Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

575 results about "Maltose Syrup" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for processing broad beans

The invention relates to a method for processing broad beans, which is characterized in that the broad beans serve as the raw material, white granulated sugar, high maltose syrup, gourmet powder, edible salt, water and palm oil serve as auxiliary ingredients, selection, peeling, air separation, soaking, washing, frying, feed preparation, cooling and packaging are carried out to obtain the finished product; in the invention, as mechanical production facilities are employed to produce broad beans, so that the obtained broad beans enjoy more full-bodied fragment and crispy taste and fine mouth-feel.In the invention, dry method peeling replaces wet method alkaline peeling, thus improving safety of the product.In addition, as glucose and sodium carboxymethylcellulose are employed, adhesive force of the coated powder of the finished product is enhanced and mouth-feel and yield of the product are improved.The method of the invention is not only reasonable and practical but also features simple operation, good effect and easy promotion.

Owner:CHACHA FOOD CO LTD

Glutinous rice product and preparation method thereof

The invention relates to the technical field of food processing, in particular to a glutinous rice product and a preparation method thereof. The glutinous rice product has an improved preparation recipe consisting of 80 to 120 parts of high-quality glutinous rice flour, 10 to 20 parts of corn modified starch, 300 to 400 parts of high maltose syrup, 50 to 70 parts of water and compound improving agents which are 5 to 10 percent of the weight of the glutinous rice flour, wherein wrappers account for 70 to 80 percent of the total weight, and the stuffing accounts for 30 to 20 percent of the total weight. The preparation method comprises the following steps of: preparing wrapper, preparing stuffing, filling stuffing automatically, shaping and processing by smoothening agent; then, carrying out ozone sterilization for 1h; and packing to obtain finished products. The invention is characterized in that through the recipe and the process optimization, the preparation process has high automation degree, and the prepared glutinous rice product has strong water preservation performance, high elasticity, good flavor and rich nutrition and is convenient to eat. The problem that the traditional glutinous rice product has short shelf life and can be easily hardened is solved, and the shelf life of the glutinous rice product can reach more than 6 months.

Owner:东莞市圣心食品有限公司

Non-sulfur low-sugar Prunus humilis preserved fruits and method for preparing the same

InactiveCN101273746AReduce sugar penetration rateSave the cost of osmosisConfectionerySweetmeatsSulfurNitrogen

The invention relates to a method for preparing non-sulfur low-sugar prunus humilis preserved fruit; the method comprises the following steps: pitted prunus humilis fruits are added into mixing liquid of CaCl2 solution, in which the CaCl2 occupies 0.2 to 0.4 percent of the mass of water, 0.1 to 0.3 percent of citric acid and 0.1 to 0.2 percent of NaCl; the prunus humilis is taken out after being soaked for one hour at the temperature of 60 DEG C, and is put into a pot with water according to weight ratio of 1.5:1; then white granulated sugar solution, in which the white granulated sugar occupies 25 to 30 percent of the mass of water, 15 to 20 percent of maltose syrup and 10 to 15 percent of glucose are added into the pot, the temperature in the pot is controlled at 80DEG C, sugar permeability is carried out for 2 to 3 hours with the ultrasonic frequency in 28KHz to 40KHz, and the sugar permeability is carried out for one hour at normal temperature and pressure; after the sugar permeability is completed, the preserved fruit is put into an oven with the temperature of 60DEG C, is taken out when the water content in the preserved fruit is reduced to 20 percent, and is packed by adopting that nitrogen is filled in vacuum; the prepared prunus humilis preserved fruit has bright color, strong fruity, soft mouth feeling and good taste, and is sweet instead of greasy.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

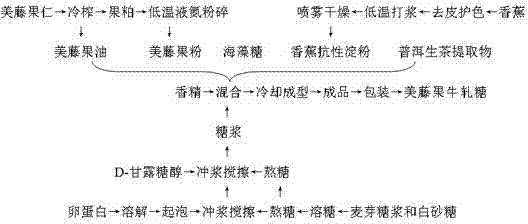

Plukenetia volubilis linneo health-care nougat

ActiveCN103039687APrevent oxidationPrevent rancidityConfectionerySweetmeatsAdditive ingredientNutrient

The invention discloses plukenetia volubilis linneo health-care nougat. The nougat comprises maltose syrup, white granulated sugar, ovalbumin, plukenetia volubilis linneo powder, diglycerol fatty acid ester, D-mannitol, banana resistant starch, trehalose, plukenetia volubilis linneo oil, edible essence, Pu-Er raw tea extract and water. The nougat is prepared by the following steps of: extruding plukenetia volubilis linneo kernels by a cold press to prepare the plukenetia volubilis linneo oil, crushing plukenetia volubilis linneo dregs into the plukenetia volubilis linneo powder by a low-temperature liquid nitrogen crushing technology, preparing the banana resistant starch by a spray drying technology, and mixing and boiling the nutrients including the trehalose, the plukenetia volubilis linneo oil, the plukenetia volubilis linneo powder, the banana resistant starch and the Pu-Er raw tea extract and other accessories. The nougat is stable in preservation, delicate in mouthfeel during eating, moderate in toughness, non-sticky, high in sweetness and low in calorie, has less possibility of softening, has the effects of clearing free radicals in body, improving the immunity of organism, regulating the level of blood sugar and the like, can prevent human osteoporosis and promote proliferation of human bifidobacteria, and is beneficial to gastrointestinal health.

Owner:普洱联众生物资源开发有限公司

Pulp nougat and production method thereof

The invention relates to a pulp nougat, which comprises the following raw materials, by weight, 75-125 parts of white granulated sugar, 75-125 parts of high maltose syrup, 30-80 parts of fruit candies or preserved fruits, 4-12 parts of fresh protein, 15-25 parts of puffed rice, 1-4 parts of butter, 2-5 parts of plant hydrogenated oil, 0.2-0.8 parts of glycerin monostearate, 0.3-0.8 parts of soybean phospholipid, and 0.1-0.3 parts of foaming powder. The production steps comprise: dissolving the sugar, preparing a protein foaming agent, decocting the sugar, carrying out pulping two times, mixing and stirring the materials, cooling, shaping, forming, and packaging. The pulp nougat and the production method have the following advantages that: the fruit candies or the preserved fruits are adopted as the main foil raw material, and form the soft taste with the sandy nougat main body, and the moderate sour and sweet taste is provideed for the product so as to develop another style of the nougat, and provide a rare good combination of the candy and the pulp; the pulp nougat is further applicable for consumer groups incapable of hard use of the teeth, and is a high-end product suitable for different consumer groups, wherein the consumer groups incapable of hard use of the teeth comprise old people and children.

Owner:JINSHI ZHONGYI CANDY

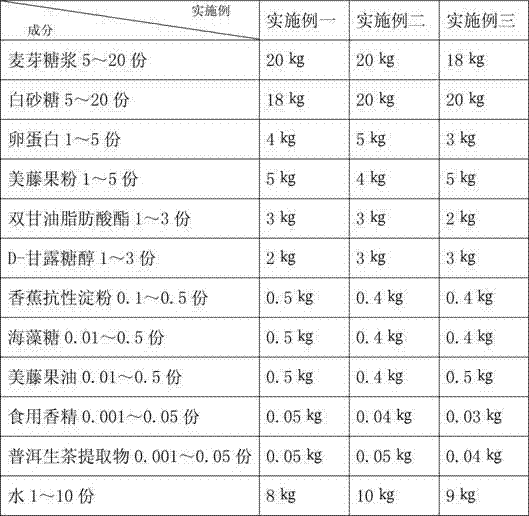

Method for preparing double protein polypeptide soya bean milk powder solid drink

ActiveCN101326981AHigh nutritional valueReduce solubilityFood preparationMilk substitutesAnimal proteinWhole milk

The invention relates to a preparation method of double-protein polypeptide soya-bean milk powder solid beverage, which comprises the following steps: (1) soybean is used to prepare soya-bean milk; (2) the enzyme in partial soybean protein of the soya-bean milk is treated with enzymolysis by prolease into soybean polypeptide; (3) the enzyme is killed to obtain polypeptide soya-bean milk; (4) the following raw materials are first prepared: the polypeptide soya-bean milk, whole milk powder, maltose syrup, white sugar, soybean fiber, edible soybean oil, soybean oligosaccharide, edible calcium carbonate, vitamin A and vitamin D; and then the whole milk powder, the maltose syrup, the white sugar, the soybean fiber, the edible soybean oil, the soybean oligosaccharide, the edible calcium carbonate, the vitamin A and the vitamin D are added into the polypeptide soya-bean milk and mixed evenly, to obtain mixed liquid; (5) the mixed liquid receives spray drying treatment, and the double-protein polypeptide soya-bean milk powder solid beverage is obtained. The double-protein polypeptide soya-bean milk powder solid beverage prepared by the invention has vegetable protein, animal protein, the soybean polypeptide, high nutrition value and is better for the health of human body.

