Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about How to "Effective leaching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A comprehensive utilization method of red mud

ActiveCN104340995AEfficient separationAchieve cycleChlorine/hydrogen-chlorideSolid waste disposalFerric hydroxideAluminium hydroxide

The invention relates to a comprehensive utilization method of bauxite and particularly relates to a comprehensive utilization method of red mud. The method includes: a step of mixing the red mud with hydrochloric acid, adding the mixture into a hydrochloric acid-resistant reactor, and reacting; a step of cooling after the reaction is finished, performing solid liquid separation and washing; a step of adding the obtained solution into a sodium hydroxide solution to obtain an aluminium hydroxide precipitate, an iron hydroxide precipitate and a sodium chloride solution, performing solid liquid separation, and washing; a step of preparing the aluminium hydroxide and iron hydroxide solid into metallurgy-level aluminum oxide and high-iron slag through a simple Bayer process; a step of subjecting the sodium chloride solution to electrolysis by an ionic exchange membrane electrolytic cell to obtain hydrogen, chlorine and a sodium hydroxide solution; a step of returning the sodium hydroxide solution discharged from an ionic membrane cathode zone and recycling; and a step of returning and recycling the obtained hydrogen and the obtained chlorine. The method is obvious in environment protection effects, effectively separates aluminum, iron and silicon in the red mud, and recovers the aluminum, the iron, sodium and other useful elements, thus achieving comprehensive utilization.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

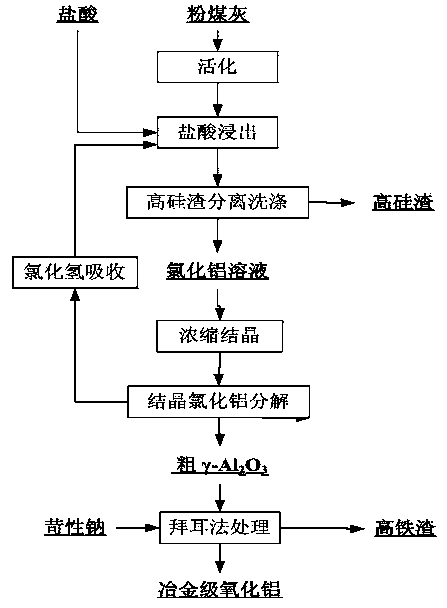

Method for preparing aluminum oxide through treatment of coal ashes with hydrochloric acid

ActiveCN103663511AEffective leachingAchieve cycleAluminium oxides/hydroxidesAluminium chlorideSteelmaking

The invention discloses a method for producing aluminum oxide through treatment and utilization of industrial solid wastes and particularly relates to a method for preparing aluminum oxide through treatment of coal ashes with hydrochloric acid. The method comprises the following steps: activating coal ashes; mixing the activated coal ashes with 15%-36% hydrochloric acid, wherein a molar ratio of HCl in the hydrochloric acid to aluminum oxide and iron oxide in the coal ashes is 4-9; feeding mixed serous fluid into a reactor, heating to 90 DEG C-230 DEG C, wherein reaction time is 1 hour-8 hours; carrying out solid-liquid separation after reacting and cooling to obtain aluminum chloride liquid and high-silicon residue, and evaporating, concentrating or drying to obtain crystallized aluminum chloride; decomposing the crystallize aluminum chloride to obtain crude gamma-Al2O3 and a hydrogen chloride gas; and preparing metallurgical-level aluminum oxide by gamma-Al2O3 through a Bayer process, wherein the residue is high-iron residue and can be used as a steelmaking material. According to the method, any auxiliary agent is not added, so that aluminum oxide in the coal ashes can be effectively leached out, and the leaching rate of the aluminum oxide can reach over 85%.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Method for efficient and comprehensive utilization of high-iron bauxite

ActiveCN102515223AAchieve cycleEffective leachingAluminium oxides/hydroxidesAluminium chlorideAluminium hydroxide

The invention relates to a method for efficient and comprehensive utilization of high-iron bauxite. The method provided by the invention comprises the following steps that 1, high-iron bauxite and hydrochloric acid are mixed, then are added into a hydrochloric acid-resistant medium-pressure reactor and undergo a heating reaction; 2, after cooling, the reaction products are subjected to solid-liquid separation so that high-silicon dregs and a solution containing aluminum chloride and ferric chloride are obtained; 3, the solution containing aluminum chloride and ferric chloride is added with an excess amount of a sodium hydroxide alkaline solution so that a sodium aluminate solution and high-iron dregs are obtained; and the sodium aluminate solution is electrolyzed to produce chlorine, hydrogen, a sodium hydroxide solution and a pure sodium aluminate solution; 4, the pure sodium aluminate solution is introduced into a crystal seed precipitation tank, is subjected to precipitation and then is subjected to solid-liquid separation so that aluminum hydroxide products and a mother liquor are obtained by the precipitation; and 5, the aluminum hydroxide products are graded, wherein the aluminum hydroxide products having small granularity are utilized as crystal seeds for precipitation and the aluminum hydroxide products having big granularity are washed and then are subjected to high-temperature calcination to form metallurgical-grade alumina products. The method provided by the invention can realize effective precipitation of alumina and iron of high-iron bauxite, has low energy consumption in a whole flow, avoids waste production, realizes full green production and is conducive to industrialization.

Owner:SHENYANG POLYTECHNIC UNIV

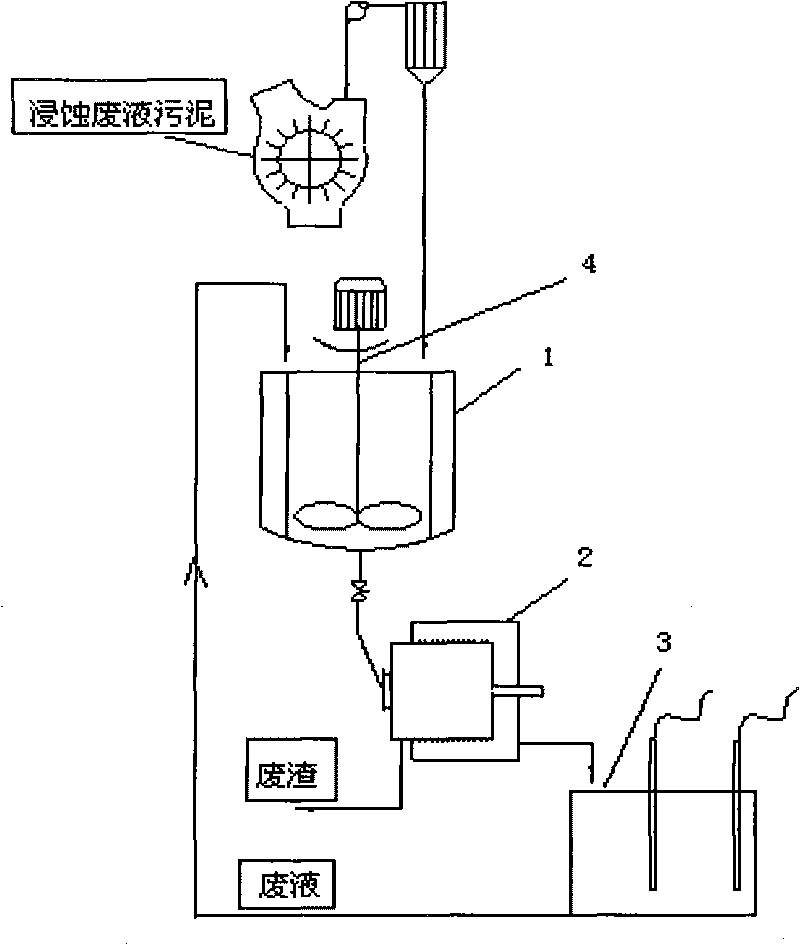

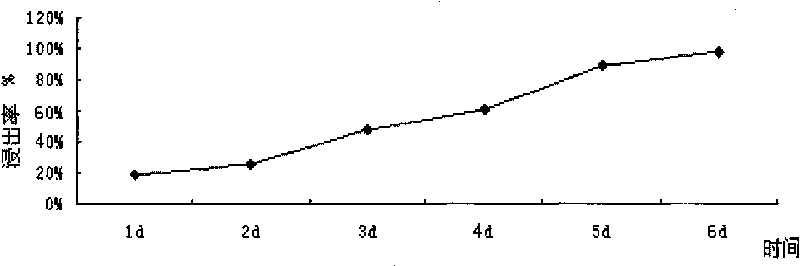

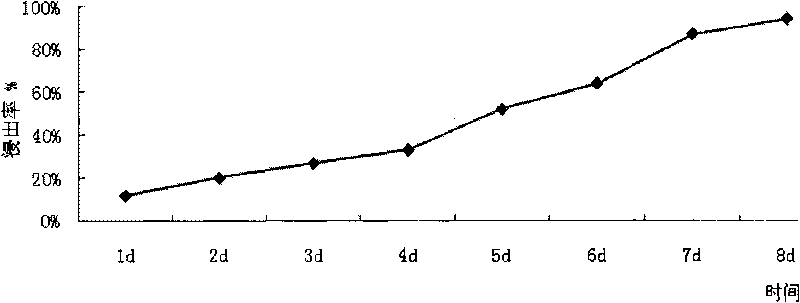

Method for recovering metallic copper in mud by using microorganism and special device

InactiveCN101760619AIncreased content of metal elementsIncrease element contentPhotography auxillary processesProcess efficiency improvementHeating systemMetal leaching

The invention relates to a method for recovering metallic copper in mud generated after production of a circuit board and / or treatment of electroplating rinse-waste water by using a microorganism and a special device. The method comprises the following steps: A, adding a culture medium into a reactor, inoculating a pre-cultured T.f bacteria and T.t bacteria inoculation liquid, starting a heating system and pre-culturing the mixture for 1+ / -0.5 day to obtain a reaction liquid; B, adding the mud into the reaction liquid obtained in the step A with stirring, starting an aeration machine to culture the mixture for 3 to 10 days, opening a valve at the bottom of the reactor, then pumping a leaching agent which contains mud granules from the reactor with stirring, filtering the mud granules with a filter press to obtain the metallic leaching agent; and C, after extracting and condensing the metallic leaching agent obtained in the step B, allowing the metallic leaching agent to enter an electrolytic bath for electrolysis to obtain copper with the purity of over 99 percent, or directly evaporating the concentrated liquor to obtain high-purity CuSO4. The method has the advantages of simple technique, low cost and environmental friendliness.

Owner:惠州市雄越保环科技有限公司

Sulfur-free sparkling wine production technology

ActiveCN104789402AImprove refreshmentLow costMicroorganism based processesWine preparationBiotechnologyVitis vinifera

The invention relates to the sparkling wine processing technology, and particularly relates to fresh sulfur-free sparkling wine and a production technology thereof. The production technology comprises the following steps: adopting fresh grapes or frozen grape mashes as the raw materials; carrying out low-temperature extraction and high-temperature sterilization to prepare grape juice; completing the whole process of low-temperature fermentation, fermentation tank sealing, pressure boosting, yeast separation and aroma formation in a closed fermentation tank. The brewing method is simple to operate and free from secondary fermentation; in the whole brewing process, sulfur dioxide and other preservatives are not needed to add, and human health is facilitated; the colors of the sparkling wine can be classified into light green, pink, red and the like according to different raw materials; the sparkling wine has special fruity flavor and vinous flavor, is full-bodied in wine body, tasty and refreshing, and is suitable for people of all ages.

Owner:德州奥德曼葡萄酒庄有限公司

Technology for immersing corn in a corn starch production process

The invention discloses a technology for immersing corn in a corn starch production process, wherein the technology uses a seven-can immersing method, and comprises a seventh into fragmentation grinding and a first can where new core is added, new-prepared acid is added into a sixth can before into fragmentation grinding, and concentration of sulfurous acid in the new-prepared acid is 0.15-0.17%; before the new-prepared acid is added, a can-inversing method is used, that is opposite to the direction in which the core is fed, a immersion liquid in the first to sixth cans is orderly poured form a can with a bigger sequence number to a can with a smaller sequence number, the liquid is poured until a liquid level that the immersed core is not exposed, and the immersion liquid level in each can is same; and the a total immersion time of the core is controlled in a range from 25h to 29h. The technology for immersing corn in the corn starch production process, strictly controls the immersion concentration and temperature, needs short immersion time, can effectively immerse out effective components in the corn, and has advantages of high yield, low concentration of sulfurous acid, short immersion time, and low power consumption and steam consumption.

