Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about "Sugar crystal separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

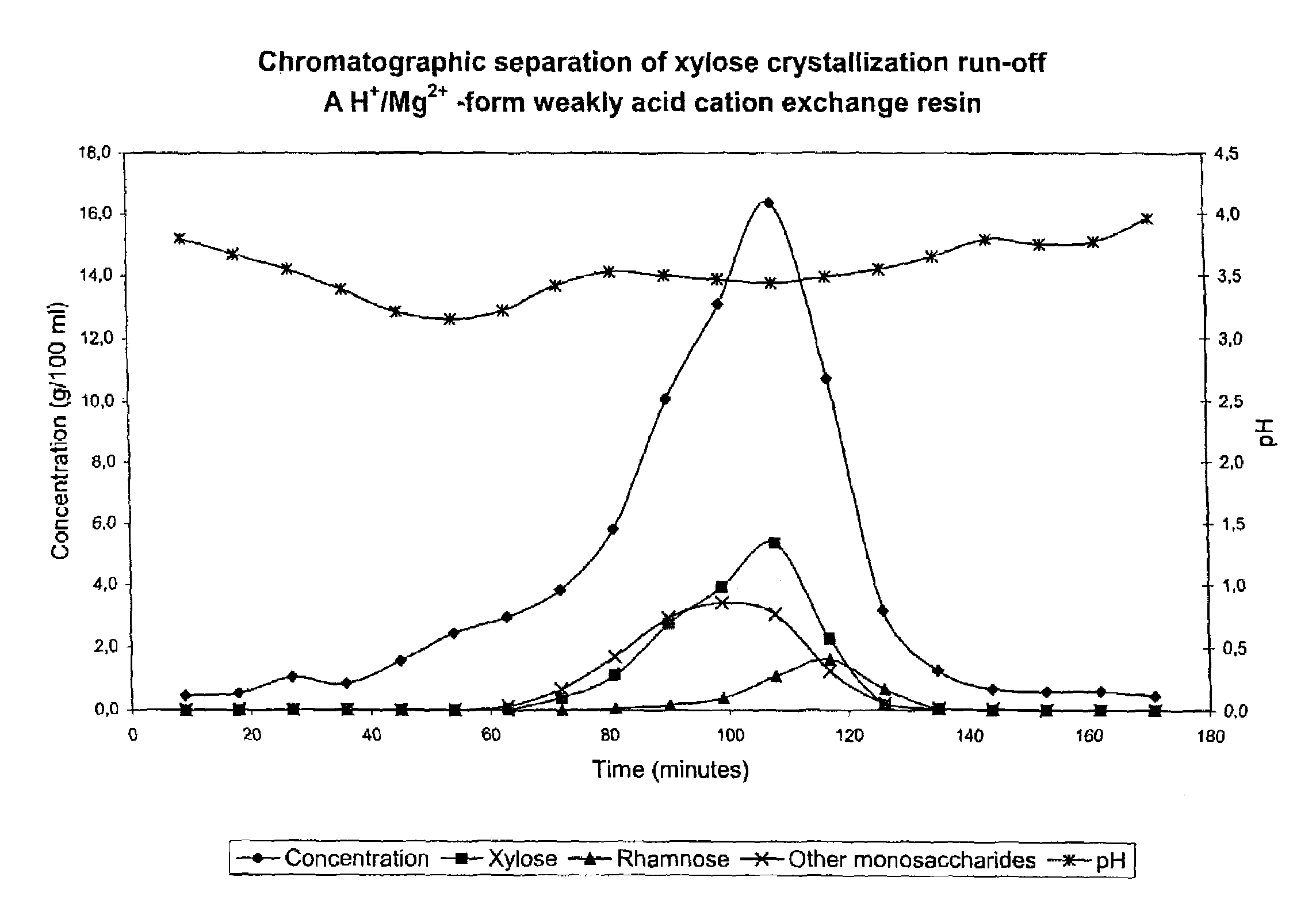

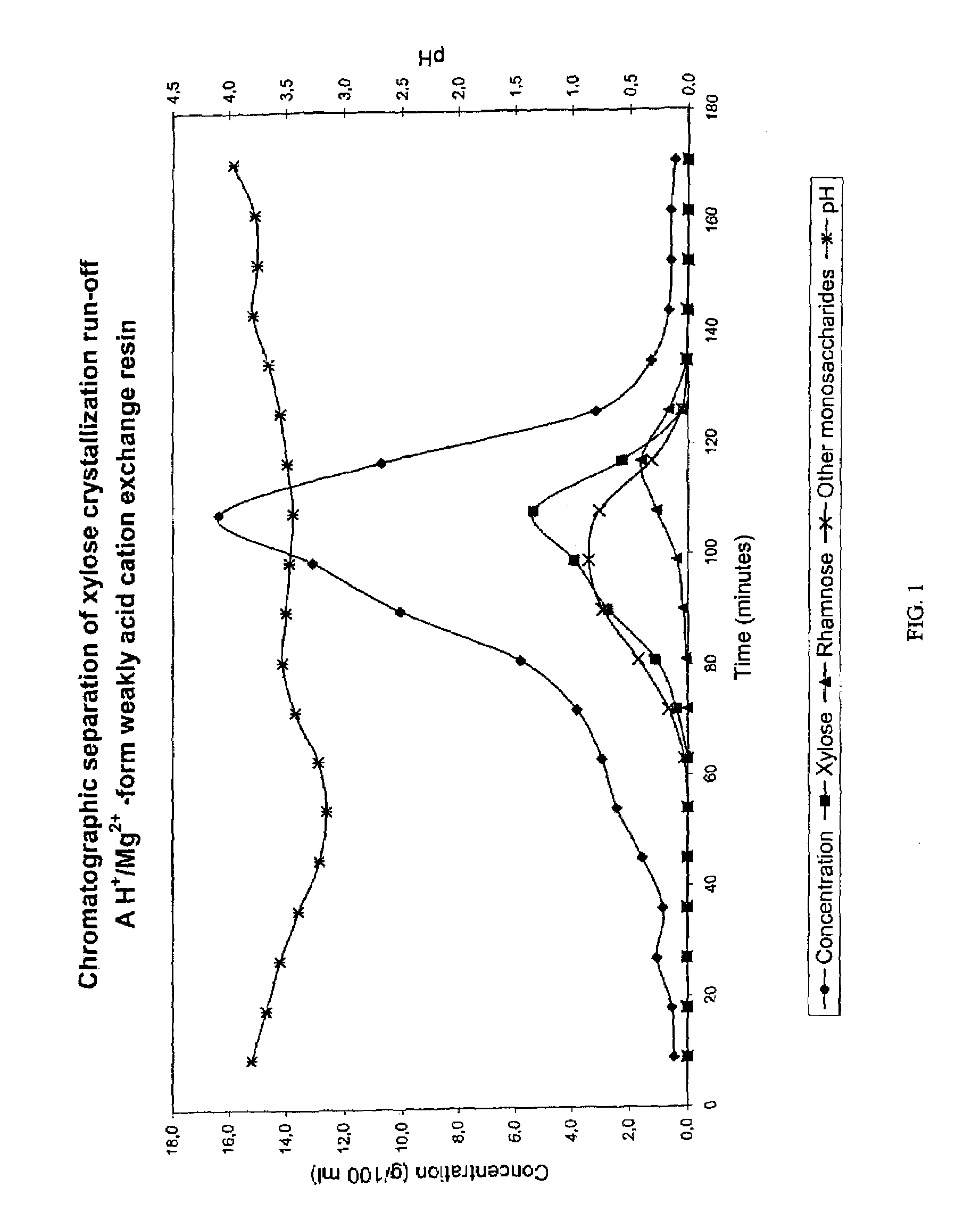

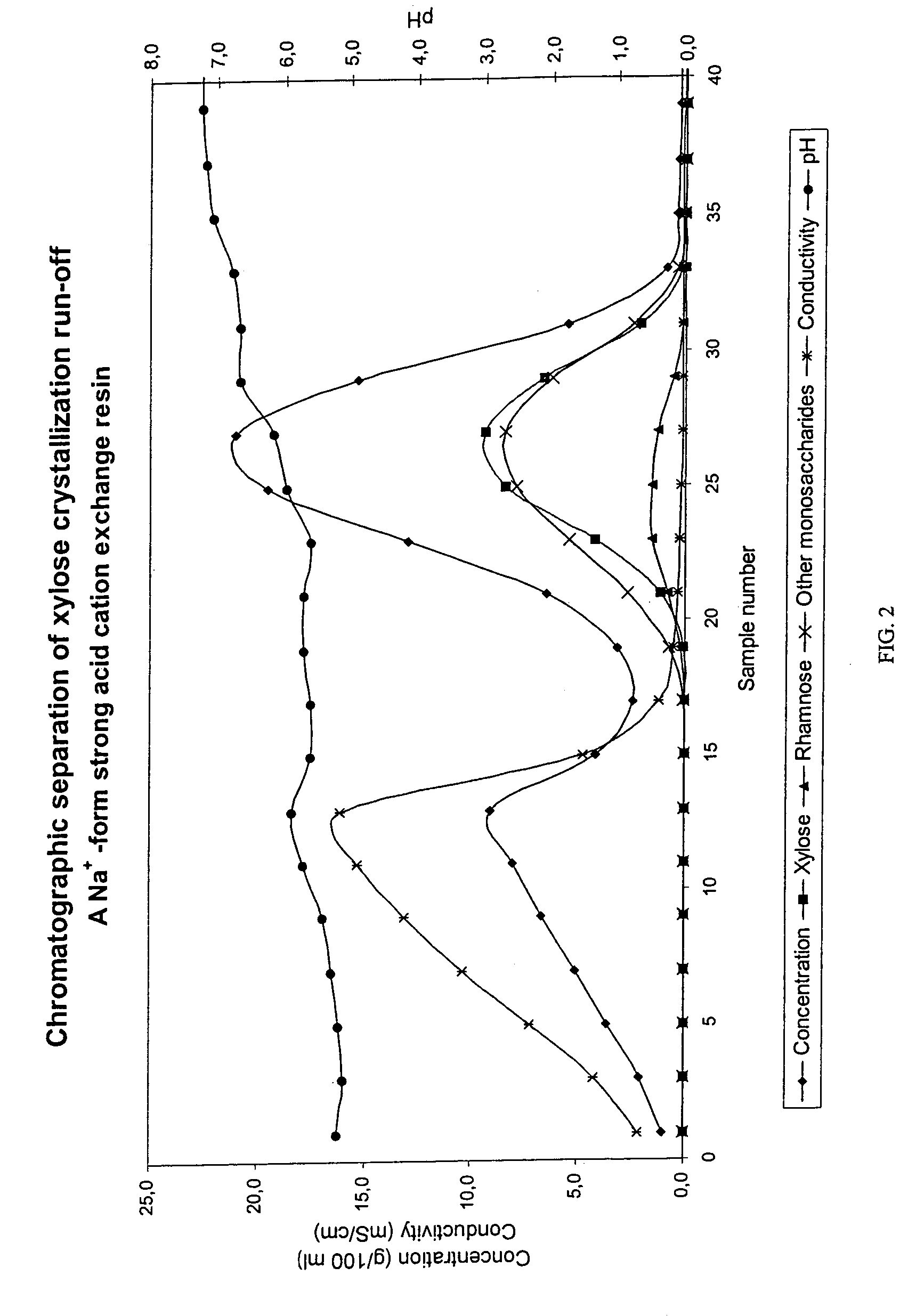

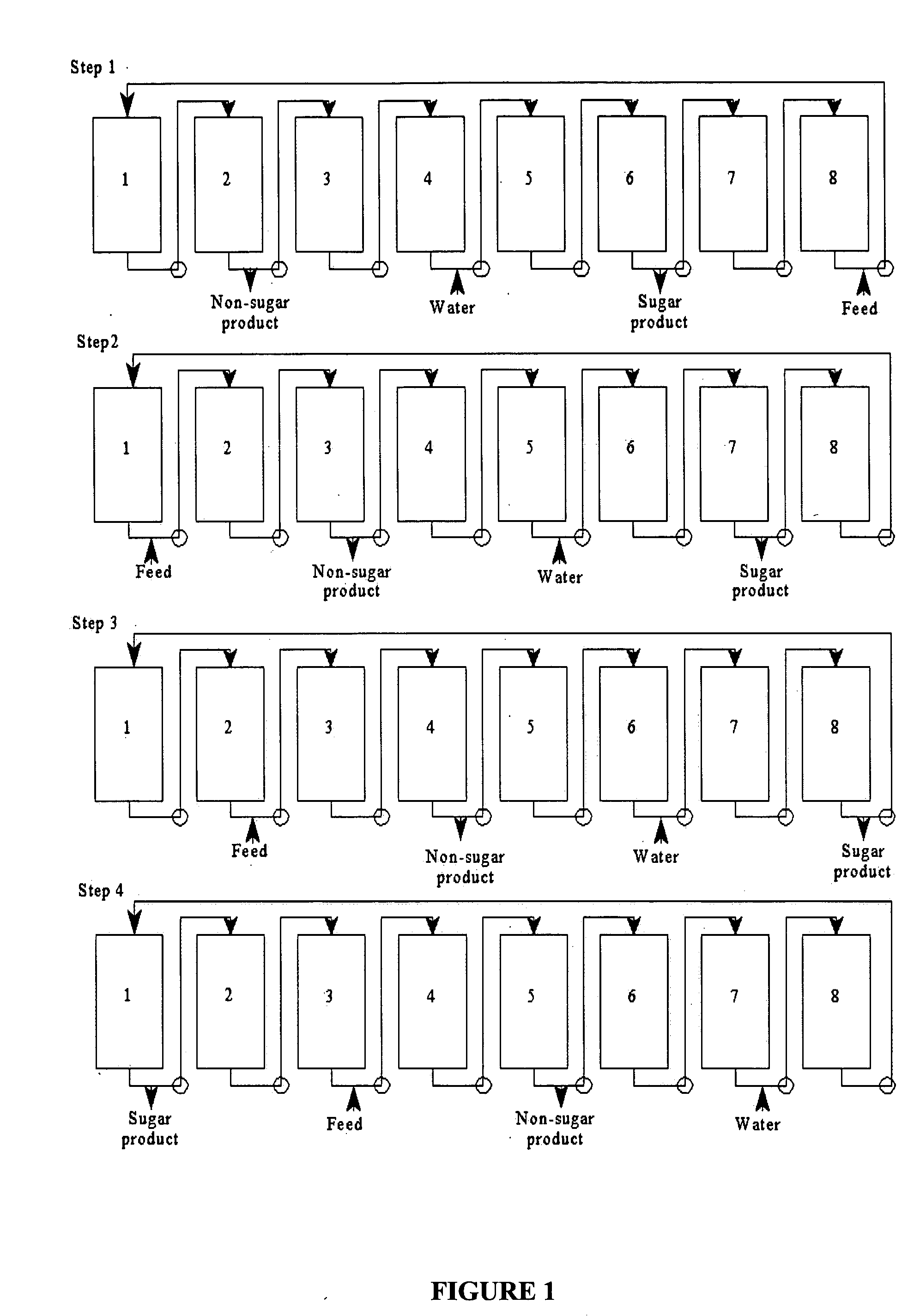

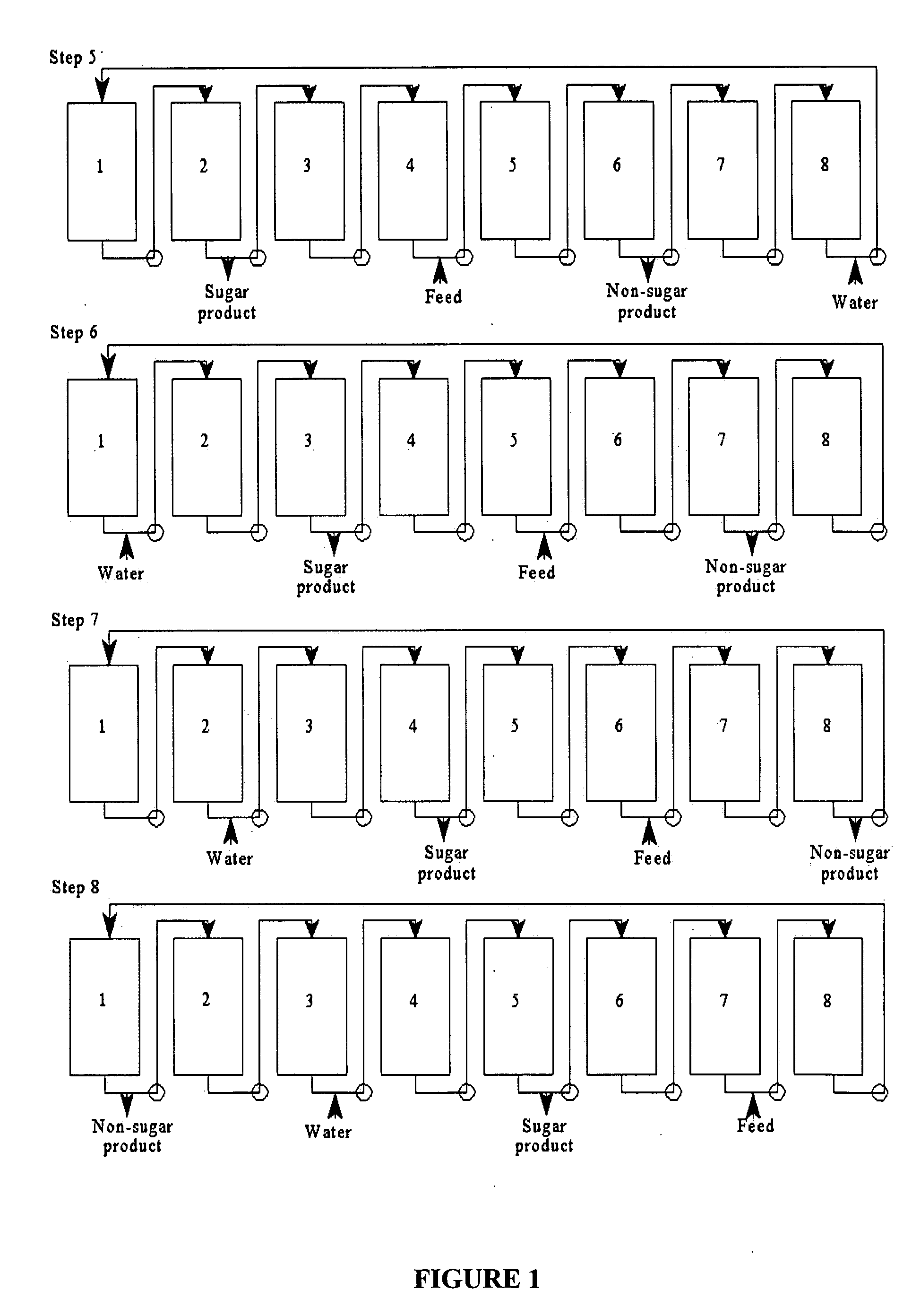

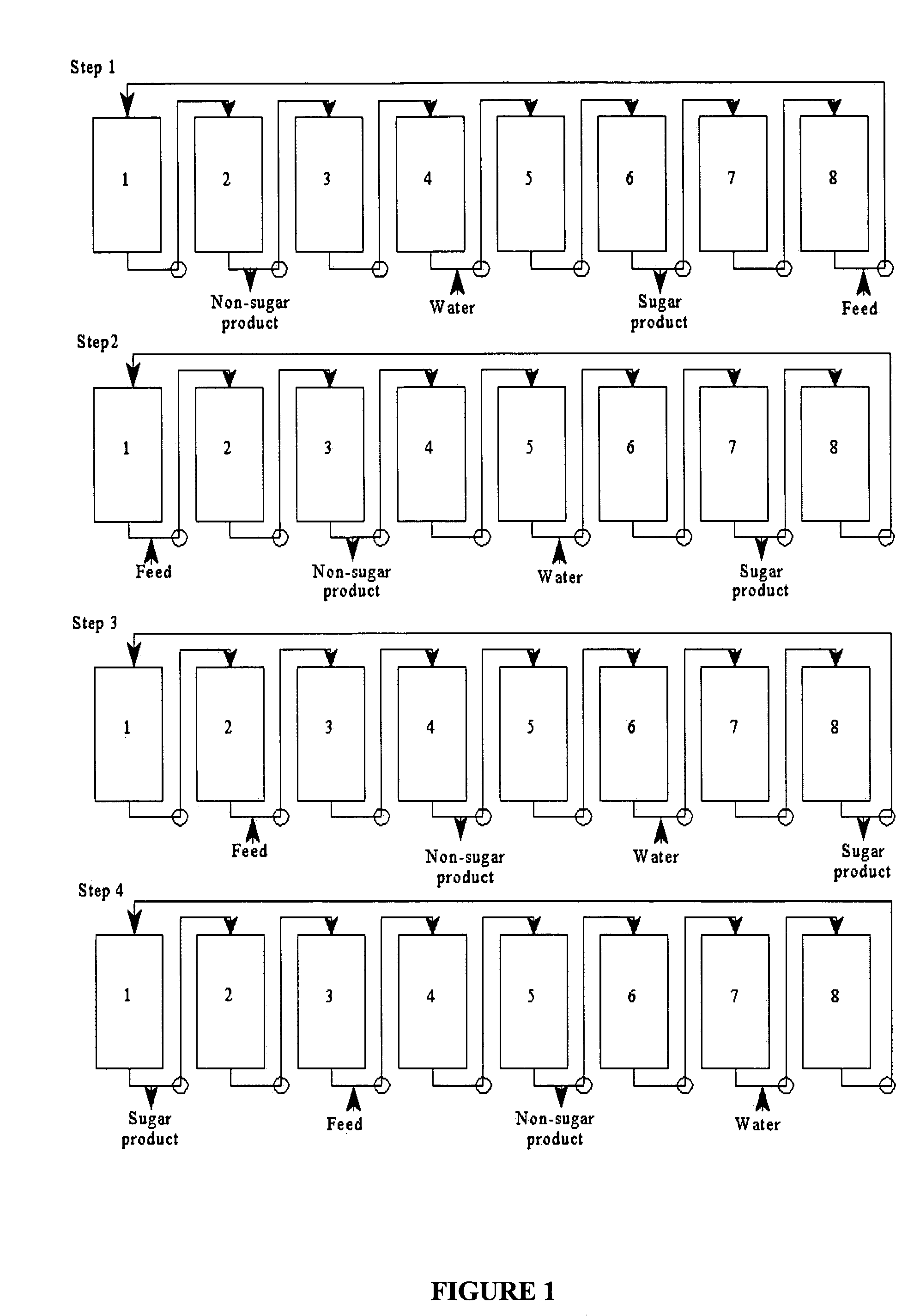

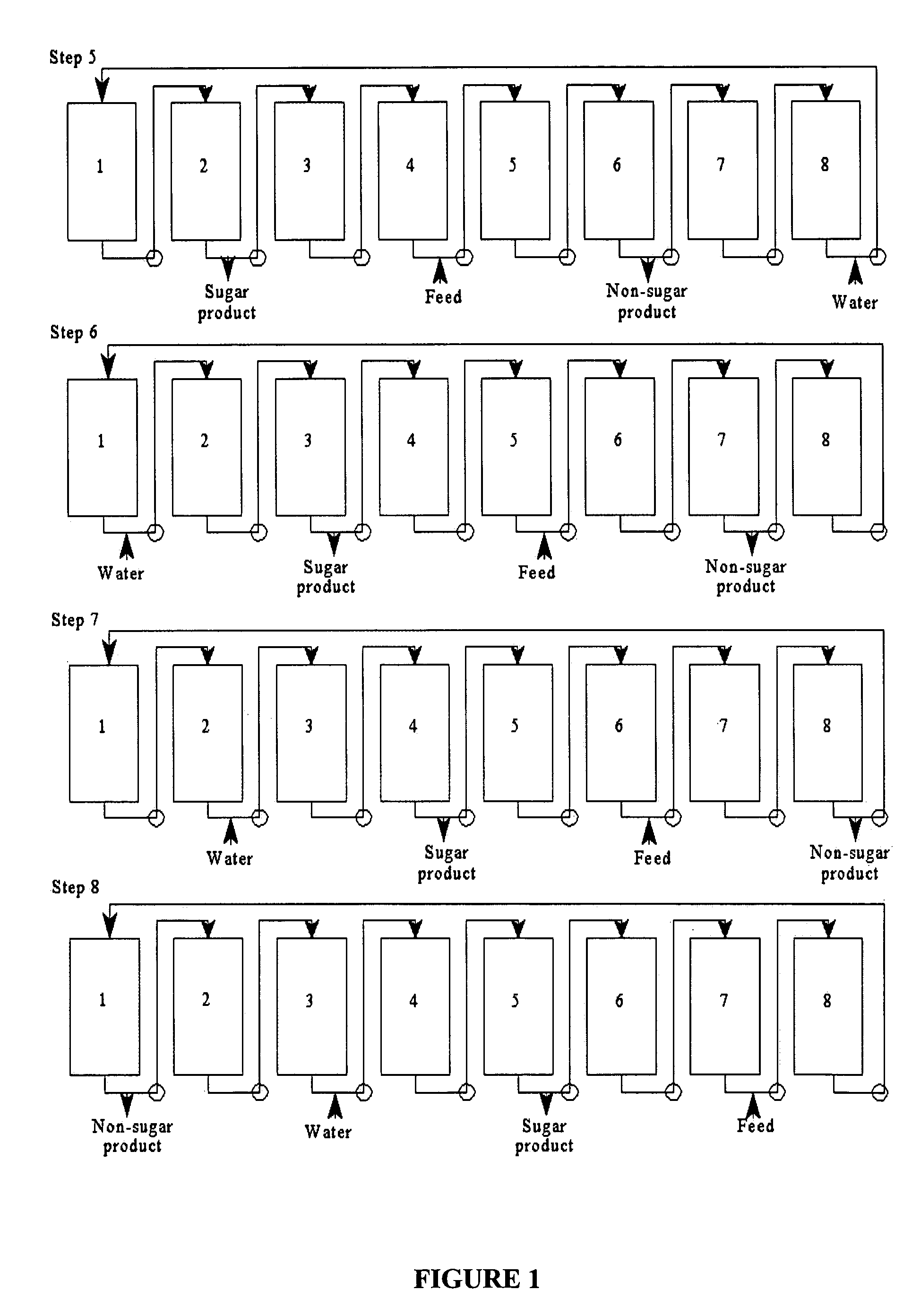

Separation of sugars, sugar alcohols, carbohydrates and mixtures thereof

InactiveUS7361273B2Efficient separationCation exchanger materialsIon-exchanger regenerationChromatographic separationAlcohol sugars

The present invention relates to a method of separating sugars and sugar alcohols from each other. More particularly the present invention relates to the use of a weakly basic anion exchange resin in a chromatographic separation process. The advantage of the present invention compared with the prior art is that it is especially suitable for separating reducing sugars in acidic conditions as well as for example in weakly acidic conditions. The method using chromatographic separation comprises at least one step where a weakly basic anion exchange resin is used in a chromatographic column or in a part of a column.

