Dry feeding device and process for hops

A hop and process technology, applied in the field of winemaking, can solve problems such as ineffective leaching, and achieve the effect of improving efficiency and improving leaching efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] This specific embodiment is only an explanation of the present invention, and it is not a limitation of the present invention. Those skilled in the art can make modifications to this embodiment without creative contribution as required after reading this specification, but as long as they are within the rights of the present invention All claims are protected by patent law.

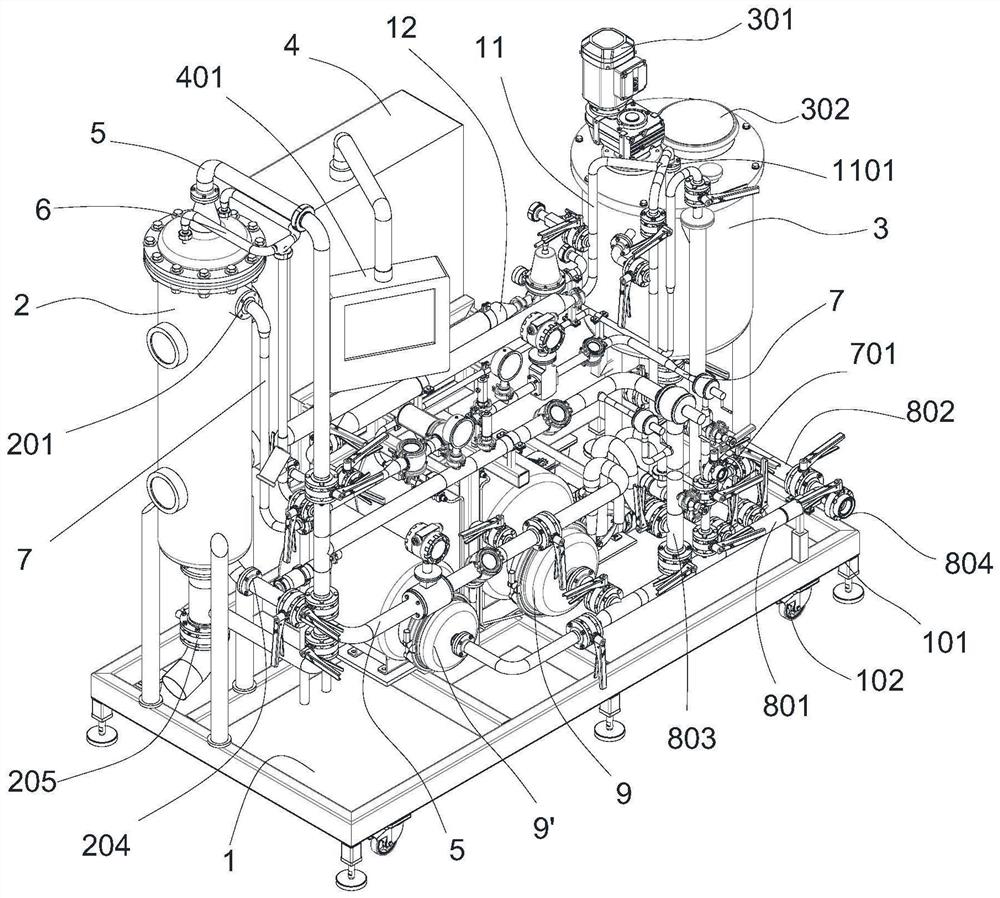

