Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

190 results about "Nuclear grade" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nuclear grade means that the system is based on just the appearance of the nuclei of the cancer cells, rather than the appearance or structure of the cells as a whole. Nuclear characteristics used in the Fuhrman Grade particularly indicate how actively the cells are making protein.

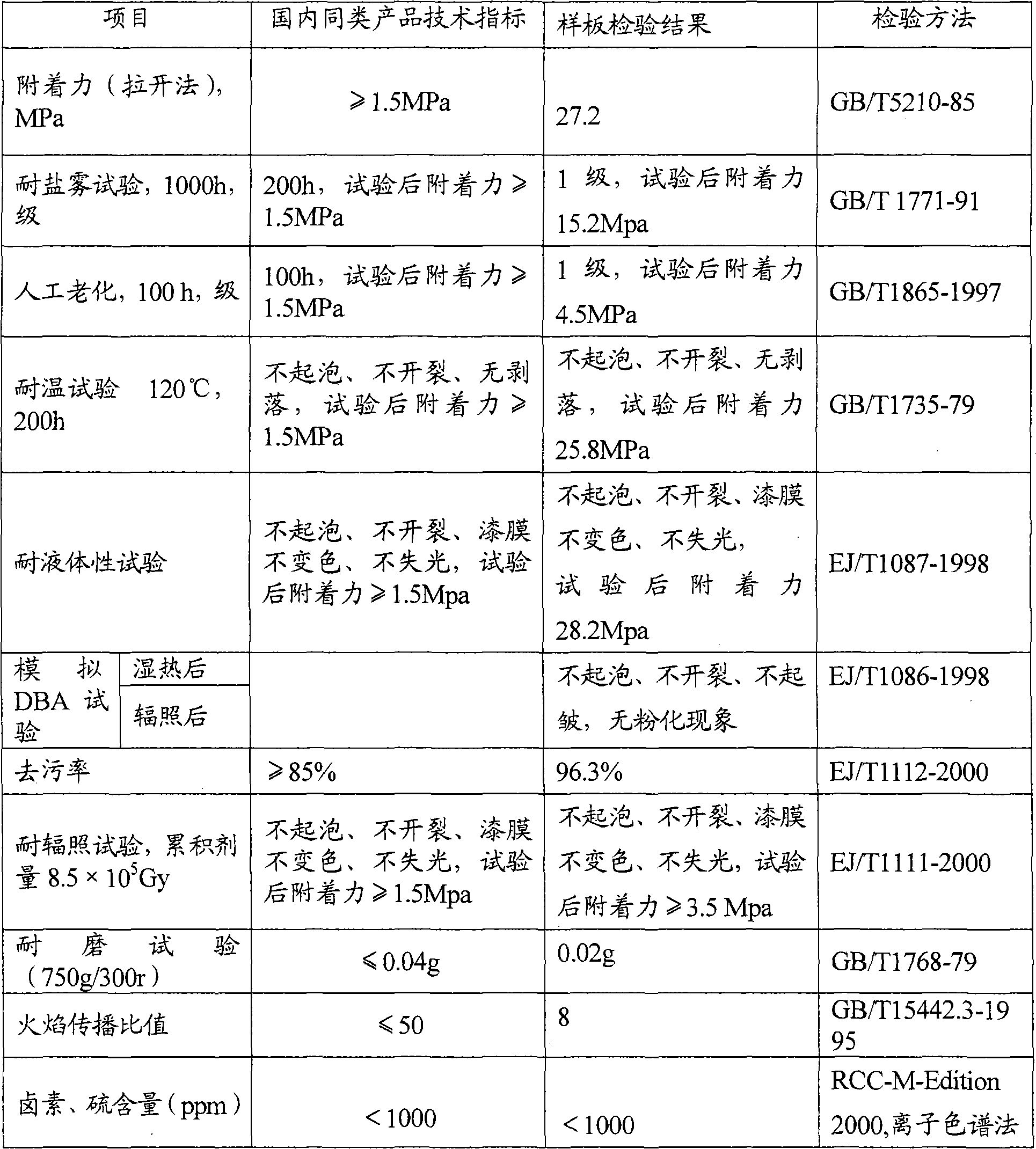

Epoxy protective coating system for high-power nuclear power station

ActiveCN101781508AImprove corrosion resistanceGood radiation protectionAnti-corrosive paintsShieldingNuclear gradeNuclear power

The invention relates to an epoxy protective coating system for a high-power nuclear power station. Priming coat comprises a component A1 and a component B with the weight ratio of 4-6, and finishing coat comprises a component A2 and the component B with the weight ratio of 3-5:1.. The component A1 comprises 20 to 50% of epoxy resin, 10 to 40% of anti-corrosion paint, 10 to 25% of radiation-resistant stuffing, 0.1 to 3% of addition agent and the balance of menstruum by weight percent. The component A2 comprises 20 to 50% of the epoxy resin, 10 to 40% of the anti-corrosion paint, 5 to 20% of the radiation-resistant stuffing, 0.1 to 3% of the addition agent and the balance of the menstruum by weight percent. The component B is a radiation-resistant epoxy-amine adduct curing agent, and is synthesized by 10 to 30% of liquid epoxy resin, 30 to 70% of polyamine with primary amine groups and 20 to 60% of the menstruum. The corrosion resistance and radiation resistance can meet the requirements of nuclear grade paint and can pass simulation DBA tests when the coating system is used for a high-power nuclear power station.

Owner:CHINA NAT OFFSHORE OIL CORP +2

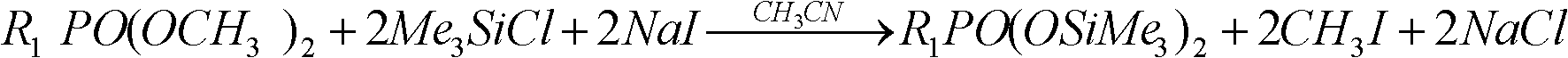

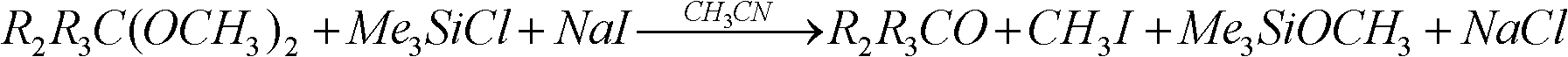

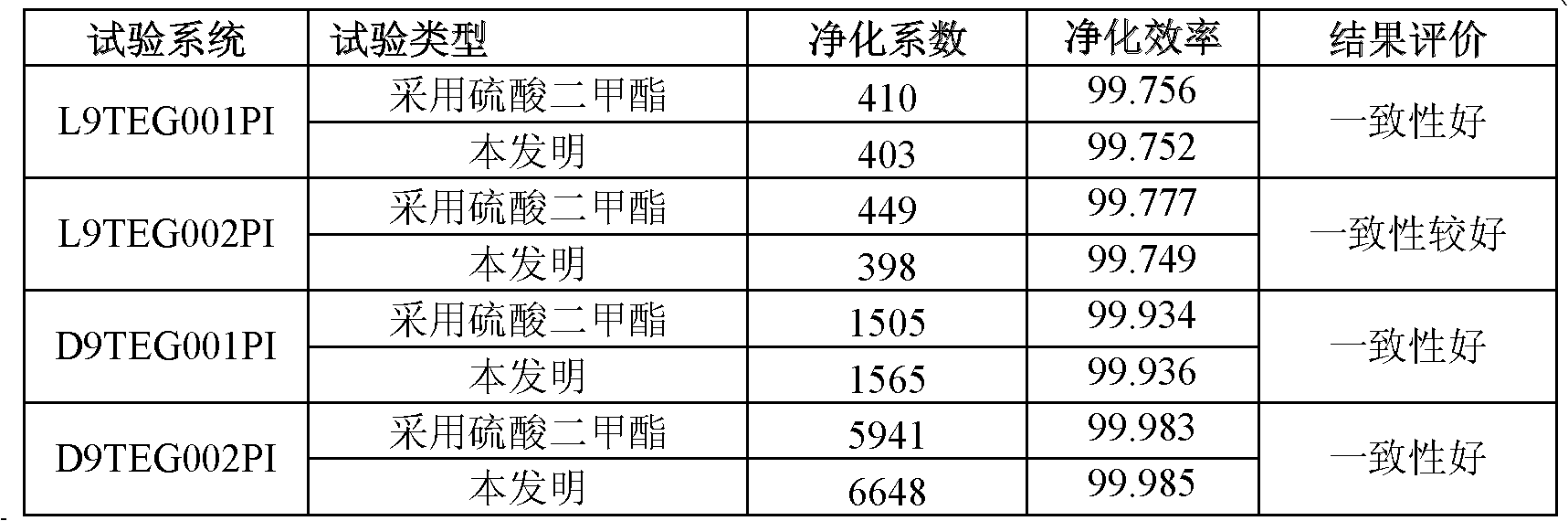

Preparation method of preparation for radioactive gas purifying capability test in nuclear power plant

