 wt. % titanium in the form of elemental titanium, titanium-containing substances and / or titanium-containing alloys; and wherein the outlet is connected to an electrochemical detection (ECD) device, a NMR spectrometer or a mass spectrometer (MS) when the working electrode is a ruthenium-plated titanium electrode.

Owner:ANTEC LEYDEN

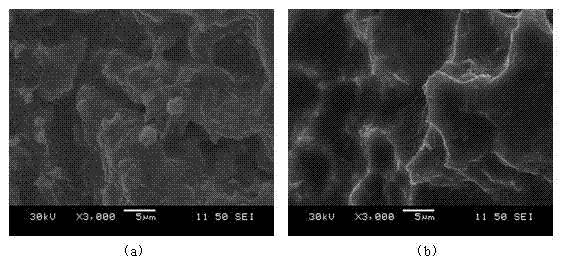

Rare-earth doped titanium-base SnO2 electrolytic electrode and its preparation

ActiveCN1896320AHigh oxygen evolution potentialPromote degradationElectrodesRare-earth elementTitanium electrode

A rare earth-doped Ti-base SnO2 electrocatalytic electrode relates to one type of DSA electrode and its preparing process. The rare earth-doped electrode in this invention is composed of the Titanium substrate and the rare earth-doped SnO2 coat in which the mol ratio of Sn, rare earth elements and Sb is 75-99.8:0.1-10:0.1-15. In this process the Titanium electrode is polished, washed with alkaline and acid, then undergoes delaminated impregnation and gradient temperature rise to realize the formation of the functionally gradient membrane that endows the electrode with relatively high potential of oxygen evolution, strong degrading ability of organic compounds and inert composition without dissolving out. The electrode has strong degrading ability especially of the materials persistent to biodegration or toxic to organisms.

Owner:HARBIN INST OF TECH

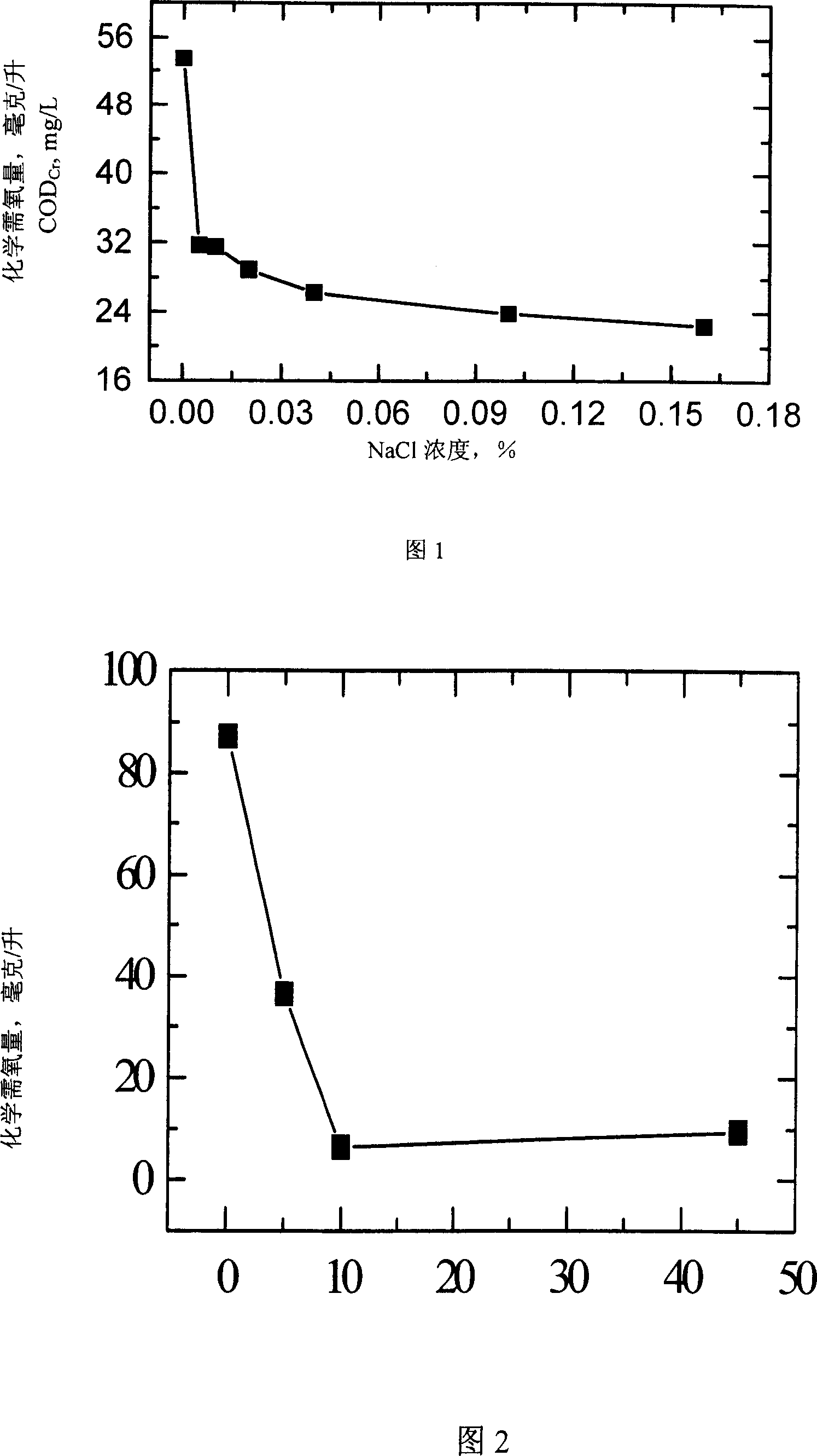

Method for electrolyzing organic waste water using iridium tantalum stannum oxide coating titanium electrode

InactiveCN1962471AImprove electrocatalytic performanceImprove stabilityWater/sewage treatmentElectrodesWater useIridium

The invention discloses an organic waste water disposing method through coating electrode electrolytic disposal of iridium tantalum tin oxide in the electrochemical and environmental chemical technique domain, which is characterized by the following: adding additive in the electrolytic procedure; adopting DC or pulse current with DC density at 1000-2000A .m-2 and electrode board gap at 0.3-1.0cm; possessing saw pulse current with peak current density at 1200-3000A .m-2 and pulse period at 0.5-2.0ms; setting the on-off rate at 1: 3-3: 1 with auxiliary DC component at 0-1000A .m-2 and electrode board gap at 0.5-1.5cm.

Owner:UNIV OF SCI & TECH BEIJING

Method for removing semimetal antimony ion from waste water

InactiveCN101186376AImprove effective utilizationShort processing timeWater/sewage treatmentSemimetalTitanium electrode

The invention discloses an electrochemical deposition method which is used for eliminating semimetal antimony ions from waste water. By adopting a three-electrode or two-electrode system and using a titanium mesh as working electrode, semimetal antimony ions in the solution are precipitated in the form of semimetals or the oxide thereof in the working electrode by constant current electrochemical reduction deposition, so as to effectively eliminate the toxic antimony ions from the waste water with weak acid and low content, etc.; meanwhile, the electrodeposition of trivalent, quintavalent and total antimony can be realized through the adjustment of the acidity of mediums. The titanium which is inert to the reduction of hydrogen ion is adopted as the electrode material, thus improving the effective utilization of the electrode; meanwhile the abundant electrons in the titanium electrode which is a green chemical reagent leading the semimetal antimony ions in the solution to be precipitated after being reduced to solid by one-step method is utilized, therefore the treatment technology without second pollution is clean and has good environmental protection property. Furthermore, the invention has the advantages of simple technology, short process and high efficiency.

Owner:SUZHOU UNIV

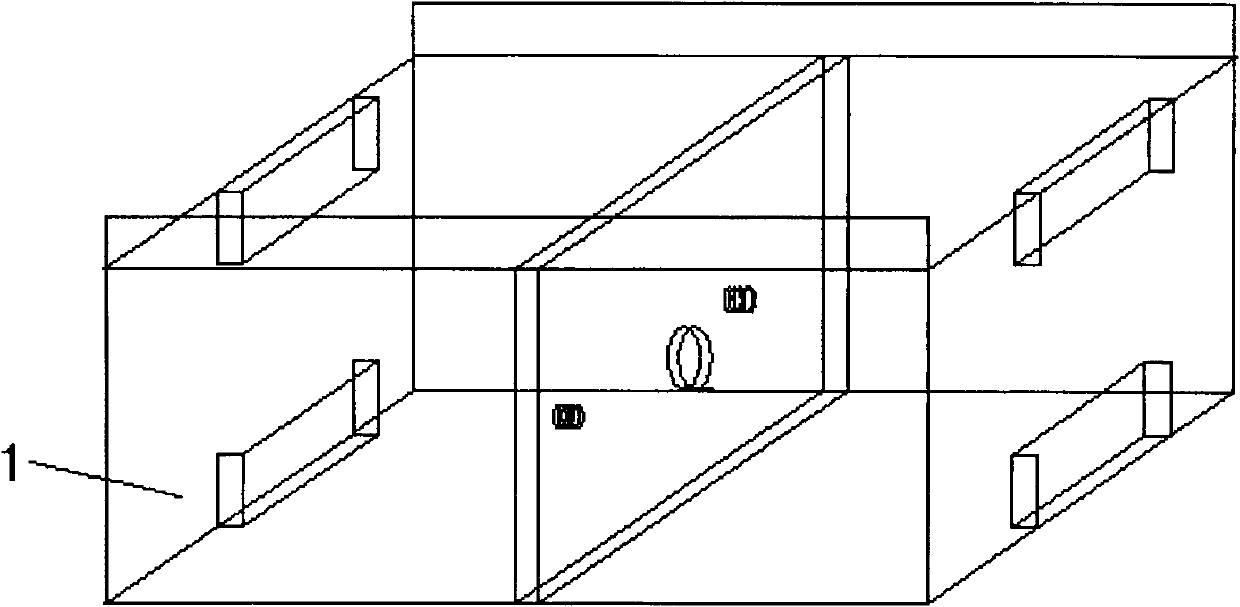

Detecting device and detection method of ion transmembrane migration number tracking

InactiveCN101995430AIntuitive reflection of concentration changesAvoid errorsMaterial resistanceLiquid storage tankTitanium

The invention discloses a device and a method for tracking and detecting ion transmembrane migration number. The device comprises a liquid storage tank, a cover plate, an electrode, a big separator board, a small separator and the like. All the components have the following mutual connection relation: the cover plate and the liquid storage tank are connected with each other from top to down through clamping; a titanium electrode is fixed on a tank wall of the liquid storage tank through a slot; a silver / silver chloride electrode is fixed in the centre of the left and right parts of the cover plate; and the separators are connected with a separator of the liquid storage tank through a nut. The invention can be used for researching influence on ion migration by a film and ion selectivity of the film, and membranoid substances all can test the ion transmission performance of the film through the device, and can be applied to external electric field, thereby the device has the advantages of simple operation, low cost and strong comprehensive function.

Owner:SOUTH CHINA NORMAL UNIVERSITY

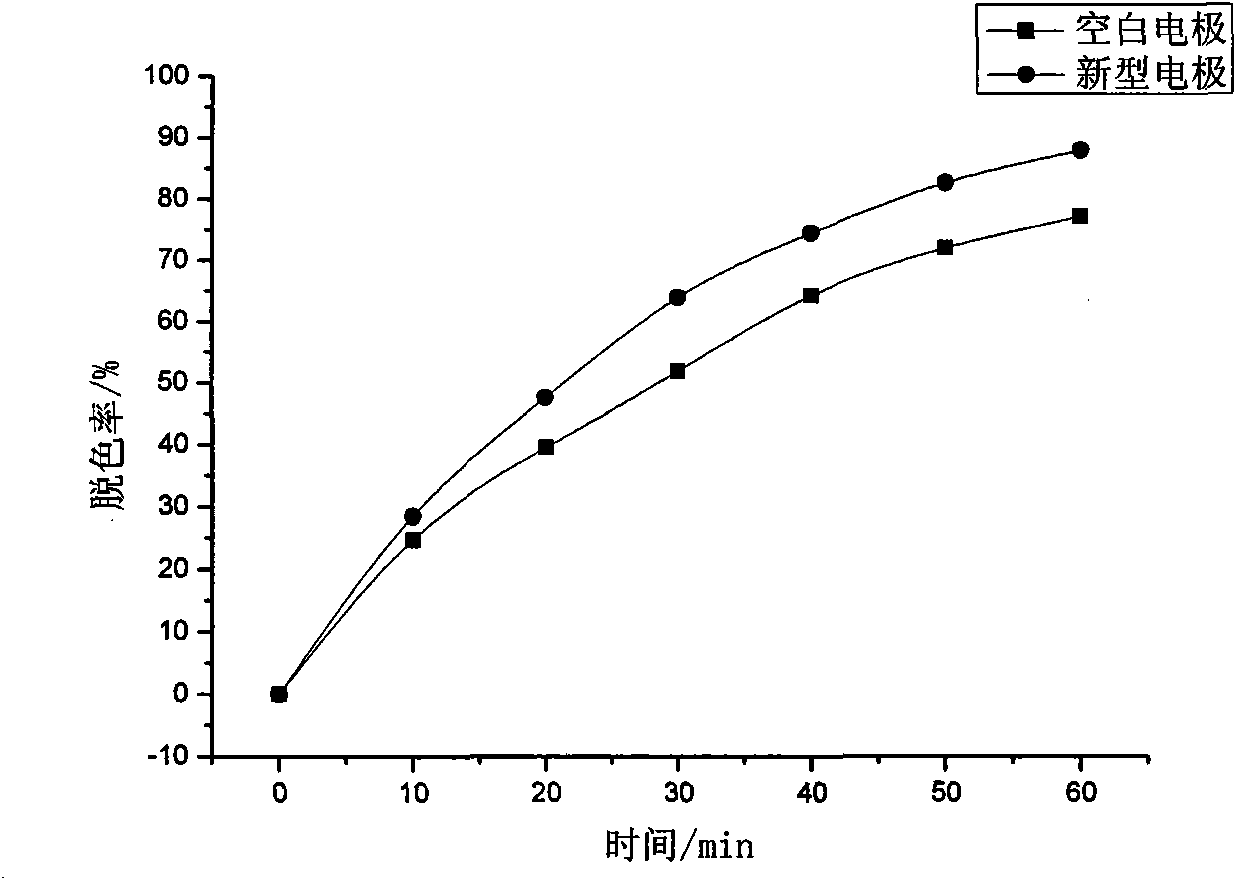

Method for electrolyzing orange G by adopting cerium-doped tin antimony oxide coated titanium electrode

