Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

692results about How to "Reduce processing temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

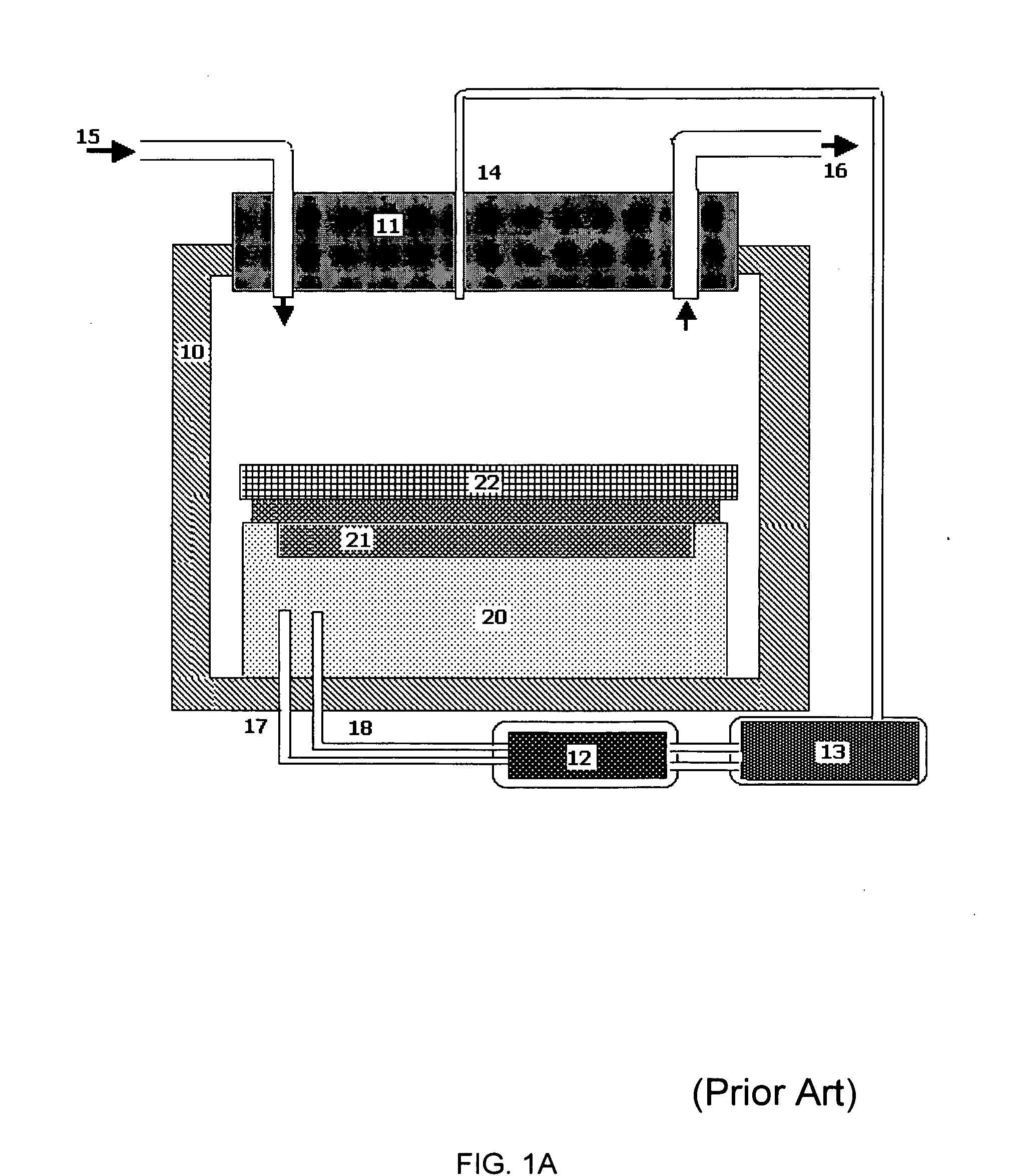

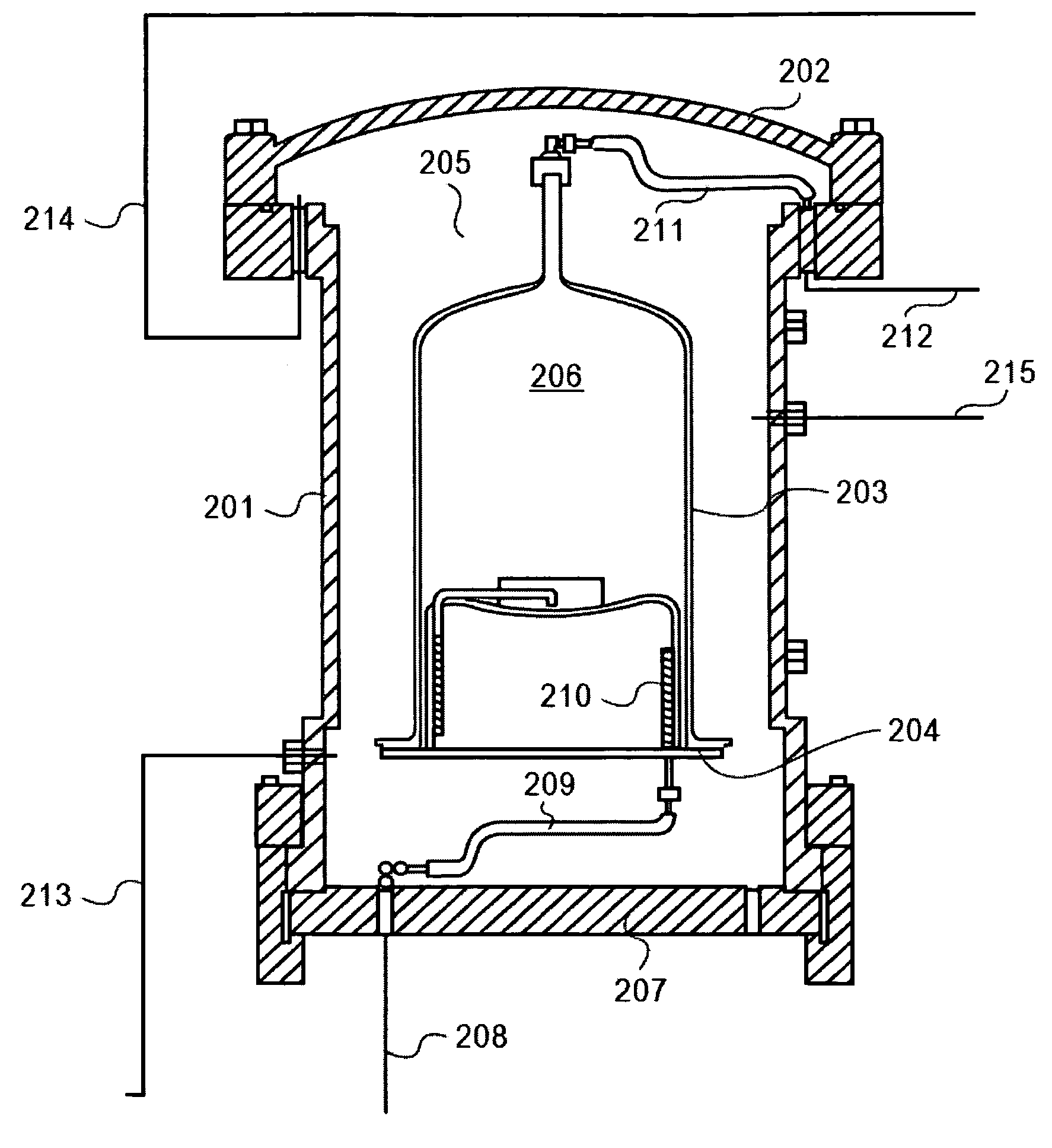

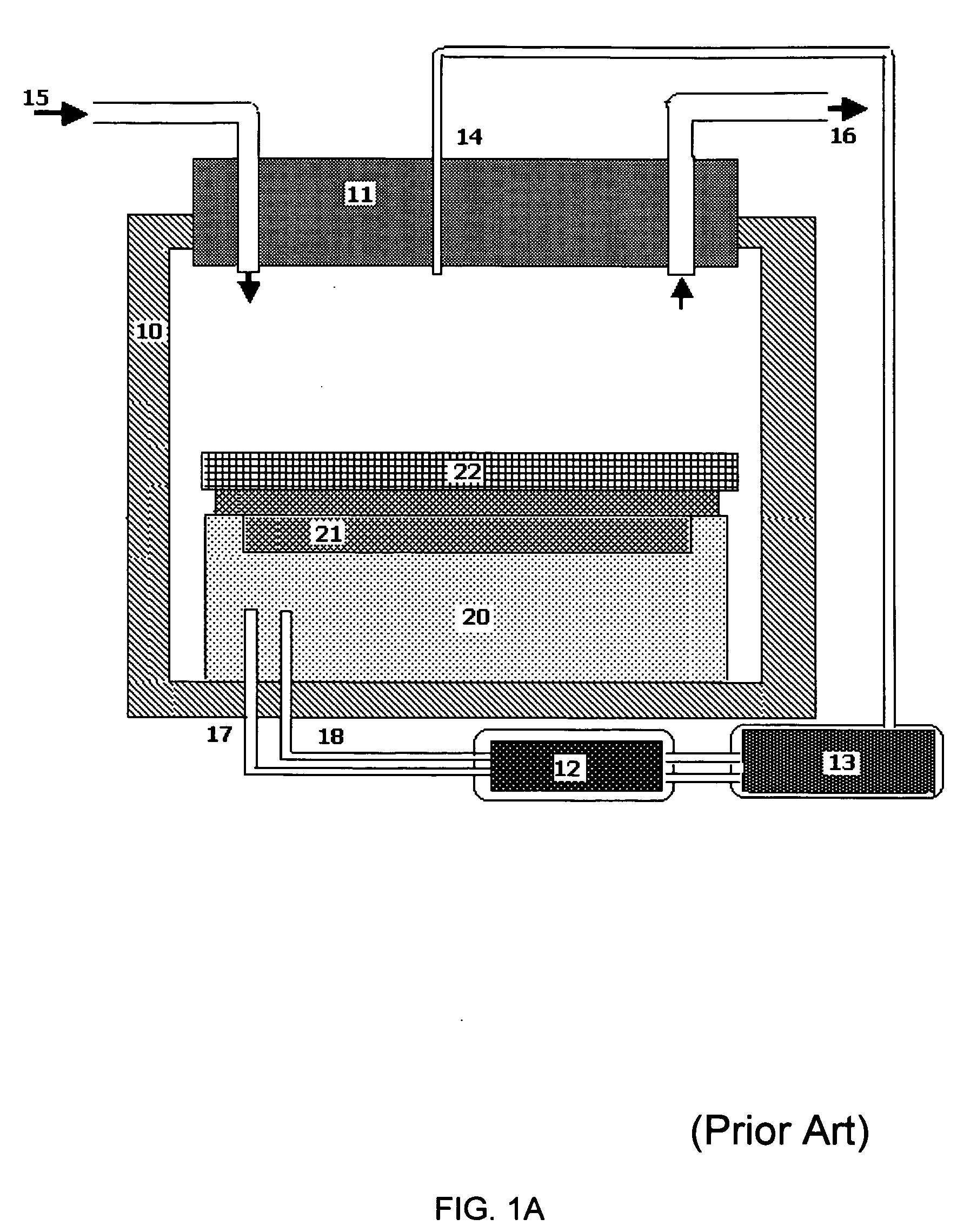

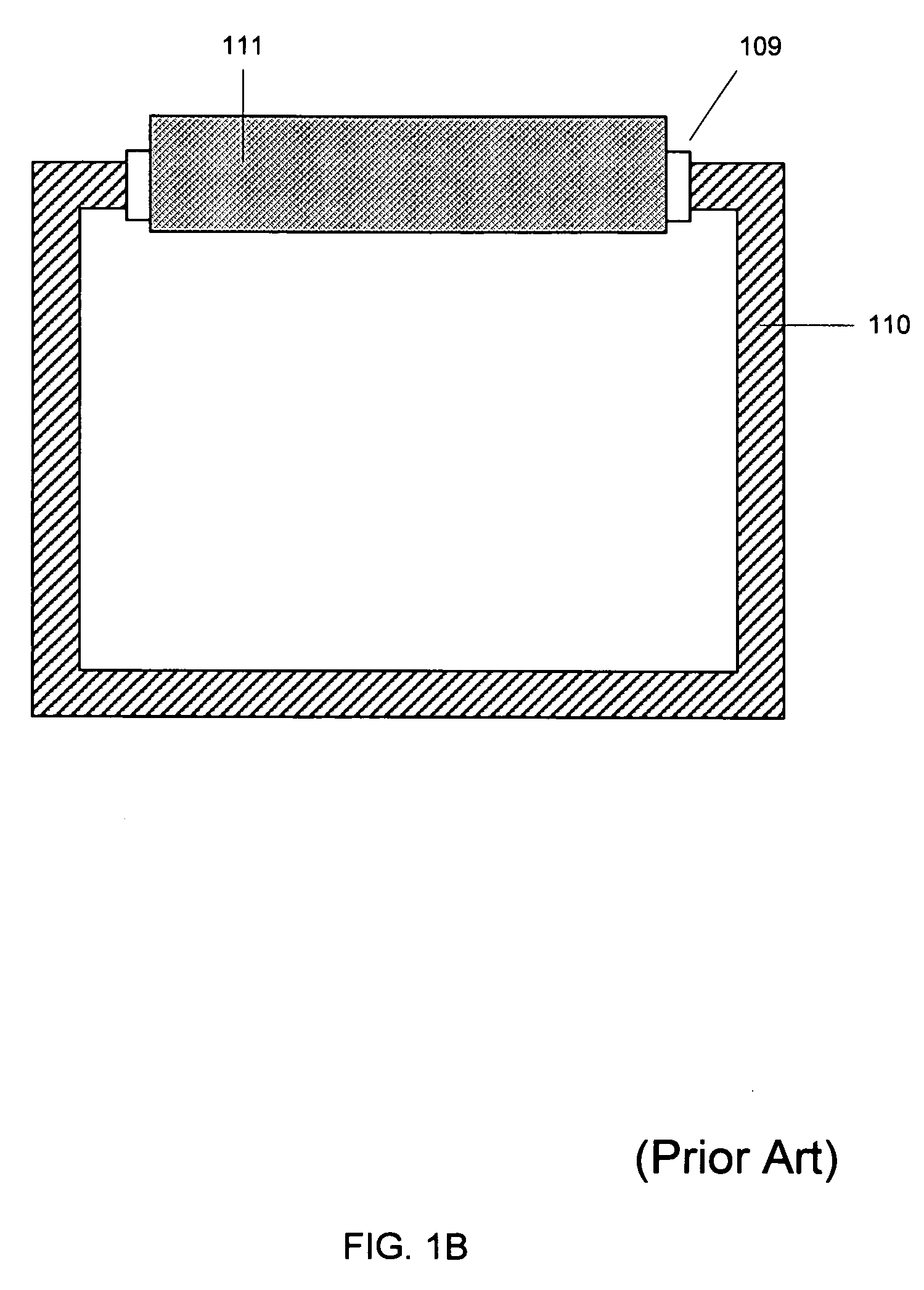

Methods and apparatuses for high pressure gas annealing

InactiveUS20070187386A1Improve device performanceIncrease device 's lifetimeSemiconductor/solid-state device testing/measurementSolid-state devicesForming gasGate dielectric

Novel methods and apparatuses for annealing semiconductor devices in a high pressure gas environment. According to an embodiment, the annealing vessel has a dual chamber structure, and potentially toxic, flammable, or otherwise reactive gas is confined in an inner chamber which is protected by pressures of inert gas contained in the outer chamber. The incoming gas delivery system and exhaust gas venting system are likewise protected by various methods. Embodiments of the present invention can be used, for example, for high-K gate dielectric anneal, post metallization sintering anneal, and forming gas anneal in the semiconductor manufacturing process.

Owner:PSMC

Composite foaming agent and preparation method and application thereof

The invention discloses a composite foaming agent, a preparation method thereof and application thereof. The composite foaming agent comprises azodicarbonamide, sodium bicarbonate and an auxiliary foaming agent in a weight ratio of (0.3-0.9):(0.2-0.6):(0.1-0.8). The auxiliary foaming agent is prepared by uniformly stirring attapulgite, zeolite and calcite, soaking the mixture in diluted hydrochloric acid of which the concentration is 0.5 to 6 weight percent, drying the mixture, crushing the dried mixture into powder, blending the powder and powdery white carbon black and uniformly stirring the mixture, wherein the weight ratio of the attapulgite to the zeolite to the calcite to the white carbon black is (0.3-0.8):(0.02-0.6):(0.1-0.8):(0.01-0.8). The composite foaming agent disclosed by the invention has relatively high liquidity and dispersibility, a low decomposition temperature and a long decomposition temperature period.