The invention discloses a preparation method of a preparation for a radioactive gas purifying capability test in a nuclear power plant, which comprises the following steps of: mixing by using a methyl phosphate compound or a dimethylacetal compound, acetonitrile, trimethylchlorosilane and a radioactive iodine source as raw materials, and then reacting for 10-40 minutes at the temperature of 20-50DEG C to obtain the preparation for the radioactive gas purifying capability test in the nuclear power plant. The invention provides the preparation method of the preparation for the radioactive gas purifying capability test in the nuclear power plant, wherein reactants are not virulent, the reaction can be carried out at high speed and high efficiency without high temperature, and other productsexcept methyl iodide have no harm or small toxicity to nuclear-grade impregnated active carbon in an iodine filter.

Owner:CHINA GENERAL NUCLEAR POWER CORP +2

Manufacture method of nuclear grade zirconium-niobium alloy cast ingot

The invention relates to the field of a manufacture method of a nuclear grade zirconium-niobium alloy cast ingot, adopting the following technical scheme: firstly, forming a pure niobium bar and sponge zirconium into zirconium-niobium master alloy scraps by the steps of pressing an electrode block, firstly smelting, secondly smelting and thirdly smelting, and the like; using the zirconium-niobium master alloy scraps and the sponge zirconium to form the zirconium-niobium alloy cast ingot by the steps of materials mixing, materials distributing, electrodes manufacturing and vacuum self-consumable electric arc smelting; and detecting that the zirconium-niobium alloy cast ingot has no defects such as components segregation and niobium impurity, and the like, to complete the manufacture of the nuclear grade zirconium-niobium alloy cast ingot. The nuclear grade zirconium-niobium alloy cast ingot has even components, has no metallurgical defects such as niobium impurity, and the like, has high raw materials yield, saves the production cost to a certain degree, and voids the waste.

Owner:国核宝钛锆业股份公司 +1

Method for smelting ultra-pure austenite nuclear grade stainless steel

The invention relates to the field of metal smelting, in particular to a method for smelting ultra-pure austenite nuclear grade stainless steel. The method is characterized by comprising the following steps: selecting high-quality raw materials, performing purification treatment, washing a furnace, and forging. The method has the advantages that the produced stainless steel meets the requirementsof RCC-M, 22Cn18-10 and AISI 304L, and also meets the requirement of OCT 04X18H10 standard and the requirement of GB / T1220-2007 00Cr19Ni10 standard, non-metallic inclusions are far lower than the standards of GB00Cr19Ni10, RCC-MZ2Cn18-10, AISI 304L, OCT 04X18H10, and the H and O gas content is low.

Owner:上海一郎合金材料有限公司

Method for producing enriched boric-10 acid from trifluoride-anisole complex and application thereof

The invention relates to a method for producing enriched boric-10 acid from a trifluoride-anisole complex and application thereof. The method comprises the following steps: reacting a boron trifluoride-anisole complex with excessive sodium methoxide methanol solution, operating in an ice bath for 5-25 minutes, carrying out thermostatic water bath, reacting for 40-60 hours while keeping the reaction temperature within the range of 40-60 DEG C, stopping heating, and carrying out centrifugal stratification; fractionating the centrifugated supernatant: heating the mixture, starting to collect the fraction when the temperature rises to 50 DEG C, and stopping collecting the fraction when the temperature rises to 60 DEG C; and carrying out salting-out stratification on the collected fraction, mixing with deionized water, carrying out vacuum filtration on the mixture to obtain a solid, and drying to obtain the boric acid. The enriched boric-10 acid is used in the field of production of 10B-isotope-enriched downstream boric acid products, nuclear-grade boric acids and other enriched boric-10 acids by an anisole chemical exchange fractionation process. The production raw materials are from a closed system; and the invention has the impurity removal link, so the product purity is higher, thereby lowering the difficulty of subsequent boric acid production.

