Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

165 results about "Sodium antimonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition of sodium antimonate. : an antimonate of sodium; especially : the meta-antimonate 2NaSbO3.7H2O obtained as a granular powder and used chiefly as an opacifier for enamels.

Treatment method for vitrifying arsenic-alkali residue

InactiveCN102965517ARecycling and recovery technologiesProcess efficiency improvementMolten stateIngot casting

The invention discloses a treatment method for vitrifying arsenic-alkali residue, aiming at solving the problem of pollution or potential menace of the existing arsenic-alkali residue treatment process on environment. The treatment method for vitrifying the arsenic-alkali residue comprises the following steps of: selectively reducing sodium antimonate in the arsenic-alkali residue to metallic antimony by a carbon reducing agent in a molten state and keeping arsenic in the residue in the form of sodium arsenate; and then adding a glass molten solvent in the arsenic-containing residue to form a low-temperature glass phase, discharging the glass phase, and then carrying out water-quenching on the glass phase into broken glass pieces or directly casting the glass phase into a glass ingot in an ingot casting mould, thus facilitating piling up or returning to a pit and land-filling. According to the invention, the recovery rate of antimony in the arsenic-alkali residue is greater than 95%, and the content of arsenic in the metallic antimony is less than 3%; and the arsenic-containing glass pieces belong to general solid wastes and can be directly piled up in the open air or land-filled.

Owner:CENT SOUTH UNIV

Glass ink-jet printing ink

The invention discloses a glass ink-jet printing ink. The ink comprises, by weight, 20-60% of inorganic colored frits, 35-65% of an organic solvent, 1-15% of a dispersing agent and 0.1-4.5 % of an antistatic agent, and all the components account for 100%. The inorganic colored frits comprise, by weight, 35-65% of Bi2O3, 10-40% of SiO2, 5-18% of B2O3, 1-5% of ZrO, 0.7-8% of Al2O3, 0.3-2.5% of K2O, 1-28% of a glass color former and 0.1-3% of a frit stabilizing agent. The frit stabilizing agent is selected from any one of vanadium pentoxide, sodium dihydrogen phosphate, sodium selenite, ammonium dihydrogen phosphate and sodium antimonite. The glass ink-jet printing ink is stable in quality, printed patterns are accurate, uniform and bright in color, the finished product is attractive, and the glass ink-jet printing ink has the good weather resistance and chemical-resistance stability.

Owner:宁波美科数码智能技术有限公司

Production process for preparing ultra-white nanometer sodium pyroantimonate

InactiveCN101693553AHigh whitenessLower requirementAntimonates/antimonitesDominant whiteDecomposition

The invention relates to a production process for preparing ultra-white nanometer sodium pyroantimonate. The process comprises the following steps: adopting low-quality antimonious oxide powder and adding 27.5 percent hydrogen peroxide for reacting at 60-120 DEG C for 1-2 h by using a potassium hydroxide solution as a leaching agent, wherein the solid-liquid ratio of the antimonious oxide powder and the potassium hydroxide solution is 1:5-20; clarifying the reaction liquid for more than half an hour, pumping the supernate into a double decomposition kettle and adding a sodium hydroxide solution into the double decomposition kettle for reaction under normal pressure to convert potassium antimonate into sodium antimonate; separating the sediment by centrifugation, drying and screening to obtain the ultra-white nanometer sodium pyroantimonate product with the whiteness of more than 93 percent; and leaching and oxidizing the double decomposition mother liquor for recycling. The obtained product has the whiteness of more than 93 percent and can be used as a clarifying defoaming agent and a flame retardant agent in solar power generation and dominant white glass.

