Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Leaching is effective" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

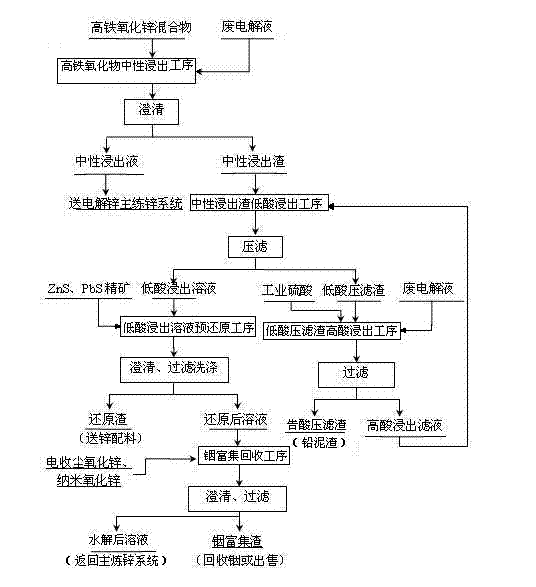

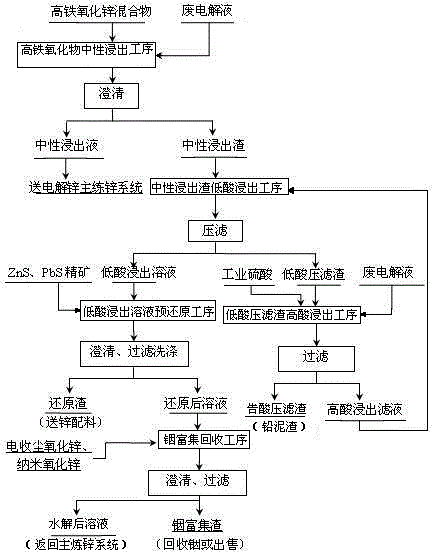

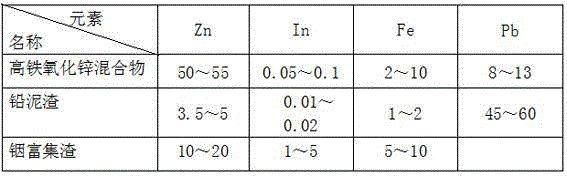

Method for recovering zinc, indium, iron, and lead from high-iron zinc oxide mixture smelted with zinc

ActiveCN103667720ASolve processing problemsReduce the amount addedProcess efficiency improvementPregnant leach solutionElectrolysis

The invention relates to the field of metal smelting, particularly to a method for recovering zinc, indium, iron, and lead from a high-iron zinc oxide mixture smelted with zinc. The method comprises the following processes: a high-iron zinc oxide mixture neutral leaching process, a neutral leaching residue low acid leaching process, a low acid pressure filter residue peracid leaching process, a low acid leaching liquid prereduction process, and a indium enrichment recycling process; valuable metals are comprehensively recovered from the high-iron zinc oxide mixture; a generated neutral leaching liquid is adopted by a main zinc smelting system to generate electrolytic zinc; a hydrolyzing filter liquor generated from the indium enrichment recycling process contains relatively rich ferrous ions; the hydrolyzing filter liquor is adopted by the main system for removing impurities and generating high-grade indium enrichment residues; therefore, the high-iron zinc oxide mixture is effectively recycled, the problem of high-iron zinc oxide mixture treatment is solved, capability of comprehensive utilization of metal resources is increased, so that resources are comprehensively recycled, and environment protection is facilitated; the method has relatively good economic benefits and social benefits.

Owner:HENAN YUGUANG ZINC IND

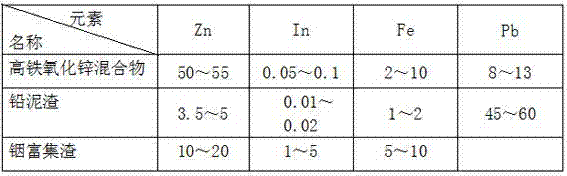

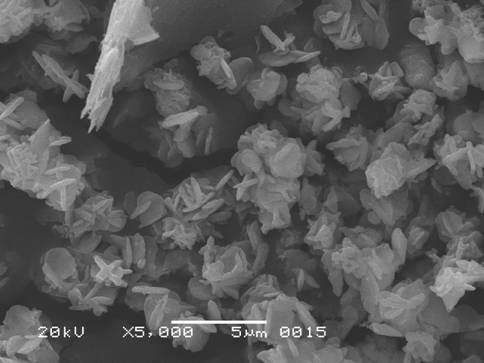

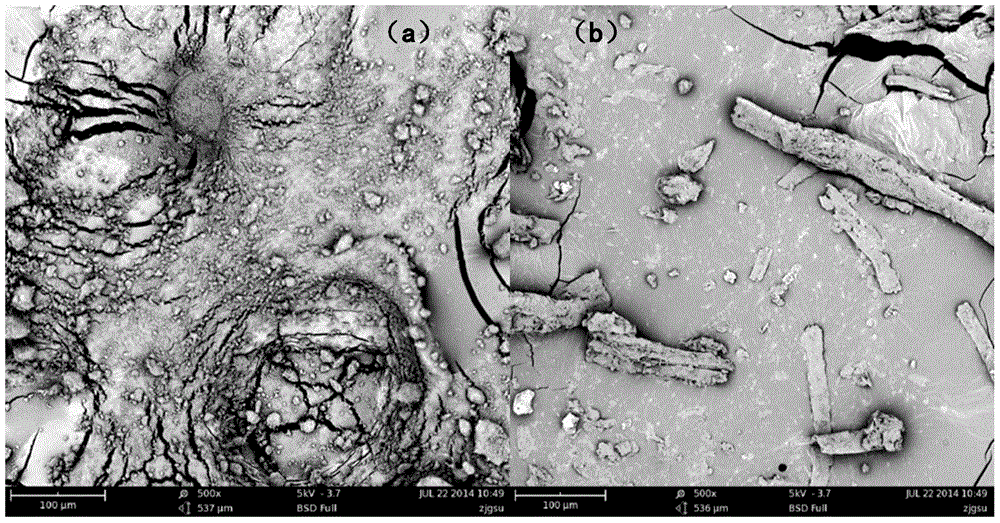

Method of leaching copper, cobalt and nickel from smelting alloy

A method of leaching copper, cobalt and nickel from smelting alloy comprises the following steps: the smelting alloy containing at least two of copper, cobalt and nickel and iron impurities is molten, and then the molten smelting alloy is atomized into alloy powder by high-pressure gas or high-pressure water; the atomized alloy powder is added into a stir aeration reaction device, a sulfuric acid solution is used as a leaching medium in the stir aeration reaction device, air or oxygen is uniformly brought from a stirring shaft system of the stir aeration reaction device, the brought gas is uniformly dispersed under the shear action of stirring blades in high-speed rotation at the bottom of the stirring shaft system, and under the effects of an oxidizing agent and a catalyst, the alloy powder is subjected to corrosion oxidizing leaching reaction in the stir aeration reaction device; after reaction is completed, most iron impurities enter a leaching residue, and solid-liquid separation is finally carried out to collect and obtain a leaching liquid containing at least two of copper, cobalt and nickel. The method of leaching copper, cobalt and nickel from the smelting alloy has the advantages that the process cost is low; the technology is convenient to control; the production is stable and reliable; the environment pollution is low and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Method for preparing ternary lithium battery cathode material precursor by utilizing spent lithium-ion batteries

ActiveCN109449434AImprove recyclingShort processCell electrodesWaste accumulators reclaimingScrapLithium electrode

The invention provides a method for preparing a ternary lithium battery material precursor by utilizing spent lithium-ion batteries. Main ingredients comprise cathode material waste powder and metal sulfides, ternary lithium battery cathode scraps and nickel sulfide intermediate goods are taken as raw materials, nickel sulfide intermediate goods waste is added into lithium-ion battery cathode material scraps, a right amount of sulfuric acid is added and reaction and leaching are performed under high pressure condition, after pressure relief, a small amount of hydrogen peroxide is added to be taken as a reducing agent for continuously leaching valuable elements such as nickel, cobalt and manganese, impurity removal and matching are performed on leachate, and then metal ion mixed solution after the matching, ammonia water and sodium hydroxide are taken as raw materials for preparing a lithium-ion battery cathode material precursor. The method provided by the invention has high waste leaching rate, short flow, simple process and low cost, not only can treat lithium battery cathode material scraps in a large scale but also can treat abandoned nickel sulfide intermediate goods, so thatrecycling of the lithium-ion battery cathode material scraps and the abandoned nickel sulfide intermediate goods is promoted.

