Petrolatum spraying equipment for pipeline corrosion prevention

A technology of spraying equipment and pipelines, which is applied in spray booths, spraying devices, cleaning methods and appliances, etc., can solve the problems of uneven and thorough spraying, difficult construction, and inconvenient operation, so as to improve the flexibility and convenience of use, The effect of reducing the amount of equipment and improving the degree of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

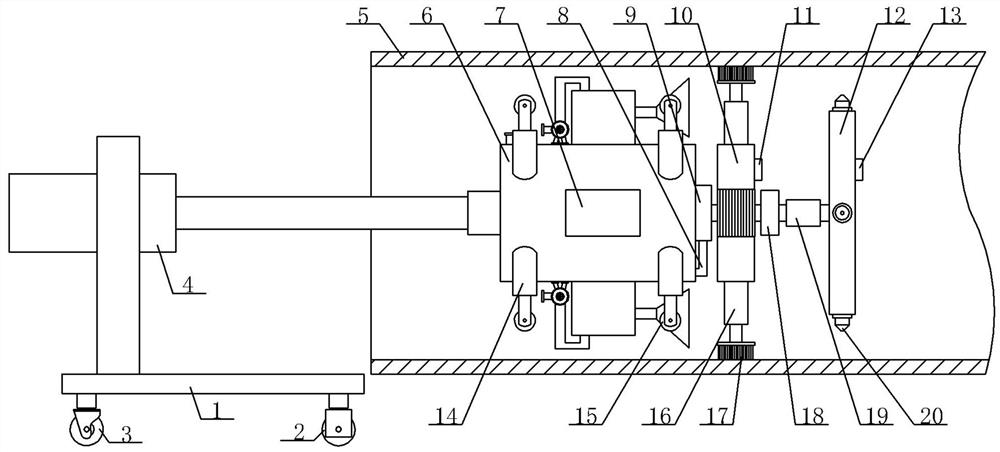

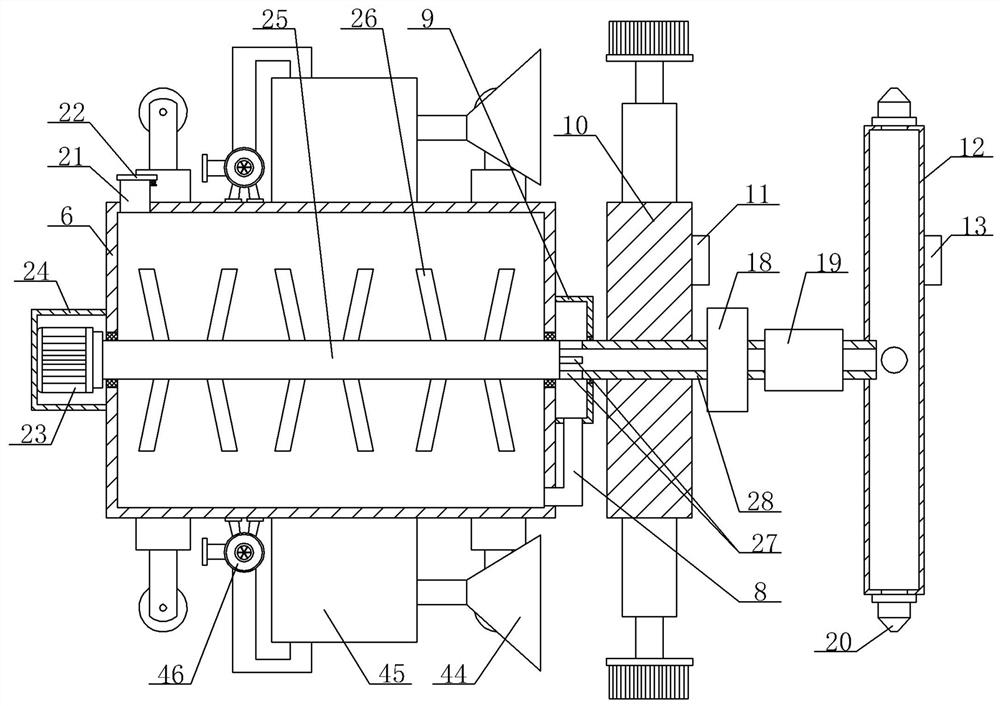

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0026] Such as Figures 1 to 5 Shown, a kind of petrolatum spraying equipment for pipeline anticorrosion, comprising pipeline 5, spraying device in pipeline 5 and traction device outside pipeline 5;