Owner:DUPONT NUTRITION BIOSCIENCES APS

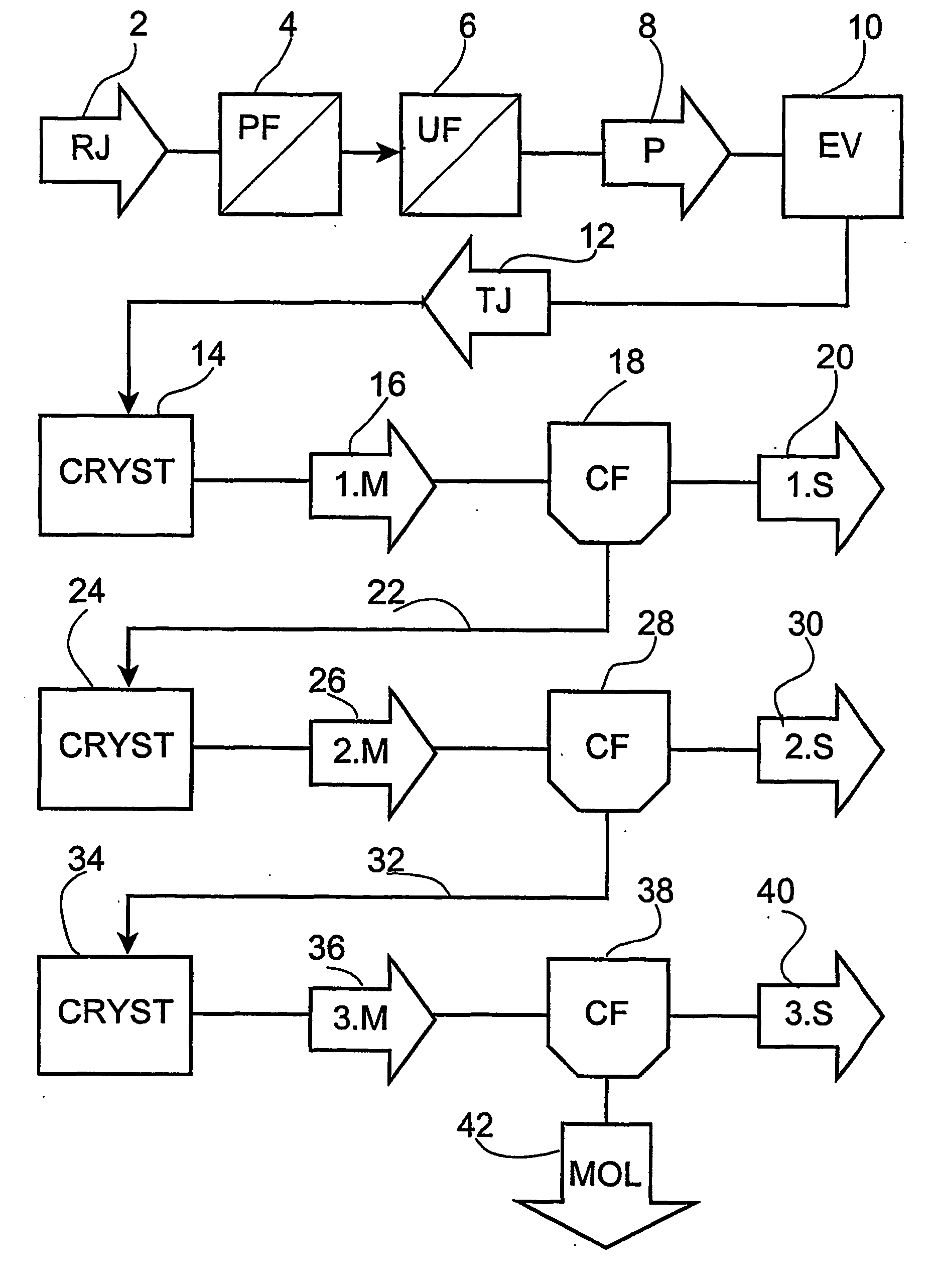

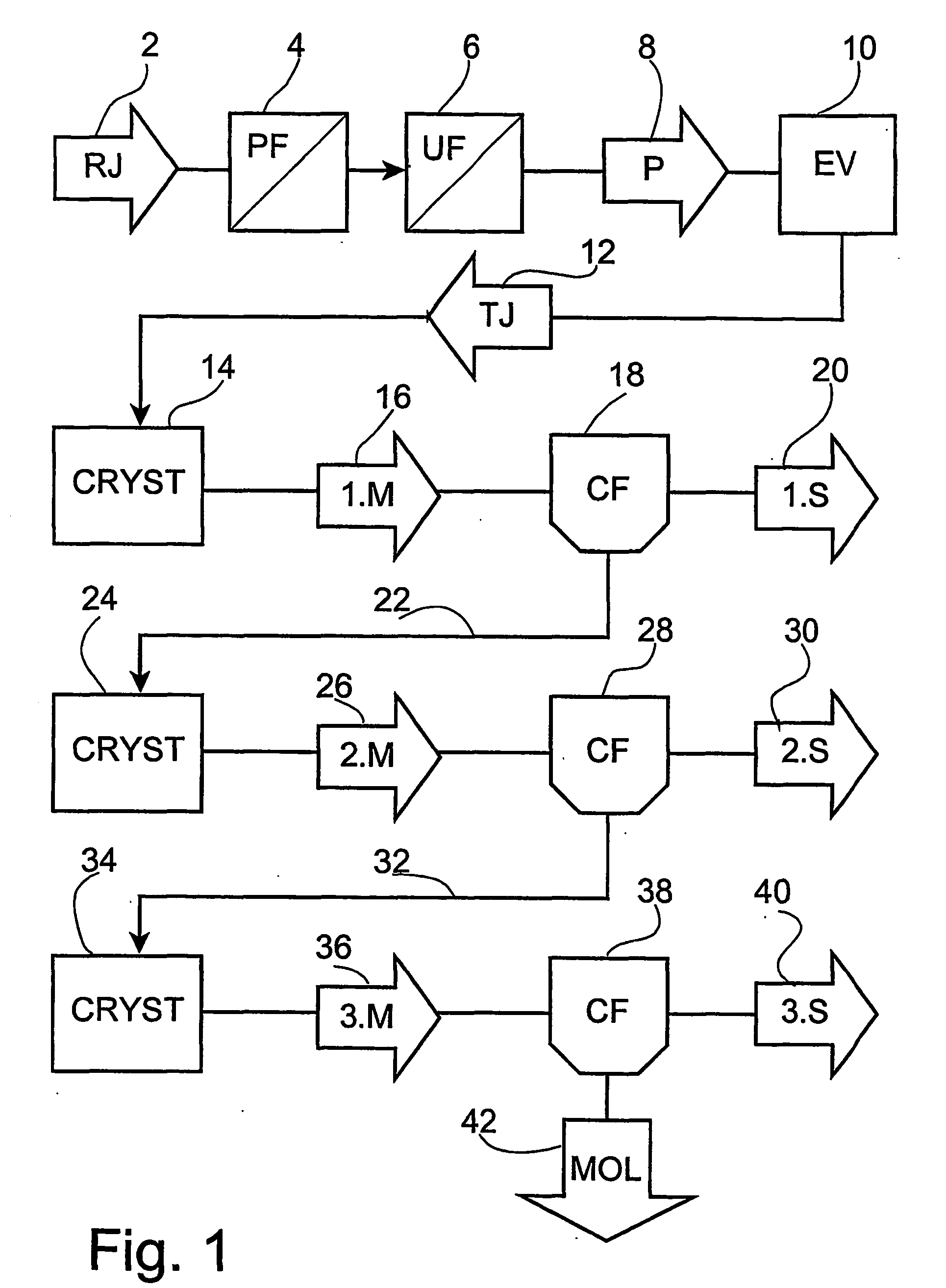

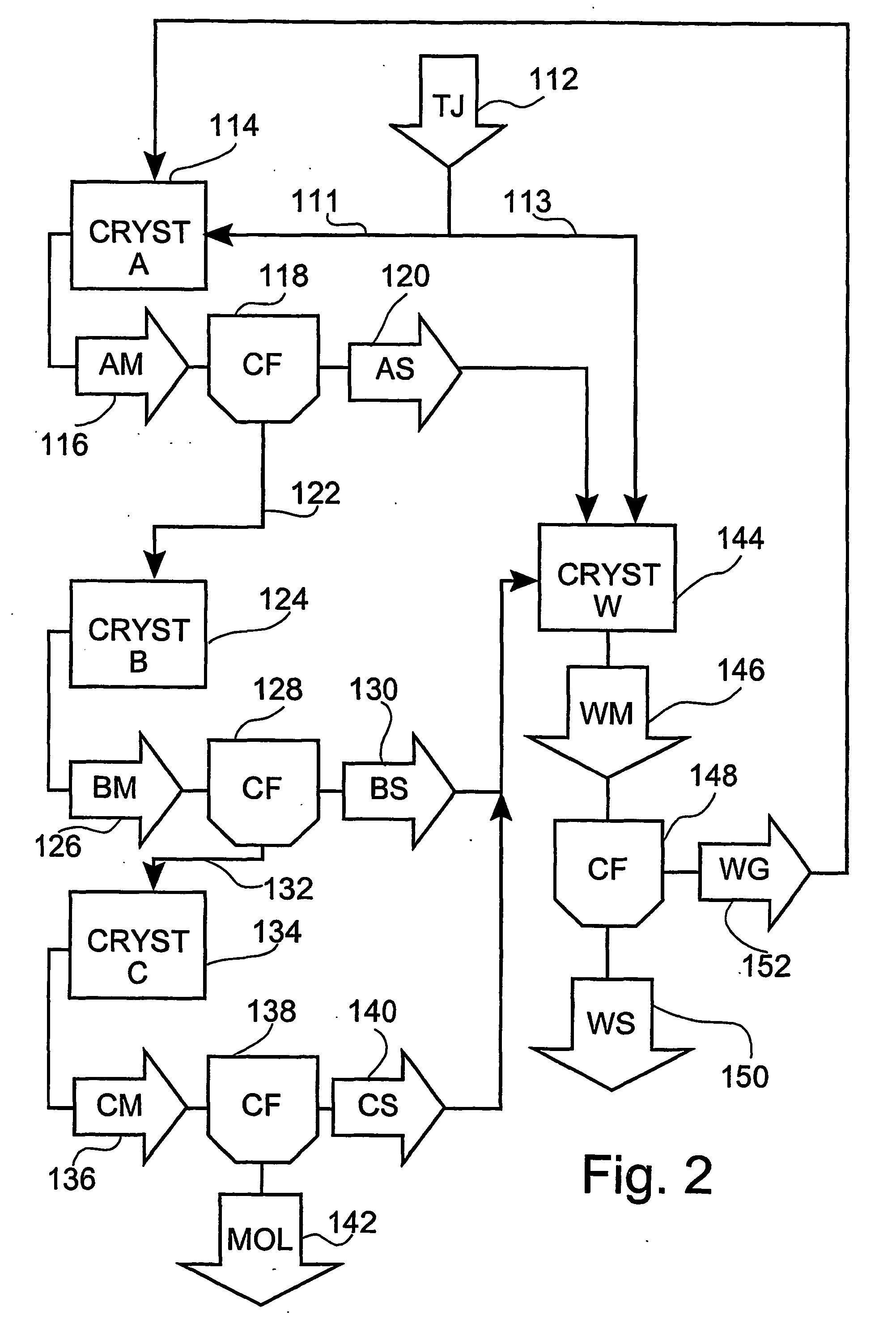

Process for the preparation of white and brown sugar from sugar beets

InactiveUS20040231663A1Avoid the needEasy to mergeSugar productsSugar crystal separationBiotechnologySugar

A process for the preparation of white and brown sugar from raw diffuser beet juice. The juice is purified by membrane filtration at 70-95° C. on a filter having a molecular weight cut-off between 2,000 and 500,000 Dalton and evaporated to a dry matter content of between 60 and 80% by weight under vacuum to a thick juice. A conventional multi-step evaporative crystallisation of the thick juice gives crops of white and brown sugar crystals. The brown sugar obtained have valuable organoleptic properties.

Owner:AS DE DANSKE SUKKERFABRIKKER

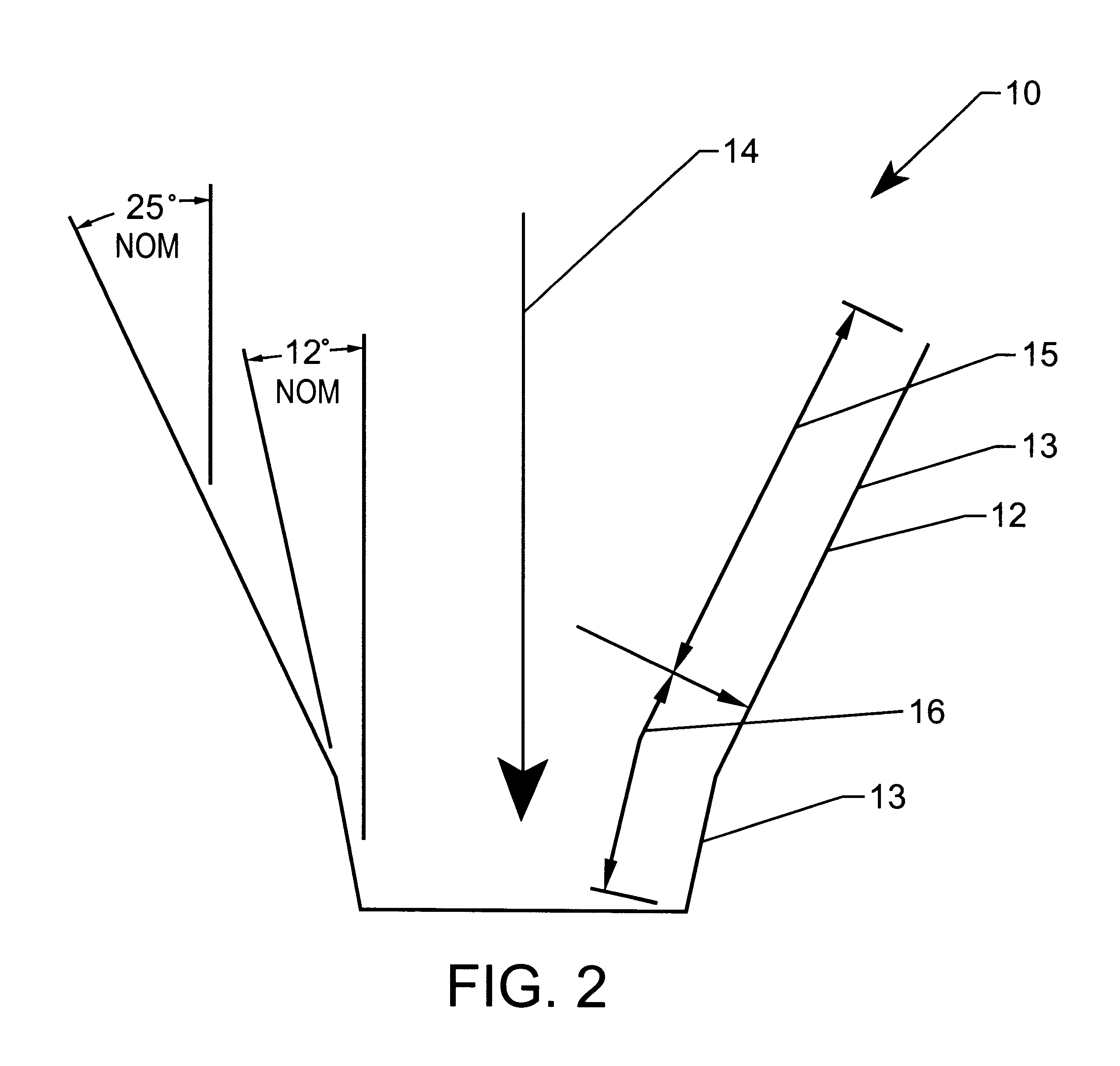

Centrifugal separation apparatus and method of using the same

InactiveUS6267899B1Water/sewage treatment by centrifugal separationSugar crystal separationCentrifugationEngineering

Centrifugation separations apparatus including centrifugation means having an inlet, a liquids discharge and a solids discharge, a deflector operatively associated with the solids discharge, wherein the solids discharge is adapted to operatively discharge solids being discharged from the centrifugation means at a trajectory and the deflector is adapted to interrupt the trajectory to decelerate and change the direction of travel of the solids, or wherein the deflector is operatively associated with the solids discharge and cooperable with solids being discharged from the solids discharge whereby buildup of solids on the deflector is substantially prevented, or wherein the solids discharge includes a lip configuration which causes the trajectories of the discharging crystals to be relatively independent of their size and / or their residual syrup / moisture content, or including support means, such as a spider like construction having one or more webs substantially parallel to the angular motion of the solids being discharged from the solids discharge, operatively supporting the centrifugation means whereby the impact area for solids discharged from the solids discharge may be minimized, or including blending means operatively associated with the solids discharge for blending solids discharged from the centrifugation separations apparatus.

Owner:STG FCB HLDG

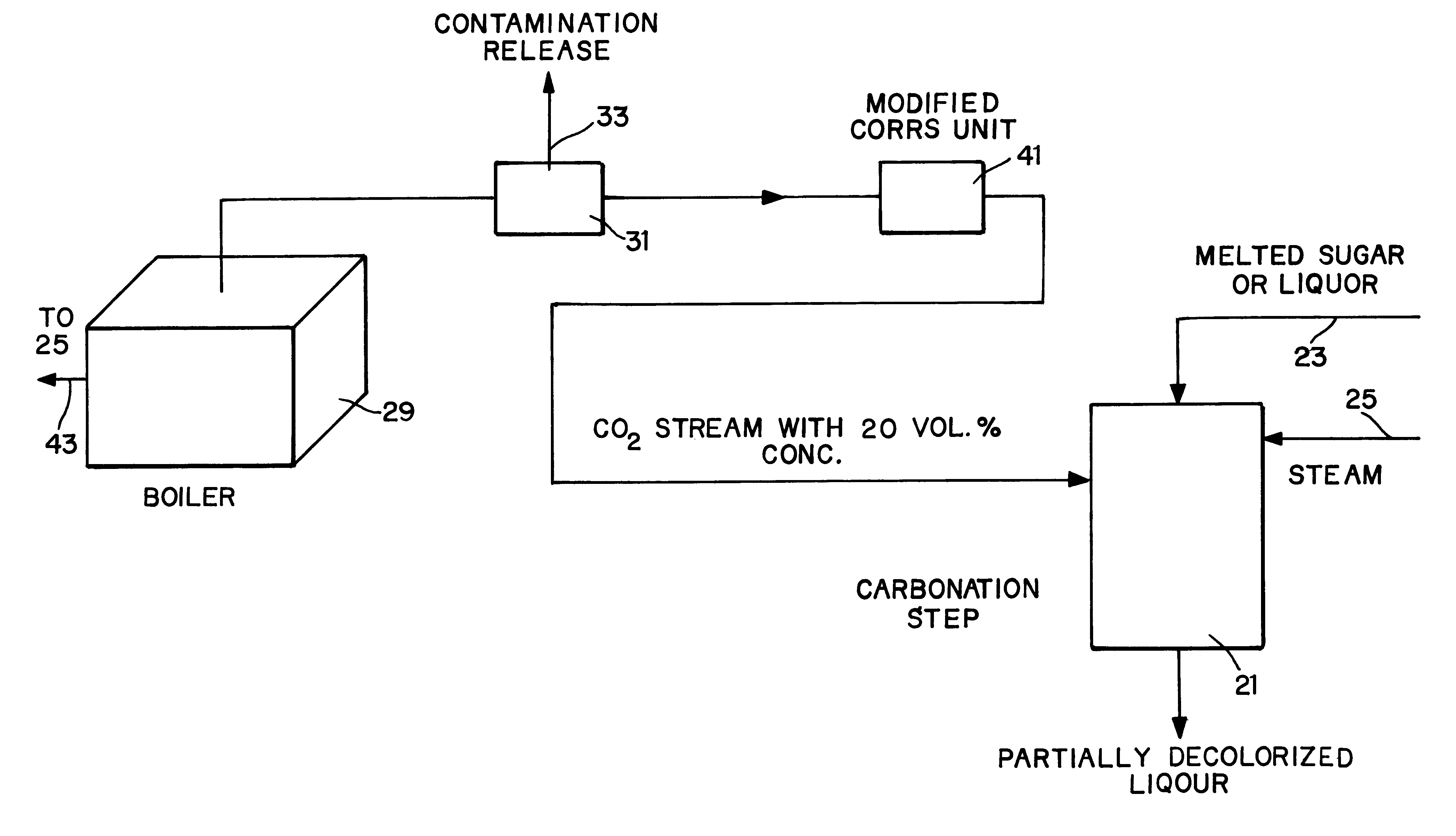

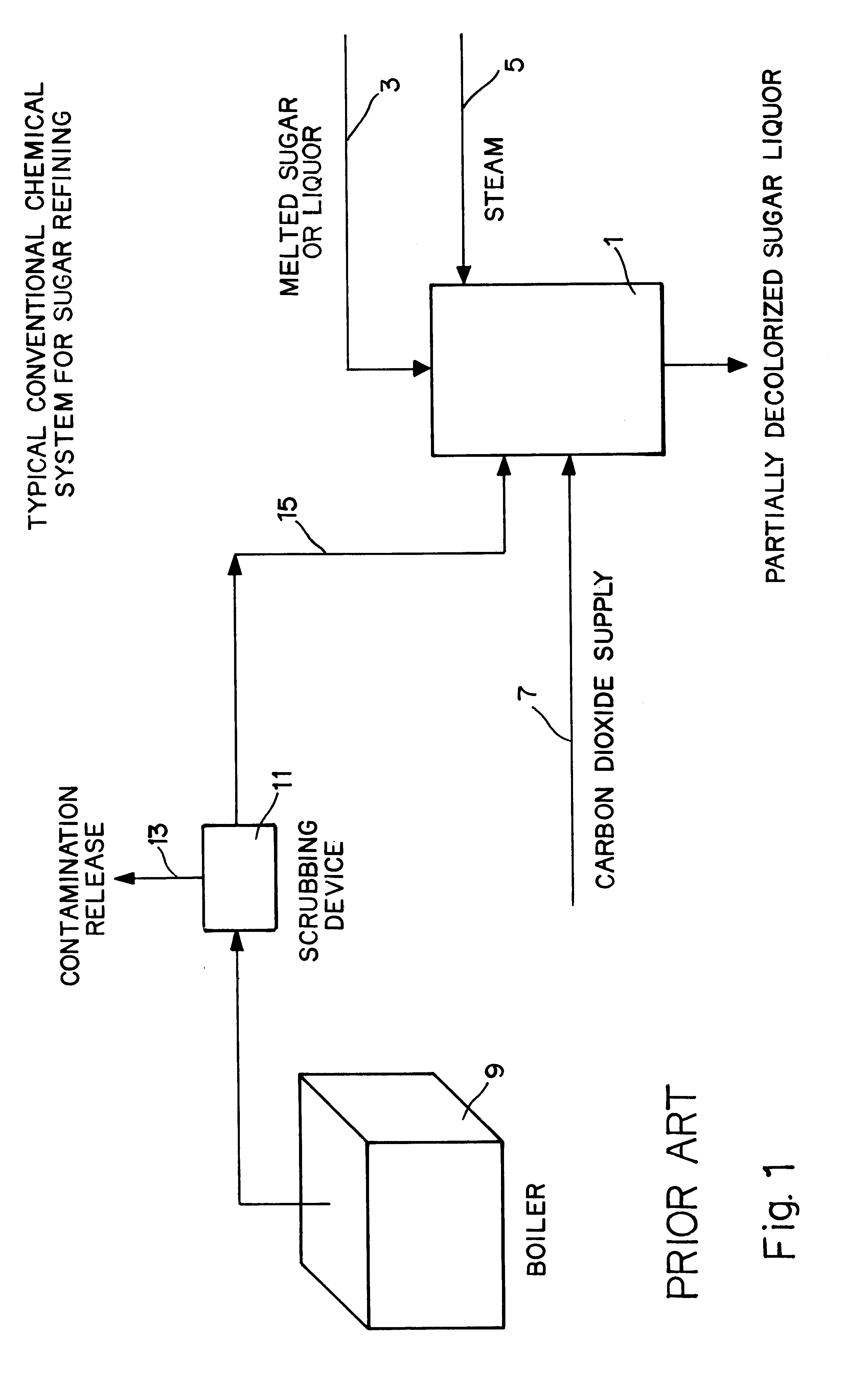

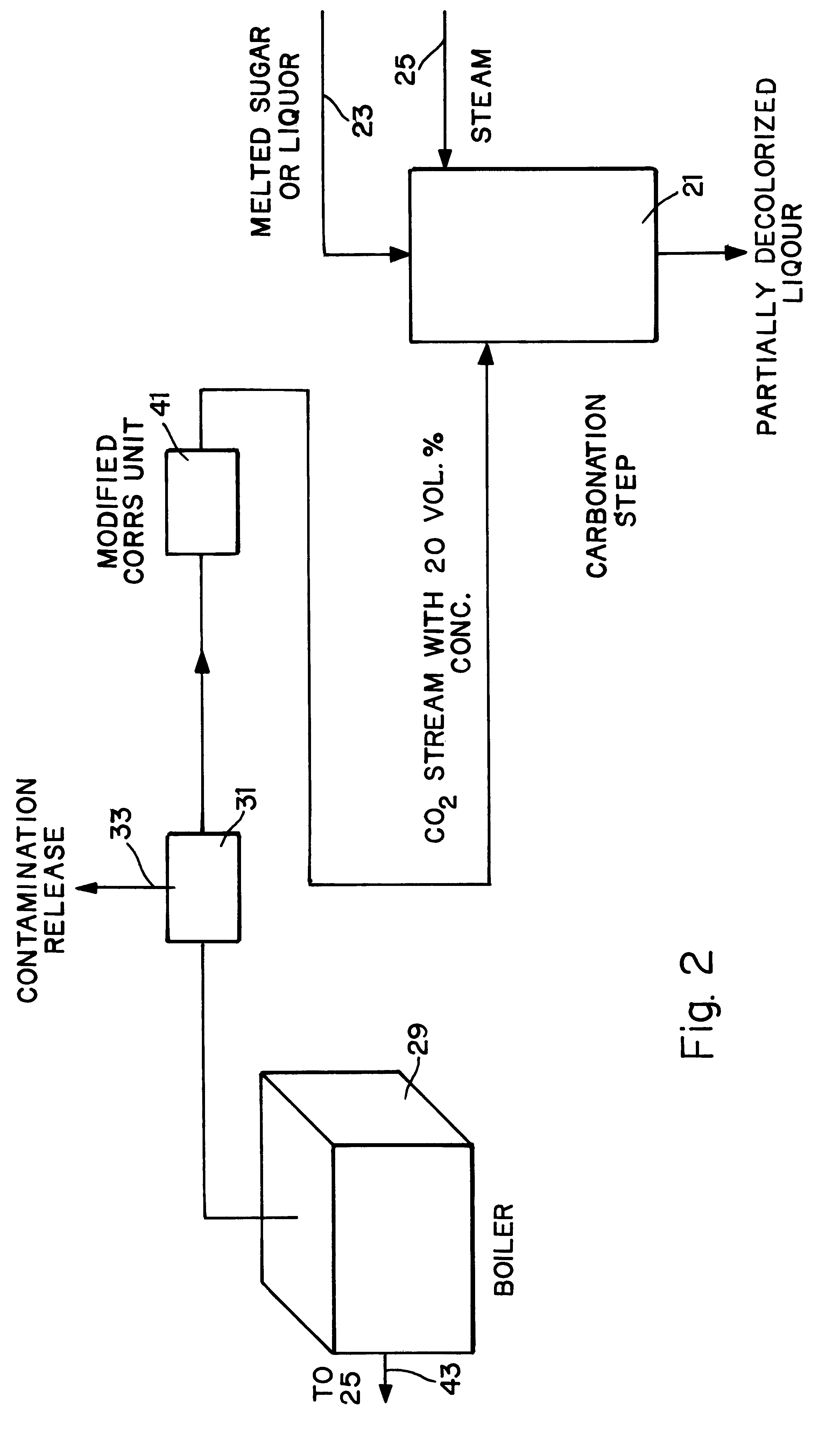

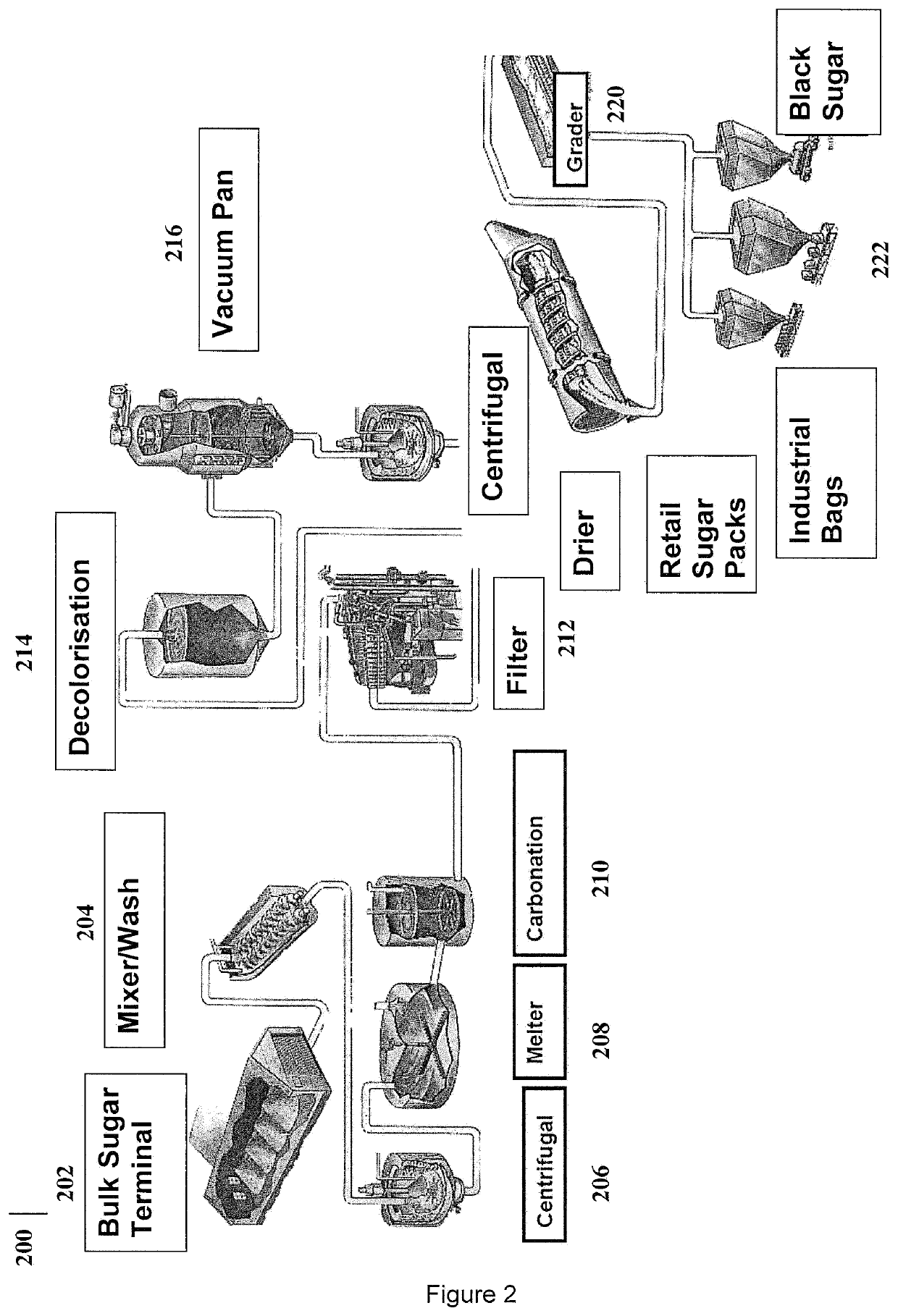

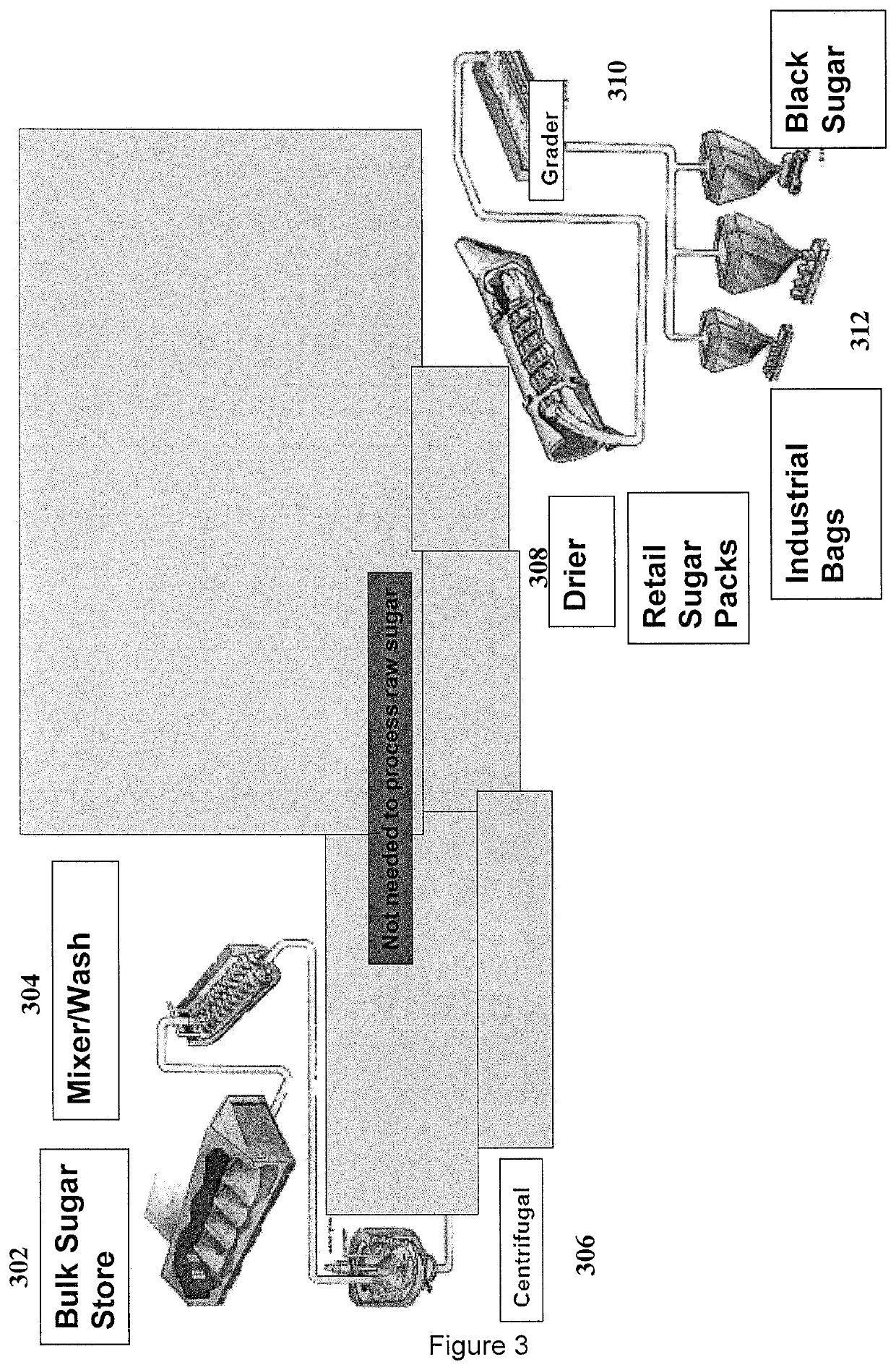

System and method for refining sugar

InactiveUS6176935B1Speed up the processEasily incorporated into existing refineryPurification using alkaline earth metal compoundsSugar crystal separationFlue gasSugar refining

A sugar refining process uses carbon dioxide obtained from a module containing a plurality of gas-permeable polymeric membranes. Flue gas from a boiler is scrubbed, and then passed through the gas-separation module. The output of the module contains an enhanced concentration of carbon dioxide, in the range of about 20% by volume. The carbon dioxide enhanced gas is then directed into a reactor in which raw sugar is exposed to carbon dioxide to cause carbonation, an essential step in the decolorization of the raw sugar. The same boiler used to produce the carbon dioxide is also used to produce steam which drives the reaction. The present invention provides carbon dioxide for carbonation in a highly efficient manner, as the gas separation membrane has no moving parts and requires little maintenance. The invention is especially suited for retrofitting existing sugar refining plants, to improve their efficiency, at a relatively small cost.