Owner:GUANGDONG JIANA ENERGY TECH CO LTD +1

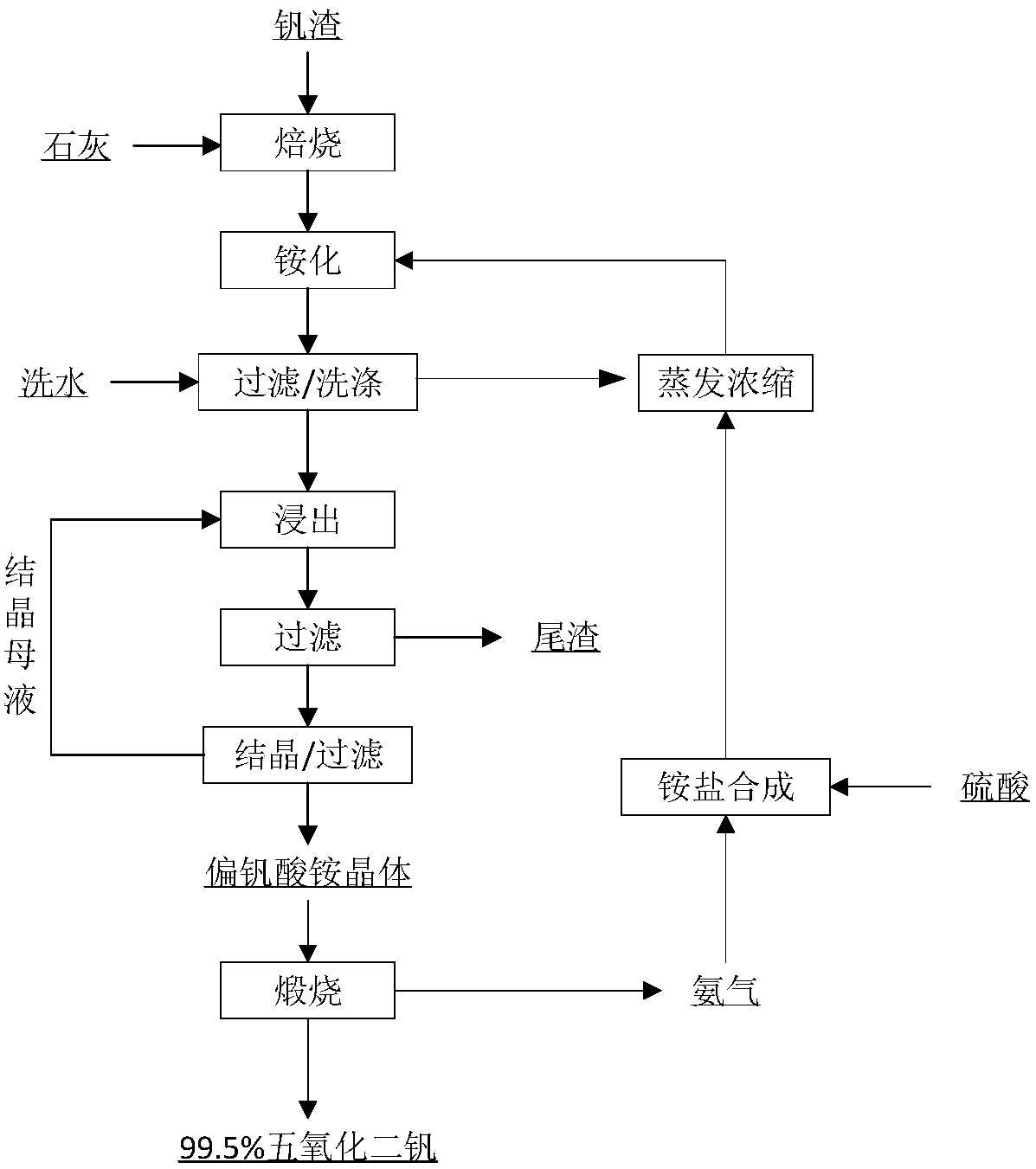

Clean method for extracting vanadium during roasting vanadium slag

InactiveCN110408772AHigh recovery rateImprove conversion rateProcess efficiency improvementSolubilityHigh concentration

The invention relates to a clean method for extracting vanadium during roasting vanadium slag. The method comprises the following steps that vanadium in the vanadium slag is converted into calcium vanadate which is stable at high temperature by adopting a calcification roasting method, high-concentration ammonium sulfate and / or ammonium bisulfate solution are utilized for leaching roasted clinkerto enable most of ammonium metavanadate to be crystallized and then to be mixed with tailings to form crystal-containing slag, then the crystal-containing slag is dissolved in a hot liquid to obtain avanadium-containing solution, and efficient extraction of the vanadium can be realized. According to the method, the problem of high-temperature vanadium volatilization does not exist, the comprehensive recovery rate of the vanadium is higher, ammonia gas is not generated in the leaching process, and compared with other easily-decomposed ammonium salts, the conversion rate of the vanadium is higher under the same concentration and the same leaching temperature; and meanwhile, the problems of small solubility of ammonium metavanadate in the ammonium salt solution and low vanadium extraction rate can be effectively solved. In the subsequent processes, ammonia gas generated by calcining ammonium metavanadate is adsorbed by using a sulfuric acid solution, the ammonium sulfate can be resynthesized, the ammonia recycling can be realized, the whole process is clean, the production cost is greatly reduced, and the method has good economic benefit and application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

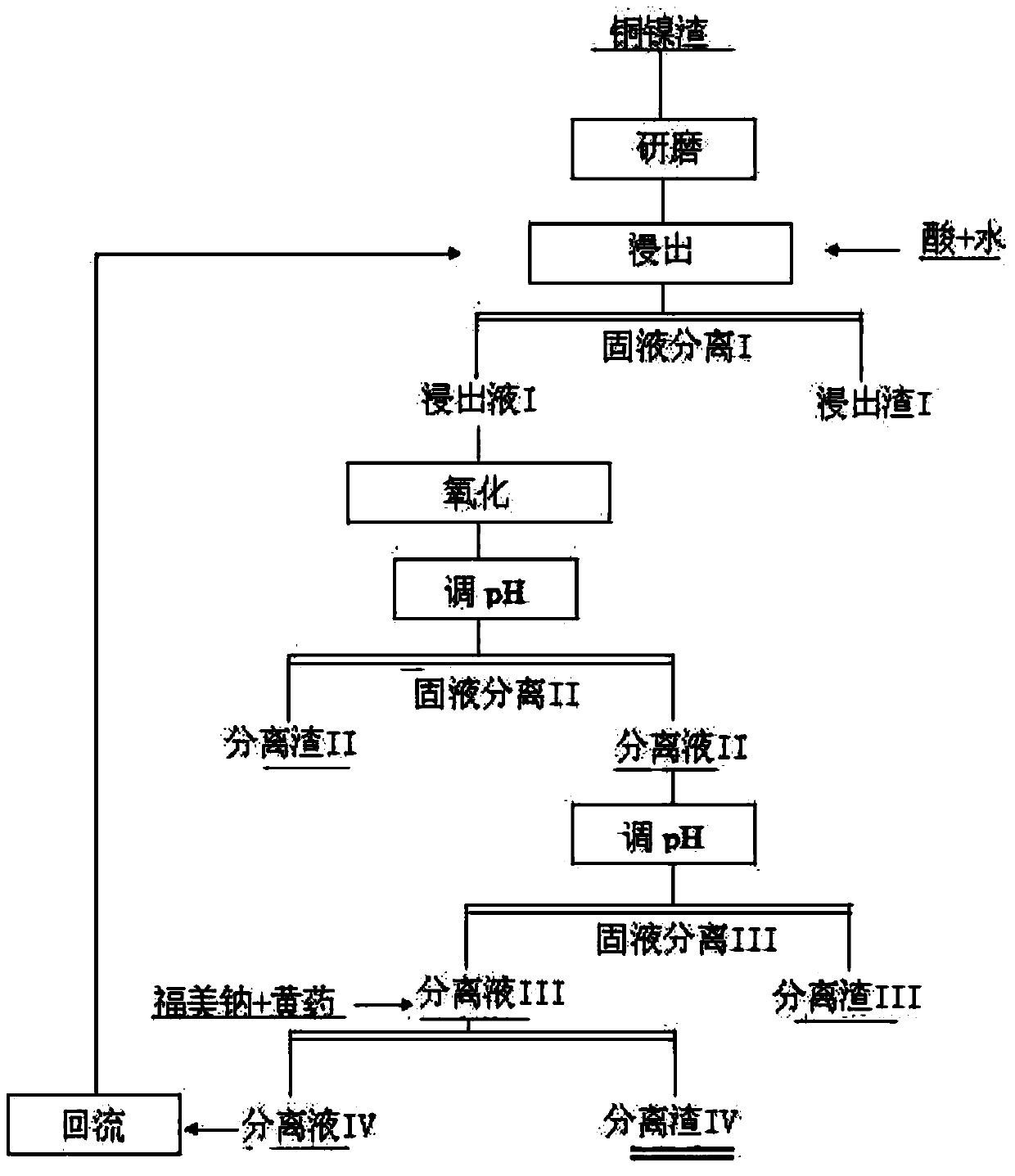

Method for recovering copper, cobalt and nickel from copper and nickel slag

InactiveCN103805788AEfficient extractionAvoid massive dissolutionProcess efficiency improvementPregnant leach solutionSlag

The invention discloses a method for recovering copper, cobalt and nickel from copper and nickel slag. The method comprises the following steps: leaching a soluble substance through ore grinding and powder concentration by using an acid, performing solid-liquid separation to obtain a leaching solution I and leaching slag I; oxidizing soluble metals in the leaching slag I, regulating the pH value, precipitating and separating the iron, and performing solid-liquid separation to obtain a separation solution II and separation slag II; continuously adding the copper and nickel slag into the separation solution II, regulating the pH value so as to ensure that soluble silicon is precipitated in a silicate form, and performing solid-liquid separation to obtain a separation solution III and separation slag III; finally, precipitating the copper, cobalt and nickel in the separation solution III by using sodium dimethyl dithiocarbamate and xanthate, and performing solid-liquid separation to obtain separation slag IV, namely the recovery product. According to the reasonable process design, common chemicals and methods are used, the copper, cobalt and nickel are recovered from the copper and nickel slag, the environment can be prevented from being polluted by waste residues, and rare metals such as copper, cobalt and nickel can be effectively recovered. Moreover, the product process parameters are easily controlled, and novel environmental pollution is avoided.

Owner:斯莱登(北京)化工科技有限公司

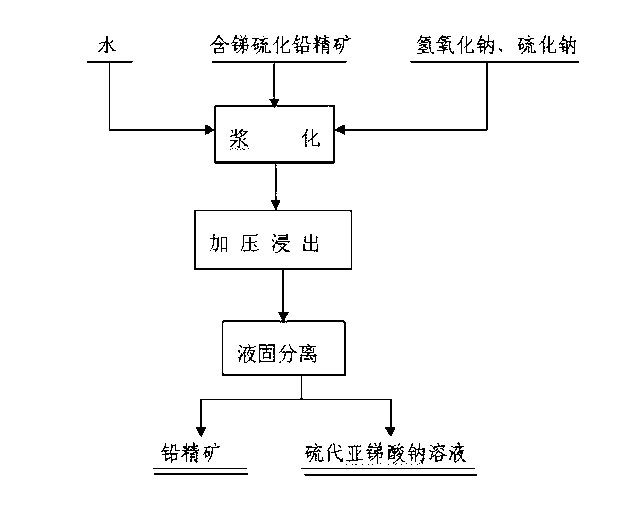

Method for separating lead and antimony in antimony-containing lead concentrates

ActiveCN102912125ALeaching is effectiveReduce concentrationProcess efficiency improvementPregnant leach solutionNonferrous metal

The invention discloses a method for separating lead and antimony in antimony-containing lead concentrates, belongs to the technical field of nonferrous metallurgy, and particularly relates to a method for leaching antimony from antimony-containing lead sulfide concentrates in a pressure manner. The method includes leaching the antimony from antimony-containing lead sulfide concentrates by sodium hydroxide reaction solution containing sodium sulfide in a closed stirred reactor; and separating solution from solid to obtain lead sulfide concentrates and leachate containing sodium thioantimonious acid. The reaction solution contains from 10g / L to 40g / L of the sodium sulfide and from 80g / L to 120g / L of sodium hydroxide. The method has the advantages that the antimony in the lead sulfide concentrates can be effectively removed, the sodium sulfide is prevented from being oxidized in a high-temperature leaching process, and the method is suitable for leaching antimony in antimony-containing lead sulfide concentrates in a complicated mode of occurrence.

