Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

89results about How to "Low content of harmful elements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

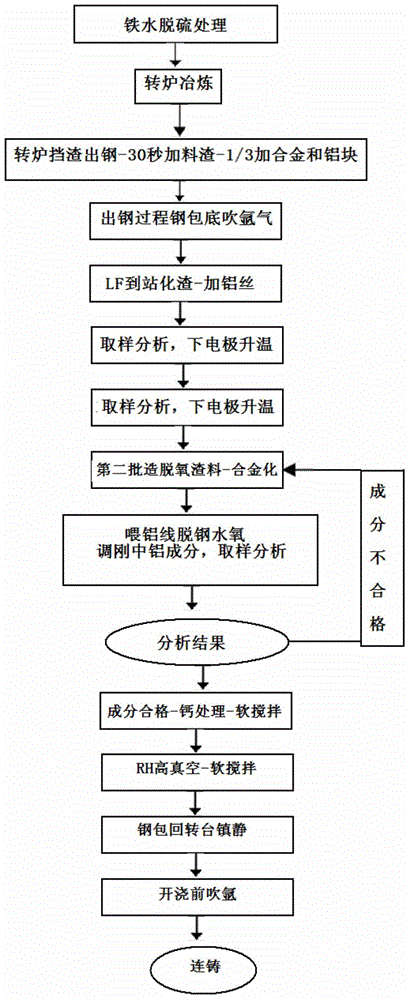

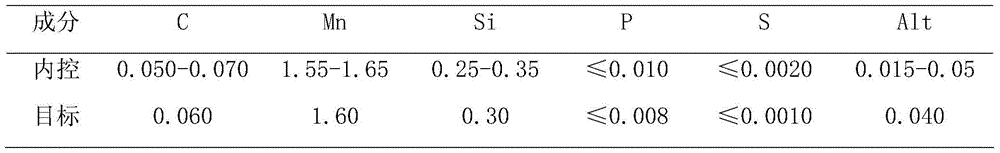

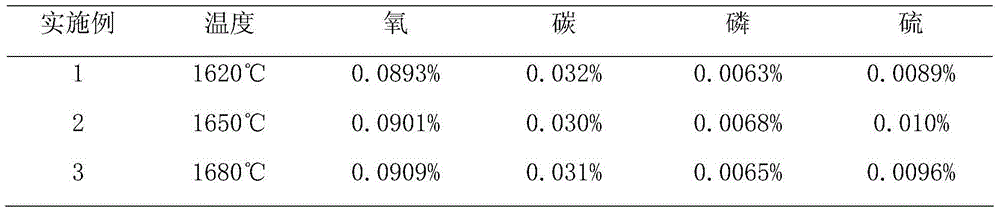

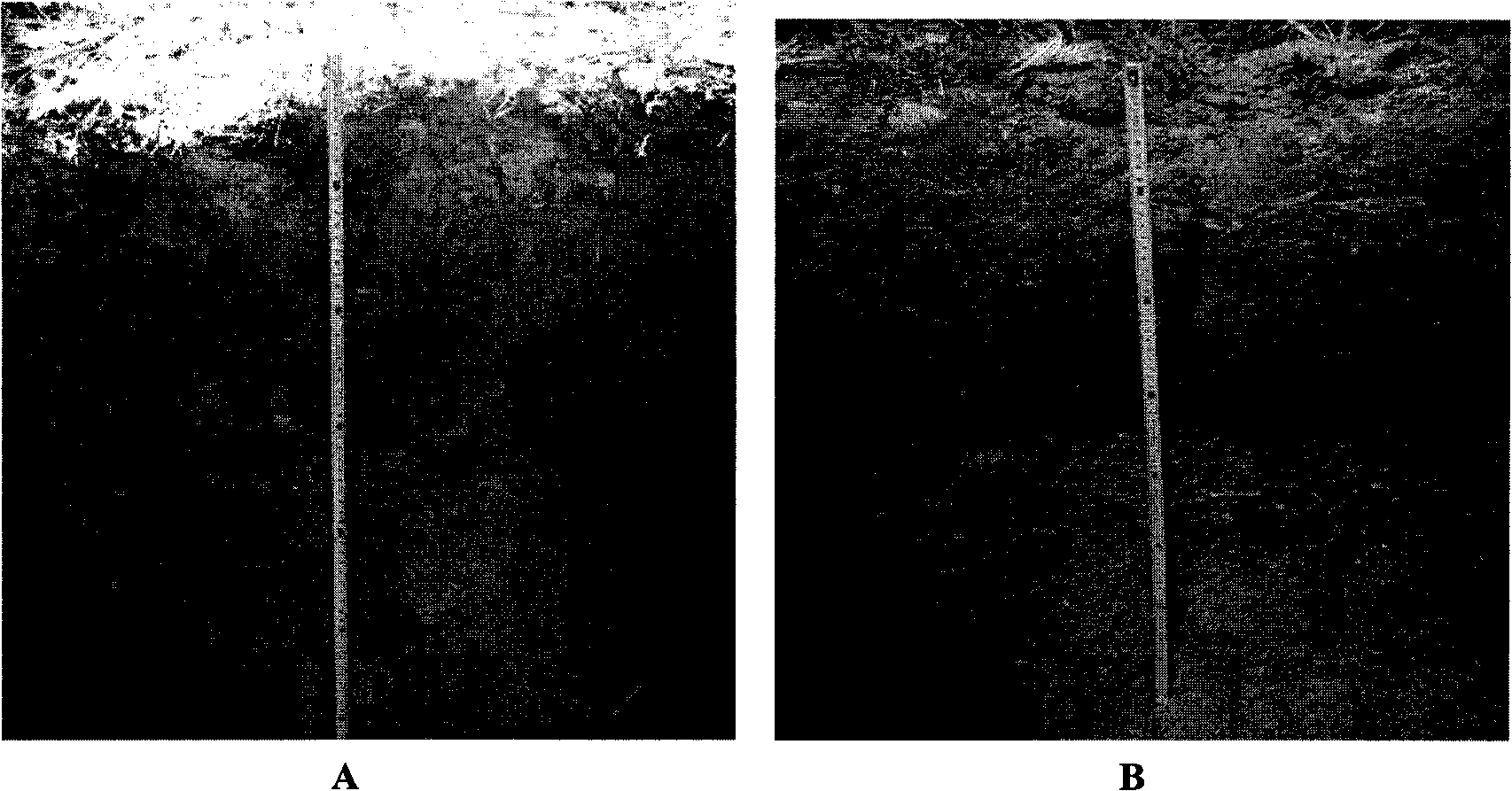

High-cleanliness pipeline steel smelting process

ActiveCN104630418ASolve the difficulty of cleanliness controlQuality improvementManufacturing convertersSulfurNon-metallic inclusions

The invention discloses a high-cleanliness pipeline steel smelting process. The process route comprises molten iron pouring, molten iron pretreatment, converter smelting, tapping, deoxidizing, alloying, LF refining furnace, treating with calcium, RH vacuum furnace and continuous casting and is characterized by comprising the following specific steps: firstly, converter smelting process; secondly, refining furnace smelting process; and thirdly, continuous casting process. The invention belongs to a steel-making process in the field of metallurgy and relates to a method for smelting and controlling a high-cleanliness pipeline steel. By molten iron desulphurization pretreatment, optimizing a converter tapping and deoxidizing system and a slagging system, LF refining furnace deep deoxygenation and reducing slag manufacturing processes, RH high-vacuum-degree degassing and inclusion removal process, the pouring is protected by the continuous casting in the whole process so that the composition of a casting billet is uniform, the contents of harmful elements such as S, P, O, N and H are low, the non-metallic inclusions are effectively controlled, the casting billet is good in internal quality and the production of high value-added ultra-low sulfur steel is ensured.