Owner:AIR LIQUIDE AMERICA INC +1

Carbohybrate purification using ultrafiltration, reverse osmosis and nanofiltration

InactiveCN1242776APurification using adsorption agentsSugar derivativesEnzymatic synthesisUltrafiltration

The invention provides methods for purifying carbohydrates, including oligosaccharides, nucleotide sugars, and related compounds, by use of ultrafiltration, nanofiltration and / or reverse osmosis. The carbohydrates are purified away from undesired contaminants such as compounds present in reaction mixtures following enzymatic synthesis or degradation of oligosaccharides.

Owner:NEOSE TECH

Method for purification of high purity sucrose material

ActiveUS20050056273A1Improve sugar qualityQuality improvementCation exchanger materialsSugar productsSucroseSugar

A method for purifying a sucrose material already in a high purity liquid, crystalline or other form of sucrose, such as raw sugar, utilizing chromatography, or utilizing chromatography in connection with other methods of purification.

Owner:AMALGAMATED RES

Method for purification of high purity sucrose material

ActiveUS7125455B2Improve sugar qualityQuality improvementCation exchanger materialsSugar productsPurification methodsSucrose

A method for purifying a sucrose material already in a high purity liquid, crystalline or other form of sucrose, such as raw sugar, utilizing chromatography, or utilizing chromatography in connection with other methods of purification.

Owner:AMALGAMATED RES

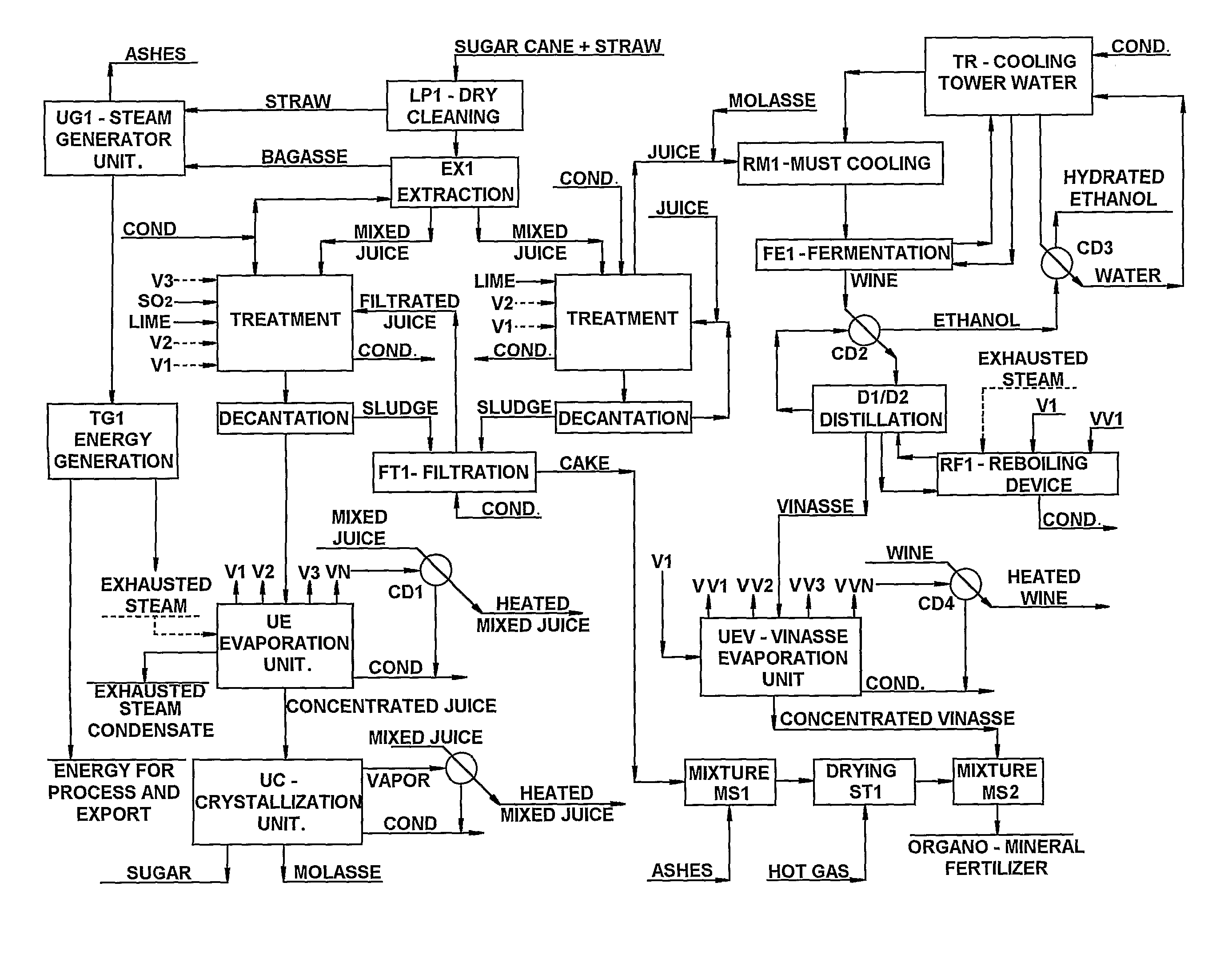

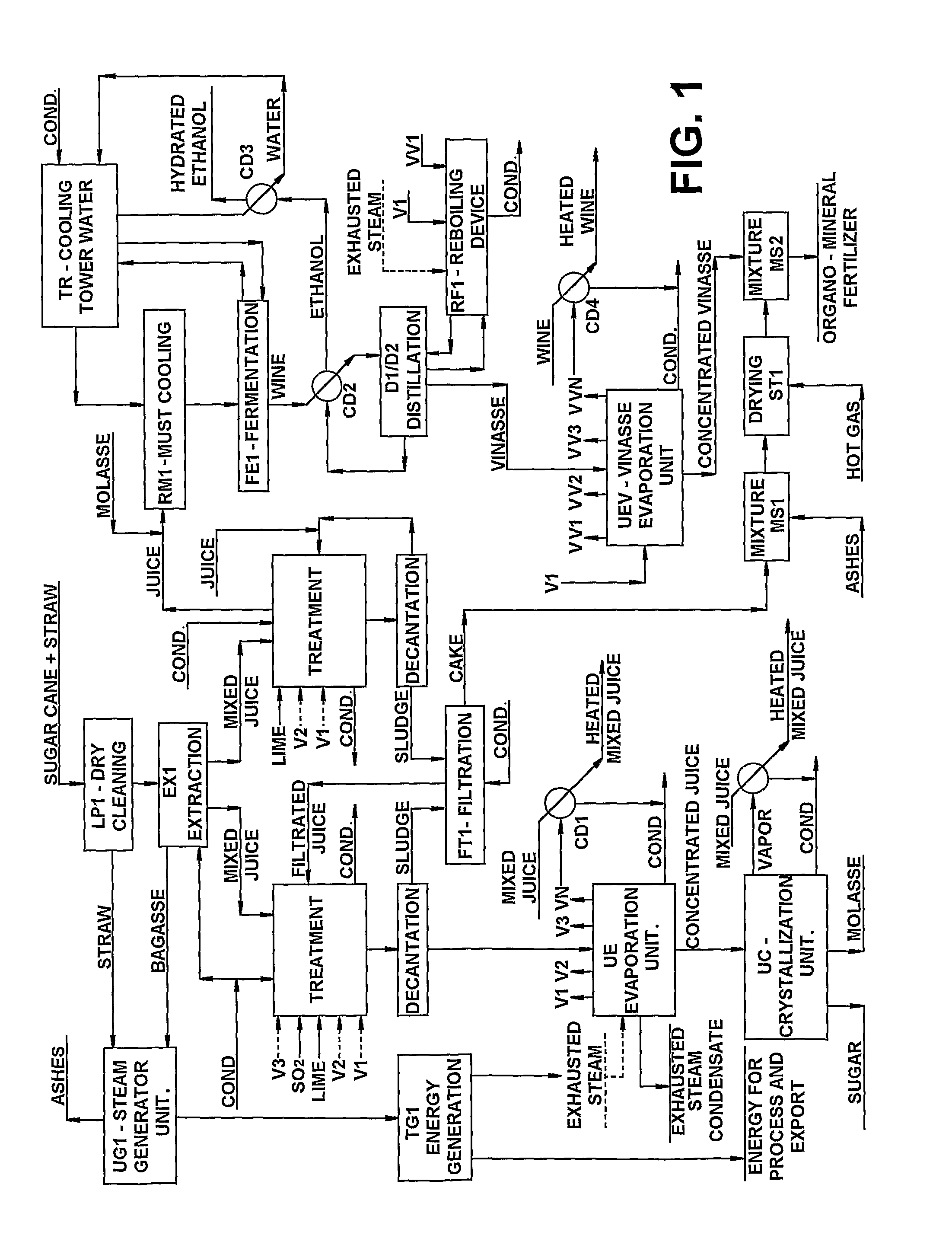

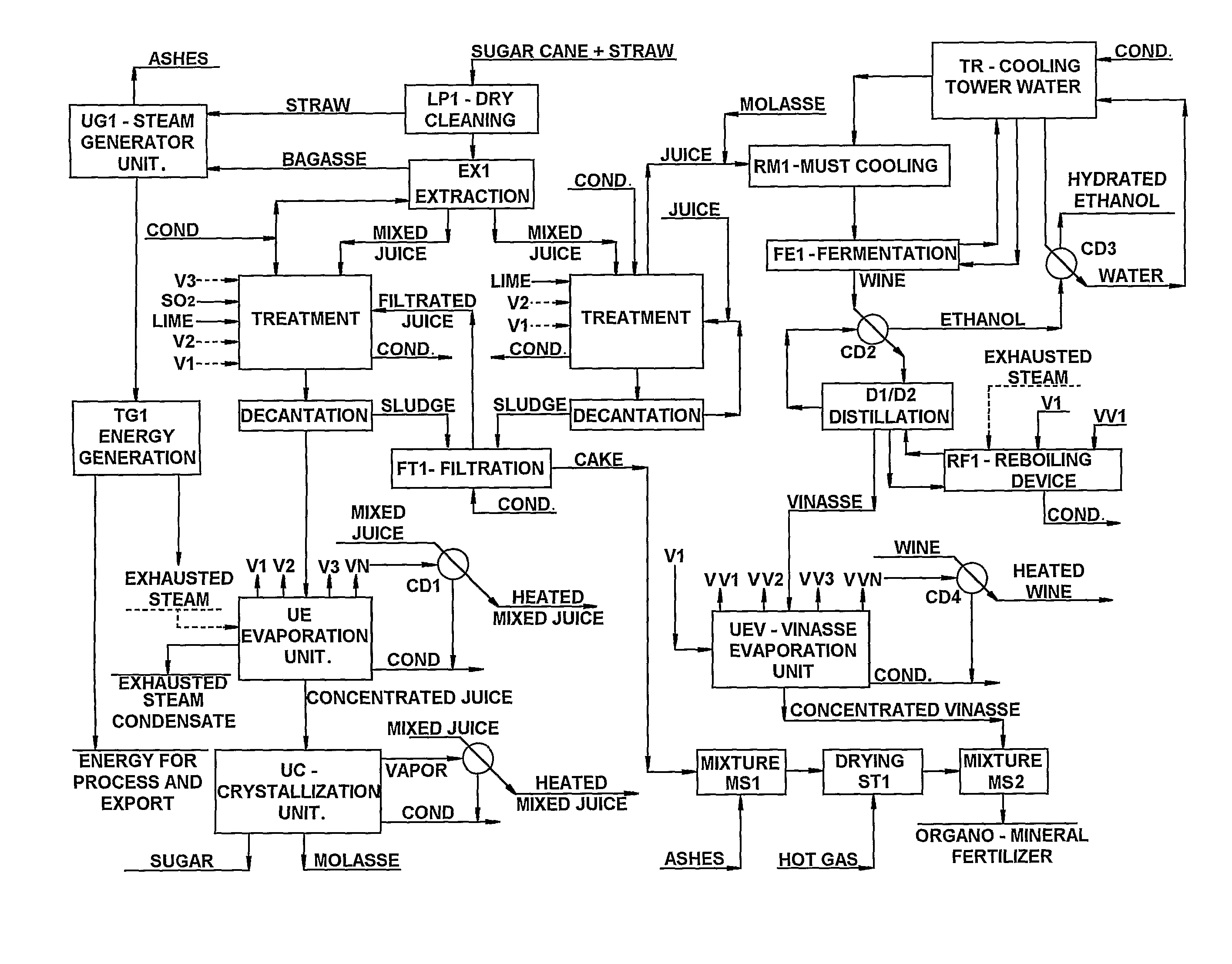

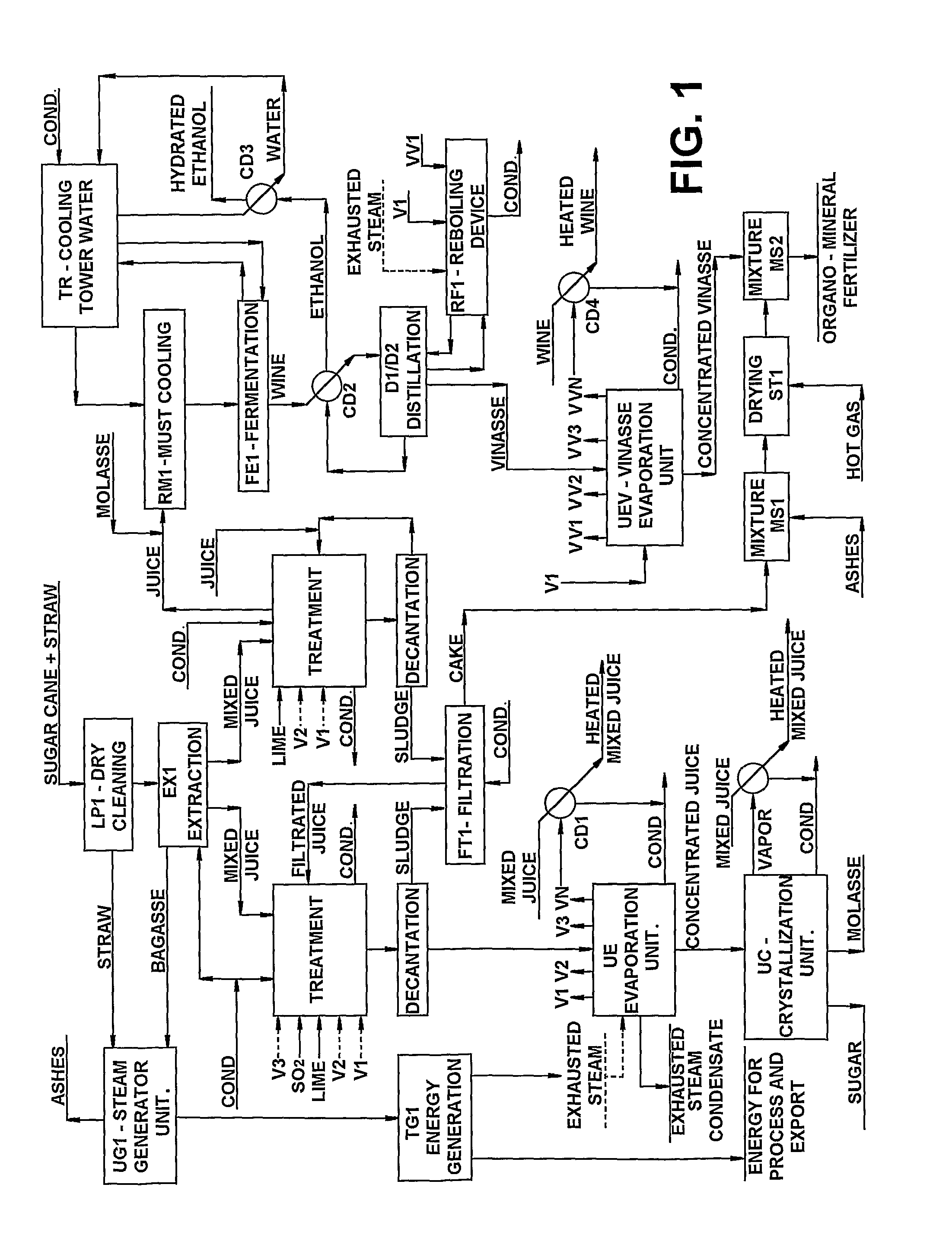

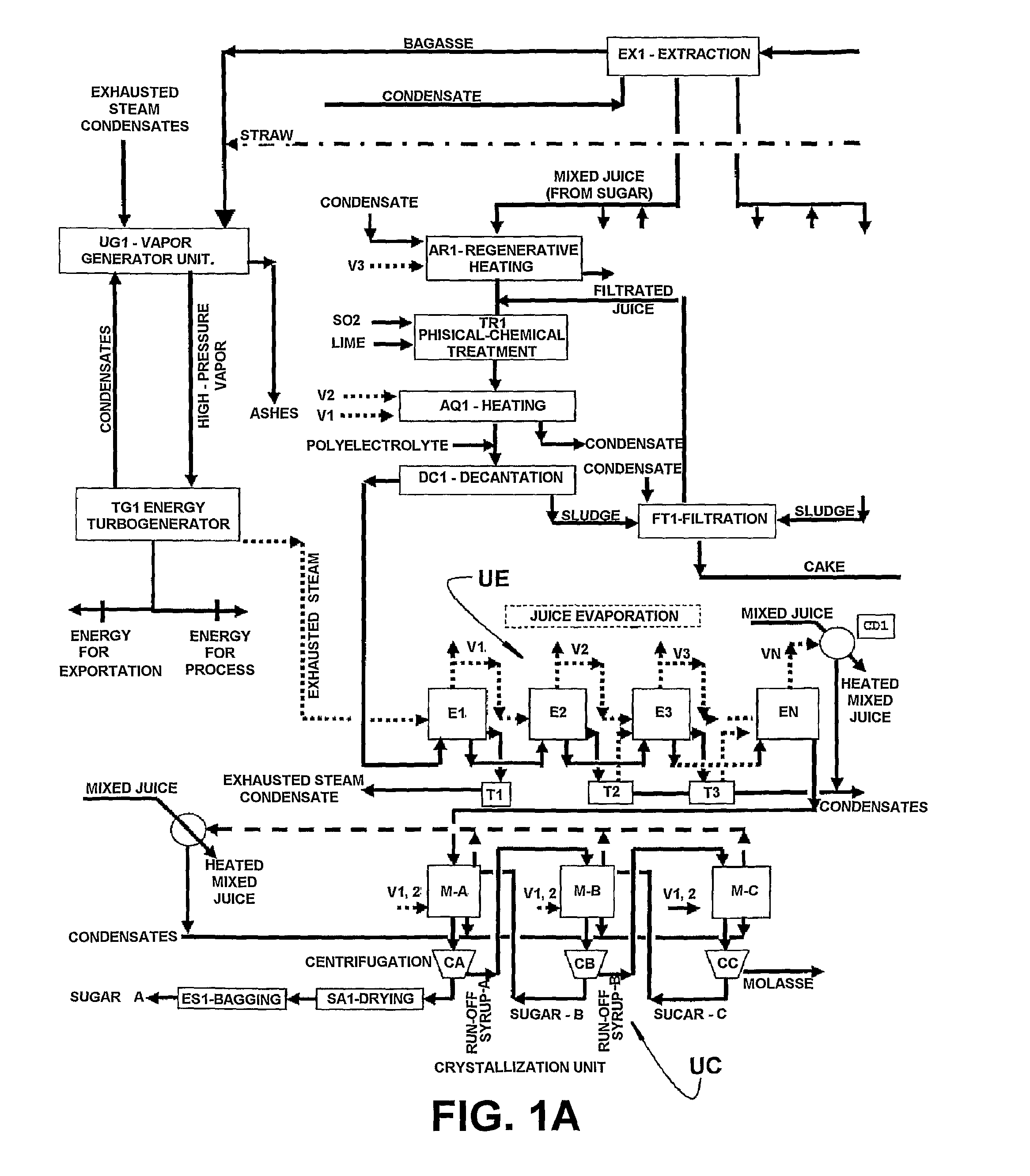

Process for the recovery of water and energy from the processing of sugar cane in sugar and ethanol production mills

ActiveUS20110232343A1Reduce consumptionEconomic savingsBio-organic fraction processingSugar crystal separationThermal energyCooling tower

A process is proposed for recovery of water in the sugar cane processing in production mills of sugar and alcohol or only alcohol (ethanol). In the process, the thermal energy available in the exhausted steam from the electric energy generation turbines is transferred to the different mixed juice processing phases, with the reuse of the exhausted steam condensates in the boilers and of the other condensates, after using thermal energy, for imbibition, in the juice extraction phase, for cooling in the process, after passing through cooling towers, for other industrial uses and for possible treatment or use in the irrigation out of the productive system in the mill