Owner:TIANJIN UNIV

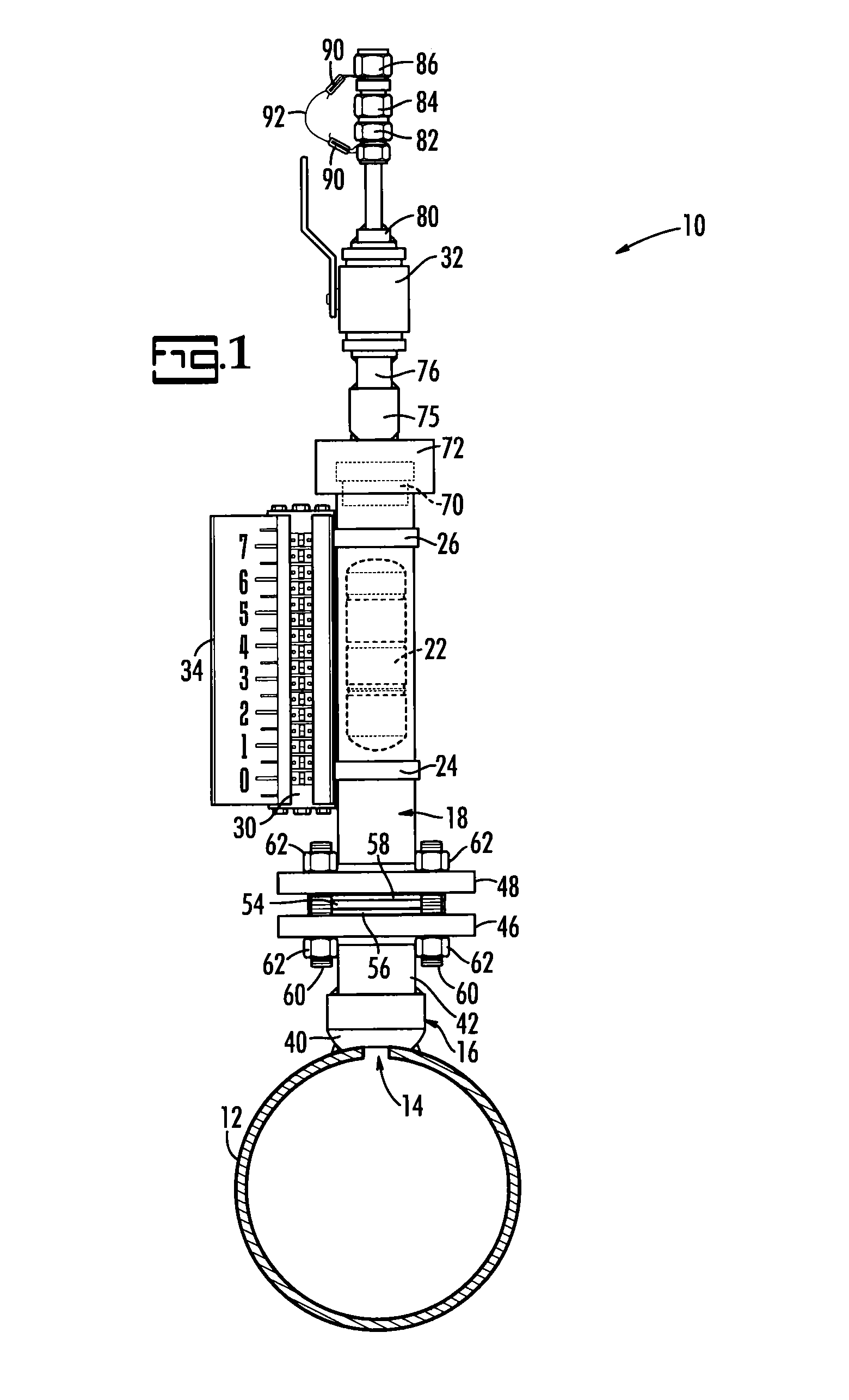

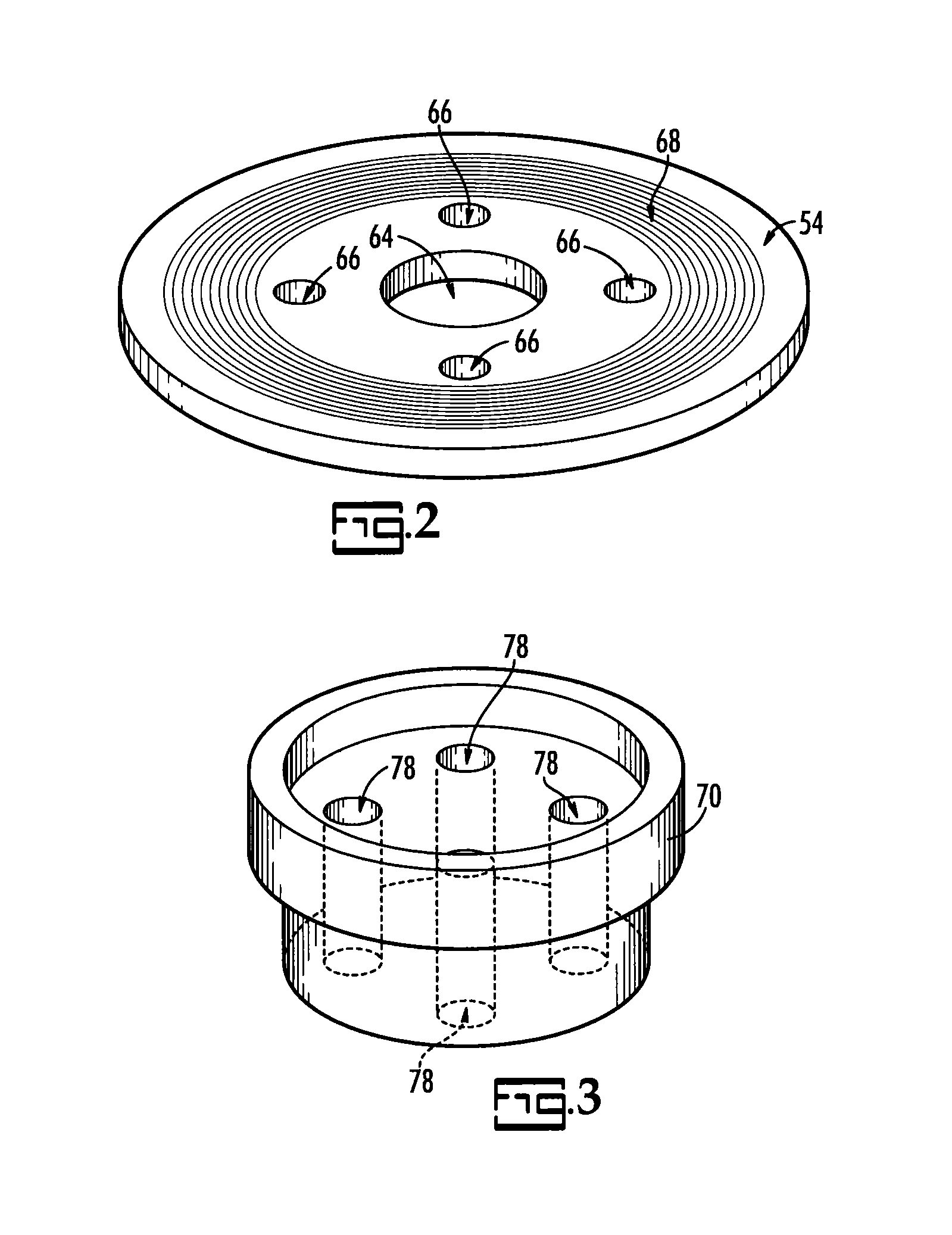

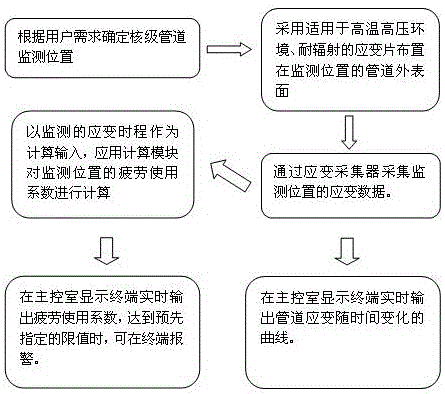

Nuclear Grade Air Accumulation, Indication and Venting Device

A device for accumulating, isolating, indicating and venting accumulated gas in a fluid system pipe includes a main pipe fitting affixed to a system pipe in which a hole has been drilled. A stand pipe attached to the pipe fitting houses a magnetic float. A magnetic-float level indicator exterior to the pipe and responsive to the magnetic float indicates the magnetic float's level. A valve attached to the stand pipe above the magnetic float allows controlled ventilation of the gas in the standpipe and thus in the piping system. Gas from the system pipe accumulates in the standpipe, removed from the primary fluid flow path of the system pipe. In the standpipe, as the liquid / gas interface drops, the float drops to a pre-determined level, at which point the user vents the gas from the piping system, causing the magnetic float to rise to a level indicating that gas is again at acceptable levels in the piping system.

Owner:NUCCORP

Nuclear-grade dye check penetrant and preparation method thereof

InactiveCN101915766AHarm reductionSuitable for testingOptically investigating flaws/contaminationNuclear gradeSolvent

The invention provides a nuclear-grade dye check penetrant which comprises the following components in parts by weight: 45-70 parts of penetration solvent, 5-22 parts of cosolvent, 7-25 parts of other regents, 5-15 parts of surfactant and 1.5-5 parts of dye. The invention has the following benefits: the penetrant is made from raw materials which are free from three elements of fluorine, chlorine and sulfur; and all the raw materials are purified so that the contents of fluorine, chlorine and sulfur which are brought in the form of impurities are not more than 100ppm. The total content of fluorine and chlorine in the finished product is not more than 100ppm and the sulfur content is not more than 100ppm, and thus, the harm of the penetrant to workpiece is minimized and the penetrant is especially suitable for equipment detection in nuclear industry. In addition, the penetrant has the advantages of high sensitivity and high flashing point, can detect a flaw of the opening width of 0.4 mu m and can be washed with both organic solvents and deionized water.

Owner:SHANGHAI CHENGYOU INDAL GROUP +2

Digital volume acquisition circuit with dynamic fault diagnosis ability

ActiveCN107065716ACoverage failure rateReal-time uploadProgramme controlElectric signal transmission systemsNuclear gradeElectricity

The present invention provides a digital volume acquisition circuit with dynamic fault diagnosis ability. A dynamic read-back signal is used to achieve more complete channel self diagnosis. The circuit is applied to a nuclear grade DCS system and comprises an opto-coupler signal acquisition circuit and an optical relay dynamic diagnosis circuit. The opto-coupler signal acquisition circuit is applied to a dual FPGA architecture system, one channel is connected to a processing FPGA, and the other channel is connected to a diagnosis FPGA. According to the fault diagnosis of the invention, the judgment is carried out according to a condition whether a read square wave can be received, after the FPGA reads a condition that a channel is in a power or loss of power state from an optocoupler output end, a dynamic diagnosis test is carried out, corresponding high and low level pulses can be read, and passed diagnosis is judged. According to the circuit of the invention, whether the digital volume acquisition circuit collects a fault can be judged, and state information can be uploaded in real time.

