Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

398 results about "Starch production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Starch production is an isolation of starch from plant sources. It takes place in starch plants. Starch industry is a part of food processing which is using starch as a starting material for production of starch derivatives, hydrolysates, dextrins.

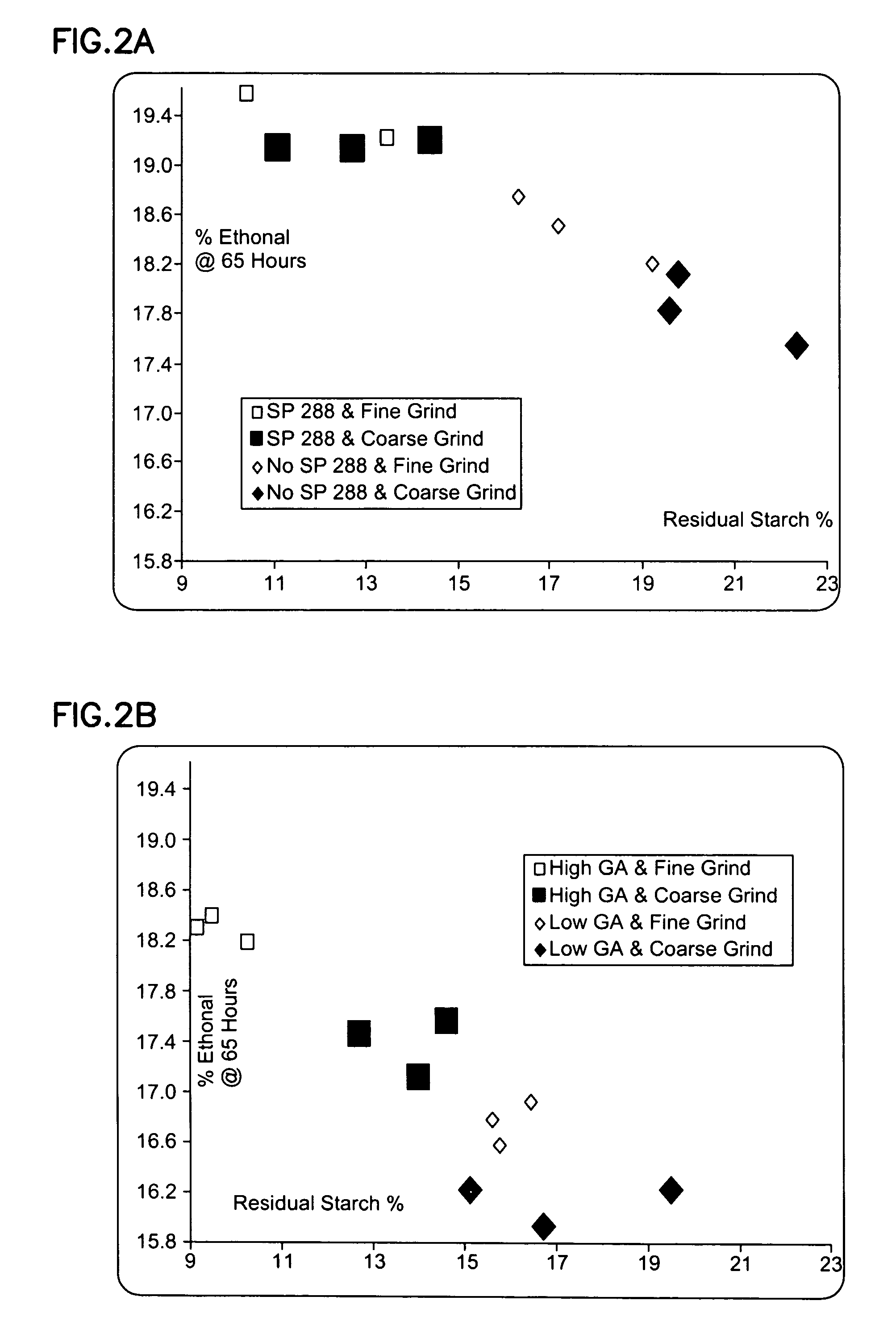

Methods and systems for producing ethanol using raw starch and selecting plant material

ActiveUS20070178567A1Improve the level ofDough treatmentWort preparationHigh alcohol beerStarch production