Owner:DEDINI S A IND DE BASE

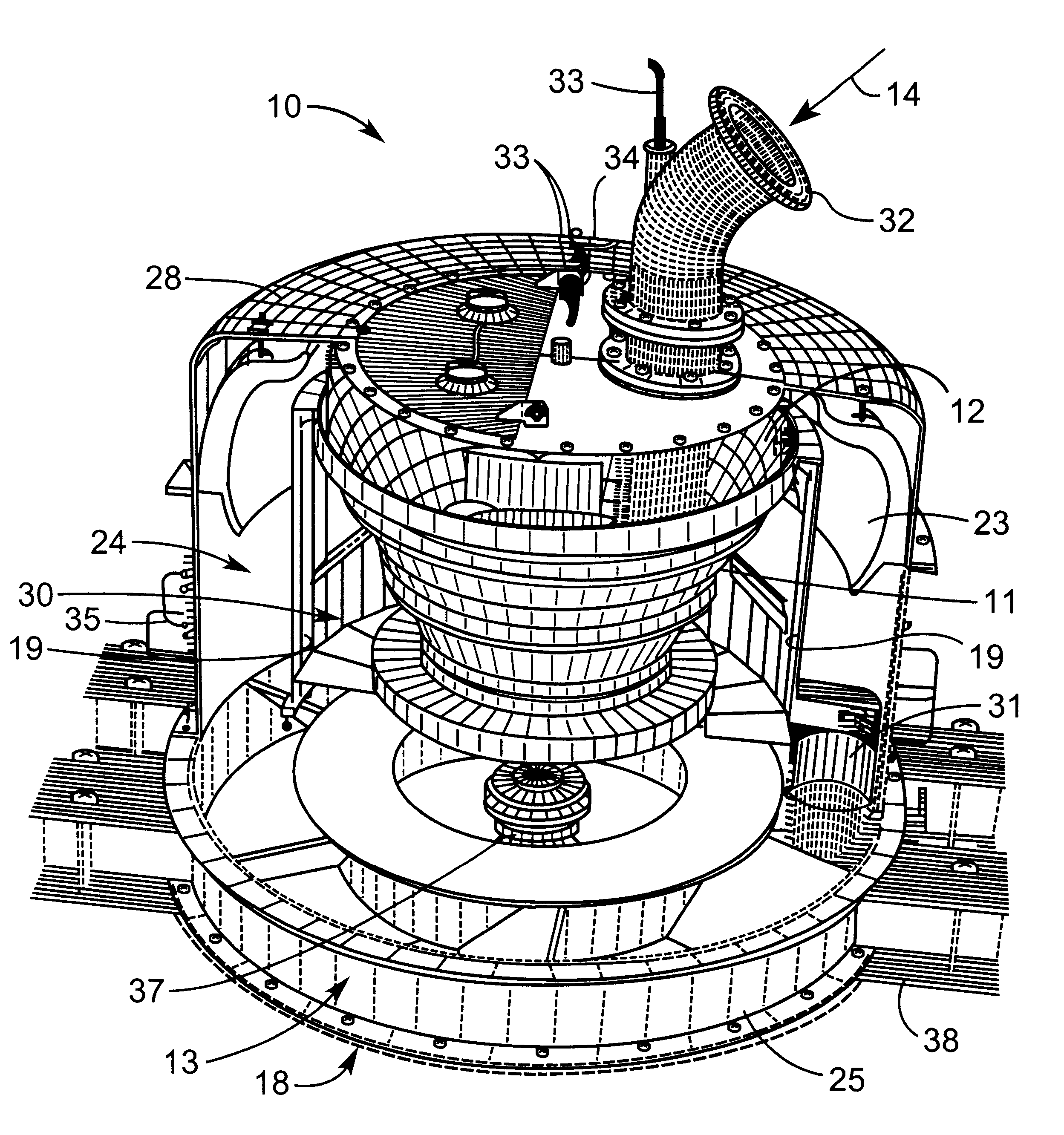

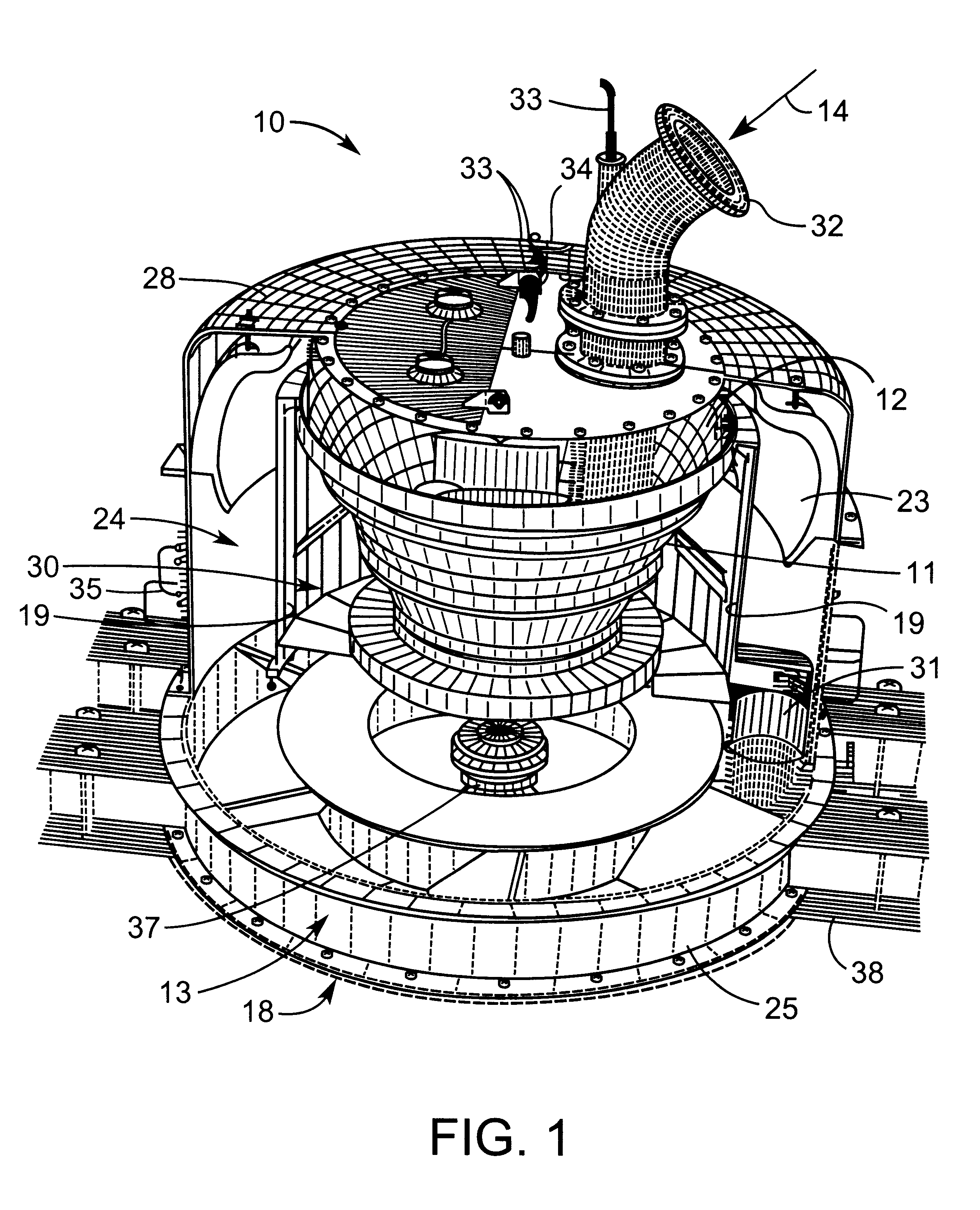

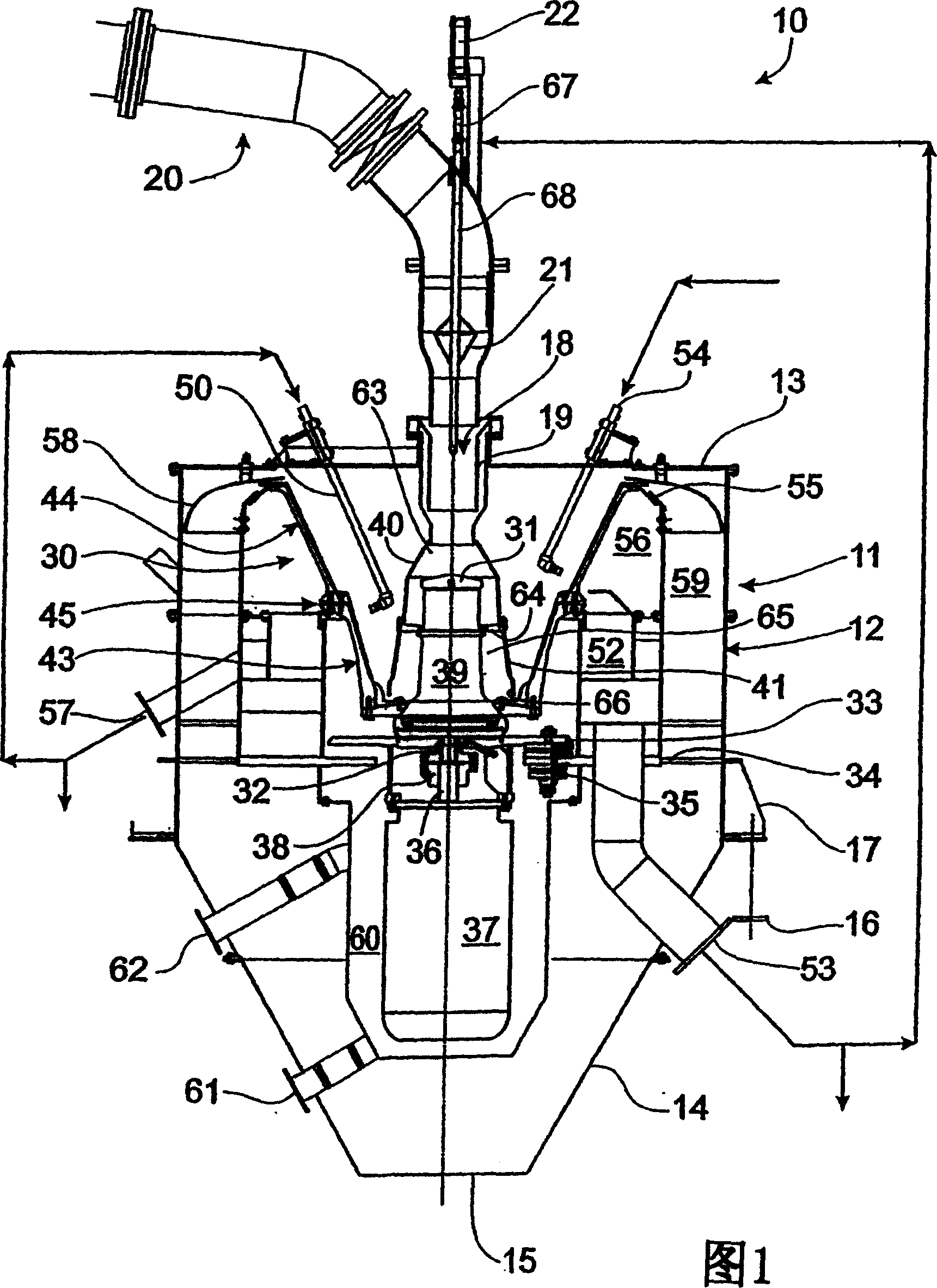

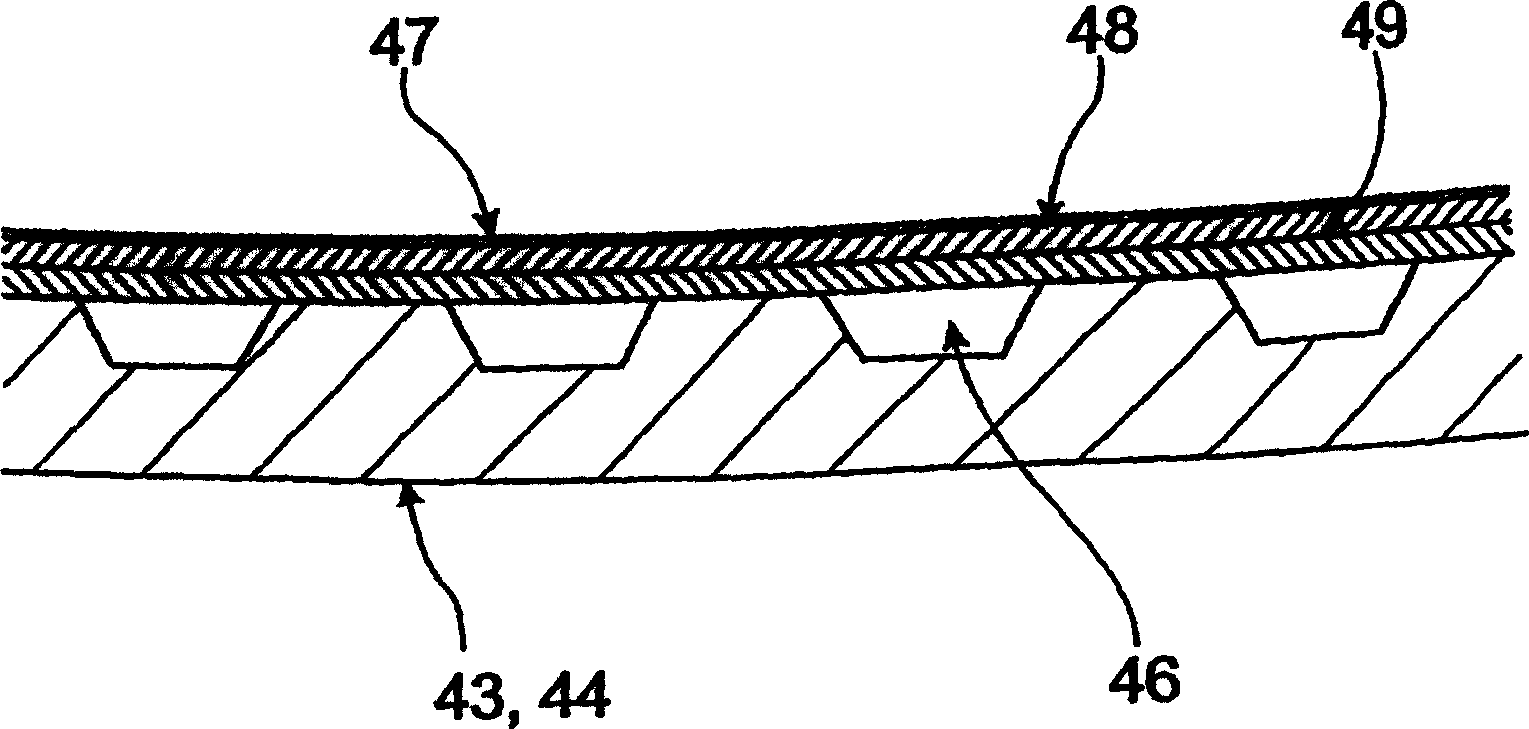

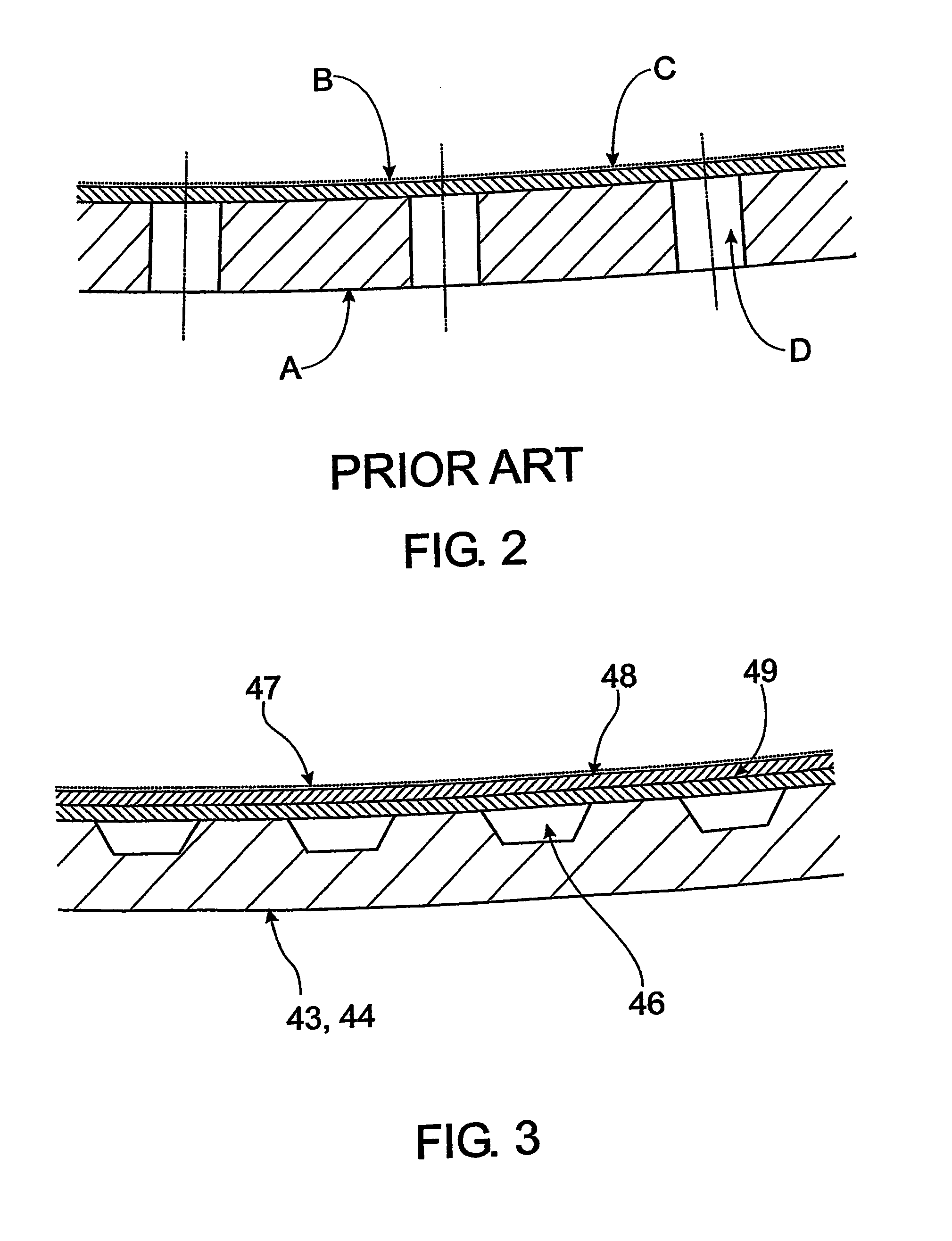

Continuous centrifuge

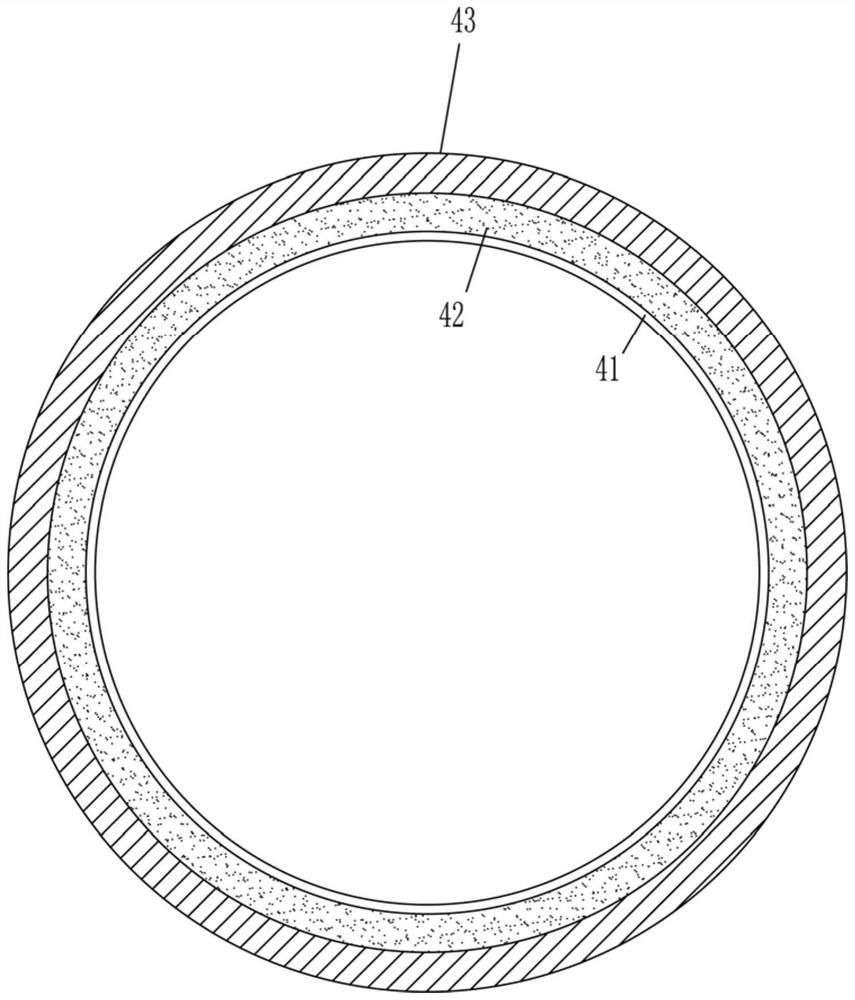

InactiveCN1571702AEfficient separationAvoid damageSugar crystal separationRotary centrifugesEngineeringMechanical engineering

A continuous centrifuge (10) has a basket (30) with upper and lower basket portions (43, 44) separated by an intermediate slip portion (45). The lower basket portion (43) has an included angle of 40-50 DEG , to separate 'green' molasses from the sugar crystals, while the upper basket portion (44) has an included angle of 50-60 DEG , to separate washed molasses from the sugar crystals. The inner faces of the walls of the basket portions (43, 44) have radial drainage grooves (46), closed at their lower ends and open at their upper ends, to discharge the molasses.

Owner:WDT ENGINEERS PTY LTD

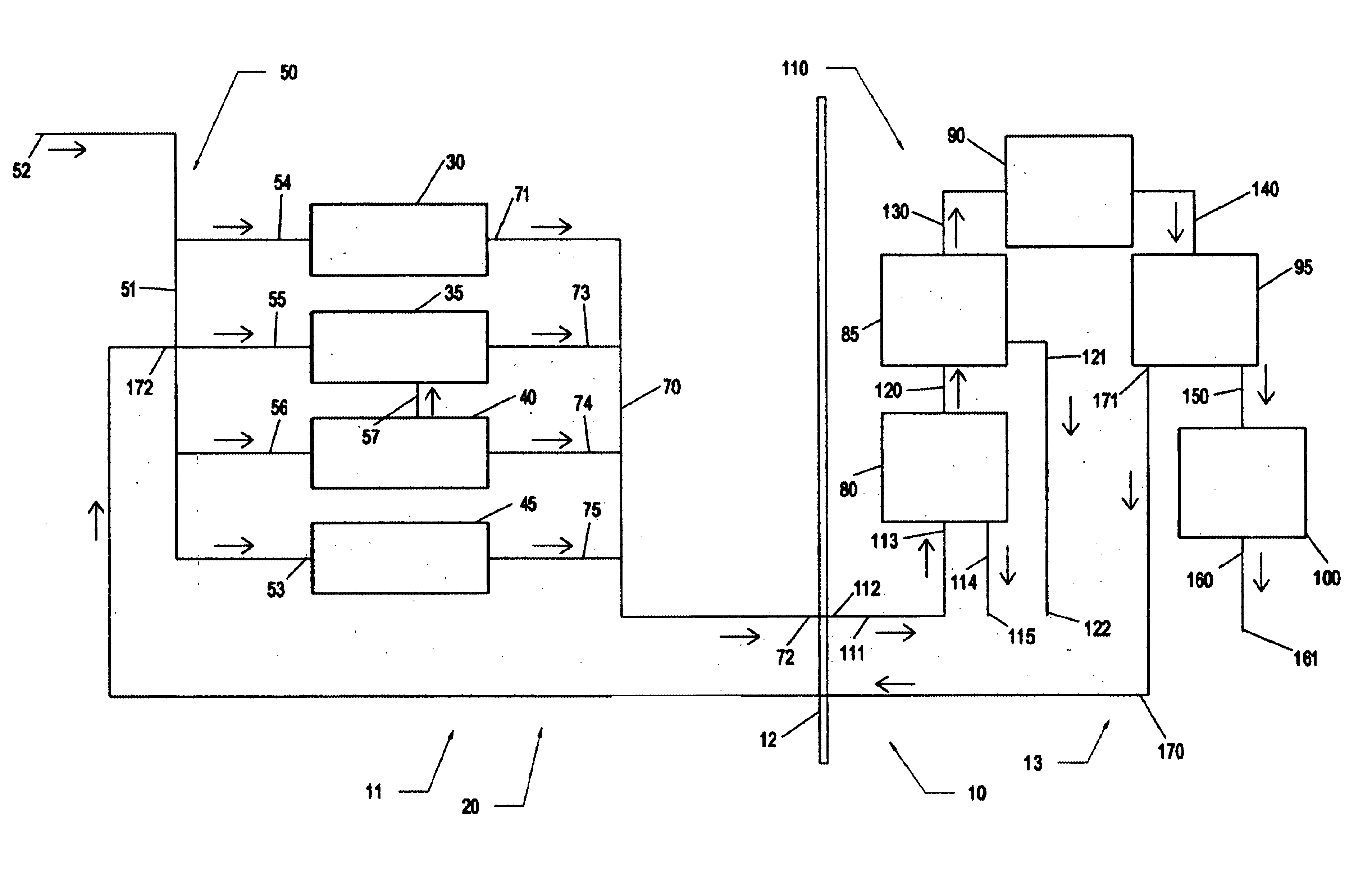

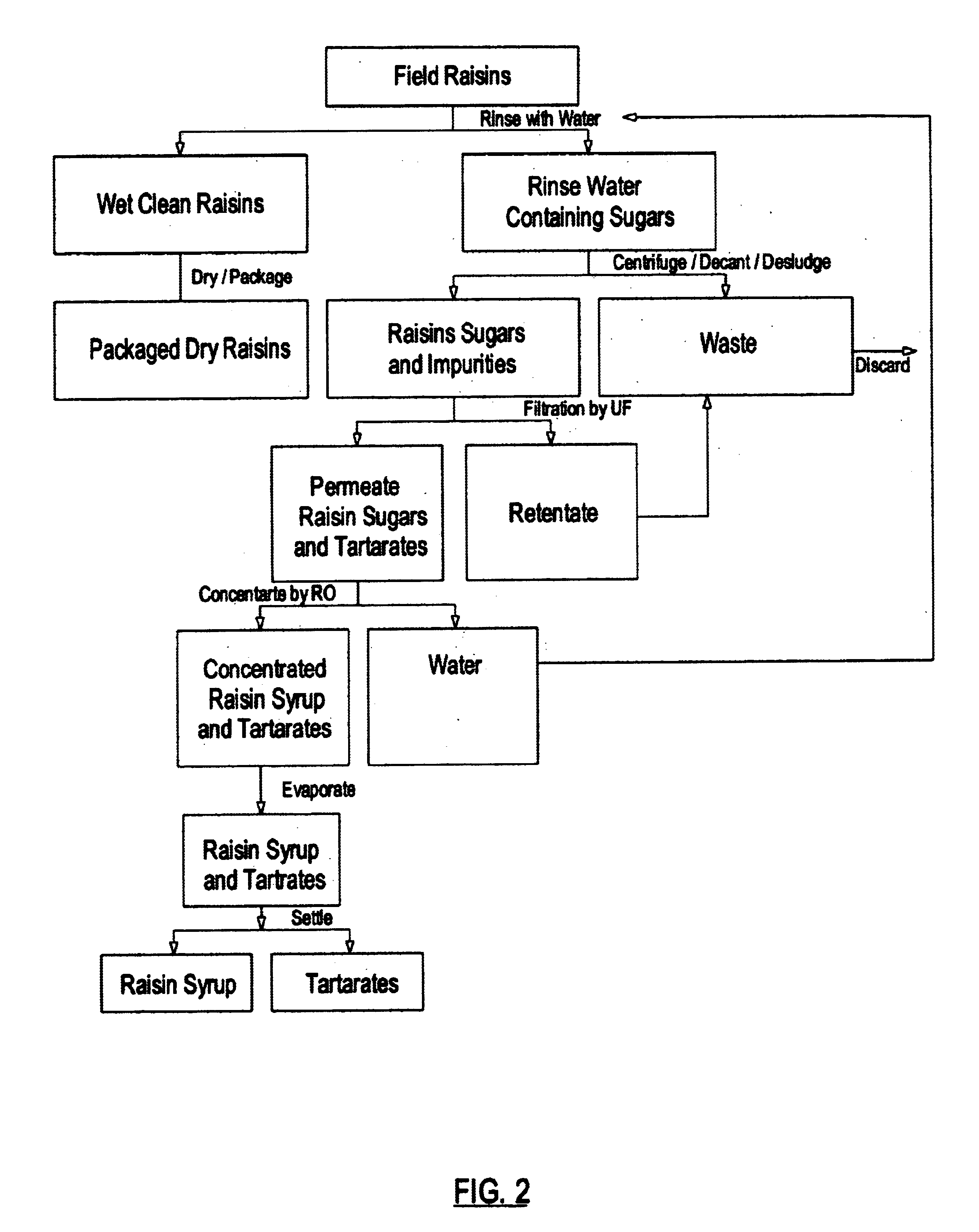

Method and apparatus for producing a work product

InactiveUS6736903B2Low costReduce the ratioPressurized chemical processSugar crystal separationReverse osmosisEngineering

A method for producing a work product including the steps of receiving a first fluid composed of a liquid, a target substance and at least one residual substance; passing the first fluid through a first work station for separating the residual substance from the first fluid to produce a secondary fluid substantially composed of the liquid and the target substance; and treating the secondary fluid to reduce the proportion of the liquid relative to the target substance in the secondary fluid to form the work product. An apparatus for producing a work product including an intake conduit adapted to receive a first fluid, composed substantially of water, a sugar substance and residual substances, from a rinsing system for raisins or the like; a first processing station adapted to remove the residual substances from the first fluid to form a second fluid, composed substantially of water and the sugar substance; and a second processing station adapted to treat the second fluid by reverse osmosis, nanofiltration, or the like to reduce the proportion of water relative to the sugar substance in the second fluid to form the work product.