Owner:NANJING IRON & STEEL CO LTD

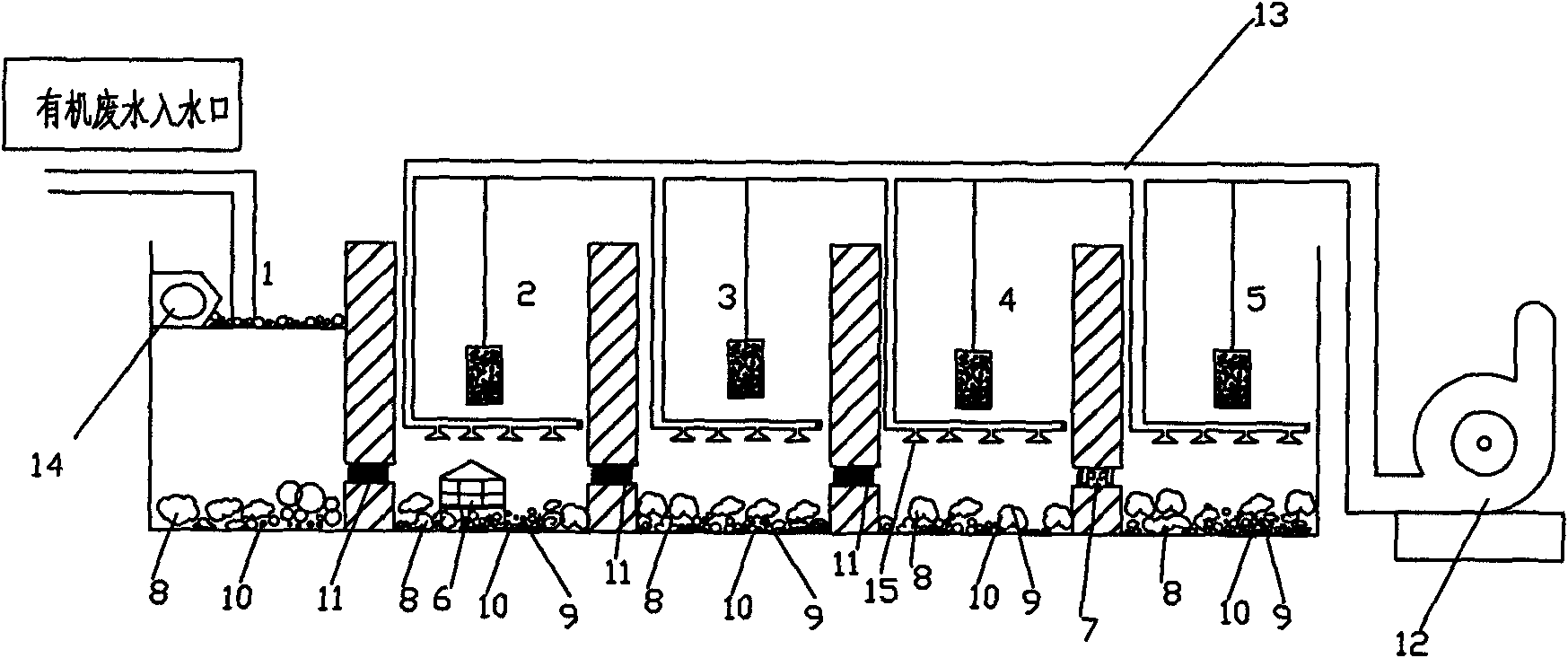

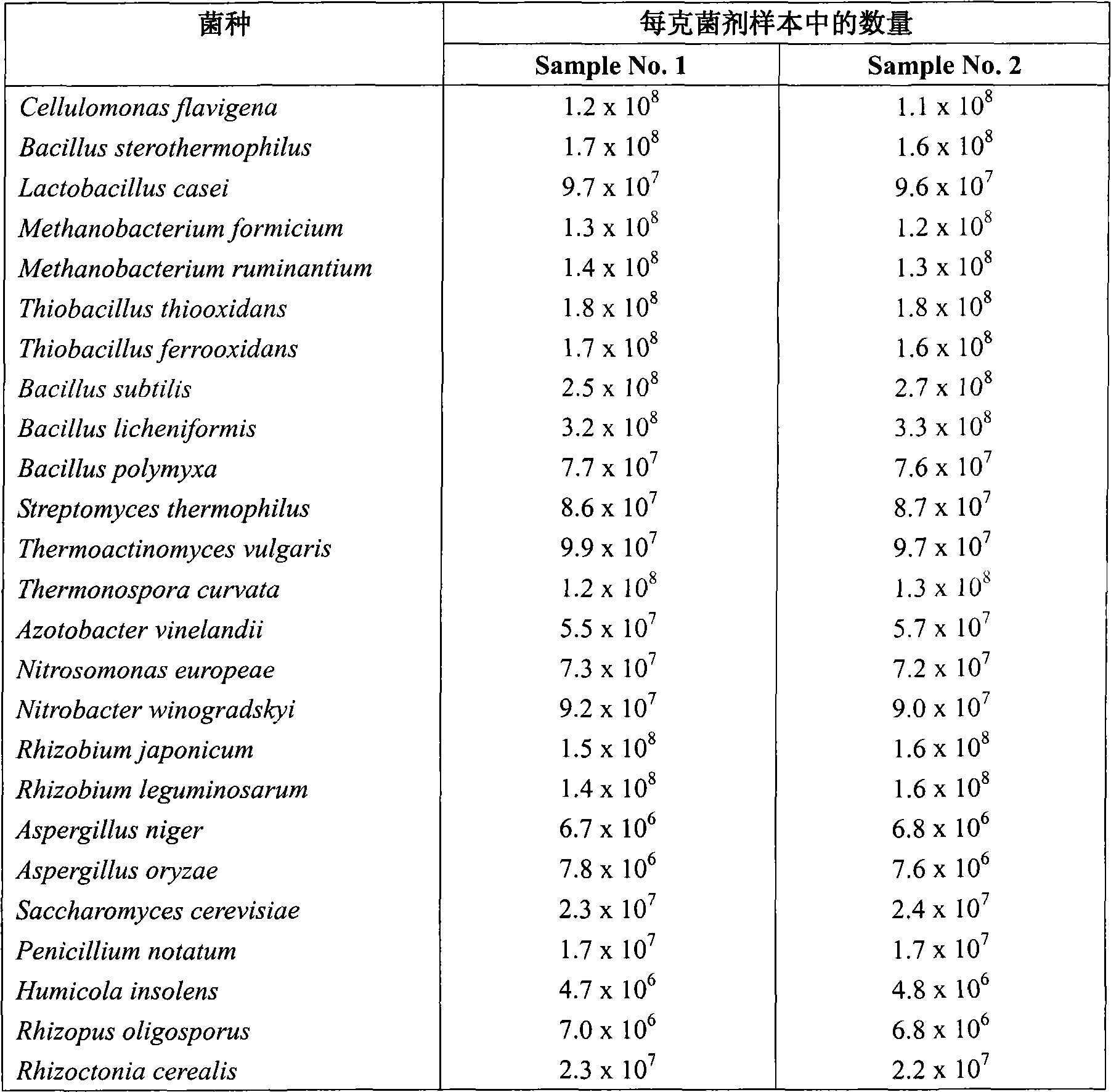

Microbial inoculum and organic fertilizers fermented by same

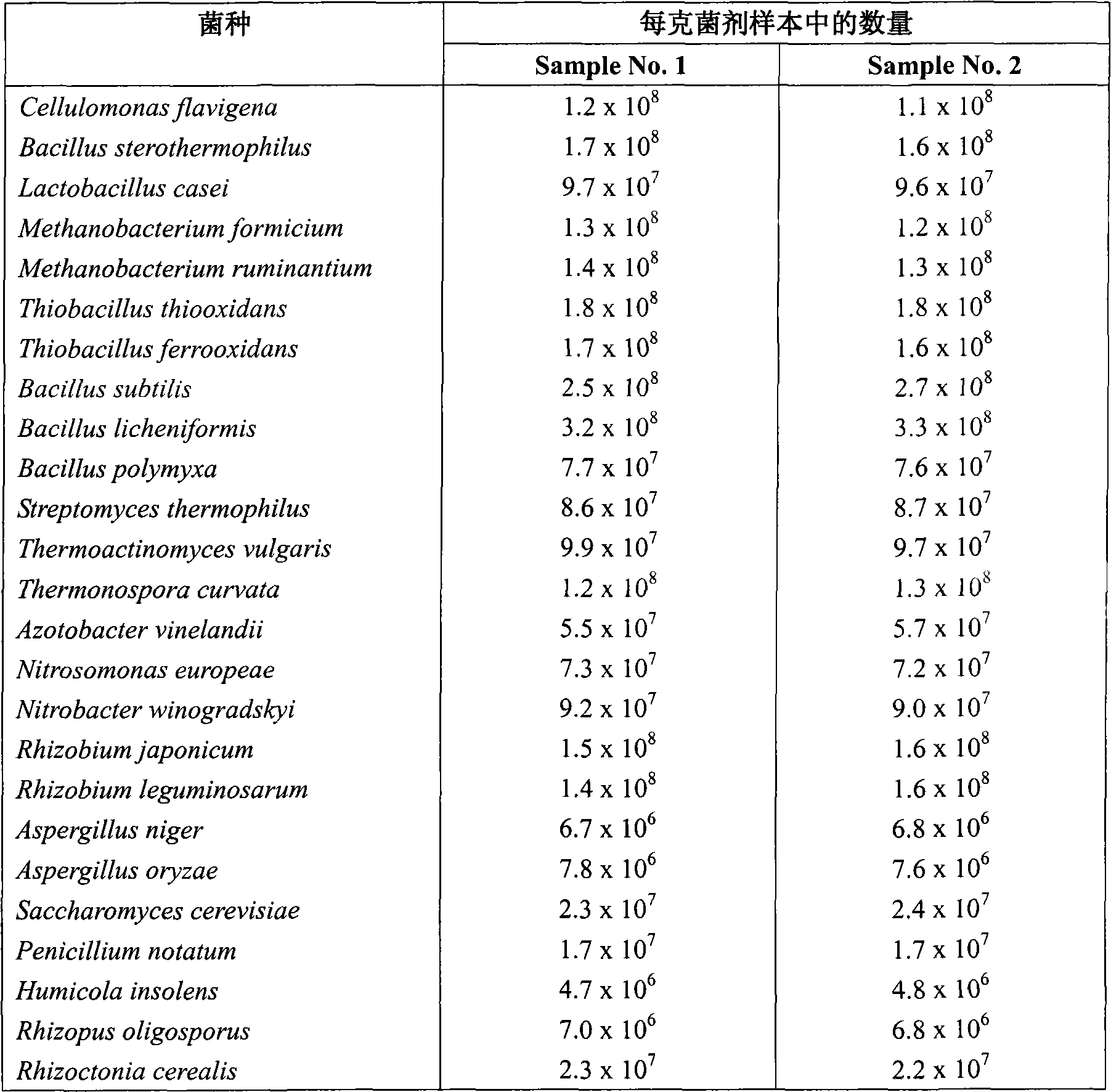

ActiveCN101643718AImprove adaptabilityImprove qualityFungiBio-organic fraction processingPenicilliumRhizobium

The invention relates to a microbial inoculum for fermenting and producing organic fertilizers, comprising cellulomonas, bacillus, lactobacillus, methagen, thiobacillus, streptomyces, thermoactinomyces, thermomonospora, azotobacter, nitrosomonas, nitrobacter, rhizobium, aspergillus, yeast, penicillium, humicola, rhizopus and mycorrhizal fungi. In addition, the invention also relates to organic fertilizers fermented and produced by using the microbial inoculum and a method for fermentation and production.

Owner:宋彦耕

Microbial agent and soil modifying agent produced by fermentation thereof

ActiveCN101629156AImprove adaptabilityImprove fertilityAgriculture tools and machinesFungiFiberMicrobial agent

The invention relates to a microbial agent used for producing a soil modifying agent by fermentation, consisting of fiber monad, bacillus, lactobacillus, methanobacteria, thiobacillus, streptomycete, high-temperature actinomyces, high-temperature monad, azotobacteria, nitration monad, nitration bacilus, rhizobium, koji mold, leaven, blue mold, detritus mold, rhizopus as well as mycorrhizal fungi and substrate. In addition, the invention also relates to a soil modifying agent produced by the fermentation of the microbial agent, application thereof and the like.

Owner:宋彦耕

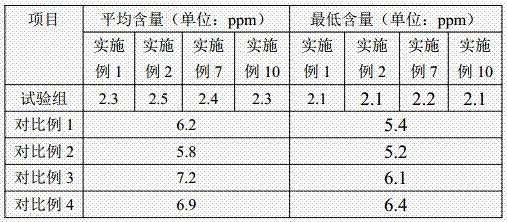

Electroslag remelting method for difficult-processing high alloy stainless steel and electroslag remelting slag system adopting electroslag remelting method

InactiveCN102925712AImprove or increase thermoplasticityHigh yieldIncreasing energy efficiencySlagAlloy

The invention relates to an electroslag remelting method for difficult-processing high alloy stainless steel and an electroslag remelting slag system adopting the electroslag remelting method. The slag system comprises the components in parts by weight: 46-72 parts of CaF2, 15-28 parts of CaO, 24-10 parts of Al2O3 and 8-2 parts of MgO, wherein the content of impurities is less than 1.0%. The electroslag remelting slag system and the electroslag remelting method reduce the contents of harmful elements in steel, improve the purity, optimize the organization, particularly and remarkably improve the processing performance of the difficult-processing high alloy stainless steel and greatly improve the material yield.

Owner:CHONGQING MATERIALS RES INST

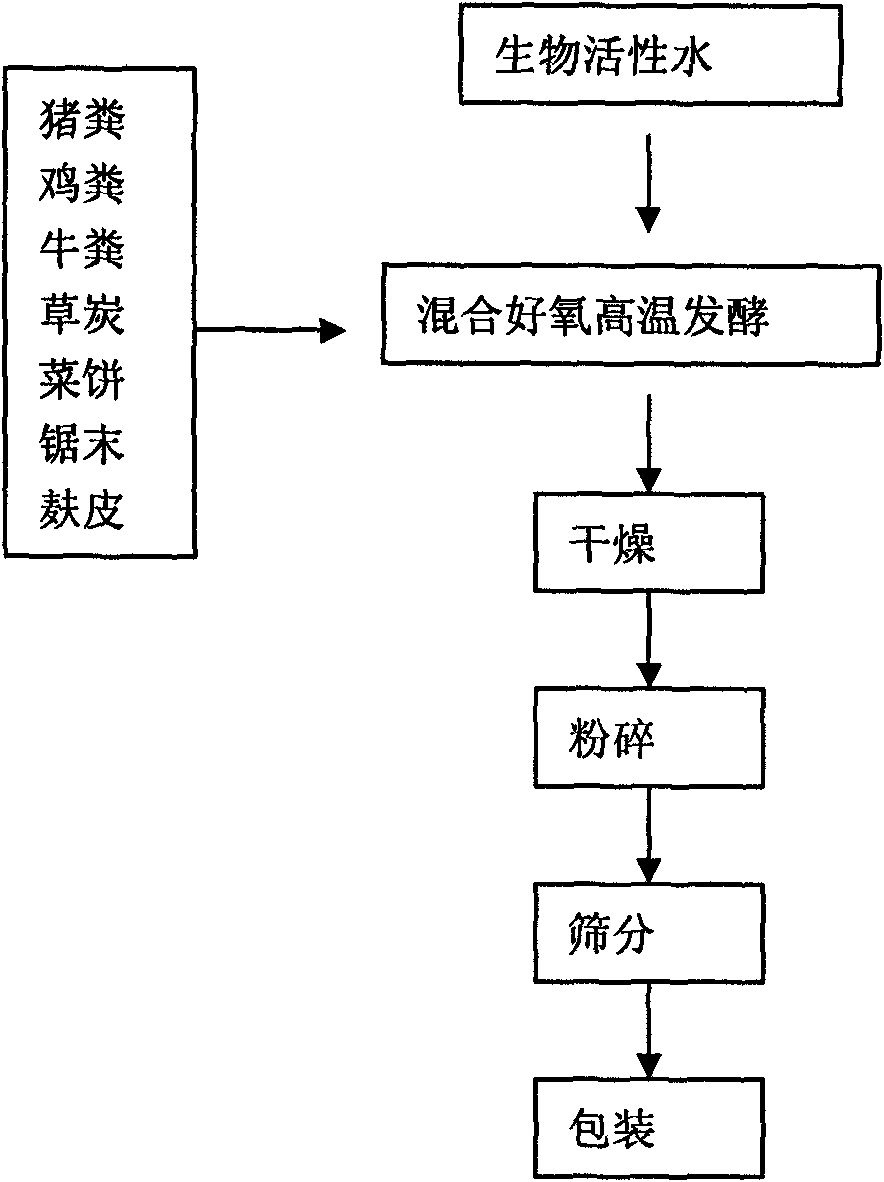

Biological organic fertilizer and preparation method thereof

InactiveCN102219572AQuality improvementWide range of adaptabilityBio-organic fraction processingOrganic fertiliser preparationAlkali soilPesticide residue

The invention relates to a biological organic fertilizer adopting microbial fermentation and a preparation method thereof. The method comprises the following steps: firstly uniformly mixing pig manure, chicken manure, cow manure, grass carbon, vegetable cake, sawdust and bran according to weight proportion, then adding biological active water with certain concentration, stirring uniformly, and simultaneously regulating pH to be 6.9-8.9 to start fermentation, overturning every 2-7 days after stacking (when the temperature in the stack can reach 55 DEG C), then stacking in a concentrated way for fermentation again until fermentation maturing is finished (the total time is 7-15 days), namely, the temperature does not rise any more; and drying, smashing, screening and packing the obtained material when the water content is lower than 20 percent, thus obtaining the product. The organic fertilizer not only can improve soil, replace chemical fertilizers, cause yield of crops to be increased and improve crop quality, but also can reduce the content of harmful element, eliminate pesticide residue in soil, and can improve saline-alkali soil.

Owner:YULIN UNIV

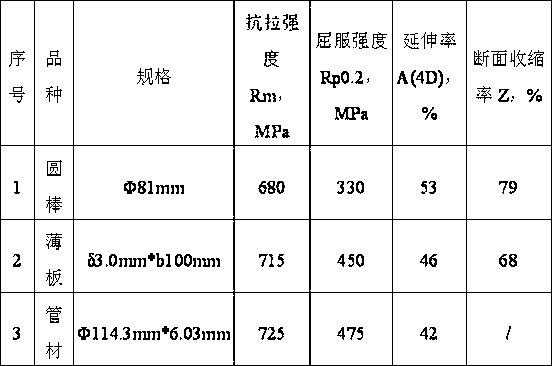

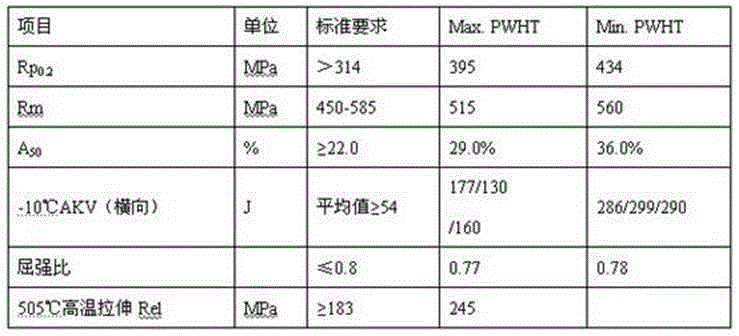

Thick chromium-molybdenum steel plate for hydrogenation equipment and production method thereof

InactiveCN102181806AImprove toughnessDoes not reduce weldabilityRoll mill control devicesMetal rolling arrangementsSheet steelIngot

The invention discloses a thick chromium-molybdenum steel plate for hydrogenation equipment, and also discloses a production method of a steel plate. The steel plate comprises the following components by weight percent: 0.12%-0.15% of C, 0.02%-0.07% of Si, 0.50%-0.60% of Mn, less than or equal to 0.007% of P, less than or equal to 0.005% of S, 2.35%-2.50% of Cr, 0.95%-1.10% of Mo, 0.012%-0.02% ofNb, less than or equal to 0.20% of Cu, less than or equal to 0.20% of Ni, less than or equal to 0.003% of Sb, less than or equal to 0.005% of Sn, less than or equal to 0.016% of As, less than or equal to 0.003% of O, less than or equal to 0.008% of N and less or equal to 0.0002% of H, the balance of Fe and inevitable impurities. For the steel plate, an electroslag remelting technology is adopted,electroslag ingot with the maximum piece weight being 50t is melted, and the maximum thickness of the produced thick chromium-molybdenum steel plate for the hydrogenation equipment can achieve 198mm,and the maximum piece weight of the single-piece finished steel plate can achieve 37.2t by a heating-rolling technology and thermal-processing production equipment of normalizing plus accelerated cooling plus tempering.