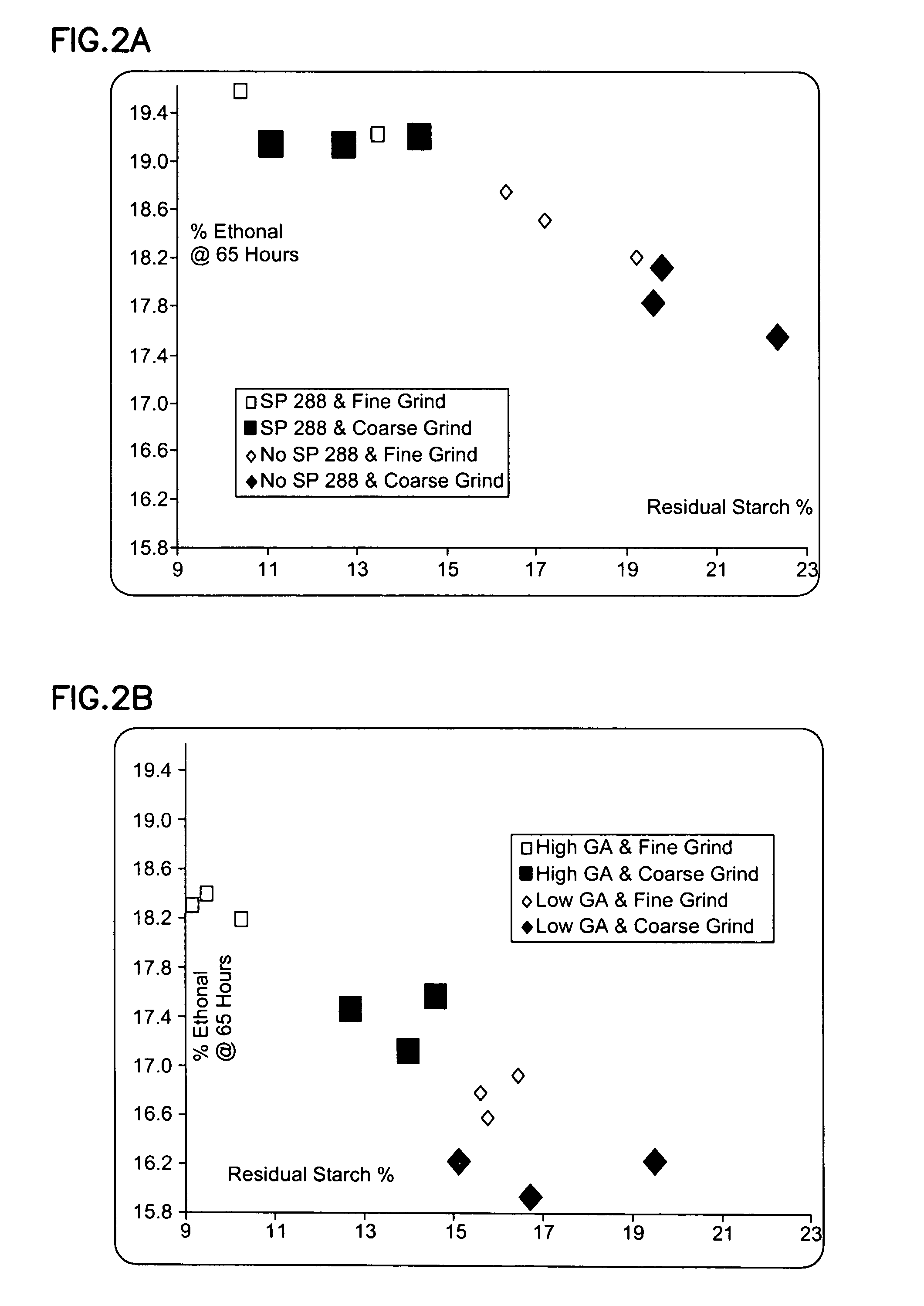

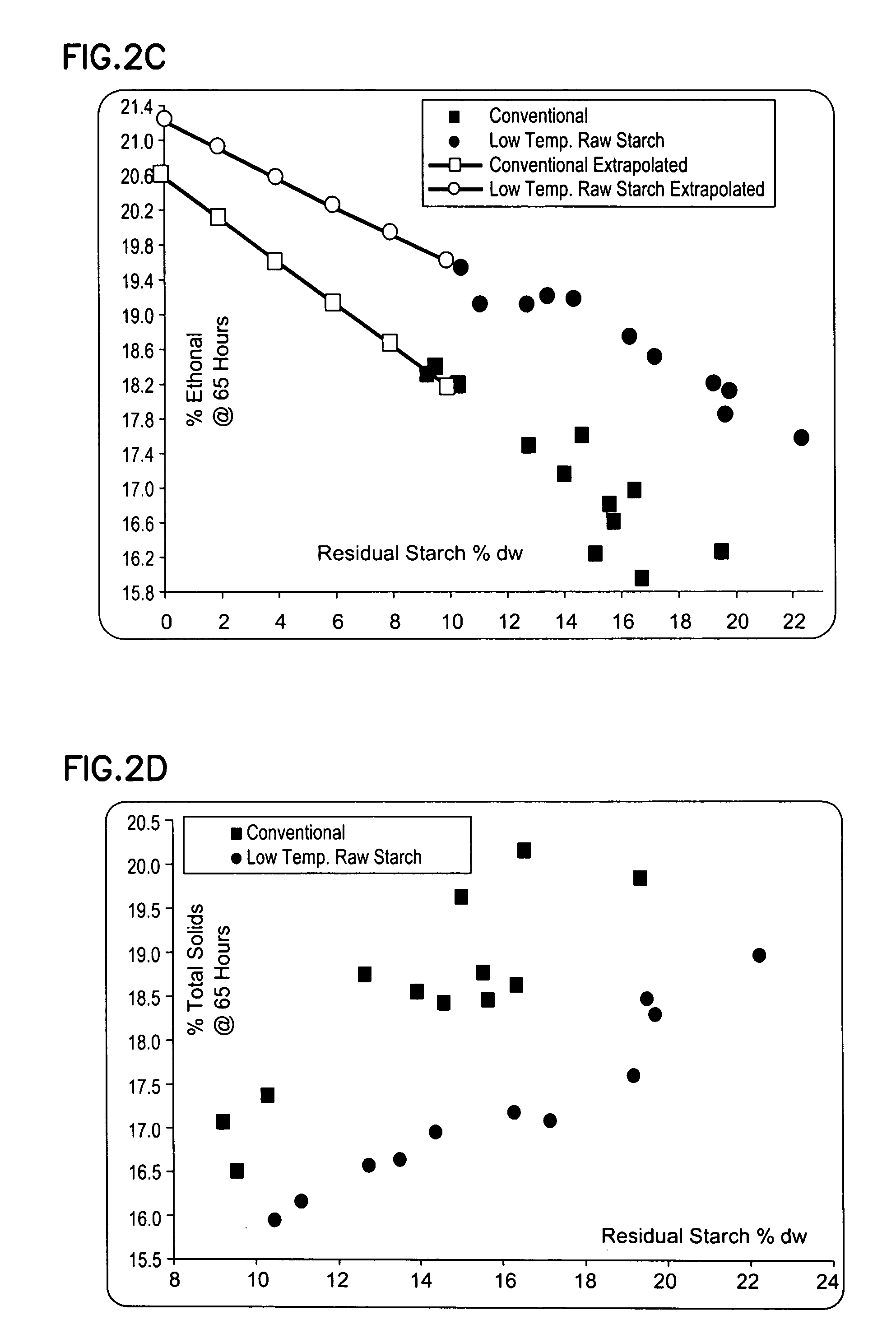

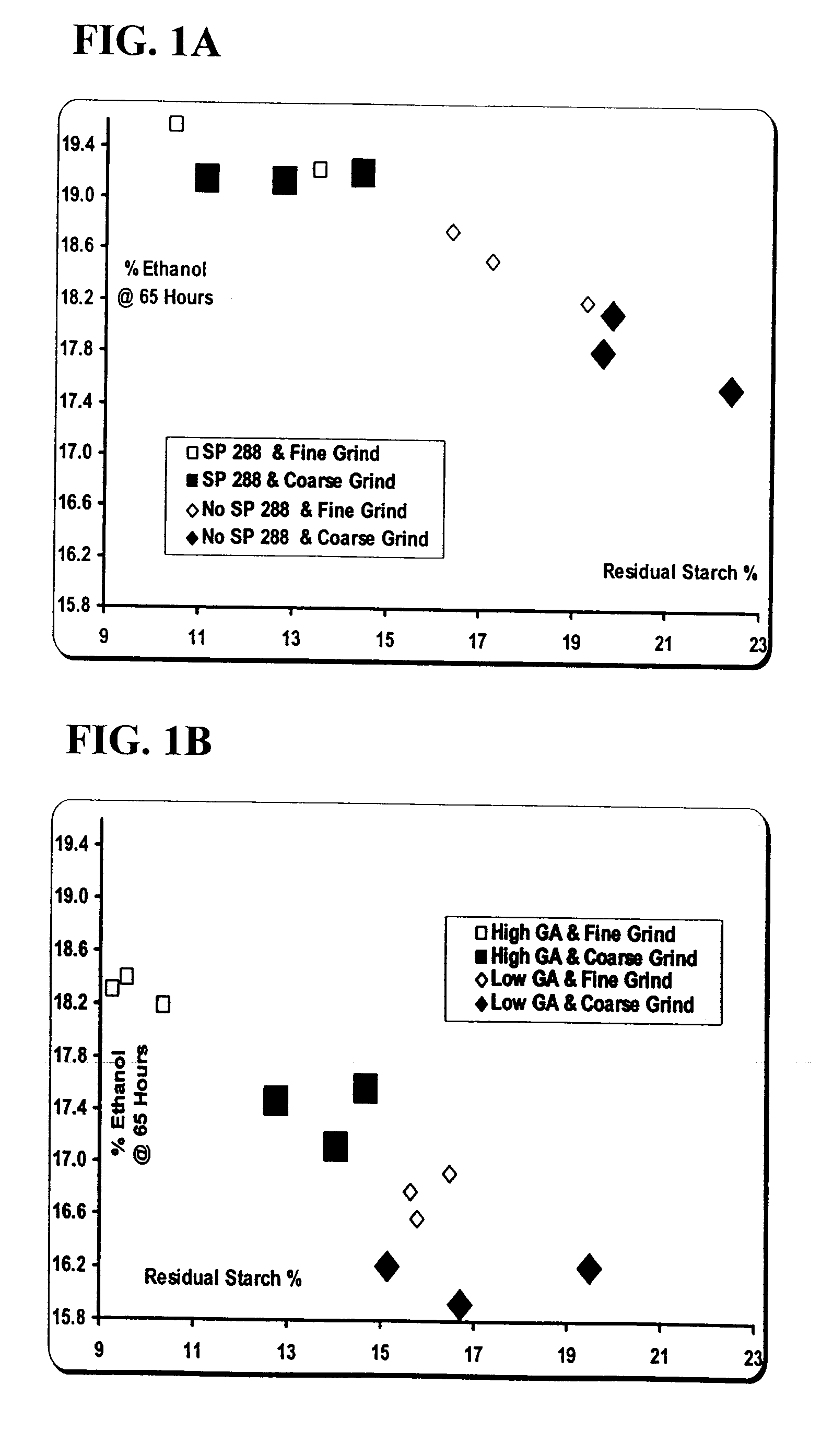

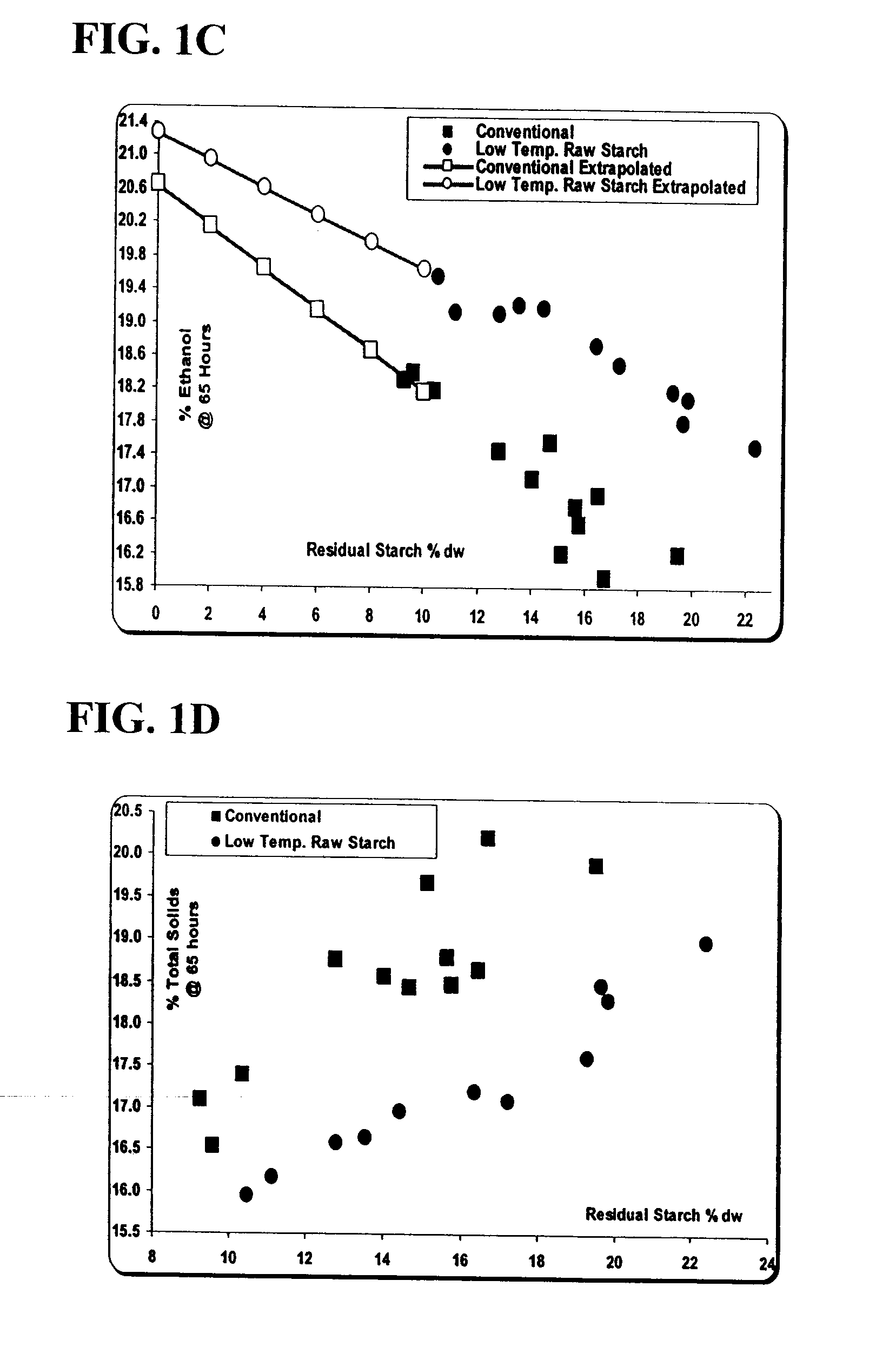

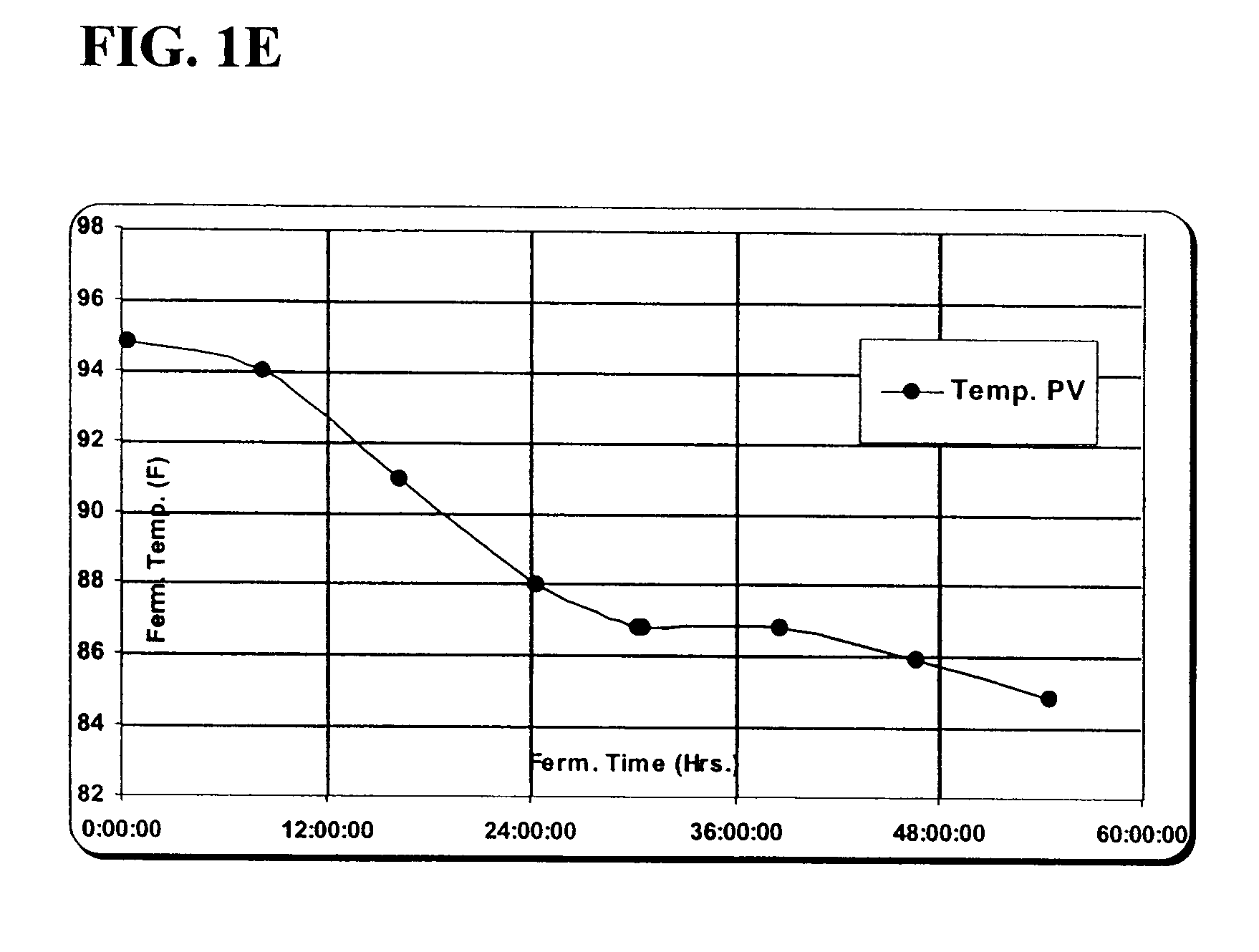

The present invention relates to methods for producing high levels of alcohol during fermentation of plant material, and to the high alcohol beer produced. The method can include selecting plant material. Selecting can include excluding plant material that has been exposed to high temperatures or that has had high moisture content.

