Dry-process firing method of bauxite with low aluminum-silicon ratio

A bauxite, aluminum-silicon ratio technology, applied in the field of bauxite dry sintering, can solve the problems of poor product quality, increased infrastructure investment, difficult control, etc., to reduce equipment and personnel investment, reduce energy consumption, reduce The effect of operational difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The present invention will be described below through different embodiments. The present invention is not limited to these embodiments, and can be implemented within the scope of the aforementioned chemical components and manufacturing methods.

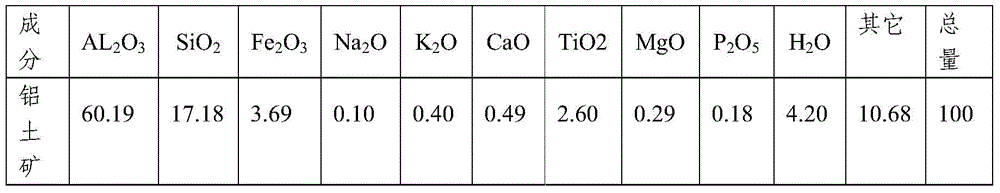

[0033] The raw materials of bauxite and limestone are mines in Xiaoyi area, Shanxi Province, and their compositions are shown in Tables 1 and 2.

[0034] Table 1: Bauxite Composition

[0035]

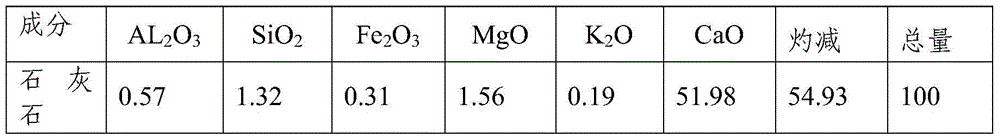

[0036] Table 2: Limestone Composition

[0037]

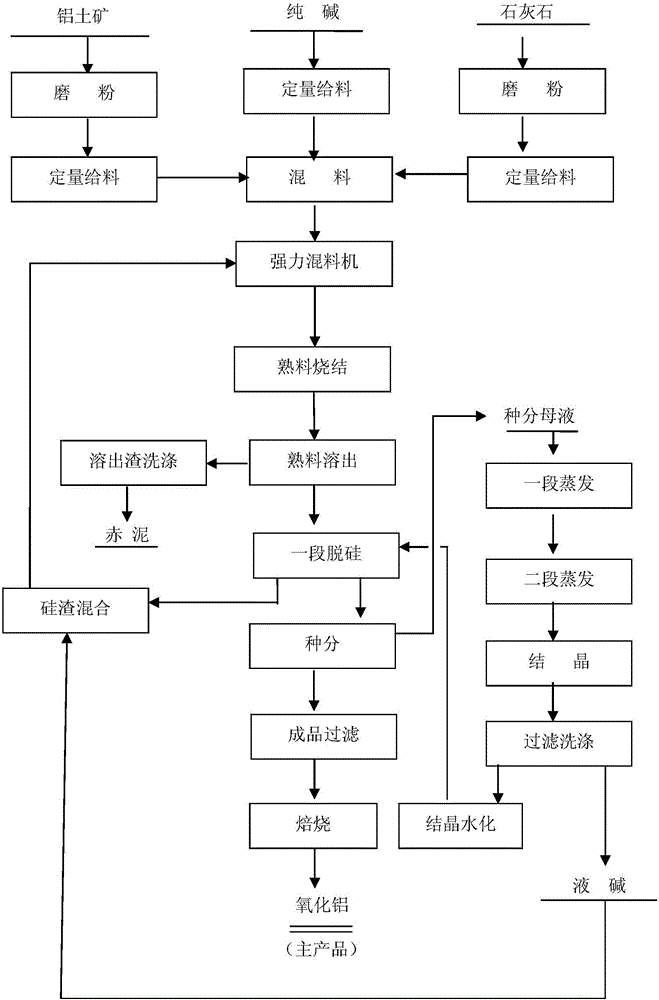

[0038] Operation process see figure 1 . Firstly, bauxite (composition as shown in Table 1) and limestone (composition as in Table 2) are respectively crushed to 2-5mm, and then they are respectively ground until the particle size is -0.074mm, accounting for more than 85%. Then bauxite powder, limestone powder, soda ash powder and lye (the circulating mother liquor after the evaporation of the second step, the concentration Na 2 (0500g / L, αk=14) 35 parts by mass of bauxite, 28 pa...

Embodiment 2

[0050] Table 3: Bauxite composition

[0051]

[0052]Firstly, bauxite (composition is as shown in Table 3) and limestone (composition is the same as in Example 1) were crushed to 2-5 mm respectively, and then they were respectively ground until the particle size was -0.074 mm, accounting for more than 85%. Then bauxite powder, limestone powder, soda ash powder and lye are fully mixed in proportion to 40 mass parts of bauxite, 30 mass parts of limestone, and 10 mass parts of soda ash, and the concentration of lye is Na 2 O600g / L, αk=25. After mixing, the alkali ratio is 1, the calcium ratio is 2, the A / S is 4.5, and the water content is 16%.

[0053] Put the prepared materials into a powerful mixer for thorough mixing, and the mixing uniformity is 98%.

[0054] Put the mixed material into the dryer for drying, the flue gas used for drying is the flue gas of the sintering kiln, the temperature is 1000-1100°C, the dried material enters the rotary kiln for sintering, the sint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com