Owner:ZHUZHOU ANTE ANTIMONY CHEM IND

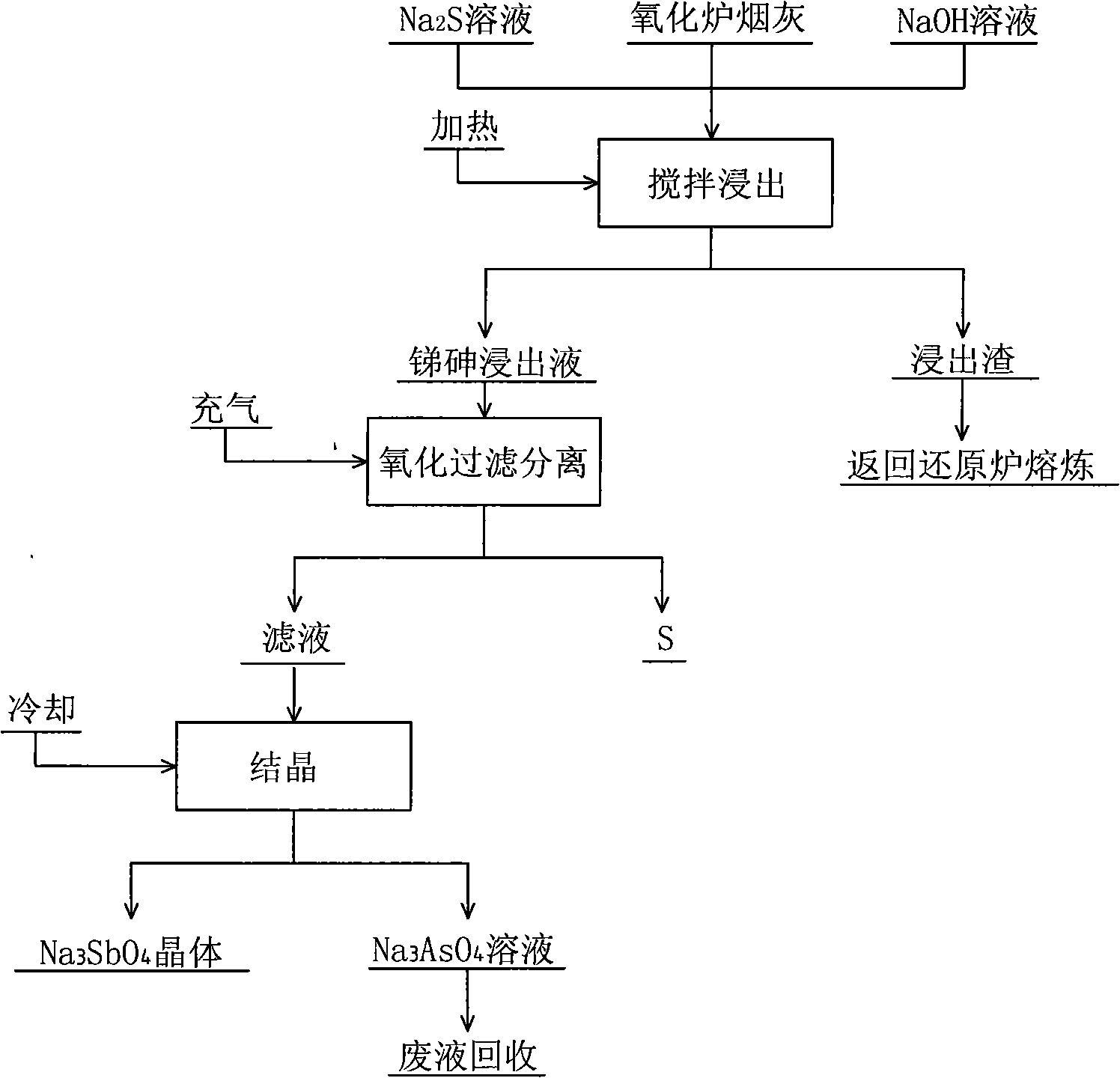

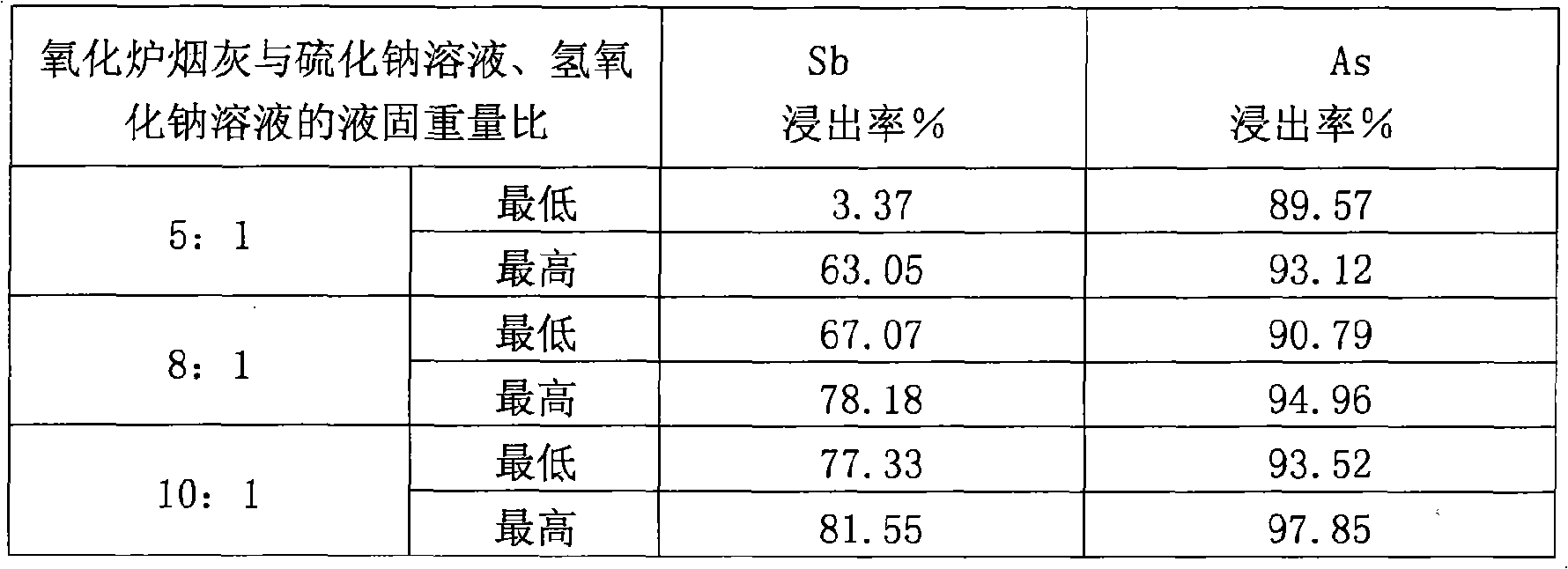

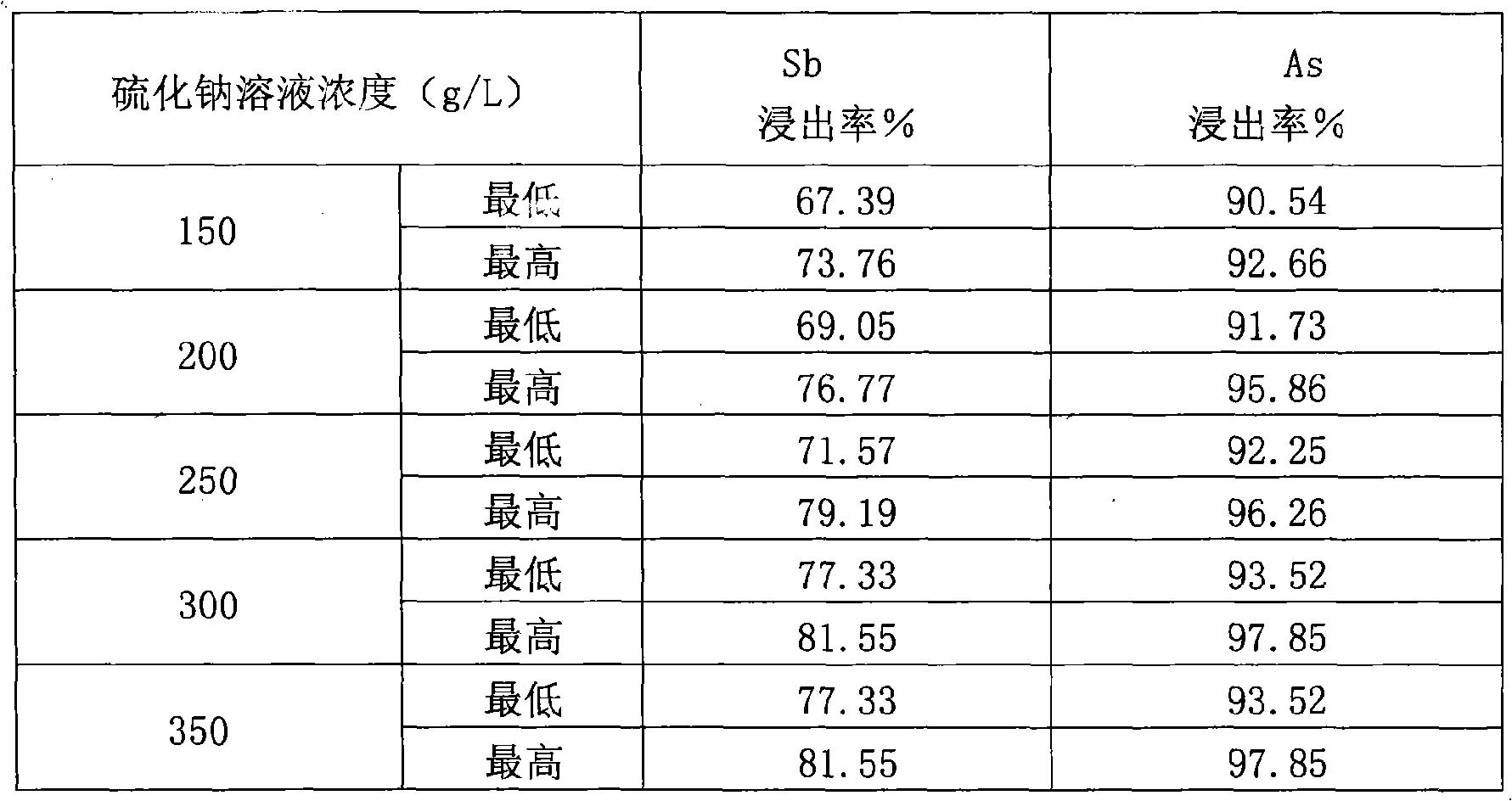

Oxidation oven ash hydrometallurgical leaching process

InactiveCN101328539AEasy to removeEfficient separationProcess efficiency improvementArsenic oxideSoot

The invention provides a leaching process of the oxidation oven soot wet method, belonging to the treatment on side products of soot generated in the smelting process technical field. In the process, antimony oxide and arsenic oxide in the oxidation oven soot are simultaneously leached out by the reducing capacity of sodium sulphide first, and generated sodium thioadtimonate and sodium sulfarsenate enter leaching liquid; filter residues are returned for silver smelting reduction smelting; the leaching liquid is passed through air, the sodium thioadtimonate is oxidized into sodium antimonate, free sulfurs in the sodium antimonate are separated by filtering; the mixed filtrate of the sodium antimonate and the sodium sulfarsenate has coarse sodium antimonate crystals extracted by condensed crystallization; and the remained sodium sulfarsenate liquid is taken as waste liquid for reclaiming treatment, so that the effective separation of Pb and Ag and Sb and As is realized. The process of the invention can effectively reduce the quantity of soot returned to the oven for smelting, improving the capability of a reducing furnace for treating anode mud and achieving the double-win aims of improving the efficiency of the reducing furnace and reducing environmental pollution.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

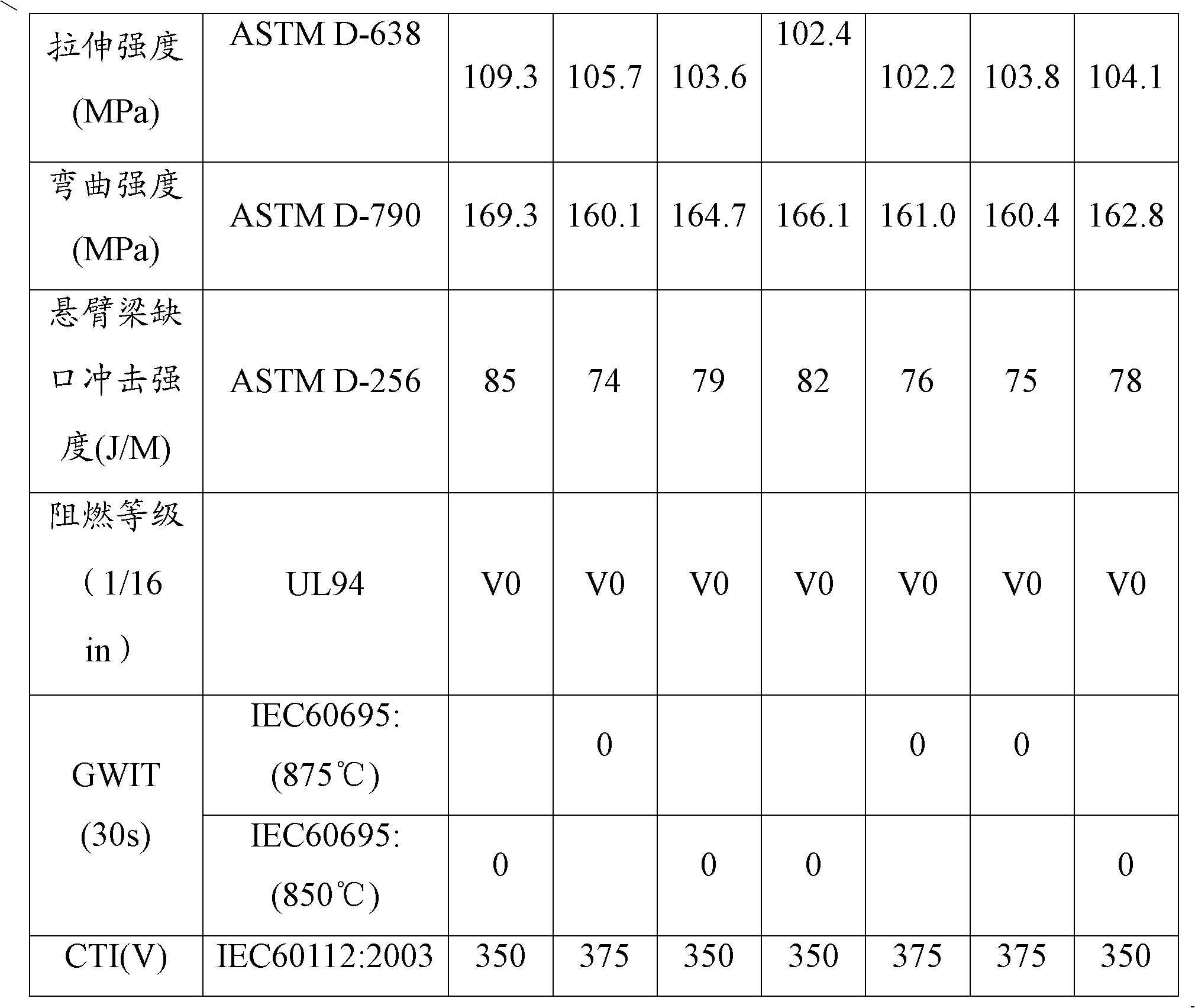

Polybutylece terephthalate (PBT) engineering plastics as well as preparation method and application thereof

InactiveCN102040810AGlow wire test value increasedImproved tracking indexPlastic/resin/waxes insulatorsTetrabromobisphenol AAntioxidant

The invention is suitable for the technical field of high polymer materials and provides polybutylece terephthalate (PBT) engineering plastics as well as a preparation method and an application thereof. The PBT engineering plastics comprise the following components in parts by weight: 45-75 parts of PBT resins, 15-30 parts of fire retardants, 4-10 parts of flame retardant synergist, 0.8-1.2 parts of lubricating agents, 28-33 parts of glass fibers, 3-5 parts of flexibilizer, and 0.2-0.5 part of antioxidant, wherein the fire retardants are two or more of decabromdiphenylethane (DBDPE), brominated triazine, phosphorus-nitrogen based flame retardant and tetrabromobisphenol A; and the flame retardant synergist is antimonous oxide or sodium antimonite. The glowing filament test value, the proof tracking index (PTI) and the like of the PBT engineering plastics can be greatly improved by the modification effect of the flame retardants and the flame retardant synergist. In the preparation method of the PBT engineering plastics, sources of the raw materials are wide, the cost is low, the preparation process is simple, the production process is smooth and controllable, and the productivity effect is high; and the preparation method of the PBT engineering plastics is suitable for industrial production.

Owner:SHENZHEN KEJU NEW MATERIAL

Comprehensive recovery method of smoke with high arsenic and antimony oxide contents

A comprehensive recovery method of smoke with high arsenic and antimony oxide contents comprises the following steps of: (1) roasting: after uniformly mixing the smoke with the high arsenic and antimony oxide contents, sodium nitrate and alkali, putting in a furnace for roasting at 400-680 DEG C, cooling after roasting to obtain a roasting material, (2) leaching: adding the roasting material into hot water for leaching, filtering to obtain a sodium antimonate filter cake and a sodium arsenate solution, and (3) drying: drying the sodium antimonate filter cake and the concentrated sodium arsenate solution to obtain a sodium antimonate product and a sodium arsenate product. The method integrates the advantages of a fire method and a wet method, and thoroughly separates antimony and arsenic from the smoke with the high arsenic and antimony oxide contents; an antimony content in sodium antimonate is 56-62%; an arsenic content in sodium antimonate is less than 0.5%; the arsenic content in sodium arsenate is 17-30%; the antimony content in sodium arsenate is less than 0.5%; the direct yield of the method reaches above 95%; recovery rates of antimony and arsenic are 96-99%; a recovery process is short; very little waste gas is generated and can be absorbed and returned by an alkaline liquor; and the method is short in flow and environment-friendly.

Owner:锡矿山闪星锑业有限责任公司

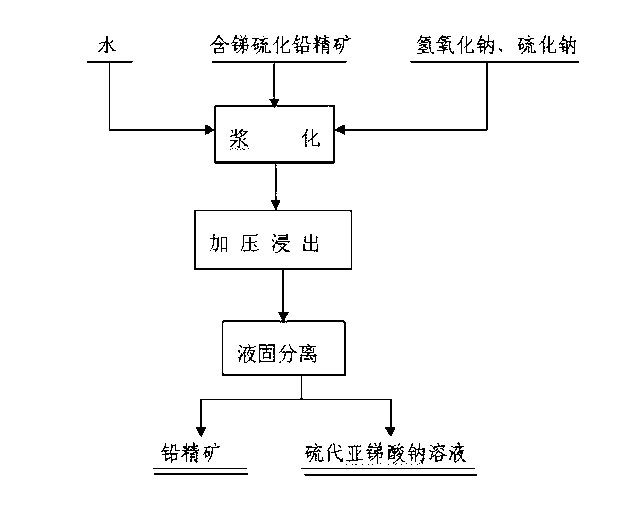

Method for separating lead and antimony in antimony-containing lead concentrates

ActiveCN102912125ALeaching is effectiveReduce concentrationProcess efficiency improvementPregnant leach solutionNonferrous metal

The invention discloses a method for separating lead and antimony in antimony-containing lead concentrates, belongs to the technical field of nonferrous metallurgy, and particularly relates to a method for leaching antimony from antimony-containing lead sulfide concentrates in a pressure manner. The method includes leaching the antimony from antimony-containing lead sulfide concentrates by sodium hydroxide reaction solution containing sodium sulfide in a closed stirred reactor; and separating solution from solid to obtain lead sulfide concentrates and leachate containing sodium thioantimonious acid. The reaction solution contains from 10g / L to 40g / L of the sodium sulfide and from 80g / L to 120g / L of sodium hydroxide. The method has the advantages that the antimony in the lead sulfide concentrates can be effectively removed, the sodium sulfide is prevented from being oxidized in a high-temperature leaching process, and the method is suitable for leaching antimony in antimony-containing lead sulfide concentrates in a complicated mode of occurrence.