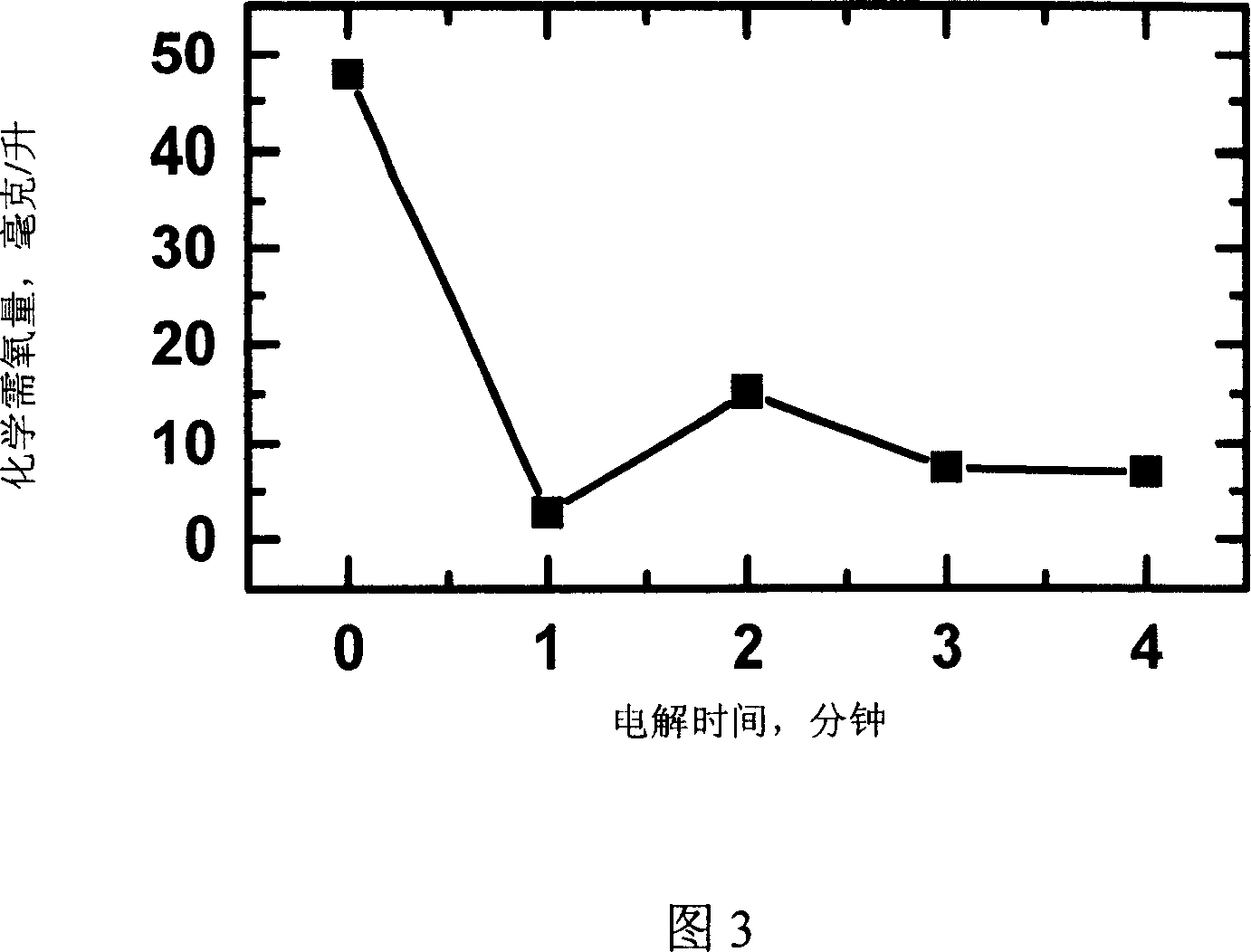

InactiveCN101830542AHas strong oxidizing propertiesNo secondary pollutionWater contaminantsWater/sewage treatmentTitanium electrodeElectrolysis

The invention relates to a method for electrolyzing orange G by adopting a cerium-doped tin antimony oxide coated titanium electrode. The invention belongs to the technical field of electrochemistry and environmental chemistry, in particular to a method of carrying out oxidative degradation research on orange G analog waste water in an aseptate electrode tank by adopting a constant current electrolytic method by taking a self-made cerium-doped tin antimony oxide coated titanium electrode as the anode and a titanium plate as the cathode. Under the optimum process conditions that the effective areas of a negative electrode and a positive electrode are both 2.5cm*2.5cm, the distance between the electrodes is 1.5cm, i is equal to 4.8mA / cm<2>, the concentration of the orange G is 40mg / L, the concentration of NaCl is 0.35mol / L and pH is 7, the time of electrolysis is 30min, and the removing rate of the orange G reaches 99.4 percent. The invention improves the removing effect of the orange G with low energy consumption and no secondary pollution and meets the actual demands of industry.

Owner:SOUTH CHINA NORMAL UNIVERSITY

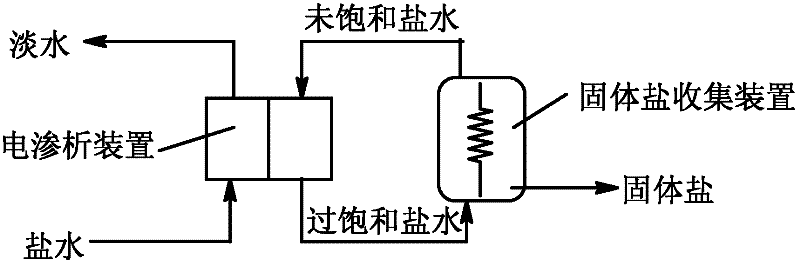

An electrodialysis concentration salt production device

ActiveCN102267747AReduce energy consumptionPrevent evaporationDispersed particle separationAlkali metal chloridesHigh current densityTitanium electrode

The invention belongs to the technical field of water treatment and particularly relates to an electrodialysis concentration salt-making device. The device comprises a membrane stack, electrodes, baffle plates, an electrodialysis mechanism of a runner isolating net and a solid salt separation and collection mechanism, wherein platinum-coated titanium electrodes or ruthenium-coated titanium electrodes are used; an upper runner, a connecting runner and a lower runner are arranged on a water distribution runner plate; an inclined plate is arranged in the solid salt separation and collection mechanism; and a structural design of counterflow heat exchange is utilized to realize the aim of the invention. The invention has the following advantages: the evaporation process is avoided, the energy consumption of salt-making is greatly reduced, the problems such as secondary pollution are not solved, and the service life of the device is greatly prolonged; and the device can be used in the high-current density condition. The electrodialysis concentration salt-making device has wide application prospects in the water treatment industry.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

Drinking water electrochemical preoxidation device and method

ActiveCN102745794AEfficient degradationImprove pre-oxidation effectElectrolysis componentsWater/sewage treatment by oxidationIridiumElectrolysis

The invention relates to a method for raw water preoxidation with an electrochemical preoxidation device, which includes a hydrogen peroxide electroproduction appratus and a hydroxyl free radical generating apparatus. Raw water flows through the hydrogen peroxide electroproduction apparatus taking a graphite felt electrode as a negative electrode and a reticular ruthenium-iridium plated titanium electrode as a positive electrode, and air is introduced from the bottom of the apparatus for electrolysis to produce hydrogen peroxide and other active oxygen free radicals, so that the bacteria, turbidiness, odor and smell and the like of a water body can be eliminated. If the raw water has a high organic substance content and turbidiness, the water can further flow through the hydroxyl free radical generating apparatus. With no need for any additional chemical reagent, the device and method of the invention can reduce the total bacteria, turbidiness, odor and smell of the raw water, and avoid the problem of generation of a large number of disinfection by-products from prechlorination, thus being able to serve as a preoxidation technology for a water supply plant or a water treatment means for other purposes.

Owner:PIPE NETWORK MANAGEMENT BRANCH OF BEIJING WATERWORKS GRP CO LTD +1

Ru-Pd-Co-coated Titanium Electrode with Sn-Sb Interlayer

InactiveCN102268688AChlorine evolution potential is lowHigh oxygen evolution potentialElectrodesTitanium electrodeOxygen evolution

The invention discloses a ruthenium-palladium-cobalt coating electrode containing a tin-antimony intermediate layer. The surface of the main body of a titanium plate is coated with 3-7 layers of tin-antimony oxide coating as the intermediate layer of the target electrode; the surface of the intermediate layer is coated with There are 15-24 layers of ruthenium palladium cobalt oxide coating as the surface layer of the target electrode. Compared with the traditional ruthenium dioxide coated titanium electrode (RuO2 / Ti), the coated titanium electrode of the present invention has higher oxygen evolution potential and lower Excellent chlorine evolution potential and longer service life can effectively improve the current efficiency and electrode service life of the electrocatalytic oxidation reaction system.

Owner:NANJING UNIV OF SCI & TECH

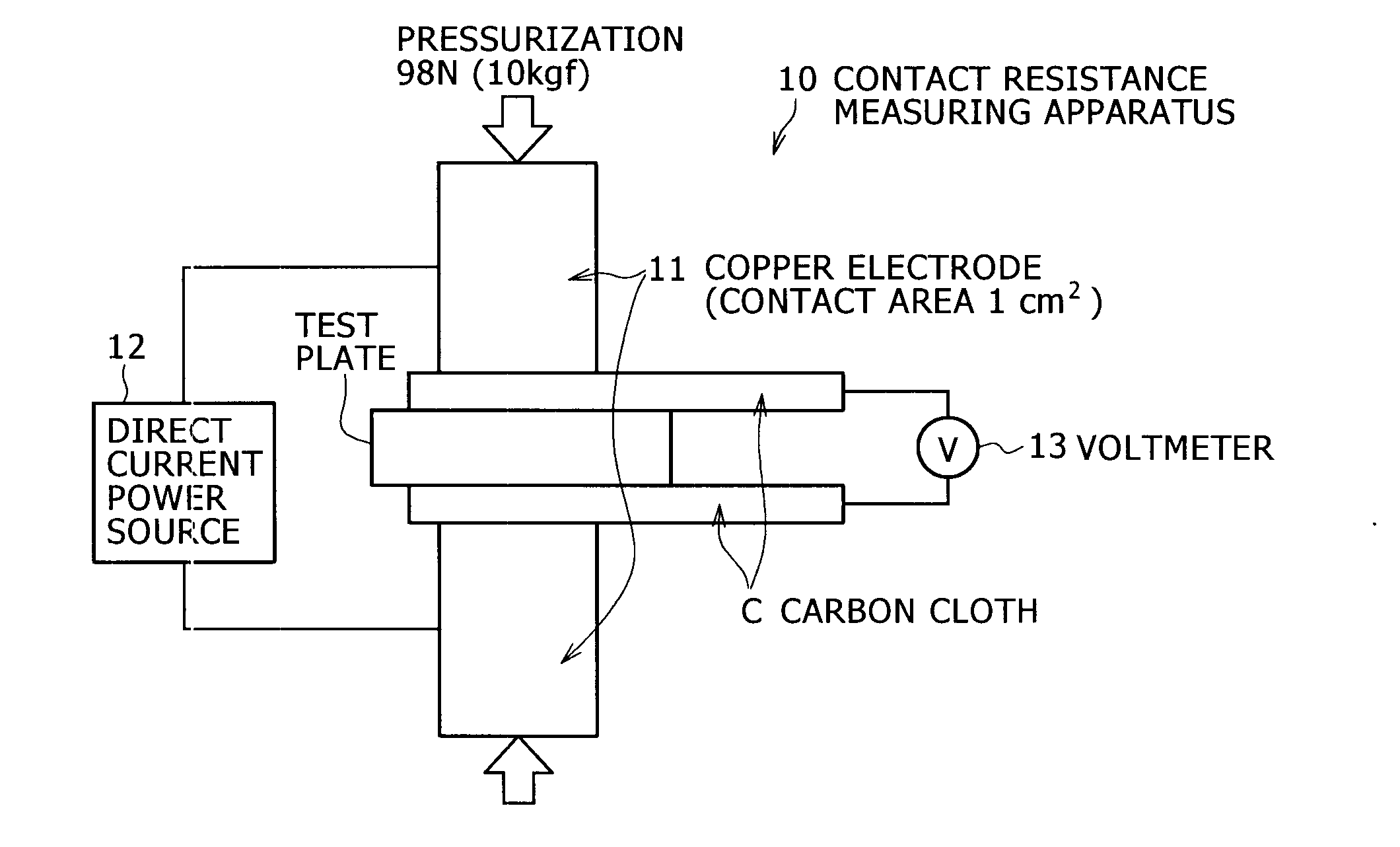

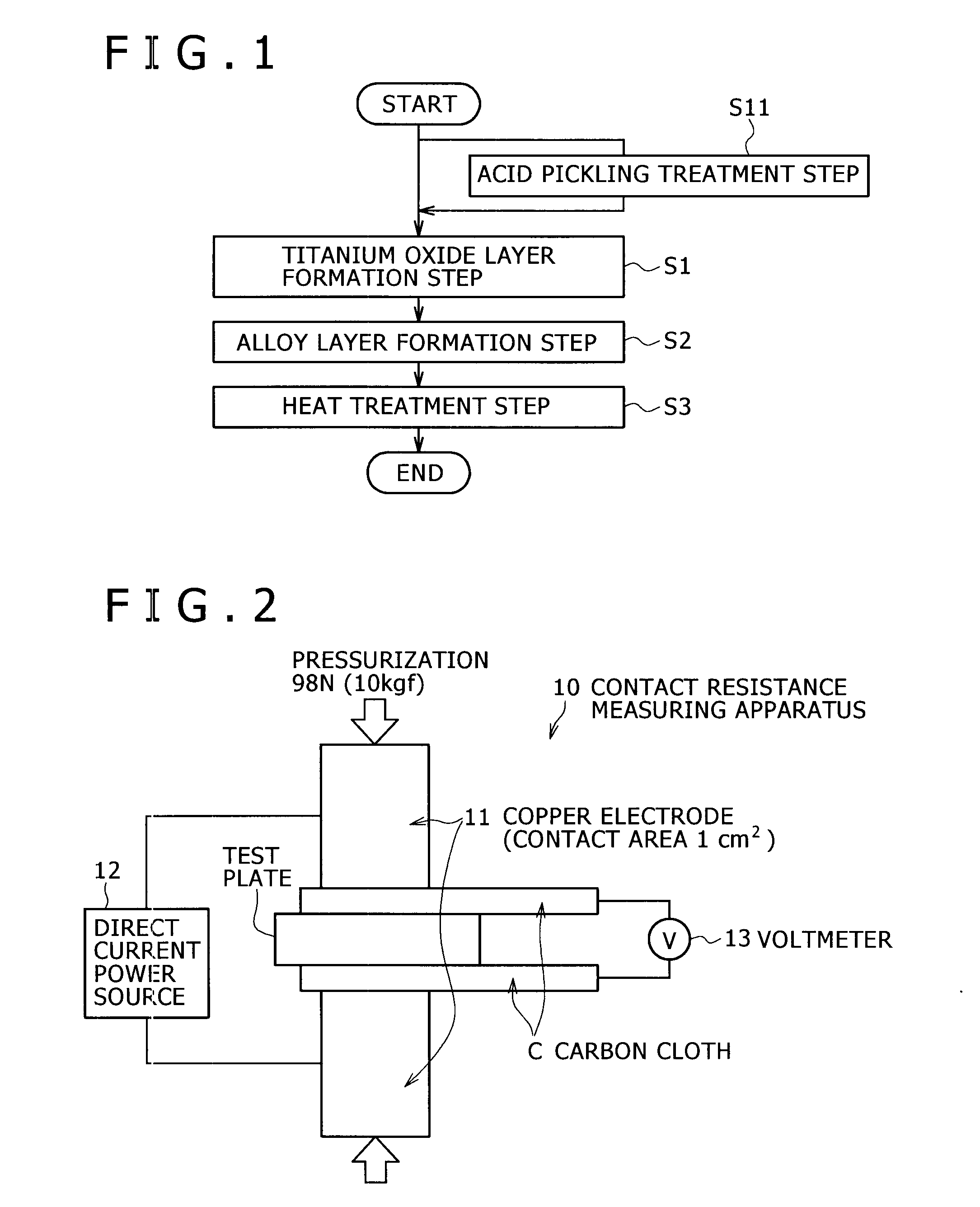

Titanium electrode material and surface treatment method of titanium electrode material