Owner:云南锡业研究院有限公司研究设计院

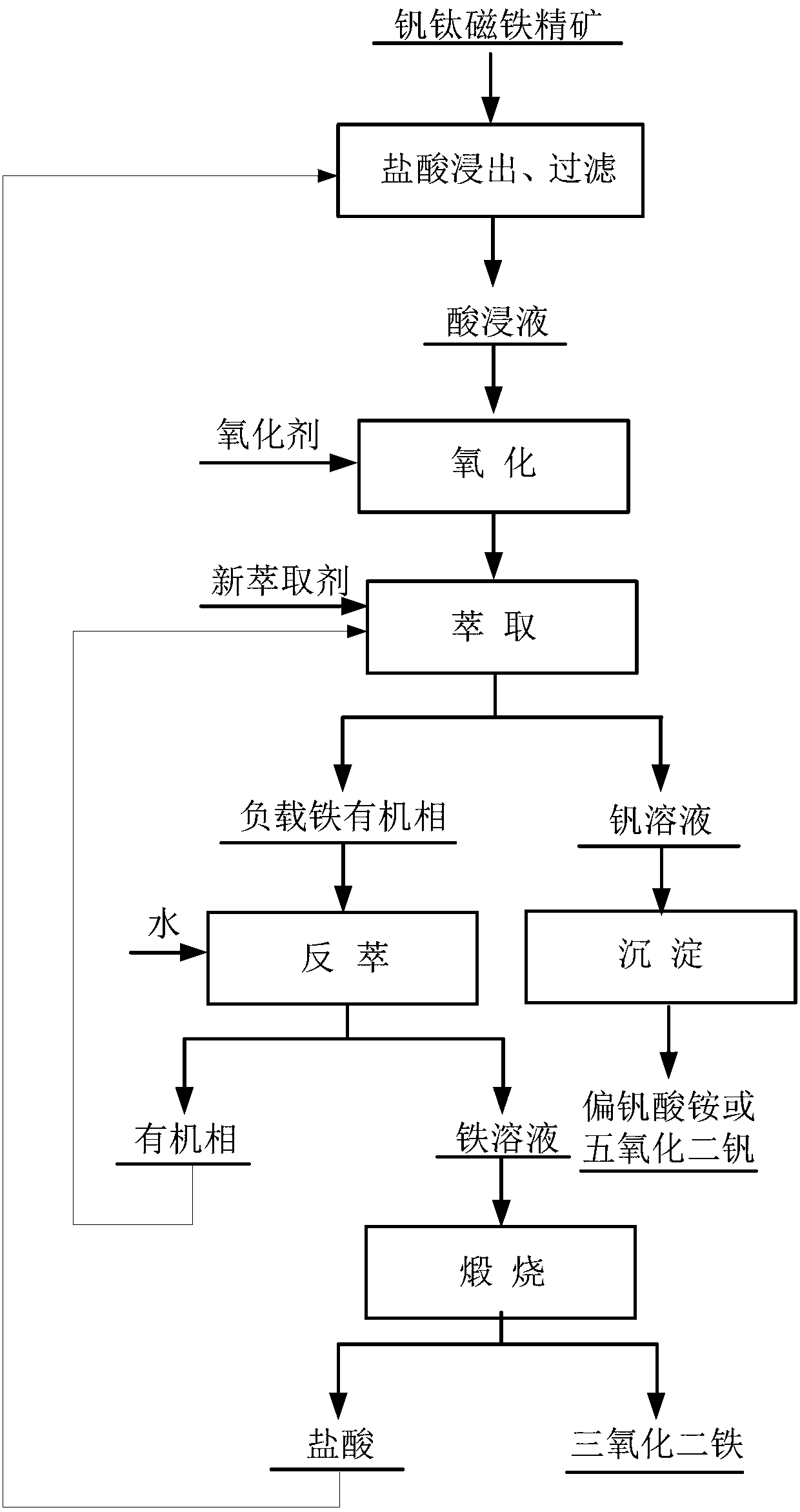

Method for extracting iron and vanadium from vanadium-titanium magnetite concentrates

ActiveCN103276211AImprove reaction efficiencyEfficient leachingFerric oxidesAcid dissolutionMagnetite

The invention belongs to the field of hydrometallurgy and in particular relates to a method for extracting iron and vanadium from vanadium-titanium magnetite concentrates. The method comprises the following steps of: 1) carrying out acid dissolution and leaching on vanadium-titanium magnetite concentrates and hydrochloric acid; 2) oxidizing Fe<2+> in acid leaching solution obtained in the step 1) into Fe<3+> with an oxidizing agent; 3) extracting iron from the oxidized acid leaching solution obtained in the step 2) with an extracting agent to obtain an organic phase and vanadium-containing raffinate; (4) carrying out back extraction on the organic phase obtained in the step 3) to obtain an extracting agent and an iron-containing acid solution; 5) calcining the iron-containing acid solution obtained in the step 4) to obtain hydrochloric acid and iron trioxide; and 6) treating the vanadium-containing raffinate obtained in the step 3) to obtain ammonium vanadate or vanadium pentoxide. The method has the advantages that the added values of products are high, the recovery rate of vanadium is greatly increased, and the environmental pollution can be avoided.

Owner:河北中科同创钒钛科技有限公司

Production method of instant green tea coffee powder

The invention relates to a production method of instant green tea coffee powder, belonging to the technical field of instant tea beverages. In order to solve the problem that the mouthfeel and the taste are affected as the two tastes of the green tea and the coffee can not be very well mixed in an existing coffee tea powder product, two different powered objects are not easy to brew and dissolve, the invention provides the production method of the instant green tea coffee powder. The production method comprises the following steps: leaching green tea, filtering and concentrating so as to obtain a concentrated solution, and then, mixing the concentrated solution with coffee powder; mixing the green tea and the coffee powder very well by adopting an ultrasonic dispersing technology; and finally, performing pressurizing spraying drying to obtain the instant green tea coffee powder. In the instant green tea coffee powder, the flavor and the active ingredients of the green tea are mixed, so that the instant green tea coffee powder is relatively easy to dissolve in water, convenient to brew, and relatively good in flavor and nutrition.

Owner:SICHUAN YINGJING COUNTY TASHAN

Supersonic lixiviating nimbin

InactiveCN1524858AEffective membrane rupturePromote dissolutionOrganic chemistrySupersonic wavesSolvent

A method for preparing nimbin through supersonic wave extraction which comprises the steps of, disintegrating the nim seeds after oil extraction, charging it into extraction solvent, carrying out leaching process by supersonic wave. The method for preparing nimbin by the invention realizes low cost, and increased nimbin extraction efficiency.

Owner:KUNMING UNIV OF SCI & TECH

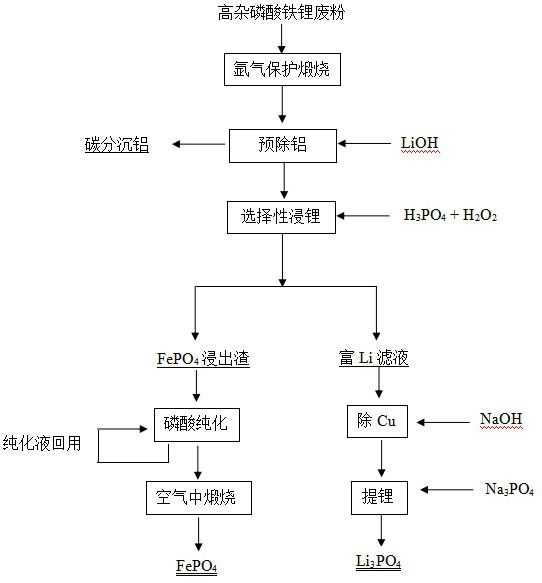

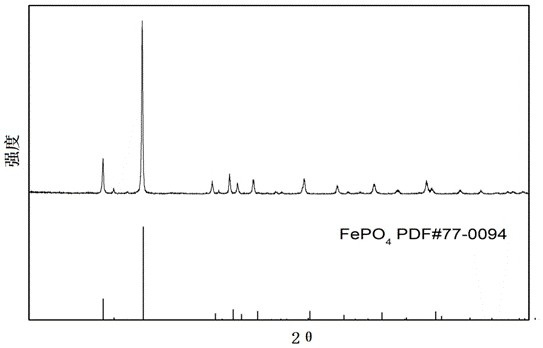

Method for treating high-impurity lithium iron phosphate waste powder by using low-consumption phosphoric acid

PendingCN113880064AReduce dosageImprove leaching ratePhosphorus compoundsBattery recyclingChemistryProcess engineering

The invention discloses a method for treating high-impurity lithium iron phosphate waste powder by using low-consumption phosphoric acid, which comprises the following steps of: pre-removing aluminum from lithium iron phosphate waste powder subjected to calcination treatment in an alkaline system, leaching aluminum-removed filter residues by using phosphoric acid and hydrogen peroxide, keeping the pH value at 2-3 all the time in the leaching process, selectively leaching Li, removing impurity copper and residual Al in the aluminum-removed filter residues to obtain FePO4 leaching residues, purifying the FePO4 leaching residues by adopting excessive phosphoric acid, supplementing a proper amount of Fe and an oxidizing agent at the same time, further removing impurities such as residual Cu, and converting hydroxyl iron phosphate generated in the selective leaching process into high-purity iron phosphate. The method is simple in process, suitable for treating high-impurity waste lithium iron phosphate powder obtained through disassembly, and capable of directly obtaining battery-grade iron phosphate and lithium phosphate. The method is easy to operate, the consumption of phosphoric acid as a leaching agent is low, the cost is low, the lithium recovery rate is high, and the iron phosphate is high in purity and meets the requirements of battery-grade iron phosphate.

Owner:ZHUZHOU SMELTER GRP

Production method of instant green tea soybean milk powder

ActiveCN104351350AEasy to brewGood flavorPre-extraction tea treatmentMilk substitutesBiotechnologyInstant tea

The invention relates to a production method of instant green tea soybean milk powder, belonging to the technical field of instant tea beverages. In order to solve the problem that the mouthfeel and the waste are affected as two tastes of the soybean milk and the tea powder very well can not be very well mixed in an existing soybean milk tea powder product, and two different powdered objects are not easy to brew and dissolve, the invention provides the production method of the instant green tea soybean milk powder. The production method comprises the following steps: leaching green tea, filtering and concentrating to form a concentrated solution; then, mixing the concentrated solution with soybean milk powder, and mixing the concentrated solution and the soybean milk powder very well by adopting an ultrasonic dispersing technology; and finally, pressurizing spraying drying to obtain the instant green tea soybean milk powder. In the instant green tea soybean milk powder, the flavor and the active ingredients of the green tea are mixed so that the instant green tea soybean milk powder is relatively easy to dissolve in water, convenient to brew, and relatively good in flavor and nutrition.

