Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

184 results about "Adipamide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

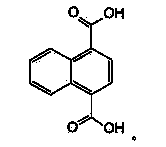

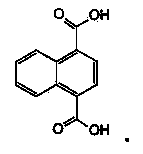

Adipamide is the organic compound with the formula (CH₂CH₂C(O)NH₂)₂. It is a white solid. The dominant commercial interest in adipamides is related to their presence in nylons. Adipamide is formed by treating dimethyl adipate with concentrated ammonia.

Rhodococcus ruber and method for preparing 5-cyanovaleramide by utilizing same

ActiveCN101619299ASimple separation and purification processHigh catalytic efficiencyBacteriaMicroorganism based processesSporeMicroorganism

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

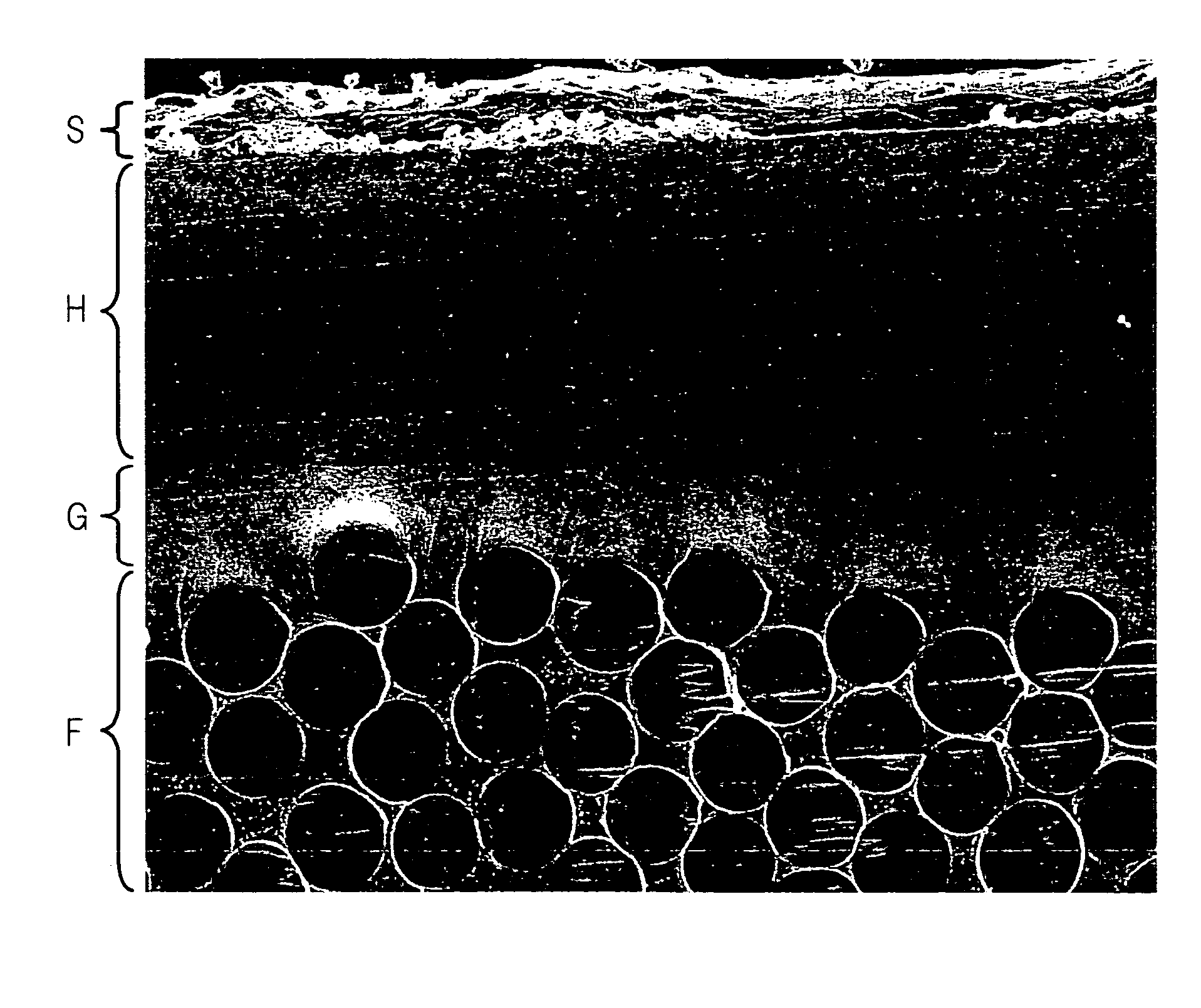

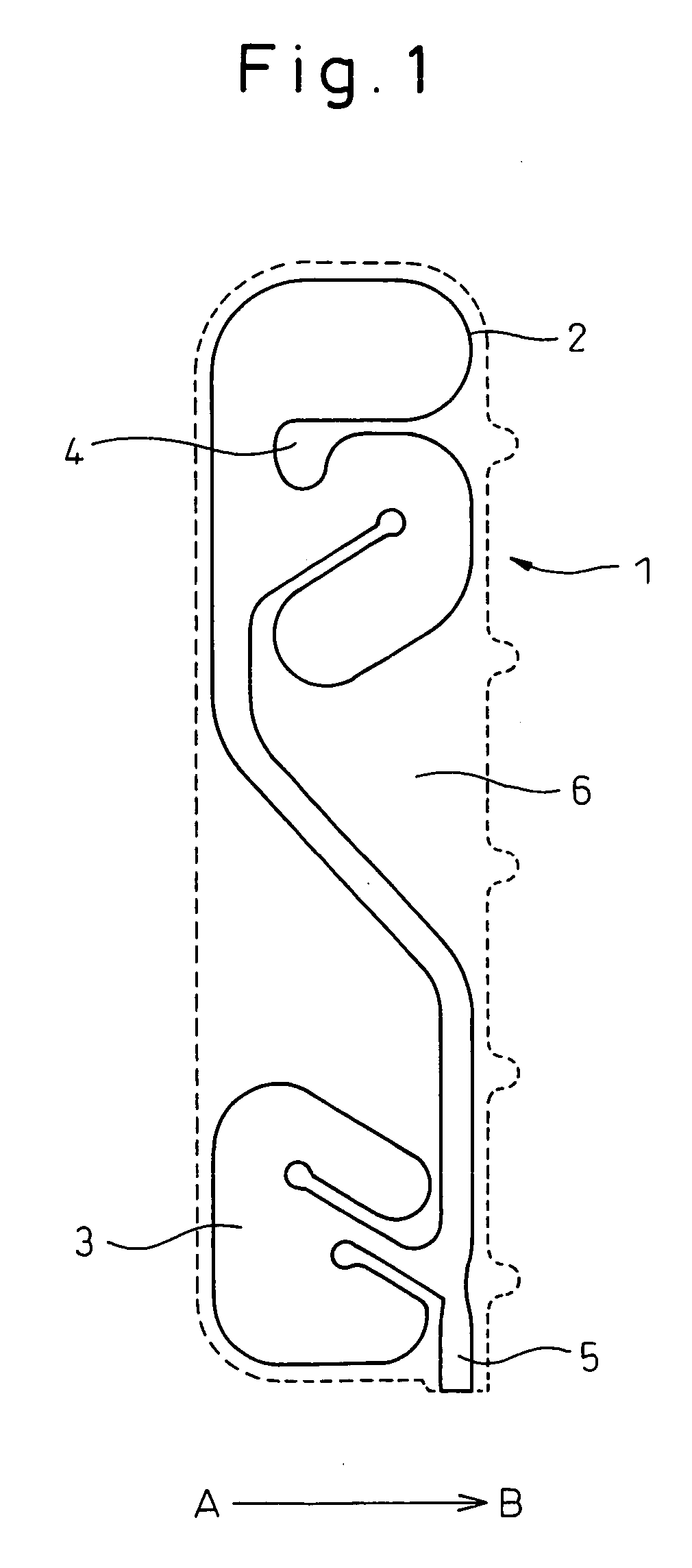

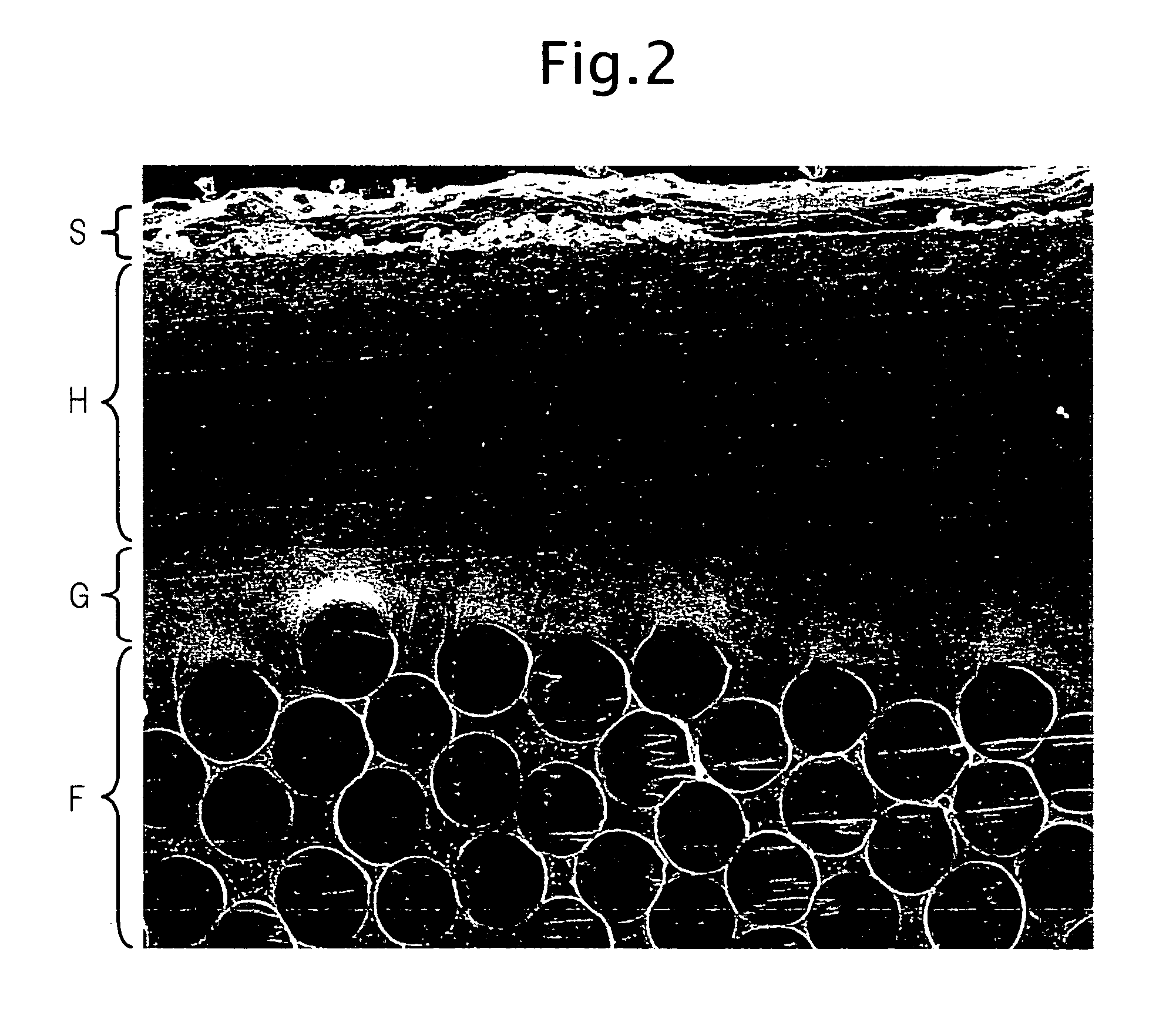

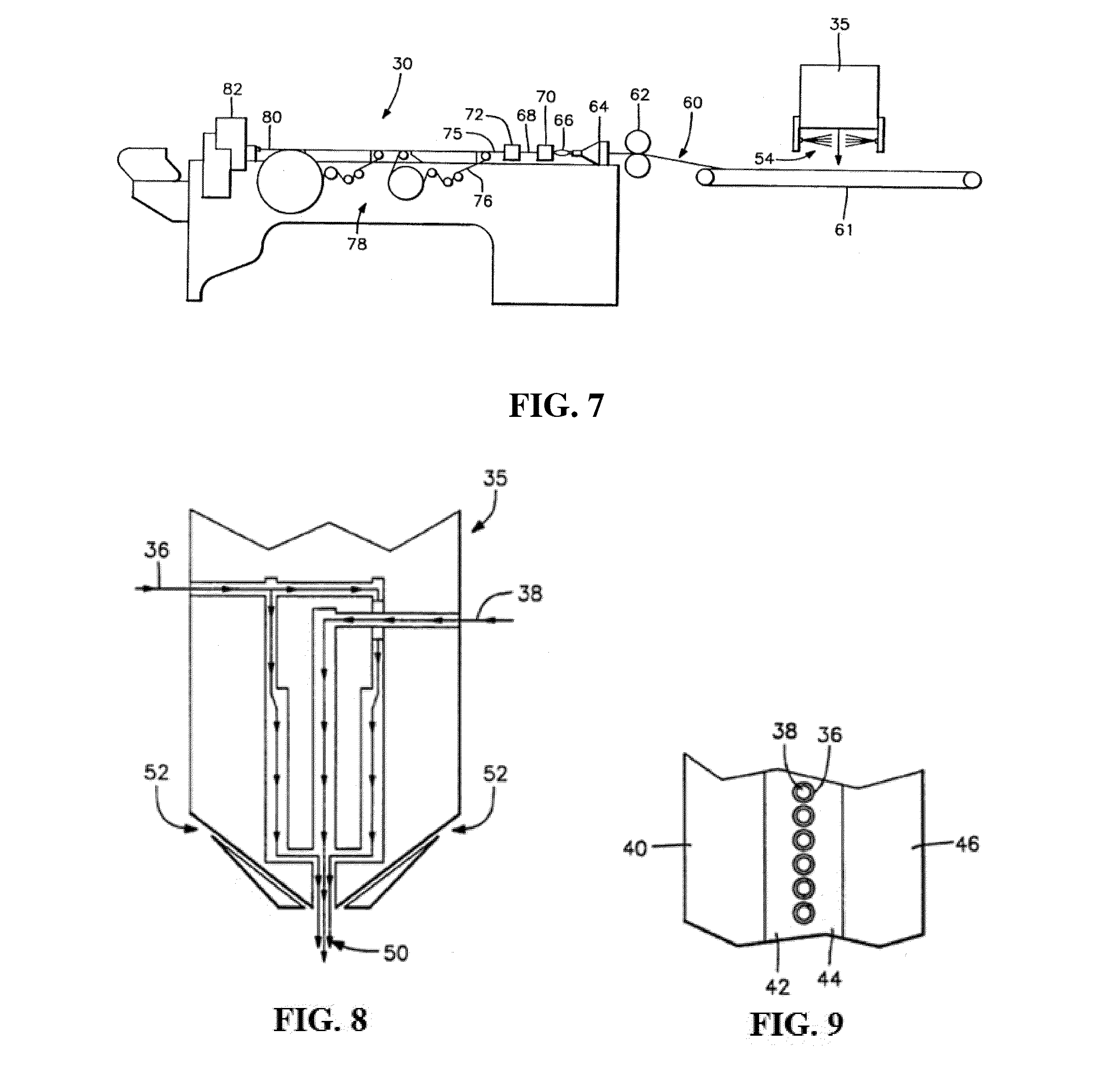

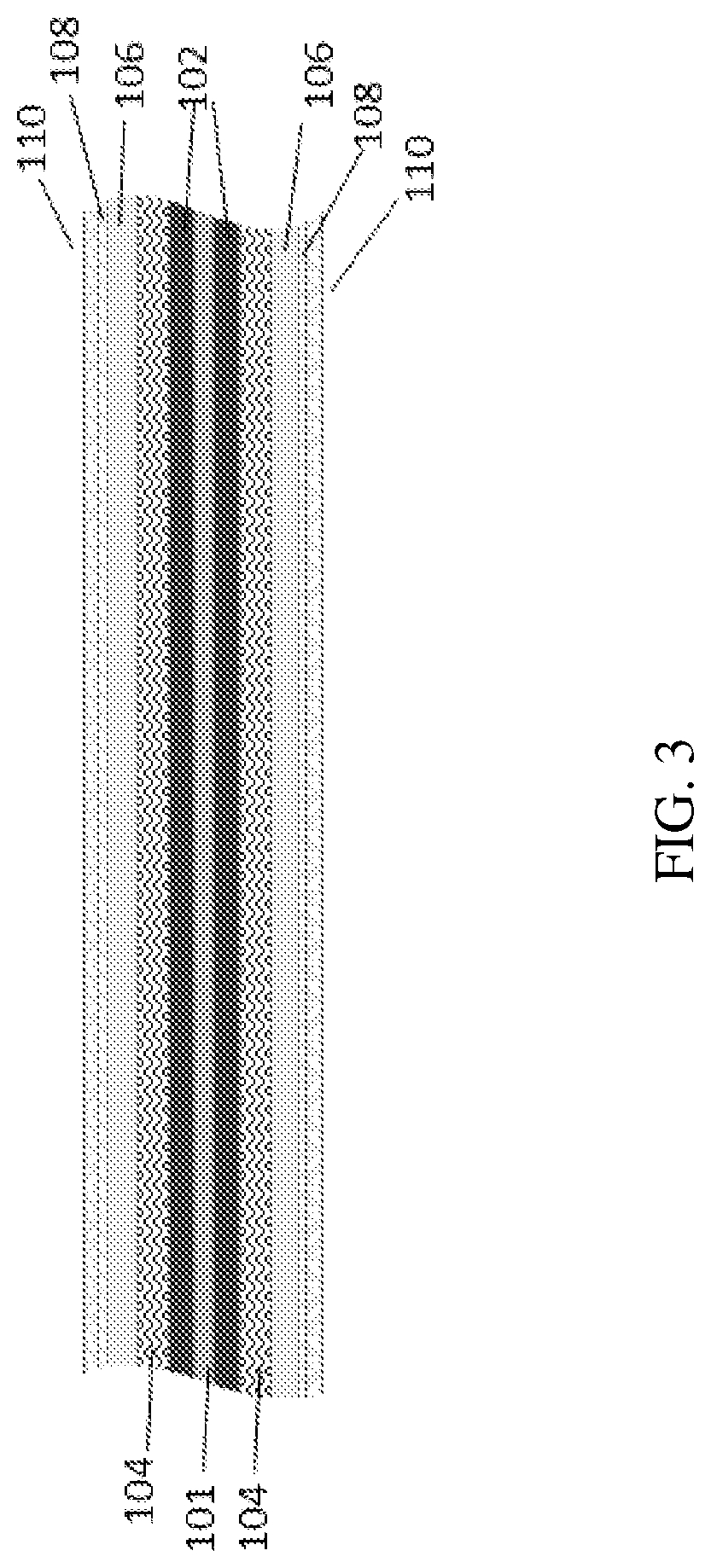

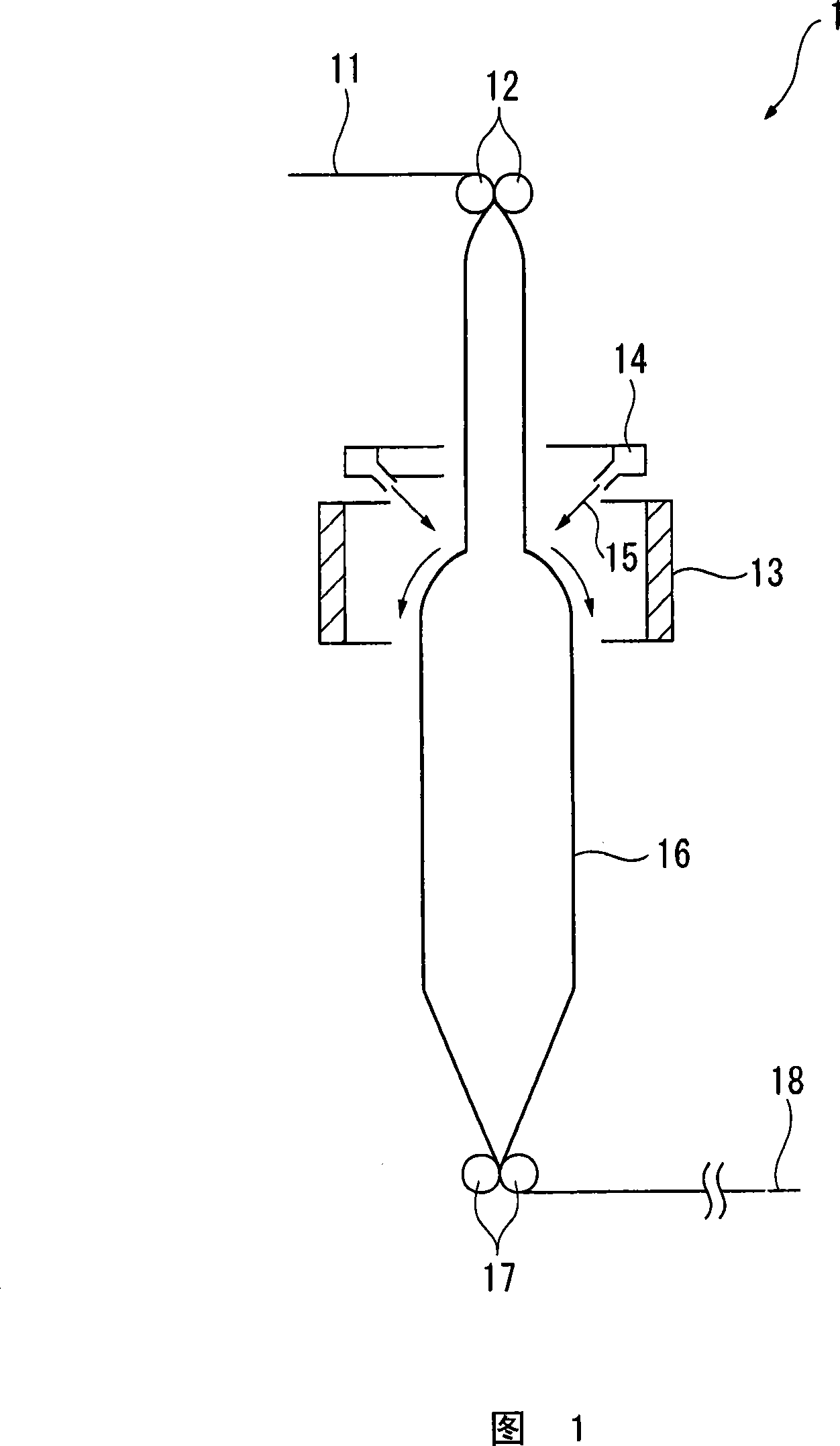

Hollow Weave Fabric for an Air Bag and Method of Producing the Same

InactiveUS20080042414A1Excellent in internal pressure retentionReduce weightLoomsFibre treatmentFiberPolymer science