Owner:MENGZHOU GOLDEN CORN

A comprehensive utilization method for low-grade bauxite

InactiveCN104340998AEfficient separationAchieve cycleElectrolysis componentsAluminium hydroxide preparationFerric hydroxideAluminium hydroxide

The invention relates to a comprehensive utilization method for bauxite and particularly relates to a comprehensive utilization method for low-grade bauxite. The method includes following steps of: (1) mixing the low-grade bauxite with hydrochloric acid after ore grinding; (2) performing solid liquid separation and washing after the reaction is cooled; (3) adding the solution obtained in the step (2) into a sodium hydroxide solution to obtain an aluminium hydroxide precipitate, an iron hydroxide precipitate and a sodium chloride solution, performing solid liquid separation, and washing; (4) preparing the aluminium hydroxide and iron hydroxide solid obtained in the step (3) into metallurgy-level aluminum oxide and high-iron slag through a simple Bayer process; (5) subjecting the sodium chloride solution obtained in the step (3) to electrolysis by an ionic exchange membrane electrolytic cell to obtain hydrogen, chlorine and a sodium hydroxide solution; and (6) returning the sodium hydroxide solution that is discharged from an ionic membrane cathode zone in the step (5) into the step (3) and recycling. The method is obvious in environment protection effects, and effectively separates aluminum, iron and silicon in the low-grade bauxite to achieve comprehensive utilization.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

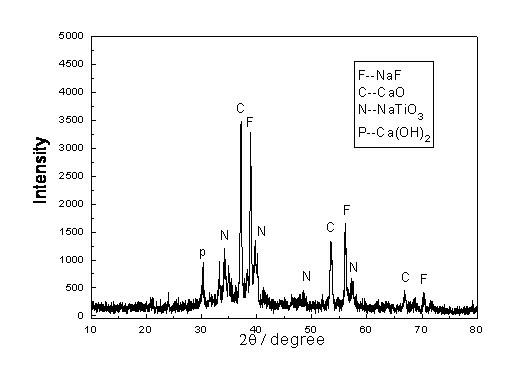

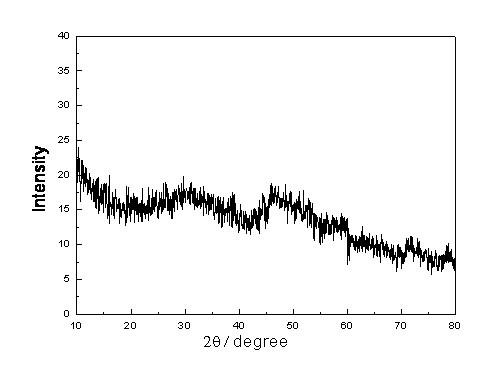

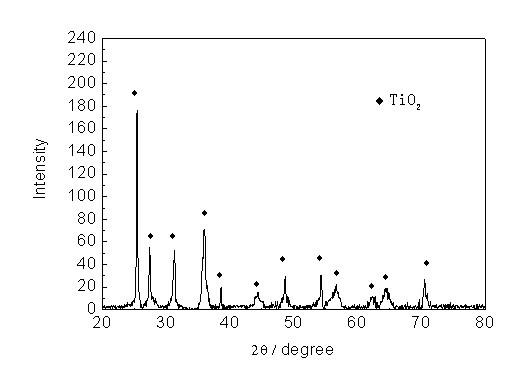

Method for decomposing titanium-containing blast-furnace slag through fused salt

InactiveCN102212707AReduce energy consumptionReduced technical difficulty and equipment investment costsRecycling and recovery technologiesCarbon dioxidePollution

The invention relates to the field of metallurgy and resource comprehensive utilization, in particular to a method for decomposing titanium-containing blast-furnace slag through fused salt, which has the advantages of environment friendliness, low pollution and high efficiency. The method comprises the following steps of: by taking the titanium-containing blast-furnace slag as the raw material; after ball-milling, reacting the titanium-containing blast-furnace slag with a NaOH and NaF fused salt system at 200-700 DEG C to generate a solid intermediate phase; after hydrolyzing, extraction-filtering, dissolving with acid and extraction-filtering the solid intermediate phase to obtain a metatitanic acid solution; hydrolyzing and extraction-filtering the metatitanic acid solution to obtain hydration titanium dioxide powder; and calcining the hydration titanium dioxide powder at 600-1300 DEG C to finally obtain rutile type carbon dioxide. By means of the method disclosed by the invention, alkali circulation and acid circulation in the system are realized; the production energy consumption is reduced; the production process is simplified; the equipment investment is reduced; the process operability is improved; and meanwhile, a lot of accumulated titanium-bearing blast-furnace slag is utilized; the environmental problem is solved; and the titanium resource is sufficiently utilized.