Owner:POET RES INC

Acid fungal protease in fermentation of insoluble starch substrates

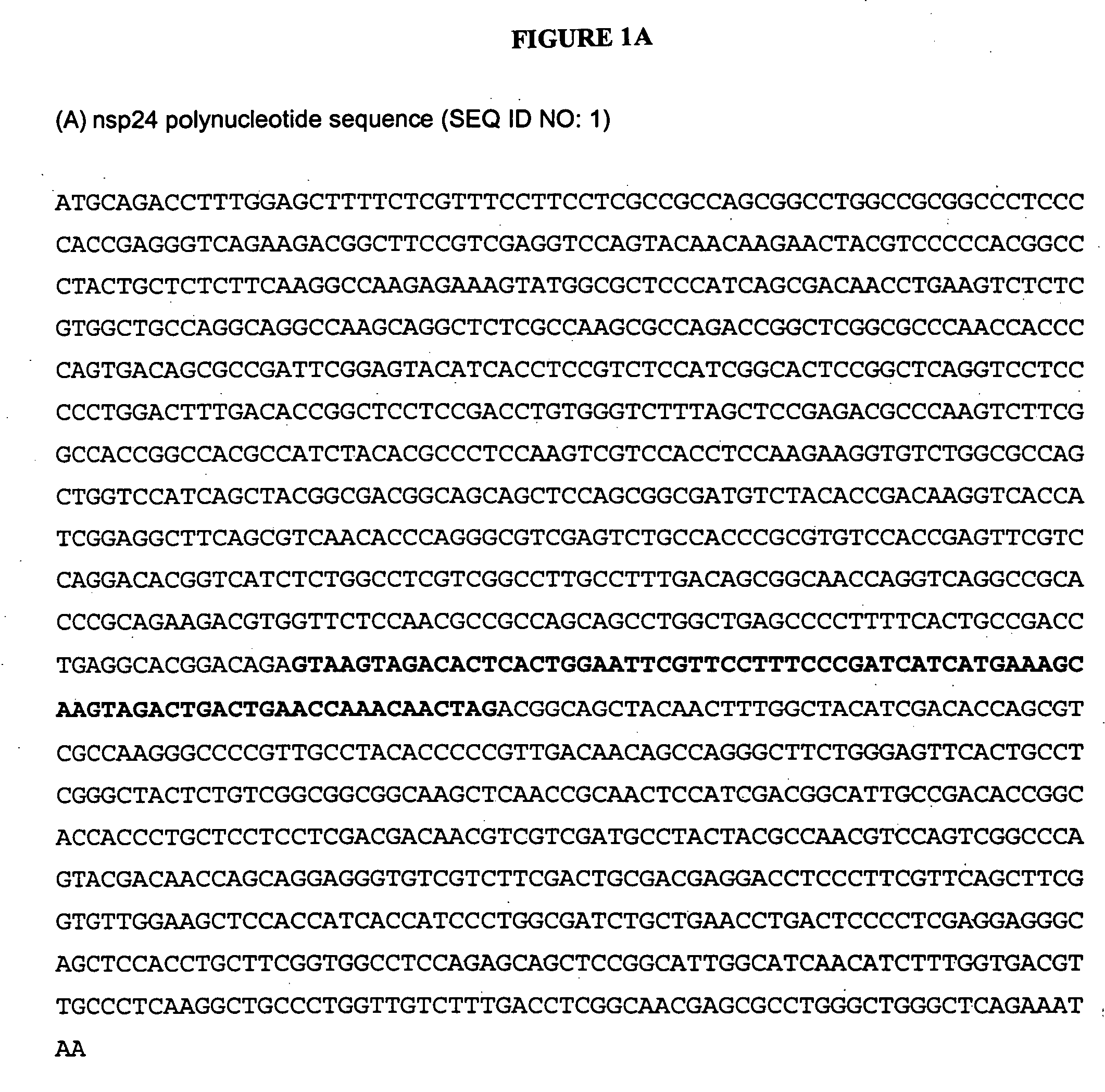

The invention is directed to methods of producing ethanol and decreasing residual starch production in a no cook fermentation comprising contacting granular starch containing substrates with a granular starch hydrolyzing enzyme, a protease, and a fermenting microorganism under suitable fermentation conditions at a temperature below the starch gelatinization temperature of the starch substrate to produce ethanol, wherein the ethanol production is increased and the amount of residual starch is decreased compared to a substantially similar method conducted without the protease.

Owner:GENENCOR INT INC

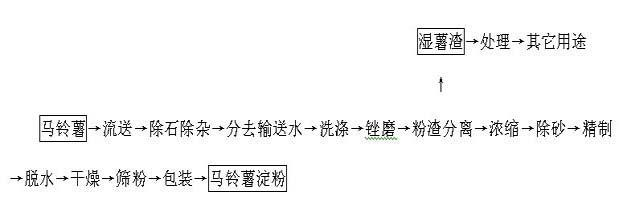

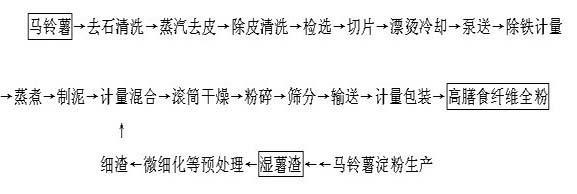

Method for producing potato flake with high dietary fiber content

The invention discloses a method for producing potato flake with high dietary fiber content. The method comprises the following steps: after the byproduct of wet potato residue generated through flour-residue separation during potato starch production is subject to acid base interaction, oxidation or enzymolysis and micronization, the micronized dietary fiber of potato is mixed with mashed potatoes obtained through steaming, boiling and smashing in a certain content ratio, the mixture is dried through a roller dryer, the moisture content in the product is smaller than or equal to 10 percent, and the potato flake rich in dietary fiber is produced after crushing and sieving. The method of the invention is suitable for being implemented in whole potato processing production enterprises, the produced potato flake is rich in an excess amount of dietary fiber and can be used as an auxiliary material for processing other foods, therefore, the economic value of the byproduct of starch production, i.e., wet potato residue is greatly increased, and pollution to the environment is reduced.

