Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

291results about How to "With energy saving" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alcohol-based biological fuel oil for boiler and preparation method thereof

InactiveCN101948702ALow costRaw materials are cheap and easy to getBiofuelsLiquid carbonaceous fuelsBiodieselAlcohol

The invention provides a biodiesel-based alcoholic fuel oil, which consists of the following substances in percentage by mass: 20 to 50 percent of refined biodiesel, 40 to 80 percent of industrial methanol and 5 to 30 percent of additive, wherein the additive comprises 5 to 20 percent of solvent aid, 1 to 15 percent of cosurfactant, 0.2 to 2 percent of stabilizer and 0.1 to 1 percent of corrosion inhibitor. A preparation method comprises the following steps of: mixing the substances in percentage by mass, and stirring the mixture uniformly at normal temperature to obtain the fuel oil. The fuel oil has the advantages of low cost, high heat value and stable performance; the preparation method has the advantages of simple process, convenience and safety of use and good adaptability to the boiler; and compared with diesel oil, the fuel oil is economic and energy-saving, has low environmental pollution, is regenerative energy, and can be used as commercial oil for great popularization and use.

Owner:KUNMING UNIV OF SCI & TECH

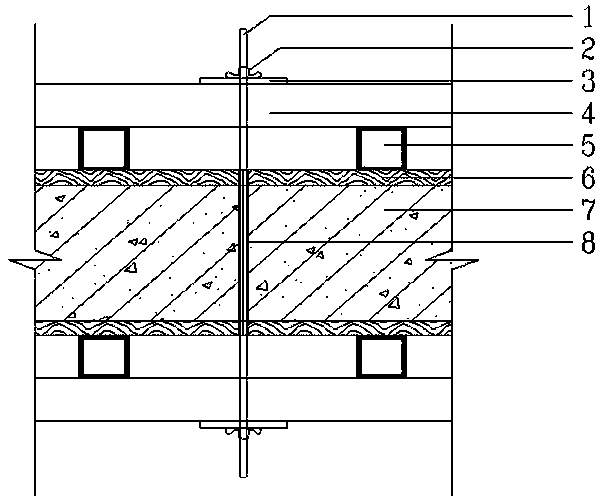

Metal composite plate with fireproof interlayer and manufacturing method thereof

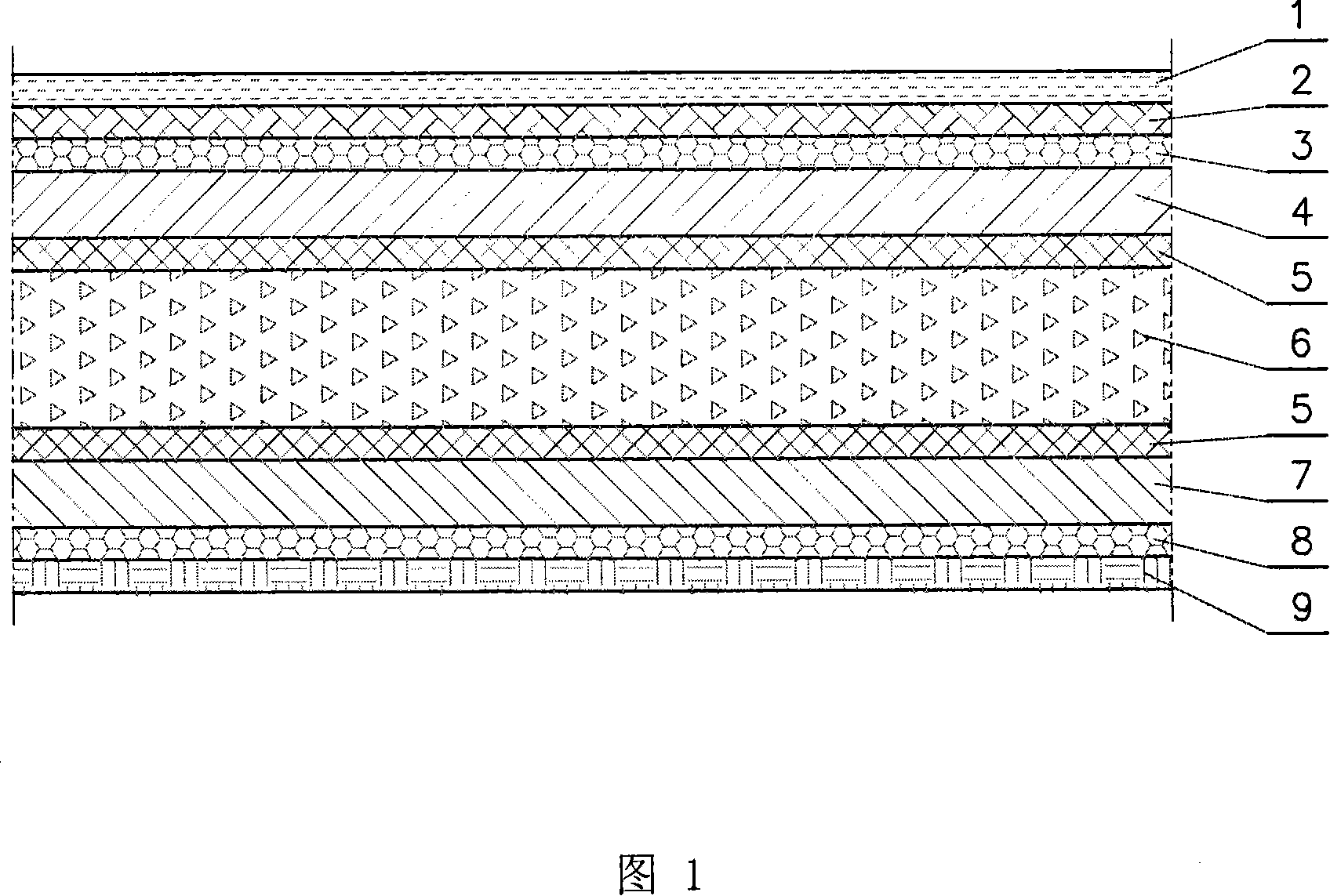

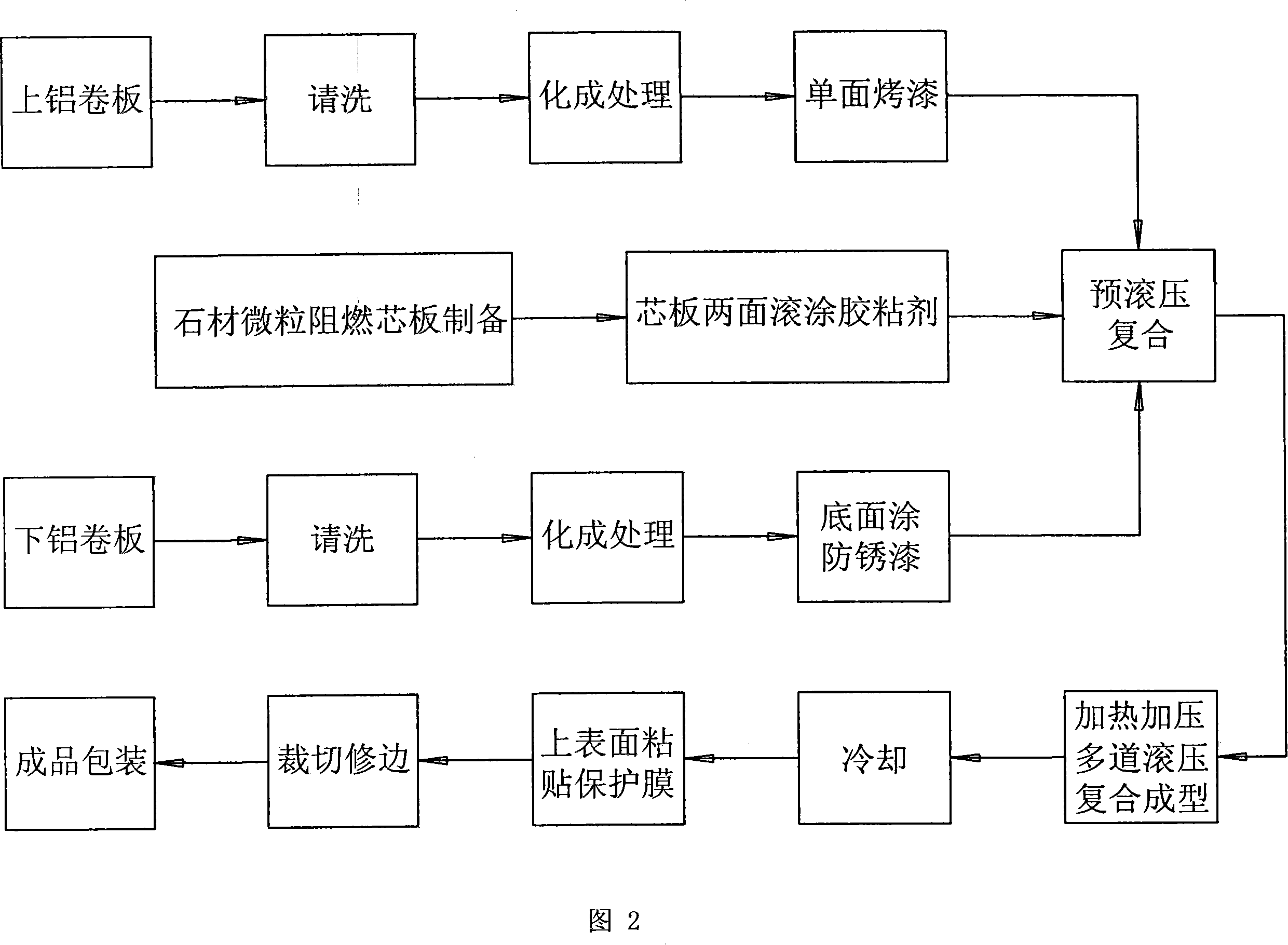

ActiveCN101148936AWon't happenWith thermal insulationCovering/liningsLamination ancillary operationsTectorial membraneAdhesive

The present invention is one kind of composite metal plate with sandwiched fireproof layer and its making process. The composite metal plate with sandwiched fireproof layer consists of a protecting film layer, a baking varnish layer, a first chemically formed film layer, a first metal sheet, a first adhesive layer, a sandwiched fireproof layer, a second adhesive layer, a second metal sheet, a second chemically formed film layer and an antirust primer layer superposed successively and compounded integrally. Its making process includes the steps of: hot pressing the mixture of fine ore grains, fire retardant, coupling agent and adhesive to form the fireproof core board; treating the first metal sheet to form the first film layer and the baking varnish layer, and treating the second metal sheet to form the second film layer and the antirust primer layer; painting adhesive to two sides of the core board and hot pressing to combine the core board and two metal sheets; adhering the protecting film layer and cutting.

Owner:江阴新泓泰复合材料有限公司

Composite flame-retardant expandable polystyrene particles and preparation technology thereof

Disclosed are composite flame-retardant expandable polystyrene particles and a preparation technology thereof. The particles are prepared from the following components of: by weight, 100 parts of styrene monomer, 100-150 parts of water, 1-10 parts of expandable graphite, 1-12 parts of a phosphorus compound, 0.1-0.5 part of white oil, 0.1-0.5 part of polyethylene wax, 0.05-0.2 part of dicumyl peroxide, 0.2-0.8 part of benzoyl peroxide, 0.1-0.4 part of polyvinyl alcohol, 1.1-2.1 parts of tricalcium phosphate and 8-12 parts of pentane. By the addition of a composite fire retardant of expandable graphite and the phosphorus compound before polymerization of styrene, adverse influence of the fire retardant on performance of the product is reduced; expandable graphite and the phosphorus compound are halogen-free fire retardants, the particles have good environmental protection performance; by the addition of white oil, the particles have plasticising and internal lubricant functions as well as good stability and low volatility, and fluidity during the forming of polystyrene particles can be greatly improved; polyvinyl alcohol and tricalcium phosphate are dispersion stabilizers and by timely adding a proper amount of the dispersion stabilizers, the product appearance can be improved, the production efficiency can be raised, and cost can be reduced; and the addition of all the components guarantees the performance of the product.

Owner:BEIJING HUACHEN DECHUANG CHEM TECH

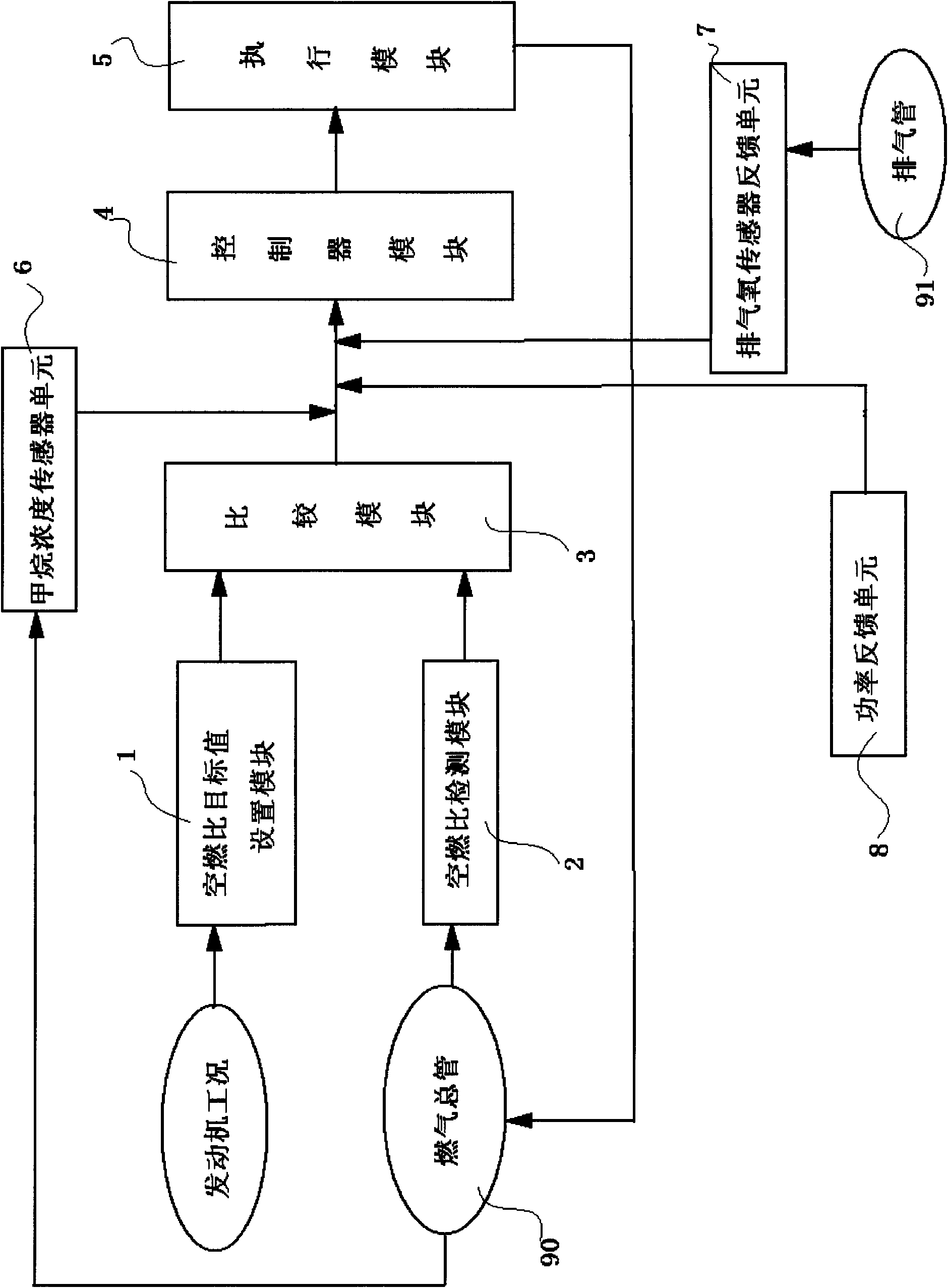

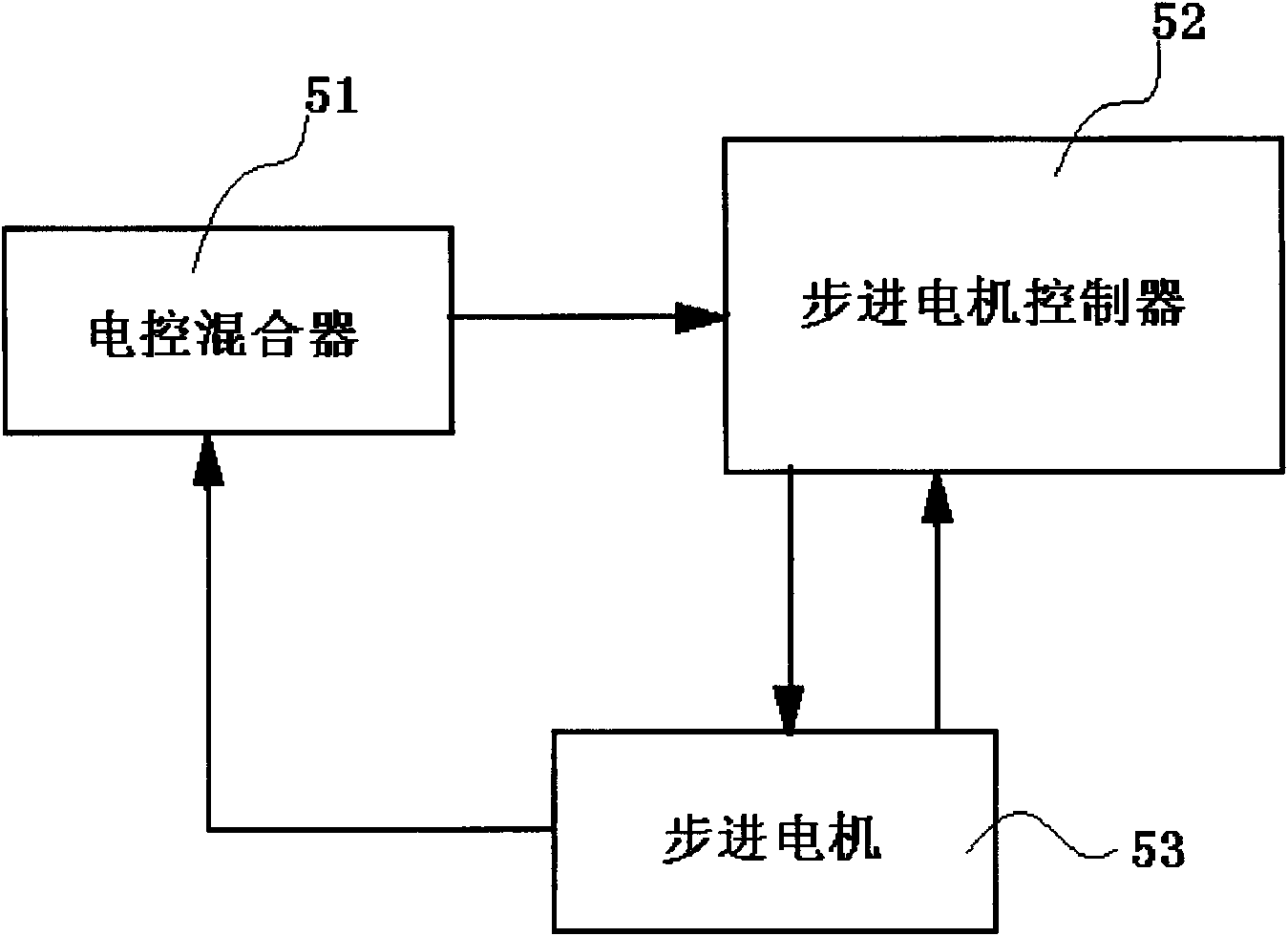

Device for controlling air-fuel ratio

ActiveCN101614161ATimely adjustment of air-fuel ratioImprove performanceElectrical controlMachines/enginesValue setOxygen sensor

