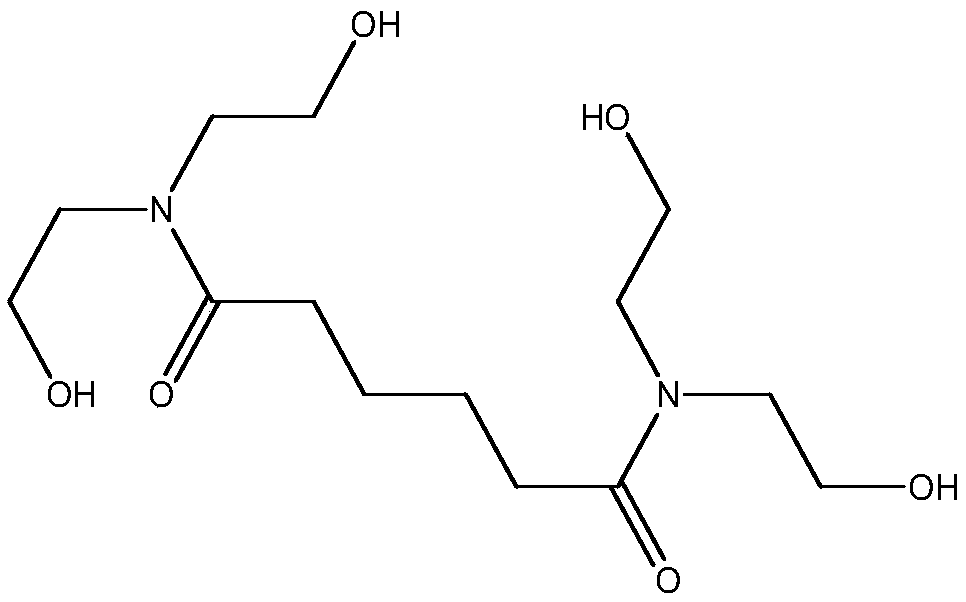

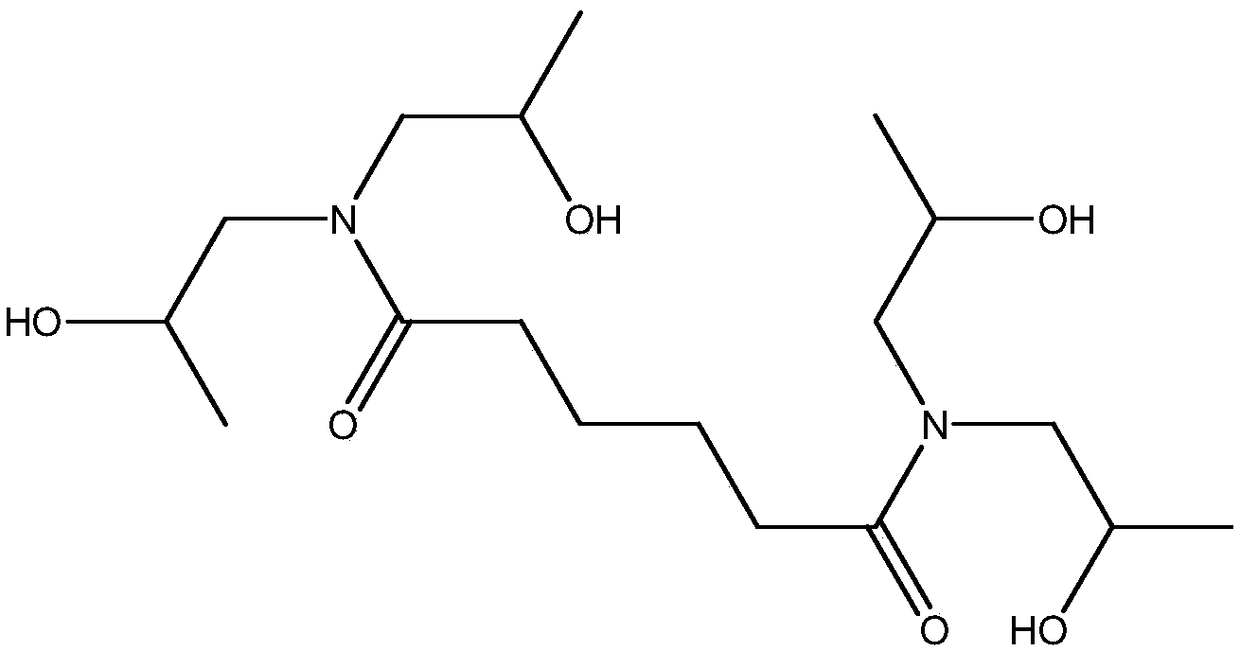

Polyester resin for N,N,N',N'-tetra(2-hydroxypropyl) adipamide system and preparation method thereof

A technology of polyester resin and adipamide, which is applied in the field of polyester resin and polyester resin preparation for N,N,N',N'-tetraadipamide system, can solve the impact resistance and boiling resistance. Unsatisfactory, low reactivity, insufficient curing, etc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