Owner:常州市英特玛柯橡塑科技有限公司

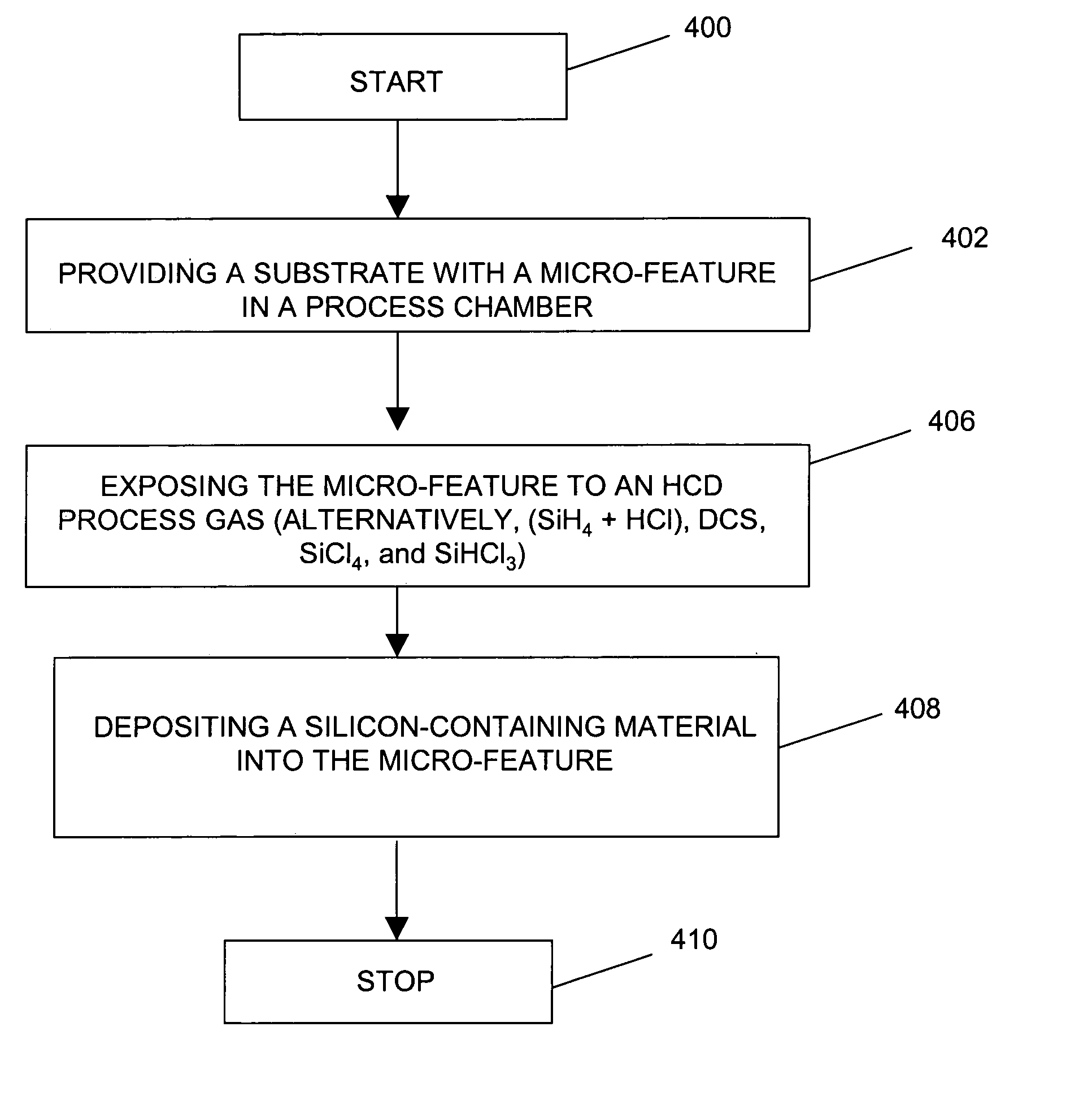

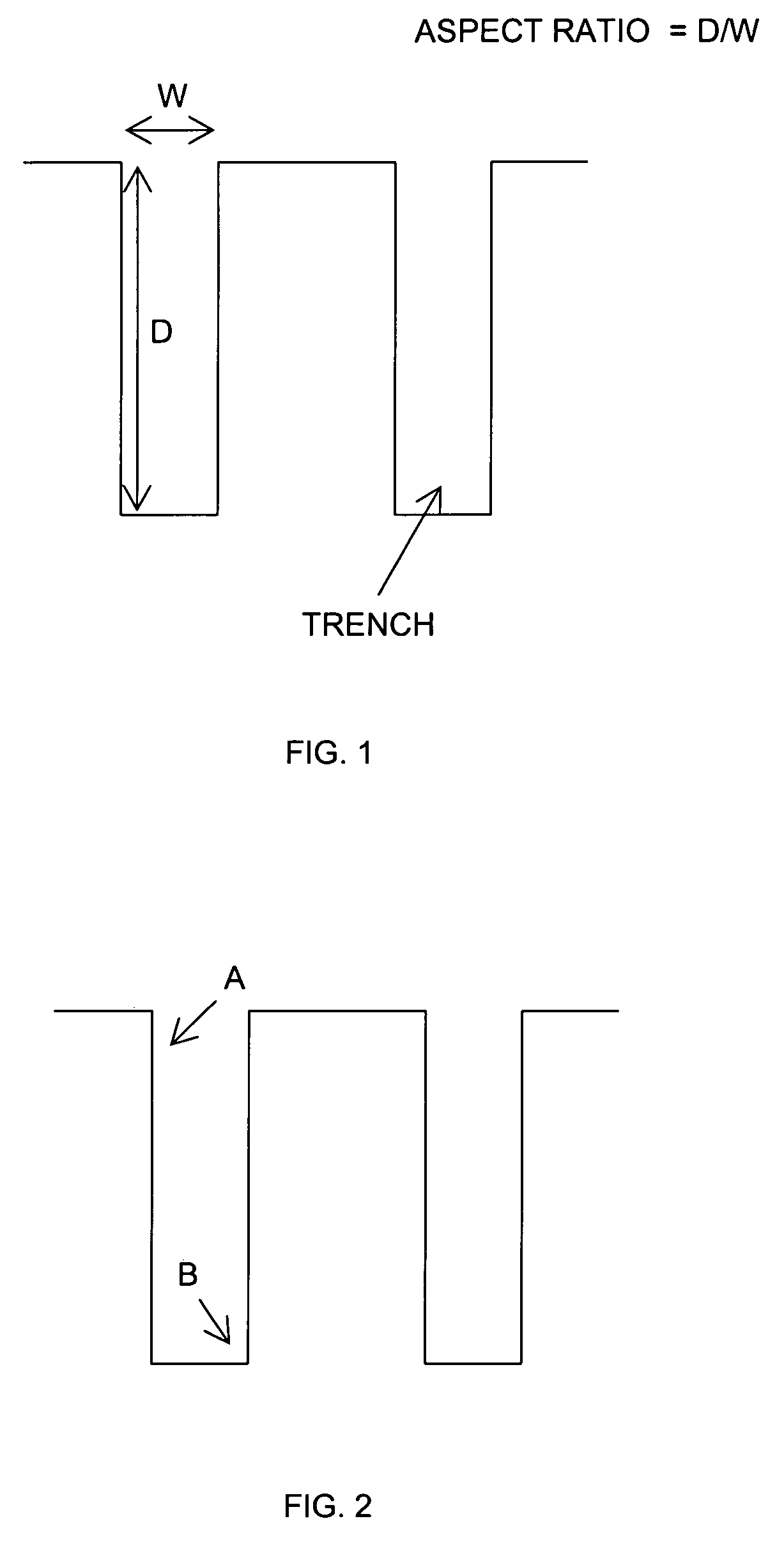

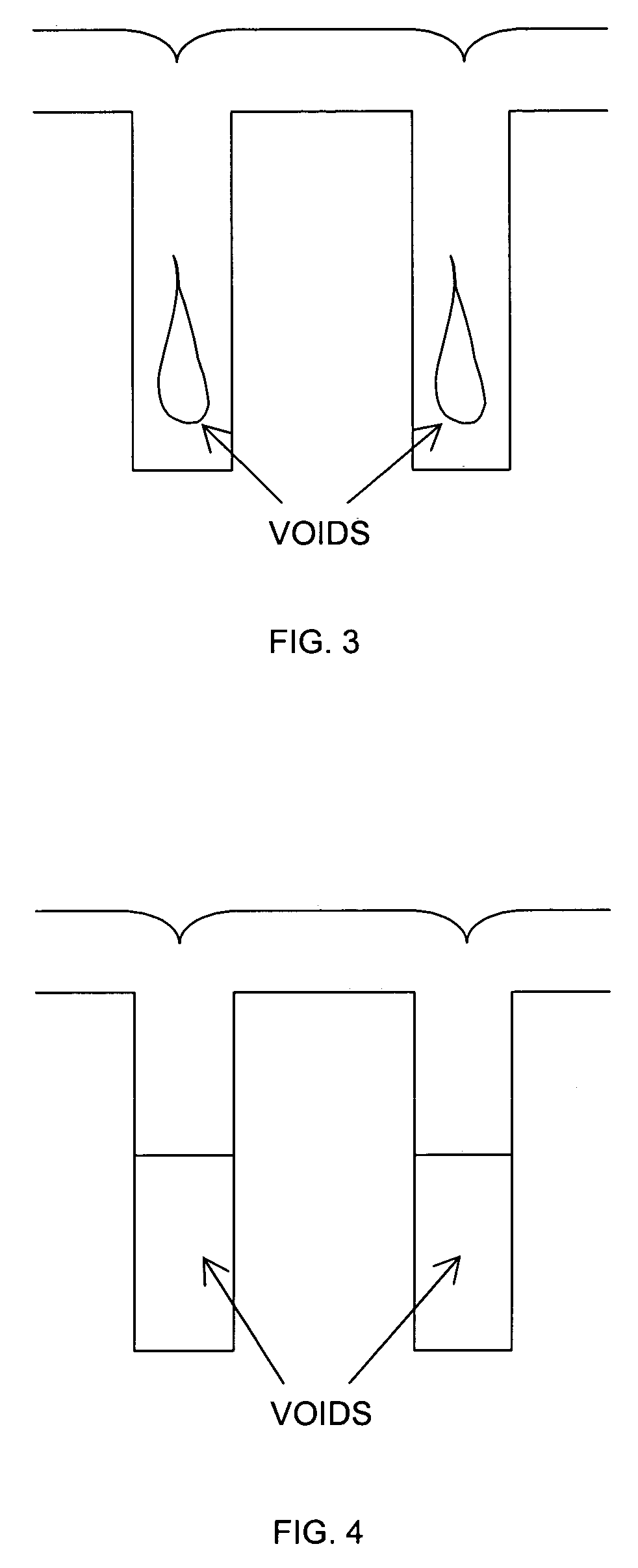

Micro-feature fill process and apparatus using hexachlorodisilane or other chlorine-containing silicon precursor

ActiveUS7205187B2Inhibition formationIncrease deposition rateSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilicon membraneDeposition process

A method is provided for depositing a silicon-containing film in a micro-feature on a substrate by a low pressure deposition process in a processing system. A silicon-containing film can be formed in a micro-feature by providing a substrate in a process chamber of a processing system, and exposing a hexachlorodisilane (HCD) process gas to the substrate. A processing tool containing a processing system for forming a silicon-containing film in a micro-feature using a silicon and chlorine-containing gas such as a HCD process gas is provided. Alternatively, the micro-feature can be exposed to DCS, SiCl4, and SiHCl3 gases. Alternatively, the micro-feature can be exposed to (SiH4+HCl).

Owner:TOKYO ELECTRON LTD

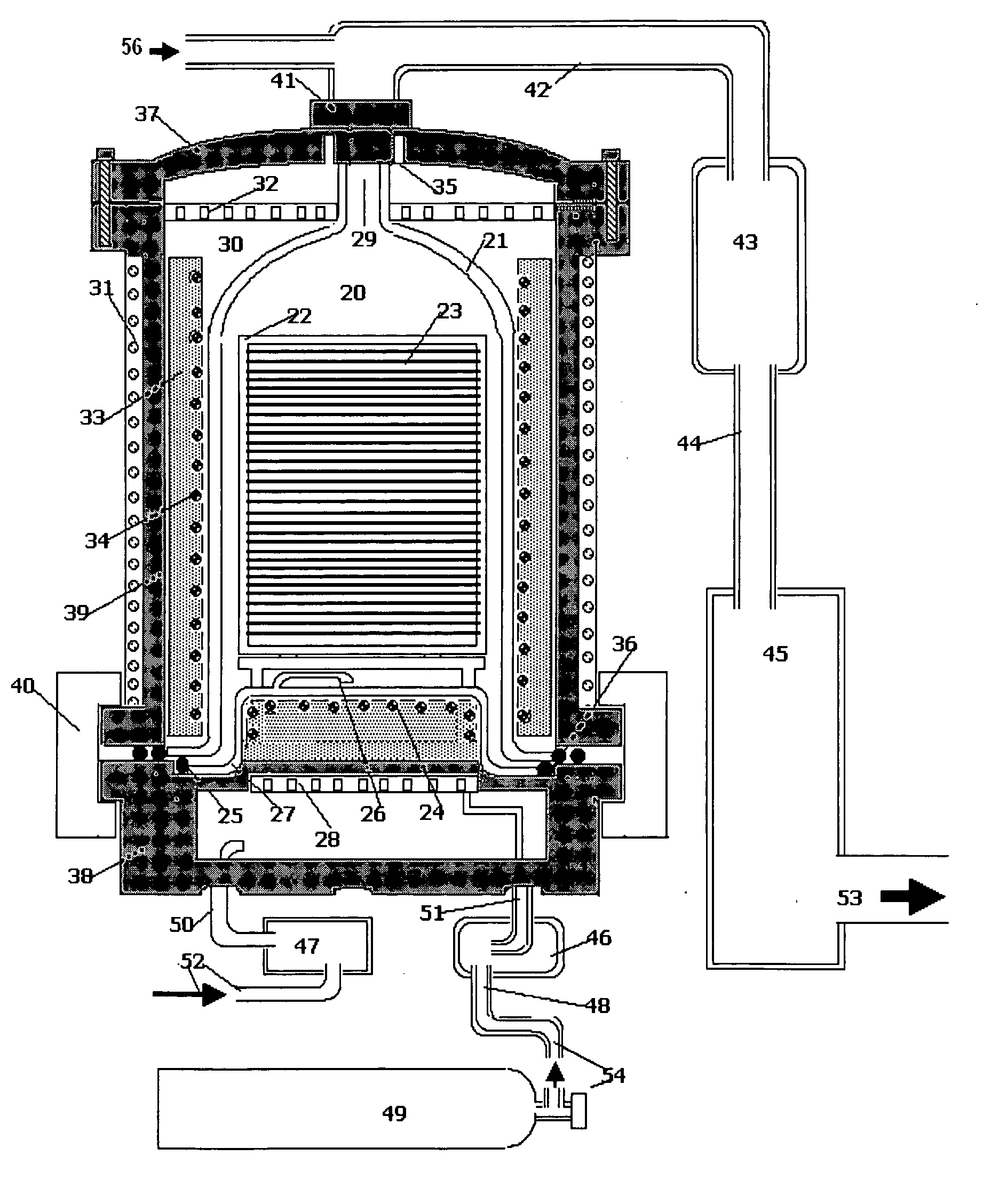

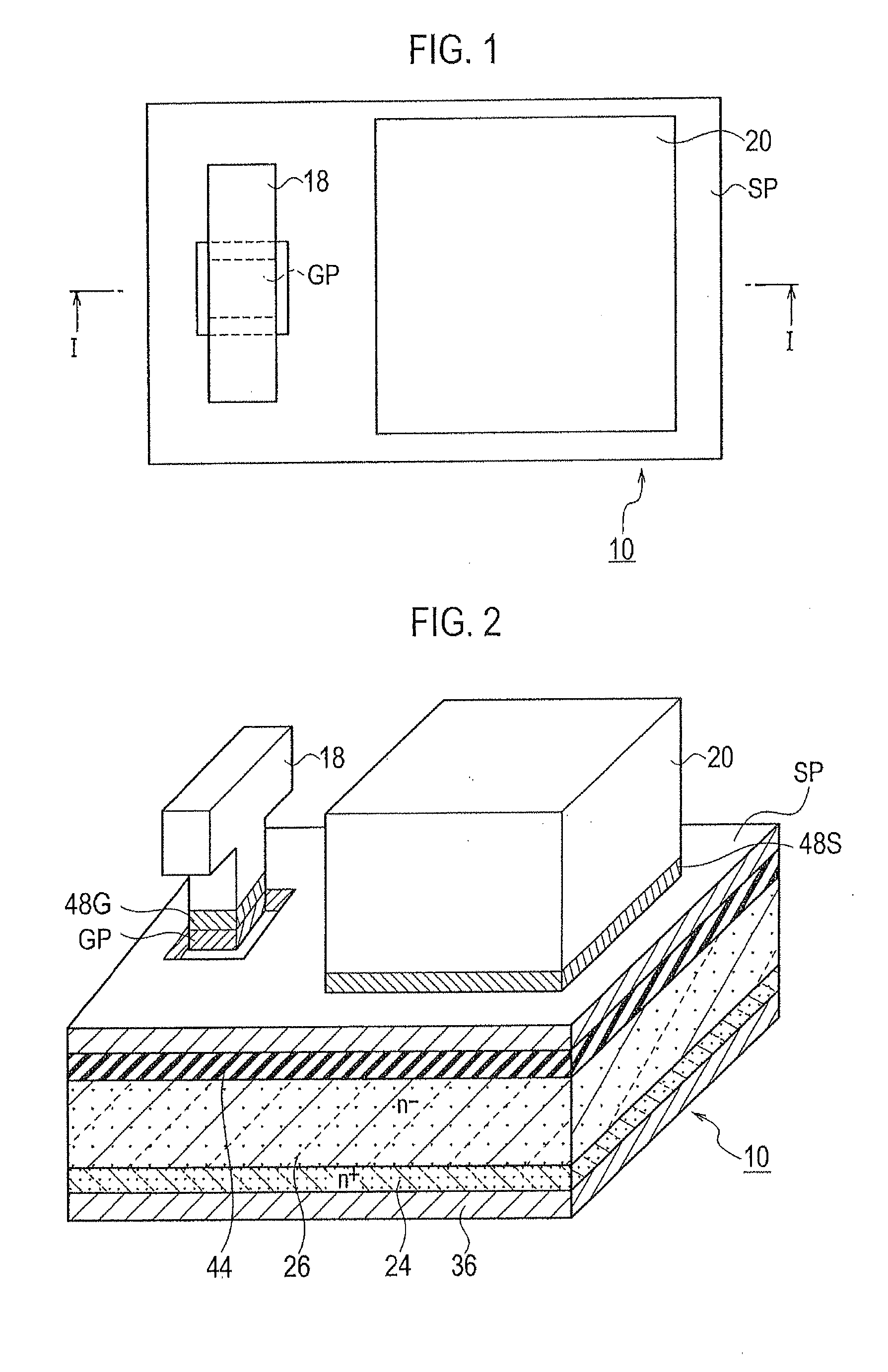

Method and apparatuses for high pressure gas annealing

ActiveUS20090148965A1Reduce in quantityImprove device performanceSemiconductor/solid-state device testing/measurementSolid-state devicesGate dielectricForming gas

Novel methods and apparatuses for annealing semiconductor devices in a high pressure gas environment. According to an embodiment, the annealing vessel has a dual chamber structure, and potentially toxic, flammable, or otherwise reactive gas is confined in an inner chamber which is protected by pressures of inert gas contained in the outer chamber. The incoming gas delivery system and exhaust gas venting system are likewise protected by various methods. Embodiments of the present invention can be used, for example, for high-K gate dielectric anneal, post metallization sintering anneal, and forming gas anneal in the semiconductor manufacturing process.