A hollow weave fabric for an air bag in which the periphery of a double-layer hollow weave portion is formed with a seam zone, wherein the warp yarn and the weft yarn forming the base fabric are each a poly(hexamethylene adipamide) fiber having a total size of 150 to 500 dtex, the double-layer hollow weave portion has a fabric weight of 120 to 350 g / m2 on one side, and the fabric shows a logarithmic decrement of 0.01 to 0.10.

Owner:ASAHI KASEI CHEM CORP

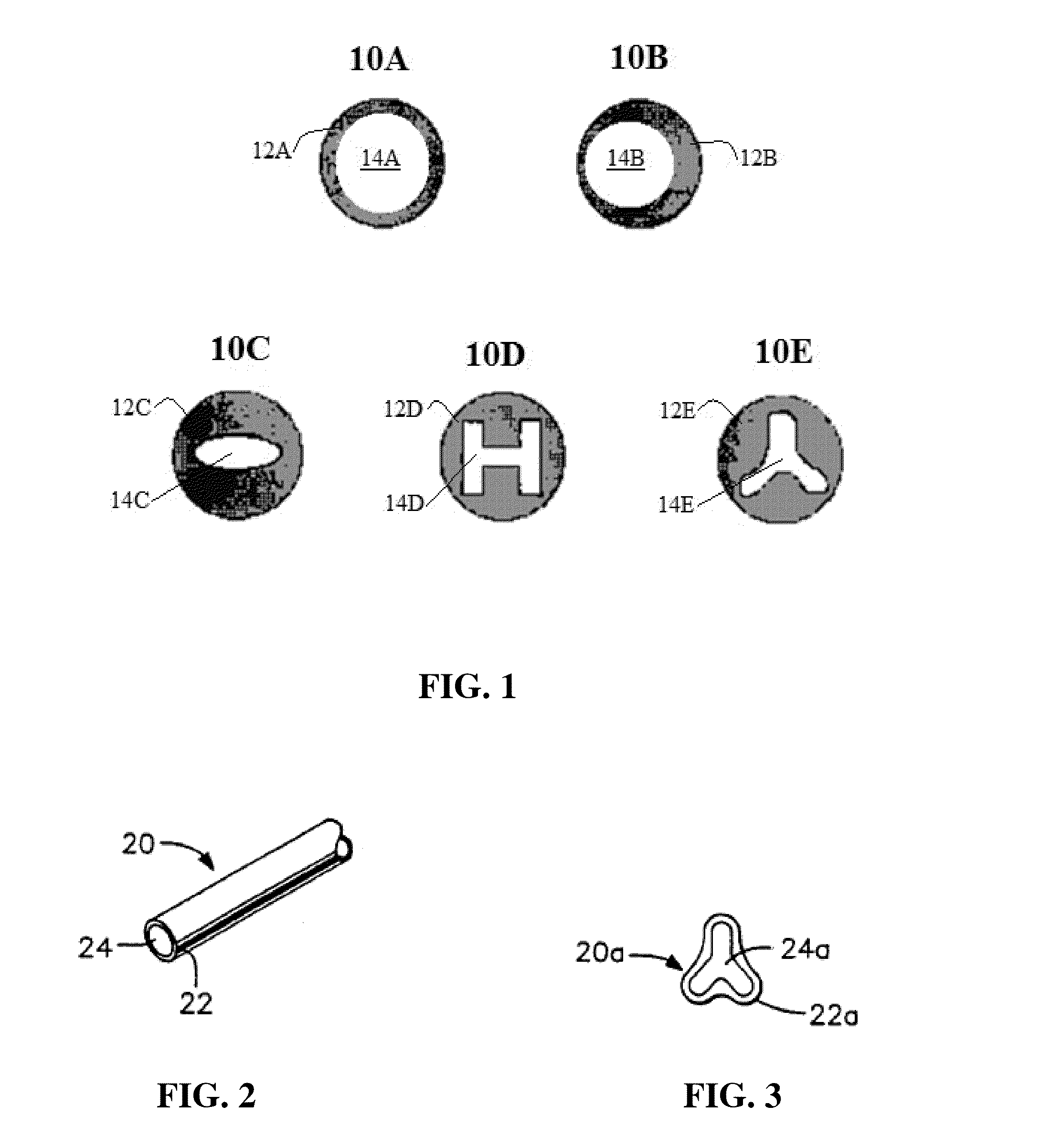

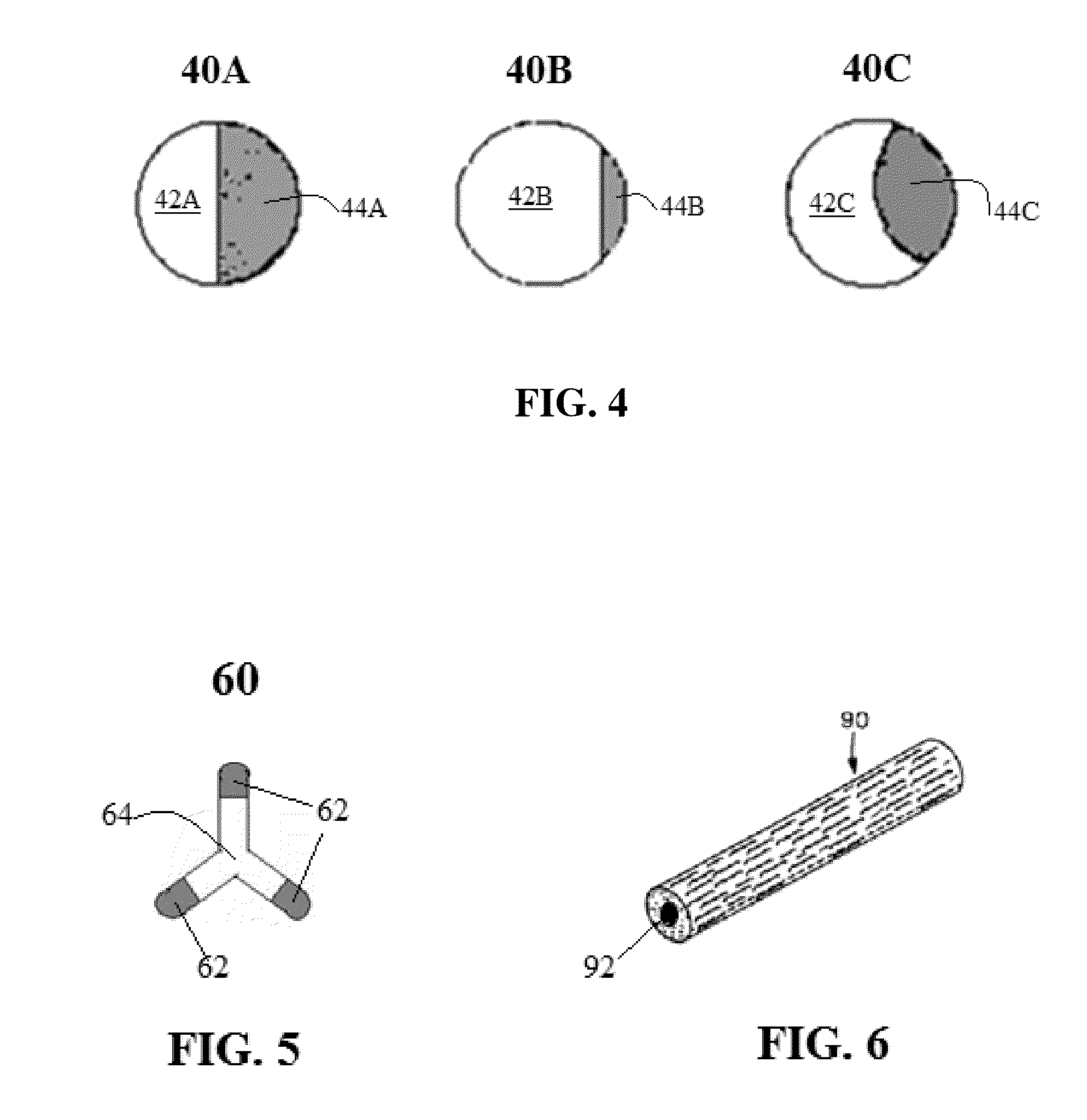

Bicomponent fibers, products formed therefrom and methods of making the same

Melt blown bicomponent fibers comprising a first thermoplastic polymeric material and a second thermoplastic polymeric material comprising homo- or co-polymer(s) of poly(m-xylene adipamide) or polyphenylene sulfide. The first thermoplastic polymeric material may be one or more homo- or co-polymer(s) of nylon 6 (polycaprolactam), nylon 6,6 (poly(hexamethylene adipamide)), polypropylene, and / or polybutylene terephthalate. A plurality of bicomponent fibers may thermally bonded to one another at spaced apart points of contact to define a porous structure that substantially resists crushing. The nonwoven fabric webs and rovings and self-supporting, three-dimensional porous elements may be formed from the plurality of bicomponent fibers.