Owner:WUYANG IRON & STEEL +1

Steel for linear guide rail and hot-rolling production method for steel

ActiveCN109182901ALow content of harmful elementsPrevention of large-scale generation of inclusionsProcess efficiency improvementNon-metallic inclusionsWear resistance

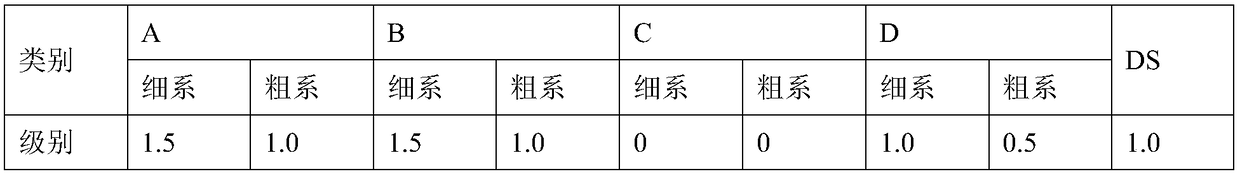

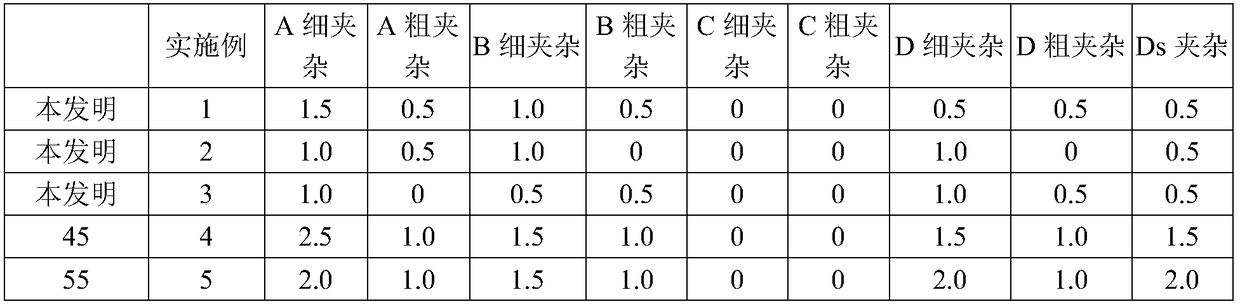

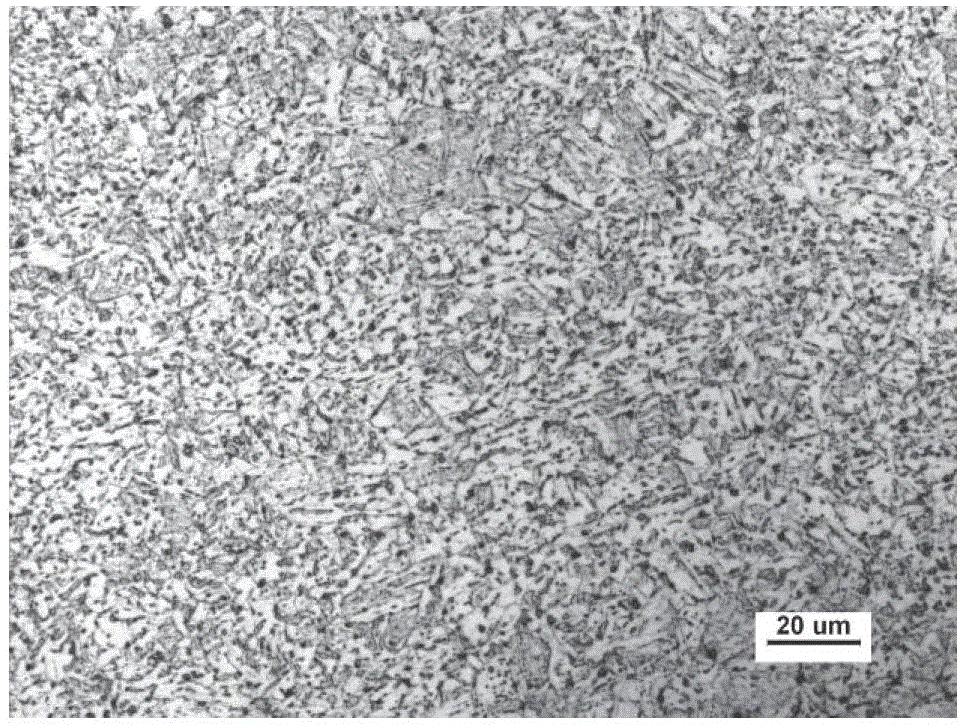

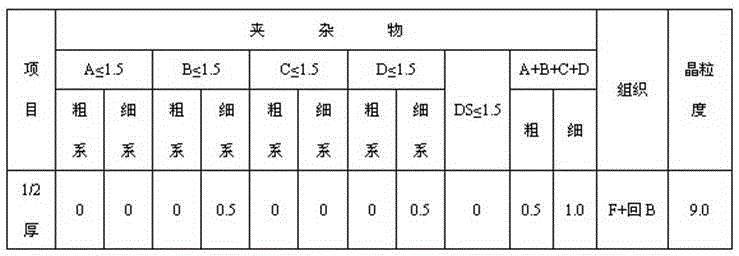

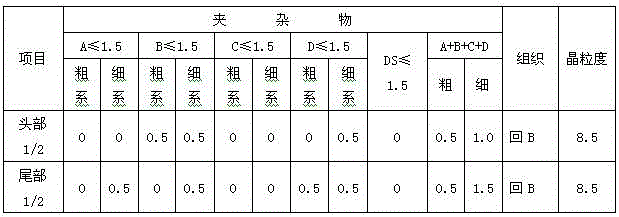

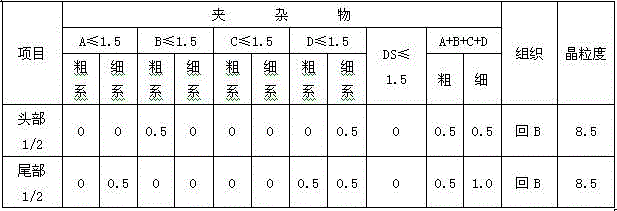

The invention relates to steel for a linear guide rail. The steel is prepared from the following chemical components in percentage by weight: 0.40-0.70% of C, 0.15-0.40% of Si, 1.30-1.80% of Mn, 0.30-0.60% of Cr, 0.005-0.030% of S, less than or equal to 0.025% of P, less than or equal to 0.25% of Ni, less than or equal to 0.30% of Cu, less than or equal to 0.10% of Mo, less than or equal to 0.05%of Al, less than or equal to 0.0010% of Ca, less than or equal to 0.003% of Ti, less than or equal to 0.0010% of O, less than or equal to 0.04% of As, less than or equal to 0.03% of Sn, less than or equal to 0.005% of Sb, less than or equal to 0.002% of Pb, and the balance of Fe and inevitable impurities. After being subjected to quenching and tempering, the steel has yield strength higher than orequal to 785 MPa, tensile strength higher than or equal to 930 MPa, ductility higher than or equal to 12%, and Charpy impact work AKU higher than or equal to 50 J at the normal temperature. Non-metalimpurities meet the following relationship: A-series fine system less than or equal to 1.5, A-series rough system less than or equal to 1.0, B-series fine system less than or equal to 1.5, B-series rough system less than or equal to 1.0, C-series fine system equal to 0, C-series rough system equal to 0, D-series fine system less than or equal to 1.0, D-series rough system less than or equal to 0.5, Ds-series less than or equal to 1.0. Main process comprises electric furnace or converter-external refining-VD or RH vacuum degassing-continuous casting-continuous rolling-stack cooling. By optimizing chemical components of a steel plate, hardenability, strength and wear resistance of the steel are remarkably improved.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