Owner:云南锡业研究院有限公司研究设计院

Laser carving powder applied to laser marking and preparation process thereof

The invention discloses laser carving powder applied to laser marking. The laser carving powder comprises the following raw materials in parts by weight: polypropylene resin, C5 petroleum resin, barium sulfate, a nucleating agent, an antioxidant, toner, a lubricant, silicon oxide, titanium dioxide, zinc sulfide, chromium sesquioxide, neodymium oxide, bismuth oxide, tin oxide, zinc molybdate, ammonium molybdate, basic copper phosphate, copper oxide, copper chromite black, copper carbonate, copper sulfate, copper chloride, copper chromite, copper thiocyanate, spinel, tin dioxide, tin ash, sodiumstannate, potassium stannate, zinc sulfate, antimony trioxide, antimony pentoxide, sodium antimonate, potassium carbonate, syndiotactic polystyrene and polyhexamethylene adipamide; according to the preparation process of the laser carving powder applied to laser marking, the laser carving powder applied to laser marking is prepared, and the preparation process comprises the following steps: S1, grinding; S2, performing crushing; S3, performing mixing; S4, adding a chemical agent; S5, drying; and S6, crushing.

Owner:东莞市烁康新材料科技有限公司

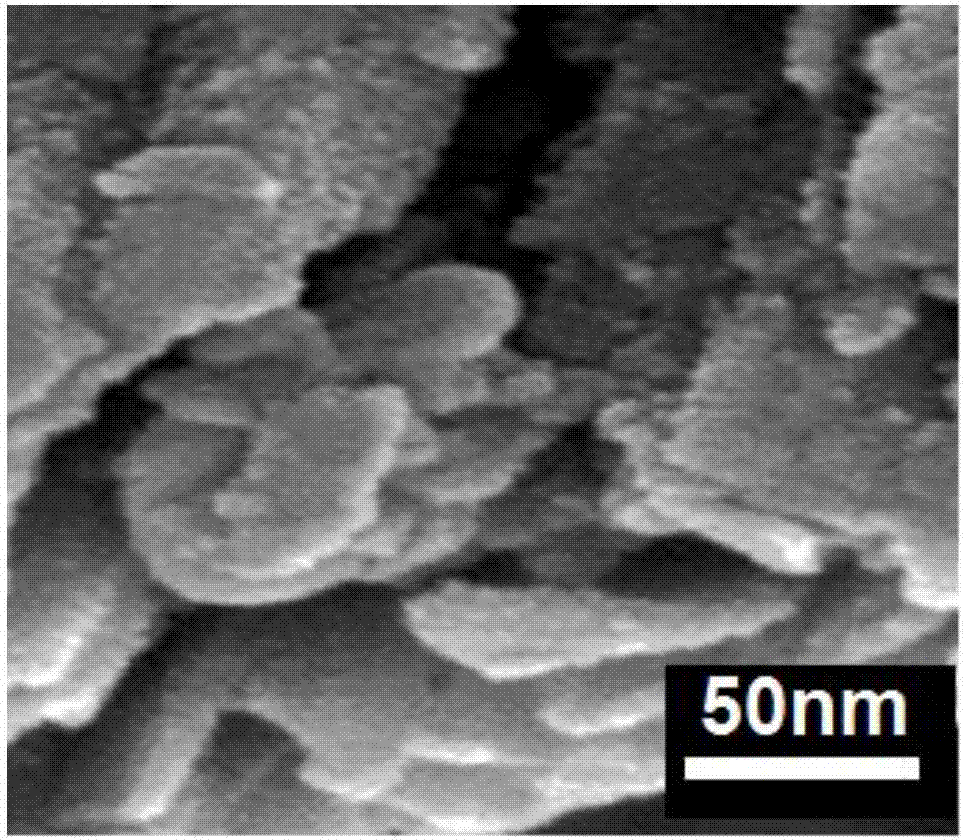

Preparation method of solid-state sodium-ion battery electrolyte

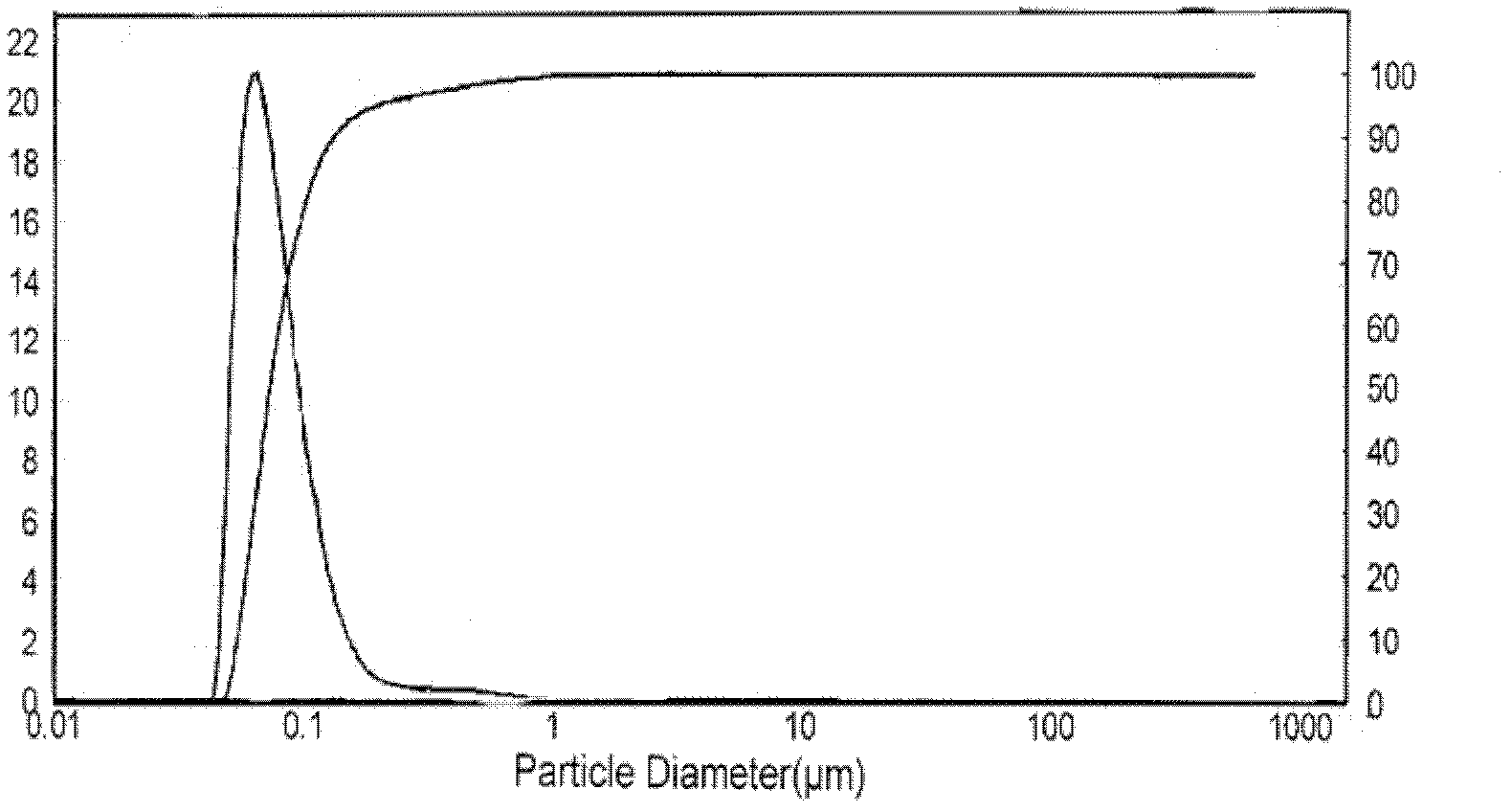

InactiveCN107482249ALarge specific surface areaImproved magnification performanceSecondary cellsElectrolytesWater bathsNano structuring

The invention discloses a preparation method of solid-state sodium-ion battery electrolyte. The preparation method comprises the following steps: dissolving sodium sulfide into 1L of deionized water; heating the mixed solution in a thermostat water bath to 80-90 DEG C; adding sodium antimonite and NH4F into the mixed solution, wherein the mass ratio of sodium sulfide, sodium antimonite and NH4F is 3.5-1.5:1:0.5-2.5; slowing stirring the mixed solution for 3-4h, naturally cooling to room temperature and filtering; drying at the temperature of 70-80 DEG C in a drying box and then heating up to 300-400 DEG C for a reaction in a furnace tube. The chemical formula of the prepared solid-state sodium-ion battery electrolyte is Na3-xSbS4-xFx, the electrolyte contains F ions, is in a nano-structure and is formed by stacked nanosheets; a lot of gaps are contained between every two adjacent nanosheets. The doped F ions provide an efficient channel for conductive ions. When the electrolyte is applied in a sodium-ion battery, the rate capability and the cycling stability of the battery can be enhanced.