Owner:SUNSHIE RAISIN CORP

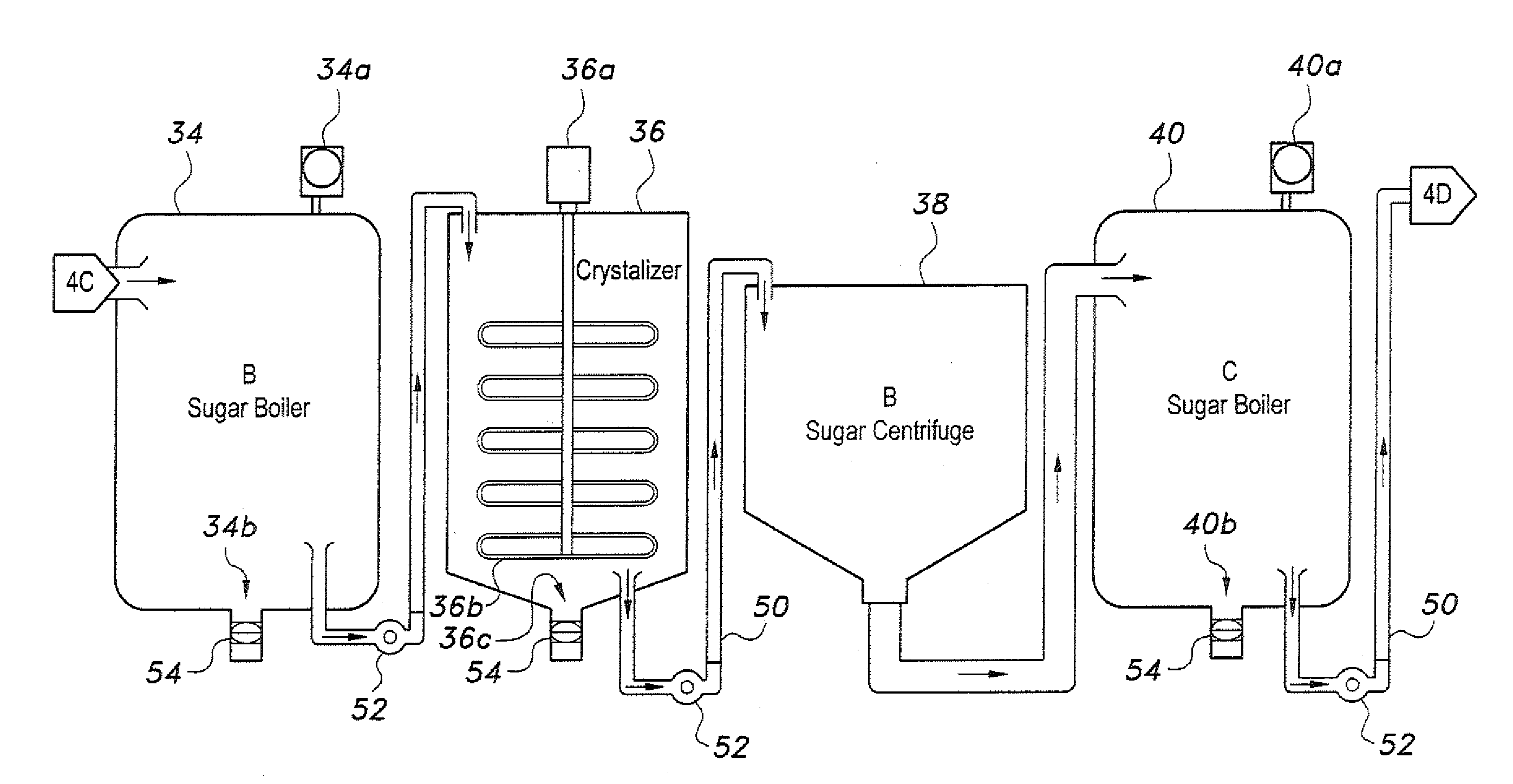

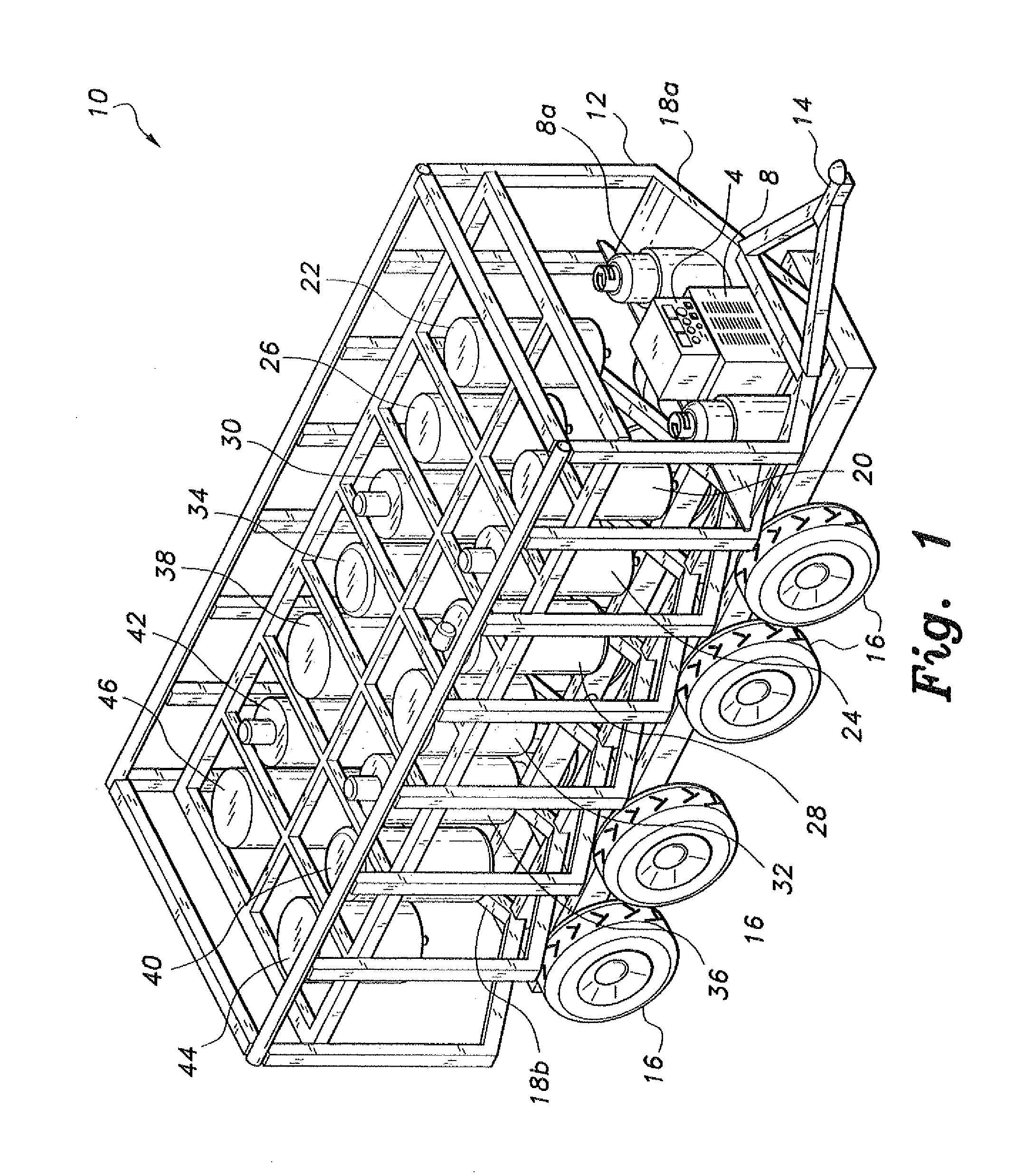

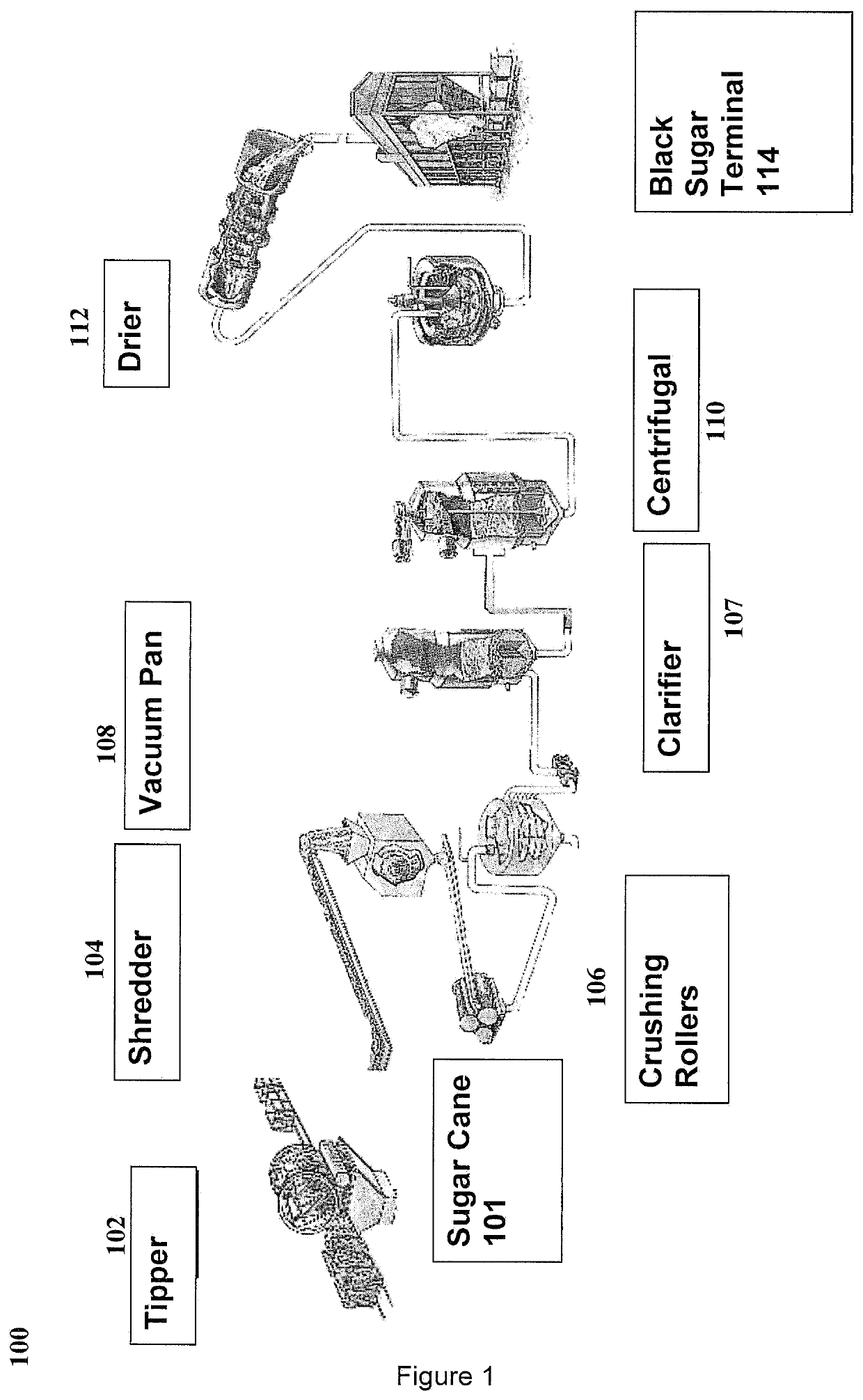

Portable sugar mill

InactiveUS20130042858A1Readily apparentSugar crystal separationCentrifugal force sediment separationFruit juiceSaccharum

The portable sugar mill is established on a mobile platform for transport to the harvesting field, so that the juice of the harvested sugar cane may be processed and refined in the field. The portable sugar mill converts the juice, which contains sucrose, into raw sugar crystals (brown sugar) and molasses. The portable sugar mill includes a separator tank, a pre-heating tank, a clarifier, and three successive stages of evaporative crystallization and separation of crystals from syrup. The portable sugar mill has a programmable logic controller and a plurality of sensors, control relays, pumps, motors, heaters, and valves that operate automatically under direction of the programmable logic controller.

Owner:JEDWIN MARKETING

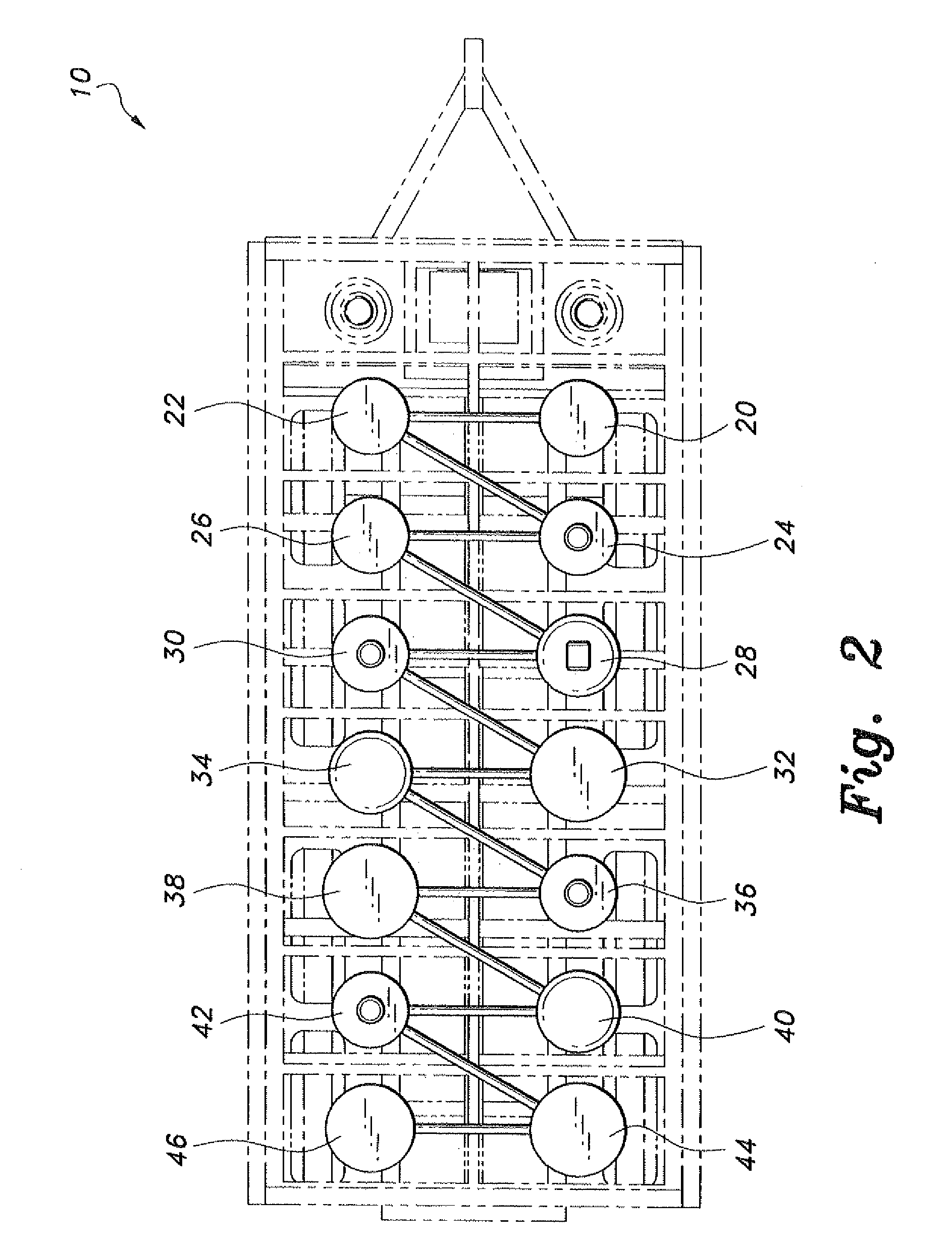

Producing method of pharmaceutic adjuvant cane sugar by carbonic acid method process

InactiveCN104611473ALow equipment requirementsSimple processSugar dryingPurification using chemicalsSucroseImpurity

A producing method of a pharmaceutic adjuvant cane sugar by a carbonic acid method process is disclosed. The producing method directly adopts sugarcane as a raw material and obtains the pharmaceutic cane sugar by steps of smashing, squeezing, clearing, evaporating, sugar boiling, separating molasses and drying. A sulphur bleaching-floating combined step is added between the evaporating step and the sugar boiling step to further remove various impurities in the cane sugar and to improve the cleanliness level of the cane sugar, so that contents of sulfates, residues on ignition, calcium salts, heavy metals, and the like in the cane sugar meet the index requirements in the Chinese Pharmacopoeia of the 2010 edition. The carbonic acid method is low in equipment requirement and simple in process, and therefore the producing method is suitable for large-scale production of cane sugar, and overcomes the problem that cane sugar produced by traditional carbonic acid method processes cannot meet the standards of the pharmaceutic cane sugar and the problem that the pharmaceutic cane sugar is difficult in large-scale production.

Owner:NANNING SUGAR INDUSTRY CO LTD

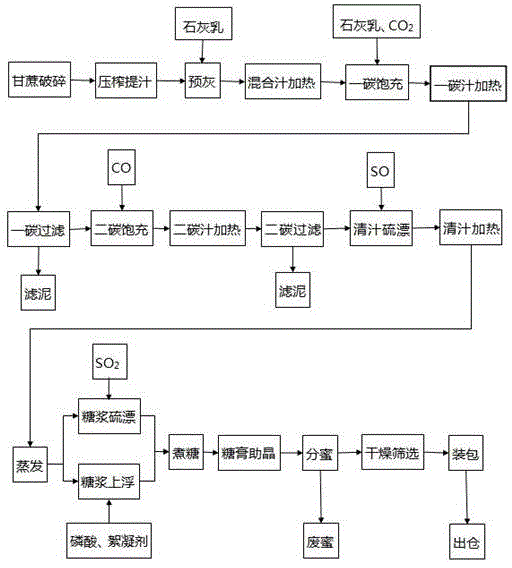

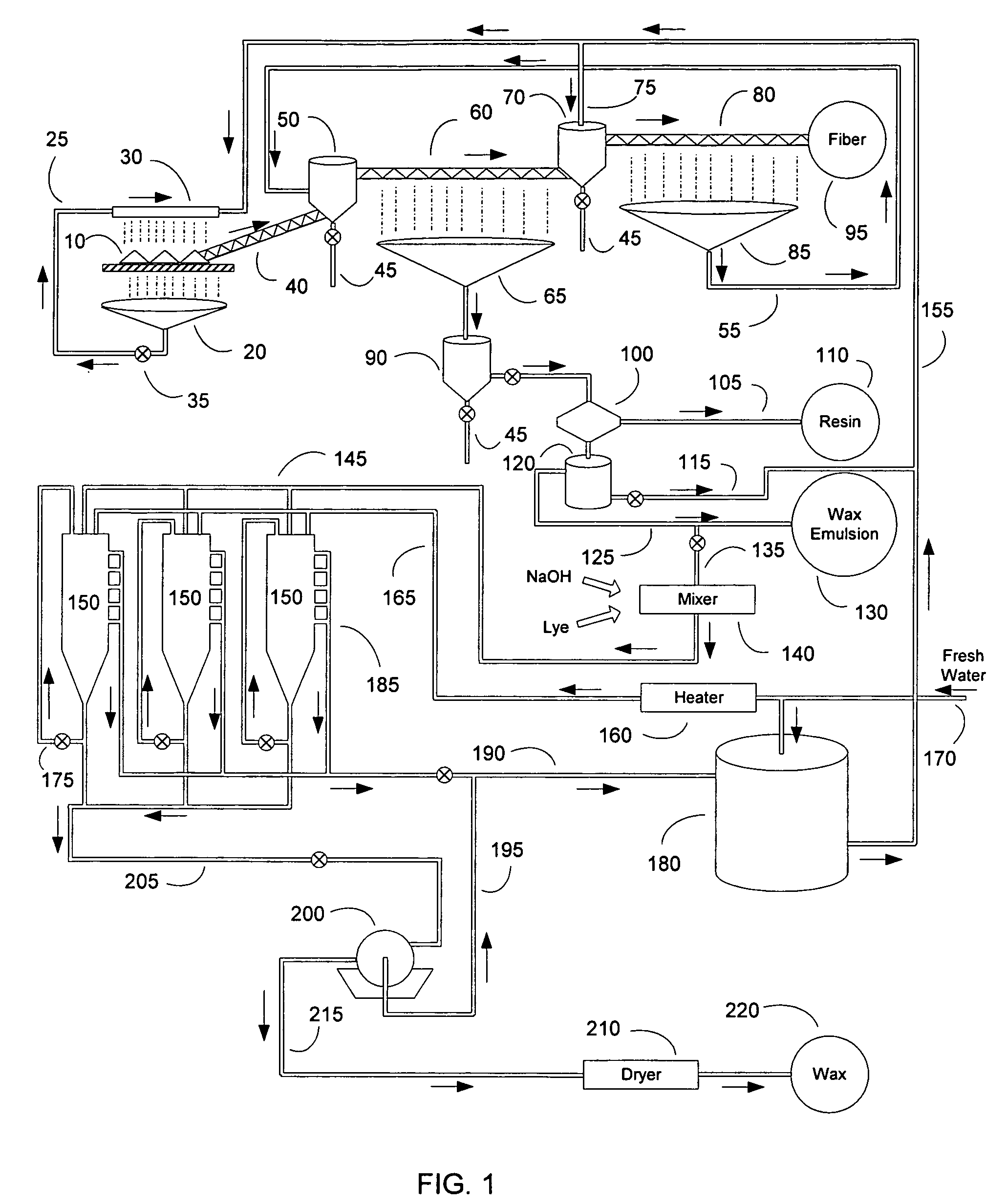

Method for processing sugar cane filter cake mud and extracting component products

InactiveUS7192524B2Inexpensively separatedEliminate needSugar crystal separationBioloigcal waste fertilisersFiberBeta-Carotene

Owner:SYMCORE TECH

Method for producing a powder containing xylitol crystal particles with another polyol

Owner:ROQUETTE FRERES SA

Continuous centrifuge

InactiveUS7208048B2Efficient separationShorten speedWater/sewage treatment by centrifugal separationSugar crystal separationEngineeringCentrifuge

A continuous centrifuge (10) has a basket (30) with upper and lower basket portions (43, 44) separated by an intermediate slip portion (45). The lower basket portion (43) has an included angle of 40–50°, to separate “green” molasses from the sugar crystals, while the upper basket portion (44) has an included angle of 50–60°, to separate washed molasses from the sugar crystals. The inner faces of the walls of the basket portions (43, 44) have radial drainage grooves (46), closed at their lower ends and opens at their upper ends, to discharge the molasses.

Owner:WDT ENGINEERS PTY LTD

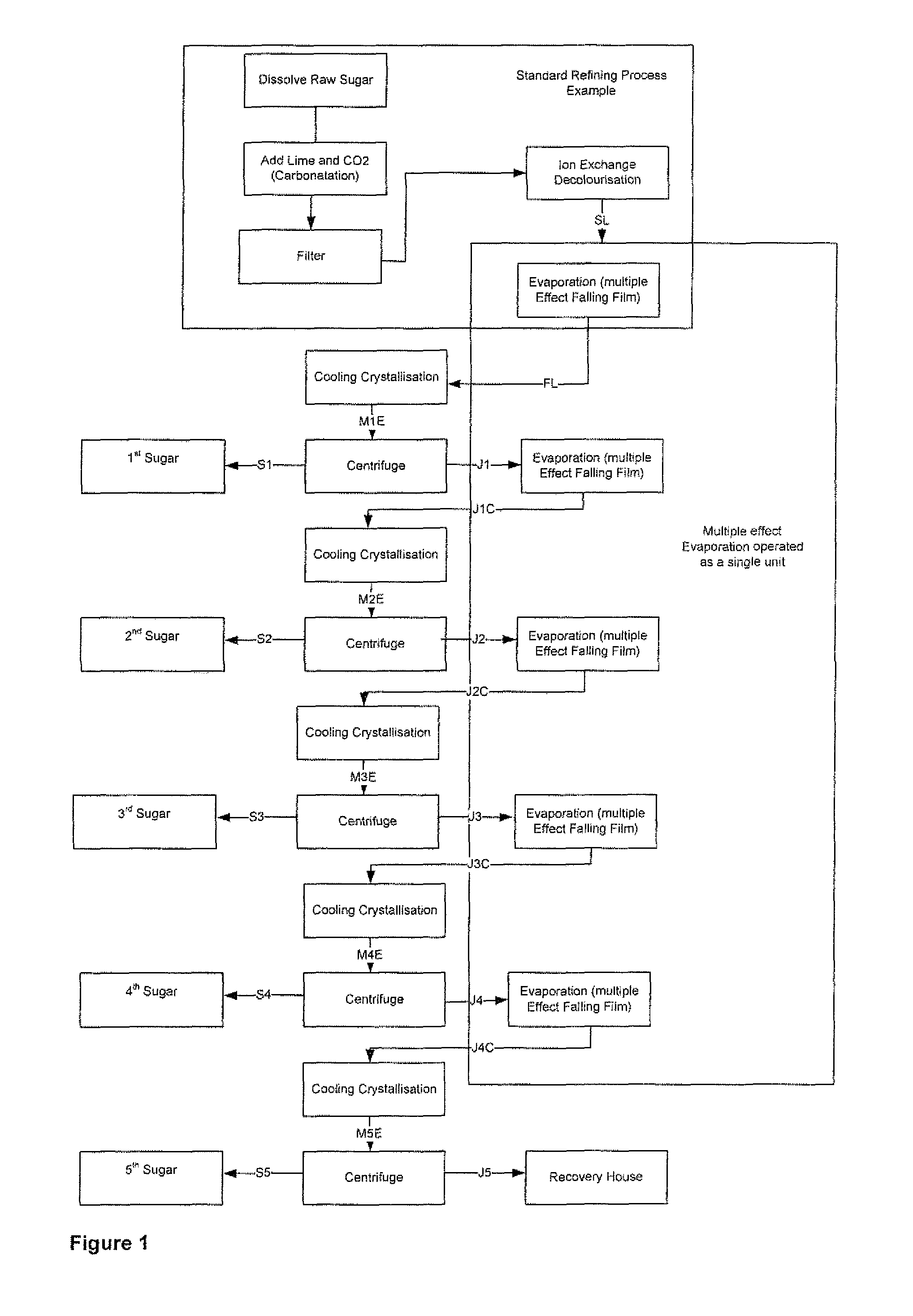

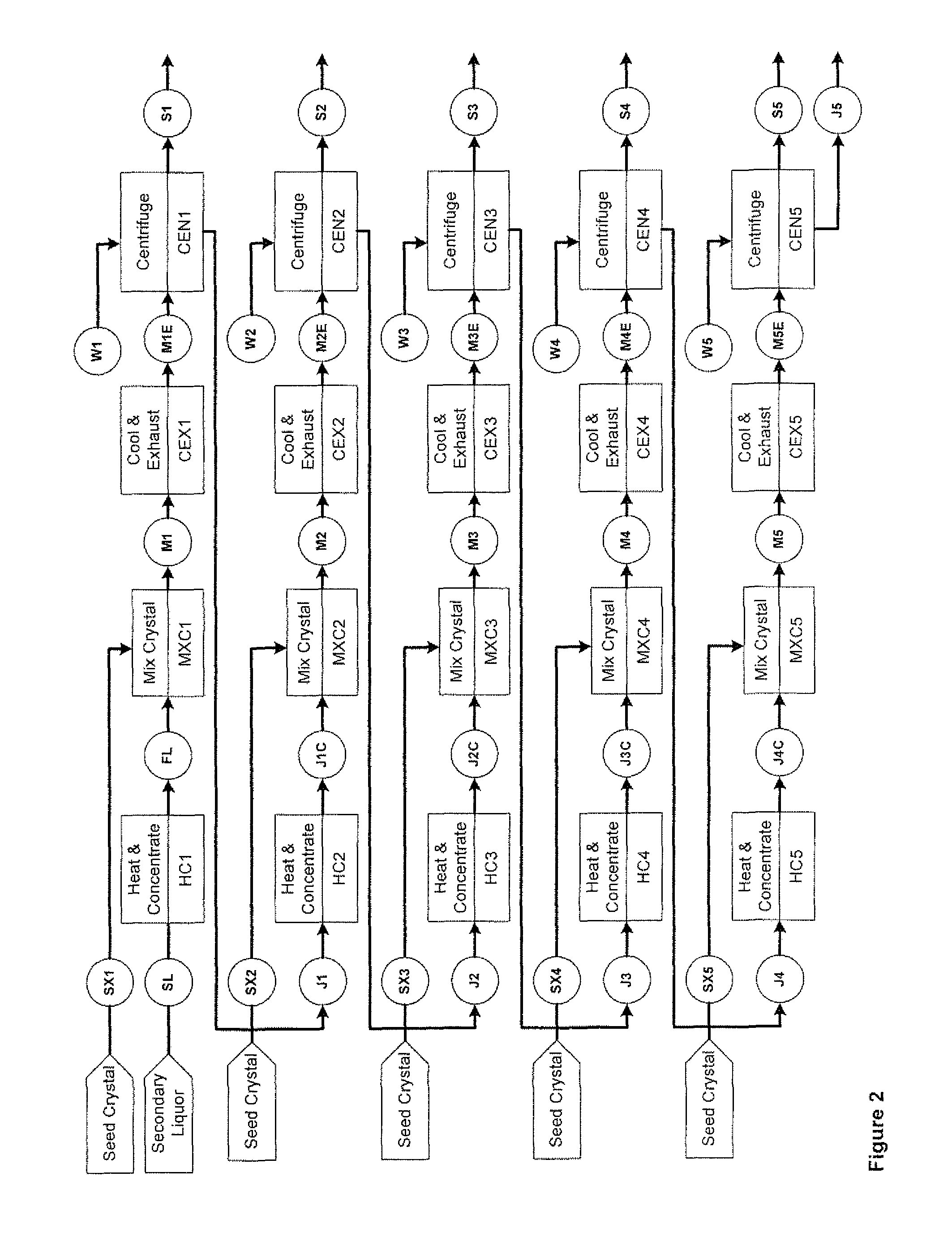

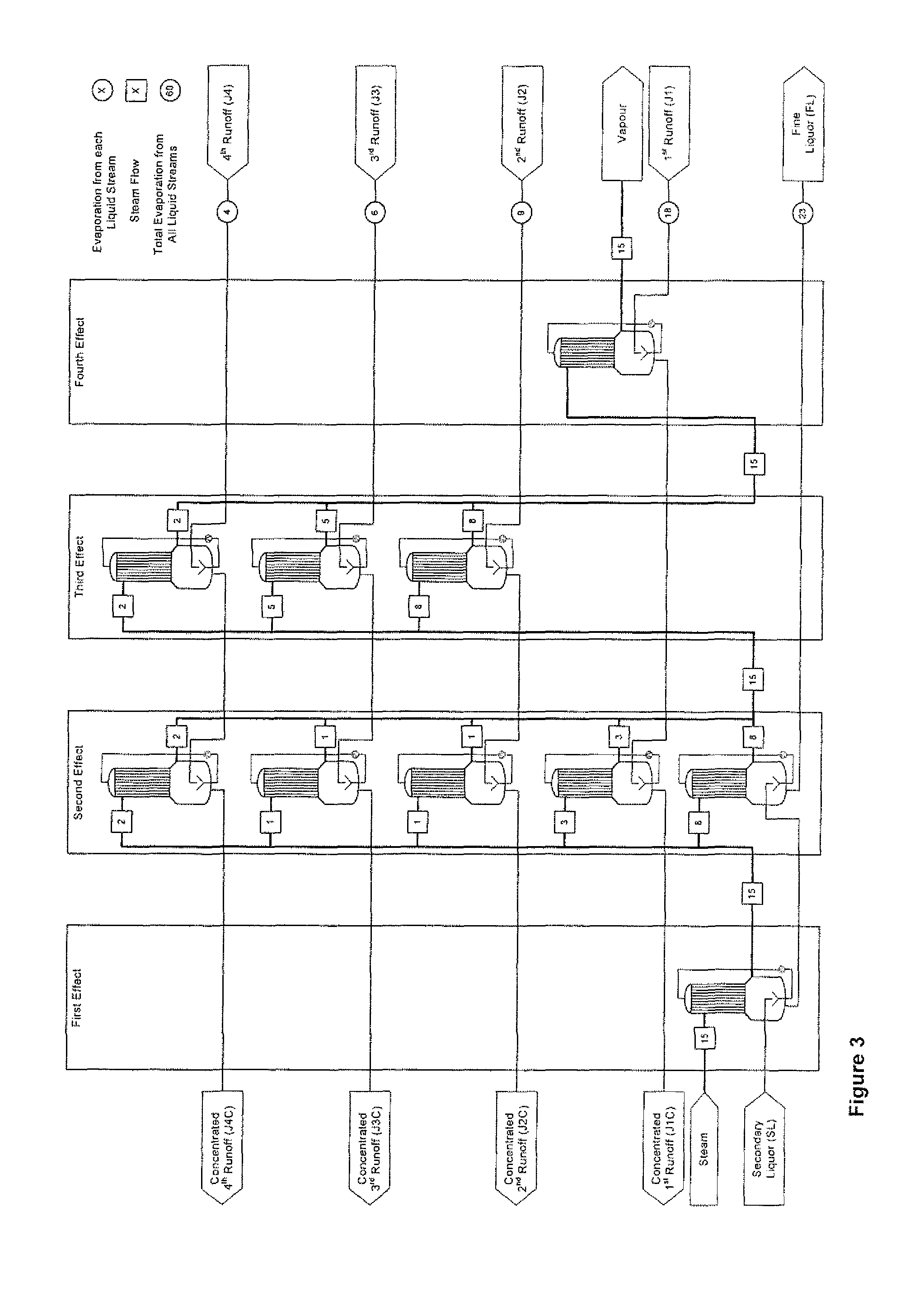

Process for Refining Impure Crystallised Sucrose

InactiveUS20150211081A1Minimize energy consumptionImprove economySugar crystal separationSugar crystallisationSucroseCentrifugation

The invention relates to a process for refining impure crystallised sucrose which process comprises the application of multiple effect falling film evaporation to concentrate without crystallisation a runoff produced on centrifugation of massecuite arising from a sucrose crystallisation process.