Owner:CHINA NUCLEAR CONTROL SYST ENG

Nuclear grade ultrasonic inspection couplant and preparation method thereof

ActiveCN101942165AHarm reductionSuitable for testingMaterial analysis using sonic/ultrasonic/infrasonic wavesNuclear gradeSulfur

The invention relates to nuclear grade ultrasonic inspection couplant, which is characterized by comprising the following components in parts by weight: 50-90 parts of deionized water, 0.3-5 parts of gel matrix, 0.3-8 parts of pH value modifier, 5-30 parts of moisturizing agent, 1-10 parts of anti-rusting agent and 0.1-11 parts of antibacterial preservative. The invention also provides a preparation method of the nuclear grade ultrasonic inspection couplant. The nuclear grade ultrasonic inspection couplant has low content of fluorine, chlorine and sulfur and has the advantages of having no toxicity or harm, pure and transparent appearance, no bubble, adjustable viscosity, good anti-rust capability, stable storage, good sound transparent performance and the like, and is easy to clear.

Owner:苏州新美达探伤器材有限公司 +2

T3 test loop of reactor protection system in nuclear power station and optimization method thereof

ActiveCN103794255AImprove reliabilityReduce misuseNuclear energy generationNuclear monitoringNuclear gradeFailure rate

The application discloses a T3 test loop of a reactor protection system in a nuclear power station and an optimization method thereof. In the optimization method, the T3 test loop employs parallel resistance to check current loop, and comprises a plurality of test switches, wherein at least one test switch is corresponding to a multiple paths of devices, and the at least one test switch has at least two pairs of contact in parallel connection to form parallel contacts. The application has the beneficial effects that: at least two pairs of contact in the test switches are in parallel output to drive the test loop and reduce the risk of maloperation caused by high failure rate of contacts; in one embodiment, nuclear grade relay nodes are connected into the test loop to further improve the reliability of the equipment; in another embodiment, self-locking of test signal is added for interlocking test signal in the case of switch contact failure to reduce the maloperation; and in another embodiment, additional alarm signal sent to a main control enables the normal operation and monitoring on the loop, in order to reduce the risk of refusal-operation caused by scheme optimization.

Owner:CHINA GENERAL NUCLEAR POWER CORP +1

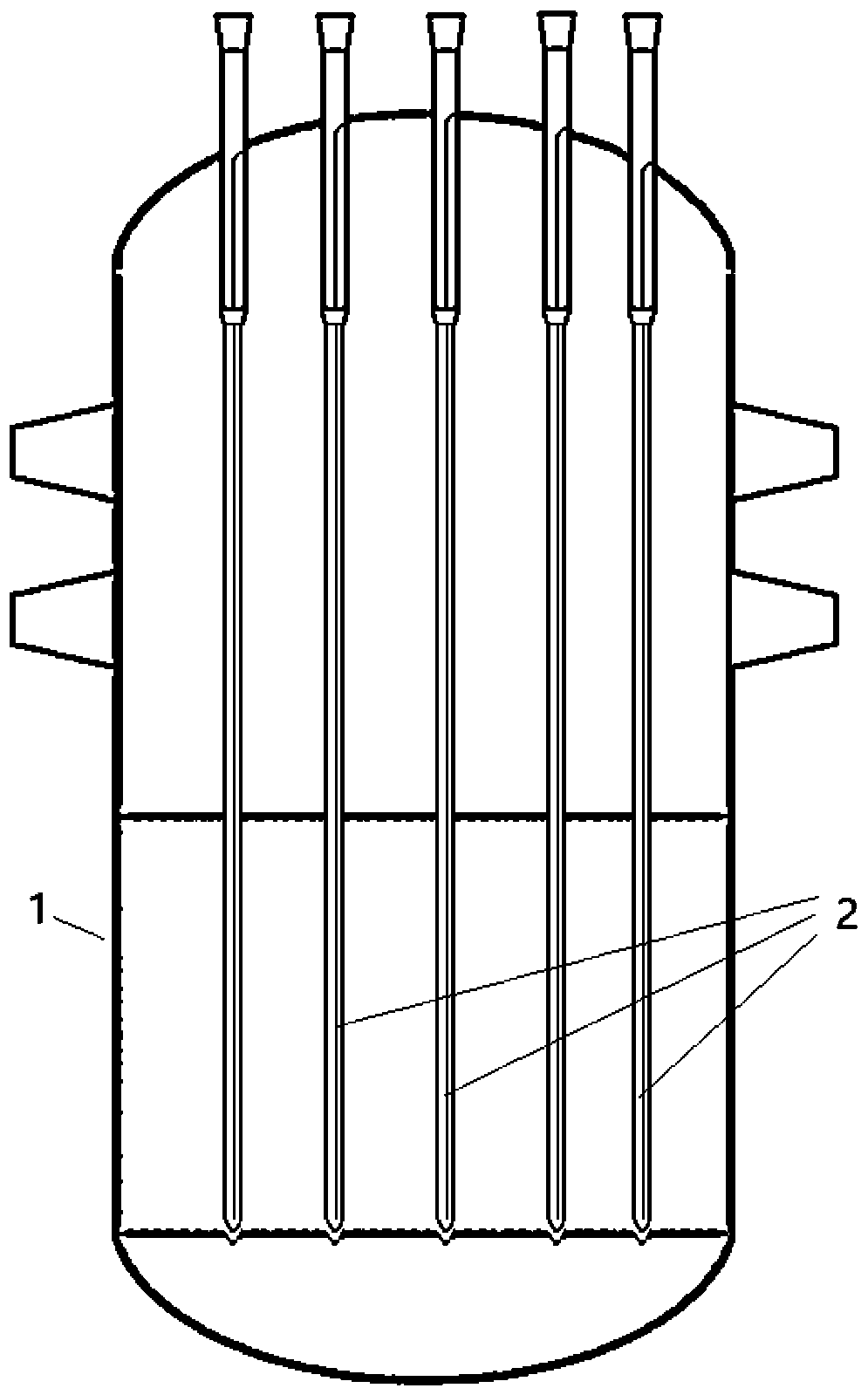

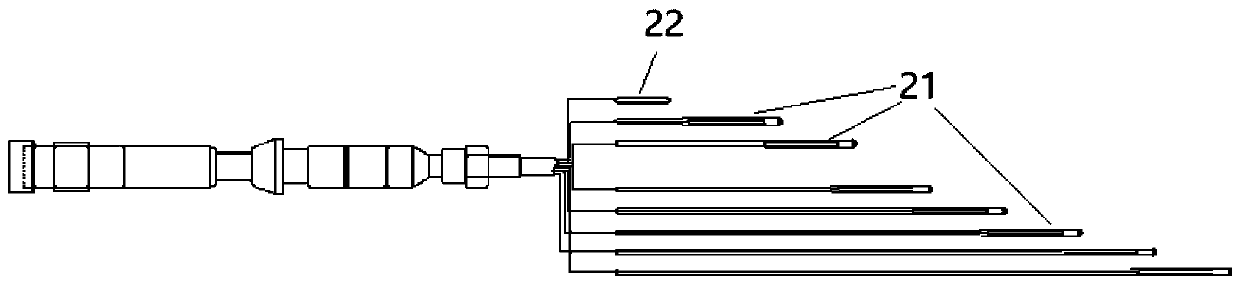

Method of adopting strain sensor to monitor fatigue of nuclear grade pipelines

InactiveCN106198218AIntegrity is not affectedReasonable correction of fatigue service factorMaterial strength using tensile/compressive forcesNuclear gradeEnvironmental effect

