Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

659 results about "Sugar production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sugar is produced in 121 Countries and global production now exceeds 120 Million tons a year. Approximately 70% is produced from sugar cane, a very tall grass with big stems which is largely grown in the tropical countries.

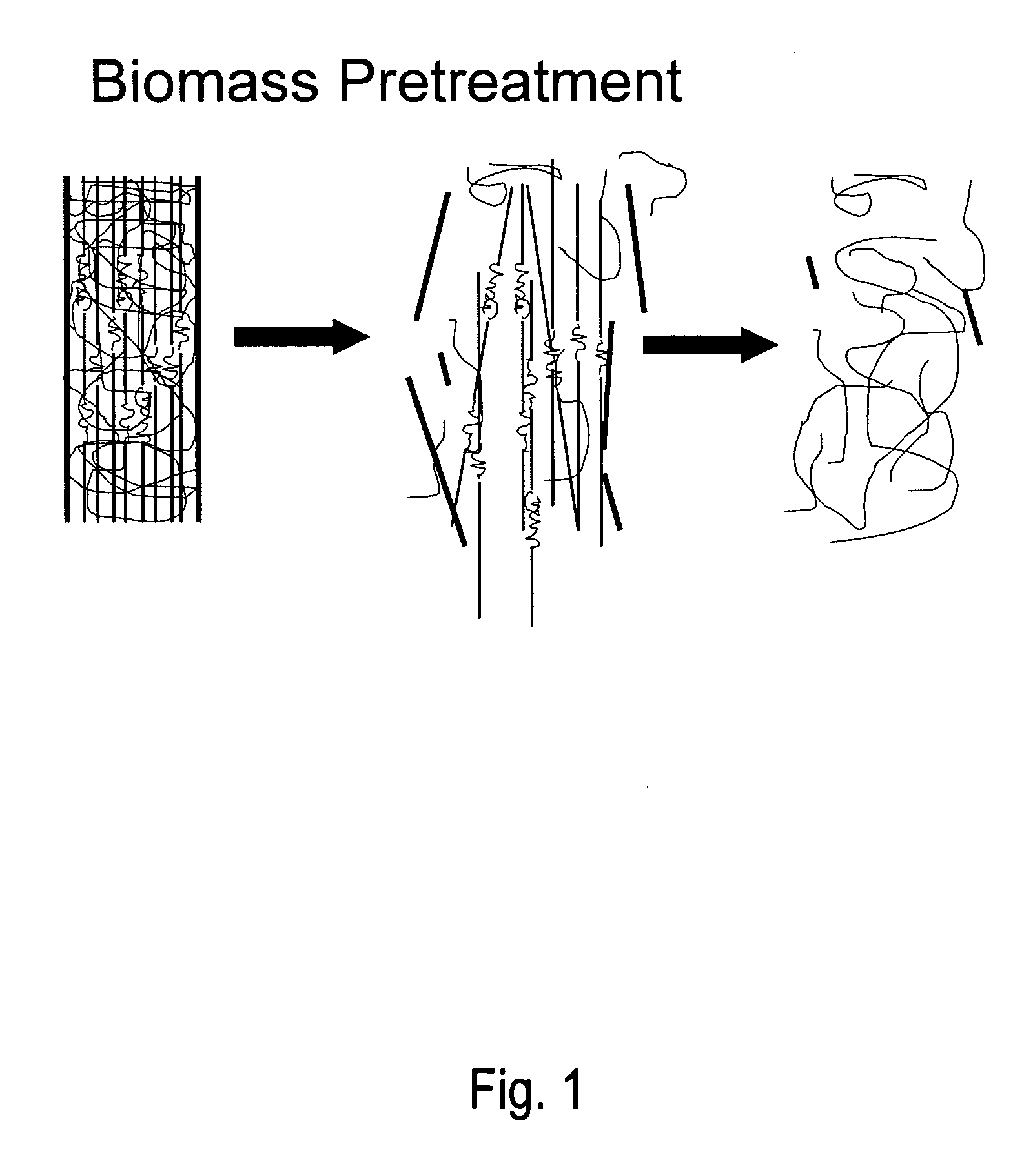

Biomass pretreatment

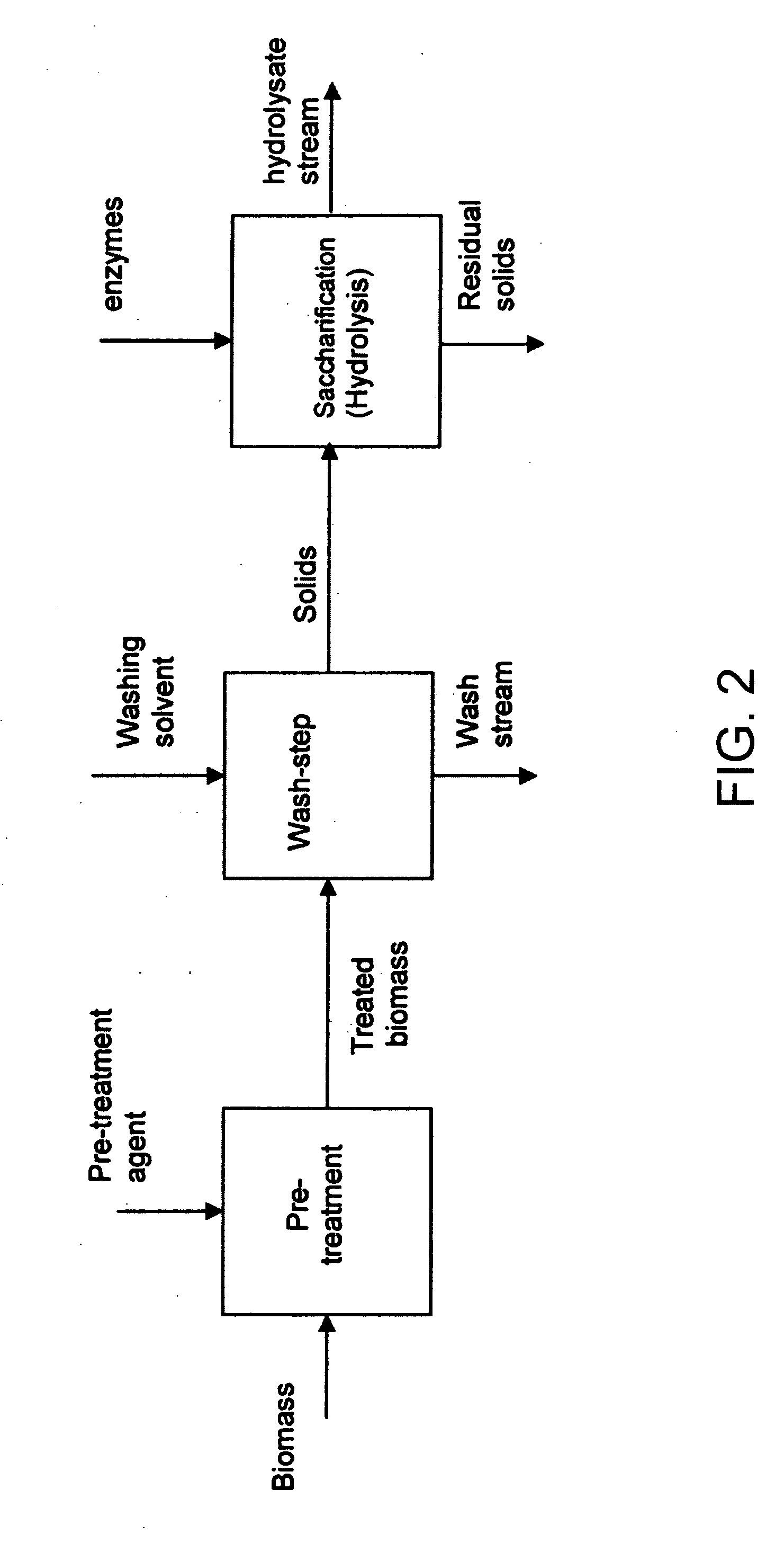

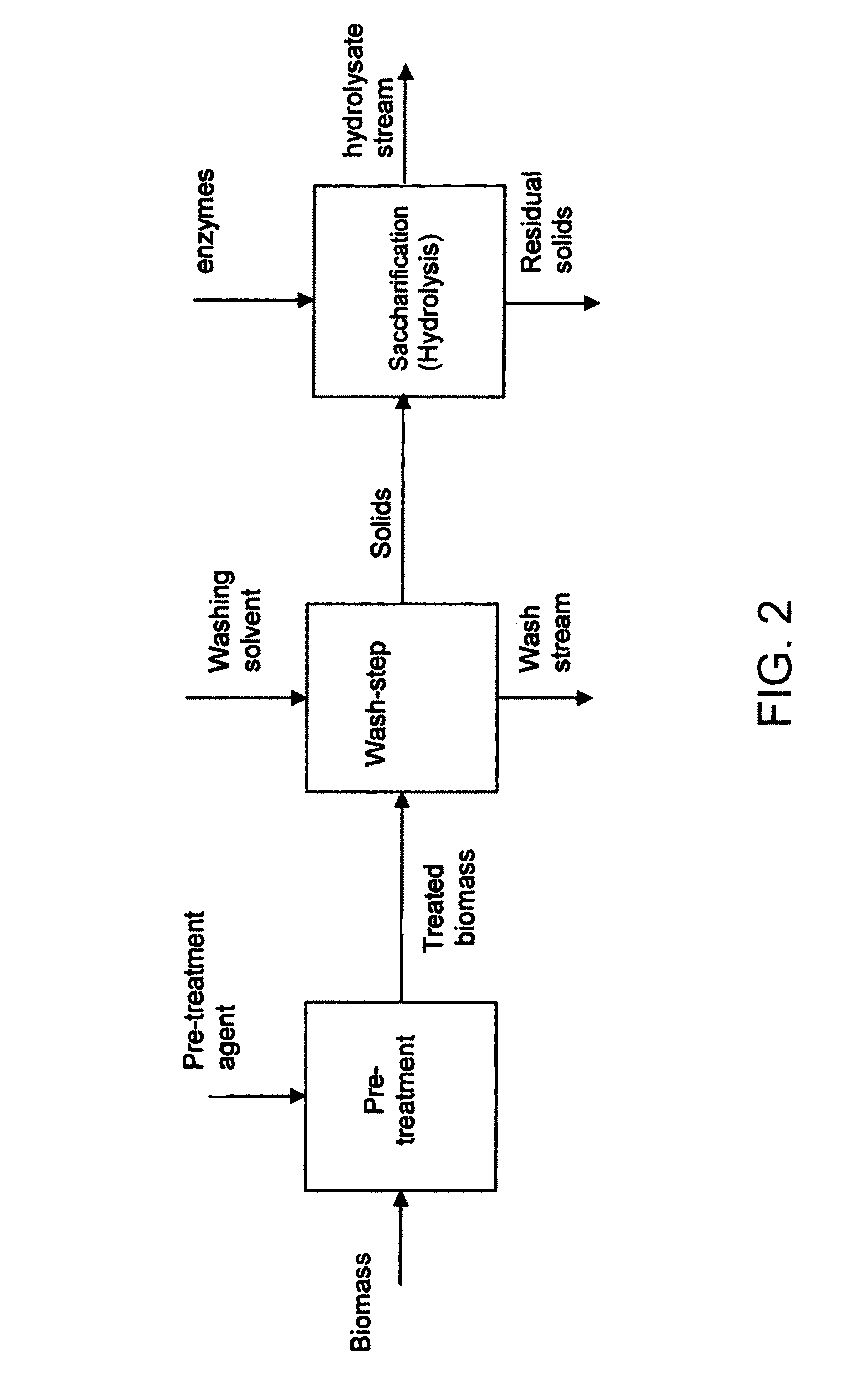

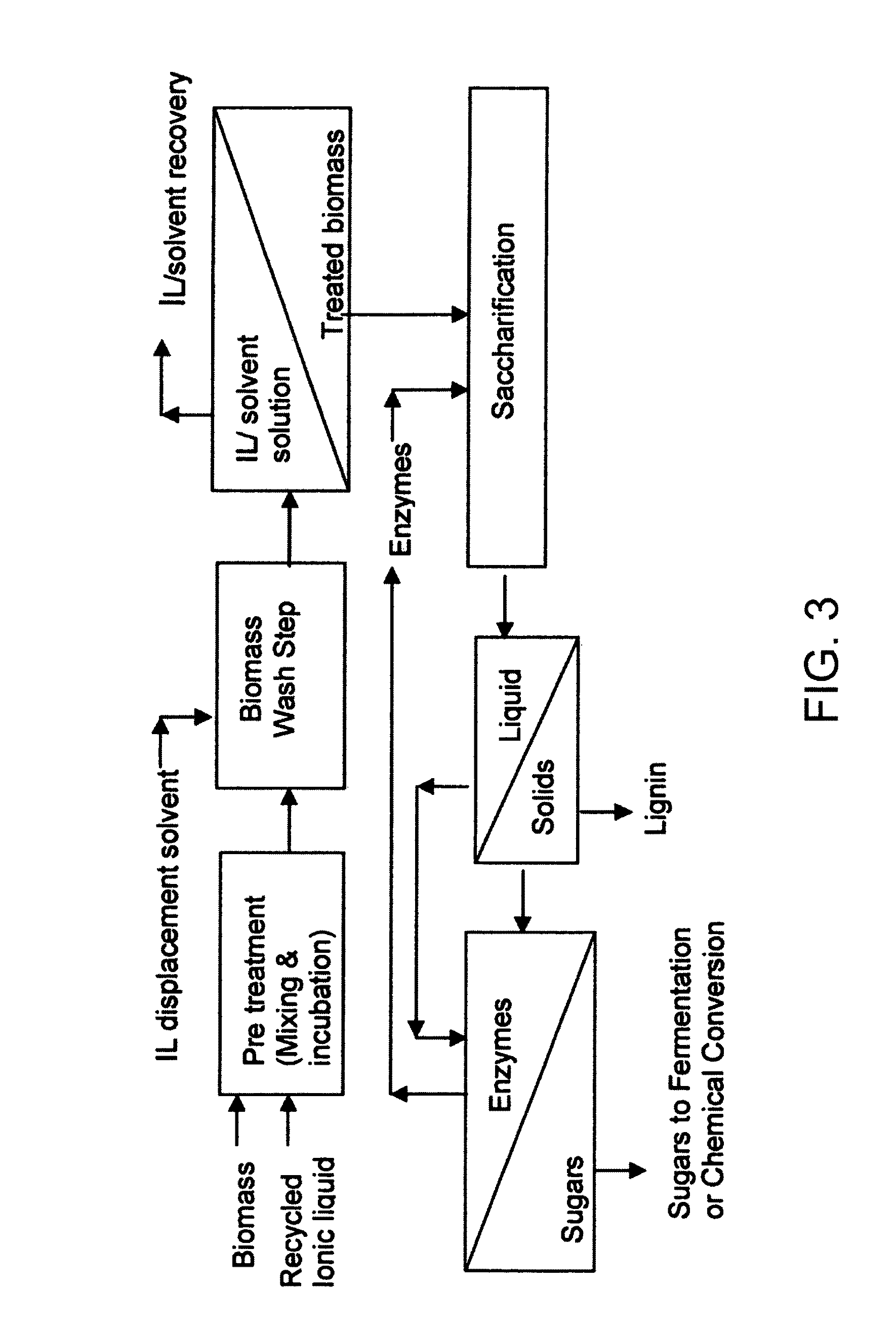

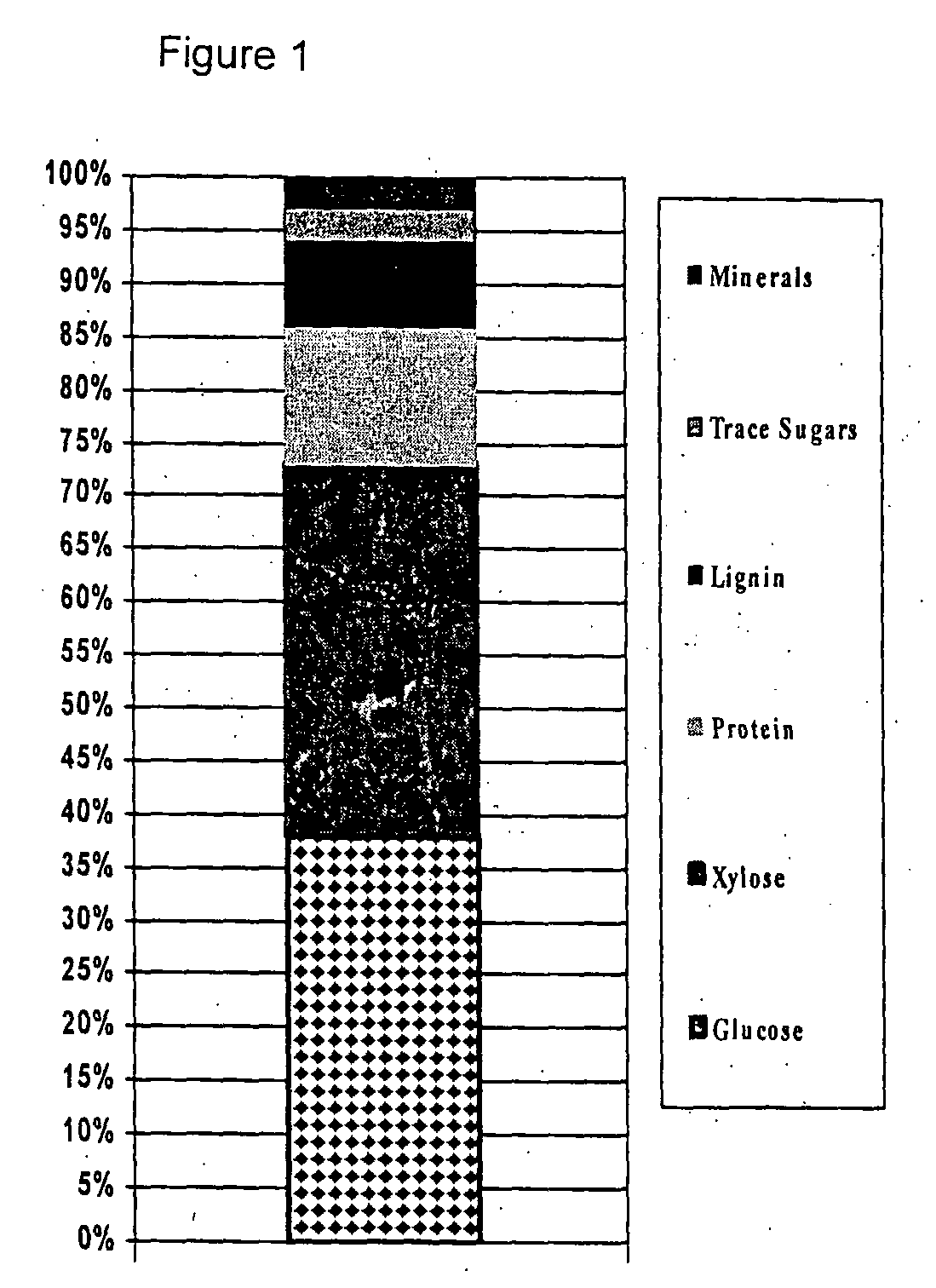

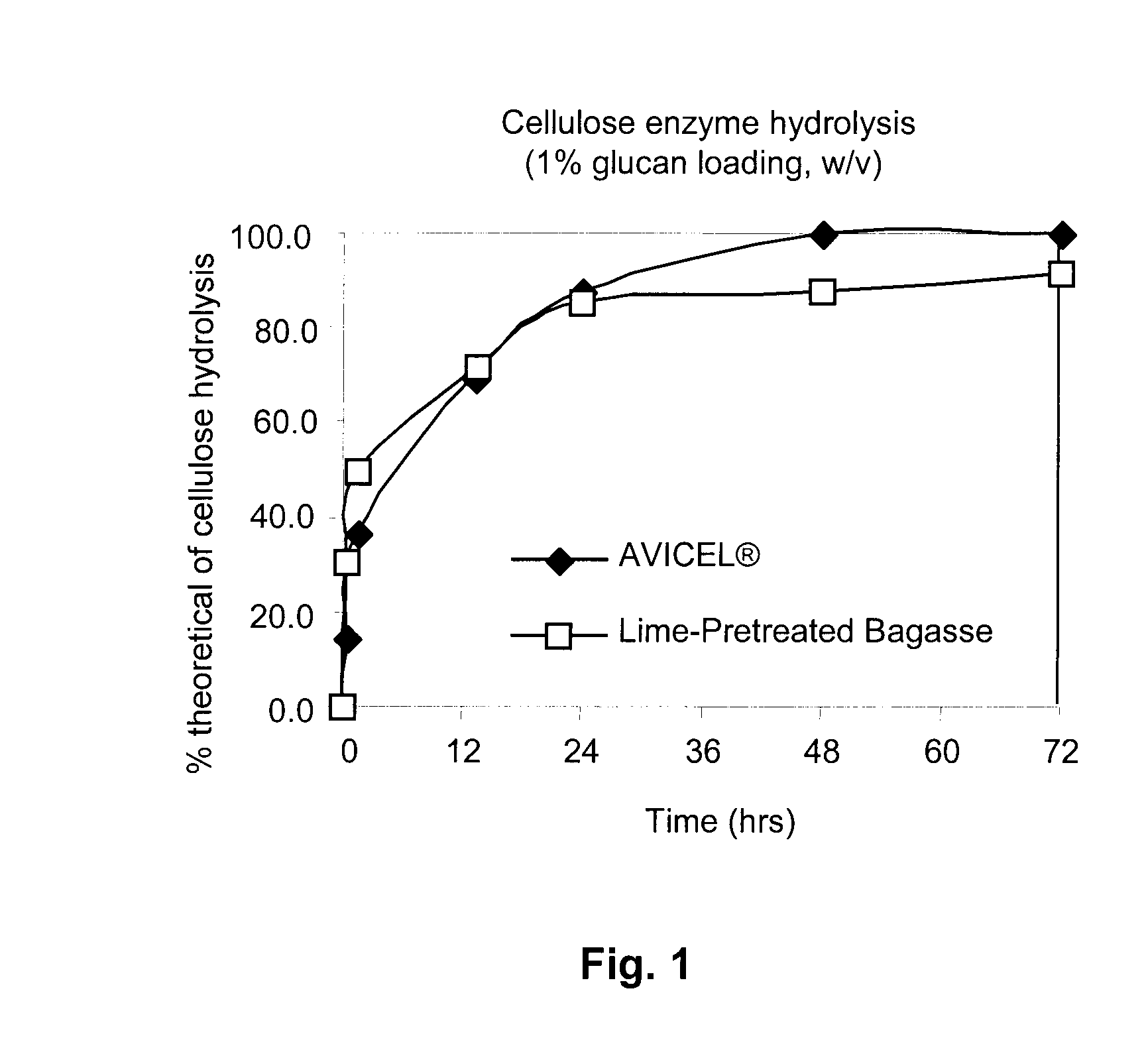

A method for lignocellulose conversion to sugar with improvements in yield and rate of sugar production has been developed by using ionic liquid pretreatment. This new pretreatment strategy substantially improves the efficiency (in terms of yield and reaction rates) of saccharification of lignocellulosic biomass. Cellulose and hemicellulose, when hydrolyzed into their sugars, can be converted into ethanol fuel through well established fermentation technologies. These sugars also form the feedstocks for production of variety of chemicals and polymers. The complex structure of biomass requires proper pretreatment to enable efficient saccharification of cellulose and hemicellulose components to their constituent sugars. Current pretreatment approaches suffer from slow reaction rates of cellulose hydrolysis (by using the enzyme cellulase) and low yields.

Owner:UNIVERSITY OF TOLEDO +1

Biomass pretreatment

ActiveUS8030030B2Improvement in yield and rateImprove efficiencyHydrolasesBiofuelsPretreatment methodReaction rate