InactiveUS20100233587A1Promote absorptionImprove corrosion resistanceActive material electrodesCollectors/separatorsTitanium electrodeConcentration ratio

It is an object of the present invention to provide a titanium electrode material which is low in cost and is excellent in electric conductivity, corrosion resistance and hydrogen absorption resistance, and a surface treatment method of a titanium electrode material. A titanium electrode material includes: on the surface of a titanium material including pure titanium or a titanium alloy, a titanium oxide layer having a thickness of 3 nm or more and 75 nm or less, and having an atomic concentration ratio of oxygen and titanium (O / Ti) at a site having the maximum oxygen concentration in the layer of 0.3 or more and 1.7 or less; and an alloy layer including at least one noble metal selected from Au, Pt, and Pd, and at least one non-noble metal selected from Zr, Nb, Ta, and Hf, having a content ratio of the noble metal and the non-noble metal of 35:65 to 95:5 by atomic ratio, and having a thickness of 2 nm or more, on the titanium oxide layer. The surface treatment method of a titanium electrode material includes a titanium oxide layer formation step, an alloy layer formation step, and a heat treatment step.

Owner:KOBE STEEL LTD

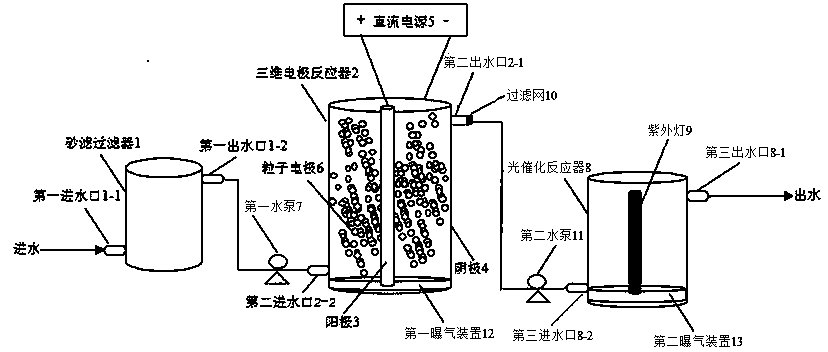

Novel three-dimensional electrode water treatment system and graphene conductive particle preparation method

PendingCN109824185AOvercoming "dead spots"Uniform responseWater contaminantsMultistage water/sewage treatmentTitanium electrodeElectrolysis

The invention discloses a novel three-dimensional electrode water treatment system and graphene conductive particle preparation method. The novel three-dimensional electrode water treatment system comprises a pretreatment system, an electrolytic treatment system and an organic contamination treatment system which are sequentially communicated, the pretreatment system performs sand filtering treatment on sewage through a sand filter, the water inlet turbidity is lowered, the electrolytic treatment system electrolyzes organic contaminations and adsorbs sediment heavy metal through the three-dimensional electrode reactor, the organic contamination treatment system further degrades organic contaminations through ultraviolet catalysis, the sewage treatment system is perfect, and the purifying effect is remarkable. The cylindrical three-dimensional electrode reactor is adopted, a coating titanium electrode is selected as an anode, the treatment efficiency and the current utilization efficiency can be improved, and electric energy consumption is low, insulation particles and conductive particles filled proportionally are selected as particle electrodes, the insulation particles can solvethe problem of short-circuit current of the three-dimensional electrode reactor, and the metal-loaded graphene conductive particles can remarkably improve the wastewater degrading effect.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

