Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

231results about "Sugar crystallisation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

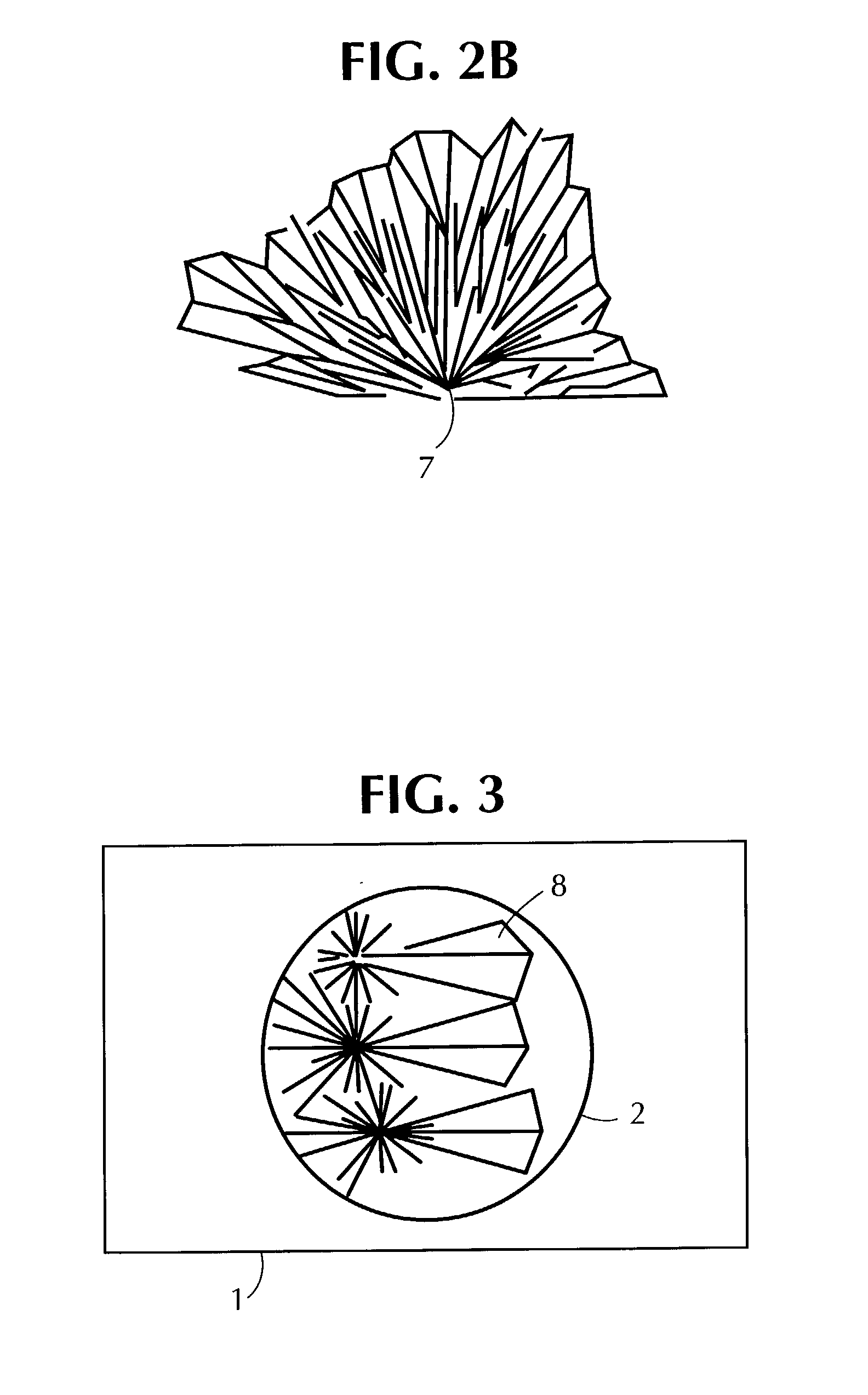

Processes and Apparatuses for the Production of Crystalline Organic Microparticle Compositions by Micro-Milling and Crystallization on Micro-Seed and Their Use