The invention discloses a method of adopting a strain sensor to monitor the fatigue of nuclear grade pipelines. At first, a strain sensor (a strain sheet or a strain meter) is used to monitor the strain of the external surface of a nuclear grade pipeline; then according to the external surface strain of the nuclear grade pipeline, the properties of the material of the nuclear grade pipeline, and information of an existed monitoring device of the nuclear power plant, the strain of the internal wall of the nuclear grade pipeline can be determined; then alternation amplitude in strain circulations and corresponding circulation times can be determined; according to a preset epsilon-N curve, the fatigue use coefficient is calculated; then according to the pipeline strain history, the reasonable environmental influence coefficient (Fen) is determined, the fatigue use coefficient is corrected; finally, the fatigue use coefficient is output on the display terminal of the master-control room, and an accumulated fatigue use coefficient curve, which changes along the time, can be outputted and can be used to evaluate the change trend of accumulated fatigue use coefficient of a monitored position.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Preparation method of nuclear-grade zirconium alloy cast ingot

ActiveCN107686902AExcellent compositional uniformity controlImprove processing economyIncreasing energy efficiencyNuclear gradeIngot

The invention belongs to the technical field of zirconium alloy preparation and particularly relates to a preparation method of a nuclear-grade zirconium alloy cast ingot. The preparation method comprises the following steps that (1) the alloy component and the total mass of the finished cast ingot are determined; (2) an intermediate alloy and an alloy cladding are prepared; (3) material mixing isconducted; (4) electrode pressing is conducted; (5) N electrodes are welded into one electrode; (6) vacuum self-consuming arc melting is conducted; and (7) surface machining and dead head cutting areconducted. According to a technology suitable for industrial scale production and used for preparation of the Zr-Sn-Nb-Fe / Cr zirconium alloy cast ingot, the technological economical efficiency can beobviously improved, meanwhile component evenness control over the cast ingot is superior to that of a traditional technology, and the preparation method can be used for industrial scale production ofthe nuclear-grade zirconium alloy cast ingot accordingly.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Nuclear class cable sheath material

ActiveCN103524898ANo peelingMeet the mechanical propertiesRubber insulatorsInsulated cablesNuclear gradeAntioxidant

A nuclear class cable sheath material comprises the following components by weight: 30-50 parts of ethylene-vinyl acetate copolymer; 50-70 parts of ethylene propylene rubber; 5-10 parts of silicone rubber; 70-90 parts of magnesium hydroxide; 5-10 parts of boron nitride and 4-12 parts of an antioxidant. After the nuclear class cable sheath material is used for 60 years at 90 DEG C, and a radiation dose of 2400KGy is applied, a sheath layer may not peel, and the nuclear class cable sheath material is high in flame retardant efficiency, low in adding amount and uniform in dispersion, may not agglomerate, and meets material mechanical properties, meanwhile can get through a single vertical combustion (B-type bundling) test.

Owner:CHANGYUAN GRP

Pressurized water reactor nuclear power plant nuclear-grade digital instrument control system logical function test device

InactiveCN106569477AIncrease labor costIncrease time costProgramme controlElectric testing/monitoringNuclear gradeNuclear plant

The invention belongs to the nuclear process control system reliability detection field and relates to a pressurized water reactor nuclear power plant nuclear-grade digital instrument control system logical function test device. The pressurized water reactor nuclear power plant nuclear-grade digital instrument control system logical function test device includes a host computer, a switch, a printer and a network connection medium. According to the device, a network communication mode-based device structure is adopted. Before a logic function test is performed, a KCS is connected into the special test device, after the test is completed, the communication connection of the special test device and the KCS is cut off; a test network and a network which is adopted under a normal operation condition are relatively independent; and an independent communication card is adopted, so that the safety of the KCS can be ensured.

Owner:CNNC FUJIAN FUQING NUCLEAR POWER

Two step dry UO2 production process utilizing a positive sealing valve means between steps

ActiveUS7824640B1Inhibition amountHigh densityTransuranic element compoundsNuclear energy generationTemperature controlNuclear grade

The present invention provides a two-step process for producing nuclear grade, active uranium dioxide (UO2) powder in which the first step comprises reacting uranium hexafluoride (UF6) with steam in a flame reactor to yield uranyl fluoride (UO2F2); and the second step comprises removing fluoride and reducing UO2F2 to uranium dioxide (UO2) in a kiln under a steam / hydrogen atmosphere. The two-step process, each step separated by a positive sealed valve means to prevent gas, particularly H2 flow back, tightly controls the exothermicity of the reaction, which allows for a very tight temperature control which controls the growth of the particles and results in UO2 powder that is active and of consistent morphology.

Owner:WESTINGHOUSE ELECTRIC CORP

Nuclear-grade dual-phase stainless steel welding rod for CAP1400 master device

ActiveCN105537798AUniform coverageSimple welding processWelding/cutting media/materialsSoldering mediaNuclear gradeManganese

The invention discloses a nuclear-grade dual-phase stainless steel welding rod used for welding a nuclear power plant CAP1400 master device. The nuclear-grade dual-phase stainless steel welding rod comprises a low-carbon low-sulfur-phosphorus welding core and a low-hydrogen sodium coating. The low-carbon low-sulfur-phosphorus welding core comprises, by weight, 0-0.015% of C, 1.20%-2.00% of Mn, 0-0.10% of Si, 22.5%-23.5% of Cr, 8.50%-9.50% of Ni, 0-0.015% of Co, 0-0.010% of S, 0-0.015% of P and the balance Fe and impurities. The low-hydrogen sodium coating comprises, by weight, 10%-20% of sodium cryolite powder, 10%-20% of marble powder, 35%-55% of fluorite powder, 0-1% of ferrotitanium powder, 0.5%-1.5% of alginate salt, 1.0%-3.0% of titanium dioxide, 0.3%-0.8% of soda ash, 0-2% of electrolytic manganese, 8%-20% of rutile, 3%-7% of ferrosilicon, 0.5%-1% of ferromolybdenum and sodium silicate binders. According to the nuclear-grade dual-phase stainless steel welding rod used for welding the nuclear power plant CAP1400 master device, electric arcs are stable, a formed welding seam is beautiful, operation is easy, and the deslagging effect and the all-position welding effect are good; deposited metal has good tensile performance and low temperature impact performance.

Owner:SHANGHAI ATLANTIC WELDING CONSUMABLES

Method of calculating strength of nuclear grade pipeline support

ActiveCN106599478AQuick calculationFast batch applicationGeometric CADDesign optimisation/simulationNuclear gradeMechanical models