Owner:TONGAAT HULETT LTD

Process for the recovery of water and energy from the processing of sugar cane in sugar and ethanol production mills

ActiveUS8617315B2Reduce consumptionEconomic savingsBio-organic fraction processingOrganic compound preparationThermal energyCooling tower

A process is proposed for recovery of water in the sugar cane processing in production mills of sugar and alcohol or only alcohol (ethanol). In the process, the thermal energy available in the exhausted steam from the electric energy generation turbines is transferred to the different mixed juice processing phases, with the reuse of the exhausted steam condensates in the boilers and of the other condensates, after using thermal energy, for imbibition, in the juice extraction phase, for cooling in the process, after passing through cooling towers, for other industrial uses and for possible treatment or use in the irrigation out of the productive system in the mill.

Owner:DEDINI S A IND DE BASE

Process for producing crystalline tagatose

InactiveUS20050188912A1Polycrystalline material growthFrom normal temperature solutionsTagatoseOrganic solvent

The present invention provides a method for producing tagatose crystals from an aqueous system using no organic solvent. In this method, seed crystals of tagatose are added to a tagatose solution in which a tagatose purity of solid contents in the solution is at least 70% and a solid contents concentration in the solution is 60 to 98 mass %, and crystallization of tagatose is carried out by stirring and cooling the solution while keeping a degree of super saturation of tagatose at 1.25 or lower. It is preferred that the solution containing tagatose is a solution containing no organic solvent. It is further preferred that a part of massecuite for which the crystallization is completed is added to a mother liquor so as to produce the tagatose crystals semi-continuously or continuously. It is furthermore preferred that the tagatose crystals formed from the massecuite are separated by centrifugation or filtration and dried to obtain tagatose crystals.

Owner:NIHON SHOKUHIN KAKO CO LTD

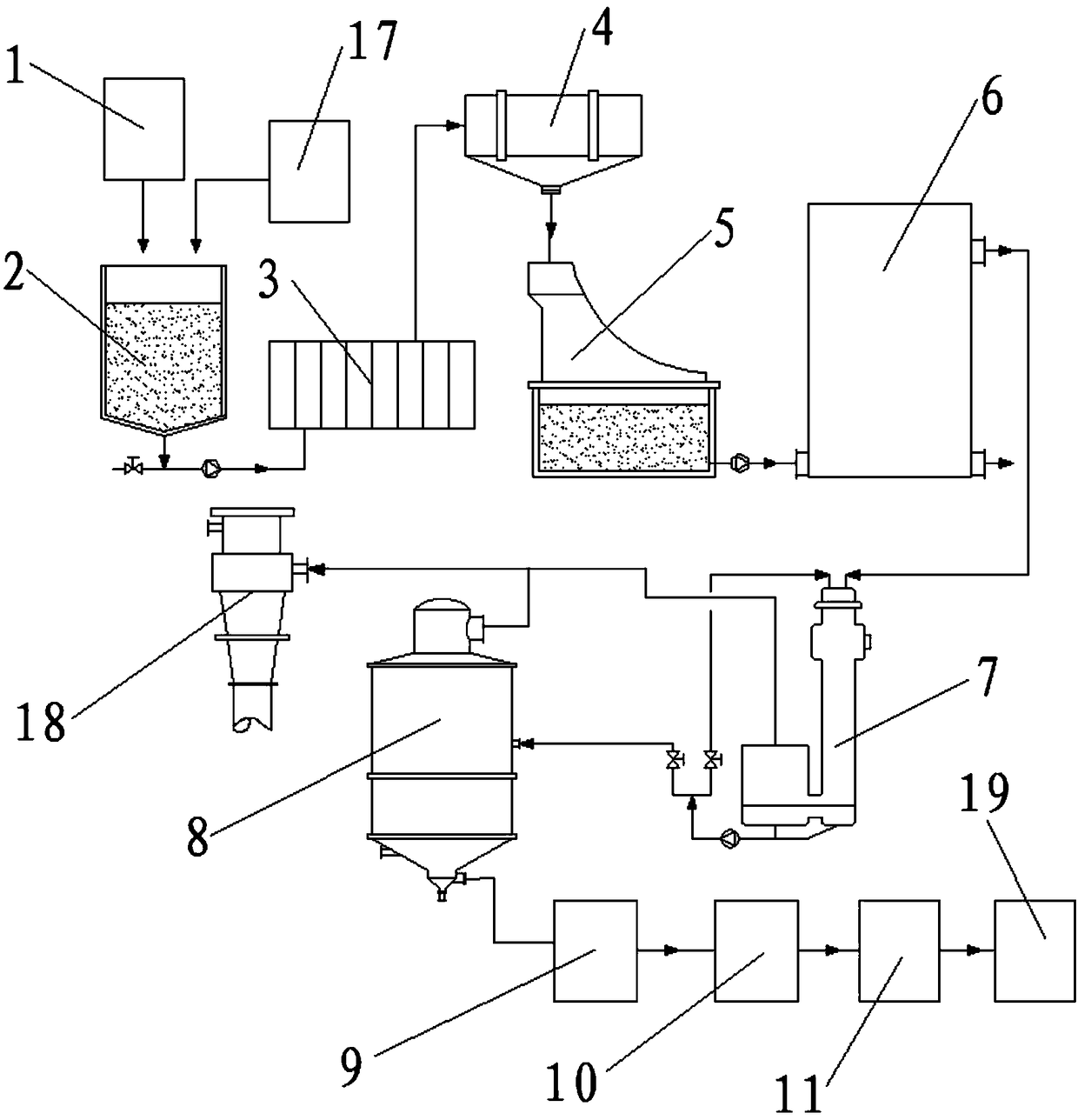

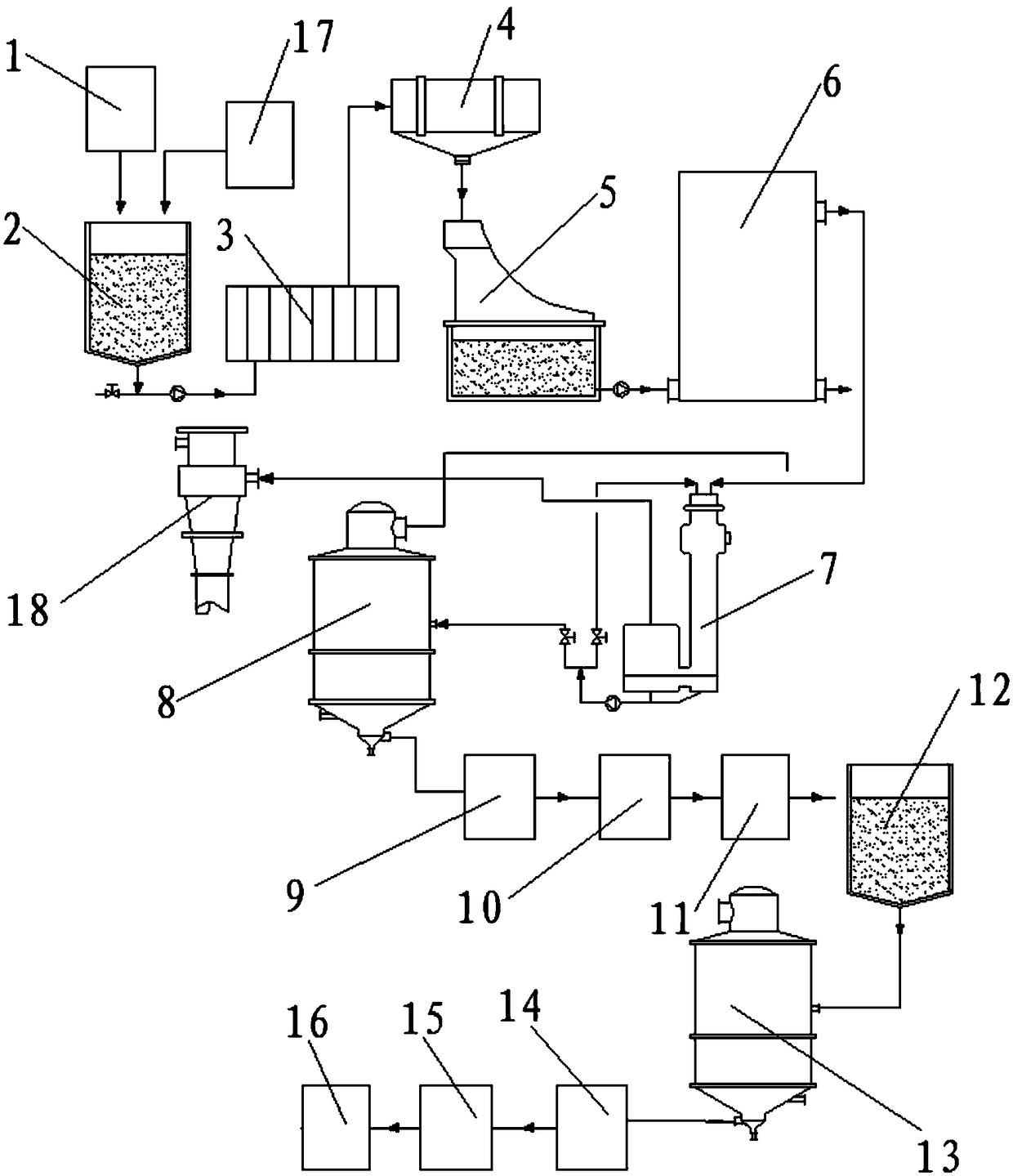

Method and device for producing granulated sugar and refined sugar by membrane method

PendingCN108251563AAddressing the hidden dangers of sugar safetyEasy to upgradeSugar dryingPurification using alkaline earth metal compoundsMembrane methodFiltration

The invention provides a method for producing granulated sugar and refined sugar by a membrane method. The method comprises the following steps: adding ash, heating, carrying out coarse filtration, carrying out ultra-filtration by utilizing an inorganic membrane with the pore diameter of 0.02 to 0.2mu m, separating molasses and drying and recrystallizing to obtain membrane-method refined sugar. Adevice for producing the granulated sugar and the refined sugar by the membrane method comprises a sugarcane mixed juice source, an ash adding stirring tank, a heat exchanger, a linear sieve with thesize of 40 to 60 meshes, a bent sieve with the size of 80 to 100 meshes, inorganic membrane ultra-filtration equipment with the pore diameter of 0.02 to 0.2mu m, evaporation and concentration equipment, a first sugar boiling tank, a first crystallization-assisting box, first centrifuging and molasses separating equipment and first frying equipment, which are connected in sequence. In a granulatedsugar production process, less lime cream is used and any chemical auxiliary agent is not added, so that the problem of hidden dangers of sugar safety is solved.

Owner:GUANGXI UNIV

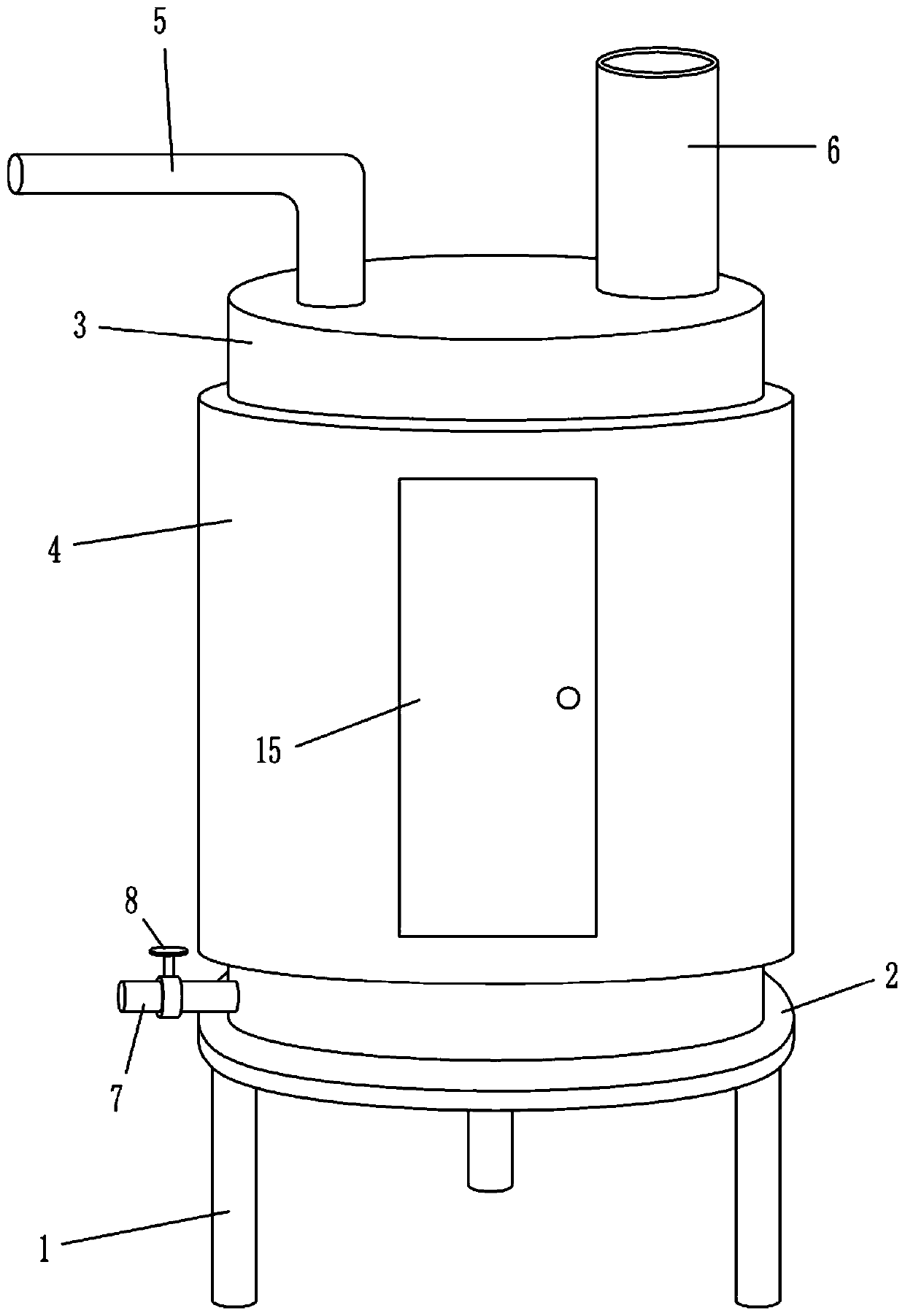

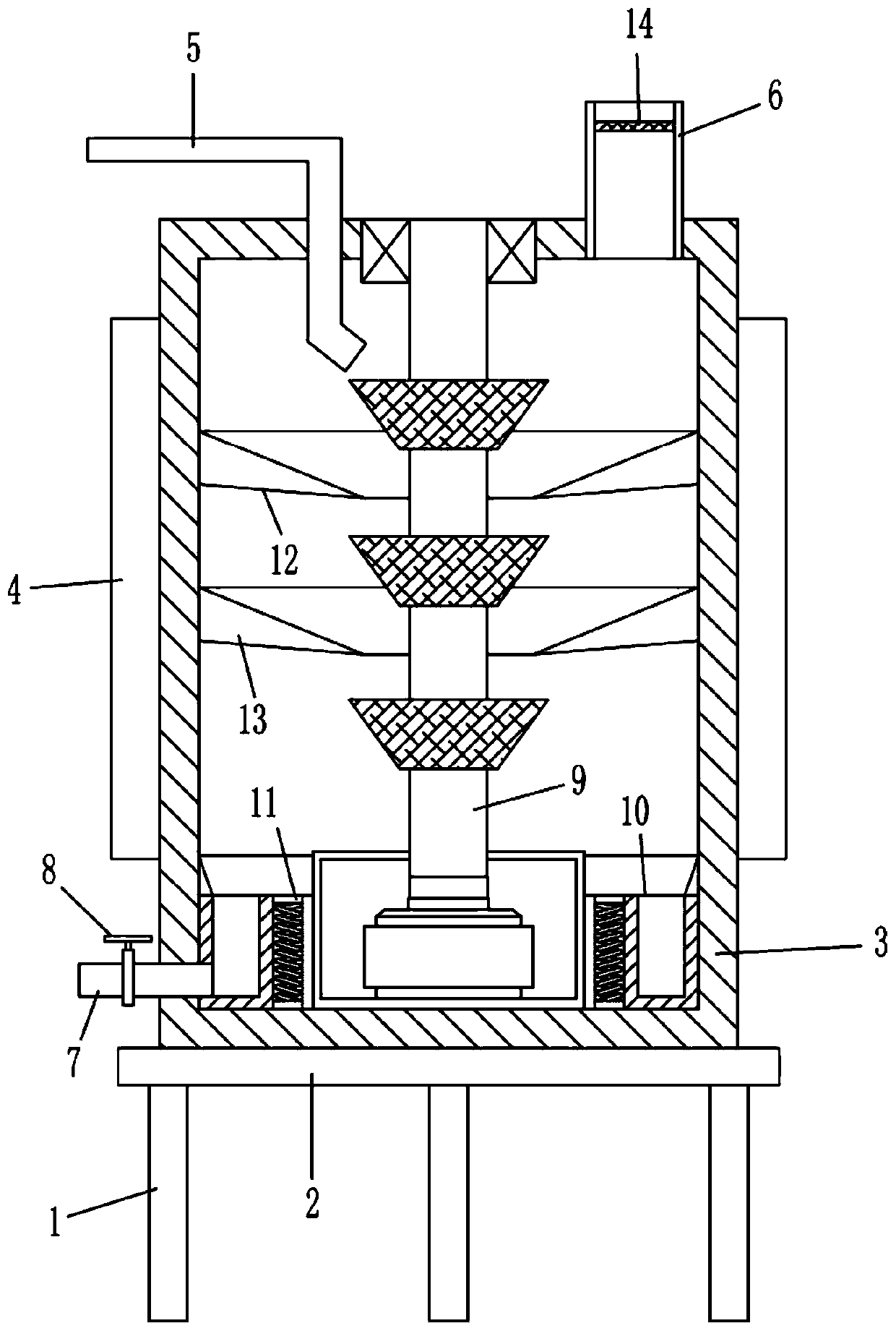

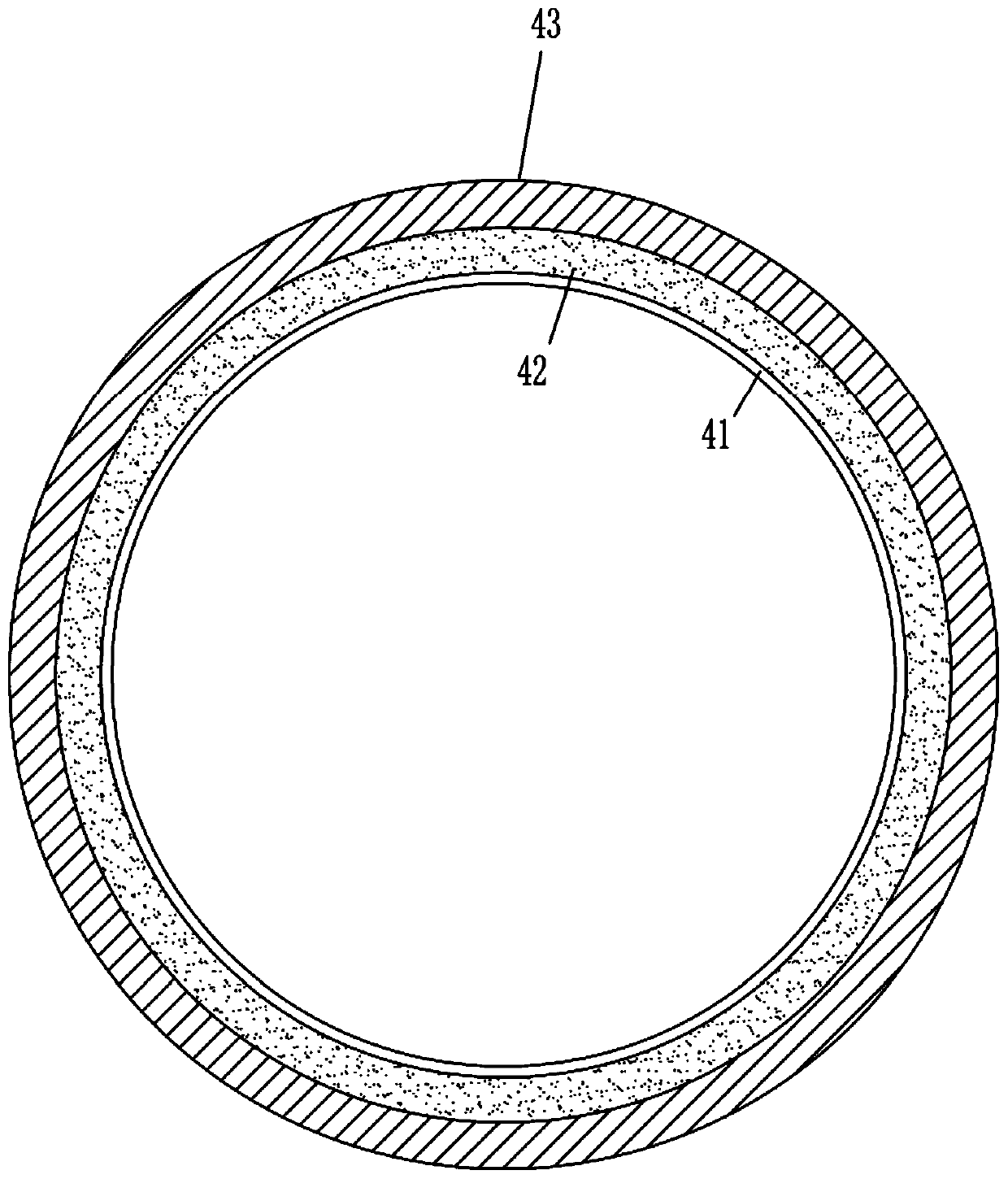

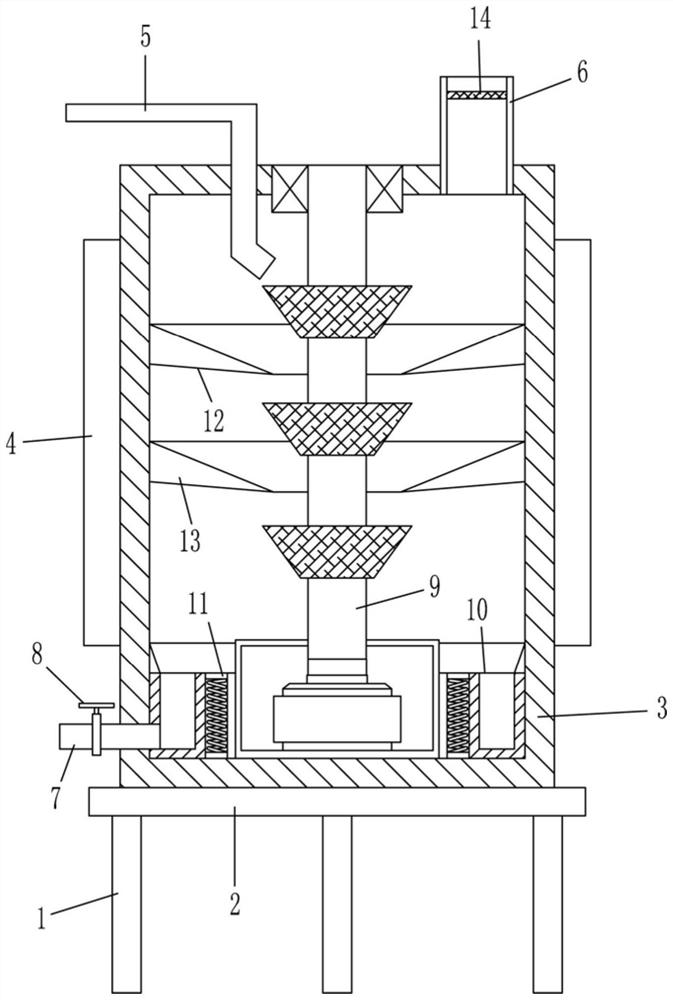

Efficient massecuite separator for sugar making

ActiveCN111214888APrevent solidificationAvoid cloggingSugar crystal separationSugar crystallisationSucroseProcess engineering

The invention relates to the field of granulated sugar production, in particular to an efficient massecuite separator for sugar making. The technical problem to be solved by the invention is to provide an efficient massecuite separator for sugar making, which can for fully separate sucrose crystals and molasses through multi-layer and multi-stage separation and screening, meanwhile, can collect the molasses in a unified mode and avoid solidification of the molasses in the collecting process, and can provide a noise reduction function and an air pressure stabilizing function to avoid the situation that noise is too large and air pressure is unstable in the equipment running process. The efficient massecuite separator for sugar making comprises supporting frames, a bearing base, a separationcylinder, a noise reduction component, a feeding pipe, an anti-solidification component, a first liquid dropping hopper and a filter screen. The support frames are uniformly and fixedly connected tothe bottom surface of the bearing base. The effects that sucrose crystals and molasses are fully separated out through multi-layer and multi-stage separation and screening, meanwhile, the molasses iscollected in a unified mode, solidification of the molasses during collection is avoided, and the noise reduction function and the air pressure stabilizing function are provided to avoid excessive noise and unstable air pressure during equipment operation are achieved.