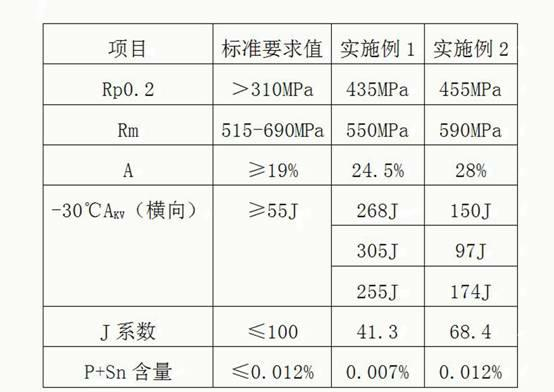

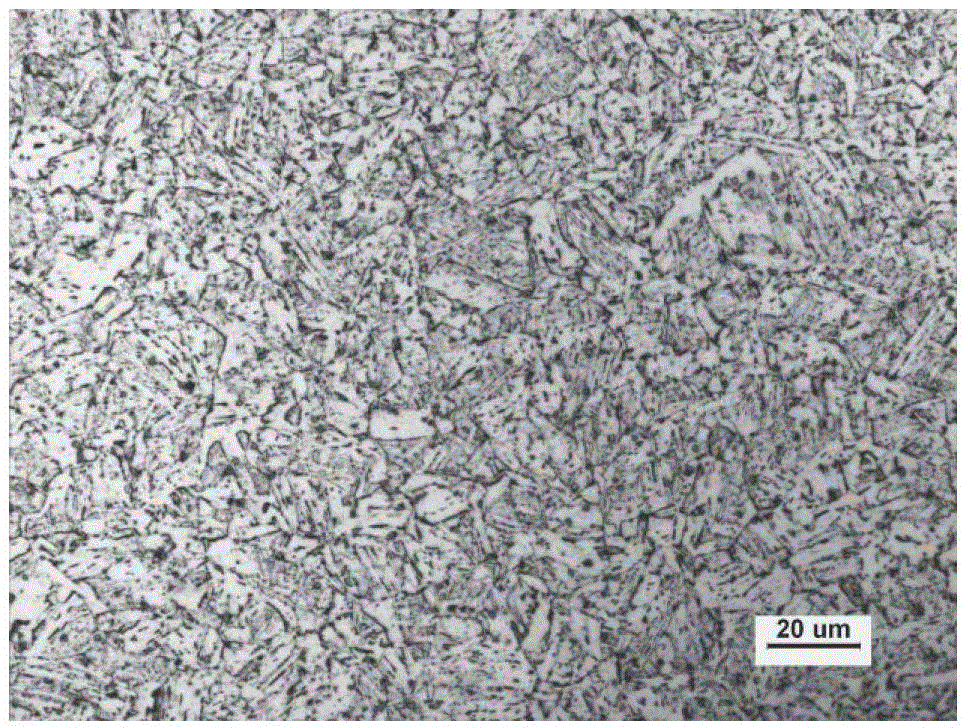

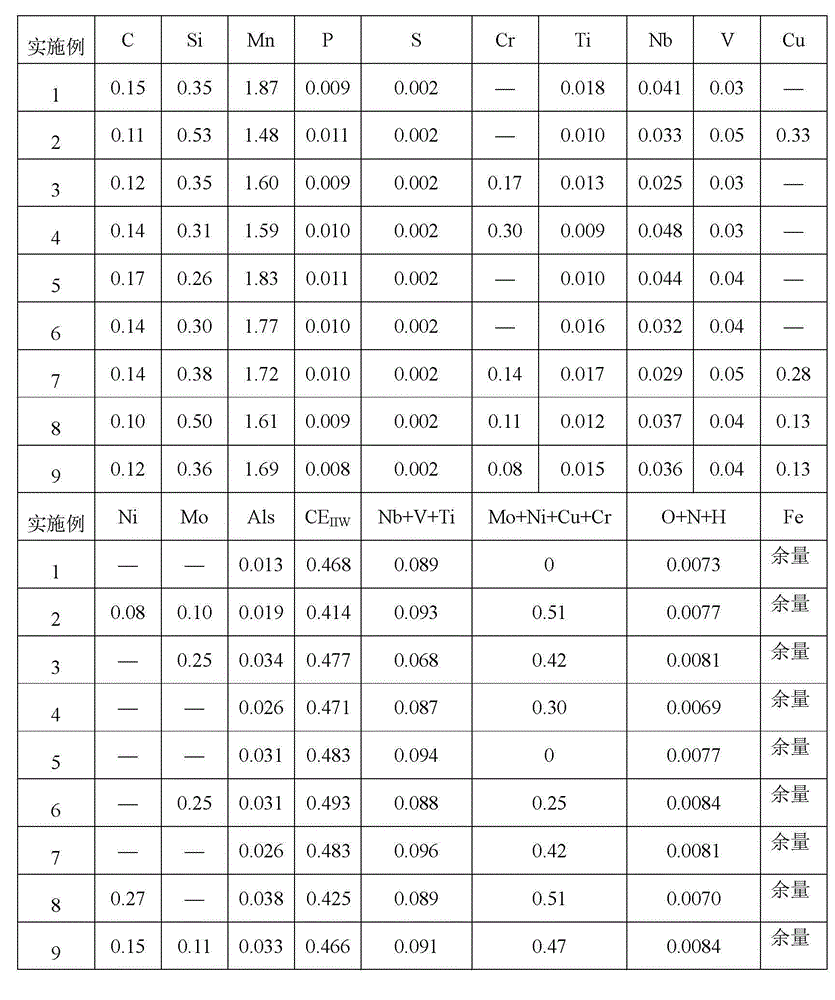

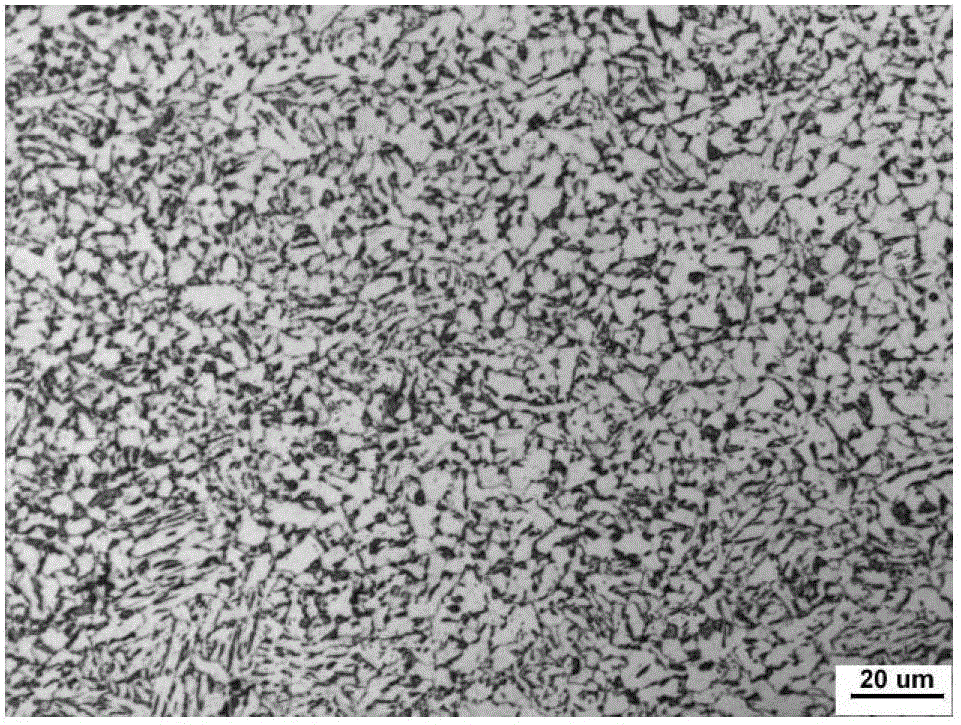

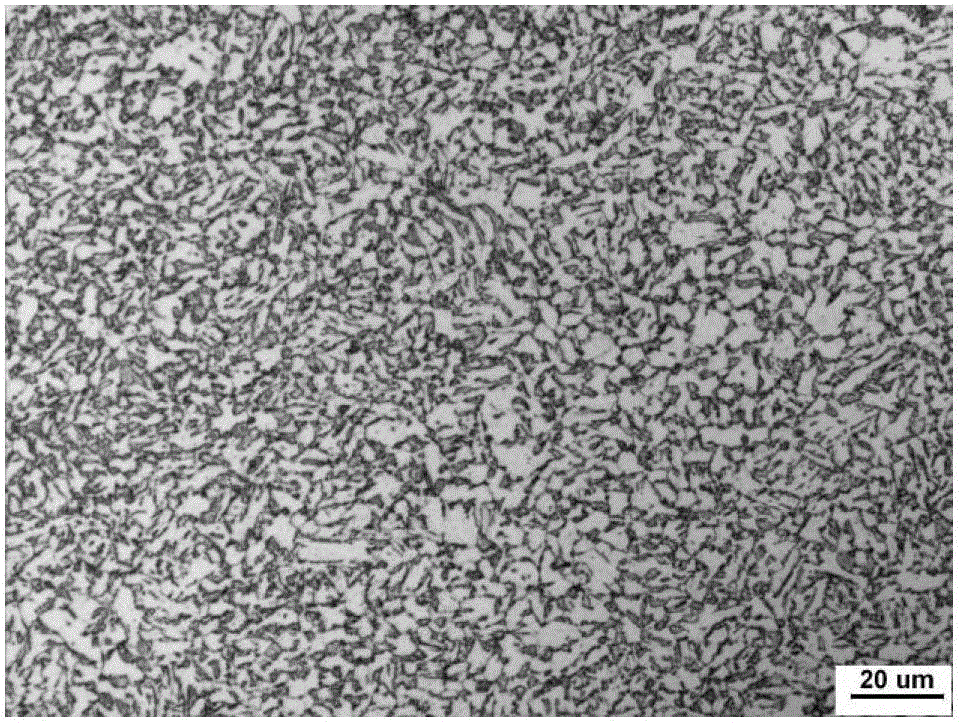

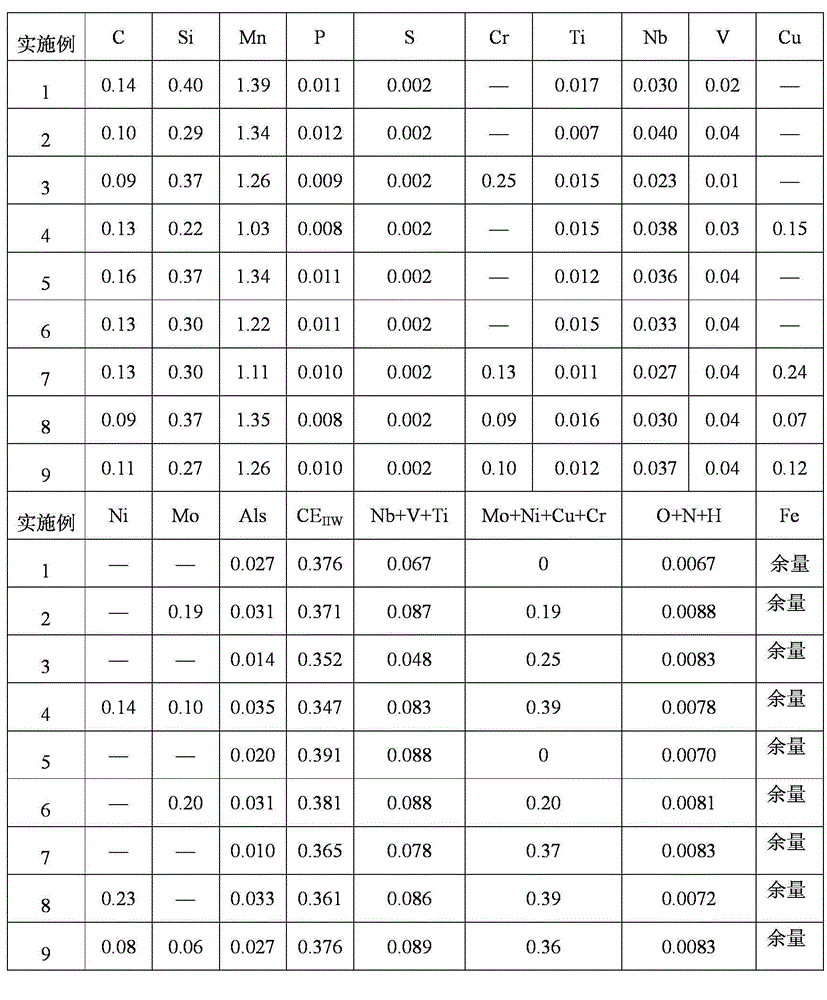

Economic-type pipe fitting steel with high strength and low yield ratio and production method thereof

The invention discloses an economic-type pipe fitting steel with high strength and low yield ratio, which comprises the following elements: 0.10%-0.18% of C, 0.25%-0.55% of Si, 1.40%-1.90% of Mn, 0.02%-0.05% of Nb, 0.008%-0.020% of Ti, 0.02%-0.05% of V, 0.010%-0.040% of Als, smaller than or equal to 0.10% of Nb, V and Ti, 0-0.25% of Mo, 0-0.30% of Ni, 0-0.35% of Cu, 0-0.30% of Cr, smaller than or equal to 0.55% of Mo, Ni, Cu and Cr, and the balance of ferrum and unavoidable impurities. The yield strength after heat treatment can reach more than 630MPa or 690MPa, the tensile strength reaches more than 775MPa or 870MPa, the yield ratio is lower than 0.85, the impact ductility at minus 46 DEG C is not lower than 80J, and the technical requirements for X90 level and X100 level pipe fitting steel are completely satisfied.

Owner:ANGANG STEEL CO LTD

Economical low-yield-ratio steel for pipe fittings for oil and gas transmission and method for producing economical low-yield-ratio steel

The invention discloses economical low-yield-ratio steel for pipe fittings for oil and gas transmission and a method for producing the economical low-yield-ratio steel. The economical low-yield-ratio steel comprises from 0.09% to 0.16% of C, from 0.20% to 0.40% of Si, from 1.00% to 1.39% of Mn, from 0.01% to 0.04% of Nb, from 0.005% to 0.018% of Ti, from 0.01% to 0.04% of V, from 0.008% to 0.035% of Als, from 0% to 0.20% of Mo, from 0% to 0.30% of Ni, from 0% to 0.30% of Cu, from 0% to 0.25% of Cr, the balance iron and inevitable impurities, wherein the total content of the Nb, the V and the Ti is lower than or equal to 0.09%, and the total content of the Mo, the Ni, the Cu and the Cr is lower than or equal to 0.40%. After the economical low-yield-ratio steel is subjected to heat treatment, the yield strength of the economical low-yield-ratio steel for the pipe fittings can be higher than 490MPa or 560MPa, the tensile strength of the economical low-yield-ratio steel can be higher than 670MPa or 720MPa, the yield ratio of the economical low-yield-ratio steel is lower than 0.80, the impact toughness of the economical low-yield-ratio steel at the temperature of minus 46 Celsius degrees is not lower than 80J, and technical requirements of X70-grade steel for pipe fittings and X80-grade steel for pipe fittings are met completely.

Owner:ANGANG STEEL CO LTD

Smelting technological process of low-silicon low-manganese ultrapure rotor steel

InactiveCN102011059ALow content of harmful elementsImprove purityElectric arc furnaceSmelting process

The invention discloses a smelting technological process of low-silicon low-manganese ultrapure rotor steel, which comprises the following procedures: (1) selecting raw materials and controlling the content of impurity elements in the raw materials; (2) smelting with a basic electric arc furnace, dephosphorizing with efficient dephosphorization slags, degassing and removing inclusions, and strictly controlling components of tapping molten steel within a target range; (3) refining with a ladle furnace (LF), taking efficient desulfurization slags as reducing and refining slags, deoxidizing, desulfurizing, alloying, modifying inclusions and removing the inclusions in the LF, and adjusting the temperature and the components of the molten steel within a target range; (4) refining with a VD (vacuum degassing) furnace, and carrying out deep desulfurization, degassing (dehydrogenizing) and removing the inclusions in high vacuum; and (5) casting by a vacuum protection mode. By adopting the smelting technological process, the phenomena of silicon increase, manganese increase and rephosphorization of the molten steel are effectively avoided during the smelting process, and the tapping quality of the molten steel is improved; and the obtained rotor steel has high purity, low content of harmful elements and excellent quality.

Owner:CHONGQING UNIV

Organic fermentation fertilizer and preparation method thereof

InactiveCN106478167AImprove conversion rateReduce incidenceBio-organic fraction processingExcrement fertilisersInsect diseaseLivestock manure

The invention relates to the field of an organic fertilizer, and concretely relates to an organic fermentation fertilizer and a preparation method thereof. The method comprises the following steps: 1) aerobic fermentation: mixing livestock manure and anaerobic bacteria, fermenting a mixture for 8-15 days at the temperature of 60-80 DEG C to form a primary fermentation fertilizer; 2) facultative anaerobic fermentation: mixing the primary fermentation fertilizer and facultative anaerobe, fermenting a mixture for 10-20 days at the temperature of 50-60 DEG C to form a secondary fermentation fertilizer; and 3) anaerobic fermentation: mixing the secondary fermentation fertilizer and anacerobe, and fermenting a mixture at the temperature of no higher than 45 DEG C for more than 3 months to form the organic fermentation fertilizer. The method has the advantages of rapid fermentation and deodorizing, high nutrient conversion rate, high organic matter conversion rate and effective inhibition of insect disease.