Owner:NORTHEASTERN UNIV

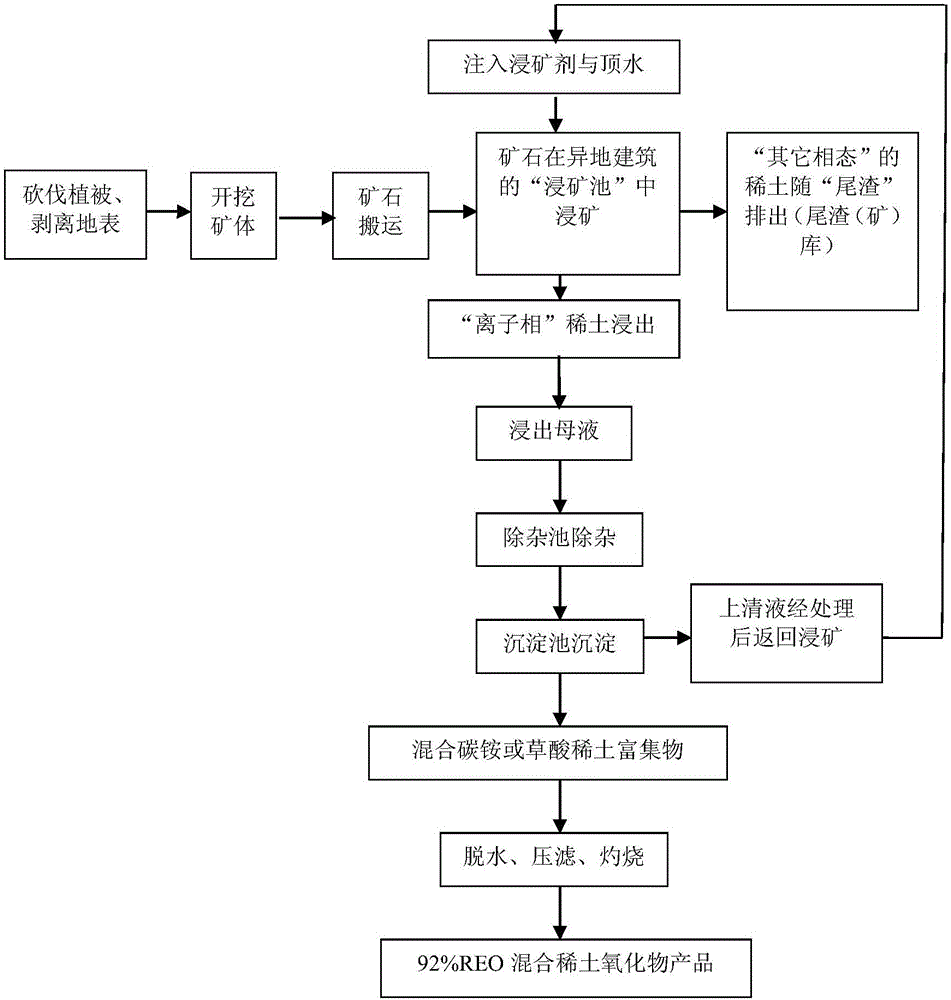

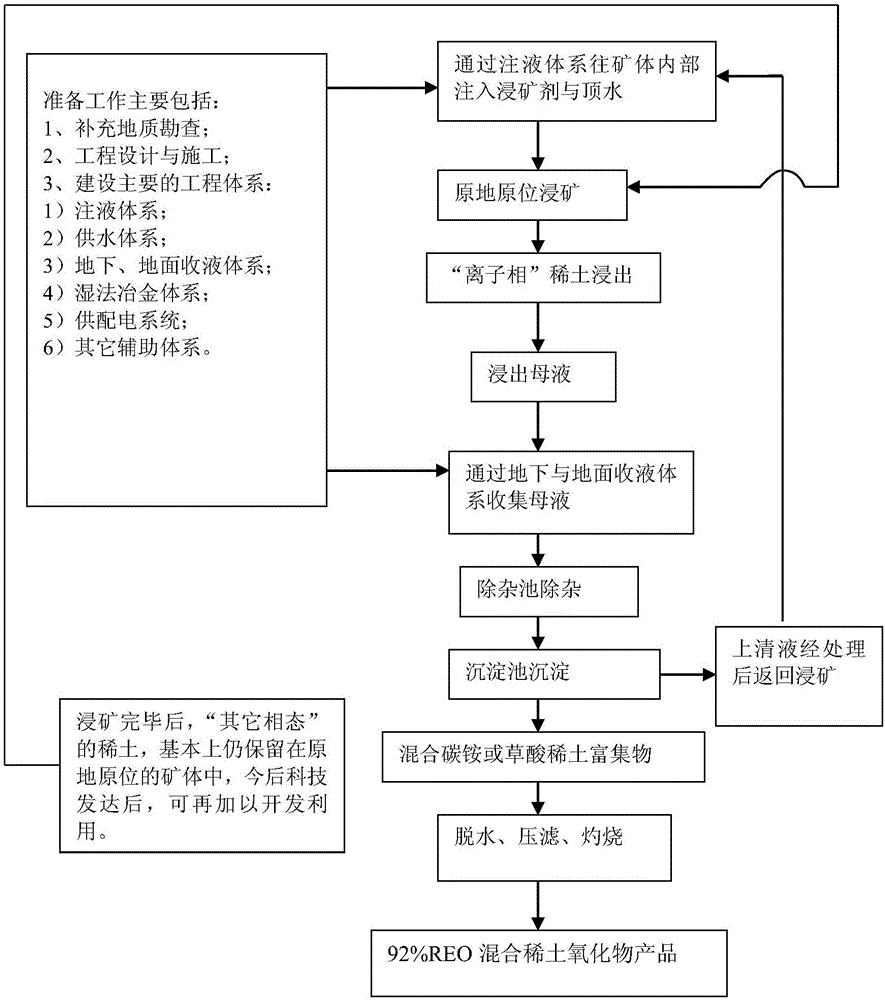

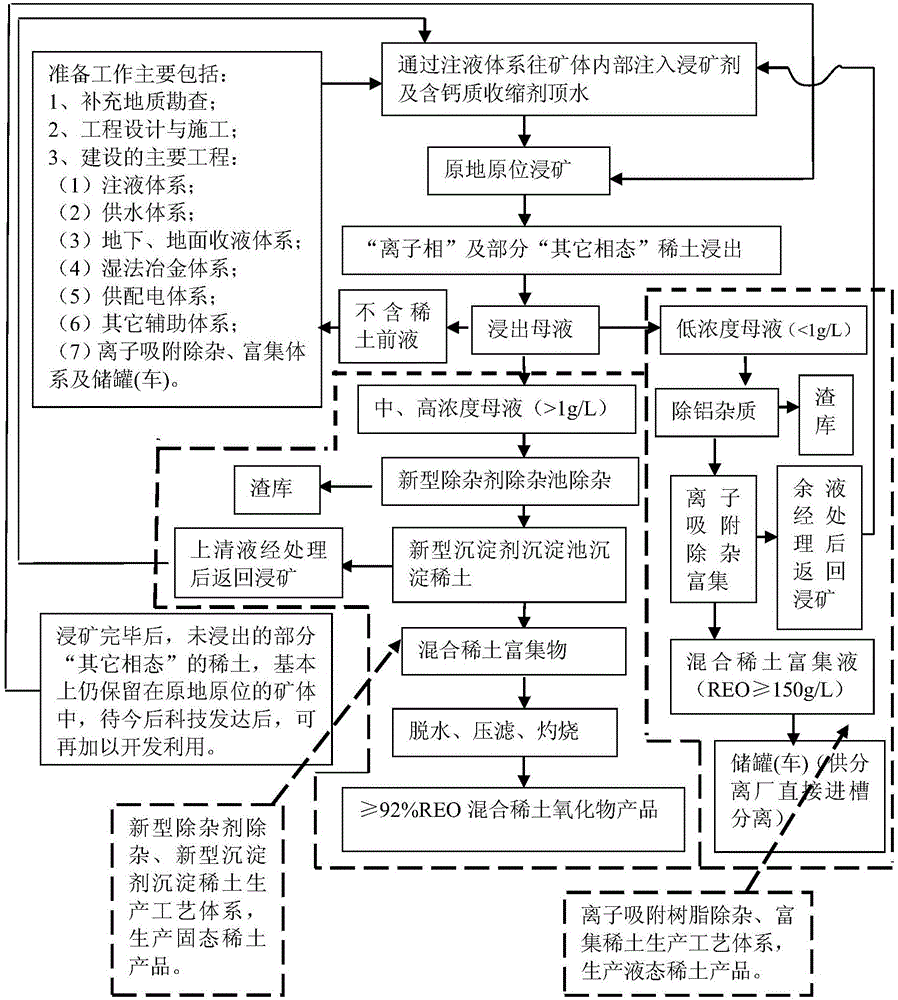

Rare earth in-situ leaching and enriching process for ionic rare earth ore

The invention discloses a rare earth in-situ leaching and enriching process for ionic rare earth ore. The rare earth in-situ leaching and enriching process comprises the following steps: step 1, injection an ore leaching agent and a shrinkage agent into ore body, and performing sited and in-situ ore leaching to enable 'ion-phase' and part of 'other-phase' rare earth to leach out to obtain a mother liquor; step 2, pumping an impurity removal agent I into the medium and high-concentration mother liquor for impurity removal, precipitating through a precipitator, washing with clear water, filtering, and firing to obtain a solid rare earth product, wherein the impurity removal agent I is a mixed solution of a sodium bicarbonate solution and a sodium carbonate solution, and the precipitator is a sodium bicarbonate solution; and pumping an impurity removal agent II into the low-concentration mother liquid for neutralization to remove aluminum impurities, pumping ion exchange columns into the mother liquor from which aluminum is removed for adsorptive enrichment of rare earth ions, and desorbing with acid to obtain a liquid rare earth product, wherein the impurity removal agent II is lime cream. The independently researched and developed brand-new agents are used together with the whole set of innovative technology to achieve the purposes of significant change of the ionic rare earth extraction process, comprehensive optimization of technical-economic indicators and friendly ecological environment.

Owner:赣州弘茂稀土工程有限公司

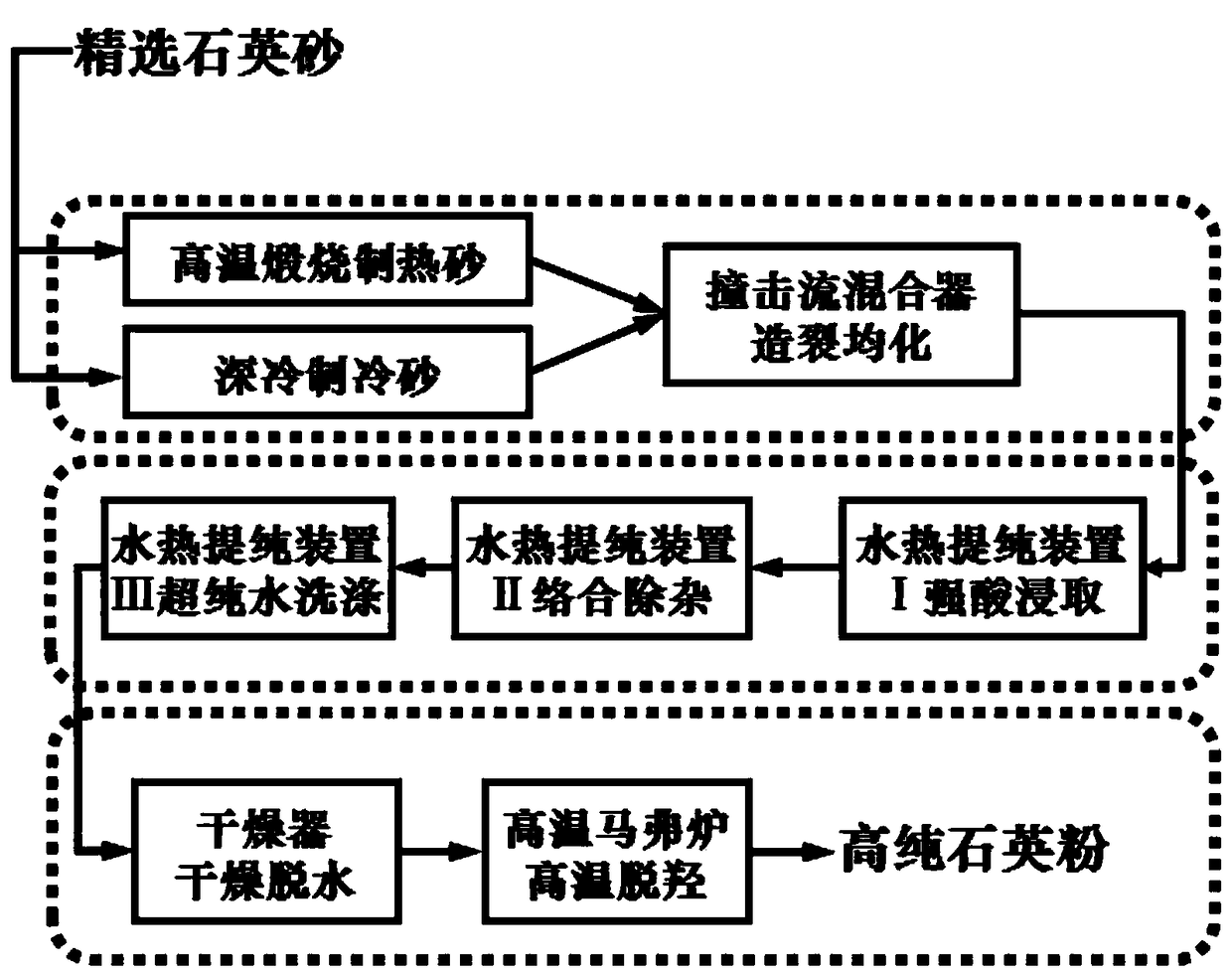

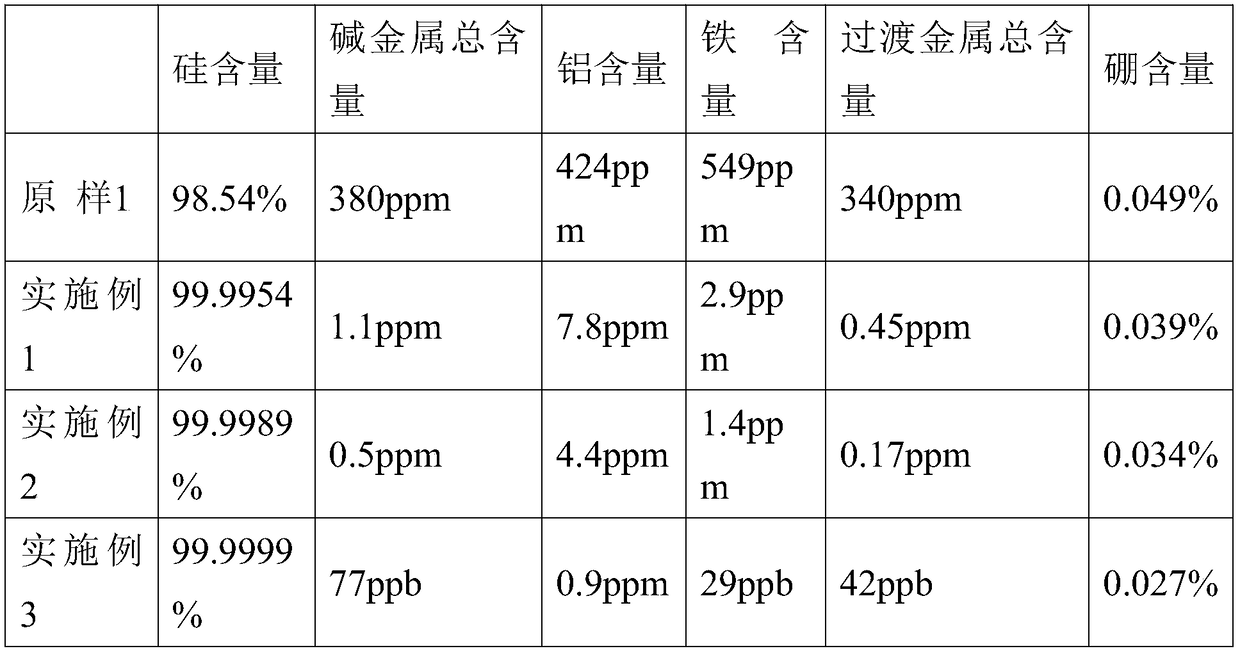

Ultrapure quartz sand and purification process thereof

The invention relates to ultrapure quartz sand and a purification process thereof. The purification process includes: preparing preliminarily washed sand; preparing a secondary particle size homogenized quartz sand product; preparing pickled quartz sand; removing impurities; preparing an ultrapure quartz sand product. The purification process has the advantages that the purification requirements of quartz sand of different metallogenic types can be satisfied, and the purity of the purified products of different quartz sand can reach 99.999-99.99999%; the purification process is simple, practical, innovative, capable of greatly increasing the purification efficiency and purity of high-purity quartz sand and evident in economic and actual application value.