The invention provides a device for controlling an air-fuel ratio, which comprises an air-fuel ratio target value setting module, an air-fuel ratio detection module, a comparison module, a controller module and an execution module, wherein, the air-fuel ratio target value setting module determines the air-fuel ratio of a fuel power generation internal-combustion engine according to the working conditions of the internal-combustion engine; the air-fuel ratio detection module detects the air-fuel ratio actual value under the current working condition of the internal-combustion engine; the comparison module compares the air-fuel ratio actual value with the air-fuel ratio target value and sends the comparison results to the controller module; the controller module outputs the control signals to the execution module; and the execution module regulates the air flow and fuel flow in the main fuel pipe. The device further comprises a methane concentration sensor unit, an exhaust gas oxygen sensor feedback unit and a power feedback unit; wherein, the comparison results of the comparison module are modified by the methane concentration sensor unit, the exhaust gas oxygen sensor feedback unit and the power feedback unit and further sent to the controller module for treatment. The invention has the characteristics of timely detection, accurate control, energy conservation, environment friendliness, high efficiency and the like.

Owner:湖南省力宇燃气动力有限公司

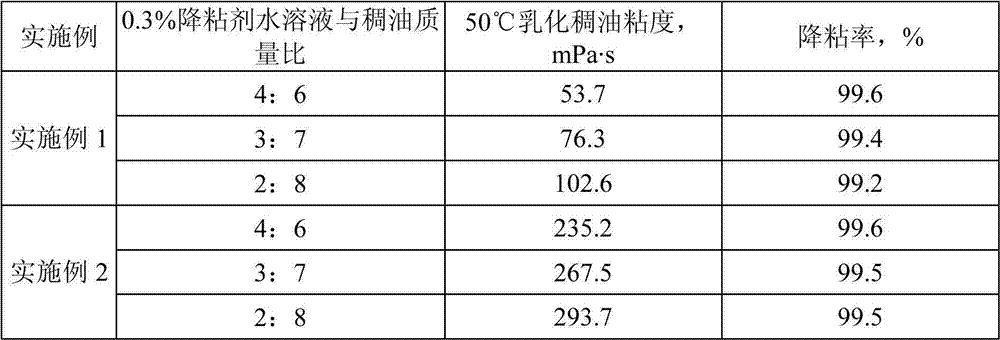

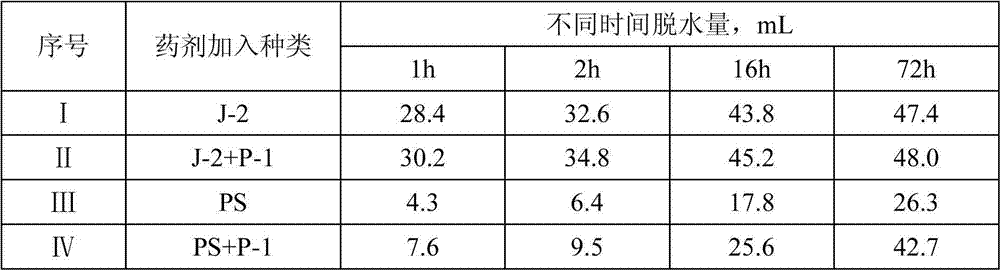

Temperature-resistant salt-tolerant viscous-oil biological viscosity reducer and preparation method thereof

ActiveCN105154050AAvoid scaling and corrosionThe implementation method is simpleDrilling compositionLiquid mediumTemperature resistance

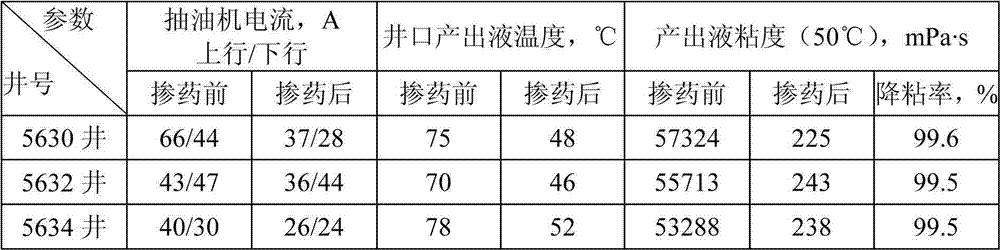

The invention discloses a temperature-resistant salt-tolerant viscous-oil biological viscosity reducer and a preparation method thereof, and belongs to the technical field of petroleum exploitation. The temperature-resistant salt-tolerant viscous-oil biological viscosity reducer is composed of microzyme, a seed liquid medium, a fermentation liquor medium and water. The microzyme is torulopsis candida. The preparation method of the viscosity reducer comprises (1) preparation of a microzyme seed liquid; (2) early-stage preparation of the fermentation liquor medium; (3) fermentation production of microzyme; (4) collection of a fermentation product; and (5) preparation of the viscous-oil biological viscosity reducer. The viscous-oil biological viscosity reducer is green and free of pollution by employing agricultural and sideline products as raw materials. The provided viscous-oil biological viscosity reducer possesses the temperature resistance up to 150 DEG C, the salt tolerance up to 2*10<5> mg / L, and the viscous-oil viscosity reduction rate up to 99% or more. The enforcement method of the viscous-oil biological viscosity reducer is simple. The viscous-oil biological viscosity reducer is substantial in effect, is capable of saving energy, reducing consumption and preventing pipelines from fouling and being corroded, and the subsequent crude-oil demulsification dewatering processing is easy. Therefore, the viscous-oil biological viscosity reducer is widely applicable to shaft elevation of a viscous oil well and ground pipeline conveying technology.

Owner:CHINA PETROLEUM & CHEM CORP +1

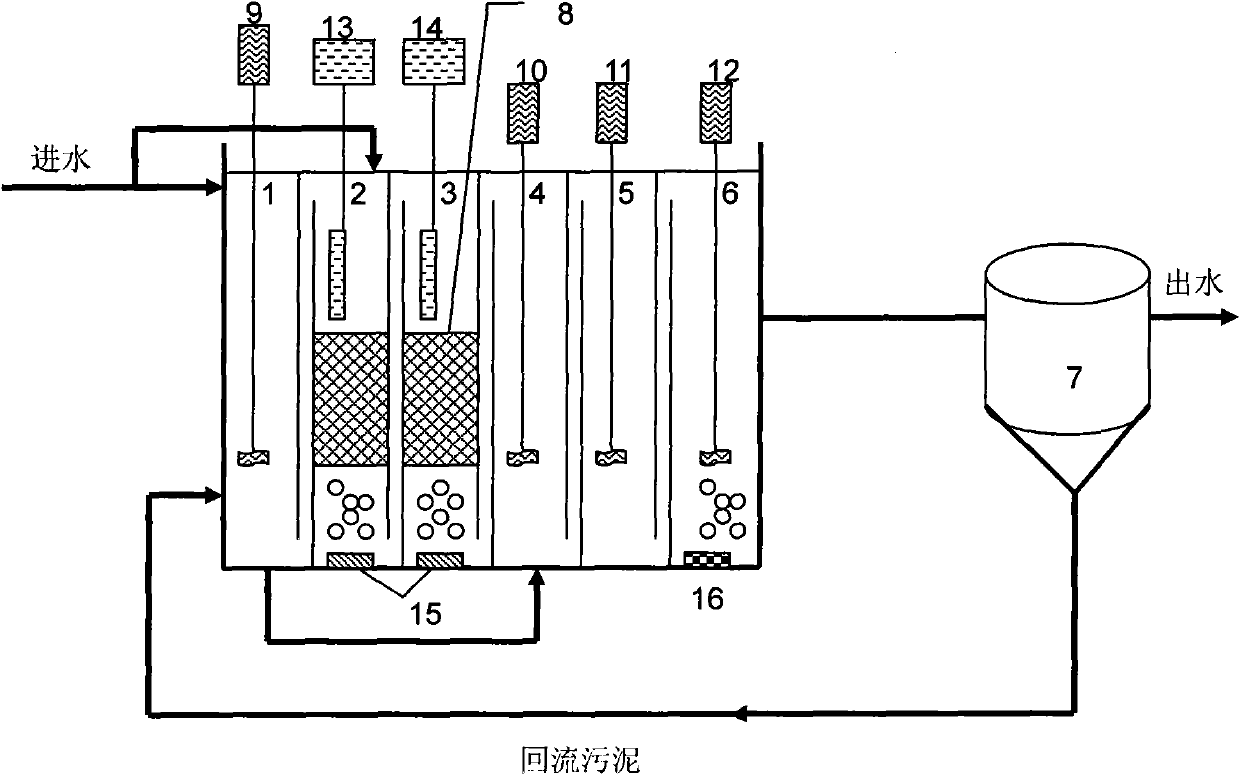

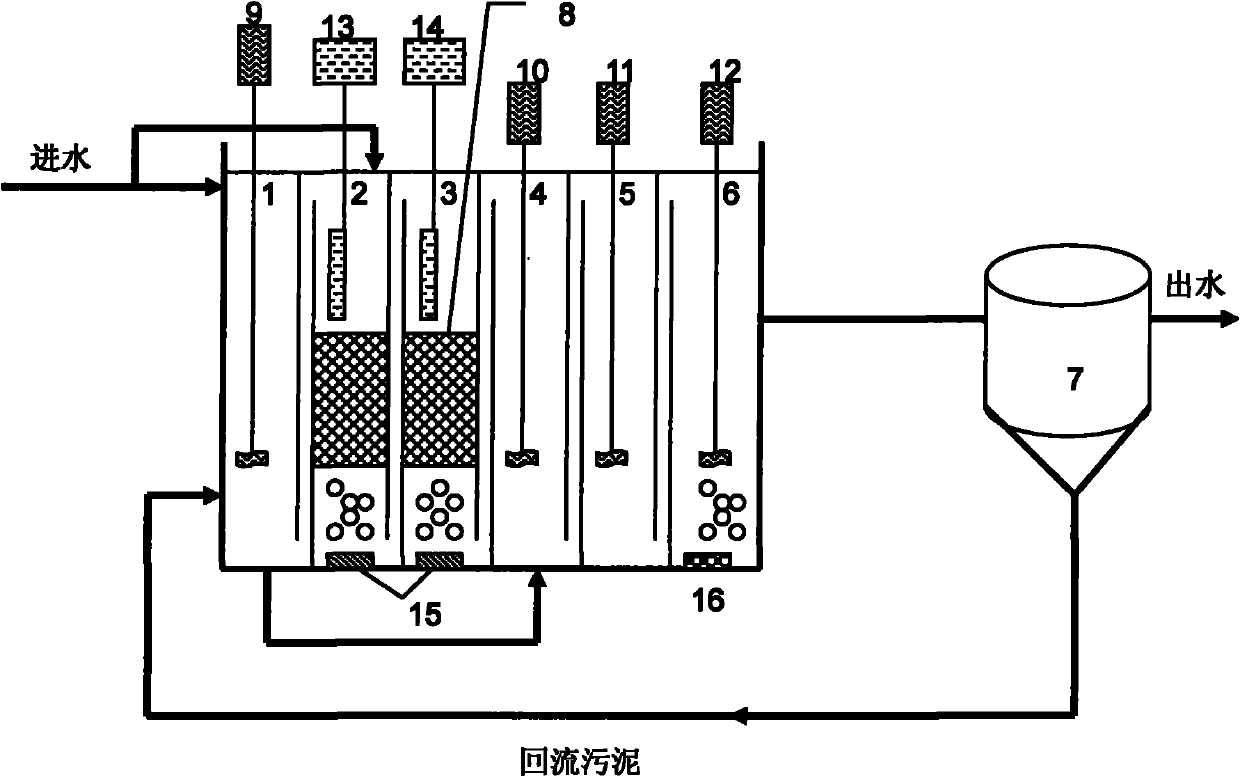

Energy-saving consumption-reducing short-range nitration dephosphorizing coupling technique with synchronous denitrification and device thereof

ActiveCN101792233AAccumulation and stabilityRealize energy saving and consumption reductionWater contaminantsMultistage water/sewage treatmentElectron donorNitration

The invention discloses an energy-saving consumption-reducing short-range nitration dephosphorizing coupling technique with synchronous denitrification and a device thereof, belonging to technical field of domestic and industrial sewage treatment. A metal carrier bed is installed in an aerobic section with integrated reaction, and is made of iron wood shaving washed through acid cleaning; and the outer part of the iron wood shaving is covered by wire netting. Under conditions of normal temperature and low dissolved oxygen, the aims of short-range nitration and synchronous denitrification can be realized; an anaerobic section is used for finishing phosphorous releasing; the aerobic section is used for finishing short-range nitration, an anoxic section is used for finishing denitrification for removing phosphorous, a fast aerobic section is used for removing remaining ammonia and nitrogen and phosphorous. The invention uses iron wood shaving with low cost to realize stable accumulation of nitrite; the aerating amount is small, the carbon source is saved, and denitrification for phosphorous removing is carried out by taking the nitrite produced via short-range nitration as electron donor, thus the nitrogen and phosphorous can be removed synchronously; and the problem that the nitrite in water could damage the environment and has toxicity is solved. The invention can realize the aims of saving energy and reducing consumption to the largest extent, and is suitable for purifying and treating domestic sewage continuously for a long time.