A method for lignocellulose conversion to sugar with improvements in yield and rate of sugar production has been developed by using ionic liquid pretreatment. This new pretreatment strategy substantially improves the efficiency (in terms of yield and reaction rates) of saccharification of lignocellulosic biomass. Cellulose and hemicellulose, when hydrolyzed into their sugars, can be converted into ethanol fuel through well established fermentation technologies. These sugars also form the feedstocks for production of variety of chemicals and polymers. The complex structure of biomass requires proper pretreatment to enable efficient saccharification of cellulose and hemicellulose components to their constituent sugars. Current pretreatment approaches suffer from slow reaction rates of cellulose hydrolysis (by using the enzyme cellulase) and low yields.

Owner:UNIVERSITY OF TOLEDO +1

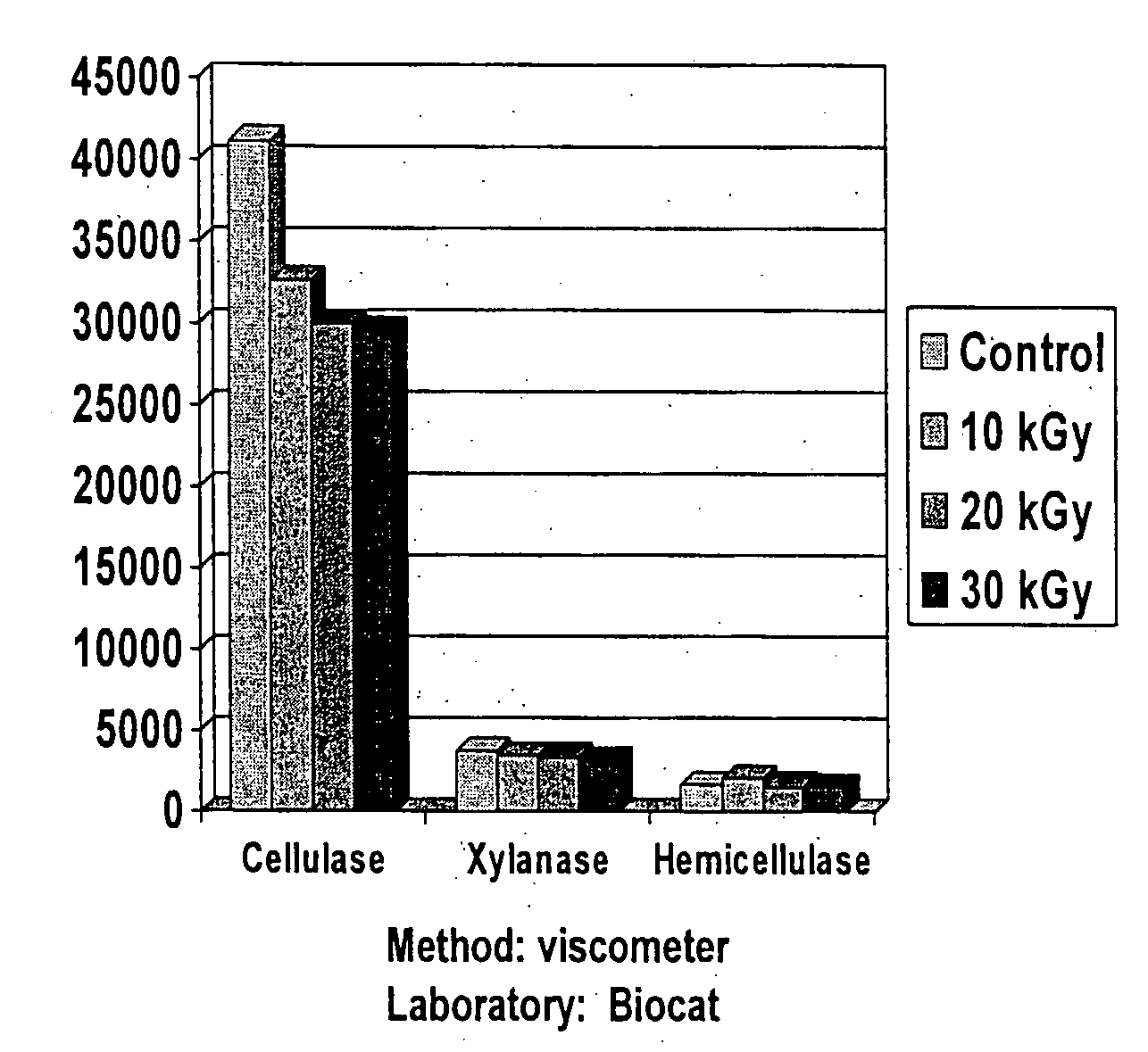

Effect of radiation on cellulase enzymes

A method for recycling cellulase enzymes. Also provided is a method for producing fermentable carbohydrates, plant leaf protein, and lignin, by adding a cellulase enzyme complex expressed from and on irradiated cellulase complex-producing organisms with sufficient radiation to kill biological activity without destroying all cellulase enzyme complex activity to biomass. The fermentable carbohydrates produced by the method. Also provided are irradiated cellulase-producing organisms for use in converting biomass to fermentable sugars, plant leaf protein, and lignin. A method for producing cellulase enzymes for glucose and other sugar production and protein and lignin extraction by irradiating cellulase-producing organisms, thereby producing the cellulase enzymes is also provided. A system for producing fermentable carbohydrates, plant protein, and lignin, said system comprising irradiated cellulase-producing organisms and biomass is provided.