Owner:卢荣红

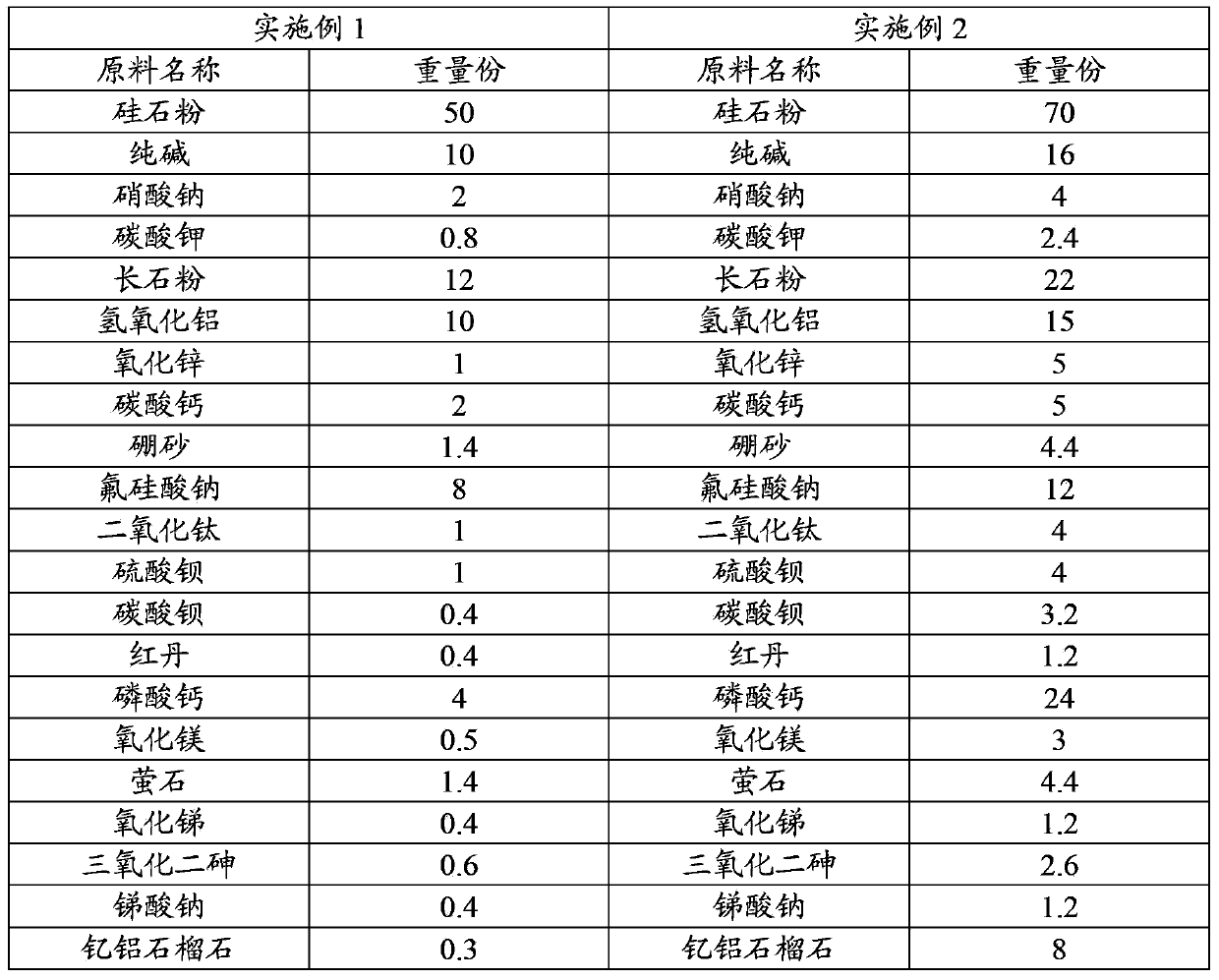

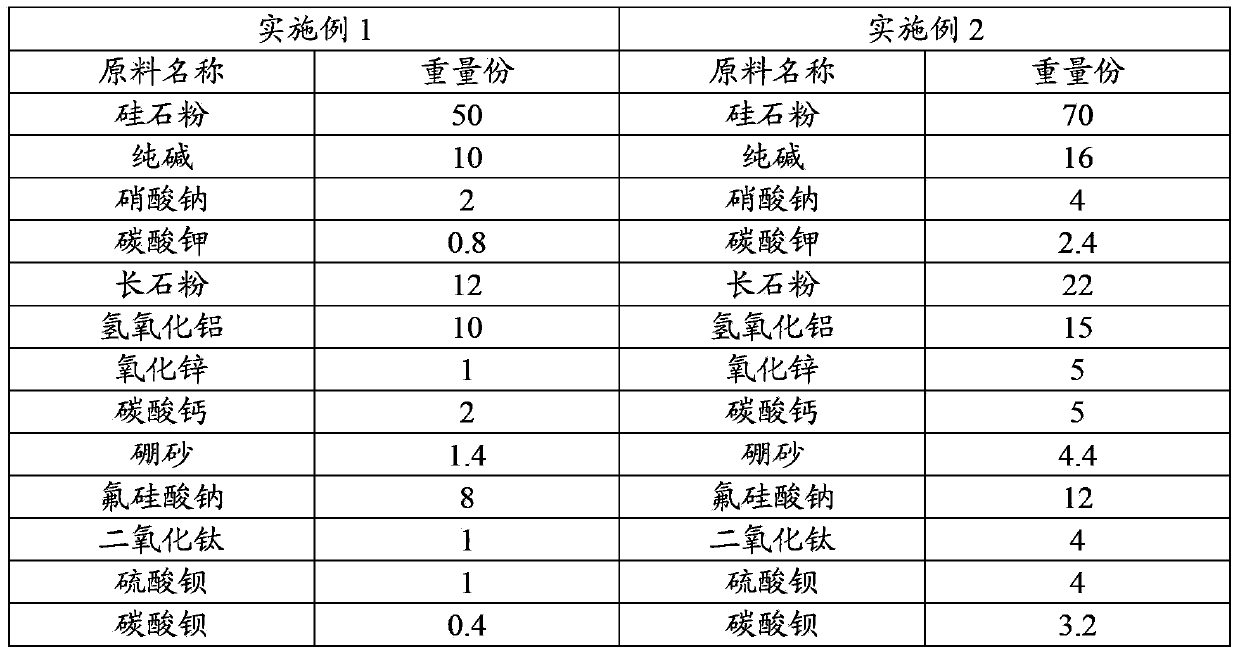

Soft-light colored glass, and preparation method and use thereof

InactiveCN103466938ACompatibility is reasonableWide range of usesGlass furnace apparatusCadmium CationPotassium carbonate

The invention relates to a soft-light colored glass, and a preparation method and a use thereof. The soft-light colored glass is prepared through using the following raw materials, by weight, 50-70 parts of silica powder, 10-16 parts of sodium carbonate, 12-22 parts of feldspar powder, 10-24 parts of aluminum hydroxide, 1-12 parts of zinc oxide, 4-24 parts of calcium carbonate, 1.4-12 parts of borax, 8-16 parts of sodium fluosilicate, 0.8-5.8 parts of potassium carbonate, 0.4-4 parts of sodium nitrate and 6.6-70 parts of an auxiliary material, and the auxiliary material comprises several selected from titania, barium carbonate, red lead, calcium phosphate, barium sulfate, magnesium oxide, fluorite, arsenic trioxide, antimony oxide, cobalt oxide, copper oxide, chrome oxide green, sodium antimonate, cadmium yellow, sulfur, uranium oxide, cerium oxide, cadmium red, cadmium sulfide, selenium powder and yttrium aluminum garnet. The soft-light colored glass can solve a blue light polluting problem and has a long service life, and required raw materials do not pollute the environment, and the soft-light colored glass can be directly processed to form a lamp tube, a lamp cover or a lamp for use and avoids the easy color change and shedding problems of a coat of coated glass.

Owner:申英良 +1

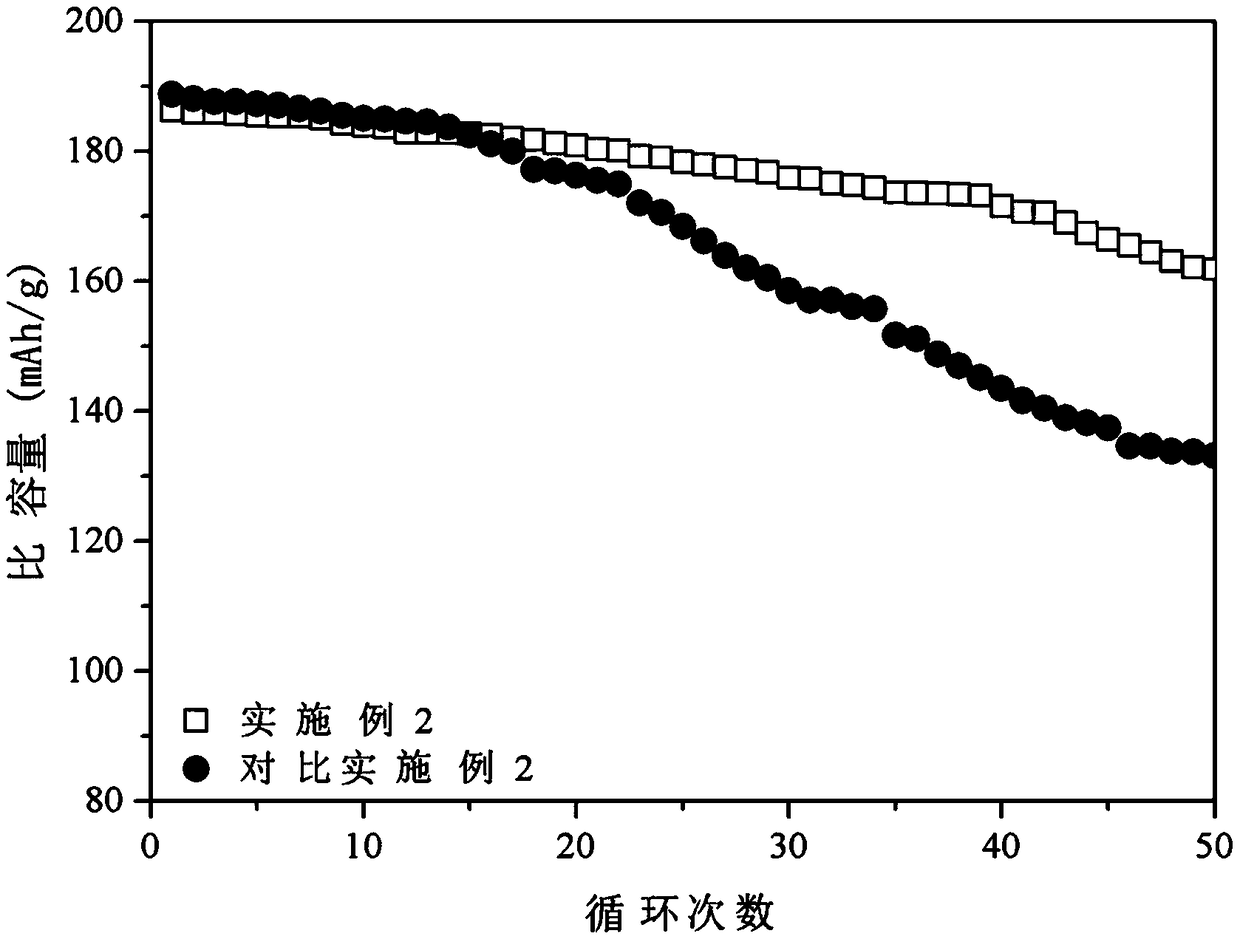

Nickel-cobalt lithium aluminate material coated with sodium-based oxidizing agent and preparation method thereof

ActiveCN108695506AFacilitate de-intercalationReduced activation energy for diffusionCell electrodesSecondary cellsLithium aluminateSodium antimonate

The invention discloses a nickel-cobalt lithium aluminate material coated with a sodium-based oxidizing agent and a preparation method thereof. According to the method, the surface of the nickel-cobalt lithium aluminate material is coated with a layer of sodium-based oxidizing agent, the sodium-based oxidizing agent is one or more of sodium peroxide, sodium bismuthate and sodium antimonate and hasstrong oxidability, in the sintering process, the oxidizing agent is partially diffused into crystal nuclei of the material, the oxidation of Ni<2+> is promoted, the lithium-nickel synchysis is reduced, a coating layer with a proper thickness is formed on the surface of the material by other part of the oxidizing agent, the material is prevented from being corroded by electrolyte in the chargingand discharging processes, and the cycling stability of the material is improved.