Owner:ESSENTRA POROUS TECH

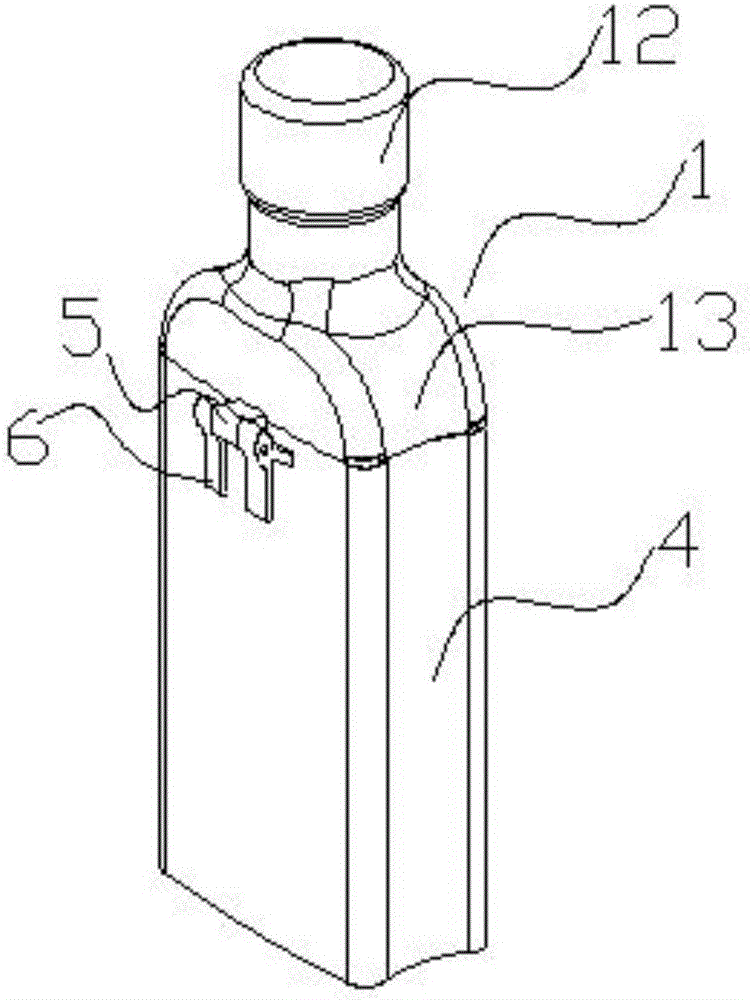

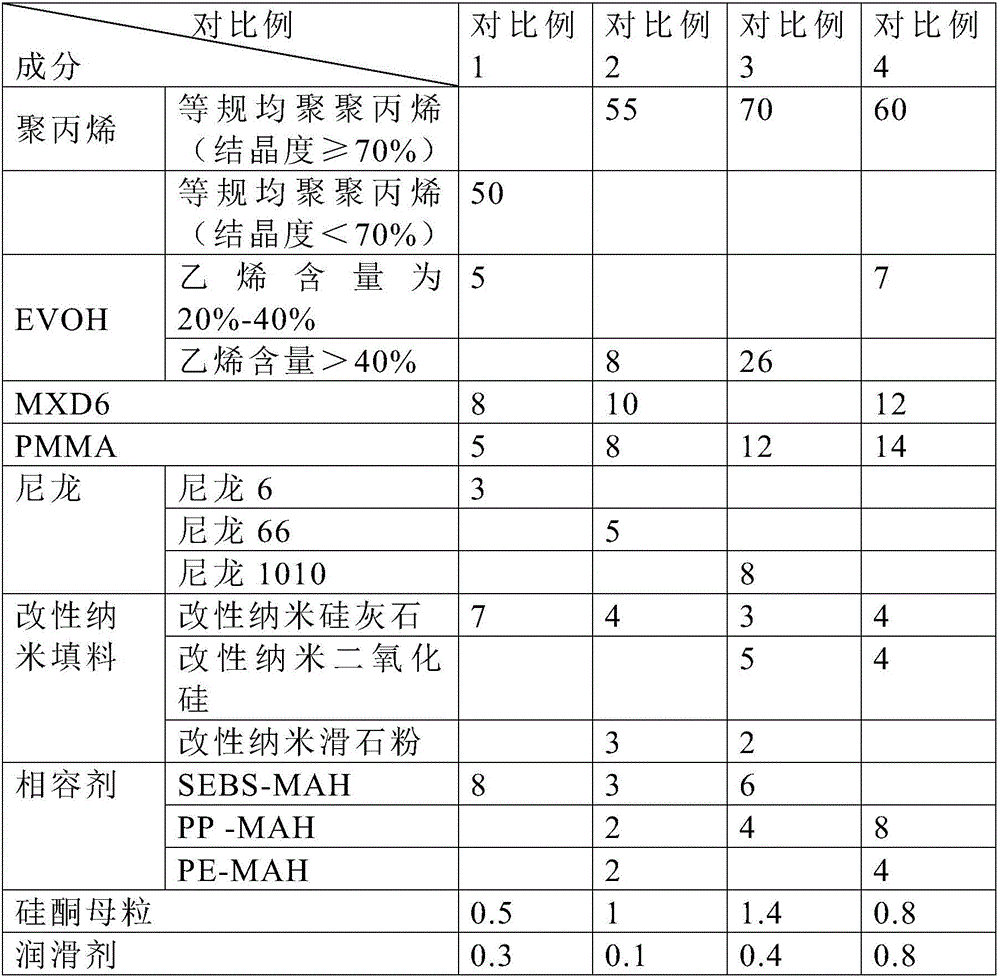

High barrier anti-aging water cup and preparation method thereof

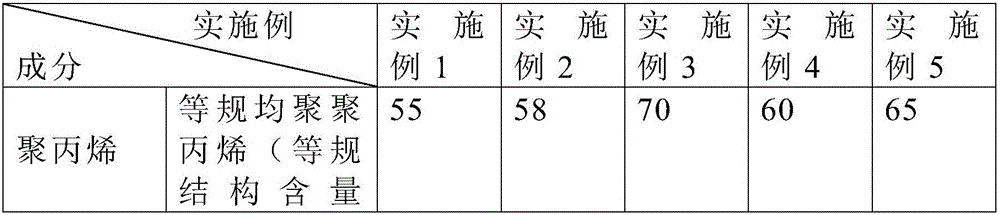

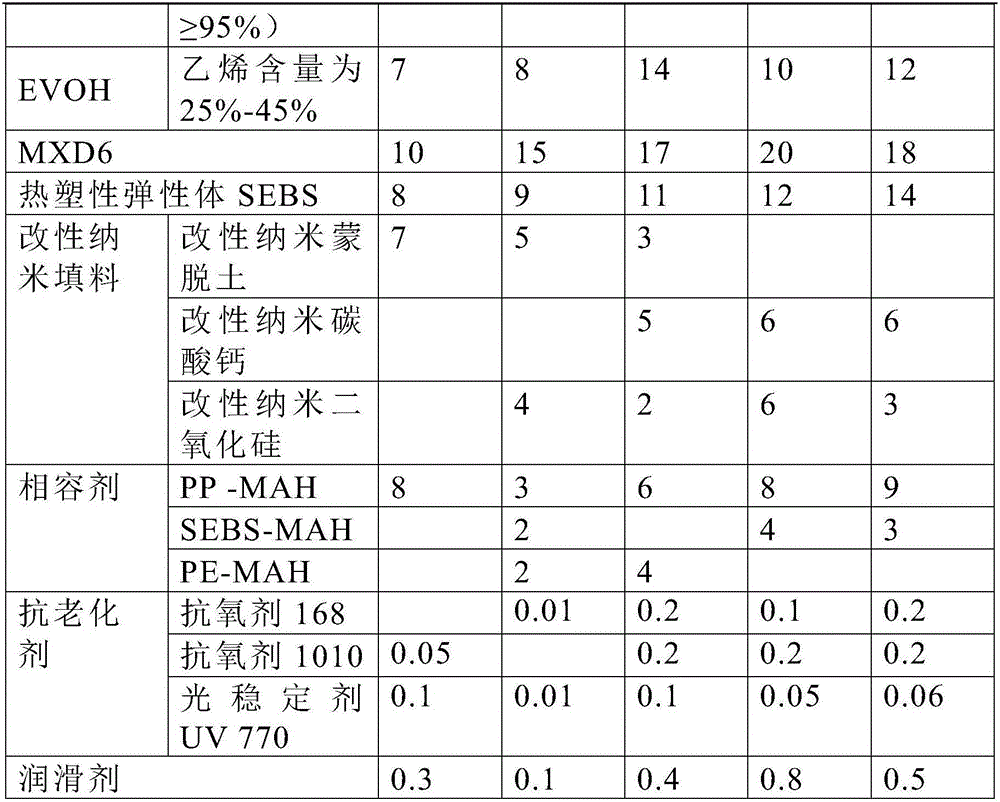

The invention relates to a high barrier anti-aging water cup, and belongs to the technical field of life utilities. The water cup comprises a cup body and a cup lid. The cup lid comprises a small lid and a connection lid. One side of the connection lid is connected with the cup body. The other side is connected with the small lid through thread rotationally. The joint between the cup body and the connection lid is provided with a hanging hook connected by hinges. The cup body and the cup lid are made of the same composite material. The composite material comprises, by weight, 55-70 parts of polypropylene, 7-15 parts of ethylene-vinyl alcohol copolymer, 10-20 parts of poly-meta-xylylene adipamide, 8-15 parts of thermal plastic SEBS, 5-13 parts of modified nano filler, 5-12 parts of compatilizer, 0.02-0.5 part of anti-aging agent and 0.2-0.8 part of lubricant. The cup has the advantages of high barrier, good anti-aging property, excellent mechanical performance, strong impact resistance, less inclination for breaking and long service life.

Owner:NINGBO YINZHOU KELI PLASTIC

Boiling and high-temperature resistant polyester thermal contraction material and preparation method thereof

ActiveCN102153841ASolve the problem of poor appearanceGood lookingCapacitor detailsPolytetramethylene terephthalateElastomer

The invention discloses a boiling and high-temperature resistant polyester thermal contraction material. The thermal contraction material comprises the following components in part by weight: 20 to 40 parts of polyethylene terephthalate (PET), 15 to 25 parts of modified polyethylene terephthalate glycol (PETG), 10 to 20 parts of polybutylene terephthalate (PBT), 5 to 10 parts of polyhexamethylene adipamide (PA66), 1 to 5 parts of thermoplastic elastomer (TPE) and 5 to 15 parts of polyethylene naphthalate (PEN). After a sleeve made of the thermal contraction material is contracted on the surface of a capacitor and then directly boiled for 5 minutes in boiling water or contracted and aged and then boiled for 15 minutes in boiling water and contracted on the surface of the capacitor and then repeatedly aged for 6 hours at the high temperature of 125 DEG C, good appearance can be kept. The invention also discloses a preparation method for the boiling and high-temperature resistant polyester thermal contraction material.