Owner:南充禾香生物科技有限公司 +1

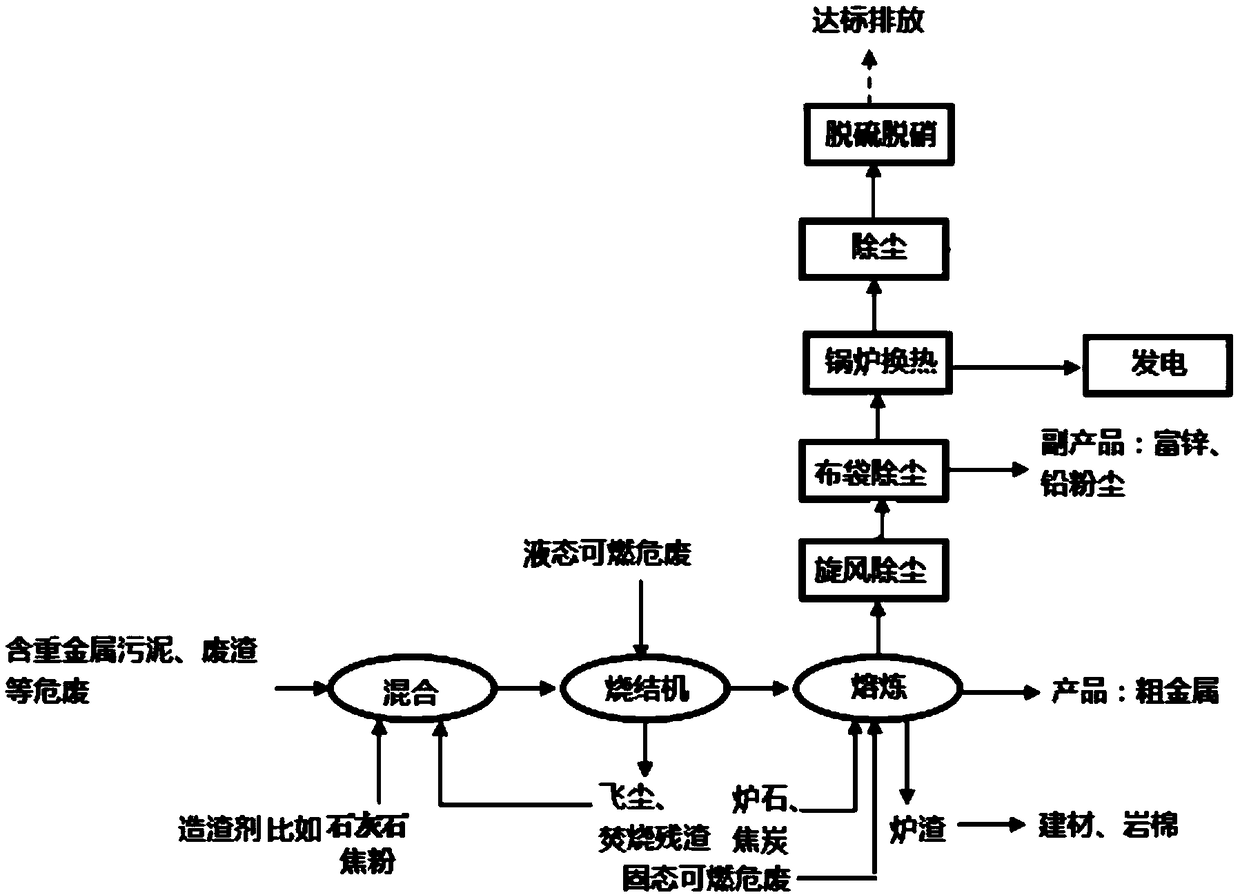

Method for treating hazardous wastes through cooperation of metallurgical furnace

ActiveCN109457113AAchieve reductionImplement resourcesProcess efficiency improvementSmelting processAlloy

The invention discloses a method for treating hazardous wastes through the cooperation of a metallurgical furnace. The method comprises the steps of sintering for agglomerating the hazardous wastes containing heavy metal, or condensing for agglomeratingthe hazardous wastes containing the heavy metal, and smelting the combustible hazardous wastes to form a finished product block so as to obtain analloy crude product containing the heavy metal. According to the method for treating the hazardous wastes through the cooperation of the metallurgical furnace provided by the invention, the hazardouswastes containing the heavy metal are treated through a melting furnace, valuable metal in the hazardous wastes containing the heavy metal is recycled, meanwhile, organic matters inthe combustible hazardous wastes are decomposed by high temperature of the melting furnace, and heat values in the organic matters are utilized, so that inthe smelting process of the hazardous wastes containing the heavy metal, the harmful element of the combustible hazardous wastes, and fly ash used as a first slag former or furnace slags produced by residue incineration is reduced to be below 0.1 percent, the wastes can be directly used as building materials and used for preparing rock wool and the like, and the metal recovery rate reaches to more than 90 percent.

Owner:唐山市丰润区明营再生资源有限公司

Low yield ratio chromium-molybdenum steel plate and production method thereof

The invention relates to a low yield ratio chromium-molybdenum steel plate and a production method thereof, belonging to the technical field of steel smelting. The production method comprises the following processes of smelting continuous casting, heating and rolling, and thermal treating. The steel plate comprises the following components by weight percent: more than or equal to 0.13% and less than or equal to 0.17% of C, more than or equal to 0.30% and less than or equal to 0.40% of Si, more than or equal to 0.50% and less than or equal to 0.70% of Mn, less than or equal to 0.007% of P, less than or equal to 0.005% of S, more than or equal to 1.00% and less than or equal to 1.10% of Cr, more than or equal to 0.50% and less than or equal to 0.65% of Mo, less than or equal to 0.20% of Cu, more than or equal to 0.10% and less than or equal to 0.20% of Ni, less than or equal to 0.003% of Sb, less than or equal to 0.010% of Sn, less than or equal to 0.010% of As, the balance of Fe and inevitable impurities. The low yield ratio chromium-molybdenum steel plate meets the requirement of domestic and aboard petrifaction and coalification industries on lowing the yield ratio of the chromium-molybdenum steel plate used at high temperature environment, can be widely used on devices such as delay coking devices of coke drums and hydrogenation reactor and the like, has good cold bending property, does not crack when being manufactured, and has good rebound elasticity and good plate shape.

Owner:WUYANG IRON & STEEL +1

Steel for ball screws and manufacturing method thereof

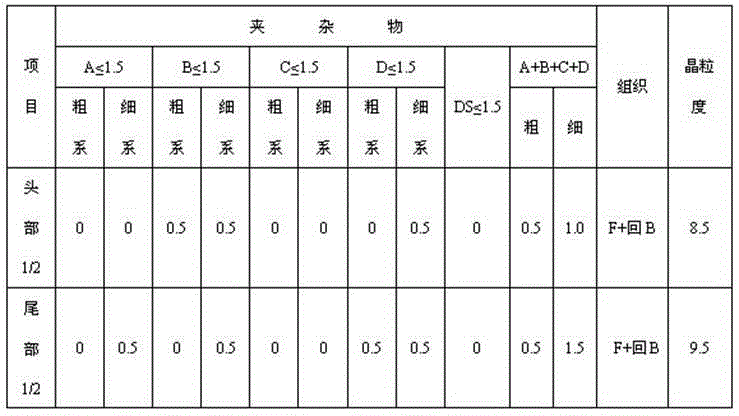

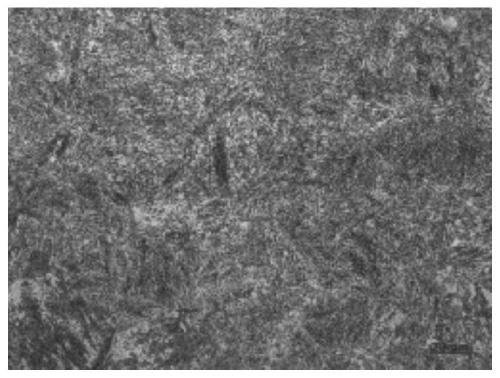

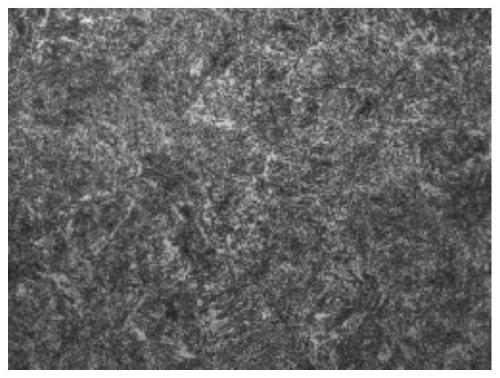

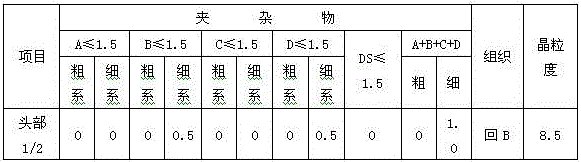

PendingCN110484837ALow content of harmful elementsGuaranteed amount of residual aluminumBall screwWater immersion

The invention relates to steel for ball screws. The steel for ball screws comprises, by mass: 0.45%-0.60% of C, 0.15-0.40% of Si, 0.90-1.10% of Mn, 0.70-1.20% of Cr, less than or equal to 0.015% of S,less than or equal to 0.025% of P, less than or equal to 0.25% of Ni, 0.15-0.40% of Mo, less than or equal to 0.30% of Cu, less than or equal to 0.05% of Al, less than or equal to 0.0010% of Ca, lessthan or equal to 0.003% of Ti, less than or equal to 0.0010% of O, 0.0050-0.0090% of N, less than or equal to 0.04% of As, less than or equal to 0.03% of Sn, less than or equal to 0.005% of Sb, lessthan or equal to 0.002% of Pb, and the balance Fe and inevitable impurities. The delivery state of the steel is as follows: high-temperature quenching and tempering are carried out, and the hardness meets 220-280 HBW, and the microscopic structure is of a sorbite and bainite structure, and is subjected to SEP 1927 water immersion high-frequency flaw detection, so that the defect length is requirednot to exceed 5 mm. The manufacturing process comprises the steps of electric furnace or converter, external refining, VD or RH vacuum degassing, continuous casting, continuous casting blank squaringto form an intermediate billet (a square billet), intermediate billet heating and rolling, finishing, quenched-tempered heat treatment (including high temperature quenching and tempering), surface lathing and warehousing.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

High-strength weather-resisting hot rolled steel strip and manufacturing method thereof

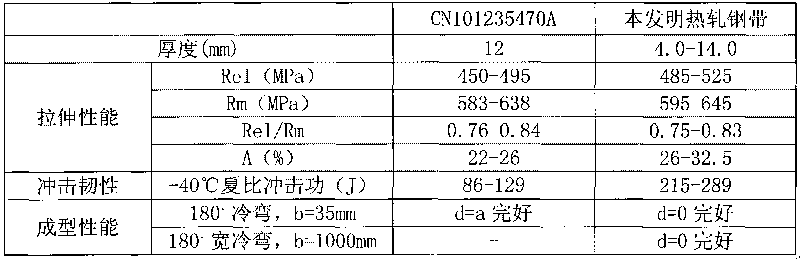

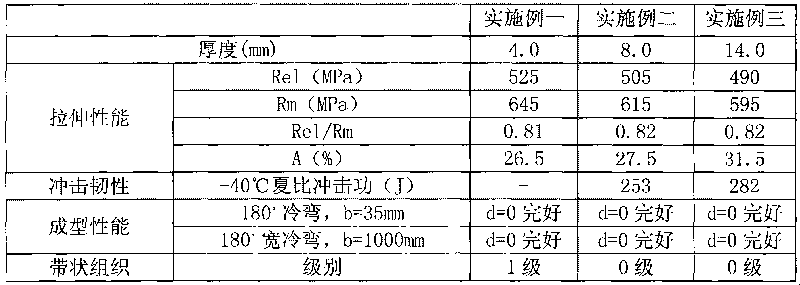

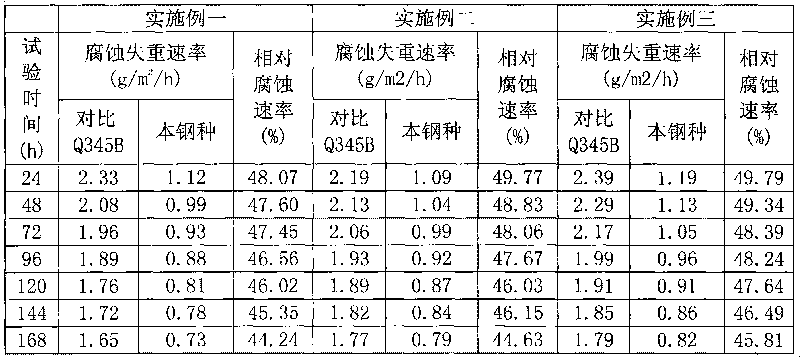

ActiveCN101736203ALow costLow content of harmful elementsManufacturing convertersMetal rolling arrangementsBand shapeMechanical property

The invention relates to a high-strength weather-resisting hot rolled steel strip and a manufacturing method thereof. The hot rolled steel strip comprises the following chemical components in percentage by weight: C is more than 0 and is less than or equal to 0.10, Si is more than or equal to 0.15 and is less than or equal to 0.45, Mn is more than or equal to 0.70 and is less than or equal to 1.40, P is more than 0 and is less than or equal to 0.020, S is more than 0 and is less than or equal to 0.008, Cr is more than or equal to 0.35 and is less than or equal to 1.00, Ni is more than or equal to 0.15 and is less than or equal to 0.55, Cu is more than or equal to 0.25 and is less than or equal to 0.50, Nb+V+Ti is more than 0 and is less than or equal to 0.22, and the balance of Fe and other unavoidable impurities. The manufacturing method of the hot rolled steel strip comprises the following steps: A. continuous casting billet preparation is realized by hot metal pretreatment desulfuration, top and bottom combined blown converter smelting, LF refining and thick plate blank continuous casting; B. controlled rolling and controlled cooling technology are adopted to process the continuous casting billet into the hot rolled steel strip, finish rolling temperature is 790-890 DEG C, water cooling is quickly carried out to 450-650 DEG C for reeling, and then the obtained product is cooled to room temperature. The steel strip processed by the manufacturing method of the high-strength weather-resisting hot rolled steel strip has low hazardous element content and banded structure rank, higher comprehensive mechanical property, weather resisting performance and favourable formability.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

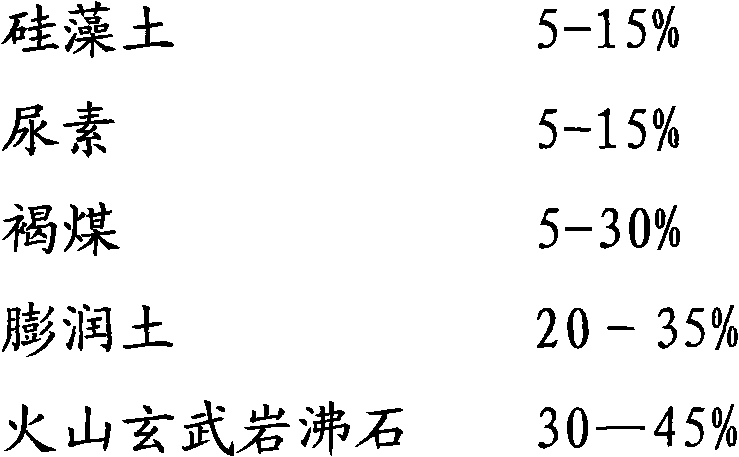

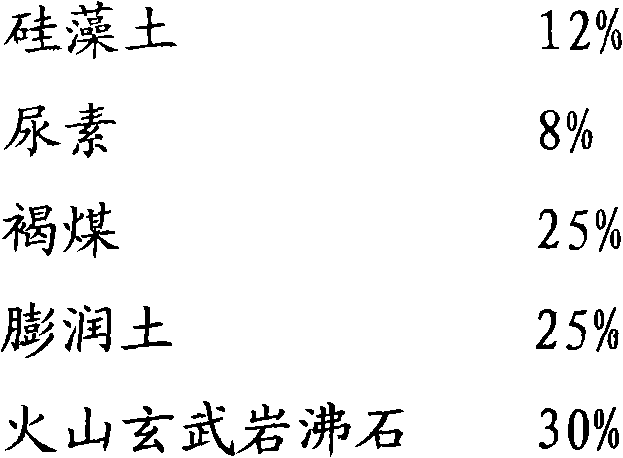

Environmentally-friendly water-saving water-holding fertilizer and preparation method thereof

InactiveCN102206119AStrong exchange abilityImprove adsorption capacityFertilizer mixturesPowder mixtureSodium Bentonite

The invention discloses an environmentally-friendly water-saving water-holding fertilizer and a preparation method thereof. The environmentally-friendly water-saving water-holding fertilizer comprises the following raw materials in percentage by weight: 5-15% of diatomite, 5-15% of urea, 5-30% of lignite, 20-35% of bentonite and 30-45% of volcano basalt zeolite. The preparation method of the environmentally-friendly water-saving water-holding fertilizer comprises the following steps of: step 1: separately crushing diatomite, urea, lignite, bentonite and volcano basalt zeolite, drying to water content of 5-10% and screening by 180-200 mesh; step 2: stirring for mixing diatomite, urea, lignite, bentonite and volcano basalt zeolite powders acquired in step 1 for 30 minutes; and step 3: adding the diatomite, urea, lignite, bentonite and volcano basalt zeolite powder mixture acquired in step 2 to a fermenting tank, adding microorganism Bacillus subtilis fermenting agent 1% of total weight, mixing and stirring for 15 minutes and naturally fermenting for 5-10 days. The invention has the advantages of simple preparation method, low cost, no pollution of a product, high fertilizer effect and good water-holding and water-saving effects, and is convenient to use,.