Owner:RA ENERGY CORP

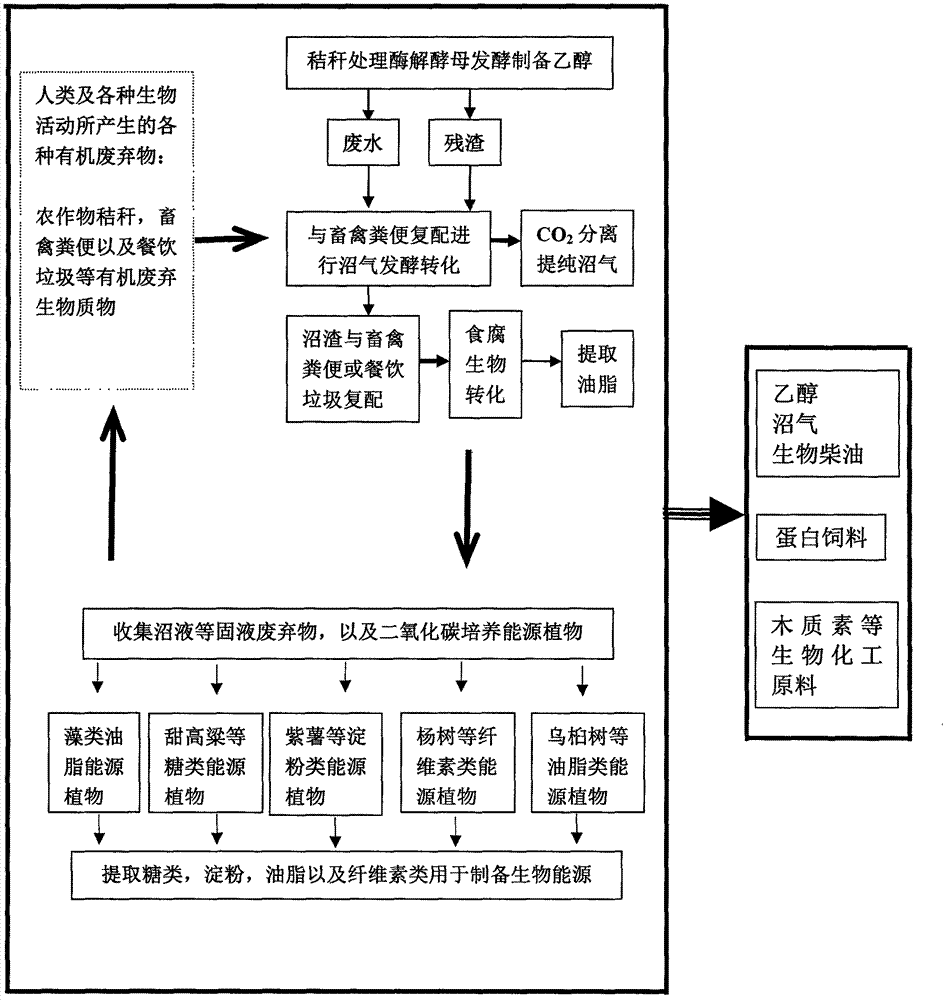

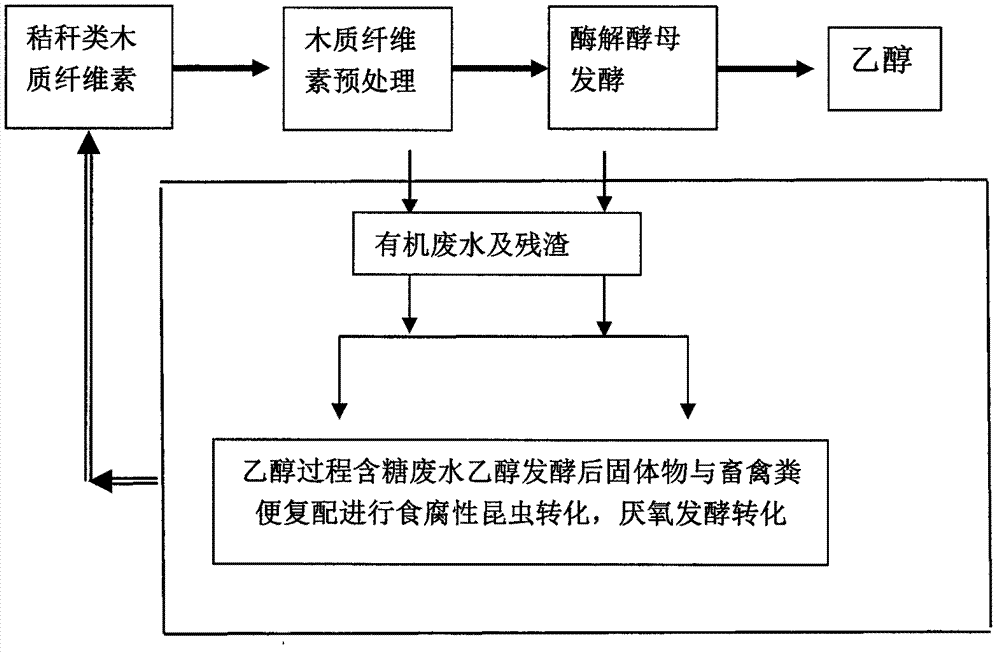

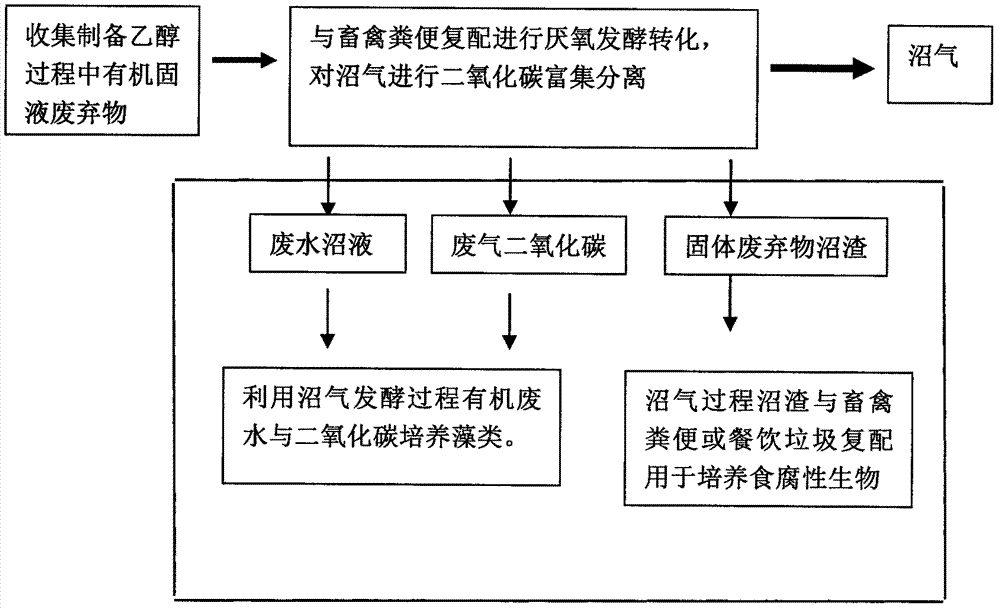

Co-production method for preparing ethanol, biogas and biodiesel by using organic waste

ActiveCN103923948AHigh yieldAbundant raw materialsBio-organic fraction processingClimate change adaptationCelluloseBiodiesel

The present invention provides a method for co-producing ethanol, biodiesel, biogas and other biological energy sources by using organic waste as a raw material. The method comprises that: a lignocellulose raw material is pretreated, enzymolysis sugar production and ethanol fermentation are performed, livestock and poultry manure is added to the enzymolysis residue, anaerobic fermentation is performed to produce biogas, the biogas residue is converted through saprophagous insects, organic wastewater is adopted to culture microalgae, and the insects and the microalgae are adopted to prepare the biodiesel; and an energy source plant conversion and utilization system is adopted to collect the process wastewater, the biogas liquid, the waste gas, the biogas residue and other solids and separate and enrich the biogas process carbon dioxide so as to be used for culture of sweet sorghum, sugar cane and other sugar-containing energy source plants, purple sweet potato and other starch-containing energy source plants, aspen and other cellulose-containing energy source plants, and sapium sebiferum and other grease-containing energy source plants, and the biomass produced by the energy source plants can further be used for extracting sugar sources, starch, fat and cellulose for biological energy source production.