Owner:TSINGHUA UNIV

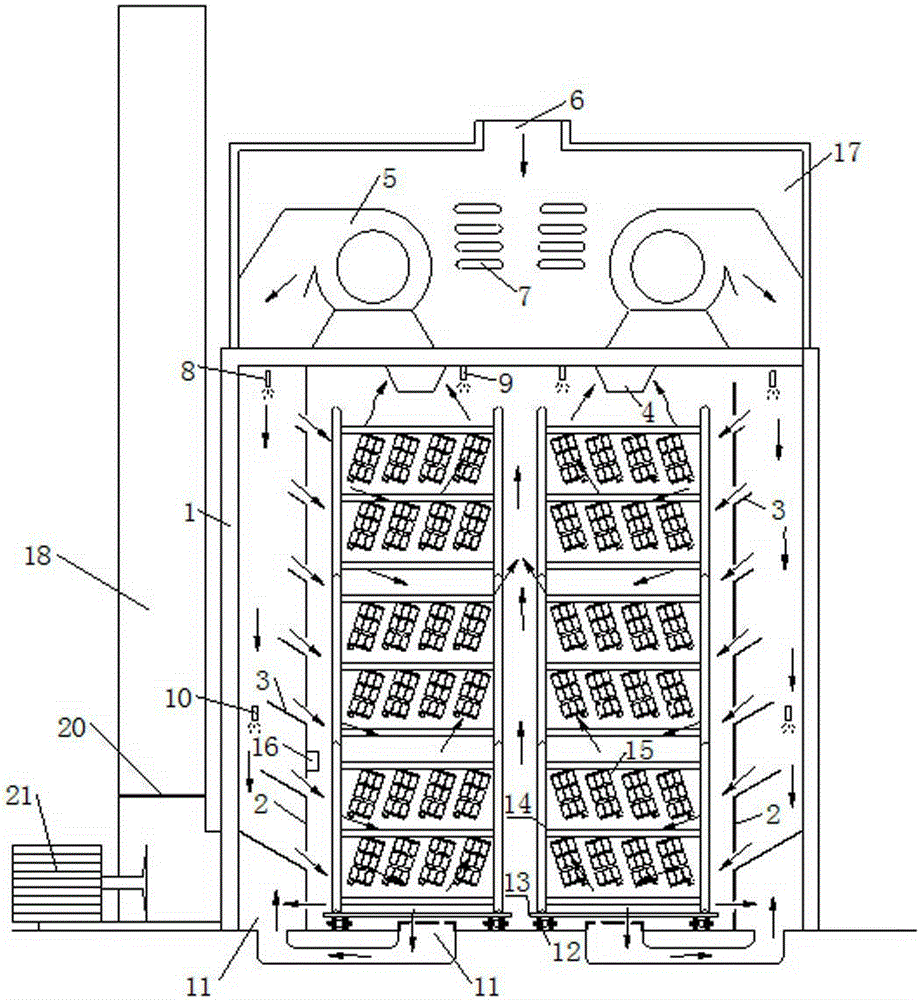

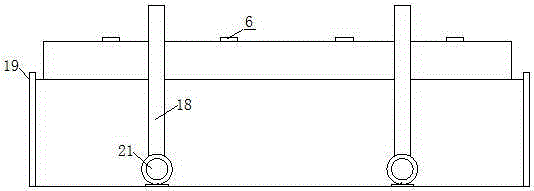

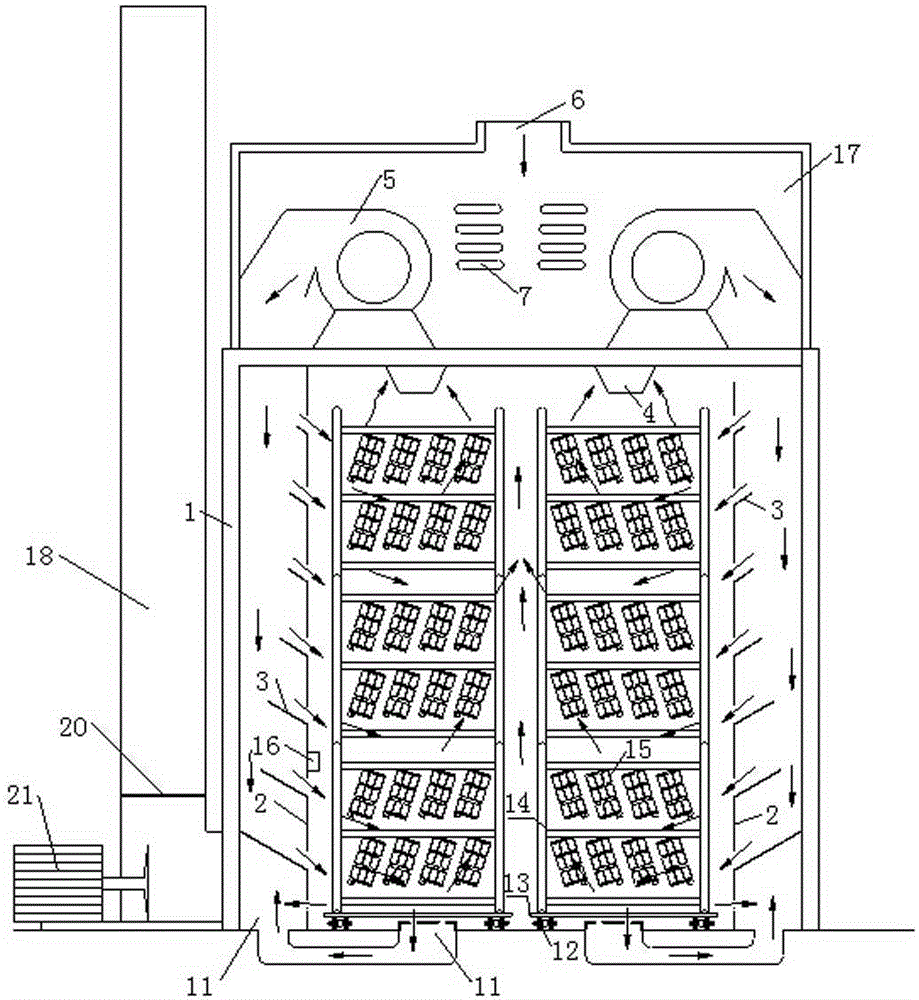

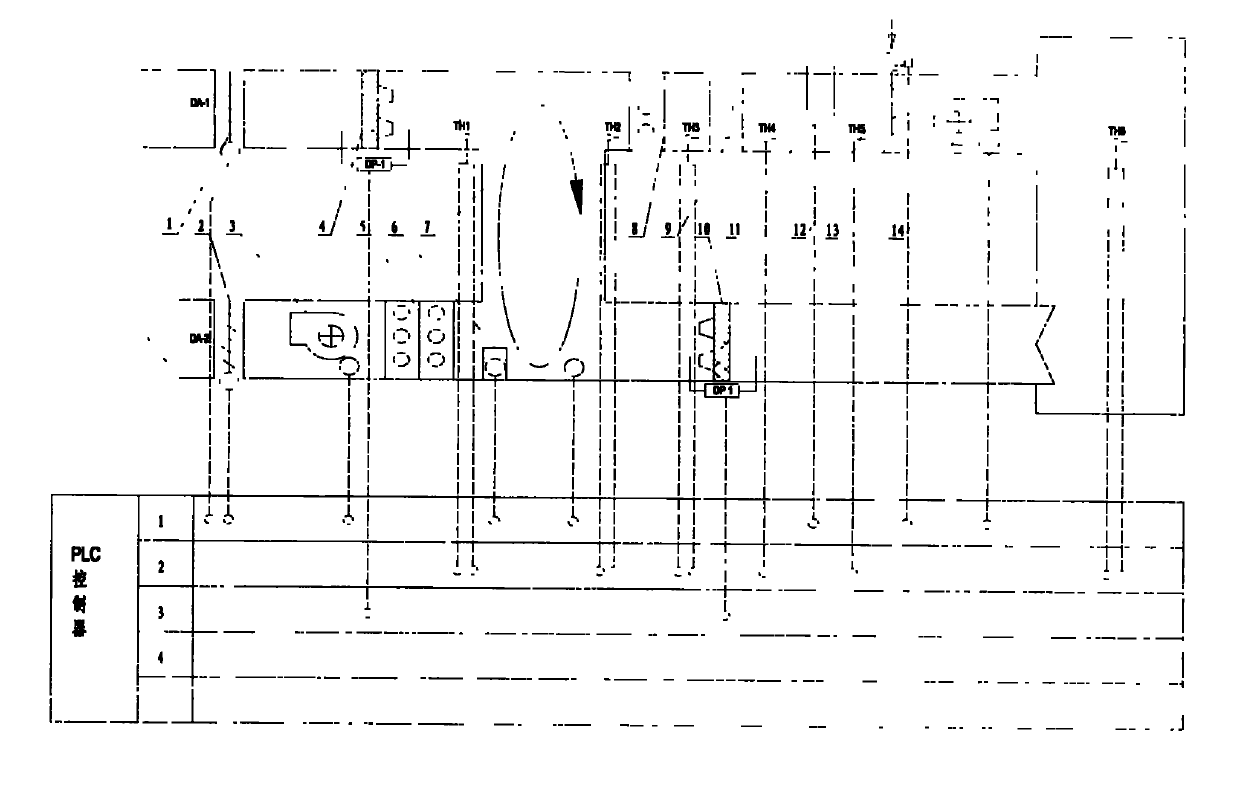

High-temperature curing chamber and curing technology for battery pole plates

ActiveCN105185950AUniform curingReduce varianceElectrode thermal treatmentProgrammable logic controllerEngineering

The invention discloses a high-temperature curing chamber for battery pole plates. The high-temperature curing chamber comprises a curing chamber and a drying chamber, wherein the curing chamber is divided into a primary chamber and an auxiliary chamber; wind distribution screens are arranged at the left side and the right side of the primary chamber; curing racks and a curing rack tray are arranged at the middle part of the primary chamber; wind shields are arranged on the wind distribution screens; steam humidifying sprinklers are arranged at the inner sides of the wind distribution screens; temperature and humidity sensors are arranged at the outer sides of the wind distribution screens; atomizing humidifying sprinklers, circulating air outlet pipes and plate-feeding atomizing humidifying sprinklers are arranged at the top of the curing chamber; circulating fans are arranged at the left side and the right side of the auxiliary chamber; an air intake door is arranged at the top of the auxiliary chamber; steam heating pipes are arranged at the middle part of the auxiliary chamber; and the atomizing humidifying sprinklers and the steam humidifying sprinklers are reduced from the curing chamber to form the drying chamber. Technological parameters of various stages are set through a programmable logic controller (PLC); the pole plates are fed into the curing chamber, and directly enter the rapid drying chamber after being cured; and the pole plates are cured after being dried in the rapid drying chamber. The curing chamber has the characteristics of curing uniformity, energy conservation and consumption reduction; according to the high-temperature curing technology, the curing time is shortened; the equipment utilization rate is increased; and meanwhile, the energy consumption is reduced.