Owner:广州市拿森生物科技有限公司

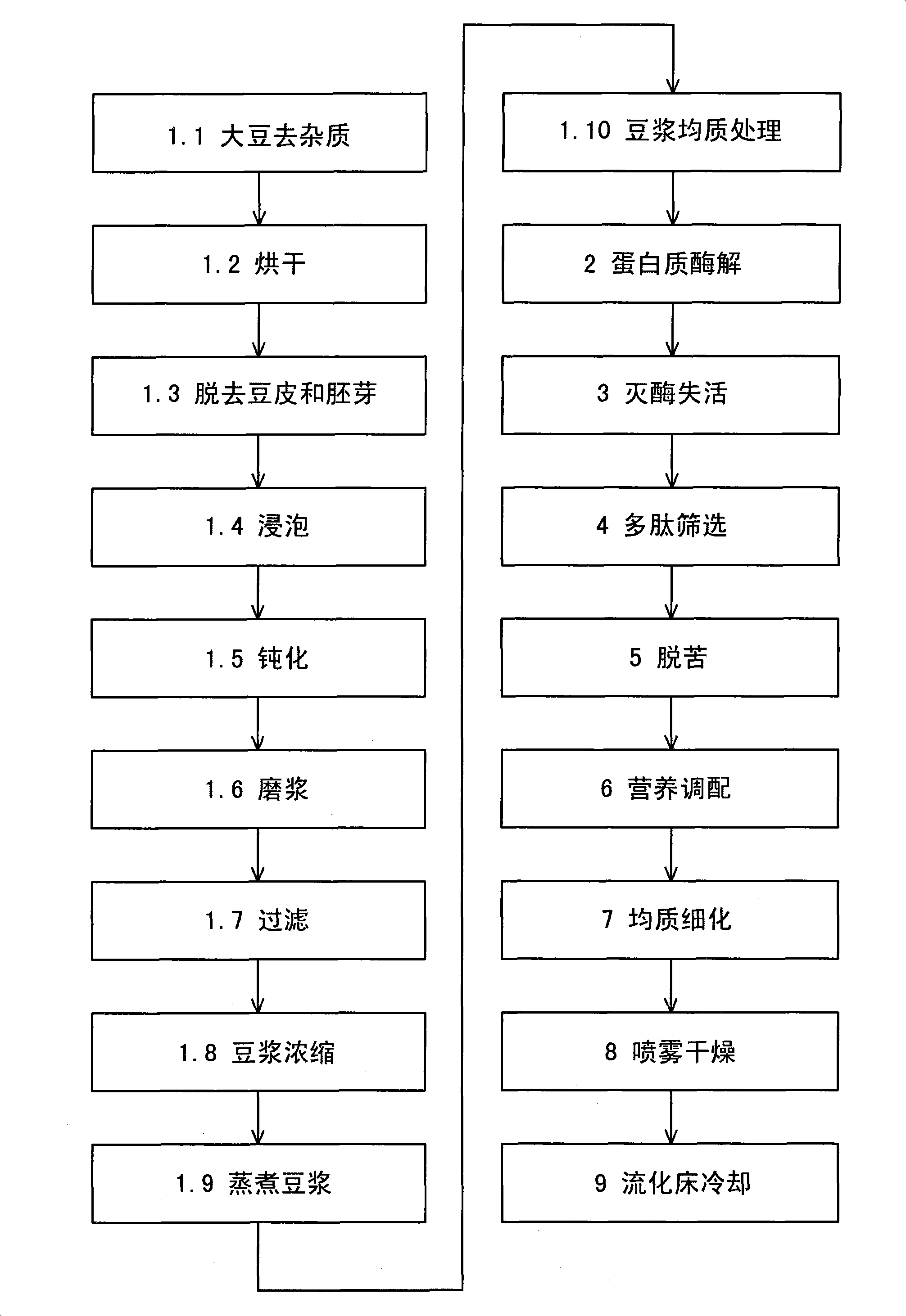

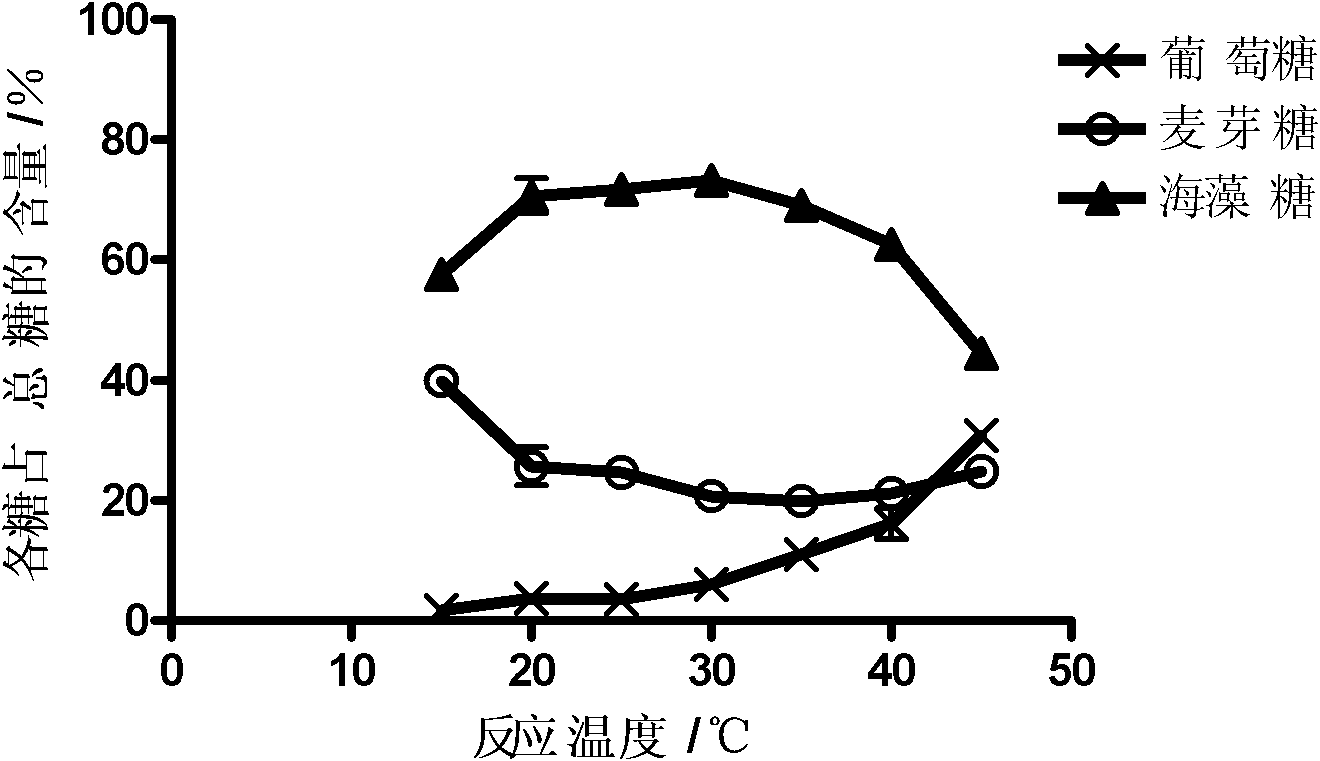

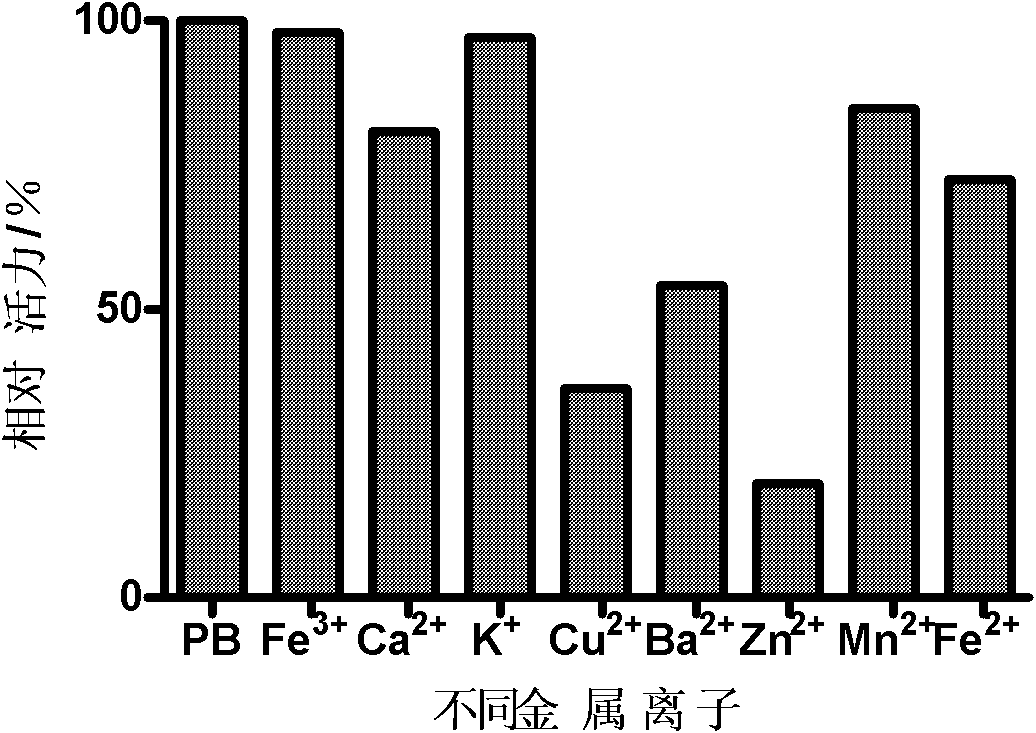

Trehalose synthase of streptomyces griseochromogenes and coding gene and application of trehalose synthase

ActiveCN102690795AReduce occupancyReduce energy consumptionBacteriaTransferasesHydrogenStreptomyces griseochromogenes

The invention discloses trehalose synthase of streptomyces griseochromogenes and a coding gene and application of the trehalose synthase. The trehalose synthase gene is cloned from the streptomyces griseochromogenes. The trehalose synthase can convert maltose to generate trehalose, the proper reaction temperature of the trehalose synthase is 15-35 DEG C and is 20-25 DEG C preferably, and the proper pH (potential of hydrogen) of the trehalose synthase ranges from 6.0 to 8.0 and ranges from 7.0 to 7.5 preferably. The conversion efficiency of the trehalose synthase is high, the maltose is used as a substrate, conversion rate of the maltose is about 80% at the reaction temperature of 25 DEG C, and less than 5% of glucose is generated to be beneficial to increase of the conversion rate of the substrate. The trehalose synthase can be used for converting commercial ultrahigh malt syrup to prepare the trehalose, and a novel method using an enzymic method to produce the trehalose industrially can be provided.