Owner:YUNNAN TENGCHONG JINGNONG TECH

Microbial strain agent and organic fertilizers fermented by same

ActiveCN101643718BImprove adaptabilityImprove qualityBio-organic fraction processingFungiBiotechnologyRhizopus

The invention relates to a microbial inoculum for fermenting and producing organic fertilizers, comprising cellulomonas, bacillus, lactobacillus, methagen, thiobacillus, streptomyces, thermoactinomyces, thermomonospora, azotobacter, nitrosomonas, nitrobacter, rhizobium, aspergillus, yeast, penicillium, humicola, rhizopus and mycorrhizal fungi. In addition, the invention also relates to organic fertilizers fermented and produced by using the microbial inoculum and a method for fermentation and production.

Owner:宋彦耕

Microbial agent and soil modifying agent produced by fermentation thereof

ActiveCN101629156BImprove adaptabilityImprove fertilityFungiAgriculture tools and machinesBiotechnologyMicrobial agent

The invention relates to a microbial agent used for producing a soil modifying agent by fermentation, consisting of fiber monad, bacillus, lactobacillus, methanobacteria, thiobacillus, streptomycete, high-temperature actinomyces, high-temperature monad, azotobacteria, nitration monad, nitration bacilus, rhizobium, koji mold, leaven, blue mold, detritus mold, rhizopus as well as mycorrhizal fungi and substrate. In addition, the invention also relates to a soil modifying agent produced by the fermentation of the microbial agent, application thereof and the like.

Owner:宋彦耕

Heat processing technology for improving impact energy of 20CrNiMo alloy steel

The invention provides a heat processing technology for improving the impact energy of 20CrNiMo alloy steel. The technology includes the following steps: I, performing carburizing treatment to the 20CrNiMo alloy steel until the depth of a carburizing layer reaches 1.4 mm to 1.7 mm; II, performing primary quenching; III, performing primary tempering, V, performing secondary quenching; IV, performing secondary tempering. According to the invention, through improving the heat processing technology of the 20CrNiMo alloy steel, the problem that other excellent performances of the 20CrNiMo alloy steel cannot be fully exerted due to lower impact energy is solved, the material usability is better, and the application range is wider.

Owner:XIAN COAL MINING MACHINERY

Method for producing martensite cast steel ball

The invention provides a production method of martensite cast-steel shots, belonging to a production method of steel shot abrasive, which is characterized in that the production method comprises the steps as follows: heat preservation of molten steel in a blast furnace mixer, oxygen top-blown converter refining, high-pressure water pulverization and granulation, drying, rough separation, roundness selection, quenching, tempering, and handpicking, etc. The martensite cast-steel shots produced by the method have reasonable alloy components and low contents of harmful elements such as sulphur and phosphor, etc., thus improving the anti-fatigue capability of the steel shots and prolonging the service life of the steel shots; the maximum shotting time is improved by 300 to 400 times compared with the steel shots smelted and manufactured by the existing medium frequency furnace or electric arc furnace; furthermore, the operation is simple and the production capacity of the single furnace is large.