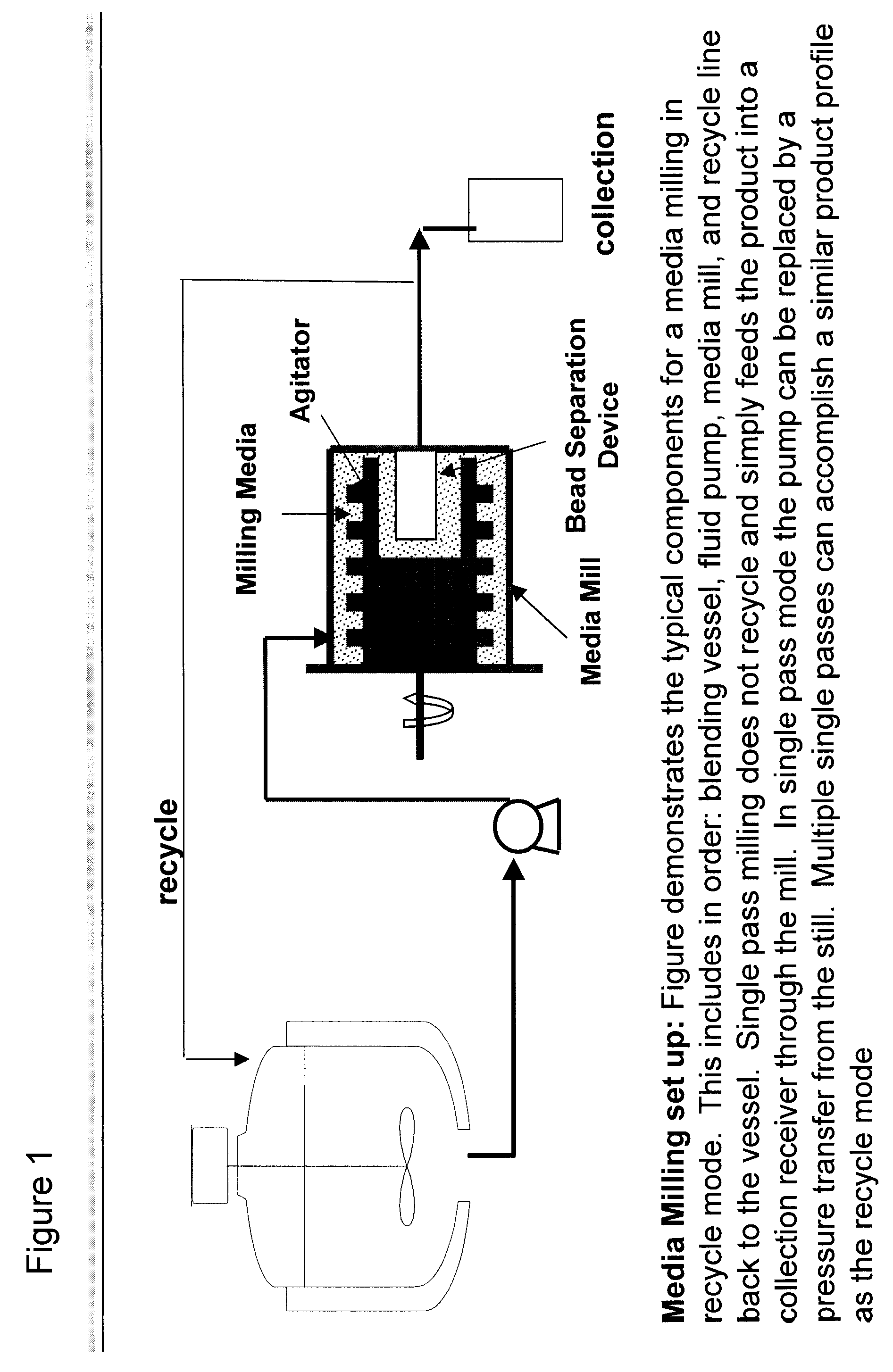

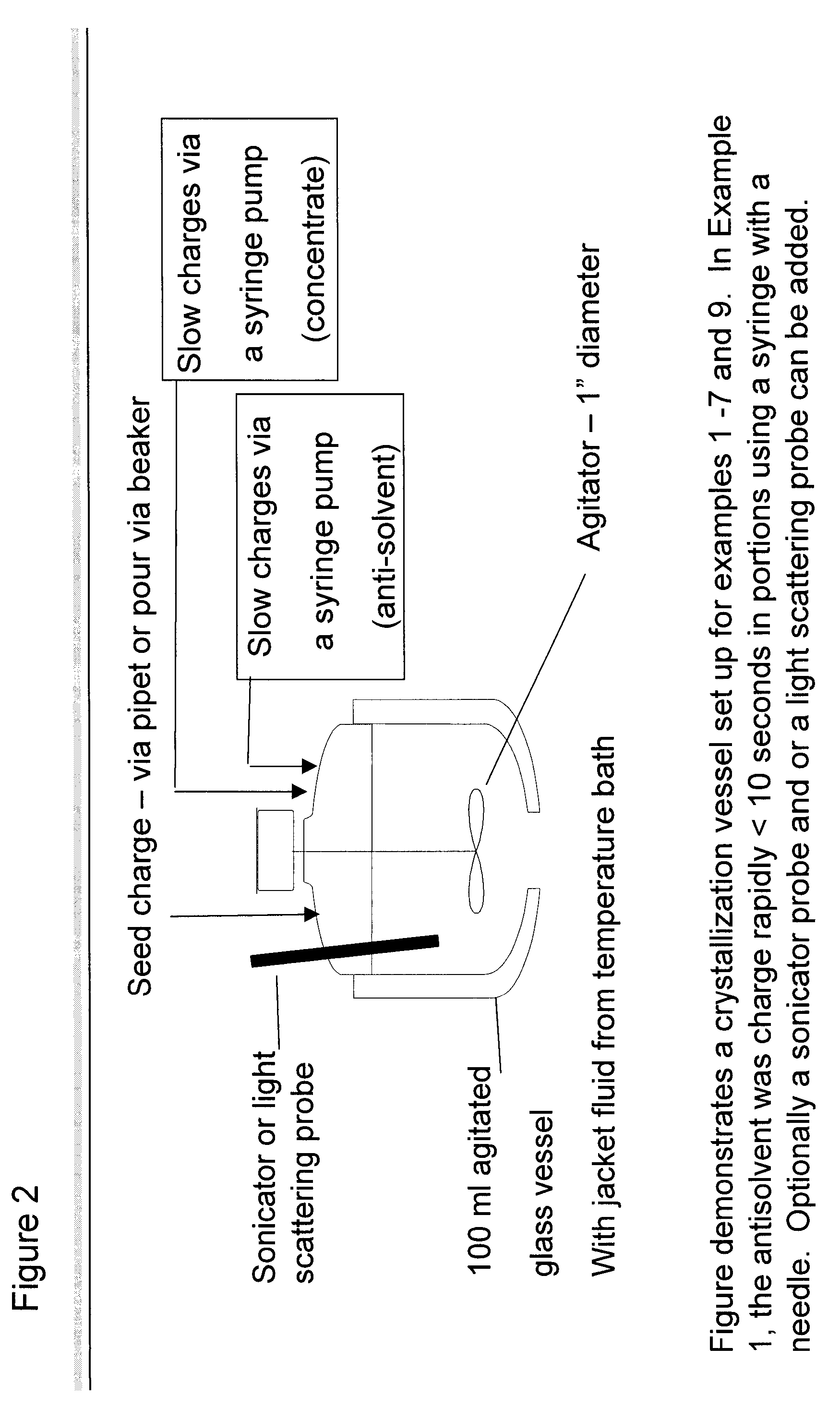

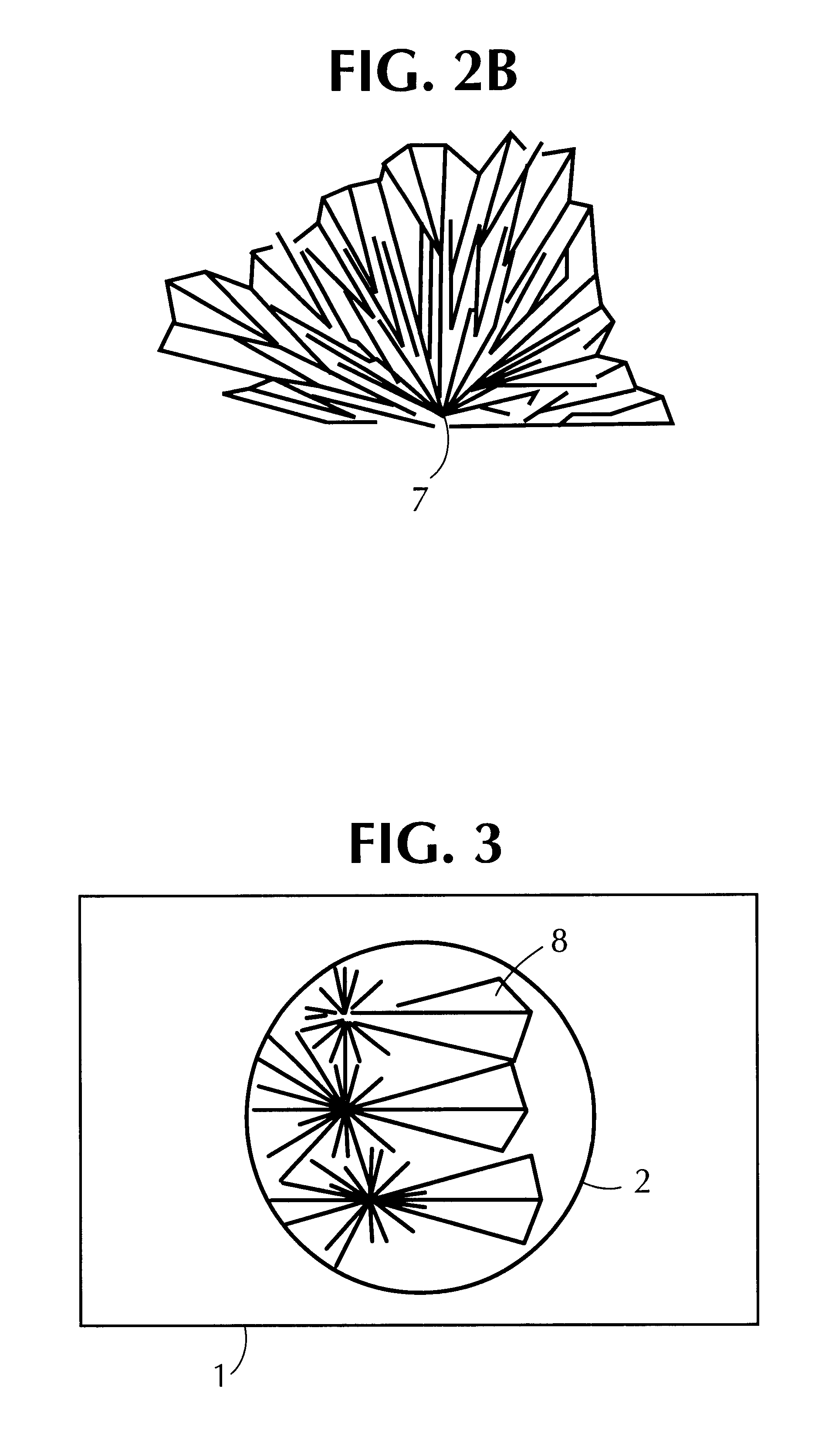

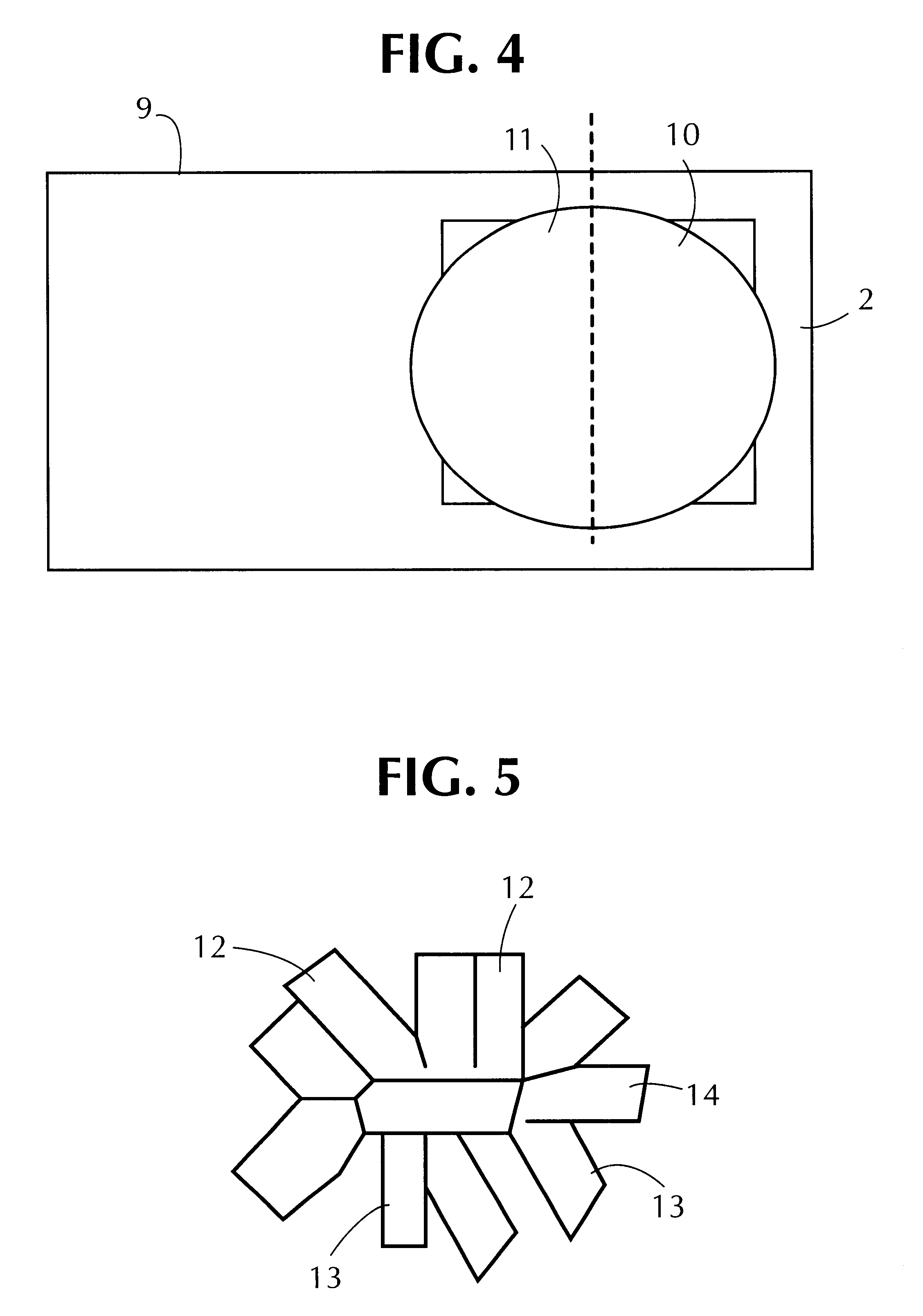

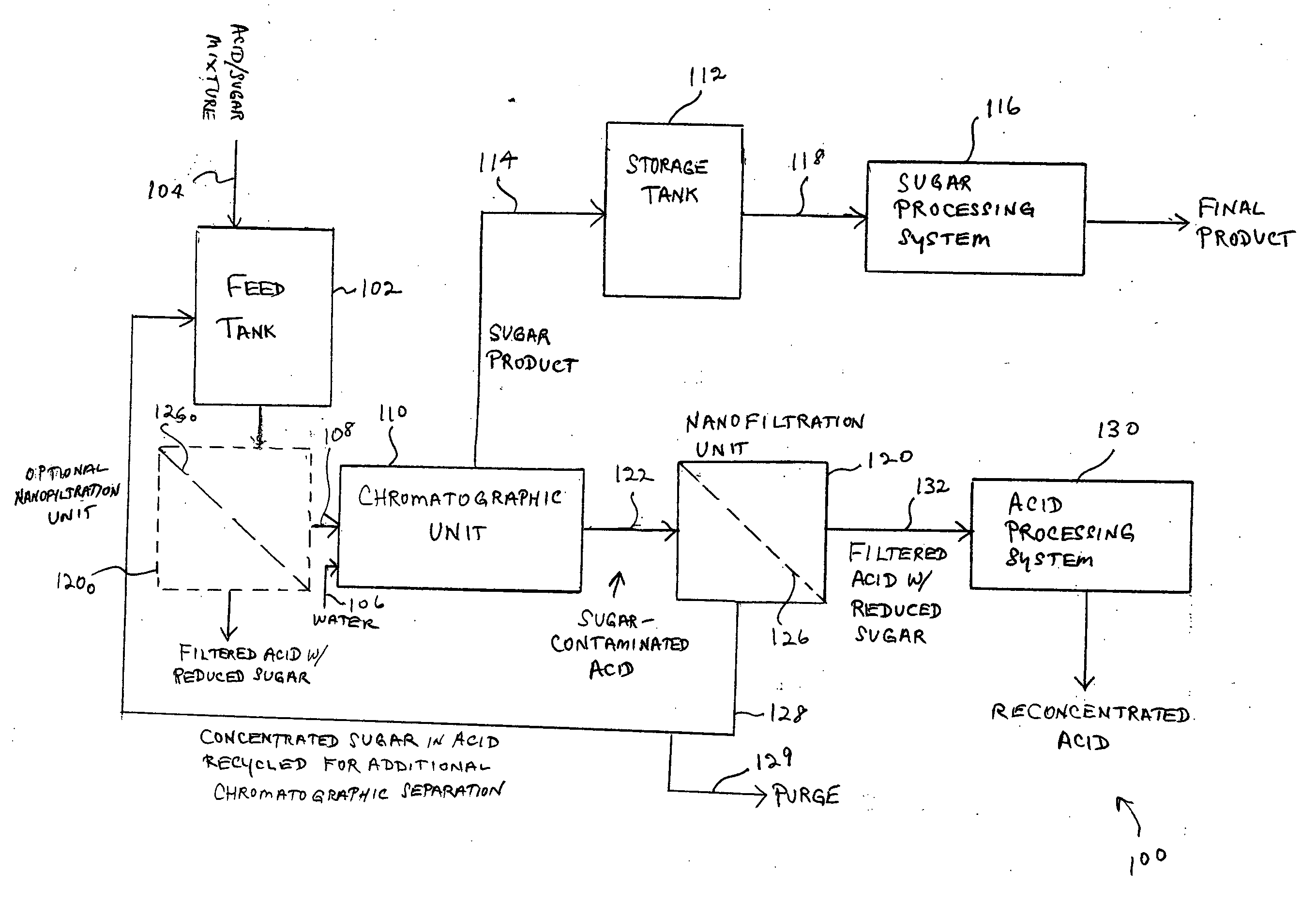

InactiveUS20090087492A1Large specific surface areaIncrease ratingsBiocideNervous disorderMicroparticleOrganic compound

The present invention relates to a process, for the production of crystalline particles of an active organic compound The process includes the steps of generating a micro-seed by a wet-milling process and subjecting the micro-seed to a crystallization process. The resulting crystalline particles have a mean particle size of less than about 100 μm. The present invention also provides for a pharmaceutical composition which includes the crystalline particles produced by the method described herein and a pharmaceutically acceptable carrier.

Owner:MERCK SHARP & DOHME CORP

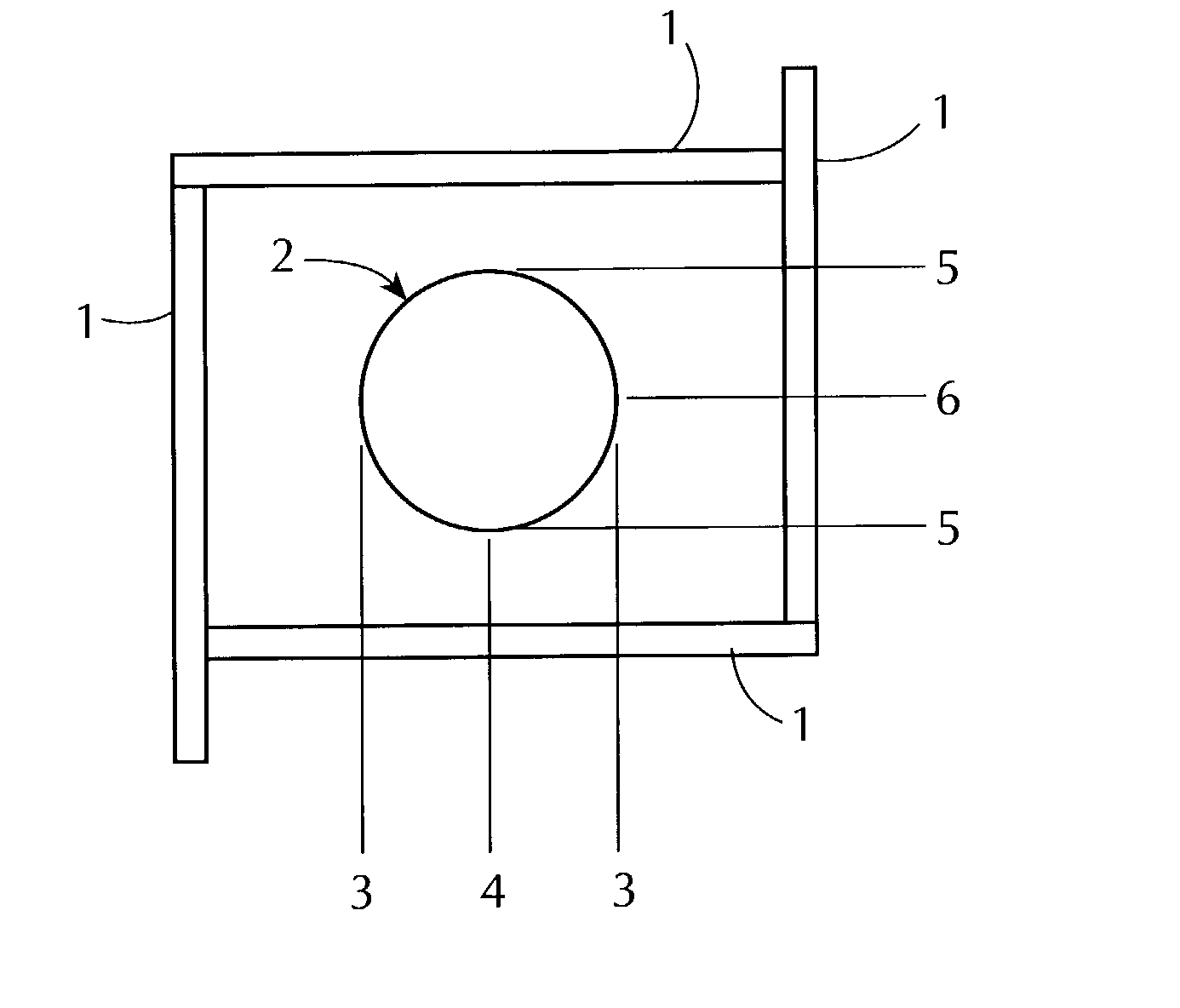

Crystallization of sugars

InactiveUS6579375B2Reduce in quantityPromote growthDough treatmentMilk preservationCrystallinitySolvent

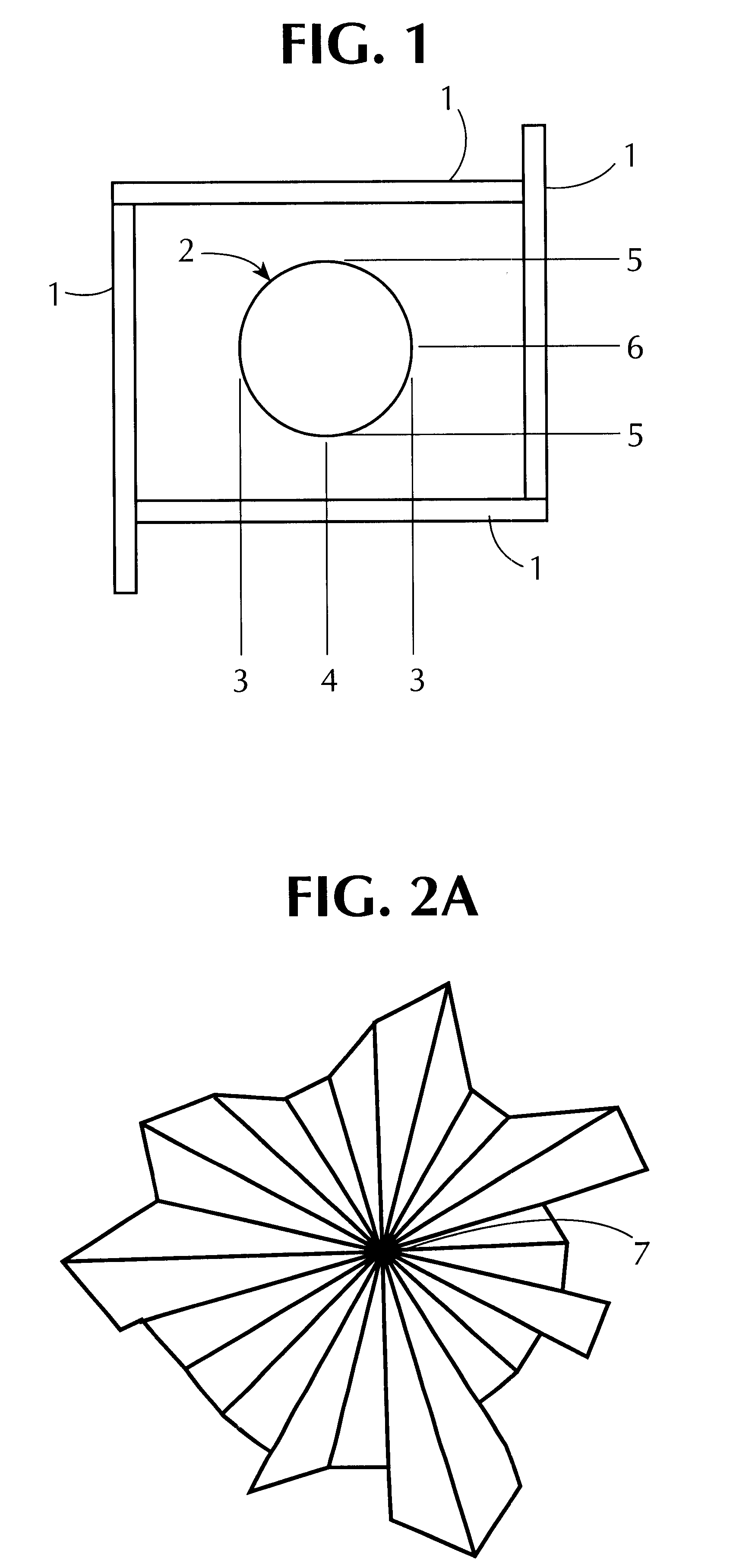

A process for preparing crystalline sugar by providing a solution of a solvent and sugar, exposing the solution to a magentic field having a strength which is sufficient to impart improvements in the processing of the sugar or the properties of the resulting crystalline sugar product, and providing conditions suitable for crystallization to obtain a substantially crystalline sugar product. The magnetic field strength is sufficient to influence at least one of morphology, size, nucleation rate or, crystallinity of the crystalline sugar product.