Owner:CYG CHANGTONG NEW MATERIAL

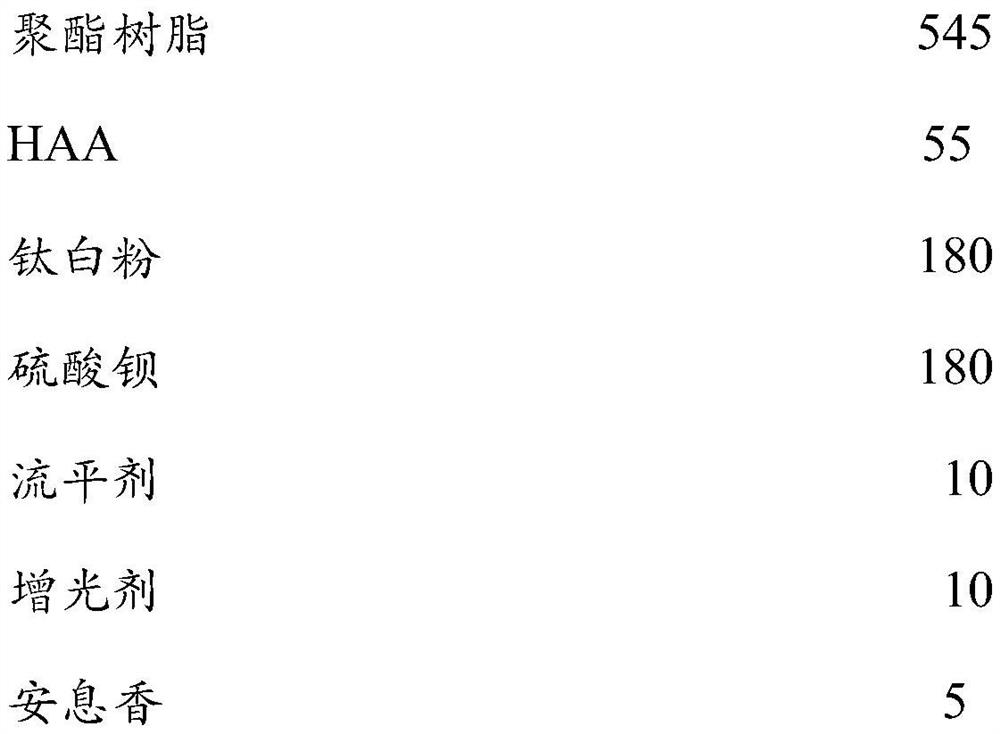

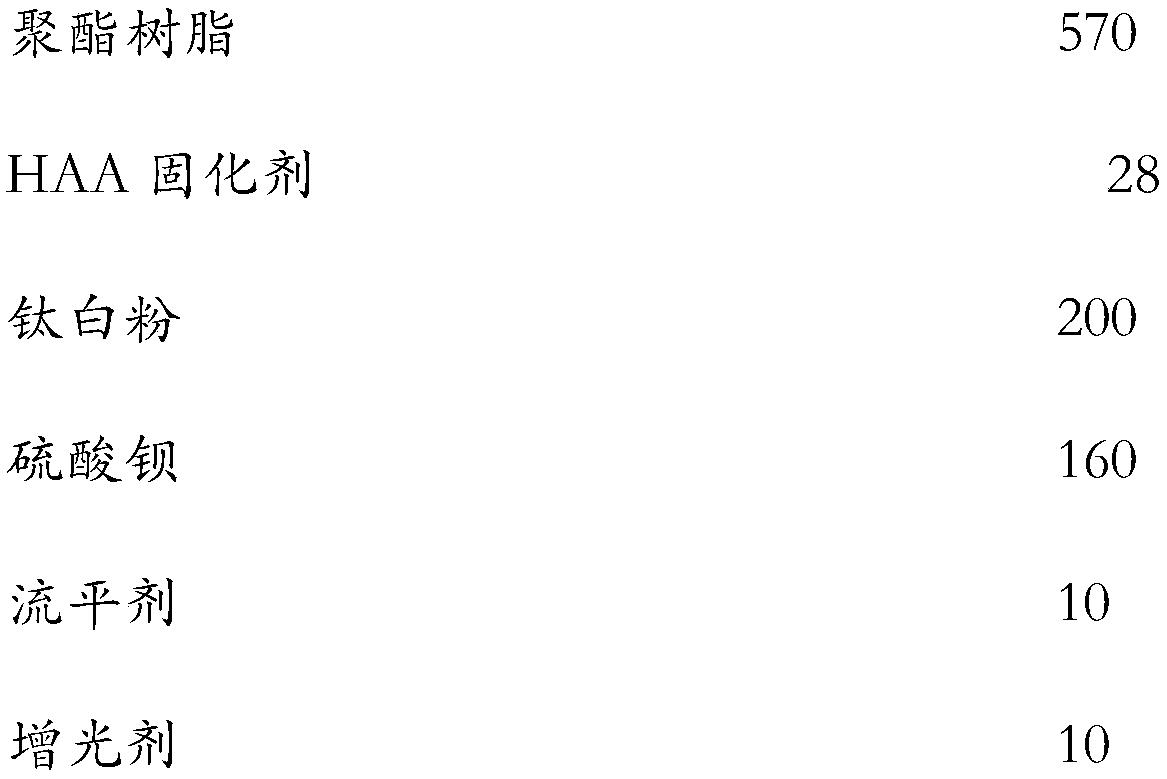

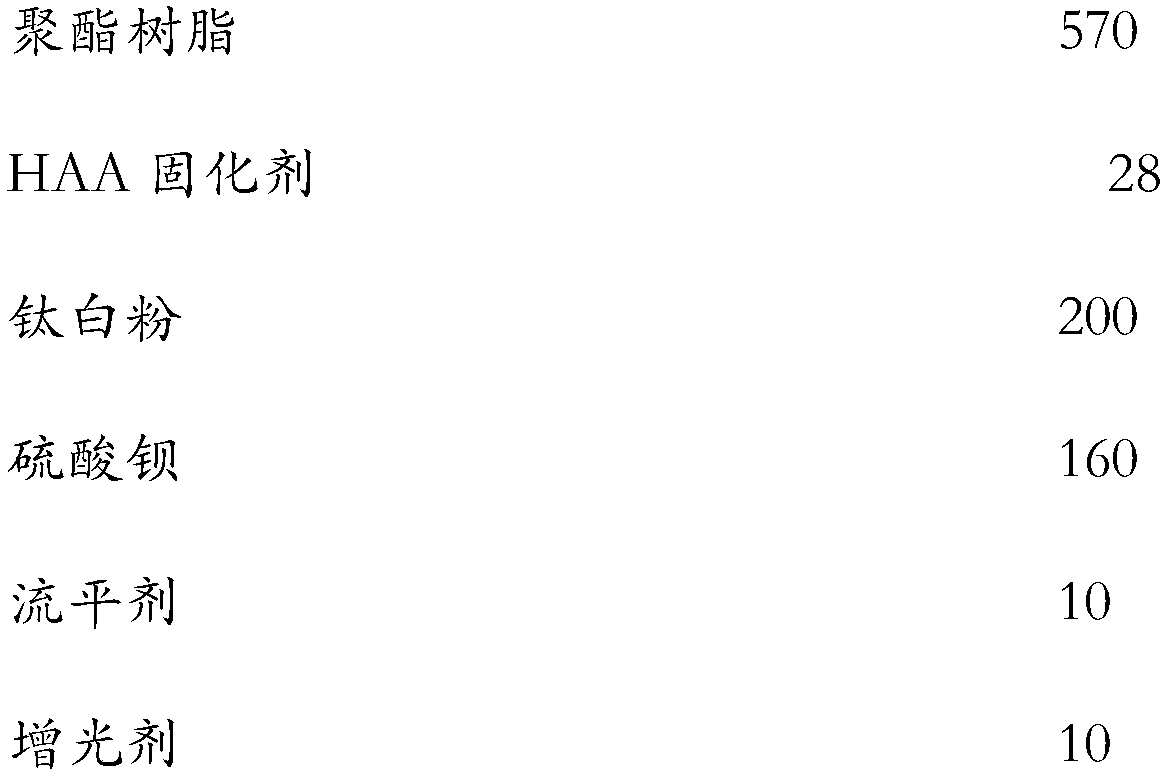

Water-resistance polyester powder coating

InactiveCN105062329AImprove water resistanceImprove heat resistanceAntifouling/underwater paintsPaints with biocidesPolyvinyl butyralEpoxy

The invention discloses water-resistance polyester powder coating. The powder coating is prepared from the following raw materials in parts by weight: 50-65 parts of pure polyester resin, 5-10 parts of fluorine-containing polyester resin, 3-10 parts of epoxy resin, 5-15 parts of organic silicon resin, 3-10 parts of carboxyl-terminated nitrile rubber, 1-5 parts of N,N,N',N'-tetrakis(2-hydroxyethyl)adipamide, 3-12 parts of tetrahydro-1,3,4,6-tetrakis(methoxymethyl)imidazo[4,5-d]imidazole-2,5(1H,3H)-dione, 1-5 parts of 2-phenyl-2-imidazoline, 1-5 parts of 2-methylimidazole, 2-5 parts of polyethylene, 3-10 parts of polyvinyl butyral, 10-25 parts of pigment and 2-10 parts of auxiliaries. The water-resistance polyester powder coating has good water resistance and good oil resistance, excellent acid and alkali corrosion resistance, can be used for outdoor coating, and has the advantages of good comprehensive performance and long service life.

Owner:安徽圣德建材科技有限公司

High-performance thermosetting polyester powder coating

ActiveCN105062330AImprove water resistanceImprove heat resistanceAntifouling/underwater paintsPaints with biocides2-ImidazolineCorrosion

The discloses a high-performance thermosetting polyester powder coating which comprises the raw materials: pure polyester resin, fluorinated polyester resin, epoxy resin, terminal carboxyl nitrile rubber, N,N,N,N'-tetra(2-ethoxyl) adipamide, tetramethoxyl methyl glycoluril, triglycidyl isocyanurate, amino resin, phenyl-2-imidazoline, 2-methylimidazole, chitosan, sodium lignin sulfonate, starch, polyethylene, polyvinyl butyral, nano titanium dioxide, aluminium oxide, zinc borate, mica iron oxide, montmorillonite, nanosilver, activated carbon powder, lanthanum oxide and auxiliaries. The high-performance thermosetting polyester powder coating disclosed by the invention is good in water resistance, oil resistance and heat resistance and excellent in weather resistance, acid and alkaline corrosion resistance and pollution resistance, and is good in comprehensive performance and long in service life if being used as an outdoor coating.

Owner:黄山佳杰新材料科技有限公司

Transparent copolymer nylon and preparation method thereof

The invention provides transparent copolymer nylon. The transparent copolymer nylon is prepared by polymerizing the following components by mass percent: 80-96% of a monomer A, 2-10% of a monomer B and 2-10% of a monomer E, wherein the monomer A is lactam; the monomer B is a mixture of an adipic acid monomer and an m-xylylenediamine monomer in a mole ratio of 1:1, a poly-m-xylylenediamine adipamide (MXD6) salt or an MXD6 prepolymer; the monomer E is obtained through reaction between a monomer C and a monomer D in a mole ratio of 1:1; the monomer C is alicyclic diamine; the monomer D is an aliphatic binary acid. The transparent copolymer nylon is prepared by polymerizing the monomer A, the monomer B, the monomer C and the monomer D together and has excellent transparency and comprehensive properties compared with the conventional nylon 6, nylon 66 and nylon 6 / 66 copolymer.

Owner:GUANGZHOU CHENDONG NEW MATERIALS +1

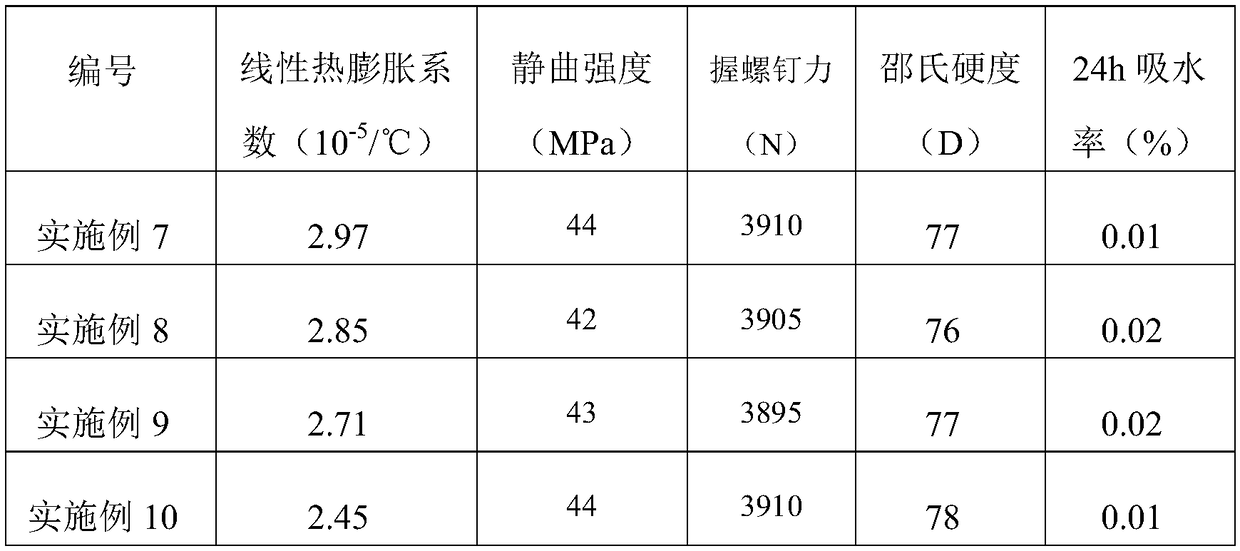

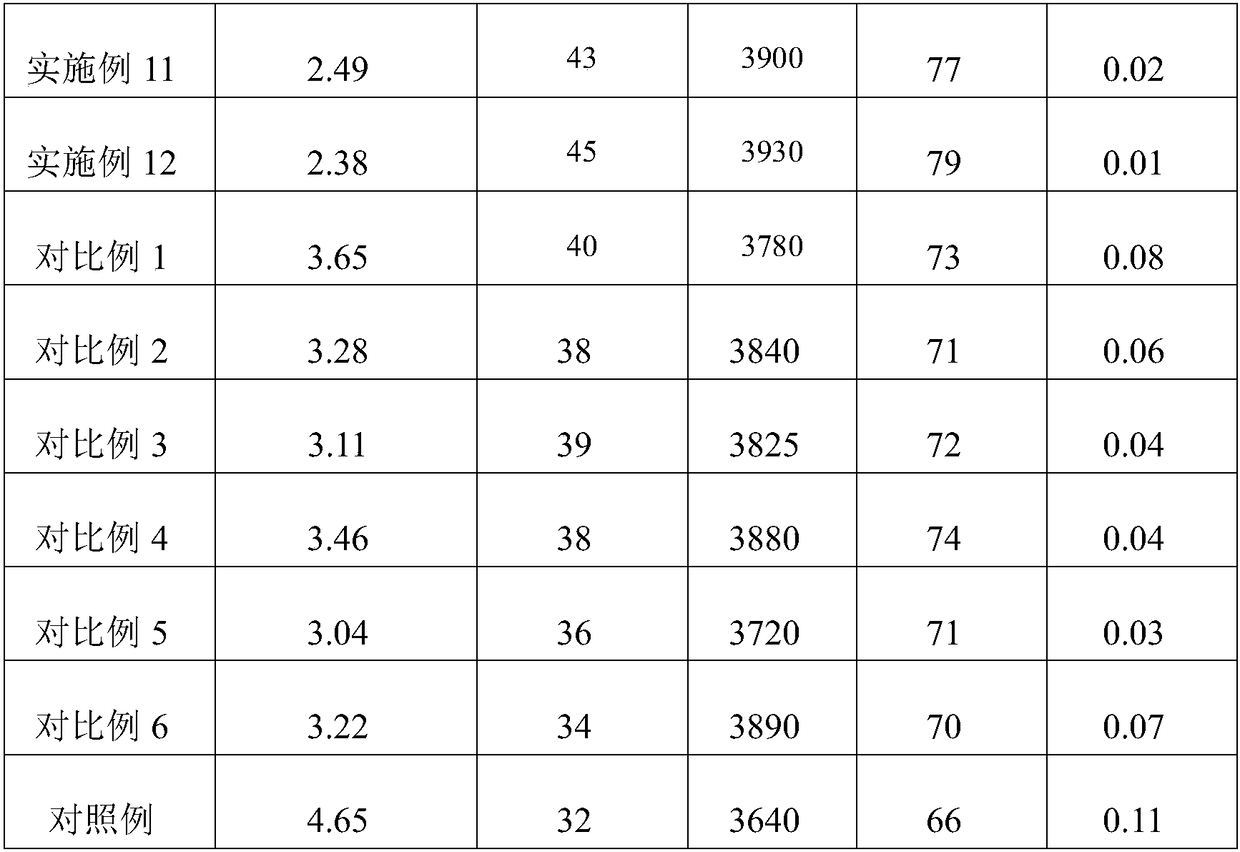

Plastic-wood composite material with low linear thermal expansion coefficient and preparation method thereof

The invention belongs to the technical field of plastic-wood composite material processing, and particularly relates to a plastic-wood composite material with a low linear thermal expansion coefficient, and the invention further discloses a preparation method for the plastic-wood composite material. The plastic-wood composite material with a low linear thermal expansion coefficient which is disclosed by the invention is prepared from the following materials of modified wood powder, high-density polyethylene, carboxyl-polyester resin, N,N,N',N'-tetrakis(2-hydroxyethyl)adipamide, asbestos fiberpowder, nylon 1010 resin, hafnium carbide ceramic powder, coupling agent and lubricating agent. The obtained plastic-wood composite material has excellent thermal expansion-resistant property, so theoutdoor service life of the plastic-wood composite material is prolonged and appearance smoothness of the plastic-wood composite material is greatly improved; and since the plastic-wood composite material with a low linear thermal expansion coefficient can be obtained only by the conventional extrusion process, the preparation process is simple and easy to implement.

Owner:HUANGSHAN MEISEN NEW MATERIAL TECH

Laser carving powder applied to laser marking and preparation process thereof

The invention discloses laser carving powder applied to laser marking. The laser carving powder comprises the following raw materials in parts by weight: polypropylene resin, C5 petroleum resin, barium sulfate, a nucleating agent, an antioxidant, toner, a lubricant, silicon oxide, titanium dioxide, zinc sulfide, chromium sesquioxide, neodymium oxide, bismuth oxide, tin oxide, zinc molybdate, ammonium molybdate, basic copper phosphate, copper oxide, copper chromite black, copper carbonate, copper sulfate, copper chloride, copper chromite, copper thiocyanate, spinel, tin dioxide, tin ash, sodiumstannate, potassium stannate, zinc sulfate, antimony trioxide, antimony pentoxide, sodium antimonate, potassium carbonate, syndiotactic polystyrene and polyhexamethylene adipamide; according to the preparation process of the laser carving powder applied to laser marking, the laser carving powder applied to laser marking is prepared, and the preparation process comprises the following steps: S1, grinding; S2, performing crushing; S3, performing mixing; S4, adding a chemical agent; S5, drying; and S6, crushing.