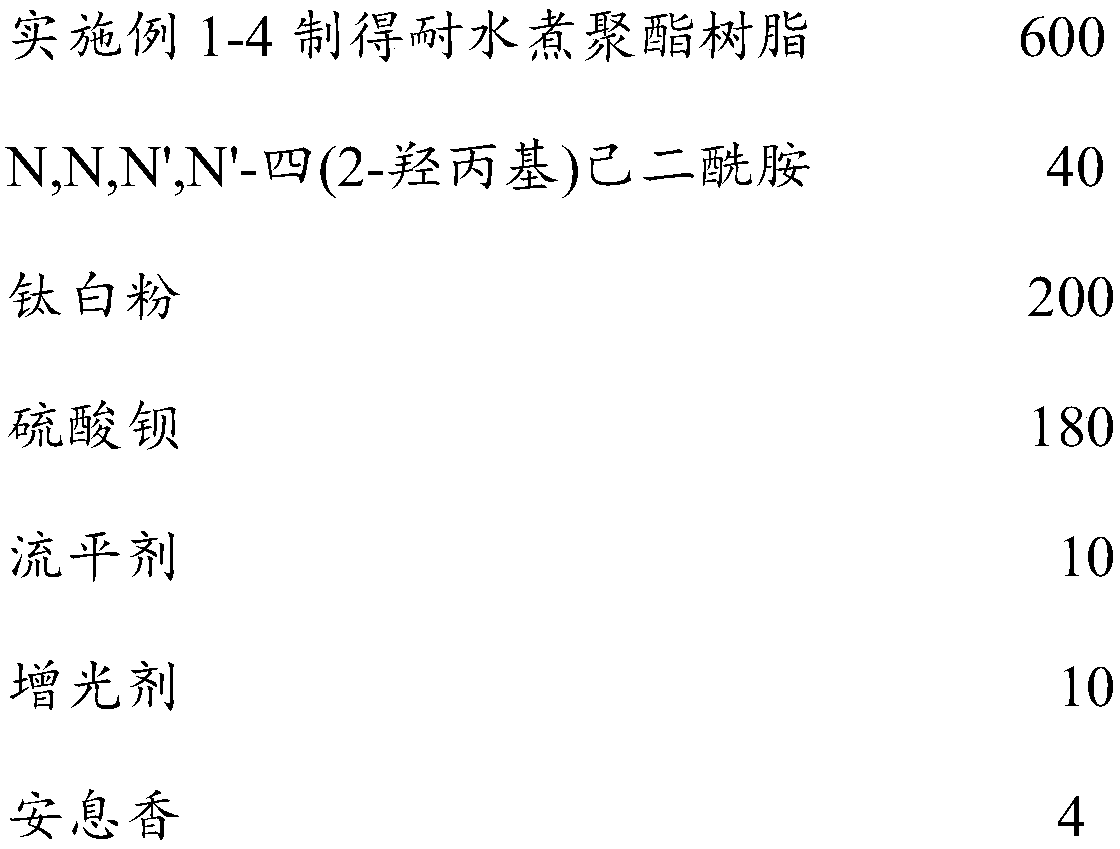

Examples

Embodiment 1

[0048] A, 12mol% of 1,8-octanediol, 15mol% of 3-(trimethylsilyl)-1,2-propanediol, 6mol% of 5-hydroxycapric glyceride, 18mol% of neopentyl Diol is added into the mixer, and heated and melted at 110-125°C to obtain a mixed material;

[0049] B. Add 15mol% terephthalic acid, 18mol% o-carboxyphenylacetic acid and 12mol% 1,1'-ferrocenedicarboxylic acid to the mixed material in A, and add 0.2mol% catalyst at the same time, under nitrogen protection Slowly raise the temperature to about 200°C, then keep warm for 3 hours, then gradually raise the temperature until no obvious distillate is distilled out, and the acid value of the reactant is 18mgKOH / g; the temperature of the reaction kettle is less than or equal to 248°C;

[0050] C. Add 0.4mol% antioxidant 1,3,5-tris(3,5-di-tert-butyl-4-hydroxybenzyl) isocyanuric acid, keep a vacuum of 45mmHg for 6h to promote the formation of polyester resin , stop vacuuming when the acid value drops to 10mgKOH / g;

[0051] D. When the temperature i...

Embodiment 2

[0057] The difference with embodiment 1 is that the consumption of each raw material in embodiment 2 is as follows:

[0058] Terephthalic acid 8mol%

[0059] o-Carboxyphenylacetic acid 20mol%

[0060] 1,1′-Ferrocenedicarboxylic acid 12mol%

[0061] 1,8-octanediol 14mol%

[0062] 3-(trimethylsilyl)-1,2-propanediol 18mol%

[0063] 5-Hydroxycapric Glyceride 6mol%

[0064] Neopentyl glycol 18mol%

[0065] Calcein 4mol%.

[0066] All the other steps are identical to Example 1.

[0067] Polyester resin acid value: 32mgKOH / g, softening point 114°C.

Embodiment 3

[0069] The difference with embodiment 1 is that the consumption of each raw material in embodiment 2 is as follows:

[0070] Terephthalic acid 16mol%

[0071] o-Carboxyphenylacetic acid 15mol%

[0072] 1,1′-Ferrocenedicarboxylic acid 8mol%

[0073] 1,8-octanediol 12mol%

[0074] 3-(trimethylsilyl)-1,2-propanediol 16mol%

[0075] 5-Hydroxycapric Glyceride 8mol%

[0076] Neopentyl glycol 21mol%

[0077] Calcein 4mol%.

[0078] All the other steps are identical to Example 1.

[0079] Polyester resin acid value: 28mgKOH / g, softening point 115°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com