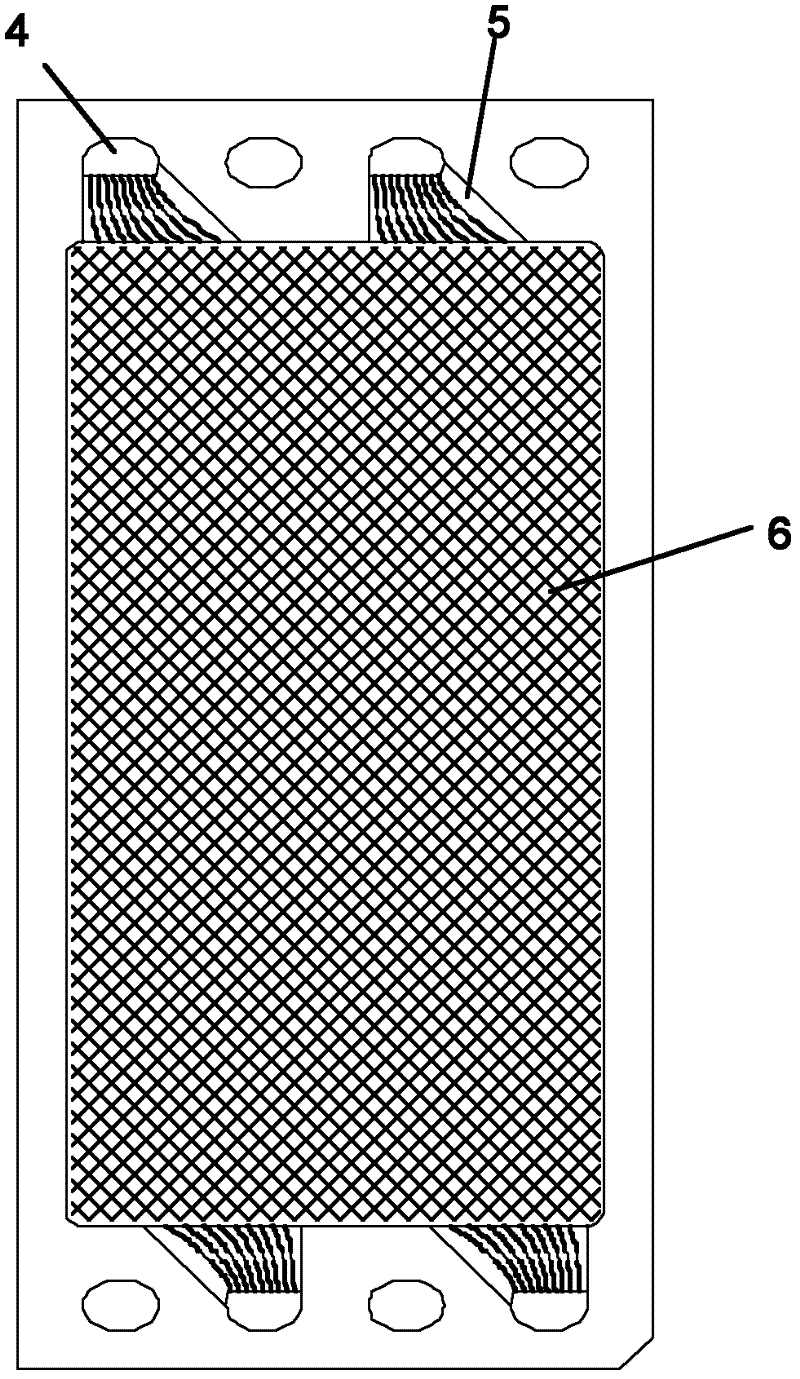

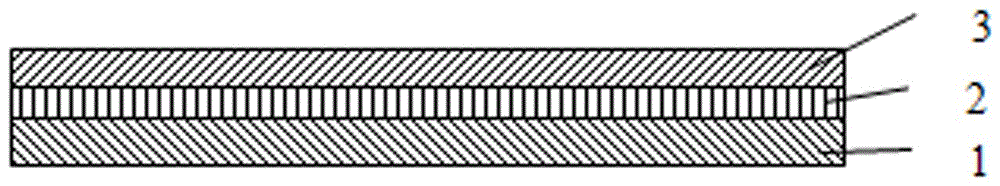

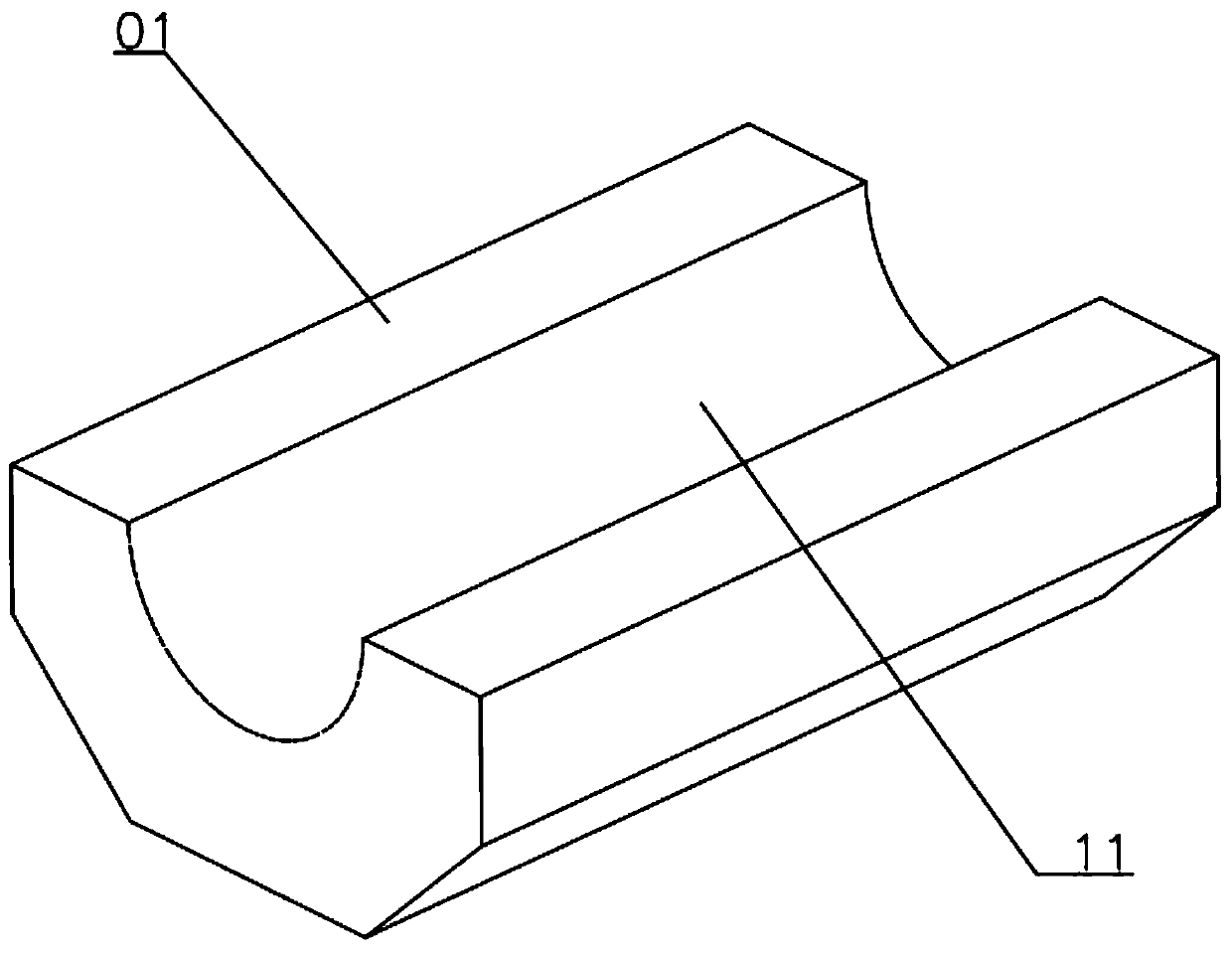

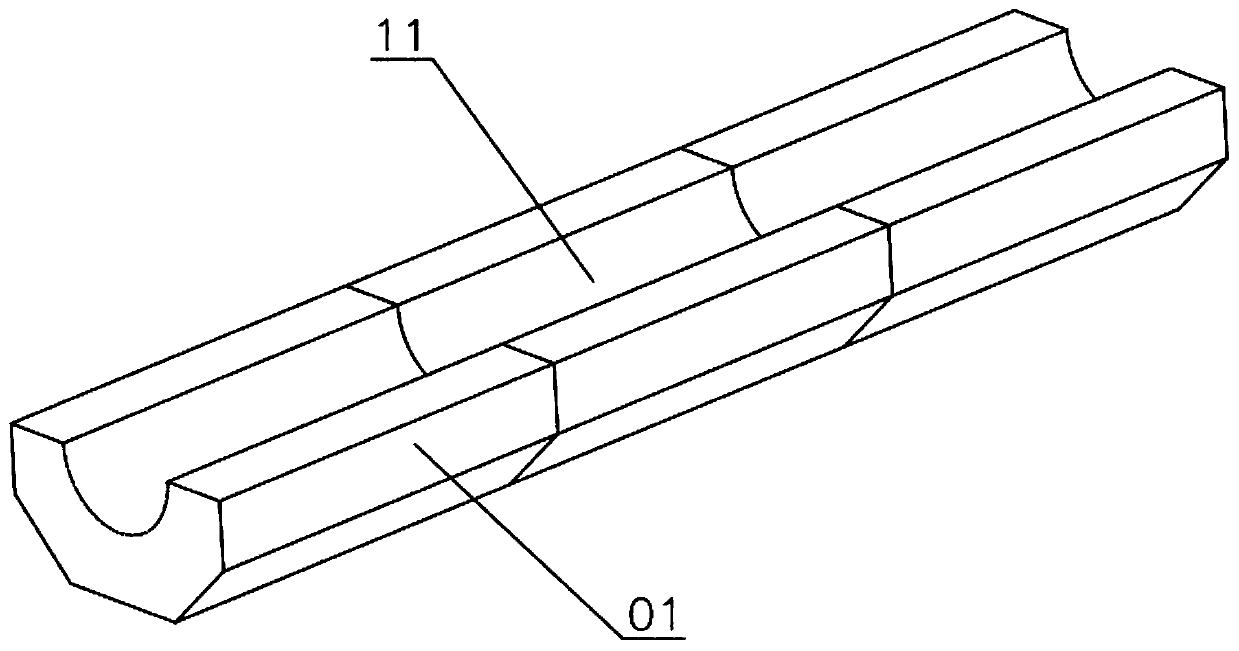

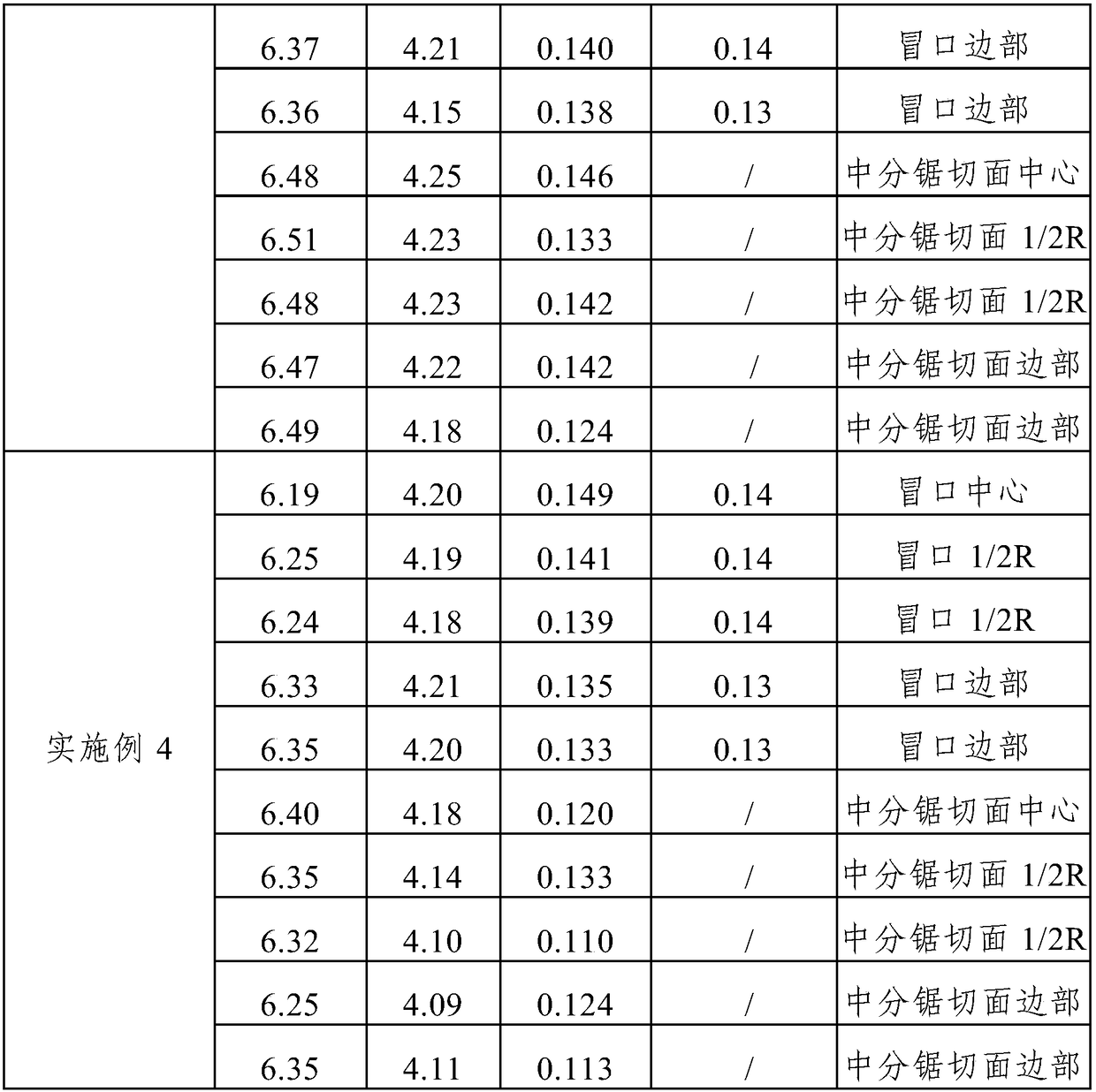

Coating titanium electrode for metal electrodeposition and preparation method of coating titanium electrode

InactiveCN106283125AGood chemical stabilityNo pollution in the processVacuum evaporation coatingPretreated surfacesTitanium electrodeChemical plating

The invention relates to a coating titanium electrode for metal electrodeposition and a preparation method of the coating titanium electrode and belongs to the technical fields of wet metallurgy and electrochemical industries. The coating titanium electrode comprises a matrix (1), a middle layer (2) and an outer coating (3). The preparation method comprises the following steps: boiling the matrix (1) in a soda solution and an oxalic acid solution, washing, and drying the matrix (1); preparing a platinum plating layer, a platinum coating or the middle layer (2) containing a platinum tin oxide layer by virtue one or combination of a chemical plating method, a thermal decomposition method, an electroplating method or a magnetron sputtering method; and immersing the matrix (1) into outer-layer coating liquid, coating the middle layer (2) with the outer-layer coating liquid in a dipping or brushing manner, drying, and carrying out oxidation and thermal processing, so as to prepare the outer coating (3). The coating titanium electrode has the beneficial effects that the oxygen deposition potential is low, the strength of the matrix is high, the short circuit is unlikely to occur, the cathode current efficiency is high, the chemical stability of the coating is high, and a cathode product is not polluted; and the coating titanium electrode is applicable to the metal electrodeposition in sulfuric acid solution systems containing impurities of F<-->, Mn<2+> and the like.

Owner:GUANGDONG INST OF RARE METALS

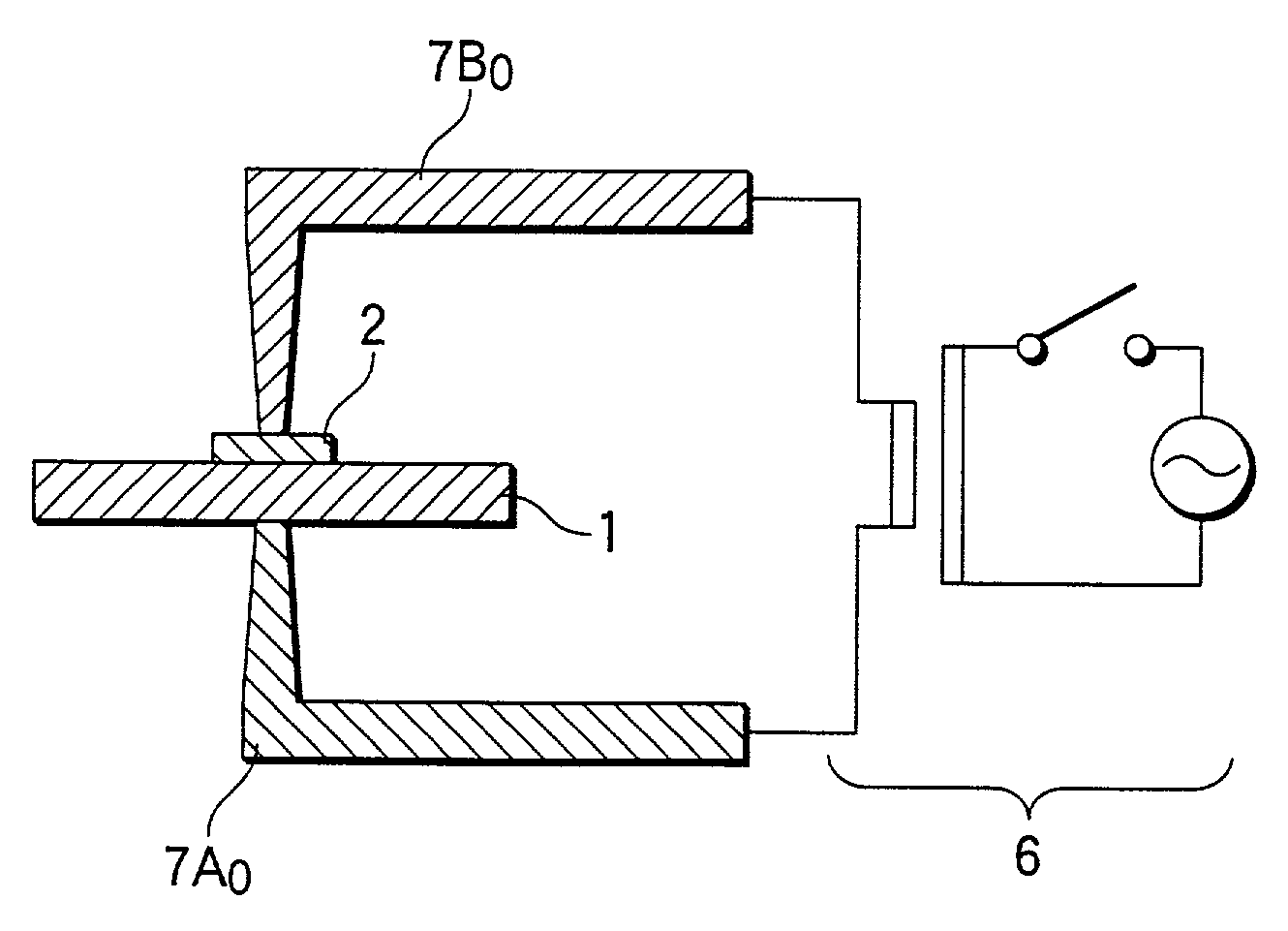

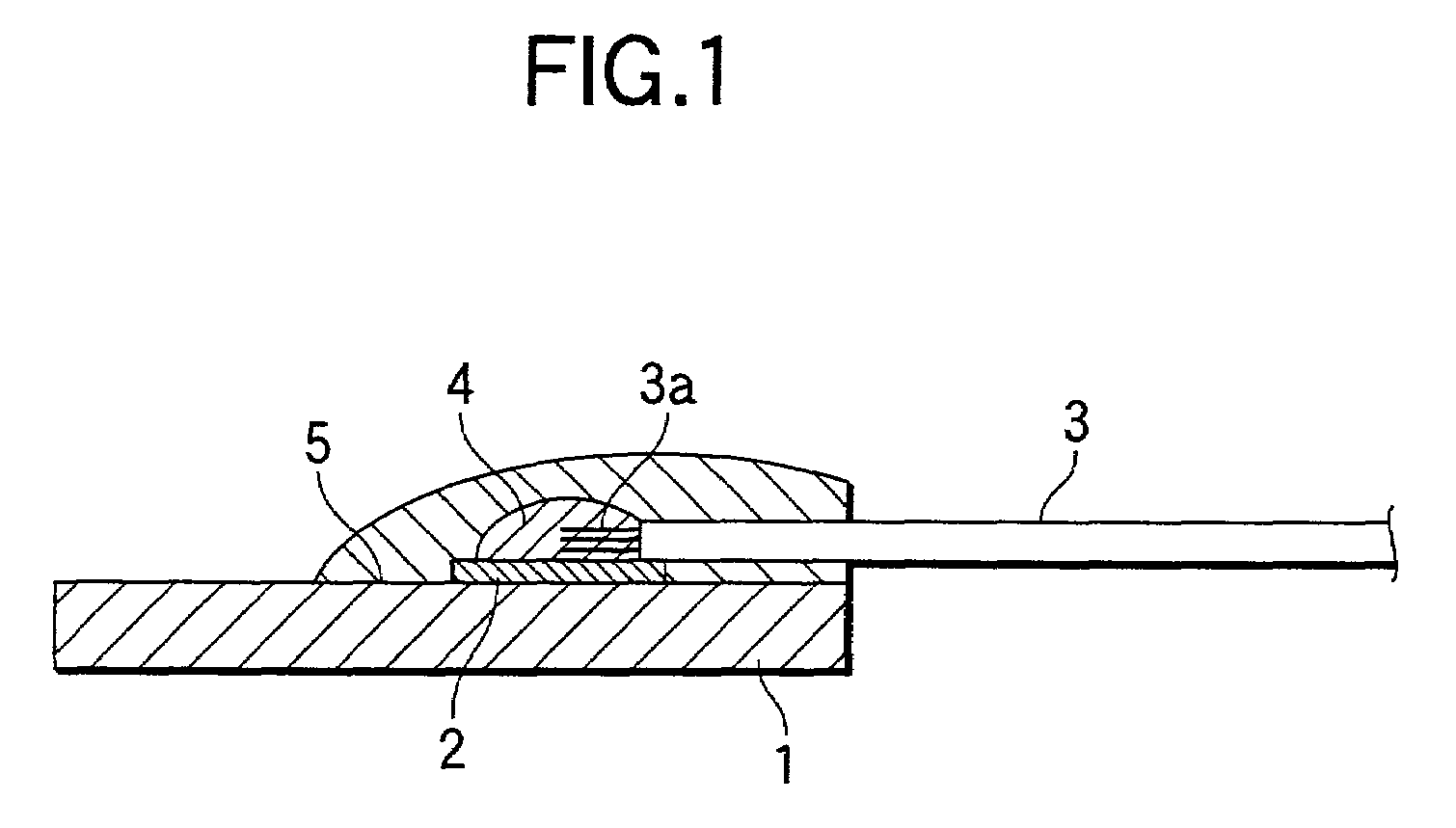

Lead wire attachment method, electrode, and spot welder

InactiveUS7010856B2Good adhesionHigh strengthSpinal electrodesContact member assembly/disassemblyTitanium electrodeTitanium

A copper plate 2 is mounted on a titanium electrode element 1 by spot welding, and a lead wire 3a is attached to the copper plate 2 by solder 4.

