Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39 results about "Phase diffusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Back point-contact silicon solar cell based on silk-screen printing technology and making method

InactiveCN1815760AImprove performanceSimple manufacturing methodFinal product manufacturePhotovoltaic energy generationGas phaseSilicon solar cell

Phosphorus diffusion formed PN junction is setup on P type silicon chip. There is silicon nitride layer, or surface passivation layer of silica, reflection reducing coating and positive electrode on front face. Characters are that through P type punctual alloy diffusion zone, back metal layer of silicon chip constitutes ohmic contact. Preparing method includes steps: selecting P type chip; preparing knap surface and cleaning; forming PN junction through phosphorus diffusion; etching and corroding edges by using plasma; developing silicon nitride or silica at both sides; preparing point contacted dense P+ zone at back side through screen printing by using solid-solid phase diffusion or selective gaseous phase diffusion; printing and sintering electrode through screen printing; adding metal layer to full back side. The solar cell reaches indexes: open circuit voltage larger than 650mV, current density larger than 38mA / cm2, fill factor as 74úÑ-78úÑ and conversion efficiency 18úÑ-20úÑ.

Owner:WUXI SUNTECH POWER CO LTD

Method for forming ultra-shallow boron doping regions by solid phase diffusion

A method for forming an ultra-shallow boron dopant region in a substrate is provided. In one embodiment, the method includes depositing, by atomic layer deposition (ALD), a boron dopant layer in direct contact with the substrate, where the boron dopant layer contains an oxide, a nitride, or an oxynitride formed by alternating gaseous exposures of boron amide precursor or an organoboron precursor and a reactant gas. The method further includes patterning the dopant layer and forming an ultra-shallow dopant region in the substrate by diffusing boron from the boron dopant layer into the substrate by a thermal treatment.

Owner:TOKYO ELECTRON LTD

Hydrogen diffusion electrode for protonic ceramic fuel cell

A proton conducting fuel cell that includes an electrolyte having a proton conducting ceramic electrolyte and a two-phase diffusion membrane electrode contacting the electrolyte, where the electrode is substantially non-porous and permeable to hydrogen. Also, a method of generating molecular hydrogen from a proton conducting fuel cell having a positive and negative electrode in contact with a proton conducting ceramic electrolyte, including selectively extracting pure hydrogen from a hydrogen gas mixture, and electrolyzing water vapor at a positive electrode of the fuel cell to form molecular oxygen (O2) and hydrogen ions, and reducing the hydrogen ions at a negative electrode of the fuel cell to form molecular hydrogen (H2).

Owner:PROTONETICS INT

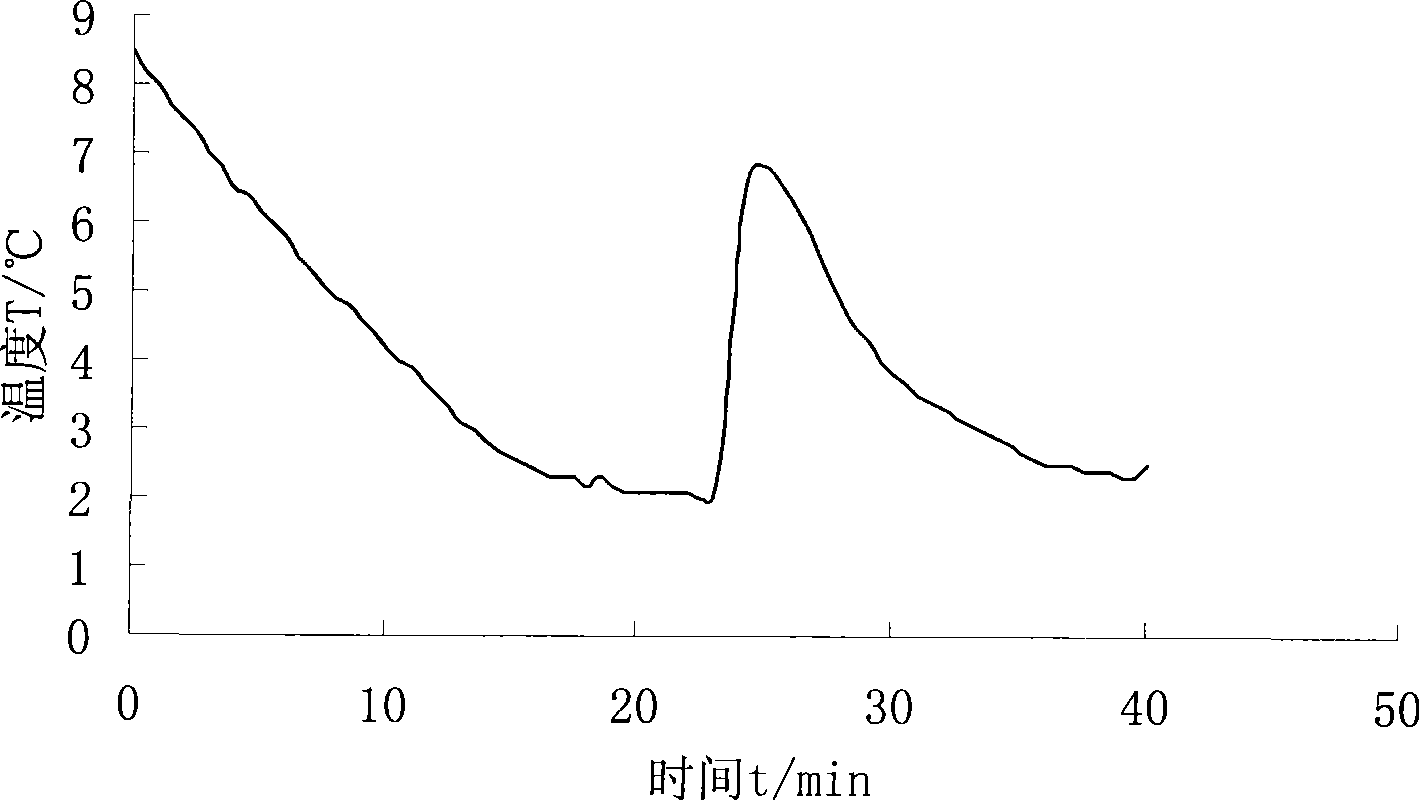

Nano refrigerant hydrate phase change cold-storage working substance and preparation thereof

InactiveCN101434833AEasy to passReduce running power consumptionHeat-exchange elementsSolubilityTurbidity

The invention provides a nano-refrigerant hydrate phase change cool-storage refrigerant and a preparation method thereof; surfactant is dissolved in water to prepare the water solution of the surfactant; subsequently, the refrigerant is dripped into the water solution of the surfactant and mixed till that the solution is changed from turbidity to brightness. According to the solubility of the surfactant in water and in the refrigerant, the surfactant can be dissolved in the water and can also be dissolved in the refrigerant. Under static state, the water phase and the refrigerant phase are uniformly mixed in microscopic scale to augment the two-phase diffusion interface, thus promoting the growth of the hydrate crystal. The system can lead the water phase and the refrigerant phase to be mixed uniformly without applying mixing, disturbing and external field; the refrigerant phase is dispersed in water in the form of micelle or (and) microemulsion; and alternatively, the water phase is dispersed in the refrigerant phase in the form of micelle or (and) microemulsion; the dripping size of the dispersing phase is 100nm or less. The hydrate phase change cool-storage refrigerant does not delaminate after being placed for a long time, is single-dispersion system with stable thermal-mechanics performance and has the appearance of transparent or semi-transparent solution.