Owner:NESTEC SA

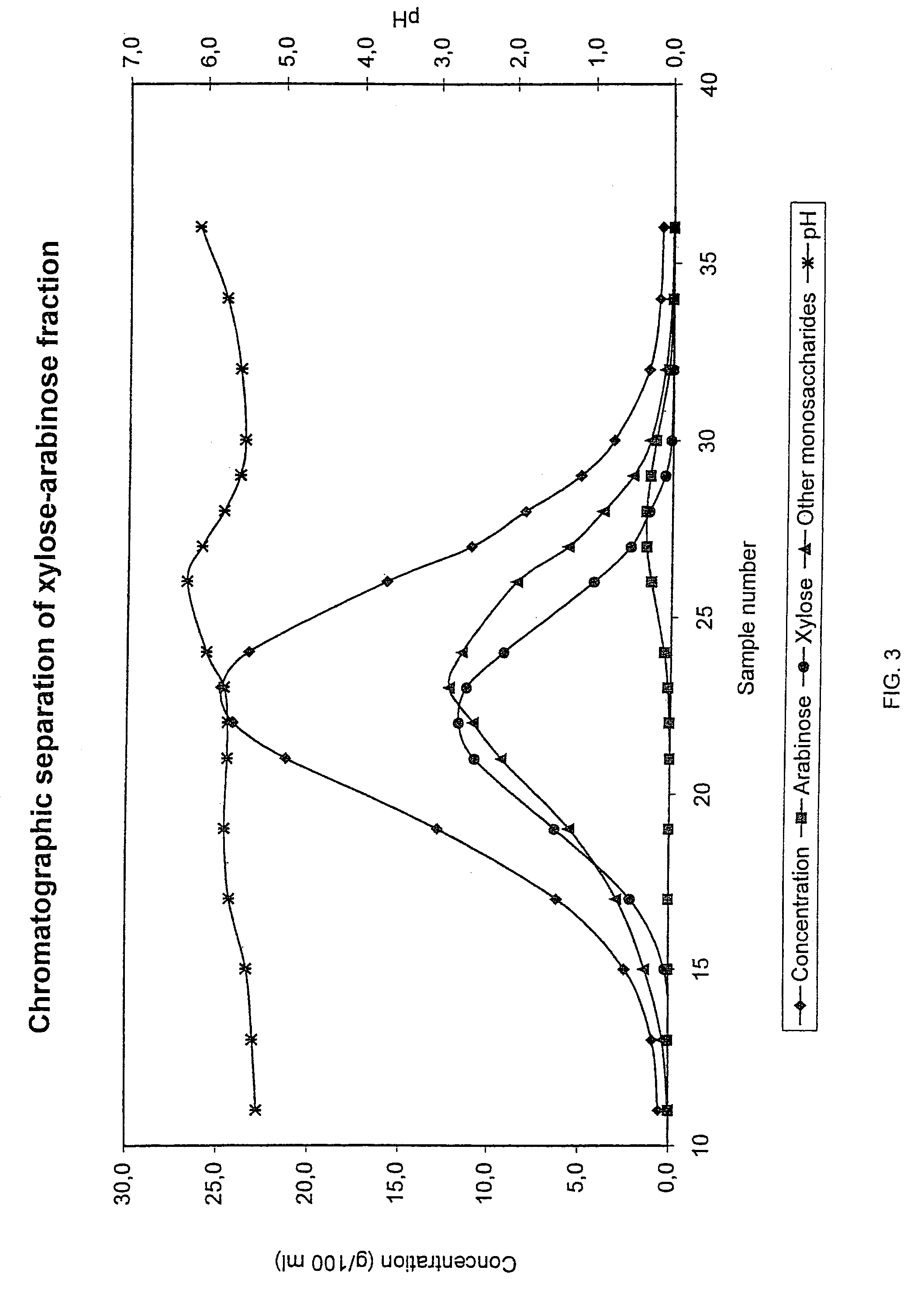

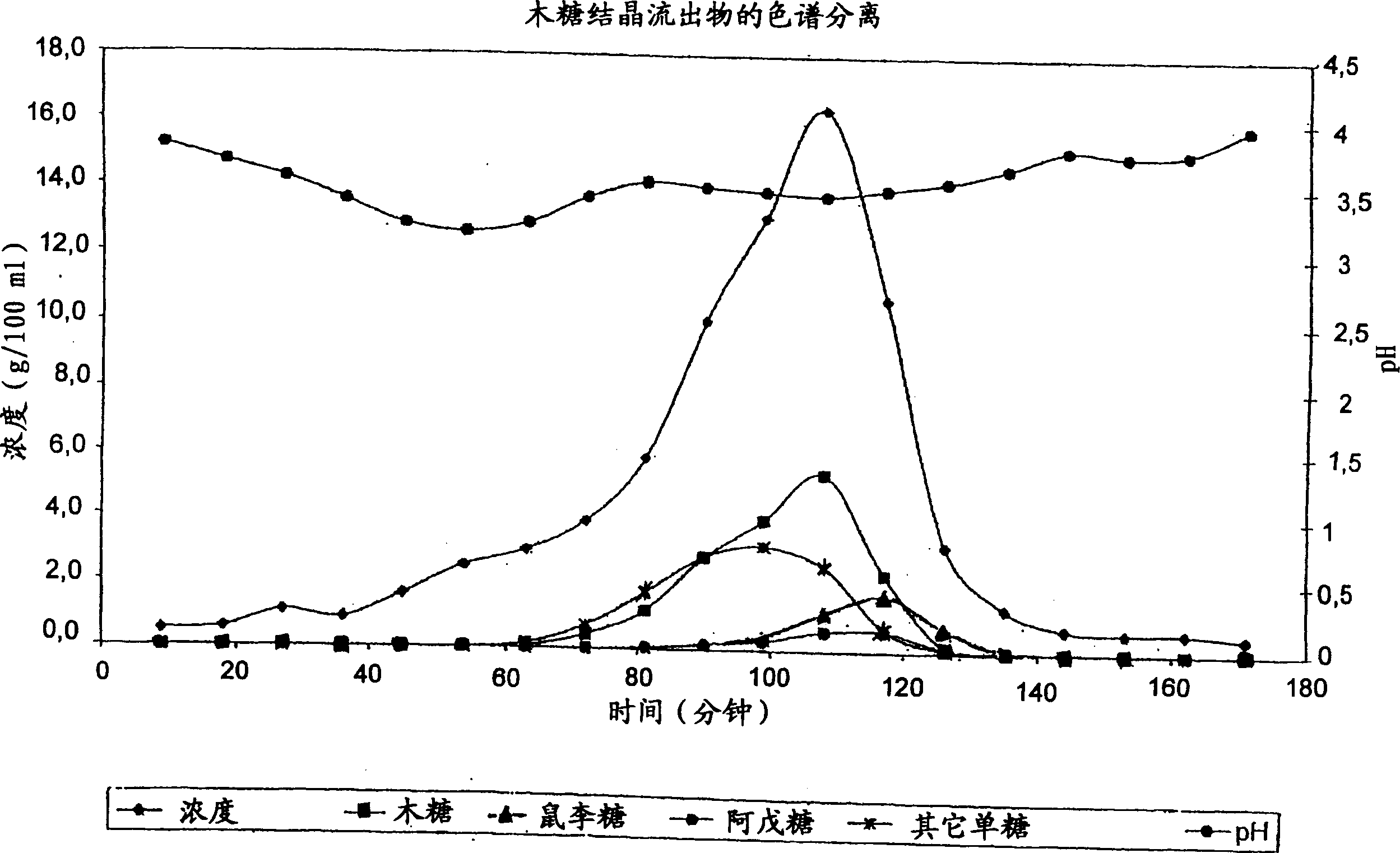

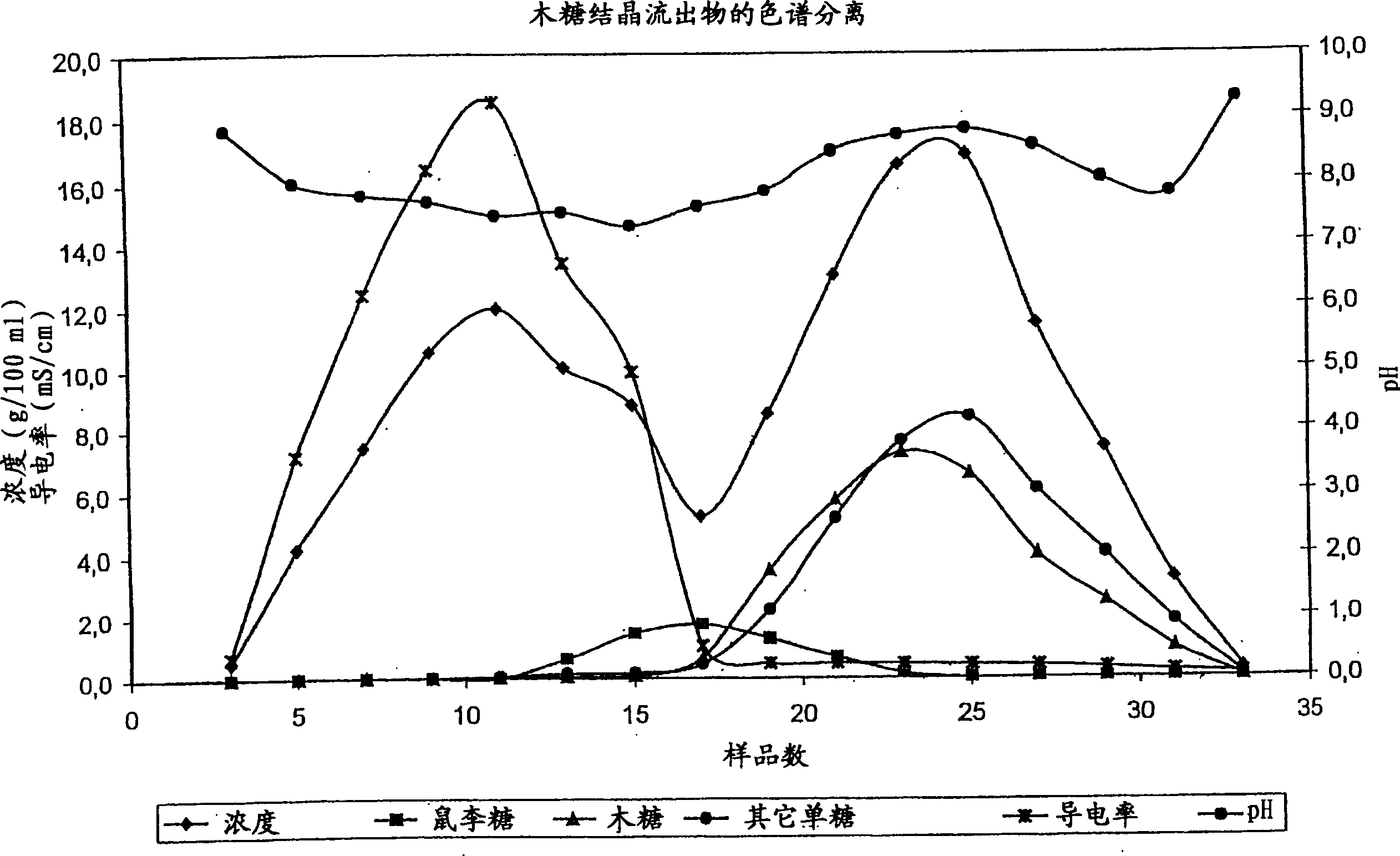

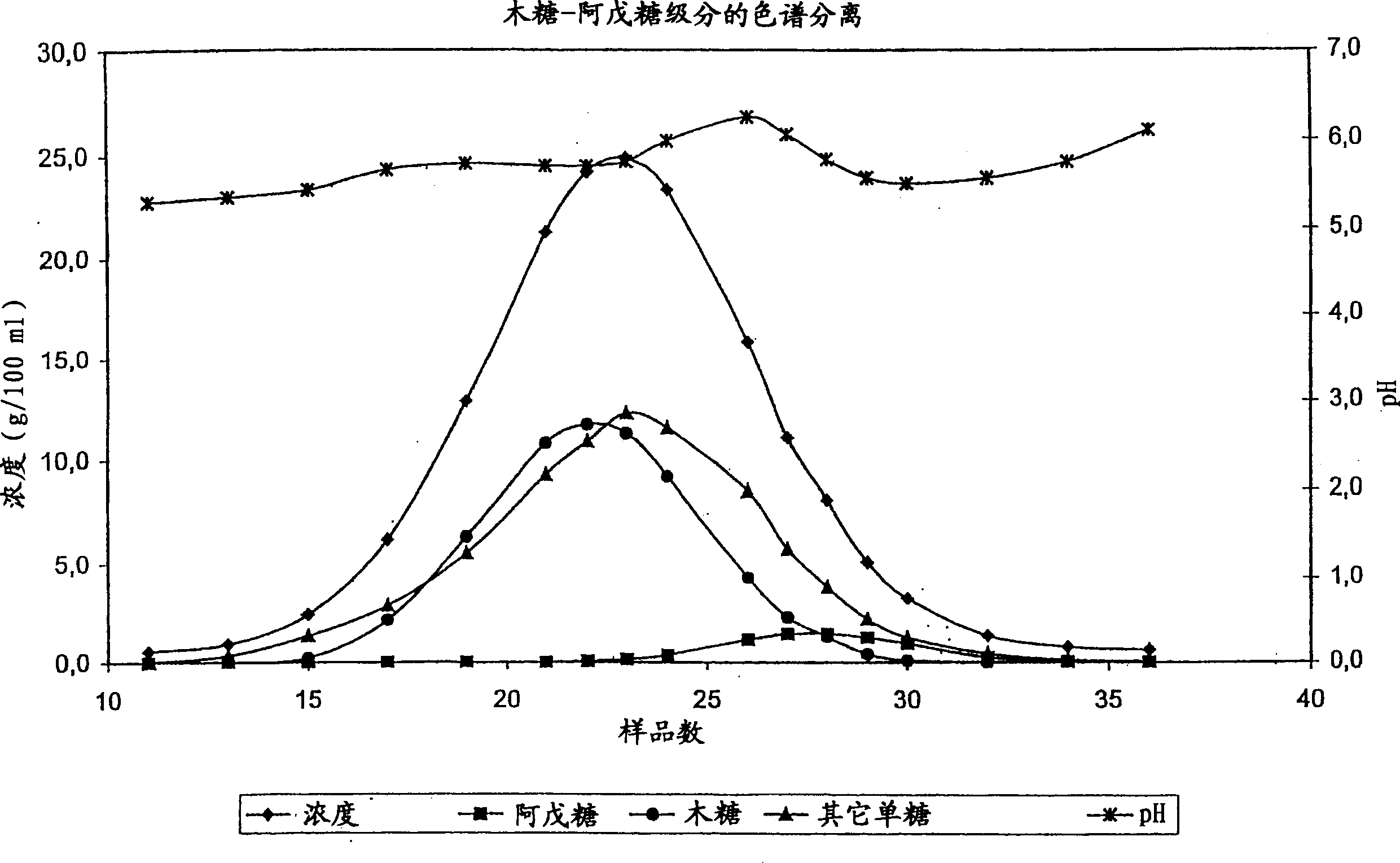

Process of producing xylose and dissolving pulp

ActiveUS20110192560A1High yieldReduce the amount requiredPretreatment with water/steamWashing/displacing pulp-treating liquorsChromatographic separationXylan

The present invention relates to a process for the production of xylose and dissolving pulp from xylan-containing biomass, such as hardwood. The invention is based on prehydrolysis of the xylan-containing biomass with SO2 in specified conditions, followed by chromatographic fractionation, nanofiltration or precipitation crystallization of the xylose-containing prehydrolyzate to obtain a xylose product having a xylose content of at least 55% on DS. The dissolving pulp obtained from the process can be used for example for the production of viscose.