Owner:SICHUAN YINGJING COUNTY TASHAN

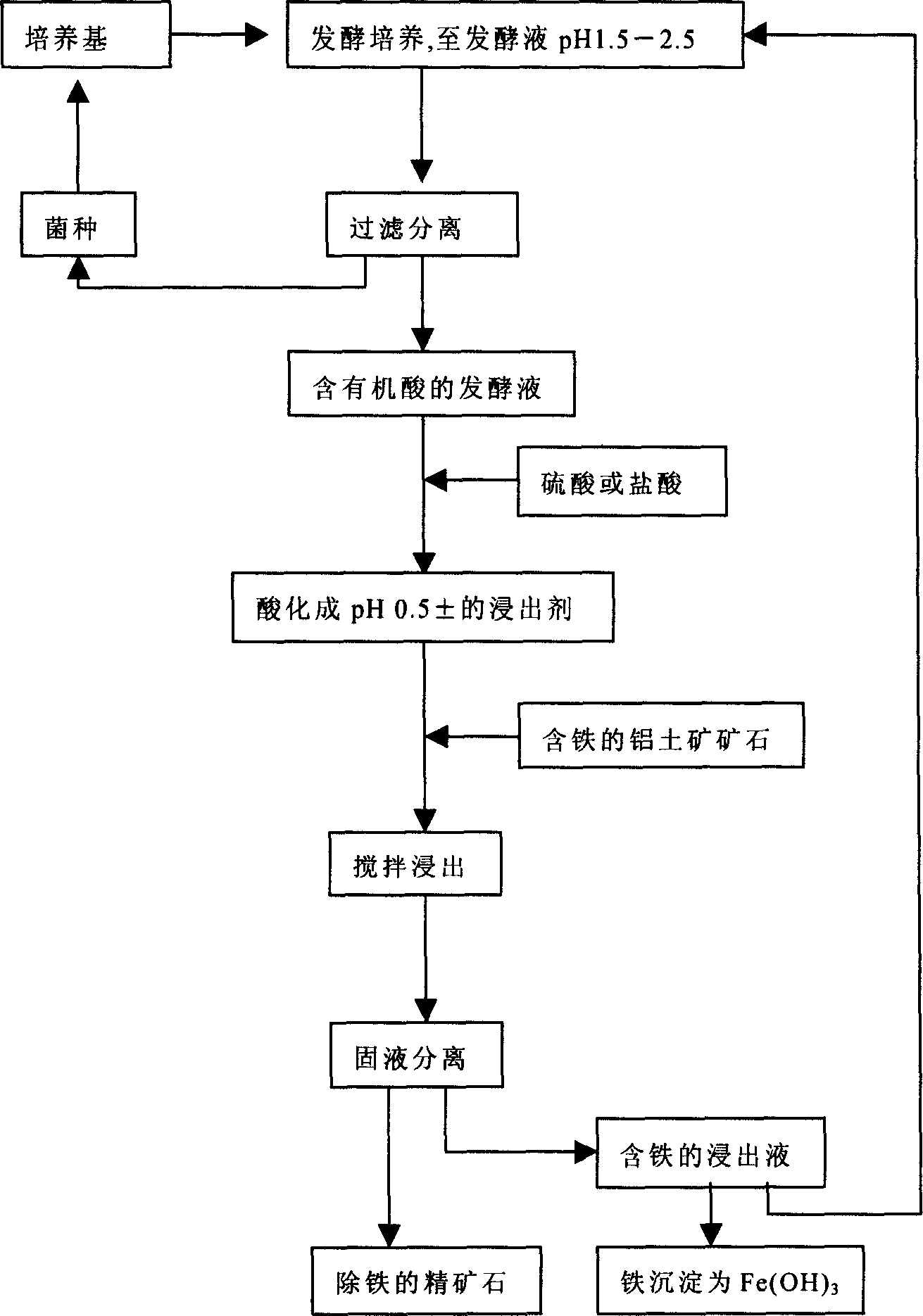

Method for leaching out inpurity iron in bauxite by chemical-biological method

InactiveCN1775969ALeaching is effectiveEffective leachingProcess efficiency improvementFermentationAspergillus niger

The invention relates to a biology and chemical method to remove the impurity iron in bauxite ore. The feature is that it adopts fermentation liquor leaching out iron of aspergillus niger bacterium that has strong ability to produce acid. 1-4% vitriol is added into the fermentation liquor as leaching out agent. After process by the method, the ferric oxide content is 0.4-0.9% and the aluminum leaching out ratio is less than 1.0%.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

A method for preparing battery grade lithium carbonate from waste lithium iron phosphate electrode sheet

ActiveCN109088120AImprove leaching rateHigh purityCell electrodesWaste accumulators reclaimingLithium carbonateSodium carbonate

A method for preparing battery grade lithium carbonate from waste lithium iron phosphate electrode sheets relates to that technical field of lithium batteries. The method comprises the steps of: 1, releasing electricity; 2, performing oxidizing and roasting to obtain electrode sheet roast material containing lithium iron phosphate active material and current collector aluminum foil; 3, pulverizingthe roasted material and performing screening to obtain separated aluminum powder and lithium iron phosphate electrode sheet powder; 4, detecting the content of the lithium element in the lithium iron phosphate electrode sheet powder, preparing an acid solution according to a certain molar ratio according to the content of the lithium element, adding the lithium iron phosphate electrode sheet powder into the acid solution according to a certain mass-solid-liquid ratio for reaction, and finally filtering to obtain a first mixed liquid; 5, adding sodium hydroxide into the first mixed solution for reaction, and filtering to obtain a second mixed solution; 6, reacting the second mixed solution with the sodium carbonate solution and filtering to obtain battery-grade lithium carbonate. The invention can effectively improve the leaching rate of the lithium element and the purity of lithium carbonate.