Owner:HPSP CO LTD

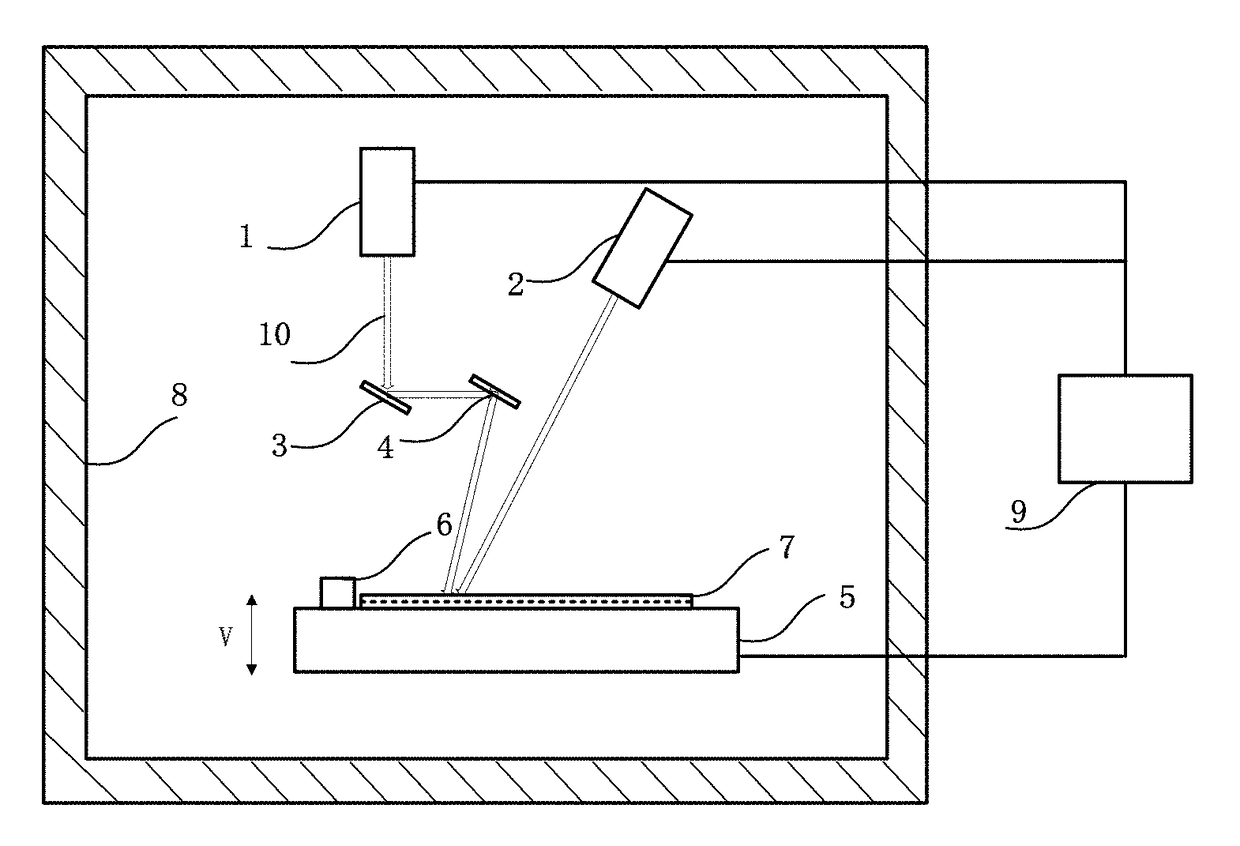

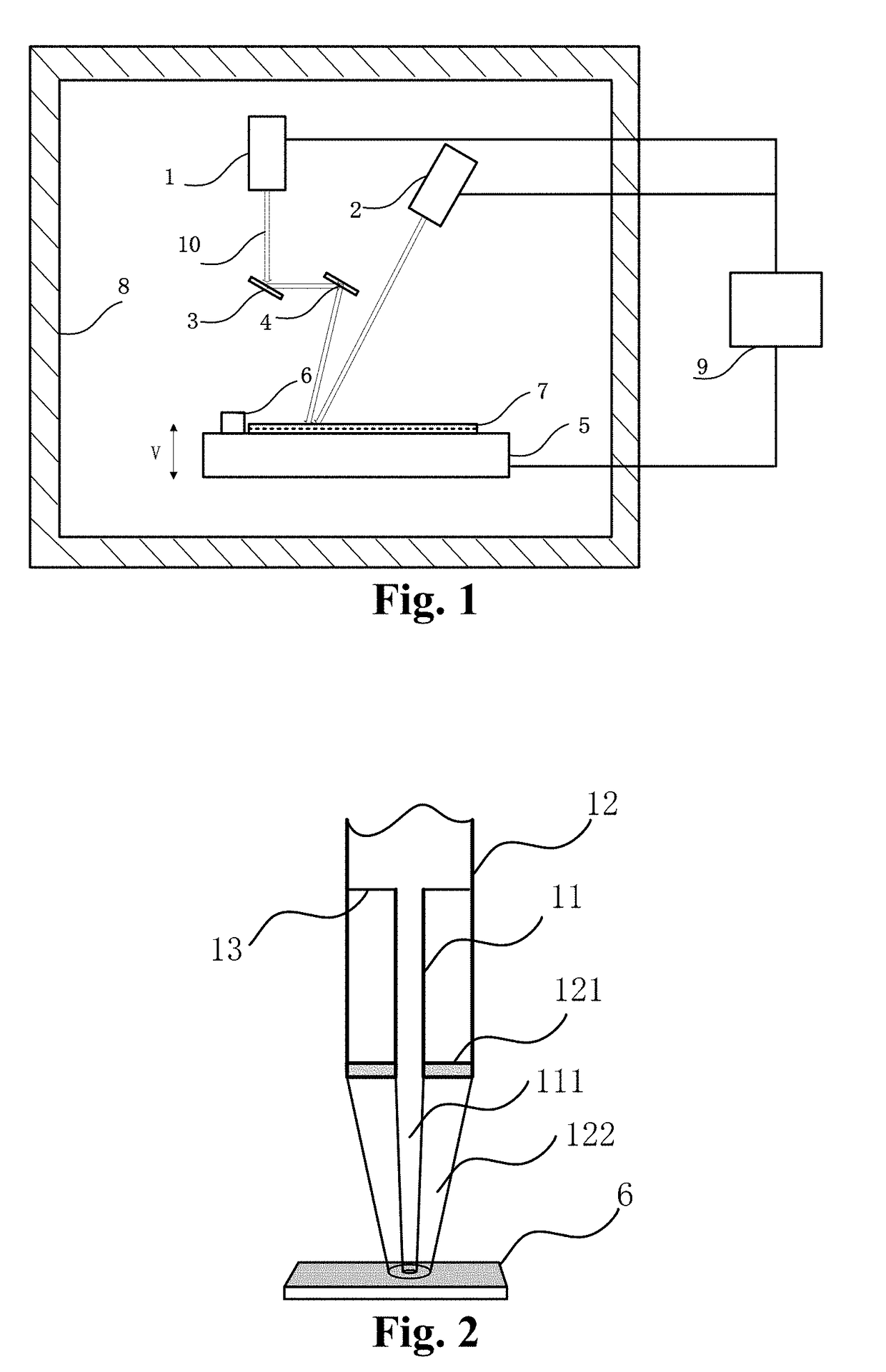

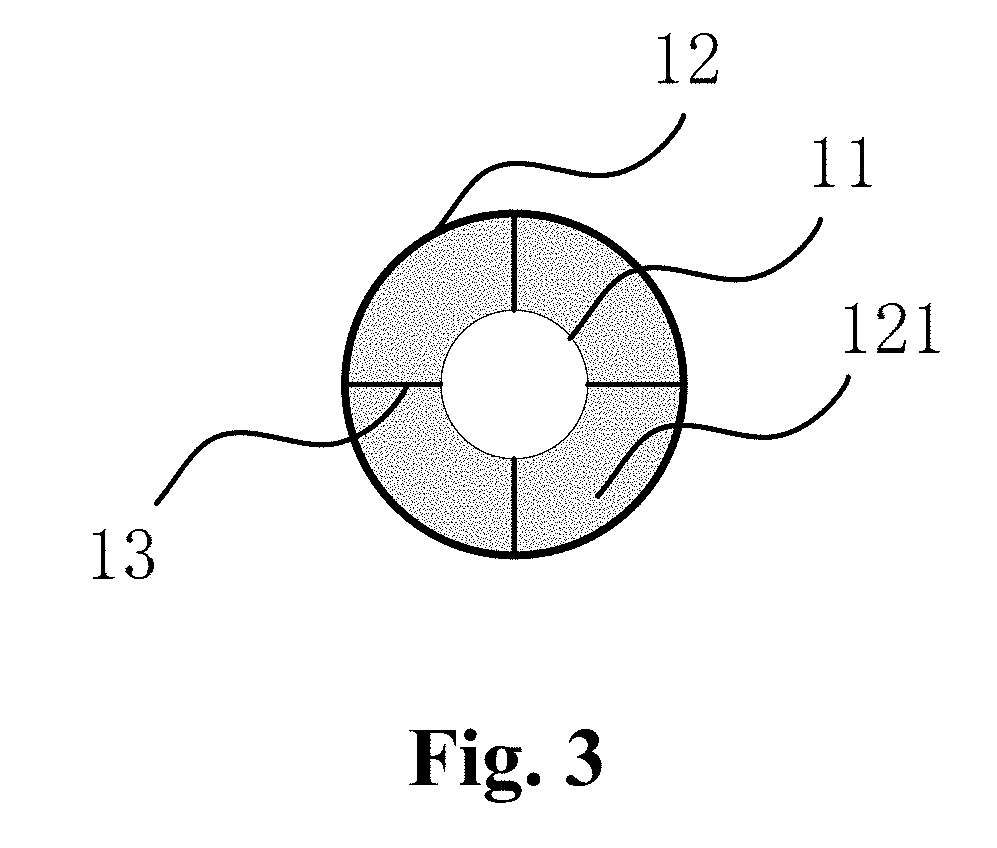

Ultraviolet laser 3D printing method for precise temperature control of polymer material and device thereof

ActiveUS20170259504A1Easy to controlPrevent materialAdditive manufacturing apparatus3D object support structuresComputer control systemTemperature control

The present disclosure disclosed an ultraviolet laser 3D printing method for the precise temperature control of polymer material and device thereof. The device comprises a thermostat, a laser head, a non-contact type temperature monitoring device, a scanning galvanometer, a processing platform, a powder laying device, a material to be processed, a computer control system and so on. The method comprises: presetting a processing temperature by the control system; during the processing procedure, the temperature rise condition of the processed object is monitored by the non-contact type temperature monitoring device and fed back in real time to the control system; and by recording the rise value of the temperature within a certain period, the system can obtain the absorption capability of the laser and the temperature rise degree of the processed material, so that the laser output power can be calculated according to the preset processing temperature value, and the laser power can be adjusted in real time to precisely control the processing temperature. By means of the above device and method, precise temperature control of ultraviolet laser 3D printing prototyping for polymer materials can be realized.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Application of hyperbranched polyester to plastic processing

The invention discloses an application of hyperbranched polyester to plastic processing, and belongs to the technical field of plastic processing assistants. The application of the hyperbranched polyester to plastic processing includes the steps that by mass, 0.1% to 5% of the hydroxyl-terminated hyperbranched polyester is added into plastic; the mixture is mixed to be even, extruded, prilled and dried, and a modified plastic product is obtained. According to the application, the plastic such as PPC and the hyperbranched polyester are melted and blended, and the plastic such PPC is modified through a double-screw extruder; after the hyperbranched polyester is added into a base material of the plastic such as PPC, the effective melt viscosity of the plastic such as PPC can be remarkably reduced; in other words, processing temperature and thermal degradation are reduced; in addition, melting fluidity improved in this way can also be achieved through the small adding amount,, and extruding film forming can be more easily achieved; the tensile strength of the modified plastic such as PPC is up to 30 MPa, and the strength can be higher than the strength of thin-film-level LLDPE and the strength of thin-film-level PVC.

Owner:WEIHAI CY DENDRIMER TECH

Polystyrene reclamation process

InactiveUS20020062054A1Avoid lostEasy to reuseHydrocarbon by hydrogenationPlastic recyclingPropyl bromideBoiling point

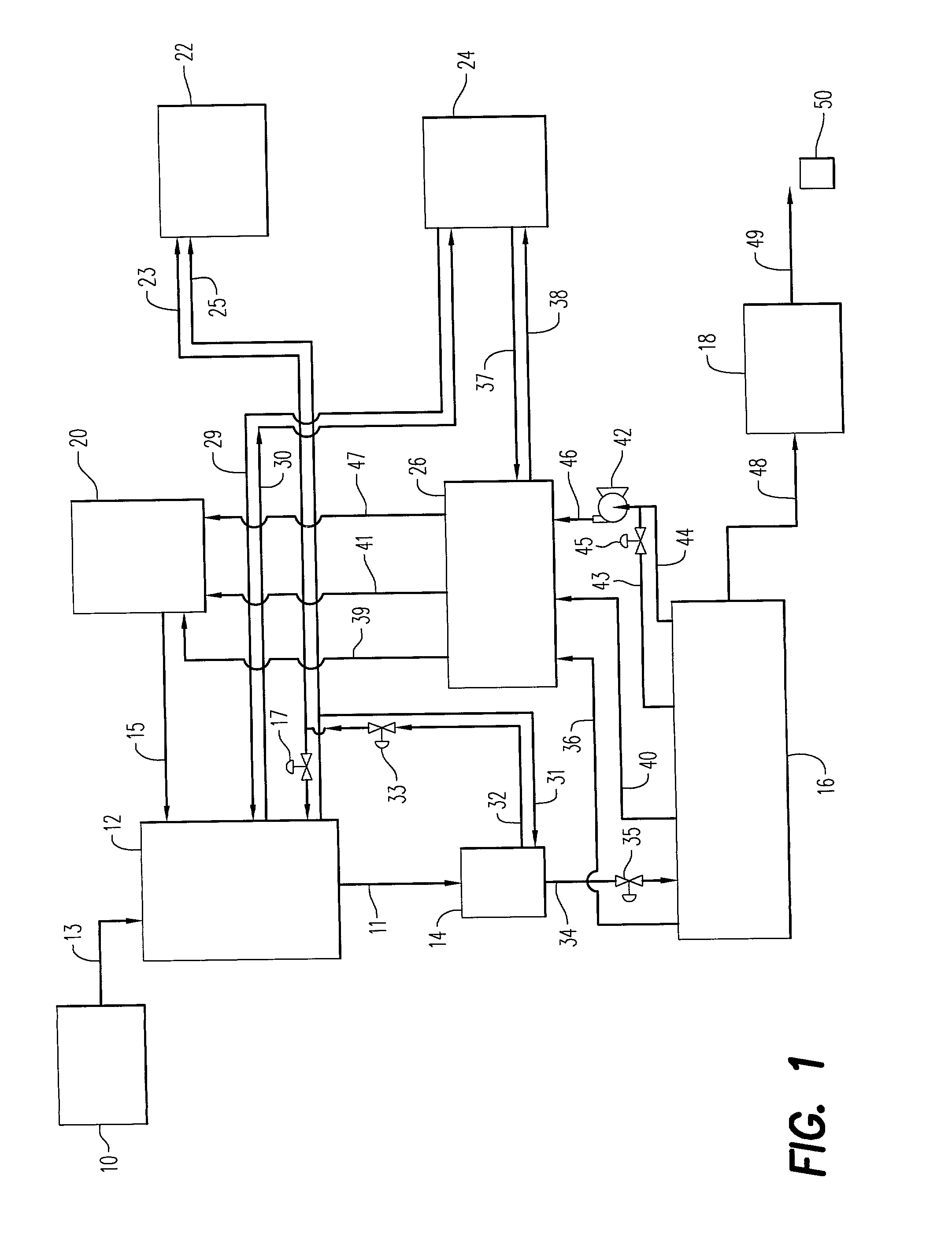

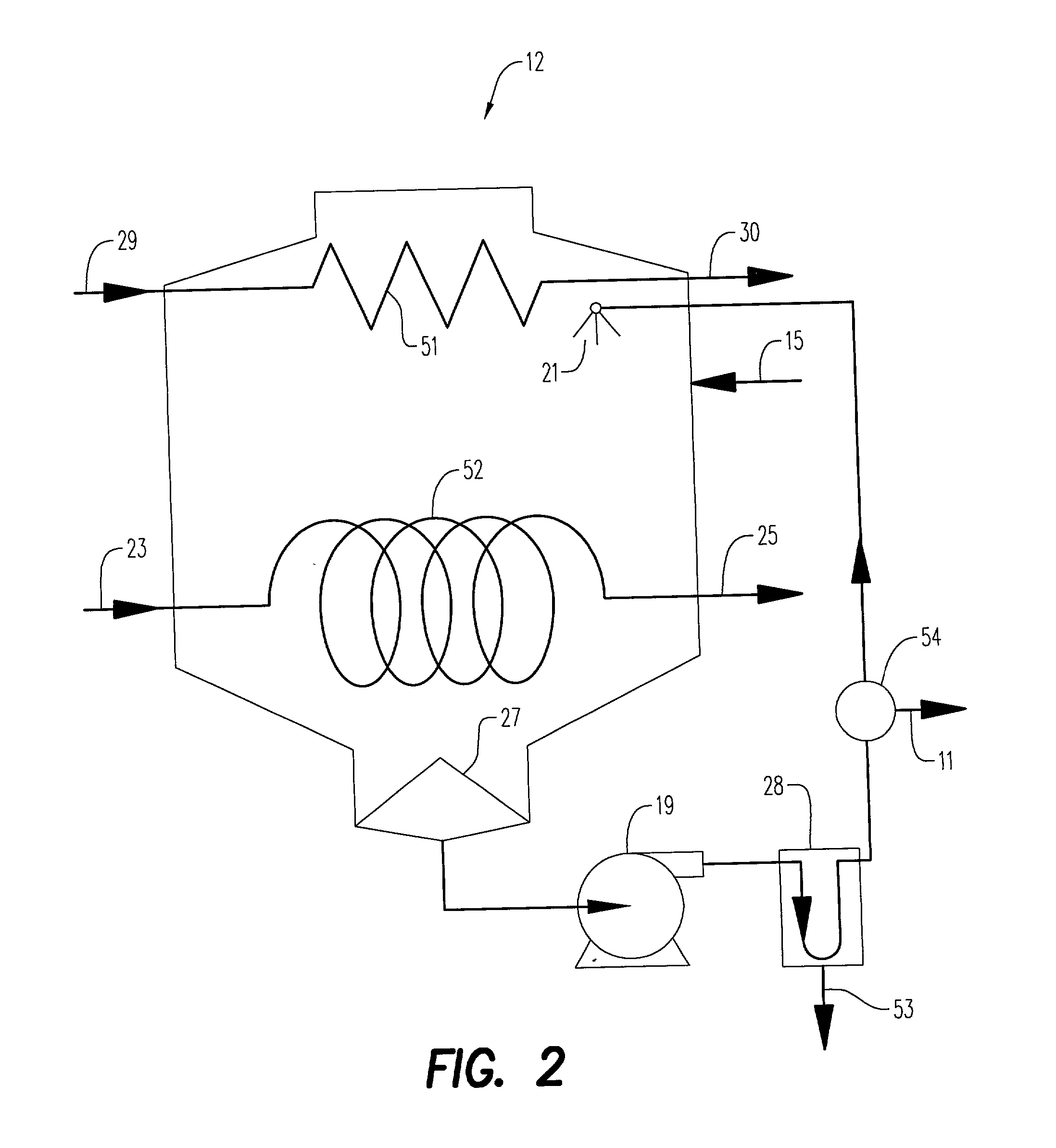

This disclosure concerns a process and apparatus for reclamation of waste polystyrene-type materials for reuse within the specification ranges of the input polystyrene-type material. The disclosed process and apparatus include dissolution of the waste polystyrene-type materials in a dissolve section utilizing a reusable solvent having a low boiling point and high vaporization rate, removal of solid contaminants in one or more filter sections, devolatilization of the dissolved polystyrene and recovery of the polystyrene-type material in a solid form in a recovery section. Preferably the process and apparatus provide a closed system and include recycling and reuse in the process of the vaporized solvent. The maximum temperature in the recovery section is 190° C. The reusable solvent is preferably environmentally safe and has a low boiling point and high vaporization rate. n-Propyl bromide, or environmentally safe mixtures thereof, including mixtures with isopropyl alcohol, is the preferred reusable solvent.