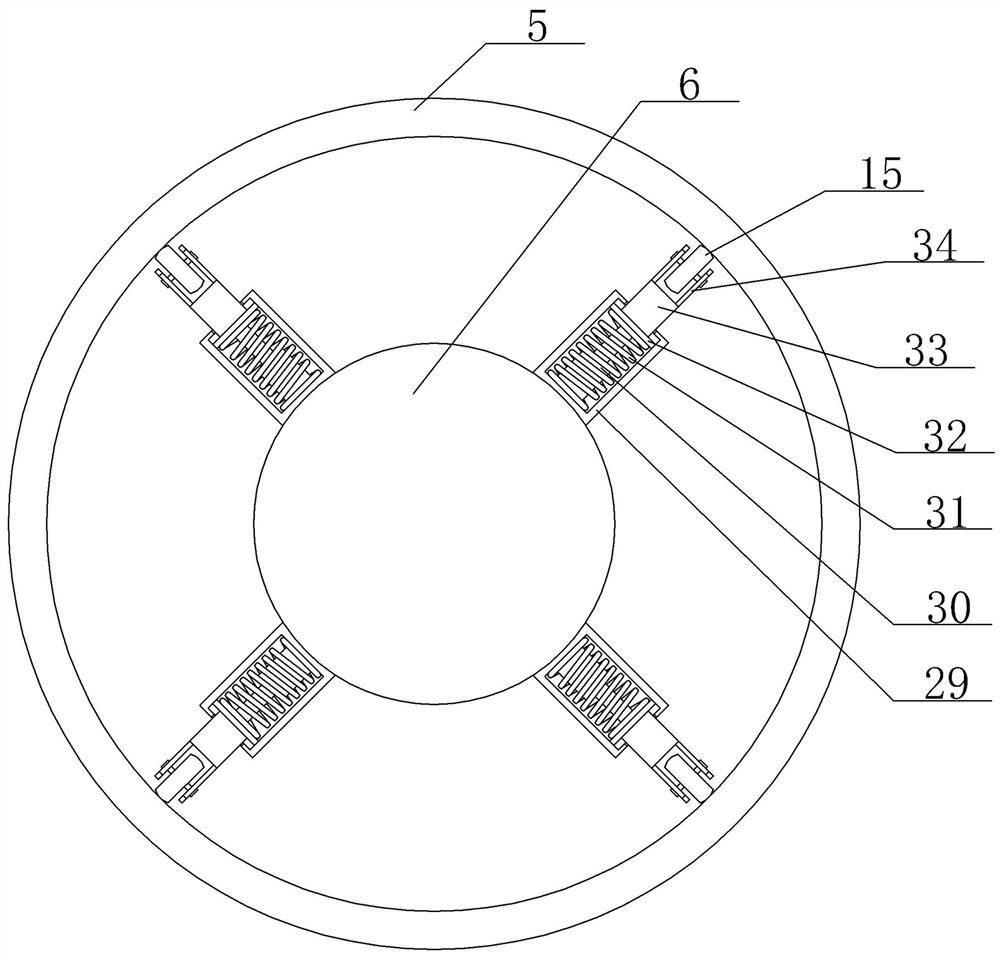

[0027]The spraying device includes a paint tube 6 arranged horizontally, and the top and bottom of the outer wall of the paint tube 6 are provided with dust removal mechanisms for dust removal. The left and right ends of the outer wall of the paint tube 6 are provided with running gears. The running gears include four sets of first self-telescopic adjustment mechanisms 14 arranged radially and evenly spaced around the circumference. The first self-telescopic adjustment mechanisms 14 are far away from the One end of the paint tube 6 is rotatably connected with a roller 15, which can realize the walking and movement of the spraying device in the pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com