Owner:湖南金凯循环科技有限公司

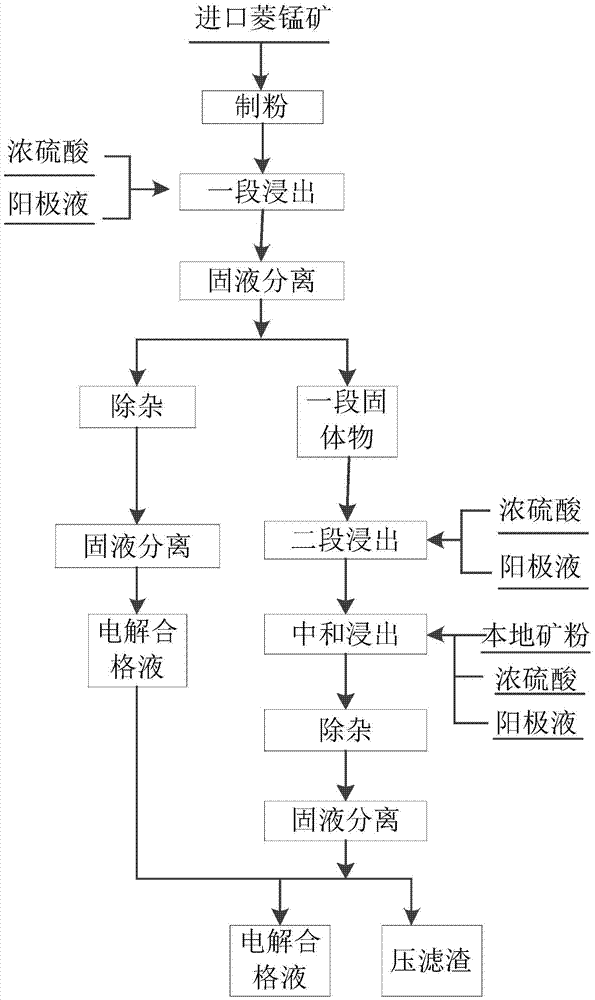

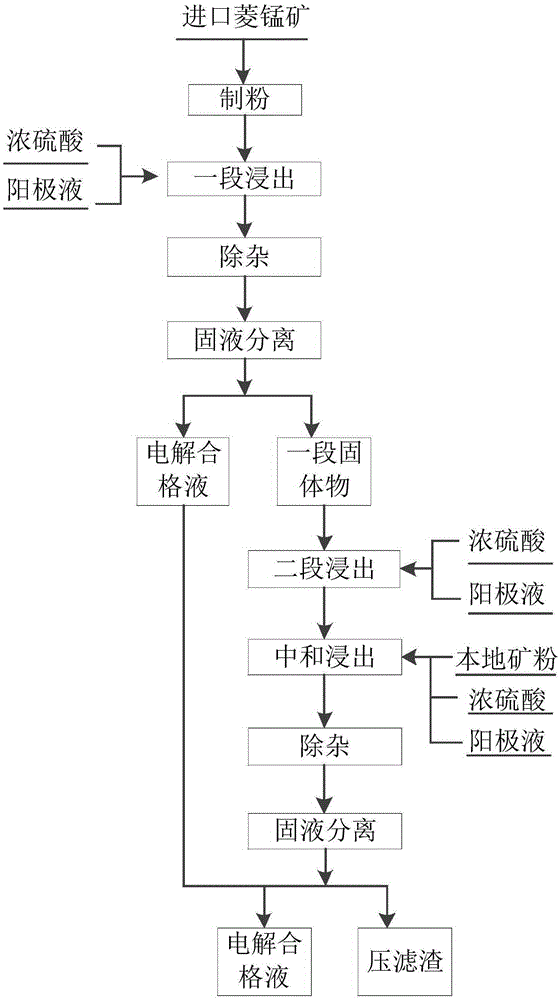

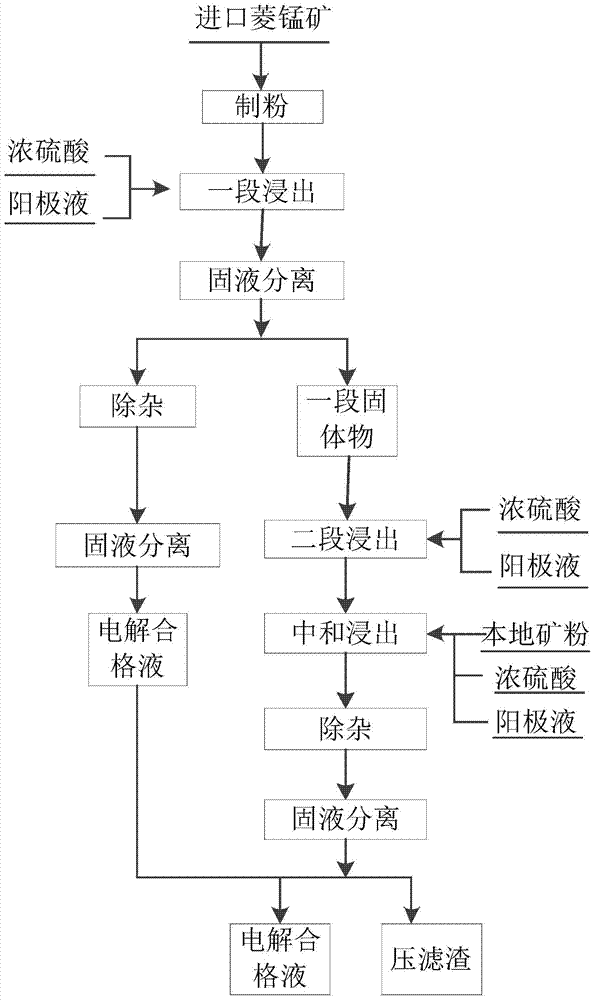

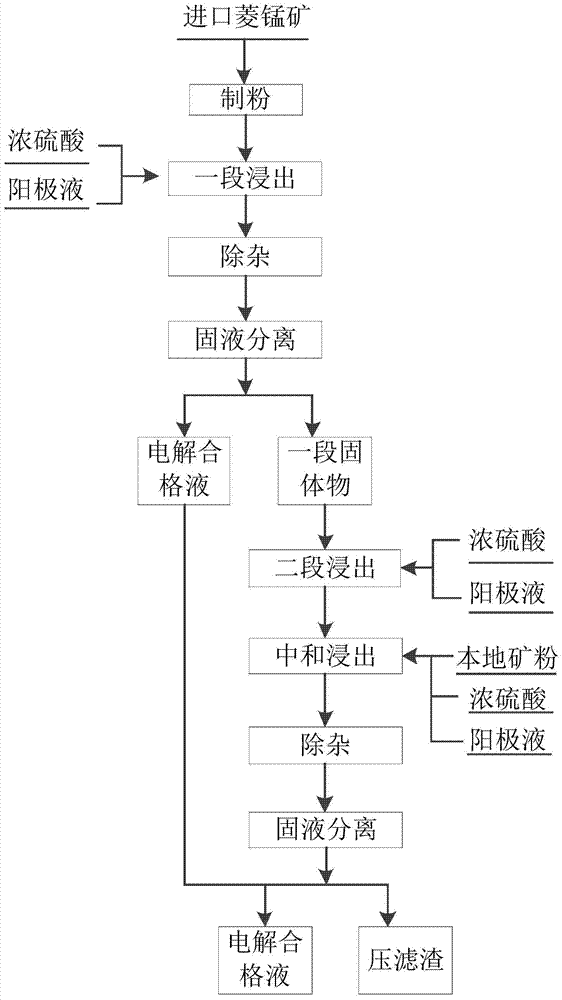

Manganese carbonate ore leaching method based on two-section leaching

The invention discloses a manganese carbonate ore leaching method based on two-section leaching. The method includes the following steps that high-grade manganese carbonate ore is ground into powder and added into a reactor; then, anode liquor and concentrated sulfuric acid are added for the first-section leaching reaction, wherein the leaching reaction time is at least 2 h; remaining acid left after the reaction is detected, and a neutralizer is added on this basis to conduct neutralization; solid-liquid separation is conducted on neutralized ore pulp, obtained first-section solid substances are thrown into the reactor, and concentrated sulfuric acid and anode liquor are added for second-section leaching, wherein the leaching reaction time is at least 2 h; impurity removal and solid-liquid separation are conducted on the obtained leaching agent to obtain qualified electrolysis liquid; low-grade manganese carbonate ore powder, anode liquid and concentrated sulfuric acid are added after the second-section leaching is finished to conduct neutralization leaching; and finally, adding a neutralizer again, and impurity removal is conducted; and solid-liquid separation is conducted on impurity-removed ore pulp to obtain qualified electrolysis liquid and solid residues. The method has the beneficial effects of being small in residue amount, high in leaching rate, low in sulfuric acid consumption, high in comprehensive recovery rate and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Preparation process of agarwood essential oil

The invention relates to a preparation method of agarwood essential oil. The method comprises the following steps: step 1, mixing agarwood powder with a solvent and heating until the mixture is boiling slightly, wherein the ratio of the agarwood powder to the solvent is 1: 10; refluxing and stirring for 1.5-2.5 hours; naturally cooling for 20-30 minutes, and continuing cooling until solid is separated out; filtering to obtain solid powder and recycling filtrate; step 2, secondarily extracting the solid powder obtained by filtering with a solvent by a method which is the same as the method in the step 1; step 3, carrying out tertiary extraction on the filtered solid powder by using a solvent by a method which is the same as the method used in the step 1; step 4, merging filtrates obtained by three-time extraction, and standing for 12-24 hours in a closed environment at the room temperature; step 5, after standing, filtering the filtrates, filtering out solid, and collecting the filtrates; and step 6, heating concentrated filtrates, stopping heating until sand rising, filtering to obtain a concentrated solution, and mixing uniformly to obtain the agarwood essential oil.

Owner:杨敦阶

Method for recycling metal lead from lead-containing material such as lead sulfate slag

ActiveCN110923468AEfficientWith energy savingPhotography auxillary processesProcess efficiency improvementMethane sulfonic acidSlag

The invention provides a method for recycling metal lead from a lead-containing material such as lead sulfate slag. The problems that when metal lead is recycled from a lead-containing material such as lead sulfate slag in the prior art, energy consumption is high, cost is high, pollution is severe, the application range is limited, potential safety hazards exist, and metal cannot be sufficientlyutilized are solved. According to the method, the lead in the lead-containing material such as the lead sulfate slag is recycled in the following steps of (1) a chlorination leaching process; (2) a sodium carbonate conversion process; (3) a methane sulfonic acid leaching process; (4) an electrodeposition process; and (5) a melting-casting process

Owner:赵坤

Method for extracting nickel and molybdenum from nickel-molybdenum ore acidic leaching solution

ActiveCN109022787AOvercome the disadvantage of high alkali consumptionLeaching is effectiveProcess efficiency improvementHeteropoly acidSulfate

The invention relates to a method for extracting nickel and molybdenum from a nickel-molybdenum ore acidic leaching solution. The method for extracting nickel and molybdenum from the nickel-molybdenumore acidic leaching solution comprises the steps of 1) adding phosphoric acid to the nickel-molybdenum ore acidic leaching solution so that molybdenum in the solution is transformed into phosphorus molybdenum heteropoly acid; 2) using TBP as an extraction agent to extract the phosphorus molybdenum heteropoly acid to obtain an organic phase containing the phosphorus molybdenum heteropoly acid; andusing ammonium hydroxide to reversely extract the organic phase containing the phosphorus molybdenum heteropoly acid to obtain a molybdenum containing a reverse extraction liquor; and 3) supplementing sulfuric acid to an extraction raffinate after TBP extraction at 90-95 degrees centigrade; and when the concentration of nickel sulfate reaches 150-200 g / L, cooling the nickel sulfate at a room temperature to separate out nickel sulfate crystals, wherein a filter liquor after solid and liquid separation can be used for acidic leaching of nickel-molybdenum ores. By changing the occurrence state of molybdenum in the acidic solution, the molybdenum and the nickle in the high acid solution can be effectively extracted without adjusting the pH value of the solution. The method for extracting nickel and molybdenum from the nickel-molybdenum ore acidic leaching solution has the advantages of short process, simple and convenient operation, low production cost and easy industrialization.

Owner:CENT SOUTH UNIV

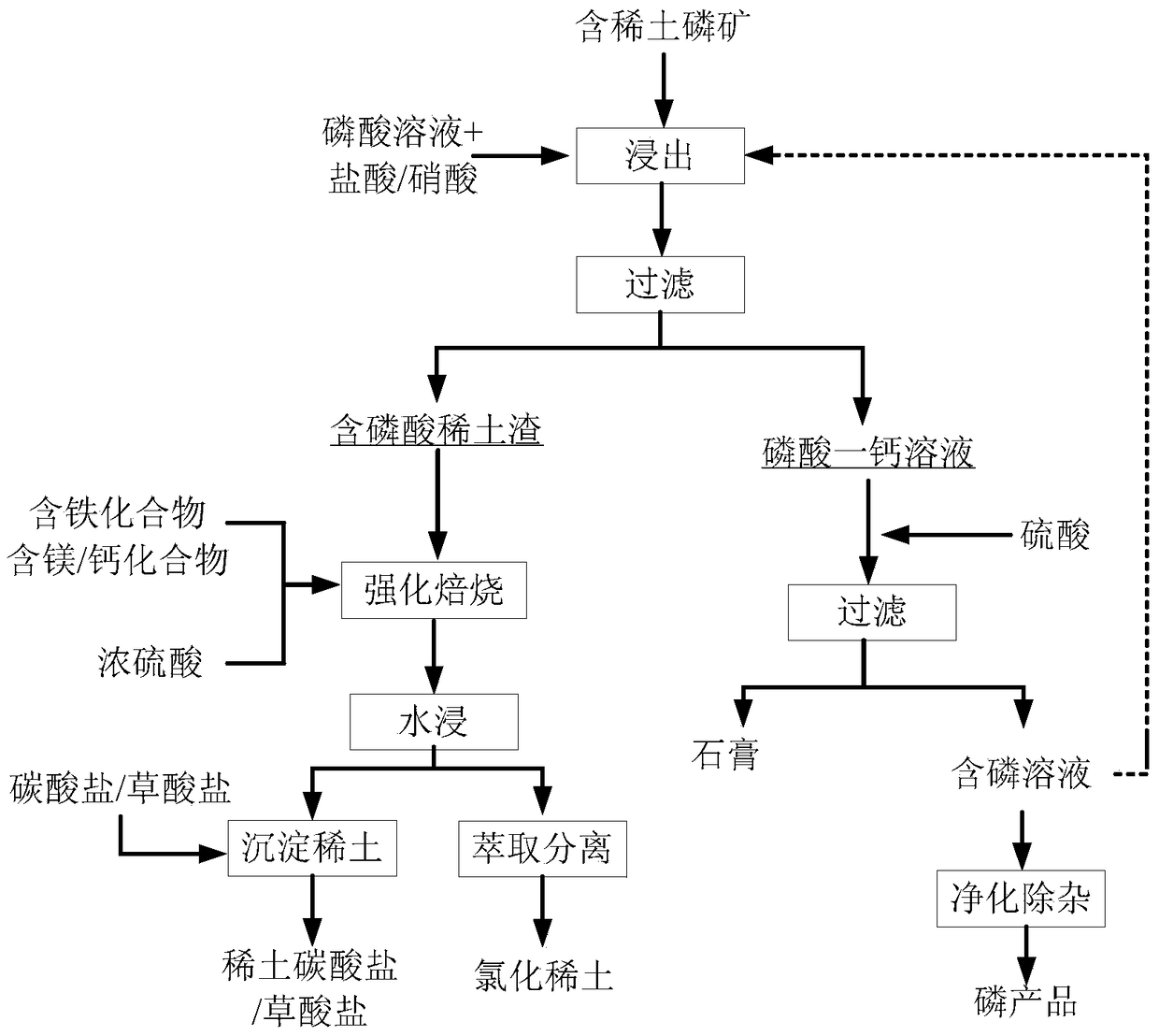

Method for recovering phosphorus and rare earth from rare earth-containing phosphate rock