Owner:XI AN JIAOTONG UNIV

Method for preparing ultra-thin film through micro-phase diffusion control interface polymerization

InactiveCN107519769ASemi-permeable membranesWater/sewage treatment bu osmosis/dialysisCross-linkFiltration

The invention discloses a method for preparing an ultra-thin film through micro-phase diffusion control interface polymerization and belongs to the technical field of membrane separation. The method comprises the following steps: firstly, spraying a layer of an active amino monomer on a porous support, further spraying a layer of an active acyl chloride monomer, enabling the two components to react to generate a polyamide layer, and repeatedly spraying to generate multiple polyamide separation layers; soaking a prepared membrane into a glutaraldehyde solution, and performing a cross-linking reaction with unreacted amino to form an internal network structure, thereby improving the density grade and the structural stability of the membrane. The method is a novel interface polymerization method by dispersing a bulk phase reaction solution into micro droplets, converting bulk phase diffusion into micro phase diffusion and eliminating later diffusion process. Through a spraying atomization function, a reaction solution is dispersed into micron-order droplets, and the bulk phase diffusion is converted into micro phase diffusion. The sizes of the droplets are at a micron grade, and reaction monomers in the droplets can be completely reacted in the bulk phase diffusion process. When being applied to the field of nano filtration, the prepared membrane has super-high flux and a relatively high retention rate.

Owner:BEIJING UNIV OF TECH

Laser beam light balancing and shaping and speckle eliminating integrated device

InactiveCN102103270ACompact structureImprove light energy utilizationDiffraction gratingsLight energyLaser light

The invention provides a laser beam light balancing and shaping and speckle eliminating integrated device, which belongs to the field of laser displaying and illuminating and particularly relates to the fields of laser projection displaying and infrared laser night viewing. In the device, laser beam light balancing and shaping and speckle eliminating are considered uniformly, speckles are eliminated by adopting a rotary holographic scattering device, light balancing and shaping are realized by adopting a pure phase diffusion apparatus, and a holographic scattering apparatus, a micro direct current motor, the pure phase diffusion apparatus and a Fourier transform lens are connected and fixed into an entire body with a compact structure, so that the aims of balancing and shaping laser beam light and eliminating speckles are fulfilled simultaneously. The holographic scattering apparatus and the pure phase diffusion apparatus are thin-sheet diffusion optical apparatuses, have small sizes and are thin and light, so that optical-mechanical-electrical integration and miniaturization are easy to realize; moreover, the integrated device is made of a double refraction material, so that the integrated device has polarization maintaining performance, makes full use of the inherit linear polarization property of laser light and further increases the utilization ratio of light energy.

Owner:SHANDONG UNIV

Method for measuring liquid phase diffusion coefficient by utilizing instant refractive index spatial distribution of liquid core cylindrical lens

ActiveCN104165863AEasy accessAccurate acquisitionPhase-affecting property measurementsFluid phaseRefractive index

The invention discloses a method for measuring the liquid phase diffusion coefficient by utilizing instant refractive index spatial distribution of a liquid core cylindrical lens, and belongs to a method for optical measurement of the liquid phase diffusion coefficient. The method comprises the following steps: selecting a plurality of sampling points in the medium diffusion time by taking the liquid core cylindrical lens as a liquid phase diffusion tank and an imaging element, controlling a CMOS chip to collect an instant diffusion image by utilizing a Microsoft Visual Basic program, acquiring a set of ordered pairs of the refractive index n and the position Z according to the corresponding relationship between the image width of the image and the refractive index, and then directly calculating the liquid phase diffusion coefficient by the Fick second law. A diffusion experiment of pure water with ethylene glycol and saccharose solutions with different concentrations respectively shows that the method is extremely rapid in measurement speed (less than one second), and is accurate in measurement value (the relative error is less than 3%).