Owner:DUPONT NUTRITION BIOSCIENCES APS

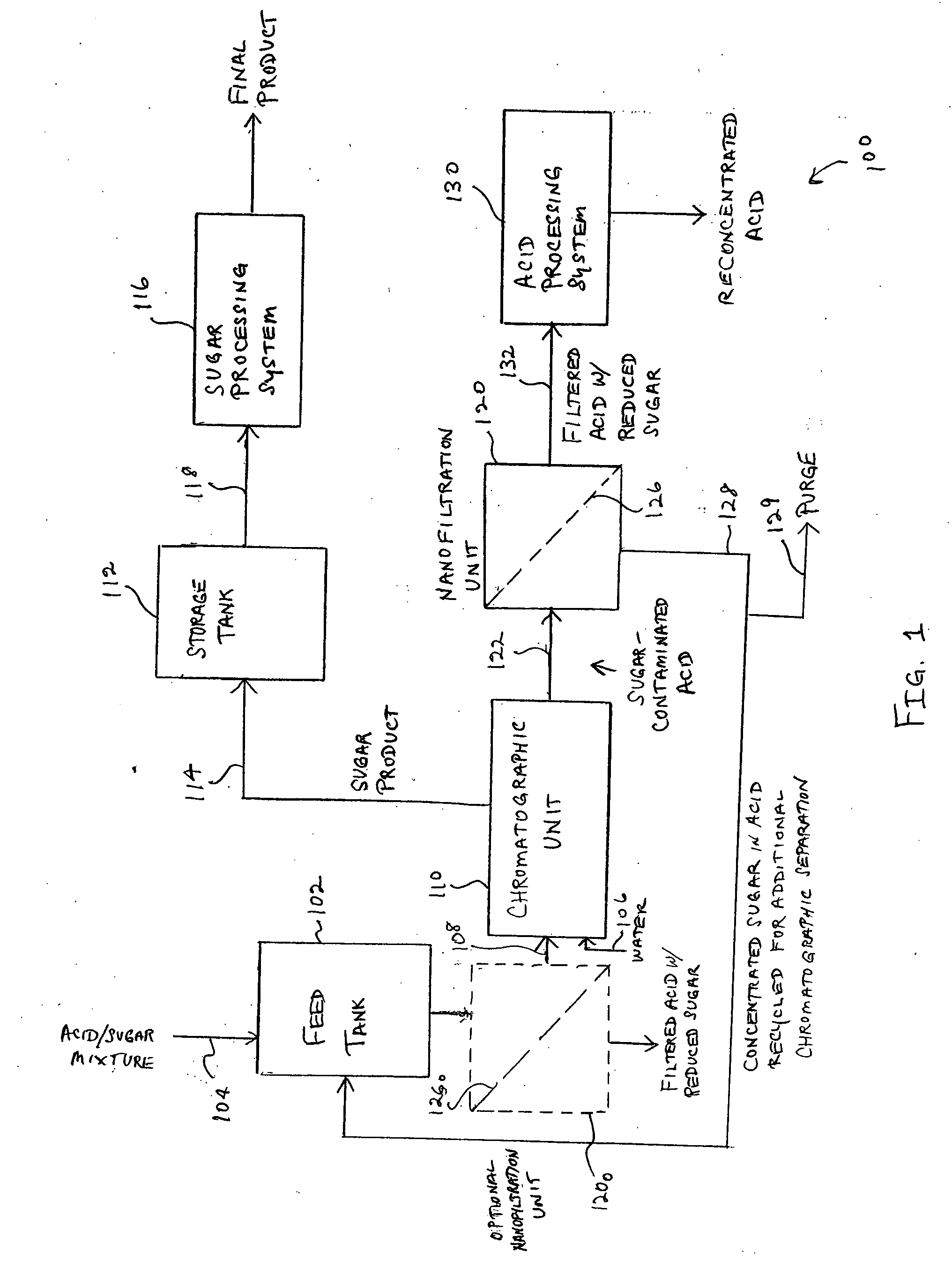

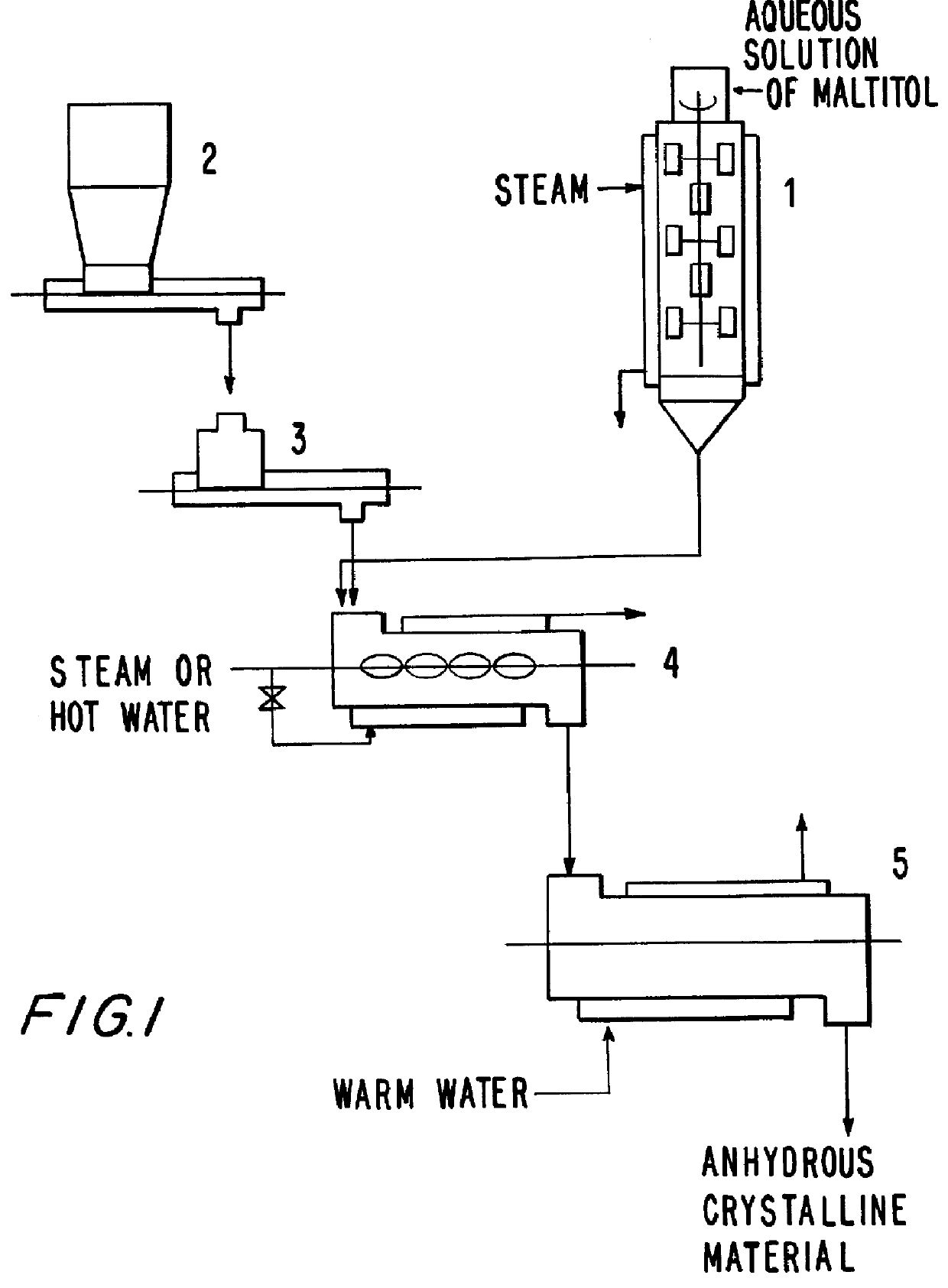

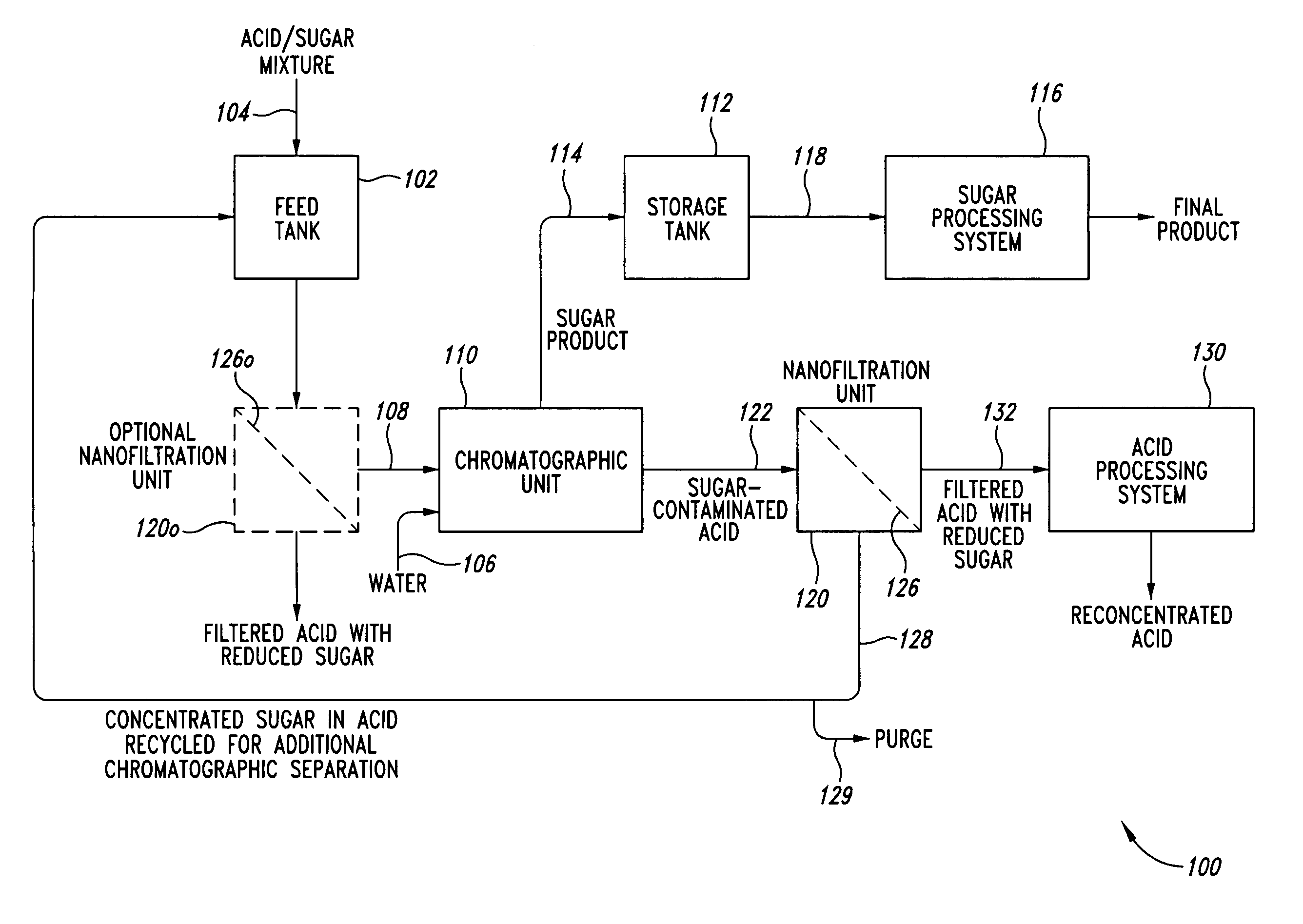

Nanofilter system and method of use

An acid recovery system used in a hydrolysis operation includes a chromatographic unit to provide initial separation of sugar and acid. The sugar product provided by the chromatographic unit is processed to produce higher value products, such as ethanol. The remaining acid is contaminated by sugar. A nanofiltration unit containing a nanofilter membrane processes the sugar contaminated acid. The acid is allowed to permeate across the nanofilter membrane while sugar is rejected. The permeate is provided to a conventional acid recovery system and recycled for use in the hydrolysis process.

Owner:HARRIS GROUP

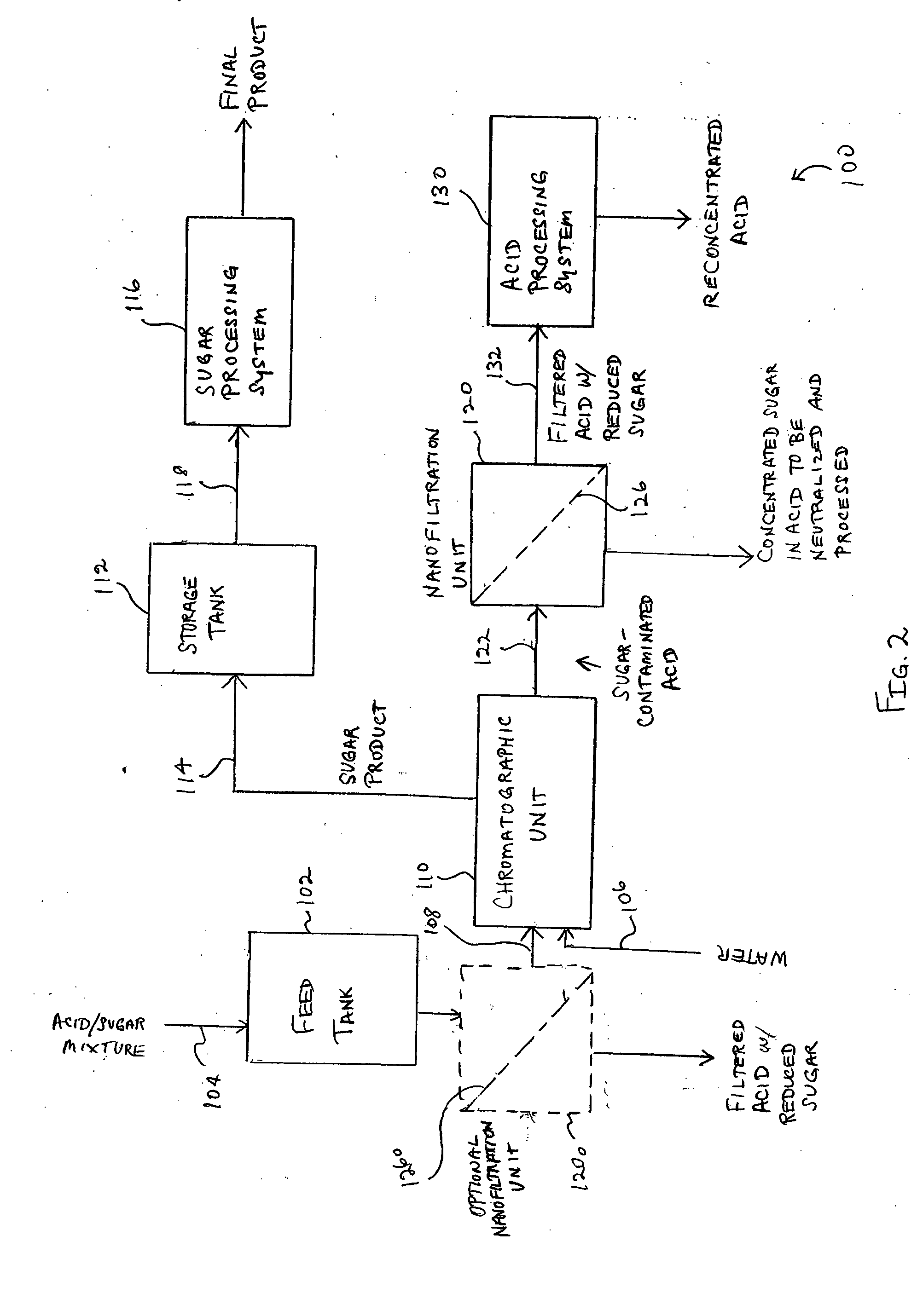

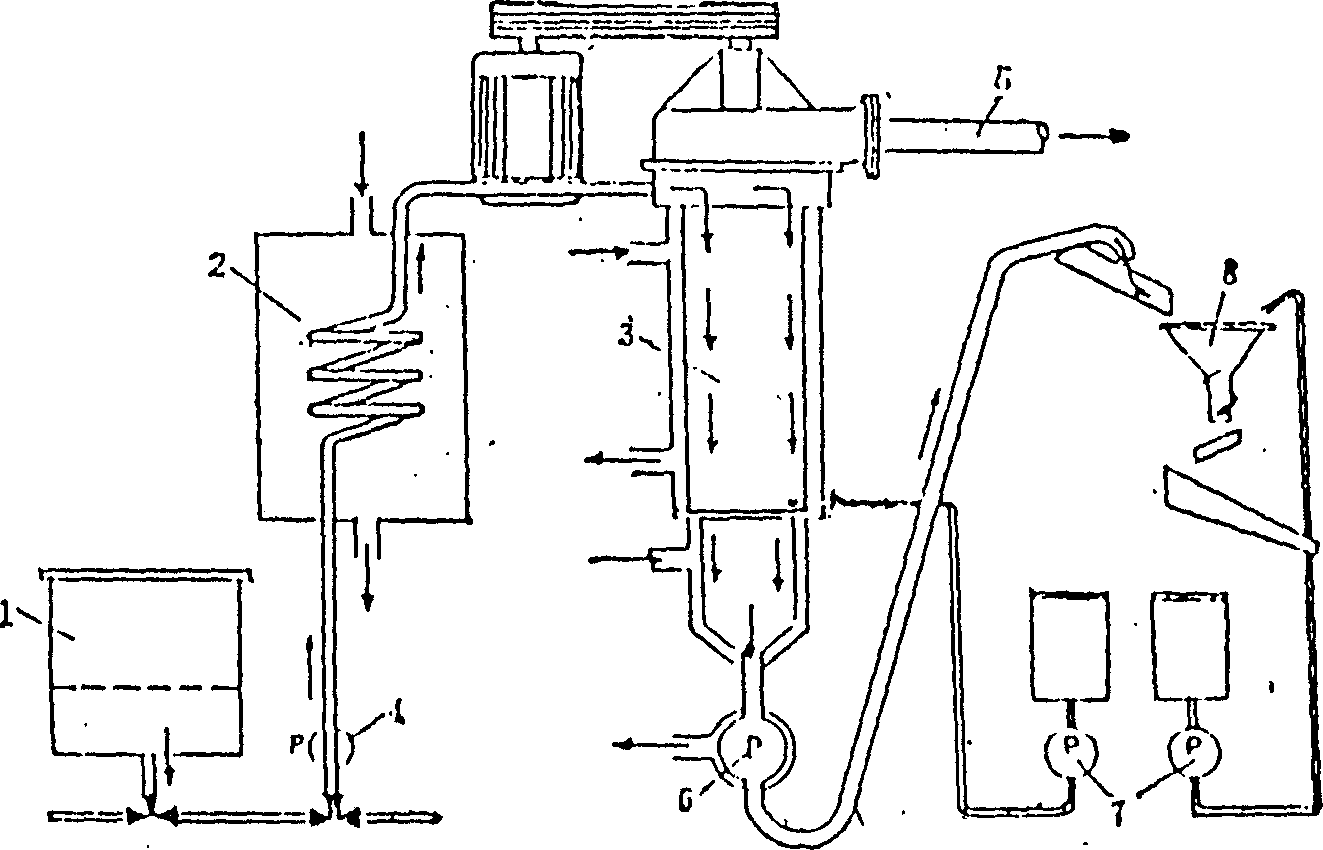

Method for the continuous manufacture of anhydrous crystalline maltitol and a manufacturing apparatus therefor

InactiveUS6120612ALow production costLabor expenseSugar derivativesSugar crystallisationHigh concentrationPolymer science

Disclosed herein is a continuous manufacturing method for anhydrous crystalline maltitol comprising the following steps: (i) a heating and concentrating step where an aqueous solution containing maltitol in which maltitol is a main ingredient is continuously heated and concentrated to give a concentrated solution having a high concentration; (ii) a seed crystal adding and mixing step where the seed crystals are added to and mixed with the above concentrated solution with heating to give a massceuite containing the seed crystals; and (iii) a crystal aging step where the massceuite is subjected to disintegration, mixing, stirring and transfer in an atmosphere in which temperature and moisture are adjusted to proceed the crystallization.

Owner:HAYASHIBARA BIOCHEMICAL LAB INC +1

Nanofilter system and method of use

An acid recovery system used in a hydrolysis operation includes a chromatographic unit to provide initial separation of sugar and acid. The sugar product provided by the chromatographic unit is processed to produce higher value products, such as ethanol. The remaining acid is contaminated by sugar. A nanofiltration unit containing a nanofilter membrane processes the sugar contaminated acid. The acid is allowed to permeate across the nanofilter membrane while sugar is rejected. The permeate is provided to a conventional acid recovery system and recycled for use in the hydrolysis process.