Owner:SHAANXI COAL & CHEM TECH INST

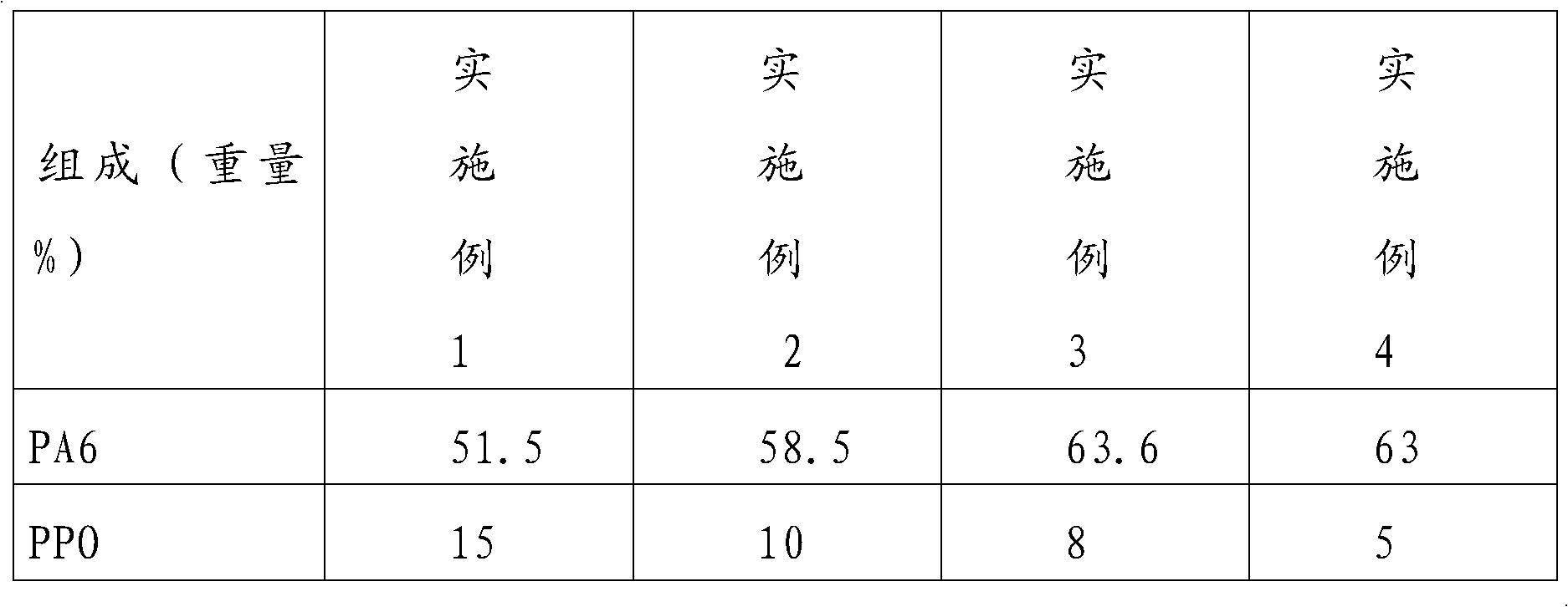

High glowing filament flame-retardant PA (polyamide)/PPO (polyphenyleneoxide) alloy and preparation method thereof

The invention discloses a high glowing filament flame-retardant PA (polyamide) / PPO (polyphenyleneoxide) alloy and a preparation method thereof. The high glowing filament flame-retardant PA / PPO alloy consists of the following components in percentage by weight: 55 to 70 percent of PA6, 5 to 15 percent of PP0, 2 to 5 percent of compatilizer, 2 to 4 percent of toughening agent, 18 to 20 percent of flame retardant, 6 to 6.5 percent of flame-retardant synergist, 0.2 to 0.6 percent of antioxidant and 0.1 to 0.3 percent of other auxiliaries. The flame retardant is brominated polystyrene. The flame-retardant synergist is sodium antimonate. In the invention, by selecting the suitable flame retardant with high compatibility with the PA and the PPO, the high glowing filament flame-retardant PA / PPO alloy with excellent mechanical property can be obtained and the standard that glowing filaments are not ignited at a temperature of 850 DEG C can be reached.

Owner:SHENZHEN KEJU NEW MATERIAL

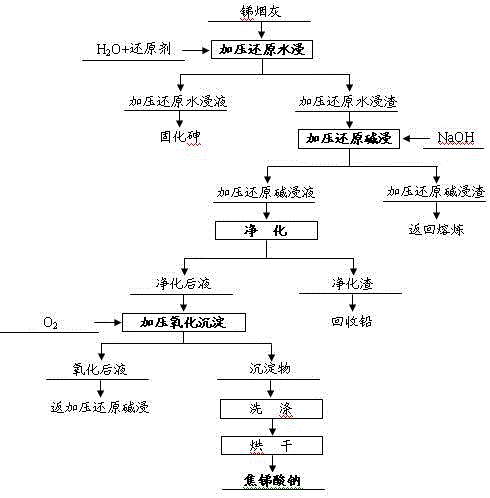

Method for preparing sodium antimonate through pressurizing oxidation of sodium salt system

ActiveCN107523702AReduce manufacturing costImprove solubilityProcess efficiency improvementSlagDissolution

A method for preparing sodium antimonate through pressurizing oxidation of a sodium salt system comprises the following steps: at first, a reductant is added into a high-temperature water solution of antimony soot to perform pressurizing reduction water leaching to remove arsenic; then pressurizing reduction alkali antimony leaching is performed on pressurizing reduction water leaching slag in a sodium hydroxide system; after that, sodium sulfide is added into the pressurizing reduction alkali leaching solution for purification and lead removal; at last, oxygen is injected into the purified solution at high temperature to perform pressurizing oxidation to precipitate a sodium antimonate product; and the solution subjected to oxidation is returned to the pressurizing reduction alkali leaching process. Substantially, the three purposes of arsenic dissolution, antimony dissolution and antimony oxidation are achieved by adoption of three modes including pressurizing reduction water leaching, pressurizing reduction alkali leaching and pressurizing oxidation precipitation, the leaching rate of arsenic in the pressurizing reduction water leaching process is 90.0% or above, the leaching rate of antimony in the pressurizing reduction alkali leaching process is 90.0% or above, the antimony precipitation rate in the pressurizing oxidation precipitation process is 99.0% or above, the qualified sodium antimonate product is finally prepared, and under the combined function, the purposes of removing arsenic from antimony soot and preparing the qualified sodium antimonate product are achieved. The method has the advantages of high antimony direct recovery rate, good product quality and low cost.

Owner:CENT SOUTH UNIV

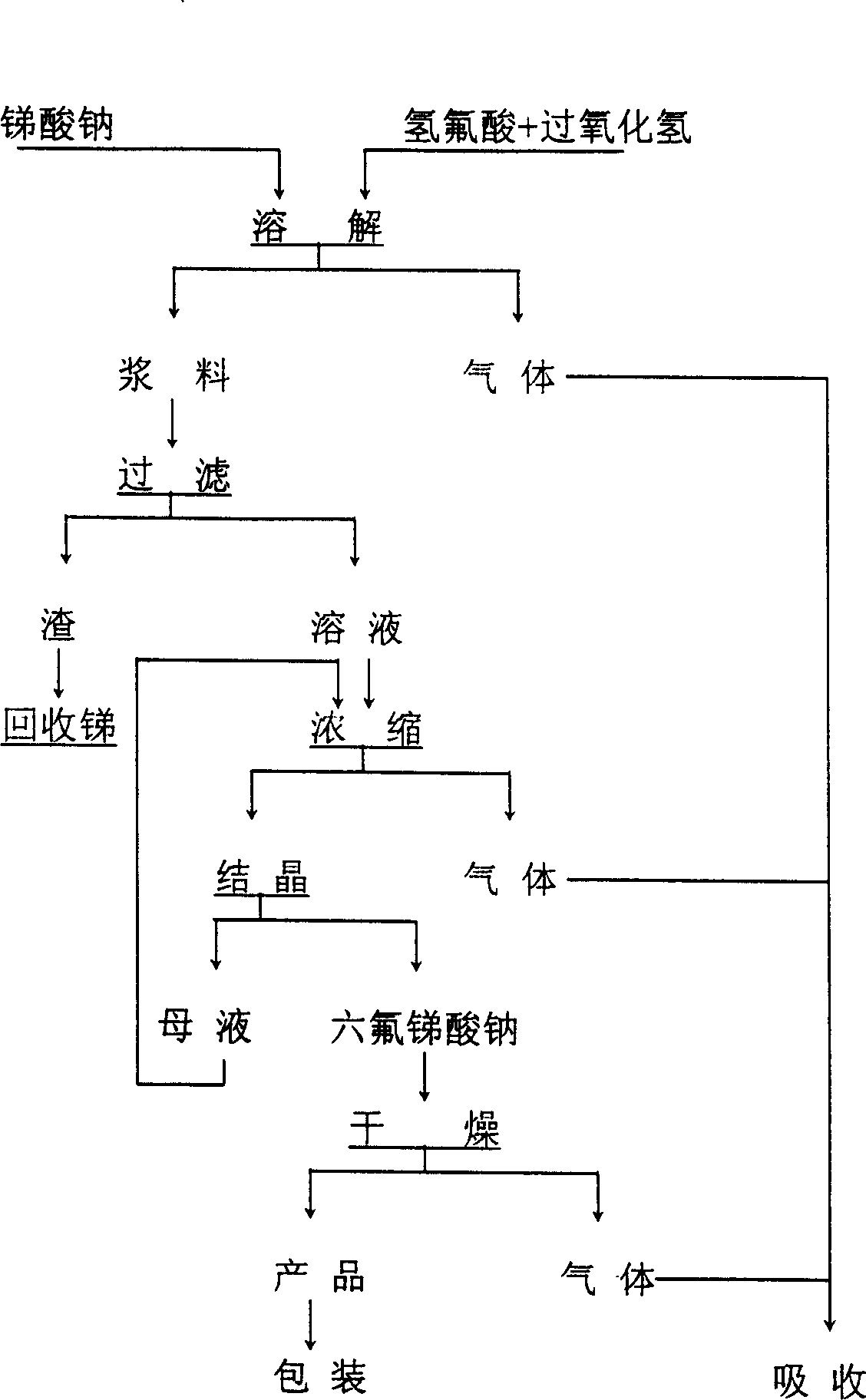

Method for preparing sodium hexafluoroantimonate

InactiveCN1743273AReduce productionEasy to control stoichiometryAntimonates/antimonitesChemical industryHydrofluoric acid

This method relates to the preparation of fine chemicals in chemical industry, especially the method for the preparation of sodium hexafluoroantimonate(Na3SbF6) with sodium antimonate(Na3SbO4) as raw material, which is as follow: first, after reaction between Na3SbO4 and fluohydric acid in proportion of 1: 6.6~9.5 under 50-100 degree C, filtrate to remove insoluble residue and condense the filter liquor under 95~136 deg.c; then cool, crystallization and centrifugal separation to obtain the product Na3SbF6, then the mother liquor is returned for recondensation. Advantages: directly product Na3SbF6 to save the preparation if the intermediate product of H3SbF6 or SbF5, easy and accurate control to stoichiometry of sodium and antimony; lower comprehensive cost.

Owner:CENT SOUTH UNIV

Organosilane crosslinked polyethylene power cable material with sound absorption and sound insulation functions and preparation method thereof

InactiveCN104829910AImprove barrier propertiesImprove tear resistancePlastic/resin/waxes insulatorsAcoustic absorptionAntimony trioxide

The invention discloses an organosilane crosslinked polyethylene power cable material with sound absorption and sound insulation functions. The material is characterized by being made of the following raw materials by weight: 60 to 70 parts of high-density polyethylene, 30 to 40 parts of medium-density polyethylene, 14 to 17 parts of nylon 6, 11 to 14 parts of acrylic fibers, 10 to 15 parts of vermiculite, 30 to 40 parts of polyurethane emulsion, 14 to 20 parts of vinyltriethoxvsilane, 13 to 18 parts of StronWi powder, 1.4 to 2.8 parts of antimonous oxide, 2 to 4 parts of sodium antimonate, 0.1 to 0.3 part of an antioxidant 1010, 0.2 to 0.4 part of vinyl benzene, 0.3 to 0.5 part of dibutyltin dilaurate, 2.1 to 3.5 parts of dioctyl phthalate, 3 to 5 parts of isopropyl palmitate and a proper amount of water. According to the invention, the addition of modified acrylic fibers improves tear resistance of the power cable material; the addition of vermiculite with pores of different sizes as a filler can improve sound absorption and sound insulation properties of the power cable material; meanwhile, the organosilane crosslinked polyethylene power cable material provided by the invention is low in smoke and free of halogen, does not release poisonous and harmful gas, is safe and environment friendly, has excellent properties like thermal aging resistance, oil resistance and wear resistance and has broad application prospects.