Owner:NANJING UNIV OF TECH

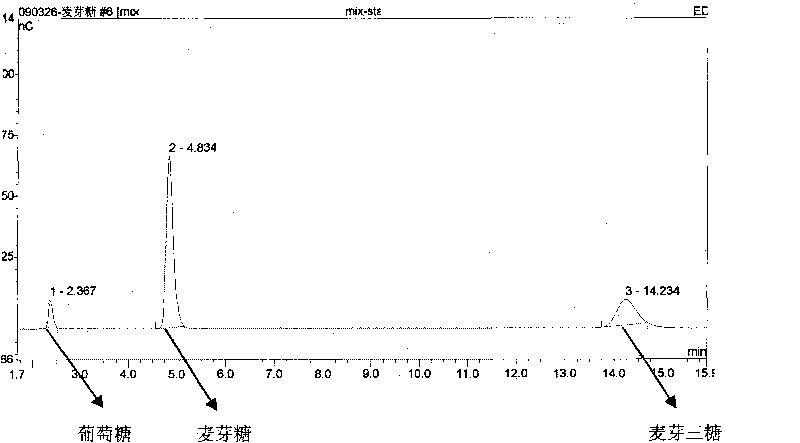

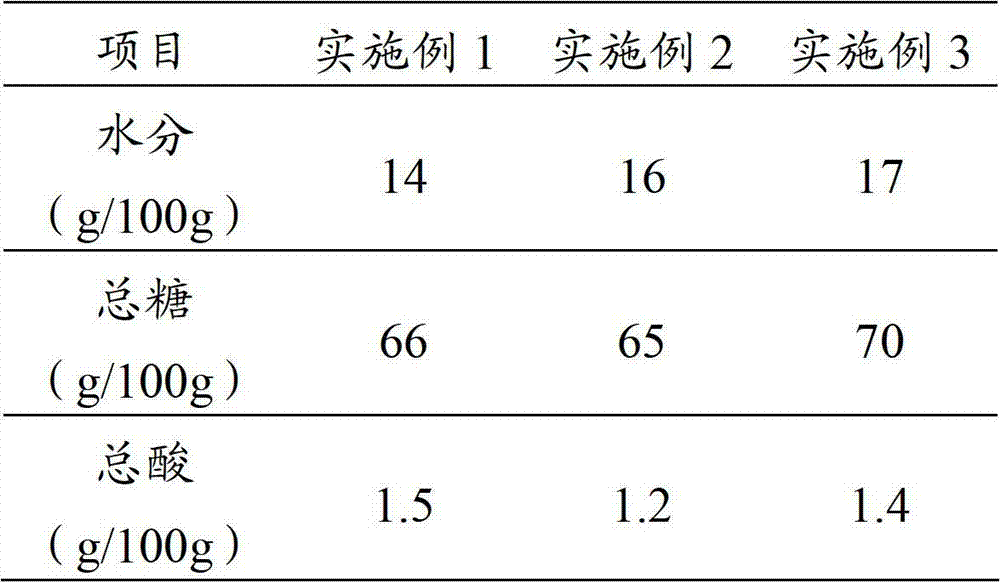

Preparation method of ultra-high maltose syrup

The invention discloses a preparation method of ultra-high maltose syrup, which liquefies and saccharifies rice starch taken as raw material sequentially. The liquefying comprises the steps of adding 0.3-0.5g / kg of calcium chloride and 0.2-0.3g / kg of alpha-amylase into starch slurry with the specific gravity of 14-17OBe and the pH value of 5.0-6.0, and then utilizing a spraying liquefier to carry out liquefying twice so as to obtain rice starch liquefying feed, wherein the first-time liquefying temperature is 110-115 DEG C, the temperature of 90-100 DEG C of the feed liquid is kept for 40-60min and the second-time liquefying temperature is 130-140 DEG C. The saccharification comprises the steps of adding 0.4-0.6g / kg of beta-amylase and 1.0-1.2g / kg Pullulanase into rice starch liquefying feed, and then saccharifying the Pullulanase at the temperature of 55-65 DEG C for 45-60h to obtain the saccharifying solution, separating and purifying the saccharifying solution by ion exchange resin and column chromatography, and then concentrating to obtain the ultra-high maltose syrup of which the maltose content is larger than 80%.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Multilayer composite energy bar and preparation method