Owner:RESOURCE RECOVERY TECH

Antimicrobial Packaging Material

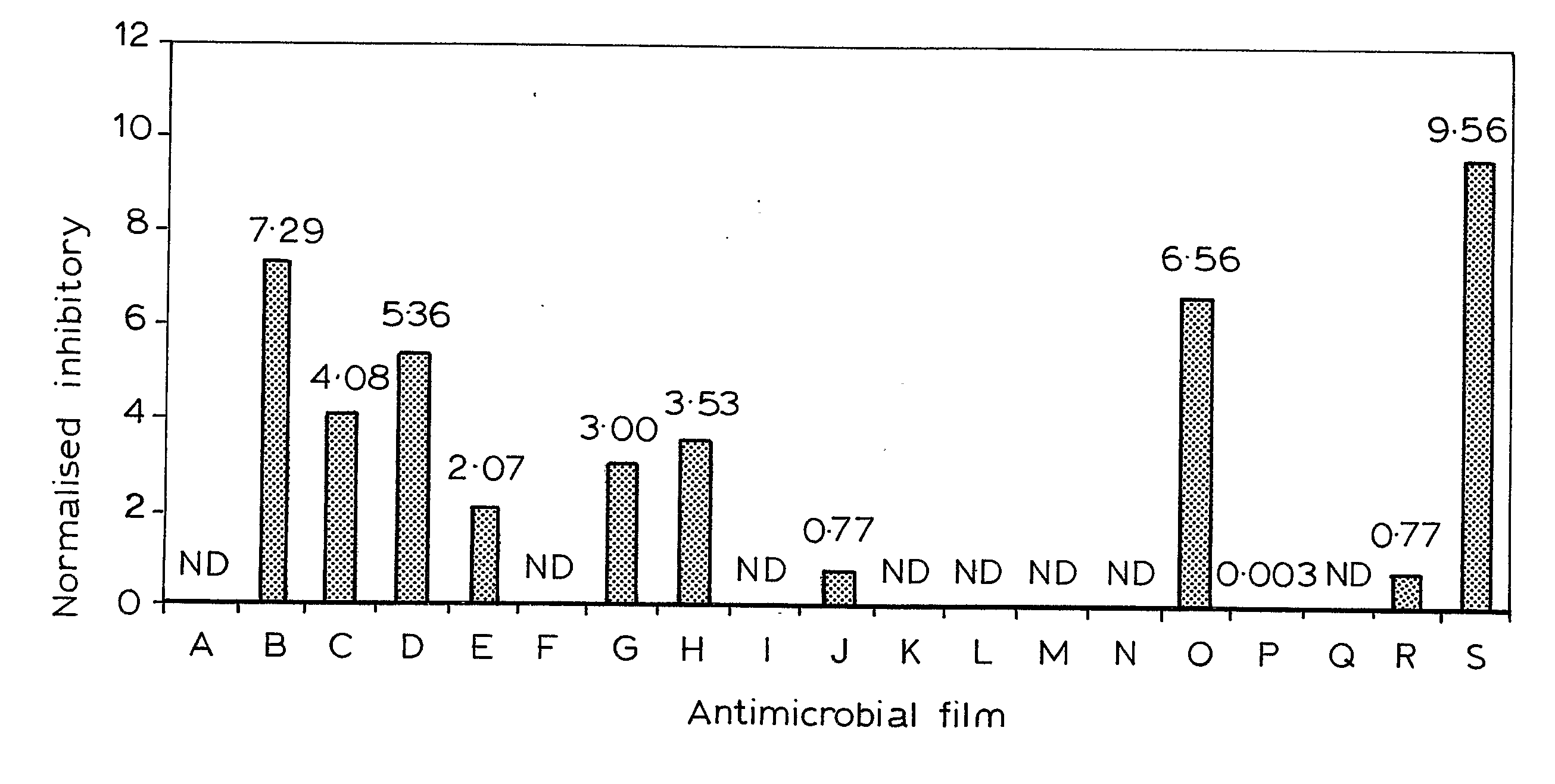

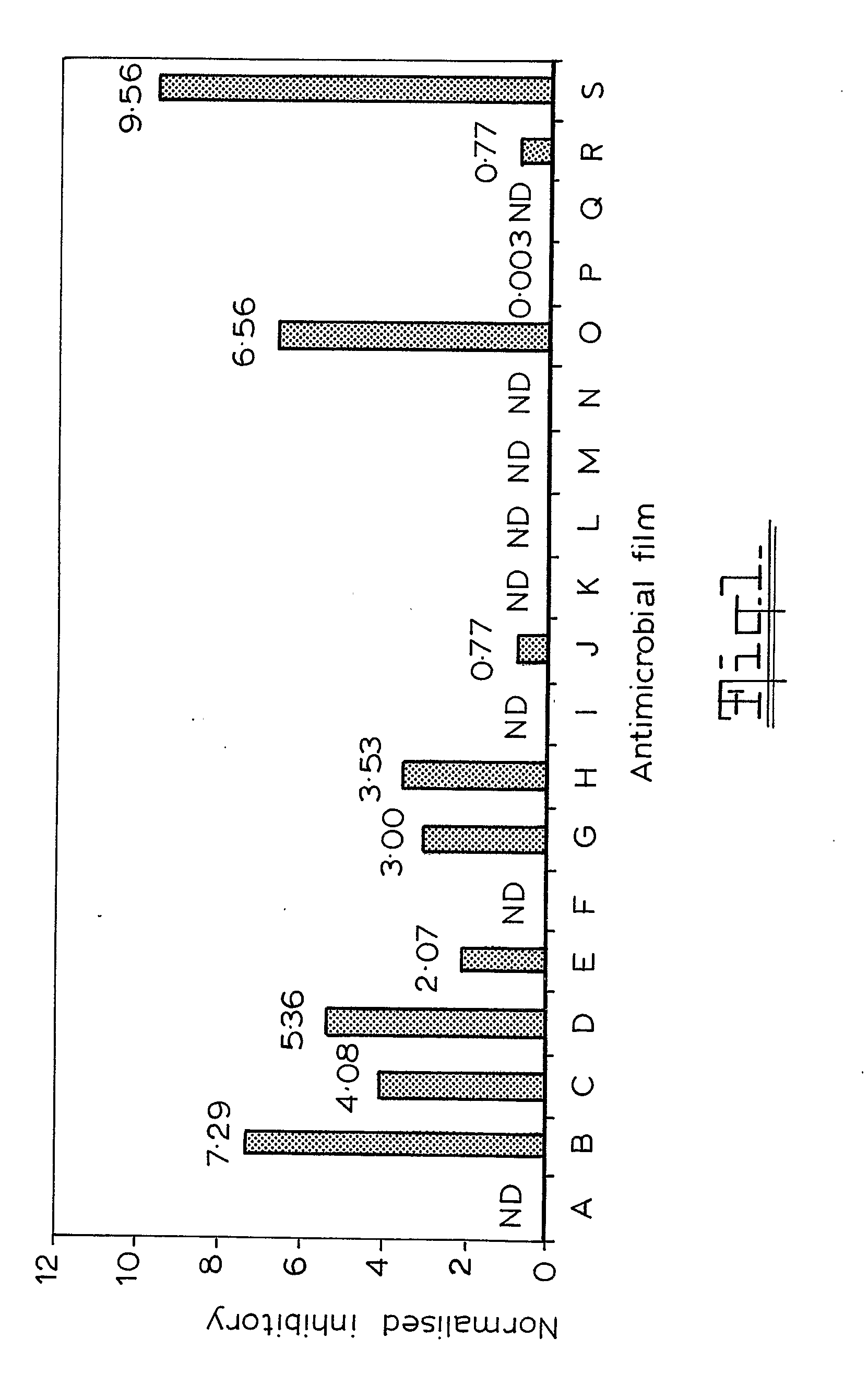

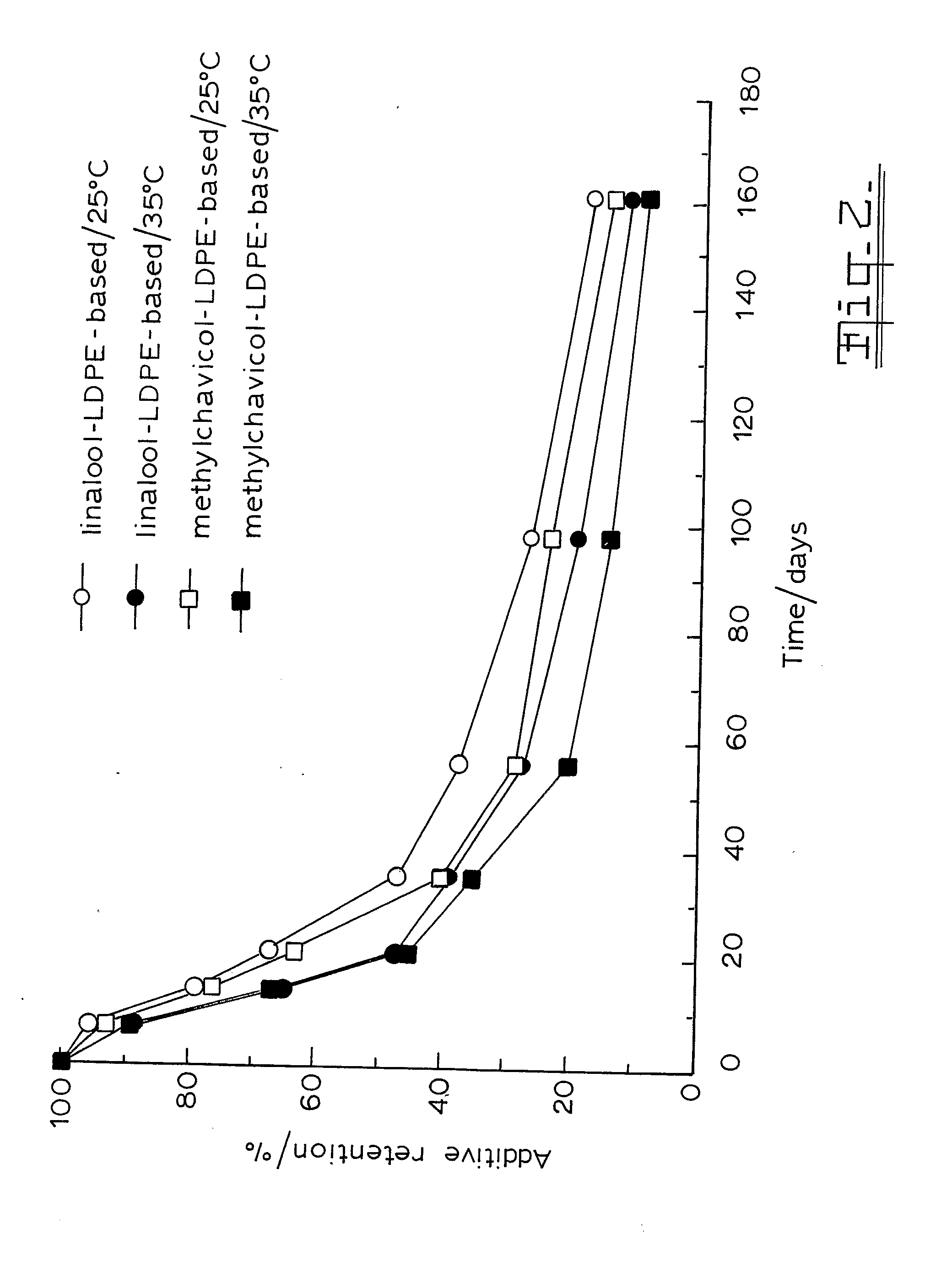

InactiveUS20080220036A1Release rate be controlHigh valueBiocideAntifouling/underwater paintsMethyl cinnamateMethyl acrylate

An antimicrobial packaging material for food stuffs containing from 0.05% to 1.5% by weight of a natural essential oil. The oil can be selected from primarily linalool and / or methylchavicol, but also from one or more of citral, geraniol, methyl cinnamate, methyl eugenol, 1,8-cineole, trans-a-bergamotene, carvacrol and thymol blended with one or more polymers selected from ethylene vinyl alcohol copolymer, polyacrylates, including ethyl acrylate methyl methacrylate copolymers, lonomers, nylons and other hydrophilic polymers or polymers possessing functional groups capable of partially anchoring the additives and the blender mix is coated onto the food contact face of a food grade packaging film or incorporated into a food grade packaging film. A binding agent such as polyethylene glycol is added to the blend to improve the retention of the volatile oil in the polymer during processing. This material has no regulatory limitations and, at the referred concentrations, does not form detectable off-flavours.

Owner:UNIVERSITY OF VICTORIA +1

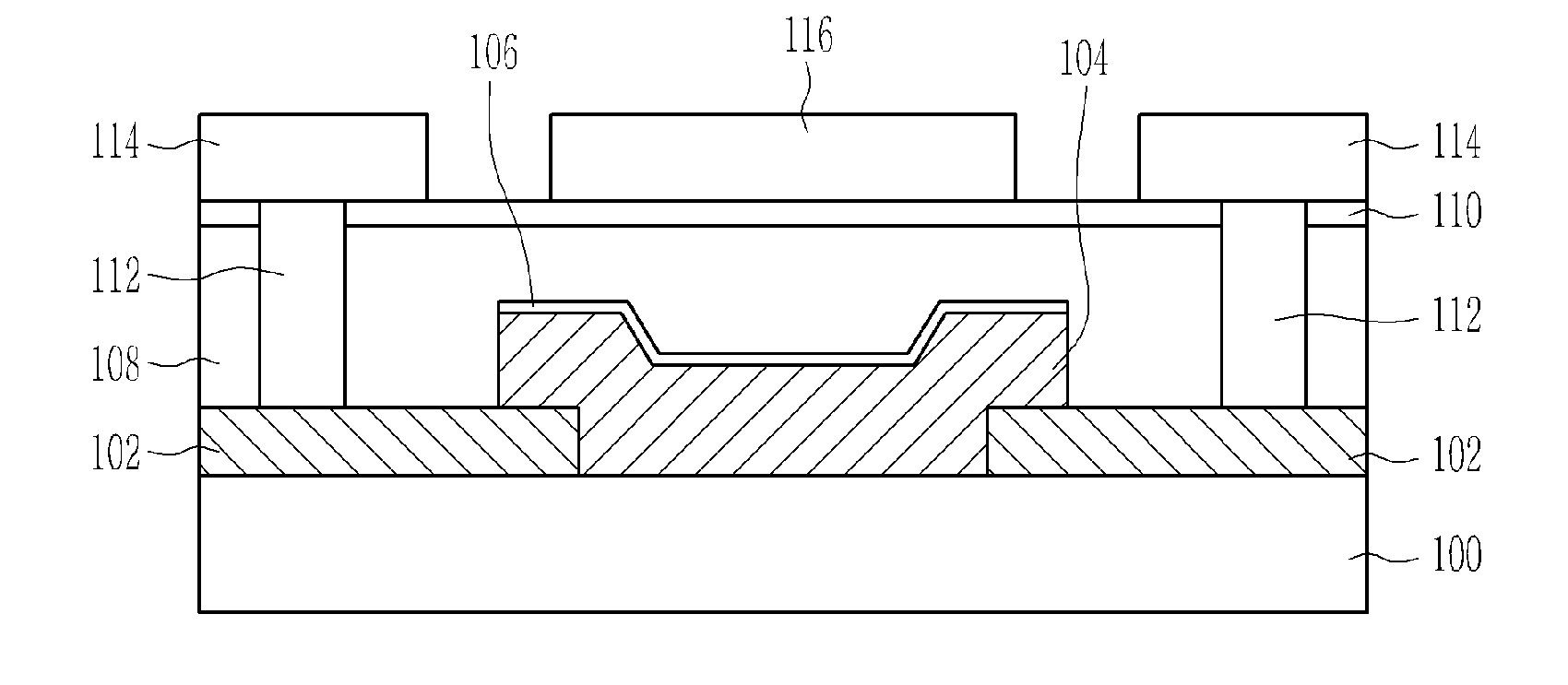

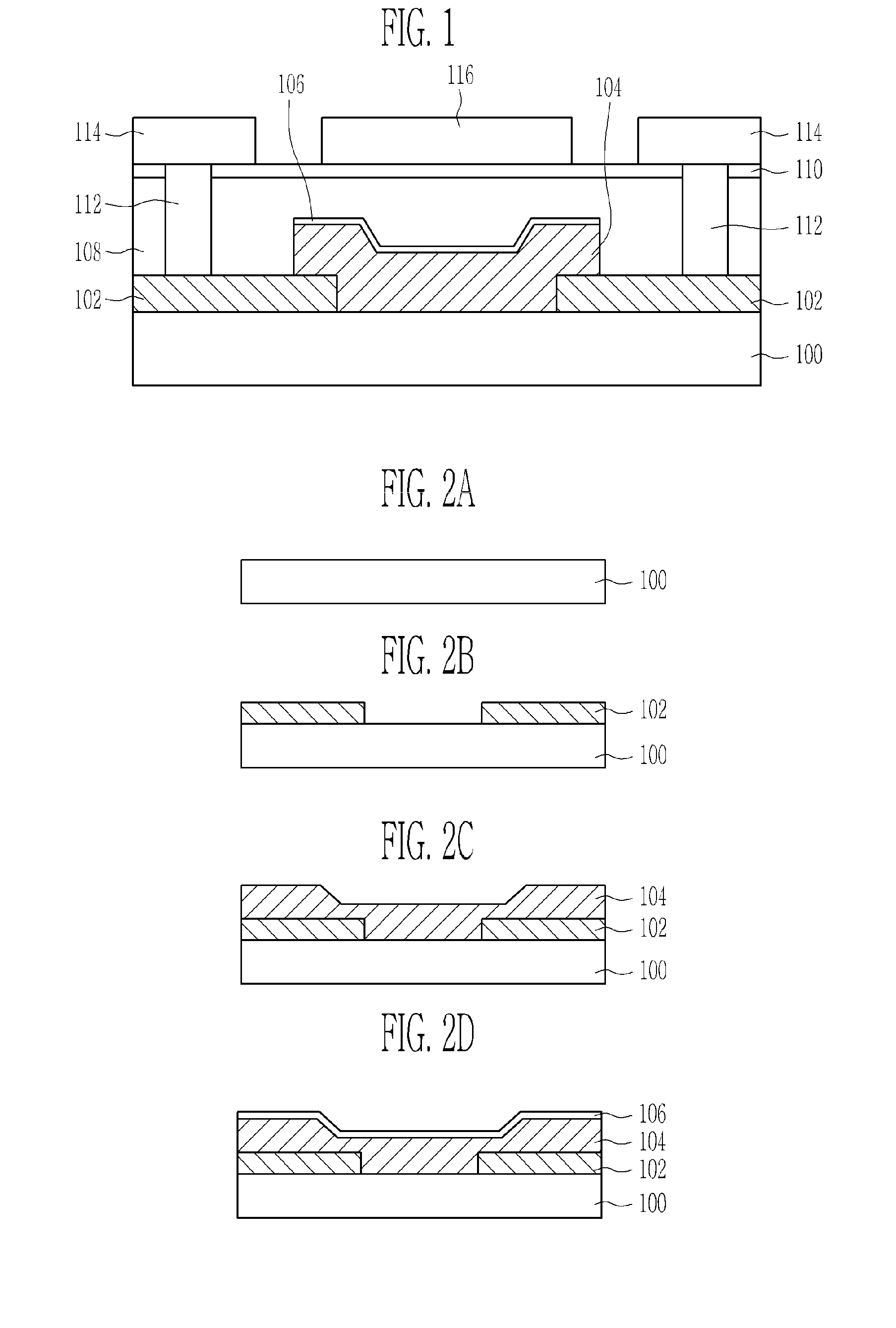

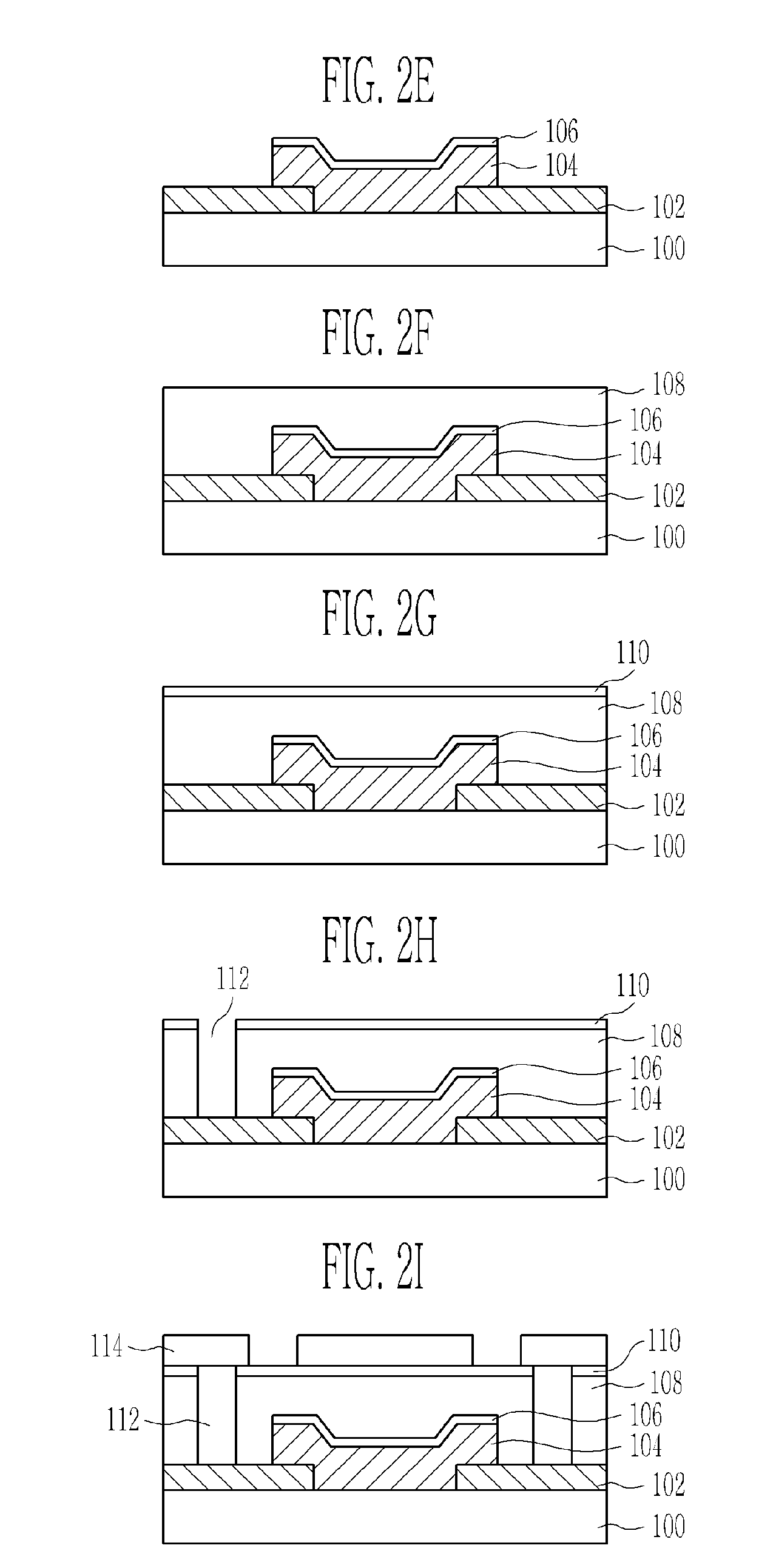

Transparent nonvolatile memory thin film transistor and method of manufacturing the same

ActiveUS20100243994A1Reduce processing temperatureEnsure process compatibilitySolid-state devicesSemiconductor/solid-state device manufacturingThin layerSemiconductor

Provided are a transparent nonvolatile memory thin film transistor (TFT) and a method of manufacturing the same. The memory TFT includes source and drain electrodes disposed on a transparent substrate. A transparent semiconductor thin layer is disposed on the source and drain electrodes and the transparent substrate interposed between the source and drain electrodes. An organic ferroelectric thin layer is disposed on the transparent semiconductor thin layer. A gate electrode is disposed on the organic ferroelectric thin layer in alignment with the transparent semiconductor thin layer. Thus, the transparent nonvolatile memory TFT employs the organic ferroelectric thin layer, the oxide semiconductor thin layer, and auxiliary insulating layers disposed above and below the organic ferroelectric thin layer, thereby enabling low-cost manufacture of a transparent nonvolatile memory device capable of a low-temperature process.