Owner:ANHUI SCI & TECH UNIV

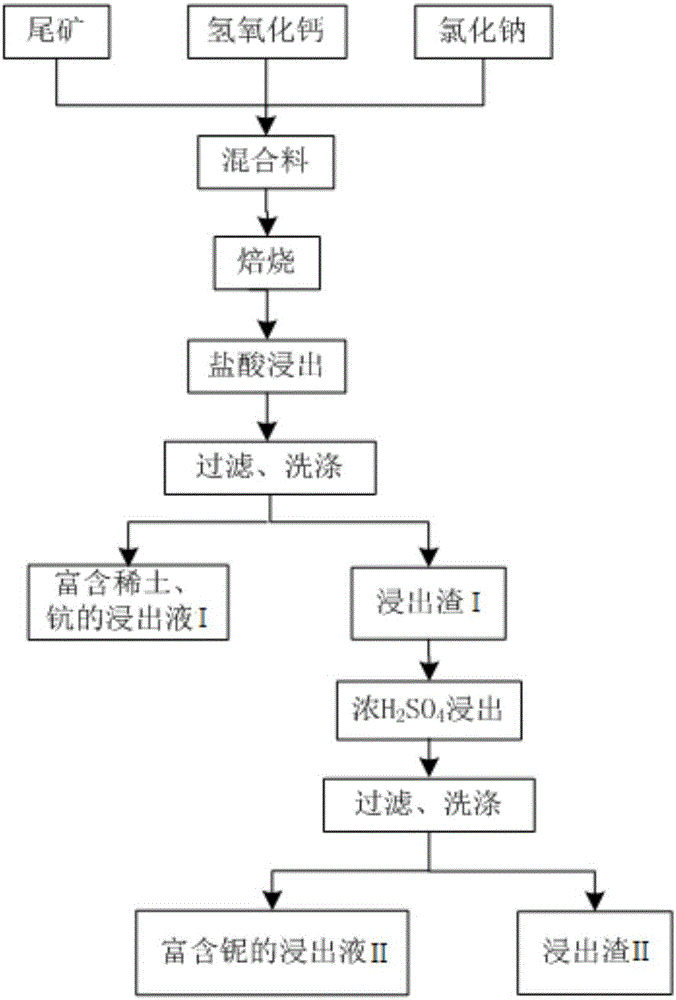

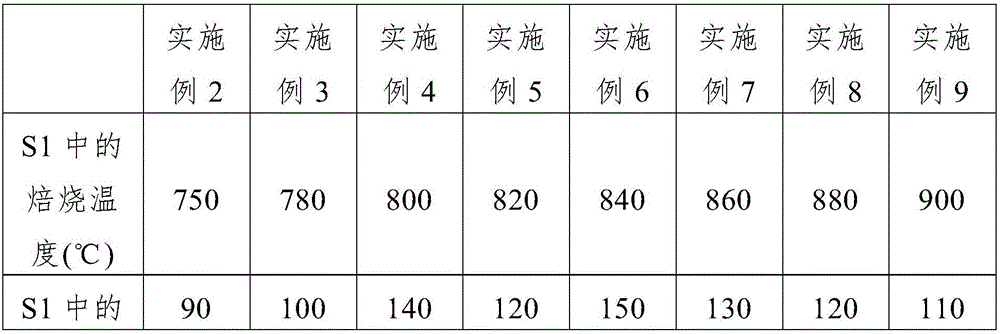

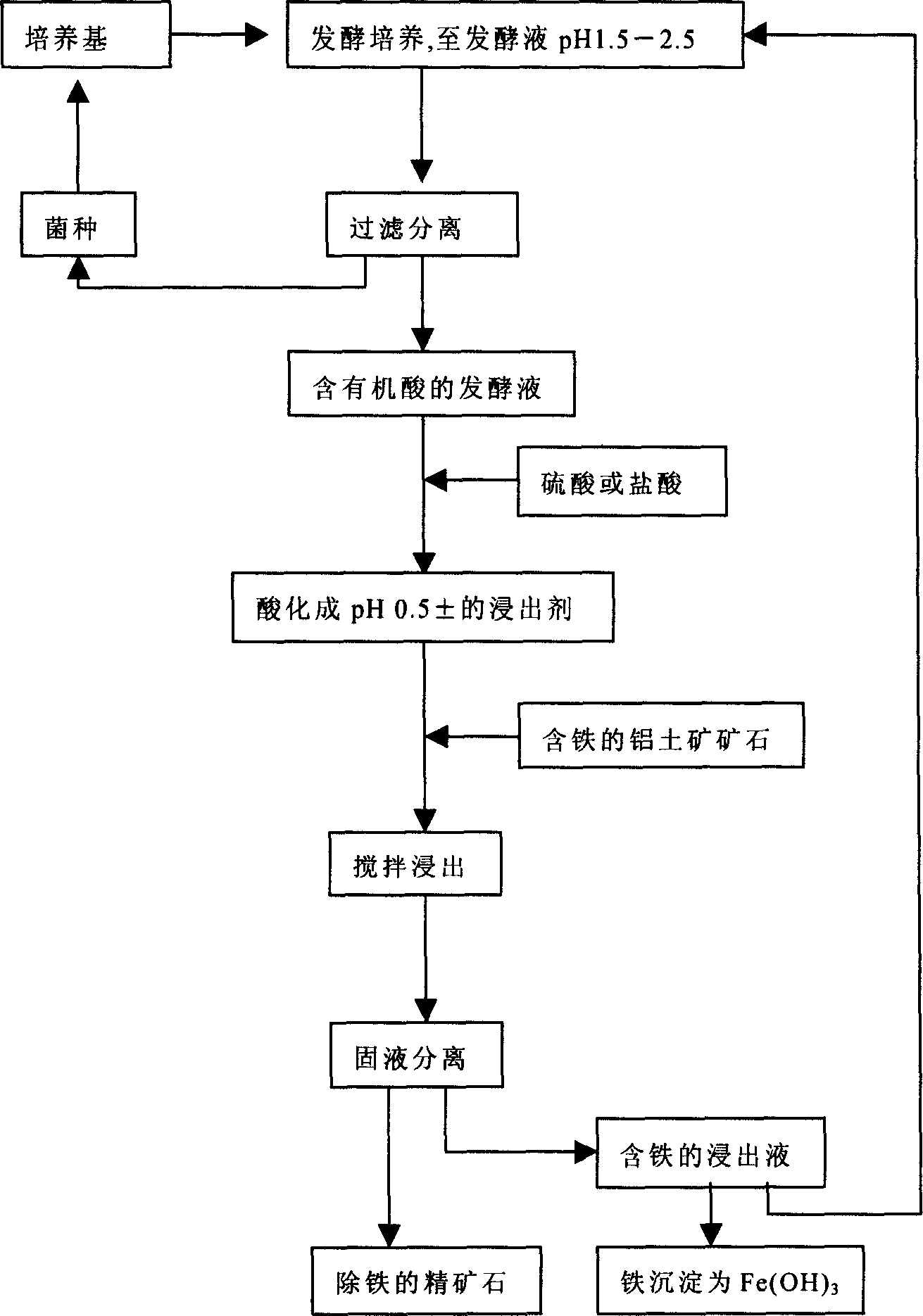

Method for leaching niobium, scandium and rare earth elements from tailings

ActiveCN106636614ALow reaction temperaturePromote leachingProcess efficiency improvementRare-earth elementNiobium

The invention discloses a method for leaching niobium, scandium and rare earth elements from tailings and relates to the technical field of hydrometallurgy. The method comprises the following steps: S1, adding calcium hydroxide and sodium chloride into iron ore dressing, rare earth and fluorite tailings, uniformly mixing to obtain a mixture, and roasting the mixture to obtain roasted ore; S2, performing ball-milling treatment on the roasted ore; S3, mixing the roasted ore subjected to ball-milling treatment with hydrochloric acid, heating for leaching, and filtering an extract to obtain a leaching residue I and a leaching liquor I rich in rare earth and scandium; and S4, drying the leaching residue I, leaching the leaching residue I by adoption of a concentrated sulfuric acid heating leaching method, and filtering an extract to obtain a leaching residue II and a leaching liquor II rich in niobium. The method is simple to operate, low in energy consumption, green and environmentally friendly, and low in process cost, can effectively leach niobium, scandium and rear earth in the iron ore dressing, rare earth and fluorite tailings, and is high in leaching rate of niobium, scandium and rear earth.

Owner:NORTHEASTERN UNIV

Washing method of roller washing machine

InactiveCN105040354AAromaEffective leachingControl devices for washing apparatusTextiles and paperProcess engineeringWarm water

The invention relates to the field of life, in particular to a washing method of a roller washing machine. The method includes the following steps that S1, detergent is acquired, and soaking water is injected into a washing cavity; S2, washing water is injected into the washing cavity for the first time after soaking is performed for a preset period of time; S3, a roller is controller to rotate, clothes are washed for the first time, and the washing water is discharged; S4, detergent is acquired again, and washing water is injected into the washing cavity for the second time; S5, the roller is controlled to rotate, the clothes are washed for the second time, and the washing water is discharged. The method includes the soaking step and the washing step. Warm water and the detergent are mixed for soaking, blots attached to the clothes can be effectively leached, washing is performed two times, the first time of washing is used for separating dirt from the clothes, the second time of washing is used for immersing the clothes in fragrance factors of the detergent while the clothes are cleaned, and the washed clothes smell fragrant.

Owner:韦振彬

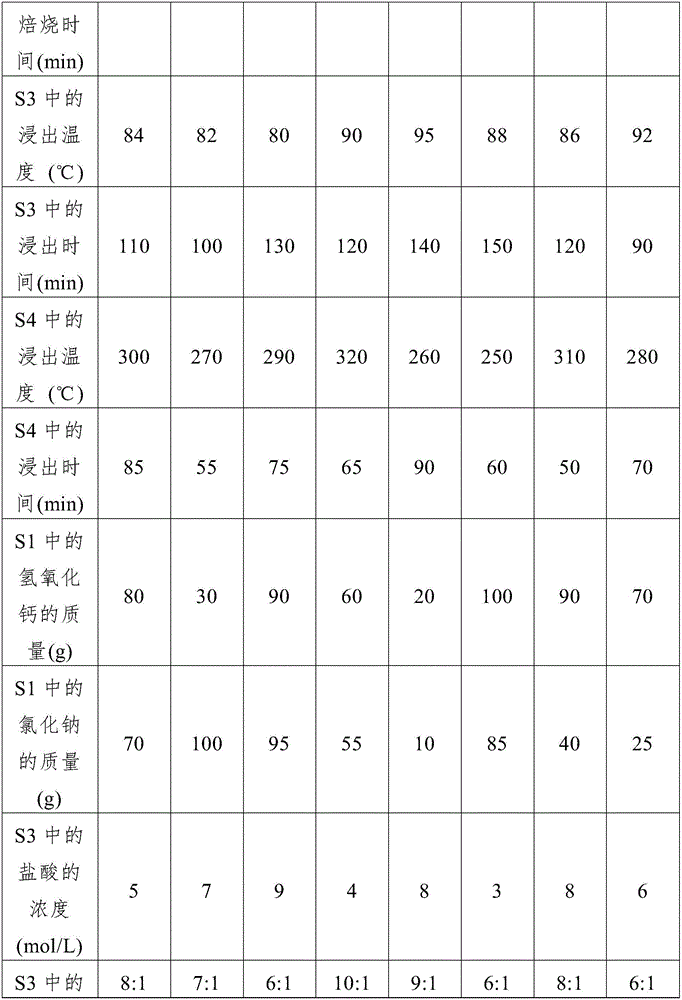

Method for leaching out inpurity iron in bauxite by chemical-biological method

InactiveCN1775969ALeaching is effectiveEffective leachingProcess efficiency improvementFermentationAspergillus niger

The invention relates to a biology and chemical method to remove the impurity iron in bauxite ore. The feature is that it adopts fermentation liquor leaching out iron of aspergillus niger bacterium that has strong ability to produce acid. 1-4% vitriol is added into the fermentation liquor as leaching out agent. After process by the method, the ferric oxide content is 0.4-0.9% and the aluminum leaching out ratio is less than 1.0%.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Graphene and nonferrous metal tailings-based foamed light wallboard and preparation method thereof

ActiveCN108996987AIncrease the areaHigh strengthCeramic materials productionCeramicwareFiberAluminum silicate

The invention belongs to the field of enclosure wall materials of buildings, and particularly relates to a graphene and nonferrous metal tailings-based foamed light wallboard and a preparation methodthereof. The graphene and nonferrous metal tailings-based foamed light wallboard comprises a main material and an auxiliary material. The main material comprises the following component in parts by weight: 70-90 parts of nonferrous metal tailings; and the auxiliary material comprises the following components in parts by weight: 0.5-8 part of graphene, 1-15 parts of vermiculite, 2-10 parts of aluminum fluoride, 3-8 parts of aluminum silicate fibers, 5-15 parts of montmorillonite, 1-10 parts of clay, 5-20 parts of a cosolvent, 0.1-5 parts of a foamer and 0.1-5 parts of a stabilizer. The foamed light wallboard provided by the invention has the characteristics of being light, high in strength, light, high in toughness, fireproof, high-temperature-resistant, waterproof, anti-seepage, green, environmentally-friendly and the like.