InactiveCN105325879AOvercome the shortcomings of single tasteReduce sweetness and greasy tasteFood coatingFood ingredient functionsBiotechnologyVegetable oil

The present invention discloses a multilayer composite energy bar and a preparation method, and the multilayer composite energy bar comprises the following raw materials in parts by weight: 20-30 parts of puffed rice, 12-15 parts of beef grains, 5-10 parts of seaweed, 10-15 parts of beef cakes, 3-5 parts of sesame, 10-15 parts of biscuit crumbs, 10-15 parts of dried fish, 5-10 parts of puffed wheat kernels, 5-10 parts of dried cranberries, 5-10 parts of almond broken grains, 5-10 parts of baking resistant chocolate, 5-10 parts of pumpkin seed kernels, 5-10 parts of walnuts Kernels, 3-6 parts of pine nuts, 5-10 parts of sunflower seed kernels and 35-40 parts of a binder. The binder comprises the following raw materials by weight: 10-20 parts of maltitol, 15-25 parts of maltose syrup, 2-3 parts of glycerol, 1-2 parts of lecithin, 1-2 parts of vegetable oil and 2-4 parts of dextrin; and the multilayer composite energy bar manufactured by rolling with multiple rollers avoids the single sweet greasy taste, and is mellow in taste, salty, fresh, palatable, richly chewy, un-greasy for long term eating, and healthy.

Owner:CHACHA FOOD CO LTD

Concentrated food having rehydration characteristics and the processing method

InactiveCN101061815AImprove food acceptanceHas rehydrating propertiesBakery productsFood preparationIsomaltooligosaccharideInverted sugar syrup

The invention discloses a compressed foodstuff which is prepared mainly from bread flour 40-60 weight parts, instant cereal powder 5-10 weight parts, syrup 15-20 weight parts, plant oil 10-20 weight parts and right amount of other auxiliary materials, wherein the syrup is selected from barley syrup, isomaltose hypgather, fructose syrupand inverted syrup or their combination.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

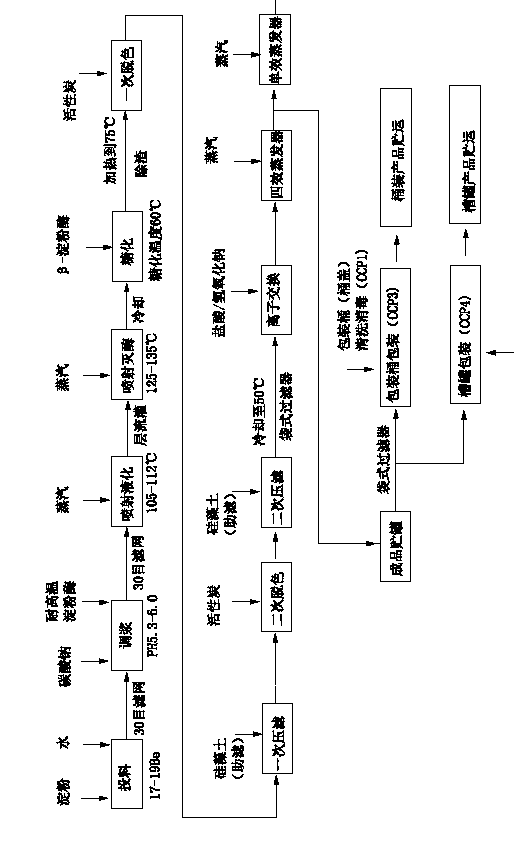

Maltose production and refining method

InactiveCN102586363AOvercome viscosityImprove conversion rateFermentationMaltose productionAutomatic controlFiltration

The invention belongs to the technical field of functional sugar production, and particularly discloses a maltose production and refining method. The maltose production and refining method uses an automatically controlled water heater to spray and liquefy starch milk for two times, an automatic enzyme-dosing system to carry out a liquefied liquid saccharification process, and membrane filtration in the process of refining obtained crude syrup into maltose syrup in the end, and the obtained maltose syrup is then refined, purified, concentrated, centrifuged and dried, so that high-purity maltose is obtained. According to the invention, the steps are simple, the operation is easy, the production period is short, the automation degree is high, the production cost can be effectively reduced, and the industrialized production of maltose with a content being more than 90 percent can be realized.

Owner:山东绿健生物技术有限公司

Method for processing sandwich cakes

ActiveCN102405952ADelicate tasteCrispy tastePreservation by coatingBakery productsFoaming agentFlavoring essences

The invention relates to a method for processing sandwich cakes, comprising the following steps of adopting fresh egg liquid, wheat powder, white granulated sugar, salad oil, margarine and maltose syrup as raw materials; adopting milk powder, citric acid, cake foaming agent, flavoring essence and food coloring as auxiliary materials; whipping, casting to form, baking, cooling, cutting, drying, sorting and sandwiching to obtain the sandwich cakes. The auxiliary materials comprise the following components by weight in parts: 35-40 parts of the fresh egg liquid, 22-25 parts of the wheat powder, 20-22 parts of the white granulated sugar, 5-7 parts of the salad oil, 2-3 parts of the milk powder, 1.3-1.6 parts of the cake foaming agent, 4.7-5 parts of the margarine, 5-6 parts of the maltose syrup, 0.15-0.2 parts of the citric acid, 0.1-0.15 parts of the flavoring essence and suitable quantity of the food pigment. The invention not only can prepare the sandwich cakes which have low water contents, long storage time, rich nutrition, exquisite tastes and crisp properties, but also have mature production equipment, and can realize the large-scale production.

Owner:CHACHA FOOD CO LTD

Squeezing enzymolysis and saccharify method for producing ultrahigh malt syrup raw material

The invention belongs to the technical field of a squeezing processing method of malt syrup by adding enzymic preparation and a saccharifying method of squeezing substance in a malt sugar production technology. The invention has the main technical points of providing the squeezing processing method of the malt syrup raw material for producing ultrahigh malt syrup by adding the enzymic preparation and the saccharifying method of the squeezing substance of the malt syrup raw material using the added enzymic preparation. Compared with the traditional multienzyme cooperation method for producing the malt syrup without squeezing the malt syrup raw material, which is generally adopted at present, the needed saccharifying time is just 2 / 3-1 / 2 of the traditional saccharifying time at present when the malt syrup content of sacharifying liquid without squeezing the malt syrup raw material which is added with the enzyme preparation is reached more than 90%, and a starch production process and a spray liquefaction process are saved. The method disclosed by the invention can be used for producing the ultrahigh malt syrup with the malt syrup content being larger than 90%, and can also be used for producing common malt syrup with the malt syrup content being less than 60^ and the high malt syrup with the malt syrup content being 60-80 %.

Owner:申德超 +2

Tomato fruit cake and making method thereof

The invention relates to a tomato fruit cake and a making method thereof. The tomato fruit cake comprises the components by weight: 100kg of fruit puree, 15-25kg of white sugar, 0.9kg of agar, 0.7kg of carrageenan, 0.04kg of potassium sorbate, 10-20kg of 80% high maltose syrup, 8-12kg of high fructose corn syrup, 0.08-0.10kg of citric acid, 0.04-0.06kg of sodium citrate, 0.04-0.06kg of malic acid and 0.03-0.05kg of malto dextrin. The making method comprises the following steps: feeding materials, and carrying out vacuum cooking for concentration so as to ensure the content of solid substances to be 63wt%-66wt%; and casting, and drying. The tomato fruit cake has the advantages that the taste is cool and palatefull, the sourness and sweetness are suitable, the nutrition is rich, the eating is convenient, the shelf life is long, the production technique is simple and the popularization and the promotion are convenient.