Owner:东莞市烁康新材料科技有限公司

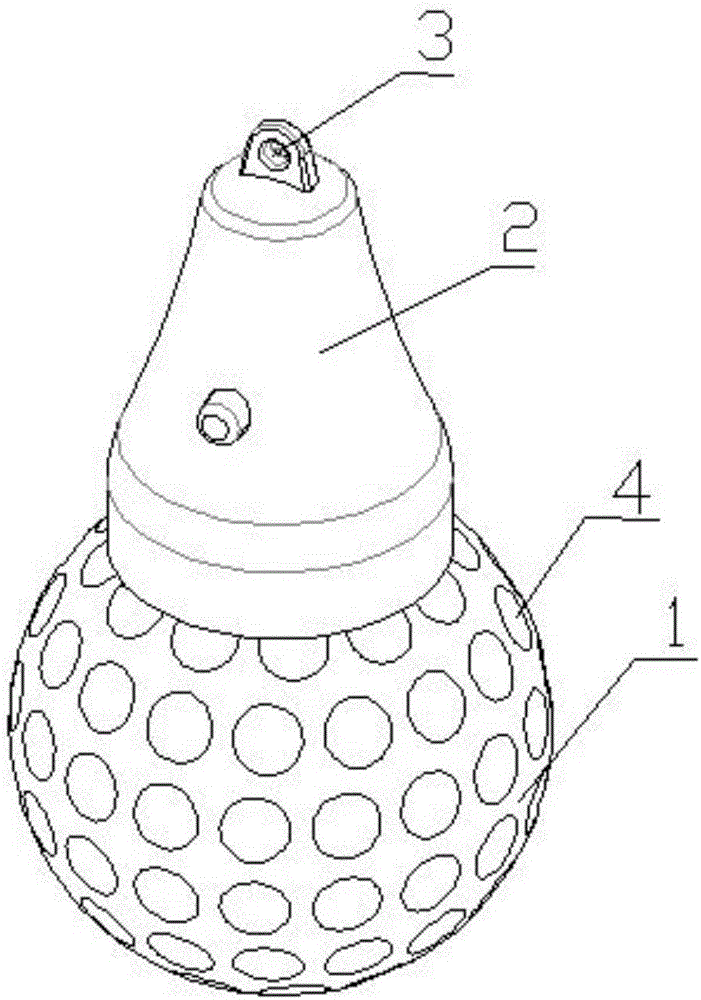

Plugging control ball and preparation method thereof

The invention provides a plugging control ball and a preparation method thereof. The plugging control ball comprises, by weight, 10-15% of polycaprolactam, 15-20% of polyhexamethylene adipamide, 65-80% of polyacrylamide, 1-1.5% of nanometer calcium oxide and 2-3% of a solubizing agent, wherein the sum of the percentages of all the components is 100%. Preferably, the sum of the weight percentages of the consumption of the polycaprolactam, the polyhexamethylene adipamide and the polyacrylamide is 95-97.5%. The invention further provides the preparation method of the plugging control ball. The method comprises the steps that the polycaprolactam, the polyhexamethylene adipamide, the polyacrylamide, the nanometer calcium oxide and the solubizing agent are mixed uniformly to obtain a mixture; the mixture is sufficiently stirred and injected into a vacuum spherical mold; the mold is cooled to obtain the plugging control ball. The plugging control ball has the advantages of being high in density, precision and strength and is easy and convenient to use and obvious in effect when applied to a water injection well.

Owner:PETROCHINA CO LTD

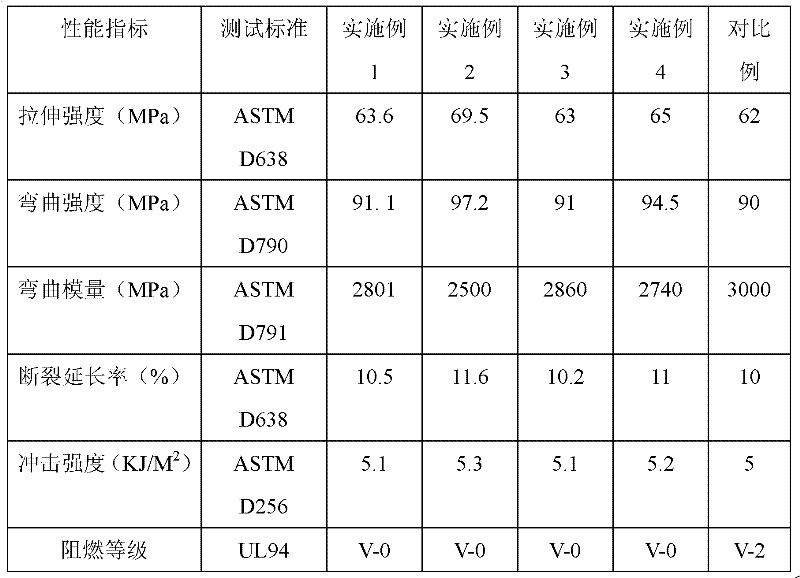

Flame retardant poly(hexamethylene adipamide)

ActiveUS20160185962A1Additive manufacturing apparatusAdditive mnaufacturing with solid and fluidNylon 6Ether

Poly(hexamethylene adipamide), (also referred to as Nylon 6,6) compounds that are flame retardant using non-halogenated ingredients are disclosed. Polyphenylene ether or bismaleimides act as synergists when used in specific amounts in combination with polyphosphonate to achieve a V-1 or V-0 rating in a UL 94 test at thicknesses of about 3.18 mm.

Owner:AVIENT CORP

Polyester resin with excellent wear resistance and chemical resistance for powder and preparation method of polyester resin

ActiveCN111647149AImprove performanceImprove adhesionPowdery paintsPolyester coatingsXylylenePolymer science

Owner:安徽永利新材料科技有限公司

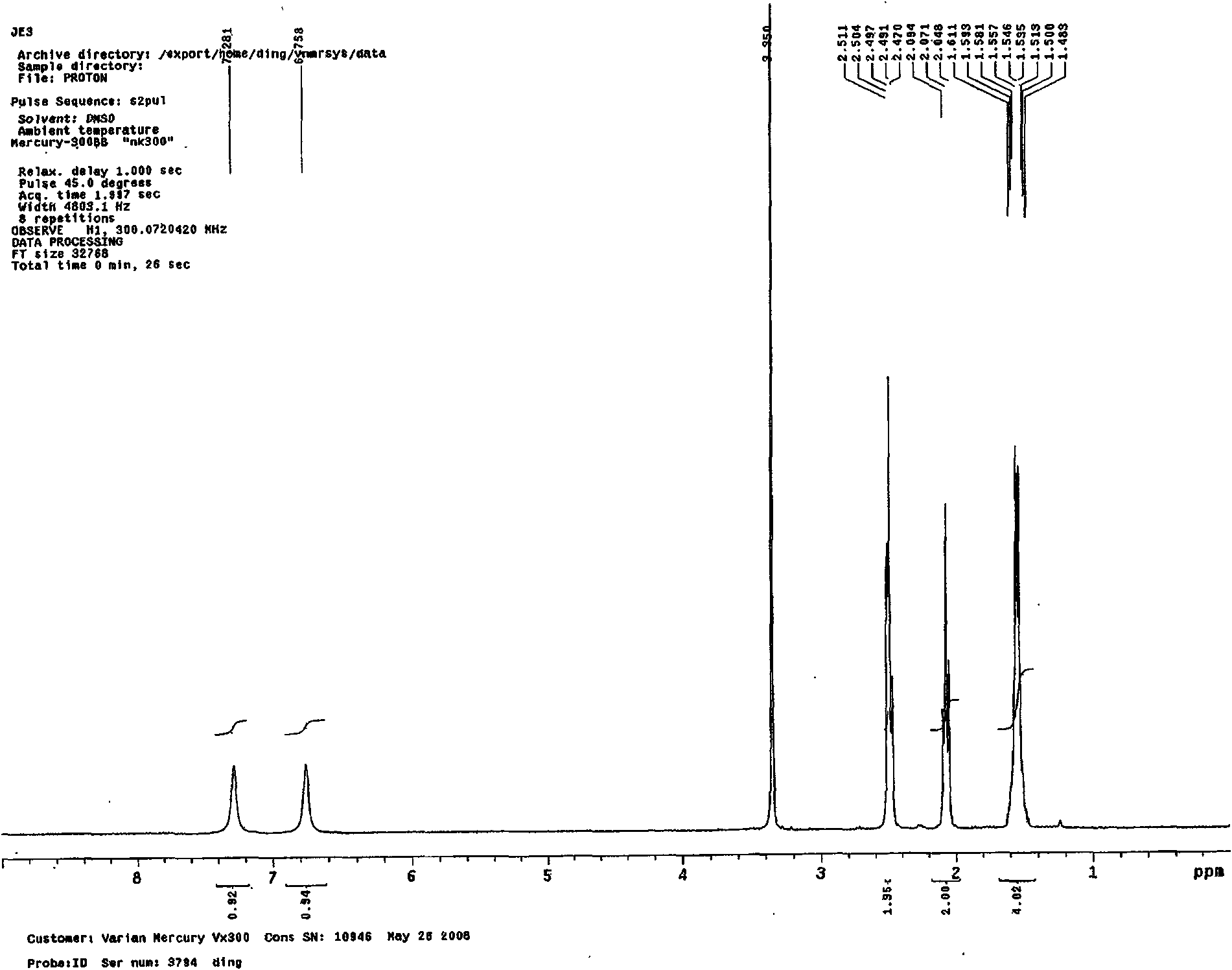

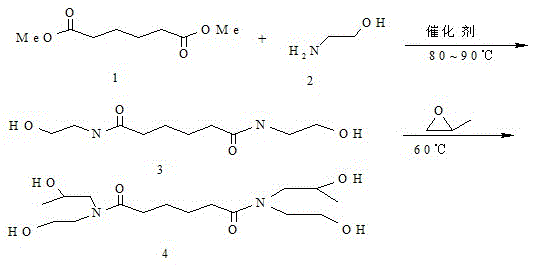

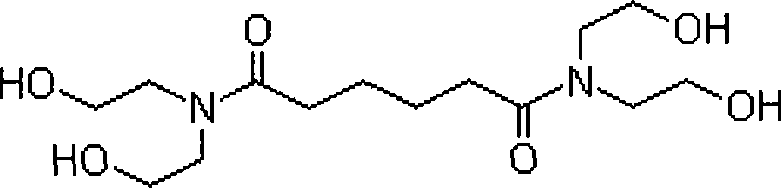

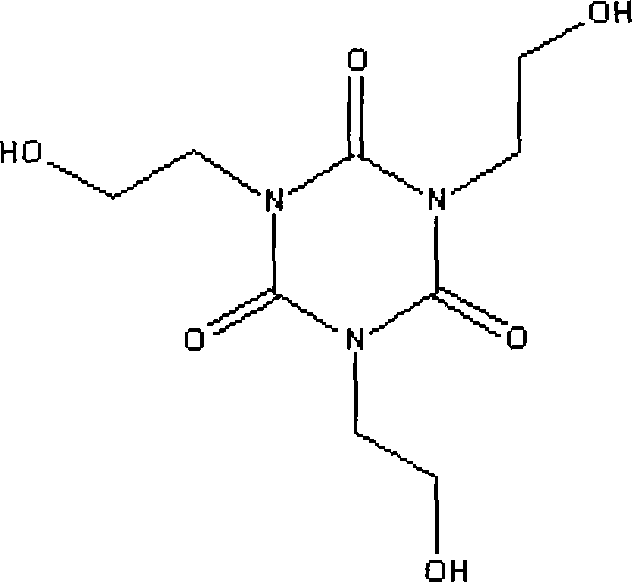

Method for preparing N,N,N',N'-tetrakis(2-hydroxyethyl)adipamide

InactiveCN101928225ASimple processEasy to industrializeOrganic compound preparationCarboxylic acid amides preparationReaction speedAdipate

The invention discloses a method for preparing N,N,N',N'-tetrakis(2-hydroxyethyl)adipamide. The method comprises the following steps: dimethyl adipate is used as an initial raw material to react with diethanol amine to prepare a crude product, and solid alkali serving as catalyst is added in the reacting process, so that the reaction speed is accelerated; the crude product is separated from refined methanol, and is filtered and dried to obtain the N,N,N',N'-tetrakis(2-hydroxyethyl)adipamide product, and the filtrate can be recycled to improve the product yield and reduce the consumption. The molar ratio of the dimethyl adipate to the diethanol amine to the methanol is 1:2-2.5:5-25. The method has the advantages of simple process and easy industrialization, and can improve the product yield to over 80 percent and the purity to over 99 percent.

Owner:太仓市运通化工厂

Halogen-free flame-retardant nylon 66 masterbatch

The invention discloses a halogen-free flame-retardant nylon 66 masterbatch, which comprises the following components in percentage by weight: 20 to 90 percent of polyhexamethylene adipamide, 5 to 60 percent of flame retardant A, 5 to 60 percent of flame retardant B, 0.1 to 2 percent of antioxidant and 0.1 to 2 percent of light stabilizer. The invention has the advantages that: different from a method of directly adding the flame retardants, the method comprises the following steps of: preparing a halogen-free flame-retardant masterbatch taking nylon 66 as a matrix and blending with nylon 66 to obtain halogen-free flame-retardant nylon 66 masterbatch; and the halogen-free flame-retardant nylon 66 masterbatch is more convenient to store and use and has better operability and higher mechanical properties and flame retardancy.

Owner:NIUK NEW PLASTIC TECH CO LTD

Energy storage devices and systems

InactiveUS20190341584A1Process stabilityGood dispersionElectrode manufacturing processesFinal product manufactureXylyleneEpoxy

Provided is a packaging element including a polymer layer and having a thickness of between 10 and 200 micro meter; wherein the packaging element being for use in providing an essentially sealed, void-free enclosure of an energy storage device, and wherein the polymer is selected from: poly(para-xylylene), poly-m-xylylene adipamide, dielectric polymer, silicone-based polymer, polyurethane, acrylic polymer, rigid gas impermeable polymer, fluorinated polymer, epoxy, polyisocyanate, PET, silicone rubber, silicone elastomer, polyamide and any combinations thereof.