Owner:江苏海宝新能源有限公司

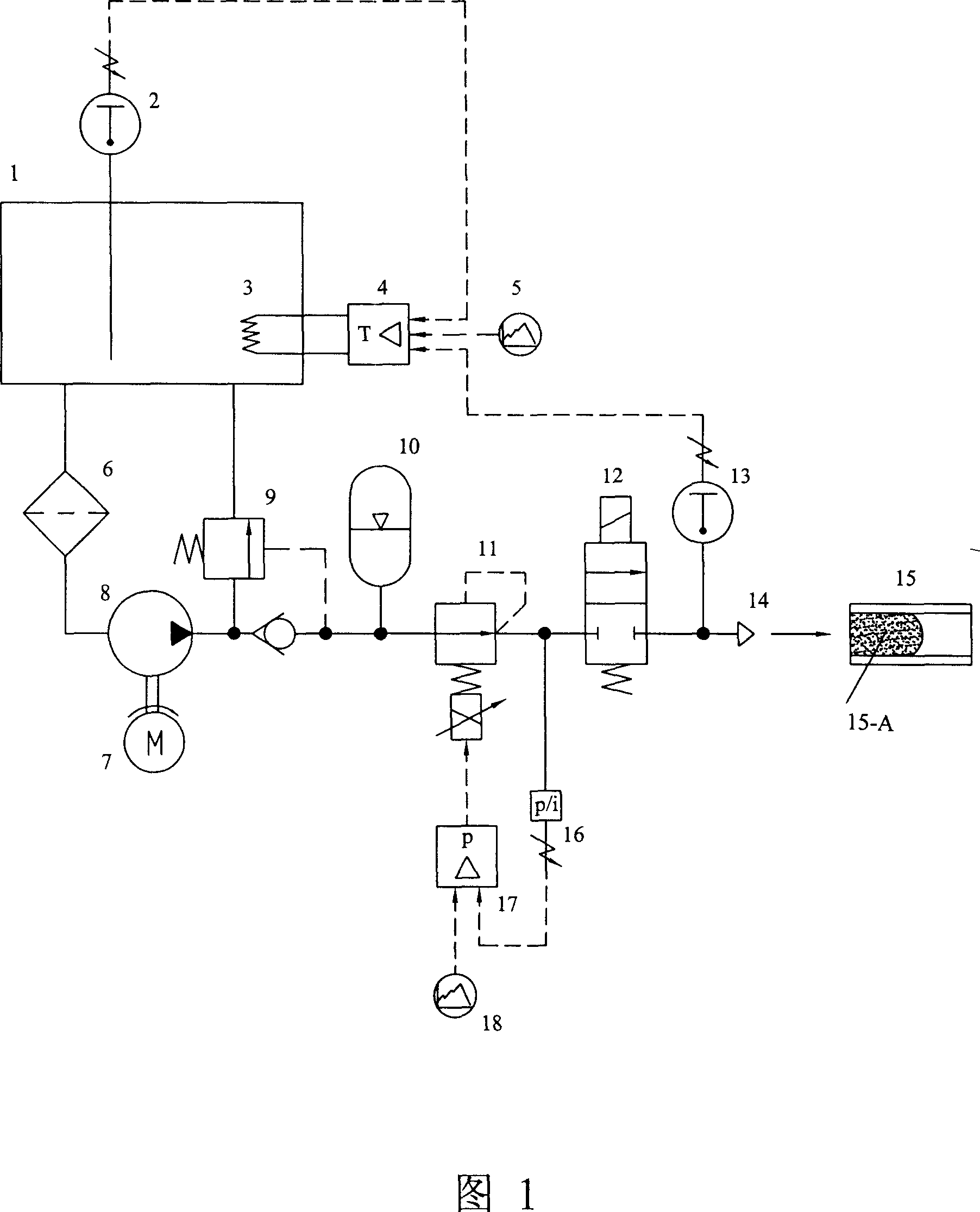

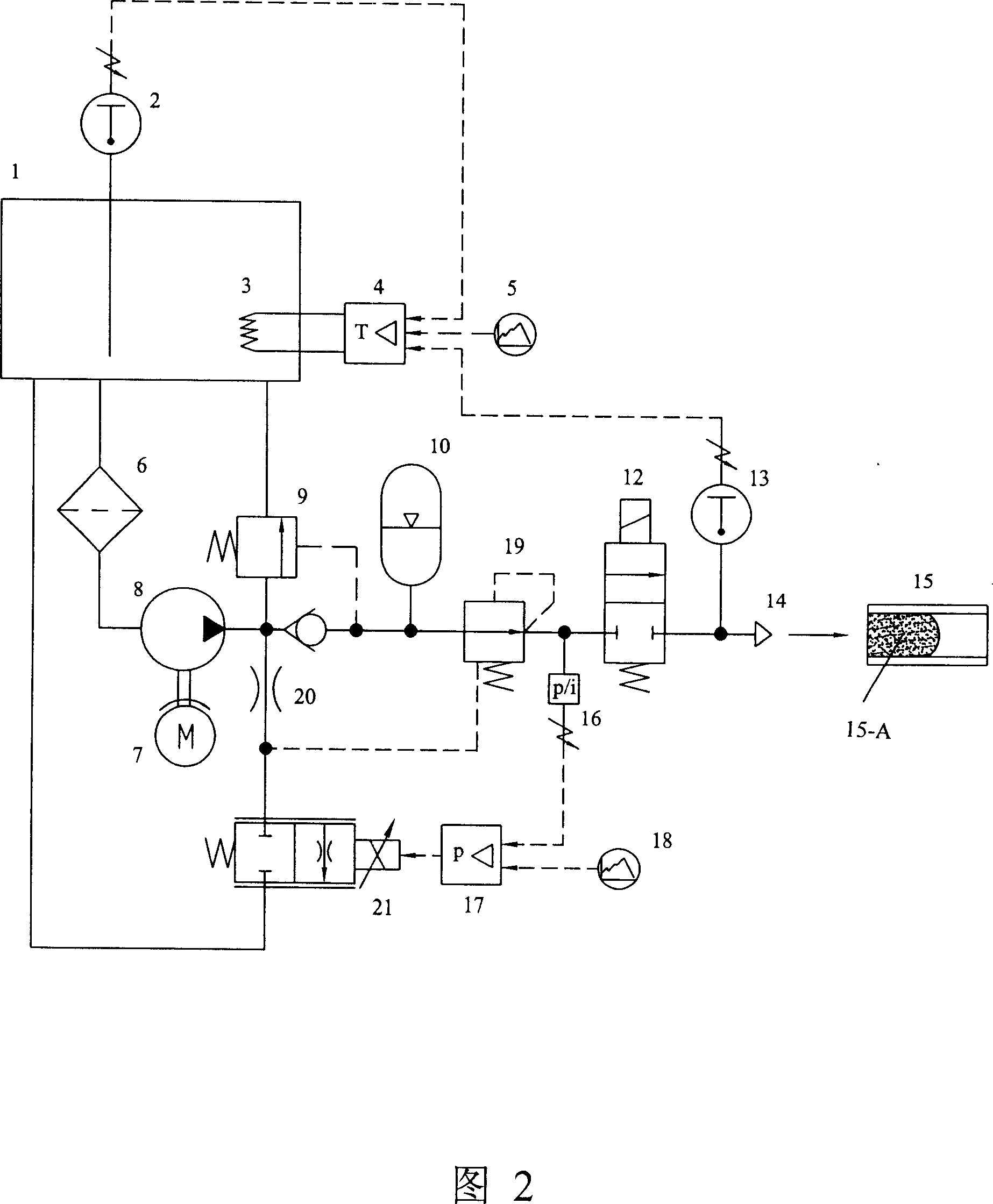

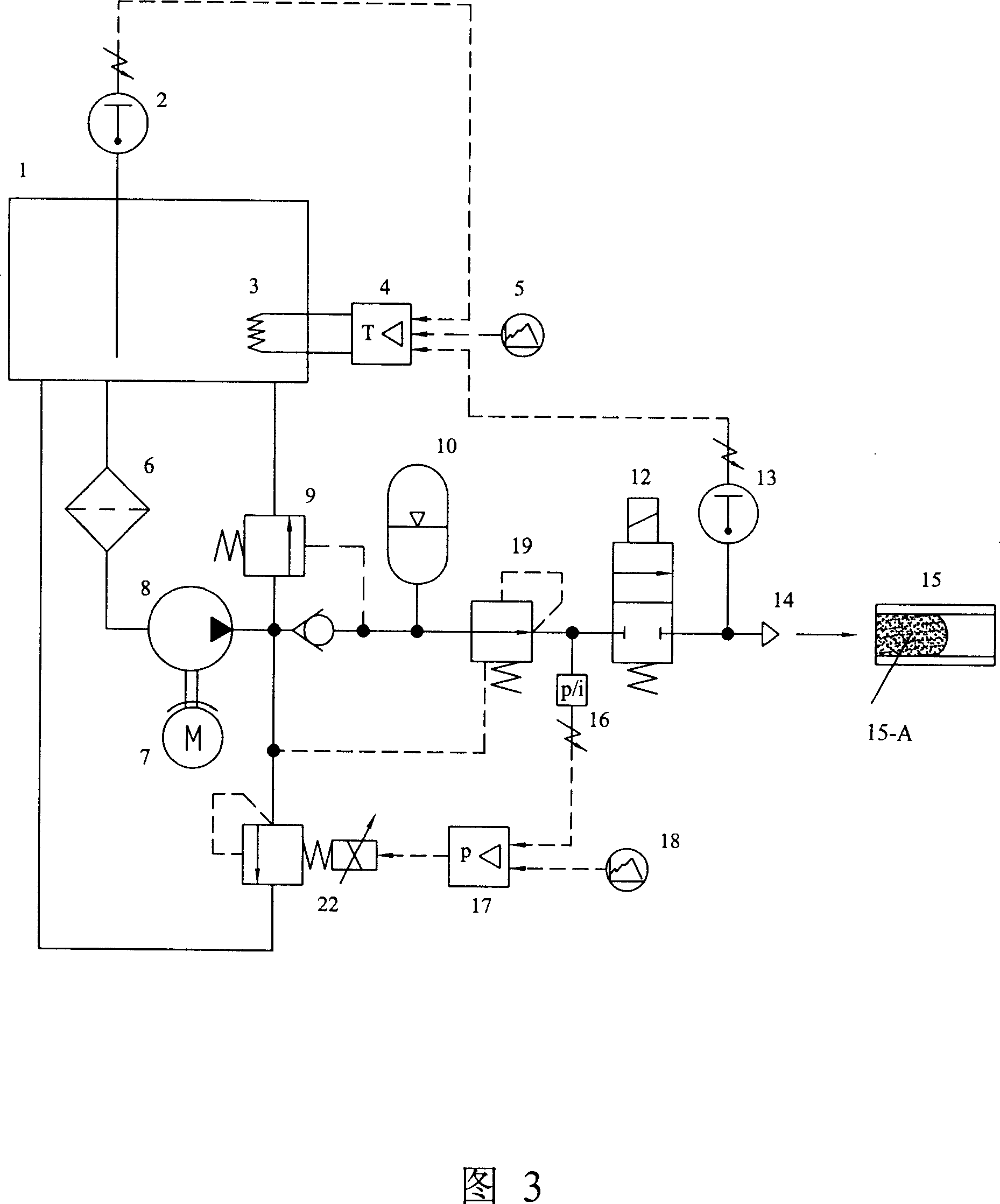

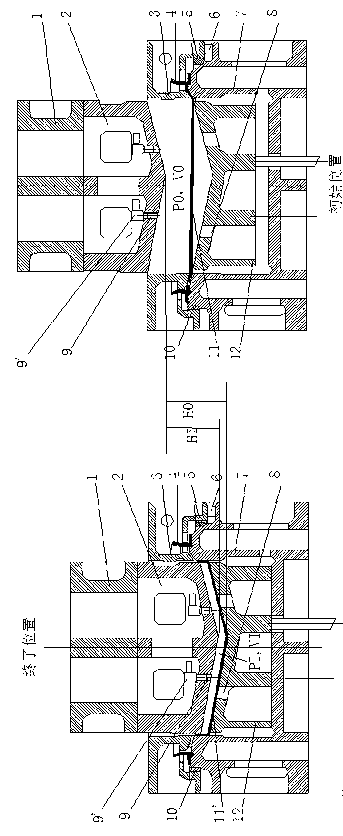

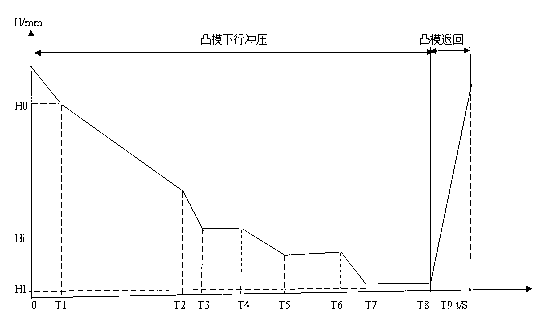

Water moulding water-fluid pressure ratio system

The present invention discloses a water auxiliary moulding water hydraulic proportion system. It is characterized by that in the outlet of water hydraulic pump driven by motor are successively connected a pressure control valve, a reversal valve and nozzle, between the pressure control valve and reversal valve a booster can be used for implementing pressurization, between the pressure control valve and water hydraulic pump an accumulator can be connected for saving energy, the pressure sensor can be used for feeding back the pressure to pressure controller so as to form closed-loop control, the pressure controller can be used for receiving injection pressure instruction signal given out by computer to control pressure control value and further control injection pressure, the temperature sensor can be used for feeding back the temperature of temperature-controlled water tank and the temperature of injection water to the water temperature controller, the water temperature controller can be used for controlling heater closed-loop to regulate water temperature, the temperature produced by water hydraulic proportion system and injection water controlled by pressure can be injected into the plastic melt in the mould cavity by means of nozzle so as to implement water auxiliary injection moulding of hollow plastic product.

Owner:ZHEJIANG UNIV

Method for recycling sodium hypochlorite purifying liquid used for purifying acetylene gas

ActiveCN101525264AAchieve recyclingReduce consumptionHydrocarbon purification/separationMultistage water/sewage treatmentWastewaterChiller

The invention discloses a method for recycling sodium hypochlorite purifying liquid used for purifying acetylene gas. Low-pressure steam heating is carried out on waste sodium hypochlorite liquid after being subjected to acetylene purifying technology, and the waste sodium hypochlorite liquid is sent into a steam-water separator to ensure that the acetylene gas dissolved in the waste sodium hypochlorite liquid volatilizes completely, and the acetylene gas is sent into an acetylene cooler to be cooled and dehydrated, so as to achieve the aim of recycling the acetylene gas. The waste sodium hypochlorite liquid after removing the acetylene gas is subjected to gas stripping and flocculent settling, and supernatant liquid is sent into a fresh sodium hypochlorite configuration pipeline, so as to realize the recycle of the waste sodium hypochlorite liquid. The technology recycles the acetylene gas from the waste sodium hypochlorite liquid to the utmost extent, thereby not only reducing the consumption of raw material calcium carbide, but also saving water greatly, as waste water does not contain the acetylene gas which has the explosive risk when meeting chlorine, so the waste water can be reused for configuring the fresh sodium hypochlorite. The invention has the technical effects of saving energy, reducing consumption, reducing emission and protecting environment.

Owner:内蒙古君正化工有限责任公司

A method of simultaneously measuring contents of Al, Cu, Mn, P and Si in ferrotitanium by utilizing an inductively coupled plasma emission spectrometer

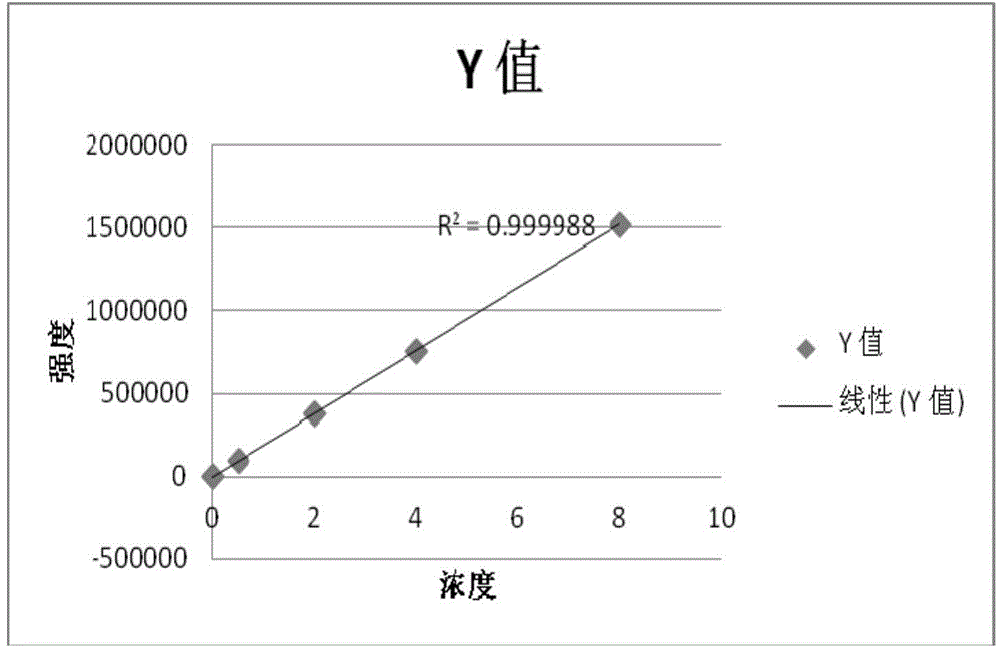

ActiveCN105699361AWith energy savingAvoid pollutionPreparing sample for investigationAnalysis by thermal excitationSubstrate compositionStandard samples

A method of simultaneously measuring contents of Al, Cu, Mn, P and Si in ferrotitanium by utilizing an inductively coupled plasma emission spectrometer is provided. The method includes (1) a step of preparing a test sample solution, (2) a step of selecting element spectral lines, namely a step of selecting the optimum spectral line of each element according to substrate composition of a test sample, (3) a step of mapping standard curves, namely a step of preparing standard solutions of the Al, the Cu, the Mn, the P and the Si, measuring emission light intensity of each element under the optimum spectral line by utilizing the inductively coupled plasma emission spectrometer, and mapping the standard curves, and (4) a step of detecting the test sample, namely a step of introducing the test sample solution to the inductively coupled plasma emission spectrometer through a feeding system, measuring emission light intensity corresponding to each element, and determining the content of each element according to a corresponding standard curve. The linear relations of the standard curves obtained by the method are good, measurement of contents of the elements is high in accuracy and precision, and the method can be used for analyzing standard samples and production test samples.

Owner:CHENGDE JIANLONG SPECIAL STEEL

Energy saving and emission reduction method for retanning and dyeing high-strength cow split leather furniture

ActiveCN101798605AReduce pollutionImprove labor productivity and product qualityTanning treatmentPre-tanning chemical treatmentChromiumDyeing

The invention relates to the field of leather production and discloses an energy saving and emission reduction method for retanning and dyeing high-strength cow split leather furniture. The method comprises the following steps of: conditioning; chromium retanning; neutralizing; retanning; dyeing and greasing; and obtaining a finished product by standing, wetly toggling, oscillating, stuffing leather, lightly wrestling and lightly toggling. The invention effectively overcomes the defects that the traditional Y-shaped drum is mainly applied to the dyeing process of leather with small area (not more than 1 square meter) and less load capacity (not more than 60 percent), can be applicable for retanning, dyeing and greasing a leather pelt with larger area (not less than 5 square meters) and high loading capacity (not less than 70 percent), and solves the technical problems that furniture leather has all-area tone and saturated uniformity when produced by retanning and dyeing cow leather, thereby being a leather producing technology with high efficiency and low pollution.

Owner:浙江通天星集团股份有限公司

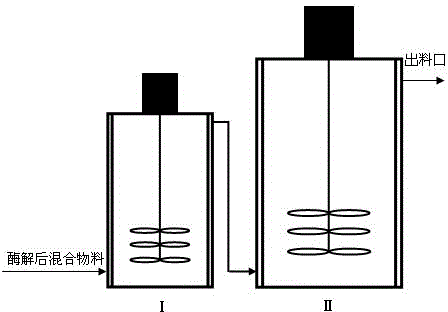

Method for producing ethanol by continuous enzymolysis and fermentation of lignocellulose

The invention relates to a method for producing ethanol by continuous enzymolysis and fermentation of lignocelluloses. The method comprises the following steps: (1) a pretreated lignocellulose raw material and an enzyme solution are added in proportion into an enzymolysis reactor with a screw device to carry out continuous enzymolysis; (2) the materials enter a fermentation tank I after enzymolysis, and microzyme is inoculated to carry out simultaneous saccharification and fermentation at 30-38 DEG C; (3) the materials in the fermentation tank I enter a fermentation tank II, and simultaneous saccharification and fermentation are continuously carried out at 39-44 DEG C; (4) the fermented materials undergo reduced pressure distillation; and (5) the distilled materials undergo solid-liquid separation, and an enzyme-containing liquid phase is reused in the step (1). By the use of the screw device, continuous supply and continuous enzymolysis of the raw materials are realized, and enzymolysis efficiency is enhanced. As simultaneous saccharification and fermentation are carried out at different temperatures, enzymolysis efficiency is further improved and yield of ethanol is then raised. The finally-obtained enzyme solution can be directly reused in the enzymolysis process, thus reducing production cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cold rolling oily wastewater treatment process

InactiveCN103408200AThe treatment effect is stableWide range of adaptationGeneral water supply conservationWaste water treatment from metallurgical processInlet temperatureSystematic process

The invention discloses a cold rolling oily wastewater treatment process, which comprises the following steps of: (1), pretreating thick-oil wastewater sequentially by filtering of an oil separation tank and a paper tape and ultra-filtration process of a ceramic membrane, and pre-treating thin-oil wastewater sequentially by adopting the oil separation tank, a CAF (Cavitation Air Flotation) process and a DAF (Dissolved Air Flotation) process; (2), mixing pre-treated thick-oil wastewater with the pre-treated thin-oil wastewater, carrying out biochemical treatment by adopting an electrochemical catalytic oxidation process and an MBR (Membrane Biological Reactor) process in sequence, controlling the water inlet temperature of the MBR process to be 20-35 DEG C, controlling the water inlet pH value to be 7-9, and adding oil-munching high-efficiency micro-organism complex microbial inoculants and MPE (Metallocene Polyethylene) into an MBR membrane tank; and (3), filtering outlet water (treated through the MBR process) by using a reverse osmosis membrane, and carrying out deep desalination treatment so that outlet water reaches emission or industrial production reuse water standard. The invention provides a set of systematic process specially aiming at treatment and reuse of cold rolling oily wastewater in steel mills; the COD (Chemical Oxygen Demand) of treated outlet water is less than 10mg / L; the electrical conductivity of treated outlet water is less than 50mu s / cm; and oil and suspended solids are nearly eliminated completely.