Owner:HUAZHONG AGRI UNIV +1

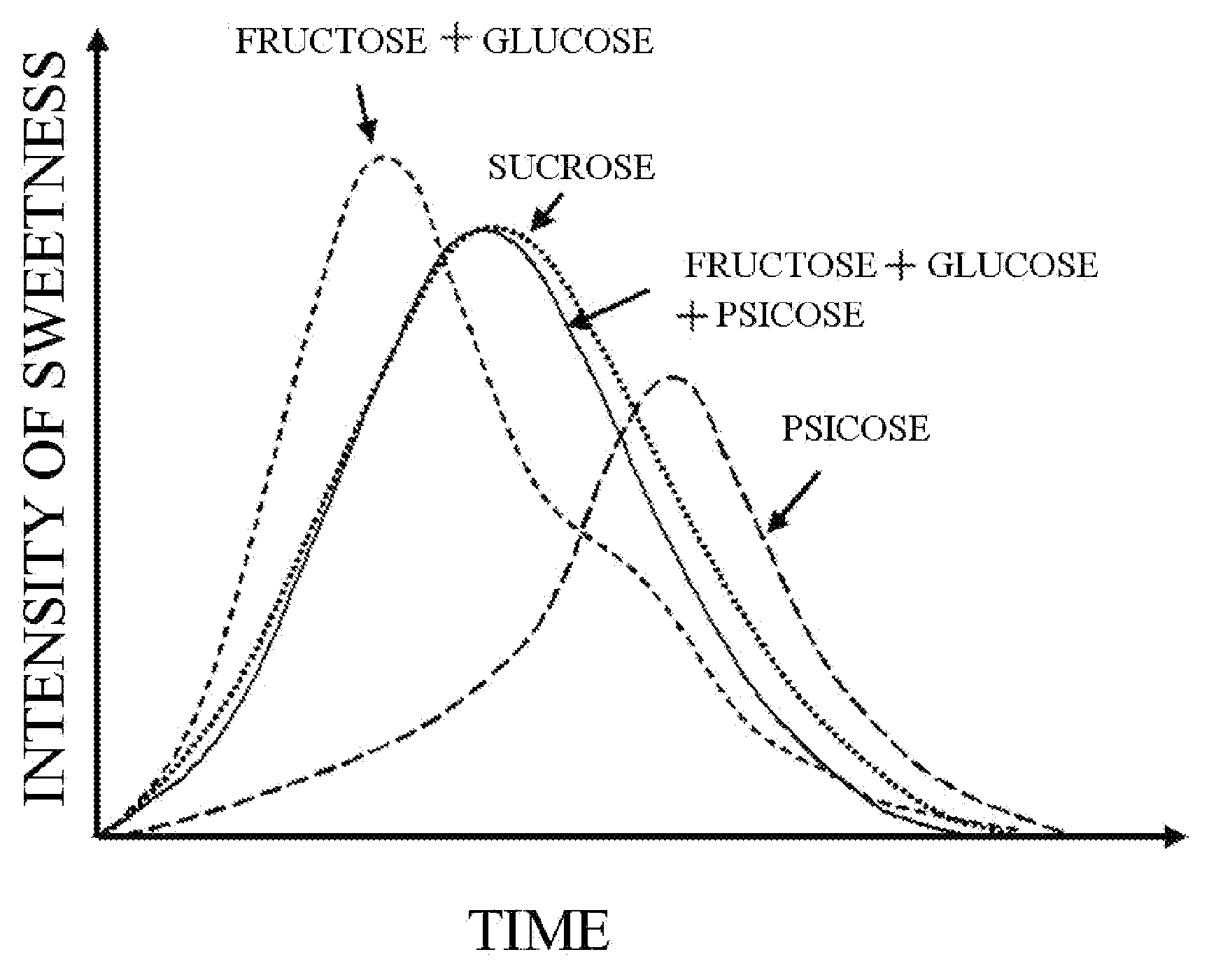

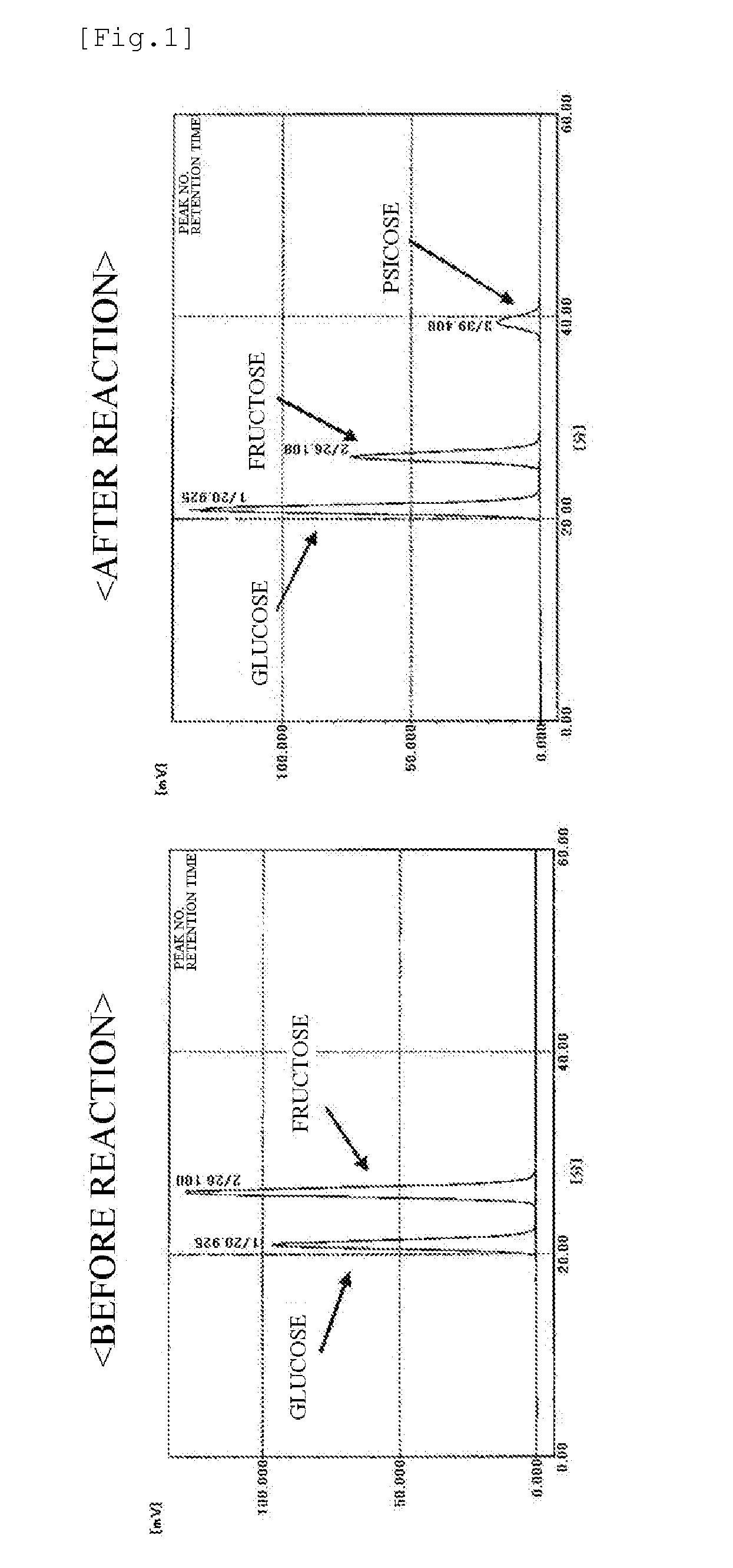

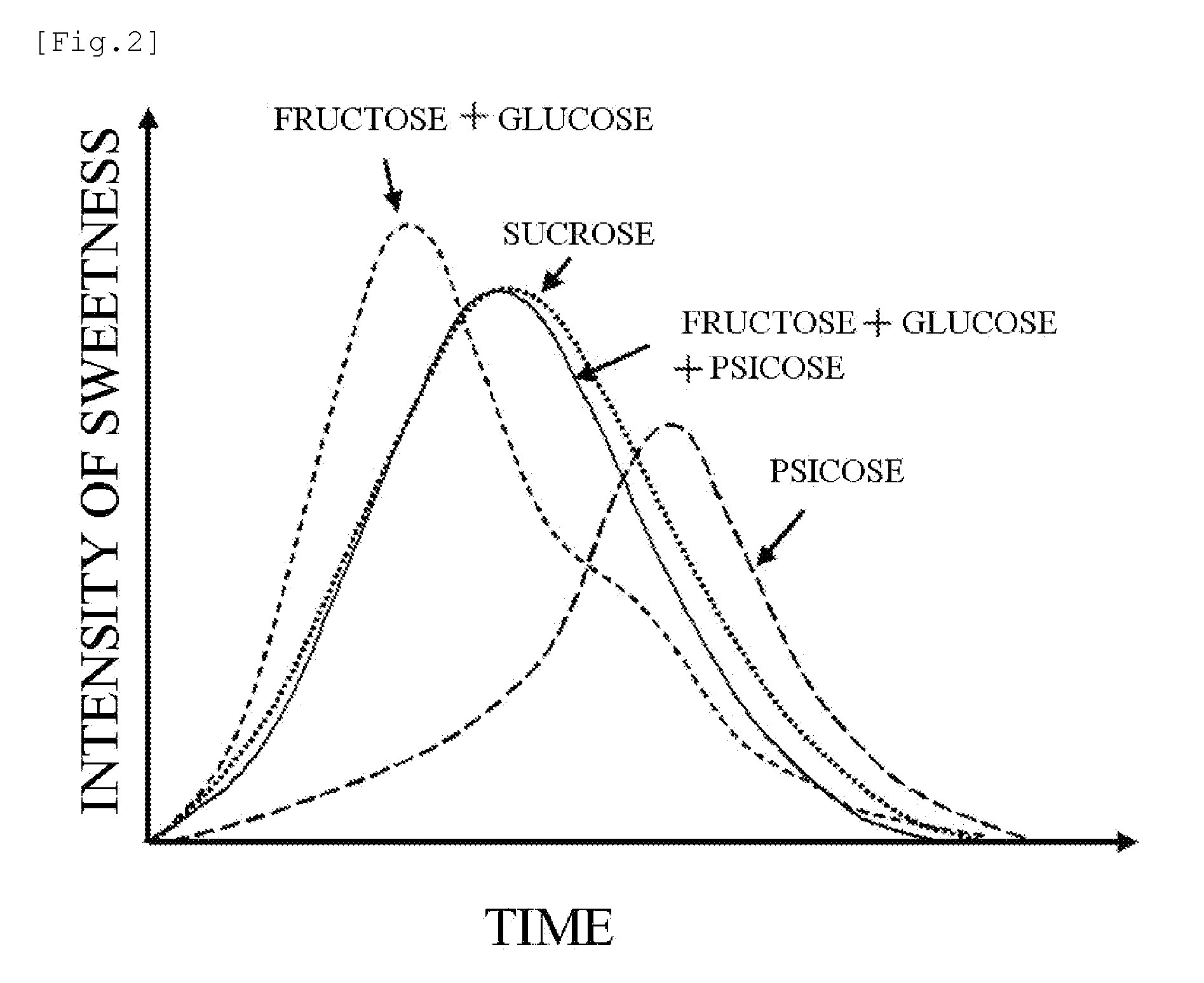

Novel sweetener having sucrose-like taste, method for producing the same, and use of the same

InactiveUS20100204346A1Great tasteLow costOrganic active ingredientsCosmetic preparationsSucroseIsomerase

Problem: To develop a method for producing a novel sweetener containing glucose, fructose, and psicose, which is produced from glucose liquid sugar using an isomerase and an epimerase; use of the novel sweetener as a food or drink material; and a novel sweetener capable of preventing obesity caused by the intake thereof.Means of Resolution: An isomerase and an epimerase are allowed to act on glucose liquid sugar produced in a glucose liquid sugar production plant to thereby produce D-psicose, thereby providing a novel sweetener (product) that maintains the degree and quality of sweetness of a glucose-fructose mixed solution and never causes obesity, a method for producing the same, and use of the same.

Owner:HAYASHIBARA CO LTD +3

Method of coloring panned confectioneries with ink-jet printing

A color coat is formed an a hard-panned, sugar shelled, pellet-shaped confectionery by placing at least one hard-panned, sugar shelled, pellet-shaped confectionery, preferably having an uncolored sugar surface, in functional association with an ink-jet head, applying at least a portion of a color coat to the hard-panned, sugar shelled, pellet-shaped confectionery by ink-jet printing at least one edible ink onto the surface of the hard-panned, sugar shelled, pellet-shaped confectionery, and drying the color coat. The hard-panned, sugar shelled, pellet-shaped confectionery may be transported and / or stored prior to the application of the color coat.

Owner:MARS INC

Preparation method of activated carbon by utilizing corncob hydrolysis residue

InactiveCN101837973ASolve the problem of effective transformation and utilizationTake advantage ofFermentationCelluloseCarbonization

The invention discloses a preparation method of activated carbon by utilizing corncob hydrolysis residue, which belongs to the technical field of functional sugar production. The process comprises four steps of removing cellulose, carbonization-activation, washing and drying and grinding. The preparation process utilizes the corncob hydrolysis residue after enzymolysis by cellulase to prepare the activated carbon for producing xylose (or xylitol), which can not only meet the demands of self-production and reduce the production cost but also be sold as a commodity to acquire economic benefits directly, thus realizing a great leap from high residue discharge amount to zero discharge in the xylitol production, reducing the environmental protection pressure, creating economic benefits and meeting the national requirements of energy saving, emission reduction and sustainable development.

Owner:FUTASTE PHARM CO LTD

Method for preparing food hygiene-level active carbon by use of bagasse

ActiveCN103803547ASolve the reuse problemHigh dry matter contentCarbon compoundsActive agentBiological waste

The invention relates to an active carbon material, and particularly relates to a method for preparing food hygiene-level active carbon by use of biological waste resource bagasse. The method comprises the steps of collecting and cleaning the residual bagasse after sugar production; sufficiently fermenting at 10-50 DEG C, drying, grinding and sieving; then performing the operation treatment such as soaking in an active agent solution, charring, activation and the like on the pretreated bagasse; washing, drying and grinding to obtain a high-performance active carbon product which can be applied to decoloration, refining and impurity removal of the sugar industry and the fields of foods and medicines such as medicinal crude drugs and the like. According to the method provided by the invention, by adopting the waste bagasse as a raw material, the comprehensive utilization of resources and environmental protection are facilitated; moreover, the price is low, the product quality is high, and the economic and social benefits are good.