ActiveCN105886798BHigh recovery ratePromote leachingProcess efficiency improvementPhosphorus compoundsSolubilityCalcium biphosphate

The invention discloses a method for recovering phosphorus and rare earth from phosphate rock containing rare earth. The method comprises the following steps: using a mixed acid solution to leach rare earth-containing phosphate rock, filtering to obtain a monocalcium phosphate solution and a phosphate-containing rare earth slag, the main body of the mixed acid solution is phosphoric acid, and the mixed acid solution also contains hydrochloric acid and / or nitric acid; recovering the monocalcium phosphate Phosphorus in calcium solution, and recovery of rare earth in phosphate-containing rare earth slag. The method uses a mixed acid solution to leach rare earth-containing phosphate rock, so that the phosphorus in the phosphate rock forms monocalcium phosphate with high solubility, and at the same time, the rare earth is precipitated and enriched in the slag in the form of rare earth phosphate by adjusting the acidity of the leaching process. The rare earth-containing phosphate rock also contains monazite, which enriches monazite and rare earth phosphate into the slag, and then separates phosphorus and rare earth, simplifies the recovery steps, improves the recovery rate of rare earth, and realizes the purpose of comprehensive recovery of rare earth at low cost.

Owner:GRIREM ADVANCED MATERIALS CO LTD

A method for selectively leaching sedimentary rare earth ores

ActiveCN109266839BLeaching is effectiveAvoid emissionsProcess efficiency improvementRare-earth elementOrganic acid

The invention discloses a method for selectively leaching sedimentary type rare earths. The method comprises the steps that a, the sedimentary type rare earths are pulverized into powder; b, the powder is calcinated for 0.5-5 hours at the temperature of 550-850 DEG C; c, the calcinated powder is cooled down for 0.5-48 hours at room temperature to obtain cooled hydrated powder; d, the hydrated powder is put into organic acid with the concentration of 0.5-5 mol / L to be reacted for 0.5-5 hours, the liquid-solid ratio is 2-20 L / kg, the leaching temperature is 20-90 DEG C, rare earth liquid is obtained, and remaining slag is washed until neutral, and acid washing liquid is recycled; the content of rare earth oxide (REO) in the sedimentary rare earths is equal to or less that 1.6%, and rare earth elements exist in clay minerals in the form of isomorphic substitution. According to the method, the rare earth element leaching rate is higher than 90% aiming at the technical difficulty of sedimentary rare earths in Guizhou province, the leaching of impurity elements can be effectively inhibited, and the method has the advantages of low energy consumption and convenient and controllable operation.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

Manganese carbonate ore leaching method based on two-stage leaching

ActiveCN105296751ARealize leaching utilizationLeaching is effectiveProcess efficiency improvementElectrolysisManganese

A manganese carbonate ore leaching method based on two sections of leaching, provided by the invention, comprises the following steps: adding high-grade manganese carbonate ore ground powder into a reactor, then adding anolyte and concentrated sulfuric acid and carrying out front-section leaching reaction for at least two hours; detecting residual acid left after reaction, accordingly adding a neutralizer to carry out neutralization, and introducing air to remove impurities; carrying out solid-liquid separation on ore pulp from which impurities are removed, then, putting one section of solids, obtained, into the reactor, adding concentrated sulfuric acid and anolyte, and carrying out leaching reaction for at least two hours; then, adding low-grade manganese carbonate ore powder, anolyte and concentrated sulfuric acid so as to carry out neutralization and leaching; finally adding a neutralizer, and introducing air to remove impurities; and carrying out solid-liquid separation on ore pulp from which impurities are removed so as to obtain an electrolysis qualified solution and solid residues. The method has the advantages of being low in residue quantity, high in leaching rate, low in sulfuric acid consumption, high in comprehensive recovery rate and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

A kind of regeneration method of heavy metal chromium in chrome tanning sludge

InactiveCN104609683BAchieve regenerationAchieve recyclingSludge treatmentProcess efficiency improvementSludgeSorbent

The invention discloses a chrome tanning sludge heavy metal chromium regeneration method, and the method includes extraction of chrome tanning sludge with hydrochloric acid, reduction of Cr<6 +> in the leaching solution by use of sodium bisulfate, adsorption of Cr<3 +> by use of 732 sodium type cation exchange resin, and desorption of the Cr<3 +> on the resin by use of hydrochloric acid or sulfuric acid. According to the method, the hydrochloric acid as an acid leaching extraction agent is cheap, and can effectively leach metal chromium in the chrome tanning sludge, the chromium efficiency is more than 80%; the sodium 732 type cation exchange resin as an adsorbent can preferentially adsorb the Cr<3 +> in the leaching solution, the adsorption and recovery rate can reach up to 96.1%, and the efficient chromium separation and purification can be realized. At the same time, the resin can be recycled by regeneration, the processing cost can be effectively reduced; by desorption of the Cr<3 +> by use of hydrochloric acid or sulfuric acid, corresponding chromium chloride solution and chromic sulfate solution products can be obtained, and the chromium chloride solution and chromic sulfate solution products can be can used in trivalent chromium electroplating industry.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