Owner:山东传洋金属磨料有限公司

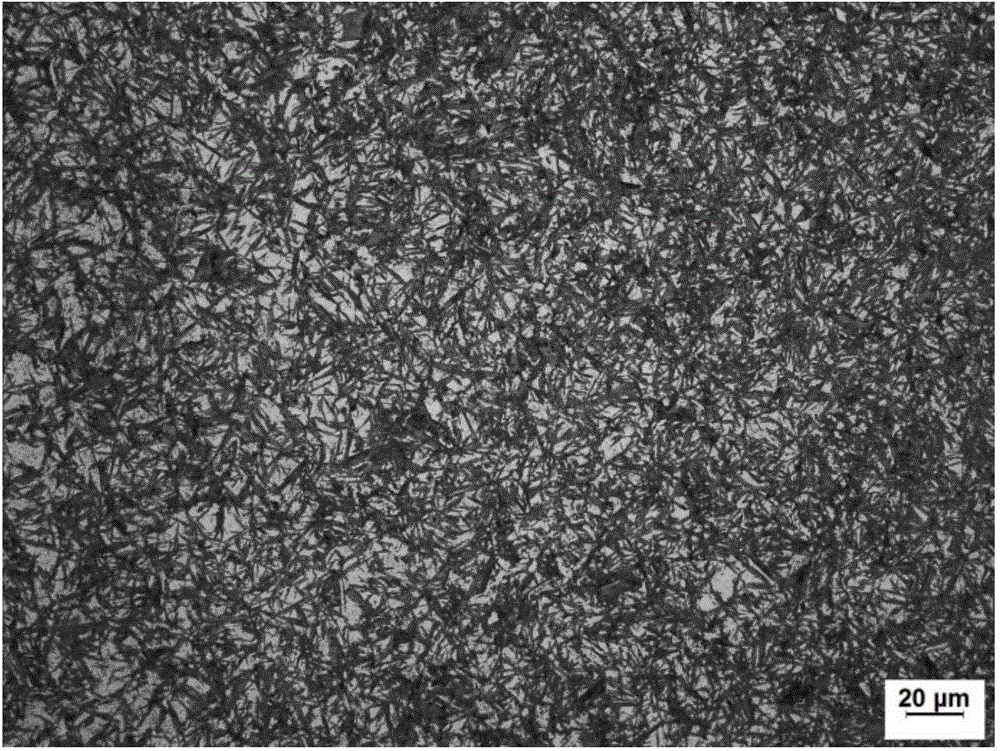

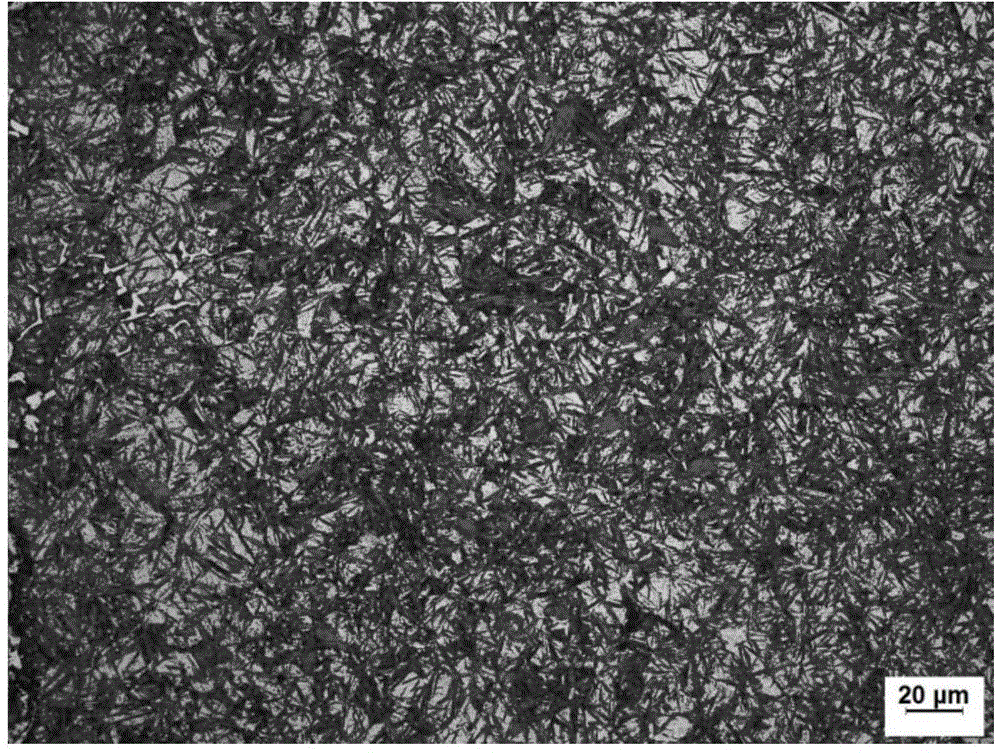

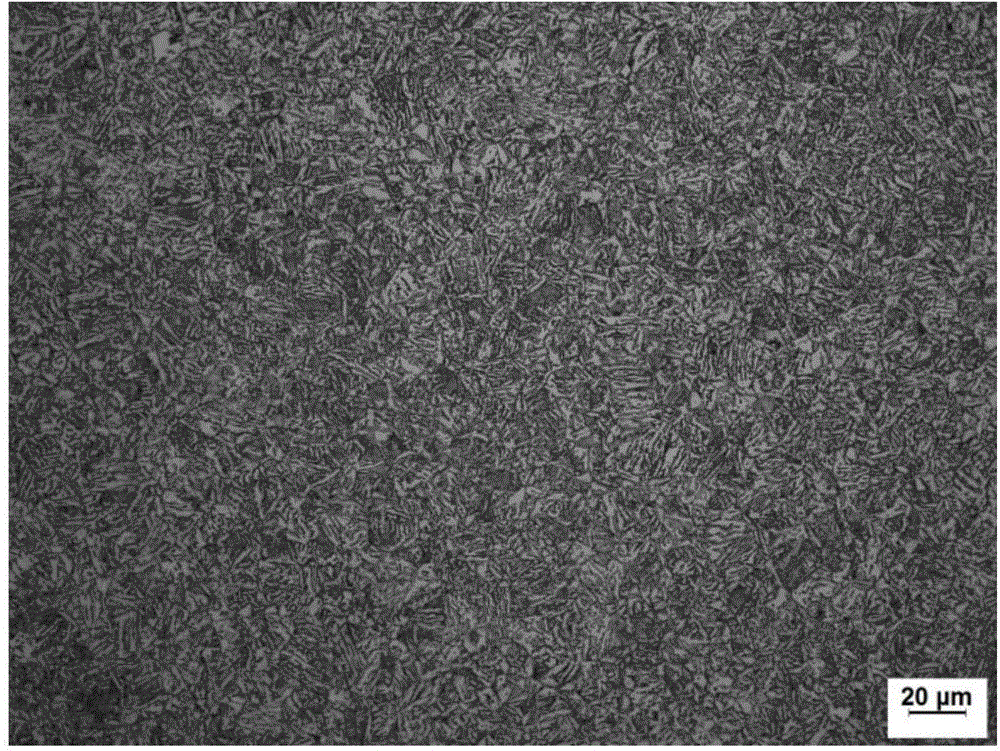

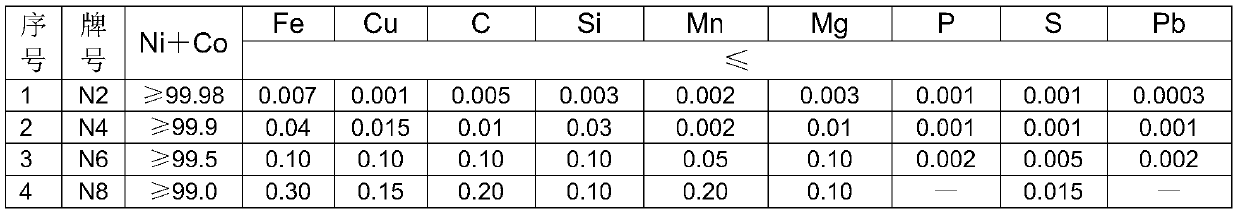

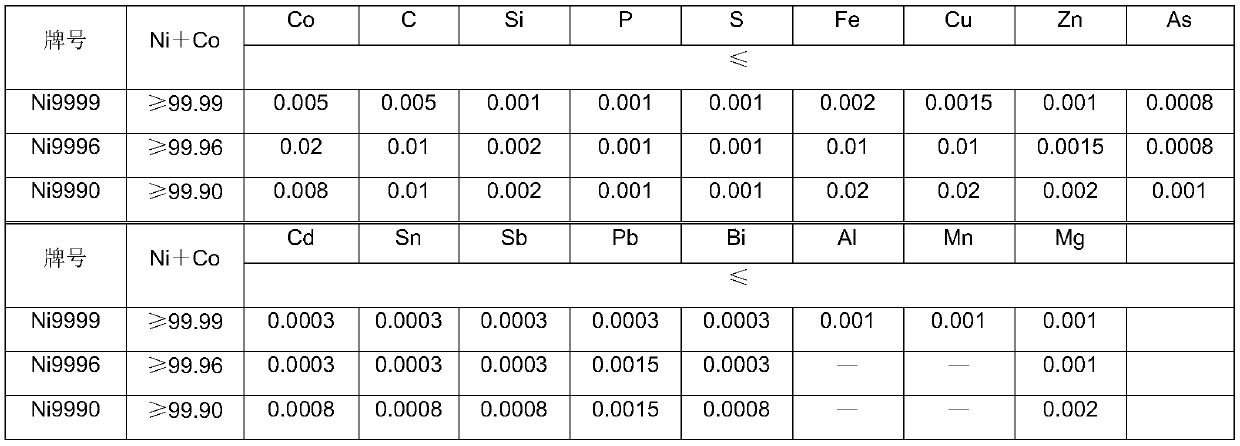

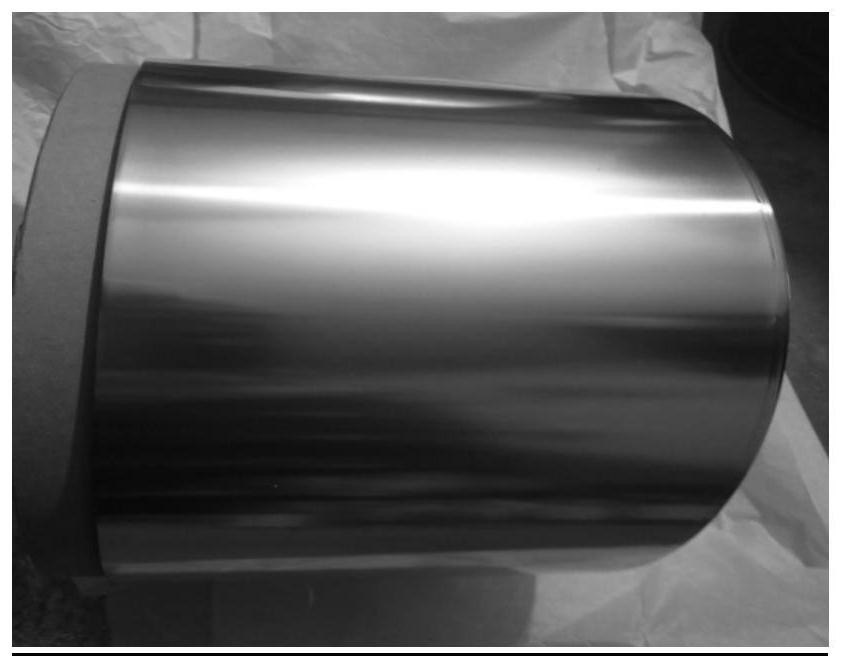

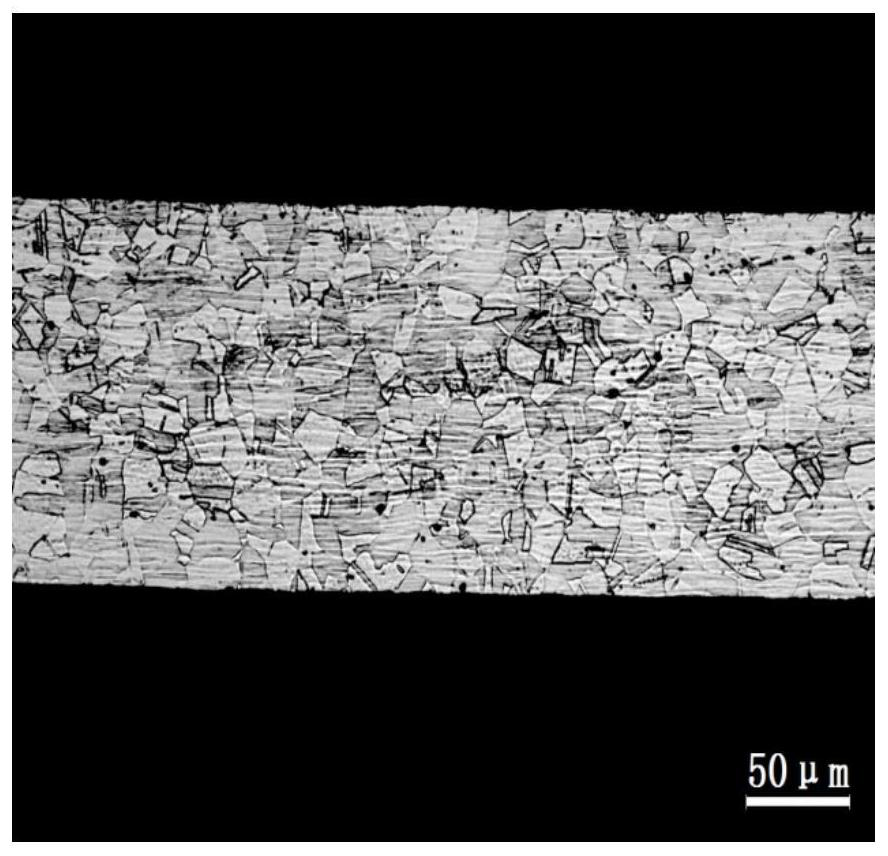

Method for preparing ultra-high-purity nickel strip by short process

InactiveCN111530961AImprove mechanical propertiesReduce pass rateMetal rolling arrangementsElectrolysisSmelting process

The invention discloses a method for preparing an ultra-high-purity nickel strip by a short process. The method comprises the steps that a high-purity nickel plate is used as a raw material, the high-purity nickel plate is sequentially subjected to the process steps of nickel plate processing, plasma welding, hot rolling, ultrasonic flaw detection and cold rolling, and the ultra-high-purity nickelstrip is prepared. According to the method, in view of the problems of high inclusion content and low purity of a domestic pure nickel strip, through the direct rolling of a high-grade electrolytic nickel plate, the process flow is shortened, the cost is lowered, the production efficiency is improved, on the premise of ensuring good mechanical properties, the high-purity nickel strip prepared bythe method can effectively avoid the reduction of qualified rate of the nickel strip caused by inclusions brought into the smelting process, the purity of materials is ensured, the product qualification rate is increased, and moreover, the pollution problem caused by inherent interlayer defects of the electrolytic nickel plate is solved; and the method is particularly suitable for the demands of electronic and mechanical industries with high quality requirements for the pure nickel strip, and high practicability is achieved.

Owner:JIANGSU YUANHANG PRECISION ALLOY TECH +1

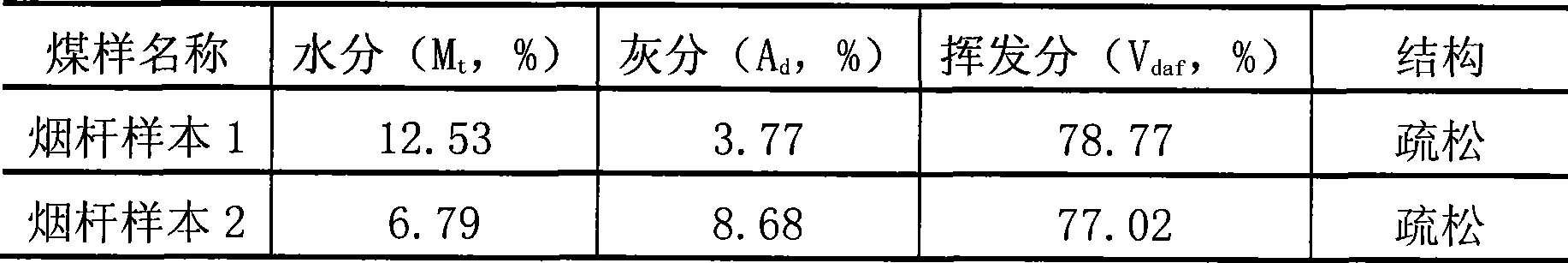

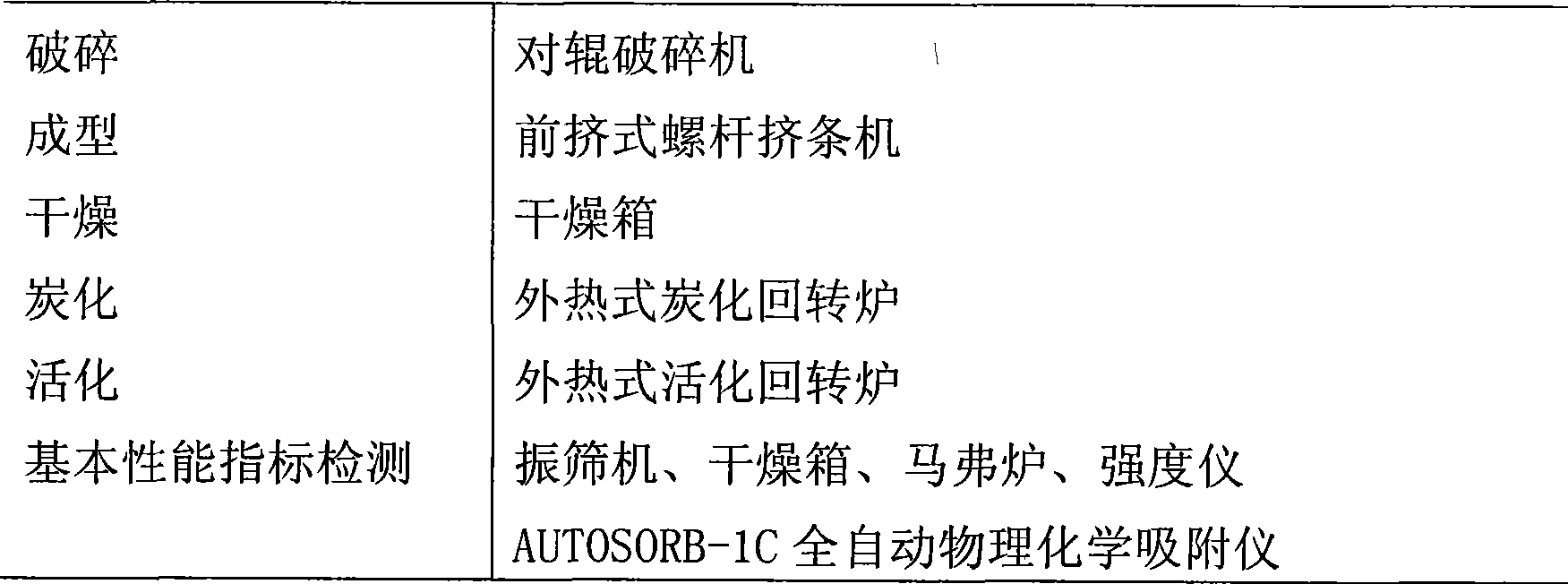

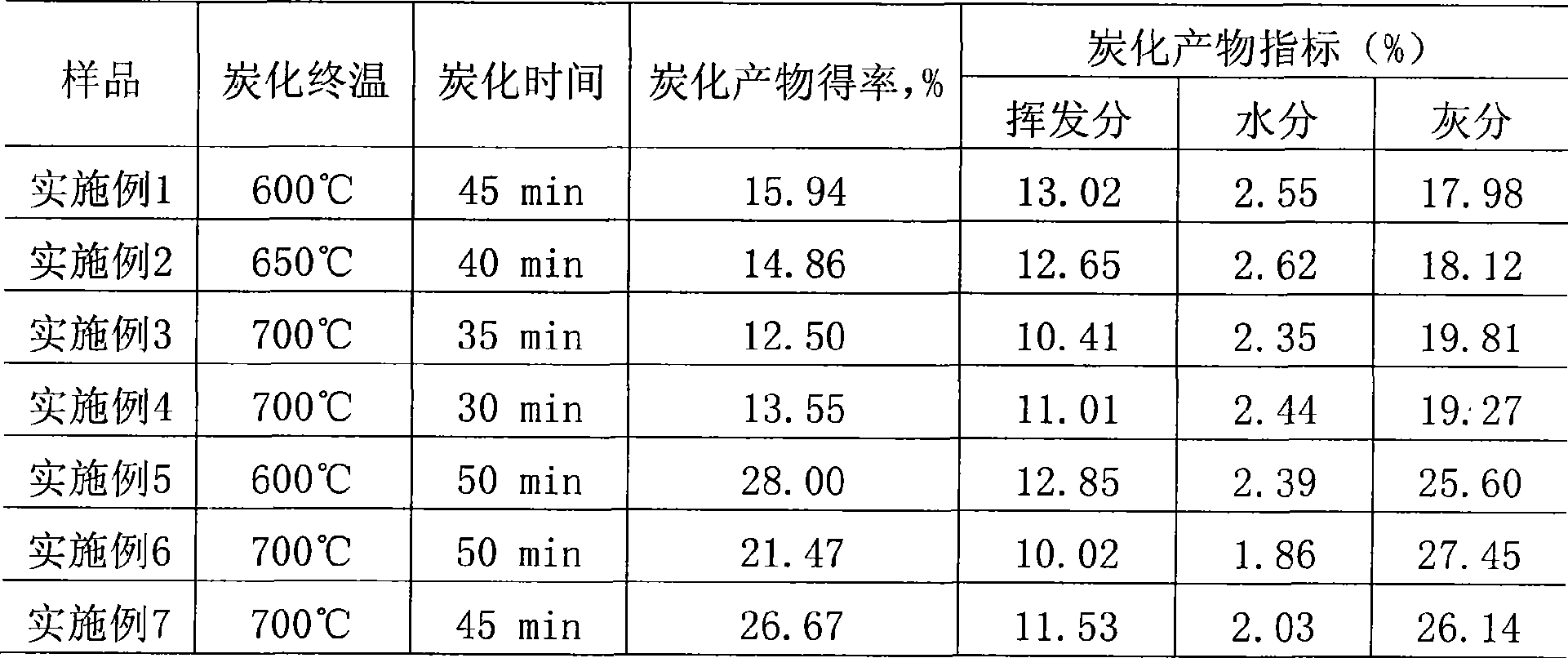

Process for producing active carbon

InactiveCN101508435AGood adsorption performanceLow content of harmful elementsActivated carbonActive carbon

The invention discloses a method for preparing active carbon. The method for preparing the active carbon comprises the following steps: 1) carbonizing crushed and dried tobacco rods to obtain carbonized products; and 2) physically activating the carbonized products to obtain the active carbon. The active carbon prepared by the method has good adsorptivity and low content of harmful substances, and can be used for sewage treatment and decolorization of chemical products, foods and medicaments because various indexes of the active carbon accord with the national standard. In addition, the method utilizes the tobacco rods as a raw material, solves the problems of resource waste and environmental pollution due to the fact that the tobacco rods are discarded and burnt, and is of great significance.