Owner:JIANGSU ZHUHAI ACTIVATED CARBON CO LTD

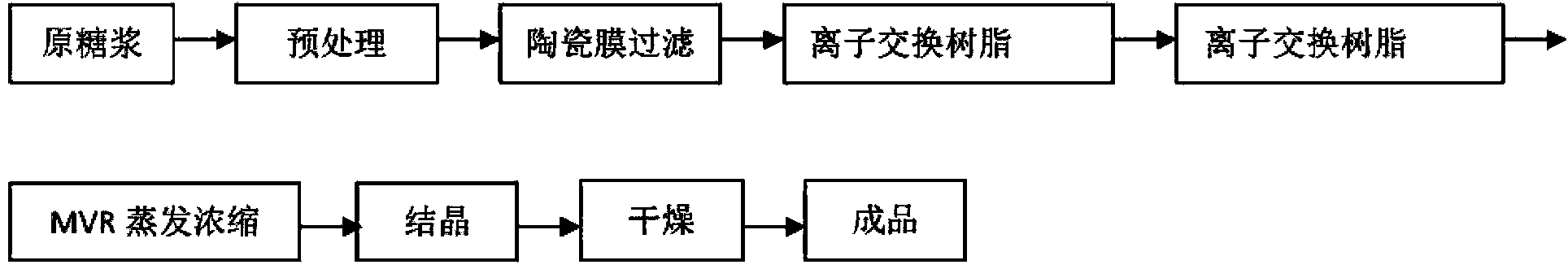

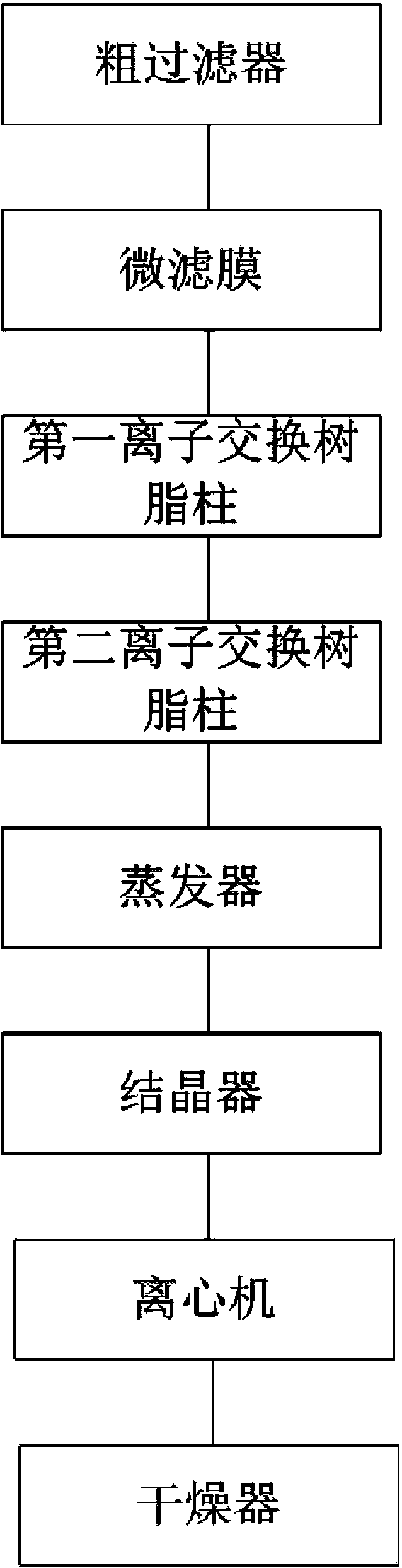

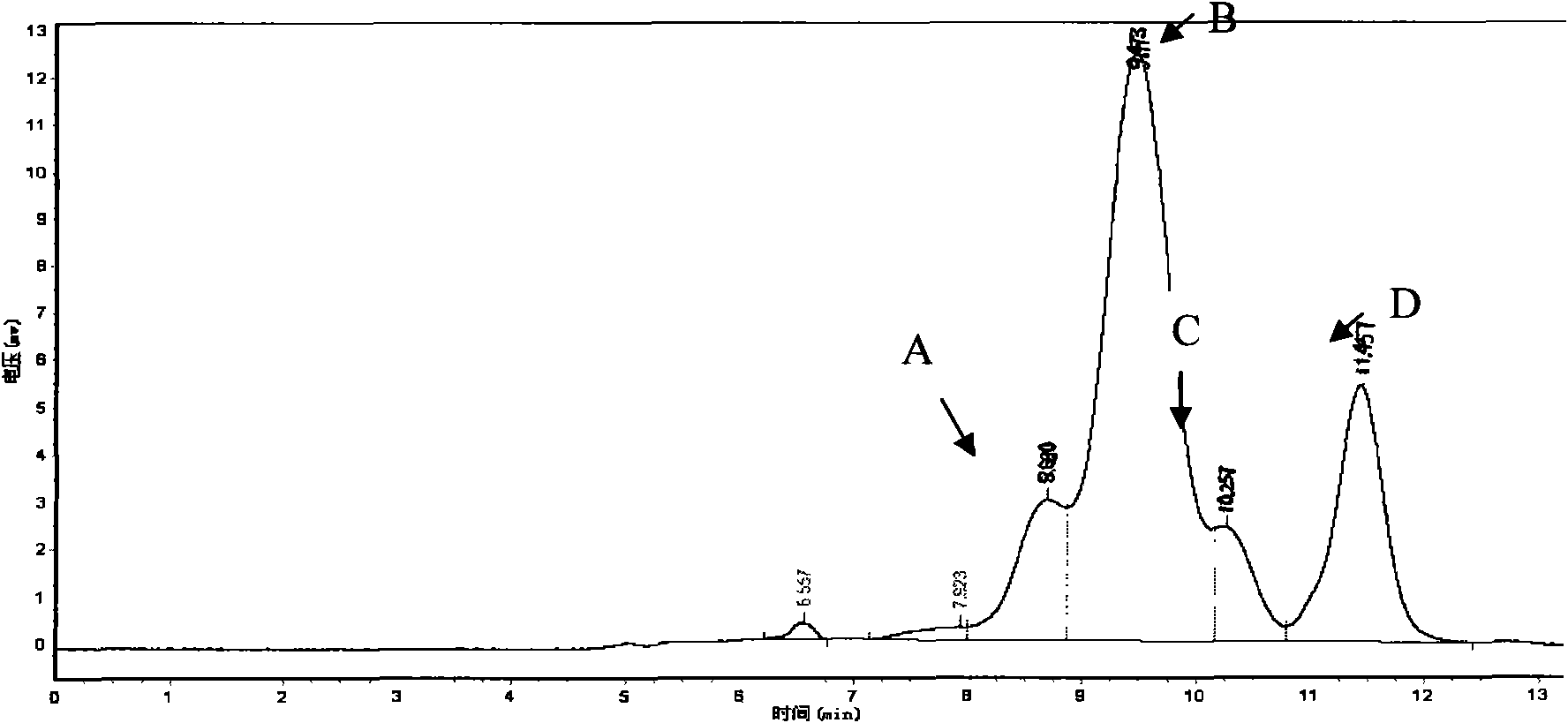

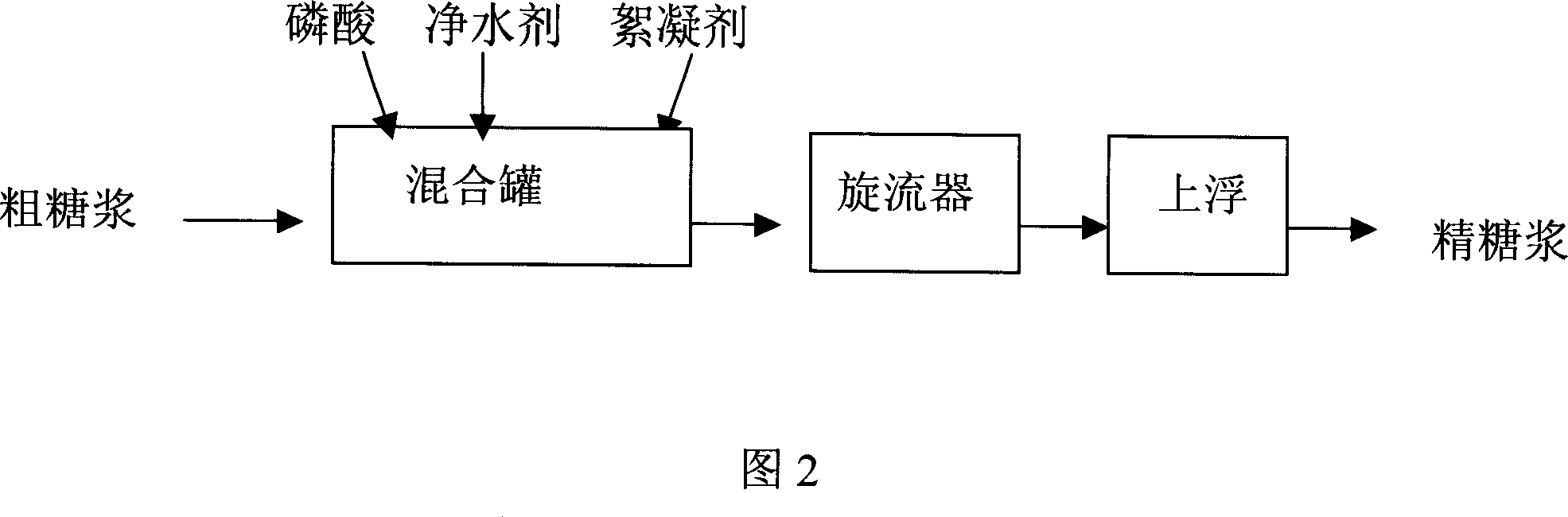

Process for preparing sugar by two-step method and device thereof

ActiveCN103710470ANo color reversionOptimal production process parametersSugar productsSucroseIon exchange

The invention discloses a process for preparing sugar by a two-step method and a device thereof. The process comprises the following steps: adding water into crude sugar for dissolving to obtain crude syrup; feeding the crude syrup into a primary filter and a micro-filtration membrane in sequence for filtering to obtain filtrate; feeding the filtrate into a first ion exchange resin tower to obtain a first penetrating fluid, wherein the first ion exchange resin refers to macroporous strong-basicity anion exchange resin; feeding the first penetrating fluid into a second ion exchange resin tower to obtain a second penetrating fluid, wherein the second ion exchange resin refers to strong-acidity cation exchange resin, weak-acidity cation exchange resin or a mixing bed of anion and cation exchange resin; feeding the second penetrating fluid into an evaporator for concentrating to obtain sucrose concentrated liquor; and crystallizing, centrifuging and drying to obtain a sucrose finished product. The process disclosed by the invention can be used for producing high-purity refined sucrose in batch, wherein a pigment removal rate reaches 99.9%, a salt removal rate reaches 98%, and sucrose component of the product reaches 99.9% which reaches the standard of national senior sugar.

Owner:JIANGSU JIUWU HITECH

Sludge bagasse active carbon and preparation method thereof

ActiveCN103241737AImprove adsorption capacitySolve the defect of poor adsorption performanceSludge treatmentOther chemical processesSludgeSugar refining

The invention relates to sludge bagasse active carbon and a preparation method thereof. The sludge bagasse active carbon is prepared from sewage treatment sludge and sugar refining industrial waste bagasse. The bagasse is added into the sludge to improve the carbon content of the sludge and the adsorptive property of sludge base active carbon, so that the problem that the adsorptive property of the sludge base active carbon is poor is solved; and the sludge is subjected to heavy metal removal to improve the using safety of the sludge base active carbon. The process comprises the following steps of: carrying out heavy metal removal on the sludge by adopting a certain technical means; drying the sludge and the bagasse, and then uniformly mixing the sludge and the bagasse according to a certain proportion; adding an activating agent ZnCl2 solution with a certain concentration to carry out immersion and activation; then carrying out pyrolysis under the protection of an inert gas; and washing and drying to obtain the active carbon. According to the preparation method, the active carbon is prepared from the sludge and the bagasse, the active carbon with good adsorptive property is prepared, and the resource utilization of the two types of industrial solid wastes is achieved at the same time, so that the sludge bagasse active carbon has good economic, social and ecological benefits.

Owner:GUANGXI UNIV

Superabsorbent composite and preparation method thereof

InactiveCN102321486AImprove water absorptionImprove water retentionOrganic fertilisersSoil conditioning compositionsSludgePolyacrylamide

The invention discloses a superabsorbent composite and a preparation method thereof. The superabsorbent composite disclosed by the invention comprises a conventional polyacrylamide or polyacrylate water-retaining agent or a mixture of a water absorbent (SAP) and an auxiliary material; the auxiliary material is an organic and / or inorganic auxiliary material; the organic auxiliary material is one or the mixture of restaurant sludge, municipal sludge, beer filtered mud, sugar mill mud, paper mud and plant residues; and preferably, the inorganic auxiliary material is one or the mixture of bentonite, zeolite, potassium feldspar, kieselguhr, magnesite and carbamide. In the invention, the superabsorbent composite is prepared by using a simple mixing and synthesis processing method through adding the cheap auxiliary material with a better cooperation effect with the SAP; the superabsorbent composite has the advantages of good water absorption and water retaining effects and low cost; and the method disclosed by the invention is simple and practical and has significant meanings in actual promotion and application.

Owner:SOUTH CHINA AGRI UNIV

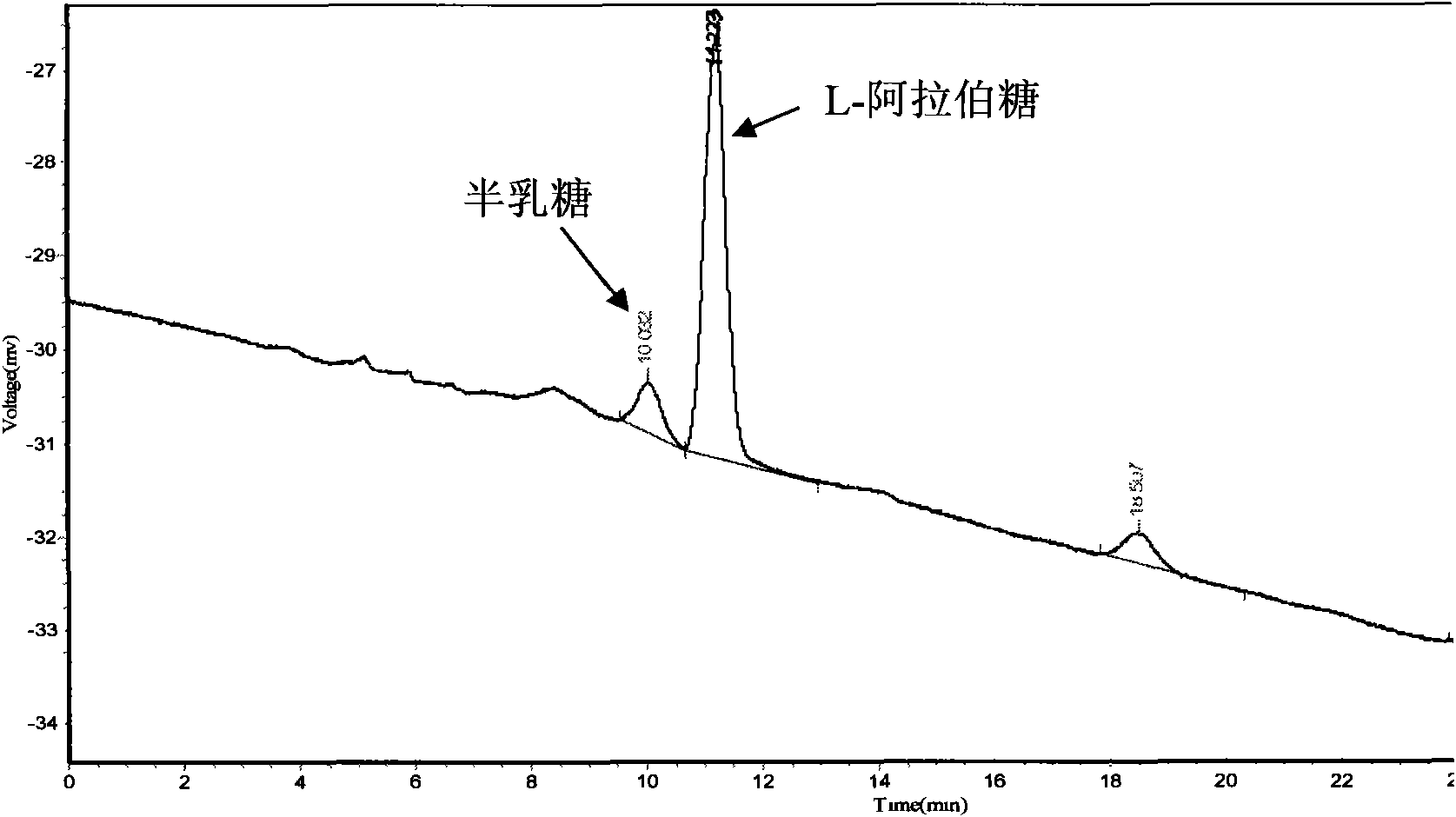

Method for separating and extracting L-arabinose from waste wood sugar mother liquid from wood sugar production

InactiveCN101555503ASolve processing problemsFacilitate subsequent separation and purificationMicroorganism based processesFermentationInorganic saltsIon exchange

The invention provides a method for separating and extracting L-arabinose from wasted wood sugar mother liquid from wood sugar production. The method comprises the following steps: the wood sugar mother liquid is decolorized; the decolorized wood sugar mother liquid is desalted by using ion exchange resin; the desalted defecated wood sugar mother liquid is diluted and added by required nitrogen source and inorganic salt for germicidal treatment; microzyme is inoculated into the sterilized wood sugar mother liquid for fermenting cultivation; the microzyme is removed after the ferment is finished, supernatant is processed with the methods of discolorationt, desaltification, concentration, and the like, to get colorless defecated fermenting liquid; the fermenting liquid is further concentrated, crystallized and dried to get the L-arabinose of high purity. The method has the advantages of no pollution, low energy consumption and low cost, and is suitable for industrial large-scale production.