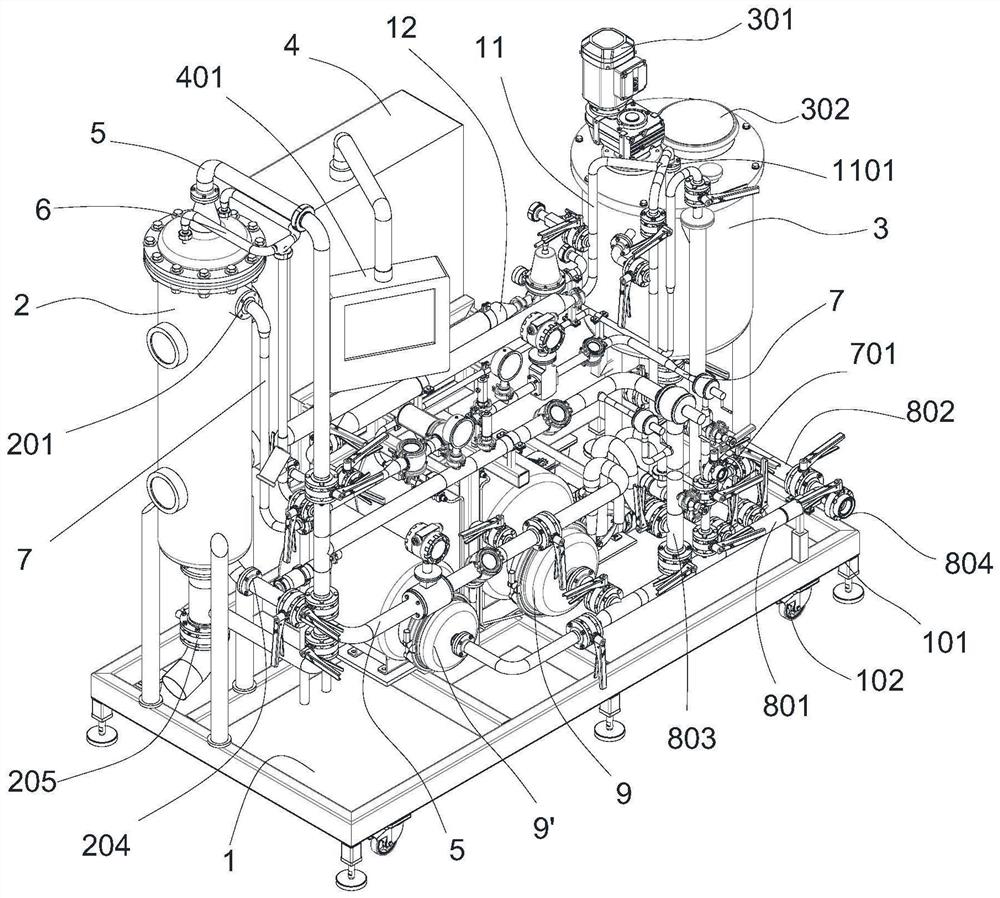

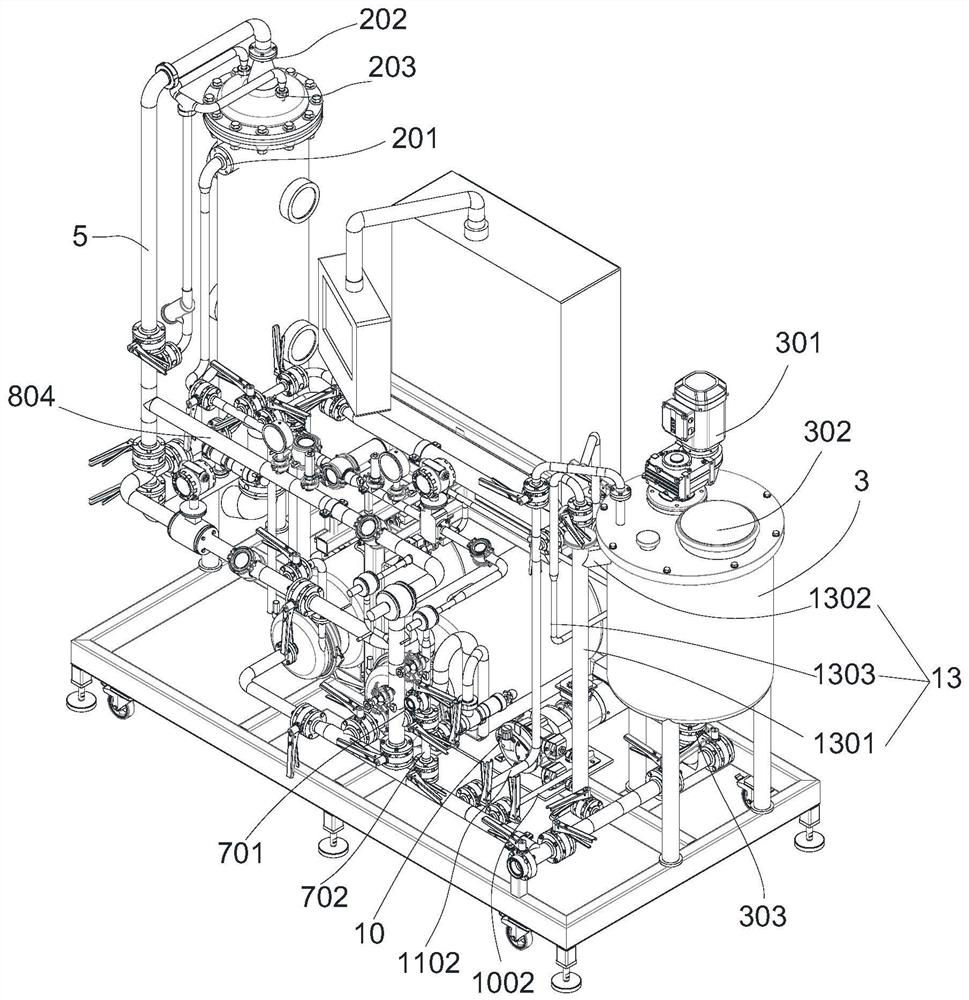

Dry feeding device and process for hops

PendingCN113136275AHigh leaching efficiencyImprove efficiencyBeer brewingProcess engineeringEnvironmental engineering

The invention discloses a hops dry feeding device and a hops dry feeding process. The hops dry feeding device comprises a fermentation tank; a hops preparation tank, which is used for pre-preparing hops suspension liquid; a double-flow filter, which is used for filtering and leaching hop particles in the hop suspension and forming a leaching solution; a circulating pipeline, which is respectively connected with the fermentation tank, the hops preparation tank and the double-flow filter and can form a circulating path, wherein the leaching liquid can circularly flow in the circulating pipeline; and a pressure adjusting device which is connected with an inlet of the hops suspension on the double-flow filter, and can adjust the pressure and the speed of liquid flowing in the circulation path. According to the invention, the double-flow filter and the circulating pipeline technology in the technical scheme are adopted, and a circulating path is formed by setting circulating reflux in a certain proportion and direction, so that circulating repeated leaching is realized, the problem of short circuit caused by bypassing of hops particles by liquid before leaching is avoided, the leaching efficiency is improved, and effective leaching is realized.

Owner:克朗斯流体技术(上海)有限公司

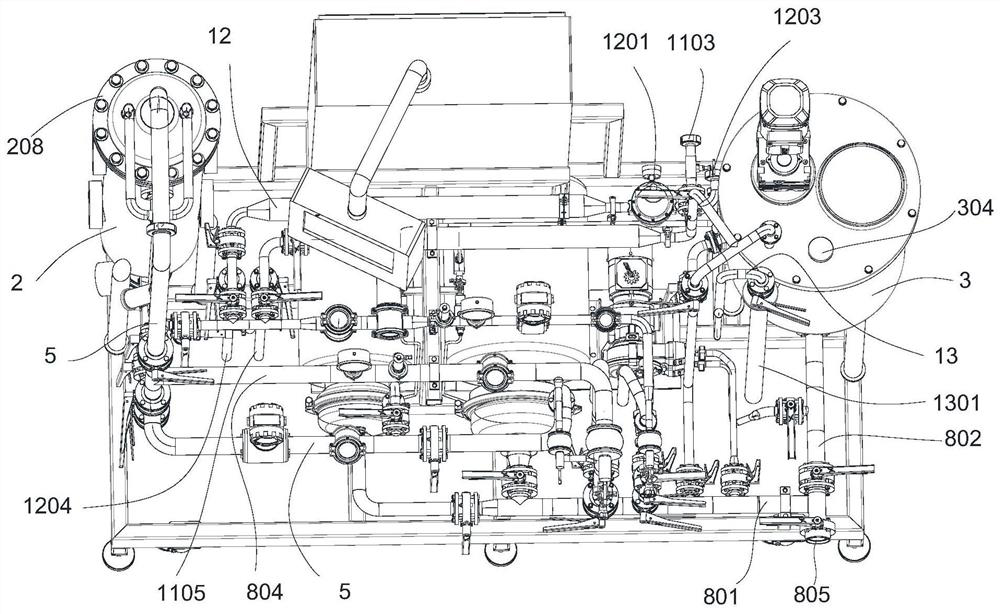

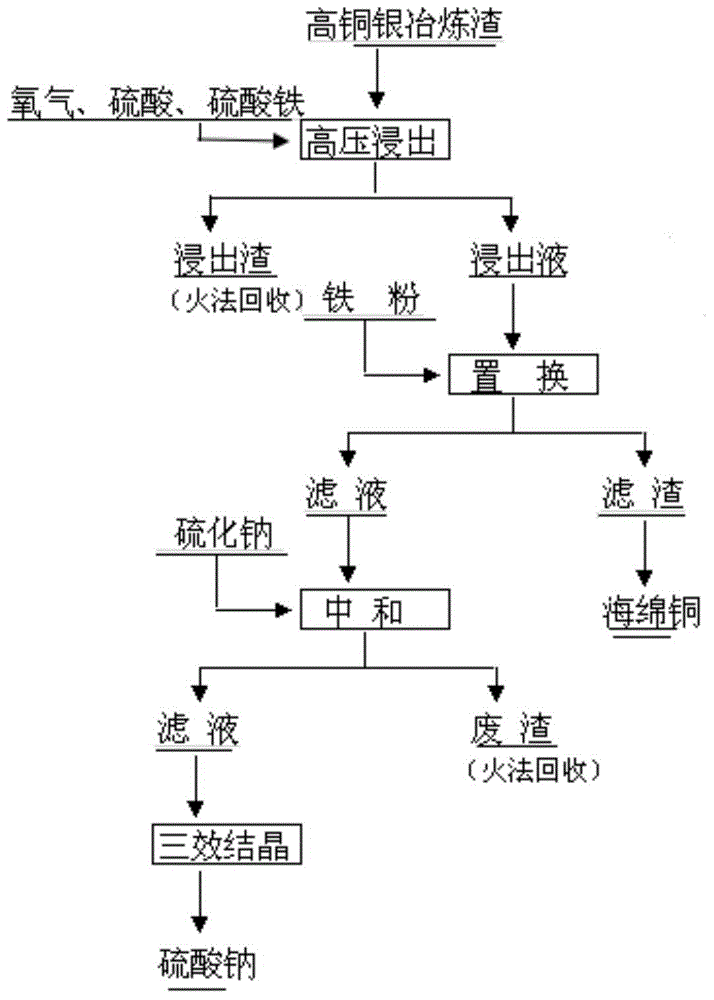

Method for processing high-copper-silver smelting slag

ActiveCN104911369ALeaching is effectiveAvoid leachingProcess efficiency improvementSlagReaction temperature

The invention discloses a method for processing high-copper-silver smelting slag. The method comprises the following steps: (1) smashing molten high-copper-silver smelting slag by virtue of high-pressure liquid or high-pressure gas; (2) adding the crushed high-copper-silver smelting slag, sulfuric acid and iron sulfate into a high-pressure reaction kettle, wherein the liquid-solid ratio is (8-10) to 1: introducing oxygen into the high-pressure reaction kettle; reacting for 3-5 hours under the pressure intensity of 1.0-0.3MPa at a reaction temperature of 140-180 DEG C; and after the reaction is finished, filtering the mixture, so as to obtain leachate and leaching residue; (3) adding iron powder into the leachate and reacting for 1-2 hours, wherein the weight of the iron powder is 1.1-1.3 times that of copper; and after the reaction is finished, filtering the mixture, so as to obtain sponge copper and filtrate; and (4) adding sodium sulfide into the filtrate obtained in the step (3) to regulate the pH to 8-9, carrying out filtering separation to obtain sulfide precipitate and filtrate, and carrying out triple crystallization on the filtrate, so as to generate sodium sulfate crystals. According to the method provided by the invention, copper in the high-copper-silver smelting slag can be effectively recycled, and silver can be enriched and the leaching of arsenic can be inhibited.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

A kind of production method of instant green tea soybean milk powder

ActiveCN104351350BEasy to brewEliminate bitternessPre-extraction tea treatmentMilk substitutesBiotechnologyInstant tea

The invention relates to a production method of instant green tea soybean milk powder, belonging to the technical field of instant tea beverages. The invention solves the problem that the existing soy milk tea powder product does not well integrate the two flavors, and the two different powders are not easy to brew and dissolve, which affects the taste and taste, and provides a production of instant green tea soy milk powder In this method, green tea is extracted, filtered and concentrated to make a concentrated solution, and then mixed with soybean milk powder, and the ultrasonic dispersion technology is used to blend the two well, and finally the instant green tea soybean milk powder is obtained through pressurized spray drying , the flavor and effective ingredients of green tea have been integrated into the soy milk powder, which is easier to dissolve in water, easy to brew, and has better flavor and nutrition.

Owner:SICHUAN YINGJING COUNTY TASHAN

Method for recovering zinc, indium, iron, and lead from high-iron zinc oxide mixture smelted with zinc

ActiveCN103667720BSolve processing problemsReduce the amount addedMetal recyclingProcess efficiency improvementPregnant leach solutionSocial benefits

The invention relates to the field of metal smelting, particularly to a method for recovering zinc, indium, iron, and lead from a high-iron zinc oxide mixture smelted with zinc. The method comprises the following processes: a high-iron zinc oxide mixture neutral leaching process, a neutral leaching residue low acid leaching process, a low acid pressure filter residue peracid leaching process, a low acid leaching liquid prereduction process, and a indium enrichment recycling process; valuable metals are comprehensively recovered from the high-iron zinc oxide mixture; a generated neutral leaching liquid is adopted by a main zinc smelting system to generate electrolytic zinc; a hydrolyzing filter liquor generated from the indium enrichment recycling process contains relatively rich ferrous ions; the hydrolyzing filter liquor is adopted by the main system for removing impurities and generating high-grade indium enrichment residues; therefore, the high-iron zinc oxide mixture is effectively recycled, the problem of high-iron zinc oxide mixture treatment is solved, capability of comprehensive utilization of metal resources is increased, so that resources are comprehensively recycled, and environment protection is facilitated; the method has relatively good economic benefits and social benefits.