Owner:HARRIS GROUP

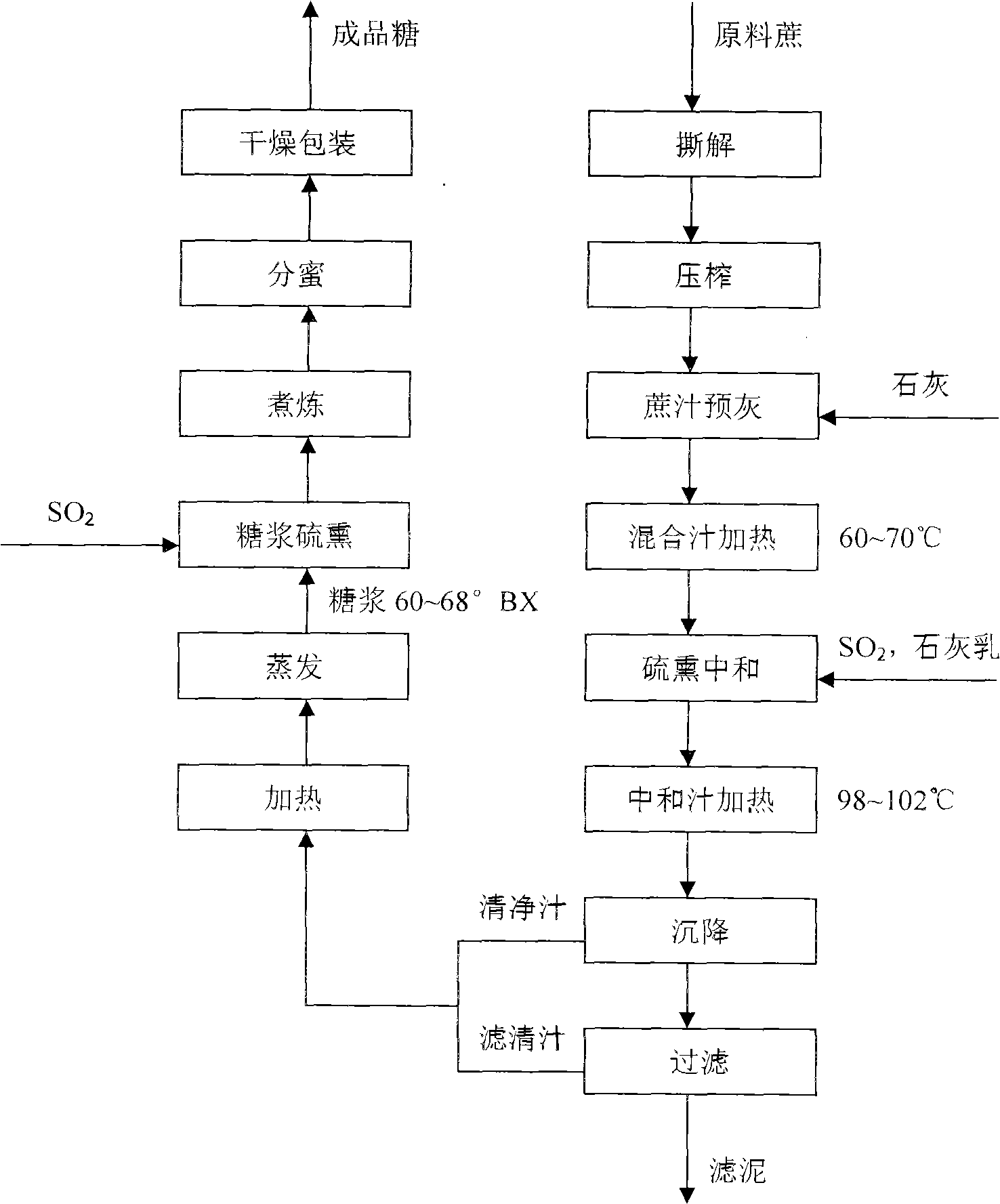

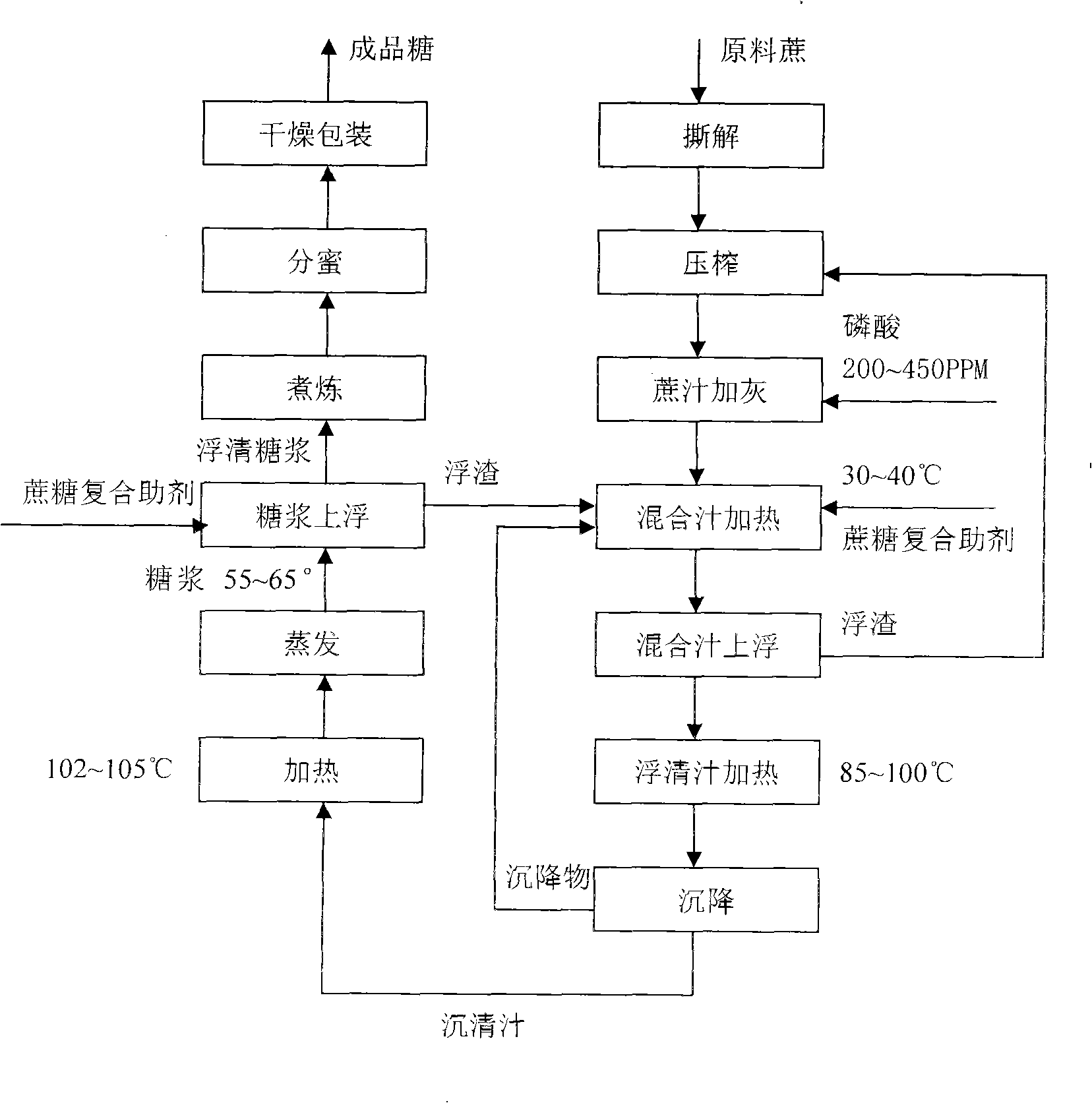

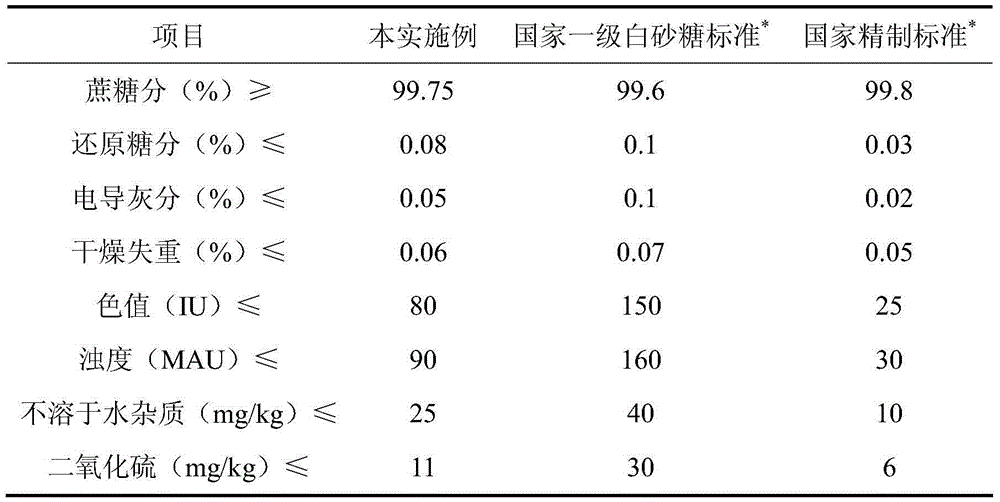

Production method of sulfurless superior saccharose

InactiveCN101323885AHigh purityPurity is higher than mixed puritySugar crystallisationSugar juice purificationRetention timeFiltration

The invention relates to a production method of high-quality sugar, specifically to an improvement of a technology of sugar refinement and purification. High-quality white granulated sugar products are obtained after sugar canes are torn, pressed, cane juice is defecated, mixed juice is heated, a cane sugar complex auxiliary agent is added, the mixed juice is stirred up, floating juice is heated, sedimentated and vaporized, phosphoric acid and the cane sugar complex auxiliary agent are added, syrup is stirred up, the process of honey separation is carried out, the mixture is boiled, refined, crystallized, dried and packed. As the method of the invention adopts a low-temperature technology and a floating treatment method of adding the phosphoric acid, lime and the cane sugar auxiliary agent to lead the floating juice to reach or exceed the effect of the floating juice by original traditional technology, and utilizes a syrup floating principle and a scruff repressing method to substitute the sediment, filtration and stoving technology in the prior art, and cancels such technologies and equipment thereof as filtration, neutralization and sulfur dioxide gas system, retention time in cane juice production process is shortened, sulfur is used as a clarifier during the whole technical process, and sugar without sulfur is produced, thus improving product quality as well as reducing cost.

Owner:高晓军 +1

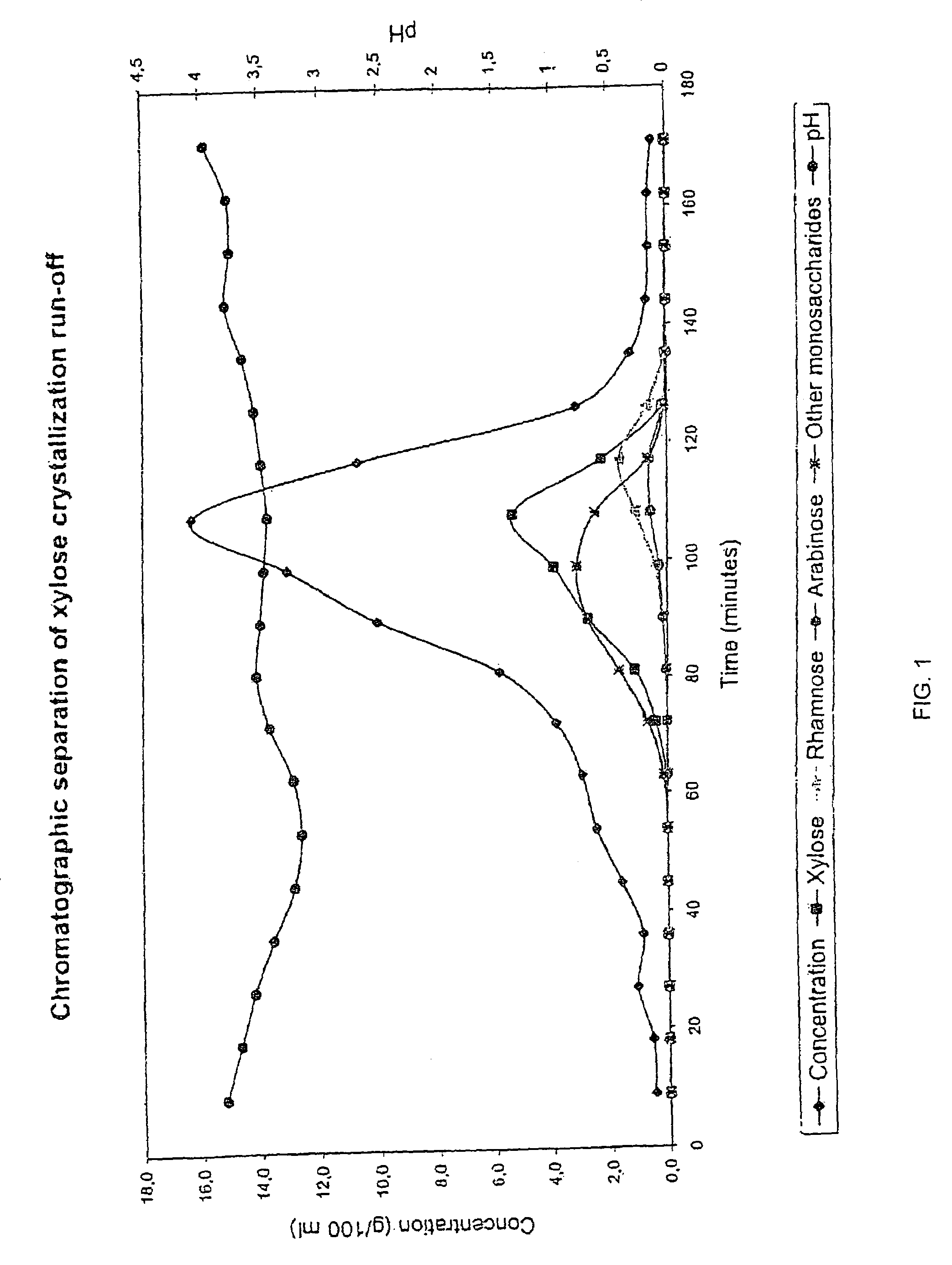

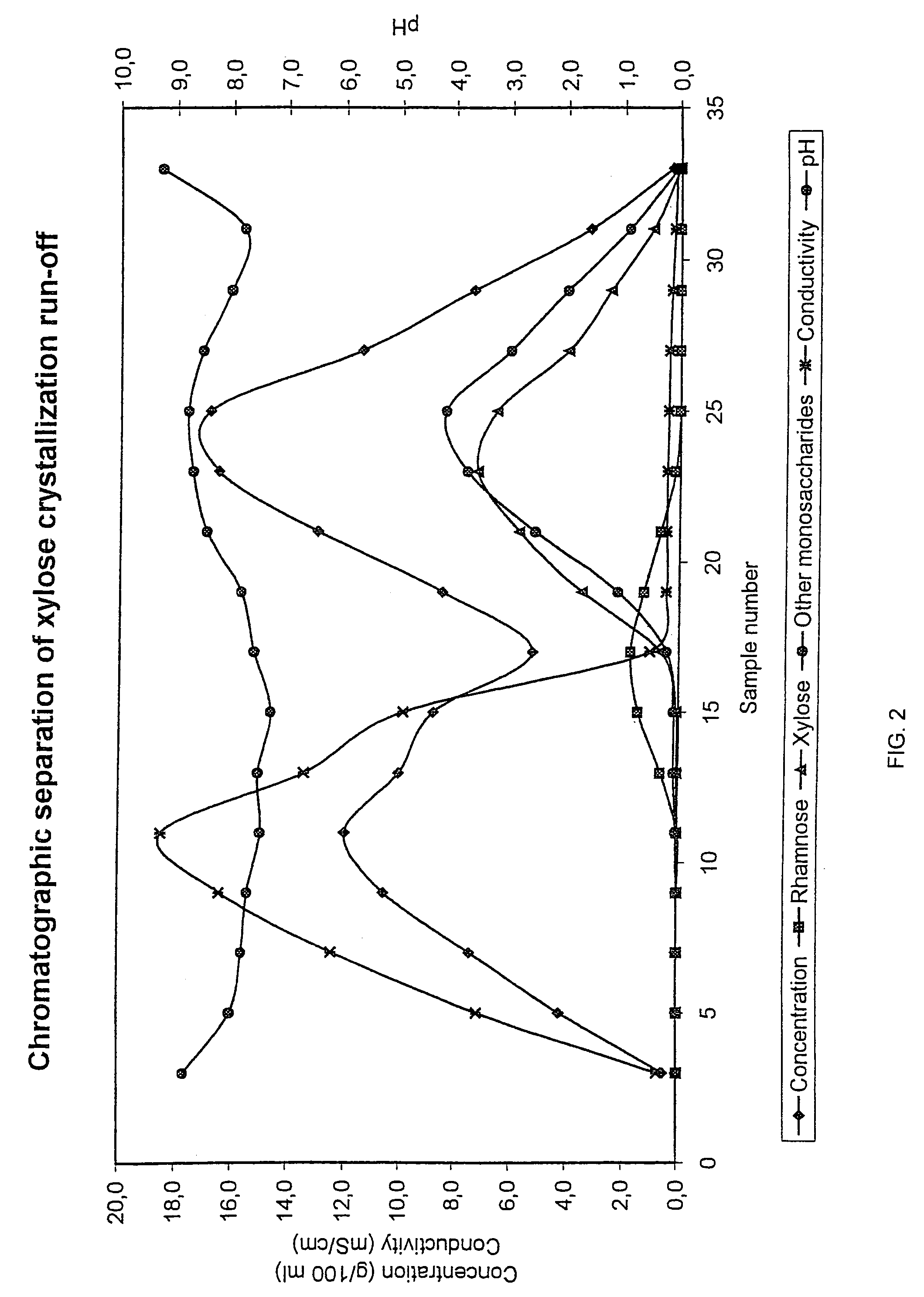

Method for recovering products

InactiveUS6987183B2Ion-exchanger regenerationSugar crystallisationChromatographic separationArabinose

The present invention is directed to a method comprising a multistep process for recovering one or more monosaccharides from a solution containing at least two monosaccharides selected from the group consisting of rhamnose, arabinose, xylose and mixtures thereof by using chromatographic separation comprising at least one step, where a weak acid cation exchange resin is used for the chromatographic separation.

Owner:DANISCO SWEETENERS

Crystallization of sugars

InactiveUS20030084898A1Attractive bright and shiny appearanceProduced conveniently and consistentlyMilk preservationDough treatmentNucleationCrystallinity

A process for preparing crystalline sugar by providing a solution of a solvent and sugar, exposing the solution to a magentic field having a strength which is sufficient to impart improvements in the processing of the sugar or the properties of the resulting crystalline sugar product, and providing conditions suitable for crystallization to obtain a substantially crystalline sugar product. The magnetic field strength is sufficient to influence at least one of morphology, size, nucleation rate or, crystallinity of the crystalline sugar product.