Owner:广州华糖食品有限公司 +1

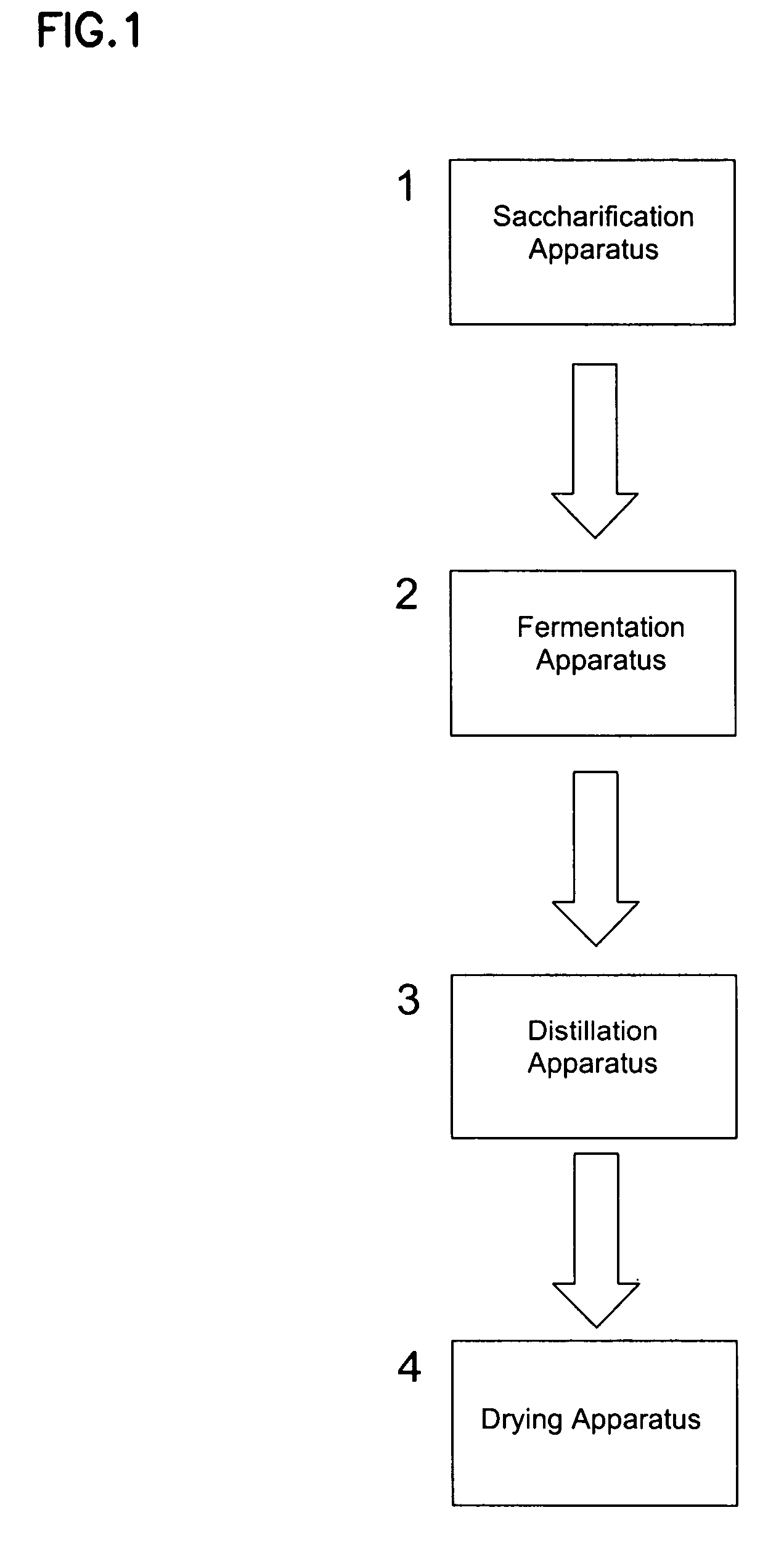

Method For Producing Ethanol Using Raw Starch

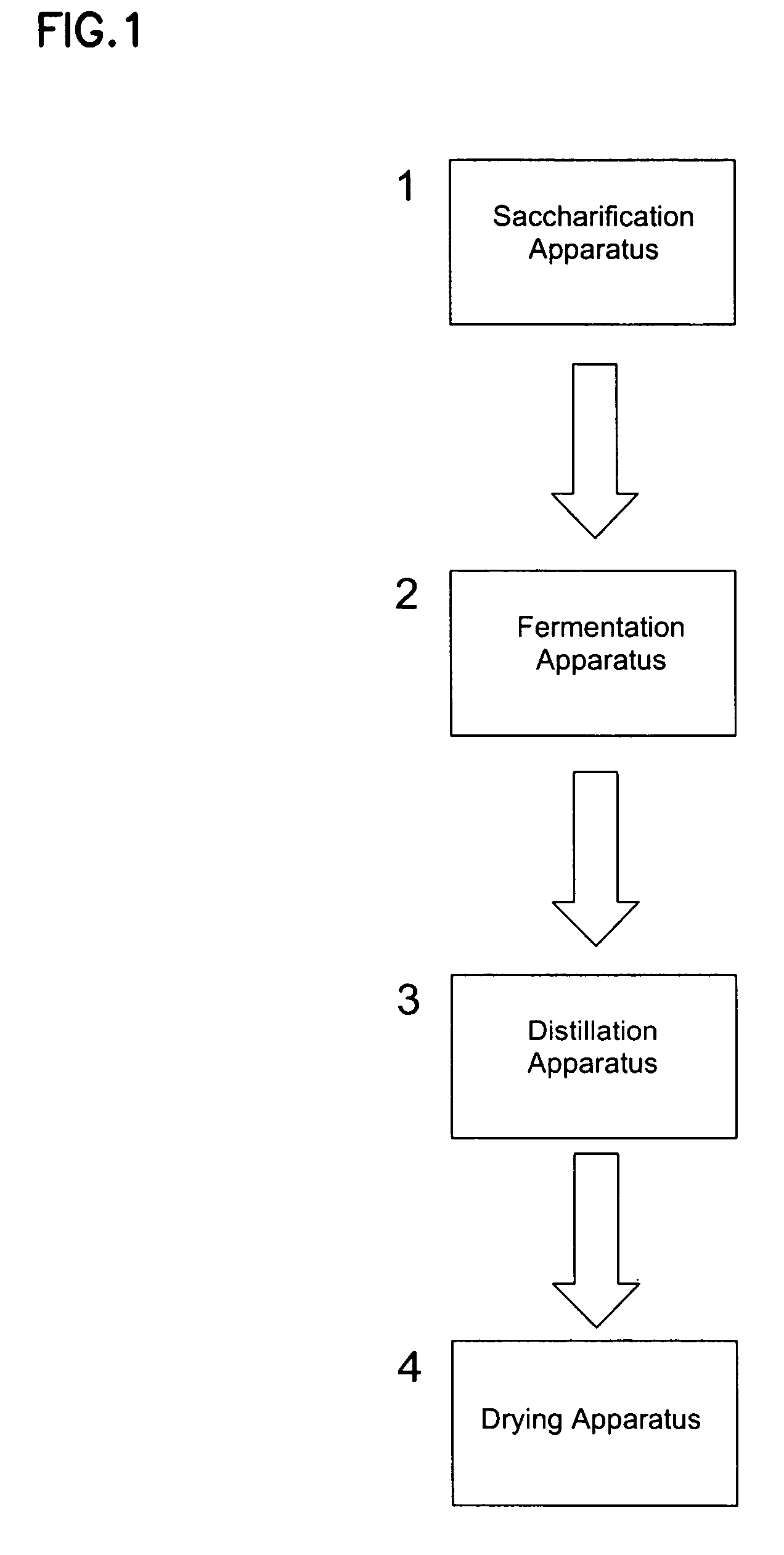

The present invention is directed to the methods for producing high levels of alcohol during fermentation of plant material, and to the high alcohol beer produced. The present invention is also directed to methods for producing high protein distiller's dried grain from fermentation of plant material, and to the high protein distiller's dried grain produced. The present invention also relates to reduced stack emissions from drying distillation products from the production of ethanol.

Owner:POET RES INC

Method for producing ethanol using raw starch

The present invention relates to methods for producing high levels of alcohol during fermentation of plant material, and to the high alcohol beer produced. The present invention also relates to methods for producing high protein distiller's dried grain from fermentation of plant material, and to the high protein distiller's dried grain produced. The present invention further relates to reduced stack emissions from drying distillation products from the production of ethanol.

Owner:POET RES INC

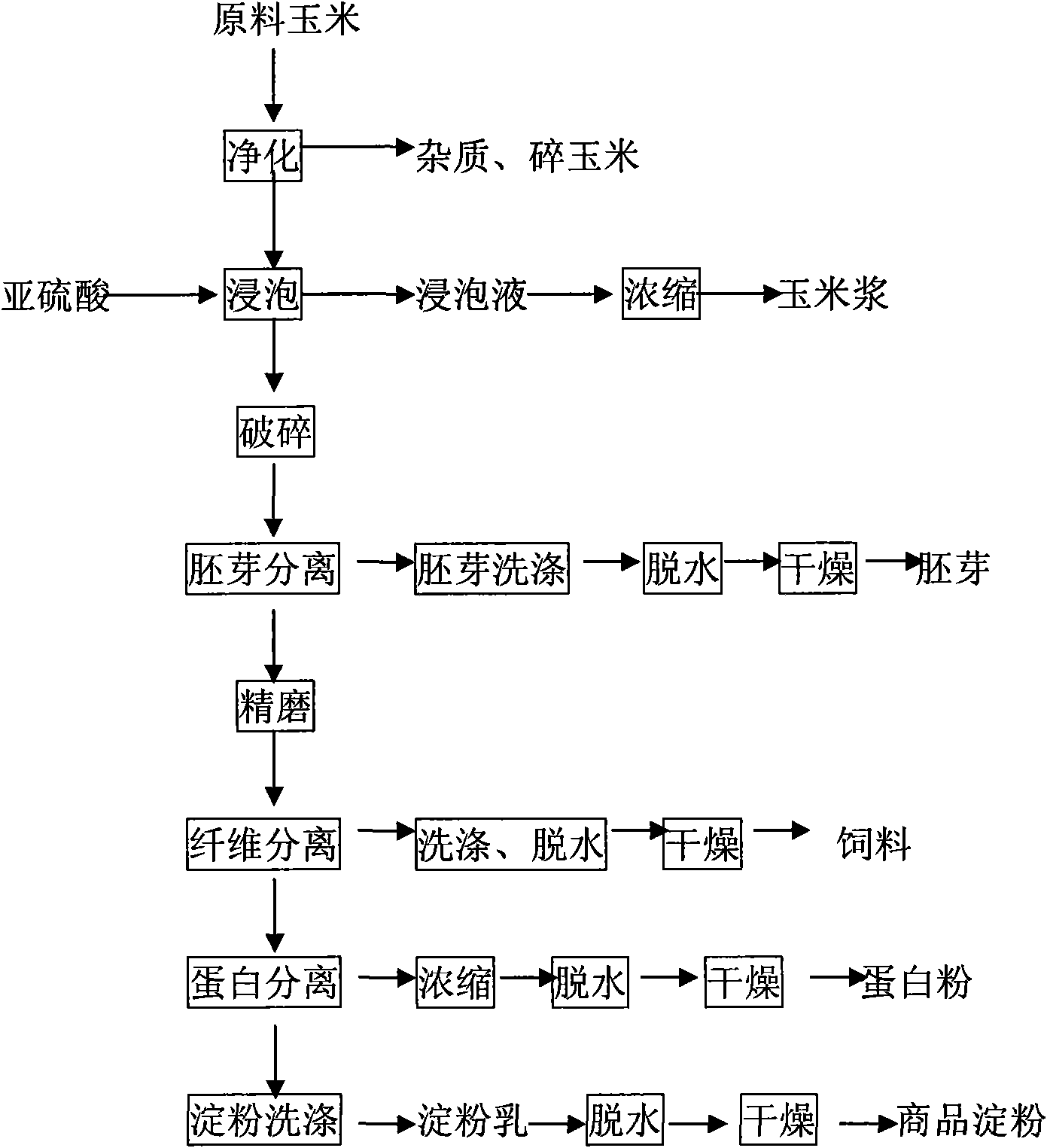

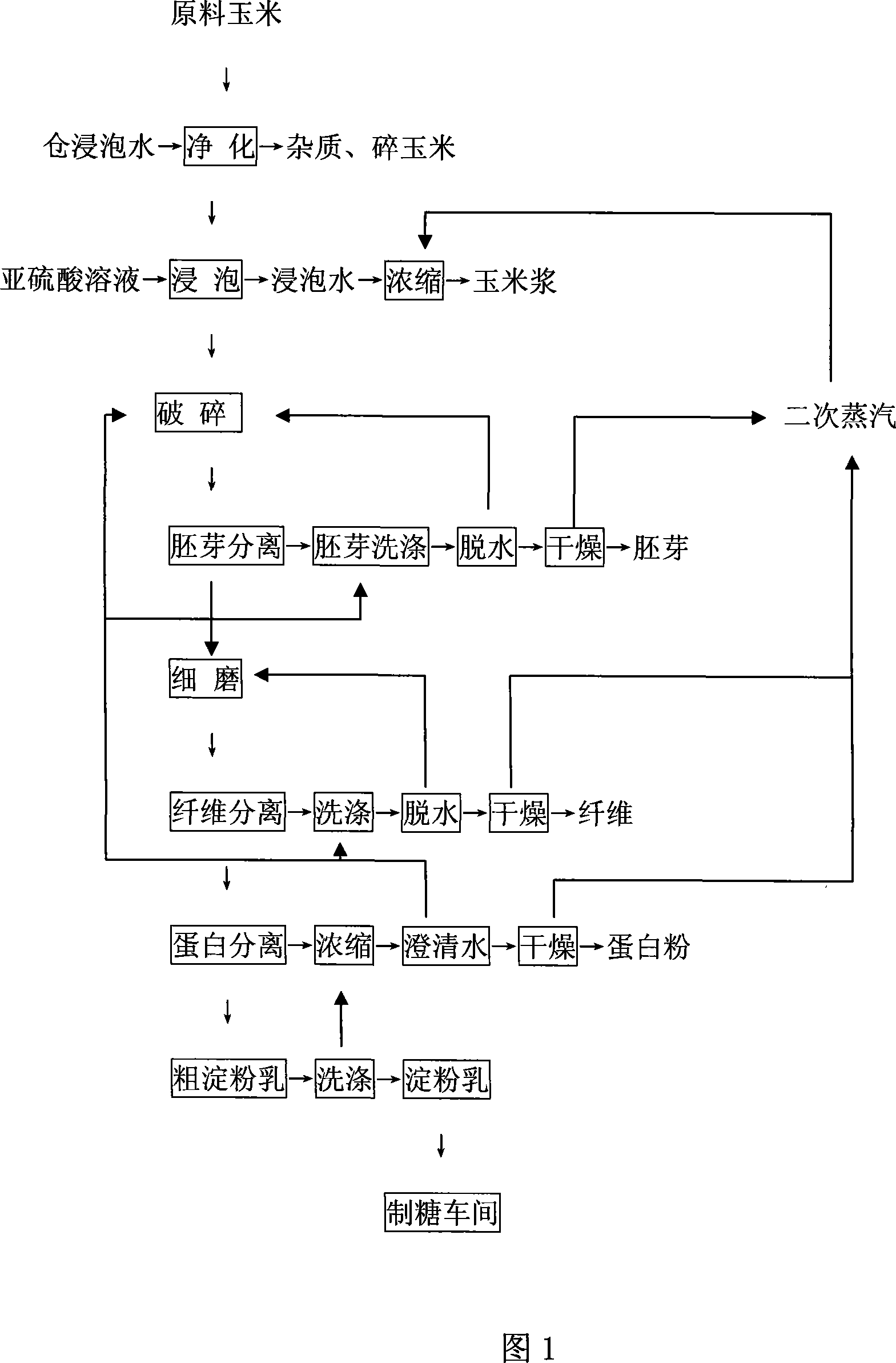

Tech. of closed water circulation in maize starch prodn. process

InactiveCN1792221AReduce water consumptionGuarantee product qualityProteins working-up by texturisingVegetable proteins working-upFiberEvaporation

A closed-loop cyclic utilization technology for the technological water in the procedure of preparing corn starch is disclosed. After the technological water is used to prepare sulfurous acid and immerse corn grains in it, it flows in technological water pool behind evaporation, condensing and regulating pH value. The technological water is also used for coarse grinding, fine grinding, and washing germinal buds and fibers. After two-stage air-floating separation, the water containing bran flows in protein depositing tank. The supernatant is drained in technological water pool and the protein deposit is recovered.