Owner:YUNNAN UNIV

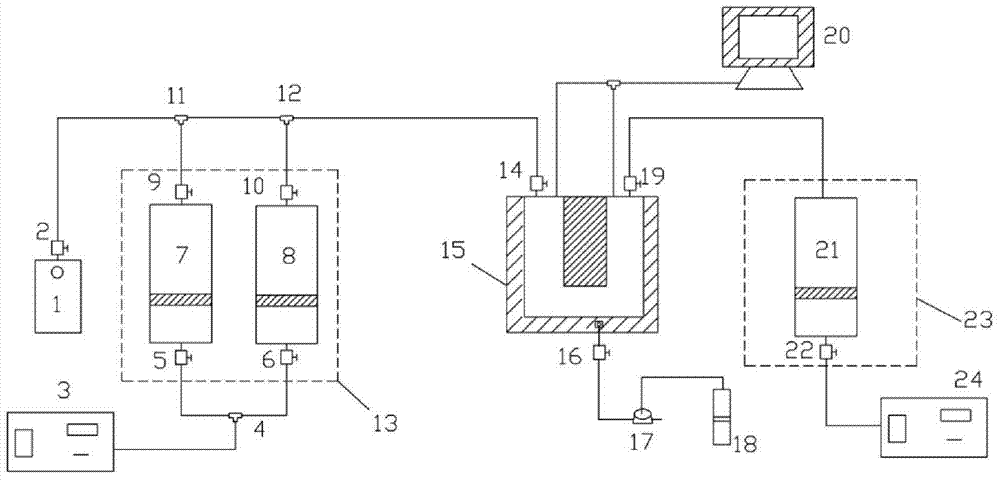

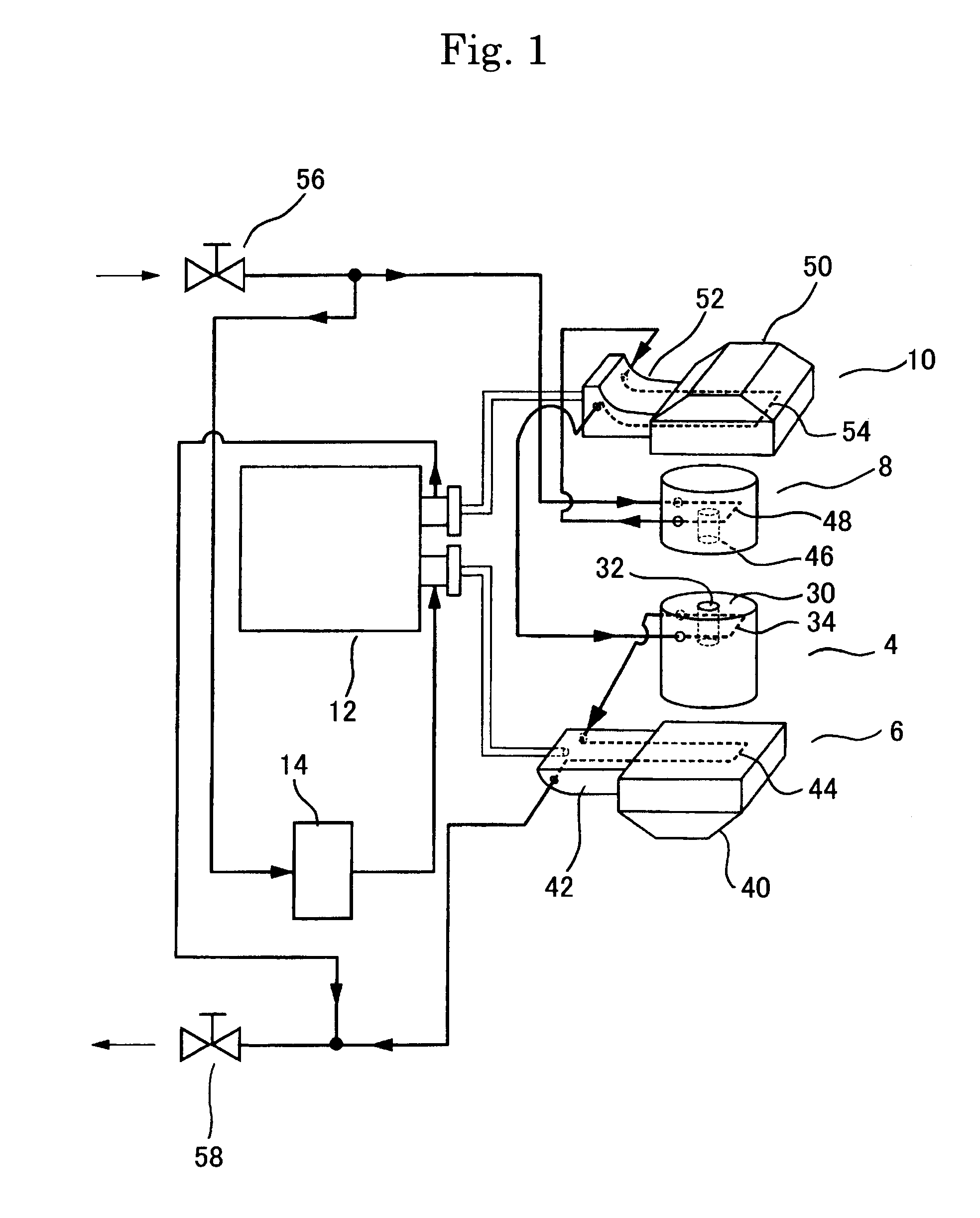

Device for measuring diffusion coefficient of CO2 diffusing from aqueous phase to oil phase and operating method thereof

The invention relates to a device for measuring a diffusion coefficient of CO2 diffusing from an aqueous phase to an oil phase. The device comprises a CO2 gas source, a distilled water source, a U-shaped high-temperature high-pressure visual diffusion device and a crude oil source which are sequentially and vertically connected in parallel to a pipeline, wherein a steel separator is vertically arranged in the U-shaped high-temperature high-pressure visual diffusion device; the interior of the U-shaped high-temperature high-pressure visual diffusion device is separated into a left-side space and a right-side space of which the bottoms are communicated by virtue of the steel separator; a temperature measuring point, a pressure measuring point and a lower outlet are formed in the bottom in the U-shaped high-temperature high-pressure visual diffusion device; and the device also comprises a pressure collection system, a return pressure gas tank, a heater and a temperature control system. The device disclosed by the invention is reliable in principle and easy and convenient to operate, the influence caused by oil-gas-water density difference is overcome, a pressure drop method for measuring the gas-liquid two-phase diffusion coefficient is applied to measuring the diffusion coefficient of gas between the aqueous phase and oil phase, the CO2 concentration change and experimental equilibrium pressure do not need to be measured, and the diffusion coefficient of CO2 diffusing from the aqueous phase to the oil phase can be solved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Process of preparing rare earth permanent magnet Sm2Fe17NX powder

Owner:北京钐元新材料股份有限公司

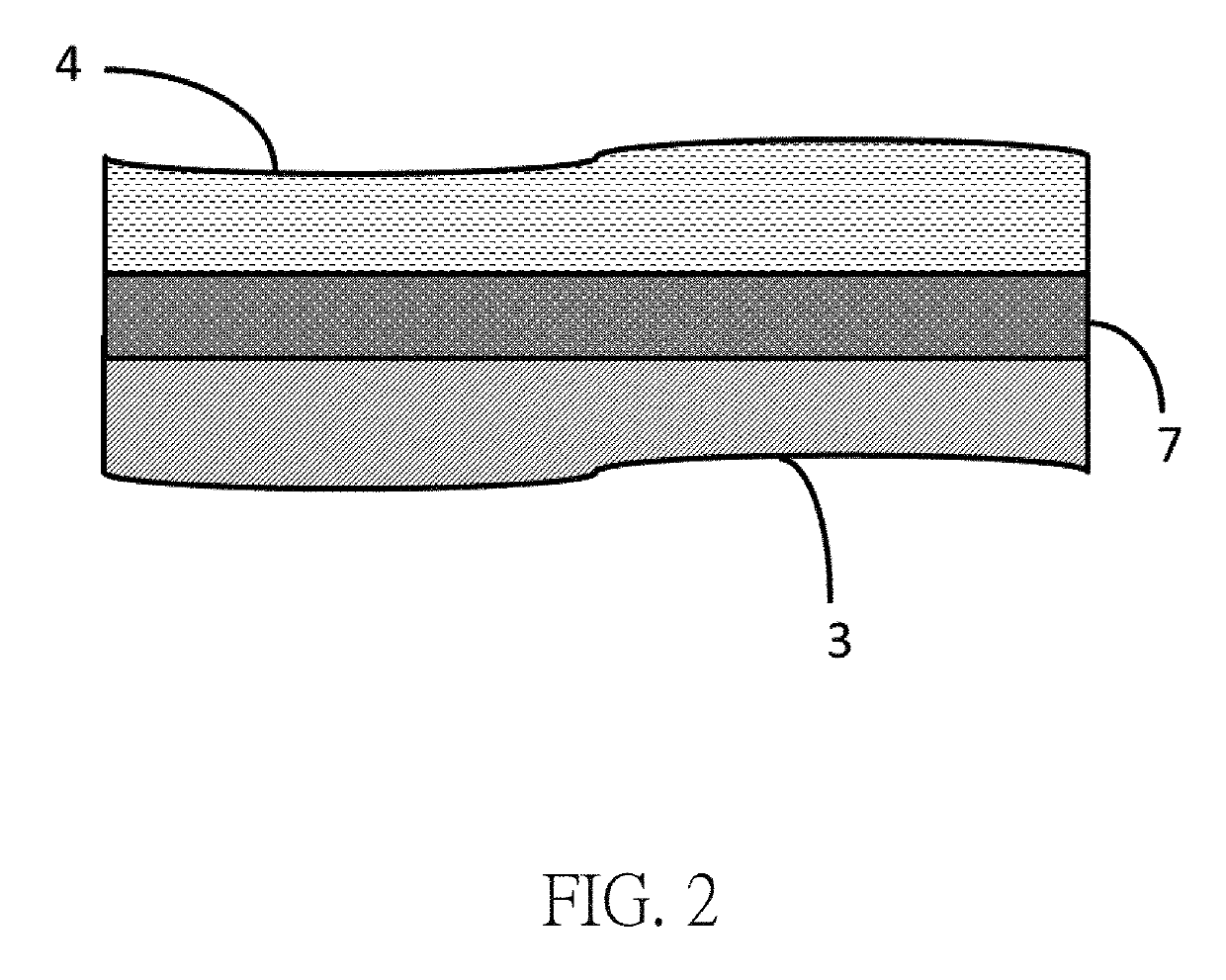

Method of joining part having high fatigue strength

ActiveUS20130133785A1Improve fatigue strengthEconomic efficiency is excellentFurnace typesVehicle componentsMartensiteMechanical engineering

A method of joining using a supporting electrode 4 having a cooling circuit and a pressure electrode 8 movably arranged above the supporting electrode, using a steel material causing martensitic transformation for one of or both of a first member 20 having an opening portion and a second member 24, engaging the second member with the opening portion of the first member, starting conduction from a power supply to the supporting electrode and the pressure electrode, allowing an insertion portion of the second member to enter the opening portion of the first member by a pressure force of the pressure electrode, causing the second member and an inner wall portion of the opening portion to be subjected to solid-phase diffusion joining, rapidly cooling the both members by thermal conduction of the supporting electrode after the joining, and quenching a joined portion and generating compressive residual stress by the rapid cooling.

