Efficient massecuite separator for sugar making

A separator and massecuite technology, applied in the direction of sugar crystal separation, filtration separation, separation method, etc., can solve problems such as difficulty in outflow collection, pipeline blockage, and reduced environmental comfort, so as to block sound transmission, prevent excessive noise, Noise canceling function Effect of air pressure function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

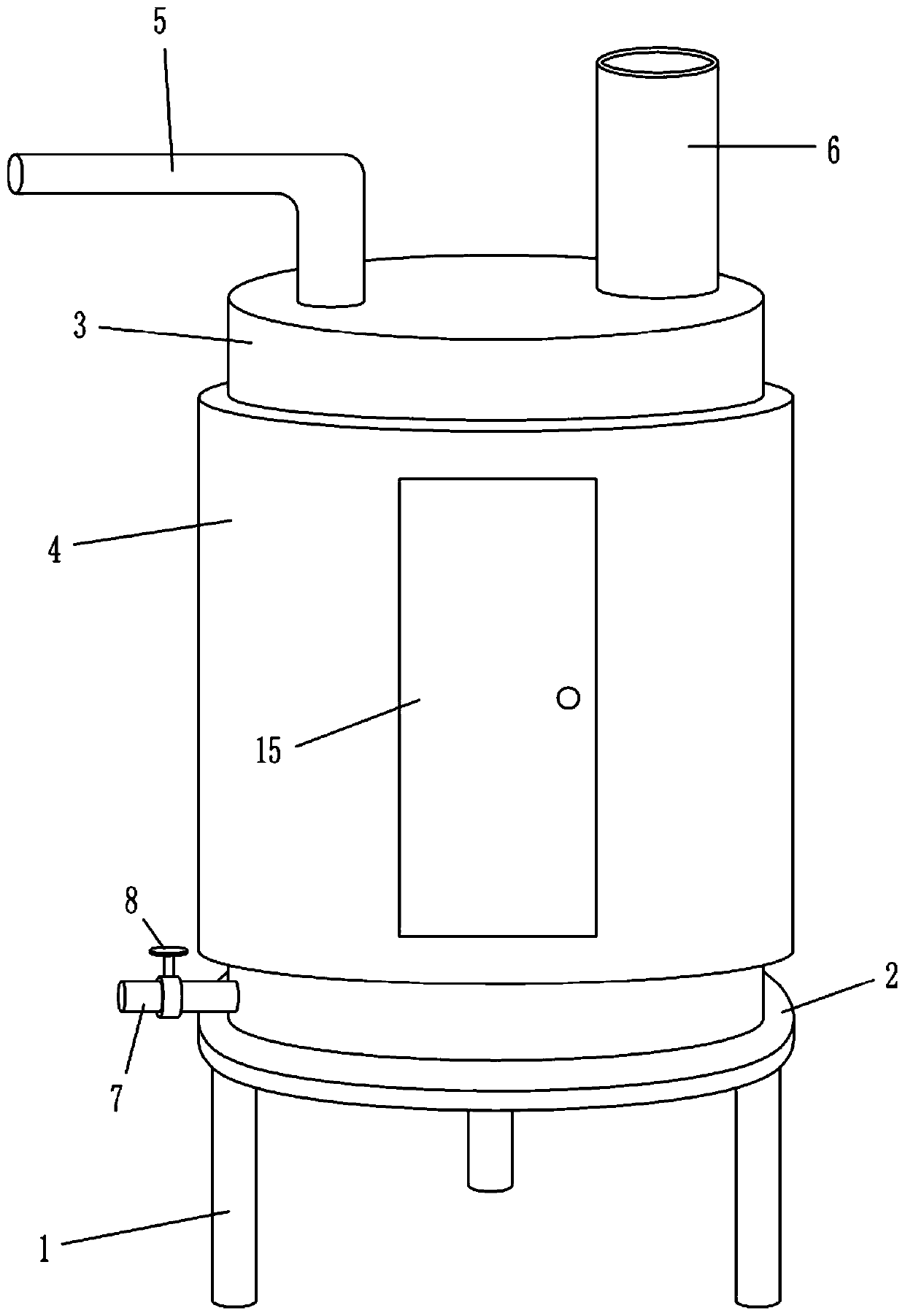

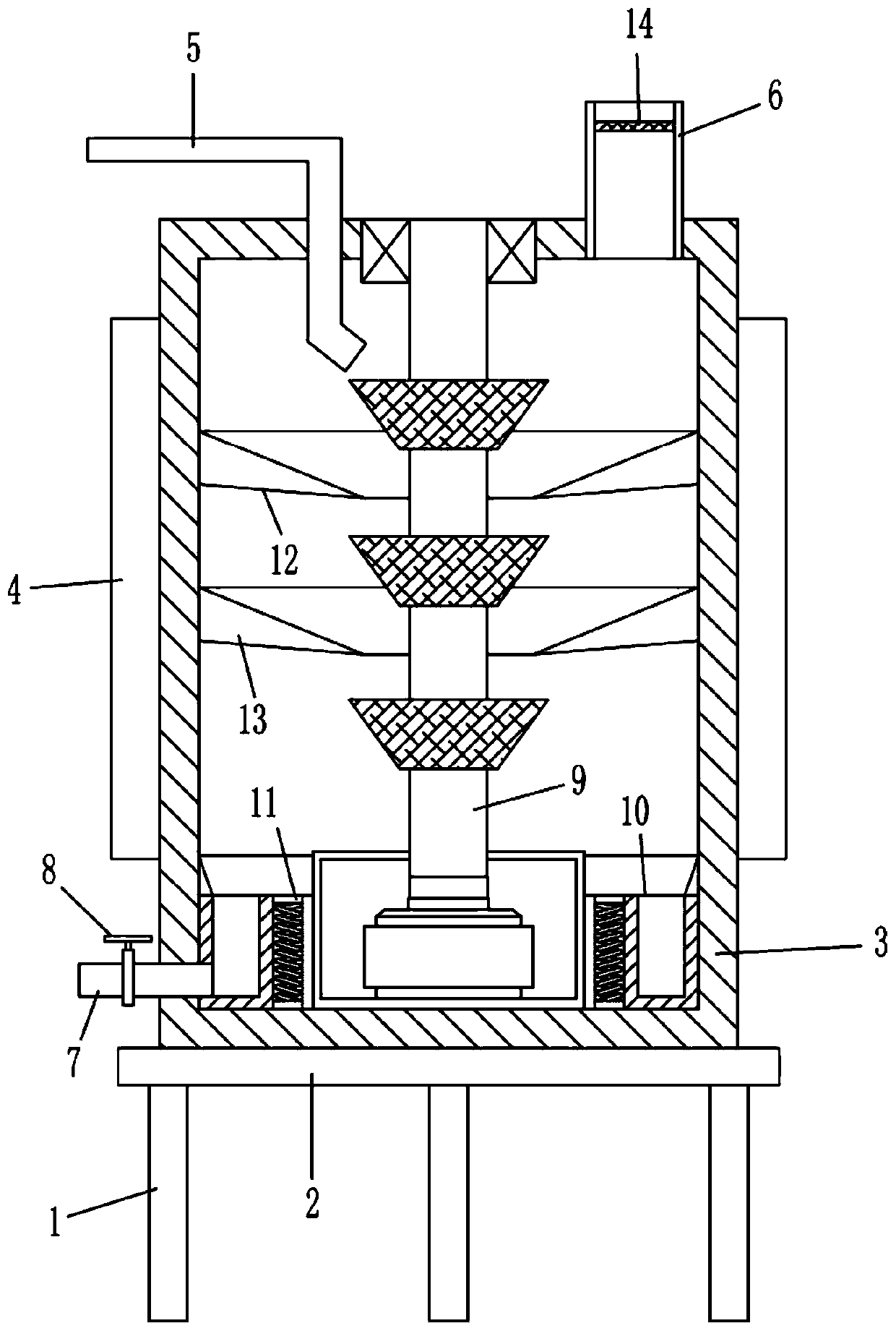