Owner:鲁洲生物科技(山东)有限公司

Potato block cutter

ActiveCN103737635ASimple structureEasy to installMetal working apparatusAgricultural scienceAgricultural engineering

A potato block cutter is characterized by comprising a frame and a cutting trough. A push plate is disposed in the rear of the cutting trough. A horizontal guide bar is fixedly connected to the back of the push plate, and the other end of the horizontal guide bar is connected with a crank-rocker mechanism. The crank-rocker is driven by a motor to drive the horizontal guide bar and the push plate to move back and forth. The horizontal guide bar penetrates a guide rail welded on the frame. A tool positioner for cutting potato blocks is vertically disposed at the front end of the cutting trough. A collection hopper is arranged above the cutting trough. A horizontal collection baffle used for preventing material from falling to the back of the push plate is fixedly connected to the top end of the push plate. The potato block cutter is simple in structure and convenient to mount. The potato block cutter has the advantages that manpower is saved, production efficiency is improved, the problem that large potato blocks cannot pass a conveyor pump during the starch production process is solved, the potato block cutter operates at low speed and is safe to use, starch block is never crushed, starch loss is avoided, and the potato block cutter is simple in structure, light in weight and convenient to move.

Owner:HENAN UNIVERSITY OF TECHNOLOGY +1

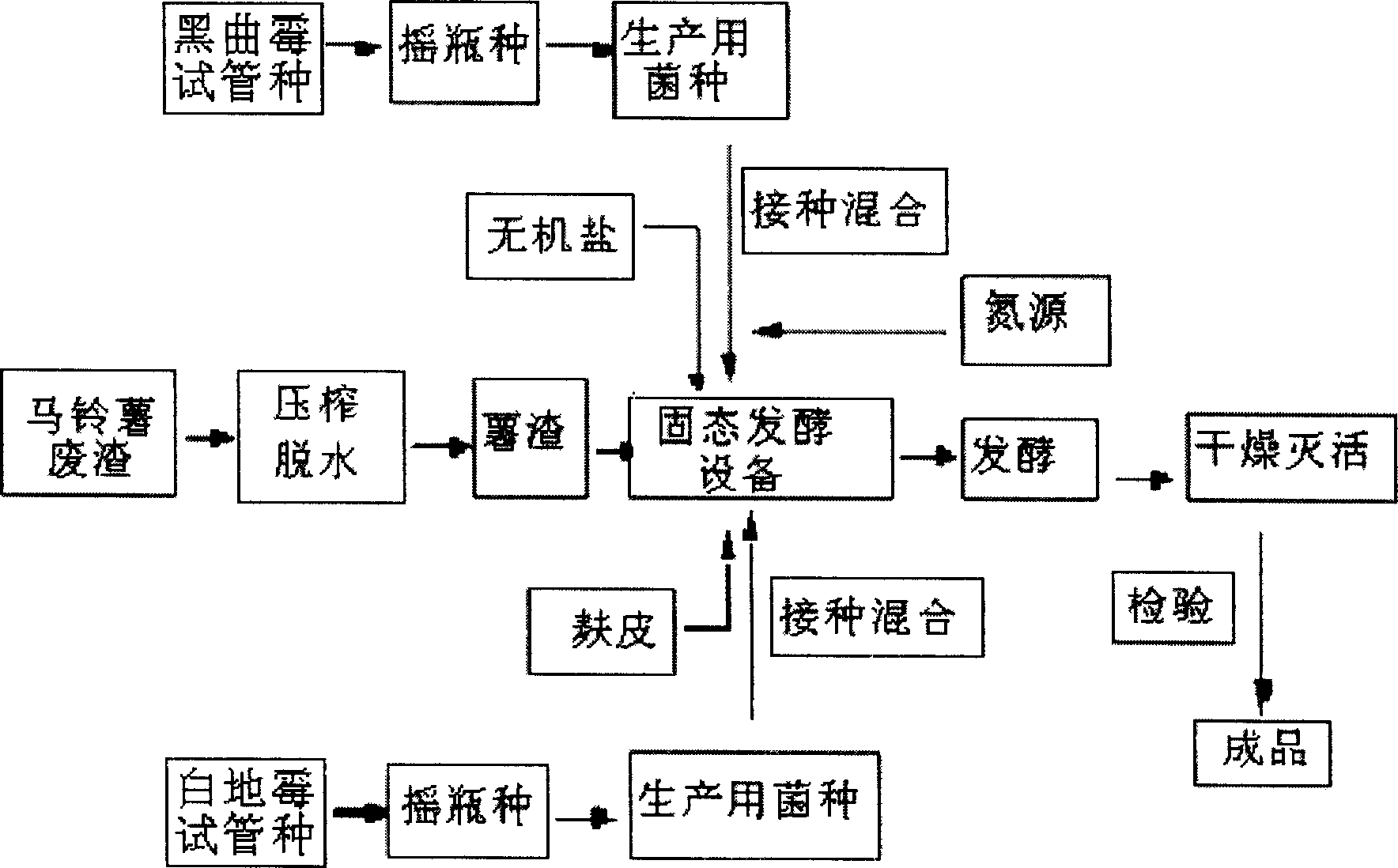

Method for preparing protein feed by solid fermenting potato slag

ActiveCN1899079ALow degree of mechanizationLess investmentAnimal feeding stuffVegetable proteins working-upMetabolitePotato starch

The present invention is protein feed and its preparation process with potato slag. Protein feed is prepared with waste potato slag from starch production, and through squeezing to dewater, adding certain amount of supplementary material, inoculating certain amount of microbe seed and solid fermentation. The said preparation process is simple, and has high yield, low investment, low power consumption and other advantages. Thus obtained feed product has the fermented product, including microbe, metabolite and substrate utilized fully, and possesses the active components maintained, high amino acid content and high nutritious value.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

Method for producing waxy corn starch

Owner:甘肃雪晶生化有限责任公司

Acid fungal protease in fermentation of insoluble starch substrates

The invention is directed to methods of producing ethanol and decreasing residual starch production in a no cook fermentation comprising contacting granular starch containing substrates with a granular starch hydrolyzing enzyme, a protease, and a fermenting microorganism under suitable fermentation conditions at a temperature below the starch gelatinization temperature of the starch substrate to produce ethanol, wherein the ethanol production is increased and the amount of residual starch is decreased compared to a substantially similar method conducted without the protease.

Owner:GENENCOR INT INC

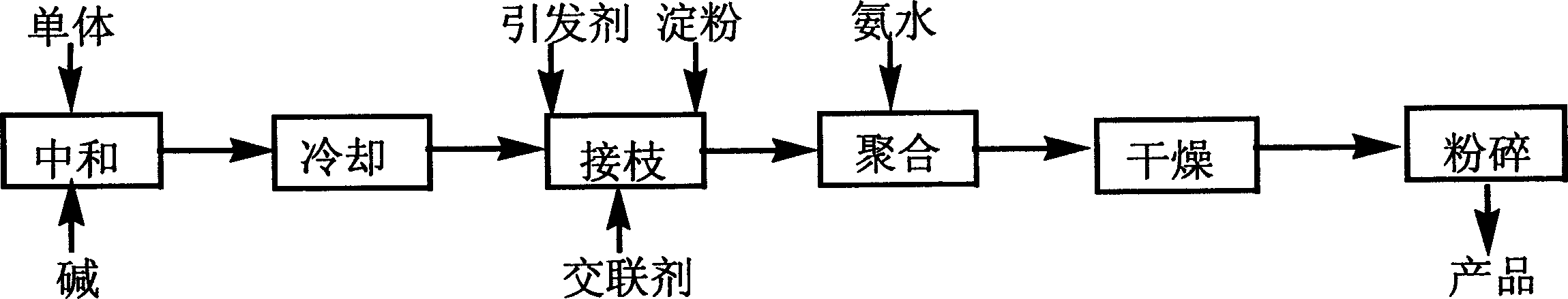

One-step synthesis process of producing biodegradable high-hydroscopicity resin directly with corn powder

The present invention belongs to chemical synthesis process of polymer and relates to the production of synthetic resin. By combining artificial polymerization and polymer grafting into one step, the present invention produces high-hydroscopicity resin with corn powder in one step. Turf is added into the material to improve performance and exothermic reaction for heat crosslinking is adopted for easy temperature control. The technological process is simple and produces no side product and waste, and the product has hydroscopicity of 800-1000 times and is biodegradable. The product may be used as water saving material in solving crop water deficiency problem.

Owner:NORTHEAST NORMAL UNIVERSITY

Squeezing enzymolysis and saccharify method for producing ultrahigh malt syrup raw material

The invention belongs to the technical field of a squeezing processing method of malt syrup by adding enzymic preparation and a saccharifying method of squeezing substance in a malt sugar production technology. The invention has the main technical points of providing the squeezing processing method of the malt syrup raw material for producing ultrahigh malt syrup by adding the enzymic preparation and the saccharifying method of the squeezing substance of the malt syrup raw material using the added enzymic preparation. Compared with the traditional multienzyme cooperation method for producing the malt syrup without squeezing the malt syrup raw material, which is generally adopted at present, the needed saccharifying time is just 2 / 3-1 / 2 of the traditional saccharifying time at present when the malt syrup content of sacharifying liquid without squeezing the malt syrup raw material which is added with the enzyme preparation is reached more than 90%, and a starch production process and a spray liquefaction process are saved. The method disclosed by the invention can be used for producing the ultrahigh malt syrup with the malt syrup content being larger than 90%, and can also be used for producing common malt syrup with the malt syrup content being less than 60^ and the high malt syrup with the malt syrup content being 60-80 %.

Owner:申德超 +2

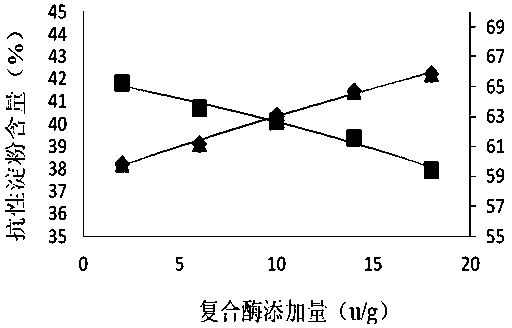

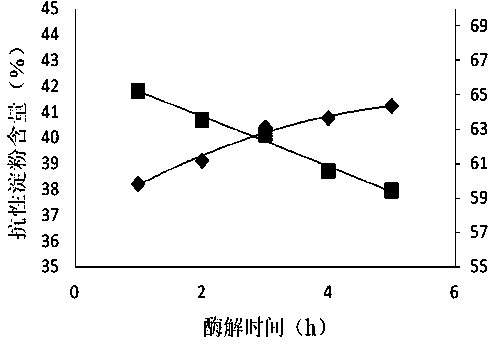

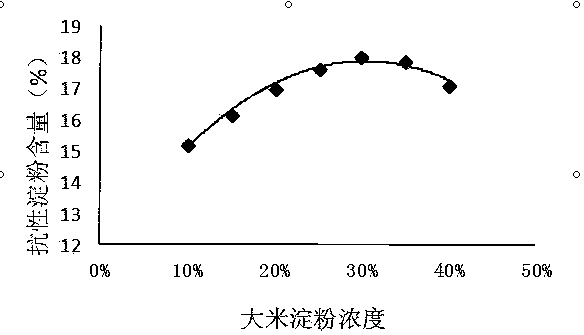

Production method for preparing resistant rice starch

ActiveCN103918872ARealize industrial productionImprove the utilization level of deep processingProtein foodstuffs working-upAmylaseDietary fiber

The invention relates to a production technology of resistant rice starch. A production method for preparing resistant rice starch comprises the following steps: firstly, gelatinizing, debranching and crystallizing the rice starch, and then drying the extracted resistant rice starch to obtain the resistant rice starch; improving the content of amylase in the rice starch by debranching treatment; controlling the concentration of the gelatinized rice starch at 20-50%, the debranching enzyme content at 12-25U / g, the debranching temperature at 45-55 DEG C and the debranching time at 12-20 hours; crystallizing under the condition of 2-12 DEG C after debranching is ended, and then extracting the resistant rice starch, and drying under the condition of 50-70 DEG C. The excessive rice resources such as broken rice and early indica rice can be reasonably utilized, the economic value of the potential resources is increased, and the produced resistant rice starch can overcome the defects of the traditional dietary fibers. By adopting the production method disclosed by the invention, the deep processing utilization level of the rice starch in China can be improved, and the method has important significance on development of grain storage enterprises and rural economy.

