Water catalyst sterilizing and detoxifying device and producing and using method thereof

A technology of sterilization and detoxification and water catalyst, applied in the direction of cleaning methods using liquids, chemical instruments and methods, cleaning methods using gas flow, etc., can solve problems such as nutrient destruction, poor use effect, pollution, etc. Convenience, simple structure, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

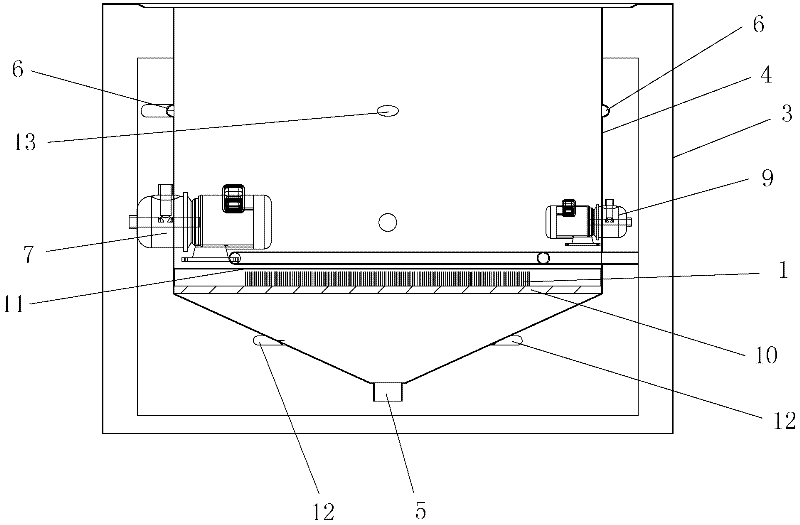

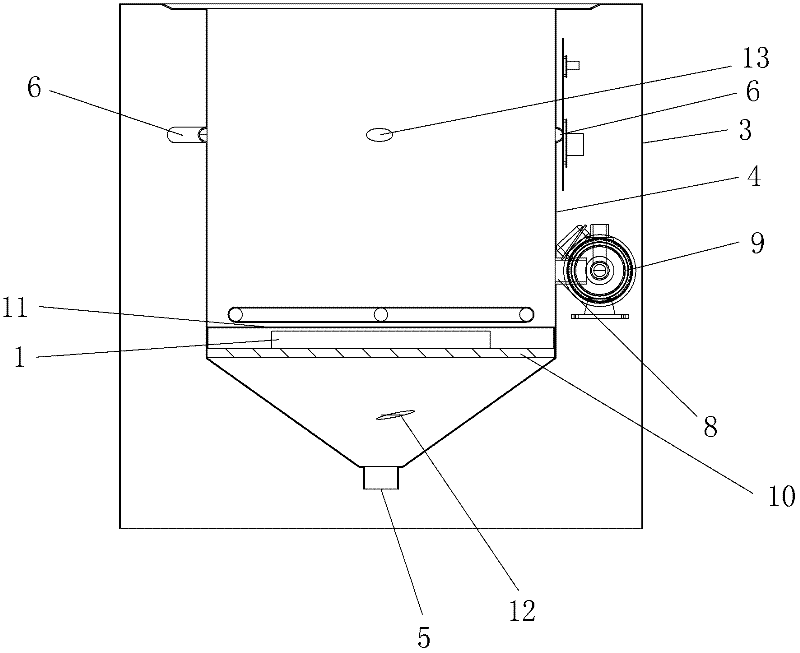

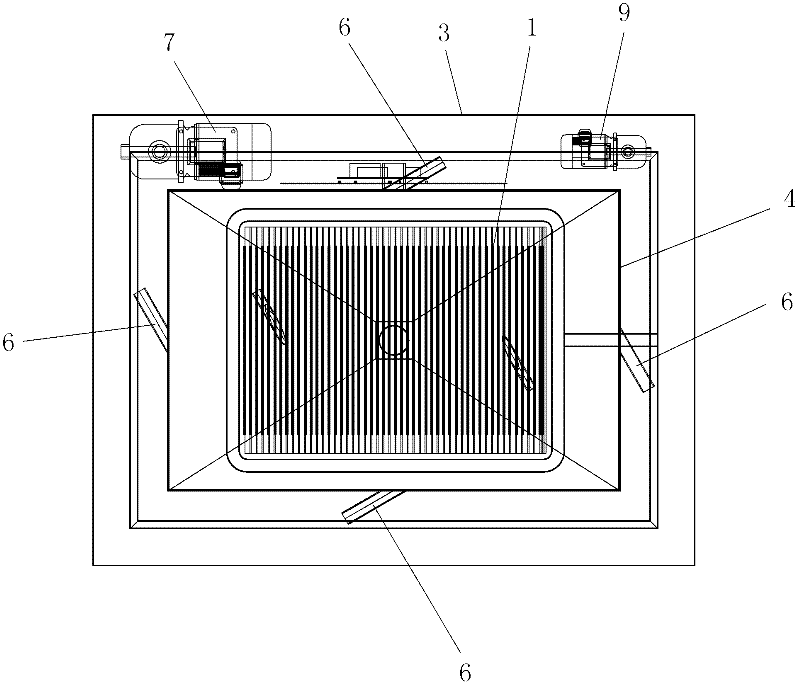

[0064] like figure 1 , figure 2 and image 3 As shown, the present invention includes a water catalyst generator 1 and a DC power supply for supplying power to the water catalyst generator 1. The water catalyst generator 1 includes two electrodes used in conjunction with each other, and the two electrodes are respectively connected to the An anode electrode and a cathode electrode connected to the positive and negative output ends of the DC power supply; the anode electrode and the cathode electrode are both titanium electrodes, and the outer surface of the anode electrode is uniformly coated with a layer of composite material coating. The composite material coating is a coating obtained after drying and sintering the composite material coating solution painted on the outer surface of the anode electrode. The composite material coating solution is uniformly composed of six kinds of powders and absolute ethanol. Mixed solution with a mass concentration of 2.5% to 4%, the six...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com