Owner:CHINA NUCLEAR POWER DESIGN COMPANY +2

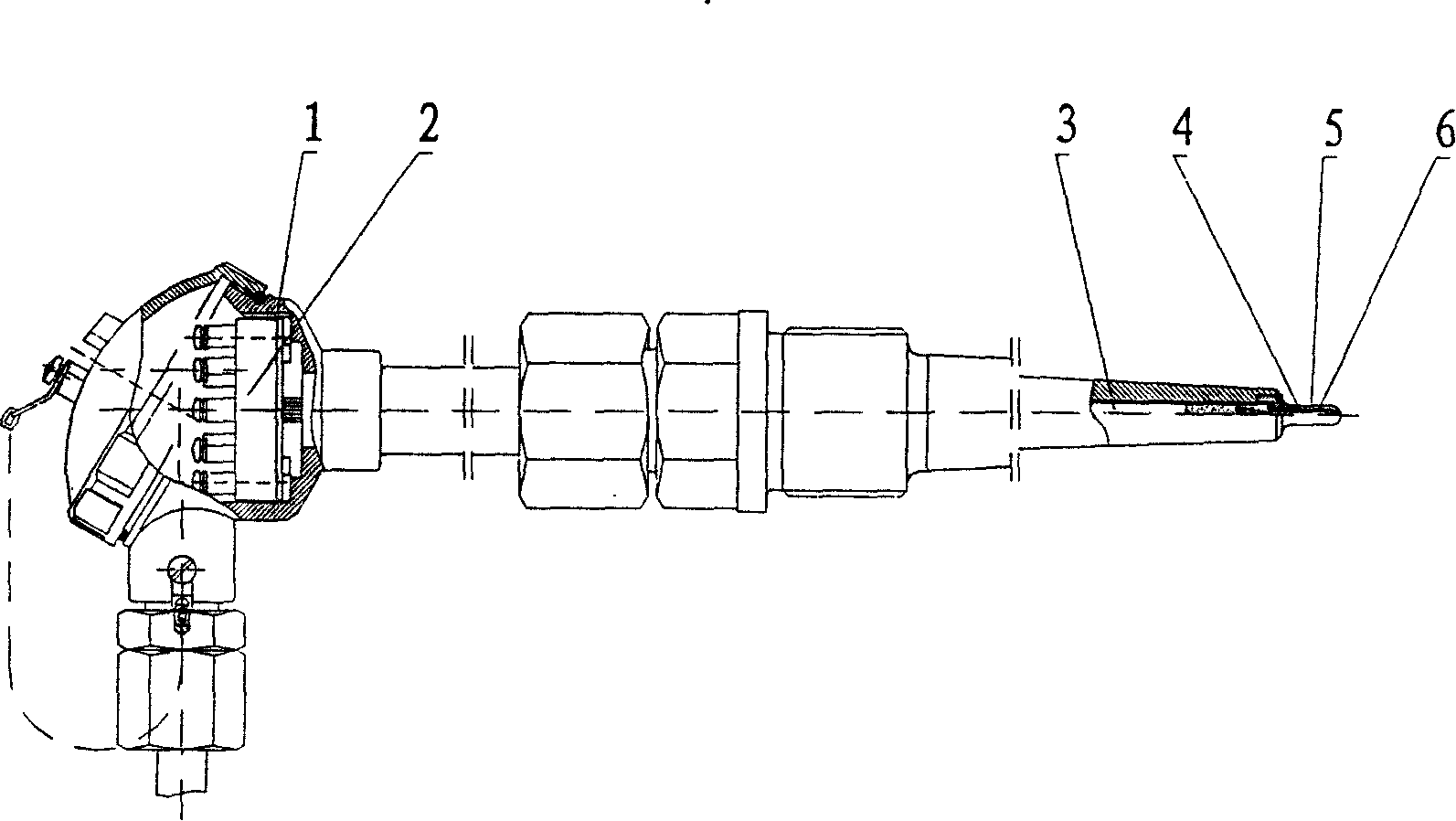

Nuclear reactor core neutron and temperature detection device

PendingCN107767974AExtended service lifeSmall sensitivity deviationNuclear energy generationNuclear monitoringNuclear reactor coreNuclear grade

Relating to the technical field of nuclear power, the invention provides a nuclear reactor core neutron and temperature detection device, and solves the technical problems of reducing the sensitivitydeviation and improving the service life. The device comprises a plurality of reactor core detection components installed in a pressure vessel, the reactor core detection components are evenly laid along the radial direction of the pressure vessel, and each reactor core detection component includes at least one armored nuclear grade thermocouple thermometer for monitoring the reactor core fuel assembly outlet coolant temperature and multiple vanadium self-powered neutron detectors for monitoring the nuclear reactor core neutron fluence rate, also the vanadium emitters of the vanadium self-powered neutron detectors have an equal length, and the vanadium self-powered neutron detectors are laid from the bottom up in order along the axial direction of the pressure vessel. The device provided by the invention is suitable for a pressurized water reactor nuclear power station reactor core instrument system.

Owner:STATE NUCLEAR POWER AUTOMATION SYST ENGCO

Nuclear-grade large equipment damper

InactiveCN102345700AEasy to replaceReasonable designSpringsLiquid based dampersNuclear gradeWorking environment

The invention belongs to the technical field of hydraulic shock-resistant supporting devices, and relates to a nuclear-grade large equipment damper. The damper solves the technical problems that the prior art is unreasonable in design and the like. A piston rod passes through a damping cylinder; a piston positioned in the damping cylinder is arranged on the piston rod; valve seats are respectively arranged at two ends of the damping cylinder; the two valve seats are respectively communicated with oil through holes at two ends of the damping cylinder; the two oil through holes are respectively communicated with a left chamber and a right chamber of the damping cylinder; valve cores, the outer ends of which are conical, are respectively arranged in the valve seats; throttling structures distributed symmetrically are arranged on the valve cores; springs for pressing the valve cores in the oil through holes are arranged between the valve cores and the valve seats; a connecting pipe is arranged between the two valve seats; an auxiliary cylinder is arranged at the outer side of the damping cylinder; and the auxiliary cylinder is connected with one of the valve seats. The damper has the advantages of reasonability in design, simple structure, high mechanical strength, stable working performance and capability of working normally for a long term even if the working environment is severe. The damper has good radiation resistance, and is easy in maintenance and convenient for changing a hydraulic medium.

Owner:常州格林电力机械制造有限公司

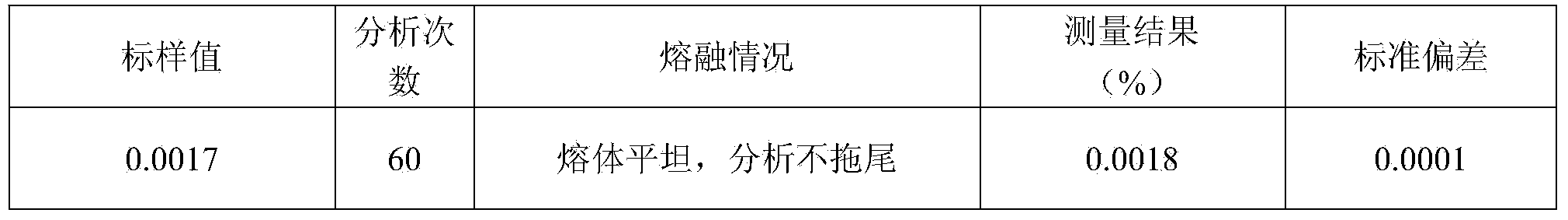

Inductive coupling plasma atomic emission spectrometry for determining elements in nuclear-grade zirconium alloy

InactiveCN104568916ASimplify detection stepsPreparing sample for investigationAnalysis by thermal excitationNuclear gradeRelative standard deviation

The invention discloses an inductive coupling plasma atomic emission spectrometry for determining elements in a nuclear-grade zirconium alloy. The inductive coupling plasma atomic emission spectrometry is used for determining 4 types of macroelements and 13 types of trace elements in the nuclear-grade zirconium alloy. The macroelements including tin, niobium, iron and chromium, and the trace elements including aluminum, cobalt, copper, molybdenum, magnesium, manganese, nickel, lead, silicon, tantalum, titanium, vanadium and tungsten in the nuclear-grade zirconium alloy are successfully determined by carrying out base body match on high-purity sponge zirconium and main alloy elements and selecting a suitable spectral line as an analysis line of detected elements. The determination of tin, iron, chromium and nickel in a 360b zirconium alloy in NIST is carried out and determination results are the same as standard values of a standard substance certificate. The nuclear-grade zirconium alloy is subjected to a marking recovery test; and a result shows that the recovery rates of niobium, cobalt, copper, molybdenum, magnesium, manganese, silicon, titanium, vanadium and tungsten are 92%-108% except that the recovery rate of tantalum is low and the recovery rates of aluminum and lead are high. According to the method, the determination result is stable; and the relative standard deviations (RSD) of the determination results of 3 days are lower than 6% and can meet the requirements of Westinghouse certification standards (RSD is less than 10%).

Owner:QINGDAO TIANHENG MACHINERY

Method and device for vacuum impregnation and vacuum predrying of nuclear grade active carbon

ActiveCN103127906AGuaranteed uniformityAdd sprinkler systemDrying using combination processesOther chemical processesVacuum pumpingActivated carbon

The invention relates to a nuclear grade active carbon production device and especially relates to a method and a device for vacuum impregnation and vacuum predrying of nuclear grade active carbon. The method comprises the following steps of putting active carbon into a rotatablely rolling vacuum tank, carrying out atomization and spraying of an impregnation liquid introduced into the vacuum tank on the surface of active carbon rolling ceaselessly by a spraying system, after active carbon impregnation, increasing the pressure in the vacuum tank to ordinary pressure, carrying out vacuum predrying, simultaneously opening a vacuum pump and an oil electric heater, and carrying out vacuum-pumping and heating on the tank body with continuous rotation of the vacuum tank so that active carbon heating is uniform and low-temperature low-pressure evaporation is realized. The device improves a double-cone vacuum rotation tank, utilizes the spraying system to atomize an impregnation agent under pressing conditions so that the atomized impregnation agent contacts with active carbon rolling in vacuum and is fast bound to the active carbon. The device has dual uses, realizes vacuum impregnation and vacuum predrying of active carbon by one step, and has effects of time, manpower and power saving.