Owner:NIHON KOHDEN CORP

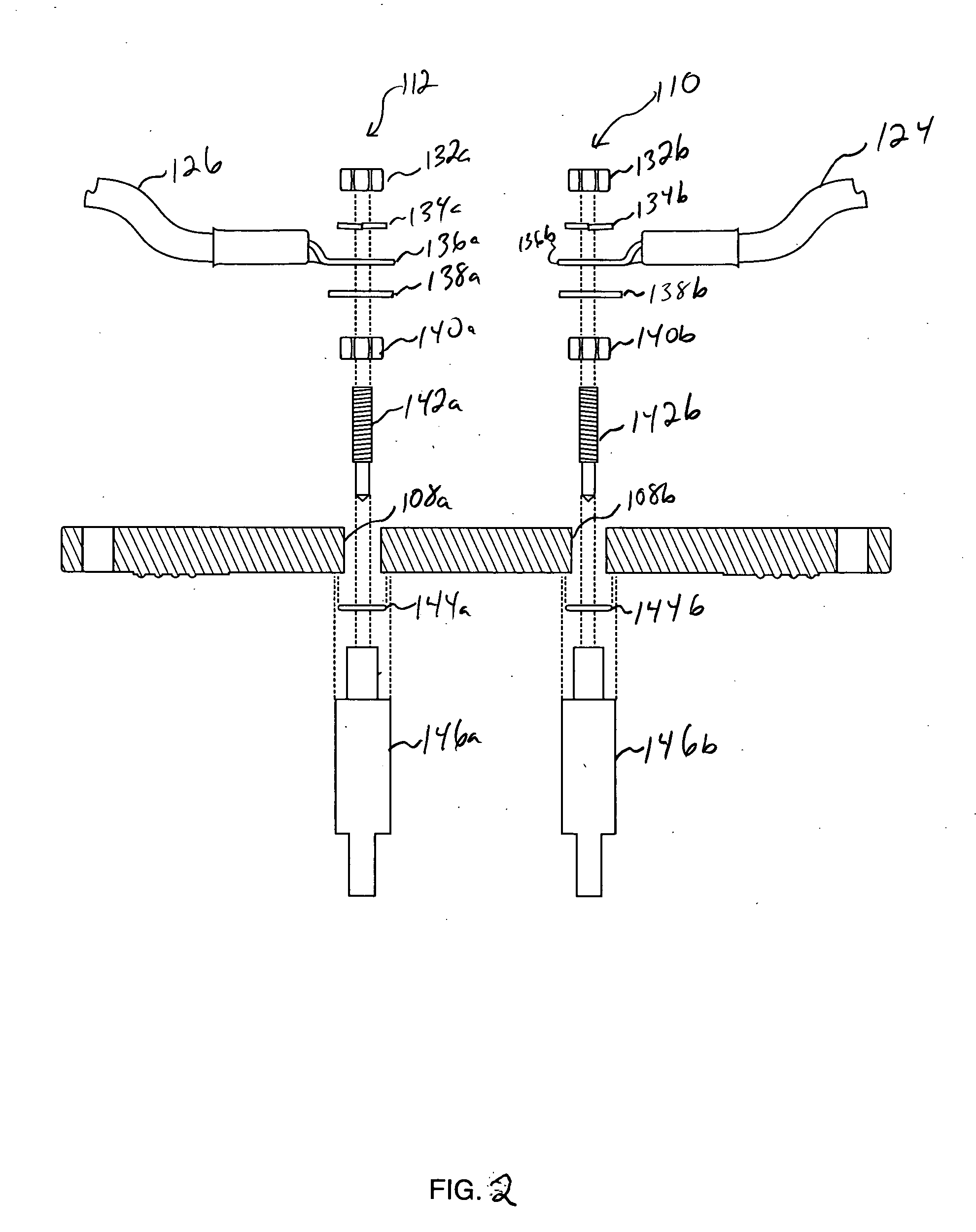

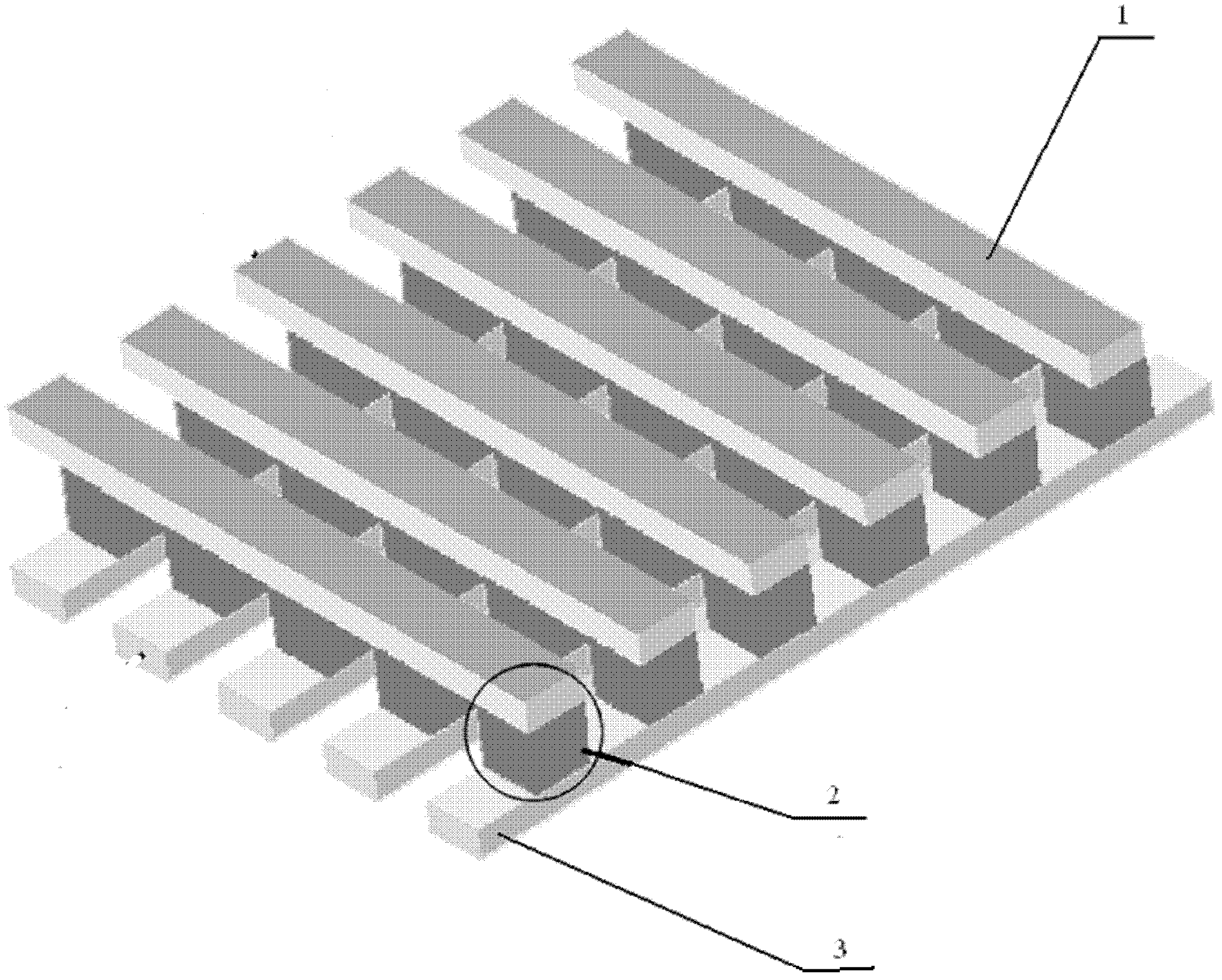

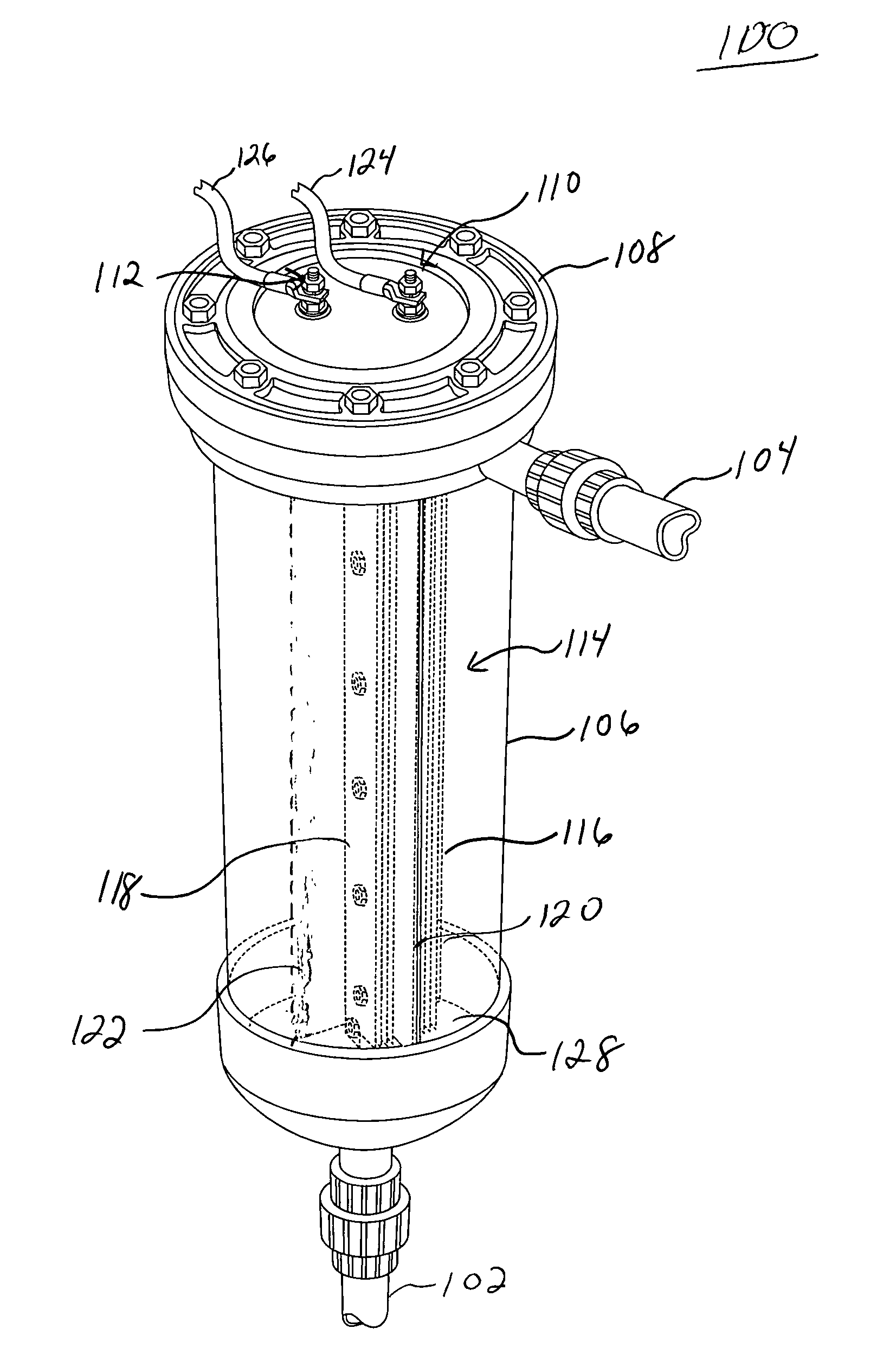

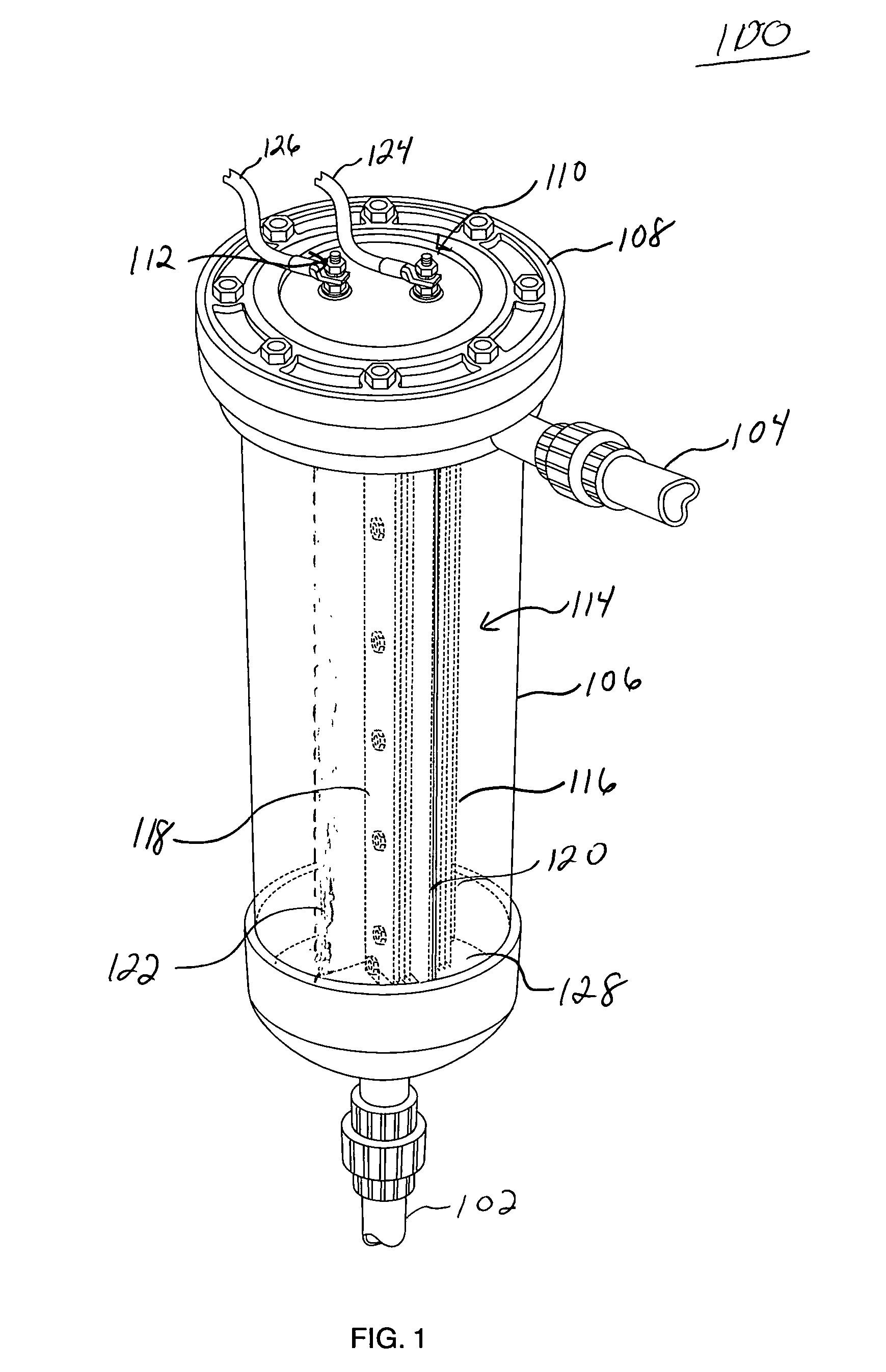

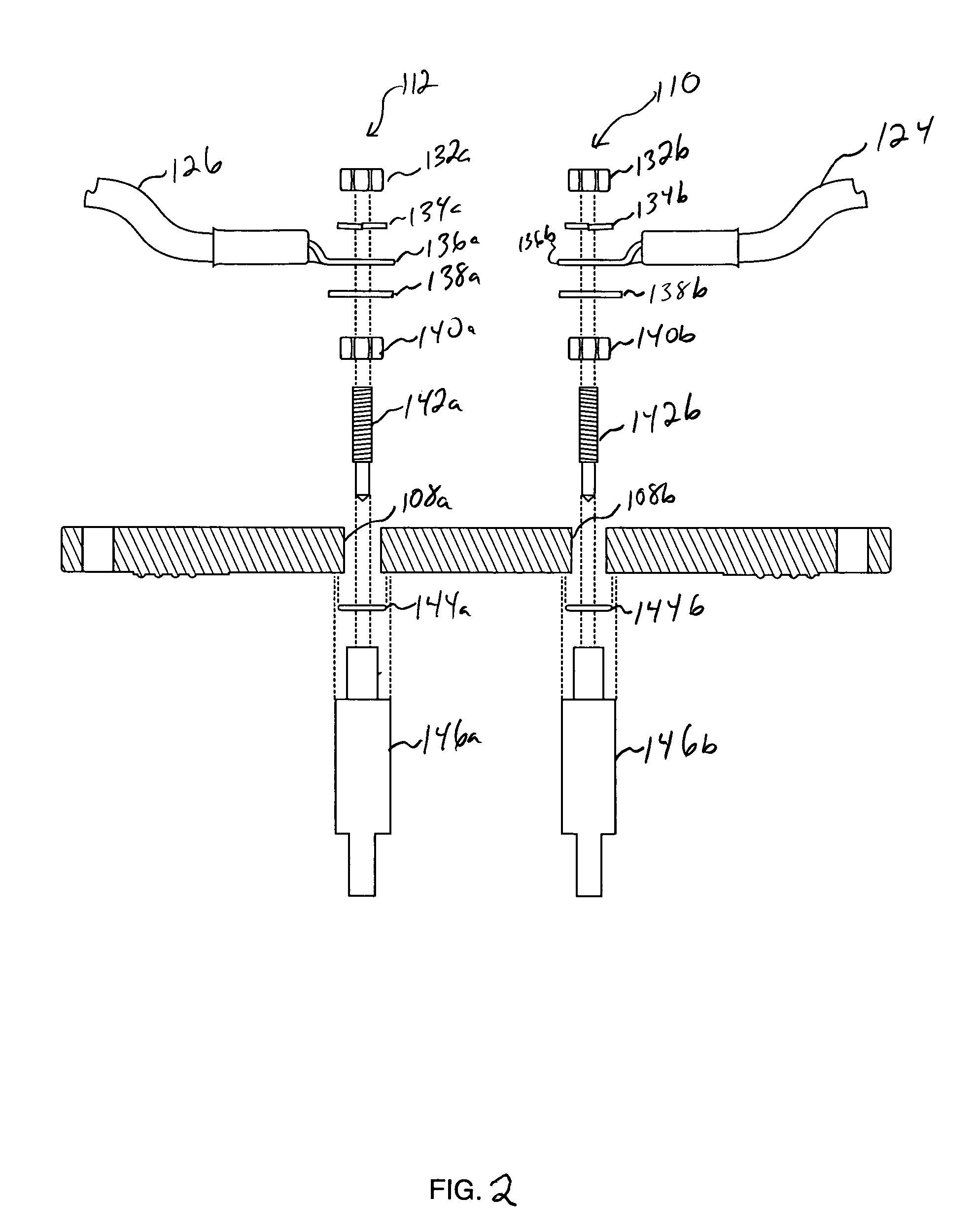

Chlorination system for swimming pools and the like

ActiveUS20060097878A1Reduce fadingReduce discolorationCellsWaste water treatment from bathing facilitiesElectricityTitanium electrode

An improved chlorination system for pools, spas, potable water supplies, and the like, provides a vertically oriented electrolytic cell connected between a pump and a lightly salinated pool. The cell preferably contains a metallic electrode, such as titanium, and a precious metal coated titanium electrode, and has means for passing an electric current through the cell. The present invention further provides a novel electrode stack design, conducive for forming an efficient chlorinator comprising a plurality of interconnecting electrode stacks of separate electrical cells.

Owner:CHLORKING

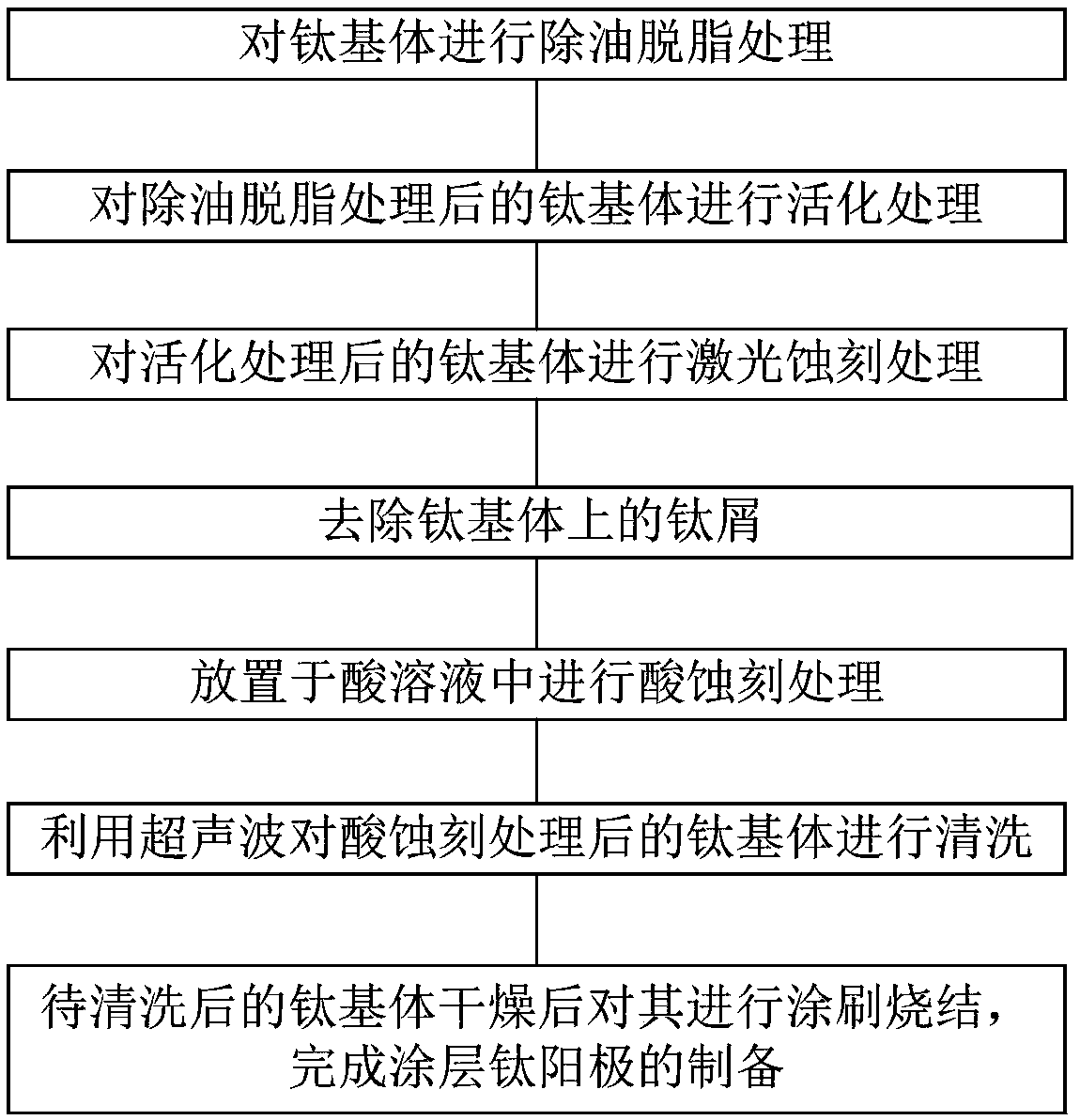

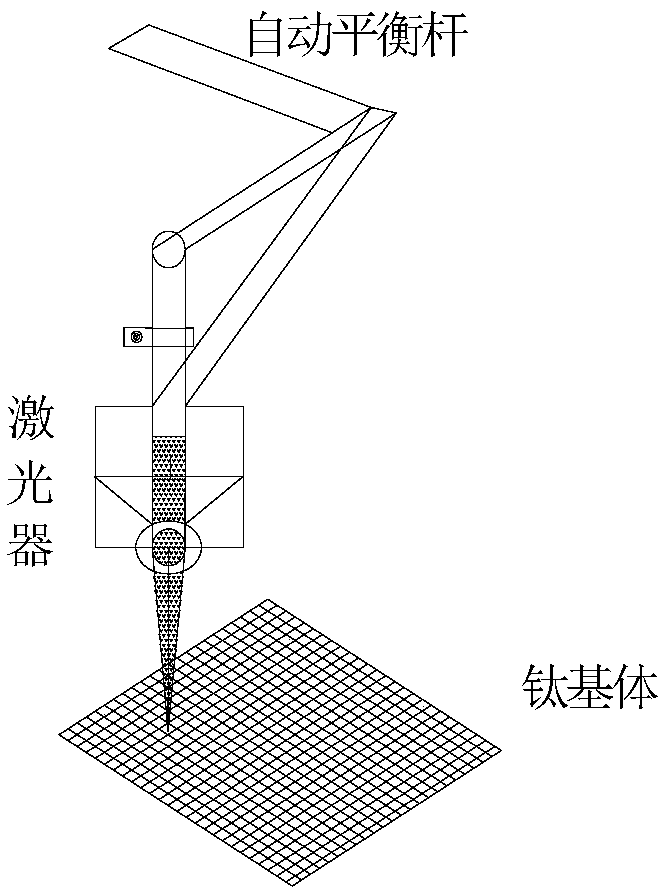

Preparing method for titanium-based coating titanium anode

The invention belongs to the technical field of electrochemistry industry titanium electrode preparing, and relates to a preparing method for a titanium-based coating titanium anode. The preparing method specifically comprises the following steps including titanium base body pretreatment, namely oil removal and degreasing, activating treatment, laser etching, titanium scrap removal, acid treatment, ultrasonic cleaning, drying, coating sintering and finished product obtaining. According to the preparing method, roughening treatment is conducted on the surface of a titanium base body through a laser etching method, the method is simple in usage and free of pollution, oxide skin generated by the titanium base body can be rapidly treated, and long-time treatment through an acid solution is notneeded any more; any regular roughening arrangement can be obtained, grid gaps are easily fully filled with coatings, a uniform and dense structure is obtained, meanwhile, the large-current work intensity can be borne, and corrosion resistance is high.

Owner:XIAN TAIJIN INDAL ELECTROCHEM TECH