Owner:ELECTRONICS & TELECOMM RES INST

Printing strippable protective ink, and preparation method and application thereof

The invention discloses a printing strippable protective ink, and a preparation method and application thereof. The ink comprises the following components in parts by weight: 50-80 parts of thermoplastic film-forming resin, 20-50 parts of low-viscosity plasticizer, 1-10 parts of filler and pigment, and 1-3 parts of functional assistant. The printing strippable protective ink has 100% solid rate, does not volatilize any solvent, is a green environment-friendly material, and satisfies the increasingly higher ecological environmental requirements. The ink has the advantages of no irritating smell, moderate viscosity and no voids, is not sticky to the printing screen, and is easy for printing operation; the ink can form a film by thermosetting at medium / low temperature, so the energy consumption is low; the thermosetting film has high flexibility, favorable heat resistance, favorable insulativity and favorable acid / alkali resistance, and effectively solves the influence on the resistance when etching the circuit on a transparent conductive film with acid and alkali in the touch screen manufacturing process; and after the conductive film protecting technique is finished in the touch screen manufacturing process, the protective ink layer can be easily stripped, and does not leave any residue, thereby effectively solving the problem of protection of the conducting film in the existing touch screen manufacturing process.

Owner:PANYU NANSHA YAN TIN CHEM

Molding material, prepreg, fiber-reinforced composite material, fiber-reinforced composite material laminate, and process for production of fiber-reinforced molding base material

InactiveUS20130295806A1Economical efficiencyEconomical productivityPretreated surfacesWoven fabricsProduction rateFiber-reinforced composite

A molding material is provided including a composite having 1 to 50 wt % of (A) a bundle of continuous reinforcing fibers and 0.1 to 40 wt % of (B) a polyarylene sulfide prepolymer or (B′) a polyarylene sulfide; and 10 to 98.9 wt % of (C) a thermoplastic resin adhered to the composite; wherein the composite further has (D) a zero-valent transition metal compound or (E) a low-valent iron compound in an amount of 0.001 to 20 mol % based on the amount of sulfur atoms contained in the component (B) or (B′). A prepreg and a method of producing a fiber-reinforced molding base material is also provided. By using the molding material according to the present invention which exhibits excellent economic efficiency and productivity, a molded article having excellent mechanical characteristics can be easily produced.

Owner:TORAY IND INC

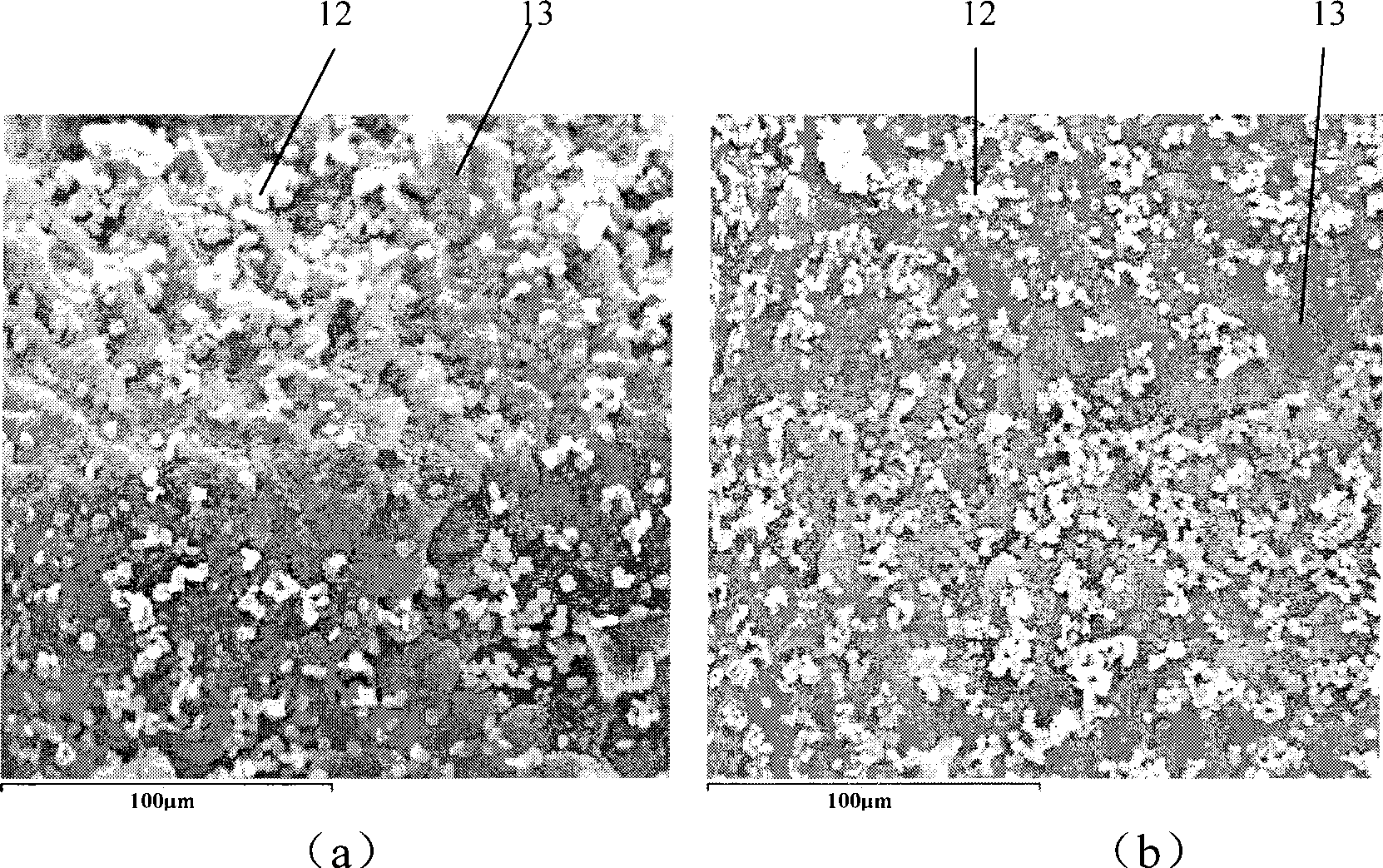

NbMoTaW high-entropy alloy, and preparation method thereof

InactiveCN106167870AImprove performanceEliminate composition segregationHigh entropy alloysSolid solution

The invention belongs to the technical field of high-entropy alloy, and discloses a NbMoTaW high-entropy alloy, and a preparation method thereof. According to the preparation method, mechanical alloying and spark plasma sintering are combined for forming, alloying of Nb, Mo, Ta, and W which are high in melting points is realized at solid states, heating to the melting points is not necessary, block materials with excellent performance can be obtained via only one time of solid phase sintering ( the sintering temperature is 1600 DEG C or lower), a difficult problem that the melting temperature (>2900 DEG C) of smelting method is high is solved, processing temperature is reduced greatly, and technology is simplified. According to the microscopic structure of the NbMoTaW high-entropy alloy, dispersion distribution of a granular second phase in an isometric crystal substrate is observed, both the substrate phase and the second phase are BCC solid solution, the substrate average particle size is smaller than 6<mu>m, the second phase average particle size is smaller than 4<mu>m, the material crystal particles are small, the structure is uniform, no dendritic segregation is caused, and strength and hardness are high.

Owner:SOUTH CHINA UNIV OF TECH

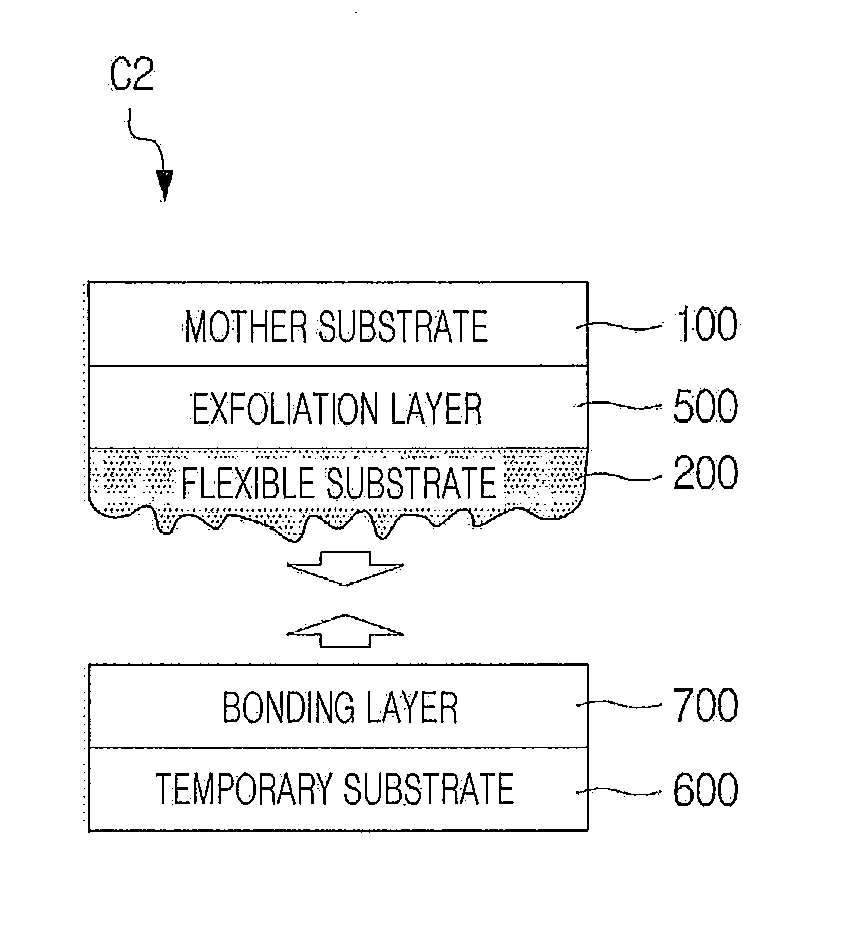

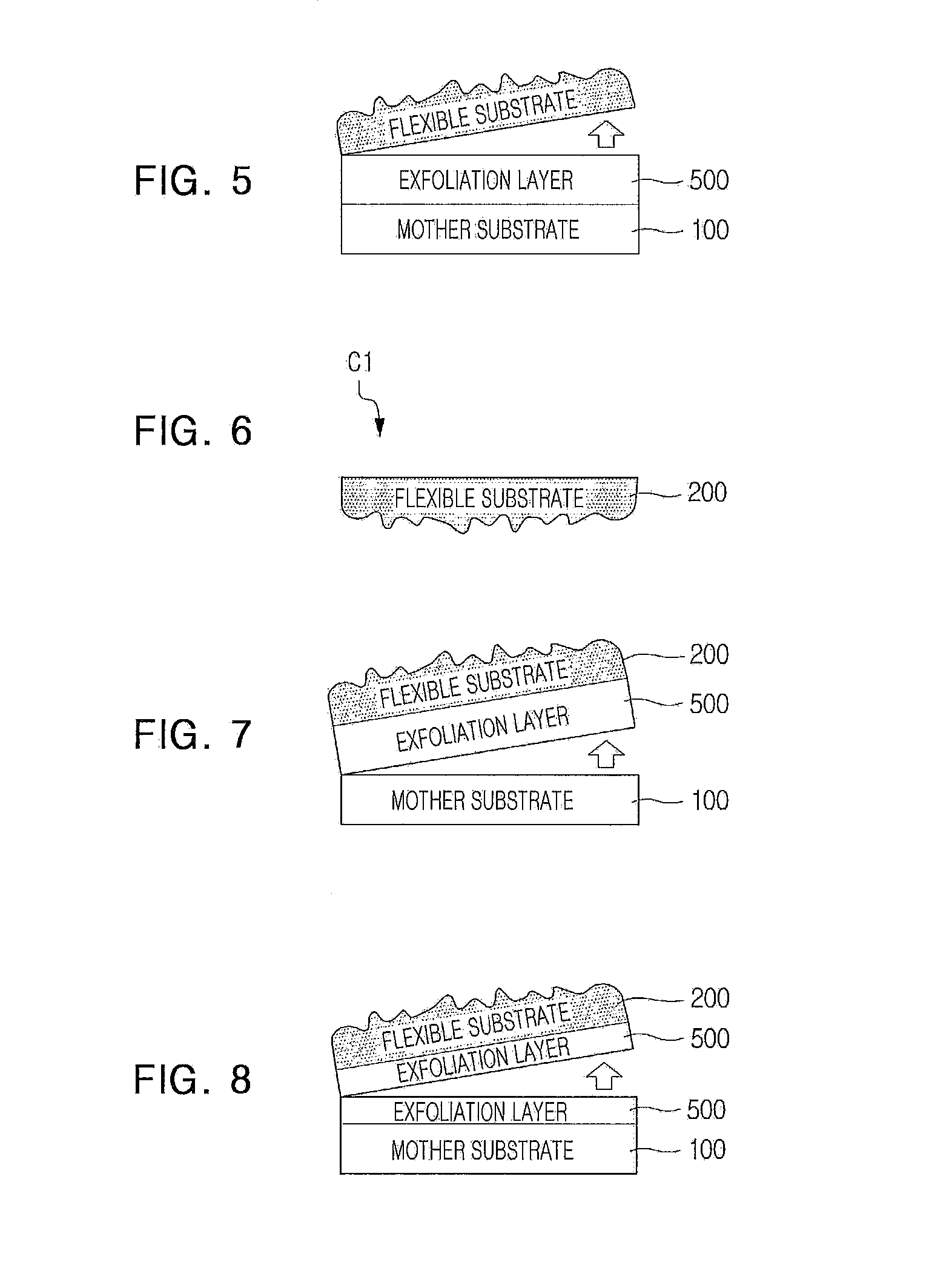

Method for Manufacturing a Flexible Electronic Device Using a Roll-Shaped Motherboard, Flexible Electronic Device, and Flexible Substrate

InactiveUS20130188324A1Cost of manufactureLow costElectric discharge heatingFinal product manufactureSurface roughnessEngineering

A method of manufacturing a flexible electronic device includes forming a flexible substrate on a roll-type mother substrate, separating the flexible substrate from the roll-type mother substrate, and forming an electronic device on a separation surface of the flexible substrate, which has contacted the roll-type mother substrate, thus solving the problems of low performance and low yield of flexible electronic devices due to a low processing temperature, high surface roughness, high thermal expansion coefficient, and poor handling characteristics.

Owner:POHANG IRON & STEEL CO LTD

Continuous long fiber reinforced composite nylon/polyolefin material and its prepn

ActiveCN1810872ANot easy to discoloration by thermal oxygenEvenly dispersedPolyolefinFiber-reinforced composite

The present invention discloses one kind of continuous long fiber reinforced composite nylon / polyolefin material and its preparation process. The composite material is prepared through mixing continuous long fiber reinforced composite polyolefin resin agglomerate with high fiber content and nylon resin, and the continuous long fiber reinforced composite polyolefin resin agglomerate is prepared with continuous long fiber in 30-80 wt% and composite polyolefin resin in 20-70 wt%. The continuous long fiber reinforced composite nylon / polyolefin material of the present invention has excellent mechanical performance compared with available technology.

Owner:KINGFA SCI & TECH CO LTD +1

Method for preparing thermoplastic elastomer by supercritical fluid assisted dynamic vulcanization

The invention discloses a method for preparing a plastic / rubber thermoplastic elastomer by supercritical fluid assisted dynamic vulcanization. The method comprises the followings steps: (1) mixing plastic, rubber and a vulcanization system at a certain proportion, and putting the mixture into an extruder or an injection molding machine to mix, fuse and plasticize the polymer into a fusant; (2) controlling gas to be in a supercritical state by a supercritical fluid conveying system and injecting the gas into a cylinder of the extruder or the injection molding machine; (3) mixing the injected supercritical fluid with the polymer fusant and the vulcanization system; (4) causing a chemical reaction of the plastic, the rubber and the vulcanization system, which is promoted by the supercritical fluid; and (5) releasing the supercritical fluid from the polymer fusant at the pressure which is lower than a critical value, converting the supercritical fluid into gas to be discharged by a vacuum pump. The supercritical fluid assisted plastic / rubber dynamic vulcanization can promote dispersion and size decrease of the rubber phase in the plastic, and effectively reduce processing energy consumption for extrusion or injection shaping.

Owner:SOUTH CHINA UNIV OF TECH

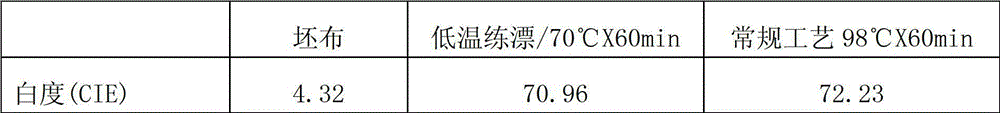

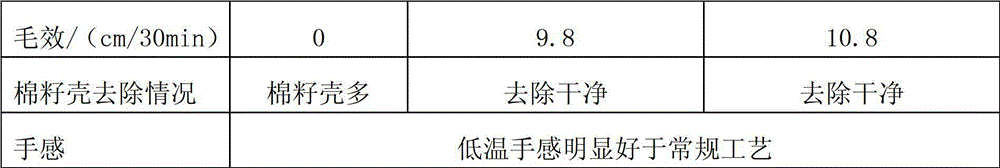

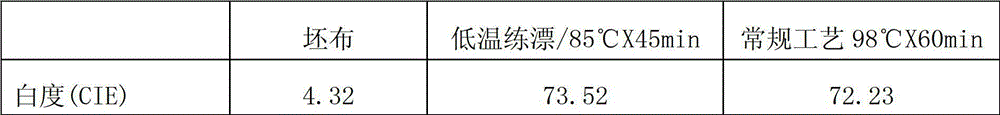

One dosage type low temperature scouring and bleaching agent and application thereof

ActiveCN103061104AWide application processEasy to packBleaching apparatusDefoamerSurface-active agents

The invention discloses one dosage type low temperature scouring and bleaching agent which comprises a surface active agent, a hydrogen peroxide activator, a bleaching synergist, a chelating agent, a hydrogen peroxide stabilizer, a defoamer and a filler in a mixing mode. The one dosage type low temperature scouring and bleaching agent can be used for scouring and bleaching cotton, cotton blend knitted fabric or cotton loose fiber in a low temperature bath of 60 DEG C- 85 DEG C and cotton or cotton mixed and blended yarns in a low temperature bath of 80 DEG C -95 DEG C and for cold pad-batch processing of cotton fabric. The one dosage type agent is a solid product which is convenient to pack and transport. One agent can replace more than three agents such as alternative scouring agent, hydrogen peroxide activator, chelating agent, brightening agent and oxygen bleaching stabilizer during processing, which is convenient to feed and process. The one dosage type low temperature scouring and bleaching agent is widely applicable to processes such as scouring and bleaching in bath and cold pad-batch processing.

