Steel-wood combined formwork and construction method

A steel-wood combination and construction method technology, which is applied in the fields of formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve the problems of poor formwork stability, complex formwork structure, inconvenient transition, etc. Achieve the effect of improving wall flatness, flexible operation and saving construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

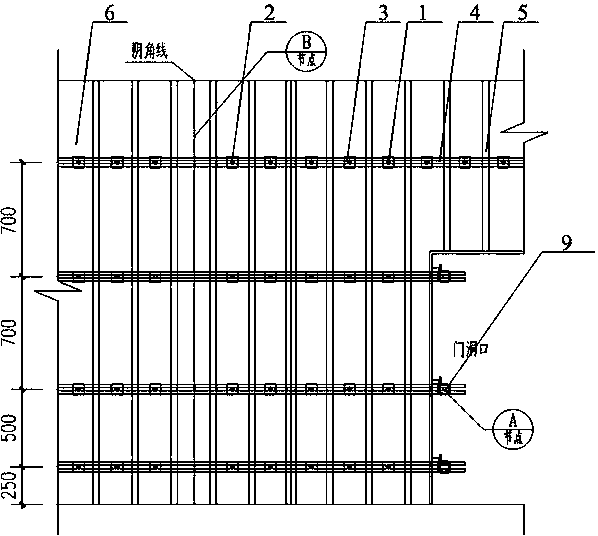

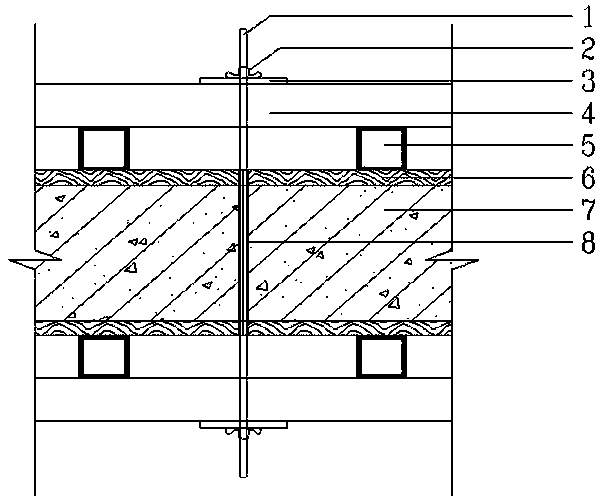

[0031] Such as figure 1 , 2 , 3, shown in 4, the steel-wood combination formwork of the present invention comprises plywood 1, square steel secondary back flute 5, both sides steel main back flute 4, wall-penetrating screw rod 1, tapered nut 2, steel gasket 3, hole lockset 9, Male corner lock 11, wherein the thickness of plywood 1 is 15mm, and according to the construction needs, a plurality of drilling holes are opened for the penetration of wall screw 1; , drill holes, and fix on the back of the assembled plywood 1 with ordinary iron nails, which is convenient for reassembly after dismantling; The steel secondary corrugations 5 are perpendicular to each other, and the square steel secondary corrugations 5 are made by welding double 50*30*2.5 square steels, and the inner corners are made into an "L"-shaped right-angle steel main corrugation 13 on both side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com