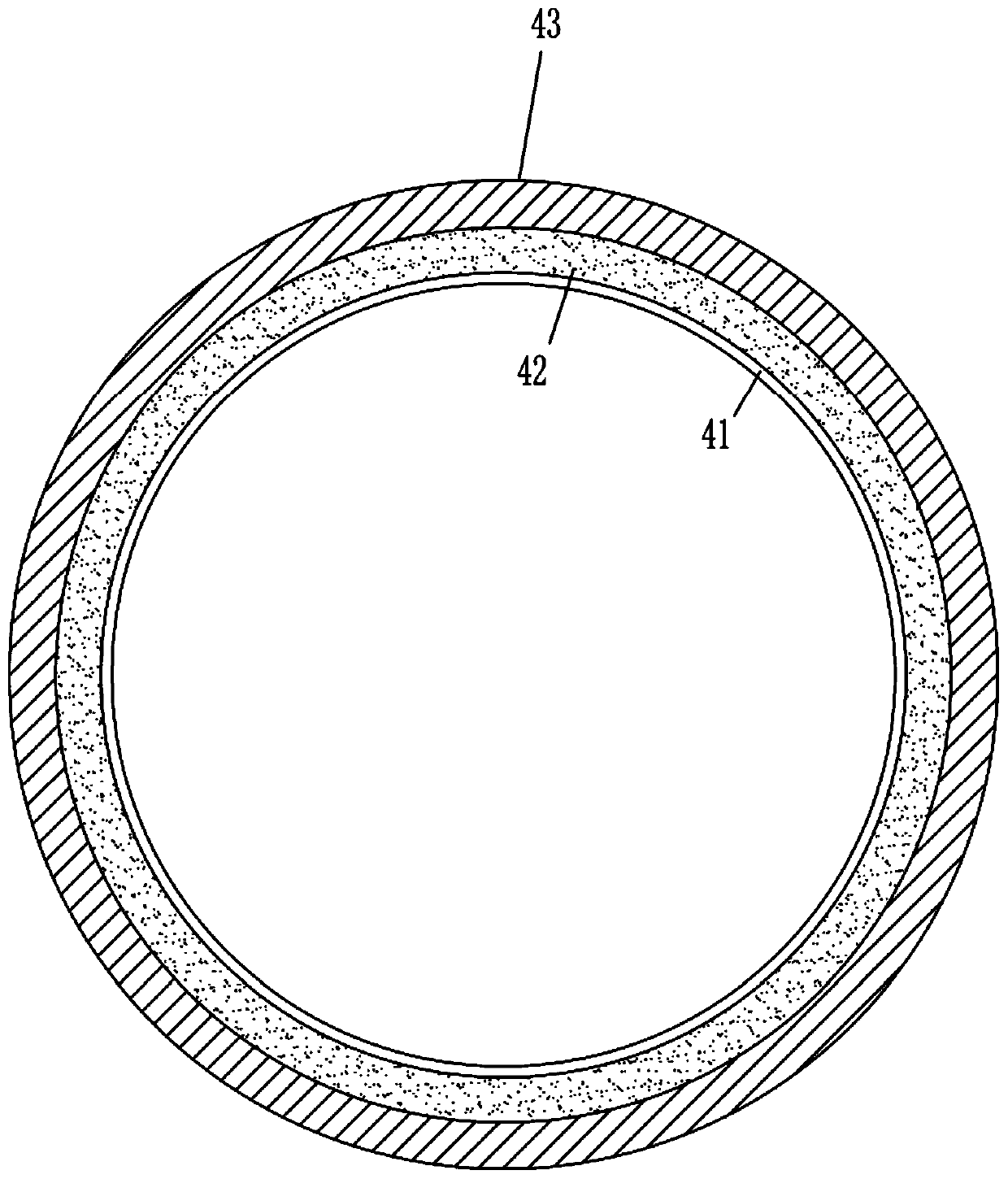

[0027] A high-efficiency massecuite separator for sugar production, such as Figure 1-8 As shown, it includes a support frame 1, a bearing seat 2, a separation cylinder 3, a noise reduction component 4, a feed pipe 5, an exhaust pipe 6, a liquid outlet pipe 7, a valve 8, a centrifugal component 9, a waste honey collection component 10, The anti-freezing component 11, the first drip bucket 12, the second drip bucket 13 and the filter screen 14; the support frame 1 is evenly fixed on the bottom surface of the load-bearing base 2; the separation cylinder 3 is fixed on the top surface of the load-bearing base 2; the liquid outlet pipe 7 is affixed to the outer wall of the separation cylinder 3 and communicated with the inside of the separation cylinder 3; the valve 8 is affixed to the outlet pipe 7; the feed pipe 5 and the exhaust pipe 6 are affixed to the top surface of the separation cylinder 3 in sequence, and are The separation cylinder 3 is connected; the filter screen 14 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com