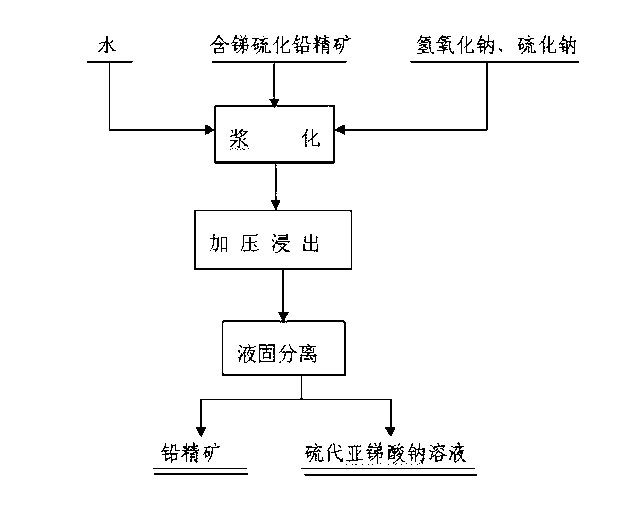

Method for separating lead and antimony in antimony-containing lead concentrates

A lead concentrate and lead separation technology, applied in the field of antimony in lead sulfide concentrate, can solve the problems of unfavorable antimony recovery, low direct recovery rate of lead and antimony metal, and achieve the effect of reducing harmful effects and concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Composition of lead concentrate containing antimony: Pb54.34%, Sb8.20%, S16.87%.

[0019] Prepare 3.00L of 100.00g / L sodium hydroxide solution containing 30.00g / L sodium sulfide, add 1.00Kg of antimony-containing lead sulfide concentrate, stir and mix for 0.5 hours, put the mixture into a closed stirring reactor, and heat to a temperature of 140°C , the pressure in the closed reactor is 0.35~0.4MPa, stirring and reacting for 1.5 hours, filtering to obtain 0.91Kg lead sulfide concentrate and 3.37L leaching solution containing sodium thioantimonite, the lead sulfide concentrate contains 0.76wt% antimony .

Embodiment 2

[0021] Composition of lead concentrate containing antimony: Pb54.34%, Sb8.20%, S16.87%.

[0022] Prepare 3.00L of 120.00g / L sodium hydroxide solution containing 10.00g / L sodium sulfide, add 1.00Kg of antimony-containing lead sulfide concentrate, stir and mix for 0.5 hours, put the mixture into a closed stirring reactor, and heat to a temperature of 160°C , the pressure in the closed reactor is 0.55~0.60MPa, stirring and reacting for 1.0 hour, filtering to obtain 0.93Kg lead sulfide concentrate and 3.43L leachate containing sodium thioantimonite, the lead sulfide concentrate contains 0.97wt% antimony .

Embodiment 3

[0024] Composition of lead concentrate containing antimony: Pb54.34%, Sb8.20%, S16.87%.

[0025] Prepare 3.00L of 80.00g / L sodium hydroxide solution containing 40.00g / L sodium sulfide, add 1.00Kg of antimony-containing lead sulfide concentrate, stir and mix for 0.5 hours, put the mixture into a closed stirring reactor, and heat to a temperature of 120°C , the pressure in the airtight reactor is 0.15~0.2MPa, stirring and reacting for 2.0 hours, filtering to obtain 0.94Kg lead sulfide concentrate and 3.22L leachate containing sodium thioantimonite, the lead sulfide concentrate contains 0.84wt% antimony .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com