Preparation process for extracting inulin from cichory root

A preparation process, the technology of chicory, applied in the field of chemical extraction process, the preparation process of extracting inulin from chicory root, can solve the problems of poor product quality and low inulin production efficiency, and achieve the improvement of production efficiency and product quality, cost and Equipment configuration requirements are low, and the effect of normal operation is guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

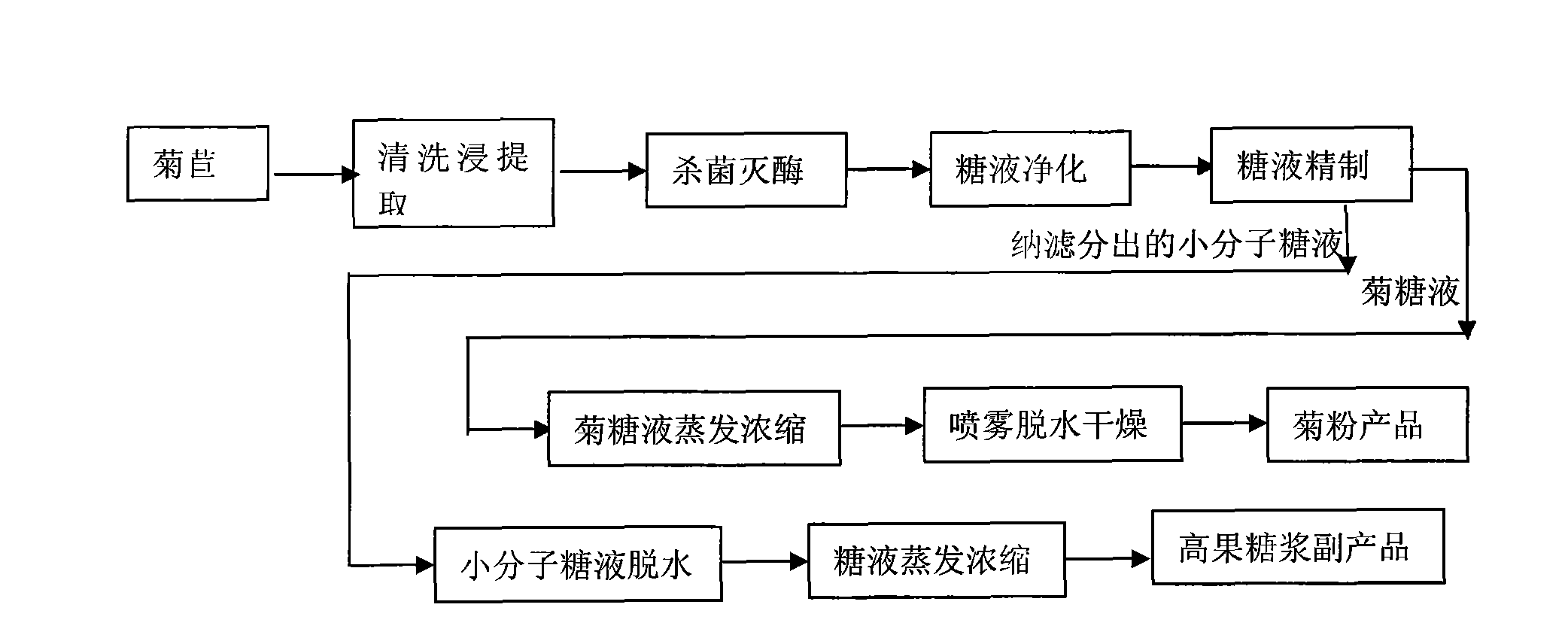

[0025] Extraction process of the present invention comprises the following steps:

[0026] Washing and extracting—clean the fresh chicory root with water to remove impurities; cut the washed fresh chicory root into shreds or thin slices; soak the shredded or thin sliced chicory root in countercurrent with hot water to extract inulin. The ratio of parts by weight of the amount of chicory root is water: chicory rhizome=8:1; the extraction water temperature is maintained at 65 degrees Celsius, the extraction time is 80 minutes, and the residue is extruded after the extraction is completed to obtain the extraction sugar solution A;

[0027] Sterilize and kill enzymes—heat the extraction sugar solution A to 95 degrees Celsius, and carry out high-temperature sterilization and kill enzymes for 20 minutes;

[0028] Purification of sugar solution——the leaching sugar solution A after sterilization and enzyme elimination is subjected to chemical flocculation, separation and purificatio...

Embodiment 2

[0034] In the described cleaning and extracting step, the ratio of water consumption to the amount of chicory root in parts by weight is: water: chicory rhizome=5:1; the extraction water temperature is maintained at 60 degrees Celsius, and the extraction time is 100 minutes;

[0035] In the step of sterilizing and deactivating enzymes, heating the extracted sugar liquid A to 90 degrees Celsius, and performing high-temperature sterilization and deactivating enzymes for 30 minutes;

[0036] In the sugar solution purification step, the calcium hydroxide emulsion with a mass percentage concentration of 10% is put into the extraction sugar solution A to carry out the chemical reaction and flocculation of non-sugar substances, the temperature is controlled at 60 degrees Celsius, and the pH value is controlled at 10 -13, and then use phosphoric acid to reverse the pH to 7-8 to precipitate calcium phosphate;

[0037] In the step of refining the sugar solution, the sugar content in the...

Embodiment 3

[0042] In the cleaning and extracting step, the ratio of water consumption to the amount of chicory root in parts by weight is: water: chicory root=10:1; the extraction water temperature is maintained at 80 degrees Celsius, and the extraction time is 60 minutes;

[0043] In the step of sterilizing and deactivating enzymes, heating the extracted sugar solution A to 100 degrees Celsius, and performing high-temperature sterilization and deactivating enzymes for 10 minutes;

[0044]In the sugar solution purification step, the calcium hydroxide emulsion with a mass percentage concentration of 20% is put into the extraction sugar solution A to carry out the chemical reaction and flocculation of non-sugar substances, and the temperature is controlled at 90 degrees Celsius;

[0045] In the step of dehydrating and concentrating the sugar solution, evaporating and dehydrating and concentrating until the solid content (Brix) reaches 40%;

[0046] In the step of dehydrating and drying the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com