Owner:3DBATTERIES LTD

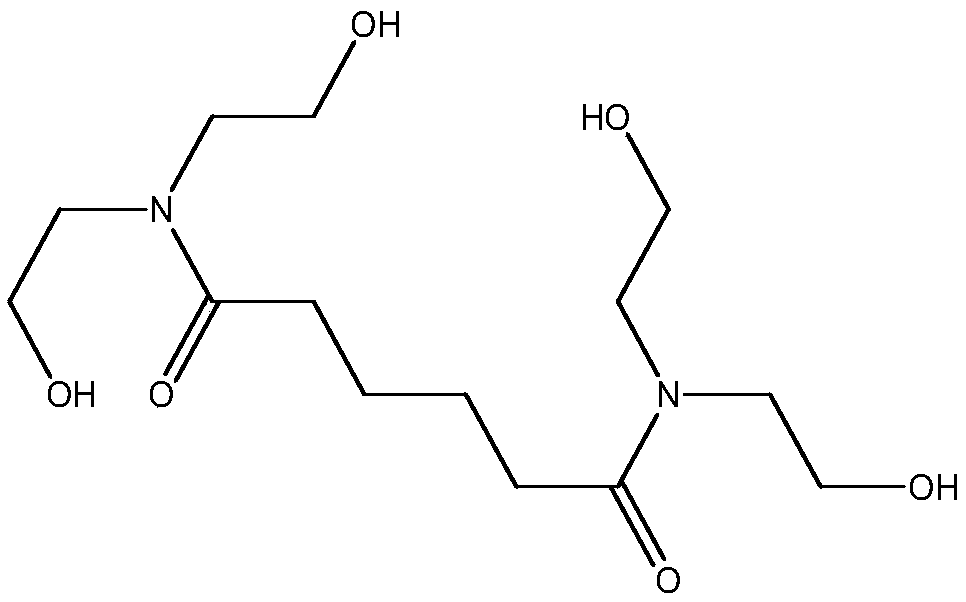

Beta-hydroxyalkylamide and preparation method thereof

ActiveCN105541654AStable storageHigh reactivityOrganic compound preparationCarboxylic acid amides preparationPolymer scienceEthanolamines

The invention discloses beta-hydroxyalkylamide and a preparation method thereof, relates to a curing agent and a preparation method thereof and provides a preparation method of N,N'-bis(beta-hydroxyethyl)-N,N'bis(beta-hydroxypropyl) adipamide. Dimethyl adipate, ethanolamine and propylene oxide are taken as raw materials for synthesis of N,N'-bis(beta-hydroxyethyl)-N,N'bis(beta-hydroxypropyl) adipamide. The synthetic method of N,N'-bis(beta-hydroxyethyl)-N,N'bis(beta-hydroxypropyl) adipamide comprises two steps: (1) synthesis of N,N'-bis(beta-hydroxyethyl) adipamide; (2) addition reaction. A product obtained with the method has high purity and good performance, and an obtained intermediate product is an important organic intermediate. The method has the advantages that the molecular reaction activity is reduced, the reaction speed is reduced, so that the viscosity of a coating film is improved, and an anti-pinhole effect is enhanced; the synthesis is simple, severe conditions such as high pressure, high vacuum and the like are avoided, the production cost is lower, and industrialization is facilitated.

Owner:NANJING JINHAO MEDICAL TECH CO LTD

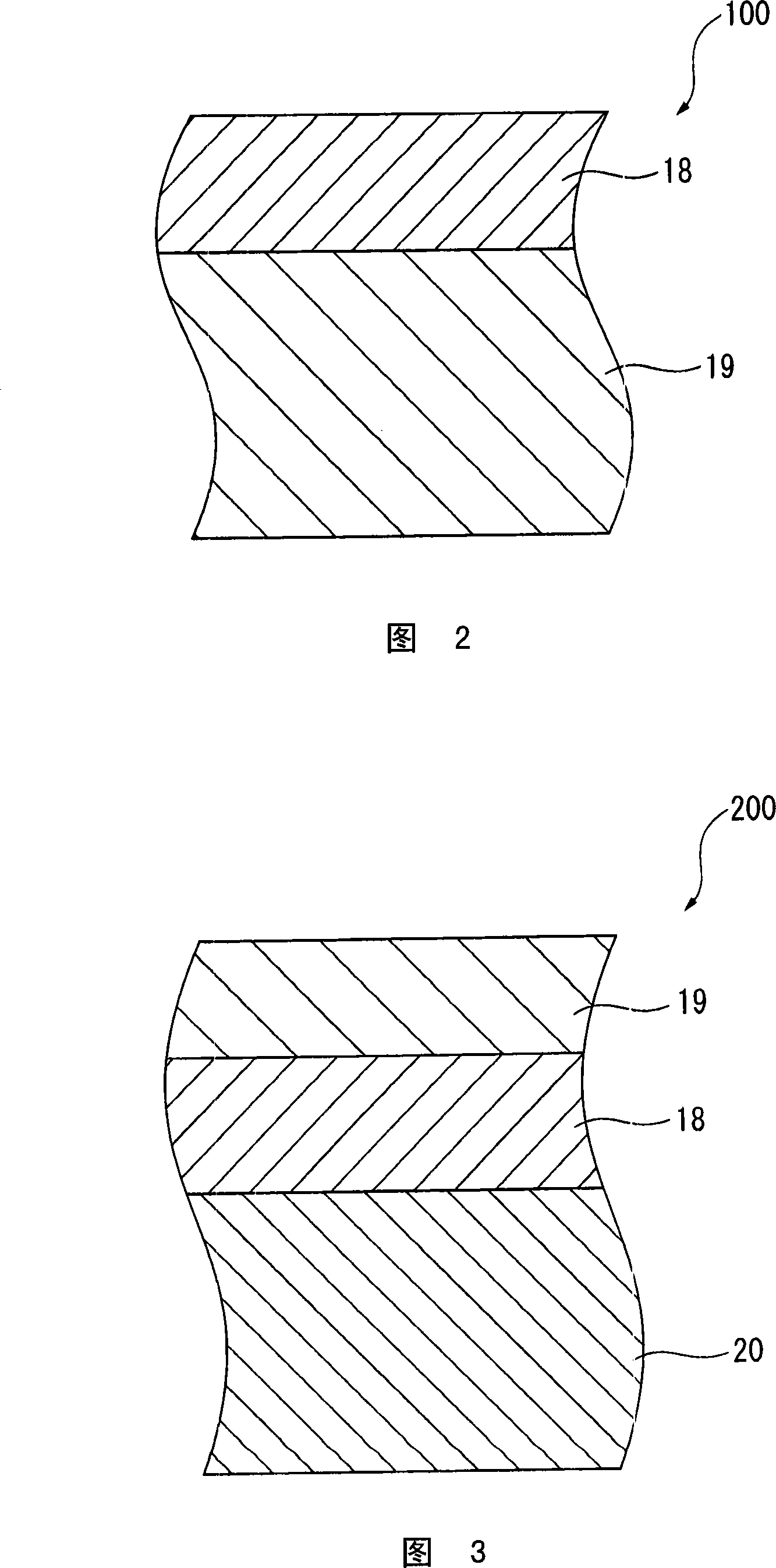

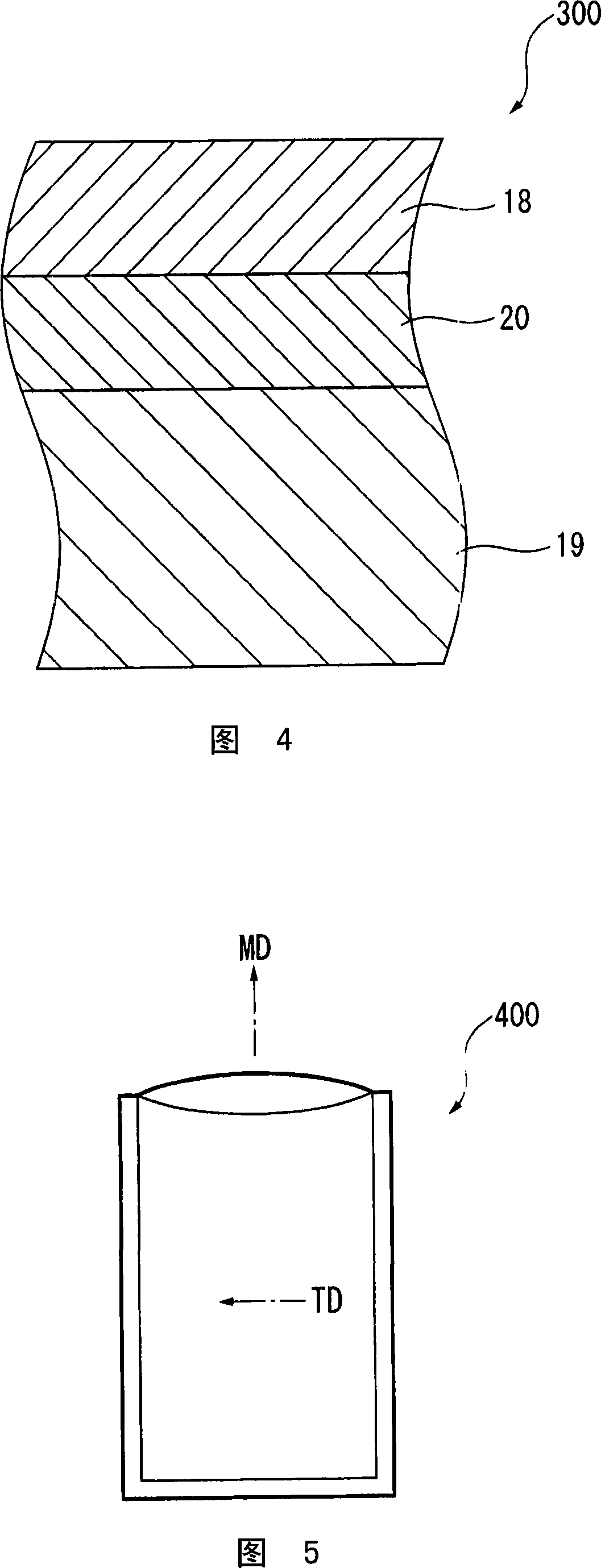

Easy-split contracted film, easy-split laminated film, easy-split bag, and manufacturing method for easy-split contracted film

ActiveCN101108898AExcellent linear cut-offImprove impact resistanceSynthetic resin layered productsPackagingXylyleneNylon 6

The invention relates to a fissility shrinkable film, containing 60-85 mass portion of nylon 6 (Ny6) and 15-40 mass portion of m(p-xylylene adipamide) (MXD6) (total is 100 mass portion) as materials. The material comprises original materials containing 60-85 mass portion of Ny and 15-40 mass portion portion of MXD, and a heat processing matter for melting refining the Ny6 and MXD6 to make the MXD6 melting point be 233-238 DEG C. The content of the heat processing matter is 5-40 mass%. The shrinkage of the fissility shrinkable film is 3-20% when keeping in the hot water at 95 DEG C for 30 mins.

Owner:IDEMITSU UNITECH CO LTD

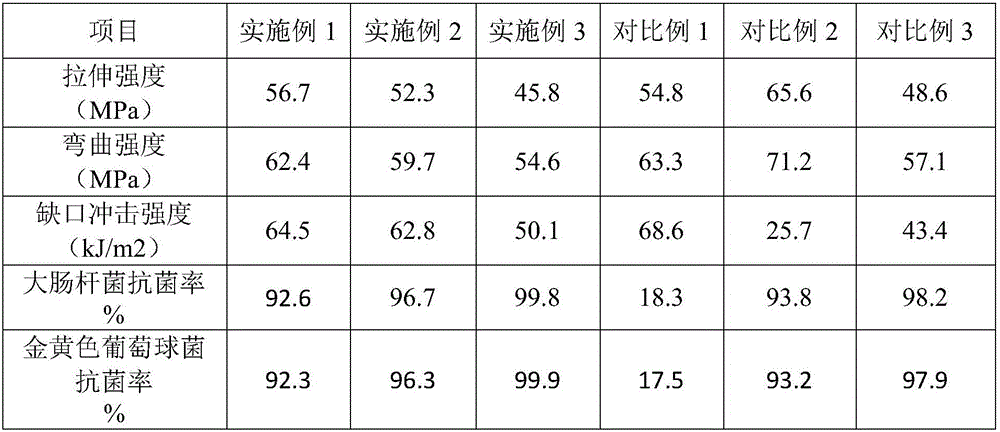

Antibacterial PA66/ABS composite material and preparation method thereof

The invention relates to an antibacterial PA66 / ABS composite material. The antibacterial PA66 / ABS composite material is mainly prepared through blending the following ingredients in parts by mass and carrying out melting: 50-70 parts of polyhexamethylene adipamide, 10-30 parts of processing activator, 30-50 parts of acrylonitrile-butadiene-styrene, 5-10 parts of compatibilizer, 5-20 parts of toughener, 0.1-0.3 part of diffusion oil, 0.6-1.5 parts of antibacterial agent and 0.2-2 parts of auxiliaries. The antibacterial PA66 / ABS composite material is prepared through firstly, thoroughly mixing weighed polyhexamethylene adipamide, weighed processing activator, weighed acrylonitrile-butadiene-styrene, weighed compatibilizer and weighed diffusion oil in a high-speed mixer, then, adding the antibacterial agent and the auxiliaries into the mixture, and finally, adding the toughener into the mixture and carrying out thorough mixing, so as to obtain a premix; carrying out melt extrusion on the premix through a twin-screw extruder, and carrying out drawing, cooling and pelleting. The product provided by the invention has the advantages of easiness in processing, high antibacterial performance, excellent mechanical properties, and the like.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

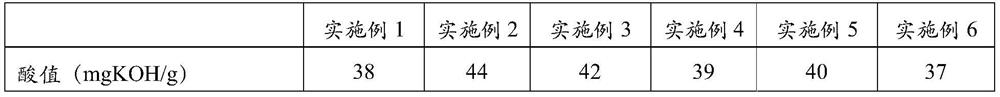

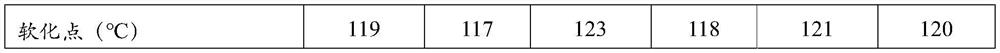

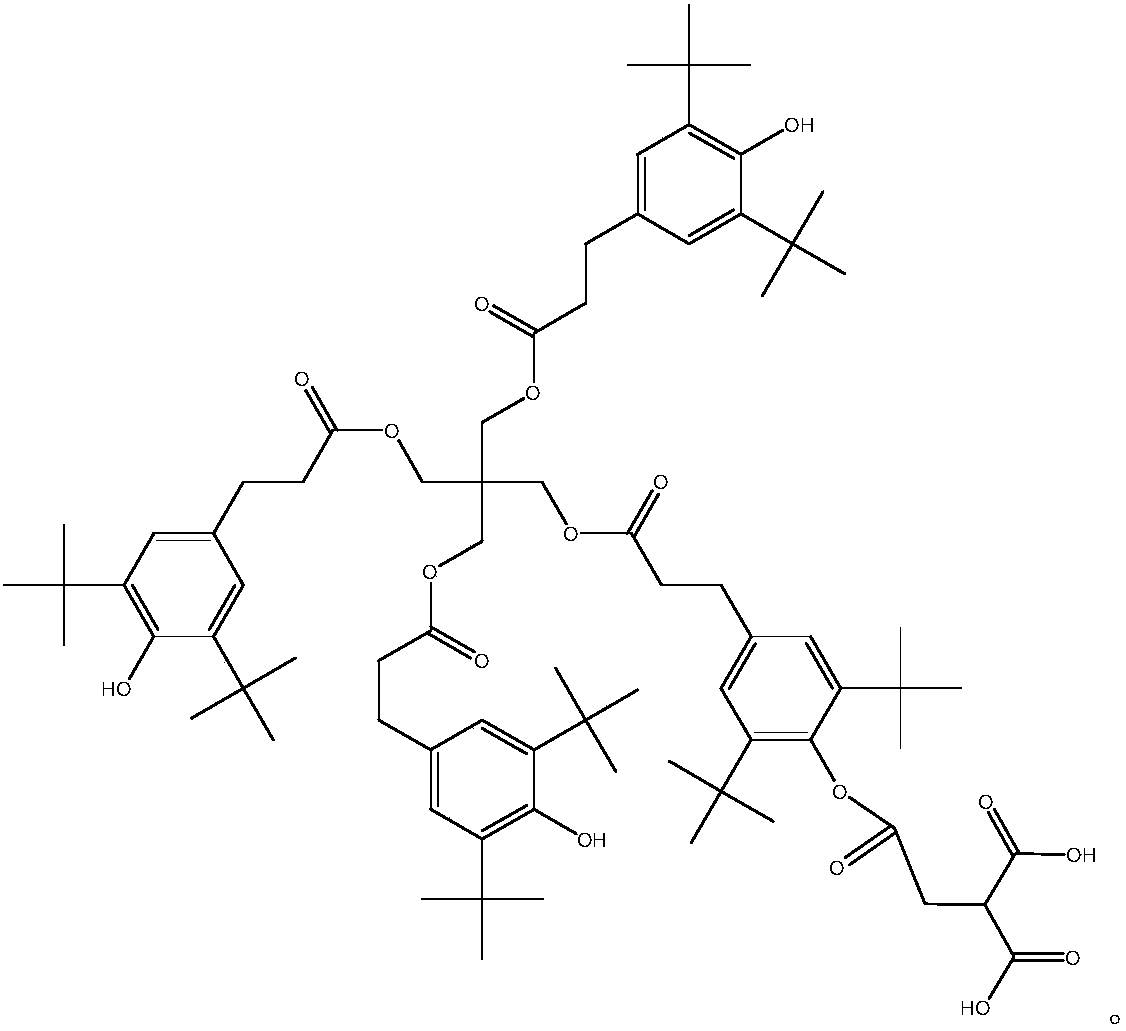

Polyester resin for anti-yellowing HAA (N,N,N',N'-tetra(Beta-hydroxyethyl)adipamide) system powder paint, preparation method and application