Owner:NESTEC SA

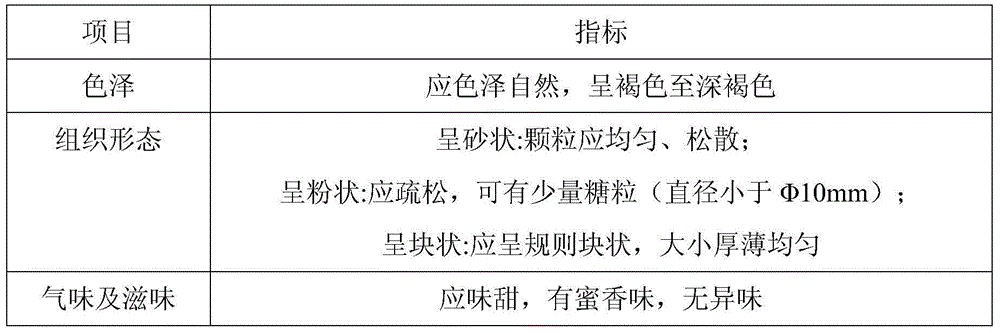

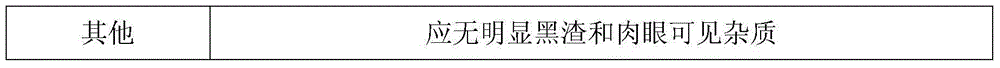

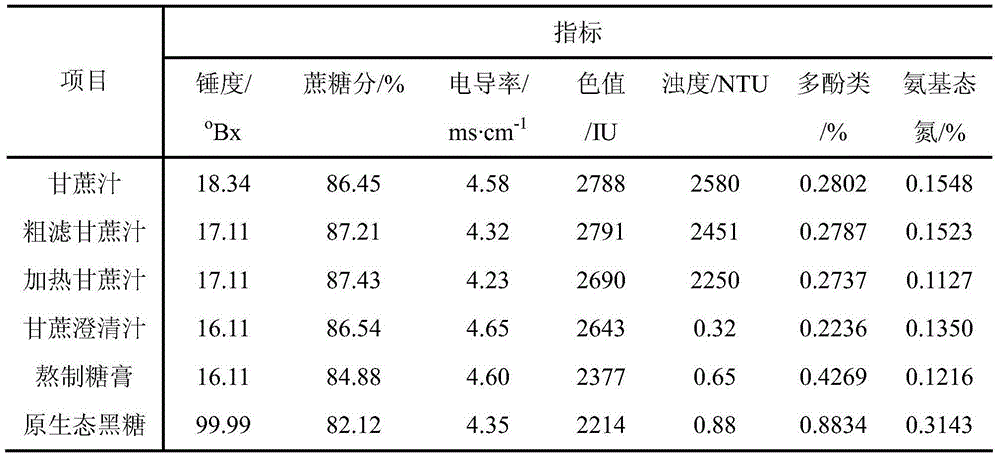

Industrialized production method of primitive brown sugar

ActiveCN103993106ARetract lowPromote recoverySugar crystallisationPurification by physical meansSlagMicrofiltration

The invention discloses an industrialized production method of primitive brown sugar. The method comprises the steps of with cane sugar factory mixed juice as a raw material, adding lime milk to regulate the pH value to 5.8-6.6; sieving and filtering; heating, floating and removing floating slag; removing impurities through microfiltration; evaporating and concentrating to obtain syrup with the concentration of 60-65-degree Bx; boiling sugar at the temperature of 125-130 DEG C at normal pressure to obtain syrup with the concentration of 95-98-degree Bx; sanding and forming to realize industrialized production of the primitive brown sugar. When used for producing brown sugar, the industrialized production method disclosed by the invention is safe and reliable in production process, high in mechanization degree, capable of realizing large-scale production of the primitive brown sugar and stable in product quality.

Owner:GUANGXI UNIV +1

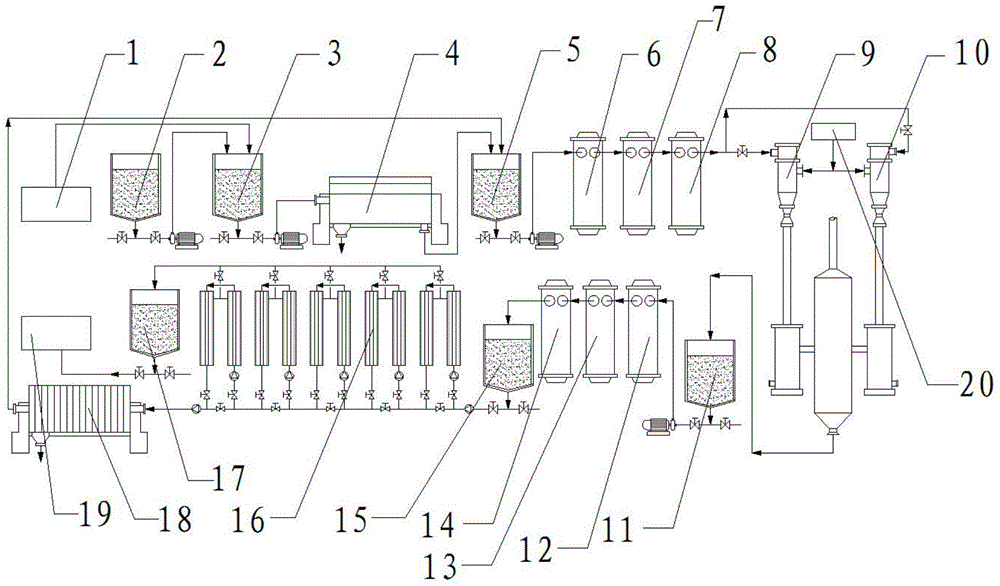

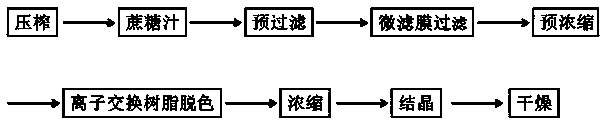

Technology for refining saccharose

ActiveCN103725802ANo color reversionOptimal production process parametersSugar crystallisationPurification using ion-exchange materialsInorganic saltsSucrose

The invention discloses a technology for refining saccharose. The technology comprises specific steps of juicing, pretreating, micro-filtering by a membrane, pre-concentrating, decoloring through ion exchange, desalting, evaporating and concentrating through MVR (mechanical vapor recompression), crystallizing, separating through centrifuging, and drying so as to obtain the saccharose crystal. The technology has the advantages that ceramic microfiltration substitutes for sedimentation by sheet frames and lime, so that the step of ultrafiltration is saved; due to concentration by the membrane, the evaporation capacity of evaporation and concentration equipment is reduced, the energy consumption is lowered, and part of inorganic salt is removed; the technology of decoloring and removing impurities through ion exchange substitutes for the technology of stoving, so that the problem of residual sulphur in the saccharose is solved, and the quality of the product is improved; the manner of ion exchange can effectively remove the salt in cane juice; energy consumption is effectively lowered due to the MVR; by adopting the membrane concentration and separation and ion exchange equipment, the floor space of the equipment is reduced, and investment of capital construction is lowered.

Owner:JIANGSU JIUWU HITECH

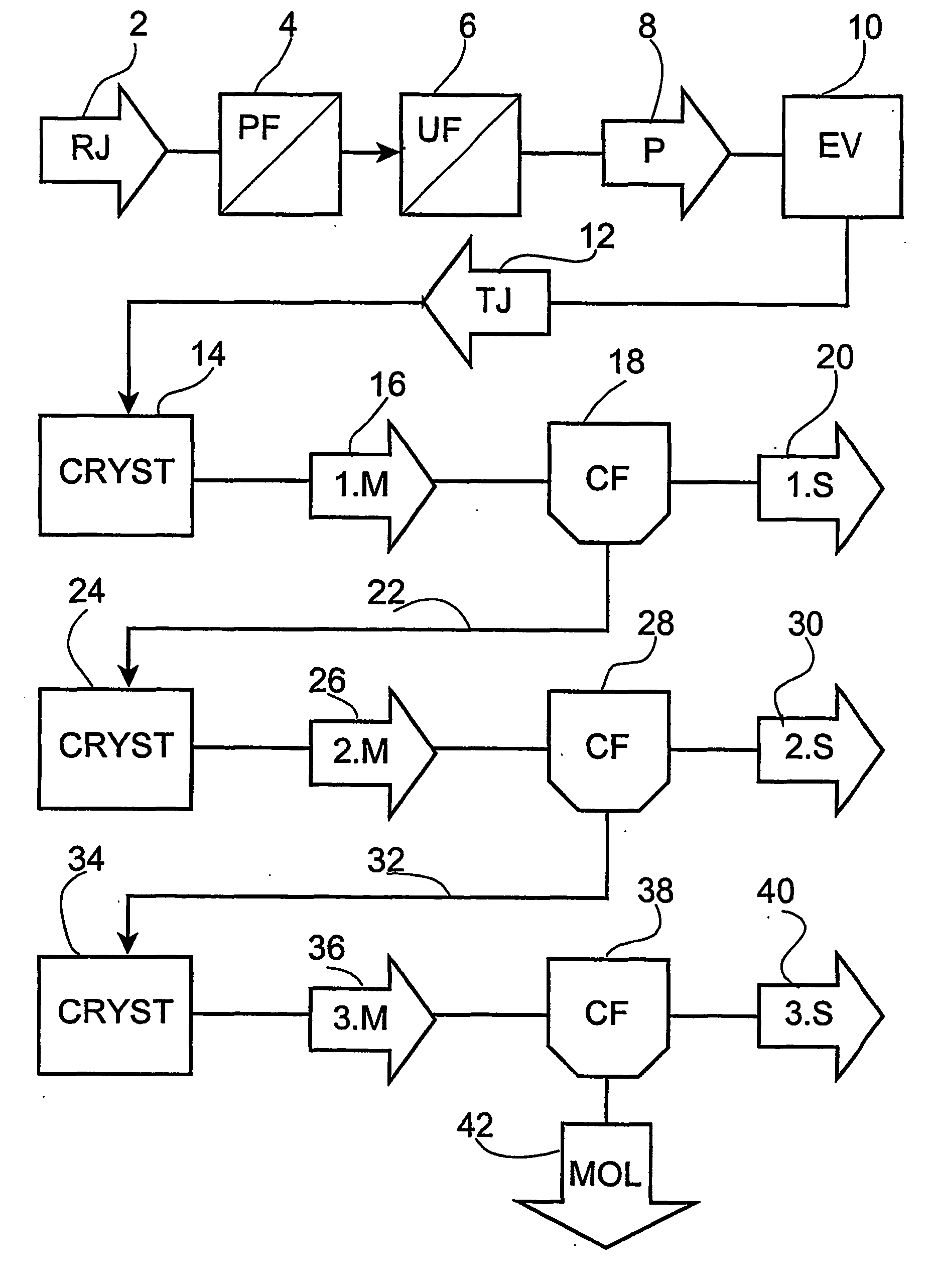

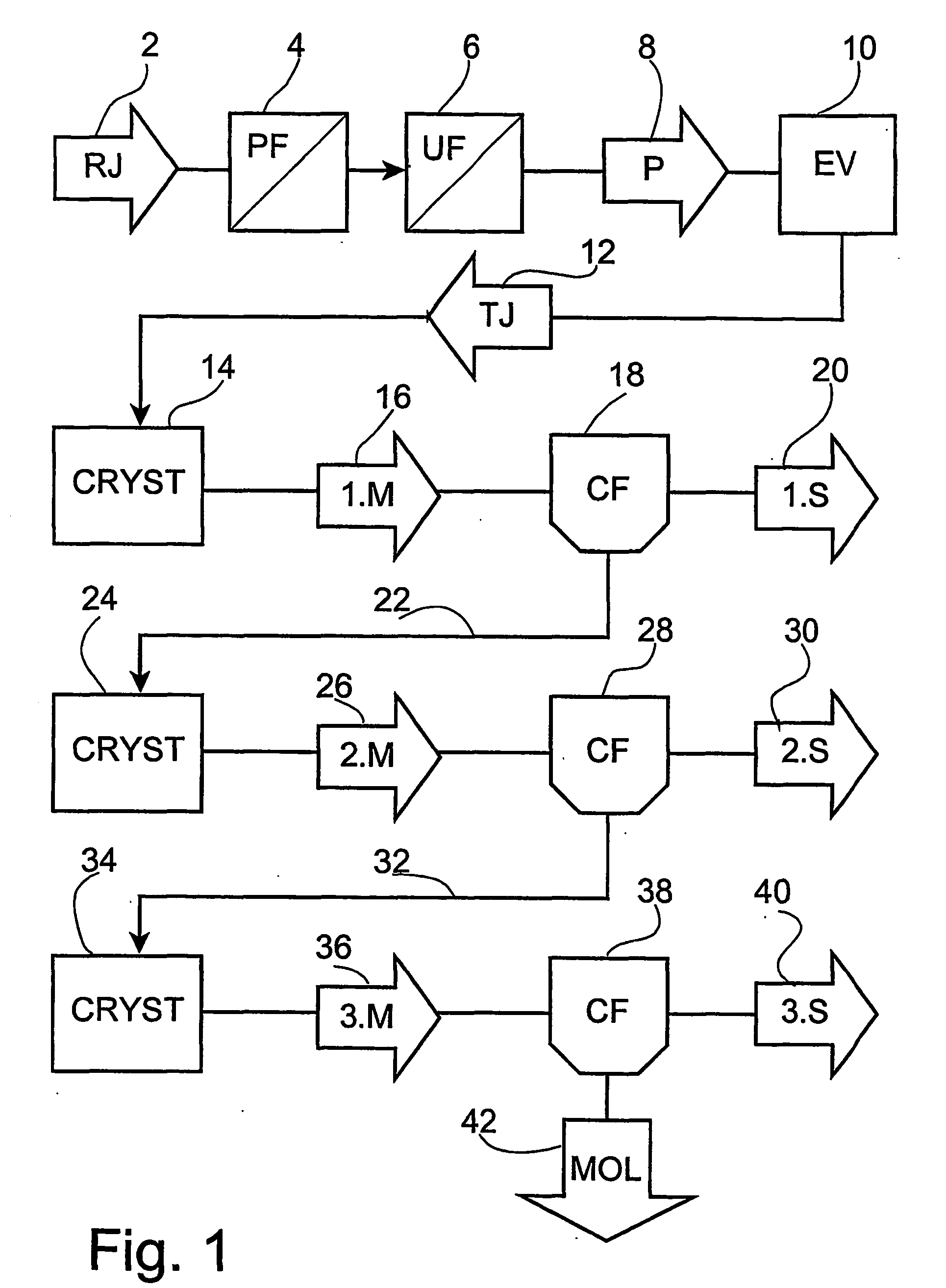

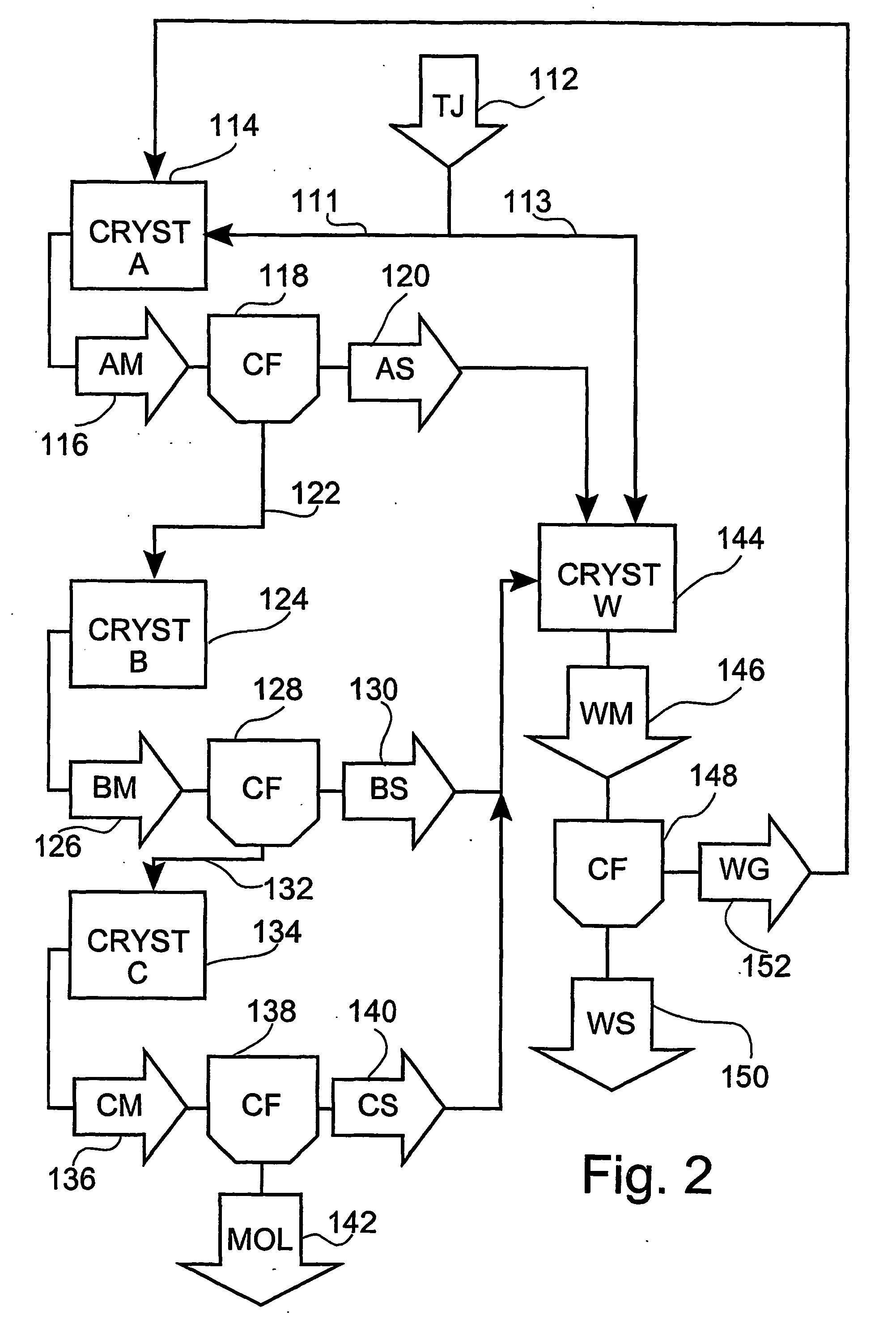

Process for the preparation of white and brown sugar from sugar beets

InactiveUS20040231663A1Avoid the needEasy to mergeSugar productsSugar crystal separationBiotechnologySugar

A process for the preparation of white and brown sugar from raw diffuser beet juice. The juice is purified by membrane filtration at 70-95° C. on a filter having a molecular weight cut-off between 2,000 and 500,000 Dalton and evaporated to a dry matter content of between 60 and 80% by weight under vacuum to a thick juice. A conventional multi-step evaporative crystallisation of the thick juice gives crops of white and brown sugar crystals. The brown sugar obtained have valuable organoleptic properties.

