Method for removing semimetal antimony ion from waste water

A semi-metal and wastewater technology, applied in the field of water treatment, can solve the problems of low effective utilization rate of electrode materials, low removal rate of heavy metal ions, removal, and low recovery rate, etc., to achieve improved effective utilization rate, short treatment time, and environmental protection good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

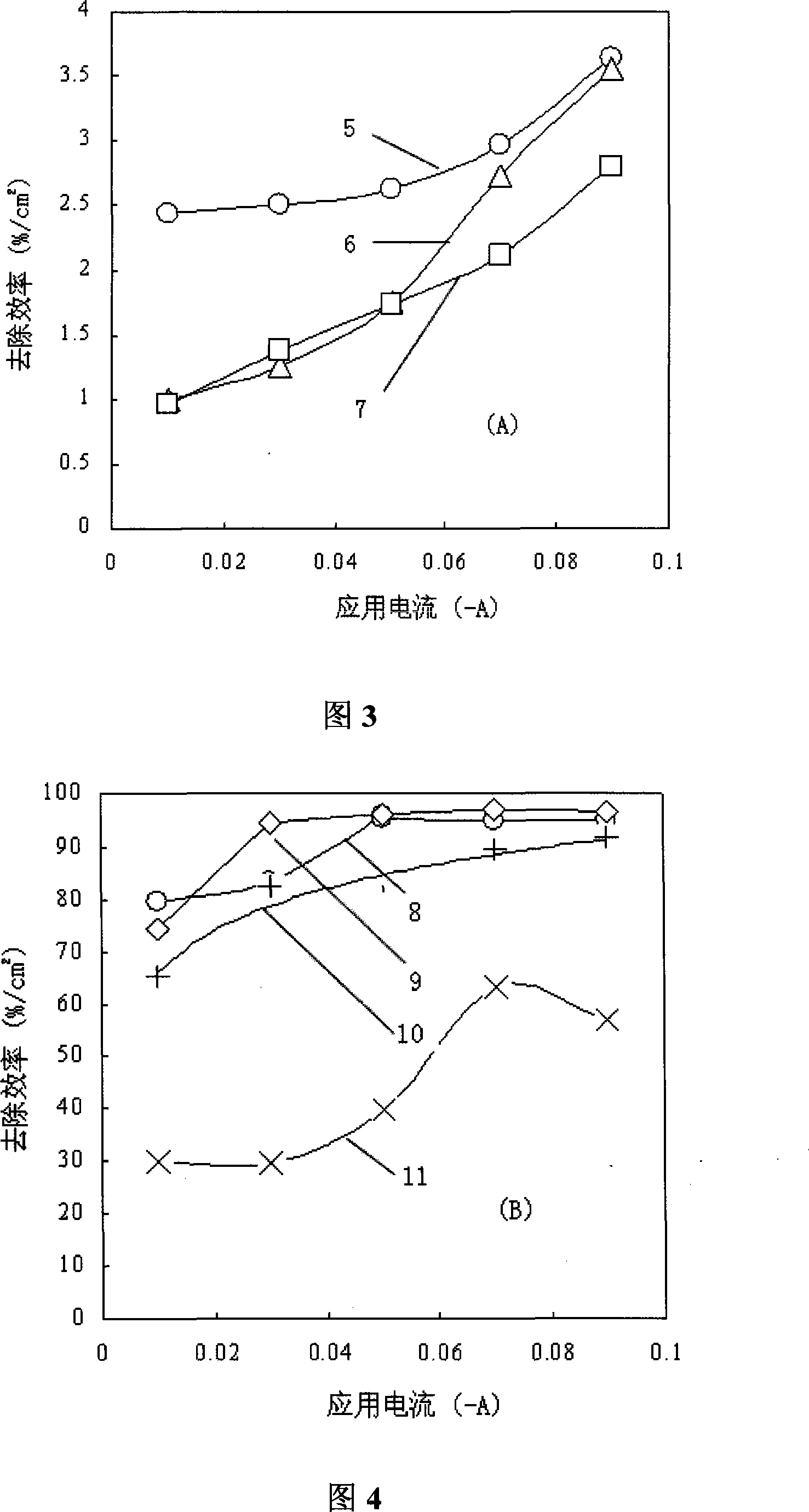

Embodiment 1

[0020] In this embodiment, a batch reactor is used to electrolyze the waste water solution, see accompanying drawing 1, in which: 1 is the working electrode, 2 is the opposite pole (platinum wire), 3 is the anode area, and 4 is the rotor. In this embodiment, a DC power electrolyzer (PAK60-12A, Kikusui Co., Ltd) with a two-electrode system (the counter electrode is a platinum wire) and a three-electrode system (the working electrode is a titanium mesh, the reference electrode is Ag / AgCl, and the counter electrode is Ag / AgCl) are respectively used. Platinum wire) electrolyzer (Potentiostat / Galvanostat HAB-151, Hokuto Denko Co., Ltd).

[0021] Adjust the wastewater solution containing semimetallic antimony ions to a concentration of 0.2mol L with sulfuric acid -1 , in a batch reactor with an effective capacity of 100mL, a titanium mesh (5×10cm) was used as the working electrode, and the conditions used were: -0.02A constant electrolysis current, electrodeposition time of 10min, r...

Embodiment 2

[0038] In this embodiment, a continuous flow reactor and a three-electrode system are used, and the schematic diagram of the reactor is shown in Figure 2.

[0039] In the figure, 1 is the working electrode, 2 is the counter electrode (platinum wire), 3 is the anode area, 4 is the rotor, and 17 is the reference electrode (Ag / AgCl). In this example, the titanium mesh (5×10cm) was used as the working electrode, and the sample provided in Example 1 was treated by constant current electrolysis, and the flow rate was 3.4-5mL min -1 , the specific steps and other conditions are as described in Example 1.

[0040] Table 2 shows the experimental test results obtained by removing semimetal antimony from the four samples provided in Example 1 using the device and process conditions described in this example.

[0041] Table 2

[0042]

sample

Antimony content

(mg L -1 )

Removal rate

(%)

residual amount ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com