Owner:OHASHI TECHNICA

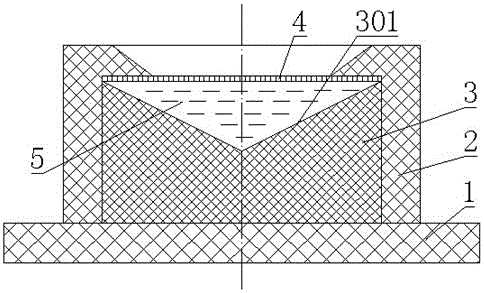

Process for producing common rail, and common rail

InactiveCN101981302AReduce manufacturing costImprove fatigue strengthFurnace typesMachines/enginesManganeseEngineering

A process for producing a common rail comprising a common-rail main body and a holder therefor, the main body and the holder containing, as chemical components, 0.01-0.3 mass% carbon, 0.01-0.5 mass% silicon, 0.01-3.0 mass% manganese, 0.0003-0.01 mass% boron, 0.001-0.01 mass% nitrogen, 0.01-0.5 mass%, excluding 0.01 mass%, aluminum, and 0.01-0.05 mass% titanium, having a phosphorus content reducedto 0.03 mass% or lower, a sulfur content reduced to 0.01 mass% or lower, an oxygen content reduced to 0.01 mass% or lower, and a total content of arsenic, tin, antimony, lead, and zinc reduced to 0.015 mass% or lower, with the remainder being iron and incidental impurities, and having a TLB value of 0.001% or higher. The process comprises an insert-metal insertion step, a liquid-phase diffusion bonding step, a laser peening step, and a surface-layer removal step.

Owner:NIPPON STEEL CORP

Conductive aluminum alloy section bar formula of subway locomotive and preparation method thereof

The invention belongs to the field of metal materials and particularly relates to a conductive aluminum alloy section bar formula and a preparation method thereof. The aluminum section bar formula is prepared from the following element components in percentage by weight: 0.45%-0.5% of Si, 0.5%-0.65% of Mg, 0.1%-0.25% of Fe, not greater than 0.03% of Mn, not greater than 0.03% of Cr, not greater than 0.05% of Cu, not greater than 0.05% of Zn, not greater than 0.05% of Ti, not greater than 0.03% of other single impurity, not greater than 0.1% of other impurities, and the balance of Al, based on 100% in total. The preparation method of the conductive aluminum alloy section bar formula comprises steps of casting, homogenizing, cast ingot heating, extruding and thermal processing, wherein the thermal processing step adopts double-stage manual ageing thermal treatment, and the ageing condition is T6 + (210+ / -5 DEG C, 2h). The aluminum alloy magnesium silicide manufactured by the conductive aluminum alloy section bar formula disclosed by the invention is uniform in strengthening phase diffusion, and has good strength and inter-crystalline corrosion resistance.

Owner:GUANGDONG XINGFA ALUMINUM +2

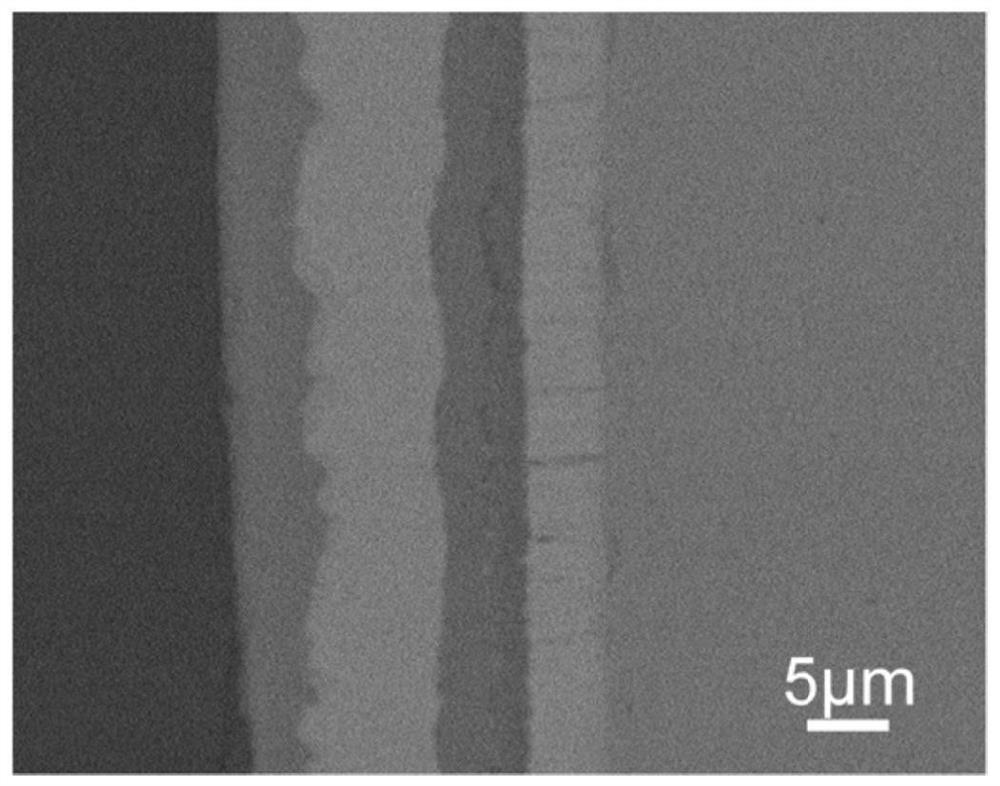

Ultrahigh nitrogen austenite phase diffusion hardening covering layer for pump shafts of nuclear grade pumps

InactiveCN102925853AMeet wear resistanceMeet the corrosion resistanceSolid state diffusion coatingNuclear gradeSurface engineering

An ultrahigh nitrogen austenite phase diffusion hardening covering layer for pump shafts of nuclear grade pumps belongs to the field of material surface engineering, and comprises pump shafts of a nuclear first-grade pump, a nuclear second-grade pump and a nuclear third-grade pump, which are made of Fe-Cr-Ni austenite stainless steel, as well as a hardening covering layer and a transition layer, wherein the hardening covering layer and the transition layer have the advantages of wear resistance, corrosion resistance, fatigue resistance and irradiation resistance and are arranged on the surfaces of the pump shafts. The covering layer is characterized in that the ultrahigh nitrogen austenite phase diffusion hardening covering layer, which is 15 to 25 micro in thickness, and has the surface roughness Ra lower than 0.5 micro, is prepared through using a plasma base nitriding method at 250 to 450 DEG C, the preparation of the covering layer is the last procedure in pump shaft manufacture, the hardening covering layer comprises a single ultrahigh nitrogen austenite phase, the peak value of the nitrogen concentrations in gradient distribution is 20 to 35 at.%, the hardness is 15 to 22 GPa, no hole and no microcrack are generated, and the residual compressive stress is higher than 2 GPa. The covering layer has the advantages that the preparation process is simple, follow-up processing is not required, no pollution is caused, and the performance is superior to the electrochromism covering layer used for the current pump shafts of the nuclear grade pumps.