Owner:CHUXIONG YUANMOUREN FOOD

Donkey-hide gelatin sandwich soft candy and preparation method thereof

ActiveCN104770557AStay flexibleGuaranteed flexibilityConfectionerySweetmeatsSodium citrateGlucose powder

The invention relates to a donkey-hide gelatin sandwich soft candy and a preparation method thereof. The soft candy is composed of outer gelatin layers and an interlayer, wherein the interlayer accounts for 10 to 22% of the total weight of the soft candy, and comprises donkey-hide gelatin or / and donkey-hide gelatin oligopeptide accounting for 0.1 to 1.8% of the total weight of the soft candy. The outer gelatin layer is composed of the following components in parts by weight: 47 to 52 parts of maltose syrup, 25 to 29 parts of white sugar, 22 to 26 parts of glucose powder, 2.6 to 3.4 parts of pectin, 1.6 to 2 parts of sodium citrate, 0.32 to 0.46 part of lactic acid, and 0.25 to 0.33 part of essence. The gelatin layer is slightly transparent and has a light yellow color, the interlayer has a typical fruit color, which is alluring, the soft candy is shiny and elastic and the chewiness is good. In the provided preparation method, the donkey-hide gelatin and pectin are boiled individually so as to avoid the phenomenon that the donkey-hide gelatin and pectin are emulsified by the air when the donkey-hide gelatin and pectin are boiled together, moreover, the sandwich layer will not float up or sink, and the appearance is more beautiful.

Owner:SHAN DONG DONG E E JIAO

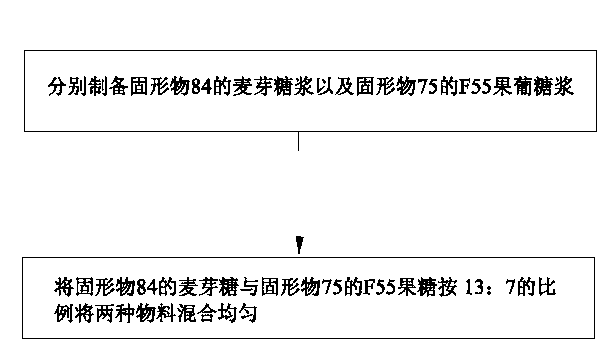

Special syrup for baking in preparation of moon cakes and bread and preparation method thereof

The invention provides a preparation method of special syrup for baking in preparation of moon cakes and bread. The preparation method comprises the following steps of: preparing malt syrup containing 84% of solids and F55 high fructose corn syrup containing 75% of solids; and uniformly mixing the malt syrup containing 84% of the solids and the F55 high fructose corn syrup containing 75% of the solids in a weight ratio of 13: 7 to prepare the special syrup for baking. The special syrup for baking prepared by the invention can replace special white granulated sugar used in a traditional baking process of the moon cakes and the bread and can be directly used in the process of preparing the moon cakes and the bread; and the dissolving of the white granulated sugar is not needed so that the process is simple, the price is lower than that of the white granulated sugar, and the preparation cost is saved.

Owner:肇庆焕发生物科技有限公司

Moon cake

The invention relates to a moon cake, which consists of a shell and filling. The moon cake has the following characteristic that: the shell is made from the following materials in part by weight: 10 to 12 parts of cassava starch, 30 to 40 parts of high maltose syrup, 17 to 20 parts of water, 0.04 to 0.06 parts of antistaling agent, 0 to 0.2 parts of flavorant and 0 to 0.02 parts of colorant. The cassava starch and the high maltose syrup are adopted as the main materials of the shell of the moon cake, the cooked shell has high transparency and uniform color, consumers can see the filling through the shell, moreover, the shell is soft and flexible, cannot be stuck on the teeth, and tastes good, and when the moon cake is eaten, few shell chips drop; the high maltose syrup has a certain moisture-preserving effect and can prevent the starch from aging and hardening, consequently, the shelf life is prolonged, and the shell cannot be cracked after the moon cake is stored for a long time, and still can be kept intact and beautiful; because the high maltose syrup also can reduce the viscosity of the shell, mechanized production can be facilitated, and the production efficiency can be increased.

Owner:广东荣诚食品有限公司

Quicksand-type stuffing with long shelf life and resistant to bake and premixed flour and manufacturing method thereof