Owner:上海金杉生物科技有限公司

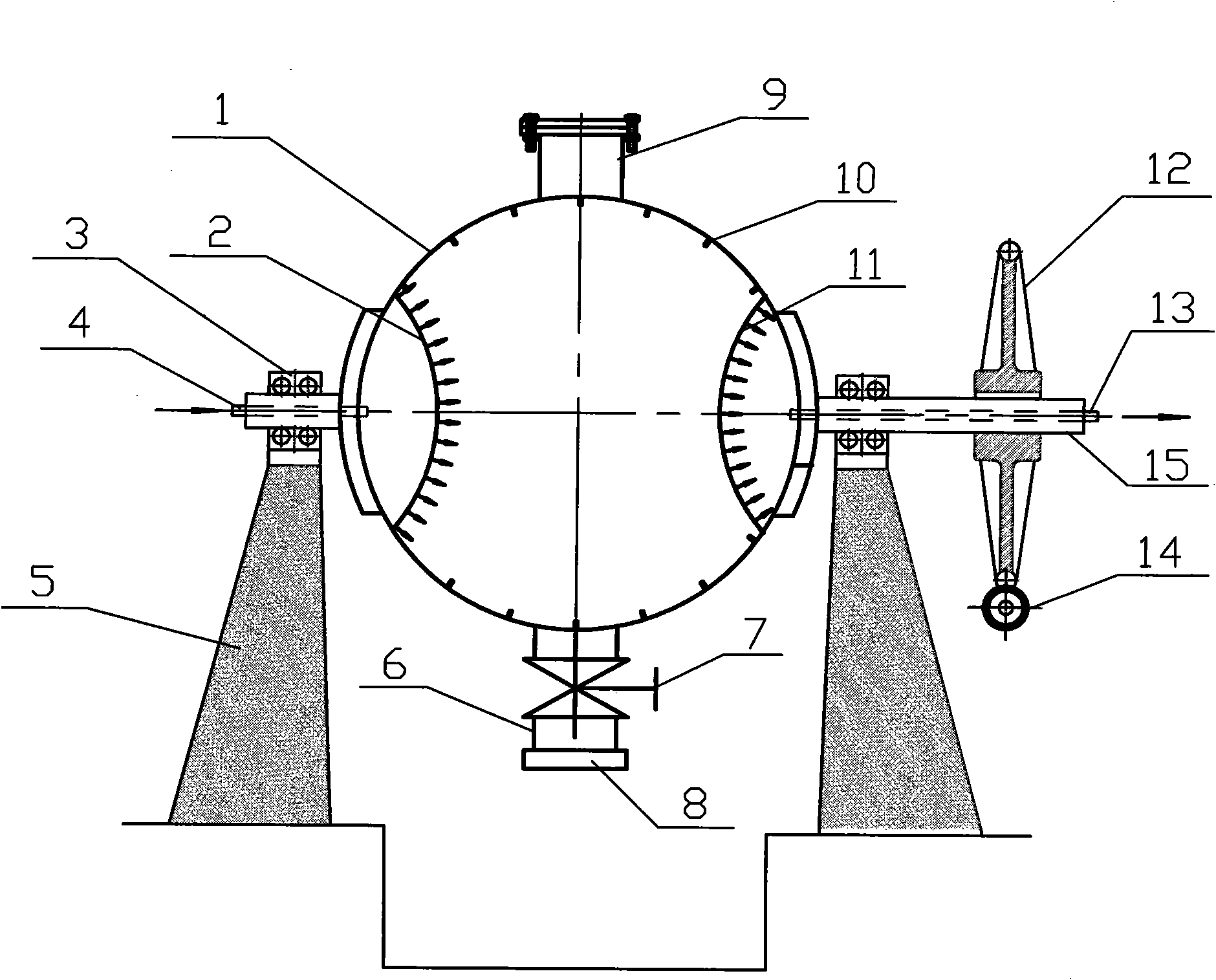

Process for producing furfural by bagasse

InactiveCN101914078AEasy dischargeSmooth slag dischargeOrganic chemistryDrying gas arrangementsDistillationFurfural

The invention discloses a process for producing furfural by bagasse, which comprises the following steps of: after drying and stirring acid into bagasse used as a raw material, delivering the bagasse into a spherical boiler for hydrolyzing for two hours so as to form an aldehyde steam stock solution; then delivering the obtained aldehyde steam stock solution into a primary distillation tower for distilling over most of water; after condensing an aldehyde water azeotropy mixture, delivering the aldehyde water azeotropy mixture into an aldehyde separating tank for delaminating; delivering rough furfural into a water scrubber for washing most acetic acid and methanol out of the rough furfural; and then refining in a rectifying tower to obtain finished product furfural; processing wastewater separated by the water scrubber by using a light component removing tower for recycling methanol; and after separating aldehyde steam in the furfural residues separated by the spherical boiler through a furfural residue steam-residue separator, adding cellulase into the furfural residues for fermenting to obtain acetone and butanol. The furfural is extracted from bagasse left after sugar production, and the cellulose left after furfural production is added into the furfural residues for fermenting to obtain the acetone and the butanol, thereby achieving the aims of clean co-production and comprehensive utilization. By adopting the self-made spherical boiler instead of the traditional hydrolysis kettle, the invention solves the problem of difficult residue discharge.

Owner:山东瑞德生物科技有限公司

Preparation method of mesoporous carbon electrode material for ionic liquid super capacitor

InactiveCN101767784AIncrease the areaLarger than capacitanceElectrolytic capacitorsFiltrationPhosphoric acid

The invention relates to a preparation method of mesoporous carbon electrode material for an ionic liquid super capacitor, comprising the following steps: (1) waste bagasse in the sugar production process is used as raw material, the bagasse is dried in the sun firstly, and then the dried bagasse is cut into fragments with a certain length; (2) the bagasse fragments are soaked in the solution with 10-90wt percent of activating agent for 2-72 hours, and then filtration is carried out to obtain the wet bagasse, the wet bagasse is dried at 100 DEG C, and the activating agent is one of zinc chloride, sodium hydroxide and phosphoric acid; (3) the dried bagasse is arranged in a quartz tube and is activated by microwaves under N2 protection; (4) the activated product is cooled, washed and dried to obtain the mesoporous carbon electrode material. The method has simple process and low cost and is suitable for industrial large-scale production. Microwave heating activation can be quickly started and stopped, and the method has the advantages of internal heating property, selectivity, integrity, uniformity, and energy saving; the biomass waste bagasse is used as the raw material, is easy to obtain and is cheap.

Owner:SHANDONG UNIV OF TECH

Composite type clearing agent in use for refining sugar, and preparation method

InactiveCN1958811AExtensive local contact condensationIncrease profitSugar juice purificationUltra fineAmmonium chloride mixture

This invention relates to a composite clarification agent used in sugar production. The composite clarification agent is composed of: polymerized AlCl3, organic polymeric materials (including chitosan, chitosan quaternary ammonium salt and dimethyl diallyl ammonium chloride), and ultra-fine powder (including perlitic powder, diatomite and clay) at a ratio of (45-90) :( 1-10) :( 5-50). The composite clarification agent has high electrical neutralization and bridge linkage performances, and has such advantages as low cost, rapid solid-liquid separation and no toxicity. The composite clarification agent is suitable for clarifying mixed juice, filtrate and syrupy in sugar production. The method has such advantages as abundant raw materials, simple process and easy operation.

Owner:GUANGZHOU SUGARCANE IND RES INST

Method for improving extraction ratio of trehalose

InactiveCN101230407ATotal production cost reductionAchieving a green circular economySaccharides productionChromatographic separationSimulated moving bed

The invention discloses a method of increasing the extraction yield of trehalose, which belongs to sugar industry technical field. Adopting the techniques of hydrogenation and chromatographic resolution, the microorganism or enzyme are used for transforming the starch and the trehalose obtained undergoes the hydrogenation reaction with the mixing solution of the maltose, glucose and maltotriose; therefore the impurity in the mixing solution produces the maltitol, sorbierite and maltotriitol; the trehalose has no reducibility, and is stable in the hydrogenation reaction; and the trehalose is separated from the maltitol, sorbierite and maltotriitol in the mixing solution by the chromatographic resolution technique simulating the moving bed; and the purity and extraction yield of the trehalose are largely increased; the trehalose is crystallized by cooling, and the trehalose product is finally obtained. Compared with the technique of producing the trehalose by adopting the original microorganism or enzyme method, the technique of the invention increases the extraction yield over 80 percent, the sub product maltitol has a comparatively high utilization value; and therefore the production cost for producing the trehalose and the market price are reduced, which makes sense for increasing the market competition of trehalose.

Owner:FUTASTE PHARM CO LTD

Method for extracting diosgenin for joint production of starch suger by prehy drolysis of yellow ginger by multienzyme process

InactiveCN1528913AReduce the amount requiredAcid hydrolysis is sufficientSteroidsFermentationAmylaseFiltration membrane

The invention provides a saponin extracting method with multi-enzyme hydrolytic which hydrolyses brown Windsor in advance and produce starch sugar. The method cleans the brown Windsor and grinds it into pulp, then adds in alpha starch enzyme to be liquefied, adds in saccharifying enzyme, heats and carries on deactivation, then the saccharified materials are separated centrifugally, gets the filtered cake and starch sugar liquiud, the sugar liquid is separated with hyperfiltration membrane with 1000-10000daltons aperture catching molecular weight or tiny filtration membrane of 100-200nm and gets the starch sugar liquid, the filter residues are mixed into centrifugated filter cake and gets sugar residue, adds in chlorhydric acid or sulfuric acid to hydrolyse the sugar residue, the hydrolysed product is filtered, cleaned, and dried, extracted by solvent, finally gets the saponin product.

Owner:TAIGU INVESTMENT WUHAN

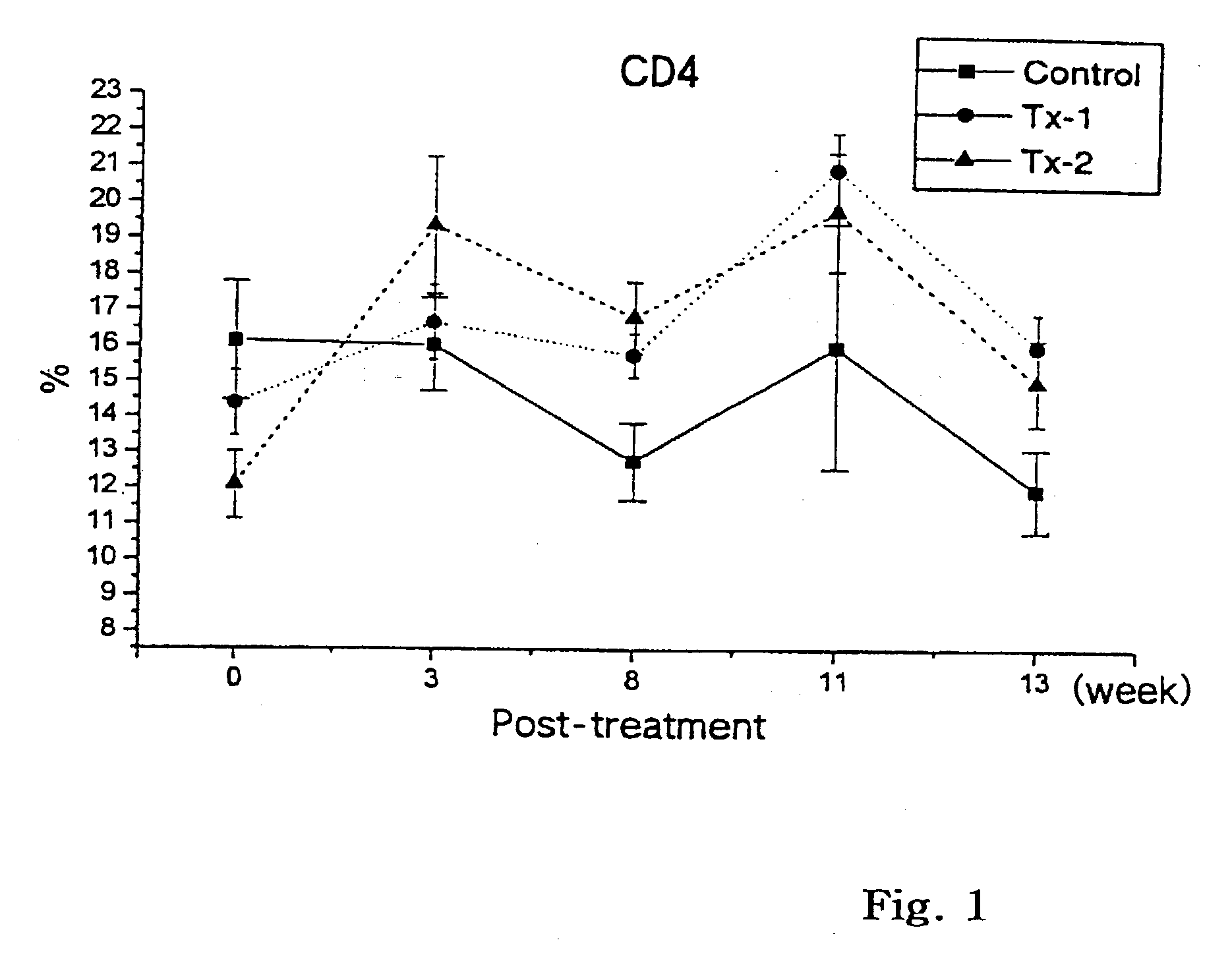

Composition of multipurpose high functional alkaline solution composition, preparation thereof, and for the use of nonspecific immunostimulator