Owner:HENAN MINGYE BIOTECH

Edible casing membrane with blend of collagen fibers and starch

ActiveCN104585289AImprove bindingSatisfied with high temperature boilingSausage casing manufactureFiberCarboxymethyl cellulose

The invention discloses an edible casing membrane with a blend of collagen fibers and starch. The edible casing membrane comprises the following components in percentage by weight: 35-50% of collagen fibers, 23-30% of starch, 2-5% of chitosan, 2-5% of sodium carboxymethyl cellulose (CMC), 16-22% of water, 2-5% of glycerol and 0.002% of glyoxal. According to the edible casing membrane with a blend of collagen fibers and starch, the casings produced by modified starch have better combination with meat stuffing, can meet the requirements of boiling at high temperature for long time and frying at high temperature above 180 DEG C of sausages, and are more suitable for breakfast sausages; compared with the previous invention, the casings have a significant improvement in resistance to boiling and frying at high temperature.

Owner:山东冠华蛋白肠衣有限公司

Production technique for starch without waste matter

This invention provides a technology of starch production without waste, belonging to water and energy-saving technology in the production of starch, and its process is: corn-> purification -> transportation immersion -> breaking into pieces -> corcle separation -> fine grinding-> fiber separation -> protein separation -> starch washing -> starch milk -> starch for commodity. The process mainly uses the advanced ''ring closure and countercurrent'' new technology with simple technology, saving investment, simplicity, and other characteristics, the technical water are that of process instead of previous one-time water to reduce water consumption and save energy significantly. The usage of water is only in the final process with quantified control, thus it increases the yield of products and by-products, makes the total dry corn yield increase 3%-5%.

Owner:LINGHUA GROUP INCORPORATED COMPANY

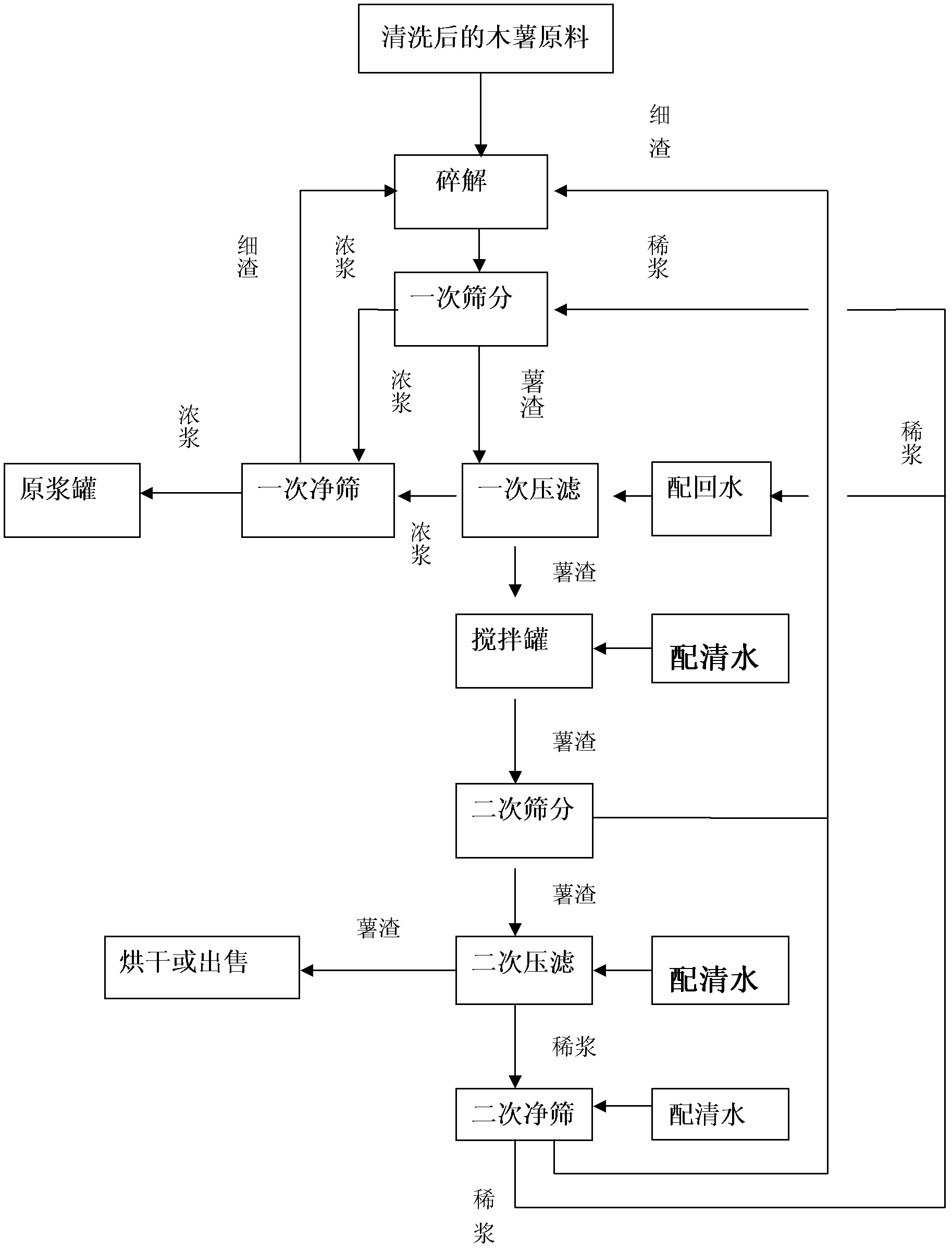

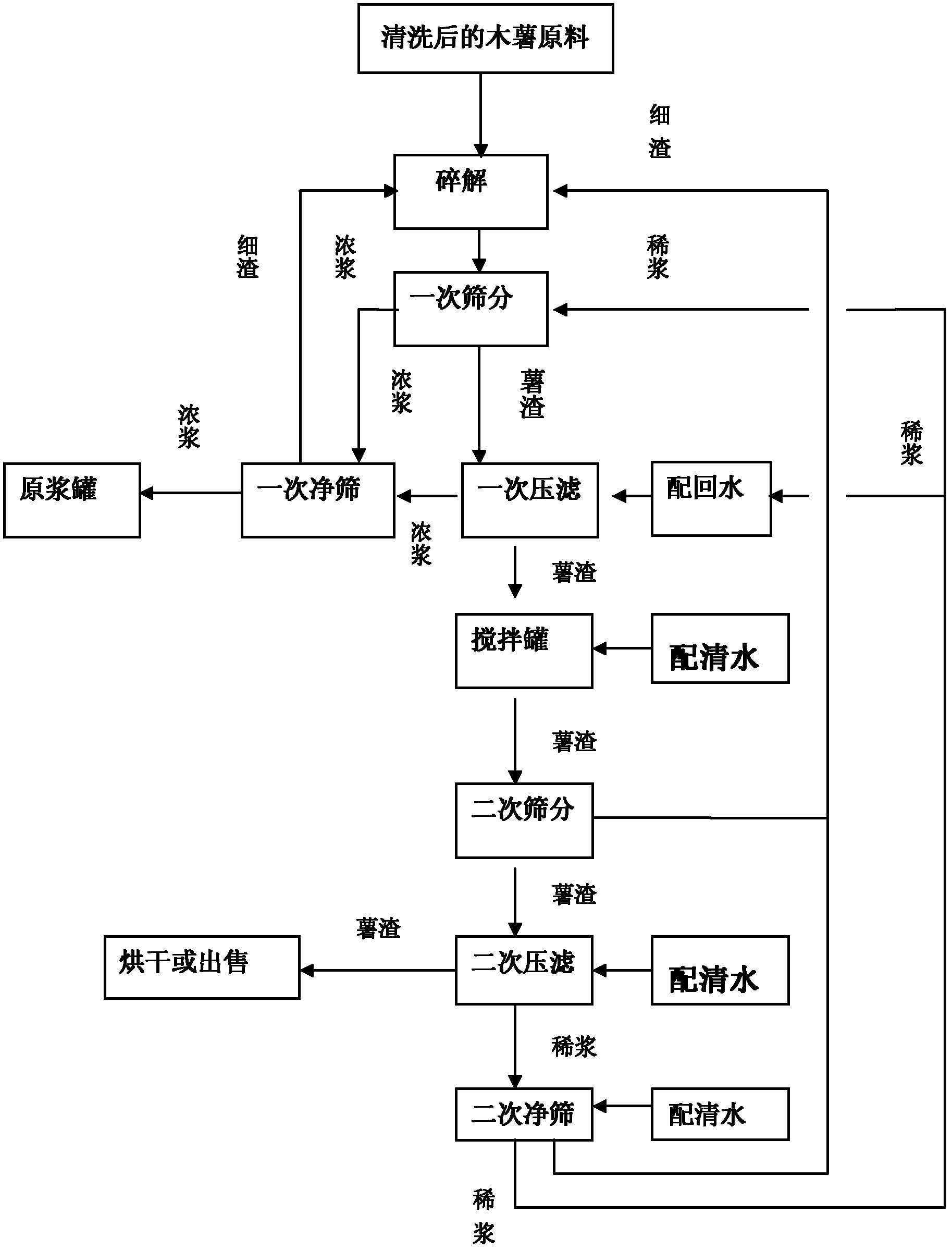

Tuberous starch slurry-residue separation technique by screening and pressure filtration

The invention provides a tuberous starch slurry-residue separation technique by screening and pressure filtration, which modifies slurry-residue separation procedures in tuberous starch production, and combines a vertical screen, a filter press and screen cleansing into a complete stereoscopic elevation difference technological process, wherein the vertical screen is used for separating residues from slurry by means of centrifugal force, the filter press is used for separating the residues from the slurry by means of extrusion force, and the vertical screen and the filter press in matched use can avoid the problem of poor cleanliness when tuberous residues are treated by vertical screen equipment, so that slurry-residue separation effect can be more effectively improved, feeding once is achieved, and multiple procedures including matched use of the emulsion slurry, the residues and process water, pressure drying of the tuberous residues can be completed by means of multiple screening and pressure filtration. Besides, power, automation, the amount of equipment, process water consumption and labor forces can be greatly reduced, the technique has the advantage of saving of operation cost and energy, emulsion slurry concentration is improved, starch extraction ratio is increased, and good technical effect is achieved.

Owner:南宁红枫王淀粉设备有限公司 +1

Methods and systems for producing ethanol using raw starch and selecting plant material

The present invention relates to methods for producing high levels of alcohol during fermentation of plant material, and to the high alcohol beer produced. The method can include selecting plant material. Selecting can include excluding plant material that has been exposed to high temperatures or that has had high moisture content.