Owner:HENAN YUGUANG ZINC IND

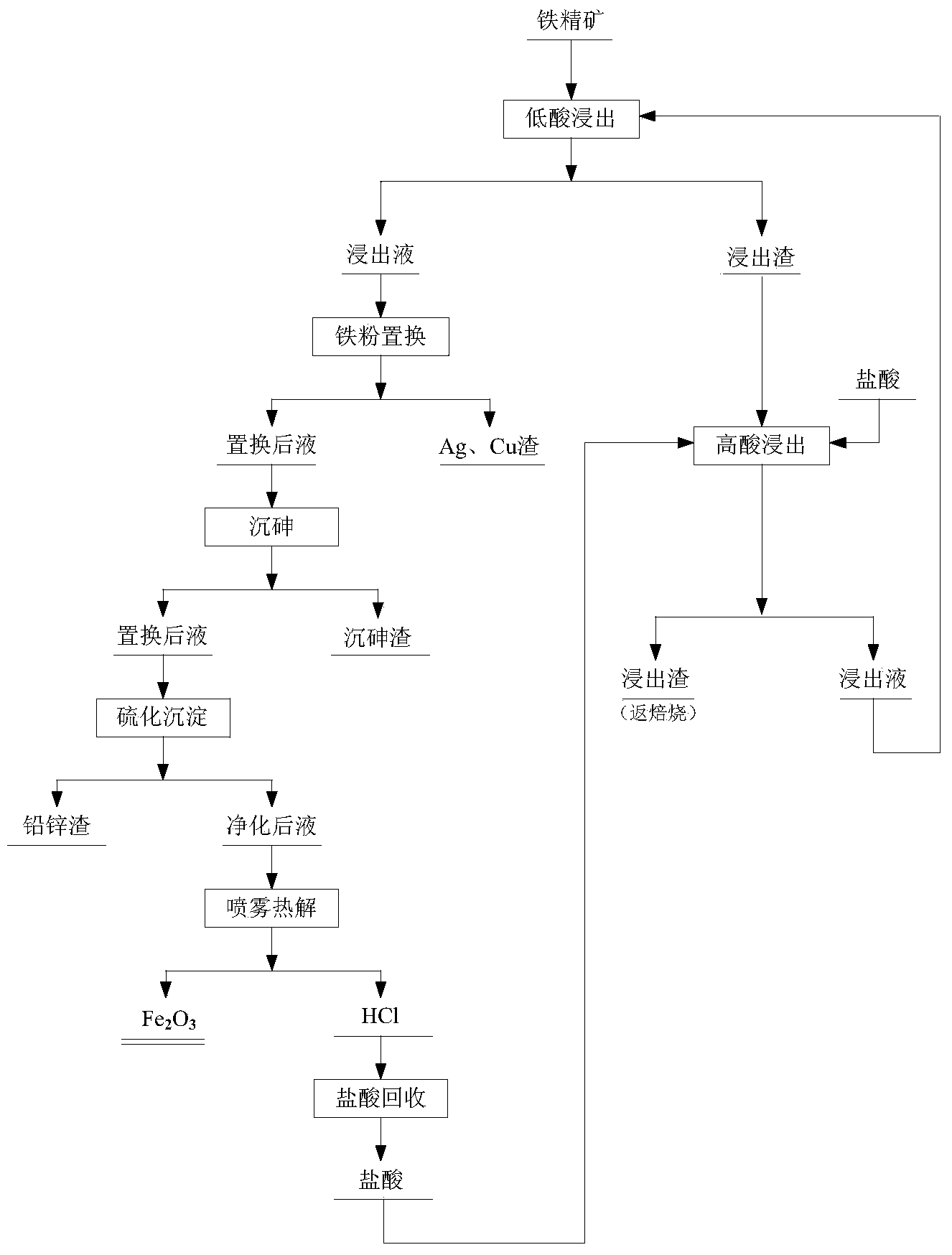

Comprehensive utilization method of slag iron concentrates of wet-type zinc smelting furnace

InactiveCN103695662BEffective dissolutionLeaching is effectiveProcess efficiency improvementResource utilizationEnergy conservation

The invention relates to a comprehensive utilization method of slag iron ore concentrates of a wet-type zinc smelting furnace and belongs to the technical field of metallurgy. The method comprises the following steps: performing two-section counterflow leaching on raw material (slag iron ore concentrates in the wet-type zinc smelting furnace) in the presence of a hydrochloric acid aqueous solution serving as a leaching agent so that valuable metals such as iron, silver, copper, lead, zinc and arsenic in the slag iron ore concentrates enter a leachate; purifying the leachate by utilizing processes of metal iron powder replacement, control over pH (Power Of Hydrogen) value, arsenic sedimentation, sulfuration precipitation and the like, separating the valuable metals such as copper, silver, lead, zinc and arsenic, wherein the purified leachate is a pure FeCl2 aqueous solution; performing thermal decomposition on the pure FeCl2 aqueous solution in a spraying manner so as to obtain Fe2O3 powder; and absorbing the generated HCL gas with water so as to regenerate hydrochloric acid which returns to the leaching process. By the method, the valuable elements in the slag iron ore concentrates of the wet-type zinc smelting furnace are comprehensively separated and recycled; and the hydrochloric acid taken as a leaching agent can be recycled, so that the method realizes resource conservation and is friendly to the environment. During the whole process, the discharge of three wastes is basically avoided; all the resources are utilized to the greatest extent; and obtained products are convenient for subsequent treatment and processing. The method has the advantages of environmental friendliness, economical performance, energy conservation and high resource utilization rate, thereby being convenient for industrial production.

Owner:CENT SOUTH UNIV

A method for preparing battery-grade lithium carbonate with waste lithium iron phosphate pole pieces

ActiveCN109088120BHigh puritySimple methodCell electrodesWaste accumulators reclaimingElectrical batterySodium hydroxide

A method for preparing battery grade lithium carbonate from waste lithium iron phosphate electrode sheets relates to that technical field of lithium batteries. The method comprises the steps of: 1, releasing electricity; 2, performing oxidizing and roasting to obtain electrode sheet roast material containing lithium iron phosphate active material and current collector aluminum foil; 3, pulverizingthe roasted material and performing screening to obtain separated aluminum powder and lithium iron phosphate electrode sheet powder; 4, detecting the content of the lithium element in the lithium iron phosphate electrode sheet powder, preparing an acid solution according to a certain molar ratio according to the content of the lithium element, adding the lithium iron phosphate electrode sheet powder into the acid solution according to a certain mass-solid-liquid ratio for reaction, and finally filtering to obtain a first mixed liquid; 5, adding sodium hydroxide into the first mixed solution for reaction, and filtering to obtain a second mixed solution; 6, reacting the second mixed solution with the sodium carbonate solution and filtering to obtain battery-grade lithium carbonate. The invention can effectively improve the leaching rate of the lithium element and the purity of lithium carbonate.

Owner:湖南金凯循环科技股份有限公司

A kind of manganese carbonate ore leaching method based on two-stage leaching

The invention discloses a manganese carbonate ore leaching method based on two-section leaching. The method includes the following steps that high-grade manganese carbonate ore is ground into powder and added into a reactor; then, anode liquor and concentrated sulfuric acid are added for the first-section leaching reaction, wherein the leaching reaction time is at least 2 h; remaining acid left after the reaction is detected, and a neutralizer is added on this basis to conduct neutralization; solid-liquid separation is conducted on neutralized ore pulp, obtained first-section solid substances are thrown into the reactor, and concentrated sulfuric acid and anode liquor are added for second-section leaching, wherein the leaching reaction time is at least 2 h; impurity removal and solid-liquid separation are conducted on the obtained leaching agent to obtain qualified electrolysis liquid; low-grade manganese carbonate ore powder, anode liquid and concentrated sulfuric acid are added after the second-section leaching is finished to conduct neutralization leaching; and finally, adding a neutralizer again, and impurity removal is conducted; and solid-liquid separation is conducted on impurity-removed ore pulp to obtain qualified electrolysis liquid and solid residues. The method has the beneficial effects of being small in residue amount, high in leaching rate, low in sulfuric acid consumption, high in comprehensive recovery rate and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

A method for recovering metallic lead from lead sulfate slag

ActiveCN110923468BEfficientWith energy savingPhotography auxillary processesProcess efficiency improvementMethane sulfonic acidSlag

The invention provides a method for recovering metallic lead from lead-containing materials such as lead sulfate slag, which solves the problems of high energy consumption, high cost, large pollution, and poor application when recovering metallic lead from lead-containing materials such as lead sulfate slag. Issues with limited range, safety hazards, and inability to take full advantage of metal. The method recovers lead in lead-containing materials such as lead sulfate slag according to the following steps: (1) chlorination leaching process; (2) sodium carbonate conversion process; 3) methanesulfonic acid leaching process; 4) electrowinning process; 5) melting and casting process.

Owner:赵坤

Manganese carbonate ore leaching method based on two-stage leaching

ActiveCN105296751BRealize leaching utilizationLeaching is effectiveProcess efficiency improvementElectrolysisLower grade

A manganese carbonate ore leaching method based on two sections of leaching, provided by the invention, comprises the following steps: adding high-grade manganese carbonate ore ground powder into a reactor, then adding anolyte and concentrated sulfuric acid and carrying out front-section leaching reaction for at least two hours; detecting residual acid left after reaction, accordingly adding a neutralizer to carry out neutralization, and introducing air to remove impurities; carrying out solid-liquid separation on ore pulp from which impurities are removed, then, putting one section of solids, obtained, into the reactor, adding concentrated sulfuric acid and anolyte, and carrying out leaching reaction for at least two hours; then, adding low-grade manganese carbonate ore powder, anolyte and concentrated sulfuric acid so as to carry out neutralization and leaching; finally adding a neutralizer, and introducing air to remove impurities; and carrying out solid-liquid separation on ore pulp from which impurities are removed so as to obtain an electrolysis qualified solution and solid residues. The method has the advantages of being low in residue quantity, high in leaching rate, low in sulfuric acid consumption, high in comprehensive recovery rate and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com