Halogen-free flame-retardant nylon 66 masterbatch

A technology of flame-retardant nylon and masterbatch, which is applied in the field of halogen-free flame-retardant nylon 66 masterbatch, and can solve the problems such as poor flame-retardant effect of flame-retardant nylon 66 masterbatch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

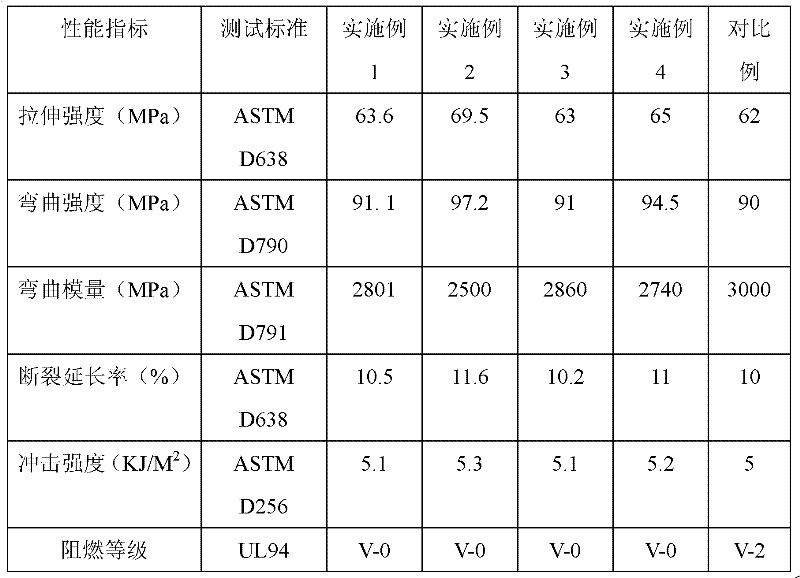

Examples

Embodiment 1

[0029] A kind of halogen-free flame-retardant nylon 66 masterbatch, by weight percentage, its composition is:

[0030] Polyhexamethylene adipamide 86.3

[0031] Melamine cyanurate 12

[0032] Tetraphenylresorcinol diphosphate 1

[0033] 3,5-di-tert-butyl-4-hydroxyphenyl propionate octadecyl 0.5

[0034] Bis-2,2,6,6-tetramethylpiperidinol sebacate 0.2

[0035] A preparation method of halogen-free flame-retardant nylon 66 masterbatch. The above-mentioned components are mixed in a high-speed mixer in proportion for several minutes, and then added to a screw extruder for granulation. The processing temperature is 200-300 ° C, and the screw rotation speed is 200-580 rpm.

Embodiment 2

[0037] A kind of halogen-free flame-retardant nylon 66 masterbatch, by weight percentage, its composition is:

[0038] Polyhexamethylene adipamide 88.5

[0039] Melamine cyanurate 10

[0040] Tetraphenylresorcinol diphosphate 1

[0041] 3,5-di-tert-butyl-4-hydroxyphenyl propionate octadecanyl 0.3

[0042] Bis-2,2,6,6-tetramethylpiperidinol sebacate 0.2

[0043] Others are the same as in Example 1.

Embodiment 3

[0045] A kind of halogen-free flame-retardant nylon 66 masterbatch, by weight percentage, its composition is:

[0046] Polyhexamethylene adipamide 85

[0047] Melamine cyanurate 12.5

[0048] Tetraphenylresorcinol diphosphate 2

[0049] 3,5-di-tert-butyl-4-hydroxyphenyl propionate octadecanyl 0.3

[0050] Bis-2,2,6,6-tetramethylpiperidinol sebacate 0.2

[0051] Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com