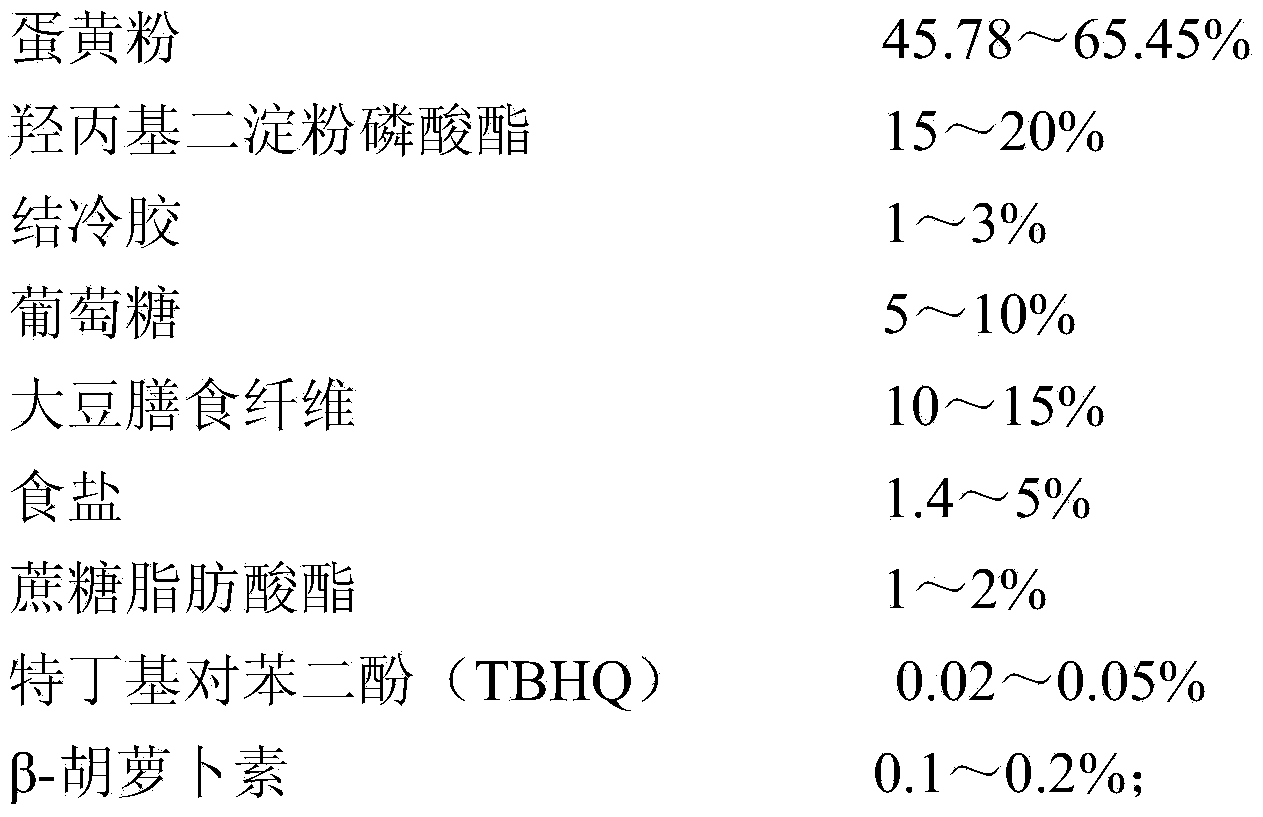

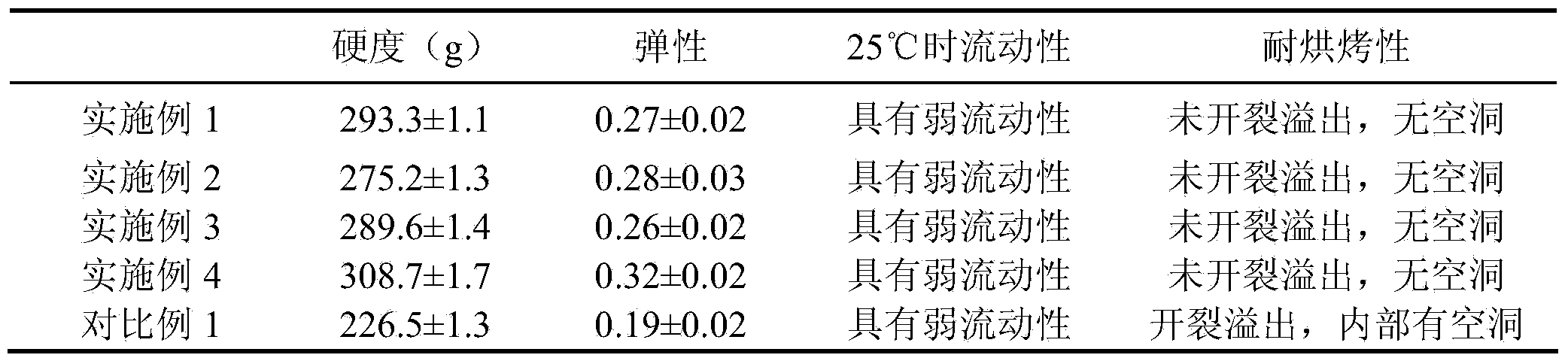

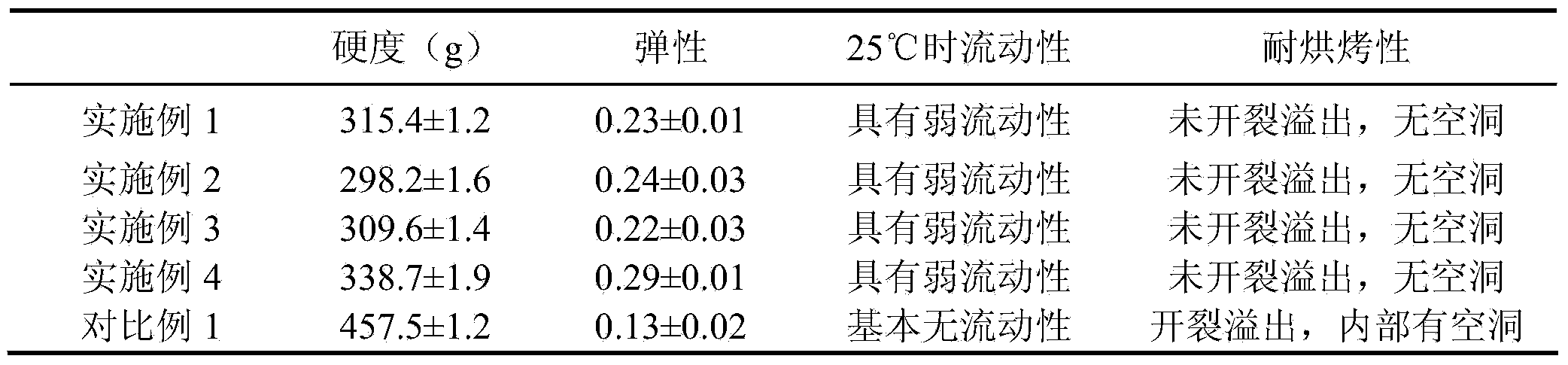

The invention provides quicksand-type stuffing with a long shelf life and resistant to bake and premixed flour and a manufacturing method thereof. The premixed flour of the quicksand-type stuffing comprises, by mass percent, 45.78-65.45% of egg yolk powder, 15-20% of hydroxy propyl distarch phosphate, 1-3% of gellan gum, 5-10% of glucose, 10-15% of soybean dietary fibers, 1.4-5% of salt, 1-2% of sucrose fatty acid ester, 0.02-0.05% of tertiary butylhydroquinone and 0.1-0.2% of beta-carotene. The ingredients are mixed to obtain the premixed flour of the quicksand-type stuffing. The premixed flour is combined with malt syrup, anhydrous ghee, edible glycerol and citric acid so that the quicksand-type stuffing can be manufactured. The quicksand-type stuffing has taste and egg yolk flavor approximate to traditional golden quicksand-type stuffing, and is resistant to bake and long in shelf life.

Owner:广州合诚实业有限公司

Monascus rice wine and preparation method thereof

InactiveCN102408966AHigh nutritional valueIncrease health functionAlcoholic beverage preparationWater bathsPurified water

The invention discloses a monascus rice wine and a preparation method thereof; each 1000 ml of monascus rice wine contains the following components by weight: 600-800 parts of high-quality base wine, 10-40 parts of high maltose syrup, 20-50 parts of honey, the rest being water. The preparation method of the monascus rice wine comprises the following steps: firstly using rice as raw material, sequentially soaking, steaming, flushing, putting into a pot, digging a hole and performing saccharification and fermentation; adding liquid monascus after 60 hours of saccharification and fermentation, uniformly mixing and fermenting, then putting into a pot, fermenting, pressing, boiling the wine and storing into a pot, so as to obtain the high-quality base wine; resolving the high maltose syrup and honey with purified water, then adding the high-quality base wine, then adding enough water, uniformly stirring, determining the quantity and sterilizing; then potting the hot rice wine after sterilizing, cooling the potted rice wine by water cooling to 25 degrees centigrade or lower, so as to obtain the monascus rice wine. The monascus rice wine has all the characters of the rice wine, and it also has the function of decreasing blood fat.

Owner:JIANGSU HENGSHUN VINEGAR IND

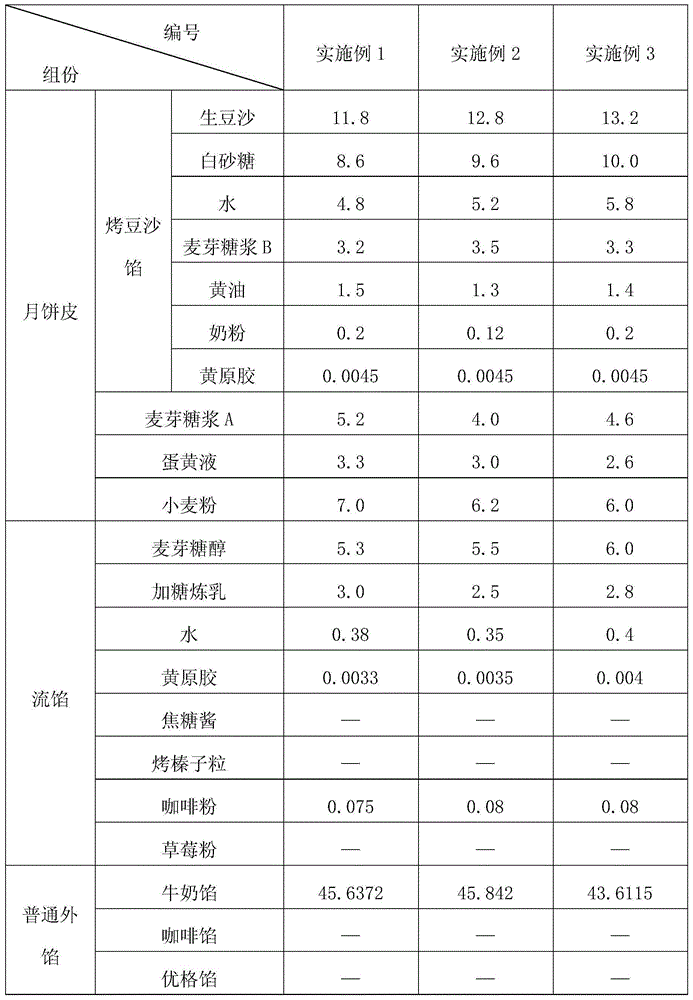

Moon cakes with mobile filling materials and preparation method of moon cakes

ActiveCN105432733AImprove plasticityGood molding effectDough treatmentBakery productsFlavorFilling materials