Owner:GUANGXI XUTENG INDUSTRIAL GROUP CO LTD

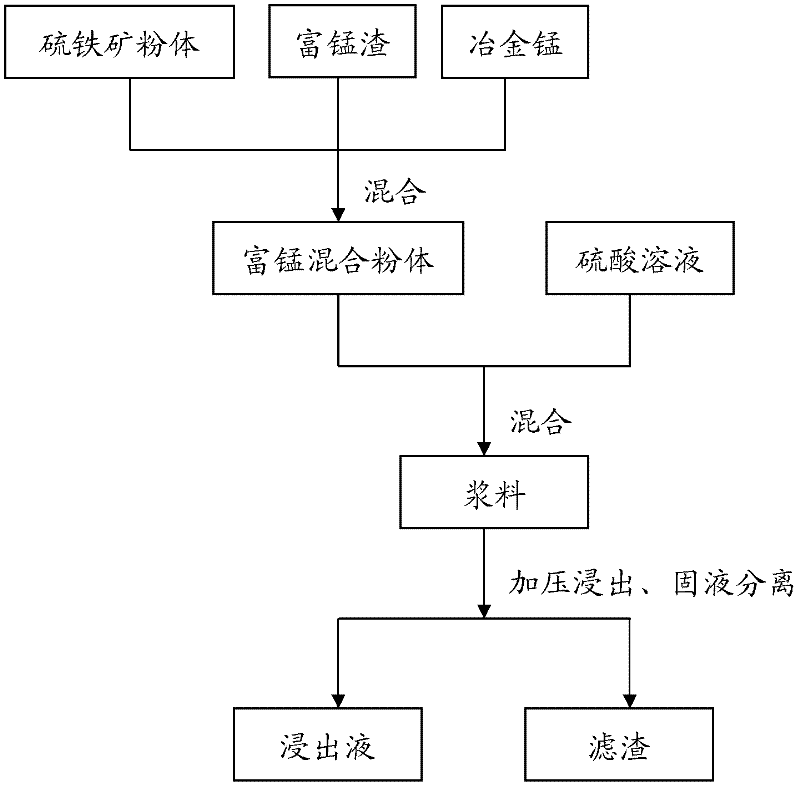

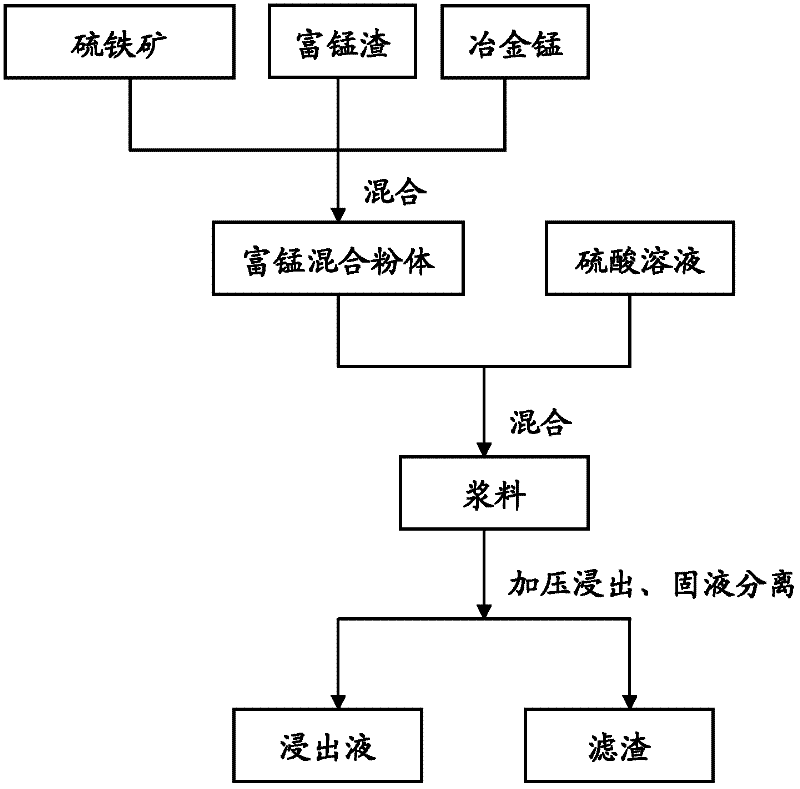

Method for leaching manganese from manganese-rich slag

The invention discloses a method for leaching manganese from manganese-rich slag. The method comprises steps that: (a) the manganese-rich slag is mixed with metallurgy manganese and pyrite powder, such that manganese-rich mixed powder is obtained; (b) a sulfuric acid solution and the manganese-rich mixed powder are mixed, such that a slurry is obtained; (c) the slurry is stirred, and is simultaneously processed through pressure leaching; the leached slurry is filtered, such that a leachate and filter residue are obtained. According to the method provided by the embodiment of the invention forleaching manganese from manganese-rich slag, simultaneous leaching of low-silicon low-grade metallurgy manganese can be realized while filtering is carried out. Also, because a pressure leaching technology is adopted, the leaching efficiency is greatly improved. According to the method provided by the embodiment of the invention for leaching manganese from manganese-rich slag, higher than 90% of manganese can be leached from the manganese-rich slag. Also, the method provided by the invention is advantaged in simple technology, high feasibility, and substantial effect.

Owner:YUNNAN JIANSHUI MANGANESE

Method of preparing aluminum sulphate by utilizing fly ash

The invention relates to a method of preparing aluminum sulphate by utilizing industrial solid waste, in particular to a method of preparing aluminum sulphate by utilizing fly ash. The method comprises the following steps: mechanically activating the fly ash; mixing the mechanically activated fly ash with water according to a weight ratio of 1: 0.5-2.5; adding concentrated sulfuric acid at a weight ratio of 0.3-2.2 : 1 to the fly ash to a reaction kettle to generate basic aluminum sulphate at a temperature of 120 to 230 DEG C kept for 1-8h and a pressure of 0.11 to 0.50 MPa; cooling the basicaluminum sulphate after a reaction, separating solid and liquid, adding sulfuric acid to the basic aluminum sulphate liquid, adjusting the system to have the basicity of 0.1 to 0.4 and the pH value of3 to 4 and converting the basic aluminum sulphate liquid into an aluminum sulphate solution; and evaporating and concentrating the aluminum sulphate solution to 110 to 120 DEG C and cooling and crystallizing the aluminum sulphate solution to separate aluminum sulphate crystals.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

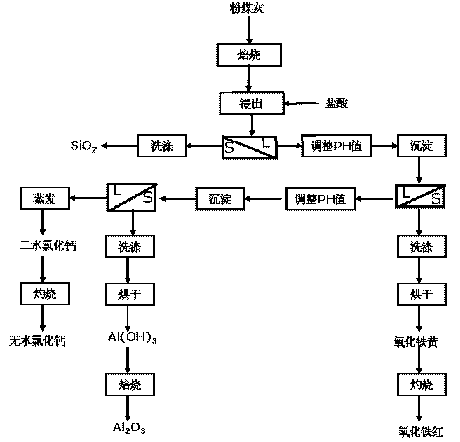

Fractional precipitation method for extraction of aluminum, silicon, iron and calcium elements in fly ash

InactiveCN103482707AHarm reductionHigh puritySilicaCalcium/strontium/barium chloridesAluminium hydroxideCalcination

The invention discloses a fractional precipitation method for extraction of aluminum, silicon, iron and calcium elements in fly ash, and the method comprises (1) the fly ash activated by roasting is leached by hydrochloric acid, and then filtered to obtain filter residue and filtrate, and the filter residue is further processed to obtain white carbon black; (2) the pH value of the filtrate obtained by the step (1) is adjusted to 1.5 - 3.5, then filter residue and filtrate are obtained by precipitation and filtering, and an iron compound is obtained by washing and drying of the filter residue; (3) the pH value of the filtrate obtained by the step (2) is adjusted to 3.8 - 5.2, then filter residue and filtrate are obtained by precipitation and filtering, and aluminum hydroxide is obtained by washing and drying of the filter residue, and then metallurgical grade alumina is obtained by further calcinations; and (4) calcium chloride dihydrate is obtained by evaporating of the filtrate obtained by the step (3), and anhydrous calcium chloride is obtained by further calcinations. Through use of the method, fractional extraction of the aluminum, silicon, iron and calcium elements in the fly ash can be realized, and the extraction rates are more than 70%. At the same time, the method is simple in process and low in cost.

Owner:GUIYANG AL-MG DESIGN & RES INST

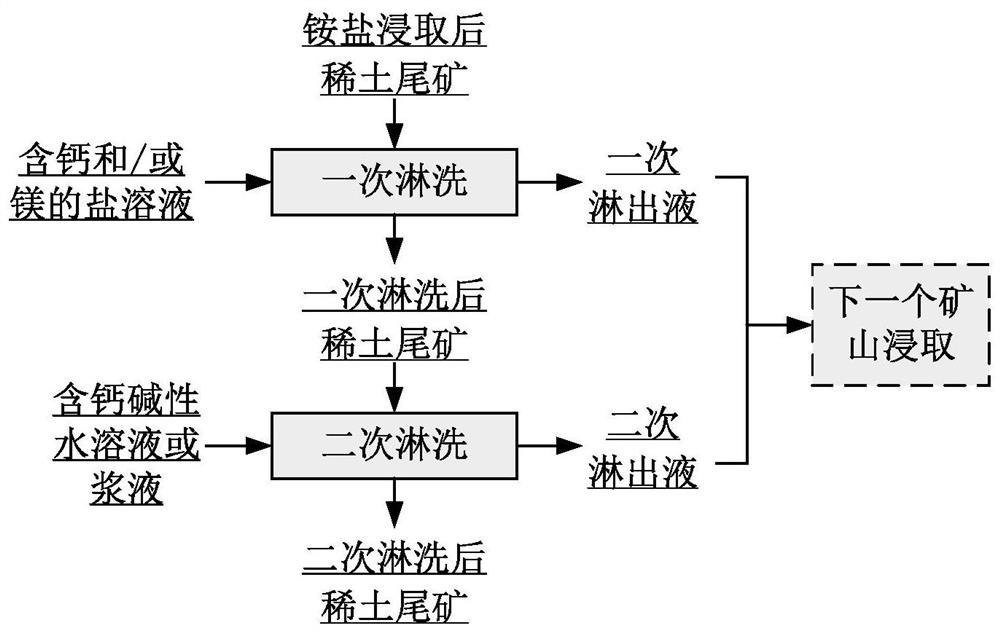

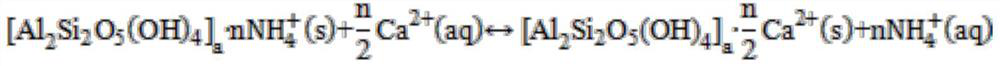

Method for restoring ionic rare earth ore ammonium salt leaching site

ActiveCN113369291AFacilitated releaseFast elutionOther chemical processesContaminated soil reclamationEnvironmental chemistryMineralogy

The invention relates to a method for restoring an ionic rare earth ore ammonium salt leaching site, which comprises the steps of carrying out primary leaching by using a calcium and / or magnesium-containing salt solution and carrying out secondary leaching by using a calcium-containing alkaline aqueous solution or slurry, so that reinforced leaching of residual ammonium salt in the ammonium salt ore leaching site, controllable adjustment of the pH value, in-situ chemical curing of sulfate radicals and rapid regulation and control of the content of calcium and magnesium nutrient elements can be achieved, the used leaching water amount is small, the leaching period is short, the leaching effect is good, the technology is simple, the cost is low, and a solid technical guarantee can be provided for ion type rare earth ore ammonium salt leaching site restoration and eco-friendliness.