ActiveCN109054008AImprove high temperature resistanceImprove anti-yellowing effectPowdery paintsPolyester coatingsDiphenic acidPyromellitic dianhydride

The invention belongs to the technical field of resin production, and particularly relates to a polyester resin for an anti-yellowing HAA (N,N,N',N'-tetra(Beta-hydroxyethyl)adipamide) system and further relates to a preparation method and application of the polyester resin. The anti-yellowing HAA system provided by the invention is polymerized by using pyromellitic dianhydride, 1,6-hexanediamine,isophthalic acid, phloroglucinol formic acid, ethanetricarboxylic acid monoester, 2,5-dihydroxy hexane, neopentyl glycol and 2,2'-diphenic acid. Because a polyimide chain is carried in the molecular chain of the polyester resin obtained by the materials and a specific process, the high temperature-resistant and anti-yellowing properties are excellent; moreover, because the materials containing phenolic hydroxyl groups, such as phloroglucinol formic acid and ethanetricarboxylic acid monoester, are used for participating in reaction and the phenolic functional group with high anti-yellowing capability is contained in the polyester chain, the polyester product has excellent high temperature-resistant and anti-yellowing properties, and is ultimately used in the powder paint of the HAA system,so that a coated panel with excellent anti-yellowing property can be obtained.

Owner:HUANGSHAN HUIZHOU KANGJIA CHEM CO LTD

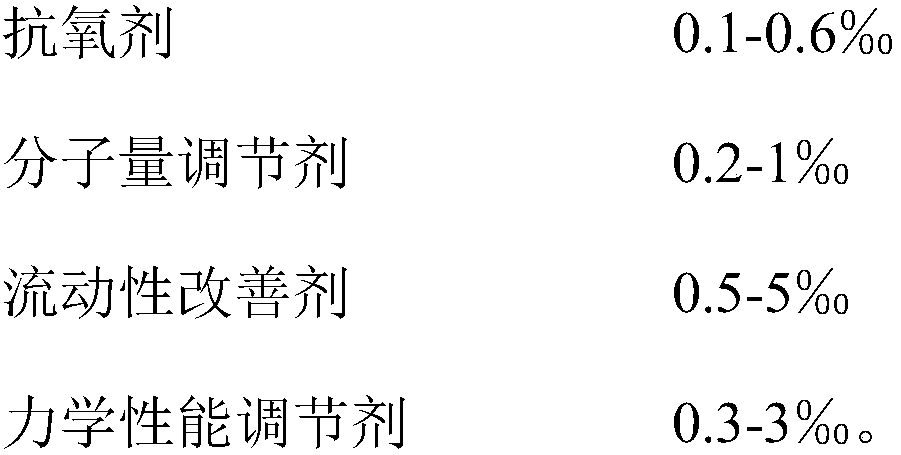

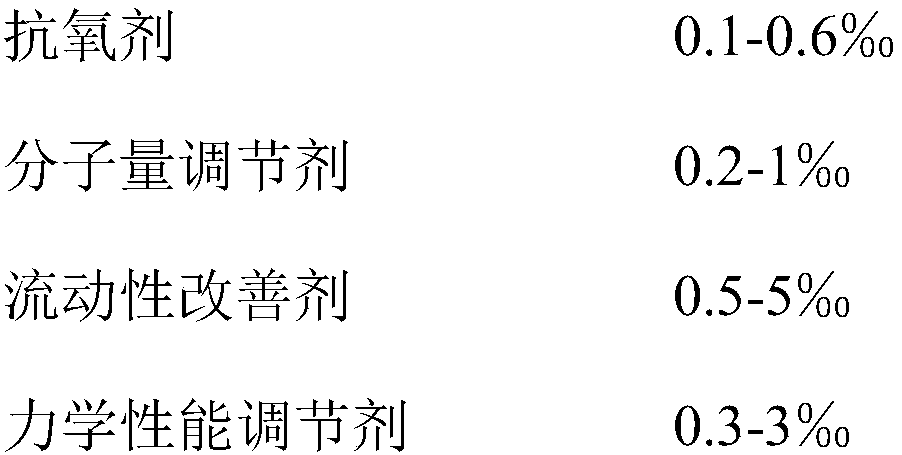

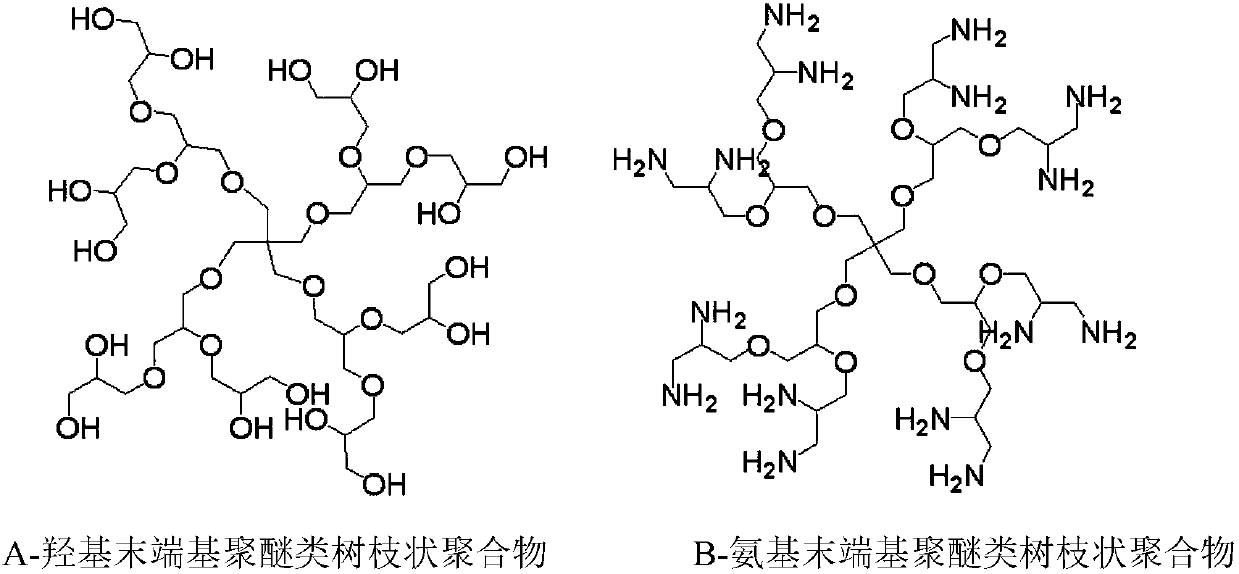

High-fluidity polyhexamethylene adipamide modified base resin and preparation method thereof

The invention discloses high-fluidity polyhexamethylene adipamide modified base resin and a preparation method thereof. The preparation method comprises the following steps: (1) mixing hexanediamine,adipic acid and desalted water for a reaction, and then adding hexanediamine to adjust the pH to obtain a polyamide salt solution; (2) performing evaporation and concentration; (3) performing heatingto obtain a prepolymer; (4) keeping the system pressure constant, and continuing heating to obtain low molecular polyamide; (5) performing depressurization to obtain a product, that is, a polyhexamethylene adipamide molten product; and (6) performing cooling, and performing pelletizing and granulation to obtain the polyhexamethylene adipamide product. The method disclosed by the invention preparesthe high-fluidity polyhexamethylene adipamide modified base resin on the premise of guaranteeing the excellent mechanical properties of the polyhexamethylene adipamide product through the additive and the process and controlling on the molecular weight of the product; and the polyhexamethylene adipamide prepared by the method is an engineering plastic grade product instead of a spinning grade product.

Owner:HUAFON GROUP +1

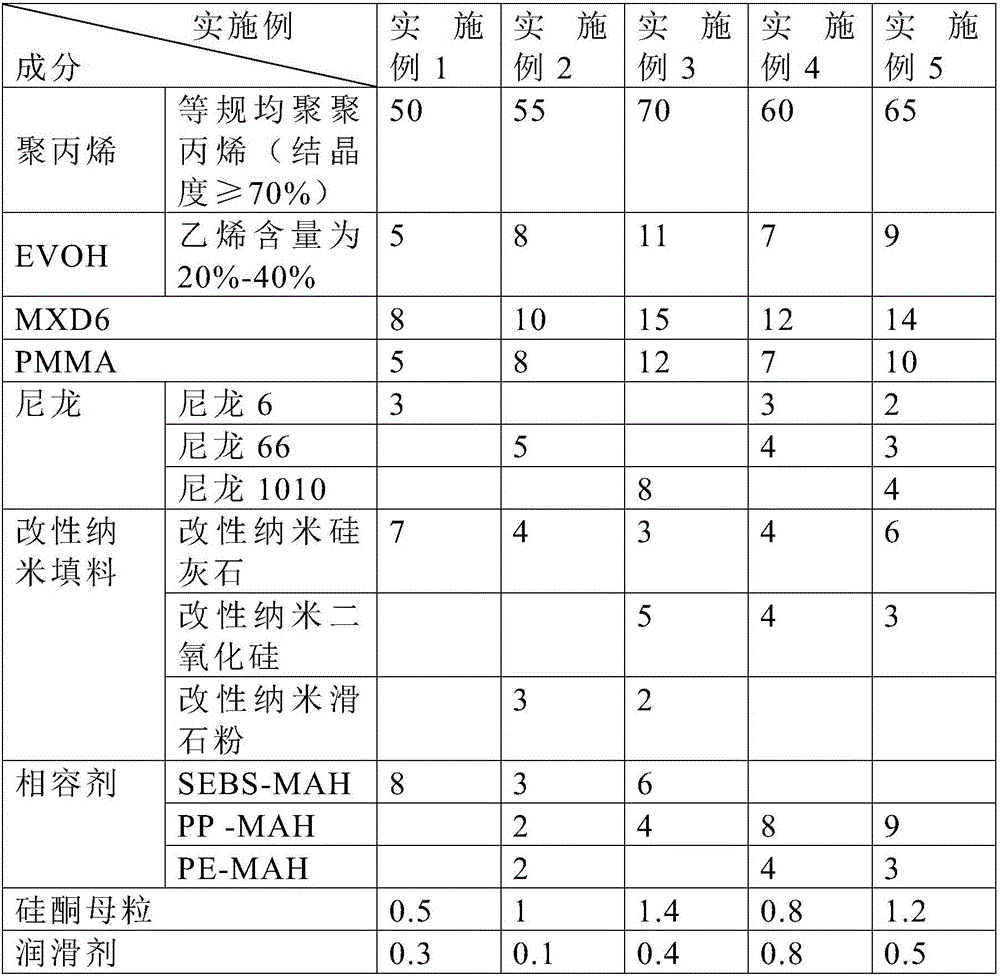

Water cup with scratch resistance and high barrier property and preparation method thereof

ActiveCN106432903AImprove scratch resistanceImprove barrier propertiesDomestic articlesDrinking vesselsXylylenePolymethyl methacrylate

The invention relates to a water cup with scratch resistance and high barrier property and belongs to the technical field of articles for daily use. The water cup comprises a cup body and a cup cover, wherein a plurality of concave points with equal intervals are distributed in the peripheral surface of the cup body; the cup body is connected with the cup cover in a manner of thread rotation; a rope penetrating port is arranged at the upper end of the cup cover; and the cup body and the cup cover are made of a same composite material. The composite material comprises the following components in parts by weight: 50-70 parts of polypropylene, 5-12 parts of ethylene-vinyl alcohol copolymer, 8-18 parts of poly-meta-xylylene adipamide, 5-12 parts of polymethyl methacrylate, 3-10 parts of nylon, 5-10 parts of modified nanofiller, 5-12 parts of compatilizer, 0.5-2 parts of silicone master batch and 0.1-1 part of lubricant. The water cup has the advantages of good scratch resistance, high barrier property, excellent mechanical property, large impact strength, difficult breaking and long service life.

Owner:NINGBO YINZHOU KELI PLASTIC

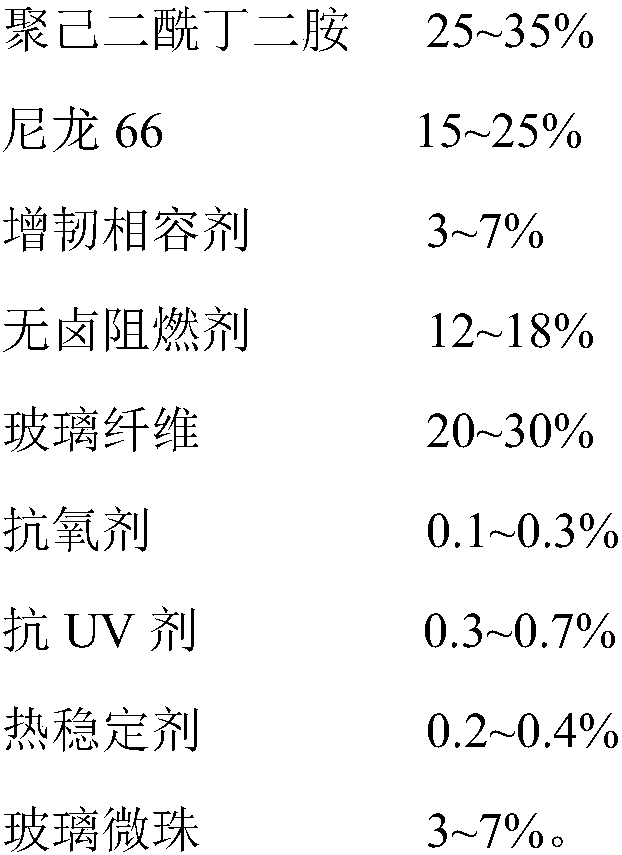

Halogen-free flame-retardant highly-temperature-resistant polytetramethylene adipamide composite material and preparation method thereof

The invention discloses a halogen-free flame-retardant highly-temperature-resistant polytetramethylene adipamide composite material and a preparation method thereof. The composite material is preparedfrom the following components in percentage by weight: 25-35% of polytetramethylene adipamide, 15-25% of nylon 66, 3-7% of a toughening compatibilizer, 12-18% of a halogen-free flame retardant, 20-30% of glass fibers, 0.1-0.3% of an antioxidant, 0.3-0.7% of a UV resistant agent, 0.2-0.4% of a heat stabilizer and 3-7% of glass beads. The preparation method comprises the following steps: weighing the various raw materials in percentage by weight, and mixing the various weighed raw materials; and adding the mixed materials into a twin-screw extruder, and performing extruded granulation. The polytetramethylene adipamide is modified, so that the prepared polytetramethylene adipamide composite material has the characteristic of high temperature resistance.