Titanium/copper laminated composite electrode plate and preparation method thereof

InactiveCN101575714AEnhanced interface bindingImprove conductivityElectrodesTitanium electrodeInternal resistance

The invention discloses a titanium / copper laminated composite plate used for insoluble anode and a preparation method thereof, belonging to the fields of nonferrous metal extraction, chlorine alkali industry and the like. The titanium / copper laminated composite plate with the inner core being copper and an outer layer being coated with titanium is prepared by adopting an electric arc spraying method, a fusion casting method or a spray deposition method. The three methods have simple preparation technique and easy operation, and adapt to industrial production; the prepared titanium / copper laminated composite plate has excellent interface coherency, conductivity and corrosion resistance, a coating titanium anode prepared by adopting the laminated composite plate as a substrate leads the internal resistance of electrode to be reduced, the current distribution to be even and the product purity to be high; and the bath voltage is reduced by 0.1 to 0.8V, compared with that of the coating titanium electrode, thus achieving the effects of saving energy and reducing consumption.

Owner:KUNMING UNIV OF SCI & TECH

Porous three dimensional copper, tin, copper-tin, copper-tin-cobalt, and copper-tin-cobalt-titanium electrodes for batteries and ultra capacitors

InactiveUS8206569B2Electrolysis componentsElectrochemical processing of electrodesTitanium electrodeCobalt

A method and apparatus for forming a reliable and cost efficient battery or electrochemical capacitor electrode structure that has an improved lifetime, lower production costs, and improved process performance are provided. In one embodiment a method for forming a three dimensional porous electrode for a battery or an electrochemical cell is provided. The method comprises depositing a columnar metal layer over a substrate at a first current density by a diffusion limited deposition process and depositing three dimensional metal porous dendritic structures over the columnar metal layer at a second current density greater than the first current density.