Owner:WUHAN IRON & STEEL (GROUP) CORP +1

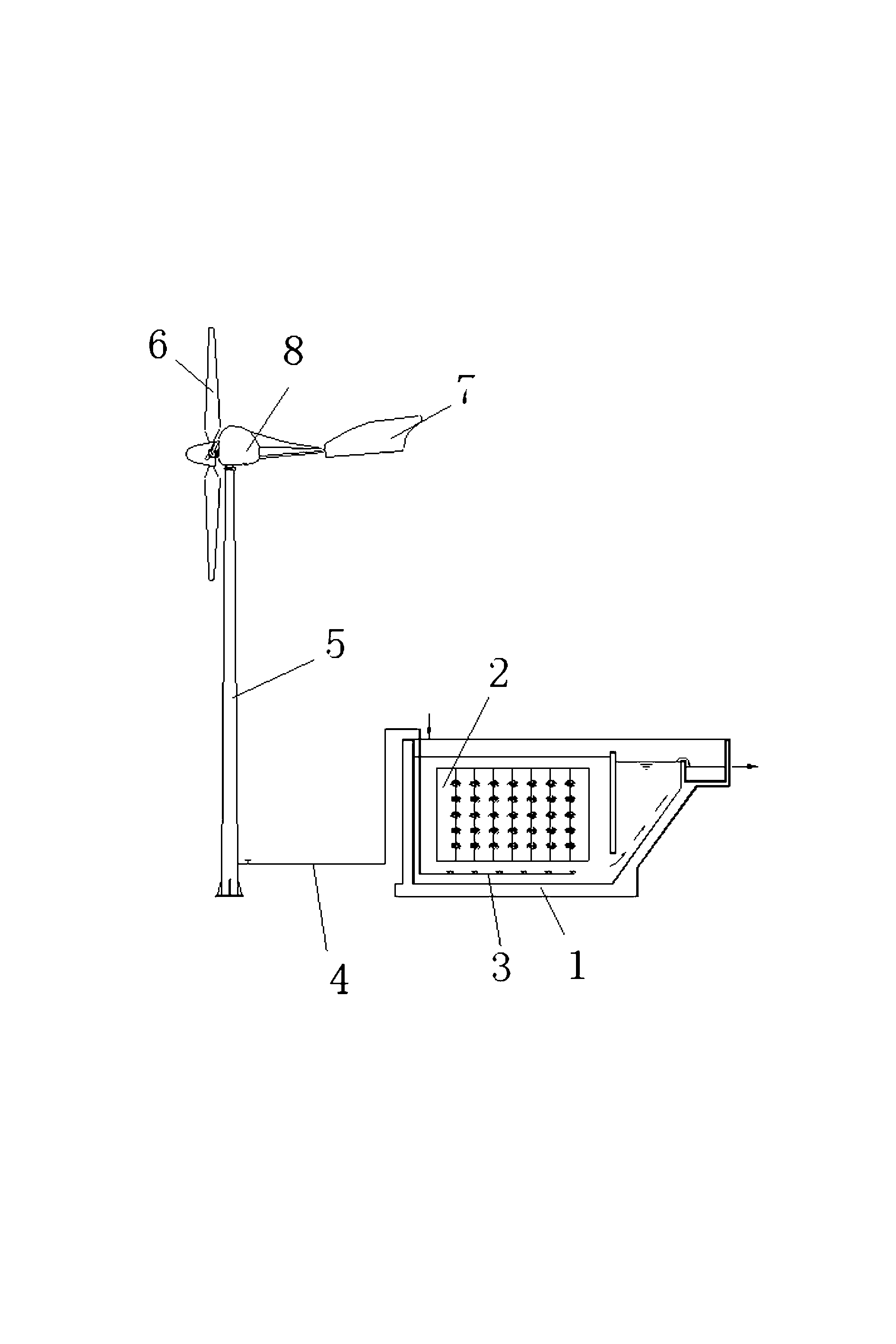

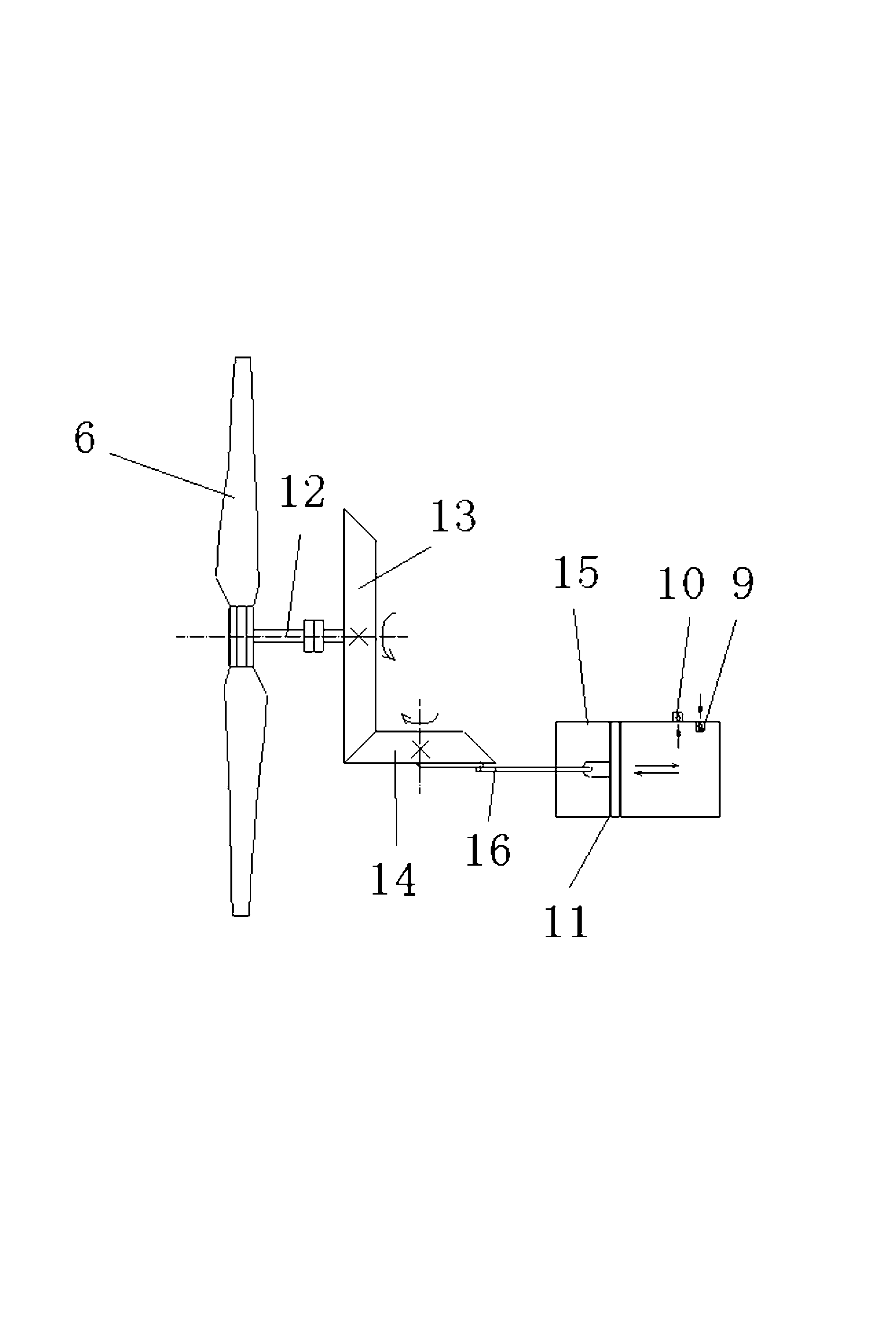

Wind-energy oxygen supply type countryside life sewage processing device and method

ActiveCN103130320AReduce lossesLarge air supplyTreatment using aerobic processesEnergy based wastewater treatmentMembrane methodSmall footprint

The invention provides a wind-energy oxygen supply type countryside life sewage processing device. The device is characterized in that a contacting oxidation pond comprises a pond body, a padding layer is arranged in the pond body, and a micro-hole aerator is arranged below the padding layer and is connected with a wind-energy oxygen supply machine through an air pipeline. According to the device, wind-energy oxygen supply technology and sewage biology membrane method processing technology are utilized, wind-energy oxygen supply type countryside sewage processing technology is developed, a corresponding device is constructed and is used for countryside life sewage processing, and therefore the improvement of the countryside ecology environment is provided with economic and effective technology support. The device gives full play to no energy consumption characteristic of the wind-energy oxygen supply technology and easy management of the biology membrane method processing technology, realizes organic integration of the energy saving and consumption reducing technology and pollution emission reduction technology, has the advantages of being free of power consumption, high in processing efficiency, convenient to manage, simple in operation, small in occupied area, and the like, and meeting requirements of countryside life for processing sewage.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

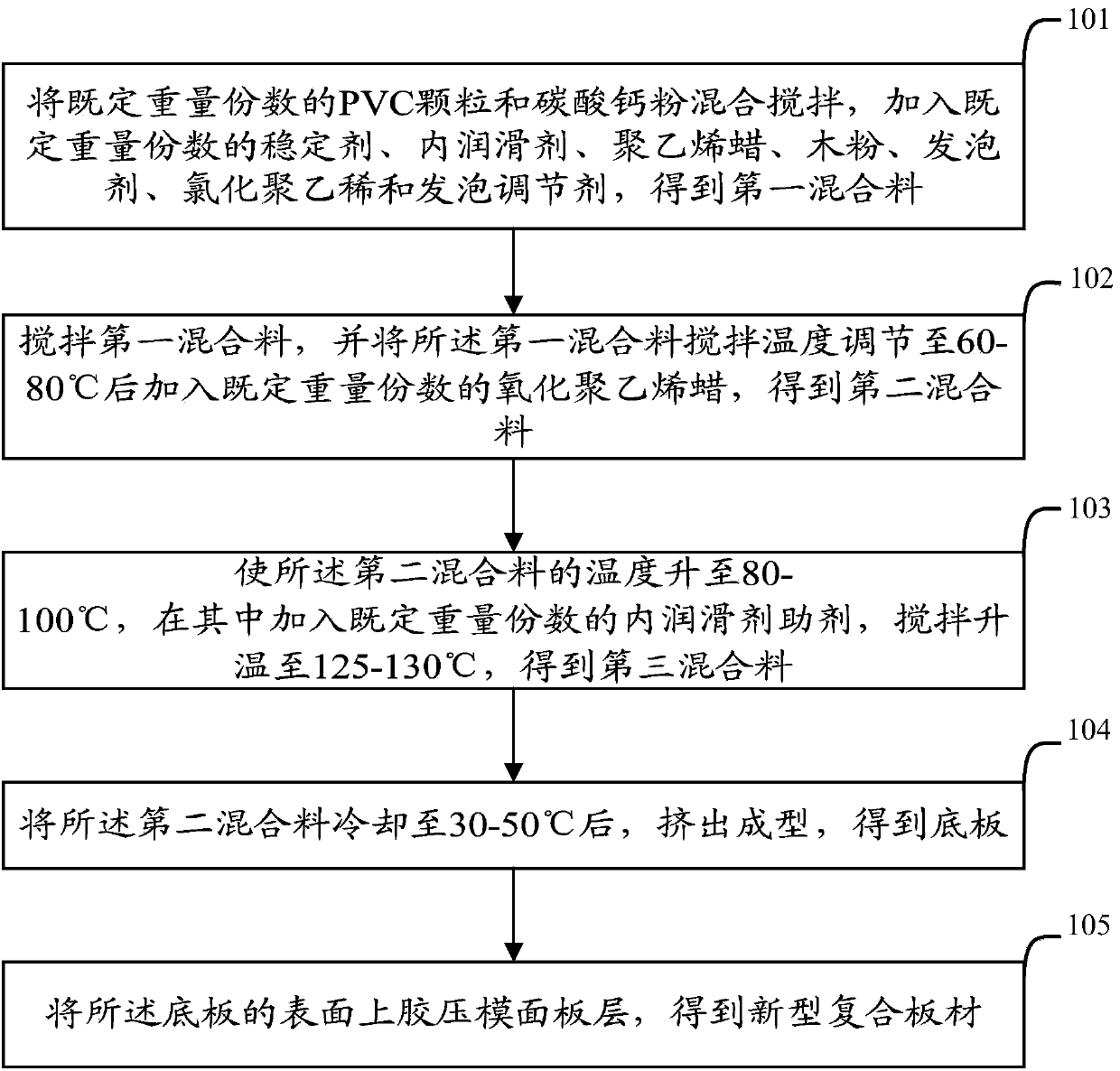

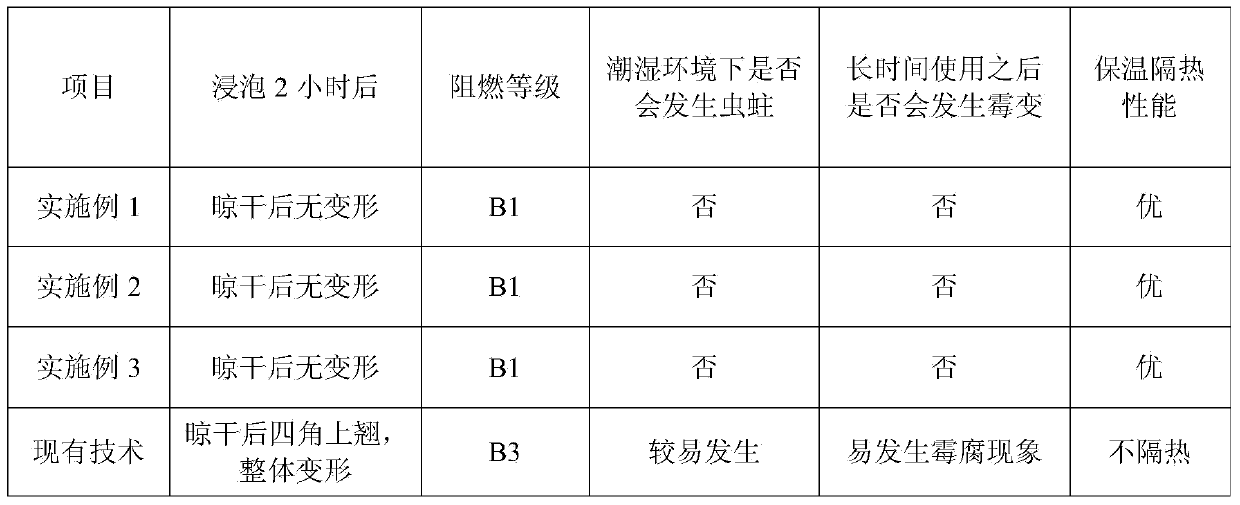

Novel composite board and preparation method thereof

ActiveCN104175660ASave resourcesRaw material environmental protectionSynthetic resin layered productsWood layered productsWaxFoaming agent

The invention relates to the field of building boards and in particular relates to a novel composite board and a preparation method thereof. The novel composite board comprises a bottom board and a panel layer which is stuck on the bottom board, wherein the bottom board comprises the following raw materials in parts by weight: 90-110 parts of PVC particles, 40-60 parts of calcium carbonate powder, 3-6 parts of a stabilizer, 1.0-1.4 parts of a foaming agent, 6-8 parts of a foaming regulator, 0.3-0.5 part of polyethylene wax, 0.3-0.4 part of internal lubricant, 0.2-0.4 part of oxidized polyethylene wax, 4-6 parts of chlorinated polyethylene, 0.5-1.5 parts of an internal lubricant additive and 9-11 parts of wood powder. The novel composite board has the good waterproof and damp-proof effects and solves the problem that common boards in the prior art are soaked by water so as to seriously deform. The novel composite board also has the recycling characteristic and solves the technical problem that a large amount of wood needs to be consumed in wooded boards in the prior art.

Owner:朱青海

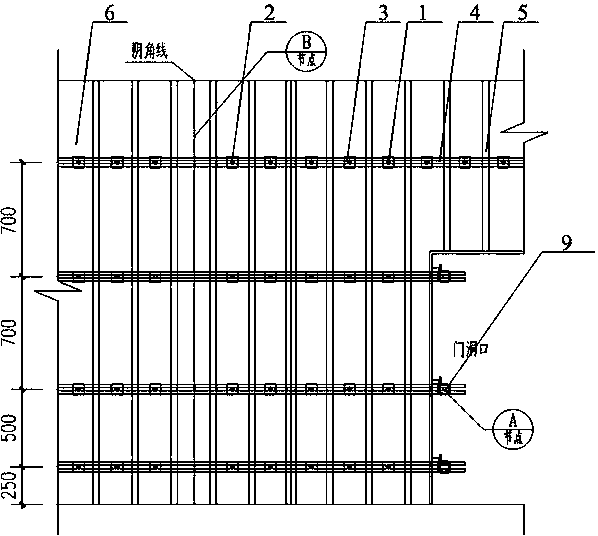

Steel-wood combined formwork and construction method

ActiveCN104032948AImprove performanceFlexible operationForms/shuttering/falseworksBuilding material handlingEngineeringMechanical engineering

The invention discloses a steel-wood combined formwork, and belongs to the field of building construction. The steel-wood combined formwork comprises a wood formwork, square steel auxiliary back edges, double-square-steel main back edges and fixing and connecting devices. A plurality of openings allowing the fixing and connecting devices to penetrate through are formed in the wood formwork. The square steel auxiliary back edges are fixedly connected to the outer side of the wood formwork. The double-square-steel main back edges are arranged outside the square steel auxiliary back edges. Each double-square-steel main back edge is formed by welding two pieces of square steel, wherein a gap allowing the corresponding fixing and connecting device to penetrate through is arranged between the two pieces of square steel. The double-square-steel main back edges, the square steel auxiliary back edges and the wood formwork are integrally connected and fixed through the fixing and connecting devices. The invention further discloses a construction method of the steel-wood combined formwork. The square steel serves as the main back edges and the auxiliary back edges, special locks are arranged on the joint portions such as exposed corners and holes, the square steel is combined with the wood formwork to form the system of the steel-wood combined formwork, and therefore rigidity and overall stable performance of the combined formwork are enhanced, the smoothness of a wall is improved, construction is easy, convenient and rapid, energy is greatly saved, and cost is reduced.

Owner:龙信集团江苏建筑产业有限公司

Multifunctional plastic additive and preparation method thereof

The invention relates to the field of plastic processing and in particular relates to a multifunctional plastic additive and a preparation method thereof. The multifunctional plastic additive comprises the following components in parts by weight: 70-89 parts of light calcium carbonate powder, 10-15 parts of stearate, 1.0-1.8 parts of mica powder, 3-5 parts of light magnesium oxide powder, 1-2 parts of organic tin, 2-3 parts of glass fiber powder, 1-2 parts of methacrylate, 1.0-1.5 parts of a coupler and 2-4 parts of a lubricant. The preparation method comprises the following steps: pre-modifying the light calcium carbonate powder by stearate, mixing the pre-modified light calcium carbonate powder, the mica powder, the light magnesium oxide powder and the glass fiber powder at a low speed, adding other formulation components, producing a high-temperature and low-speed stirring reaction, and discharging to obtain the multifunctional plastic additive. The preparation process is simple, and the prepared plastic additive can be used for improving the tensile strength, the strength, the pressure resistance and the like of a PVC (polyvinyl chloride) wood plastic composite material and a PVC engineering plastic.

