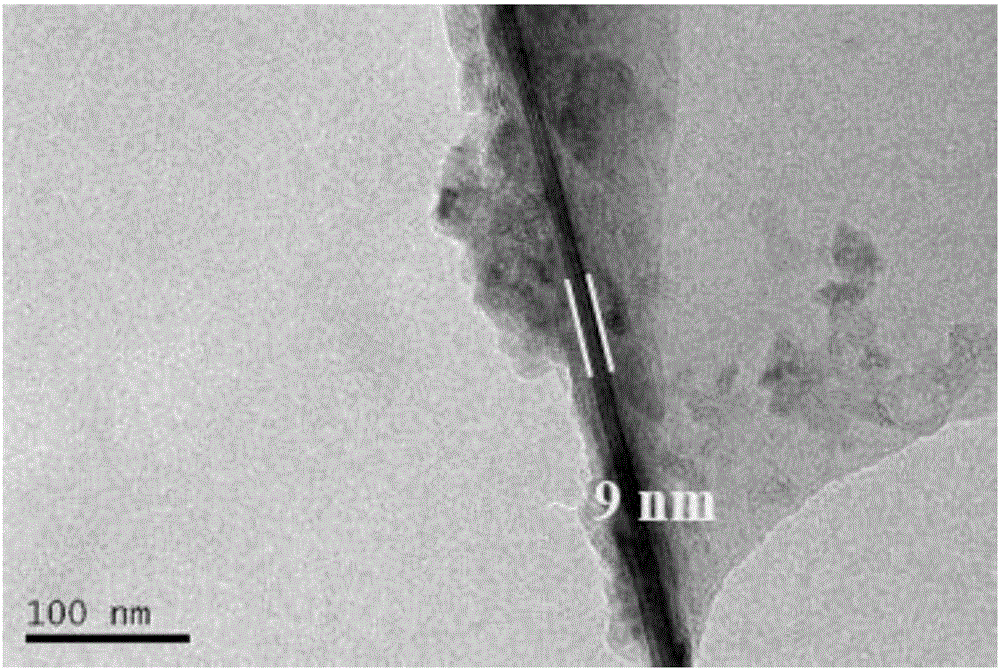

Method for preparing ultra-thin film through micro-phase diffusion control interface polymerization

A technology of diffusion control and interfacial polymerization, applied in the field of membrane separation, can solve problems such as poor treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) PEI is dissolved in water, and the concentration is 1.25wt%; TMC is dissolved in n-hexane, and the concentration is 0.15wt%, and it is evenly stirred for use;

[0038] (2) Fix the pretreated PS base film on the film carrier, and adjust the motor speed to be constant;

[0039] (3) PEI and TMC solutions are placed in pressure barrels respectively;

[0040] (4) Spray the PEI solution onto the surface of the porous support and let stand for 120s;

[0041] (5) Spray the TMC solution onto the membrane surface, let it stand for 120s, and react to form a polyamide separation layer;

[0042] (6) Remove the polyamide film that has been sprayed, put it in an oven for low-temperature drying for a certain period of time, take it out, soak it in 0.2g / L glutaraldehyde aqueous solution for 24 hours, wash it with a large amount of deionized water, and store it in deionized water. Deionized water for use.

[0043] The nanofiltration performance test of the above membrane was carri...

Embodiment 2

[0046] (1) PEI is dissolved in water, and the concentration is 1.25wt%; TMC is dissolved in n-hexane, and the concentration is 0.15wt%, and it is evenly stirred for use;

[0047](2) Fix the pretreated PS base film on the film carrier, and adjust the motor speed to be constant;

[0048] (3) PEI and TMC solutions are placed in pressure barrels respectively;

[0049] (4) Spray the PEI solution onto the surface of the porous support and let stand for 120s;

[0050] (5) The TMC solution is sprayed onto the membrane surface, and left to stand for 120s to form a polyamide separation layer;

[0051] (6) repeat (4) (5) step four times, can form five layers of polyamide separation layers on the basement membrane surface;

[0052] (7) Remove the polyamide film that has been sprayed, put it in an oven for low-temperature drying for a certain period of time, take it out, soak it in 0.2g / L glutaraldehyde aqueous solution for 24 hours, take it out, wash it with a large amount of deionized ...

Embodiment 3

[0056] (1) MPD is dissolved in water, and the concentration is 1.25wt%; TMC is dissolved in n-hexane, and the concentration is 0.15wt%, and it is evenly stirred for use;

[0057] (2) Fix the pretreated PS base film on the film carrier, and adjust the motor speed to be constant;

[0058] (3) MPD and TMC solutions are placed in pressure barrels respectively;

[0059] (4) Spray the MPD solution onto the surface of the porous support, and let it stand for 120s;

[0060] (5) The TMC solution is sprayed onto the membrane surface, and left to stand for 120s to form a polyamide separation layer;

[0061] (6) repeat (4) (5) step four times, can form five layers of polyamide separation layers on the basement membrane surface;

[0062] (7) Remove the polyamide film that has been sprayed, put it in an oven for low-temperature drying for a certain period of time, take it out, soak it in 0.2g / L glutaraldehyde aqueous solution for 24 hours, take it out, wash it with a large amount of deion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com