Owner:GRIREM ADVANCED MATERIALS CO LTD +1

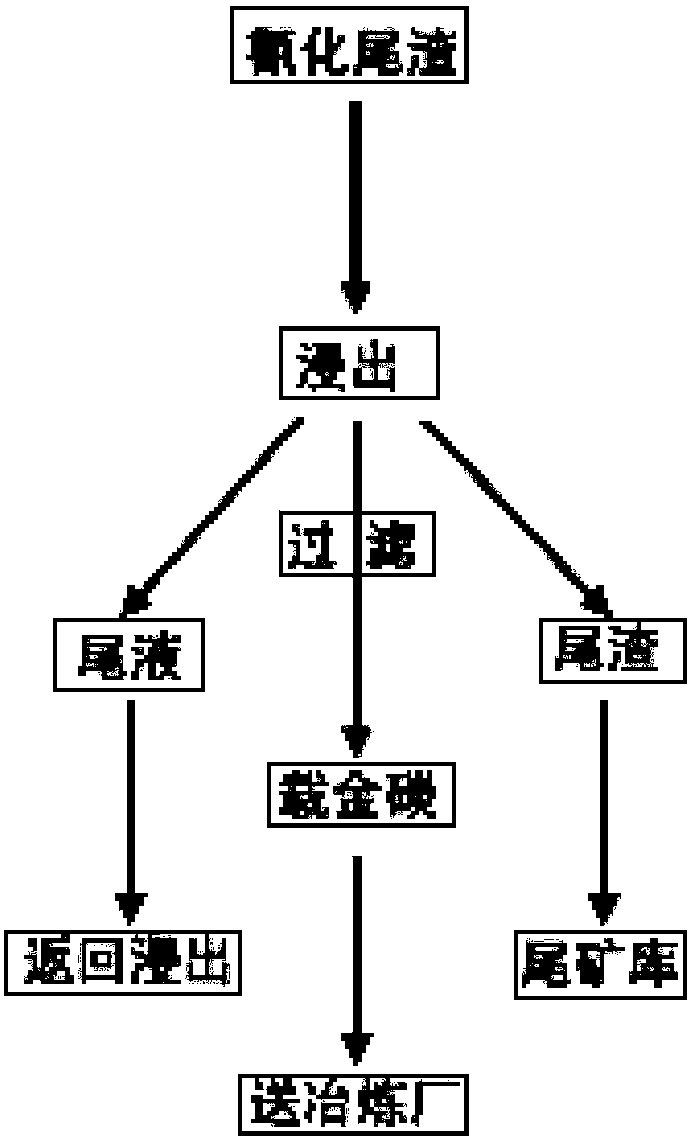

Re-leaching process for carbon refractory gold concentrate cyanide tailings

InactiveCN108239702ARealize recycling of resourcesImprove leaching rateProcess efficiency improvementCyanideRefractory

The invention discloses a re-leaching process for carbon refractory gold concentrate cyanide tailings. The process specifically comprises the following steps: performing size mixing on cyanide tailings to obtain a solution with a liquid-solid ratio of 2:1 to 5:1, adding a leaching agent and cocoanut active charcoal into the solution, and heating and leaching. According to the process disclosed bythe invention, by virtue of re-leaching of the carbon refractory gold concentrate cyanide tailings, the organic carbon can be degraded, sulfides are subjected to oxidized coating, gold in the cyanidetailings is effectively leached out, the gold in the cyanide tailings can be leached out by 50% or higher, and the leaching rate of gold concentrate is improved by 10% or higher, so that the gold in the cyanide tailings is recycled.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

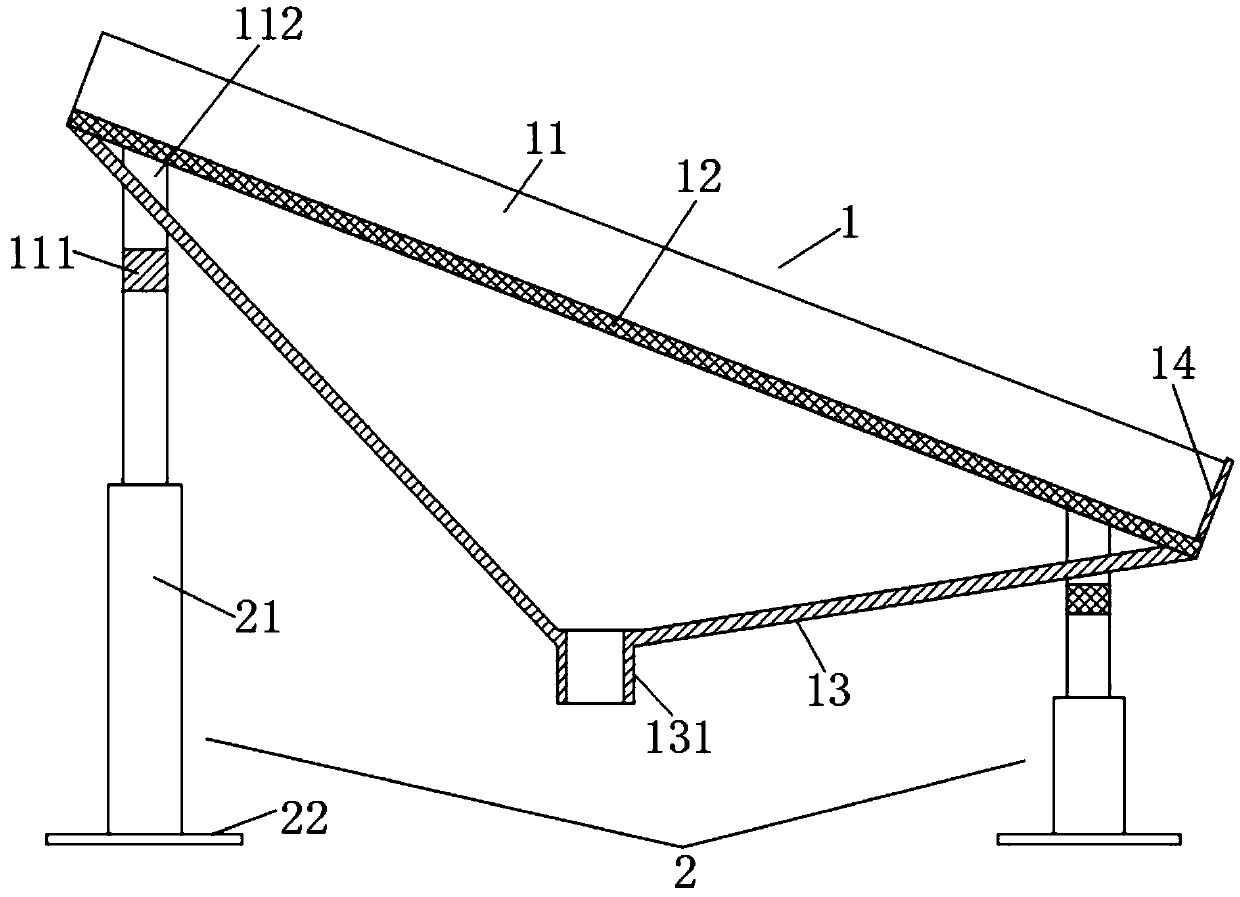

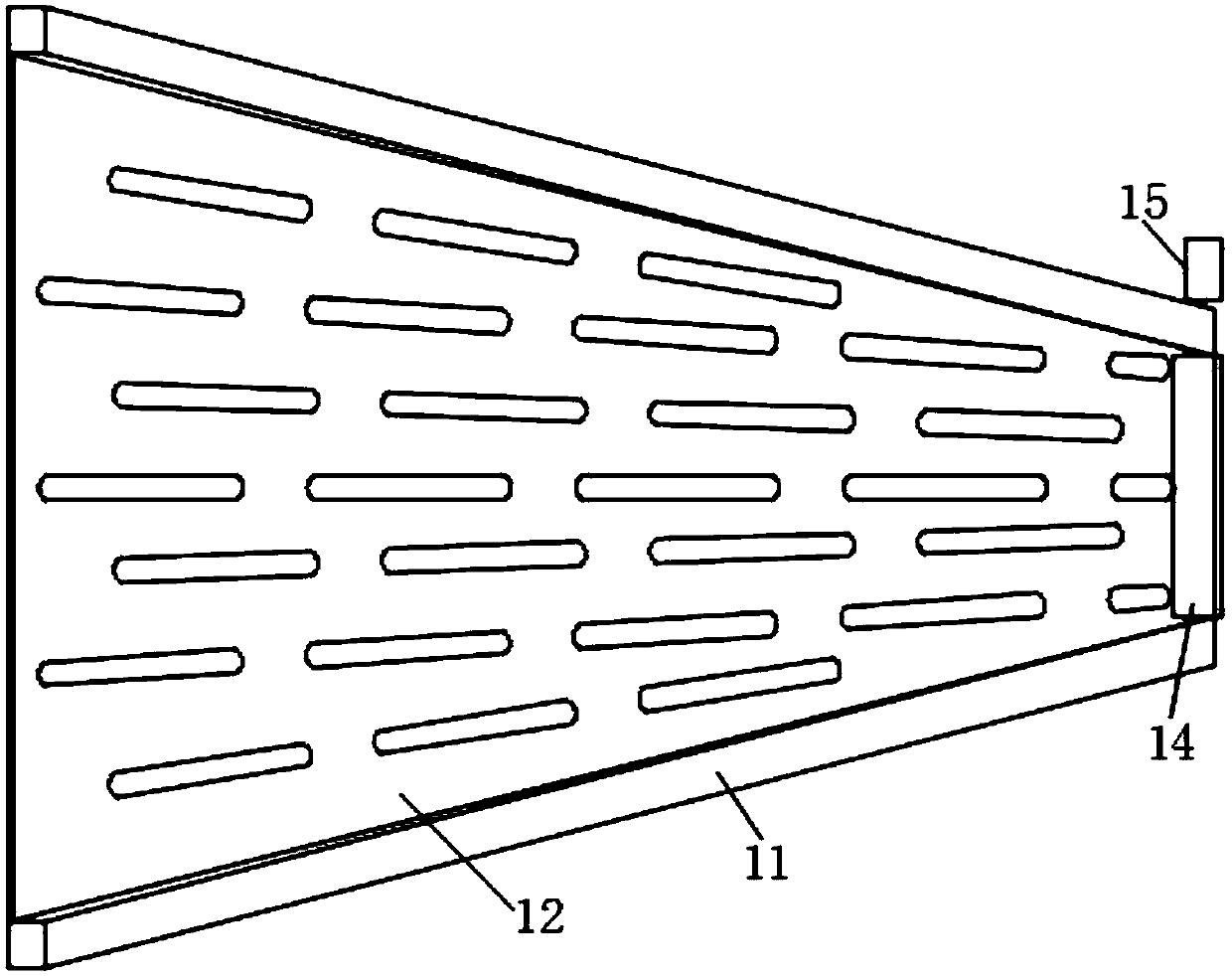

Unloading mechanism based on aquatic product carrier vehicle

PendingCN107902440AReduce labor intensityEffective leachingLoading/unloadingAgricultural engineeringAquatic product

The invention relates to the technical field of aquatic product transportation and production, in particular to an unloading mechanism based on an aquatic product carrier vehicle. The unloading mechanism based on the aquatic product carrier vehicle comprises an unloading groove and two sets of lifting mechanisms. The unloading groove is a groove body with the two ends being open, one end of the unloading groove is a feeding port, the other end of the unloading groove is a discharging port, and the horizontal height of the discharging port of the unloading groove is lower than the horizontal height of the feeding port of the unloading groove; and the two sets of lifting mechanisms are installed at the lower ends of the two ends of the unloading groove correspondingly, and used for adjustingthe overall inclination angle and the height of the unloading groove, and the unloading groove comprises two symmetrically arranged side plates and a water drainage grating plate arranged between thelower ends of the two side plates. The unloading mechanism has the advantages that the structure is simple, operation and using are convenient, the inclination angle and the height can be flexibly adjusted, unloading is convenient, the labor intensity of workers is relived, water can be effectively drained in the unloading process, and too much water is prevented from accumulating in the subsequent processing process.

Owner:湖北海瑞渔业股份有限公司

Method for lowering activity of autolytic enzymes of sea cucumbers by ultrasonic-assisted electrolyzed water

InactiveCN103892339ALow reducing sugar dissolutionLow survival rateFood ultrasonic treatmentFood preparationUltrasonic assistedElectrolysed water

The invention belongs to the field of enzyme activity inhibition and in particular relates to a method for lowering the activity of autolytic enzymes of sea cucumbers by ultrasonic-assisted electrolyzed water. The method comprises the following steps: preprocessing, performing ultrasonic-sub-acidic electrolyzed water treatment, performing secondary impurity removal, and packaging for storing or subsequently processing. The purposes of changing the internal pH value of the sea cucumbers and lowering the activity of the autolytic enzymes of body walls and intestinal tracts of the sea cucumbers are achieved through the ultrasonic-assisted sub-acidic electrolyzed water treatment. The method has the advantages that the sterilization effect is remarkable, the dissolving-out quantity of TCA-soluble oligopeptide, total sugar and reducing sugar is low, and the enzyme activity survival rate of the autolytic enzymes is lower than 15%.