Owner:AS DE DANSKE SUKKERFABRIKKER

Process and plant for evaporative concentration and crystallization of a viscous lactose-containing aqueous liquid

InactiveUS20030196957A1Crystallization separationSugar crystallisationLiquid crystallineParticulates

Crystalline alpha-lactose monohydrate is recovered frown a viscous lactose-containing aqueous liquid by subjecting said liquid to simultaneous heating, removal of evaporated vapor and mechanical agitation at high shear rate to provide a crystallization promoting decrease of the viscosity of the liquid with crystals formed and suspended therein to progressively concentrate the agitated liquid and simultaneously crystallize lactose therefrom. Subsequent cooling, drying, and disintegration yield particulate alpha-lactose monohydrate.

Owner:NIRO

Originally ecological black sugar processing method

ActiveCN104805225ATroubleshoot filter clarification issuesEfficient removalSugar dryingSugar productsUltrafiltrationAdditive ingredient

An originally ecological black sugar processing method comprises the following steps: after sugarcane is squeezed for extracting juice, carrying out rough filtration so as to obtain sugarcane juice; heating the sugarcane juice to 90-100 DEG C and keeping heat for 1-3 min so as to obtain heated sugarcane juice; conveying the heated sugarcane juice to a multistage ceramic membrane ultrafiltration device for ultrafiltration clarification so as to obtain clarified sugarcane juice; concentrating the clarified sugarcane juice into syrup; concentrating the syrup through a jacketed iron pot so as to obtain decocted massecuite; graining, cooling and forming so as to obtain originally ecological black sugar. The originally ecological black sugar prepared through the method provided by the invention is small in grain, brown-dark brown and natural in color, contains fewer impurities, has a natural caramel charcoal burning fragrance, is rich in flavor, and fine and smooth in mouthfeel, retains the nutritional ingredients of sugarcane to the greatest extent, and has a high nutritional value; the turbidity is less than 0.5 NTU after the black sugar is dissolved to 11.5 degrees Bx, so that the problem that precipitates occur after the black sugar is dissolved for a long time is solved.

Owner:广西百桂堂食品科技有限公司

Process for crystallizing amorphous lactose in milk powder

The present process is directed to a method of crystallizing the lactose in milkfat which comprises (a) mixing the milk powder with water in an amount sufficient to initiate crystallization when subjected to shearing and heating, and (b) subjecting the product of (a) to shearing and heating under conditions effective to crystallize the lactose, said heating being conducted at a temperature greater than the glass transition temperature of the lactose and below the temperature at which the product will have a burnt flavor.

Owner:THE HERSHEY COMPANY

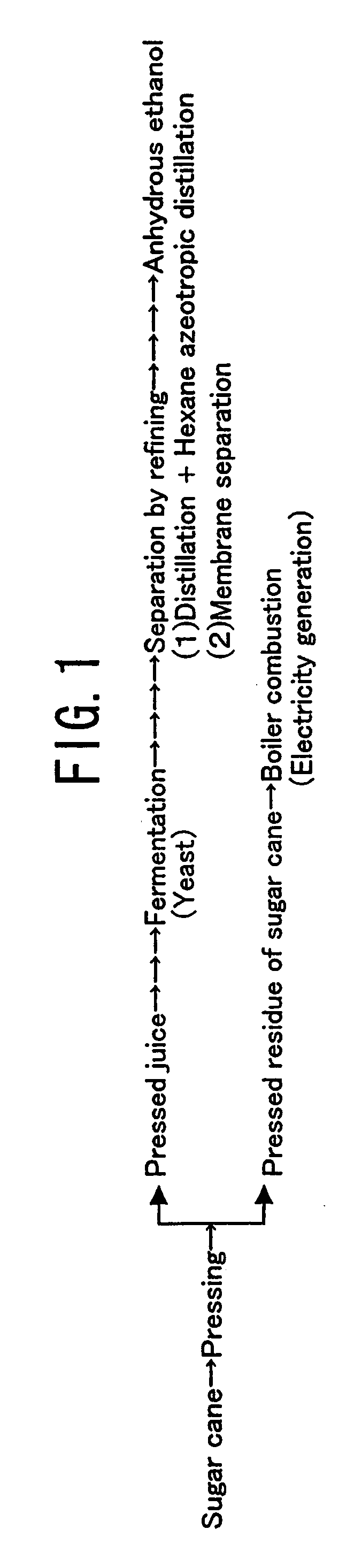

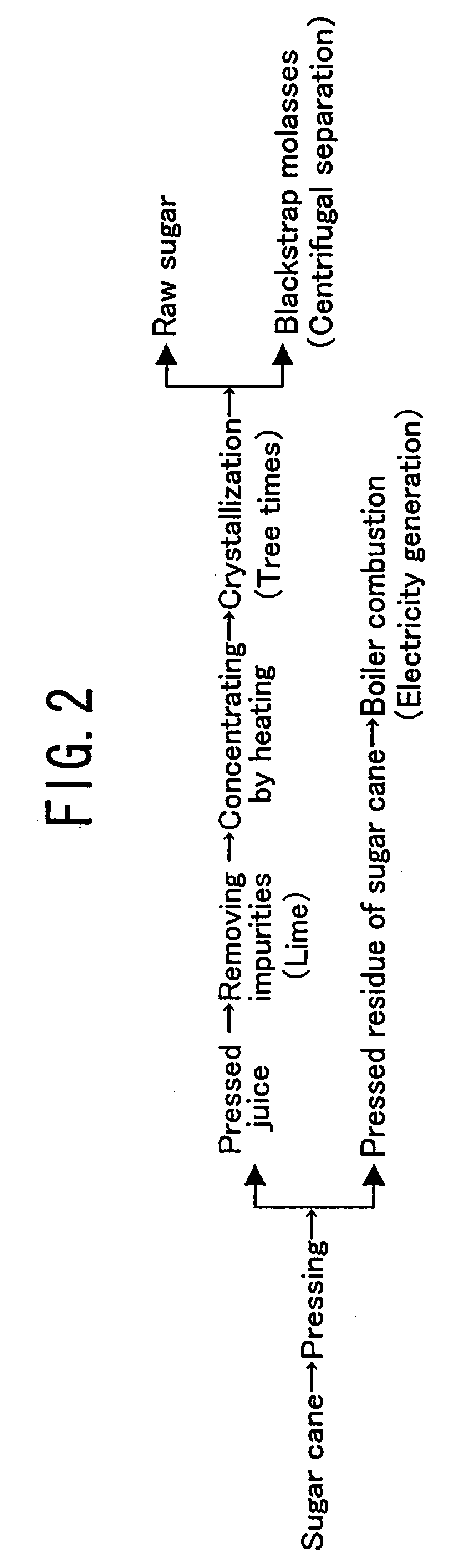

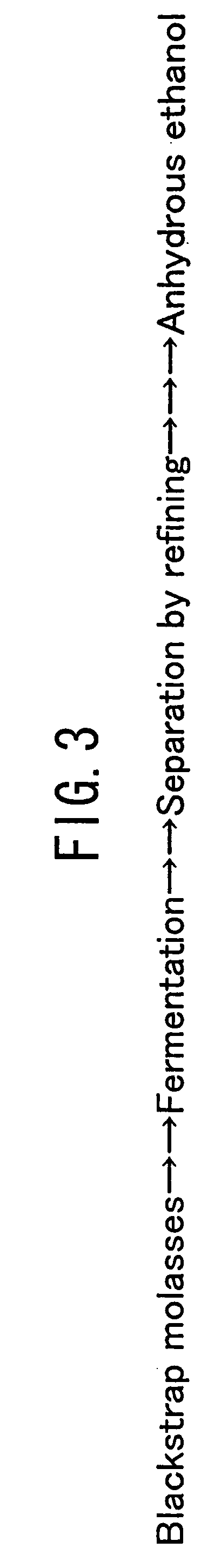

Method for producing sugar and a useful material

InactiveUS20060035355A1Increase volumeReduce productionBiofuelsSugar crystallisationBiotechnologyEngineering

An object of the present invention is to provide a method for producing sugar and ethanol from sugar cane, in which almost all of energy to be consumed in the production processes of the sugar, the ethanol and the like can be supplied by the energy obtained by burning a pressed residue of sugar cane, yet without decreasing the sugar amount to be produced. The present invention provides a method for producing sugar and a useful material from sugar cane, comprising the steps of: (a) producing from sugar cane a pressed juice and pressed residue of sugar cane; (b) producing sugar and blackstrap molasses from said pressed juice; and (c) generating an energy and a useful material by using said pressed juice, said blackstrap molasses and said pressed residue of sugar cane as source materials that have been obtained from said steps (a) and (b), wherein said sugar cane contains an amount of 15% or greater by mass of fiber component in its cane stem region and provides a dry matter yield amount per unit area of 40 t / ha / year or higher; and 90% or more of energy required for all of the steps of said production method is obtained from energy generated by burning said pressed residue of sugar cane.

Owner:ASAHI BREWERIES LTD

Method for recovering sulfuric acid from concentrated acid hydrolysate of plant cellulose material

ActiveUS8052953B2Reduce solubilityEasier the sugars precipitateSugar derivativesSugar crystallisationCelluloseOrganic solvent

Owner:CHEN PEIHAO

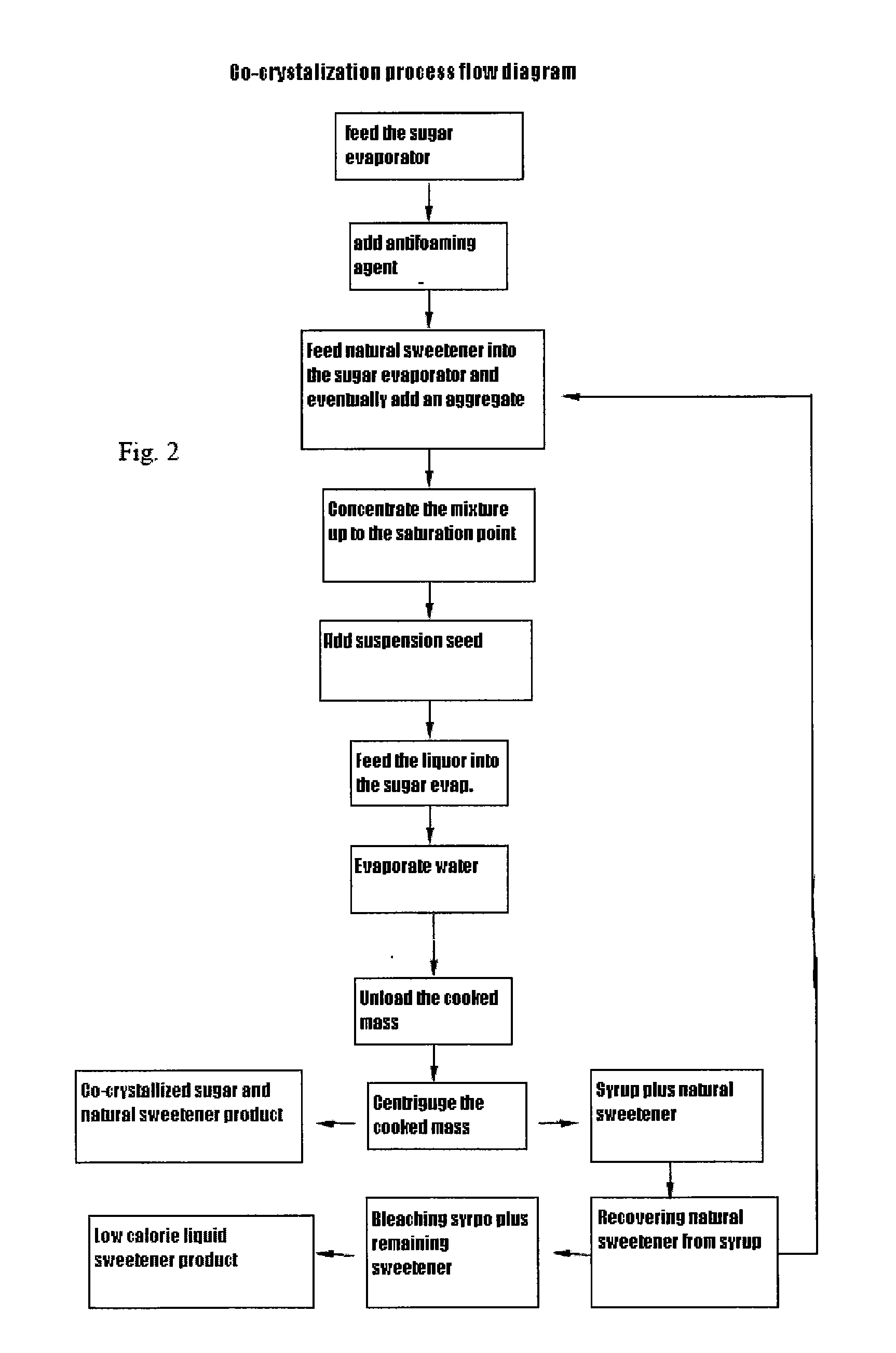

Process For Co-Crystallizing Sucrose and a Natural Sweetener And The Product Thereof

The invention relates to a preparation process of a co-crystal made of sugar and a natural sweetener and, eventually, another aggregate and with said product. The process is further related with co-crystallizing sucrose and a natural sweetener in a vacuum pan under controlled pressure and temperature conditions and separating the crystal from the sugar juice.At the end of the process, the co-crystallized sub-products are used for producing a low calorie content liquid sweetener such that in a high percentage all the stock material is used.

Owner:INGENIO DEL CAUCA S A INCAUCA

Production of resistant starch product

Owner:TATE & LYLE INGREDIENTS AMERICAS INC

Crystallization of sugars

The invention relates to removing crystallization inhibitors from a solution comprising one or more reducing sugars by nanofiltration, hydrolysis and / or chromatography. The reducing sugars are typically selected from fructose and xylose.

Owner:DANISCO SWEETENERS

Process and plant for evaporative concentration and crystallization of a viscous lactose-containing aqueous liquid

Crystalline alpha-lactose monohydrate is recovered from a viscous lactose-containing aqueous liquid by subjecting said liquid to simultaneous heating, removal of evaporated vapor and mechanical agitation at high shear rate to provide a crystallization promoting decrease of the viscosity of the liquid with crystals formed and suspended therein to progressively concentrate the agitated liquid and simultaneously crystallize lactose therefrom. Subsequent cooling, drying, and disintegration yield particulate alpha-lactose monohydrate.

Owner:NIRO

Method for recovering monosaccharide from solution using weakly acid cation exchange resin for chromatographic separation

InactiveCN1466632AChromatographic cation exchangersCation exchanger materialsChromatographic separationPhysical chemistry

The present invention relates to a method for recovering a monosaccharide selected from the group consisting of rhamnose, arabinose, xylose and mixtures thereof from a solution containing the same by a multistep process using chromatographic separation comprising at least one step, where a weakly acid cation exchange resin is used for the chromatographic separation.

Owner:DANISCO SWEETENERS

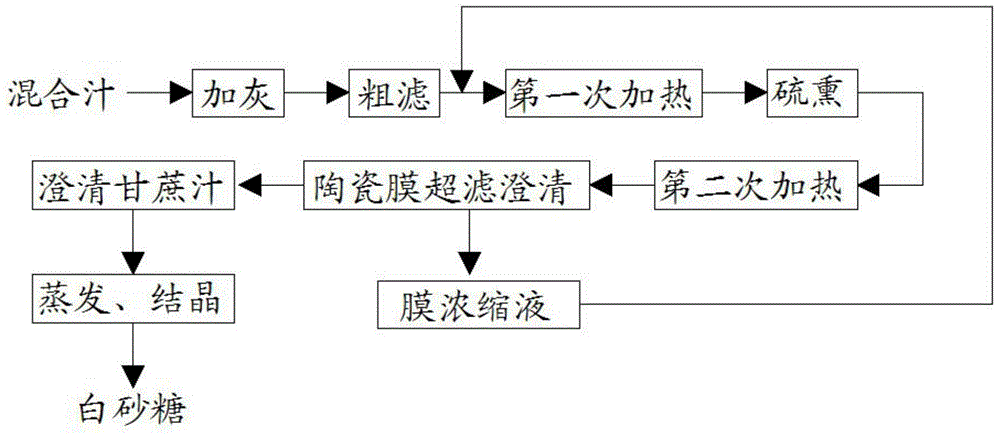

Sugar manufacture clarification process

ActiveCN104805226AReduce sulfur contentReduce color valuePurification using alkaline earth metal compoundsSugar crystallisationSulfurTurbidity

The invention discloses a sugar manufacture clarification process which comprises the following steps: adding lime milk into mixed cane juice to adjust the pH value to be 7.5-7.8, thereby obtaining lime-milk-added cane juice; filtering the lime-milk-added cane juice by using a horizontal screw centrifuge, thereby obtaining roughly filtered cane juice; heating the roughly filtered cane juice to be 55-65 DEG C, thereby obtaining cane juice which is heated for the first time; stoving the cane juice which is heated for the first time with SO2 until the intensity of sulfitation is 4-6 mL, thereby obtaining stoved cane juice; heating the stoved cane juice to be 80-90 DEG C, thereby obtaining cane juice which is heated for the second time; performing ultrafiltration clarification on the cane juice which is heated for the second time by using a ceramic membrane, thereby obtaining clear cane juice and membrane concentrated liquid; filtering the membrane concentrated liquid by using a plate-and-frame filter press, and returning the filtered membrane concentrated liquid to a roughly filtered cane juice storage tank. As a conventional sugar manufacture clarification process through a sulfurous acid method is combined with a membrane separation technique, a novel sugar manufacture clarification process is developed, the clarified cane juice prepared by using the process is low in color value, high in purity and low in turbidity, and the white sugar prepared from the cane juice is good in quality.