Owner:BENGBU TIANGUANG SENSOR

Method for preparing nanometer sulfo antimony acid antimony

ActiveCN102583534AEasy to recycleGood compatibilityNanotechnologyAntimonates/antimonitesPerformance indexLubrication

The invention discloses a method for preparing nanometer sulfo antimony acid antimony via the uniform precipitation method, comprising the following steps: employing leukonin and antimony white as the raw materials; utilizing sodium sulfide to leach leukonin, thus to obtain a pentavalent antimony solution; employing the sodium chloride solution of the hydrochloric acid to leach antimony white forpreparing a trivalent antimony solution; slowly adding the two solutions into a buffer system containing a surfactant; and employing supersonic wave stirring for homogeneous precipitation. The generated precipitation, after receiving the treatment of aging, dispersing, rinsing, and drying in a tartrate solution, is turned into the nanometer sulfo antimony acid antimony product. The method features simple process and high yield, causes no pollution to the environment, and is easy to operate and put into industrial production. The color of the produced product is umber, with granularity being 93nm, and is compatible with the grease. The produced nanometer sulfo antimony acid antimony is an excellent extreme pressure-antiwear additive and solid lubricant of the lubrication grease. As an additive, the performance index of the product far exceeds the national standards about the extreme pressure lubrication grease.

Owner:YIYANG SHENGLI CHEM IND

Preparation method of MOF framework catalyst for biomass catalytic pyrolysis

ActiveCN111939980AHigh selectivityHigh yieldOrganic-compounds/hydrides/coordination-complexes catalystsBiofuelsCatalytic pyrolysisLiquid product

The invention discloses a preparation method of an MOF framework catalyst for biomass catalytic pyrolysis. The method comprises: dropwisely and slowly adding cadmium chloride and sodium pyroantimonateisopropanol solution into 2-methylimidazole and alkene nitrile isopropanol solution, stirring, heating to 30-50 DEG C in a water bath, reacting for 6-10h, centrifugally separating a product, washingwith ethanol and deionized water, and drying to obtain the MOF skeleton catalyst with the surface alkaline constant Kb and the acid constant Ka of 0.7-1.5:1 and the pore diameter structure of 0.3-60 nm. The MOF skeleton catalyst for biomass catalytic pyrolysis is synthesized by taking cadmium chloride and sodium pyroantimonate as metal raw materials and taking 2-methylimidazole and alkene nitrileas organic ligand raw materials, and has the advantages of simple preparation process, high selectivity and yield of guaiacol in a biomass pyrolysis liquid product, easiness in large-scale productionand the like.

Owner:HANGZHOU DIANZI UNIV

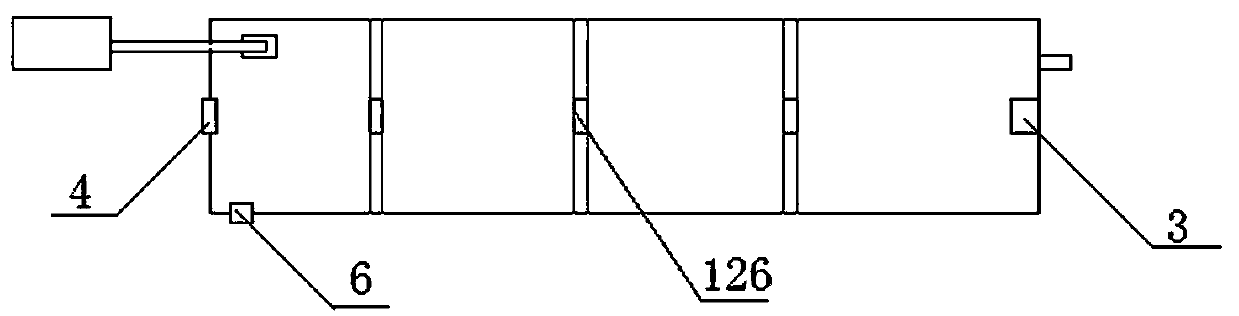

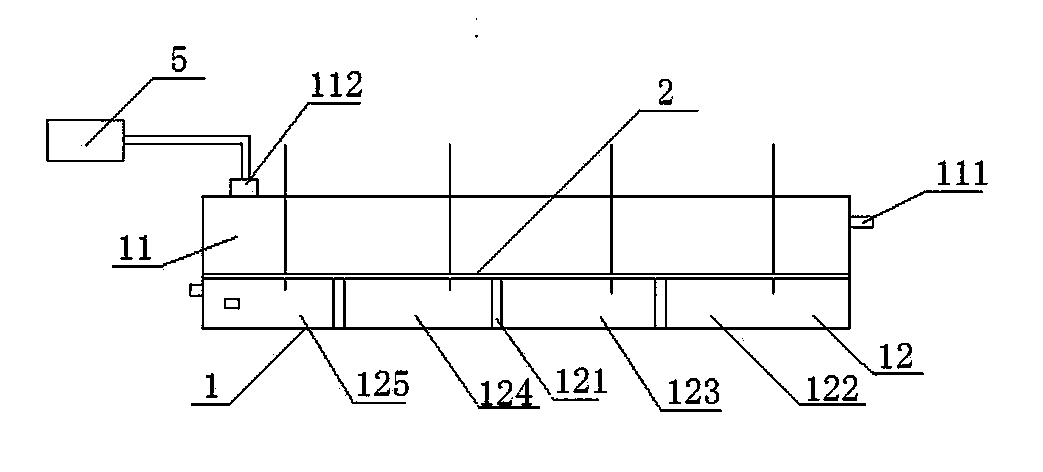

Soft-light colored glass product, and making method and special apparatus thereof

InactiveCN103466939AQuality improvementReduce volatilityGlass furnace apparatusCadmium CationPotassium carbonate

The invention relates to a soft-light colored glass product, and a making method and a special apparatus thereof. The soft-light colored glass product is made through using the following raw materials, by weight, 50-70 parts of silica powder, 10-16 parts of sodium carbonate, 12-22 parts of feldspar powder, 10-24 parts of aluminum hydroxide, 1-12 parts of zinc oxide, 4-24 parts of calcium carbonate, 1.4-12 parts of borax, 8-16 parts of sodium fluosilicate, 0.8-5.8 parts of potassium carbonate, 0.4-4 parts of sodium nitrate and 6.6-70 parts of an auxiliary material, and the auxiliary material comprises several selected from titania, barium carbonate, red lead, calcium phosphate, barium sulfate, magnesium oxide, fluorite, arsenic trioxide, antimony oxide, cobalt oxide, copper oxide, chrome oxide green, sodium antimonate, cadmium yellow, sulfur, uranium oxide, cerium oxide, cadmium red, cadmium sulfide, selenium powder and yttrium aluminum garnet. The making method comprises the following steps: 1, melting ingredients; 2, molding; and 3, cutting, annealing, examining, and packaging. The soft-light colored glass product has a long service life, required raw materials do not pollute the environment, and the soft-light colored glass product can be a lamp tube, a lamp cover or a lamp, and is used in lighting or entertainment lighting fittings.

Owner:申英良

Light plastic door and window

The invention discloses a light plastic door and window which is prepared from the following raw materials in parts by mass: 6-10 parts of sisal fiber, 60-70 parts of a 20-30% sodium hydroxide solution, 30-41 parts of dimethyl carbonate, 2-3 parts of op-10, 20-30 parts of n-butyl acrylate, 0.4-0.6 part of ammonium persulfate, 60-70 parts of vinyl acetate, 36-40 parts of benzyl chloride, 400-430 parts of polyvinyl chloride, 2-4 parts of polyvinyl butyral, 6-8 parts of dibutyl maleate, 2-4 parts of chitosan, 4-7 parts of boron, 0.4-1 part of hexabromocyclododecane, 2-4 parts of sodium antimonate, 10-17 parts of scolecite, 3-5 parts of potassium pyrophosphate, 31-40 parts of light calcium carbonate and 3-5 parts of palm wax. According to the light plastic door and window disclosed by the invention, the sisal fiber is treated by microwaves to improve the dispersibility of cellulose, so that the accessibility of benzyl chloride to cellulose is increased; after etherification treatment, the quantity of hydroxyl is reduced, and cellulose crystalline texture is damaged to obtain thermoplasticity.

Owner:阜阳市锐达不锈钢制品销售有限公司

Ultra-thin crystal glass and preparation method thereof

InactiveCN105924010AHigh strengthImprove toughnessGlass rolling apparatusSodium bicarbonateChemical synthesis

The invention belongs to the field of chemical synthesis, and concretely discloses an ultra-thin crystal glass. The ultra-thin crystal glass comprises the following raw materials: 45 to 50 parts of silicon oxide, 15 to 20 parts of calcium oxide, 15 to 20 parts of magnesium oxide, 5 to 15 parts of aluminum oxide, 3 to 8 parts of lithium oxide, 2 to 6 parts of aluminum phosphate, 3 to 5 parts of calcium fluoride, 2 to 6 parts of barium oxide, 8 to 10 parts of boron oxide, 2 to 8 parts of sodium oxide, 0.7 to 1.2 parts of zirconium oxide, 0.02 to 0.08 part of bismuth oxide, 0.03 to 0.09 part of titanium oxide, 2 to 2.5 parts of antimony oxide, 0.03 to 0.08 part of lanthanum oxide, 3 to 3.5 parts of cerium carbonate, 0.05 to 0.09 part of zinc oxide, 3 to 8 parts of mirabilite, 0.21 to 0.57 part of cerium oxide, 0.9 to 2.2 parts of tin oxide, 1.1 to 2.5 parts of sodium sulfantimonate, 0.6 to 0.9 part of sodium pyroantimonate, 2.1 to 3.2 parts of sodium hexafluoroantimonate, 6 to 8 parts of mica, 0.04 to 0.17 part of sodium bicarbonate, 0.3 to 0.5 part of fumed silica and 0.9 to 1.6 parts of silica sol. The invention also provides a preparation method for the ultra-thin crystal glass. According to the invention, the durable performance of ultra-thin glass is increased.

Owner:东莞市银泰玻璃有限公司

Corrosion resistant epoxy resin paint

ActiveCN106752721AStrong adhesionImprove corrosion resistanceAnti-corrosive paintsPolyamide coatingsSodium antimonateMechanical property

The invention discloses a corrosion resistant epoxy resin paint. The corrosion resistant epoxy resin paint comprises a component A and a component B; the component A contains the following raw materials according to weight ratio: 40-60 parts of bisphenol A epoxy resin, 15-35 parts of polyamide resin, 10-18 parts of E-44 epoxy resin, 2-4 parts of a silane coupling agent, 2-8 parts of a zeolite powder, 1-5 parts of sodium antimonate, 5-15 parts of a modified bamboo powder, 0.5-1.5 parts of epoxidized soybean oil, 2-4 parts of dibutyl ester, 1-2 parts of an anti-settling agent, 1-2 parts of a leveling agent, 1-2 parts of a dispersant and 1-2 parts of a defoaming agent; the component B contains the raw materials in parts by weight: 15-25 parts of di-hexyl triamine, 15-25 parts of hexamethylene diamine, 15-20 parts of butanol and 2-10 parts of dimethylbenzene; the weight ratio of the component A to the component B is 10: 2-4. The corrosion resistant epoxy resin paint disclosed by the invention has the advantages of strong adhesive force, good corrosion resistance and excellent mechanical property.