Owner:汕头市亨德利塑胶有限公司

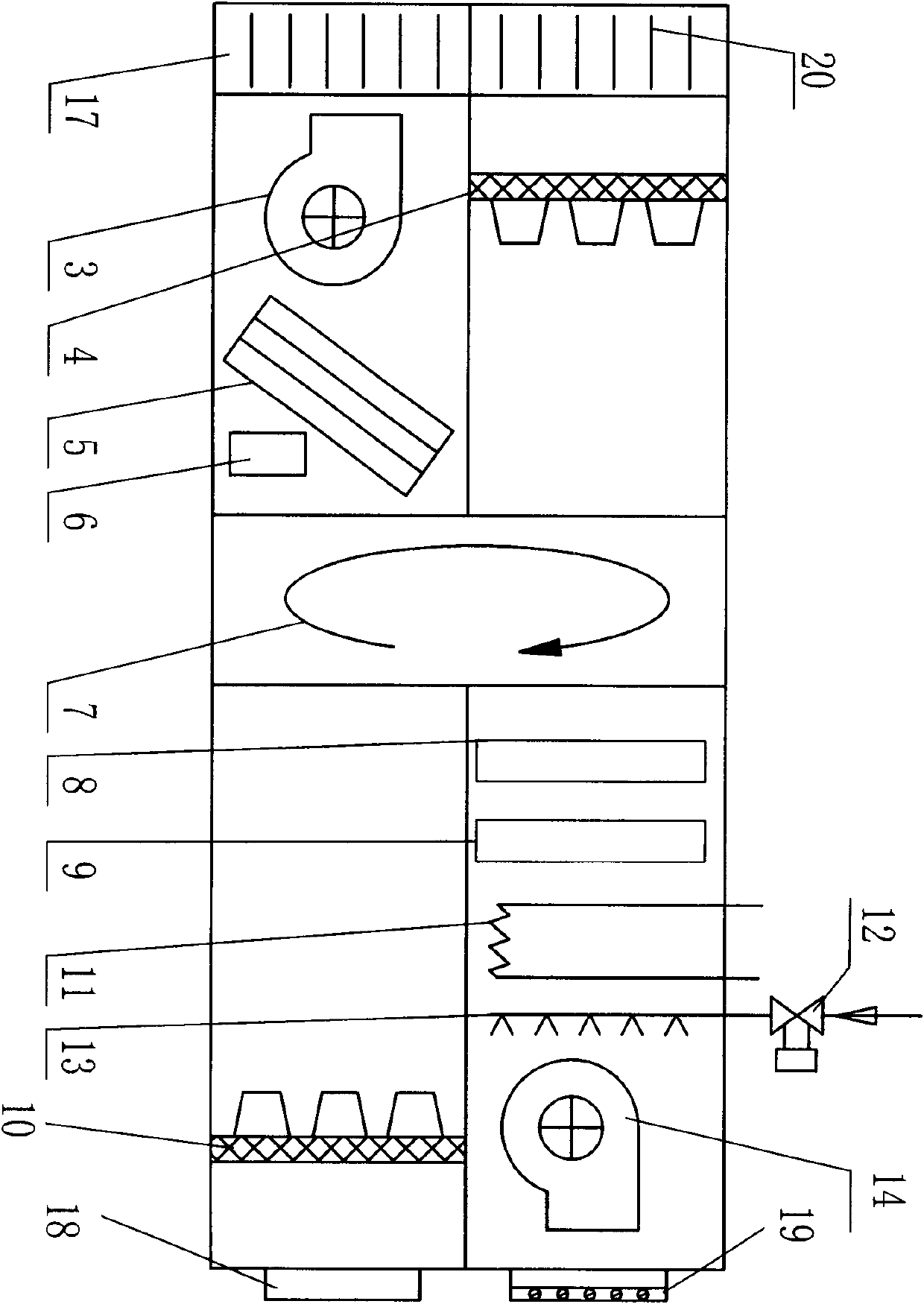

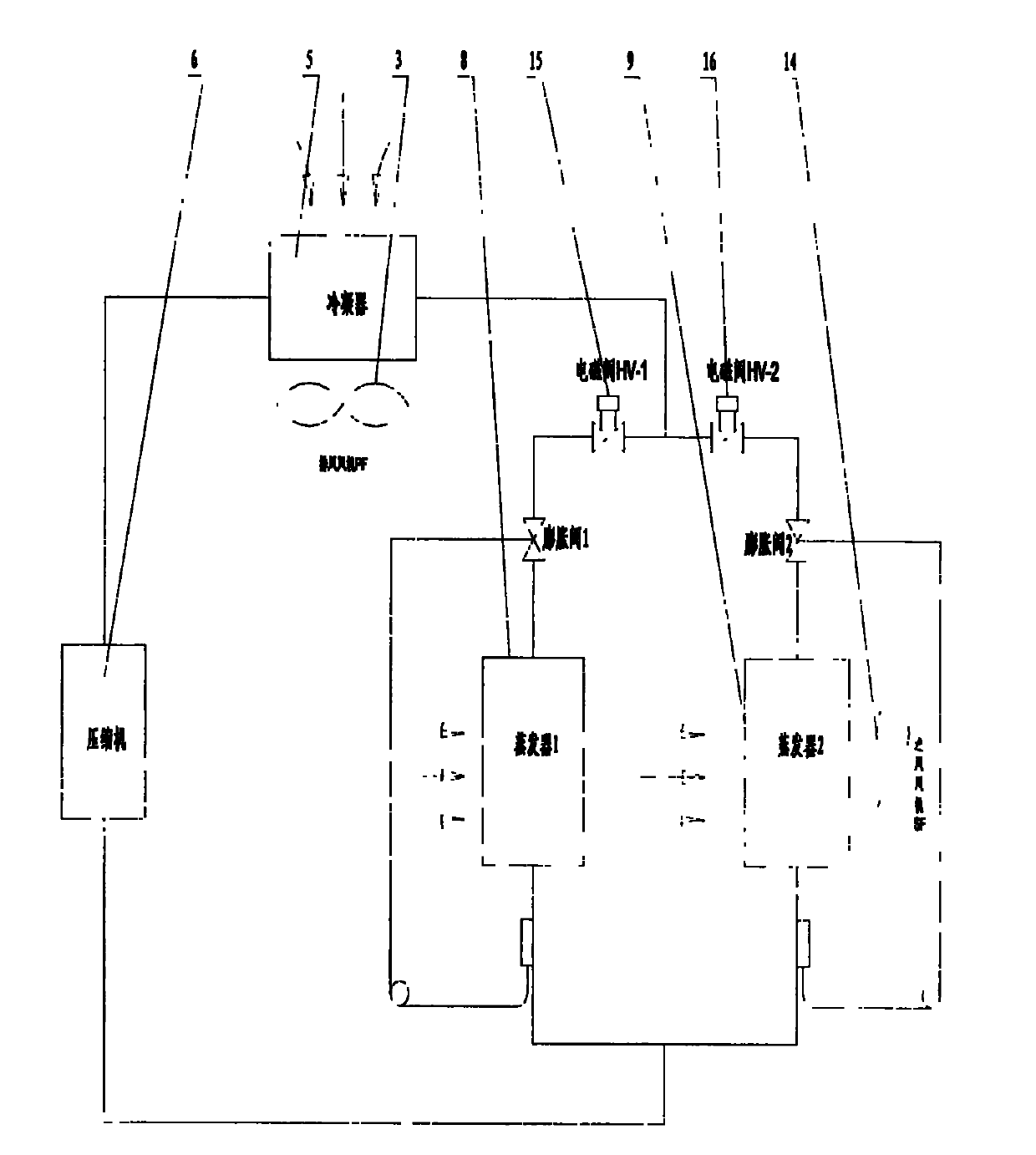

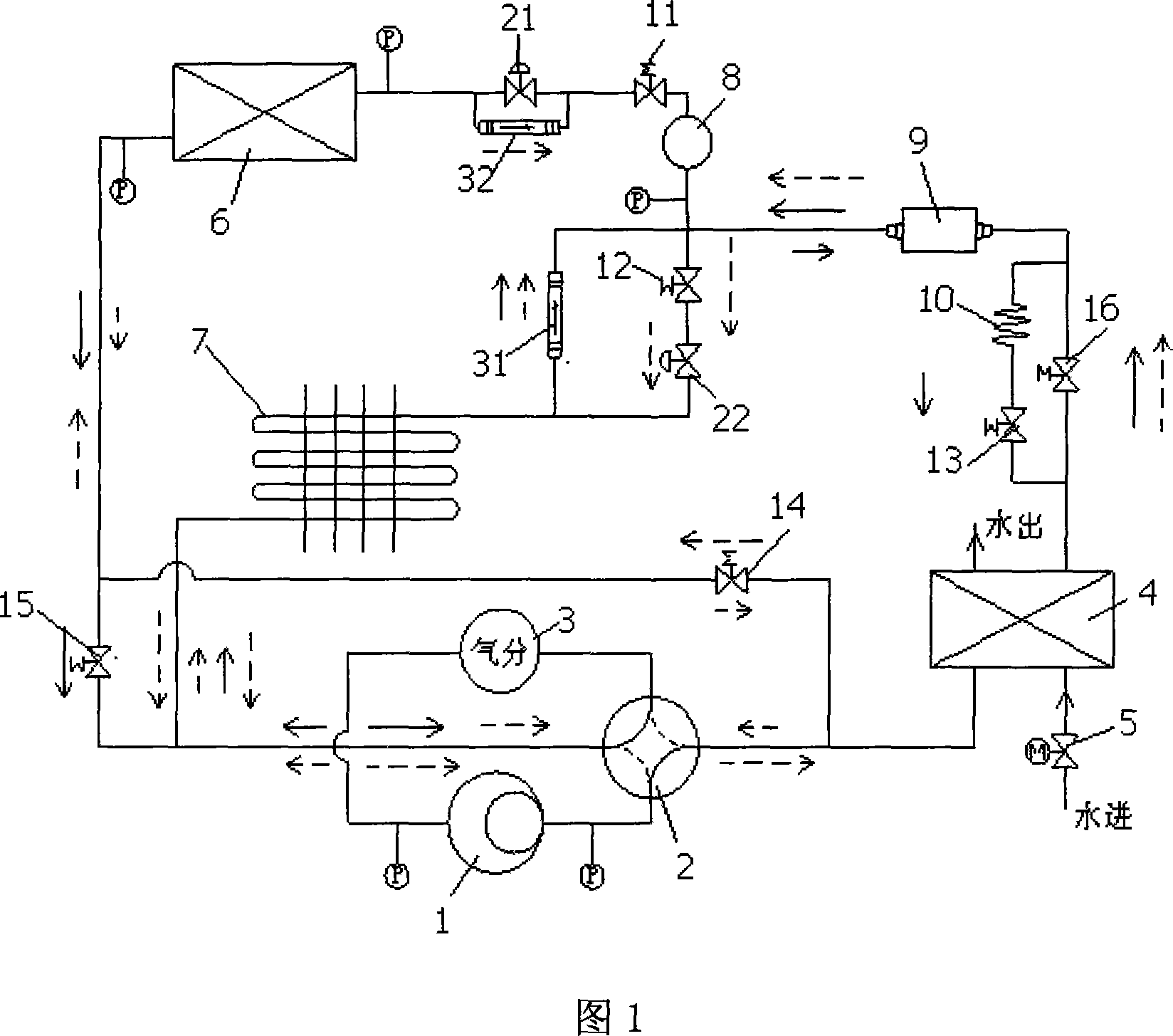

All-in-one machine for constant temperature and humidity and air processing

InactiveCN102003752AWith energy savingSmall footprintSpace heating and ventilation safety systemsLighting and heating apparatusAutomatic controlProgrammable logic controller

The invention discloses an all-in-one machine for constant temperature and humidity and air processing, wherein an exhaust fan (3) is not only the exhaust fan of a machine set but also a condensate fan of a system; an air supply fan (14) is not only the air supply fan of the machine set but also the air supply fan of an evaporator of a refrigerating / heating system. In the machine, the energy in the exhaust air is firstly exchanged with the energy in the supply air through a rotary wheel complete heat type recycling device (7); then the exchange of secondary energy is carried out on the exhaust air and the refrigerating / heating system through a condenser (5); the evaporator 1 or 8 and the evaporator 2 or 9 further process the supply air; and the supply air is precisely controlled through comprehensive calculation of a heater (11), a humidifier (13) and a PLC (Programmable Logic Controller) controller, therefore, the constant temperature and humidity of the supply air are realized. The machine set integrates the recycling of the energy in the exhaust air twice, the preprocessing and the precise processing of the temperature and the humidity of the air supply and full-automatic PLC control function into a whole, has the characteristics of energy saving and environmental protection, and is simple and convenient for operation, installation and maintenance.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

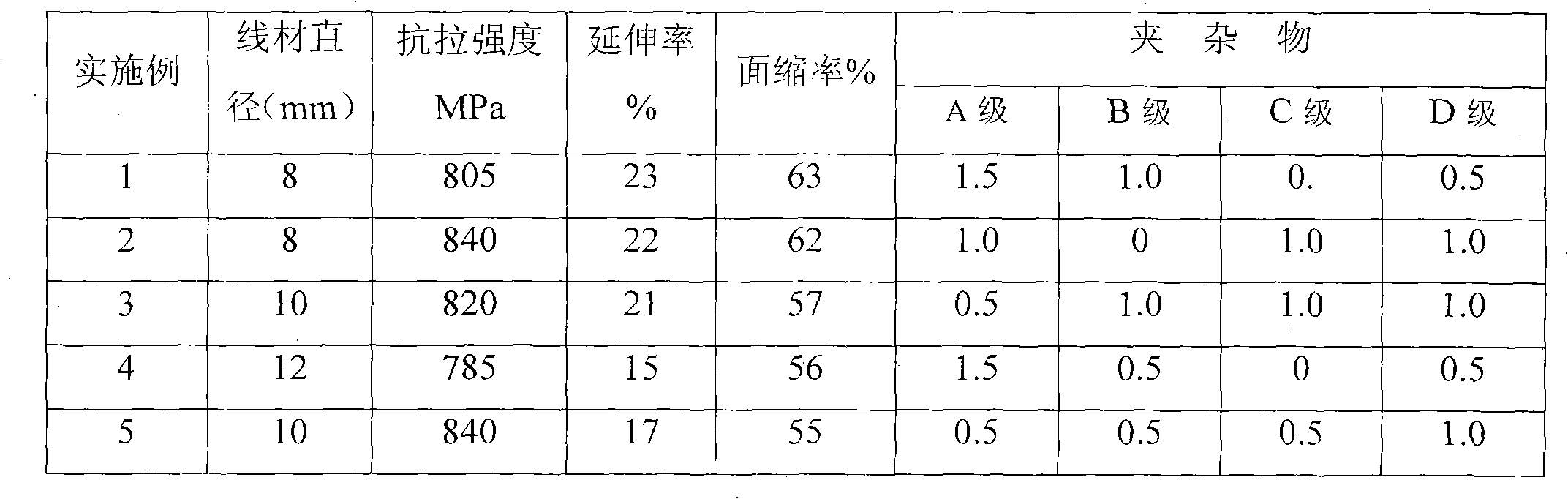

Drahtstahl for high strength fastening piece and production method thereof

InactiveCN101787491AWith energy savingReduce manufacturing costMetal rolling arrangementsWire rodHigh intensity

The invention relates to a drahtstahl for a fastening piece and a production method thereof, and the drahtstahl comprises the following components by weight percent: 0.39-0.48 % of C, 0.15-0.35% of Si, 0.30-0.90% of Mn, 0.60-1.20% of Cr, 0.010-0.07% of Als, less than or equal to 0.035% of P, less than or equal to 0.035% of S and the balance Fe and unavoidable impurity; and the production method comprises the following steps: smelting with a clean steel process and casting into a blank, and adding Si-Ca line in the refining; heating the continuous casting to 980-1,080 DEG C; rough rolling: controlling the deflection to be 70-80%; intermediate rolling: controlling the deflection to be 80-90%; pre-precision rolling: controlling the deflection to be 65-75%; water-cooling until the temperature is cooled to be 1,000-1,020 DEG C; precision rolling: controlling the deflection to be 60-90%; water-cooling for the second time until the temperature is cooled to be 800-900 DEG C; spinning; cooling to phase change initial temperature, namely the range from Ar3 to 50 DEG C higher than Ar3 by adopting an aerial fog mixed method; and continually cooling until the temperature is cooled to be 400-500 DEG C and naturally cooling to environment temperature. The invention can be drawn directly, has good cold deformation and is not easy to crack.

Owner:武钢集团有限公司

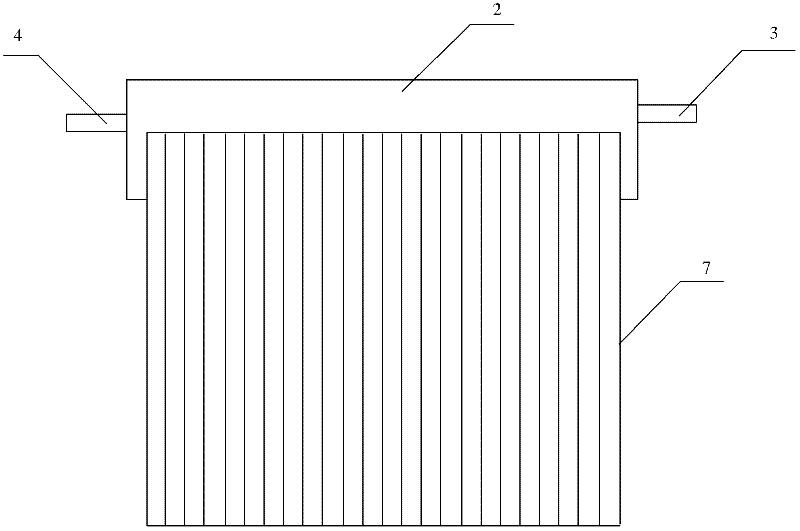

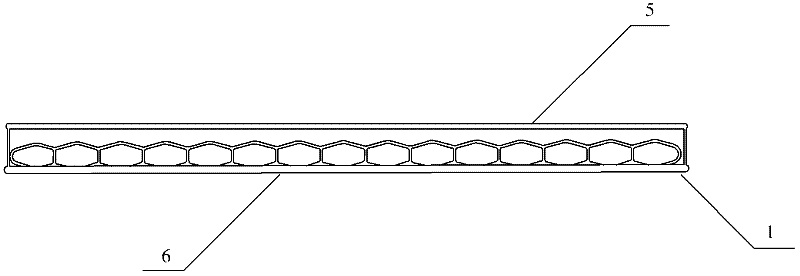

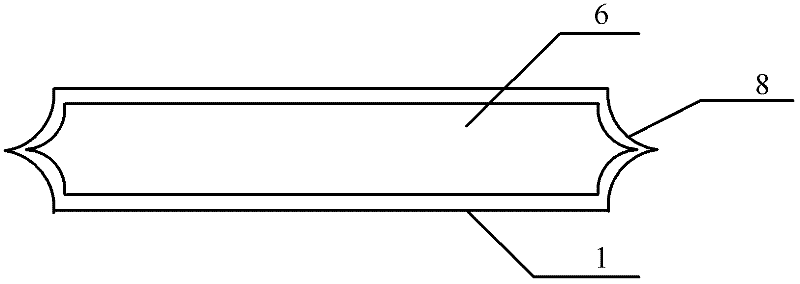

Platy heat pipe and processing technology thereof

InactiveCN102506597AImprove structural strengthWith ultra-thinSolar heating energyIndirect heat exchangersTrunk structureEngineering

The invention provides a platy heat pipe, comprising a platy heat pipe frame, wherein the platy heat pipe frame is internally provided with a microporous pipe trunk structure which is formed by a group of microporous pipes, side walls of the microporous pipes are connected to mutually enhance the strength of each microporous pipe, each microporous pipe is filled with a working medium with a phase inversion heat exchange effect, two ends of the platy heat pipe are sealed, and at least one end is provided with a gradually contractive sealing belt formed by cold welding. The platy heat pipe provided by the invention has the characteristics of high strength, super thinness, high efficiency and high heat transportation volume and can substitute an oscillation heat pipe and a common heat pipe.

Owner:赵耀华

Covering part forming mold and design and use method thereof

InactiveCN102794363ALow costShorten the design cycleShaping toolsEngineering plasticPressure controlled ventilation

The invention provides a covering part forming mold and a design and use method thereof, and relates to the field of soft molds. The covering part forming mold comprises a convex mold seat and a convex mold arranged on the convex mold seat, and also comprises a concave mold, wherein the opening part of the concave mold is provided with a stopping block; the concave mold is internally provided with a jacking plate and a concave mold ventilating hole; the mold also comprises a pressing ring; the convex mold is provided with a convex mold ventilating hole; and the position of the convex mold ventilating hole, which is communicated with the atmosphere, is provided with a one-way pressure control valve which is closed when in stamping. The covering-part forming mold provided by the invention has the advantages that the design with the convex-mold structure is adopted, the manufacture is simple, the generality is strong, the service life is greatly prolonged, and the mold is made of engineering plastic. A manufactured covering part is high in accuracy, low in cost and short in manufacturing period. The method for forming the covering part is high in accuracy and low in cost.