Owner:POET RES INC

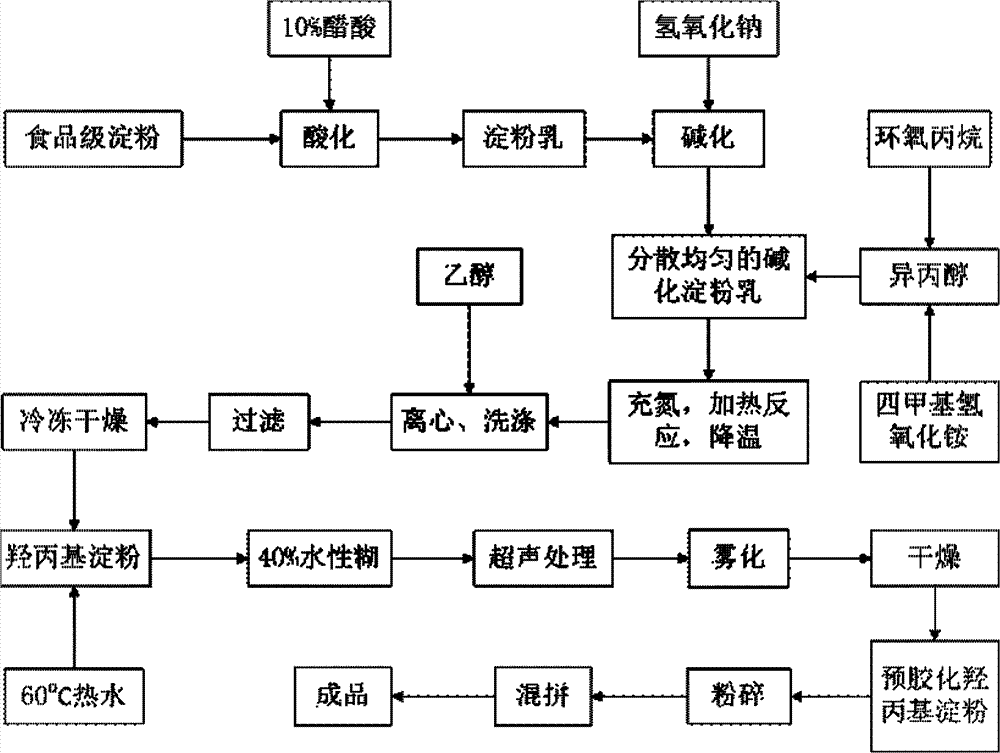

Preparation method and use of medicinal pregelatinized hydroxypropyl starch

ActiveCN104262493ASmall molecular weightGood water solubilityPharmaceutical non-active ingredientsPill deliveryBiotechnologyStarch production

The invention relates to the technical fields of starch production, and particularly relates to medicinal pregelatinized hydroxypropyl starch and a preparation method and use of the medicinal pregelatinized hydroxypropyl starch. The preparation method comprises the following steps: 1 pretreatment and activation of starch; 2 synthesis of hydroxypropyl starch; 3 refining of the hydroxypropyl starch; and 4 preparation and refining of pregelatinized hydroxypropyl starch. The pregelatinized hydroxypropyl starch obtained by the method is high in content of effective components, and low in impurity content; the microbial limit is controlled; and the solubleness and the freeze-thaw stability of the pregelatinized hydroxypropyl starch in cold water are greatly improved, thus achieving the medicinal grade standards.

Owner:HUNAN ER KANG PHARMA

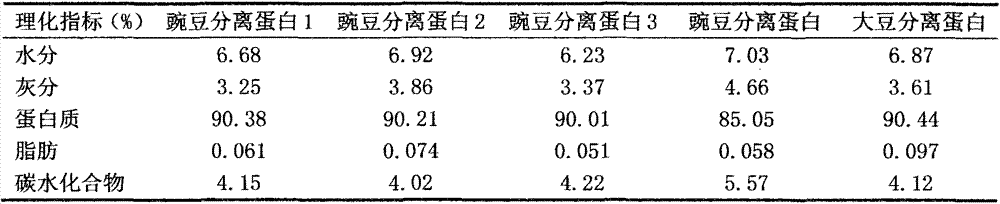

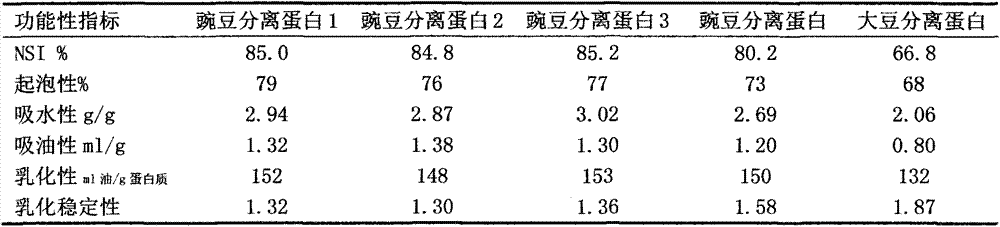

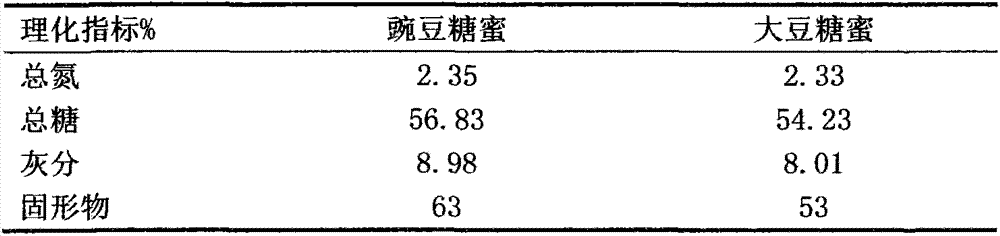

Method for extracting pea molasses and pea protein isolate from pea starch production wastewater

The invention discloses a method for extracting pea molasses and pea protein isolate from pea starch production wastewater. The method comprises the steps in sequence of protein extraction, acid sedimentation separation, washing separation, neutralization, whey concentration, flash distillation for sterilization, drying and powder-sieving. The extraction method can improve the purity and yield of pea protein isolate efficiently; wastewater generated from the production of pea protein isolate is collected for extracting pea molasses for use, so that the wastewater is fully utilized, and resource waste and environment pollution are alleviated. The pea protein isolate produced by the method has the content of more than 90%, has quite high water-retaining property and oil absorption capacity, and has gel formability better than that of soybean protein isolate. The pea molasses produced by the method is a brown syrup-shaped substance with the content of total sugar within 50%-60%, and has relatively great application prospect in the aspects of foods, medicines and light industry.

Owner:YANTAI ORIENTAL PROTEIN TECH

Technology for immersing corn in a corn starch production process

The invention discloses a technology for immersing corn in a corn starch production process, wherein the technology uses a seven-can immersing method, and comprises a seventh into fragmentation grinding and a first can where new core is added, new-prepared acid is added into a sixth can before into fragmentation grinding, and concentration of sulfurous acid in the new-prepared acid is 0.15-0.17%; before the new-prepared acid is added, a can-inversing method is used, that is opposite to the direction in which the core is fed, a immersion liquid in the first to sixth cans is orderly poured form a can with a bigger sequence number to a can with a smaller sequence number, the liquid is poured until a liquid level that the immersed core is not exposed, and the immersion liquid level in each can is same; and the a total immersion time of the core is controlled in a range from 25h to 29h. The technology for immersing corn in the corn starch production process, strictly controls the immersion concentration and temperature, needs short immersion time, can effectively immerse out effective components in the corn, and has advantages of high yield, low concentration of sulfurous acid, short immersion time, and low power consumption and steam consumption.

Owner:MENGZHOU GOLDEN CORN

Bacterial cellulose culture method based on potato waste residue

ActiveCN102337311ASolve the reuse problemLow costMicroorganism based processesFermentationBiotechnologyEngineering

The invention relates to a bacterial cellulose culture method which concretely comprises the steps of: inoculating acetobacter xylinum strain in a culture medium for recovery; after recovery, inoculating 2-20% of acetobacter xylinum strain in the culture medium; culturing the inoculated acetobacter xylinum strain by a shaking bed for 2-3 days under the condition of 100-180 rpm; and transferring the obtained fermentation liquor into a shallow tray and culturing for 2-5 days in a static state to obtain bacterial cellulose, wherein the culture temperature is 26-31 DEG C, the culture ventilation amount is 0.3-0.6vvm, and the culture medium is potato culture solution. The culture method has the characteristics that: potato waste residue obtained after starch production is firstly taken as the raw material of the culture medium, is treated by a simplest method and then is used as the culture medium for culturing the bacterial cellulose; the culture medium is low in cost and high in yield; meanwhile, the problem of recycling the potato waste residue can be solved, and the culture time is short; and in addition, the invention provides an important condition for stably culturing the bacterial cellulose in a large scale.