Owner:DALIAN UNIV OF TECH

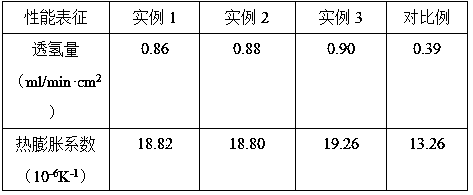

Preparation method of unsymmetrical composite ceramic hydrogen permeation membrane

InactiveCN109133919AIncreased bulk diffusion rateImprove hydrogen permeabilityElectrochemical responseComposite ceramic

The invention relates to a preparation method of an unsymmetrical composite ceramic hydrogen permeation membrane, and belongs to the technical field of environment-friendly materials. According to themethod, a tungsten acid rare earth compound with good chemical stability is selected as a membrane material, electronic conductive phase metal Ni is led into the membrane, nickel in an ion form is led into the tungsten acid rare earth compound by a citric acid-nitrate combustion method, simple-substance Ni is reduced, an electron conduction channel is formed, the bulk phase diffusion rate of themembrane is increased, hydrogen permeation amount of a diaphragm is increased, two phases of the a prepared two-phase membrane are more uniformly mixed, and the membrane has higher hydrogen permeationamount and chemical stability. According to the method, rare earth nano-particles with high catalytic activity are deposited on the inner wall of a green diaphragm of the hydrogen permeation membraneand serve as supporting frameworks, the rare earth nano-particles and conductive-phase metal Ni form continuous conductive grids, electrochemical reaction active sites are increased, the hydrogen permeation membrane has good catalytic activity, and poor stability and hydrogen permeation rate of the hydrogen permeation membrane are effectively improved.

Owner:FOSHAN WANHE NEW ENERGY TECH CO LTD

Hydrogenation catalyst and preparation method thereof

ActiveCN103143365BIncrease loadGood dispersionMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsQuaternary ammonium cationHydrodesulfurization

The invention provides a hydrogenation catalyst and a preparation method thereof. The preparation method uses metal active components of group VIB and VIII for step load, wherein metal of group VIB is molybdenum, metal of group VIII is cobalt or nickel, and a carrier is porous oxide. Load of group VIB metal uses a corresponding soluble salt as a raw material, inorganic acid is used as an acidifying agent, and a long-chain alkyl quaternary ammonium cation is used as a precipitating agent; and Mo-based single-component loaded catalyst is prepared by firstly synthesizing an organic-inorganic hybrid material suspension, performing aqueous phase diffusion and tunnel deposition, filtering, washing, drying, and roasting. Load of group VIII metal uses a corresponding soluble salt as a raw material, and the metal is loaded onto the carried through a normal-temperature isopyknic dipping technology. The method can effectively improve load capacity of the active components and dispersiveness of the active components in the tunnels; and the prepared hydrotreating catalysts is excellent in hydrodesulfurization activity.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method for manufacturing selective emitter solar cell

ActiveCN101901851AImprove conversion efficiencyOmit growthFinal product manufactureSemiconductor devicesHigh concentrationElectrical resistance and conductance

The invention provides a method for manufacturing a selective emitter solar cell, which comprises the following steps of: 1, performing heat diffusion or gaseous phase diffusion directly on a P-type conductive substrate by coating slurry containing N-type impurities to form an N-type diffusion layer; 2, forming a pattern-shaped electrode on the P-type conductive substrate on which the N-type diffusion layer is formed; and 3, implanting P-type impurities on the P-type conductive substrate on which the electrode is formed so as to ensure that the N-type diffusion concentration of the N-type diffusion layer covered with the electrode is higher than that of the N-type diffusion layer which does not cover the electrode. In the method, the high-concentration diffusion layer is formed below the electrode, so that contact resistance is reduced effectively; the low-concentration diffusion layer is formed in other light-transmitting areas to inhibit surfaces from recombining, so the conversion efficiency of the solar cell is improved, the growth step and subsequent cleaning step of an oxidation film are eliminated, and the method is favorable for reducing production cost.

Owner:HEJIAN TECH SUZHOU

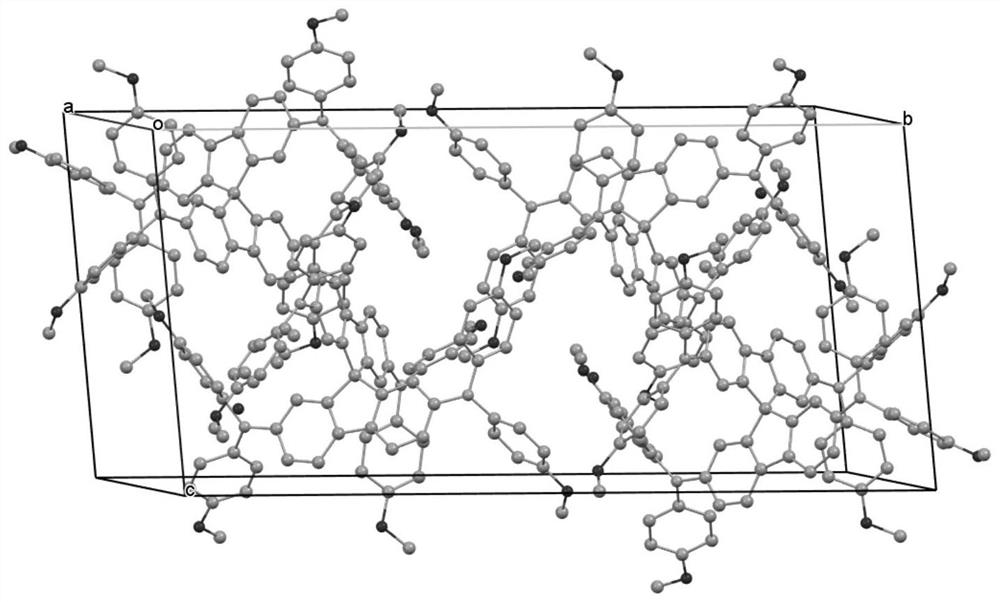

Compound crystal of PARP15 protein and inhibitor Niraparib thereof, and preparation method for compound crystal

InactiveCN112159800AHigh purityConvenient researchMicroorganism based processesPeptidesGas phaseBiochemistry

The invention discloses a compound crystal of PARP15 protein and inhibitor Niraparib thereof, and a preparation method for the compound crystal. The preparation method comprises the following steps of: mixing the PARP15 protein with the inhibitor Niraparib thereof at a ratio; and carrying out crystallization on a mixture by a hanging drop method in a gaseous phase diffusion method to obtain the compound crystal of the PARP15 protein and the inhibitor Niraparib thereof. The preparation method has the advantages that the high-purity PARP15 protein is successfully obtained, in addition, the compound crystal of the PARP15 protein and the inhibitor Niraparib thereof is obtained for the first time, research on the PARP15 protein can be accelerated, and a molecular foundation is provided for designing and optimizing a targeted PARP15 protein medicine.