Owner:APPLIED MATERIALS INC

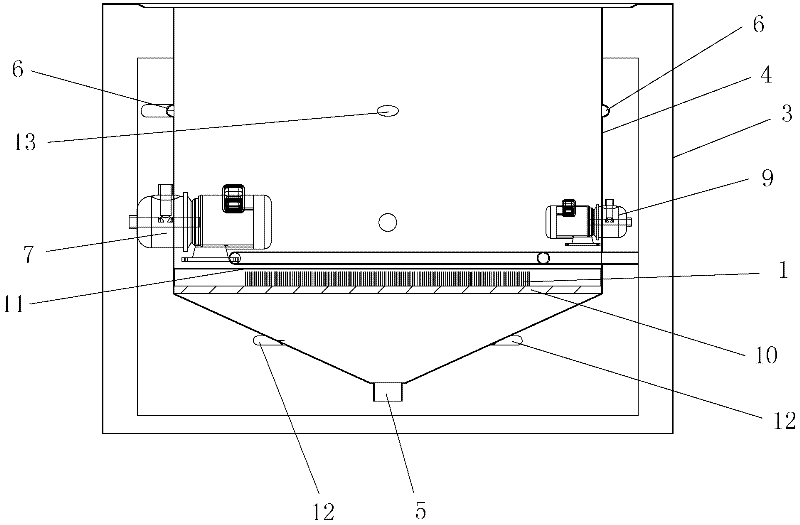

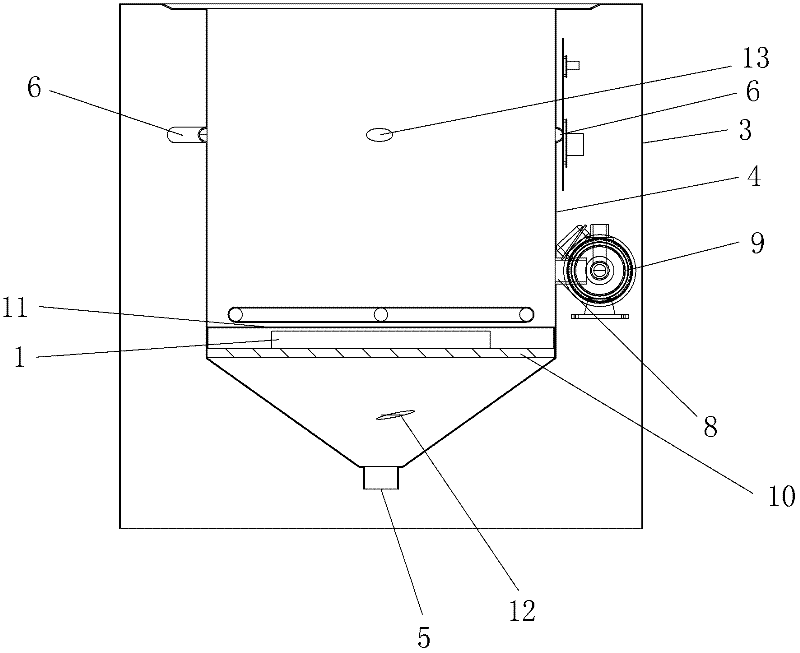

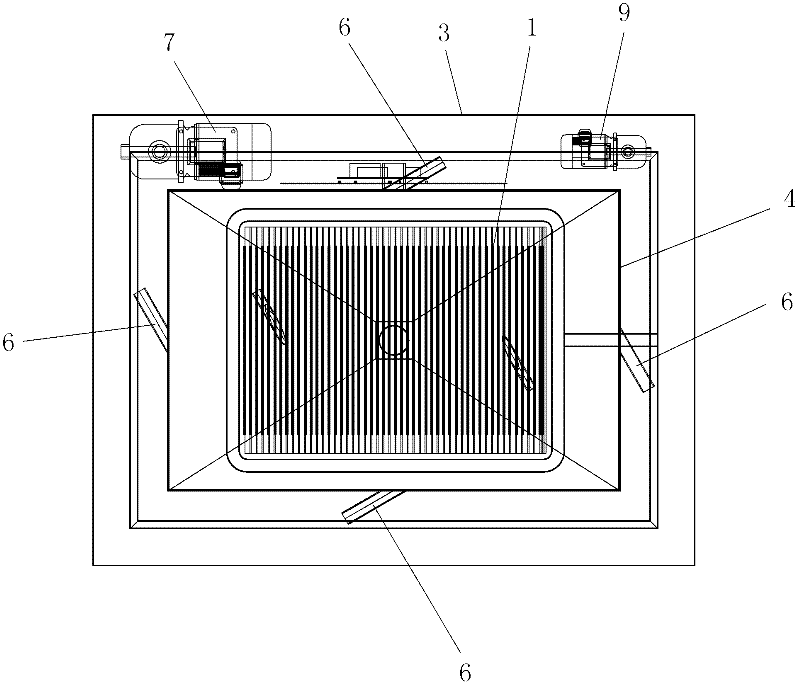

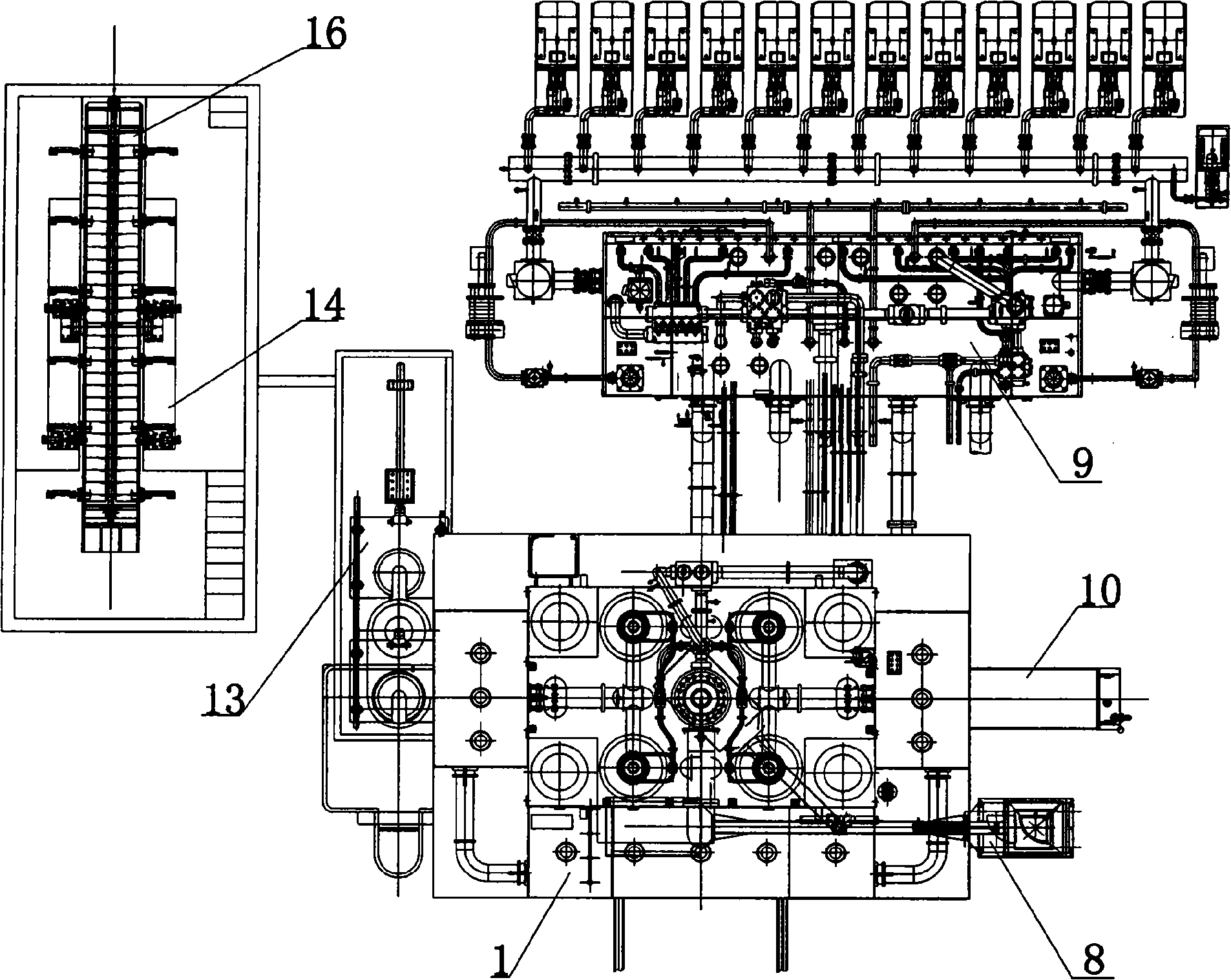

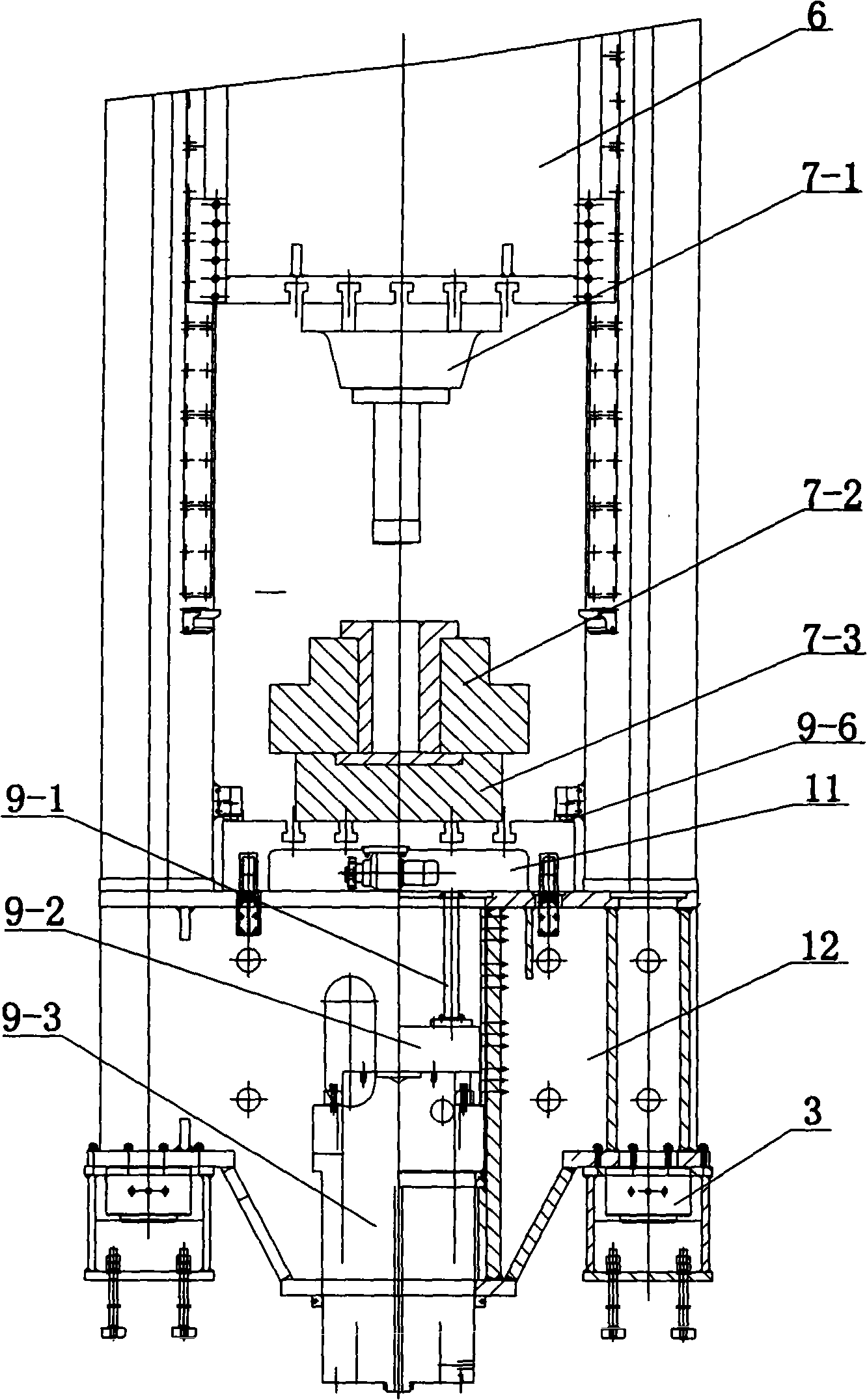

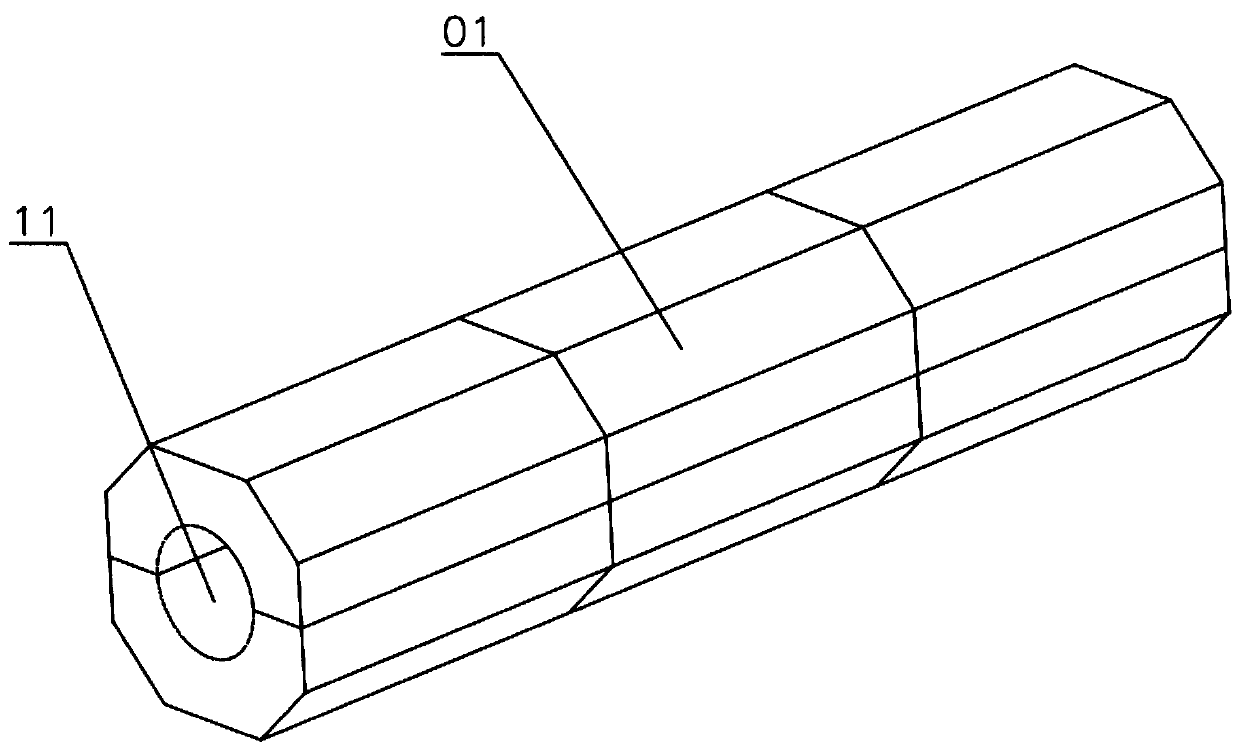

Titanium electrode products forming hydraulic press

InactiveCN101306457ASimple structureReduce manufacturing costForging/hammering/pressing machinesEngine componentsTitanium electrodeTitanium

The invention relates to a molding hydraulic press of titanium electrode products, which comprises an upright post, an upper beam, a main cylinder, a slide block, a lower beam, a shuttle table, a die, a loading device and a pushing device, and the invention is characterized in that the molding hydraulic press also comprises a demoulding system arranged on the rear side of the press body, a receiving assembly positioned on the left side of the hydraulic press and used for stacking the titanium electrode blocks into a cylindrical body, and a turnover mechanism used for realizing the turnover of the titanium electrode from a vertical state to a horizontal state. By adopting the structure of the invention which combines multiple functions as a whole, such as demoulding, pushing and stacking as well as turnover, the pressed arc-shaped titanium electrode blocks can be automatically stacked into the cylindrical electrode bar at a certain height, and then the cylindrical electrode bar is moved to the discharge working position by a double-post moving device, swung to the turnover mechanism by an overhead travelling crane and switched stably from the vertical state to the horizontal state. Therefore, the molding hydraulic press solves the problems that the electrode blocks have heavy weight and difficulties in stacking manually, reduces the labor intensity of the operators and avoids the potential safety hazard caused by moving the titanium electrode bars.