Owner:FUJIAN AGRI & FORESTRY UNIV

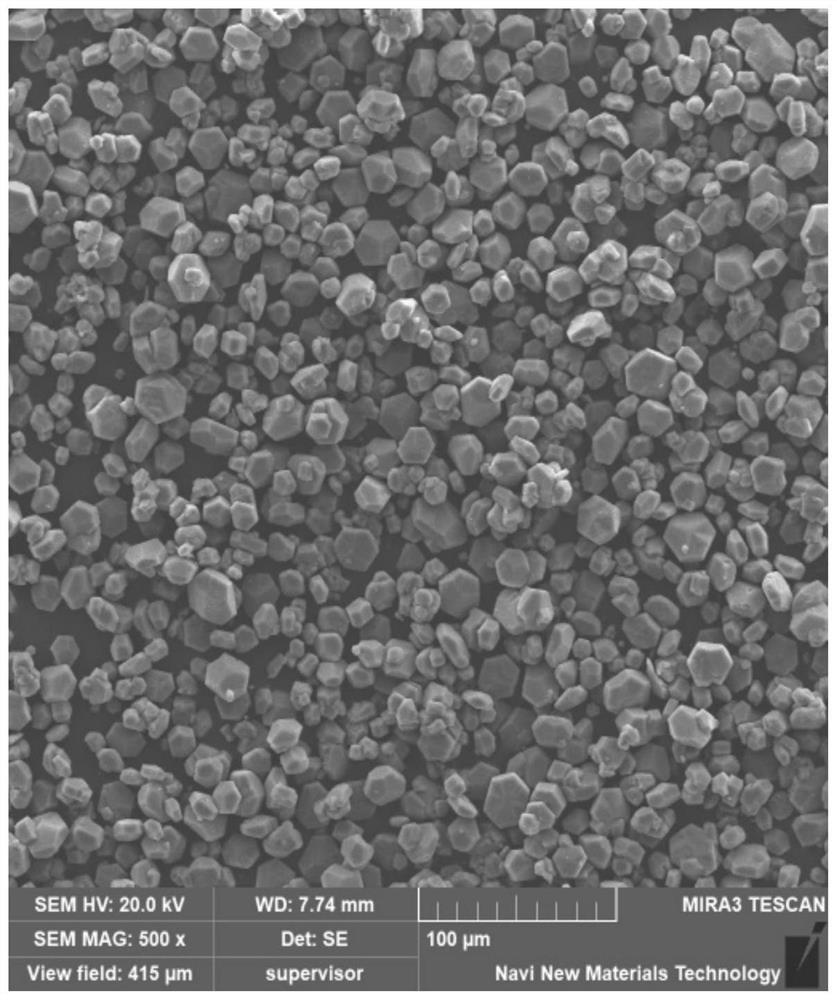

Method for regulating crystal morphology and granularity of alpha-semi-hydrated gypsum in solution system

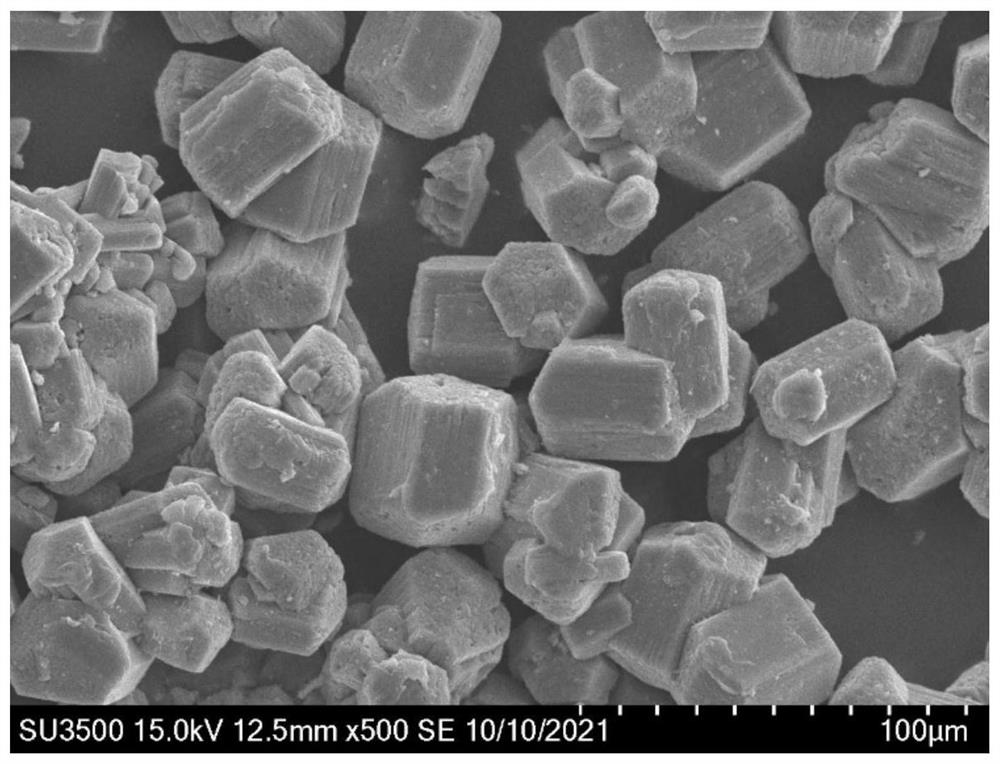

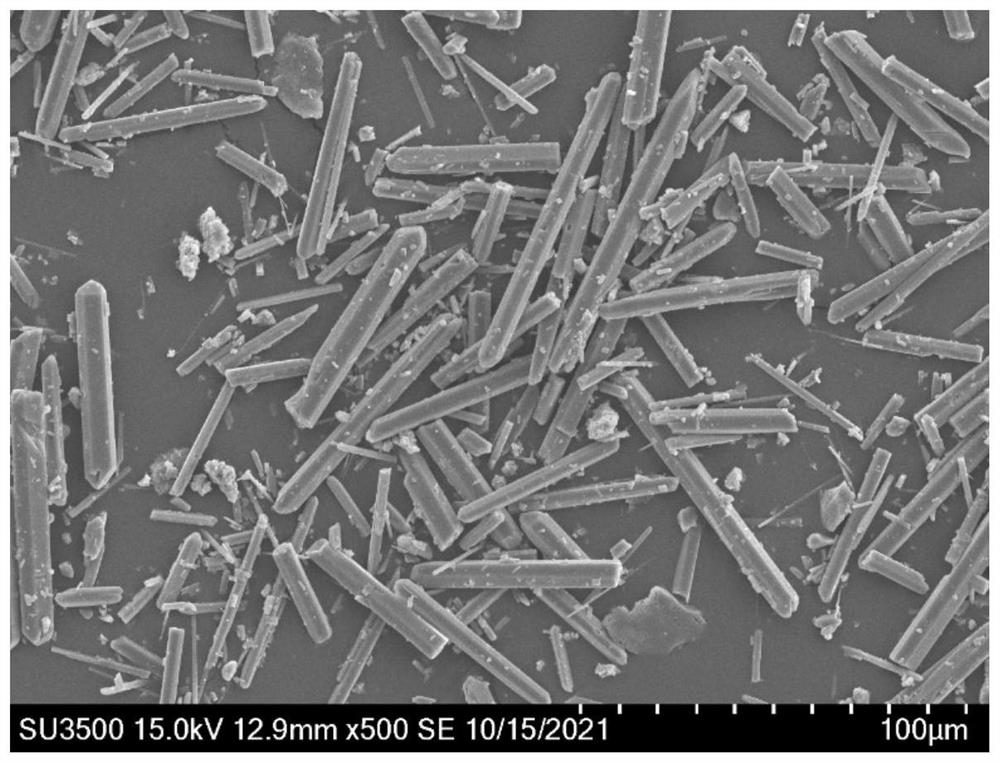

ActiveCN114349039ALarge granularityShorten the timeCalcium/strontium/barium sulfatesCrystal morphologySeed crystal

The invention relates to a method for regulating and controlling the morphology and granularity of alpha-semi-hydrated gypsum crystals by adding seed crystals. According to the invention, crystal morphology and granularity of alpha-semi-hydrated gypsum generated in a solution system are regulated and controlled by adding a seed crystal, wherein the seed crystal is alpha-semi-hydrated gypsum, and the long diameter of the seed crystal is less than or equal to 2.5. The average crystal length of the alpha-semi-hydrated gypsum product is 30-100 [mu] m, the average width is 15-30 [mu] m, and the average length-diameter ratio is 1.0-6.0. Meanwhile, the obtained product is high in purity and high in strength. The method is simple and controllable in process, and the obtained product is excellent in performance and convenient for large-scale application.

Owner:HUNAN UNIV OF SCI & TECH

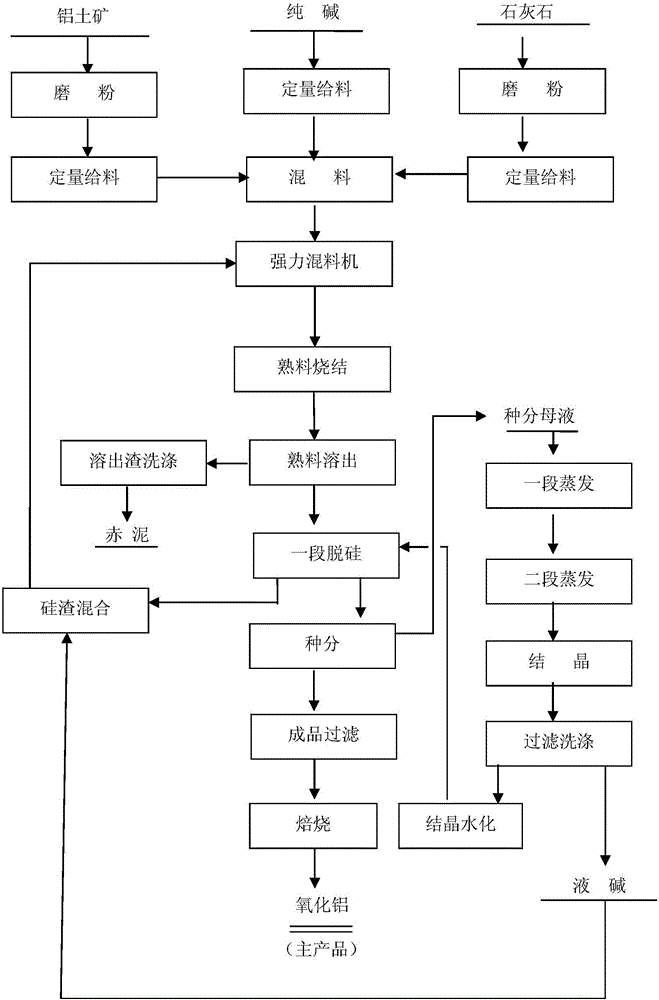

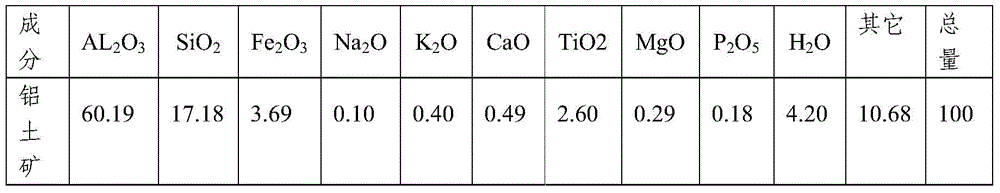

Dry-process firing method of bauxite with low aluminum-silicon ratio

ActiveCN105800652AReduce the difficulty of operationReduce equipment and personnel investmentAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationDecompositionRotary kiln

The invention provides a dry-process firing method of bauxite with low aluminum-silicon ratio. The method comprises the following steps: dosing and mixing the limestone powder, bauxite powder, sodium carbonate and evaporation-return recycled alkaline solution; sintering in a rotary kiln; cooling the sintered clinker and levigating; adding adjustment liquid into the clinker powder for dissolving out; performing reverse sufficient washing of the slag dissolved out of the clinker powder for 5-7 times, wherein the washing liquid is used as adjustment liquid while the slag is piled; mixing the solution dissolved out of the clinker powder with sodium aluminate crystal for dissolution, and desiliconizing; performing seed decomposition; and performing evaporation and salt elimination of the seed mother liquor by two steps. In the method provided by the invention, for the bauxite with low aluminum-silicon ratio, the sintering raw material is combined with appropriate limestone and sodium carbonate so that the sintered clinker powder can be effectively leached; the dry-process firing conditions are controlled so that the technological process of the sintering process is shortened by over one third, the seed composition rate is improved by 90% or over, and the total recovery rate of aluminum oxide is 90% or over.