Owner:兴平市新奇园食品有限公司

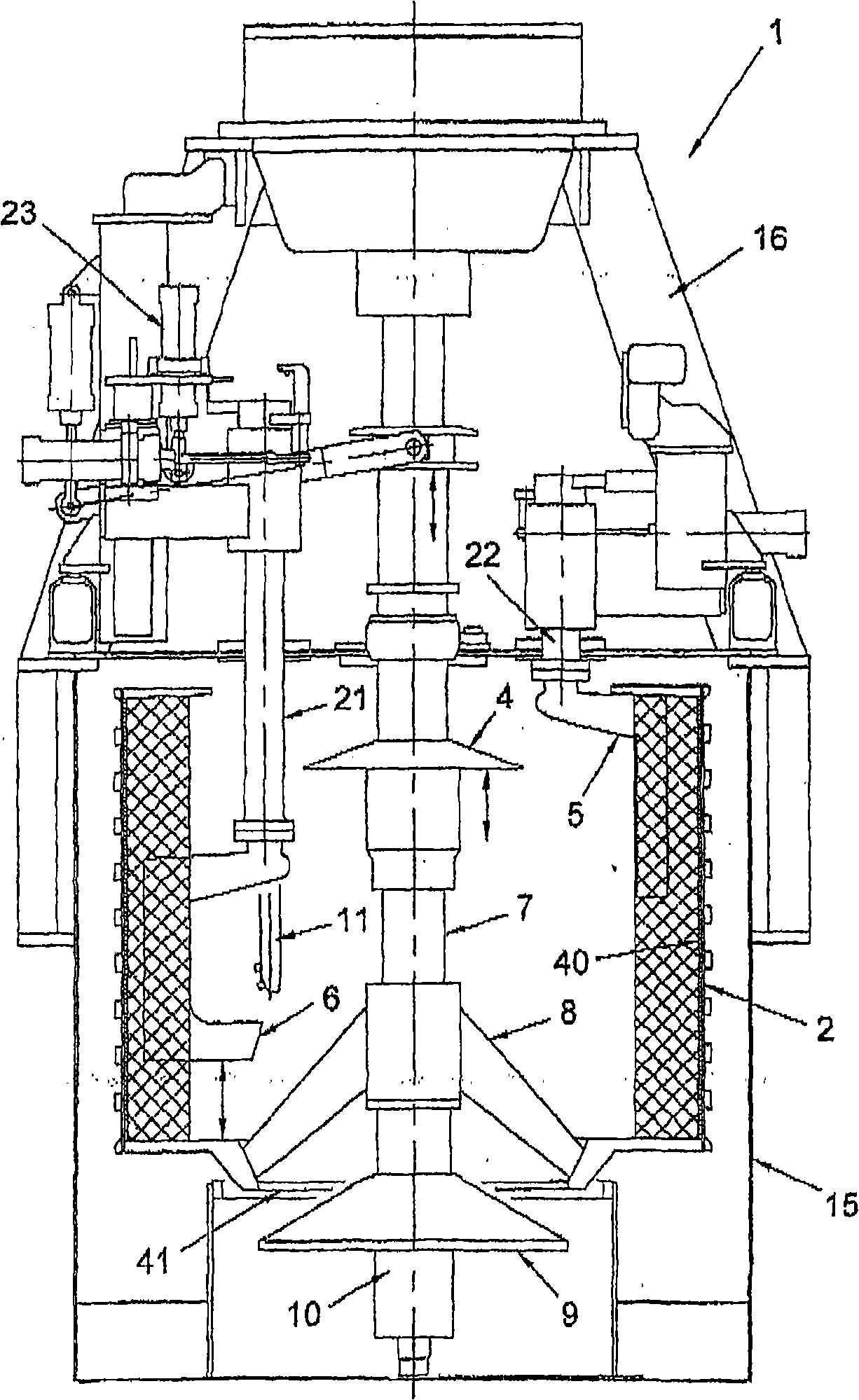

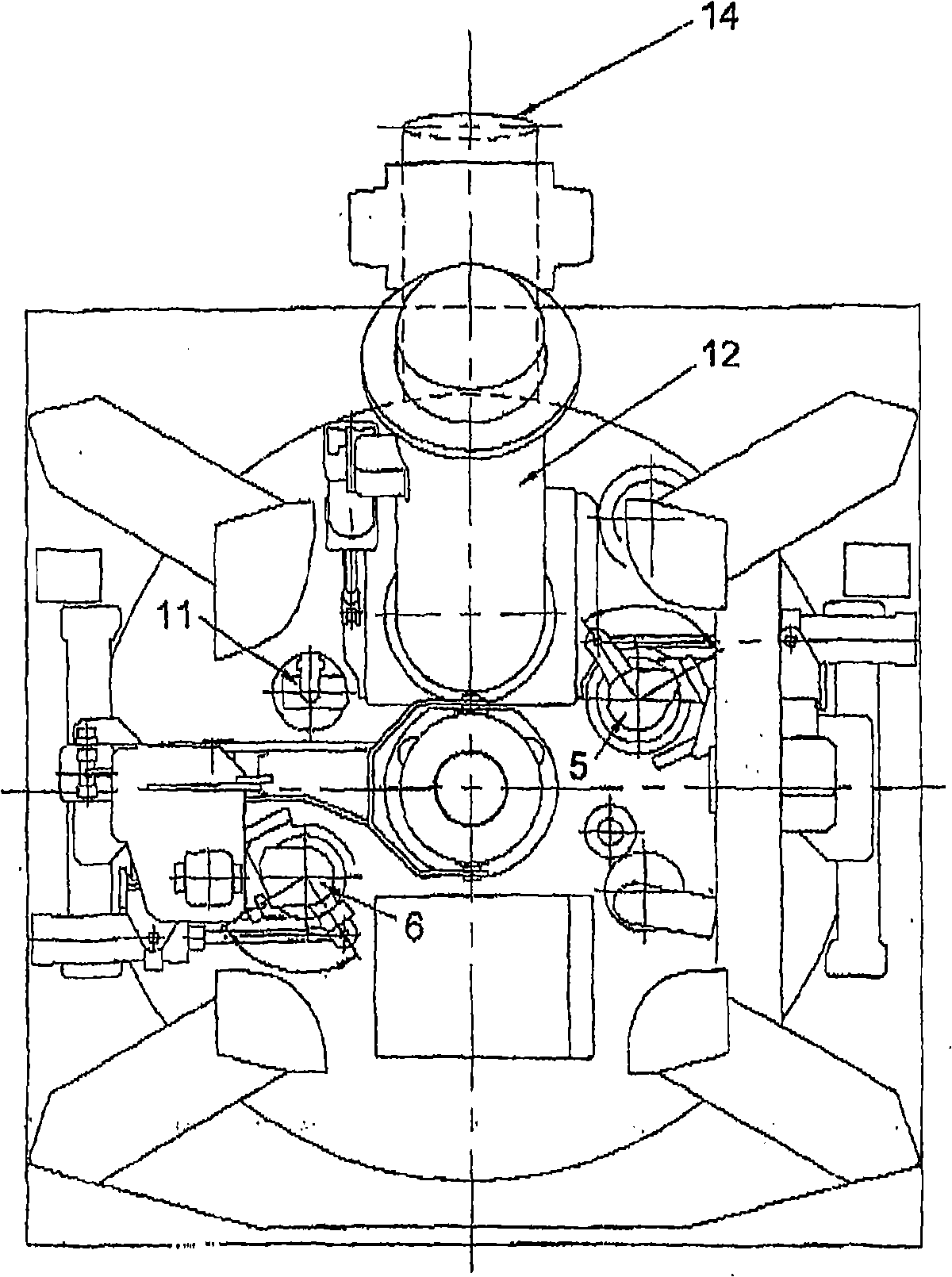

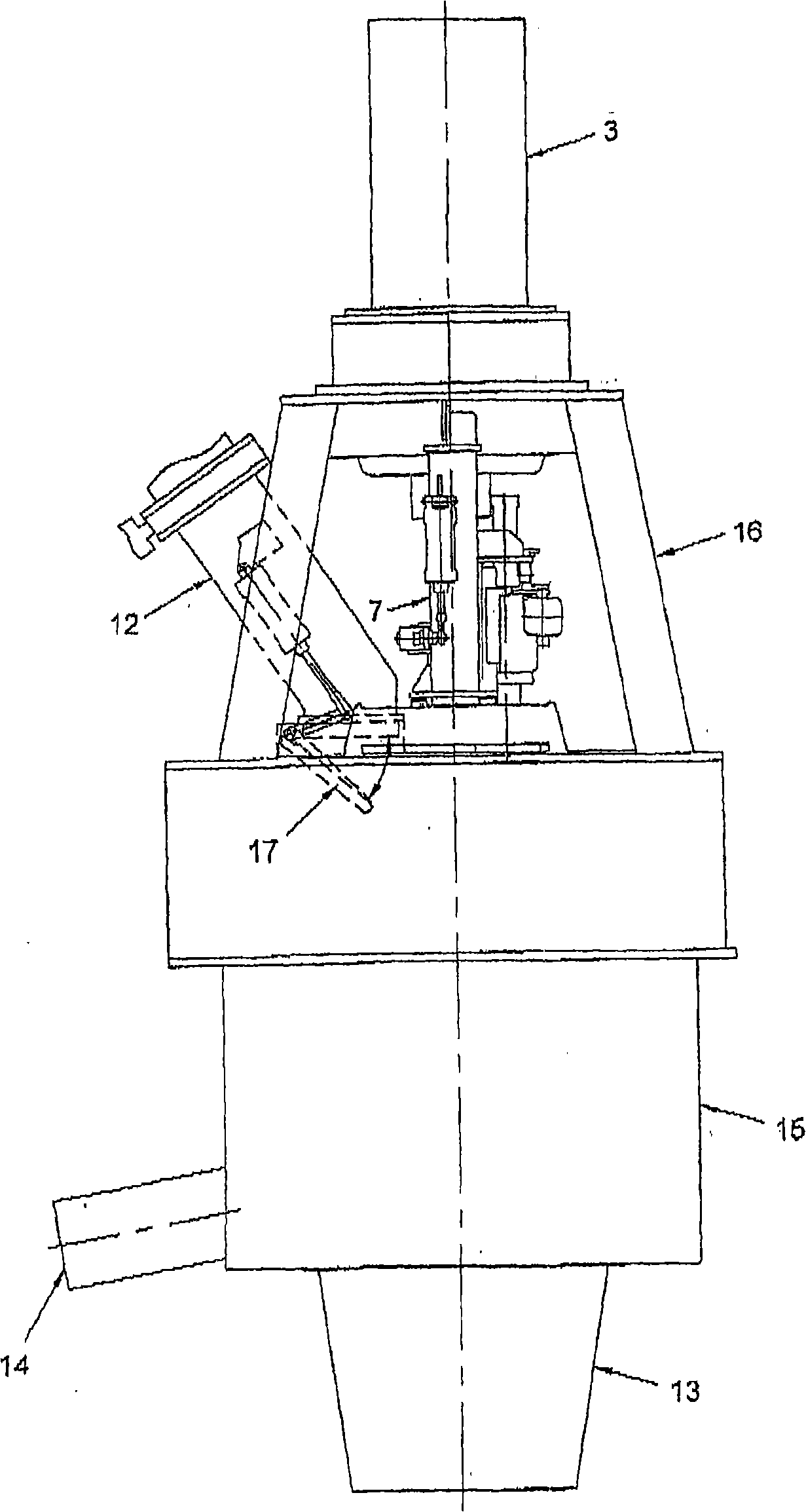

Discontinuous centrifugal machine which is intended, in particular, to separate molasses from sugar crystals in a masse-cuite

InactiveCN101277767AImprove distributionImprove productivitySugar crystal separationCentrifugesEngineeringSugar

The invention relates to a discontinuous centrifugal machine (1) which is intended, in particular, to separate molasses from sugar crystals in a masse-cuite. The invention comprises at least one perforated centrifugal drum (2) which is intended to receive products to be treated and which is equipped with a permeable wall (4), motor means (3) for rotating the drum (2) around a vertical axis of rotation and discharge means including means for scraping the permeable wall (40) inside the drum. According to the invention, the wall-scraping means comprise an assembly consisting of at least two spades (5, 6) which are distributed inside the drum (2) and which are articulated such as to rotate at least around a vertical axis.

Owner:FIVES CAIL BABCOCK SA

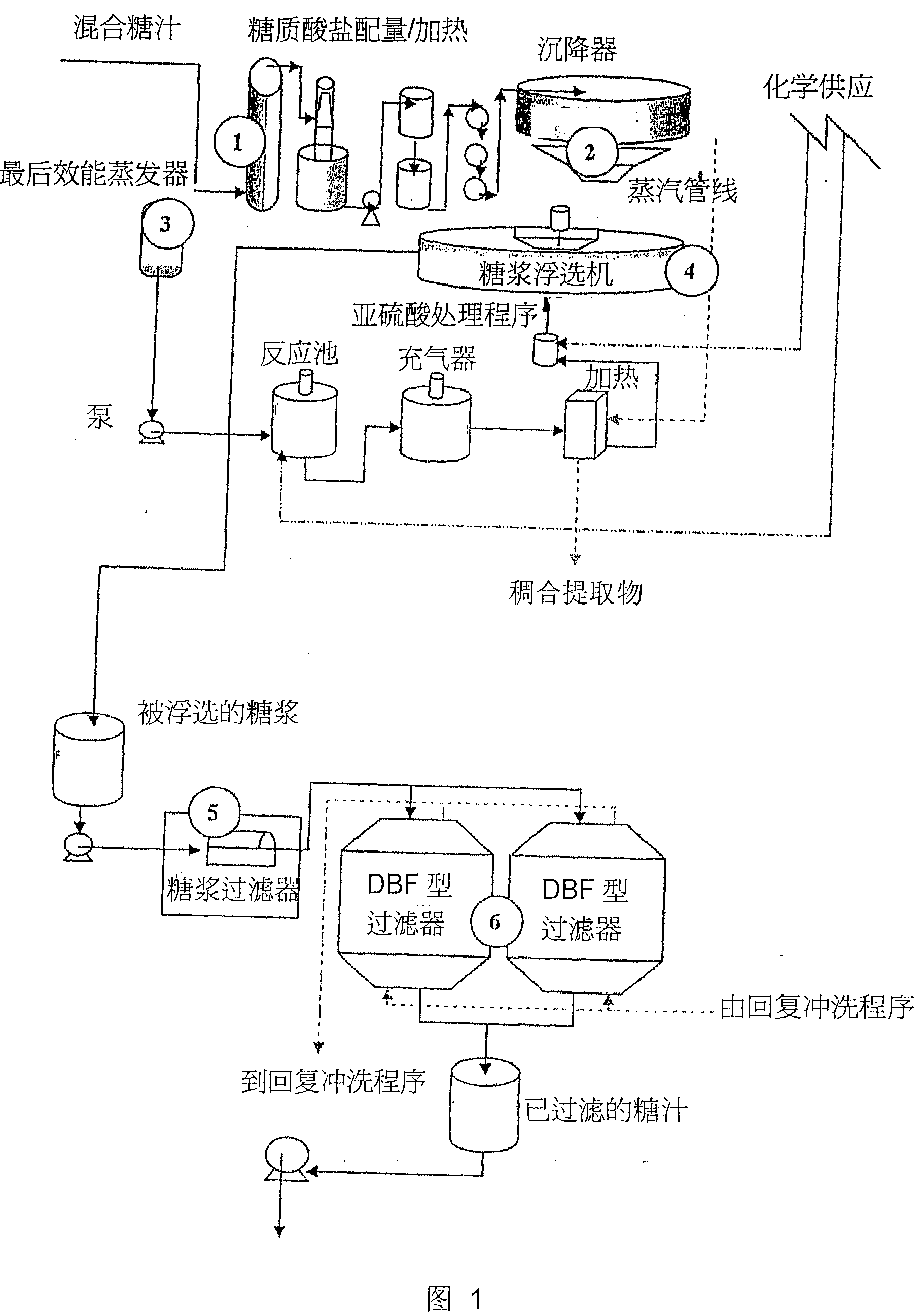

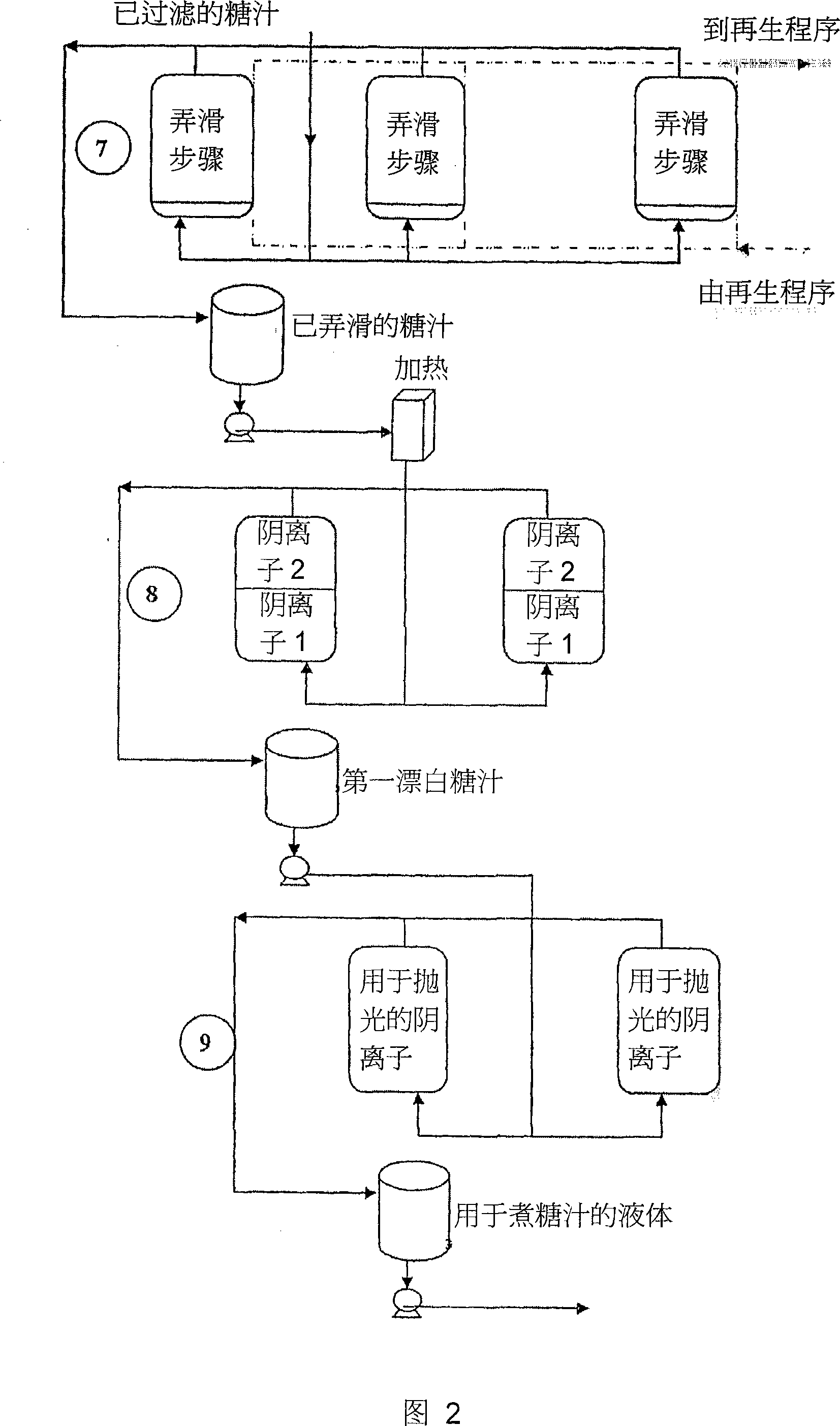

Method for producing refining sugar

InactiveCN101068938APurification by oxidation/reductionPurification using adsorption agentsComputer moduleEngineering

A lenticular optical system is described in which a composite image is viewable through a lens sheet from a first angle and an object or image placed at a preselected distance beneath the composite image is viewable from a second angle. Optical designs and alignment processes are disclosed which make possible the economical production of thin materials which facilitate the manufacturing and utilization of the optical system in packaging and the like.