Owner:TIANJIN TIANDUAN PRESS CO LTD

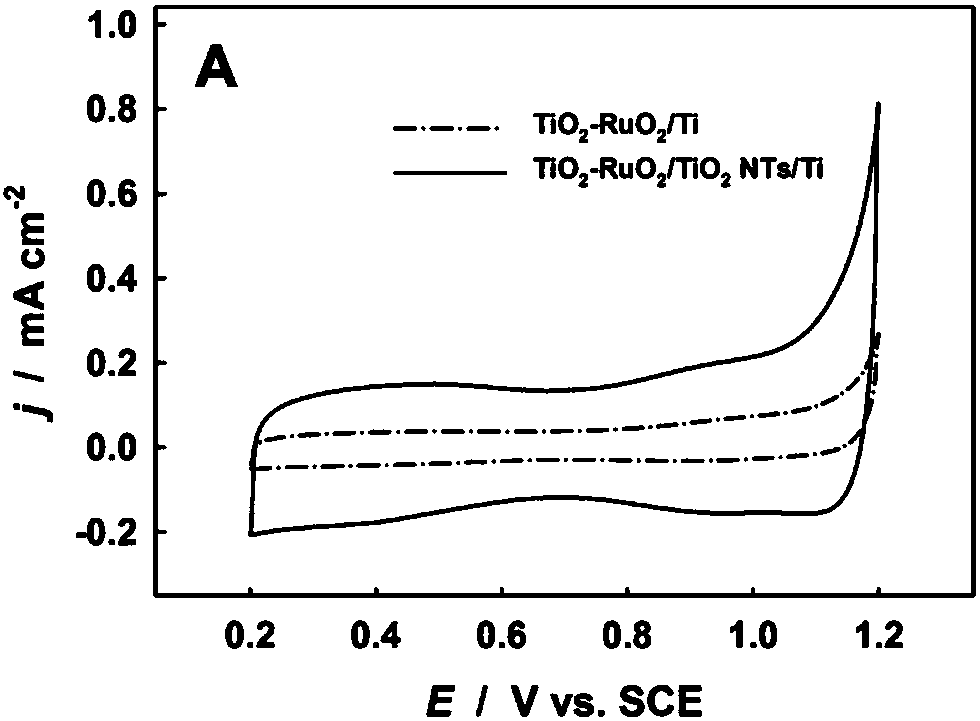

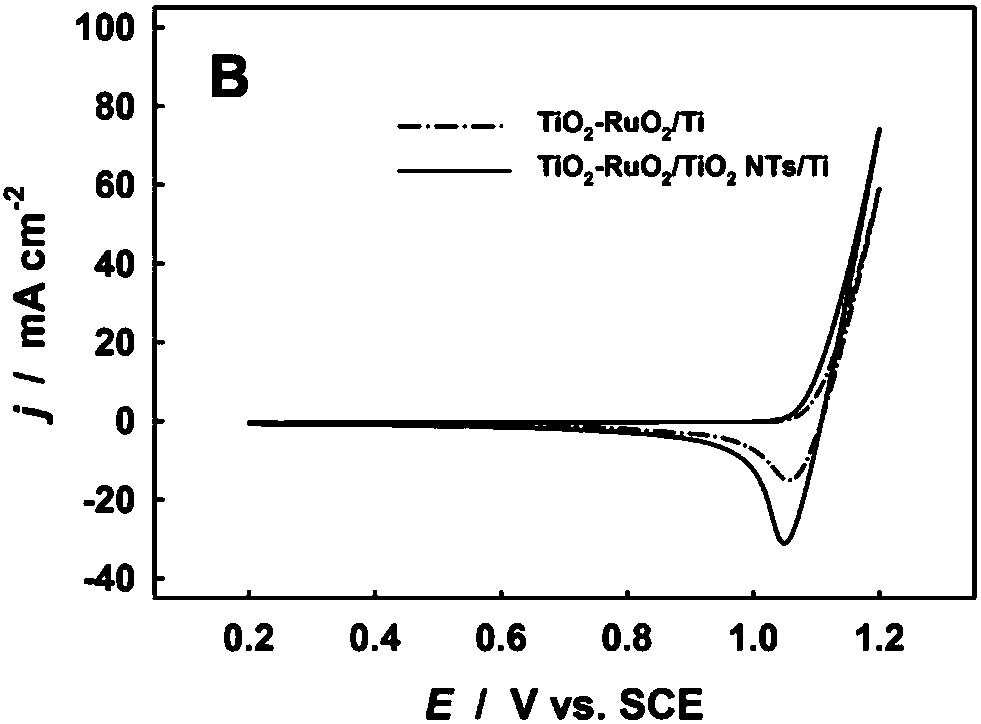

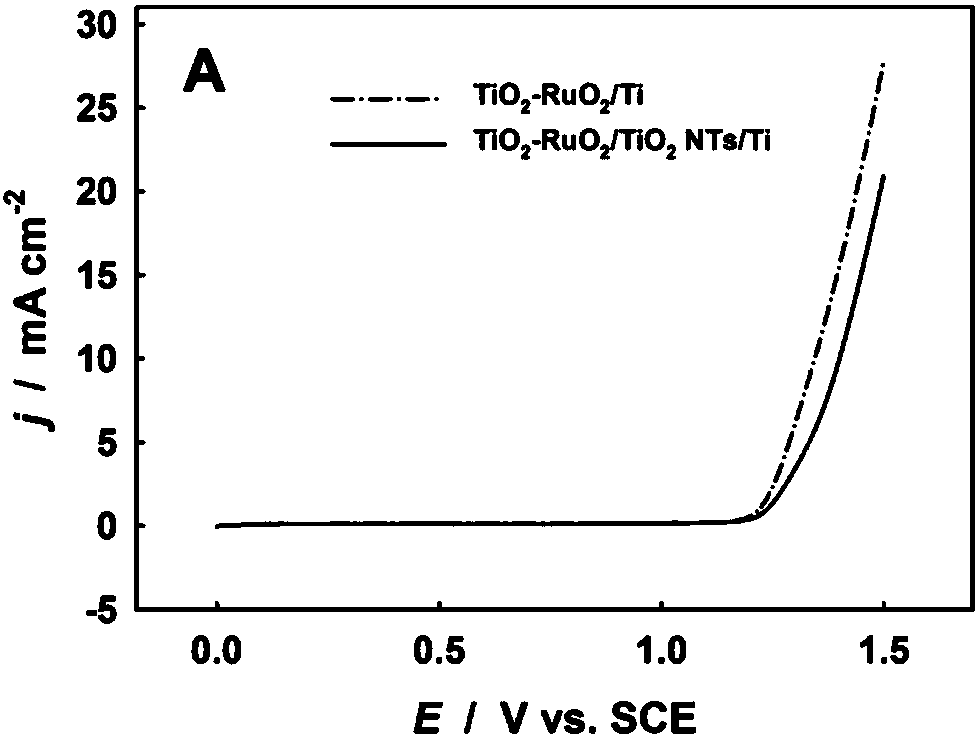

Preparation method of titanium dioxide nanotube-ruthenium-titanium oxide coating titanium electrode

InactiveCN107740138ALow degree of reunionMild preparation conditionsSurface reaction electrolytic coatingSuperimposed coating processTio2 nanotubeTitanium electrode

The invention discloses a preparation method of a titanium dioxide nanotube-ruthenium-titanium oxide coating titanium electrode. The preparation method comprises the following steps: carrying out pre-treatment on a titanium substrate, namely putting a pre-treated titanium sheet as a positive electrode and a large-area platinum mesh as a negative electrode into an electrolyte solution; then applying a direct current constant voltage to the two electrodes to anodize; in the anodizing process, keeping the temperature of the electrolyte solution constant and stirring the electrolyte solution; after anodizing, taking out the oxidized titanium sheet, namely a TiO2 nanotube / Ti electrode; ultrasonically cleaning with ethanol and water and annealing, and cooling to room temperature for later use; and coating the surface of the TiO2 nanotube / Ti electrode with coating liquid by means of a brush coating method, and drying, thermally oxidizing and cooling the TiO2 nanotube / Ti electrode to obtain the titanium dioxide nanotube-ruthenium-titanium oxide coating titanium electrode. According to the preparation method disclosed by the invention, the TiO2 nanotube can directly grow on a Ti substrate and has a very good bonding force with the titanium substrate, so that the TiO2.RuO2 / TiO2 naotube / Ti electrode is longer in fortified life, and the electrochemical active area is large.

Owner:西安博岳环保科技有限公司

Low-cost niobium-titanium alloy electrode preparation method and niobium-titanium alloy electrode

The invention relates to a low-cost niobium-titanium alloy electrode preparation method and a niobium-titanium alloy electrode. The niobium-titanium alloy electrode preparation method comprises the steps of material distribution, electrode block pressing, electrode assemble welding and electrode smelting. According to the low-cost niobium-titanium alloy electrode preparation method, compared witha traditional niobium-titanium alloy electrode preparation method, the raw material cost is low, the manufacturing cost is low, and the yield is high; by using the method, the length of an electrode block joint welding seam can be increased, the strength of the electrode is improved, the problem of niobium inclusion caused by block falling of a core during smelting of the niobium-titanium electrode prepared by the common titanium and titanium alloy electrode preparation method can be solved, and a cast ingot obtained after smelting of the prepared electrode is free of niobium inclusion.

Owner:宁夏中色金航钛业有限公司

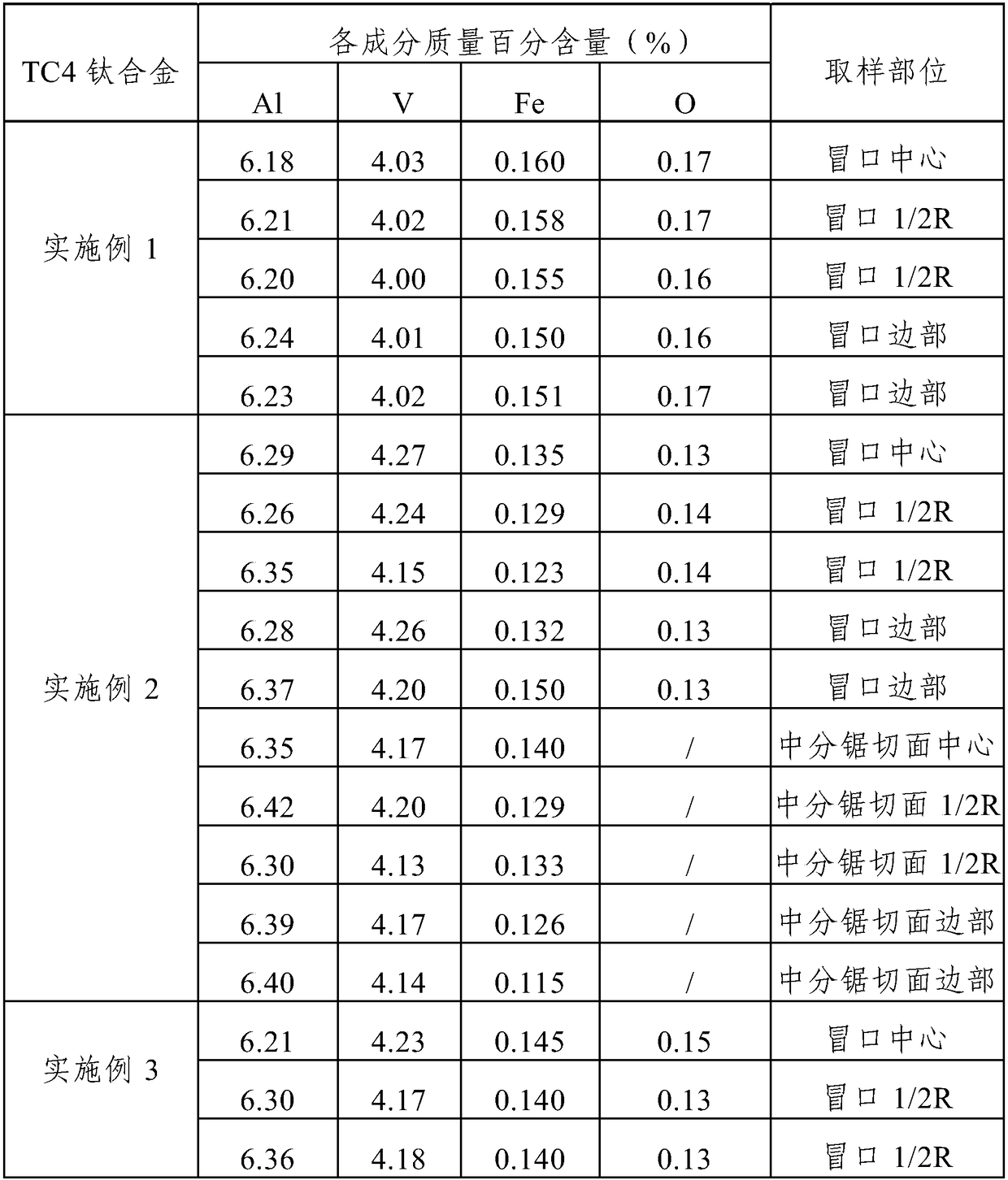

Method for preparing large-specification TC4 titanium alloy cast ingot through high-proportion defective titanium materials

ActiveCN108359808AImprove cleanlinessHigh yieldProcess efficiency improvementTitanium electrodeIngot

The invention discloses a method for preparing a large-specification TC4 titanium alloy cast ingot through high-proportion defective titanium materials. The method comprises the steps that 1, the block-shaped and sheet defective TC4 materials are tied into defective material electrodes; 2, the defective material electrodes are welded and cleaned; 3, the cleaned defective material electrodes are smelted to obtain an intermediate cast ingot; 4, the intermediate cast ingot is subjected to one heating number forging, and a long-strip-shaped electrode is obtained and subjected to coping and pickling; 5, the long-strip-shaped electrode subjected to pickling and a sponge titanium electrode block are assembled and welded, and a consumable electrode is obtained and cleaned; and 6, the cleaned consumable electrode is smelted, and the TC4 titanium alloy cast ingot is obtained. According to the method, through reasonable material distribution and multiple times of vacuum consumable electric arc smelting, the large-specification TC4 titanium alloy cast ingot is obtained, the adding proportion of the defective TC4 titanium materials is increased, the content nonuniformity of the defective TC4 titanium materials is reduced, the cleanliness of the TC4 cast ingot is ensured, and the yield and the production efficiency of the TC4 cast ingot are improved.

Owner:WESTERN TITANIUM TECH

Resistive random access memory with self-rectifying effect

InactiveCN102214790AWith self rectifying effectThe self-rectification effect obtainsSolid-state devicesSemiconductor devicesTitanium electrodeStatic random-access memory

The invention discloses a resistive random access memory which is composed of a bottom electrode, a resistive layer and an upper electrode, wherein the resistive layer is deposited on the bottom electrode; the upper electrode is deposited on the resistive layer; the bottom electrode is a bar-shaped p-shaped silicon electrode; the resistive layer is an n-shaped zinc oxide thin film; the upper electrode is a bar-shaped aluminum electrode or titanium electrode; and the bottom electrode and the upper electrode are vertical mutually. A low-resistance p-shaped silicon is selected for the bottom electrode of the resistive random access memory provided by the invention, the resistive random access memory is highly compatible with the traditional CMOS (complementary metal-oxide-semiconductor transistor) technology, can develop a nonvolatile memory with high density without changing the existing technology condition, and has the characteristics of low cost, and the like.

Owner:TSINGHUA UNIV

Chlorination system for swimming pools and the like

ActiveUS8163141B2Improved chlorinationReduce fadingCellsWater/sewage treatment by electrochemical methodsMetallic electrodeTitanium electrode

An improved chlorination system for pools, spas, potable water supplies, and the like, provides a vertically oriented electrolytic cell connected between a pump and a lightly salinated pool. The cell preferably contains a metallic electrode, such as titanium, and a precious metal coated titanium electrode, and has means for passing an electric current through the cell. The present invention further provides a novel electrode stack design, conducive for forming an efficient chlorinator comprising a plurality of interconnecting electrode stacks of separate electrical cells.

Owner:CHLORKING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com