Owner:NICCA CHEM CHINA CO LTD

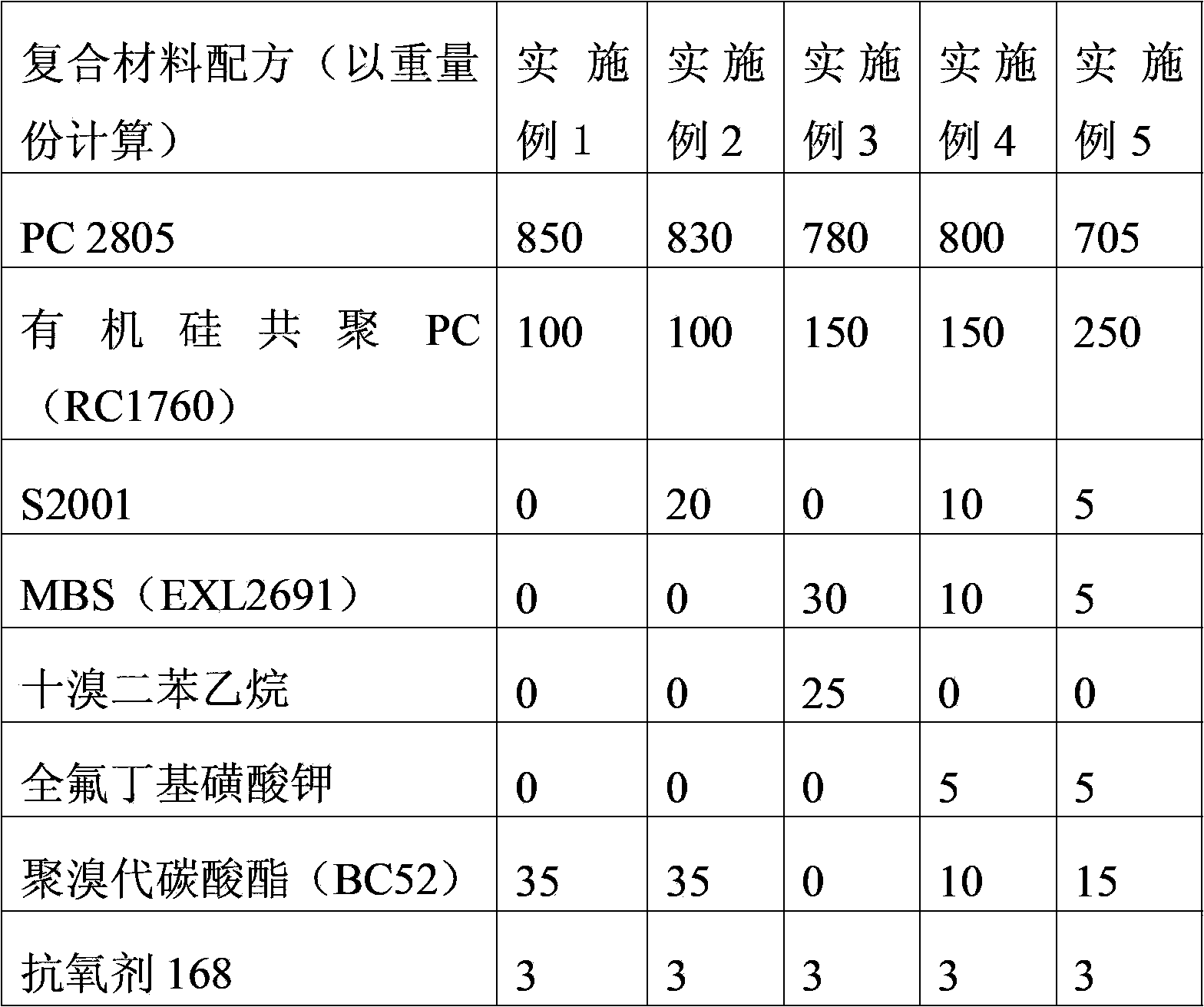

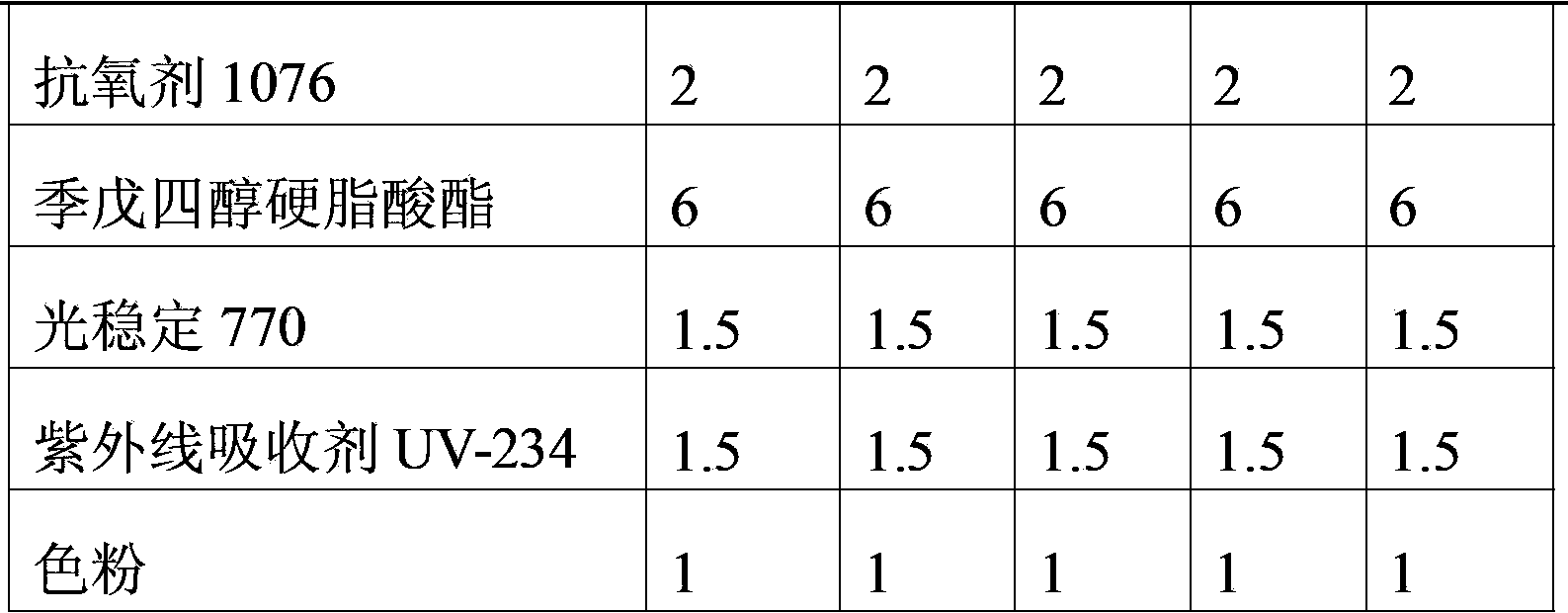

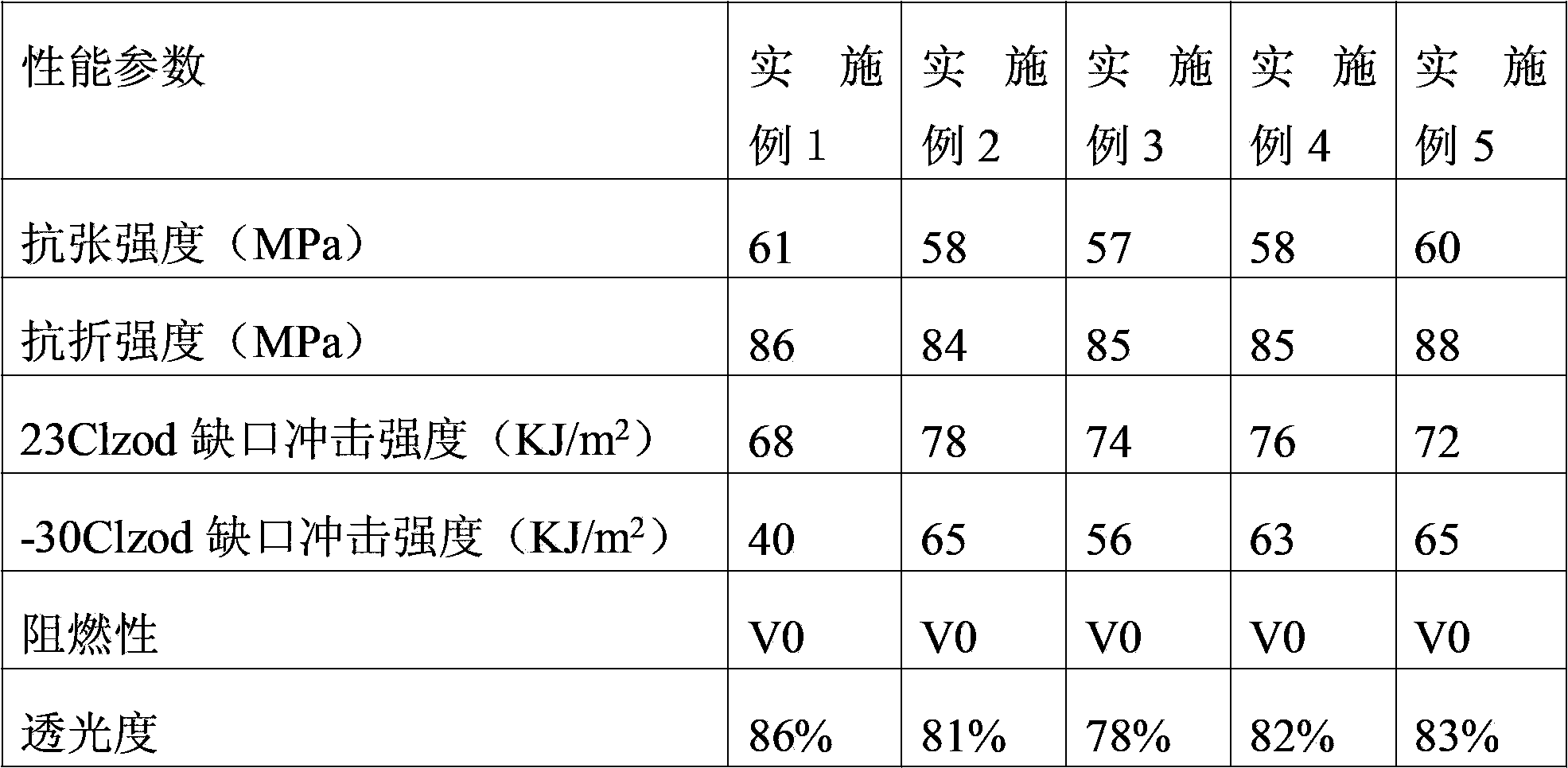

High-transparency low-temperature-impact-resistant flame-retardant polycarbonate composite material and preparation method thereof

ActiveCN103788610AImprove low temperature impact resistanceEnhance and improve low temperature impact resistanceMold fillingPotassium

The invention discloses a high-transparency low-temperature-impact-resistant flame-retardant polycarbonate composite material and a preparation method thereof. The composite material comprises following components by weight: 700-850 parts of polycarbonate resin, 100-250 parts of organosilicone co-polymer PC, 0-30 parts of a low-temperature-impact modifying agent and 10-14 parts of a flame retardant. The low-temperature-impact modifying agent is one of an organosilicone type flexibilizer and an acrylate type flexibilizer or a mixture of the organosilicone type flexibilizer and the acrylate type flexibilizer. The flame retardant is one of or a mixture of several compounds selected from decabromodiphenylethane, poly(bromocarbonate), potassium perfluorobutane sulfonate or diphenylsulfonesulfonate. The organosilicone co-polymer PC is polycarbonate resin obtained by copolymerization of bisphenol A and organosilicone and has a relative molecular weight of 20000-30000. The preparation method of the composite material is also provided. According to the composite material and the preparation method, the low-temperature-impact-resistant performance of the PC resin is largely enhanced, and the composite material has excellent flame retardance and can preserve the high transparency of the material itself. In addition, the material has advantages of easy mold filling, low processing temperature, short processing and forming period, and the like.

Owner:SHANGHAI CHANGWEI JINCI ENG PLASTIC

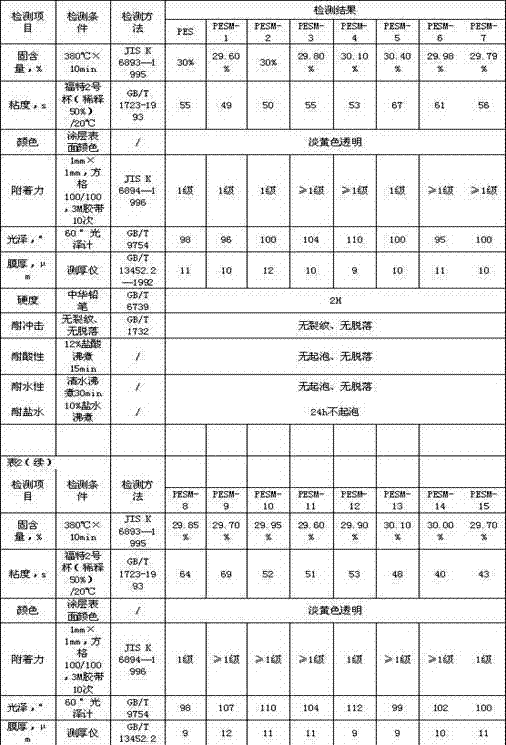

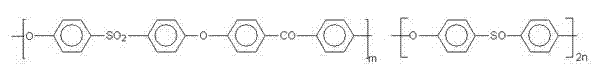

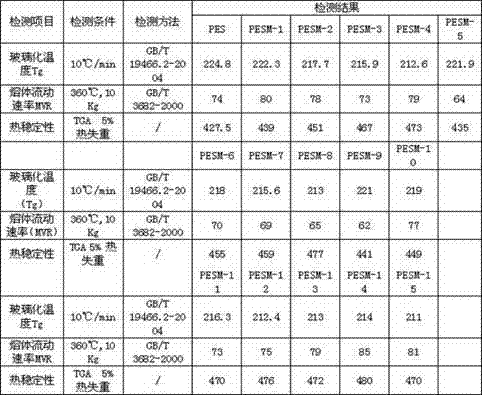

Ketone group-containing polyethersulfone resin and synthetic method thereof

The invention belongs to the technical field of polymer materials and provides ketone group-containing polyethersulfone resin which is high in thermal stability, low in processing temperature and is easier for injection-molding and extrusion-molding. The ketone group-containing polyethersulfone resin is a product synthetized through nucleophilic polycondensation reaction of the following polymerization monomers: 4,4-dihydroxyl dihydroxydiphenylsulfone, 4,4'-dichlorobenzophenone and 4,4-dichlorodiphenyl sulfone. The ketone group is introduced onto the molecular chain of polyethersulfone, so as to improve the thermal stability of the polymer, reduce the processing temperature of the polymer and ensure that the polymer is more convenient for injection-molding and extrusion-molding. The invention also provides a synthetic method of the ketone group-containing polyethersulfone resin. The method is easy to operate, and the reaction process and the viscosity of materials are easily controlled.

Owner:ZHEJIANG PFLUON TECH CO LTD +1

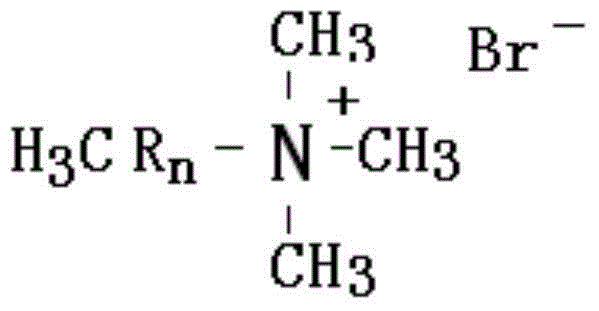

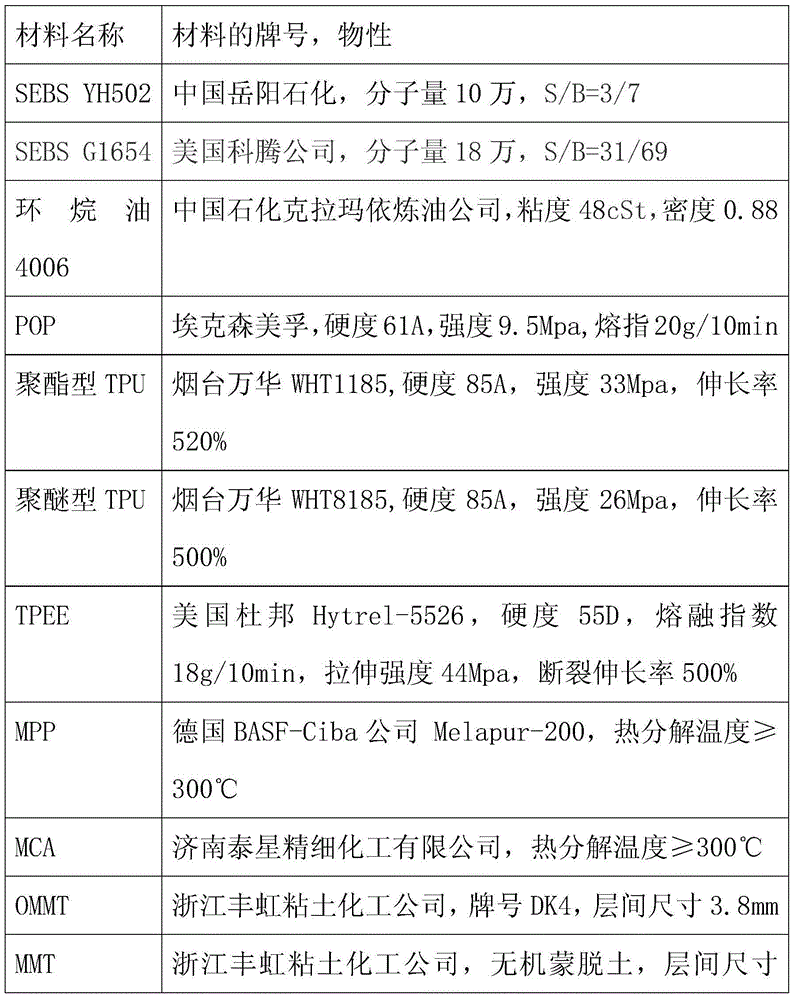

TPE flame resistant material for coating plastic and preparing method of TPE flame resistant material

The invention discloses a TPE flame resistant material for coating plastic and preparing method of the TPE flame resistant material. The TPE flame resistant material is composed of TPE-S, TPO, TPU, TPEE, a composite flame retardant, an antistatic agent, an antioxidant, a compatibilizer, a lubrication release agent and other auxiliaries. The prepared TPE flame resistant material coating plastic is good in fluidity, simple in processing technology, convenient to process and capable of being processed and formed by using an injection molding machine at the temperature between 180 DEG C and 210 DEG C, and production efficiency is high. The processing temperature is lower than 200 DEG C, processing can be conducted at 190 DEG C, energy consumption is lowered due to the low processing temperature, and energy resources are saved.