Owner:南雄市青松环保材料有限公司

Method for smelting base material of low phosphorous stainless steel by using low-grade limonite containing nickel-chromium

ActiveCN100532579CRich sourcesLow priceBlast furnace detailsManufacturing convertersHearthHigh pressure

Owner:前海索新发展科技(深圳)有限公司

High-chromium chromium-molybdenum steel plate and production method thereof

The invention discloses a high-chromium chromium-molybdenum steel plate and a production method thereof. The steel plate is composed of the following components in percentage by weight: 0.09%-0.15% of C, 0.5%-0.90% of Si, 0.30%-0.60% of Mn, at most 0.007% of P, at most 0.005% of S, 8.00%-10% of Cr, 0.90%-1.1% of Mo, at most 0.20% of Cu, 0.05%-0.10% of Ni, at most 0.003% of Sb, at most 0.005% of Sn, at most 0.012% of As, and the balance of Fe and inevitable impurities. The production method comprises the following steps: smelting and die casting, heating and rolling, and heat treatment. The high-chromium chromium-molybdenum steel plate satisfies the requirements of high strength, high toughness and high processability for domestic power equipment industry, and can be widely used for manufacturing of domestic power equipment. The steel plate has the advantages of favorable cold bending property, no cracking in the material manufacturing process, and favorable resilience.

Owner:WUYANG IRON & STEEL

Electroslag remelting slag and production technology thereof

The invention provides electroslag remelting slag and a production technology thereof, and belongs to the technical field of electroslag remelting. The electroslag remelting slag comprises, by mass percent, 2%-5% of CaF2, 40%-50% of Al2O3, 20%-30% of SiO2, 10%-20% of MgO and 5%-15% of CaO. The producing and machining performance of the electroslag remelting slag is stable and reliable, the content of harmful elements in a steel ingot is obviously reduced, no obvious surface flaws exist in the steel ingot, product components are stable and uniform, the yield of the steel ingot is increased by 15%-20%, and the power consumption of a single furnace is reduced by more than 20%.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

Production process for reducing surface cracks of chromium-molybdenum alloy steel plates with high chromium content

ActiveCN111074049AReduce crackingQuality improvementProcess efficiency improvementElectric furnacePipe fittingElectric power equipment

The invention discloses a production process for reducing surface cracks of chromium-molybdenum alloy steel plates with high chromium content. The production process includes the processes of smelting, pouring, steel ingot annealing, steel ingot cogging-down and cutting, cogging-down material primary annealing, cogging-down material cleaning, cogging-down material secondary annealing and cogging-down material rolling. According to the production process for reducing the surface cracks of the chromium-molybdenum alloy steel plates with the high chromium content, the risk of the cracks generatedon the surface of the rolled steel plates is eliminated from the source through the control over the steel ingot smelting and pouring processes; carbon arc gouging is adopted to clean micro-crack defects generated on the surface of blanks, so that the problem that the defects are difficult to overcome through traditional flame cleaning is solved; and through the control over the blank heating androlling processes, the potential adverse factors of surface cracks are reduced. According to the production process for reducing the surface cracks of the chromium-molybdenum alloy steel plates withthe high chromium content, the phenomenon of the cracks on the surface of the steel plates can be reduced, the probability of the steel plates being scrapped due to the surface cracks is reduced, goodbenefits are achieved, and the production process is suitable for the production of high-strength chromium-molybdenum alloy steel plates, with the thickness of 12-30 mm, the carbon content of 0.1%-0.13%, the molybdenum content of 0.9%-1.1% and the chromium content of 8%-10%, for power equipment and petrochemical industry pipe fittings.

Owner:WUYANG IRON & STEEL

Microorganism fermented organic fertilizer and preparation method thereof

PendingCN108863675AInhibition of hatchingImprove fertilizer efficiencyBio-organic fraction processingExcrement fertilisersMicroorganismFeces

The invention discloses microorganism fermented organic fertilizer and a preparation method thereof. After lotus corniculatus is cut, cattle, horses and sheep are fed with fresh grass or dry grass; the lotus corniculatus accounts for 50 percent or more of the total food weight of the cattle, the horses and the sheep; lotus corniculatus plants are partially decomposed and crushed when the cattle, the horses and the sheep ruminate and repeatedly chew the lotus corniculatus plants and the lotus corniculatus plants are fermented in stomachs, and then excrement is formed; the excrement is mixed with mixed straws, sawdust, plant ash and canteen waste dreg; then the materials are stacked together and are subjected to first-time fermentation; after the first-time fermentation is finished, fermented matters are turned; a microorganism nutrient solution and crushed lotus corniculatus root stalks are added layer by layer in a turning process and are subjected to secondary fermentation; a mixtureis turned for one time every other 3 to 10 days, so as to prepare the microorganism organic fertilizer. By adopting the organic fertilizer, the problem that underground insects are easy to hatch in afermentation and composting process of the biological organic fertilizer can be solved; meanwhile, after the fertilizer is applied, the breeding and reproduction capability of the underground insectsof a fertilized land can be inhibited, so that the problem of soil insect pests is radically solved, self-balance of soil is regulated and controlled and the self-recovery capability of the soil is improved.

Owner:内蒙古蒙苒生物科技有限公司

Preparation method of cupronickel strip for ship engine heat exchange

The invention discloses a preparation method of a cupronickel strip for ship engine heat exchange. The preparation method of the cupronickel strip for ship engine heat exchange comprises the followingsteps: proportioning raw materials and a smelting additive according to a weight ratio; performing vacuum induction melting on the raw materials and the melting additive to obtain a first semi-finished cupronickel cast ingot; sawing the head of the first semi-finished cupronickel cast ingot, and baking in a resistance furnace to obtain a second semi-finished cupronickel cast ingot; performing electroslag remelting on the second semi-finished cupronickel alloy cast ingot, and cutting off a riser and the bottom to obtain a finished cupronickel alloy cast ingot; forging the finished cupronickelcast ingot in an electro-hydraulic hammer to obtain a first semi-finished cupronickel plate blank; performing hot rolling on the first semi-finished cupronickel plate blank, and then performing acid pickling and intermediate annealing, so as to obtain a second semi-finished cupronickel plate blank; performing cold rolling on the second semi-finished cupronickel plate blank to obtain a semi-finished cupronickel strip; and annealing the semi-finished cupronickel strip to obtain the finished cupronickel strip. According to the preparation method of the cupronickel strip for ship engine heat exchange, the defects of looseness, inclusion, shrinkage cavities, subcutaneous pores and the like of cupronickel are eliminated.

Owner:BAOJI TITANIUM IND

Low-aluminum silicon-barium-calcium alloy and production process thereof

The invention relates to a low-aluminum silicon-barium-calcium alloy and a production process thereof, relating to the field of steel-making deoxidizing agents. At present, silicon-barium alloy, silicon-calcium alloy and ferrosilicon alloy are commonly and respectively added during steel making. As a result, high-content of impurities such as sulfur, phosphorus, and the like exists in a steel material, and the aluminum content is also over 2 percent, so that the quality of the steel material is severely affected; besides, the production cost is high, the process is complex, and the labor intensity is great. The invention adopts a compound refining method to produce the low-aluminum silicon-barium-calcium alloy, comprising the steps of adding and melting scrap iron, melting the silicon-barium alloy till ebullition, adding silicon-calcium alloy, adding dealuminzation powder, keeping the ebullition for 10-20 min, and finally casting and forming to obtain a finished deoxidizing agent. The invention has the advantages of low content of harmful elements, few impurities, capability of meeting the requirements on special good-quality steel materials, low cost, simple process and low construction investment.

Owner:王玉清

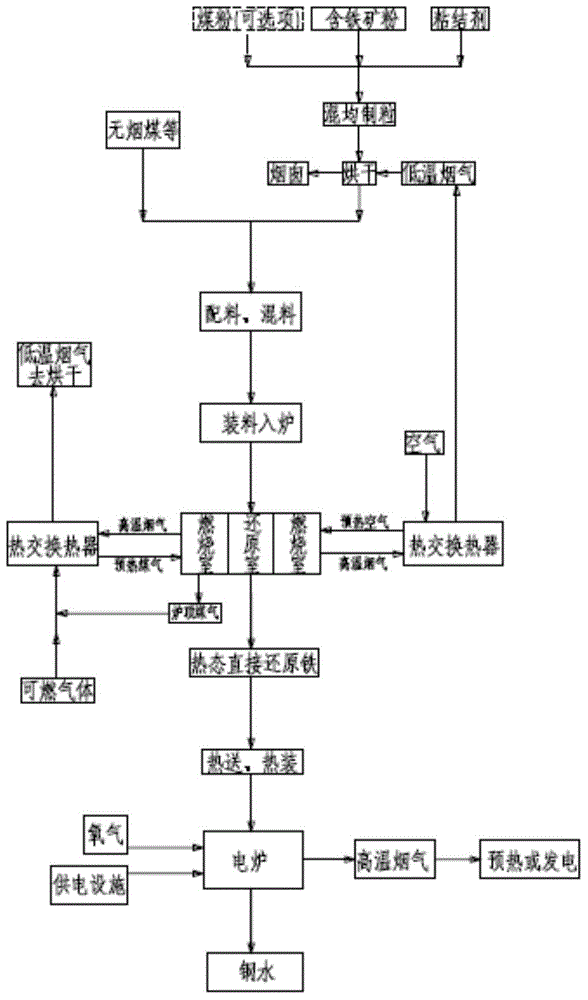

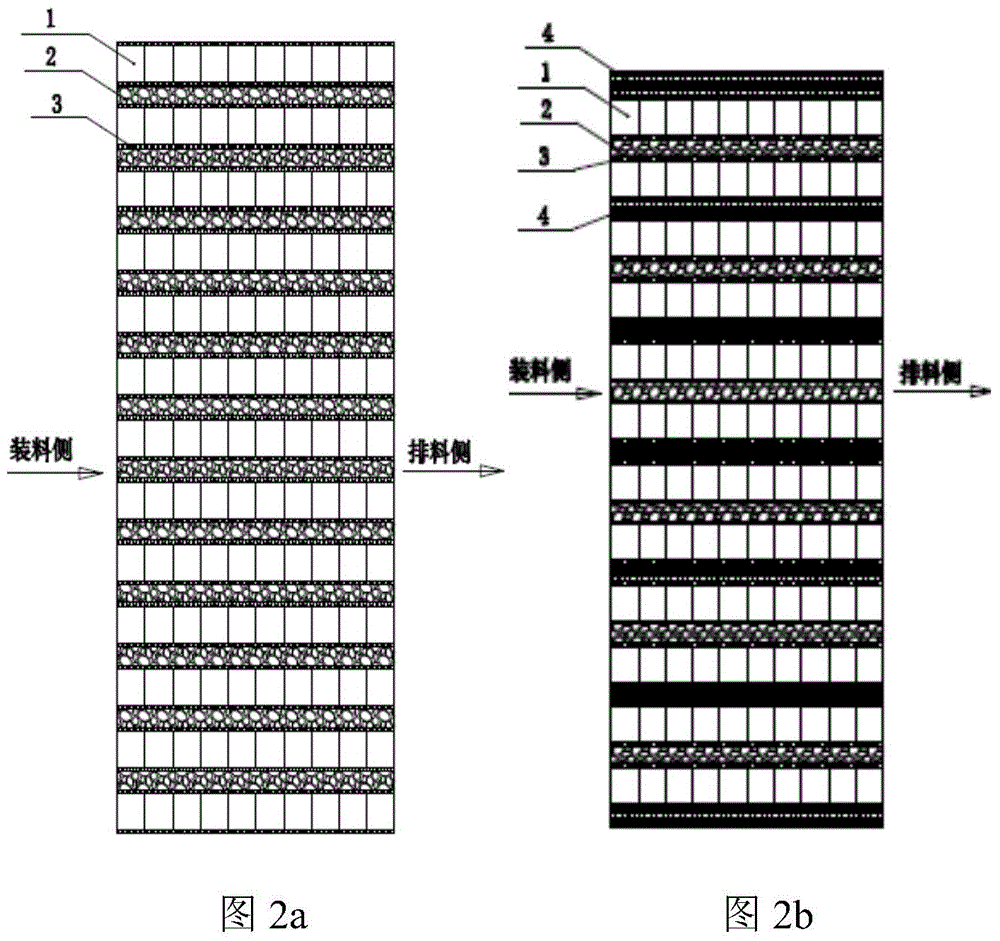

QDF electric steelmaking process

InactiveCN104630411AAchieve the desired effectReduced strength requirementsProcess efficiency improvementElectric furnaceSteelmakingCombustion

The invention relates to a QDF electric steelmaking process. The process comprises the following steps: uniformly mixing an iron-containing raw material and a powdery reducing agent, and filling each reducing room, wherein the materials are in disperse and uniformly distributed state in the reducing room, and the reducing rooms and the reduced materials are maintained in static states in the reduction process; uniformly heating the materials in the reducing room by using the heat produced by the combustion of fuel and combustion-supporting gas in a combustion room to preform the reduction reaction on the iron-containing raw material and the reducing agent, wherein the reducing room is a narrow one-part form reactor; obtaining heat-state directly reduced iron after the materials in the reducing room are completely reacted, conveying the heat-state directly reduced iron to a charging device through a hot-delivery mode, and hot-filling an electric furnace to obtain molten steel. The process has the obvious advantages of being short in flow, strong in raw material adaptability, non-coke smelting, easy in control of the reduction process, sufficient in inter-process energy utilization, and capable of obviously reducing CO2 discharge; the process is a steelmaking method with shorter process flow, lower investment, lower cost and better environment protection in comparison with a converter steelmaking process.

Owner:WISDRI ENG & RES INC LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com