Owner:CHINA INST FOR RADIATION PROTECTION

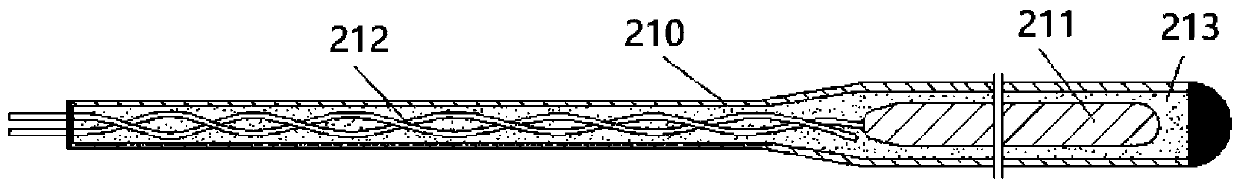

Nuclear grade platinum resistance thermometer and its method for reducing thermal response time

InactiveCN101173873AWill not stickShort thermal response timeThermometer detailsThermometers using electric/magnetic elementsPlatinum resistanceNuclear grade

The invention relates to a nuclear-grade platinum resistance thermometer and the method for reducing thermal response time with the invention, comprising a terminal box, a wiring board arranged in the terminal box, and a protective sleeve with a built-in platinum resistance element, wherein, the temperature sensing surface of the platinum resistance element is clung tightly to the inner surface of the protective sleeve, and no MgO powder is filled between the platinum resistance element and the protective sleeve; the outer surface of the protective sleeve is clung tightly to the inner surface of an external protective tube; the platinum resistance element is welded with an armored leading wire; MgO powder is filled in the armored leading wire; a metal coat is plated on the outer surface of the protective sleeve. The invention has the advantages that due to the temperature sensing surface of the platinum resistance element clung tightly to the protective sleeve and the protective sleeve clung tightly to the external protective tube, the heat conductivity of the thermometer is improved; the thermal response time is reduced; the earthquake resistant requirement for nuclear power station is satisfied; due to wear-resistant, heat-resistant, and oxidation-resistant special metal coating on the surface of the protecting sleeve, the protecting sleeve does not stick to the protective tube due to oxidation corrosion.

Owner:NO 3 AUTOMATION INSTR & METERS FACTORY SHANGHAI AUTOMATION INSTR & METERS CO LTD

Two step uo2 production process

This present invention provides a two-step process for producing nuclear grade, active uranium dioxide (UO2)powder in which the first step comprises reacting uranium hexafluoride (UF6) with steam in, for example, an integrated dry route (IDR)-type kiln or a flame reactor to yield uranyl fluoride (UO2F2); and the second step comprises removing fluoride and reducing UO2F2 to uranium dioxide (UO2) in a second kiln under a steam / hydrogen atmosphere. The two-step process tightly controls the exothermicity of the reaction, which allows for a very tight temperature control which controls the growth of the particles and results in UO2 powder that is active.

Owner:WESTINGHOUSE ELECTRIC CORP

Nuclear-grade ion-exchange resin-based composite material and preparation method thereof

ActiveCN106824272AImprove efficiencyGood recycling performanceCation exchanger materialsOrganic-compounds/hydrides/coordination-complexes catalystsNuclear gradeIon exchange

The invention discloses a nuclear-grade ion-exchange resin-based composite material and a preparation method thereof. The composite material is prepared by the steps: firstly reducing a platinum precursor into polymer-packaged nano platinum particles by using a reducing agent in existence of a polymer packaging agent; adding a silicon source and an aluminum source and then carrying out hydrothermal reaction employing a polymer as a structure-directing agent to obtain a platinum-silicon aluminum molecular sieve core-shell structure compound, wherein the inner core is nano platinum particles and the shell layer is a silicon-aluminum molecular sieve; and finally assembling the platinum-silicon aluminum molecular sieve core-shell structure compound to nuclear-grade ion-exchange resin to obtain the nuclear-grade ion-exchange resin-based composite material. The composite material has relatively high ion exchange property, relatively high catalytic removal efficiency, relatively high environment durability and extremely high recycling property, and has a good application prospect in the field of nuclear industry circulating water treatment.

Owner:NANJING INST OF TECH

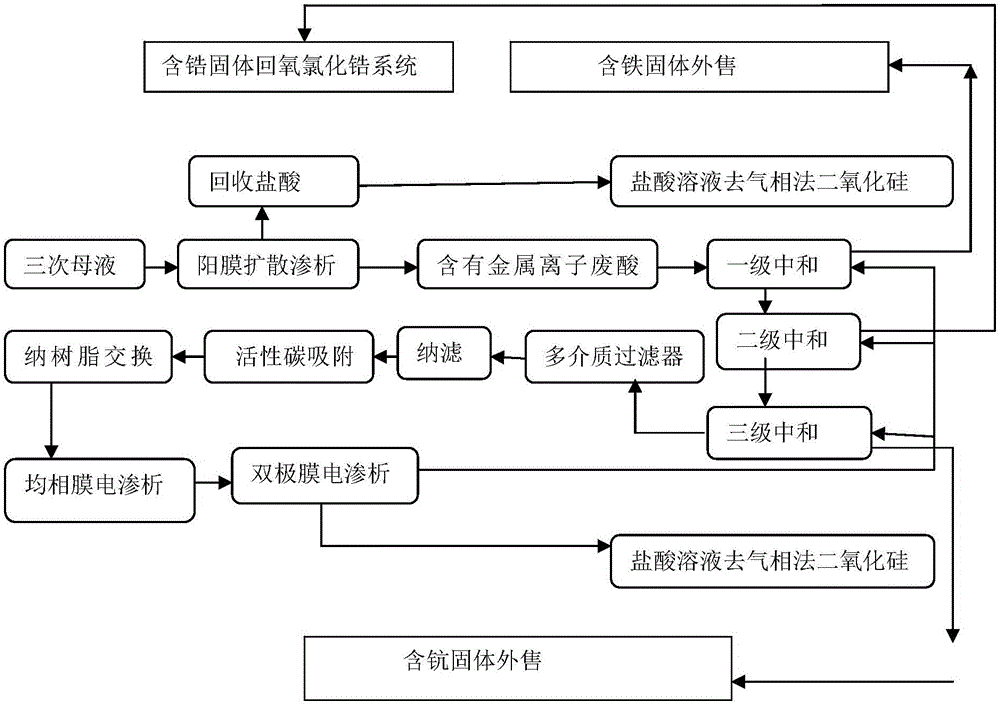

Method for preparing nuclear-grade sponge zirconium and nuclear-grade sponge hafnium

InactiveCN106435221AAchieve recyclingSolve difficult environmental problemsSilicaProcess efficiency improvementNuclear gradeElectrolysis

The invention relates to nuclear-grade sponge zirconium, in particular to a method for preparing nuclear-grade sponge zirconium and nuclear-grade sponge hafnium. Chlorine generated by hydrochloric acid electrolysis is used for producing zirconium tetrachloride and zirconium oxychloride by a zircon sand boiling chlorination method; zirconium and hafnium are seperated to obtain zirconium oxide and hafnium oxide through a TBP-Hcl-HNO3 extraction method; and then, the chlorination and the purification are performed to obtain the nuclear-grade sponge zirconium and the nuclear-grade sponge hafnium. The method radically solves the environmental protecting environment difficultly treated in the zirconium oxychloride industry and the nuclear-grade sponge zirconium industry, and realizes complete industry chain circulation for combined production of the zirconium oxychloride industry, the gas-phase method silicon dioxide industry, the nuclear-grade sponge zirconium industry and the hydrochloric acid electrolysis industry.