Owner:NANTONG POLYMAX ELASTOMER TECH

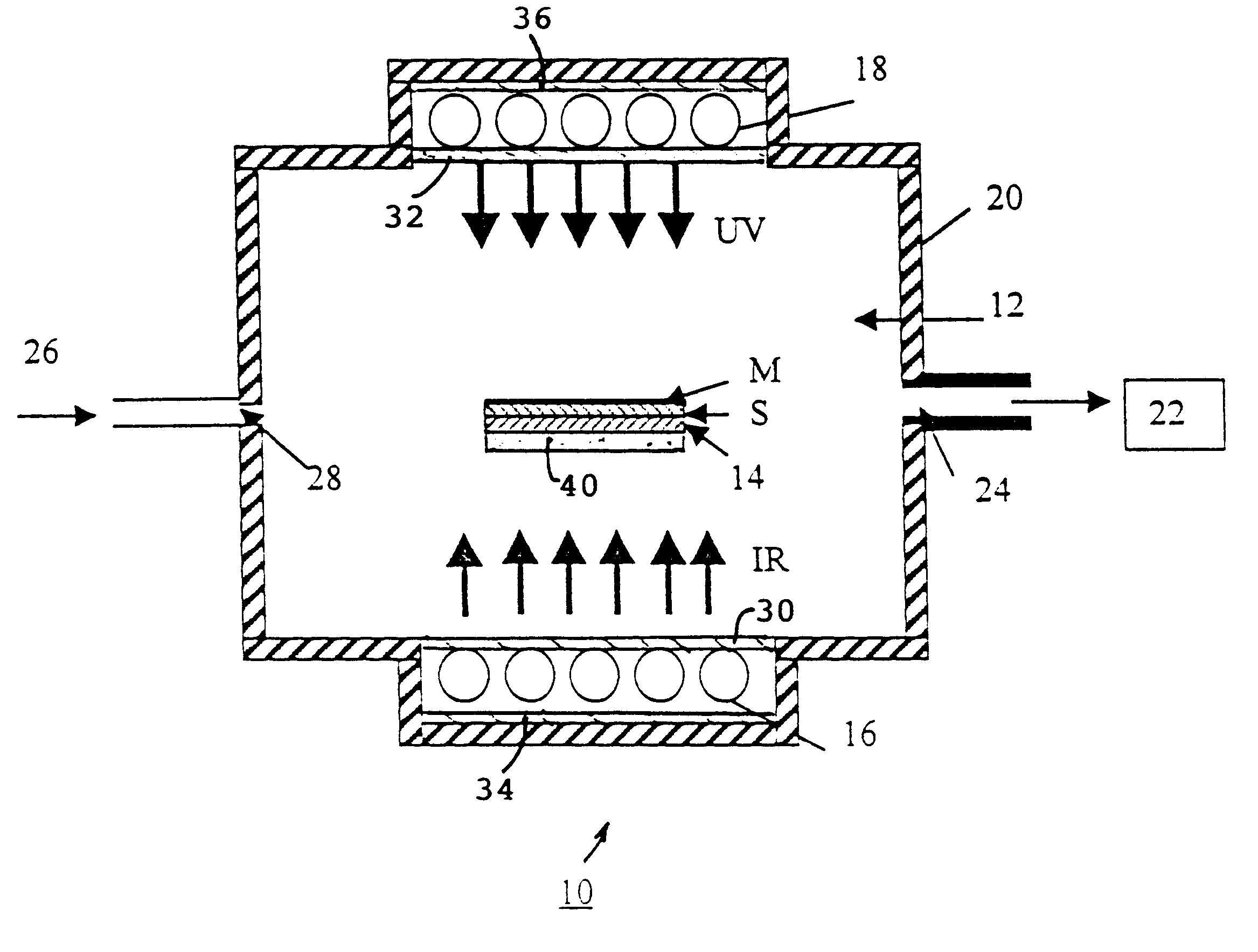

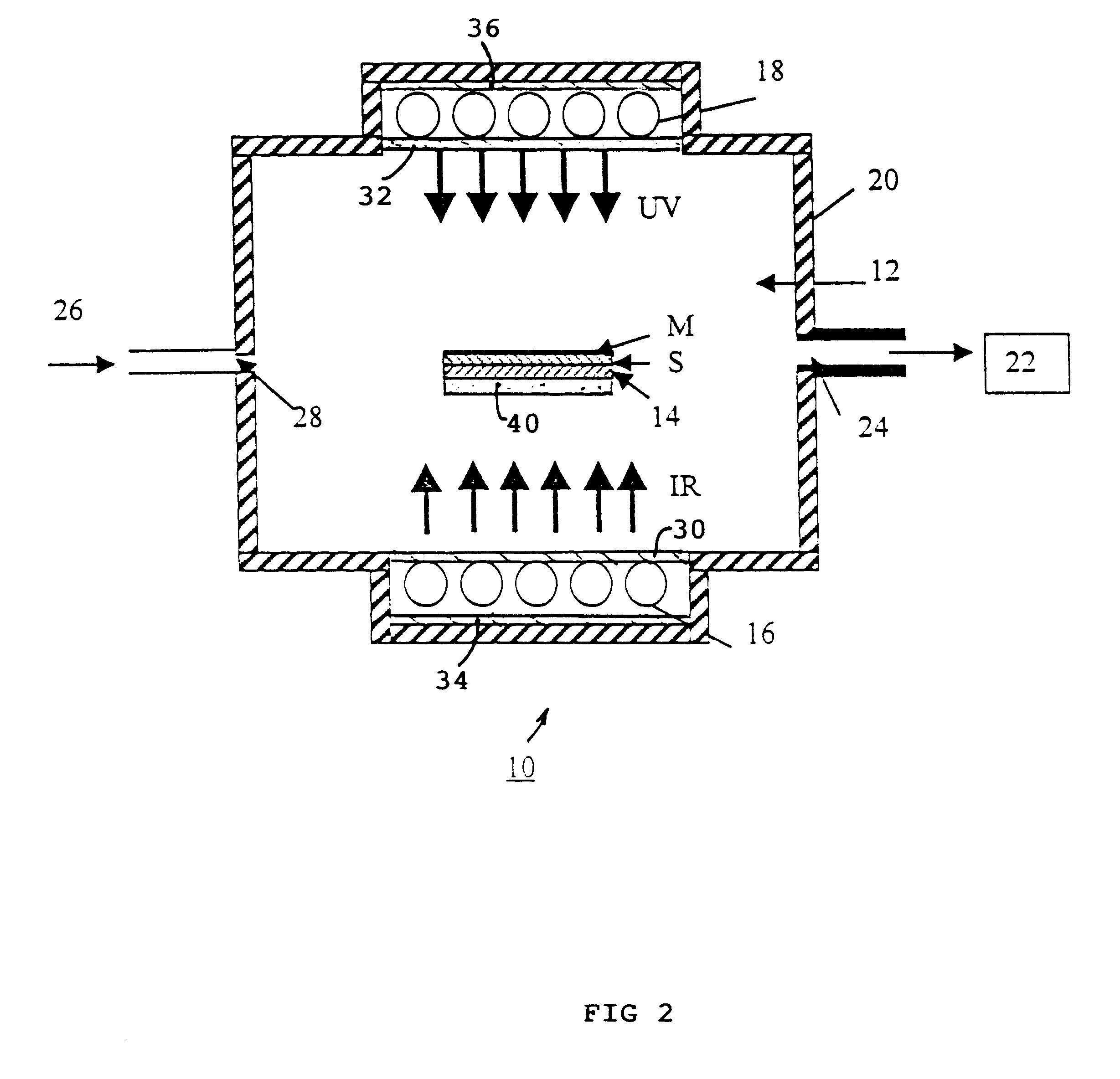

Process and device for processing a material by electromagnetic radiation in a controlled atmosphere

InactiveUS6259066B1Reduce processing temperatureNot to adversely affect resistance of substrateMuffle furnacesBaking ovenPhysicsInfrared

A process for processing or forming a material by electromagnetic radiation and in a controlled atmosphere or in a vacuum inside a reaction chamber uses a first infrared radiation causing rapid heating and a second ultraviolet radiation of the excimer type having a spectral resolution lower than 40 nm, regardless of the wavelength of the ultraviolet radiation, so as to generate a suitable photon flux either for modification of the physico-chemical properties of the material or for formation of a deposit on the substrate. The exposure time of the second ultraviolet radiation is lower than that of the first infrared radiation and the processing temperature is comprised between 70° C. and 800° C. depending on the nature of the material and of the substrate.

Owner:JOINT INDAL PROCESSORS FOR ELECTRONICS

Bamboo fiber/polypropylene composite material and preparation method thereof

InactiveCN101880423AImprove processing fluidityImprove protectionPolypropylene compositesCompression molding

The invention discloses a bamboo fiber / polypropylene composite material and a preparation method thereof. The method comprises the following steps of: adding polypropylene, bamboo fibers, a compatilizer and a plasticizer into a kneading machine, an internal mixer or a double-screw extruder according to a certain ratio for mixing so as to prepare the bamboo fiber / polypropylene composite material; and preparing sheets, plates, tubes or sections of the bamboo fiber / polypropylene composite material through extrusion molding, calendaring and compression molding, and other post-procedures. The sheets, plates, tubes or sections can be used for manufacturing structural, decorative, packaging products and the like. Because the bamboo fibers come from bamboo which has the advantages of rich resources, short growth cycle and natural mold and bacteria resistance, the bamboo fiber / polypropylene composite material is a novel and renewable material.

Owner:EAST CHINA UNIV OF SCI & TECH

Low-melting lead-free solder glass and uses thereof

The low melting solder glass contains, in wt. % on an oxide basis, >1-2, SiO2; 5-10, B2O3; 4.5-12, ZnO; 79-88, Bi2O3; and 0.6-2, Al2O3, and a weight ratio of SiO2 to Al2O3 of <2. The solder glass preferably contains from 80.5 to 85 wt. % of Bi2O3 and is free of lead. This solder glass has a linear thermal expansion coefficient α(20-300) of <11.5×10−6 / K and a transformation temperature Tg of <380° C. A solder glass preparation for connecting or sealing a glass part with a metal part contains the low melting solder glass and up to 20 wt. % of β-eukryptite, cordierite, mullite, willemite or zircon.

Owner:SCHOTT AG

Polyphenylene sulfide/polyamide composite material and method for making same

The present invention discloses one kind of polyphenyl thioether / polyamide composite material and its preparation process. The polyphenyl thioether / polyamide composite material is prepared with polyphenyl thioether 23-69.3 wt%, polyamide 10-30 wt%, glass fiber 20-40 wt%, heat stabilizer 0.2-2 wt%, silane coupler 0.1-2 wt%, processing lubricant 0.2-2 wt% and crystallization promoter 0.1-1 wt%. The polyphenyl thioether / polyamide composite material has high shock toughness, simple preparation process and low cost.

Owner:ANHUI KEJU NEW MATERIALS

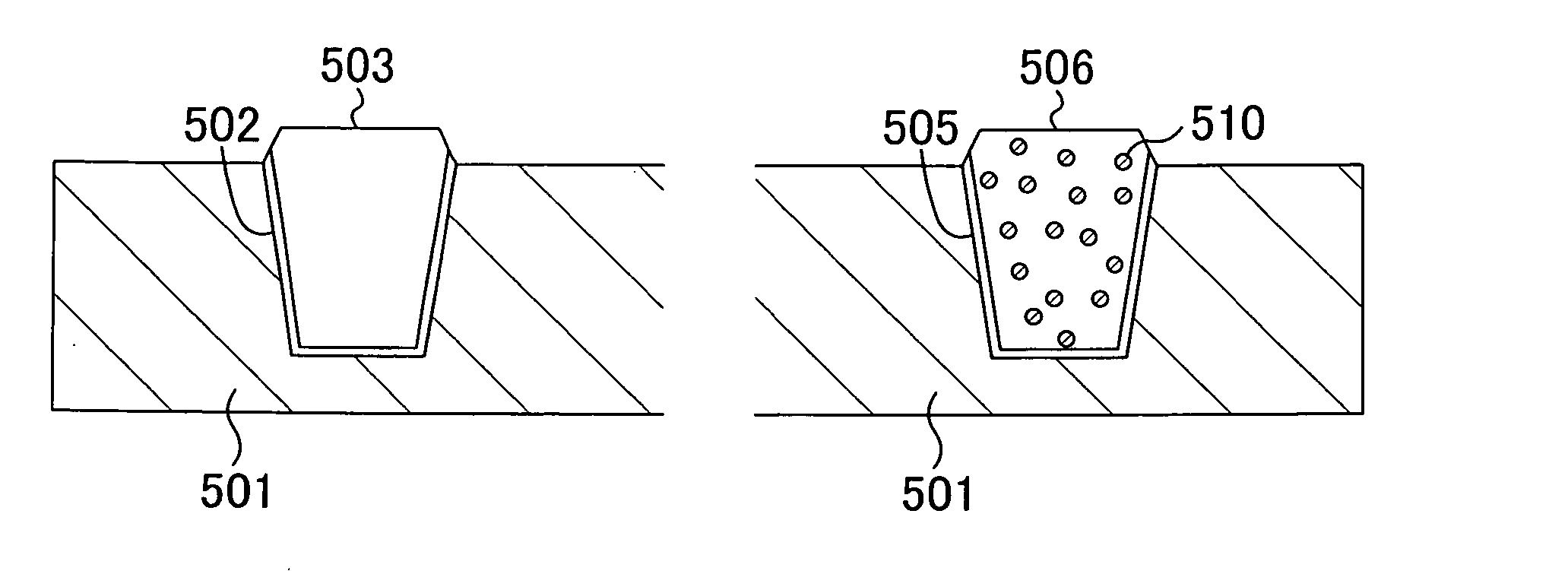

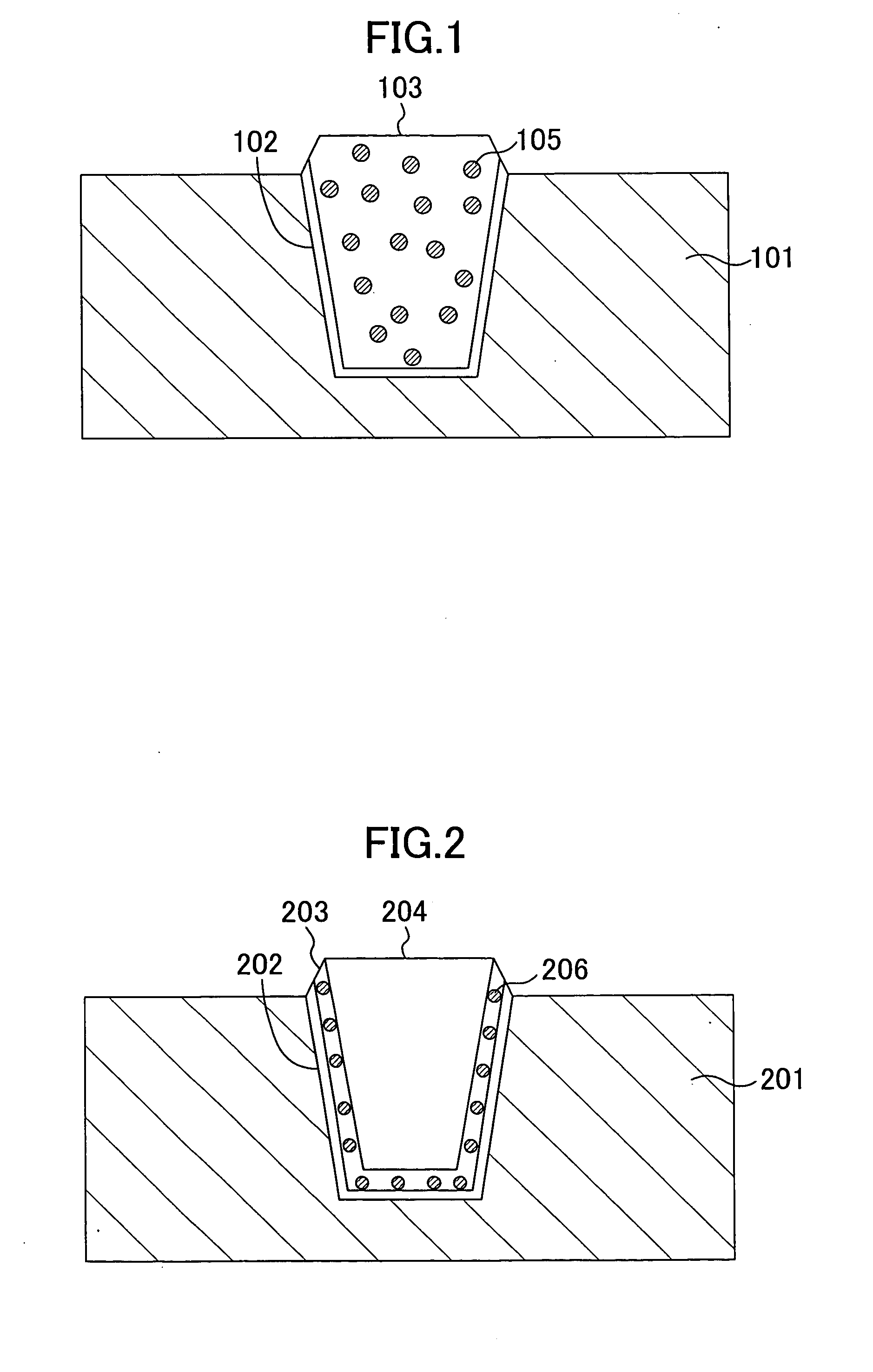

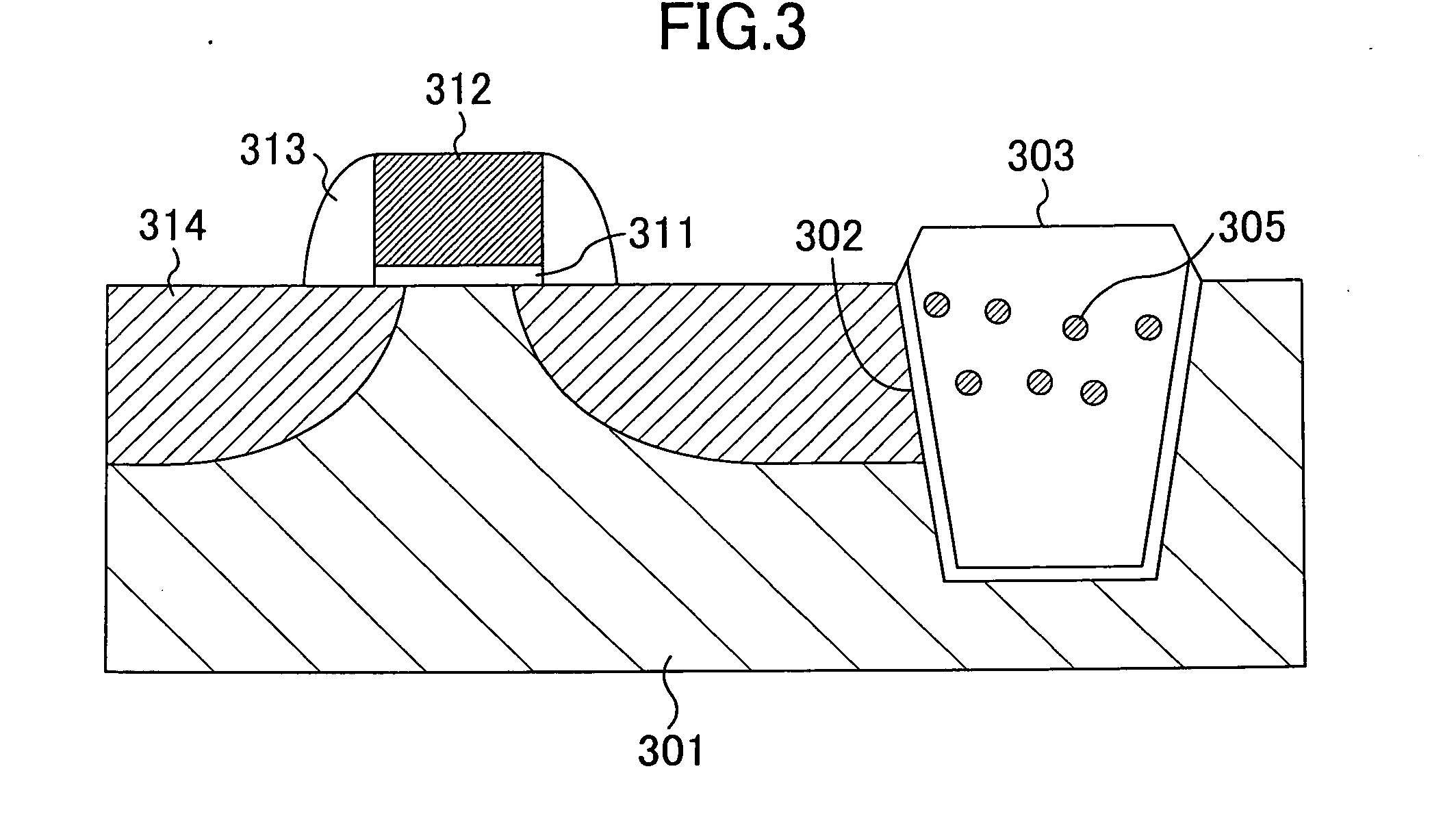

Semiconductor device and method for fabricating the same

ActiveUS20070105336A1Low process temperatureImprove liquidityTransistorRead-only memoriesDevice materialSemiconductor nanocrystals

A semiconductor device includes: a semiconductor substrate formed with an active region and an isolation region and having a trench formed in the isolation region; an isolation insulating film embedded in the trench of the semiconductor substrate; and semiconductor nanocrystals buried in the isolation insulating film. The coefficient of linear expansion of the semiconductor nanocrystal is closer to that of the semiconductor substrate rather than that of the isolation insulating film, so that stress applied to the active region after a thermal treatment or the like is reduced.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

High-strength polyimide porous membrane including benzimidazole and benzene lateral groups and manufacturing method thereof

InactiveCN103422253AImprove mechanical strengthImprove heat resistanceHeating/cooling textile fabricsNon-woven fabricsBenzimidazoleUltrafiltration

The invention discloses a polyimide porous membrane including benzimidazole and benzene lateral groups. The structure of the polyimide porous membrane including the benzimidazole and the benzene lateral groups is shown as the formula (I), wherein in the formula, n:m=4:6. The molecular mass of the polymer is 50 thousand to 150 thousand. A novel polyimide porous membrane material which is good in heat-resistant performance and processable performance is designed from the molecular viewpoint and can be widely applied to the fields of battery diaphragms, capacitor diaphragms, air purification, sewage processing, low-dielectric materials, ultrafiltration membranes, protection materials, catalytic carriers and the like.