Owner:深圳晶蛋生物医药科技有限公司

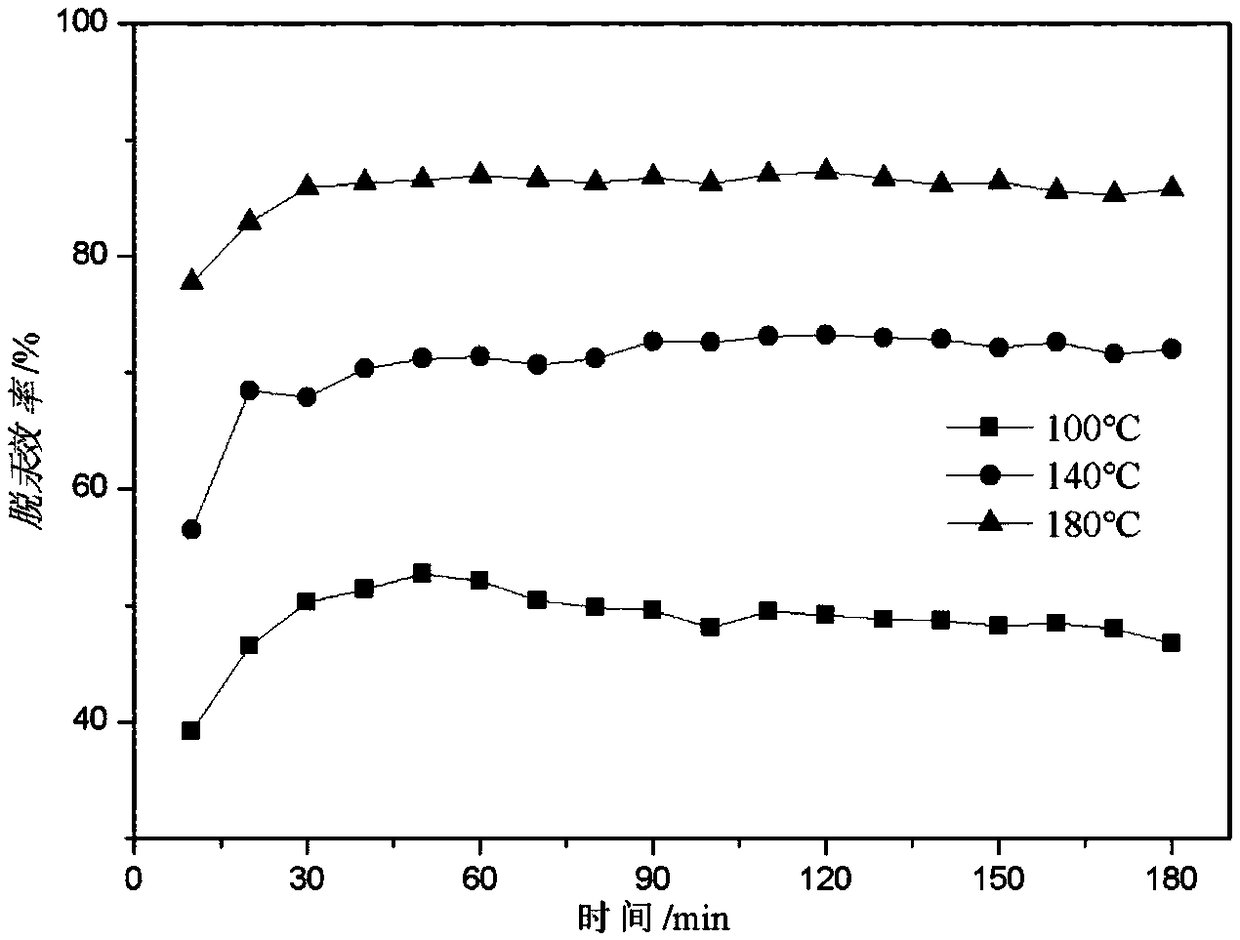

Ag2S-MMt nanometer composite adsorbent and preparation method thereof

ActiveCN109499521ASmall particle sizeEasy to removeGas treatmentOther chemical processesSodium BentoniteGas phase

The invention discloses an Ag2S-MMt nanometer composite adsorbent and a preparation method thereof. The g2S-MMt nanometer composite adsorbent is prepared by loading nanometer silver sulfide onto montmorillonite with one-step synthesis by utilizing a vapour phase diffusion method in a closed container. In the preparation method, by utilizing the vapour phase diffusion method, the prepared nanometersilver sulfide particles are small in size (about 20-49 nm), has very good surface performance, adsorption performance and storage performance and can be uniformly distributed on the surface of bentonite; and the adsorbent synthesized with a one-step method has good removal effect on gaseous elemental mercury with the mercury removal efficiency reaching 85-90 percent at the temperature of 180 DEGC.