Owner:HUAIHAI INST OF TECH

Easily-degradable alkali-free viscosity reducer for thick oil and preparation method thereof

ActiveCN102732241AEasy to degradeImprove surface activityFluid removalPipeline systemsAlkali freeReducer

The invention relates to an easily-degradable alkali-free viscosity reducer for thick oil and a preparation method thereof. The viscosity reducer consists of propylene glycol block polyether, fatty alcohol ammonium sulfate, fatty alcohol, a penetrating agent and water; and in terms of the total mass of the viscosity reducer, the sum of mass percent of propylene glycol block polyether, fatty alcohol ammonium sulfate, fatty alcohol and the penetrating agent is 45 to 60 wt%. The invention also provides the preparation method for the viscosity reducer, and the method comprises the following steps: successively adding propylene glycol block polyether, fatty alcohol ammonium sulfate, fatty alcohol and the penetrating agent into water at a temperature of 50 to 80 DEG C under normal pressure, wherein a mass ratio of the four above-mentioned raw materials to water is 15: 15: 5: 10: 55 to 25: 25: 4: 6: 40; and carrying out continuous stirring for 60 to 90 min at a rotating speed of 60 to 120 r / min while adding the four raw materials so as to obtain the easily-degradable alkali-free viscosity reducer for thick oil. Surfactant used in the viscosity reducer is nonionic and anionic surfactant, the structure of benzene rings is not included in a molecule, and therefore, the characteristics of easy degradability, no toxicity, greenness and environment friendliness are obtained.

Owner:PETROCHINA CO LTD

Low-cost self-leveling mortar

The invention discloses a low-cost self-leveling mortar. The low-cost self-leveling mortar comprises the following components in proportions: 22-35% of quartz sand, 20-40% of modified fluorine gypsum, 18-25% of silicate cement, 4-18% of aluminate cement, 3-8% of zeolite powder, 4-8% of wollastonite powder, 8-18% of rapid hardening cement, 0.05-1.5% of de-foaming agent, 0.05-1% of water reducing agent, 0.05-0.3% of retarder, 0.01-2% of leveling agent, 0.1-2% of lignocelluloses, 0.1-2% of hydroxyethylcellulose, 0.1-2% of methylcellulose, 1-6% of casein and 0.02-0.06% of lithium carbonate. The low-cost self-leveling mortar has the advantages of high leveling property, wear resistance, stability, breaking strength and the like, good quality, high efficiency, low cost and helpfulness for energy saving, consumption reduction and environment improvement.

Owner:徐敏

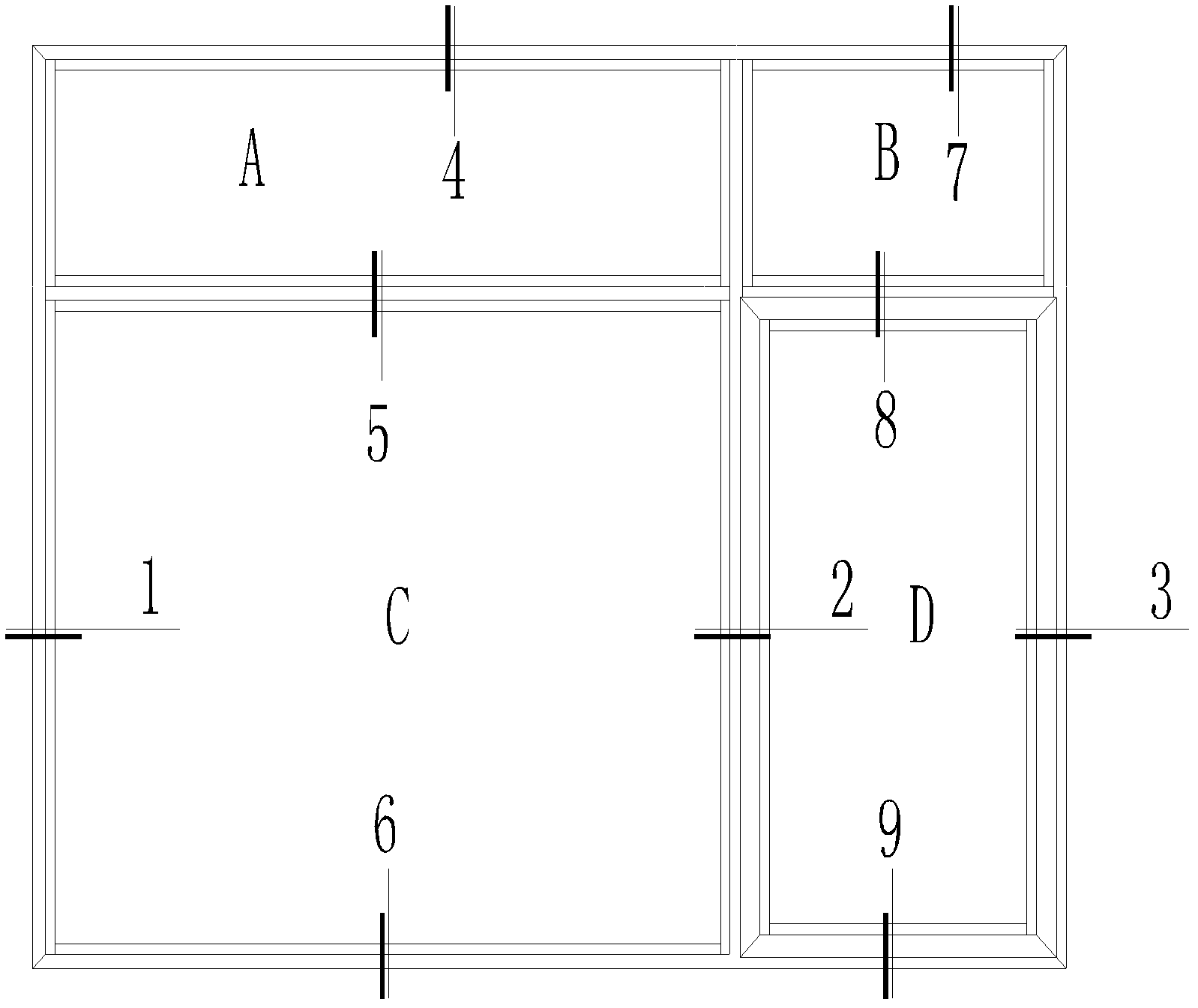

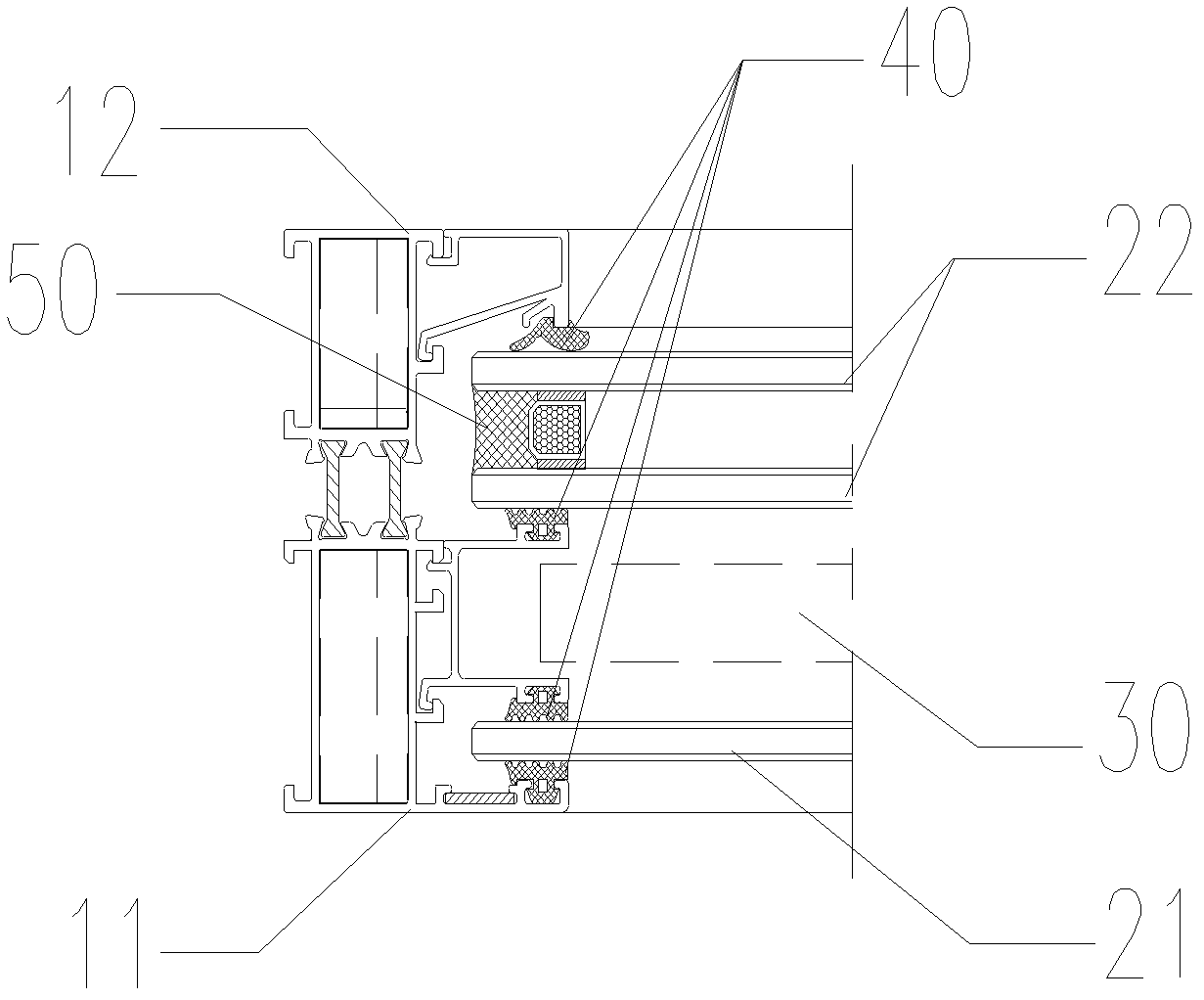

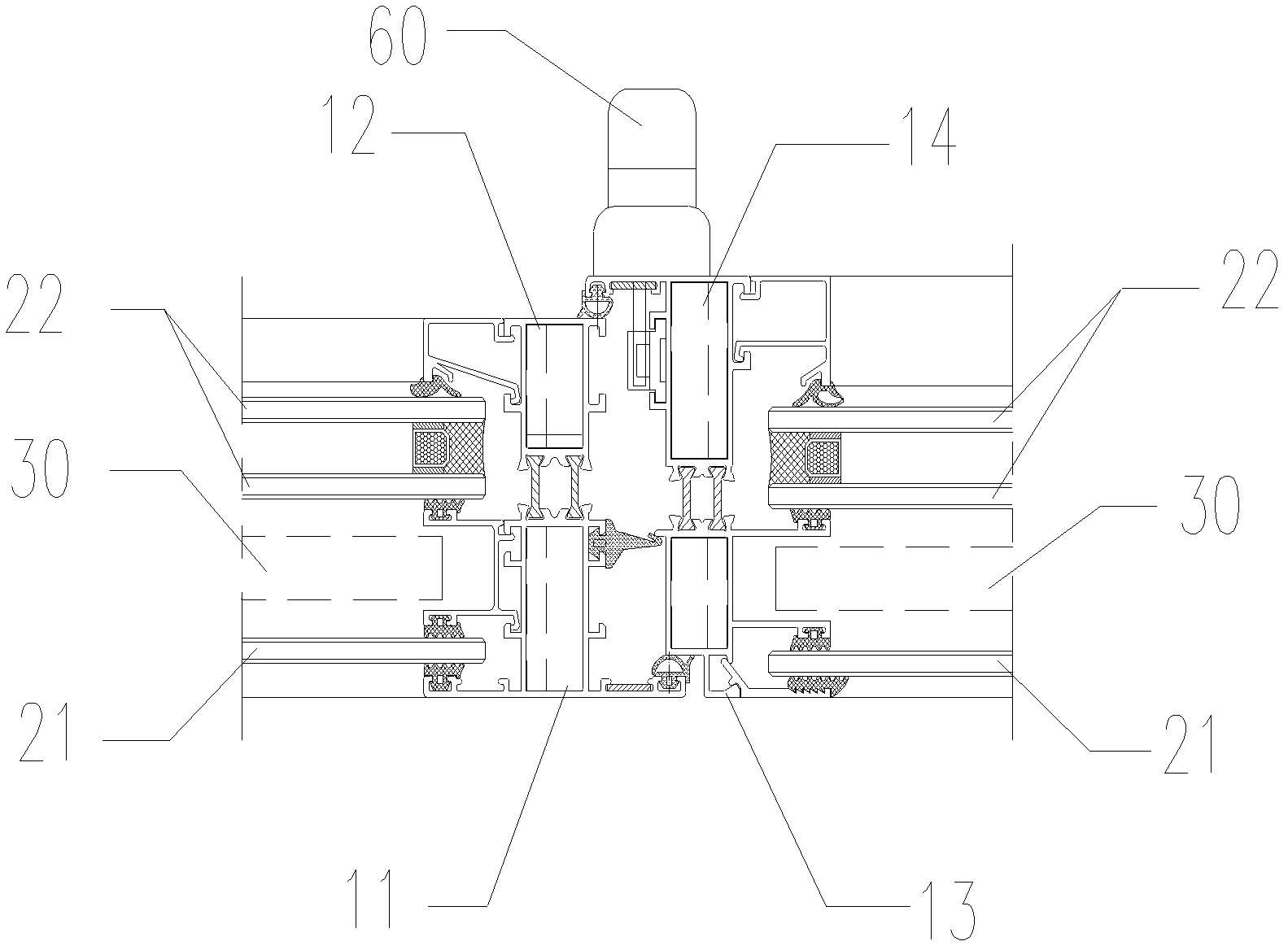

Hollow sunshade louver

InactiveCN102518380AWith energy savingPractical collocationLight protection screensWindow shutterEngineering

The invention relates to a hollow sunshade louver, which comprises exterior glass, interior glass, sunshade blinds and a window frame composed of an inner window frame and an outer window frame. The interior glass is fixed to the inner window frame, the exterior glass is fixed to the outer window frame, and the sunshade blinds are arranged between the interior glass and the exterior glass and fixed to the outer window frame. Compared with the prior art, the hollow sunshade louver is more energy-saving and practical. The glass is detachable from both inside and outside, and the glass and the inner blinds are convenient to replace.

Owner:SHANGHAI BRIGHT INTELLIGENT CURTAIN WALL

Energy saving fireproof paint and preparation method thereof

The invention provides energy saving fireproof paint and a preparation method thereof. The energy saving fireproof paint comprises the following components in parts by weight: 20-30 parts of a fire retardant, 7-12 parts of a carburization agent, 7-12 parts of a foaming agent, 9-15 parts of an inorganic hollow material, 10-22 parts of titanium dioxide, 31-43 parts of a cross-linking agent, 3-5 parts of an anti-aging agent, 2-5 parts of magnesium hydroxide, and 2-5 parts of diatomite. The energy saving fireproof paint has the advantages of solar heat reflection, heat insulation, water resistance, and corrosion resistance, and the advantages are identical to the advantages of energy saving paint; at the same time the energy saving fireproof paint has the advantages of self-extinguishing, flame retardation, formation of a compact heat insulating protective layer by expansion during fire hazard, and the like, and the advantages are identical to the advantages of fireproof paint.

