Method for extracting pectin

A pectin and ethanol technology, applied in the field of pectin extraction, can solve the problems of uneven sample extraction and reduced extraction efficiency, and achieve the effects of low energy consumption, short time and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Embodiment 1, the discussion of extracting optimum pH value

[0066] 1) After pulverizing the dry beet meal with a universal grinder, pass it through a 10-mesh sieve, mix 100g of the dry beet meal powder with 400ml of absolute ethanol, heat and boil in a water bath at 95°C, condense and reflux for 15 minutes, and filter out the liquid after cooling. The powder was washed with tap water until the eluent was colorless, and then dried at 50°C to obtain the ethanol-treated sugar beet dry meal powder.

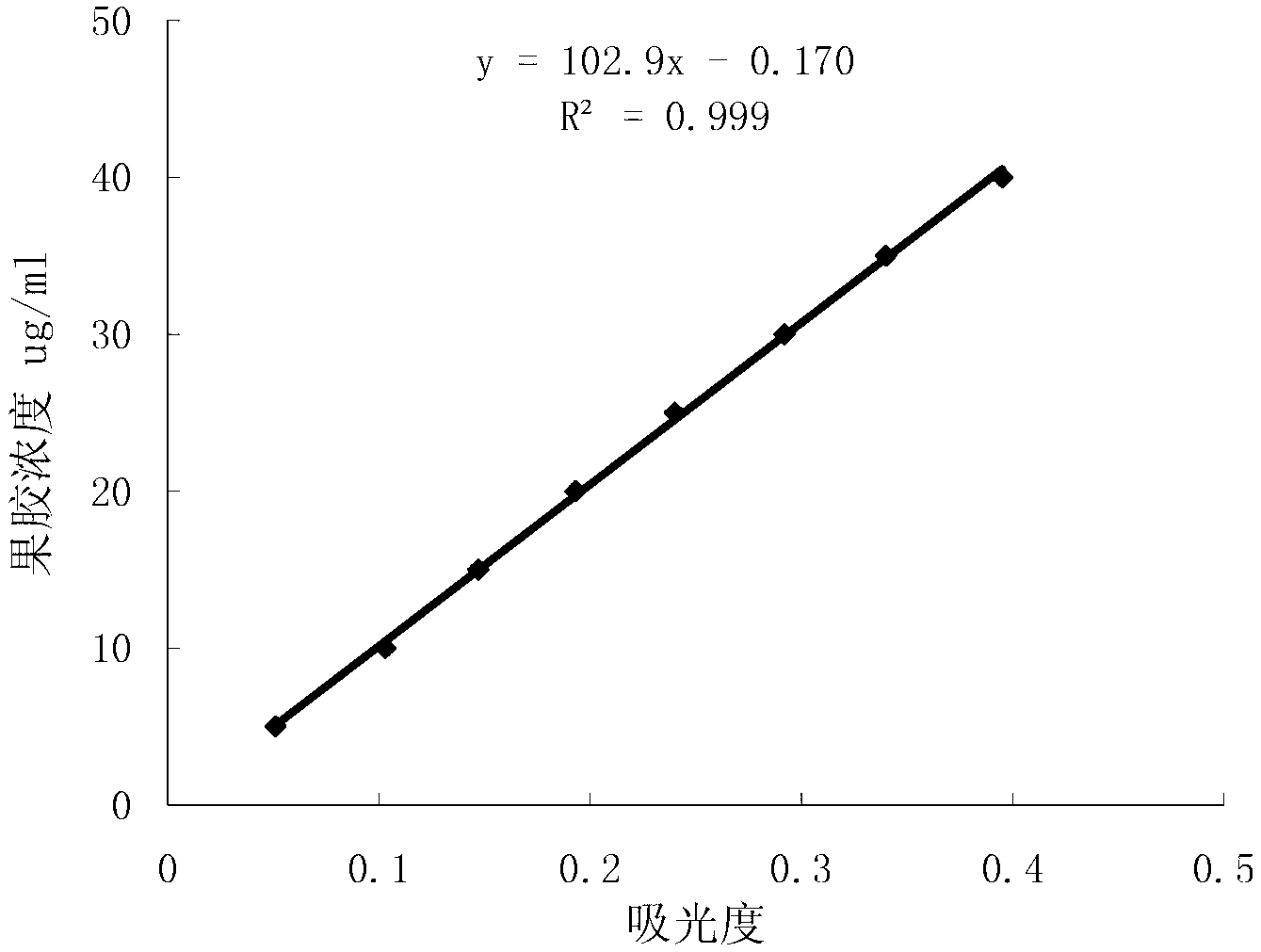

[0067] 2) Take 2.0 g of ethanol-treated sugar beet dry meal powder obtained in step 1), add 60 ml of hydrochloric acid aqueous solution with pH values of 1.0, 1.5, 2.0, 2.5, and 3.0, and put it into an extractor with an ultrasonic frequency of 40 Hz and an ultrasonic power of 50 W In the process, the microwave heating keeps the temperature at 90°C for 30 minutes, and the microwave heating power is automatically changed between 10-800W. After filtration, the filtrate was ad...

Embodiment 2

[0073] Embodiment 2, the discussion of extracting optimum temperature

[0074] According to the steps of Example 1, only the pH value of the aqueous hydrochloric acid solution was fixed at 1.0, and the temperature was sequentially replaced from 90°C to 70, 75, 80, 85, and 95°C to obtain the pectin provided by the present invention.

[0075] The pectin yield and galacturonic acid content are shown in Table 2.

[0076] Table 2. Effect of extraction temperature on pectin yield and galacturonic acid content

[0077]

[0078] Note: Different letters (a, b, c, d, e, f) in the same group indicate significant differences (P<0.05).

[0079] It can be seen from Table 2 that when the extraction temperature is 90°C, the yield of pectin is the largest, which is 24.37%, and the content of galacturonic acid reaches 78.38%.

Embodiment 3

[0080] Embodiment 3, the discussion of extracting optimal time

[0081] According to the steps of Example 1, only the pH value of the aqueous hydrochloric acid solution was fixed at 1.0, and the holding time of microwave heating was sequentially replaced with 15 min, 20 min, 25 min, 35 min, and 40 min to obtain the pectin provided by the present invention.

[0082] The pectin yield and galacturonic acid content are shown in Table 3.

[0083] Table 3. Effect of extraction time on pectin yield and galacturonic acid content

[0084]

[0085] Note: Different letters (a, b, c, d, e) in the same group indicate significant differences (P<0.05).

[0086] It can be seen from Table 3 that with the prolongation of the extraction time, the pectin content first increased, then leveled off, and decreased slightly at 40 minutes, and the content of galacturonic acid did not change significantly with the prolongation of the extraction time. When the extraction time was 35 minutes, the yie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com