InactiveUS20030206967A1Less offensive odorAntibacterial agentsHeavy metal active ingredientsDiseaseWeight gaining

Disclosed are a multipurpose, high-functional, alkaline solution composition, preparation therefor and use thereof as a nonspecific immunostimulator. The composition comprises 1-25 parts by weight of borax (Na2B4O7.10H2O), 10<-5>-10<-4 >parts by weight of sodium thiosulfate (Na2S2O3.5H2O), 30-150 parts by weight of potassium carbonate, 30-200 parts by weight of refined sugar (C12H22O11), and 100-200 parts by weight of water, based on 100 parts by weight of sodium metasilicate (Na2SiO3.5H2O). In addition to bringing about an improvement in disease resistance, weight gain rate, crop yield, crop quality, harvest time, the composition shows nonspecific immunostimulating activities, including antibody production and immune enhancement, by activating immune cells, thereby maximizing vaccination effects on malignant viral diseases.

Owner:BARODON S F CORP

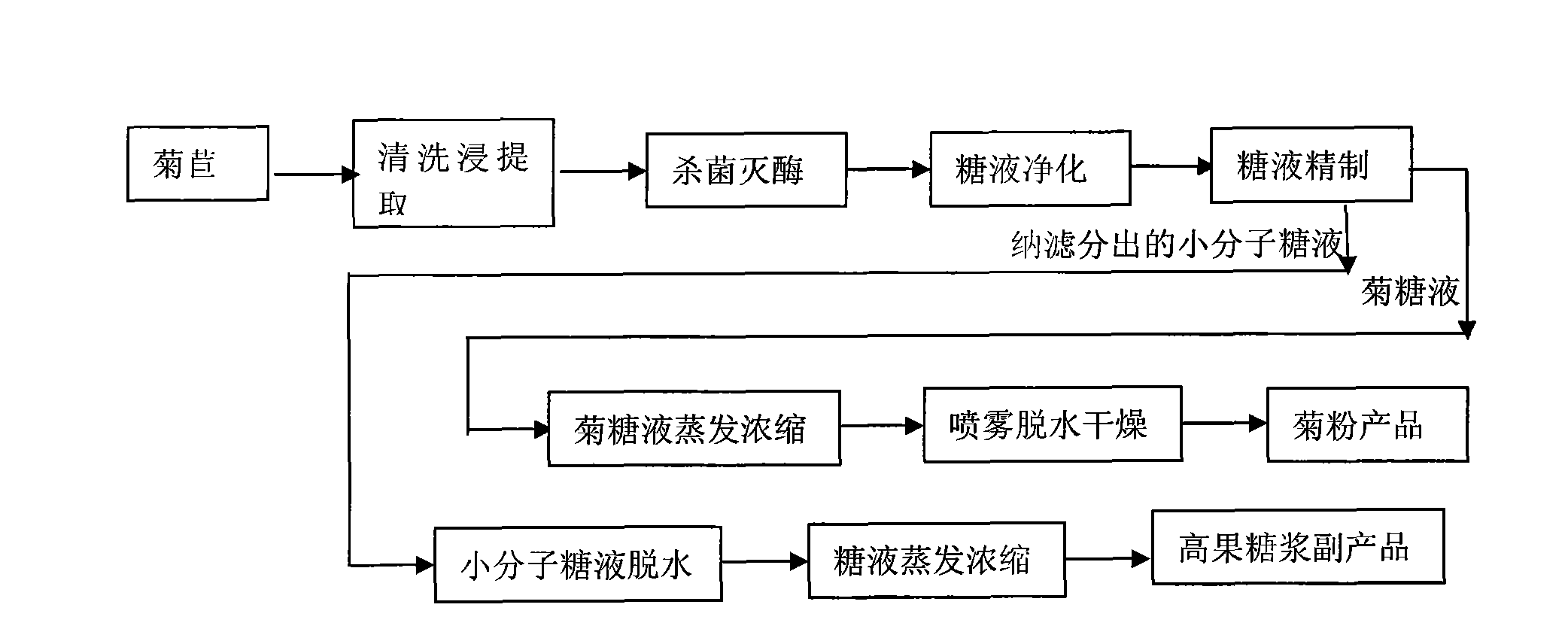

Preparation process for extracting inulin from cichory root

The invention relates to a preparation process for extracting inulin from cichory root, which mainly comprises the following steps: performing cleaning and extracting, sterilizing and inactivating enzyme, purifying sugar liquid, refining the sugar liquid, dehydrating and concentrating the sugar liquid, dehydrating and drying the sugar liquid, and reclaiming small molecular sugar. The preparation process overcomes the defects of process and equipment layout in the prior designed production process, reduces the total production cost, is safe and reliable, and has high extraction efficiency and rate of finished products.

Owner:武汉莱尔富生物科技有限公司

Process for Producing High-Purity Sucrose

InactiveUS20100160624A1Sugar productsPurification using ion-exchange materialsSucrose solutionRefined sugar

Improved processes for the purification of raw or refined sugar, or sucrose, to produce sucrose and sucrose-related products having substantially no inorganic impurities are described, wherein the processes include the use of both cation and anion exchange resins. In accordance with the process, a sucrose starting material, such as refined sugar or invert syrup, is dissolved in water at a temperature sufficient to dissolve the sucrose product and produce a low visicosity sucrose solution having not more than about 76 wt. % solids. Thereafter, the process includes contacting the low viscosity sucrose solution with one or more ion exchange resin beds, which can be separate or mixed, for a time sufficient to yield a highly-purified sucrose product that is substantially free of inorganic elemental impurities.

Owner:RAGUS HLDG

Process for Sugar Production from Lignocellulosic Biomass Using Alkali Pretreatment

InactiveUS20100143974A1Prevents inhibition of usedReduce material costsBiofuelsFermentationFiberLignocellulosic biomass

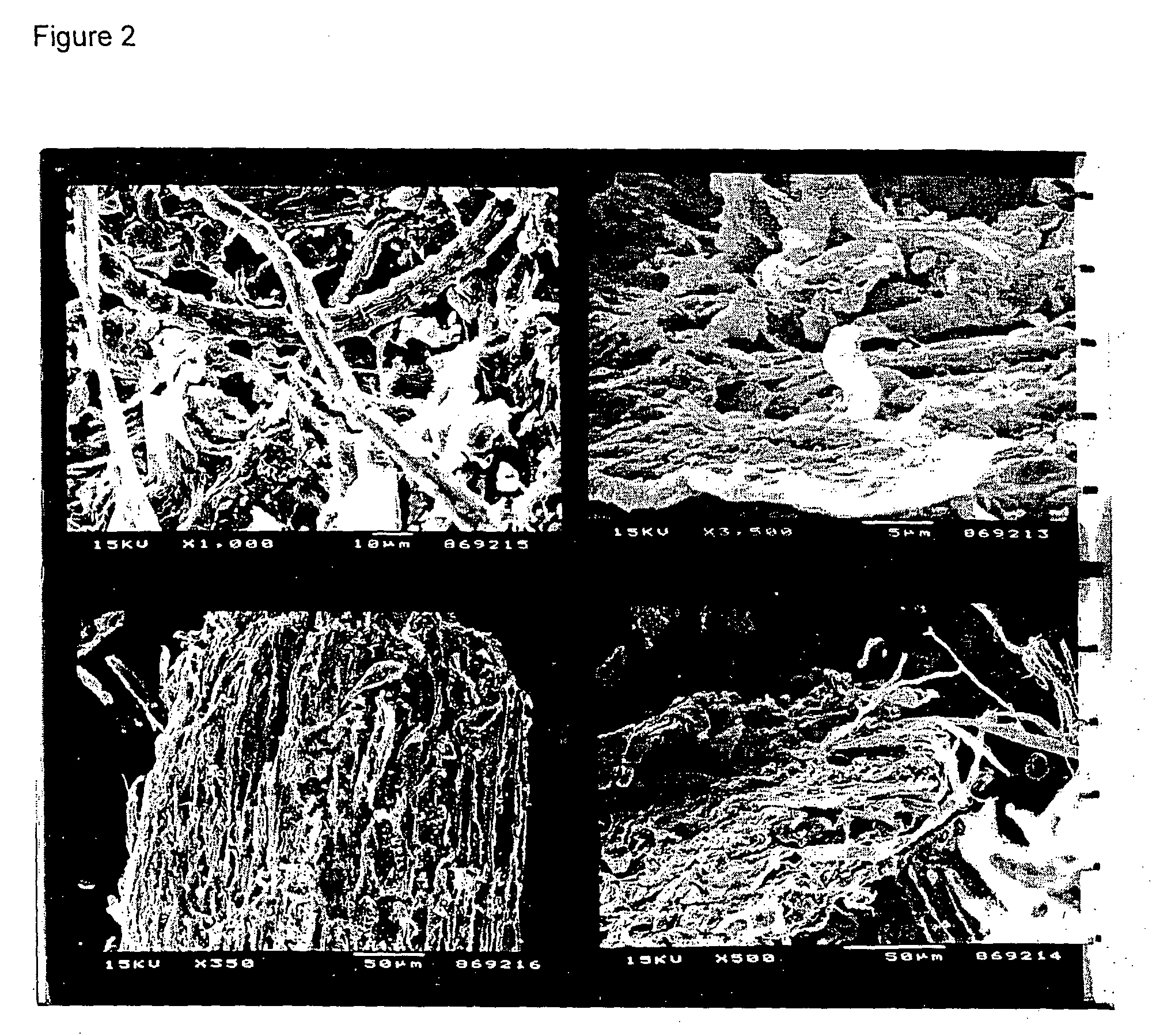

We have discovered a new method to treat biomass with alkali, for example lime. The lime and lignin was sufficiently removed from the treated biomass b> squeezing with a high pressure device to remove alkali and other potential inhibitors of the cellulase enzymes added for sacchaπfication. The resulting fibrous material was rapidly solubilzed by cellulases, even at solid loads ranging from 10 to 30% (w / w) without inhibitory effects on the cellulase activity. The lime pretreatment removed lignin effectively and left the cellulose and hemicellulose almost intact. The method yielded a biomass with structure capable of being enzyme solubilzed and fermented readily at a solids loading of 10-30% for a production of ethanol.

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE

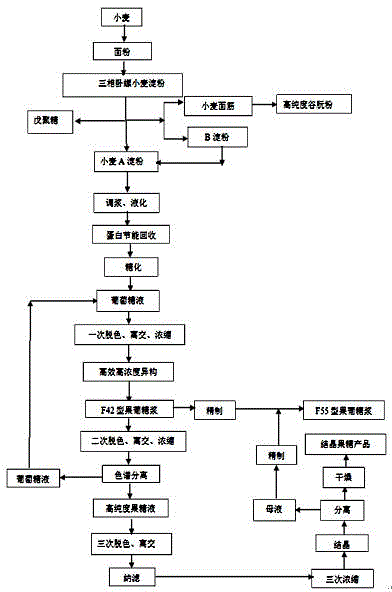

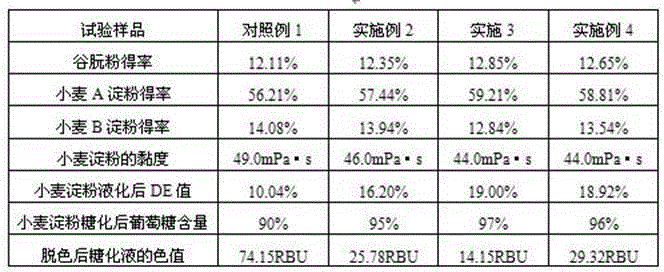

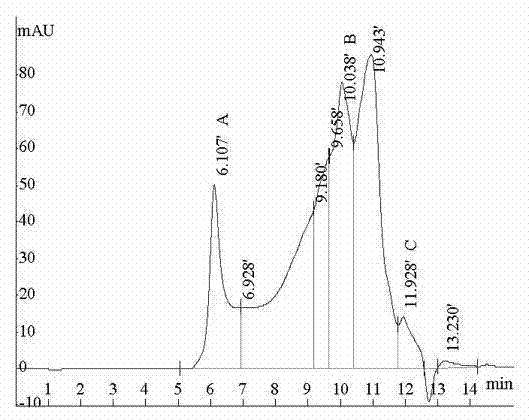

Method for co-producing crystalline fructose and fructose corn syrup by taking wheat as raw material, and preparation method of wheat starch

ActiveCN103146849ASolve constraintsExpand the field of sourcesFructose productionGlucose productionBiotechnologyGluten

The invention discloses a process for co-producing crystalline fructose and F55 fructose corn syrup by taking wheat as a raw material and belongs to the technical field of starch sugar. The process comprises the following steps: grinding the wheat used as the raw material into powder, producing wheat starch by adopting a three-phase horizontal decanter production process, adding a compound enzymic preparation containing lipase into size mixing water to produce by-products such as wheat starch, vital gluten, pentosan and B starch, returning the B starch separated by a three-phase horizontal decanter to a starch finished product tank, subsequently mixing the B starch with A starch and performing a process of producing sugar; acquiring crystalline fructose by mixed wheat starch milk through processes of liquefying, recycling protein, saccharifying, efficiently isomerizing, separating chromatograph, concentrating, crystallizing and drying; and circularly crystallizing mother liquor for a certain number of times, and then compounding the mother liquor with F42 fructose corn syrup acquired by isomerizing to acquire an F55 fructose corn syrup product. By utilizing the preparation method, the problems of high material liquid viscosity, low product yield and poor quality caused by the process of producing starch by taking the wheat as the raw material and sugaring the wheat starch are solved, and the yield and purity of the product are effectively improved.