Owner:开曼铝业(三门峡)有限公司

Preparation method of fragrant and spicy preserved meat

The present invention relates to the technical field of food processing and particularly relates to a preparation method of fragrant and spicy preserved meat. The preparation method comprises the following steps: (1) chili pretreating; (2) chili refined treating; (3) pickling; and (4) fire-curing. The preparation method is simple in operations and easy to implement. The obtained preserved meat is brightly red in color and luster, tight in texture, dry in meat body, well arranged in layers, fragrant and spicy assailing nostrils, fat but not greasy, and endless in aftertaste. The preparation method avoids the problems that traditional preserved meat is black in color and luster and smoke and dust are much. The chilies are extracted and the raw material meat is soaked. The preparation method uses the significant effects of the chilies in killing bacteria, preservation, seasoning, nutrition and dispelling cold, and uses strong irritation of the chilies, so that the effective ingredients of the chilies are maximally penetrated into the raw material meat and the preparation method improves the single mouthfeel of the traditional preserved meat.

Owner:贵州省关岭布依族苗族自治县易和食品厂

Earthworm lotion

InactiveCN108567797AEffective leachingDoes not affect healthAntinoxious agentsLeech/worm material medical ingredientsNutrientSurface-active agents

Owner:刘 洪武

Method for preparing geopolymer by using oxidized gold ore heap leaching tailings

InactiveCN109503003ARealize comprehensive utilizationEasy to operateCement productionResource utilizationCalcination

The invention discloses a method for preparing a geopolymer by using oxidized gold ore heap leaching tailings, belonging to the technical field of waste resource utilization. The method comprises thesteps of taking the oxidized gold ore heap leaching tailings for fine grinding and drying, mixing the product with kaolin and heating up to 300-900 DEG C for carrying out calcination, adding the calcined product into an alkali activator solution prepared from sodium hydroxide and sodium silicate, stirring, injecting into a mould and standing for 16-24h, and solidifying to obtain the product. The geopolymer gel material prepared by the method has the advantages of being fast in hardening and high in molding strength, and not needing high-temperature curing in a molding process, and can reach acertain strength in a short time; furthermore, the geopolymer gel material prepared by the method can effectively solidify and encapsulate heavy metals and toxic and harmful ions contained in cyanidation leaching tailings, thus preventing the heavy metals and the toxic and harmful ions from leaching and further avoiding environmental damage.

Owner:KUNMING UNIV OF SCI & TECH

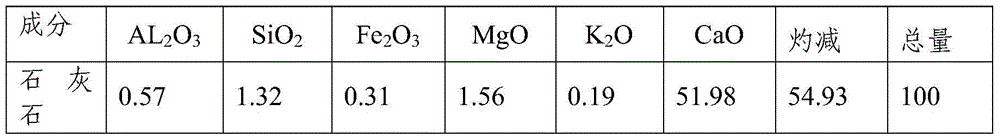

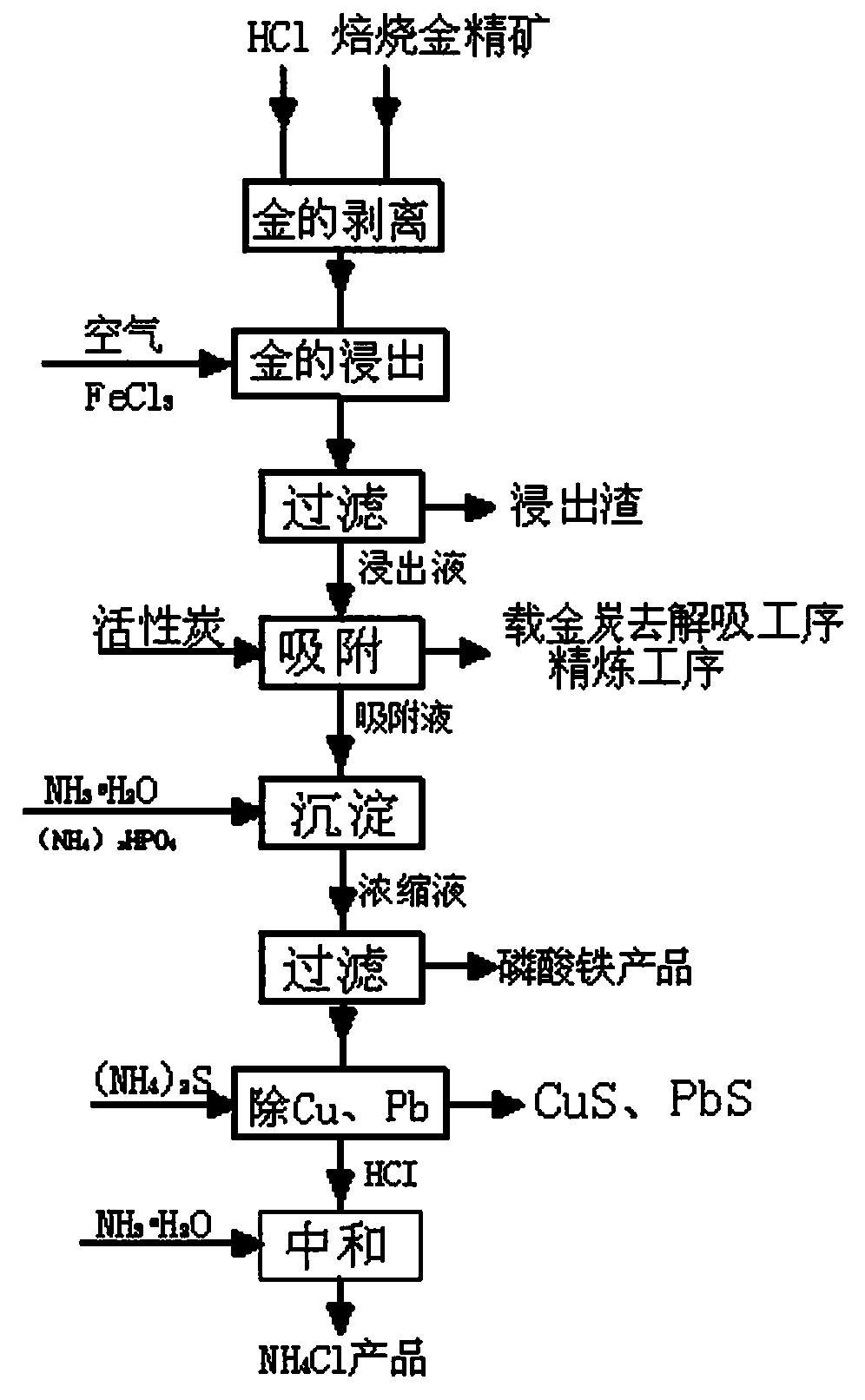

Comprehensive utilization method of roasted gold concentrate

ActiveCN109082537ASimple methodEasy to operateProcess efficiency improvementPhosphorus compoundsFractional PrecipitationActivated carbon

The invention discloses a comprehensive utilization method of a roasted gold concentrate The comprehensive utilization method of the roasted gold concentrate comprises the following steps of strippinggold, leaching the gold, filtering, adsorbing, and post-treating an adsorption solution. The comprehensive utilization method of the roasted gold concentrate comprises the concrete steps of utilizingdiluted hydrochloric acid as a leaching agent, effectively stripping the gold in the gold concentrate, filtering, adding activated carbon into a filter liquor, and obtaining gold-loaded carbon and the adsorption solution; and conventionally desorbing and refining the gold-loaded carbon, adopting a fractional precipitation method on the adsorption solution to obtain precipitates such as iron phosphate and copper sulphide, filtering, adding ammonium hydroxide into the filter liquor, and obtaining an ammonium chloride product. The method is simple in whole technological process, easy to operate,and free of pollution, the gold leaching rate and the valuable metal recovery rate are effectively improved, and the solid wastes are reduced.

Owner:KAIFENG UNIV

Method for recovering tellurium in copper anode slime through normal-pressure closed oxygenation

The invention provides a method for recovering tellurium in copper anode slime through normal-pressure closed oxygenation. The method comprises the following specific steps: adding a dilute sulphuric acid-dilute nitric acid mixed acid into copper anode slime for pulp blending, wherein the weight-volume ratio of copper anode slime in the blended pulp is controlled to be 15-25 g / mL, the dilute sulphuric acid content of the mixed acid is controlled to be 0.5-2 mol / L, and the dilute nitric acid content of the mixed acid is controlled to be 0.03-0.1 mol / L; placing the blended pulp in a closed container, introducing oxygen into the closed container for air removal, carrying out 0.5-1.5 hours' leaching under normal pressure, and then carrying out solid-liquid separation, wherein the leaching temperature is 100-115 DEG C, and the rotating speed of stirring is 300-500 r / min. The method provided by the invention has the advantages of being high in leaching rate, safe, reliable, and easy to handle; the tellurium leaching rate reaches 97.6-99.8%; moreover, the method is low in energy consumption and requirement for reaction equipment, the cost can be reduced, and the industrialized recovery of the element tellurium in copper anode slime is facilitated.

Owner:NORTHEASTERN UNIV

Fermentation method of mushroom liquid strains with high activity and high stability

InactiveCN110583371AShorten germination timeImprove stabilityCultivating equipmentsMushroom cultivationSteam pressureHypha

The invention relates to the technical field of mushroom strain fermentation, in particular to a fermentation method of mushroom liquid strains with the high activity and the high stability. The method comprises the steps that 1, preserved mushroom inclining strains are inoculated on a plating medium to be activated, advantageous hyphae are selected as a mother strain and inoculated in a shake flask containing a primary liquid culture medium, standing is performed under the temperature of 23+ / -2 DEG C for 36-48 h, the shake flask obtained after standing is placed into a constant temperature shaking table, oscillation culture is performed for 60 h, and the primary fermentation strain is obtained; 2, a fermentation tank is disinfected under the steam pressure of 0.16-0.18 Mpa and the temperature of 121 DEG C for 90-120 min, then, a secondary liquid culture medium is put into the fermentation tank, and sterilization is performed under the steam pressure of 0.15-0.16 Mpa and the temperature of 110 DEG C for 60 min; 3, after the temperature inside the fermentation tank is lowered to 28 DEG C or lower, the primary fermentation strain is inoculated into the fermentation tank, oxygen is additionally supplied, the tank pressure is 0.12-0.13 Mpa, and constant temperature culture is performed for 96 h; the fermentation method of mushroom liquid strains has the advantages that the technology is simple, operation is convenient, and the fermentation period is short, and has the good application prospect.

Owner:贵州同辉食用菌发展有限公司

Process for extracting aluminium hydroxide from flyash

InactiveCN1329301CAchieve recyclingEffective leachingAluminium oxide/hydroxide preparationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminium sulfateAluminium hydroxide

A process for extracting aluminum oxide from powdered coal ash includes such steps as grinding, calcining, mixing with H2SO4 solution, heating while reaction for extracting aluminum oxide, boiling in water, concentrating, cooling while educing out aluminum sulfate crystals, heating for dewatering, heating for decomposing to obtain gamma-Al2O3, and further preparing metallurgy-class aluminum oxide.

Owner:朔州市人民政府 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com