Owner:安徽浩丰特种电子材料有限公司

Silicone rubber environment-friendly and flame-retardant cable material used for rail locomotive vehicle

InactiveCN104017373AImprove flame retardant performanceLow smoke productionHazardous substanceDiphenylsilanediol

Owner:ANHUI KANGLIYA CO LTD

Decorative PVC (Polyvinyl Chloride) film

The invention discloses a decorative PVC (Polyvinyl Chloride) film. The decorative PVC film is prepared from the following raw materials in parts by weight: PVC440 resin powder, nano-tic, chitosan-grafted polyacrylic acid, polyoxyethylene sorbitan monostearate, tetrabutyl titanate, ethyl stearate, stearyl clcohol, titanium bis(triethanolamine)diisopropoxide, saturated fatty alcohol multiple carboxylic ester, sodium antimonate, zinc chromate, plasticizer, stabilizer and antioxidant. Through reasonable combination in a formula, the obtained decorative PVC film has the advantages of aging resistance, high toughness, good thermal stability and high flame resistance. Meanwhile, the decorative PVC film further has the characteristic of acid and alkali resistance.

Owner:黄山豪泰塑胶有限公司

Preparation method of guaranteed-reagent sodium antimonate

InactiveCN105314676ASimple preparation processControllableAntimonates/antimonitesFiltrationDistilled water

The invention relates to a preparation method of guaranteed-reagent sodium antimonate, which includes the following steps: 1) oxidization of antimonous oxide: placing the antimonous oxide and sodium hydroxide into a stainless steel barrel, adding distilled water with continuous stirring to dissolve the raw materials, heating the solution at 60 DEG C, and adding slowly a hydrogen peroxide solution with continuous stirring to obtain sodium antimonate precipitate, and spin-drying the precipitate to obtain a substance A; and (2) synthesis to prepare the guaranteed-reagent sodium antimonate: adding the substance A in the step 1) to a 37 wt% hydrochloride acid solution with continuous stirring to dissolve the substance A, regulating the pH to 2, performing filtration to obtain a solution B, adding sodium hydroxide to the solution B with continuous stirring to neutralize the solution until pH=6, separating out the precipitate and cooling the precipitate, washing the precipitate with distilled water, spin-drying the precipitate and drying the precipitate in a drier at 110 DEG C for 3 h to obtain the guaranteed-reagent sodium antimonate. In the method, under effects of the oxidizing agent hydrogen peroxide, the sodium antimonate is generated by oxidizing the antimonous oxide and carrying out a reaction to the oxidized antimonous oxide and sodium hydroxide.

Owner:TIANJIN CHEM REAGENT RES INST

High impact polystyrene (HIPS) flame-retardant plastic

InactiveCN103497477AGood flame retardant functionMechanical strength is not affectedPolymer sciencePolymer chemistry

The invention discloses high impact polystyrene (HIPS) flame-retardant plastic. The HIPS flame-retardant plastic comprises, by weight, 105-110 parts of HIPS, 10-15 parts of nano-silica, 10-15 parts of melamine cyanurate, 10-15 parts of glass fibers, 10-12 parts of sodium antimonate, 8-11 parts of styrene, 14-16 parts of alkylbenzene sulfonate, 2-3 parts of copper oxalate, 10-20 parts of triphenyl thiophosphate and 10 parts of zirconia. The HIPS flame-retardant plastic has good fire resistance and a small amount of the HIPS flame-retardant plastic can produce obvious flame retardation effects. Mechanical strength of the HIPS flame-retardant plastic is not influenced and especially, a heat deflection temperature, a kinetic temperature and electric insulation properties of a plastic product are not influenced. The HIPS flame-retardant plastic can be uniformly dispersed and has good weatherability, long action time and long-term flame resistance.

Owner:WUJIANG TIANYUAN PLASTIC

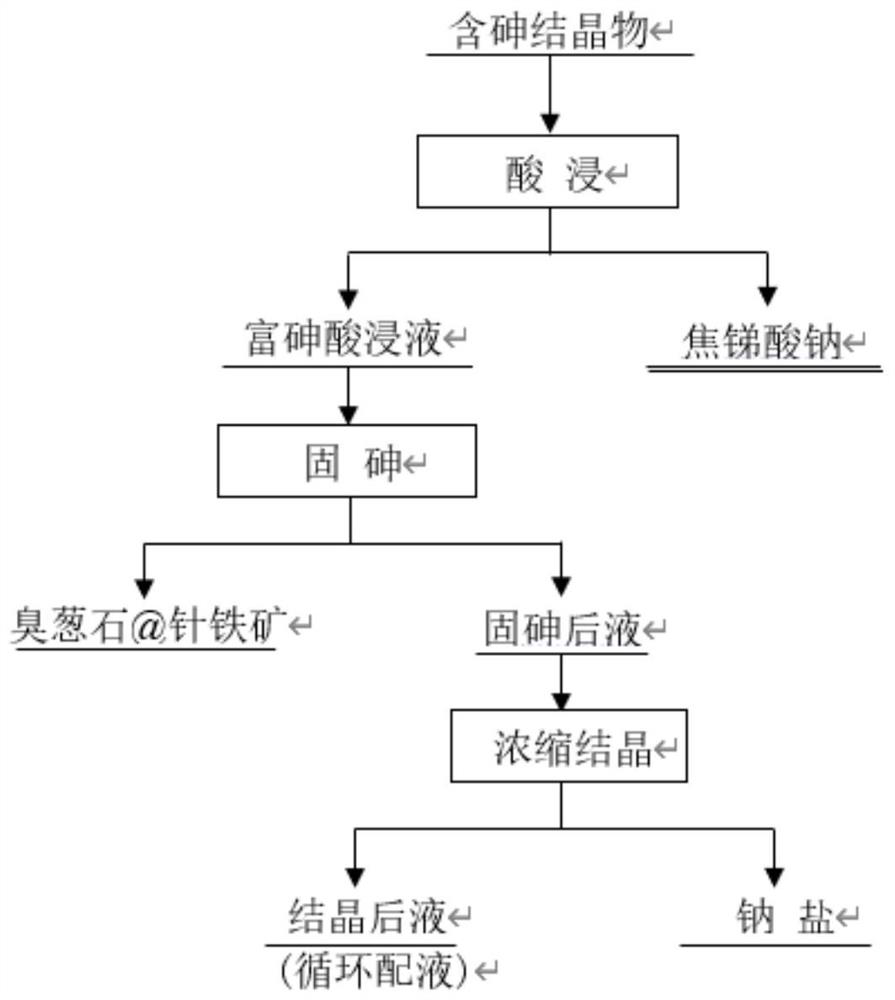

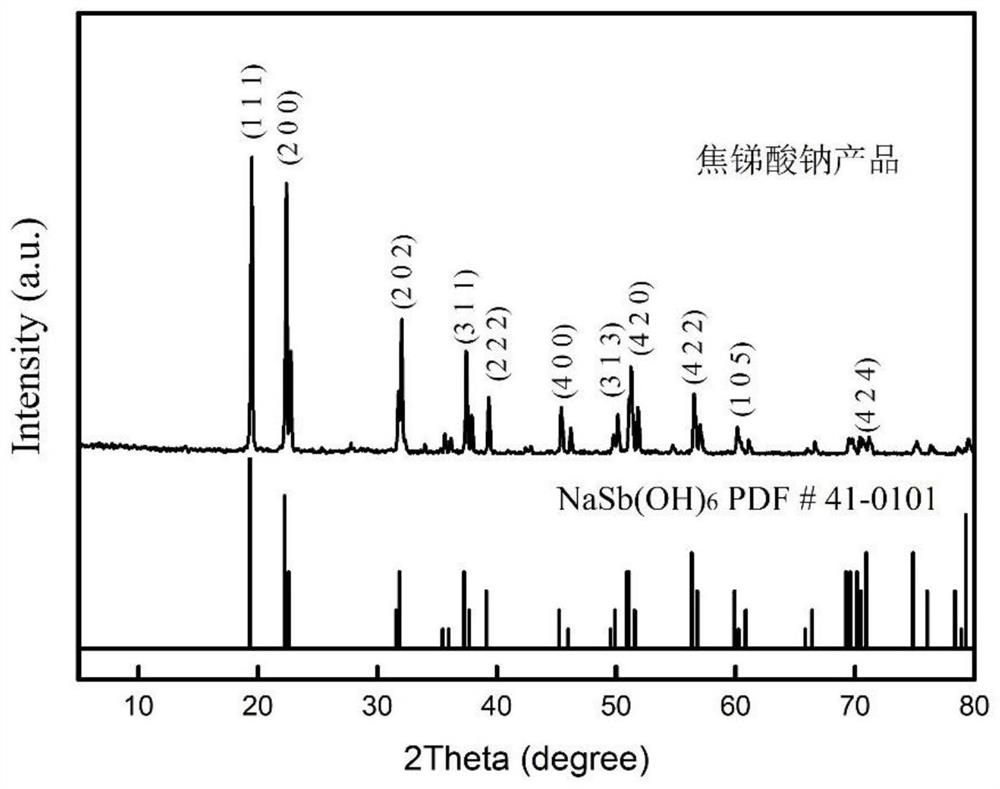

Method for recovering antimony and solid arsenic from arsenic-containing crystal substance

ActiveCN114561558ARealize closed loopClosed loop to eliminateArsenites/arsenatesIron oxides/hydroxidesNonferrous metalPhysical chemistry

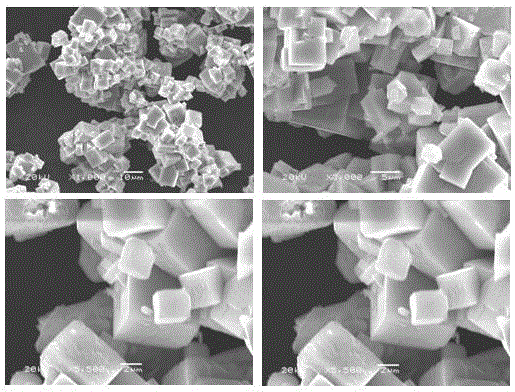

The invention discloses a method for recycling antimony through acid leaching of arsenic-containing crystal substances, fixing arsenic in arsenic-rich pickle liquor and recycling sodium salt through concentration and crystallization of liquor after arsenic fixing, and relates to the field of resource utilization of by-products in production of non-ferrous metal chemicals. According to the method, arsenic-containing crystal substances in sodium pyroantimonate production are leached through dilute sulphuric acid to obtain cubic crystal sodium pyroantimonate which meets the first-grade product of the Chinese nonferrous metal industry standard (YS / T 22-2010), and the technical problem of recycling antimony in the arsenic-containing crystal substances is solved. Ferrite is added into the arsenic-rich acid leaching solution, oxygen is introduced into the arsenic-rich acid leaching solution to synthesize the high-stability scorodite and goethite core-shell structure, the arsenic concentration in TCLP is lower than the specified value 5 mg / L of the national standard (GB5085.3-2007), and non-toxic and harmless arsenic in arsenic-containing non-ferrous metal resource utilization is achieved. And concentrating and crystallizing the arsenic-fixing liquid to recover the sodium salt, thereby completing the purification and regeneration of the solution and achieving the purpose of closed-loop cyclic utilization of the solution. The method has the advantages of simple operation, stable product components, high stability of the arsenic fixing material, good solution cycle performance and the like.