Owner:江门市荣龙新材料科技有限公司

High-toughness low-shrink polyamide material and preparation method thereof

The invention discloses a high-toughness low-shrink polyamide material and a preparation method thereof. The high-toughness low-shrink polyamide material is prepared from the following components in percentage by weight: 50-68% of polyhexamethylene adipamide resin, 20-30% of mica powder, 10-20% of toughener, 0.3-0.6% of lubricant, 0.3-0.6% of antioxidant and 1-2% of dispersant. The invention combines the enhancement and toughening technologies, regulates the overall performance of the product based on material selection, achieves an overall balance among strength, heat resistance and low-temperature characteristics, and ensures that the material has favorable mechanical properties at both low temperature and normal temperature and the strength and the toughness are relatively complemented. Besides, the high-toughness low-shrink polyamide material has the advantages of small shrinkage, high surface quality and low material cost, thereby being an economical, practical and durable modified composite material.

Owner:SHENZHEN KEJU NEW MATERIAL

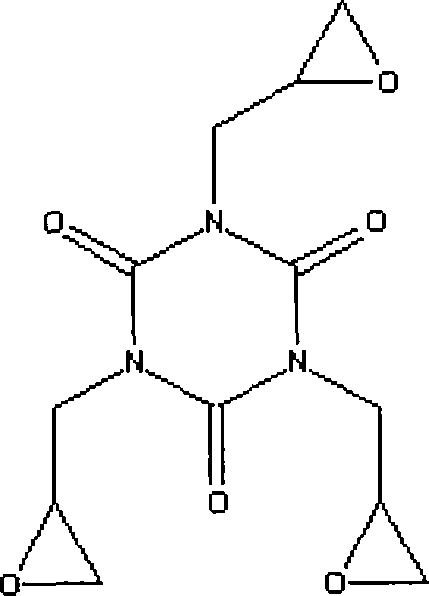

Polyester resin powder paint solidifying agent

A curing agent for powdered paint of polyester resin relates to the production technique field of powdered paint of polyester resin. The novel curing agent consists of tetra adipamide (2-hydroxyethyl group) and tris isocyanurate (2-hydroxyethyl group); wherein, the tetra adipamide (2-hydroxyethyl group) accounts for 50 to 90 percent of the gross weight and the tris isocyanurate (2-hydroxyethyl group) accounts for 10 to 50 percent of the gross weight. The invention not only has tetra adipamide (2-hydroxyethyl group) with the advantage of Beta-hydroxyl alkyl amide, but also has the widely-used tris chlorinated Isocyanurates (2-hydroxyethyl group) with the advantages of safety and low toxicity. Simultaneously, the tris chlorinated Isocyanurates (2-hydroxyethyl group) and the tetra adipamide (2-hydroxyethyl group) have similar structure of (2-hydroxyethyl group) active functional group, thus having similarities and compatibility.

Owner:YANGZHOU SANDELI CHEM +1

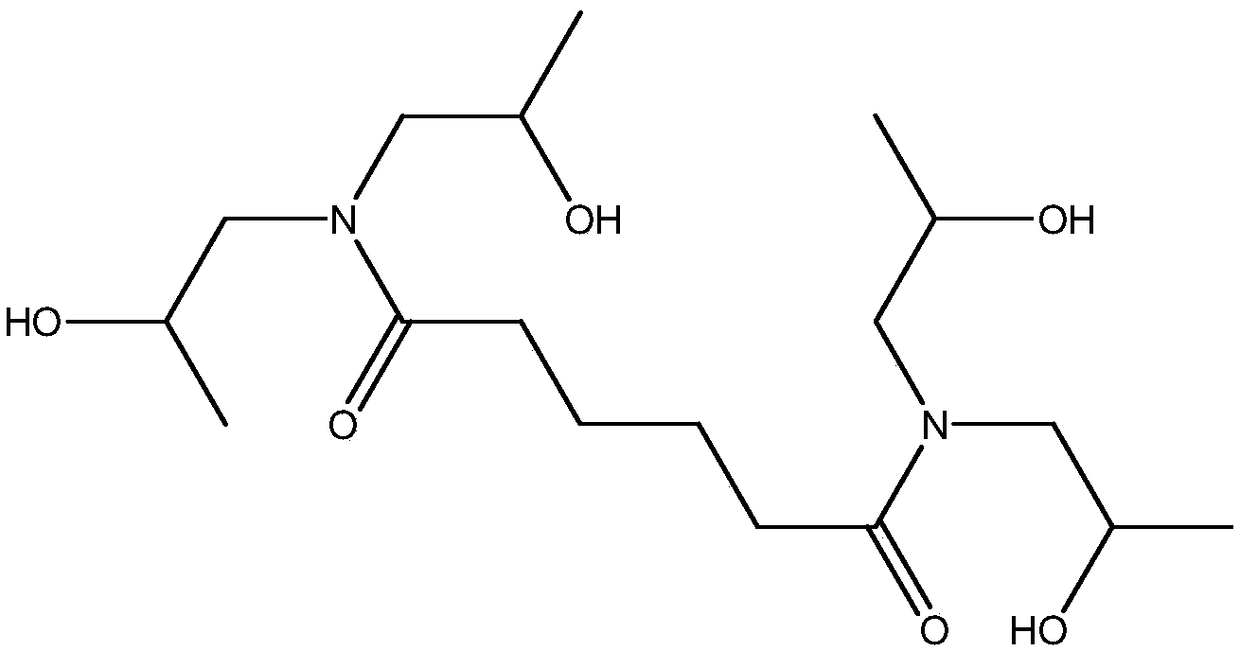

Polyester resin for N,N,N',N'-tetra(2-hydroxypropyl) adipamide system and preparation method thereof

The invention belongs to the technical field of polyester resin materials and preparation, particularly relates to a boiling-resistant polyester resin for a N,N,N',N'-tetra(2-hydroxypropyl) adipamidesystem, and furthermore relates to a preparation method of the resin. The polyester resin for the N,N,N',N'-tetra(2-hydroxypropyl) adipamide system is mainly formed by terephthalic acid, o-carboxyphenylacetic acid, 1,1'-ferrocene dicarboxylic acid, calcein, 1,8-octylene glycol, 3-(trimethylsilyl)-1,2-propanediol, 5-hydroxydecanoic acid glyceride and neopentyl glycol. The boiling-resistant polyester resin for the N,N,N',N'-tetra(2-hydroxypropyl) adipamide system obtained N, N, N', N'-tetra(2 hydroxypropyl) adipamide system is blocked by the high-activity tetrabasic acid calcein, and the final activity of the polyester resin is relatively high, so that the sufficient curing with a (N,N,N',N'-tetra(2-hydroxypropyl) adipamide) curing agent is well realized, and a coating film with a relativelyhigh crosslinking density is obtained.

Owner:HUANGSHAN UNIV

Transparent copolymer nylon and preparation method thereof

The invention provides transparent copolymer nylon. The transparent copolymer nylon is prepared by polymerizing the following components by mass percent: 80-96% of a monomer A, 2-10% of a monomer B and 2-10% of a monomer F, wherein the monomer A is lactam; the monomer B is a mixture of an adipic acid monomer and an m-xylylenediamine monomer in a mole ratio of 1:1, a poly-m-xylylenediamine adipamide (MXD6) salt or an MXD6 prepolymer; the monomer F is obtained through reaction between a monomer E and a monomer C in a mole ratio of 1:1 or reaction between the monomer E and a monomer D in a mole ratio of 1:1; the monomer C is an aromatic binary acid; the monomer D is an alicyclic binary acid; the monomer E is aliphatic diamine. The transparent copolymer nylon is prepared by polymerizing the monomer A, the monomer B, the monomer C and the monomer D together and has excellent transparency and comprehensive properties compared with the conventional nylon 6, nylon 66 and nylon 6 / 66 copolymer.

Owner:GUANGZHOU CHENDONG NEW MATERIALS +1

Process for producing polyamide

The present invention relates to a process for producing polyamide of the type of those obtained by polycondensation from diacids and diamines and / or the type of those obtained by polycondensation from lactams and / or amino acids. The process is entirely suitable for the production of polyhexamethylene adipamide.

Owner:POLYAMIDE HIGH PERFORMANCE

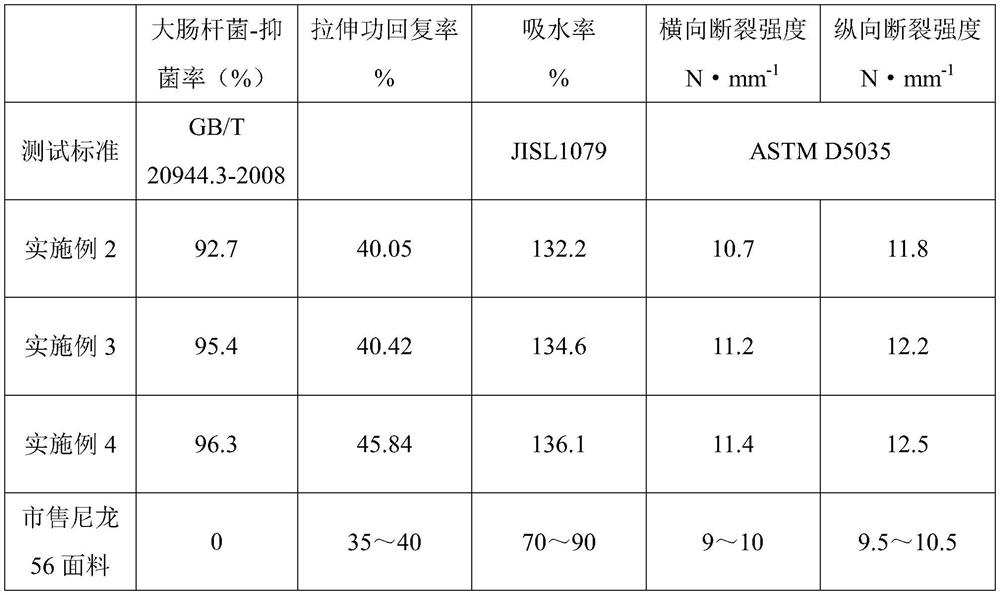

Thermal antibacterial school uniform fabric and preparation method thereof

ActiveCN112048817AHigh antibacterial rateGood antibacterial effectGarment special featuresWeft knittingFiberPolyurethane elastomer

The invention discloses a thermal antibacterial school uniform fabric and a preparation method thereof. The thermal antibacterial school uniform fabric is prepared from thermal antibacterial compositefibers through a knitting or weaving process; the thermal antibacterial composite fiber comprises an inner layer and an outer layer, wherein the outer layer covers the outer surface of the inner layer, the section profile of the outer layer is circular; the ratio of the sectional area of the inner layer to the sectional area of the outer layer is 1: 1.35-1.55; and the inner layer is prepared fromfollowing raw material in parts by weight: 88-98 parts of polyhexamethylene adipamide and 5-9 parts of polyurethane elastomers. The specially-made thermal antibacterial composite fiber adopted by thethermal antibacterial school uniform fabric is of the structure having the inner layer and the outer layer, an antibacterial rate is high, a good antibacterial effect is achieved, the school uniformfabric absorbs sweat and then bacteria are not prone to breeding when being worn by people, and the school uniform fabric is not prone to mildewing and stinking; the school uniform fabric is good in elastic performance, good in rebound resilience, soft in hand feeling, comfortable to wear, good in moisture absorption and sweat releasing properties, high in tensile strength, good in mechanical property, and suitable for producing school uniforms.

Owner:润克(集团)股份有限公司

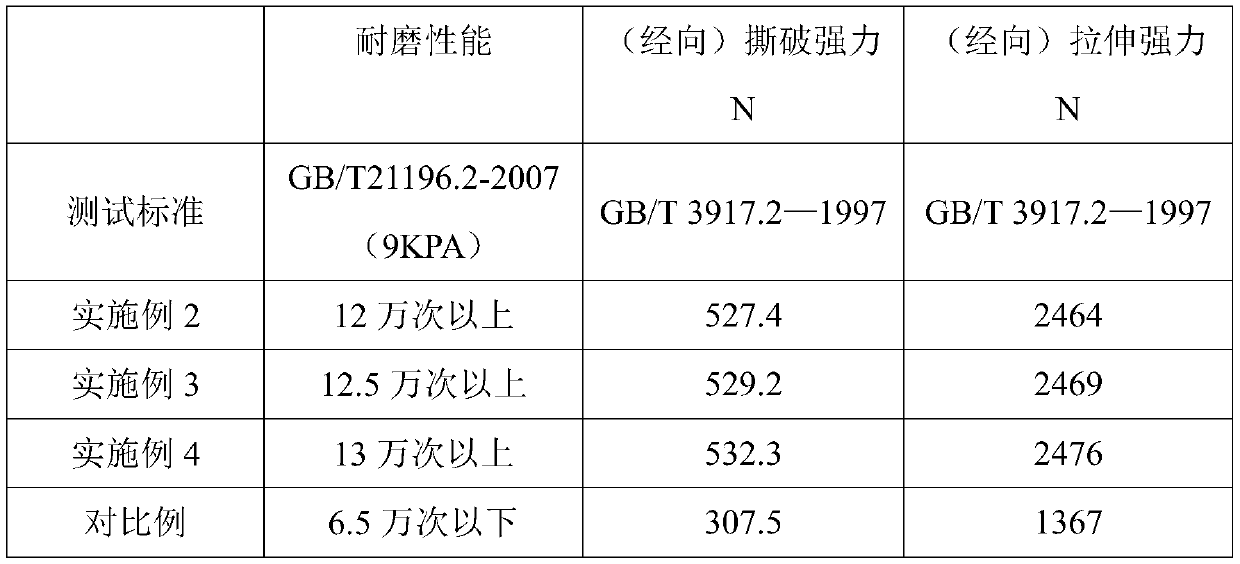

High-wear-resistance screen cloth and preparation method thereof

ActiveCN111088595AImprove wear resistanceHigh tear strengthWarp knittingConjugated synthetic polymer artificial filamentsPolymer scienceHexamethylenediamine

The invention discloses high-wear-resistance screen cloth and a preparation method thereof. The high-wear-resistance screen cloth is prepared from high-wear-resistance composite monofilaments througha weaving process. Each high-wear-resistance composite monofilament comprises an inner layer and an outer layer, wherein the periphery of the inner layer is coated with the outer layer; the ratio of the sectional area of the inner layer to the sectional area of the outer layer is 10: (7.5-9); the inner layer comprises the following raw materials in parts by weight: 90-95 parts of polyhexamethyleneadipamide, 5-8 parts of polydecamethylene sebacamide and 4-6 parts of carboxylated carbon nanotubes, and the outer layer comprises the following raw materials in parts by weight: 13-16 parts of polyhexamethylene adipamide, 80-85 parts of polydecamethylene sebacamide, 6-8 parts of poly(tetramethylene adipamide), 2-3 parts of graphene, 3-4.5 parts of nano silicon dioxide, 3-5 parts of a lubricant and 4-6 parts of a dispersant. The high-wear-resistance screen cloth disclosed by the invention is excellent in wear resistance; and the high-wear-resistance screen cloth has the advantages of high (meridional) tearing strength, high (meridional) tensile strength, high strength, favorable mechanical properties and long service life.

Owner:FUJIAN FENGYUANSHENG TEXTILE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com