Transparent copolymer nylon and preparation method thereof

A transparent and nylon technology, which is applied in the field of copolymerized transparent nylon and its preparation, can solve the problems of polyamide crystallization speed, complex process, and difficult control of process conditions, and achieve excellent transparency, simple preparation method, and excellent comprehensive performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A copolymerized transparent nylon polymerized from the following components:

[0021] Monomer A with a mass content of 96%: caprolactam

[0022] A mass content of 2% monomer B: a mixture of adipic acid monomer and m-xylylenediamine monomer in a molar ratio of 1:1;

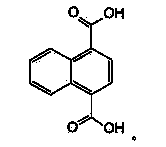

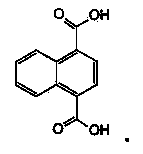

[0023] Monomer F with a mass content of 2%: monomer E and monomer C at a molar ratio of 1:1 are obtained by reacting; where monomer C is an aromatic dibasic acid isophthalic acid; monomer E is an aliphatic diamine Hexamethylenediamine.

[0024] The preparation method of described copolymerization transparent nylon, comprises the steps:

[0025] 1) Put monomer A, monomer B, monomer E and monomer C into an automatic control polymerization kettle with a stirrer, and carry out dehydration reaction at a pressure of 1-27bar and a temperature of 220-320°C; 2) carry out After the reaction, nitrogen gas is injected to discharge the water generated by the reaction, and then the copolymerized transparent nylon melt ...

Embodiment 2

[0027] A copolymerized transparent nylon polymerized from the following components:

[0028] Monomer A with a mass content of 92.5%: caprolactam

[0029] A mass content of 5.5% monomer B: poly-m-xylylene adipamide (MXD6) prepolymer;

[0030] Monomer F with a mass content of 2%: monomer E and monomer C at a molar ratio of 1:1 are obtained by reacting; where monomer C is an aromatic dibasic acid isophthalic acid; monomer E is an aliphatic diamine Hexamethylenediamine.

[0031] The preparation method of described copolymerization transparent nylon, comprises the steps:

[0032] 1) Put monomer A, monomer B, monomer E, and monomer C into an automatic control polymerization kettle with a stirrer, and perform dehydration reaction at a pressure of 1-27bar and a temperature of 220-320°C; 2) After the reaction, nitrogen gas is injected to discharge the water generated by the reaction, and then the copolymerized transparent nylon melt is discharged under pressure, and the melt is mold...

Embodiment 3

[0034] A copolymerized transparent nylon polymerized from the following components:

[0035] Monomer A with a mass content of 92.5%: caprolactam

[0036] A mass content of 2.5% monomer B: a mixture of adipic acid monomer and m-xylylenediamine monomer in a molar ratio of 1:1;

[0037] Monomer F with a mass content of 5%: monomer E and monomer C at a molar ratio of 1:1 are obtained by reacting; monomer C is an aromatic dibasic acid isophthalic acid; monomer E is an aliphatic diamine Hexamethylenediamine.

[0038] The preparation method of described copolymerization transparent nylon, comprises the steps:

[0039] 1) Put monomer A, monomer B, monomer E, and monomer C into an automatic control polymerization kettle with a stirrer, and perform dehydration reaction at a pressure of 1-27bar and a temperature of 220-320°C; 2) After the reaction, nitrogen gas is injected to discharge the water generated by the reaction, and then the copolymerized transparent nylon melt is discharged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com