Owner:广州市环康机电工程安装有限公司 +2

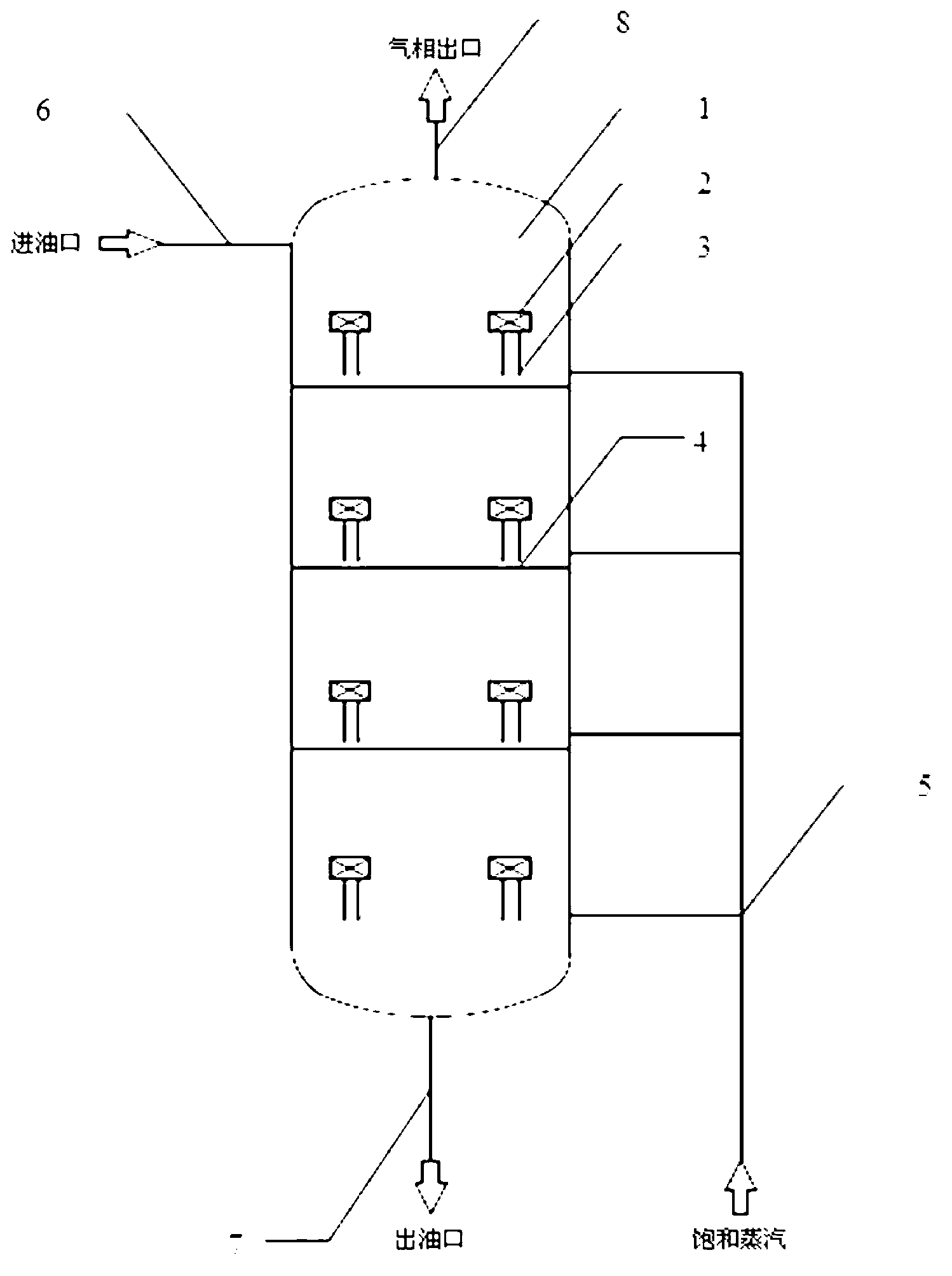

Oil deodorization device, deodorization method thereof and packing stripping pump mechanism

ActiveCN103060087ALong deodorization timeTo achieve the purpose of deodorizationFatty-oils/fats refiningEdible oils/fatsVegetable oilGas phase

The invention discloses an oil deodorization device, comprising a tower body, a multilayer tower disc and a plurality of packing stripping pump mechanisms, wherein each packing stripping pump mechanism comprise a stripping pump and a packing, the stripping pump is arranged on the tower disc, and the packing is arranged at the top end of the stripping pump. The invention further discloses a deodorization method of the oil deodorization device, comprising the following steps of: vacuumizing the interior of the tower; injecting vegetable oil in the tower body via a centrifugal pump; opening the tower body and directly conveying steam in the stripping pump; lifting the vegetable oil into the packing at the top of the stripping pump from the bottom of the tower disc, separating a steam phase from a liquid phase in the packing; continuously lifting the vegetable oil on the bottom of the tower disc into the packing at the top of the stripping pump and separating; and extracting odour substances out of the tower with a gas phase via a vacuum tube, and pumping the pure and high-quality vegetable oil out of the tower body from the bottom of the tower body via a shield pump. According to the oil deodorization device and the deodorization thereof disclosed by the invention, deodorization consumption and cost are reduced, and the characteristics of energy conservation and consumption reduction are achieved; deodorization time, investment cost, the floor area of equipment, and construction cost are reduced; and deodorization efficiency is high, and the quality of refined oil product is improved.

Owner:SHANGHAI JIAOER ENG TECH

Method for synthetizing 3,5-dichloroaniline

InactiveCN103508901AReduce pollutionWith sustainable developmentOrganic compound preparationAmino compound preparationO-nitrochlorobenzeneChlorobenzene

The invention discloses a method for synthetizing 3,5-dichloroaniline by using industrial production residues, namely meta-position oil, of p-nitrchlorobenzene and ortho-nitrochlorobenzene by two steps of chlorination and reductive dechlorination. The method adopts the following technical scheme: adding an organic solvent to nitrochlorobenzene meta-position oil as a raw material, directly producing a quintozene mixture by one-step chlorination under the effect of a catalyst, reacting for 0.5-10 hours under the condition of 10-180 DEG C, and then cooling to 30 DEG C; filtering out quintozene, and putting into an autoclave after washing into a neutral state by hot water; carrying out dechlorination reduction reaction under the effects of an organic solvent and the catalyst, wherein the reaction temperature is 60-200 DEG C, the reaction pressure is 1-20 MPa, and the reaction time is 1-20 hours; cooling to room temperature after the reaction is ended; leading in oxygen or air to stir after blowing off; filtering and distilling under reduced pressure to remove the solvent, so as to obtain the product 3,5-dichloroaniline, wherein the yield is 80-90%. Waste materials are changed into precious materials by a synthetic route adopted by the technology disclosed by the invention; the target of zero emission is achieved; the method has the advantages of sustainable development, energy conservation and consumption reduction, and small environmental pollution.

Owner:CHINA PETROLEUM & CHEM CORP +1

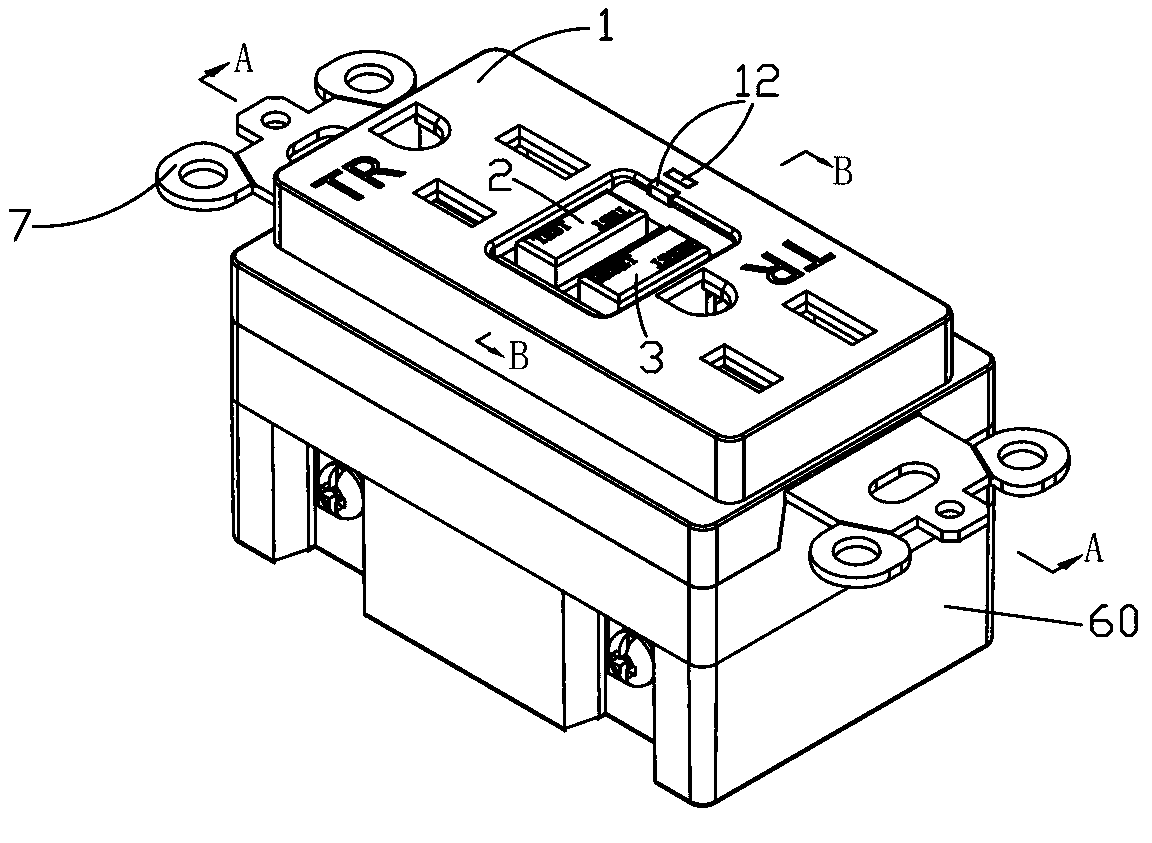

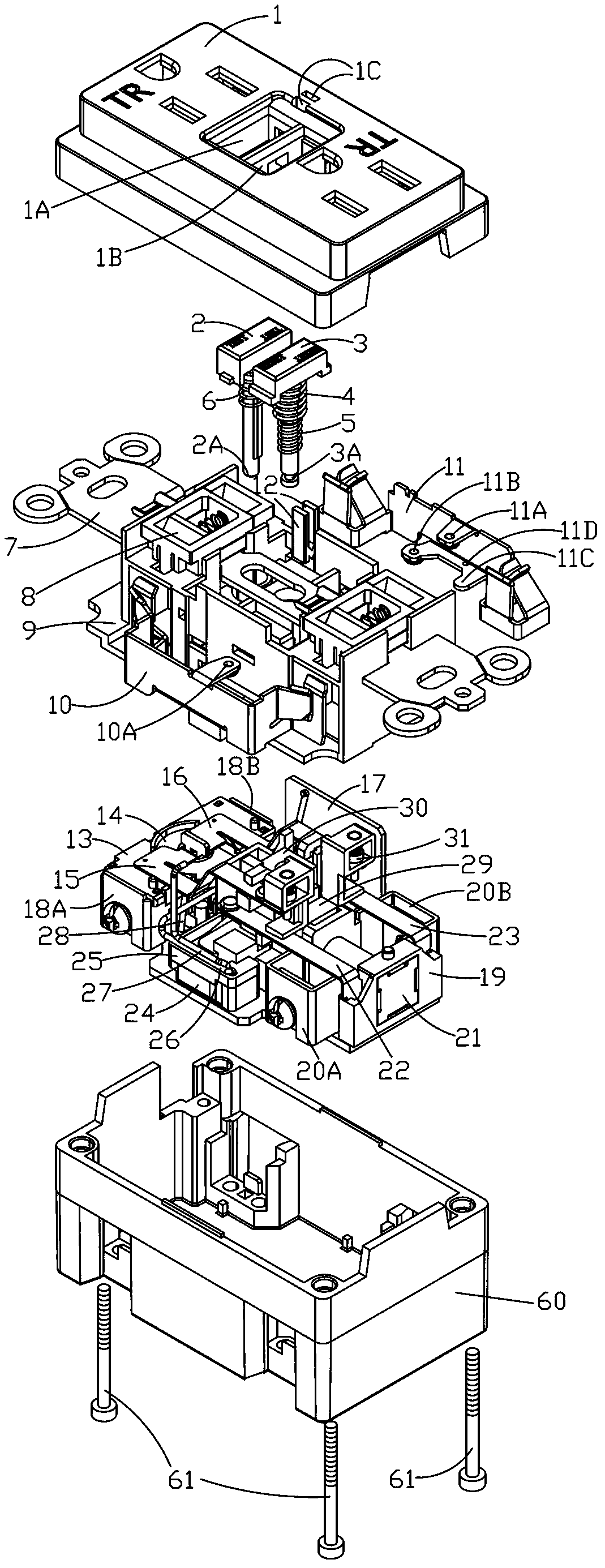

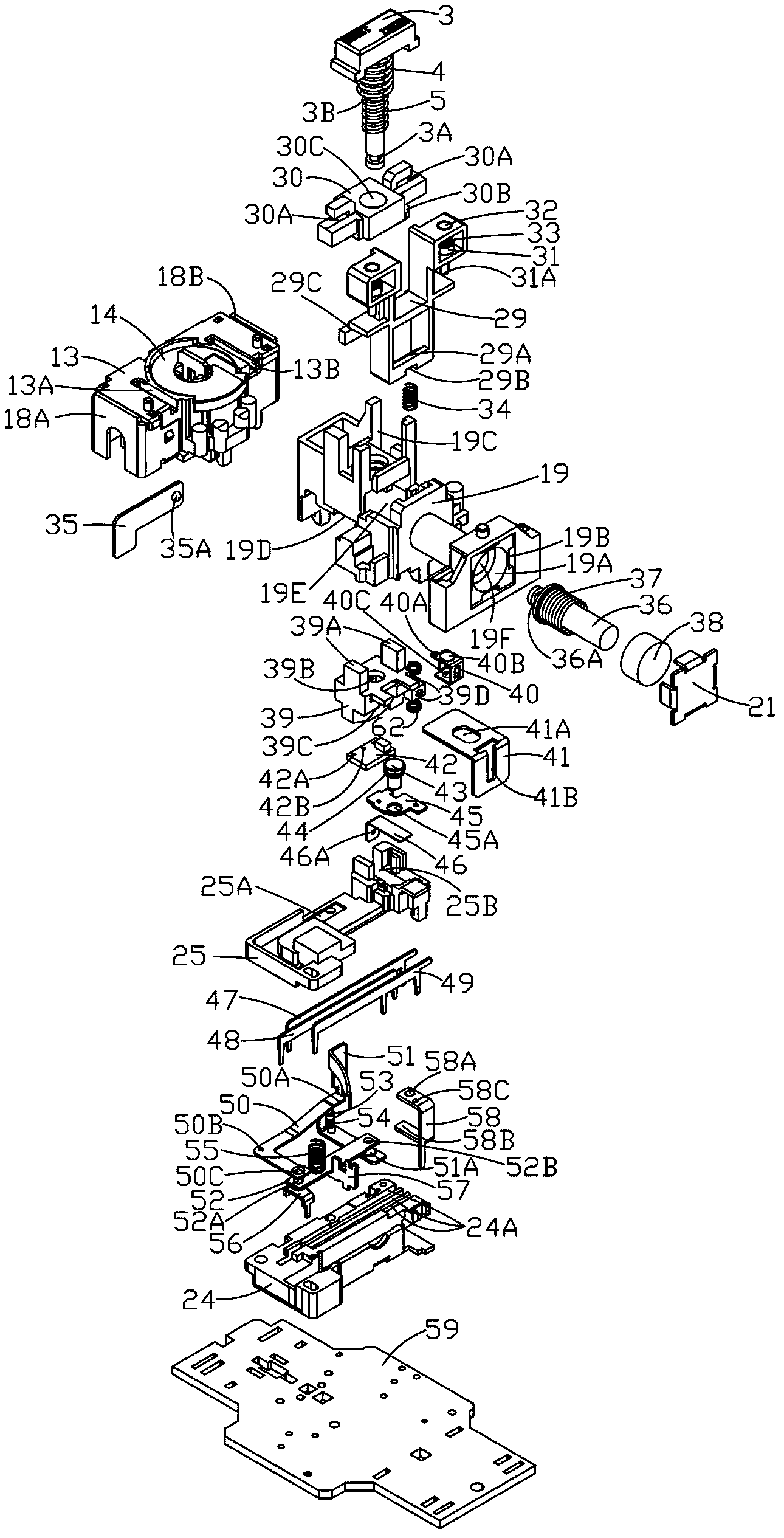

Improved-type leakage protection socket with function of negative wiring protection

ActiveCN103269000ASimple structureReliable actionIncorrect coupling preventionSwitch operated by earth fault currentsMagnetEngineering

The invention provides an improved-type leakage protection socket with a function of negative wiring protection. An electromagnetic tripping mechanism comprises a tripping coil, an iron core and a permanent magnet, wherein a rest spring is sleeved on the iron core. A boss is arranged at the front end of the iron core. An input movable contact is clamped by a ribbed groove of an upper tripping device. An output movable contact is pressed by a beam of the upper tripping device. The improved-type leakage protection socket is further provided with a negative wiring disengaged device. The negative disengaged device is provided with a slope plane matched with the boss of the iron core. During negative wiring, the tripping coil generates a magnetic field which is the same as the permanent magnet in field direction so that the iron core and the permanent magnet can be attracted to drive the negative wiring disengaged device to descend, therefore, the input movable contact is pressed so that the input movable contact can be communicated with an output conductor, and the output movable contact is compressed to be separated from the output conductor. The improved-type leakage protection socket with the function of the negative wiring protection has the advantages that under the state of the negative wiring, the output movable contact and the output conductor are rapidly separated through the negative wiring disengaged device, and the improved-type leakage protection socket is safe to use; due to the fact that a rock type selective switch is used for supplying a closed circuit to an artificial resistor and the tripping coil, the artificial resistor and the tripping coil are interlocked, the structure is simple, and motions are reliable.

Owner:WENZHOU VAN SHEEN ELECTRIC APPLIANCE

Direct-heating constant-temperature air conditioner hot pump water heater

InactiveCN101067524ALow investment costConstant high-efficiency cooling effectHeat pumpsCompression machines with reversible cycleFour-way valveSolenoid valve

The invention relates to a kind of constant heat and temperature air conditioning heat pump water machine it concludes a compressor, a four-way valve, water heater, an electromagnetic valve. The outlet of compressor connects the inlet of water heater by the four-way valve and the outlet of water heater connects the electromagnetic valve or the electromagnetic valve connects the capillary in concatenation. It is characterized in that at the cold water inlet of water heater there is connecting a water flow regulating valve. The air conditioning heat pump water machine collects the single refrigeration, single producing hot water, single heating, and either producing hot water or refrigeration in integral so it can realize that refrigeration in summer and heating in winter.

Owner:JIANGSU TENESUN ELECTRICAL APPLIANCE

Method for extracting tylosin by tylosin fermentation broth

ActiveCN102746354AComplete crystal formEfficient removalSugar derivativesSugar derivatives preparationSolubilityOrganic solvent

A method for extracting tylosin by tylosin fermentation broth is characterized by including steps of firstly pretreating the tylosin fermentation broth to obtain tylosin filtrate, then subjecting the tylosin filtrate to extracting, reextracting, decolorizing filtering, crystallizing, ageing, rinsing and vacuum drying to obtain the tylosin. The method is used for directly extracting the tylosin by the tylosin fermentation broth serving as raw materials, tylosin solubility of intermediates of the tylosin accords with quality standards of Chinese Veterinary Pharmacopoeia. The integral method is mild in production conditions, simple to operate, safe and reliable in preparation process and low in loss of organic solvent and has the advantages of energy conservation, consumption reduction, low production cost, high work efficiency and the like.

Owner:宁夏泰瑞制药股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com