The invention discloses moon cakes with mobile filling materials and a preparation method of the moon cakes. The moon cakes adopt a formula which comprises the following raw materials in percentage by weight: 45-55% of moon cake crusts, 37-46% of general outer fillings and 8-12% of mobile fillings. According to the moon cakes disclosed by the invention, optimized treatment is performed on the moon cake crusts and the filling materials; roasted sweetened bean paste fillings which are made from raw sweetened bean paste, white granulated sugar, water, malt syrup B, butter, milk powder and xanthan gum according to a definite proportion by weight are added to the moon cake crusts, so that the flavor, the mouth feel and the fine and smooth degrees of the moon cake crusts are promoted, and besides, the plasticity and the moldability of the moon cakes during baking are promoted; the mobile fillings are added, so that on one hand, the moon cakes have the filling materials in flow state, which brings ocular enjoyment to people, on the other hand, the soluble solid contents of the mobile fillings achieve 72-74%, the moon cakes can be guaranteed not to become deformed during baking, the plasticity and the moldability of the moon cakes are promoted, the situation that the water content of the moon cakes cannot migrate within shelf life can be guaranteed, the flavor and the mouth feel of products are guaranteed, and enjoyment on the sense of taste is provided.

Owner:UNI PRESIDENT ENTERPRISES CHINA INVESTMENT CO LTD KUNSHAN RES & DEV CENT +1

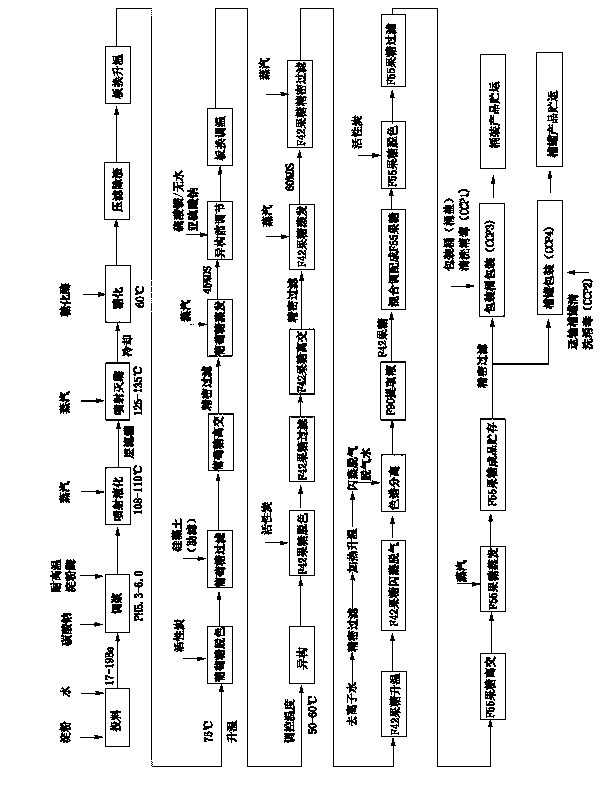

Method for preparing cerealose or maltose syrup with crushed rice enzyme method

The invention discloses a method for preparing cerealose or maltose syrup with a crushed rice enzyme method, comprising the following steps: adding water in crushed rice for washing and immersing, carrying out pulp refining, regulating the pH value of the slurry, adding thermostable alfa-amylase to carry out two times continuous injection liquefaction, keeping warm to obtain the emulsion; adjusting the temperature of the emulsion to 55-60 DEG C, regulating the pH value to 5.0-5.6, adding beta-amylase to carry out saccharification to obtain a sacchariferous liquor with the DE value of more than 40 and the maltose content of more than 40% even 50%, and processing the sacchariferous liquor to obtain a maltose syrup product; or after adjusting the temperature of the emulsion to 55-60 DEG C, regulating the pH value to 5.2-5.7, adding crushed malt with stirring to carry out saccharification until the DE value of the material exceeds 40%, and filtering and condensing the sacchariferous liquor to obtain a cerealose product. The prepared products can be edible directly, and can be used as raw material for processing cake, candy and other Chinese traditional food and as carbon source of a microbe medium.

Owner:GUANGZHOU SHUANGQIAO +1

Streptosporangium roseum trehalose synzyme gene and application thereof

InactiveCN102533822AReduce the numberConducive to improving dry conversion efficiencyMicroorganism based processesIsomerasesReaction rateReaction temperature

The invention relates to a Streptosporangium roseum trehalose synzyme gene and an application thereof. The gene is cloned from Streptosporangium roseum, and the expressed trehalose synzyme is capable of converting maltose into trehalose. The most important characteristic of the gene is as follows: the expressed trehalose synzyme has wide range of reaction temperature and pH, can maintain higher enzyme activity at temperature of 25-35 DEG C and pH of 6.5-7.5, and has high conversion efficiency and reaction rate; the content of trehalose in the reaction product produced by converting maltose into trehalose under an optimum reaction condition can reach 82 percent, and little glucose is produced, thereby the conversion efficiency of the substrate is improved, and the production cost is reduced. By application of the recombinant trehalose synzyme produced by the gene, trehalose can be prepared by taking commercial maltose syrup or maltose syrup prepared from starch as material, and the trehalose can be applied to fields of food industries, cosmetics, medicines, biological products and the like.

Owner:南宁中诺生物工程有限责任公司

Hot processing technology of a cake with stuffing

ActiveCN103518798AMeet nutritional requirementsEasy to produceDough treatmentBakery productsBiotechnologyGlycerol

The invention discloses the hot processing technology of a cake with stuffing. The cake with the stuffing comprises, by weight, 30%-32% of fresh egg, 18%-25% of white granulated sugar, 22%-24% of wheat flour, 0.8%-1.2% of starch, 5.4%-6.5% of oil, 5%-6% malt syrup, 0.45%-0.58% of strawberry powder, 2.2%-3.93% of sorbitol, 1.2%-1.4% of Tianjin Riken foaming agent, 1.5%-1.91% of glycerin, 0.01%-0.011% of citric acid, 0.08%-0.14% of xanthan gum, 0.3%-0.312% of edible salt, 1.0%-1.4% of inulin, 3.5%-3.9% of water, 0.035%-0.039% of potassium sorbate, 0.015%-0.019% of sodium dehydroacetate, 0.002%-0.0023% of edible essence and 0.00075%-0.00078% of carmine. Before the cake is baked, the stuffing is injected into the cake, the stuffing and a cake body are put into a baking oven together for baking and sterilization, so that the technology is safer than the cool processing technology that the stuffing is injected into the cake body after the cake body is baked and flow line production is facilitated.