Owner:DENDINI INDAL BASE

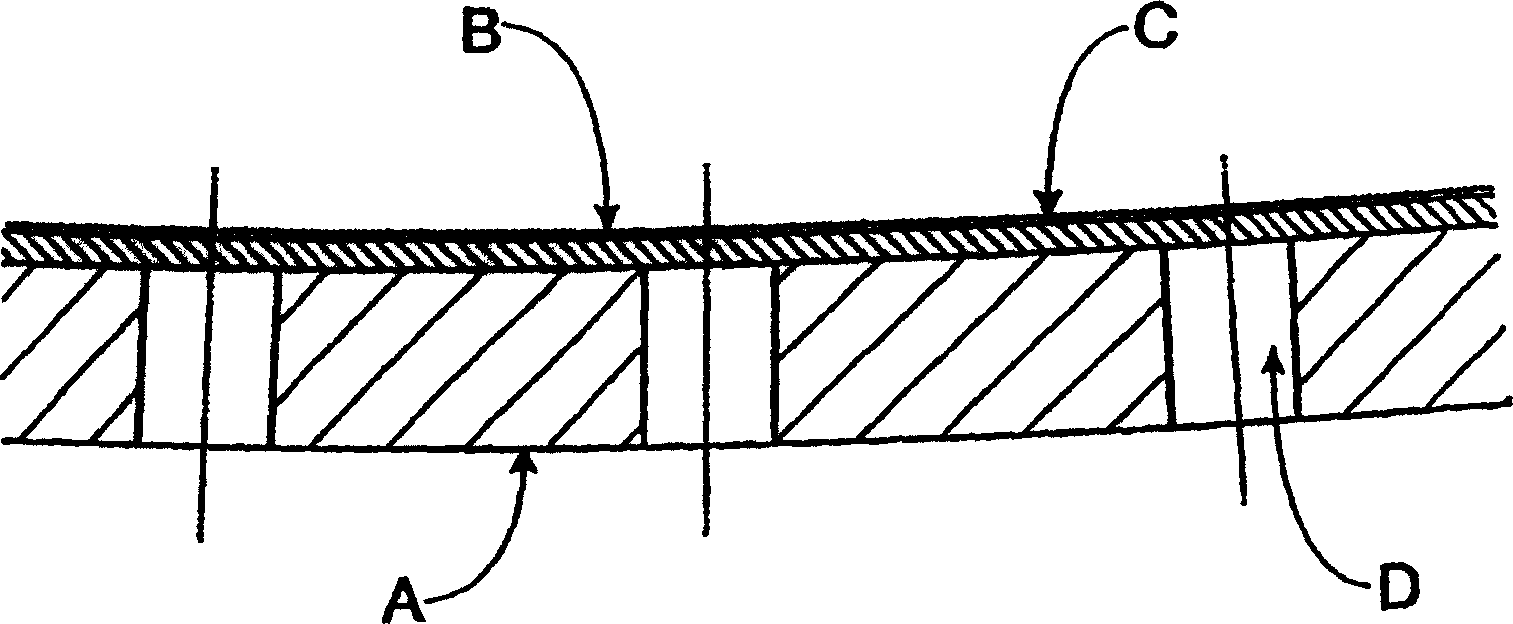

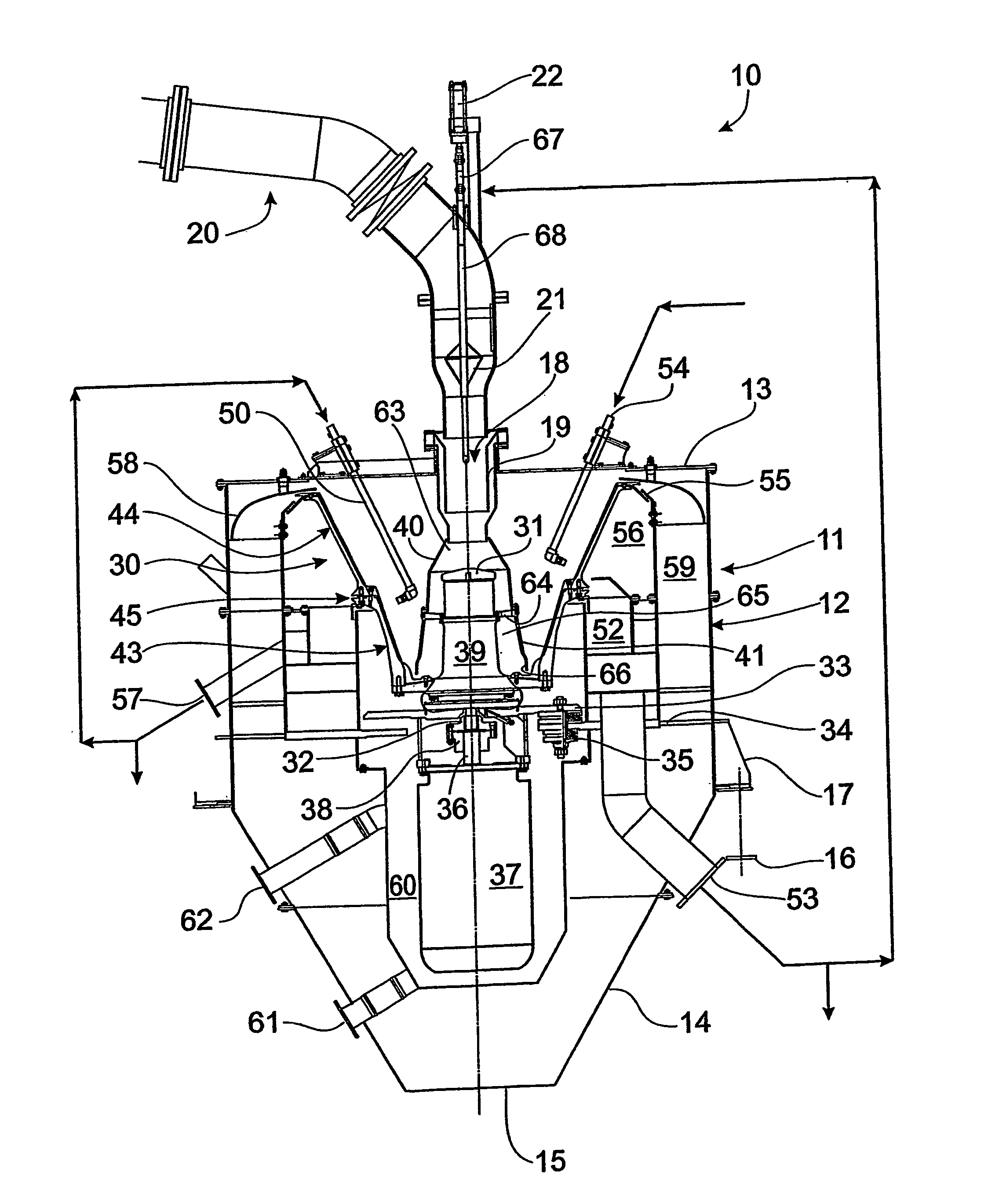

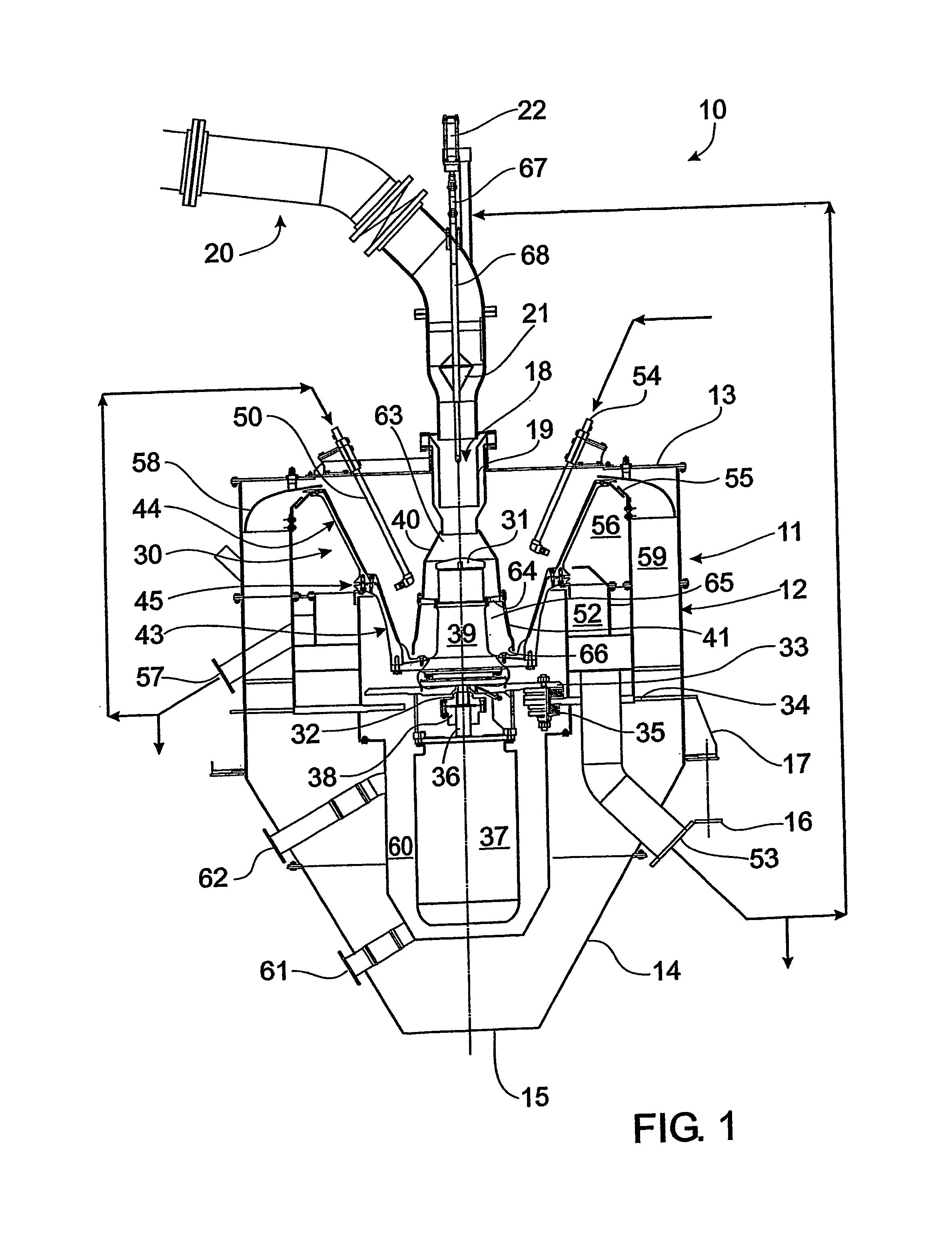

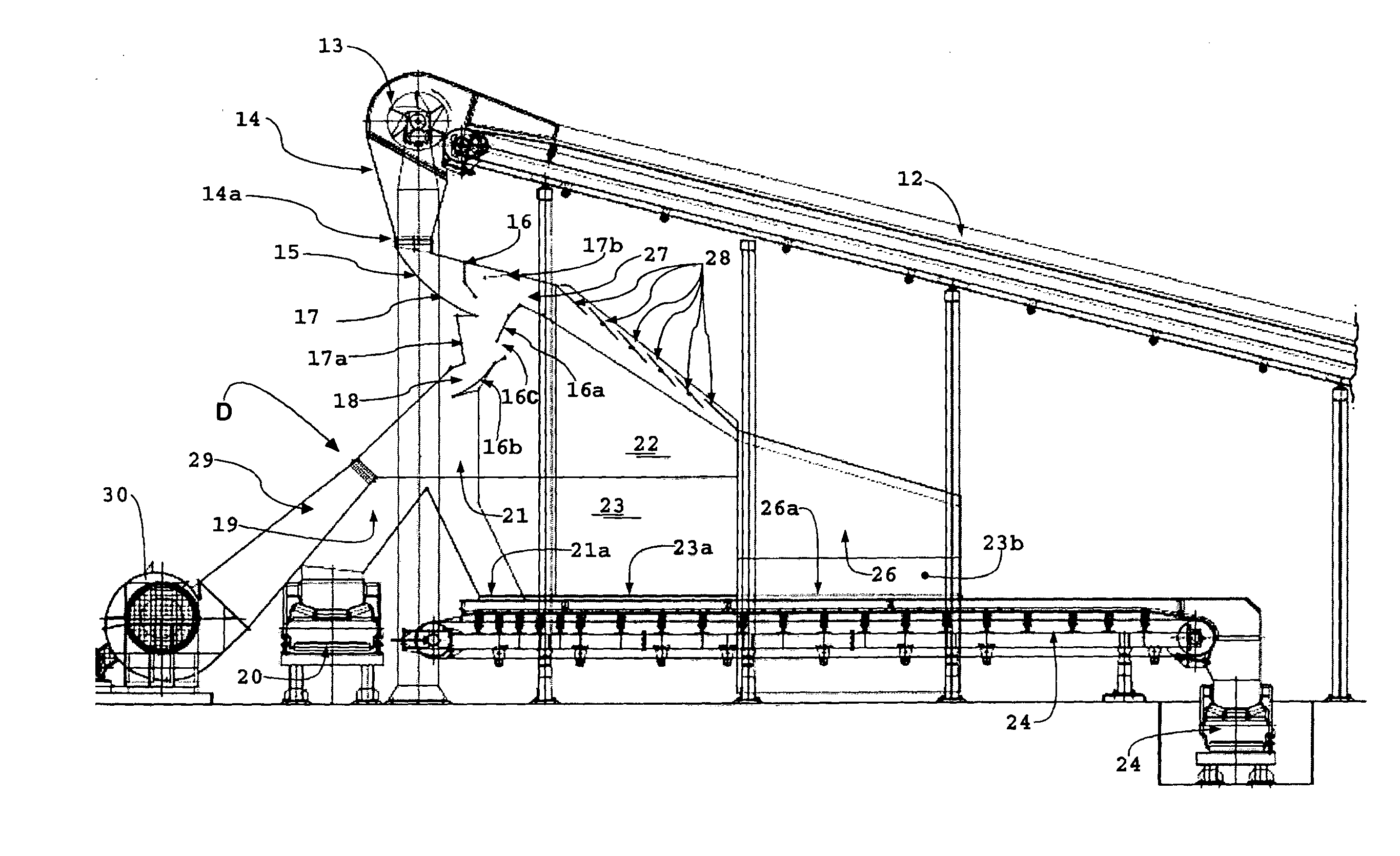

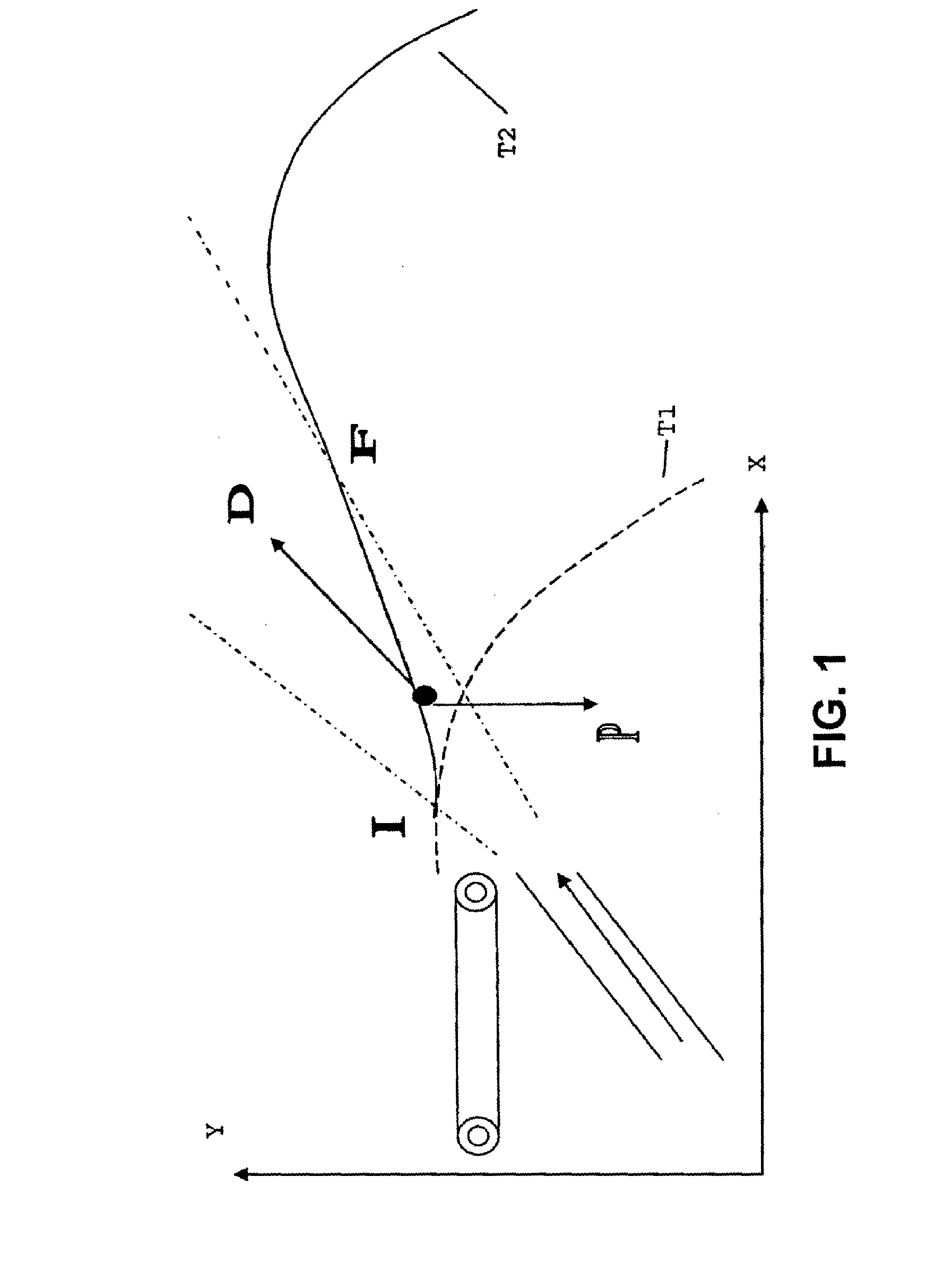

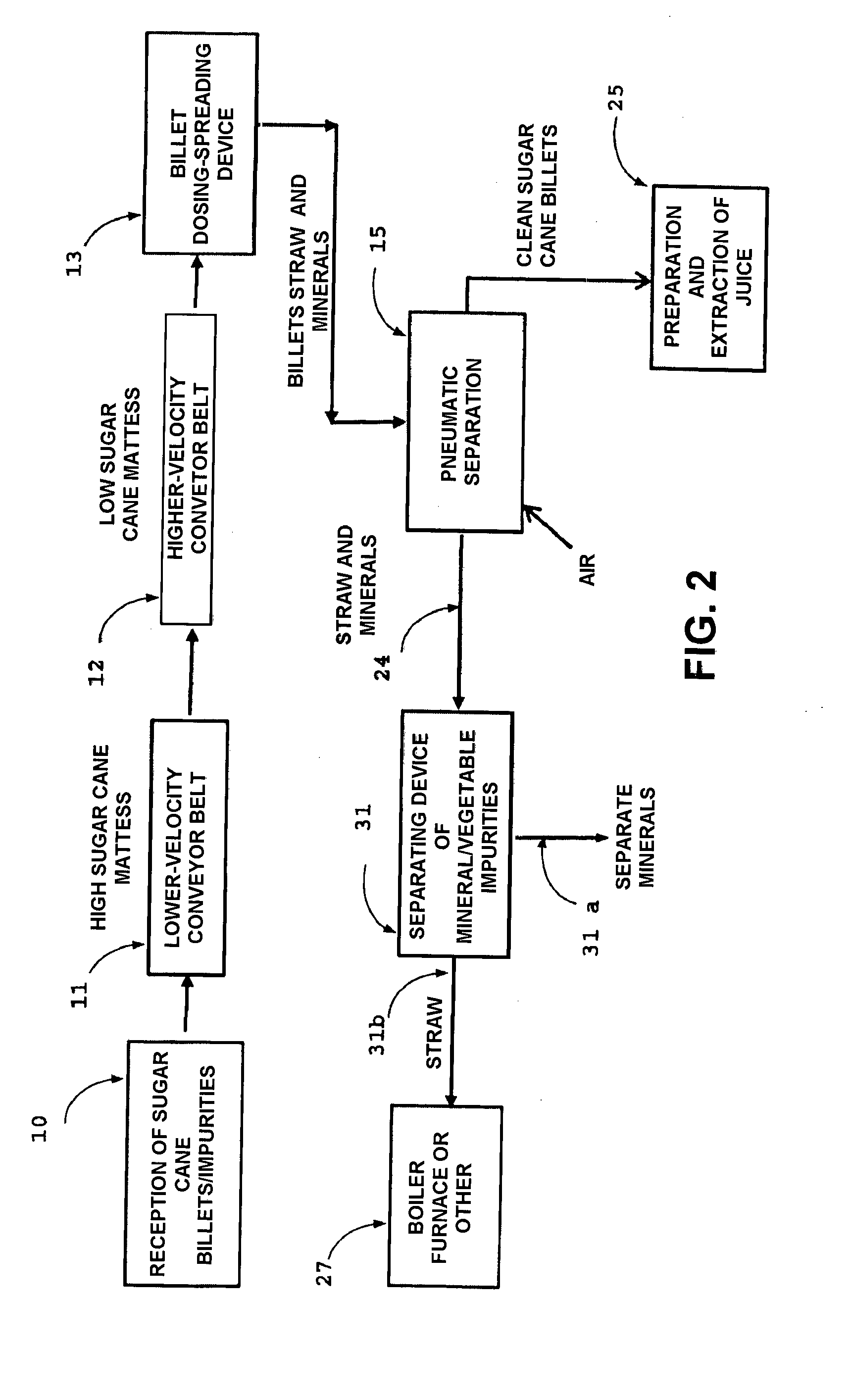

Process and equipment for the dry cleaning of sugarcane harvested in billets and containing straw and other impurities

InactiveUS20140165997A1Easy to separateEasy to spreadJuice extractionSugar productsConveyor beltImpurity

The process comprises the steps of: distributing a sugarcane load, with mineral and vegetable impurities, on a conveyor belt (12), forming thereon a sugarcane and impurity mattress; submitting the mattress to a dosing and spreading operation, forming a thin and dispersed curtain in gravitational displacement in a first chamber portion (15); submitting the sugarcane and impurity curtain to a transversal and ascending forced air flow, displacing the impurities outwards from the curtain to the interior of a first collecting compartment (21) and of a second and a third chamber portion (22 and 27); deflecting the fraction of forced air flow, received in the third chamber portion (27), obtusely in a plurality of adjustable “Persian blinds” (28), decompressing the air flow; discharging the clean sugarcane load and the impurities through a clean sugarcane lower outlet (19) and through impurity outlets (21a, 23a and 26a).

Owner:DEDINI S A IND DE BASE

Processing biomass

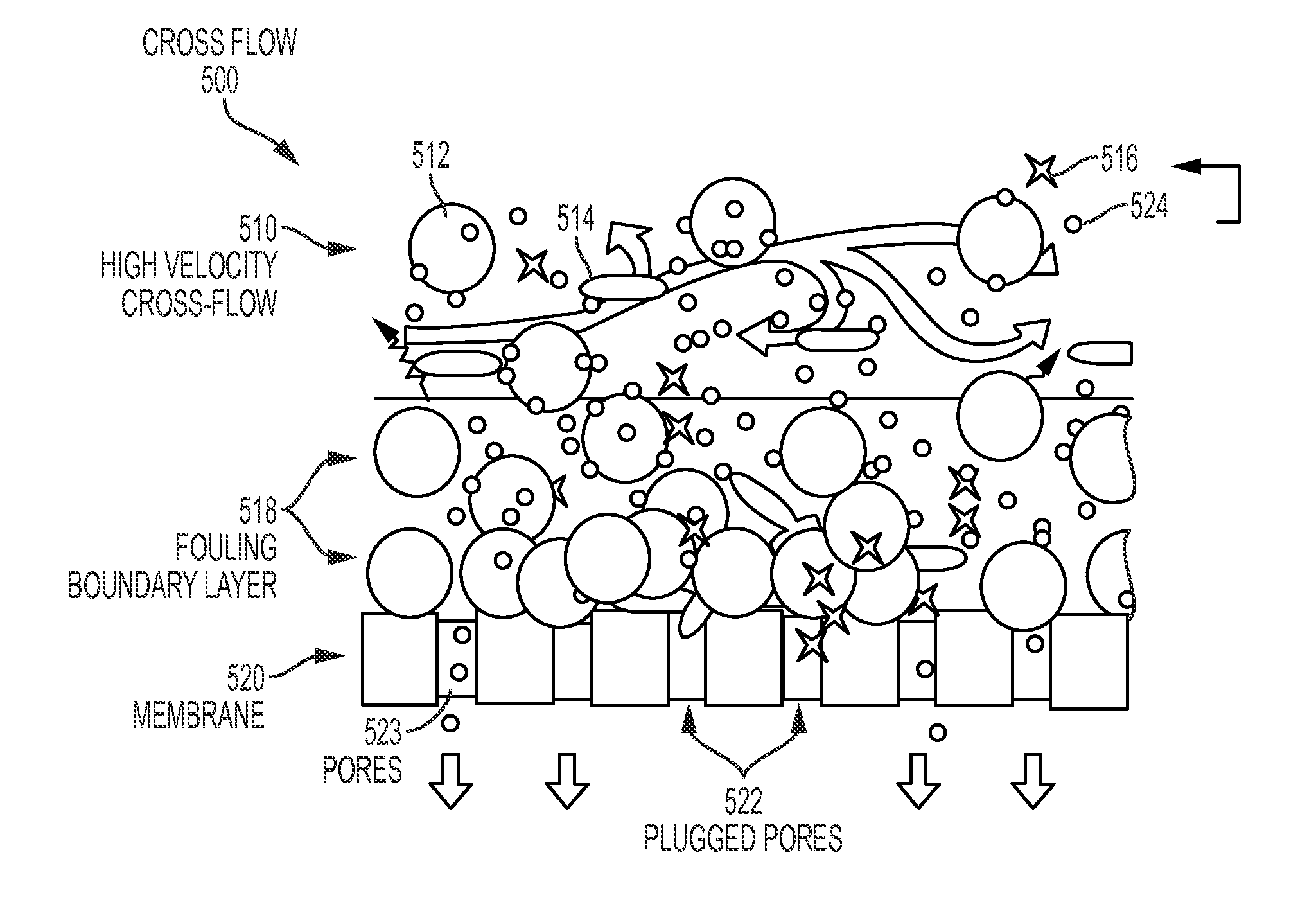

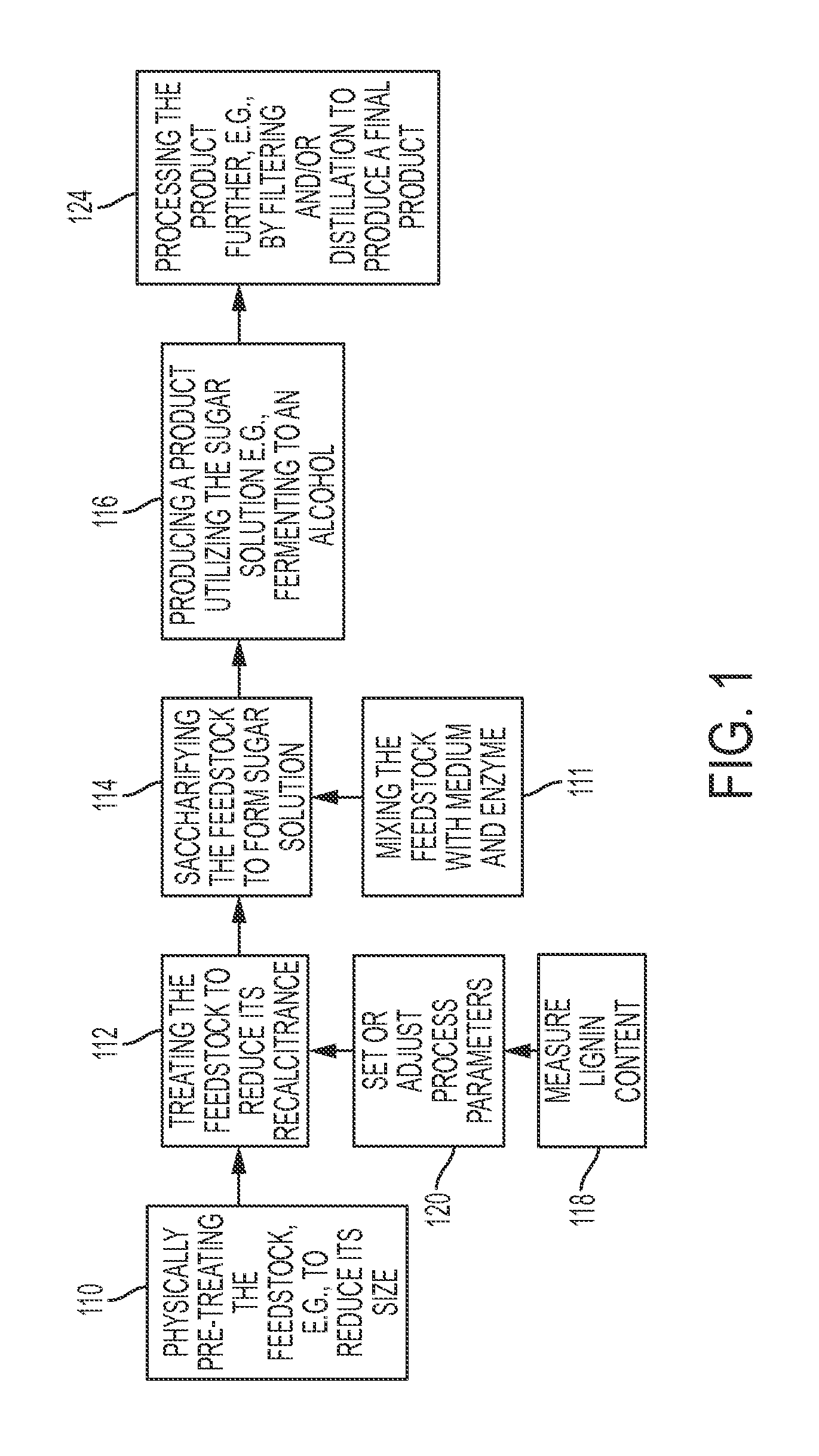

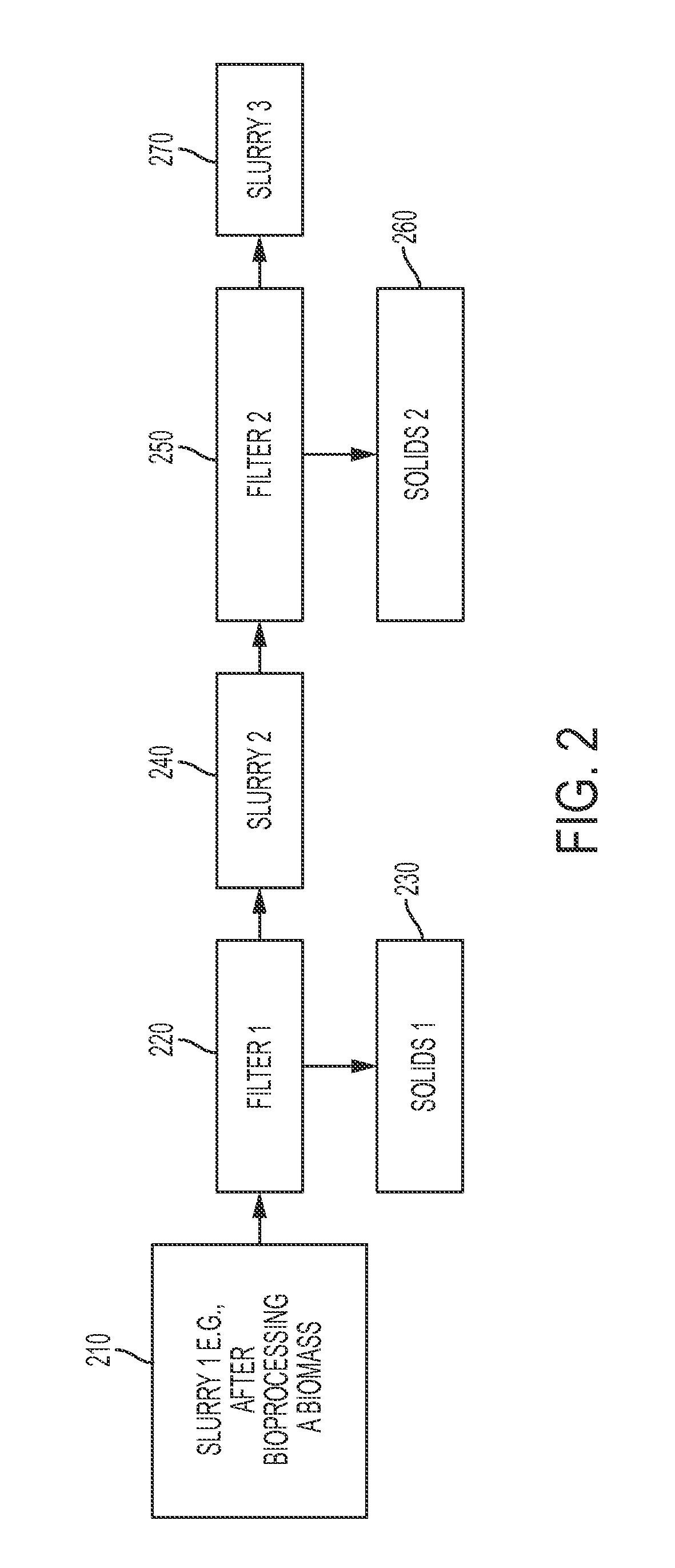

InactiveUS20160201151A1Not easily scalable to large volumeIncrease loadMembranesSugar crystal separationFiltrationSlurry

Biomass feedstocks (e.g., plant biomass, animal biomass, and municipal waste biomass) are processed to produce useful products, such as fuels. For example, systems are described that can be useful for separating solids from liquids of bioprocessed biomass material slurries. For example, filtration systems are described that include multiple centrifuges, e.g., multiple tandem centrifuges.

Owner:XYLECO INC

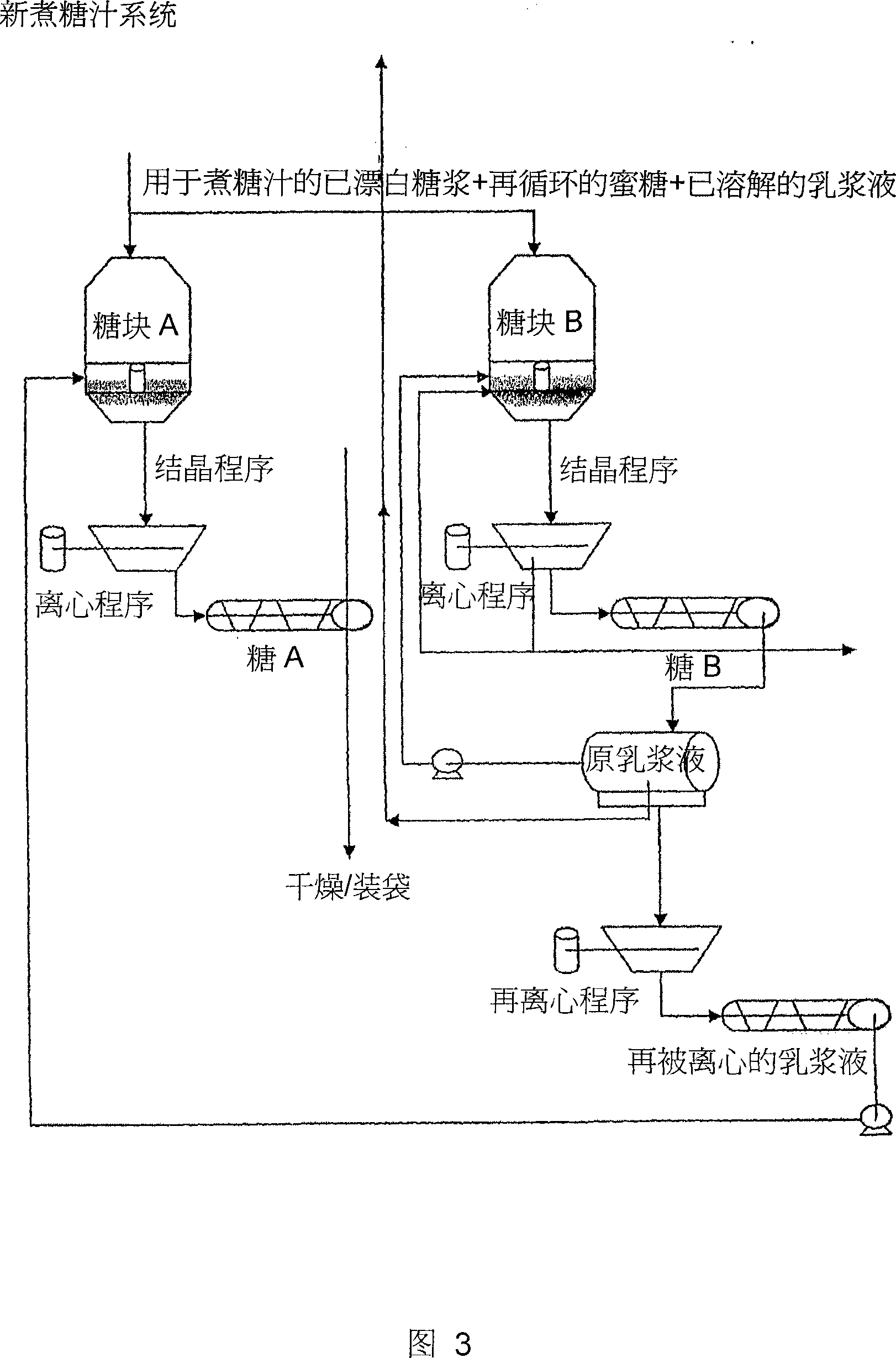

Sugar paste redissolution technology

InactiveCN105132591AInhibition of dissolutionReduce cooking timeSugar crystal separationSugar juice boiling/evaporationSugar refiningDissolution

The invention discloses a sugar paste redissolution technology and belongs to the field of a sugar refining industry. The sugar paste redissolution technology comprises 1, sugar boiling, 2, sieving, 3, gas transport and 4, redissolution. The sugar paste redissolution technology can dilute superfluous B sugar paste and then feed the superfluous B sugar paste into a syrup case by a gas transport pump for A sugar boiling under this premise of enough A sugar seed amount, prevents superfluous sugar paste dissolution in water in a sugar boiling section and saves boiling time, water and vapor.

Owner:广西糖业集团防城精制糖有限公司

Process for producing crystalline tagatose

InactiveUS7101432B2Polycrystalline material growthFrom normal temperature solutionsTagatoseOrganic solvent

The present invention provides a method for producing tagatose crystals from an aqueous system using no organic solvent. In this method, seed crystals of tagatose are added to a tagatose solution in which a tagatose purity of solid contents in the solution is at least 70% and a solid contents concentration in the solution is 60 to 98 mass %, and crystallization of tagatose is carried out by stirring and cooling the solution while keeping a degree of super saturation of tagatose at 1.25 or lower. It is preferred that the solution containing tagatose is a solution containing no organic solvent. It is further preferred that a part of massecuite for which the crystallization is completed is added to a mother liquor so as to produce the tagatose crystals semi-continuously or continuously. It is furthermore preferred that the tagatose crystals formed from the massecuite are separated by centrifugation or filtration and dried to obtain tagatose crystals.

Owner:NIHON SHOKUHIN KAKO CO LTD

A high-efficiency massecuite separator for sugar production

ActiveCN111214888BPrevent solidificationAvoid cloggingSugar crystal separationSugar crystallisationSucroseProcess engineering

The invention relates to the field of sugar production, in particular to a high-efficiency massecuite separator for sugar production. The technical problem to be solved by the present invention is to provide a method that can fully analyze sucrose crystals and waste honey through multi-layer and multi-stage separation and screening, and at the same time collect waste honey uniformly and avoid solidification of waste honey during collection, and provide noise reduction function and stable air pressure function High-efficiency massecuite separator for sugar production to prevent excessive noise and unstable air pressure during equipment operation. A high-efficiency massecuite separator for sugar production, including a support frame, a load-bearing base, a separation cylinder, a noise reduction component, a feeding pipe, an anti-solidification component, a first drip hopper, and a filter screen; the support frame is evenly fixed on the load-bearing seat bottom etc. The invention achieves the full analysis of sucrose crystals and waste honey through multi-layer and multi-stage separation and screening, and at the same time uniformly collects waste honey and avoids solidification of waste honey during collection, and provides noise reduction function and stable air pressure function to prevent excessive noise during equipment operation And the effect of air pressure instability.

Owner:兴平市新奇园食品有限公司

Process for sugar production

ActiveUS11339449B2Narrow varianceWide possible variancesSugar crystal separationMaterial analysis by optical meansControl systemProcess engineering

The application relates to methods and systems for producing a sugar product. The method includes: receiving a first input in a control system representative of a pre-treatment sugar composition characteristic; receiving a second input in the control system representative of a post-treatment sugar product target specification; using the control system to determine at least one operating parameter for a centrifuge and operating the centrifuge in accordance with the at least one determined operating parameter, wherein the at least one determined operating parameter is determined from at least: the first input, the second input, and a correlation relating at least the first input and the second input to the at least one operating parameter; and treating the pre-treatment sugar composition in the centrifuge to produce a post-treatment sugar product with a characteristic that is at or nearer to the target specification than the characteristic of the pre-treatment sugar composition.

Owner:NUTRITION SCI DESIGN PTE LTD

Recovery technology of sweet pickle syrup

InactiveCN102453772AIncrease profitEasy to recycleSugar crystal separationMultistage water/sewage treatmentFiltrationHydrolysis

The invention relates to recovery technology of sweet pickle syrup, and the invention is realized through the following process: 1) firstly filtering syrup of sweet pickle by a filter, removing residues; 2) concentrating the filtrate till saturated syrup is obtained; 3) dumping the saturated syrup in a crystal separator, performing centrifugation and crystallization; 4) performing filtration, hydrolysis, decoloration, smell removal, and sterilization of the centrifuged sugar lipid to obtain sugar-containing amino acids. The recovery way of the invention is simple and practical; the recovered sugar crystals can be used as raw materials for continued using; the sugar-containing amino acids can also be added into flavoring agents for reutilization; thus the utilization rate of syrup in sweet pickles is increased to a great extent; resources are saved; and pollution is reduced.

Owner:王春晖

Continuous process for the preparation of crystalline lactulose

Owner:FRESENIUS KABI AUSTRIA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com