Antibacterial PA66/ABS composite material and preparation method thereof

The technology of composite material and antibacterial agent is applied in the field of antibacterial nylon composite material and its preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

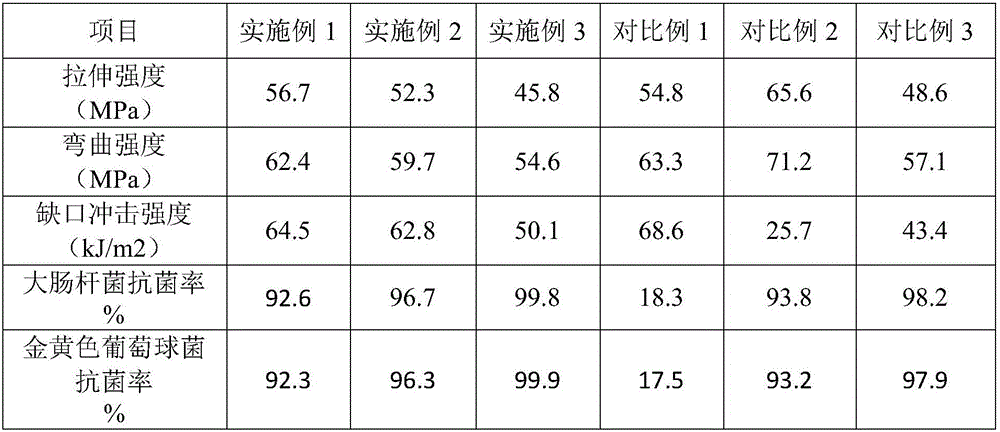

[0037] The antibacterial PA66 / ABS composite material of three embodiments of the present invention shown in the formula of Table 1, the antibacterial PA66 / ABS composite material is mainly obtained by blending and melting the components shown in the following Table 1:

[0038] Table 1: PA66 / ABS composite material formulation

[0039] components Example 1 Example 2 Example 3 Comparative example 1 Comparative example 2 Comparative example 3 PA66 50 60 70 50 60 70 processing activator 15 20 25 15 20 / ABS 50 40 30 50 40 30 Compatibilizer 5 5 5 5 5 5 Toughener 15 15 12 15 / 12 Diffuser oil 0.1 0.2 0.2 0.1 0.2 0.2 Antibacterial agents 0.8 1.1 1.5 / 1.1 1.5 antioxidant 0.3 0.3 0.3 0.3 0.3 0.3

[0040] The processing activator used in the above examples is binary copolymerized nylon of nylon 6 and nylon 66, with a melting point of 185° C. and a relative viscosity of 2.2.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com