Owner:SHANDONG UNIV OF SCI & TECH

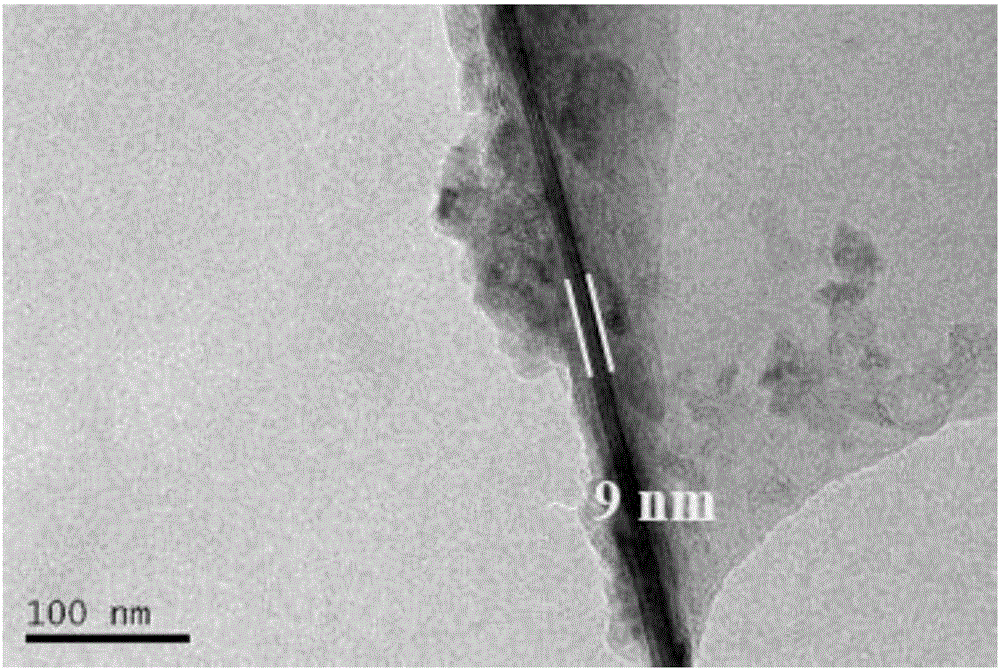

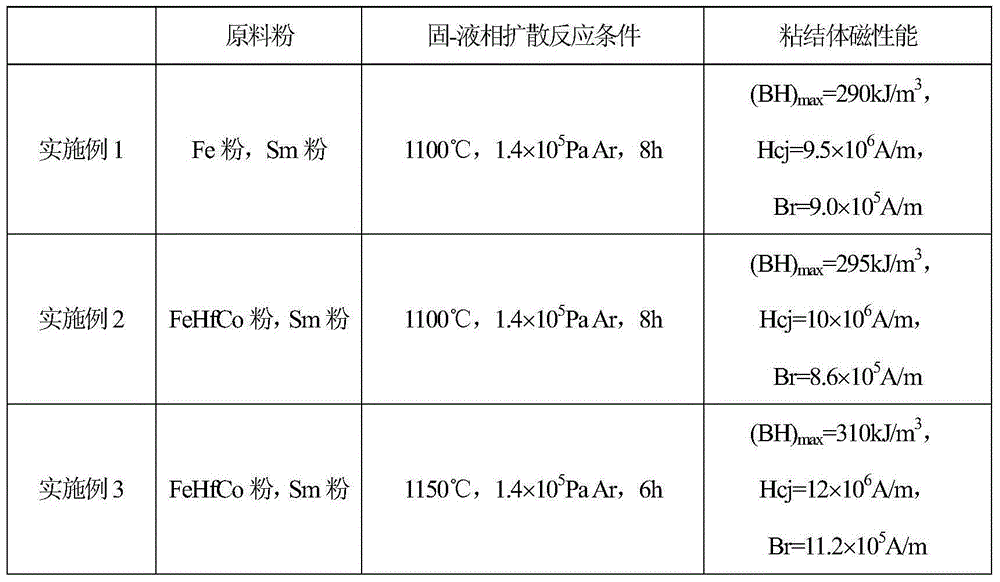

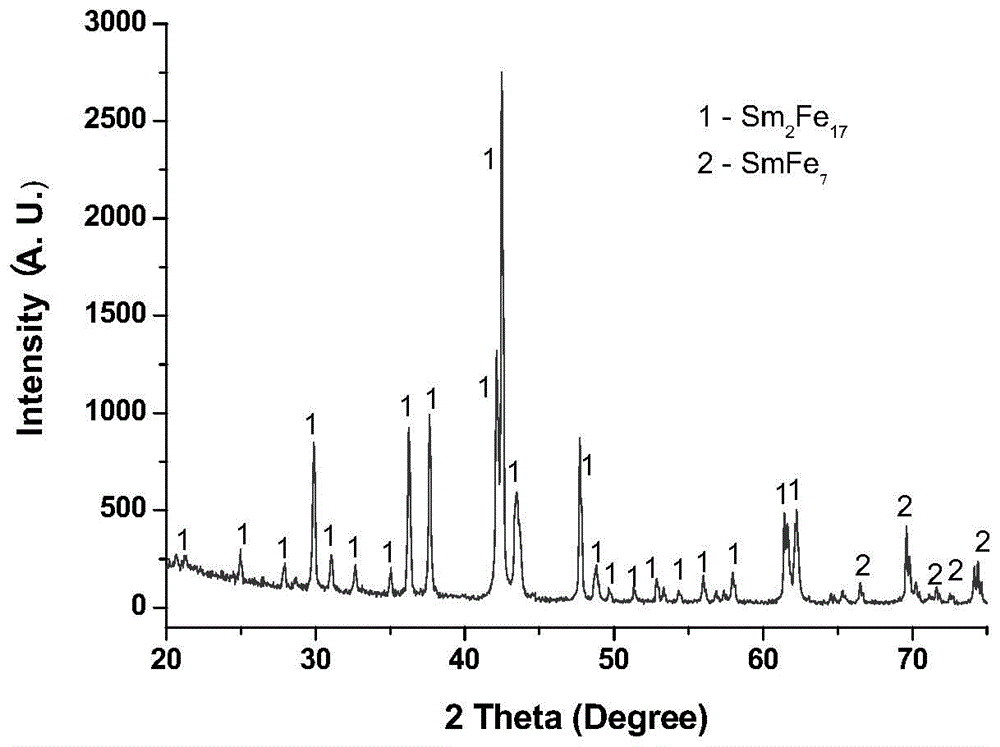

A kind of preparation of rare earth permanent magnet sm 2 fe 17 n x powder process

The invention belongs to the technical field of rare earth permanent magnets and particularly provides a process of preparing a rare earth permanent magnet Sm2Fe17NX powder. According to the process, an Fe-M powder and an Sm powder are employed as raw materials (wherein M is selected from one or more than two from Hf, Zr, Co, Nb, Cr, V, Ti, Ga, B and the like), and a solid-liquid phase diffusion reaction method is employed to prepare a Sm2Fe17 intermetallic compound, and finally the intermetallic compound is nitrided to obtain the final product Sm2Fe17NX. The process includes the steps of (1) uniformly mixing the Fe-M powder and the Sm powder; (2) performing cold-pressing moulding to the mixed raw material powder; (3) performing the solid-liquid phase diffusion reaction to the cold-pressed billet to obtain a Sm2Fe17 mono-phase block; and (4) crushing and grinding the Sm2Fe17 mono-phase block into powder, performing nitridation to the powder under an atmosphere containing nitrogen or ammonia to prepare the Sm2Fe17NX powder. On the basis of the Sm2Fe17NX powder, an aeolotropic bonded magnet having excellent performances can be produced. The process is simple in operations, is easy to control in process parameters, is environment-protective and pollution-free, and is easy to achieve large-scale production.

Owner:北京钐元新材料股份有限公司

Method for connecting graphite film and copper

ActiveCN114425647AAchieve connectionReduce residual stressVacuum evaporation coatingSputtering coatingThermal dilatationMicron scale

The invention relates to the technical field of graphite film and metal connection, in particular to a solid-phase diffusion connection method capable of realizing connection of a graphite film and metal copper, effectively reducing the width of a welding seam and reducing the stress at a joint, which is characterized by comprising the following steps of: carrying out surface metallization treatment on the graphite film to form a metal intermediate layer on the surface of the graphite film; the metal copper and the metal intermediate layer are in diffusion connection to obtain a graphite film and metal complex, and the metallization treatment on the surface of the graphite film refers to forming a nano-scale or micron-scale metal intermediate layer on the surface of the graphite film by using a magnetron sputtering technology; according to the method, the magnetron sputtering technology and the diffusion bonding method are combined, solid-phase diffusion bonding is successfully applied to connection of the high-thermal-conductivity graphite film and copper, the width of a welding seam is effectively reduced, and due to the existence of a gradient interface layer in the welding seam, the residual stress of a connector caused by the large difference of thermal expansion coefficients of base metal on the two sides is effectively reduced.

Owner:HARBIN INST OF TECH AT WEIHAI

Nano refrigerant hydrate phase change cold-storage working substance and preparation thereof

InactiveCN101434833BEasy to passReduce running power consumptionHeat-exchange elementsSolubilityTurbidity

Owner:XI AN JIAOTONG UNIV

Preparation method for supramolecular assembly body based on polyvinyl alcohol and cyclopolysaccharide

The invention discloses a preparation method for a supramolecular assembly body based on polyvinyl alcohol and cyclopolysaccharides, that is, polyvinyl alcohol is adopted as an object molecule, and cyclopolysaccharides are adopted as a main body molecule, and by using a phase diffusion method, the supramolecular assembly body is prepared by using a mechanism of high-low temperature driving molecule movement. The preparation method comprises the following reaction steps: putting cyclopolysaccharide solid powder into a polyvinyl alcohol solution, gradually heating to 70-95 DEG C, and stirring toreact for 4-8 hours; cooling to 4-25 DEG C, and stirring to react for 10-24 hours; repeating the high-low temperature process for 3-8 times; rotating, evaporating and concentrating the reaction solution, precipitating and separating the concentrated liquid; washing the product by using a composition washing solvent at a low temperature, and drying for 24 hours; repeatedly washing and drying for 2-3 times, thereby obtaining the cyclopolysaccharide supramolecular assembly body. The product prepared by using the method is green and environmentally friendly and simple in preparation process, thewater solubility of the polyvinyl alcohol is greatly improved, and the thermal stability of the polyvinyl alcohol is remarkably improved.

Owner:TIANJIN UNIV OF SCI & TECH

Method for improving adhesion between ceramic carrier and thick film circuit

ActiveUS10362684B1Improve adhesionReduce processing costsPrinted circuit assemblingCeramic layered productsPositive pressureSlurry

The present invention relates to a method for improving adhesion between ceramic and a thick film circuit. The method is particularly directed to accelerate the formation of a ceramic-metal eutectic phase between the ceramic carrier and the metal circuit by solid-phase diffusion bonding under a positive atmosphere. A metallic conductive slurry or its oxide slurry is printed on the surface of the ceramic carrier to form a circuit pattern by a thick film screen printing. The ceramic carrier is placed in an oven with temperature controlled by a program under a positive-pressure atmosphere of an inert gas including nitrogen, hydrogen or their mixtures. An eutectic phase is formed between the ceramic carrier and the metal circuit under a high temperature eutectic condition to increase the adhesion between the ceramic carrier and the thick film circuit.

