Soft-light colored glass product, and making method and special apparatus thereof

A colored glass and soft light technology, applied in glass manufacturing equipment, glass furnace equipment, manufacturing tools, etc., can solve the problems of easy discoloration of products, short service life, and easy environmental pollution of raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

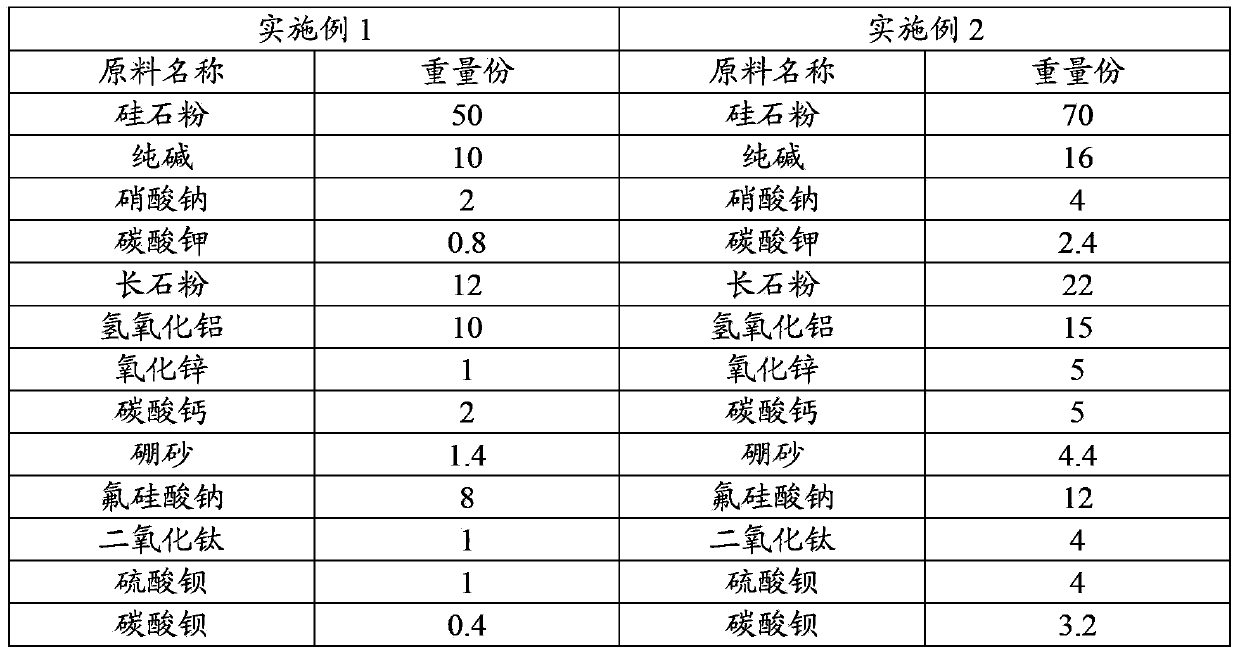

[0030] Embodiment 1: A milky white soft light stained glass lampshade made from the raw materials shown in Table 2:

[0031] The preparation method of the milky white soft light stained glass lampshade is as follows:

[0032] (1) Ingredients and melting: grind and pulverize the silica powder, soda ash, feldspar powder, aluminum hydroxide, zinc oxide, calcium carbonate, borax, sodium fluorosilicate, potassium carbonate, sodium nitrate and auxiliary materials shown in Table 2 in proportion Mix evenly to obtain the batch material. The batch material is added to the silo by a feeder, and evenly added to the melting pool of the kiln at a speed of 15kg / min. The mixture is first melted in the first melting zone at 1380°C for 5 hours, and then enters the second melting zone at 1350°C Melting at ±3°C for 3 hours, then entering the homogenization zone for melting at 1280±3°C for 2 hours, and finally entering the working area for melting at 1260±3°C for 2 hours to obtain uniform and clea...

Embodiment 2

[0035] Embodiment 2: A milky white soft light stained glass lampshade is made of the raw materials shown in Table 2, and the preparation method is as follows:

[0036](1) Ingredients and melting: grind and pulverize the silica powder, soda ash, feldspar powder, aluminum hydroxide, zinc oxide, calcium carbonate, borax, sodium fluorosilicate, potassium carbonate, sodium nitrate and auxiliary materials shown in Table 2 in proportion Mix evenly to obtain the batch material. The batch material is added into the silo with a feeder, and evenly added to the melting pool of the kiln at a speed of 15kg / min. The mixture is first melted in the first melting zone at 1380°C for 3 hours, and then enters the second melting zone at Melting at 1350±3°C for 3 hours, then entering the homogenization zone for melting at 1280±3°C for 2 hours, and finally entering the working area for melting at 1260±3°C for 2 hours to obtain uniform and clear glass liquid;

[0037] (2) Forming: The molten glass flo...

Embodiment 3

[0042] Embodiment 3: A milky blue soft light stained glass lamp tube, made of the raw materials shown in Table 3:

[0043] The preparation method of the milky blue soft light colored glass lamp tube is as follows:

[0044] (1) Ingredients and melting: grind and pulverize the silica powder, soda ash, feldspar powder, aluminum hydroxide, zinc oxide, calcium carbonate, borax, sodium fluorosilicate, potassium carbonate, sodium nitrate and auxiliary materials shown in Table 2 in proportion Mix evenly to obtain batch materials. The batch materials are added to the silo by a feeder, and evenly added to the melting pool of the kiln at a speed of 15kg / min. The mixture is first melted in the first melting zone at 1380°C for 4 hours, and then enters the second melting zone at Melting at 1350±3°C for 3 hours, then entering the homogenization zone for melting at 1280±3°C for 2 hours, and finally entering the working area for melting at 1260±3°C for 2 hours to obtain uniform and clear glass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com