Owner:CENT SOUTH UNIV

Low-after-shrinkage and high-toughness flame-retardant PBT/PC composition and preparation method and application thereof

The invention discloses a low-after-shrinkage and high-toughness flame-retardant PBT / PC composition and a preparation method and application thereof. The PBT / PC composition comprises the following components in parts by weight: 35-40 parts of PBT resin; 30-35 parts of PC resin; 4-6 parts of an ethylene-vinyl acetate copolymer; 3-5 parts of sodium antimonate; 6-8 parts of a toughening agent; 12-15 parts of brominated flame retardant; 0.05-0.2 part of a transesterification inhibitor; 0.1-0.3 part of an antioxidant; 0.5-1 part of a lubricant; the brominated flame retardant is brominated polycarbonate and / or brominated polystyrene. The PBT / PC composition has low after-shrinkage, high toughness and high flame retardant property, and is especially suitable for preparing electronic component products in a high-temperature working environment.

Owner:KINGFA SCI & TECH CO LTD

Sealing rubber strip for automobile window and preparation method of sealing rubber strip

The invention discloses a sealing rubber strip for an automobile window. The sealing rubber strip is made of the following materials in parts by weight: 22-26 parts of polyvinyl chloride, 40-45 parts of ethylene-propylene-diene-terpolymer rubber, 6-10 parts of paraffin, 7-11 parts of poly propadiene siloxane, 12-15 parts of tert-Butylhydroquinone, 18-20 parts of diisobutyl phthalate, 9-14 parts of sulfydryl acid ester, 8-12 parts of lauryl alcohol polyoxyethylene, 6-12 parts of sodium fluosilicate, 2-4 parts of coal gangue, 15-20 parts of carbon black, 2-3 parts of trichlorofluoromethane, 4-8 parts of sodium alcohol ether sulfate, 6-11 parts of aluminum borate crystal whisker, 12-14 parts of silicic acid hydrate, 9-15 parts of sodium antimonate, 3-8 parts of diisopropylamine and 7-11 parts of glyceryl tristearate. The sealing rubber strip of the automobile window is provided with bubbles inside and is good in elasticity, good in corrosion resistance and aging resistance, and long in service life.

Owner:芜湖天鸿汽车零部件有限公司

Method for manufacturing low-expansion glass-ceramics by high silicon-iron tailings

A method for manufacturing low-expansion glass-ceramics by high silicon-iron tailings comprises the step of perparing a low-expansion glass-ceramics batch which comprises the following materials in parts by weight: 40-45 parts of 80-mesh high-silicon iron tailings, 50-55 parts of 100-mesh quartz sand, 10-15 parts of 100-mesh alumina, 10-15 parts of lithium carbonate, 3-6 parts of zinc oxide, 3-6 parts of barium selenate, 2-5 parts of rare-earth cerium oxide powder, 1-4 parts of lithium zirconate, 2-5 parts of boron nitride, 3-6 parts of praseodymium chloride, 0.2-0.5 part of beryllia, 0.5-0.9 part of bismuth subcarbonate and 0.1-0.4 part of sodium antimonate. The invention aims to provide the method for manufacturing low-expansion glass-ceramics by high silicon-iron tailings, the method can reduce environmental pollution and lower manufacturing cost, and the obtained glass-ceramics is low in thermal expansion coefficient, high in thermal stability and softening temperature and very good in thermal shock resistance.

Owner:BEIJING QING MAI HUA QING HLDG GRP CO LTD

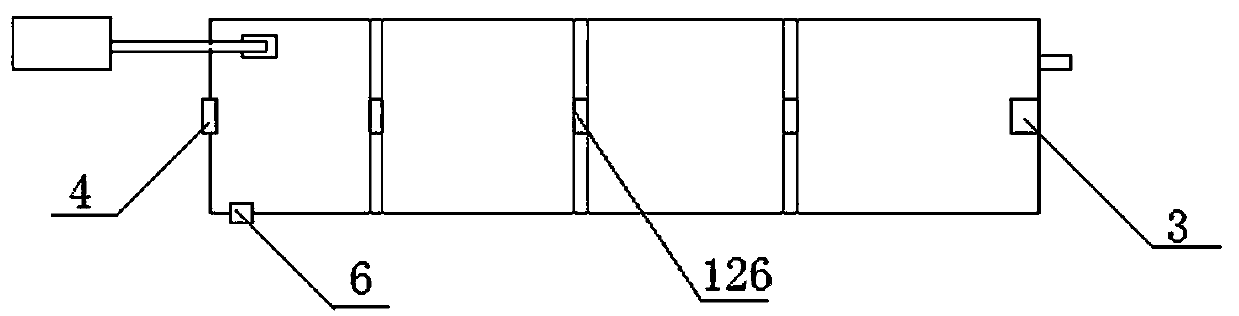

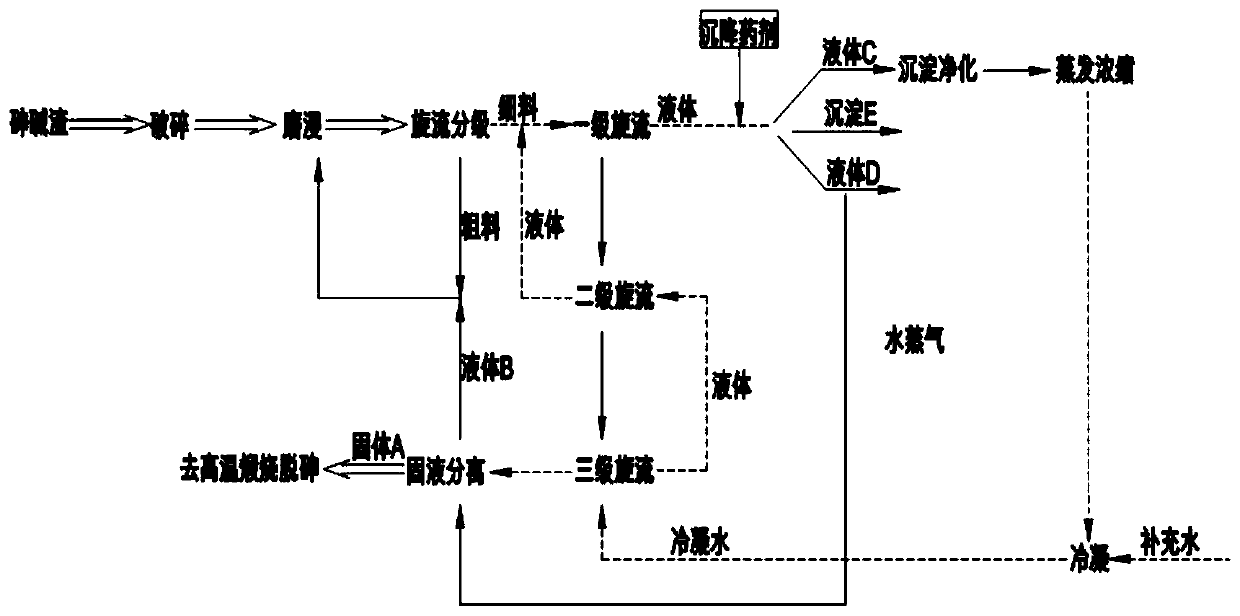

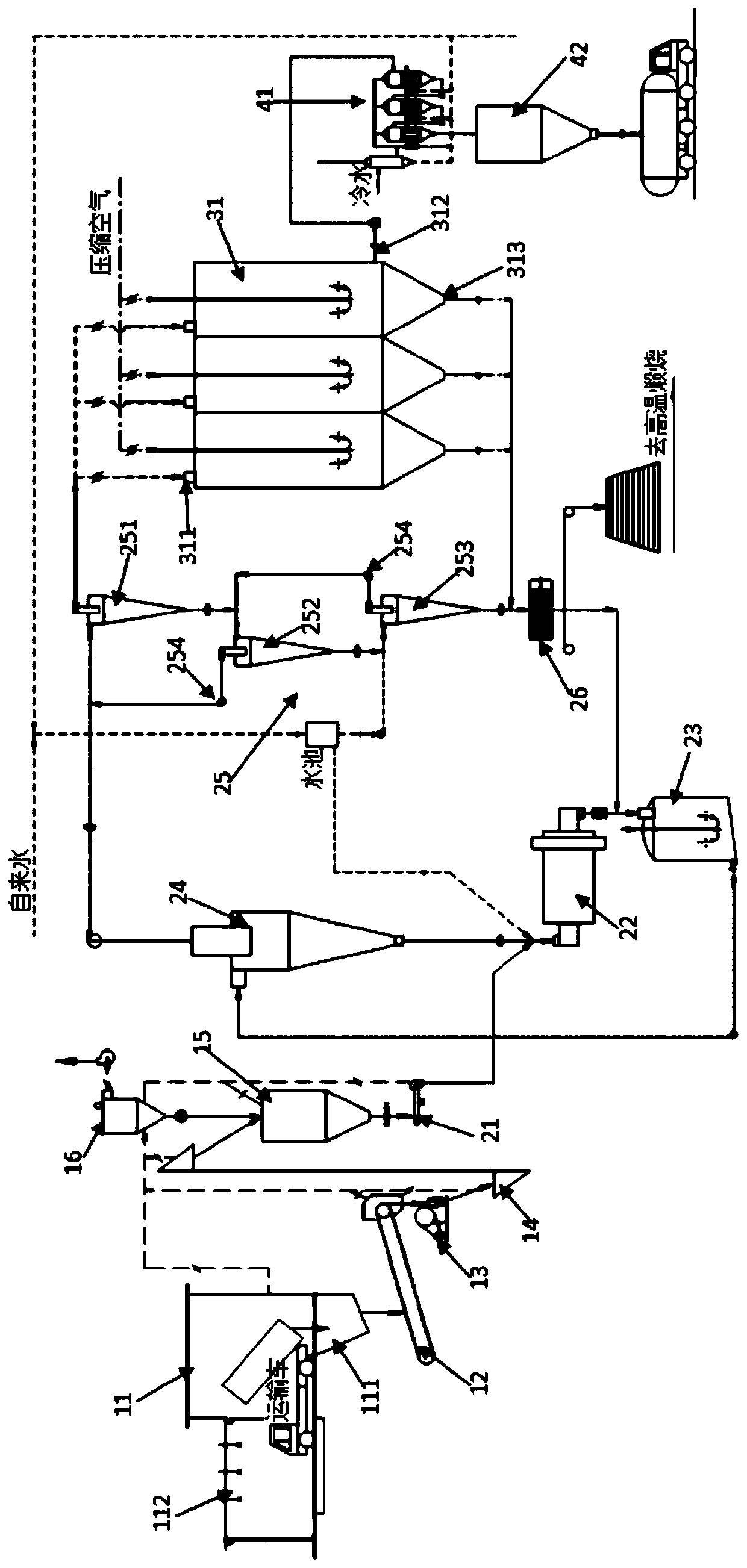

Collaborative treatment system and method for treating arsenic alkali residue grinding leaching dealkalization and cement kiln recycling

ActiveCN109776001AReduce consumptionReduce in quantityCement productionAlkali metal oxides/hydroxidesEvaporationCircular economy

The invention discloses a collaborative treatment system and method for treating arsenic alkali residue grinding leaching dealkalization and cement kiln recycling, arsenic alkali residue is sequentially subjected to crushing, grinding leaching dealkalization, alkali liquor purification and alkali liquor evaporation treatment, washing is carried out for multiple times during the grinding leaching dealkalization, the alkali content of the residue after dealkalization is greatly reduced, and sodium arsenate and sodium antimonate in the solution are converted into precipitate substances which areinsoluble in water under the action of a precipitant, so that high-temperature calcination is facilitated, arsenic and antimony in the arsenic alkali residue are removed, the alkali liquor generated in the treatment process can be evaporated and concentrated to be used as a smelting medicament or a desulfurizing agent and the like, the obtained solid can be calcined at high temperature, the calcined residue is used as a cement raw material, the production cost is saved, and the requirements of development cycle economy and sustainable development are met.

Owner:长沙中硅环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com