Owner:郭爽

Slag material for electroslag remelting of nuclear-grade stainless steel and method for electroslag remelting by slag material

ActiveCN109112319ALow content of harmful elementsUniform compositionIncreasing energy efficiencyNuclear gradeSlag

The invention relates to a slag material for electroslag remelting of nuclear-grade stainless steel and a method for electroslag remelting by the slag material. The slag material is prepared from thefollowing components in percentage by weight: 40 to 70% of CaF2, 1 to 10% of MgF2, 10 to 20% of Al2O3, 10 to 20% of CaO, 1 to 10% of MgO, and 0 to 3% of BaO. The preparation method of an electroslag ingot mainly comprises the following steps of preparation of an electrode rod, preparation of the slag material, and electroslag remelting. The prepared electroslag ingot has the advantages that the content of harmful elements of Co, B, Pb, Sn, H, P, S and the like is low, the surface quality is high, the components are uniform, the segregation is little, the microstructures are fine and dense, thesum of nonmetallic inclusions is lower than or equal to Grade 2.0, and the metallurgical quality requirement of the nuclear-grade stainless steel is met.

Owner:CHONGQING MATERIALS RES INST

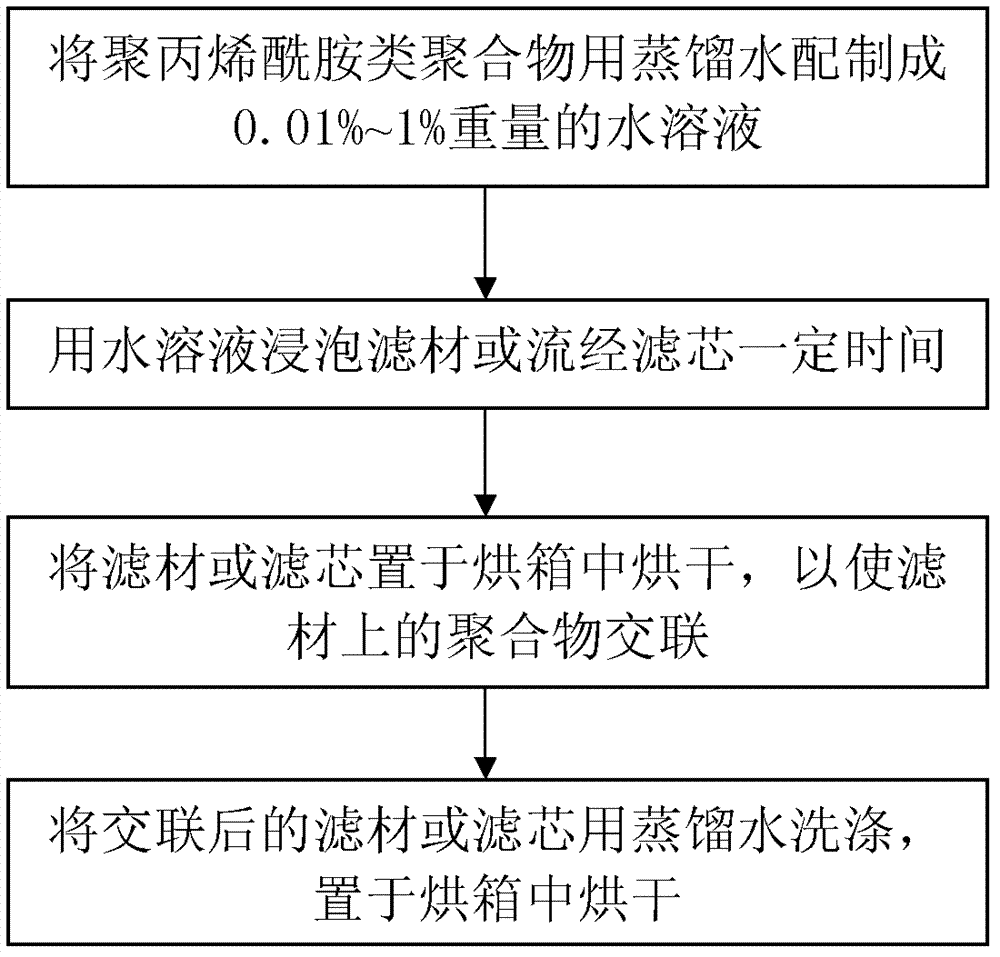

Modification method for filter material used in filter core of nuclear grade water filter

ActiveCN103084005AImprove leaching resistanceImprove filtration efficiencyFiltration separationNuclear gradeCooking & baking

The invention discloses a modification method for a filter material used in a filter core of a nuclear grade water filter. To improve leaching resistance of a filter material in a filter core of a water filter used in a nuclear power station, especially the problem of leaching of SiO2, the invention provides a following scheme: a commercially available glass fiber filter material and a commercially available paper-based filter material are treated with a polyacrylamide polymer aqueous solution, then the filter materials are dried in a baking oven so as to allow polymers on the filter materials to undergo crosslinking, and finally, the filter materials are washed and dried for subsequent usage. With the modification technology for the filter material in the invention, leaching resistance of a plurality of trace elements (especially SiO2) in the filter material can be improved, and filtration efficiency of the filter material on a subsize particle can be enhanced.

Owner:CHINA INST FOR RADIATION PROTECTION

Method for measuring content of hydrogen element in nuclear-grade zirconium material

ActiveCN103713106AGuaranteed releaseEnsure full releasePreparing sample for investigationTesting metalsNuclear gradeHydrogen

The invention discloses a method for measuring the content of a hydrogen element in a nuclear-grade zirconium material. The method comprises the following steps: 1, cutting the nuclear-grade zirconium material into 0.1-0.3g of a solid test sample; 2, firstly, pickling the solid test sample for 5-30s so as to remove an oxygen enrichment layer on the surface of the solid test sample and hydrogen and other gas elements adsorbed in the machining process, subsequently washing the pickled test sample for 10-50 seconds by using acetone, subsequently putting the test sample into an oven to be dried at 50-60 DEG C, and removing a contaminated layer on the surface of the test sample so as to ensure the cleanness of the test sample; 3, putting the test sample pretreated in the step 2 into a hydrogen measuring instrument so as to measure the content of the hydrogen in the solid test sample by using the hydrogen measuring instrument. By adopting the method, the defects of the conventional measuring method are overcome, and requirements of practical detection on the nuclear-grade zirconium material are met.

Owner:国核锆铪理化检测有限公司 +1

Pressure resistance valve for nuclear grade air passage

ActiveCN102359603ASo as not to damageSimple structureOperating means/releasing devices for valvesLift valveNuclear gradeElectricity

Owner:SHIJIAZHUANG NO 1 VALVE FACTORY

Nuclear safety grade 316L stainless steel gauge pipe

ActiveCN105525228AOptimizing Process ParametersImprove performanceElongated constructional elementsFurnace typesNuclear gradeSolid solution

The application of the invention discloses a nuclear safety grade 316L stainless steel gauge pipe. A round pipe blank is adopted as a raw material. The manufacture method comprises the steps of a cold rolling procedure, a solid solution thermal treatment procedure and storage; the cold rolling procedure comprises a cogging cold rolling step, an intermediate-product cold rolling step and a finished-product cold rolling step; the relative deformation of the cogging cold rolling step is 70%-75%; the relative deformation of the intermediate-product cold rolling step is 65%-70%; the relative deformation of the finished-product cold rolling step is 60%-65%; and the treatment temperature of the solid solution thermal treatment procedure is 1060 DEG C-1080 DEG C. The dimension precision, the surface quality and the comprehensive performance of products reach a higher level; the long-term safe service requirement in a nuclear grade environment is met; and the production efficiency and the qualification rate are both at a high level.

Owner:ZHEJIANG JIULI HI TECH METALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com