Owner:BEIJING GUANLAN TECH

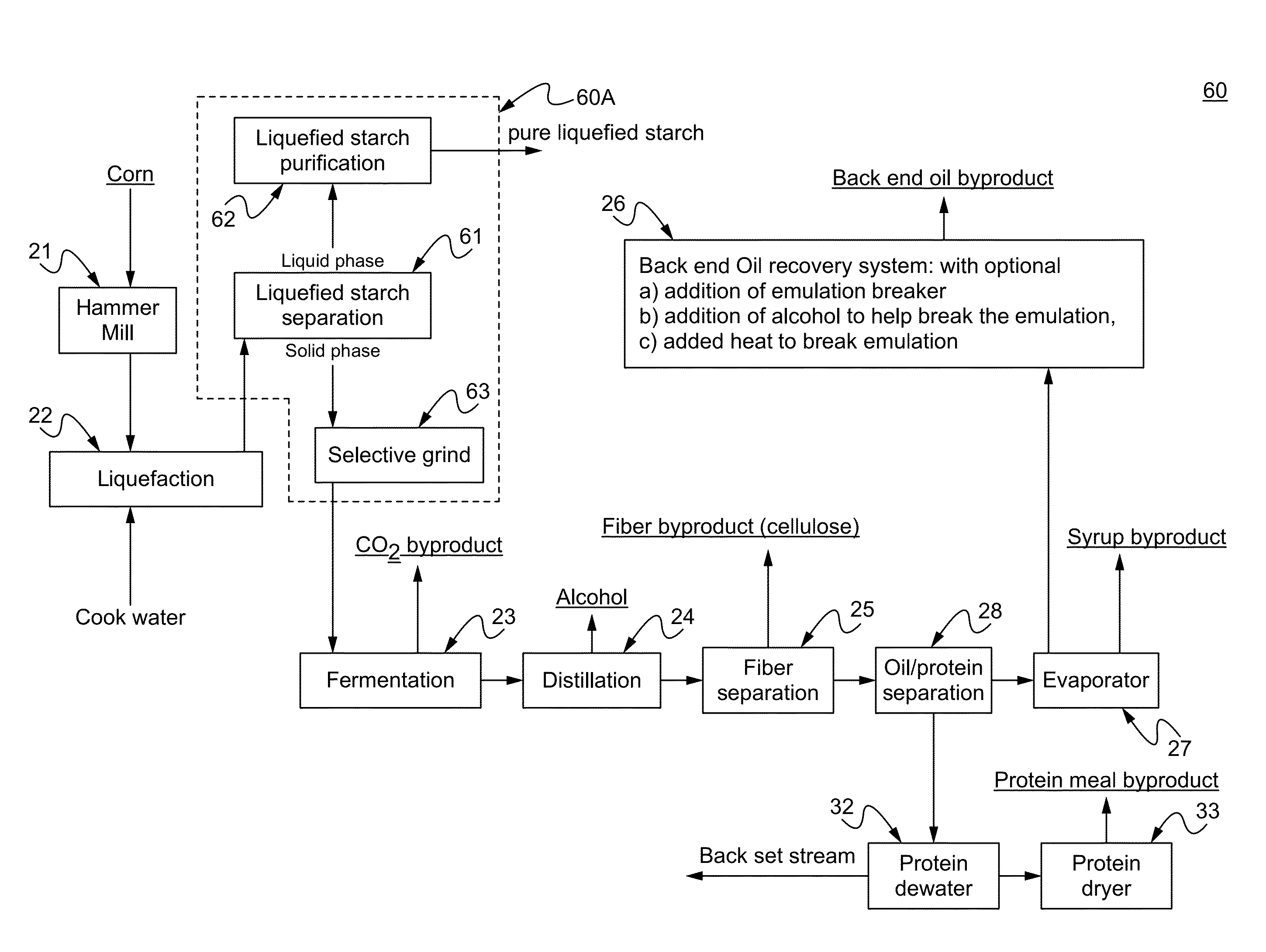

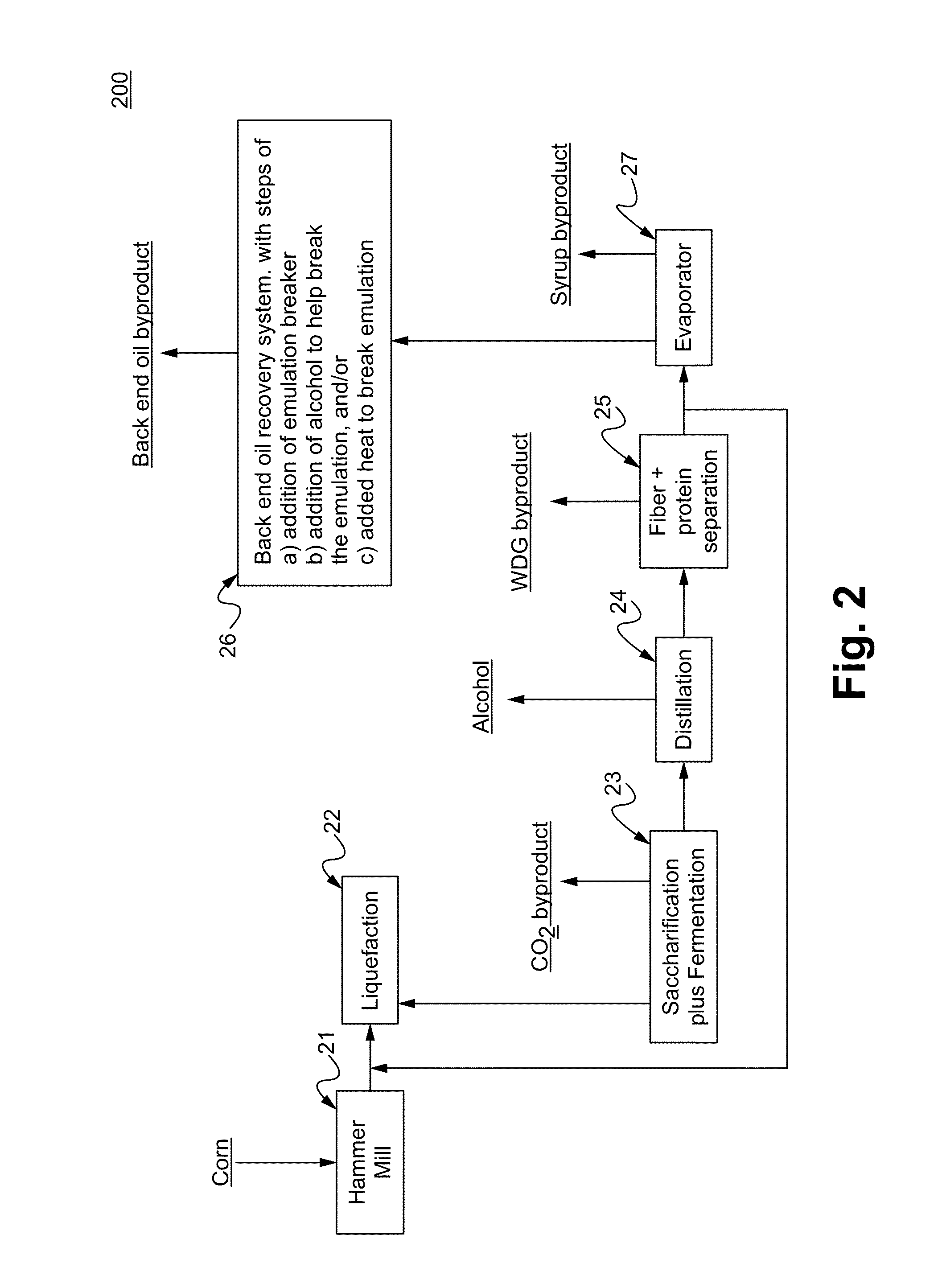

System for and method of separating pure starch from grains for alcohol production using a dry mill process

Methods of and systems for recovering starch before fermentation in a dry mill process and / or a wet mill process. The starch is able to be further purified. The starch can be used as a feedstock for biotech uses, such as, making one or more types of butanols. The method is able to recover starch from floury and horny endosperm. In some embodiments, the method includes liquefying milled corn and separating, purifying and recovering the starch in both floury and horny endosperm before fermentation. In some embodiments, the method includes subjecting the milled corn flour in a caustic condition and next recovering the starch before fermentation. In some embodiments, the method includes soaking / steeping the corn, grinding the corn and separating the germ from the starch in a wet mill similar condition before fermentation.

Owner:LEE TECH LLC

Preparation method of high-strength TPS starch for degradable materials

ActiveCN113024897AReaction conditions are easy to controlMild responseBio-packagingFermentationThermoplasticPolymer science

The invention relates to the field of high polymer materials, and discloses a preparation method of high-strength TPS starch for degradable materials. The preparation method comprises the following steps: firstly, by utilizing a wet modified starch production process, adding a bio-enzyme preparation under the conditions of controlling the temperature and pH value, then controlling the temperature of obtained slurry, adding an inhibitor, carrying out cross-linking agent and esterification treatment to obtain modified starch, mixing and adding a starch matrix reinforcement material into powder in a dry method for treatment, adding a proper amount of glycerol and a modifier, extruding by a twin-screw extruder, air-cooling, slitting and granulating to obtain a thermoplastic TPS starch granular material with good strength. Compared with common starch, the thermoplastic TPS starch particle material has the advantage that the mechanical property can be improved by adding the thermoplastic TPS starch particle material into a degradable material.

Owner:HANGZHOU PAPERMATE SCI & TECH

Sewage zero-discharge production process for corn starch

The invention relates to a corn-starch manufacturing technique, especially the corn starch sewage zero discharge manufacturing technique. It includes the following working procedure that purifying, dipping, milling and sieving, starch milk refining, fu-water treating. In the dipping working procedure, the dipping baiting is used sparse corn steep liquor as the baiting water; the dipped corn is used the process water to feed continuously; in the grinding and sieving, the process water is used when de-embryo mill is working, to clean the embryo, fiber, to make the acid water when the fibril filtering medium is returned to the fifth fiber washing tank; in the starch milk refining, the process water is used as the washing water for the separator, and the filter cloth of the protein vacuum filter; in the fu-water treating, the starch milk dehydration filtrate should be distributary used after revolving, all of the sealing cooling water in the centrifugal pump should be concentrating recycling. In the whole operation procedure, the processing water is formed closed cycle to realize sewage zero discharge, so it can solve the sewage treating problem, and each ton of starch consumes 1.5-2.2 ton of water.

Owner:王占林

Soaking process for preparing corn starch

The invention discloses a soaking process for preparing corn starch. The soaking process comprises the following steps: (1) performing primary soaking; (2) inoculating lactic acid bacteria to obtain fermentation liquor; (3) performing coarse crushing; (4) performing secondary soaking, namely adding cellulase and acid protease into the prepared fermentation liquor, keeping temperature for 4-6 hours at the temperature of 48-52 DEG C, and executing a starch production process, wherein the cellulase accounts for 0.1-0.3 percent of total weight of corn, and the acid protease accounts for 0.2-0.5 percent of total weight of the corn. In the corn soaking process, the corn soaking time can be shortened, the yield of the corn starch can be increased from about 68 percent to about 69.5 percent, and the economical benefit is remarkable.

Owner:河南飞天生物科技股份有限公司

Treatment method for recycling potato starch production factory wastewater

InactiveCN102690031AImprove water qualityHigh chroma removal rateSludge treatment by de-watering/drying/thickeningTreatment with aerobic and anaerobic processesChemical oxygen demandPotato starch

The invention discloses a treatment method for recycling potato starch production factory wastewater, relating to the technical field of starch wastewater treatment. The method comprises the following steps: precipitating, regulating the pH value of the precipitate with acid, regulating the pH value of the precipitate with alkali, exchanging and recycling heat, carrying out anaerobic treatment, aerobic biochemical treatment and ultrafiltration membrane treatment, and detecting emissions. The COD (chemical oxygen demand) of the wastewater treated by the method is less than 50 mg / L, the chroma removal rate of the wastewater is not lower than 99%, and the water quality chroma index is lower than 10 times. The invention has the advantages of low treatment cost, high operation stability and high treatment efficiency, can generate additional economic benefits, and is suitable for wide popularization.

Owner:山东博洋环境资源有限公司

Taro starch producing technology

InactiveCN101070353ASolve the problem that can not be used as starch raw materialImprove use valueBiotechnologyEngineering

This invention relates to taro starch production process, belongs to subsidiary agricultural products deep processing region. The invention mainly transit sol, filtration, chromatography, separation, dryness etc. steps to extract taro starch.

Owner:申成果

Corn soaking method in waxy corn starch production

The invention provides a corn soaking method in waxy corn starch production.The method comprises the first step of primary soaking, wherein waxy corn serves as a raw material, water, lactic acid and complex enzyme are added, and soaking is conducted; the second step of waxy corn degerming, wherein broken degerming is conducted on the soaked waxy corn; the third step of secondary soaking, wherein water and compound protease are added into the broken-degermed waxy corn, standing soaking is conducted, and after soaking, the waxy corn gets into the starch production procedure.By means of the method, the waxy corn soaking efficiency can be effectively improved, the soaking time can be shortened, a safe soaking agent is adopted, sulphurous acid is not added in the soaking process, no SO2 pollution is caused, and the yield of waxy corn starch is increased.

Owner:CHONGQING ACAD OF AGRI SCI

Preparation method of broad bean polypeptide wine

InactiveCN102443516AIncrease added valueReduce bitternessAlcoholic beverage preparationAmyrisProtein isolate

The invention discloses a method for preparing polypeptide wine from directly fermented broad bean protein hydrolysate. The method comprises steps of (1) enzymatic hydrolysis, (2) enzyme deactivation and centrifugation, (3) sugar regulating, (4) yeast activating, (5) fermenting, (6) post-fermenting, (7) clarifying and filtering, (8) blending, and (9) sterilizing. According to the invention, broadbean protein isolate extracted from a starch-production waste liquid in a broad bean starch factory is adopted as a raw material, and the broad bean polypeptide wine is prepared with a double-enzyme hydrolysis technology by using alkaline proteinase and flavor proteinase, and a fermentation technology. With the application of the flavor proteinase and yeasts, the bitter taste of broad bean polypeptide can be reduced. At last, beta-cyclodextrin is added, such that the bitter taste caused by polypeptide fermentation broth can be greatly reduced, such that the taste of the prepared broad bean polypeptide wine is more delicious and rich, the protein can be prevented from solidification caused by alcohol produced by fermentation, and the stability of the product can be improved. Also, as a test result, the polypeptide fermented wine has a good oxidative stability and an outstanding healthcare function.

Owner:QINGHAI UNIVERSITY

Method for producing oxidized starch

The invention relates to a method for producing oxidized starch. The method comprises the following steps of: adding copper sulfate accounting for 0.005 to 0.02 percent of dry starch into starch milk and uniformly stirring the mixture; adding sodium hypochlorite into the mixture, controlling liquor adding speed, keeping the pH value of the mixture at 9, adding 4 percent solution of sodium hydroxide into the mixture when the pH value of the mixture falls, adjusting the pH value to be 9 and controlling a temperature to be between 32 and 35 DEG C; adding hydrochloric acid into the mixture after an oxidation reaction is performed so as to adjust the pH of the starch milk to be neutral; and centrifugally dewatering the starch milk and performing air drying on the dewatered starch milk until the water content of the starch milk is less than or equal to 14 percent. An activation process is added in the oxidized starch production method, so that the oxidation reaction speed of the starch is increased, reaction time is shortened and the using amount of the sodium hypochlorite serving as an oxidant is reduced.

Owner:山东福洋生物科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com