Owner:NAT CHUNG SHAN INST SCI & TECH

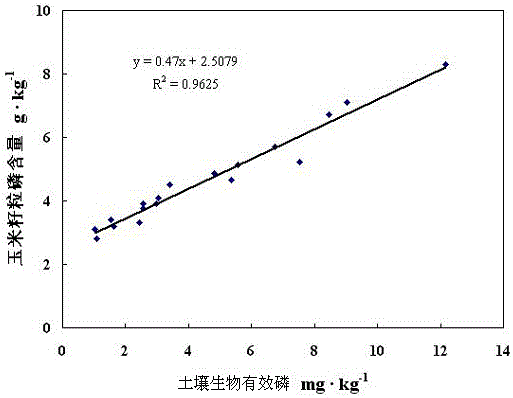

A kind of determination method of bioavailable phosphorus in soil

InactiveCN104198405BObjectively reflect the form of existenceReflect absorptionColor/spectral properties measurementsDialysis membranesCalcium Binder

A method for the determination of biologically available phosphorus in soil. Collect plant rhizosphere soil and air-dry it naturally, pass it through a 2mm nylon sieve after grinding, put it into a plastic container, add ultrapure water to make the water content of the soil to be tested reach 60%, mix well, and seal Then place it; add ultrapure water again to make the soil moisture content reach 80%, mix well to make the soil surface in the container smooth, seal it and place it, and obtain the soil test sample; dilute the purified binder solution and put it into the DGT sampling device, use Seal the DGT sampling device with the dialysis membrane; gently twist the DGT sampling device into the surface of the soil test sample so that the DGT sampling device is in good contact with the soil and place it; take out the binding phase and measure the binding phase with ammonium molybdate spectrophotometry The cumulative amount of phosphorus in the soil and the concentration of available phosphorus in the soil are calculated. The method has the advantages that the method uses liquid binding phase film gradient diffusion technology to measure biologically available phosphorus in soil, and the measured biologically available phosphorus is significantly correlated with the absorbed phosphorus in plants.

Owner:BOHAI UNIV

A kind of preparation method of spiro-ometad monoclinic crystal

ActiveCN113005523BPolycrystalline material growthFrom normal temperature solutionsCondensed matter physicsAnalytical chemistry

The invention discloses a preparation method of Spiro-OMeTAD monoclinic crystals, comprising the following steps: selecting a special solvent, adopting an anti-solvent vapor phase diffusion assisted crystallization method to induce Spiro-OMeTAD crystallization, and under the action of the anti-solvent gradually volatilizing and diffusing, the solution Gradually saturated with precipitation of Spiro‑OMeTAD monoclinic crystals. The Spiro-OMeTAD monoclinic crystal prepared by the method provided by the present invention has higher spatial symmetry, and it is found through the conductivity test that it has better conductivity than the triclinic crystal.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Method for recovering and separating lanthanum, neodymium and ytterbium from dicranopteris pedata

ActiveCN113562720AAchieve separabilityReach the purpose of recyclingRare earth metal oxides/hydroxidesCarbon preparation/purificationEngineeringLanthanum

The invention belongs to the technical field of solid waste recycling, and particularly relates to a method for recycling and separating lanthanum, neodymium and ytterbium from a rare earth hyperaccumulation plant. According to the method, lanthanum and neodymium in the hyperaccumulation plant are extracted and separated in the form of oxides by utilizing a phase diffusion principle of rare earth oxides under a high-temperature condition and a separation theory of metals and nonmetals, and an ytterbium-rich biochar raw material is produced, so that the aims of separating and recycling rare earth metals in the hyperaccumulator are fulfilled, high-value recycling is realized, the whole process is green and efficient, and the method has high application value in the field of rare earth hyperaccumulation plant recycling.

Owner:SUN YAT SEN UNIV +1

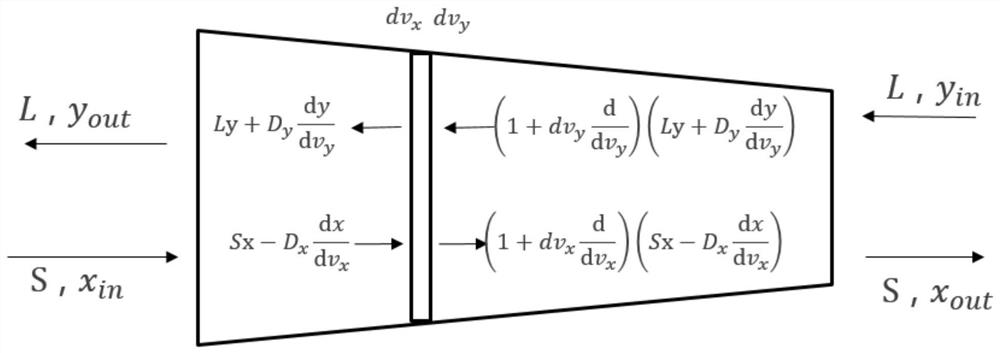

A Steady State Solute Concentration Distribution Model for Continuous Countercurrent Two-Phase Mass Transfer Process

ActiveCN109522672BEasy to controlRetention temperatureDesign optimisation/simulationSpecial data processing applicationsDistribution matrixFluid phase

Owner:SOUTH CHINA UNIV OF TECH

Back point-contact silicon solar cell based on silk-screen printing technology and making method

InactiveCN100483750CFinal product manufacturePhotovoltaic energy generationGas phaseSilicon solar cell

Phosphorus diffusion formed PN junction is setup on P type silicon chip. There is silicon nitride layer, or surface passivation layer of silica, reflection reducing coating and positive electrode on front face. Characters are that through P type punctual alloy diffusion zone, back metal layer of silicon chip constitutes ohmic contact. Preparing method includes steps: selecting P type chip; preparing knap surface and cleaning; forming PN junction through phosphorus diffusion; etching and corroding edges by using plasma; developing silicon nitride or silica at both sides; preparing point contacted dense P+ zone at back side through screen printing by using solid-solid phase diffusion or selective gaseous phase diffusion; printing and sintering electrode through screen printing; adding metal layer to full back side. The solar cell reaches indexes: open circuit voltage larger than 650mV, current density larger than 38mA / cm2, fill factor as 74úÑ-78úÑ and conversion efficiency 18úÑ-20úÑ.

Owner:WUXI SUNTECH POWER CO LTD

Method and Set of Tools for Checking the Crystallisation Conditions of Biological Macromolecules

InactiveUS20090017446A1Prevent evaporationAfter-treatment apparatusPolycrystalline material growthDiffusionGas phase

The invention relates to a method and set of tools for checking and ascertaining the crystallisation conditions of biological macromolecules using the counter-diffusion technique which employs precipitating agents, additives and buffers. The concentration of the precipitating agent(s) in the medium (solution or gel) is greater than those currently used with other available checking techniques, such as batch, microbatch or vapour phase diffusion techniques, such that, as a result of the diffusion along the length of the capillary containing the biological macromolecule, a large number of concentrations of the precipitating agent(s) used in one experiment are checked. The set of tools or kit contains the necessary elements for performing said method.

Owner:CONSEJO SUPERIOR DE INVESTIGACIONES CIENTIFICAS (CSIC)

a measure of co 2 Device and working method of diffusion coefficient in the process of diffusion from water phase to oil phase

The invention relates to a device for measuring the diffusion coefficient of CO2 in the process of diffusing CO2 from a water phase to an oil phase. The high-temperature and high-pressure visible diffusion device is vertically provided with a steel body partition, which divides the U-shaped high-temperature and high-pressure visible diffusion device into a left space and a right-side space connected at the bottom. The U-shaped high-temperature and high-pressure visible diffusion device The inner bottom is provided with a temperature measurement point, a pressure measurement point, and a lower outlet. The device also includes a pressure acquisition system, a back pressure gas tank, a heater, and a temperature control system. The principle of the invention is reliable, the operation is simple, and the influence caused by the difference in the density of oil, gas, and water is overcome. , the pressure drop method for measuring the gas-liquid two-phase diffusion coefficient is applied to the measurement of the gas diffusion coefficient between the water phase and the oil phase.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com