Owner:BAOLINGBAO BIOLOGY

Method for preparing caramel pigment

InactiveCN1594442ASufficient sourceReach the color ratioNatural dyesFood preparationFood additiveSucrose

The invention discloses a method for preparing caramel pigment mainly used as the liquor color mixing agent and food additive, the preparation process comprises the steps of disintegrating, filtering, concentration. The method can not only meet the color ratio and stability requirement for the cane sugar production, but also preserve the eighteen amino acids and part of the trace elements in the zein.

Owner:兰州金陵石化有限责任公司

Method for preparing high-purity rice protein peptide through high-pressure treatment and enzymolysis

InactiveCN103540637APromote growth and developmentImprove immune functionFermentationMortality rateRice protein

The invention discloses a method for preparing high-purity rice protein peptide through high-pressure treatment and enzymolysis. The method comprises the following steps: crushing and soaking rice residues, performing primary enzymolysis on the rice residues to obtain a primary rice protein, performing high-pressure treatment on the primary rice protein to obtain a secondary rice protein, performing secondary enzymolysis on the secondary rice protein to obtain a zymolyte of the rice protein, centrifuging, and performing spray drying to obtain the rice protein peptide. The adopted raw materials comprise byproducts in starch sugar production and fermentation industry and are wide in source and low in price. In the process of preparing the high-purity rice protein peptide, amylase impurity removal and high-pressure pretreatment are performed, and subsequent enzymolysis is promoted, so that the content of the finally prepared rice protein peptide is higher than 75 percent, and the content of the small peptide with molecular weight of 400-2000Da is higher than 65 percent; when the rice protein peptide is used in foods, growth and development of children are promoted, the immune function of a human body is improved, in-vivo peroxides are reduced, and senescence is delayed; when the rice protein peptide is used in animal feed, the production performance and stress resistance of animals can be improved, and the morbidity and mortality rates and sewage discharge are reduced.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Maltose production and refining method

InactiveCN102586363AOvercome viscosityImprove conversion rateFermentationMaltose productionAutomatic controlFiltration

The invention belongs to the technical field of functional sugar production, and particularly discloses a maltose production and refining method. The maltose production and refining method uses an automatically controlled water heater to spray and liquefy starch milk for two times, an automatic enzyme-dosing system to carry out a liquefied liquid saccharification process, and membrane filtration in the process of refining obtained crude syrup into maltose syrup in the end, and the obtained maltose syrup is then refined, purified, concentrated, centrifuged and dried, so that high-purity maltose is obtained. According to the invention, the steps are simple, the operation is easy, the production period is short, the automation degree is high, the production cost can be effectively reduced, and the industrialized production of maltose with a content being more than 90 percent can be realized.

Owner:山东绿健生物技术有限公司

Squeezing enzymolysis and saccharify method for producing ultrahigh malt syrup raw material

The invention belongs to the technical field of a squeezing processing method of malt syrup by adding enzymic preparation and a saccharifying method of squeezing substance in a malt sugar production technology. The invention has the main technical points of providing the squeezing processing method of the malt syrup raw material for producing ultrahigh malt syrup by adding the enzymic preparation and the saccharifying method of the squeezing substance of the malt syrup raw material using the added enzymic preparation. Compared with the traditional multienzyme cooperation method for producing the malt syrup without squeezing the malt syrup raw material, which is generally adopted at present, the needed saccharifying time is just 2 / 3-1 / 2 of the traditional saccharifying time at present when the malt syrup content of sacharifying liquid without squeezing the malt syrup raw material which is added with the enzyme preparation is reached more than 90%, and a starch production process and a spray liquefaction process are saved. The method disclosed by the invention can be used for producing the ultrahigh malt syrup with the malt syrup content being larger than 90%, and can also be used for producing common malt syrup with the malt syrup content being less than 60^ and the high malt syrup with the malt syrup content being 60-80 %.

Owner:申德超 +2

Insoluble dietary fiber of raisin tree and preparing method thereof

InactiveCN101548757ASmall particle sizeIncrease surface areaMetabolism disorderDigestive systemSwelling capacityAdditive ingredient

The invention discloses insoluble dietary fiber of raisin tree and a preparing method thereof. The raw material is raisin tree fruit or fruit residue thereof after brewing, vinegar production, sugar production, beverage production or active pharmaceutical ingredient extraction. According to the impurity in the raw material and the content, one or a plurality of methods of washing, acid treatment, alkali treatment and decoloring and the like are adopted to remove the impurity, and then dehydrating, drying and superfine grinding are executed. The prepared insoluble dietary fiber of raisin tree is light yellow or ivory powder with the average grain size of 10 to 90 Mum, the content of the insoluble dietary fiber is 50 percent to 100 percent, the retention ability is 1 to 10g / g, the liposuction ability is 1 to 10g / g, the swelling capacity is 1 to 10 mL / g, and the cation exchange resin capacity is 1 to 7 mmoI / g. The insoluble dietary fiber of raisin tree can be used for preparing food, functional food or medicines, or be taken as raw material or auxiliary material of food, functional food or medicines. The method for preparing the insoluble dietary fiber of raisin tree is simple, the production equipment is easily-obtained and has low cost, and the method is suitable for industrialized production.

Owner:NORTHWEST A & F UNIV

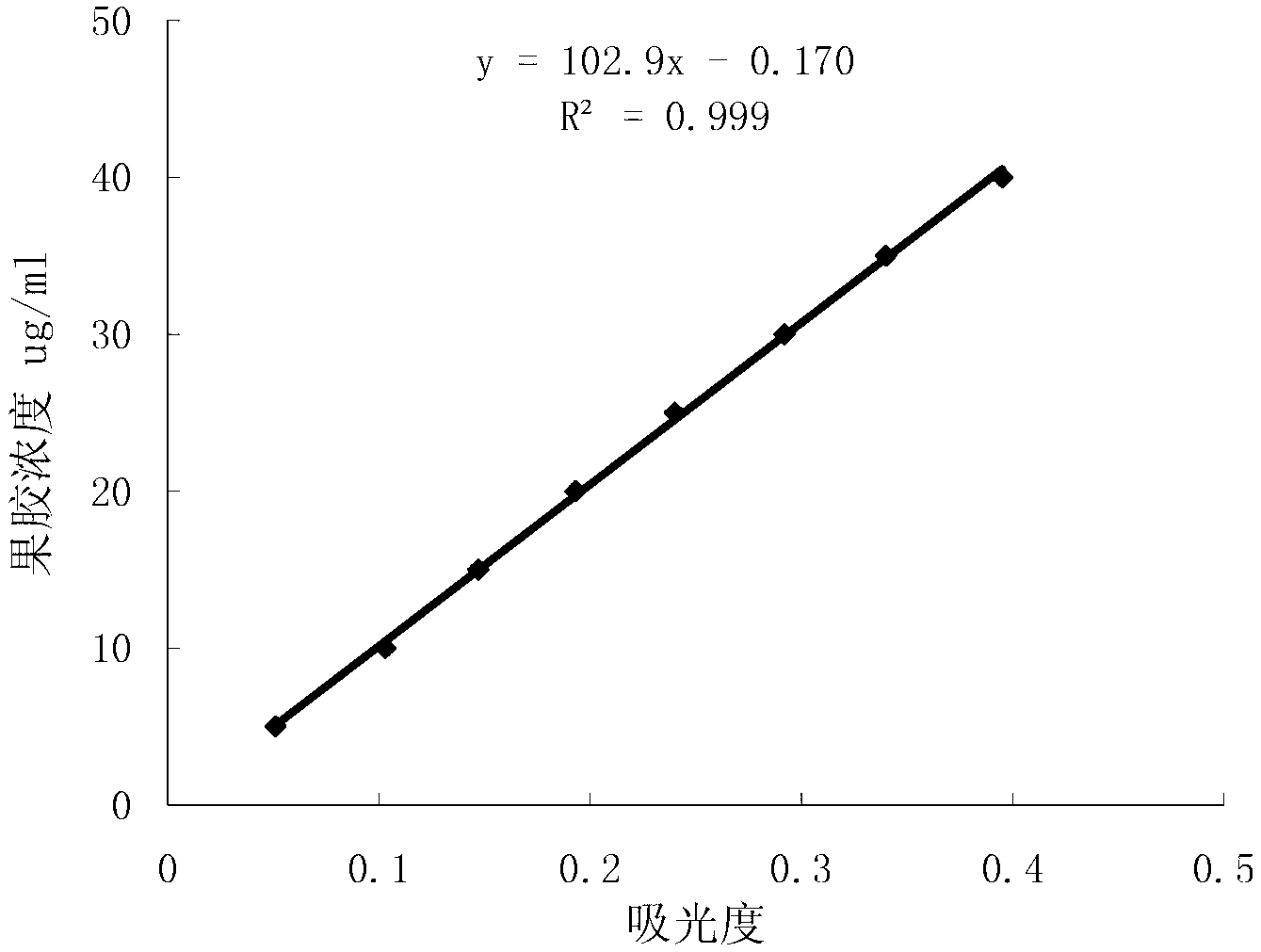

Method for extracting pectin

The invention discloses a method for extracting pectin. The method comprises the following steps of: mixing dried beet pulp powder subjected to ethanol treatment with an acid solution under the condition of ultrasonic and microwave heating and carrying out extraction; regulating the pH value of an obtained extracting solution to 2-5, and then carrying out ultrafiltration concentration; and then adding anhydrous ethanol to an obtained concentrated solution for deposition, and collecting deposits to obtain the pectin. According to the method for extracting beet pectin, which is disclosed by the invention, the resource waste and the environment pollution are reduced, the comprehensive utilization of wastes obtained from beet sugar manufacture processing is realized, and the product additional value is increased. Meanwhile, the method is simple in process and easy to carry out industrialized operation by extracting the pectin by adopting existing ultrasonic and microwave machines in the present market; and the beet pectin product has the advantages of high purity, less impurity and edible safety and reliability.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Method for producing microbial agent by using filter mud of sugar mills through fermentation

InactiveCN102924133ASimple processLow costBio-organic fraction processingOrganic fertilisersBiosphereMicrobial agent

The invention provides a method for producing a microbial agent by using filter mud of sugar mills through fermentation, belonging to the field of the production technology of the microbial agents. The method can produce the high quality microbial agent and treat the pollutions caused by the industrial waste filter mud of the sugar mills at the same time, and also can achieve the circulating economic benefits for the sugar industries. The method comprises the steps of mixing the filter mud of the sugar mills, weathered coal of the humic acid or grass carbon and dried straw to obtain a mixture, controlling the water content of the mixture to 33%-70%, adding the microbial agent into the mixture at a mass ratio of 2% of the microbial agent to the mixture, rapidly stirring to form a homogeneous mixture, loading into a sealing bag, and carrying out anaerobic fermentation for 10 days at a room temperature of the south of China to obtain the microbial agent with an effective living bacteria number being greater than or equal to 300 million / g (higher than the national standard of 200 million / g). According to the invention, the method has the advantages of low cost, simple operation and high product quality, achieves the effective resource utilization through converting the filter mud of the sugar mill into a treasure, solves the problem of the environmental pollution and saves high environmental protection cost for the sugar industries, and brings good economic benefits at the same time, which can form a closed biosphere of the sugar production; and the biosphere creates circulating economic benefits, and brings rich rewards to the sugar industries and the sugarcane farmers.

Owner:王天喜 +1

Method for producing nutrition sugar by sugar producing material

ActiveCN103098968ARetain nutrientsTake advantage ofConfectionerySweetmeatsManufacturing technologyAdditive ingredient

The invention discloses a method for producing nutrition sugar by a sugar producing material, and relates to the sugar production manufacture technical field. The method comprises the steps of juicing the raw materials, clarifying the cane juice, evaporating, boiling the sugar, crystallizing, purging and drying, the honey obtained by crystallizing and purging of the boiled sugar material is subjected to cleaning treatment, the honey is raw honey and machine syrup or molasses, the treated clean syrup is taken as the raw material for boiling the sugar paste; a sugar seed is placed in a crystallization tank, then the clean syrup is placed in the tank for boiling the sugar paste, the volume ratio of the sugar seed to the boiled sugar paste product is 1:2-3, when the concentration of the material in the tank is 104 Bx-106 Bx, the boiling is completed, the sugar paste is taken out, and the sugar paste is subjected to vacuum drying to obtain the product. The produced nutrition sugar contains the nutrition component of the sugarcane, the resource is fully utilized, the sugarcane sugar producing organic matter refuse discharge capacity is reduced, and the product has special fragrant smell of the sugarcane.

Owner:广西柳州中嘉知识产权服务有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com