Owner:BEIJING JIELANG CONTROLLABLE MEMBRANE TECH

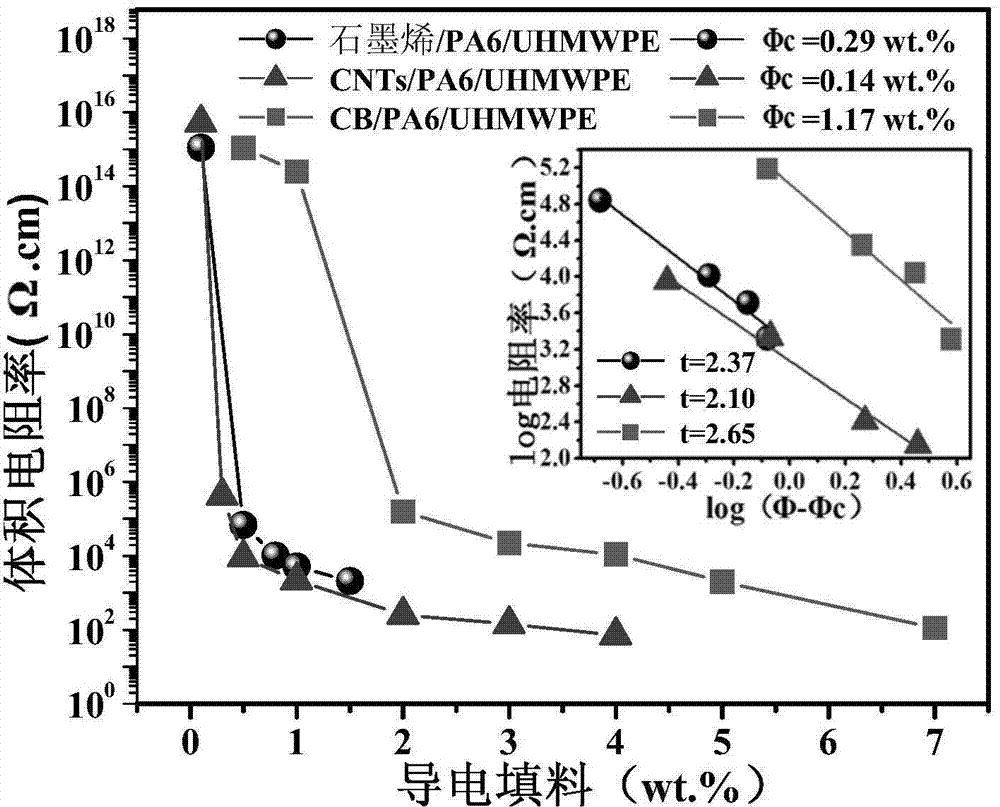

Polymer based temperature-sensitive resistance material with negative temperature coefficient (NTC) effect and preparation method thereof

ActiveCN104497394AImprove electrical performanceLow percolation valueElectrical resistance and conductanceManufacturing technology

The invention belongs to the technical field of manufacturing of conductive polymer composites, and in particular relates to a preparation method of a conductive polymer composite with negative temperature coefficient (NTC) characteristics. The invention discloses a polymer based temperature-sensitive resistance material with a NTC effect, and the polymer based temperature-sensitive resistance material comprises the following raw materials in parts by weight: 88.5-96.9 parts of a polymer 1 and a polymer 2, 0.1-1.5 parts of a conductive filler and 3-10 parts of a compatilizer; moreover, the conductive filler is selectively distributed in the polymer 2; the MFI of the polymer 1 is less than or equal to 7g / 10 minutes, and the MFI of the polymer 2 is more than or equal to 12g / 10 minutes; the thermal expansion coefficient of the polymer 2 is greater than that of the polymer 1, and the conductive filler is a two-dimensional conductive filler; and the mass ratio of the polymer 1 to the polymer 2 is (3:7)-(7:3). The resistance material prepared by the method disclosed by the invention is low in percolation threshold, the NTC characteristic repeatability of the obtained resistance material is good, and the resistance material is convenient to use for a long time.

Owner:ZHENGZHOU UNIV

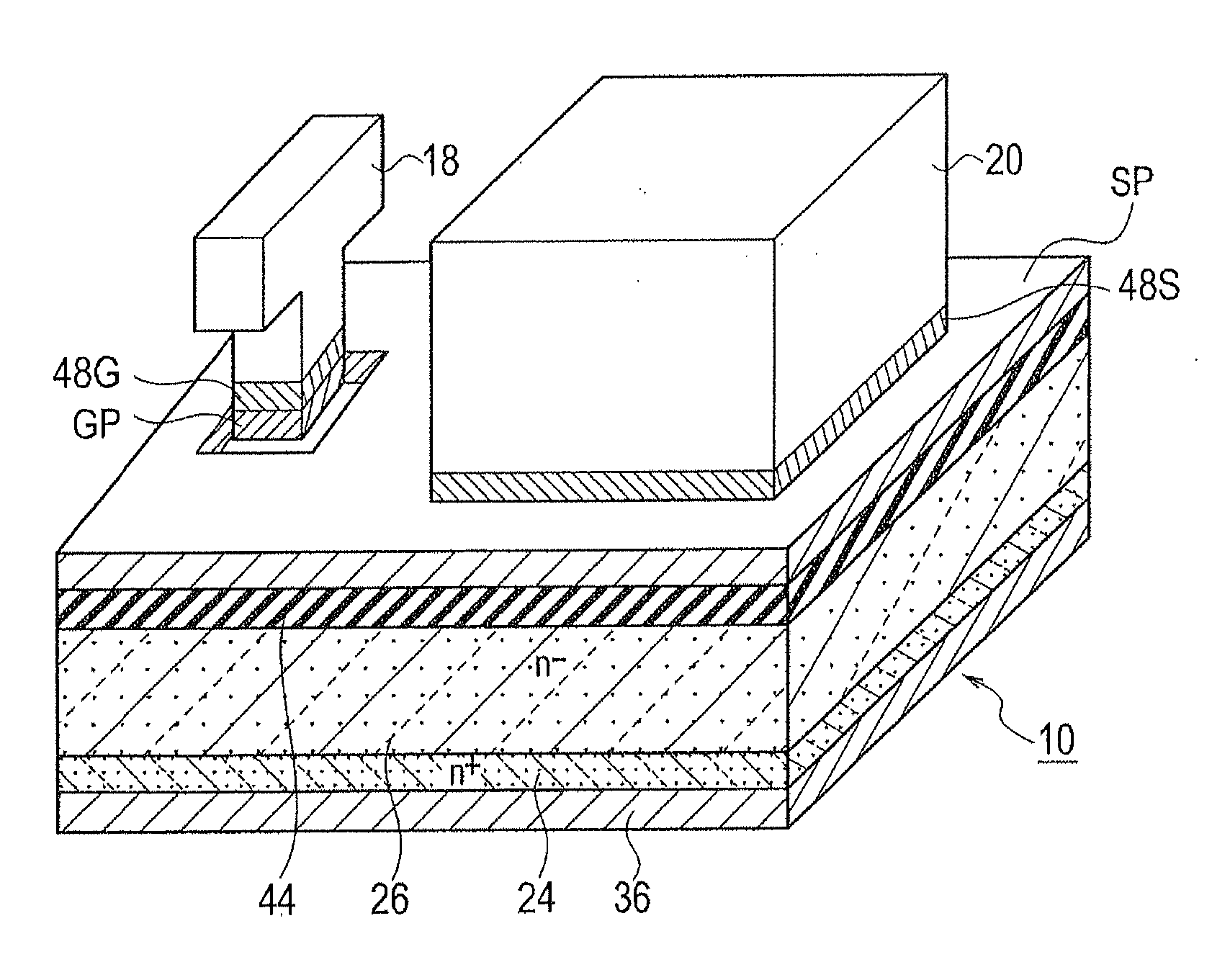

Semiconductor device and fabrication method of the semiconductor device

ActiveUS20130092948A1Shorten the length of timeReduce processing temperatureSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceSemiconductor chip

The semiconductor device having flip chip structure includes: an insulating substrate; a signal wiring electrode disposed on the insulating substrate; a power wiring electrode disposed on the insulating substrate or disposed so as to pass through the insulating substrate; a semiconductor chip disposed in flip chip configuration on the insulating substrate and comprising a semiconductor substrate, a source pad electrode and a gate pad electrode disposed on a surface of the semiconductor substrate, and a drain pad electrode disposed on a back side surface of the semiconductor substrate; agate connector disposed on the gate pad electrode; and a source connector disposed on the source pad electrode. The gate connector, the gate pad electrode and the signal wiring electrode are bonded, and the source connector, the source pad electrode and the power wiring electrode are bonded, by using solid phase diffusion bonding.

Owner:ROHM CO LTD

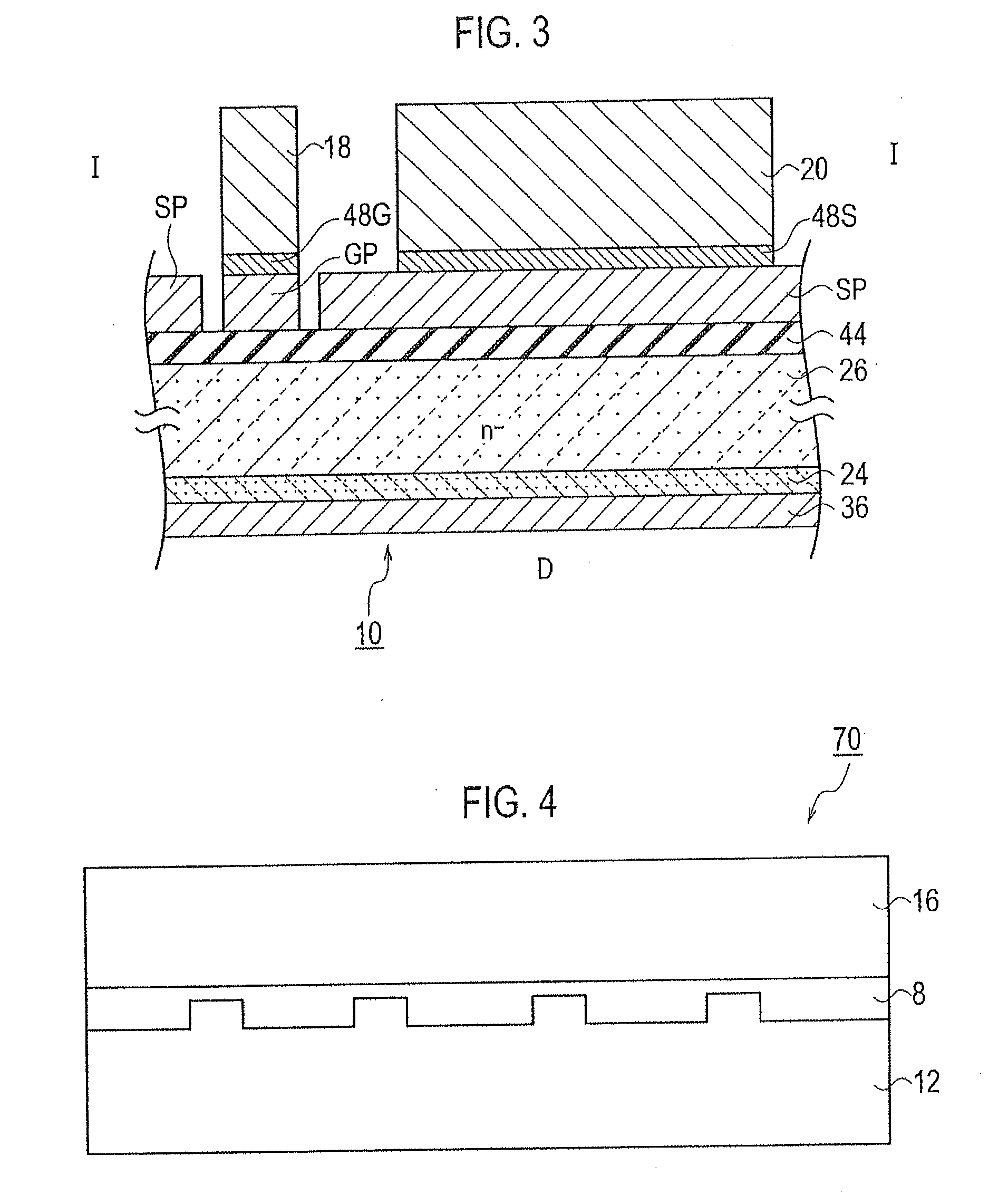

Asphalt modifier and preparation method thereof

InactiveCN101979440AGood compatibilityGood dispersionIn situ pavingsBuilding insulationsPolymer scienceSilicon dioxide

The invention aims to provide an asphalt modifier and a preparation method thereof, which overcome the disadvantages of nonuniform modification, serious pollution and hidden danger caused by adding rubber powder into asphalt and solve the technical problem of the modification and prefabrication of the rubber powder. The invention provides the asphalt modifier. The asphalt modifier is characterized by comprising the following components of: tire rubber powder, polyethylene, silicon dioxide and rubber oil, wherein the components are stirred, heated, extruded, cooled and cut to obtain plasticized rubber sticky particles, namely the asphalt modifier. The plasticized rubber sticky particle product of the invention greatly reduce high-temperature processing and pollution of rubber asphalt; the produced rubber asphalt sticky particles are a directly thrown type novel internal modification material and can be directly thrown into the asphalt and stones for mixing; and the asphalt modifier is odorless, can reduce secondary pollution, and has better meltability than that of rubber powder modified asphalt. The rubber asphalt particles are black sticky particles and are easy to package and transport.

Owner:无锡市同义路面新材料有限公司 +1

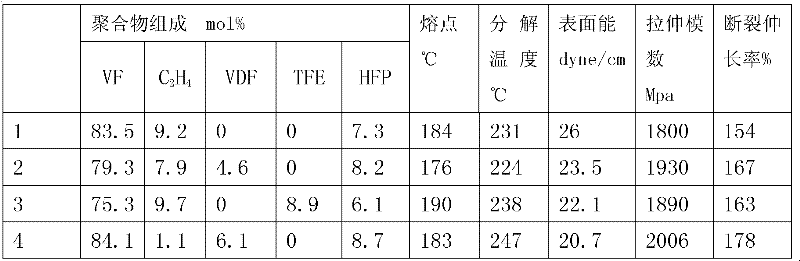

Melt-processable modified polyvinyl fluoride resin and preparation method thereof

The invention relates to a melt-processable modified polyvinyl fluoride (PVF) resin which is polymerized by vinyl fluoride, ethylene, one or more of CF2=CXY and one or more of CF2=CFRf. Reaction monomers are subjected to a copolymerization reaction under the action of an initiating agent in an aqueous phase or an emulsion, reaction temperature ranges from 40 DEG C to 100 DEG C, and reaction pressure ranges from 1 MPa to 10 MPa. According to the melt-processable modified polyvinyl fluoride resin, high-temperature performance of the PVF resin is kept, treatment temperature of the resin is reduced simultaneously, conventional melt processing can be used for processing the resin, and obtained thin-film materials have good combination properties.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

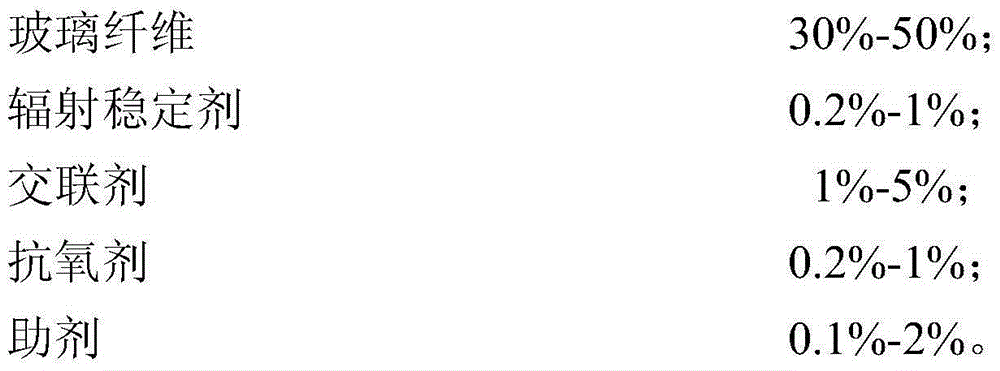

Chloride salt stress corrosion cracking resistant polyamide composition and preparation method therefor and application thereof

ActiveCN105153690AImproved resistance to salt stress corrosion crackingAchieve crack protectionCross-linkGlass fiber

The invention discloses a chloride salt stress corrosion cracking resistant polyamide composition and a preparation method therefor and application thereof. The chloride salt stress corrosion cracking resistant polyamide composition is prepared from the following raw materials in percentage by weight: 45-90% of polyamide resin, 5-50% of glass fiber, 0.1-2% of radiation stabilizer, 0.5-5% of cross-linking agent, 0.1-1% of antioxidant and 0.1-5% of auxiliaries. According to the invention, the salt stress corrosion cracking resisting capacity of polyamide, particularly, short-carbon-chain polyamide is further improved by a radiation cross-linking technology, so that cracking protection for polyamide type automobile components and parts during contacting with chloride salt snow melting agents is realized. According to the method disclosed by the invention, the chloride salt stress corrosion cracking resistant polyamide composition is prepared through a twin-screw extruder, can be used for preparing chloride salt stress corrosion cracking resistant products, has good chloride salt stress corrosion cracking resisting capacity and has a broad application prospect.

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com