Owner:CHACHA FOOD CO LTD

Curing method for sour-sweet flavor yellow pepper sauce

The invention discloses a curing method for a sour-sweet flavor yellow pepper sauce. The sauce comprises the following raw materials in parts by weight: 8-20 parts of yellow pepper, 5-8 parts of salt, 10-20 parts of garlic, 20-30 parts of drinking water, 10-20 parts of pumpkin, 15-25 parts of maltose syrup, 2-4 parts of other flavorings, 1-2 parts of an additive, and 0.1-0.5 parts of a spawn. The preparation method comprises performing initial fermentation on yellow pepper and then preparing a finished product. The preparation method for the finished product comprises: forming a sol, namely adding xanthan gum into water and fully dissolving, boiling and processing by a colloid mill; cooling, adding completely-cured yellow pepper, garlic, drinking water, pumpkin, maltose syrup, other flavorings and the additive, stirring uniformly, and performing vacuum loading and pasteurizing, so as to obtain the sour-sweet flavor yellow pepper sauce. The sour-sweet flavor yellow pepper sauce has unique garlic fragrance and refreshing pungent taste, is sweet but not greasy, is pungent but does not lead to dryness heat, is mainly applied to flavoring during cooking of seafood, cooked wheaten food, barbecue and the like, and also can be used as a pepper sauce to be eaten together with rice or bread.

Owner:ZHEJIANG ZHENGWEI FOOD

Konjak snack food and preparation method thereof

The invention discloses konjak snack food and a preparation method thereof, and belongs to the technical field of food processing. The konjak snack food takes konjak powder as an important gel component; and apart from the konjak, the snack food also comprise an auxiliary gel such as carrageenin, agar, sodium alginate, thermal gel, gelatin and the like, a flavoring such as an acidifier, a sweetening agent, common salt, spice and the like and a food additive such as sugar ester, potassium sorbate, maltose syrup and the like. The snack food has a moisture content of 25 to 70 percent and can be enjoyed with rich flavor when opened and therefore is convenience food for supplementing the daily dietary fiber.

Owner:HUBEI YIZHI KONJAC BIOTECH

Stick shaped peanut crisp and preparation method thereof

InactiveCN105639029AGood for healthFull of nutritionConfectionerySweetmeatsHigh-fructose corn syrupPhospholipid

The invention relates to the technical field of foods, and in particular relates to stick-shaped peanut crisp and a preparation method thereof. The peanut crisp is prepared from the following raw materials in parts by weight: 115-155 parts of malt syrup, 40-120 parts of white granulated sugar, 30-50 parts of high fructose corn syrup, 30-42 parts of palm oil, 300-372 parts of baked chopped peanuts, 32-112 parts of crisp cereal, 32-112 parts of corn expanded particles, 5-40 parts of white sesame seed, 5-40 parts of black sesame seed, 4-7.2 parts of edible salt, 0.1-0.3 part of phospholipid, and 2.5-3.5 parts of baking soda. The preparation method orderly comprises the following steps: preparing raw materials, decocting sugar syrup, mixing and forming, and coating. The stick-shaped peanut crisp provided by the invention is more abundant in nutrition, crisp in taste, and is more novel in the taste in matching with the chocolate. The preparation method provided by the invention is less in equipment input, low in energy consumption, simple in operation and suitable for industrial popularization.

Owner:ZHENGZHOU RONGLIDA BIOLOGICAL TECH CO LTD

Preparation technology for combined production of beta-cyclodextrin and extremely high maltose syrup

ActiveCN104762346AEffective liquefactionDelay agingFermentationChromatographic separationActivated carbon

The invention relates to a preparation technology for combined production of beta-cyclodextrin and extremely high maltose syrup. The technology comprises the following steps: carrying out starch slurry mixing to resist high temperature alpha-amylase liquefaction; adding debranching enzyme and CGT enzyme for realizing synergism; adding beta-amylase, maltogenic amylase and active carbon to synchronously carry out saccharification and decoloring; and carrying out one time crystallization, filtering, leaching the obtained solid to remove impurities in order to obtain purified beta-cyclodextrin, carrying out chromatographic separation on the obtained mother liquor, and concentrating to obtain the extremely high maltose syrup. The technology has the advantages of high starch conversion rate, one-time decoloring, one-time crystallization, simple steps, preparation of the extremely high maltose syrup, and great improvement of the integral utilization rate of a raw material.

Owner:JIANGSU OGO BIOTECH

Method for preparing high-purity maltose syrup by adopting rice as raw material

The invention discloses a method for preparing high-purity maltose syrup by adopting rice as raw material, comprising the following steps of: (1) removing the impurity in the raw material rice, adding water for soaking, grinding the syrup into grout, and filtering; (2) mixing the grout, adding high temperature-resistant Alpha amylase, stirring and mixing evenly; (3) carrying out liquefaction and discharging slag; (4) saccharifying; (5) neutralizing, decoloring and filtering; (6) carrying out ion exchange refining; (7) concentrating; and (8) packaging. The obtained dried high-purity maltose syrup has the maltose content of 80 to 86%.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY +1

Wild jujube cake and preparation method thereof

The invention relates to the field of the food, and discloses a wild jujube cake and a preparation method thereof. The wild jujube cake disclosed by the invention is prepared from choerospondias axillaris, white sugar, malt syrup, high-concentration Kefir fermentation stock solution SH-C-201, fructo-oligose, edible salt, potassium sorbate and water, wherein the flavor of the choerospondias axillaris and the flavor of the high-concentration Kefir fermentation stock solution are combined to enable the wild jujube cake to have thick yoghourt taste and also keep the due fruit aroma of the wild jujube, and the current situation that the traditional wild jujube cake product has a single taste and nutrition structure is changed. Meanwhile, the prepared wild jujube cake product represents beige and maize yellow, and the product is still beige after being put for half year, thereby solving the problem that the product appearance and the shelf life are affected. The preparation method for the wild jujube cake, which is disclosed by the invention, is convenient to operate and is suitable for industrial production.

Owner:GUANGDONG JIABAO GRP CO LTD

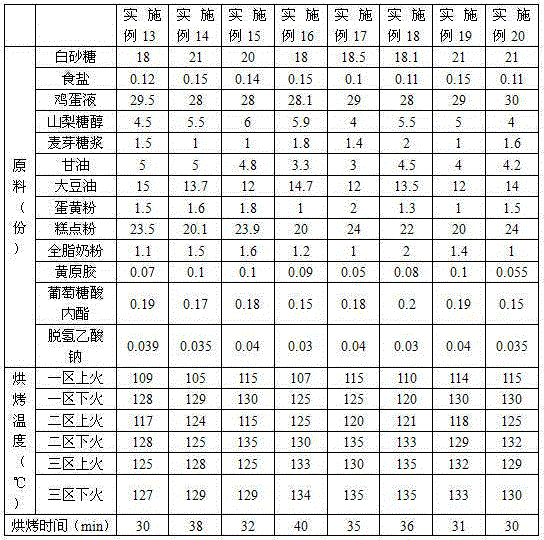

Low-temperature baking cake and manufacturing method thereof

InactiveCN105053136APromote hydrationRetain moreDough treatmentBakery productsBiotechnologyHealthy diet

The present invention discloses a low-temperature baking cake which is prepared from the flowing raw materials in parts by weight: 18-21 parts of white granulated sugar, 0.1-0.15 part of edible salt, 28-30 parts of egg liquid, 4-6 parts of sorbitol, 1-2 parts of malt syrup, 3-5 parts of glycerin, 12-15 parts of soybean oil, 1-2 parts of egg yolk powder, 20-24 parts of pastry flour, 1-2 parts of whole milk powder, 0.05-0.1 part xanthan gum, and 0.18-0.24 part of preservatives. The cakes are manufactured by using a creative baking process which employs a baking temperature of 105-135 DEG C and a baking time of more than 30 minutes. The manufactured cakes have a higher moistening degree, and have superiority in melting properties in mouth and post moisturizing ability compared with the high-temperature baking cakes. And also because the cakes are baked at low temperatures for a long-time, relatively more nutrients of the cakes are retained, and also some unhealthy caramelized products induced by high temperatures are not easily produced. The low-temperature baking cakes are good products which fit to the current healthy diet.

Owner:MAIFENG FOOD CHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com