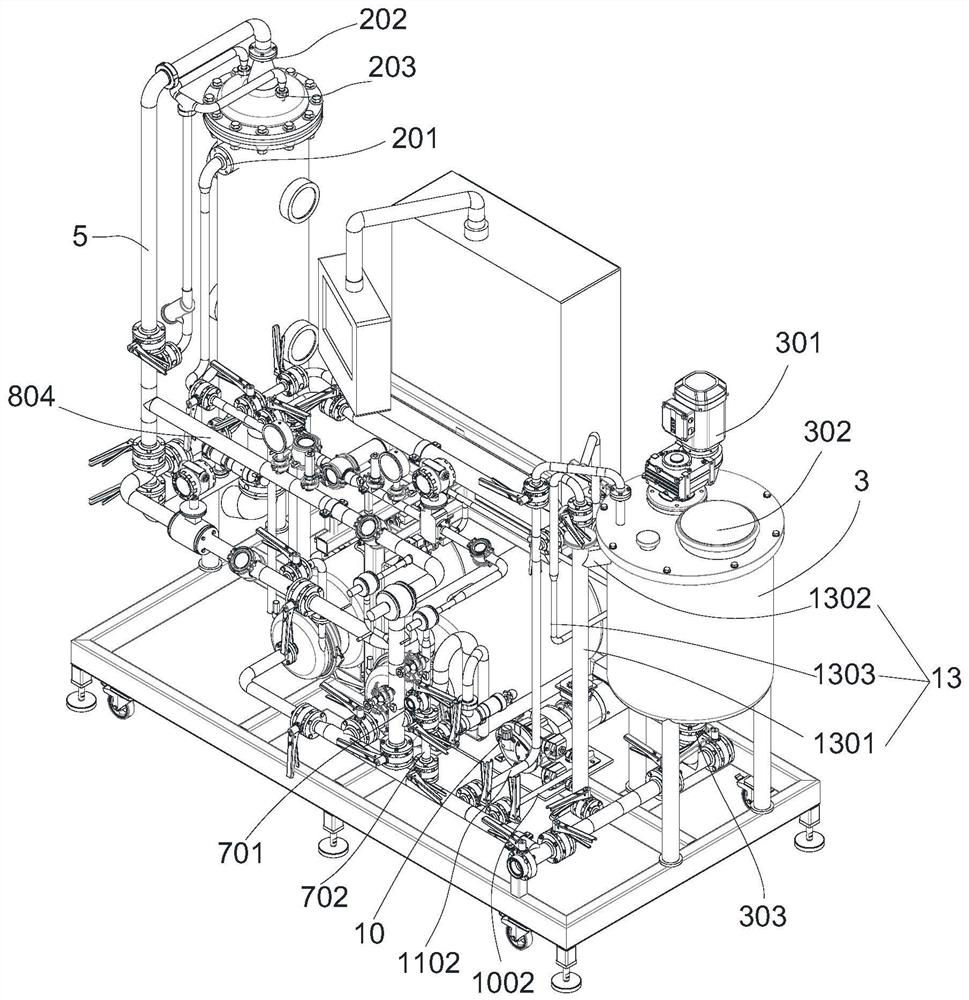

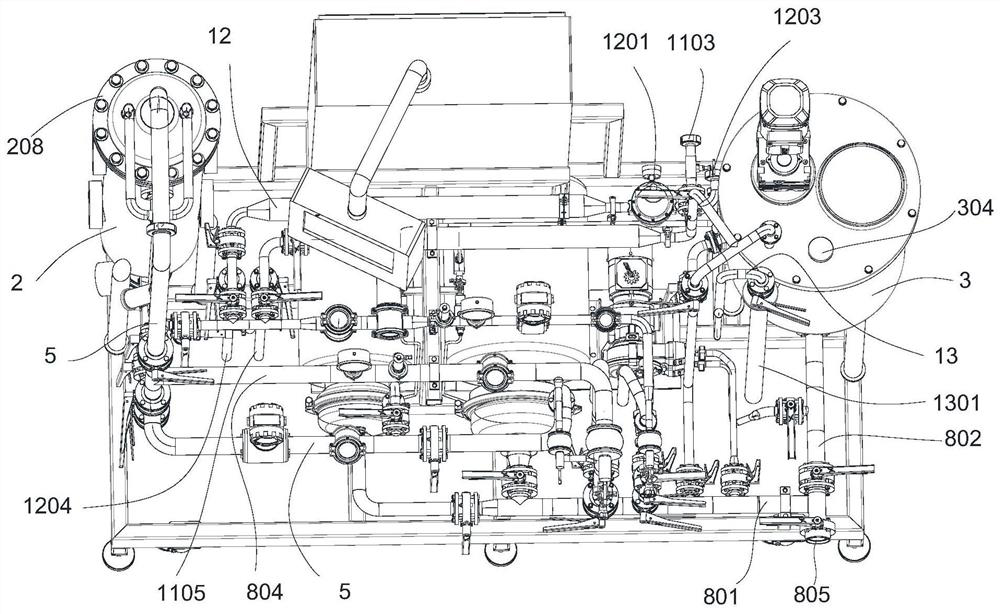

[0041]The present invention applies the candle filter method to the hop dry throwing process, and designs a double-flow filter on the basis of the prior art. On the basis of the existing candle filter, the filter adds a circulation pipeline and improves The annulus structure on the surface of the candle stick in the filter, the combination of the circulation pipe and the annulus structure, by setting a certain proportion and direction of circulation backflow, can effectively block and filter the hop particles in the wine liquid, and can also realize circulation Repeated leaching to avoid the occurr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com