Owner:GUANGXI UNIV

Crystallization method for trichlorosucrose

ActiveCN101210034AShort crystallization timeEasy to operateSugar derivativesSugar crystallisationSolubilitySucrose

The invention discloses a crystallization method of trichloro sucrose. The method dissolves a concentrate or a solid that contains the trichloro sucrose in a mixed impregnant. The mixed impregnant contains two impregnant with large difference in boiling points; wherein, the impregnant with a low boiling point has higher solubility to the trichloro sucrose while the impregnant with a high boiling point has lower solubility to the trichloro sucrose. In the condition of proper temperature and vacuum degree, the impregnant is concentrated and crystals of the trichloro sucrose are separated when the impregnant with low boiling point volatilizes and finished product of trichloro sucrose crystals is obtained through filtering and desiccation after being settled. The method has the advantages of low production cost, high production yield, mild condition, stable quality and simple equipment, etc.

Owner:JK SUCRALOSE

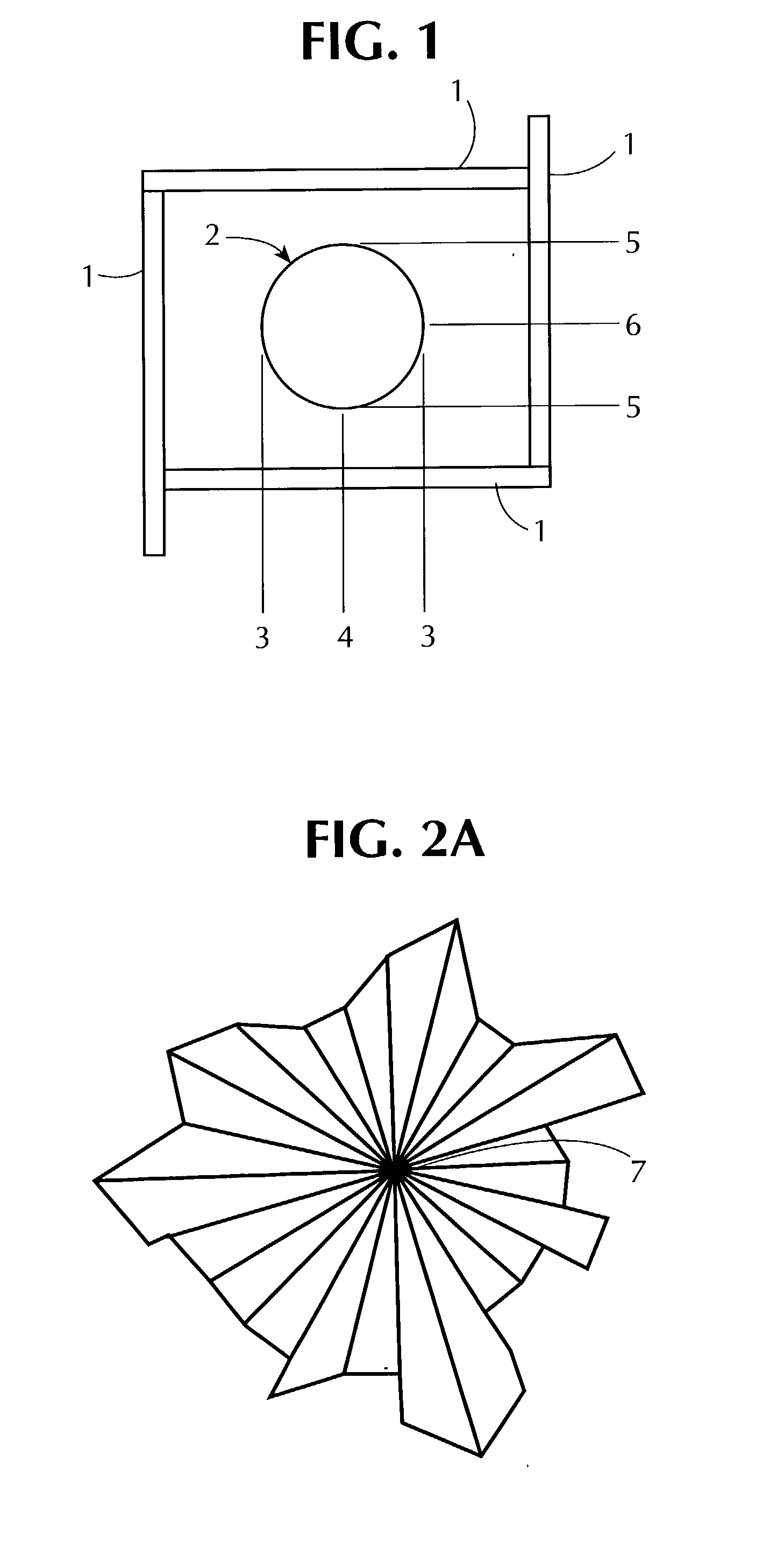

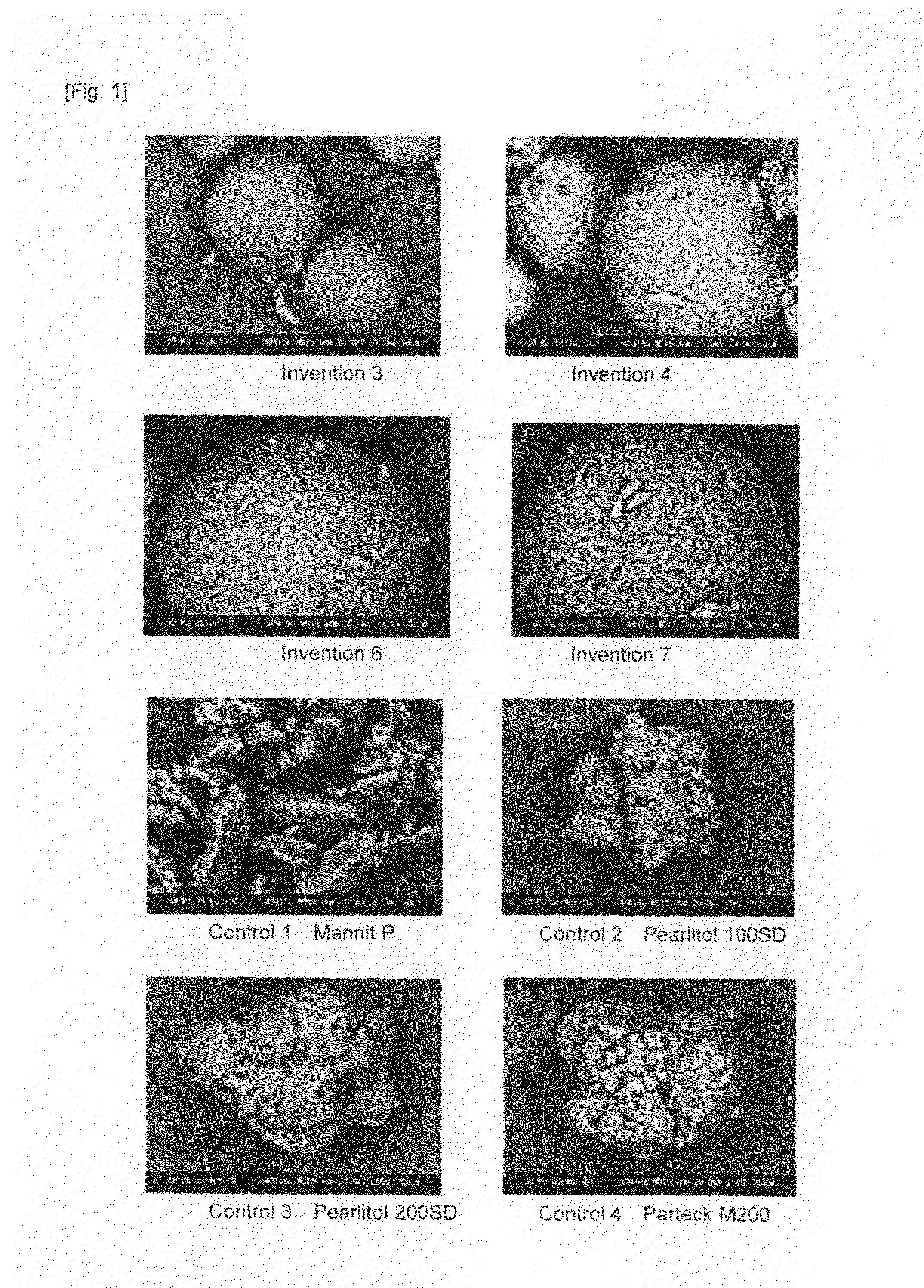

Spherical particle of crystalline mannitol

InactiveUS20100167052A1Improve liquidityHigh oil absorptionPowder deliverySynthetic resin layered productsMANNITOL/SORBITOLHardness

[Summary][Problems] To provide extremely-spherical-three-dimensional-shaped particles of crystalline mannitol containing large hollows and gaps inside.[Solution] Spherical particles of crystalline mannitol made by spray drying, extremely spherical (having an aspect ratio of 1.0 to 1.2), high oil absorption rates according to test method A, wherein powder has a mean particle diameter of 15 to 165 μm, a loose bulk density of 0.35 to 0.60 and an angle of repose of 30 to 50 degrees, and has a hardness of 7 to 20 kgf, when directly compressed.

Owner:MITSUBISHI SHOJI FOODTECH CO LTD

Crystallization of sugars

The invention relates to removing crystallization inhibitors from a solution comprising one or more reducing sugars by nanofiltration, hydrolysis and / or chromatography. The reducing sugars are typically selected from fructose and xylose.

Owner:DANISCO SWEETENERS

Production process and device of golden sugar

InactiveCN104004860AHigh desalination rateHigh yieldSugar crystallisationPurification using ion-exchange materialsSucroseIon-exchange resin

The invention provides a production process and a production device of golden sugar. The production process comprises the following steps: pressing sugarcane or beets to obtain cane sugar juice; pre-filtering the cane sugar juice through a coarse filter and feeding the pre-filtered crane sugar juice into a microfiltration membrane for filtering to obtain clear cane sugar juice; pre-concentrating the clear cane sugar juice to obtain a pre-concentrated solution; feeding the pre-concentrated solution into ion exchange resin for desalting to obtain a permeation solution; feeding the permeation solution into an evaporator for concentrating to obtain cane sugar concentrated liquid; heating the cane sugar concentrated liquid to be oversaturated, adding crystal seeds, naturally cooling and crystallizing, and centrifuging the obtained crystals to obtain golden sugar crystals; drying the golden sugar crystals to obtain a finished product of the golden sugar. The production device comprises the coarse filter, a microfiltration membrane filter, a nanofiltration membrane filter, an anion exchange resin bed, a cation exchange resin bed and the evaporator which are connected in sequence. The production method provided by the invention is capable of continuously producing high-quality golden sugar, the chromatic value of the obtained product is 800-3,000, the desalting rate is high, and the yield is high.

Owner:JIANGSU JIUWU HITECH

High yield maize derivatives

InactiveUS20090162477A1High in sugarImprove digestibilityDough treatmentBiofuelsHybrid speciesPloidy

A Method for producing triploid corn seeds and plants is described. The method comprises combining two parent inbreds of different ploidy levels, wherein one parent inbred is a tetraploid (4N) and the other parent is a diploid (2N) so as to produce a triploid hybrid corn seed; and cultivating the triploid hybrid corn seed to form a triploid corn plant. Usage of triploid corn plants as an economic source of sugar and ethanol is described, as is the production of molasses, rum and fodder from plant material of the low sterility triploid corn plants.

Owner:BIOFUELS GENETICS

Production method of transparent monocrystal sugar

White granulated sugar and high fructose syrup is dissolved in water, filtered to eliminate insoluble matter, and processed in continuous vacuum film sugar cooking apparatus to eliminate water to obtain sugar paste, which is formed in monocrystal mold to form monocrystal sugar. The said process is short, has no food additive added and high yield, and the monocrystal sugar product is pure in taste, transparent and homogeneous in size.

Owner:邱宗学

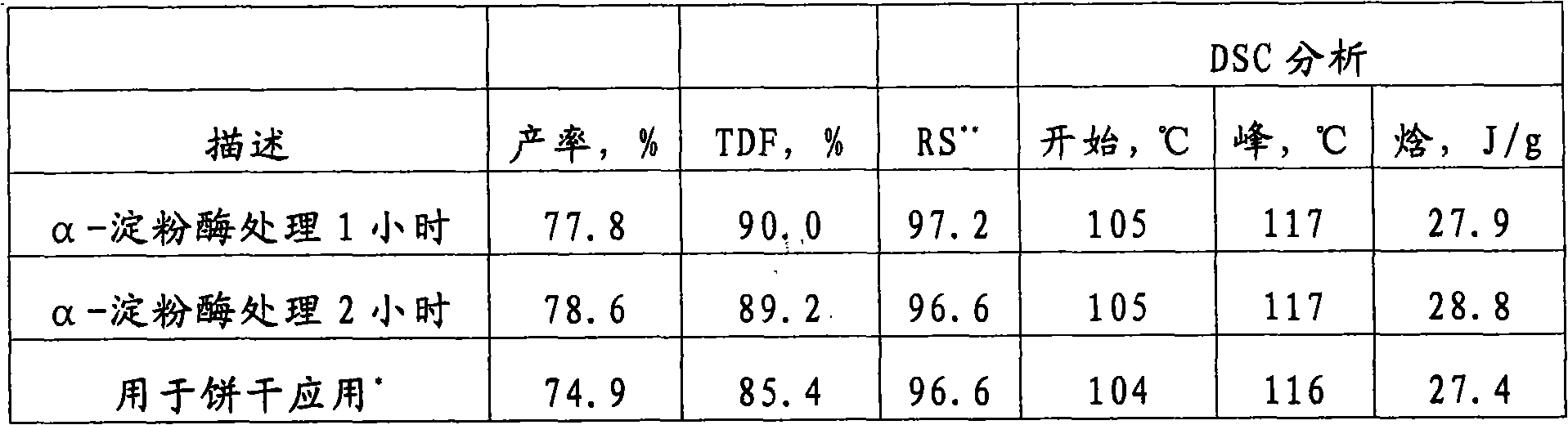

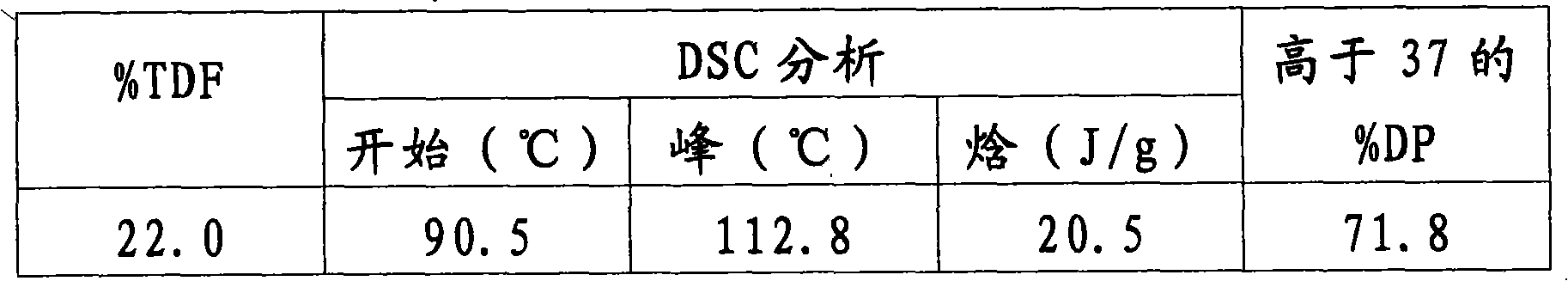

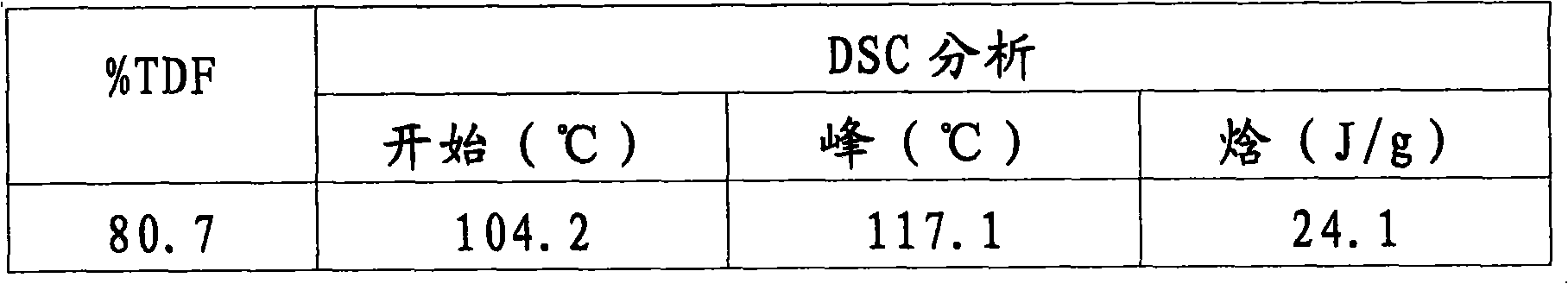

Production of Resistant Starch Product

InactiveUS20080286410A1Improve concentrationDough treatmentFood ingredient as thickening agentBiotechnologyAmylase

A process for producing a starch comprises treating a feed starch that comprises amylopectin with glucanotransferase to produce a chain-extended starch, treating the chain-extended starch with a debranching enzyme to produce a starch product that comprises amylose fragments, crystallizing at least part of the starch product, heating the starch product in the presence of moisture, treating the starch product with alpha-amylase, and washing the starch product to remove at least some non-crystallized starch. The product of this process has a relatively high total dietary fiber content.

Owner:TATE & LYLE INGREDIENTS AMERICAS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com